Patents

Literature

66results about How to "Solving Passivation Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for quickly and efficiently removing heavy metals in water body

ActiveCN104276646AImprove cleanlinessGood chromaWater contaminantsMultistage water/sewage treatmentPotassium permanganatePrecipitation

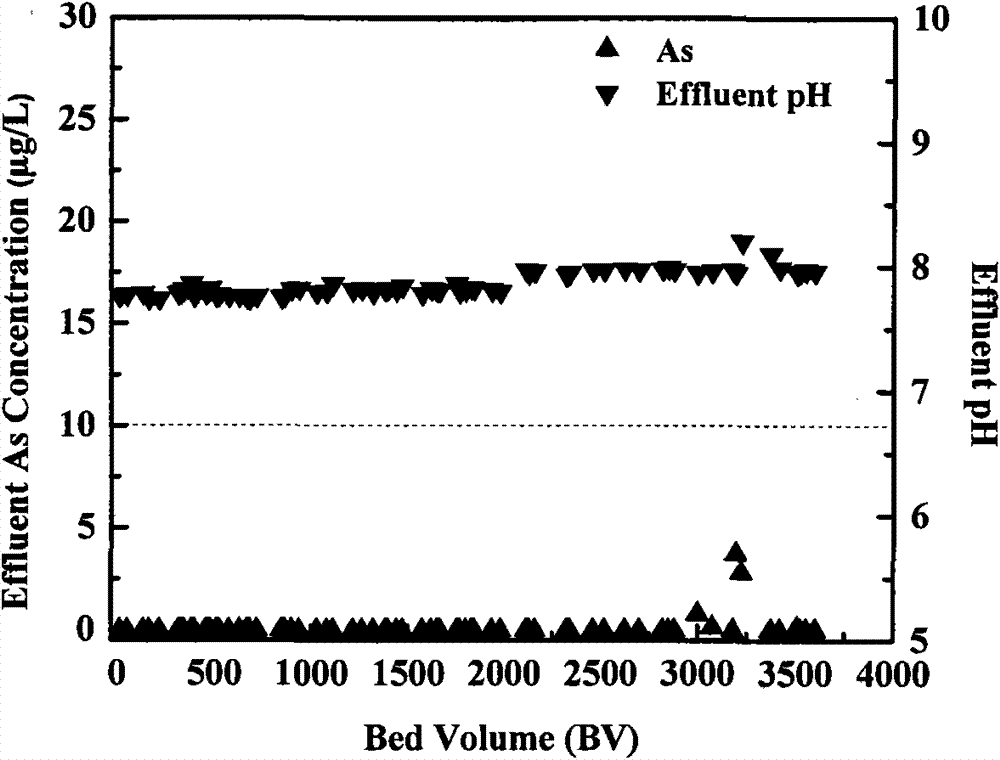

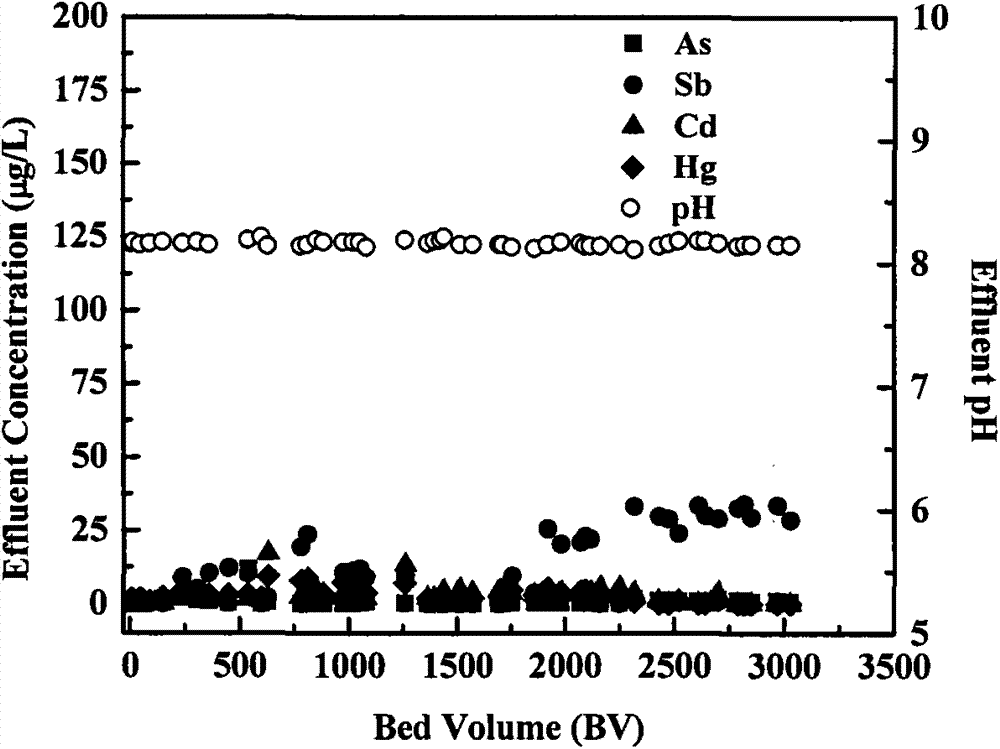

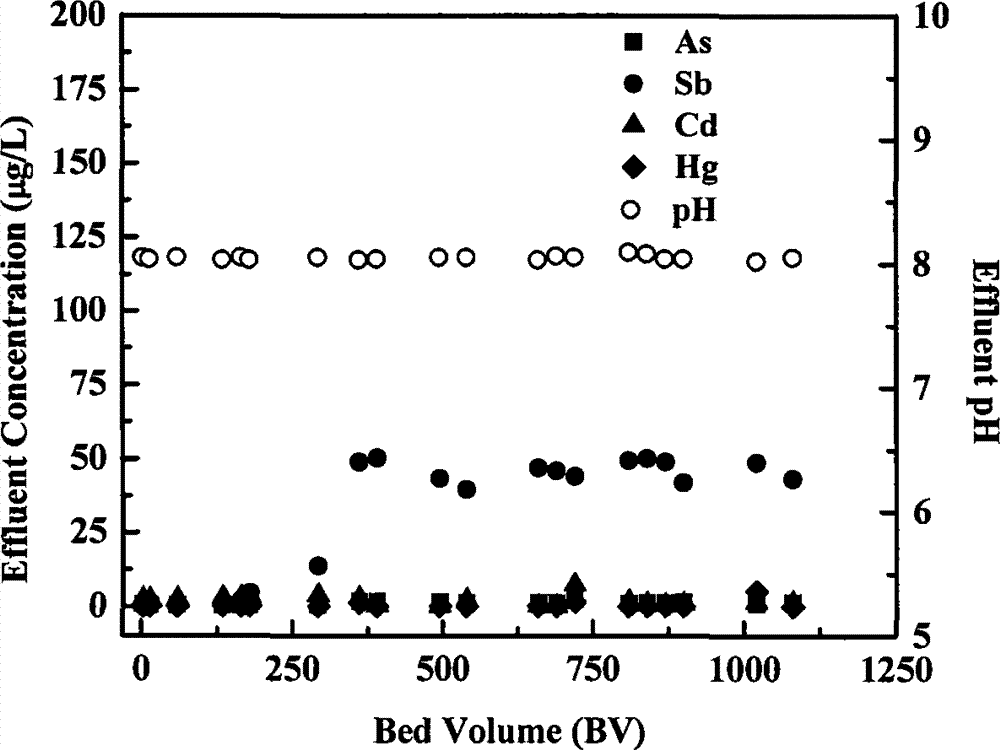

The invention relates to a method for removing heavy metals in a water body, which is characterized in that common oxidizers for water treatment, such as hydrogen peroxide, sodium hypochlorite, potassium permanganate and the like, are utilized for oxidization to activate the zero-valent iron surface and continuously generate fresh iron (III) / (II) (hydro)oxide and other active components, thereby quickly and efficiently removing heavy metals in the water body, including As, Hg, Cd, Pb, Cr, Se, Sb, Cu, Zn and the like, in a mode of adsorption, precipitation, redox or the like.

Owner:BEIJING NORMAL UNIVERSITY

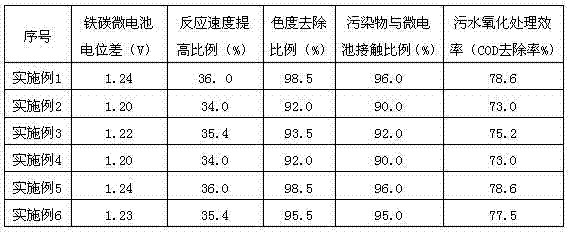

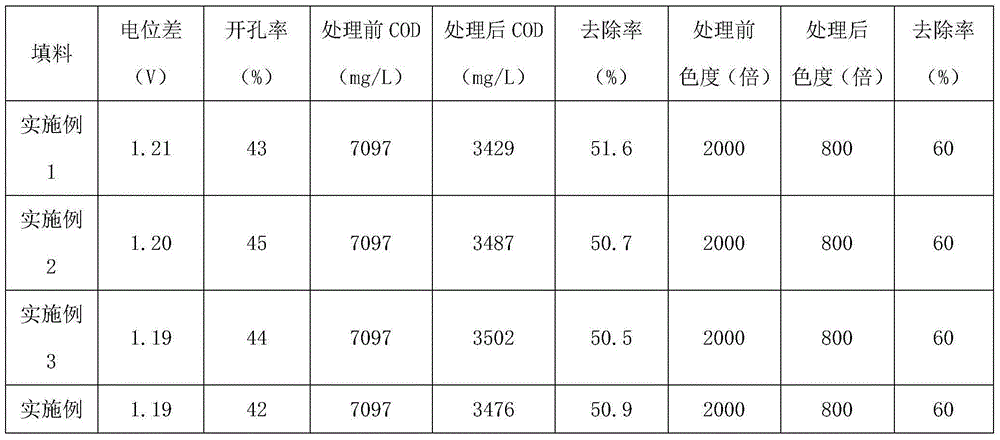

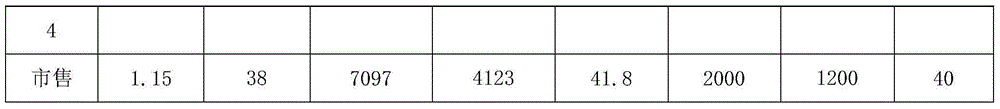

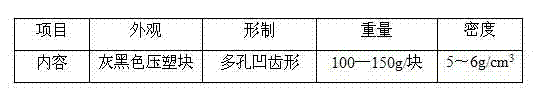

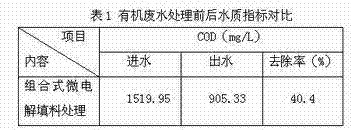

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Modified manganese dioxide catalyst, modified manganese dioxide catalyst electrode and preparation method of modified manganese dioxide catalyst and modified manganese dioxide catalyst electrode

ActiveCN104492426AImprove conductivityImprove electrochemical catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesManganese oxideRutile

The invention discloses a modified manganese dioxide catalyst, a modified manganese dioxide catalyst electrode and a preparation method of and the modified manganese dioxide catalyst and the modified manganese dioxide catalyst electrode. The manganese dioxide catalyst is prepared through an impregnation method, and is formed by fluorine ions and metal ions doped nano-manganese oxide is loaded on a metallic oxide carrier with a rutile crystal structure and an oxygen-deficiency structure simultaneously; a corrosion-resistant conductive layer formed by the metallic oxide with the rutile crystal structure and the oxygen-deficiency structure and a modified manganese dioxide catalyst layer formed by the fluorine ions and metal ions doped nano-manganese oxide are sequentially prepared on a conductive base body to prepare the modified manganese dioxide catalyst electrode; the modified manganese dioxide catalyst and the modified manganese dioxide catalyst electrode have the characteristics of high current efficiency and long service life; and besides, the preparation method can be operated simply, the cost is low and the industrial production requirement is met.

Owner:湖南久盛新材料科技有限公司

Acid single flow cell

InactiveCN101567459AIncrease discharge voltageIncrease transfer speedRegenerative fuel cellsSecondary cellsCurrent cellIndium

The invention relates to an acid single flow cell which can be applied to large-scaled energy storage and power generation. The cell comprises an electrolyte storage tank, a cadmium or indium deposited cathode current collector and a lead dioxide anode; an acid solution of soluble cadmium salt or indium salt is used as an electrolyte; and when the cell is charged, the cadmium or indium ions are deposited on the cathode current collector from the electrolyte, and when the cell is discharged, the metal cadmium or indium is dissolved in the electrolyte from the cathode current collector. The current cell has the advantages of simple structure, convenient preparation, high electric energy conversion efficiency, long cycle life, environmental protection, safe use, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Inorganic ferrous sulfide passivation abluent

ActiveCN102373122ASolve environmental problems of emissionsEfficient removalInorganic non-surface-active detergent compositionsTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateHypochlorite

The invention relates to an inorganic ferrous sulfide passivation abluent which is characterized in that: the inorganic ferrous sulfide passivation abluent is composed of components of, by mass: 5 to 15% of sodium pyrosulfate, 15 to 35% of hypochlorite, 0.5 to 10% of trisodium phosphate, 0.1 to 5% of sodium bicarbonate, and 35 to 79% of water. The pH value of the product is controlled at 11 to 12. With the inorganic ferrous sulfide passivator, FeS and oil stains on refining equipments can be effectively and quickly removed; and gases such as H2S, micro-molecular sulfur and alcohol in equipments such as towers and containers can be absorbed. Indexes such as COD of the abluent satisfy an oil refinery sewage discharging standard. With the inorganic ferrous sulfide passivation abluent, environment protection problems such as a FeS passivation problem and an abluent waste liquid discharging problem can be well solved.

