Single-layer form-wound coil winding device and method

A technology for forming coils and winding methods, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., and can solve problems such as difficulty in controlling the springback of single-layer formed coils, non-universal equipment, and insulation damage between turns. It achieves the effects of avoiding end bend springback, avoiding inter-turn insulation damage, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

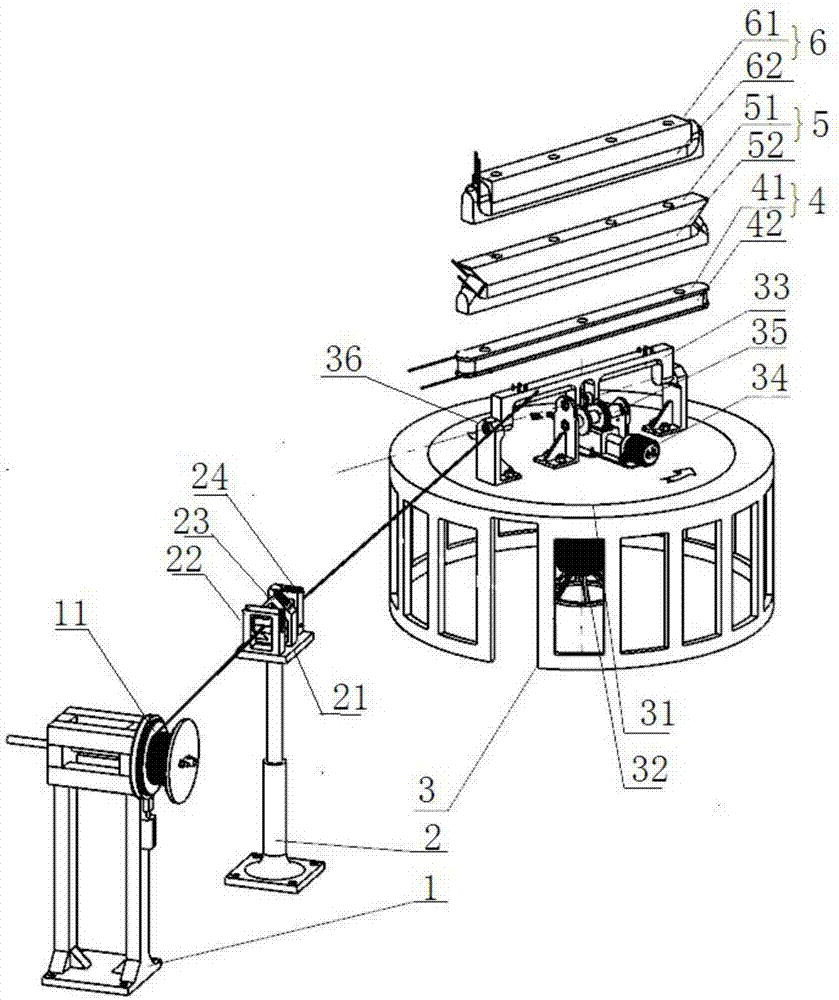

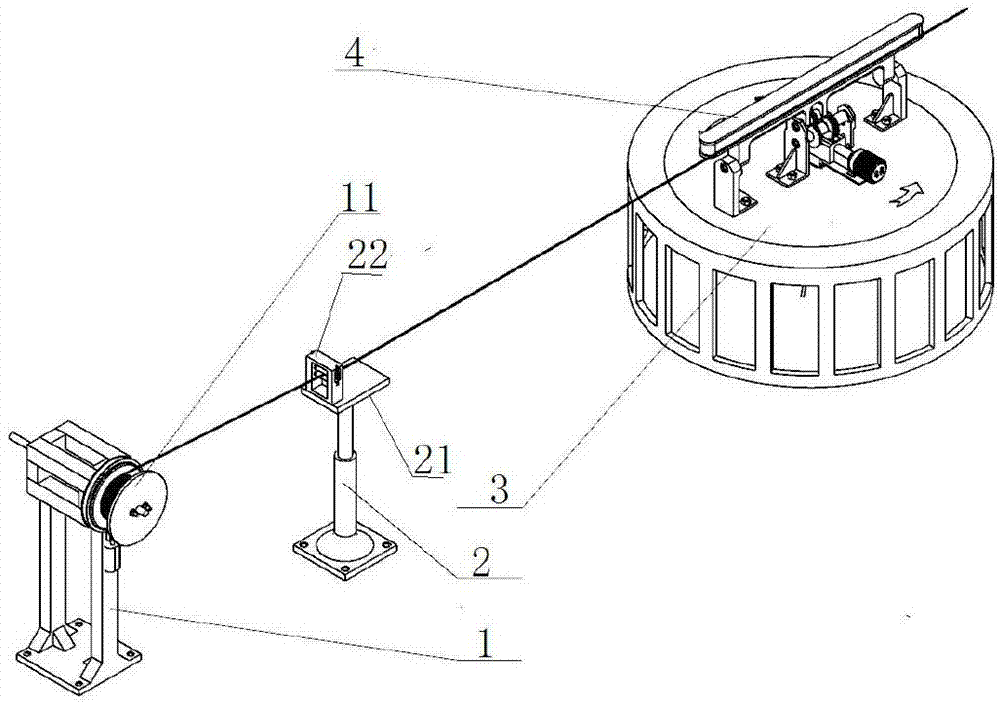

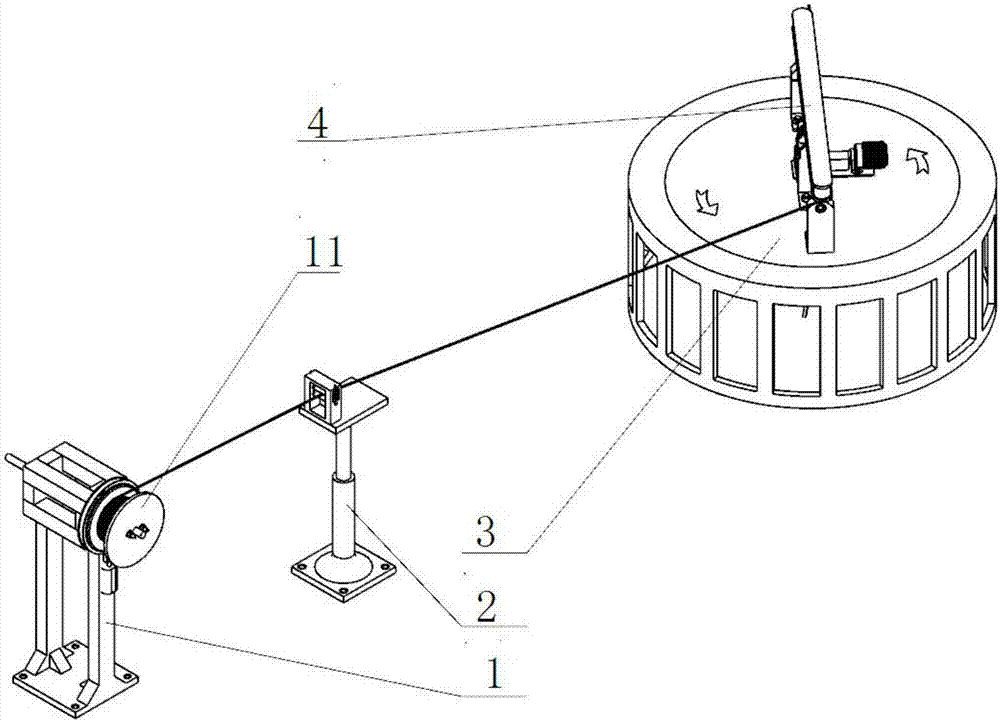

[0039] see Figure 1 to Figure 15 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

[0040] See figure 1 , a single-layer forming coil winding device of the present invention includes a pay-off machine 1, a guide frame 2, a winding machine 3, and a first winding mold 4 for winding a 0-degree coil, and for winding a 45-degree coil The second winding mold 5, and the third winding mold 6 for winding a 90-degree coil.

[0041] The winding machine 3 includes a horizontal rotating platform 31, and the rotating platform 31 is divided into a rotatable movable platform and a fixed platform located radially outside the movable platform. The center of the movable platform, that is, the bottom surface of the rotating platform 31 is provided with a vertical rotating motor 32 for driving the rotating platform 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com