Owner:CHINA PETROLEUM & CHEM CORP

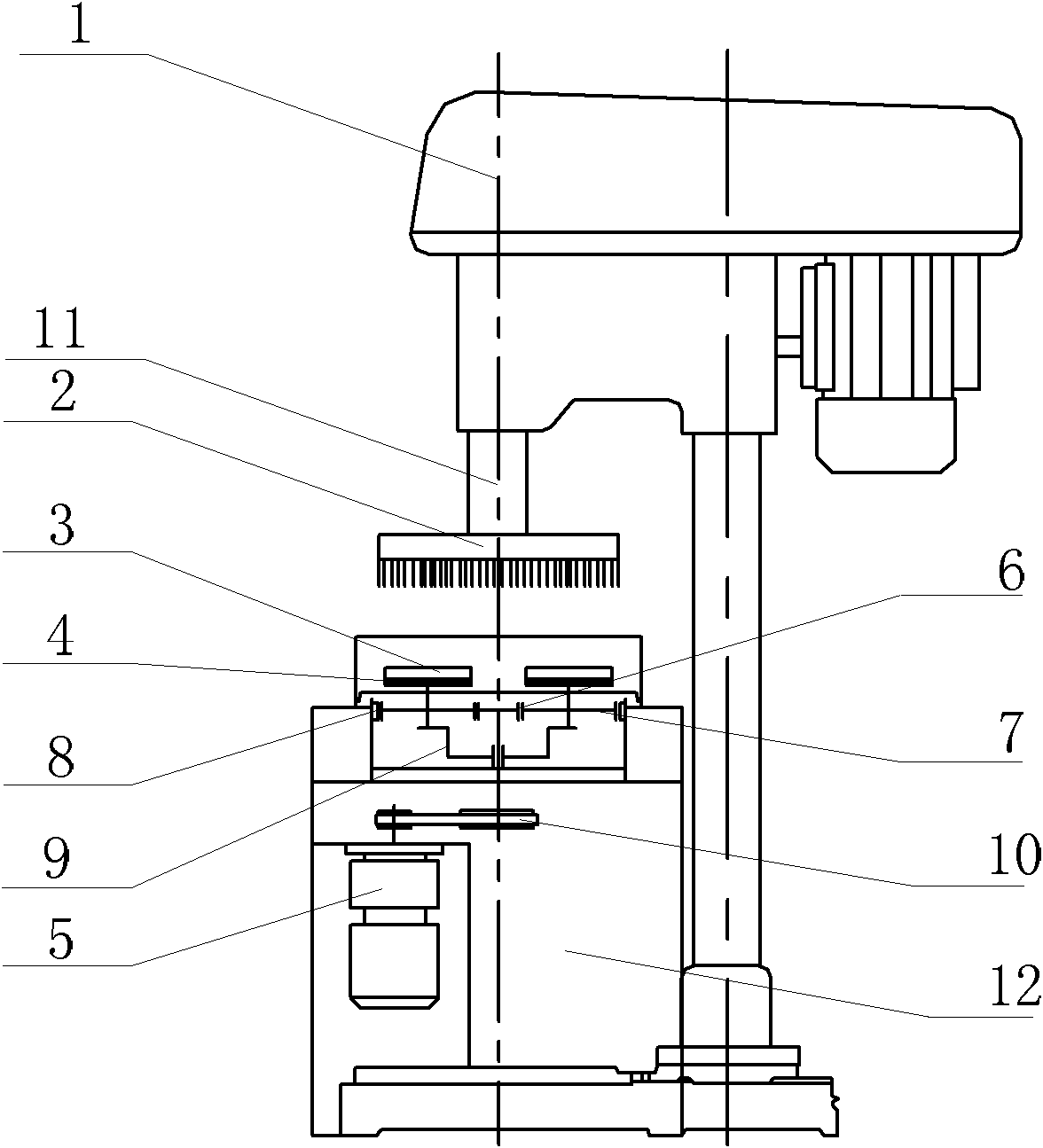

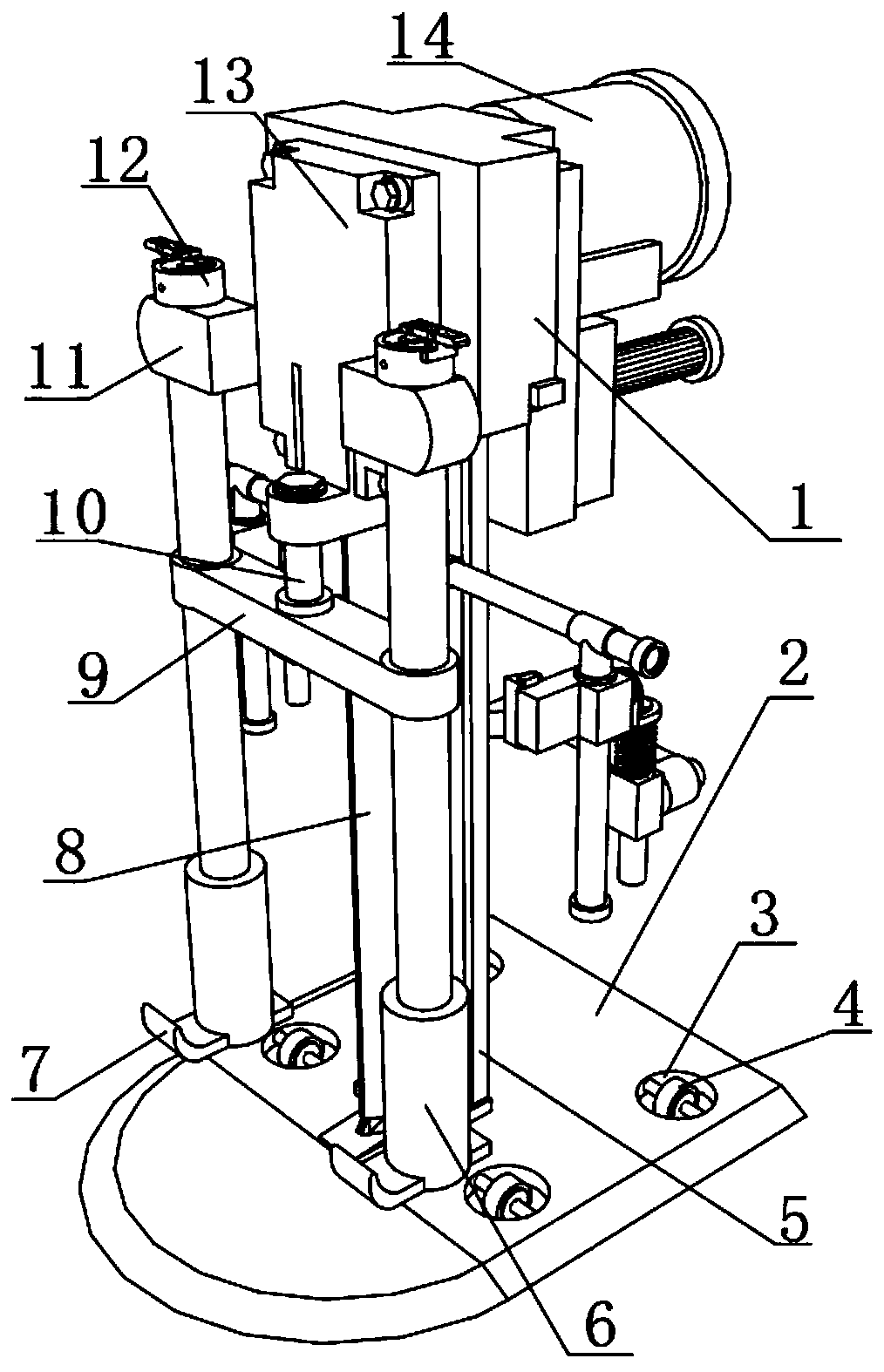

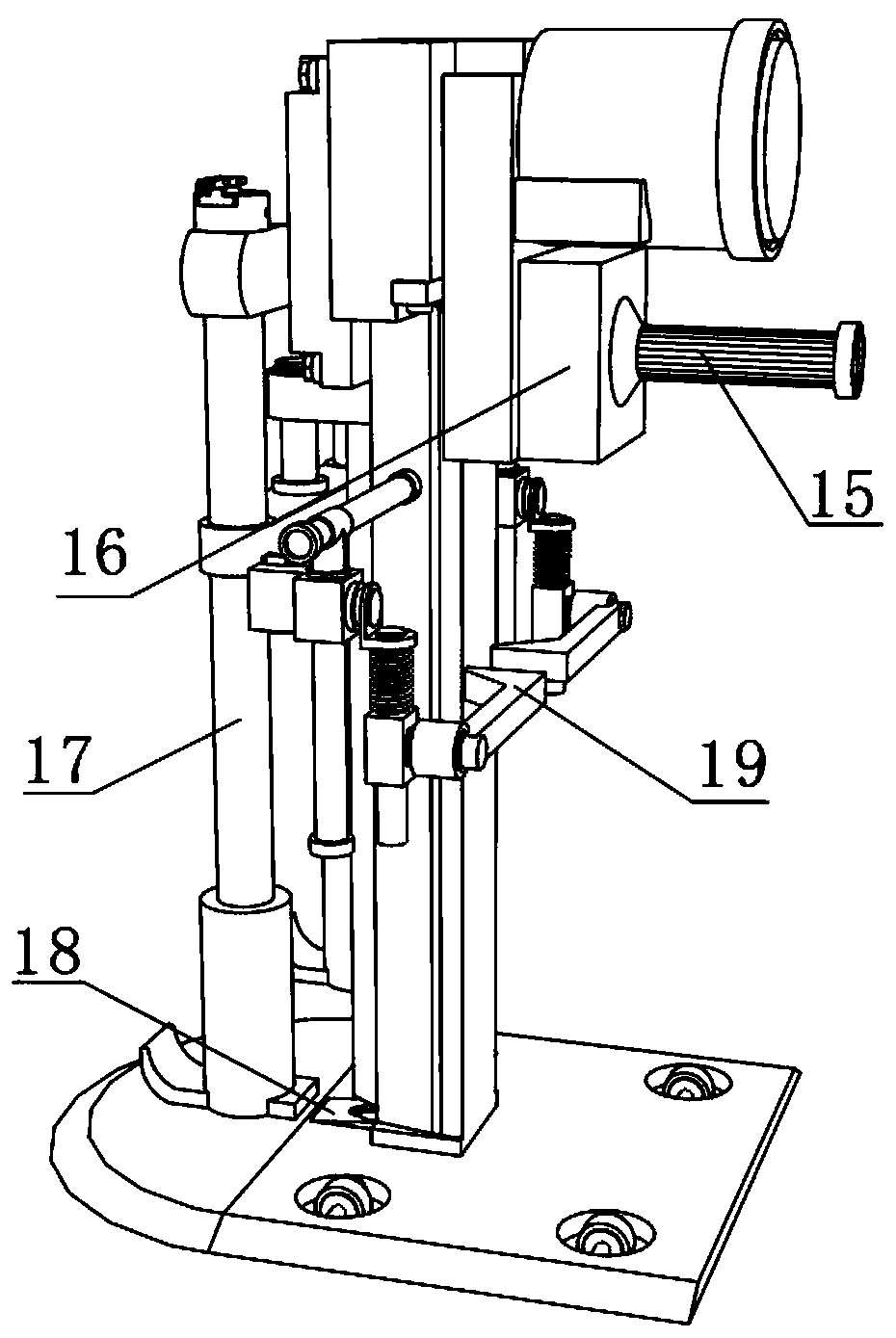

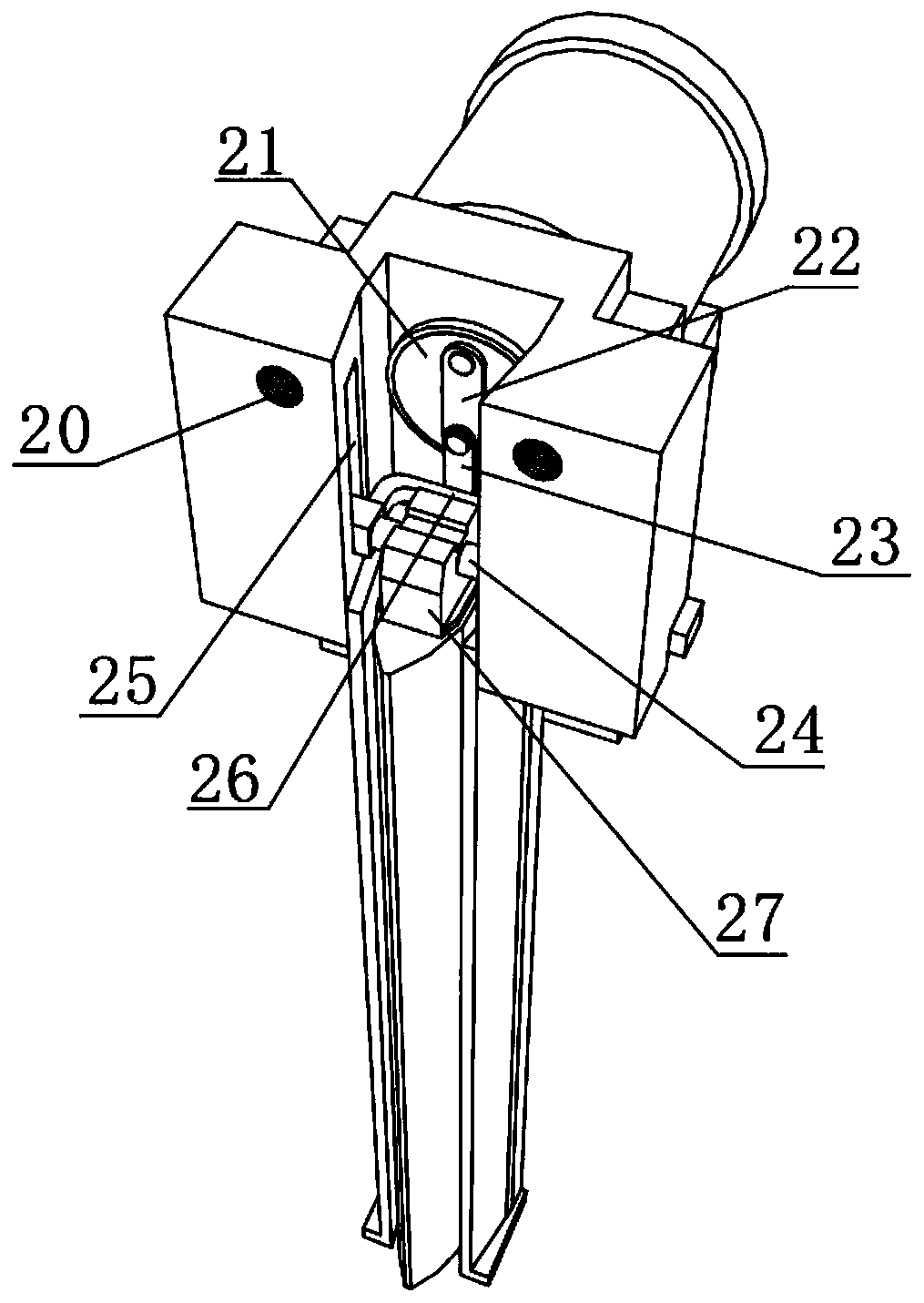

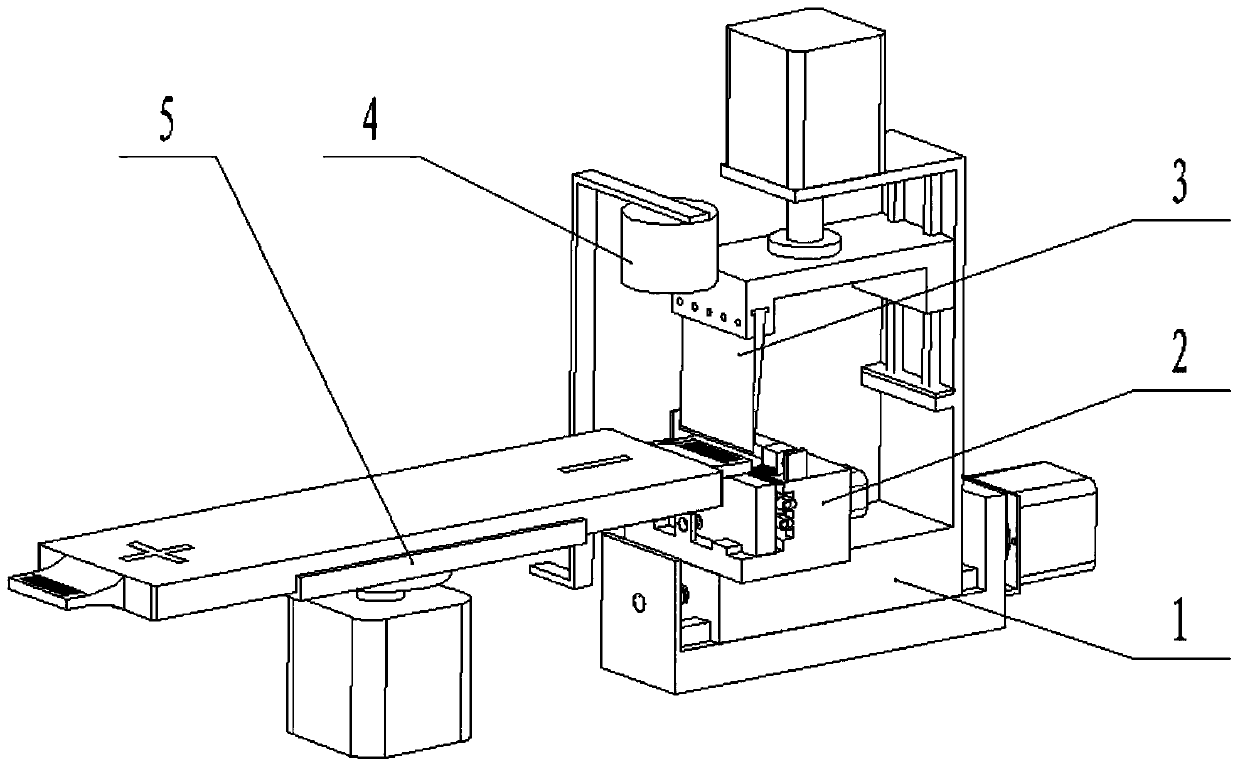

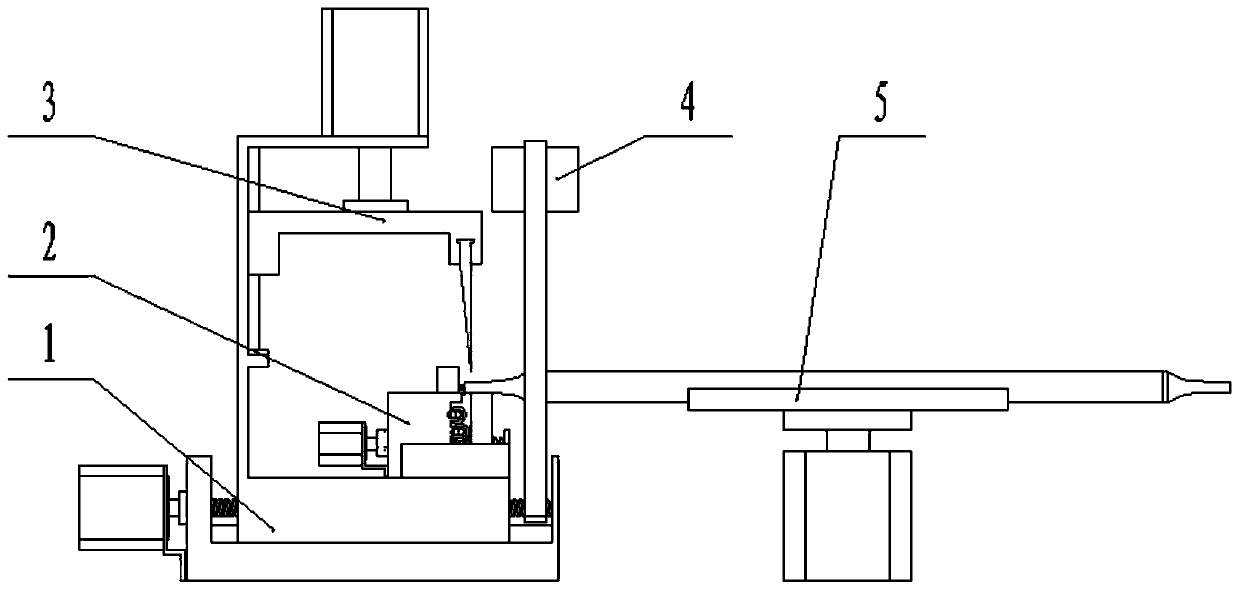

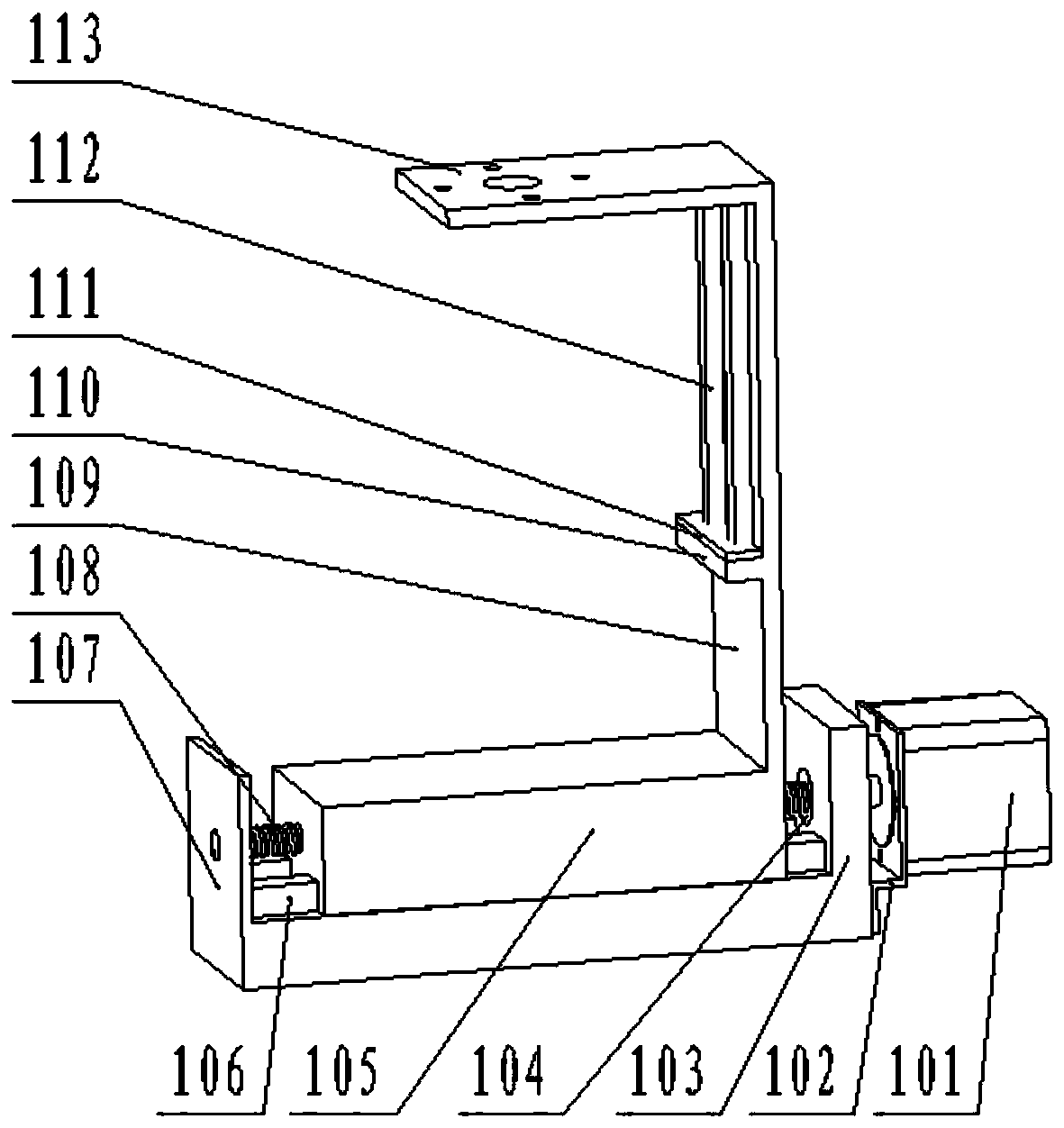

Super-hard blade passivation polishing machine

InactiveCN102179734AEasy to useExtend your lifeOther manufacturing equipments/toolsMotor driveOperational safety

The invention discloses a polishing machine, and in particular relates to a super-hard blade passivation polishing machine. The polishing machine comprises a bench drill, a hairbrush tray arranged on a main shaft of the bench drill, a base positioned below the hairbrush tray and arranged on the bench drill, a speed regulating motor and a planet carrier arranged on the base, a planet gear transmission structure arranged on the planet carrier, blade turntables and blade container trays for holding blades, wherein the planet gear transmission structure comprises a sun gear and planet gears arranged on four sides of the sun gear and engaged with the sun gear; the speed regulating motor drives the sun gear to rotate; a blade turntable is arranged on each planet gear; and the blade container trays are arranged on the blade turntables. By means of the super-hard blade passivation polishing machine, the edge passivation problem of the blades is solved, the operational performance of the super-hard blades is improved, and the service life of the super-hard blades is prolonged; and the polishing machine also has the advantages of compact structure, small volume, high efficiency, operational safety and the like.

Owner:SHENZHEN XINYUNXIANG PRECISION CUTTING TOOLS CO LTD

Composite micro-electrolysis filler as well as preparation method and application thereof

ActiveCN105110427ASolve easy hardeningSolving Passivation ProblemsWater/sewage treatmentElectrolysisIron powder

The invention discloses composite micro-electrolysis filler as well as a preparation method and application thereof, and belongs to the field of wastewater treatment. The micro-electrolysis filler is prepared from the raw materials such as iron powder, charcoal active powder, a dispersing agent, a binding agent, a catalyst and the like. By applying the micro-electrolysis filler into the wastewater treatment, the problem that traditional micro-electrolysis filler is likely to harden and passivate can be solved, the biodegradability of wastewater can be obviously improved, and the wastewater processing efficiency is improved.

Owner:东营国安化工有限公司

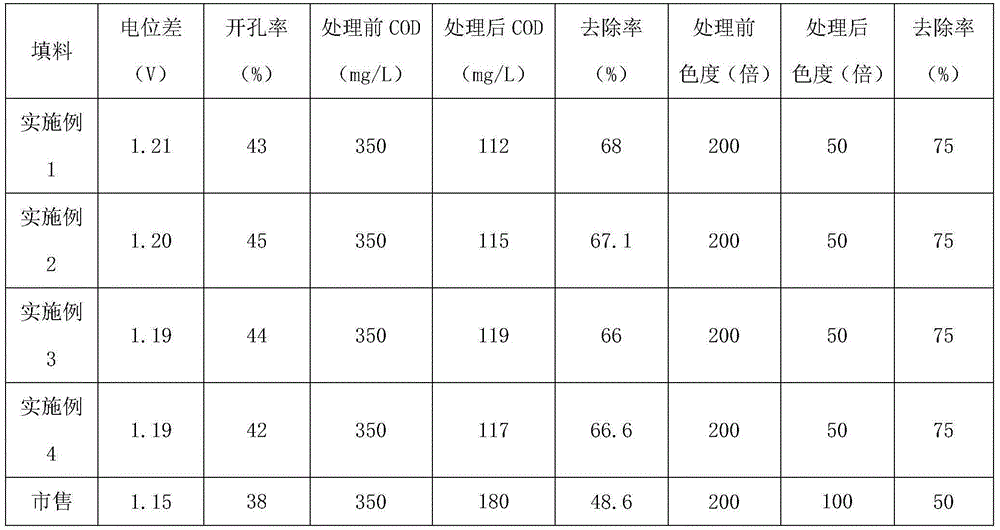

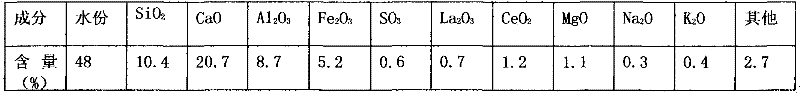

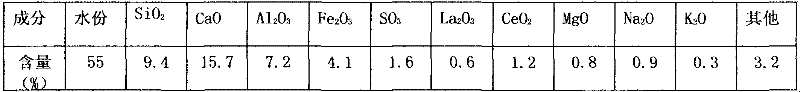

Method for preparing microelectrolysis filler by using various industrial solid wastes

InactiveCN102303915AImprove electrochemical corrosion rateSolving Passivation ProblemsSolid waste disposalWater/sewage treatmentChemical compositionEnvironmental engineering

The invention belongs to a method for preparing a microelectrolysis filler by using various industrial solid wastes and particularly relates to a treatment method for comprehensive utilization of various industrial solid wastes. Aiming at the drawbacks of the conventional microelectrolysis filler, the invention provides a method for preparing the microelectrolysis filler, which is different from the conventional microelectrolysis filler, by using various industrial solid wastes. In the method, the various industrial solid wastes are subjected to innocent treatment in high-temperature and high-heat environments by taking full advantage of the chemical components of the various industrial solid wastes, adopting a mixing, pelletizing and roasting process and fully utilizing a roasting system, and then are prepared into the microelectrolysis filler; and the method has unique technical and economic advantages and meets environment-protection requirements.

Owner:杨祺

Production method for powder porous lead dioxide electrode used for treating organics in water

InactiveCN101555051ALarge real surface areaReduce processing timeWater contaminantsWater/sewage treatmentLead dioxideWater quality

The invention relates to a production method for a powder porous lead dioxide electrode used for treating organics in water, which comprises the steps of: taking PbO2 powder as raw material, mixing the PbO2 powder into paste with sulfuric acid solution with density of 1.10 to 1.145g / L, coating the paste on lead foil and compacting and drying to obtain a PbO2 powder porous dioxide electrode. PbO powder is taken as raw material, and (a) the PbO powder is produced into paste by mixing with sulfuric acid with density of 1.10 to 1.145g / L, coating the paste on lead foil and compacting and drying are conducted so as to obtain a PbO powder porous dioxide electrode; (b) the electrode is put into sulfuric acid with density rho of 1.02 to 1.08g / cm and taken as the anode; electroanalysis is conducted until the surface of the anode turns dark brown; and (c) the anode is cleaned and dried so as to obtain the PbO2 powder porous dioxide. The production method has the advantages of easily conducted preparation process and electrode produced with stable performance and high wastewater treatment efficiency.

Owner:南通金三角石墨制造有限公司

Microelectrolysis filler and use method thereof

ActiveCN103112929ASolve compactionSolving Passivation ProblemsWater/sewage treatmentIron powderWastewater

The invention discloses a processing production and use method of a microelectrolysis filler for wastewater treatment. The prepared microelectrolysis filler consists of the following raw materials: iron powder, inert carbon powder, a binding agent, a surfactant A10, and trace amounts of molybdenum powder and chromium powder. The microelectrolysis filler disclosed by the invention can solve the problems of hardening, passivation, activation and difficulty in replacement of the filler adopted by the conventional microelectrolysis sewage treatment process.

Owner:蓝星工程有限公司

Cloth cutting device for clothing manufacture

ActiveCN110685144APlay a cutting roleLow costGrinding carriagesGrinding drivesStructural engineeringKnife holder

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cloth cutting, aiming to solve the problem that conventional bench type cutting devices are not adaptable to mass cutting of cloth. The cloth cutting device comprises a rack and a lower cutting plate; a blade carrier is arranged on the outer wall of the bottom of the rack, and the outer wall of the bottom of the blade carrier is welded to the outer wall of the top of the lower cutting plate; four mount holes are formed on the outer wall of the top of the lower cutting plate, and four rollers are respectively arranged inside the four mount holes; slide slots are respectively formed on the inner walls of two sides of the rack, two first sliders are slidably connected to the inner walls of two sides of the two slide slots respectively, the two first sliders are the same, mounting shafts are welded to outer walls of opposite sides of the two first sliders respectively, and holderssleeve the outer peripheral walls of the mounting shafts respectively; a cutting blade is fastened to the outer wall of the bottom of the holder, a U-shaped connecting frame is welded to the outer walls of backs of the two first sliders, and a second connecting plate is rotationally connected to the outer wall of the back of the U-shaped connecting frame. In application of the cloth cutting device, squeezing and fixing to single-layer or multi-layer cloth are facilitated, and accordingly, the cutting quality of the cutting blade is improved.

Owner:湖南浚林服饰有限公司

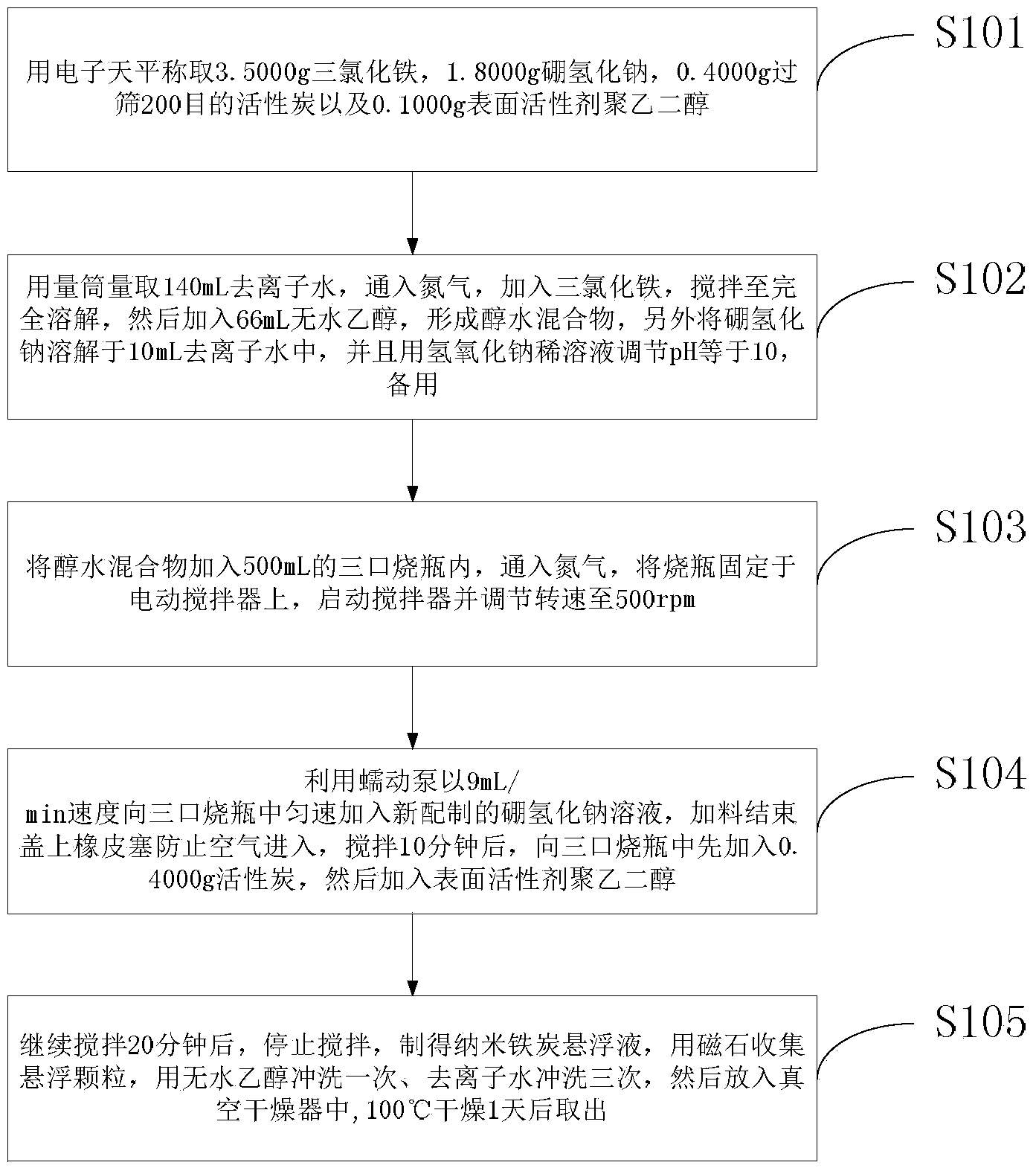

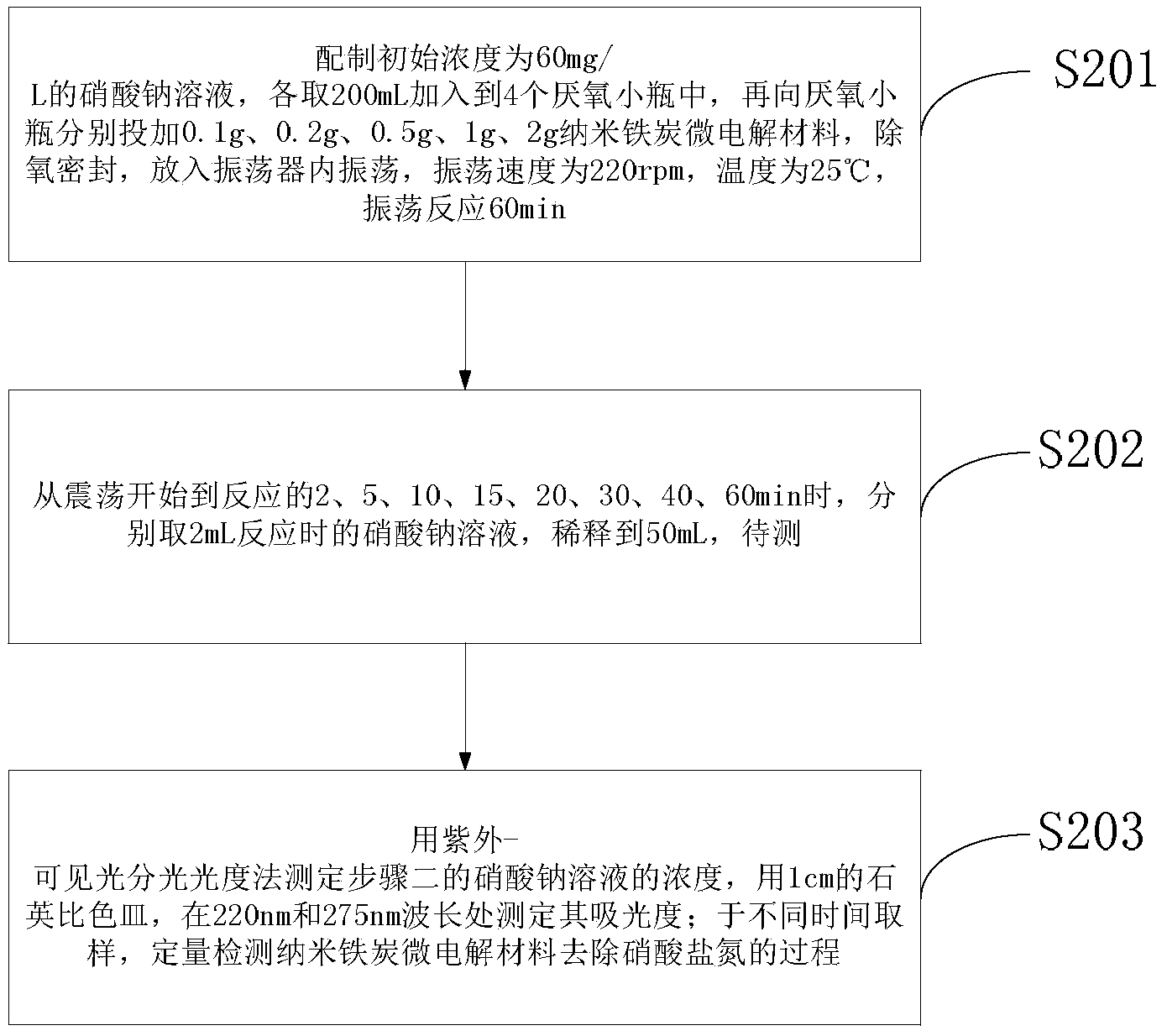

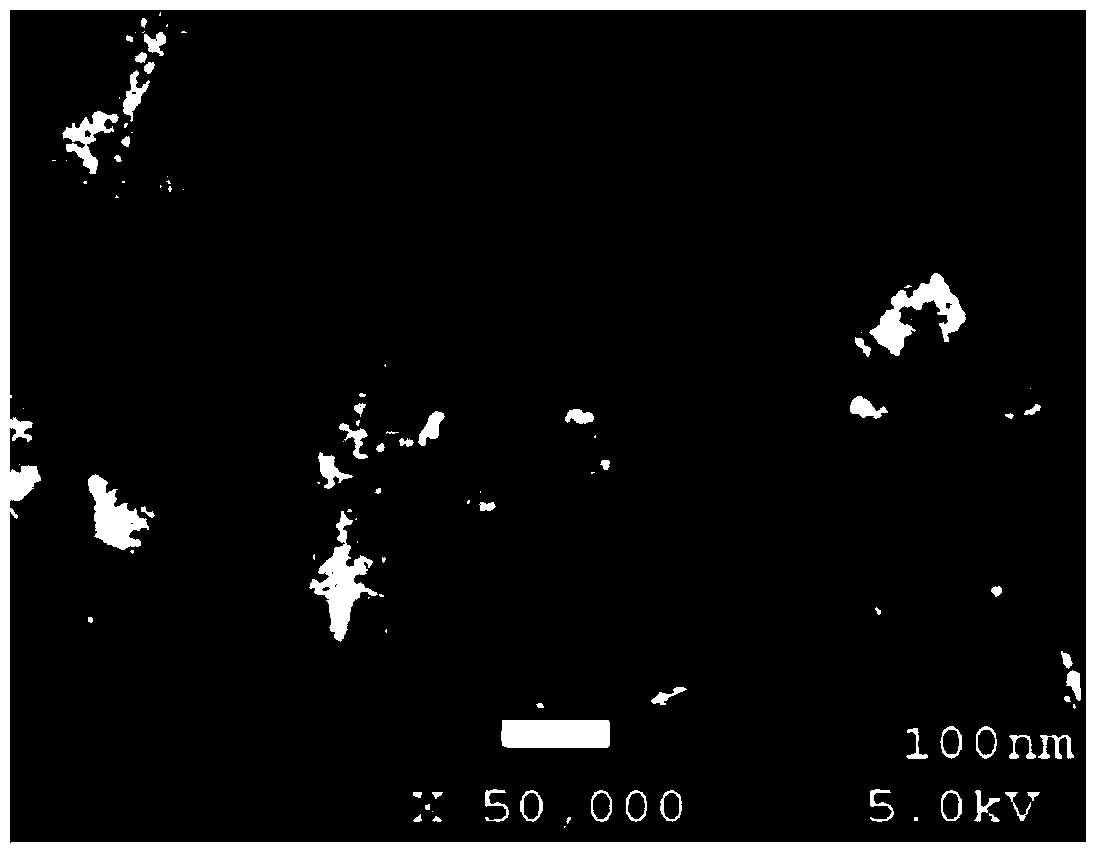

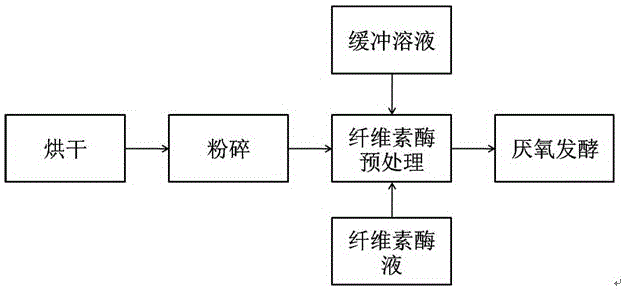

Preparation method of nitrate nitrogen-removed nano-iron-carbon micro-electrolysis material

InactiveCN104045129AIncrease the chance of nucleationImprove growth driveWater contaminantsWater/sewage treatmentGroundwater nitrateElectrolysis

The invention discloses a preparation method of a nitrate nitrogen-removed nano-iron-carbon micro-electrolysis material and belongs to the field of underground water pollutant restoration. The preparation method of the material comprises the following steps: dissolving ferric trichloride in an alcohol-water solution with the ratio of 3:7, continuously stirring, adding a sodium borohydride solution drop by drop, adding active carbon and polyethylene glycol, blowing nitrogen during the whole process, and stirring for 30 min so as to obtain nano-iron-carbon micro-electrolysis particles. The preparation method is simple to operate; raw materials are easily available; the material prepared from the surfactant polyethylene glycol has uniform particle size distribution and good dispersibility; and by combining strong reducing property of nano-iron and high adsorptivity of active carbon, nitrate nitrogen is 100 percent removed. By preparation of the novel nano-iron-carbon micro-electrolysis material, high-efficiency removal of nitrate nitrogen in underground water is realized by a nano-iron-carbon micro-electrolysis technology, and a new technical route and method is provided for effective removal of nitrate pollutants in underground water.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Powder metallurgy iron-based catalyzed internal electrolysis filler and preparation method thereof

InactiveCN105712443AManySolving Passivation ProblemsDispersed particle separationWater/sewage treatment using germicide/oligodynamic-processCompression moldingActivated carbon

The invention relates to the powder metallurgy technology, in particular to powder metallurgy iron-based catalyzed internal electrolysis filler and a preparation method thereof. The powder metallurgy iron-based catalyzed internal electrolysis filler is obtained by weighing iron powder, activated carbon powder, copper powder and nickel powder which are each of a certain particle size according to weight percentage of all components, evenly mixing the powder and refining the powder into the nanometer scale through a ball milling method, pressing the powder into a green body of a certain shape through the compression molding process, putting the green body in an industrial mesh belt sintering furnace to be sintered and conducting natural cooling in the furnace. The technological process is simple, and compared with existing internal electrolysis filler, the prepared powder metallurgy filler has the advantages of being stable in electrochemical effect, high in processing efficiency, low in loss rate, high in material finished product rate and easy to process.

Owner:TONGJI UNIV

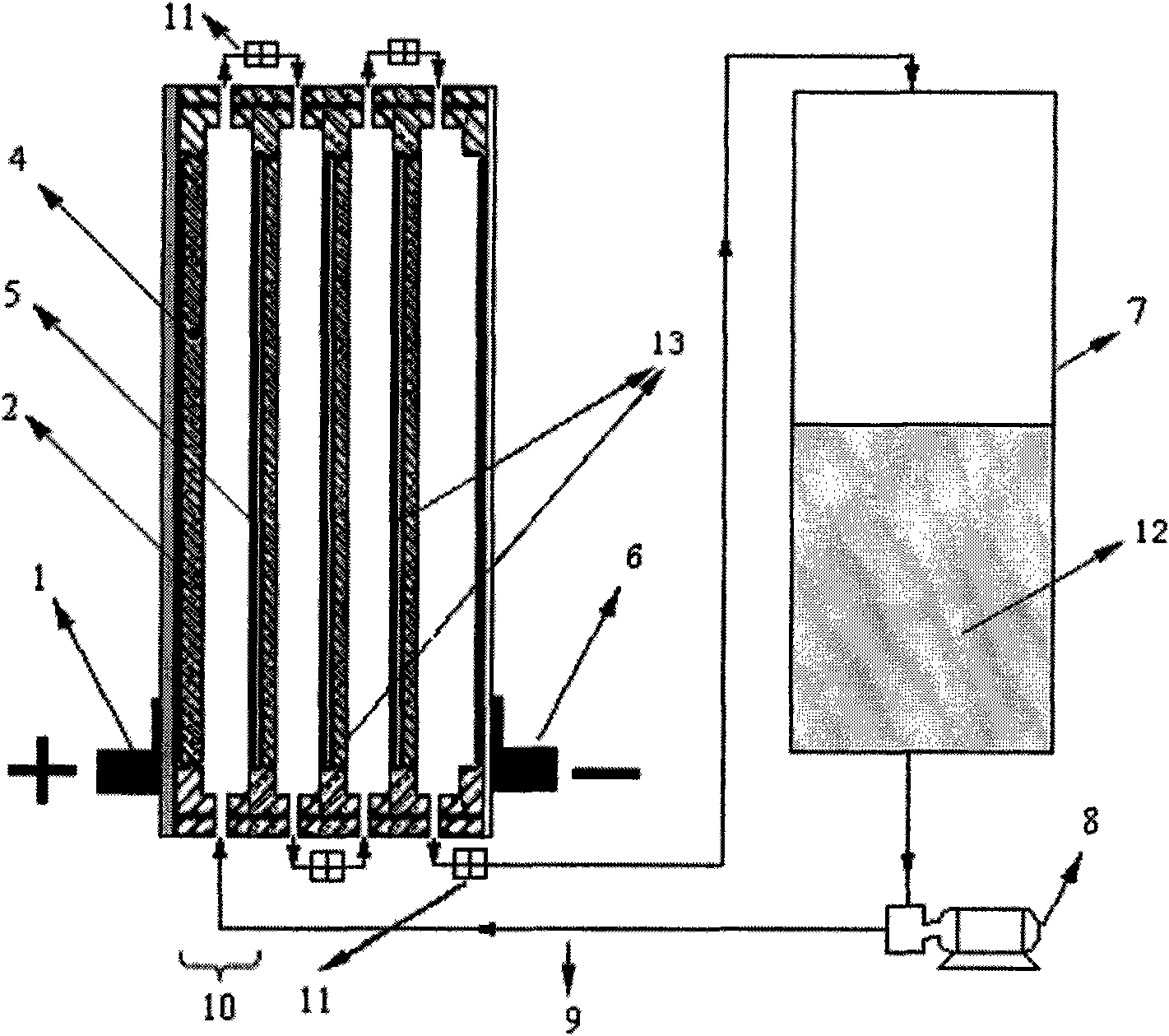

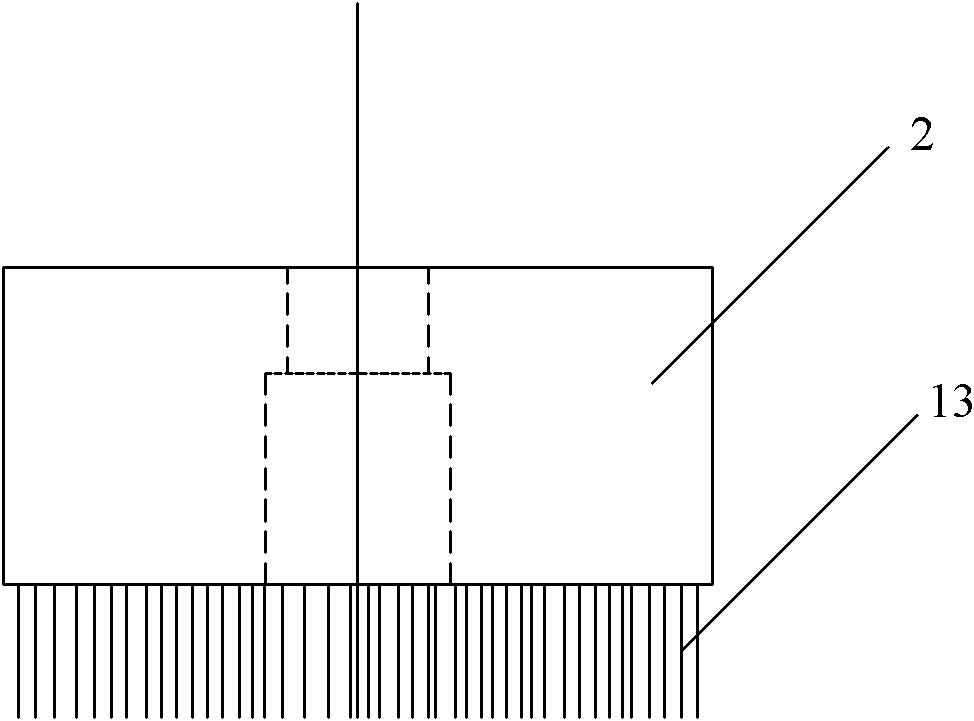

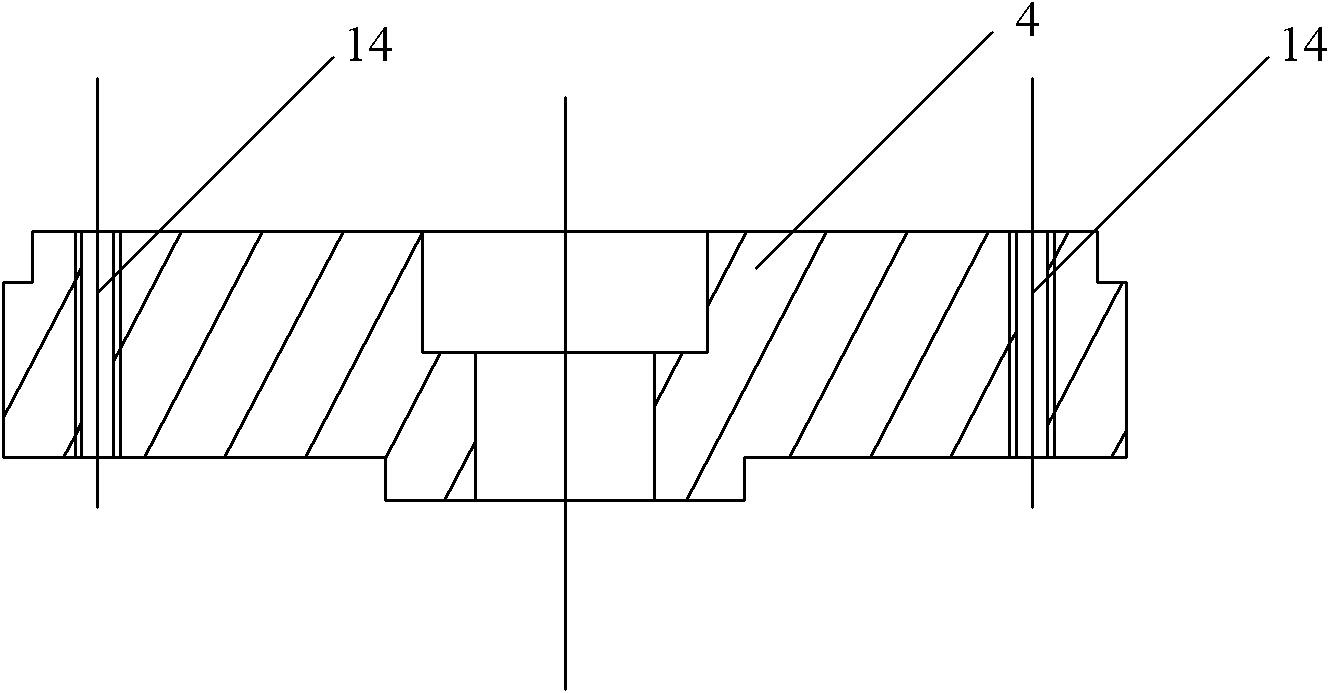

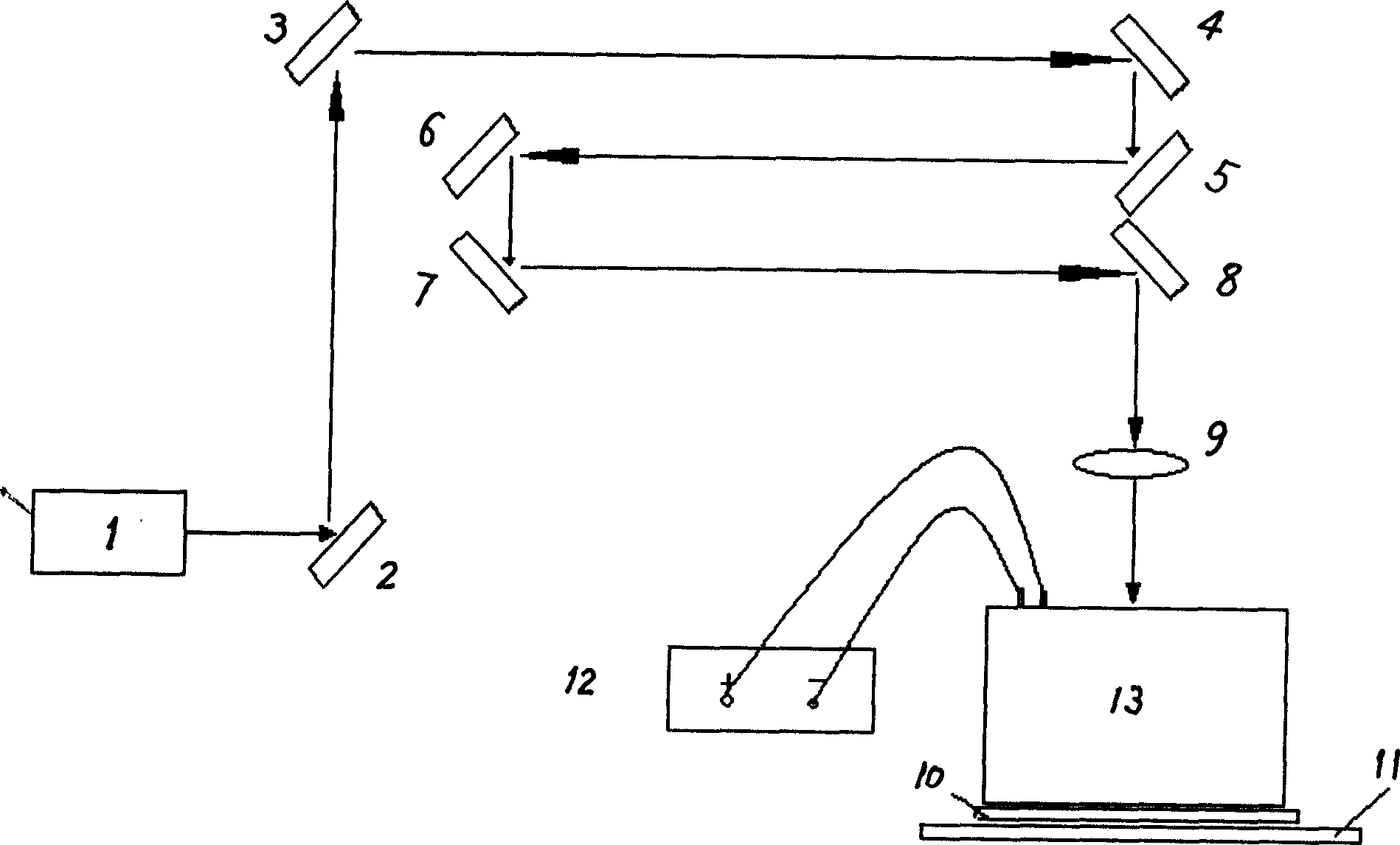

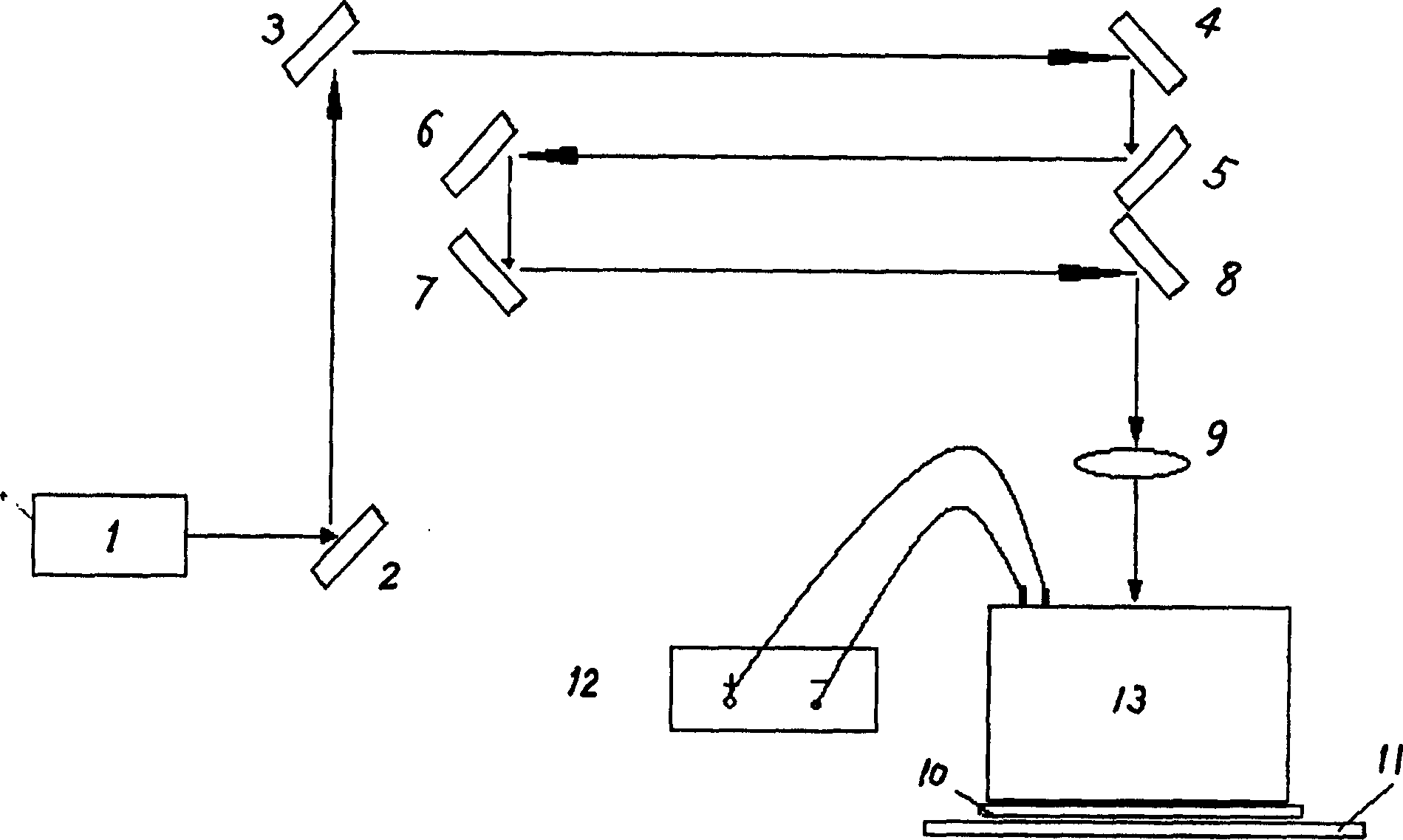

Quasi-molecule laser electrochemical microstructure manufacturing method and equipment

InactiveCN1547079AEliminate damageAspect ratio heightPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrochemical responseShielding gas

The invention belongs to micro manufacturing field, pointing to the deficiency of traditional method, the quasimolecule laser, integrated circuit producing and etching, electric chemical and scanning probe micro technology are integrated together into a new process method. The steps are: (1) produces micro probe array at first; (2) the base is fixed between the plane electrode and the micro probe array, generates the negative voltage, pours in the protection gas; (3) adds in voltage between the two polars after pouring the electrolyte liquid, at the same time, the quasimolecule laser are poured in to control the electrochemical reaction, completes the process. the correspondent device sets an electrochemical reaction room on the laser microprocess machine platform, it includes a laser air moving window, an inlet of protection air, a vacuum pump interface, an electrolyte liquid inlet, a microprobe array, a plane electrode, an assistant electrochemical reaction air inlet and the waste outlet. The invention can acquires microstructure with width-depth ratio 5-50, the character size 1-50 micro meter on the semiconductor base.

Owner:HUAZHONG UNIV OF SCI & TECH

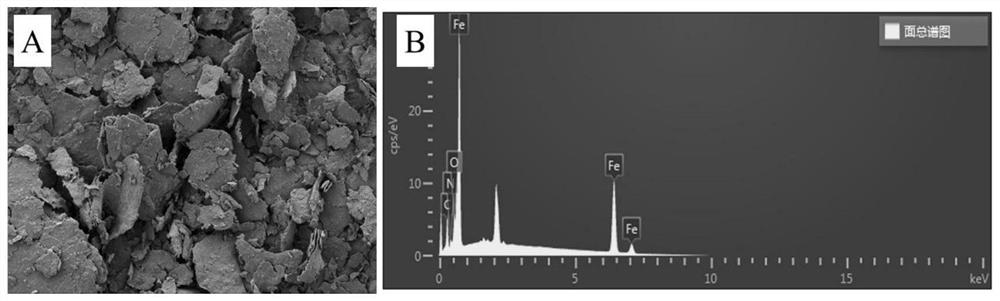

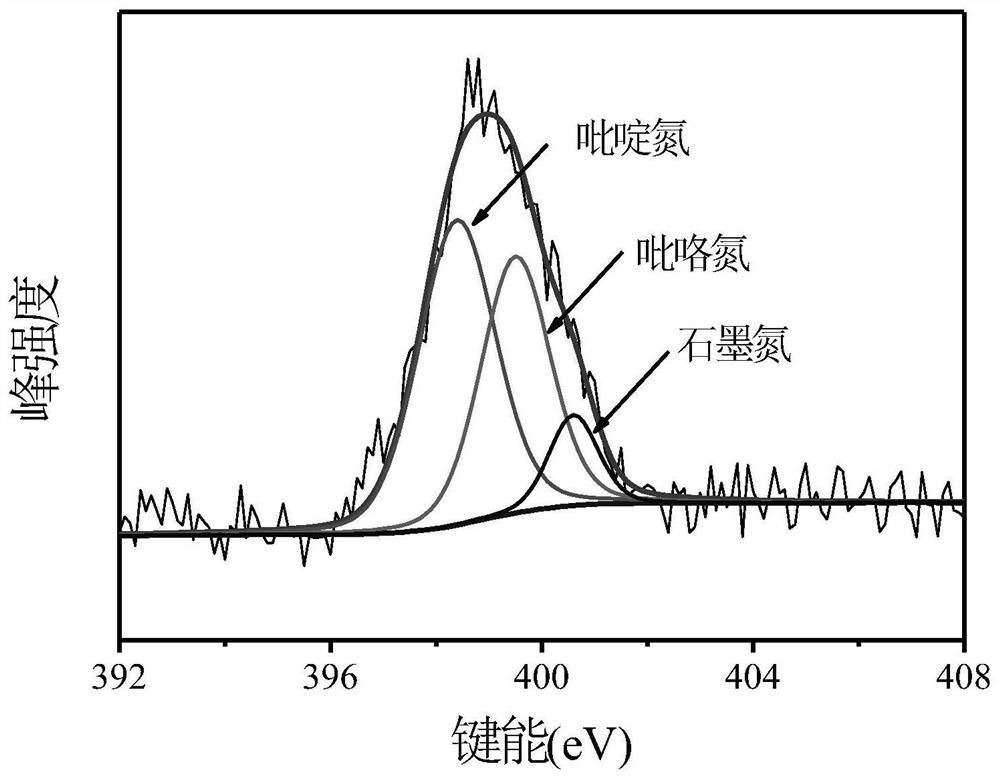

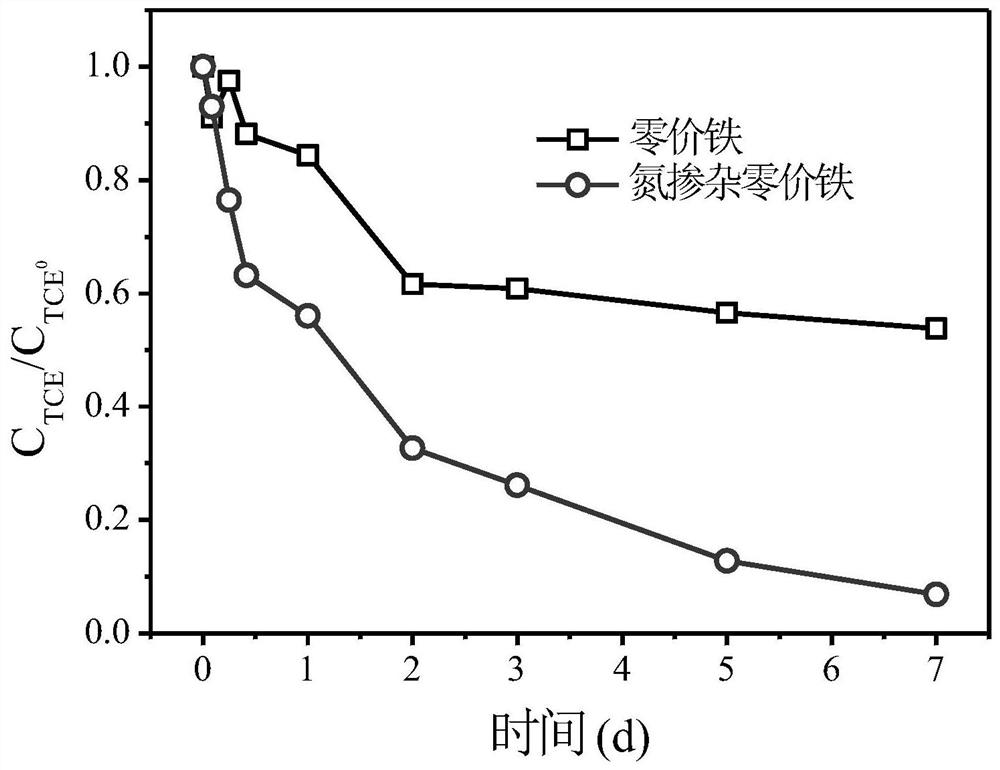

Preparation method and application of nitrogen-doped zero-valent iron composite material

ActiveCN111847541ASimple and fast operationReduce manufacturing costWater contaminantsWater/sewage treatmentIron powderIron nitride

The invention discloses a preparation method and application of a nitrogen-doped zero-valent iron composite material, and the method comprises the following steps: mixing nitrogen-containing compoundpowder and iron powder according to a mass ratio of 1: (9-125) in an inert gas atmosphere, then carrying out ball milling, and obtaining the nitrogen-doped zero-valent iron composite material after the ball milling is finished, wherein the nitrogen-containing compound is melamine, urea, iron nitride or dicyandiamide. The nitrogen-containing compound powder and the iron powder are subjected to ballmilling, pyridine nitrogen, pyrrole nitrogen and graphite nitrogen can be generated on the surface of the obtained composite material and coordinated with iron to form iron nitride, the passivation problem of a zero-valent iron material in the repairing process can be solved, and the removal efficiency of chlorine-containing organic pollutants and heavy metal pollutants is high.

Owner:ZHEJIANG UNIV OF TECH

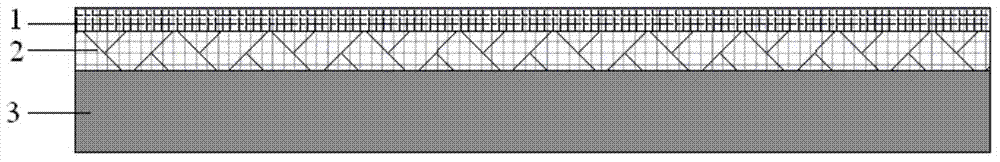

Method for preparing two-phase porous lead dioxide composite electrode

ActiveCN102173480ALarge real surface areaIncrease the reaction areaWater/sewage treatment by electrochemical methodsLead dioxideComposite electrode

The invention discloses a method for preparing a two-phase porous lead dioxide composite electrode, which comprises the following steps of: shearing preprocessed active carbon fibrofelt to have a size which is the same as that of the two-phase porous lead dioxide electrode; and bonding the fibrofelt on the two-phase porous lead dioxide electrode prepared on both sides of a lead calcium alloy net which is subjected to compacting, drying and electrochemical oxidizing and of which the surface is coated with paste lead powder by using conducting glue to obtain the two-phase porous lead dioxide composite electrode. In the method, the active carbon fibrofelt is introduced, and the high adsorbability of the active carbon fibrofelt and the high catalytic activity of the lead dioxide powder porouselectrode are combined to realize the synergistic effect of gathering-electro-catalytic oxidation, enhance the catalytic activity and improve oxidizability. In addition, the active carbon fibrofelt has excellent electrical conductivity, so energy consumption for wastewater treatment is reduced, and the method for preparing the lead dioxide electrode is easy to operate, stable in the performance of the electrode and high in efficiency of wastewater treatment.

Owner:江苏宇益环保工程设备有限公司

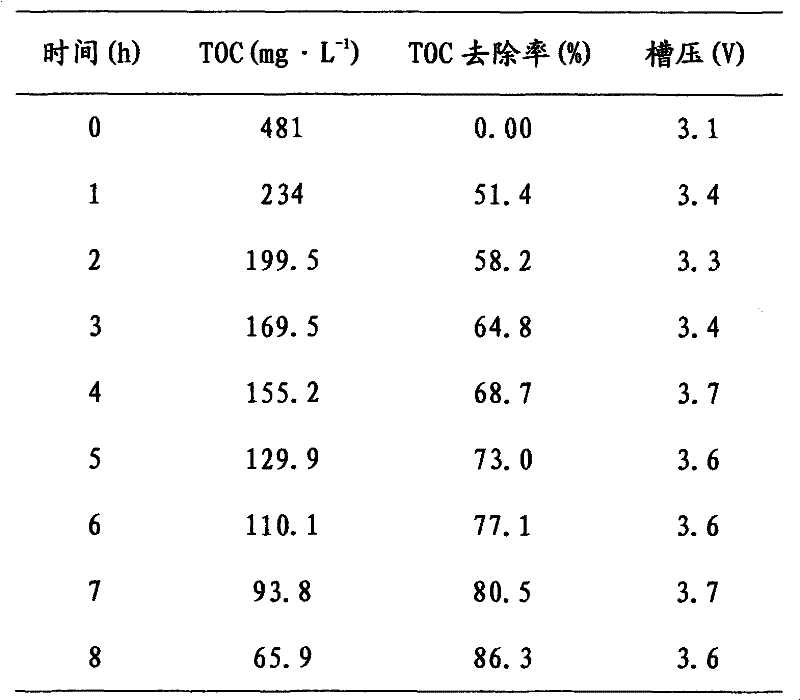

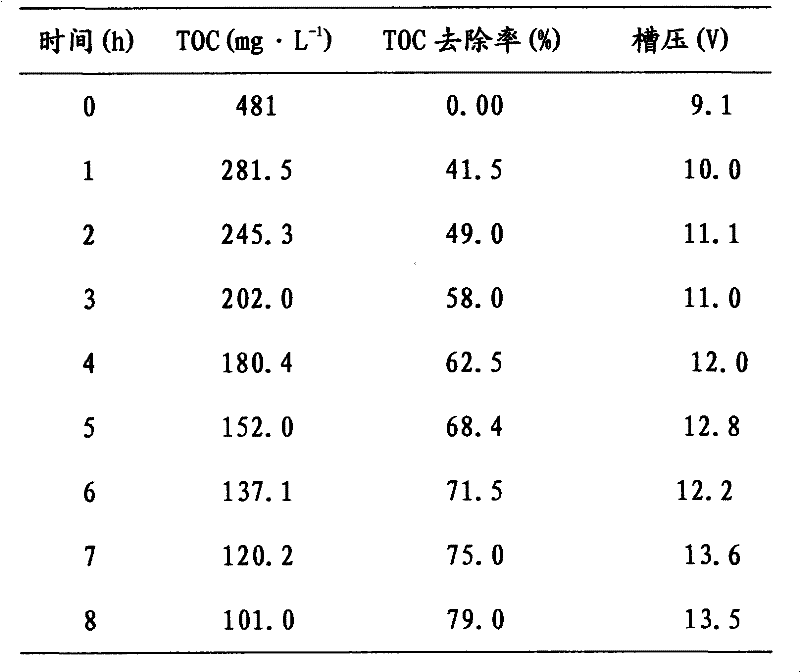

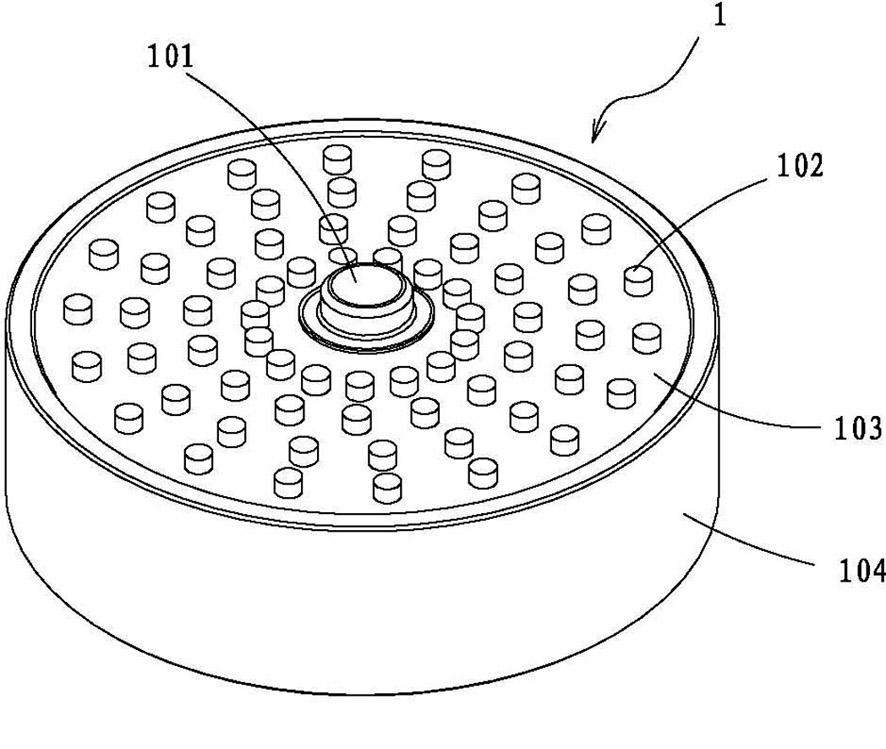

Metal carbon tube component for purifying wastewater and electrocatalytic oxidation device

ActiveCN102674506AIncrease reaction rateGuaranteed long-term stable operationWater/sewage treatment by oxidationPollutantTreatment costs

The invention provides a metal carbon tube component for purifying wastewater. The metal carbon tube component comprises a metal disk and a central tube which is arranged in the inner cavity of the metal disk, wherein a plurality of first through holes used for making wastewater flow into the metal disk are radially formed in the side wall of the central tube; an electrocatalytic material is filled between the outer wall of the central tube and the inner wall of the metal disk; and a plurality of second through holes are axially formed in the disk surface of the metal disk. Due to a structure of flowing anodes and central water distribution, the metal carbon tube component is provided with a channel with a great specific surface area and uniform water flow and gas flow, so that wastewater treatment has higher current density and better catalytic reaction effect. The invention also provides an electrocatalytic oxidation device. The electrocatalytic oxidation device comprises a plurality of metal carbon tube components which are overlapped. Each component is arranged in the inner cavity of a shell, an anode pipe passes through the central tube; both ends are fixed by a support frame respectively and are closed; and one end of the shell is provided with a water inlet and a gas outlet, and the other end of the shell is provided with a water outlet and a drain outlet. The device integrates multiple functions into a whole, has low treatment cost and a good effect of removing organic pollutants.

Owner:深圳市地大东江环境研究院

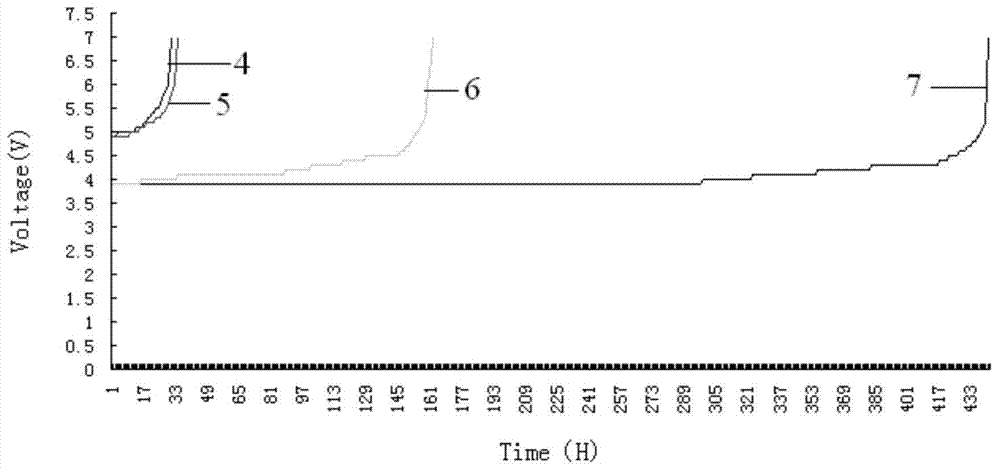

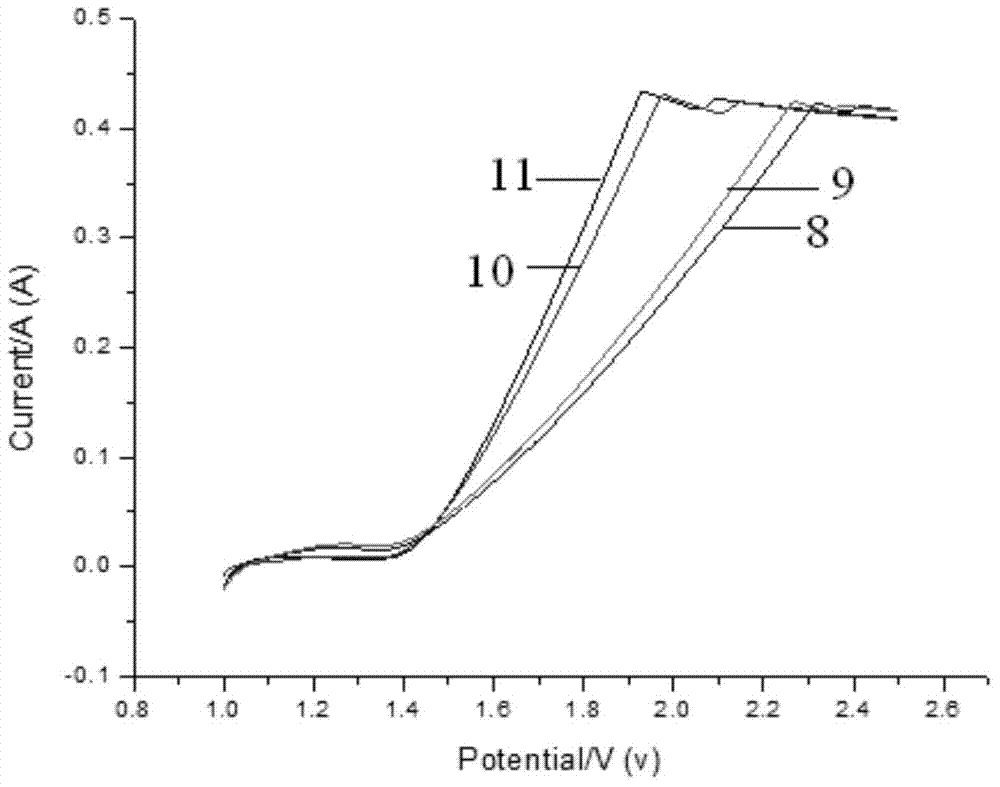

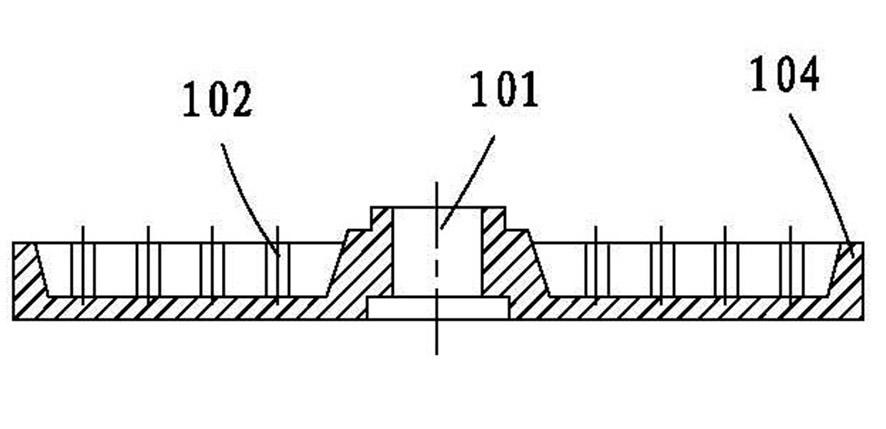

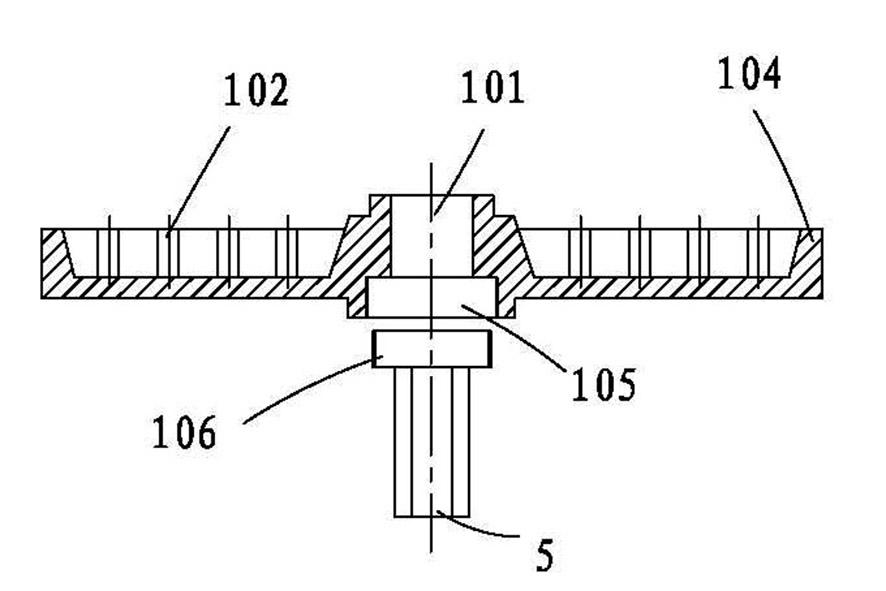

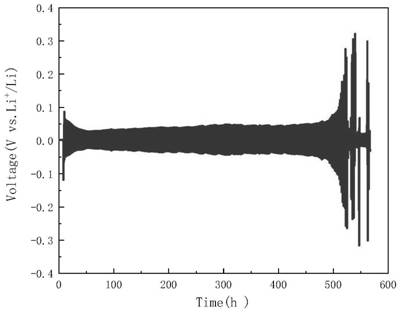

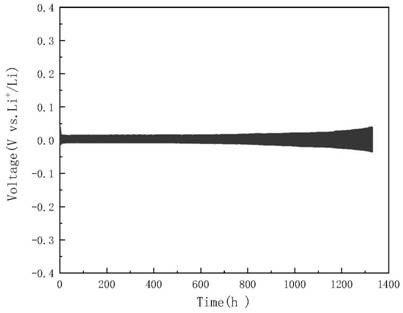

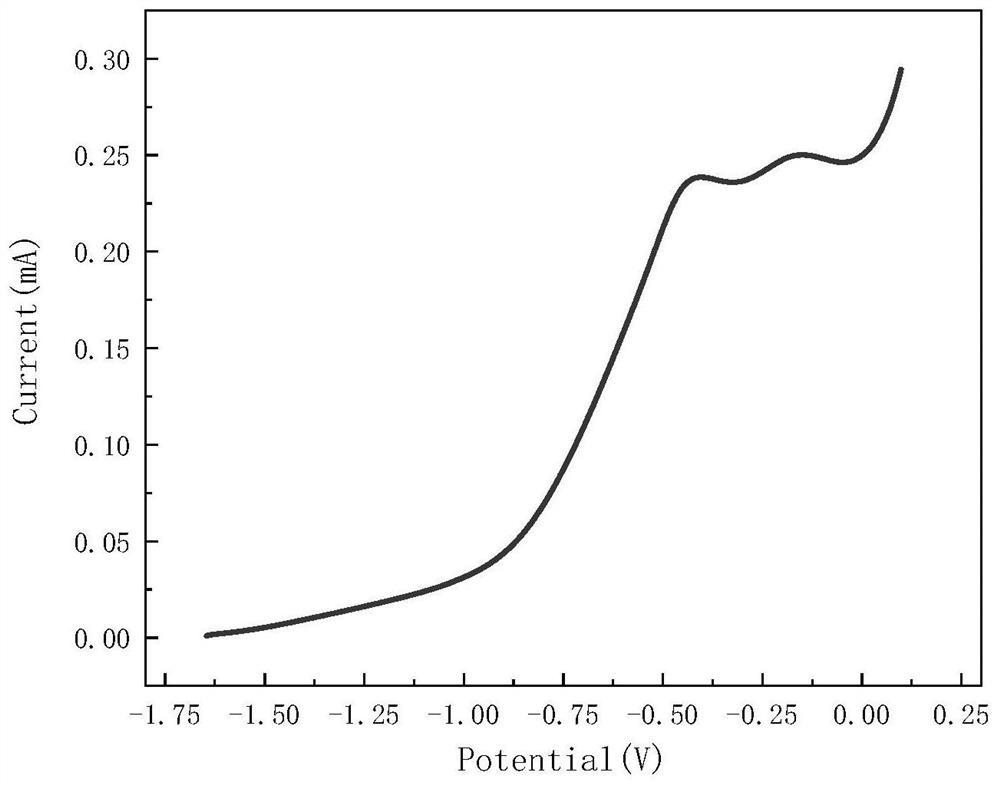

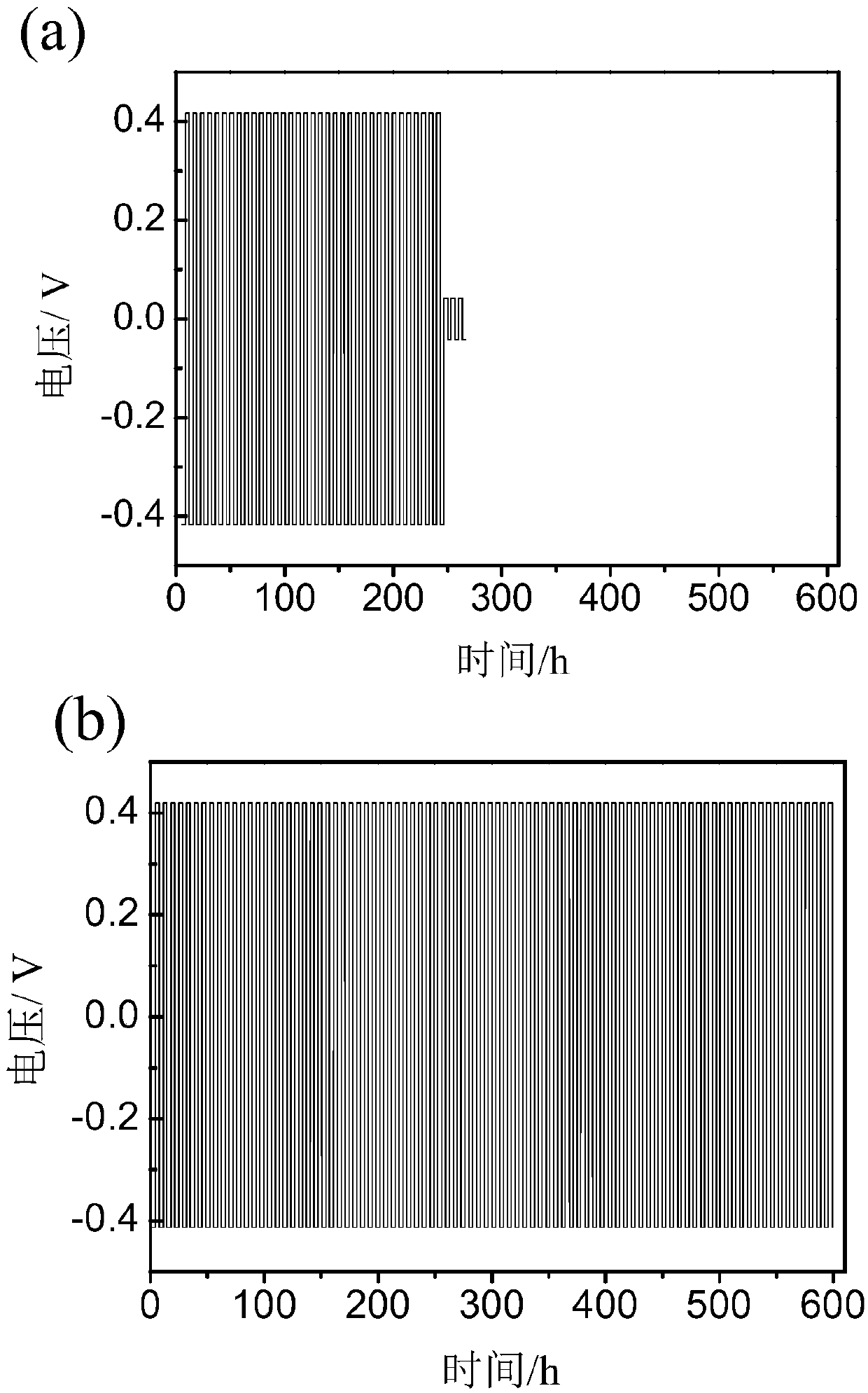

Lithium metal surface modification method and lithium metal battery

InactiveCN112786841AGood uniform depositionAvoid the formation of growthElectrochemical processing of electrodesLi-accumulatorsMaterials scienceLithium metal

The invention discloses a lithium metal surface modification method. The method is characterized by comprising the following steps: 1) preparing an electrolyte of a lithium battery; (2) measuring a polarization curve of the lithium metal in the electrolyte by using the electrolyte in step (1) in a two-electrode system, and obtaining a voltage parameter of an optimal passivation region of the lithium metal according to the polarization curve; and (3) assembling the lithium metal symmetric battery, taking the lithium metal as a positive electrode and a negative electrode, adding the electrolyte prepared in the step (1) to wet a diaphragm, sealing the assembled lithium metal symmetric battery, and then performing constant-potential charging treatment on the lithium metal symmetric battery by using the voltage parameters obtained in step (2) to obtain a surface-modified lithium metal. The method has the advantages that the surface of the lithium metal is treated by measuring the polarization curve of the lithium metal in the electrolyte to obtain the parameters of the optimal passivation region, so that the problem of surface passivation is essentially solved, the lithium metal with a smooth metallographic phase is obtained, and the long-acting cycle performance of the lithium metal battery is further improved.

Owner:NINGBO UNIV

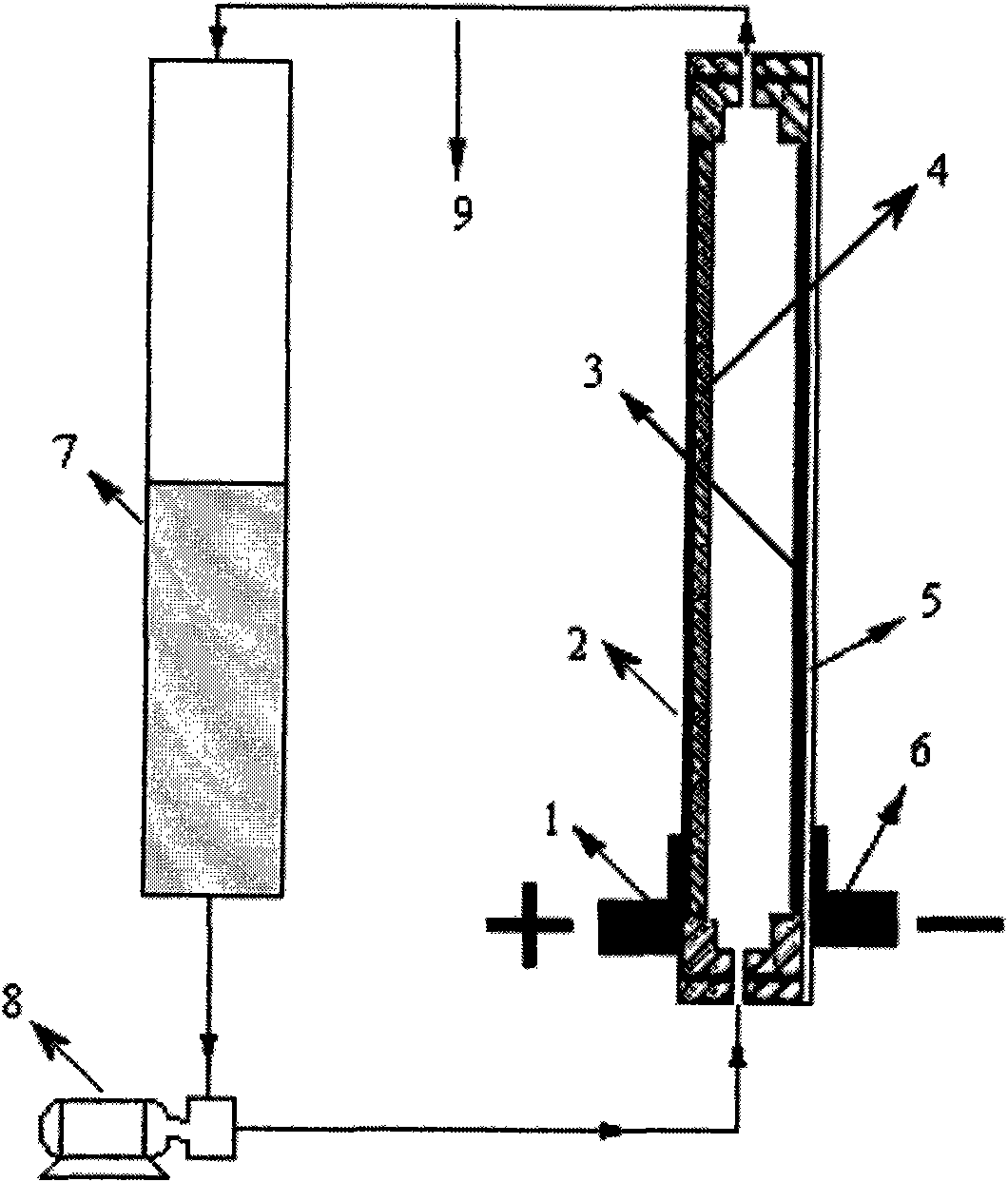

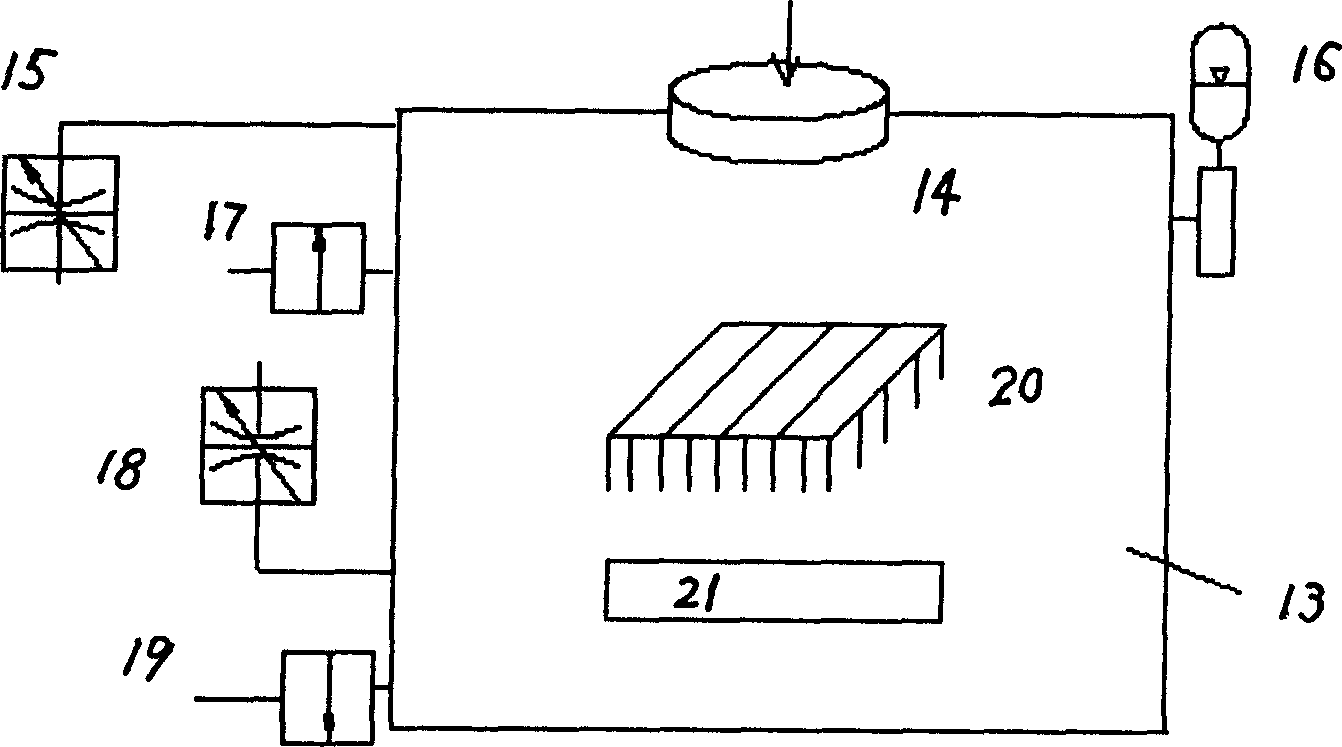

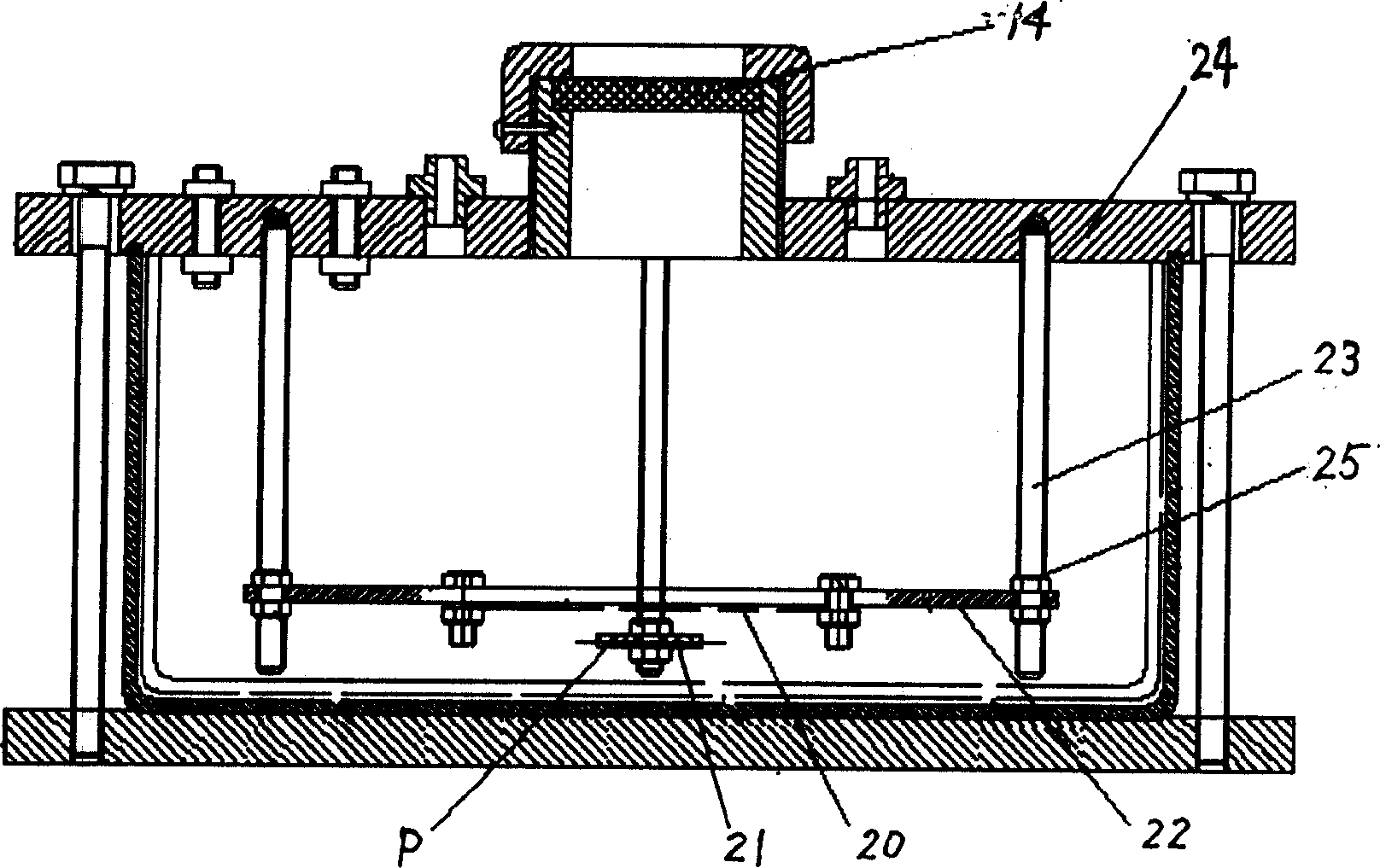

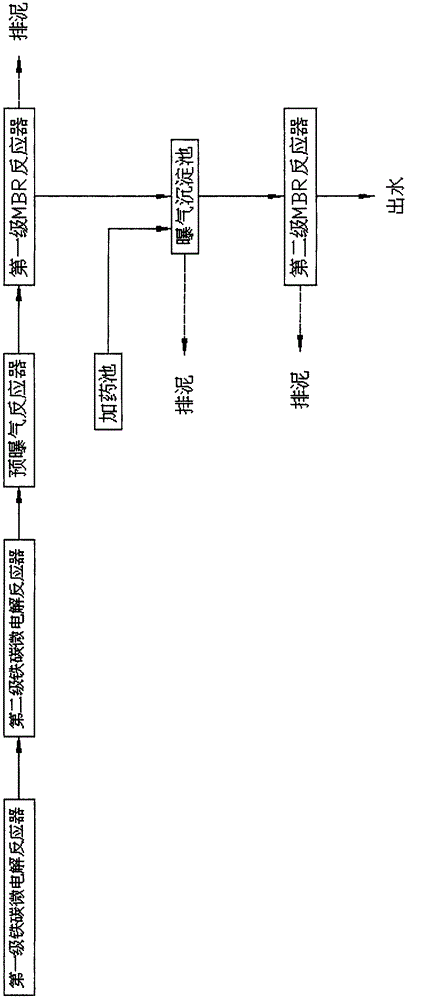

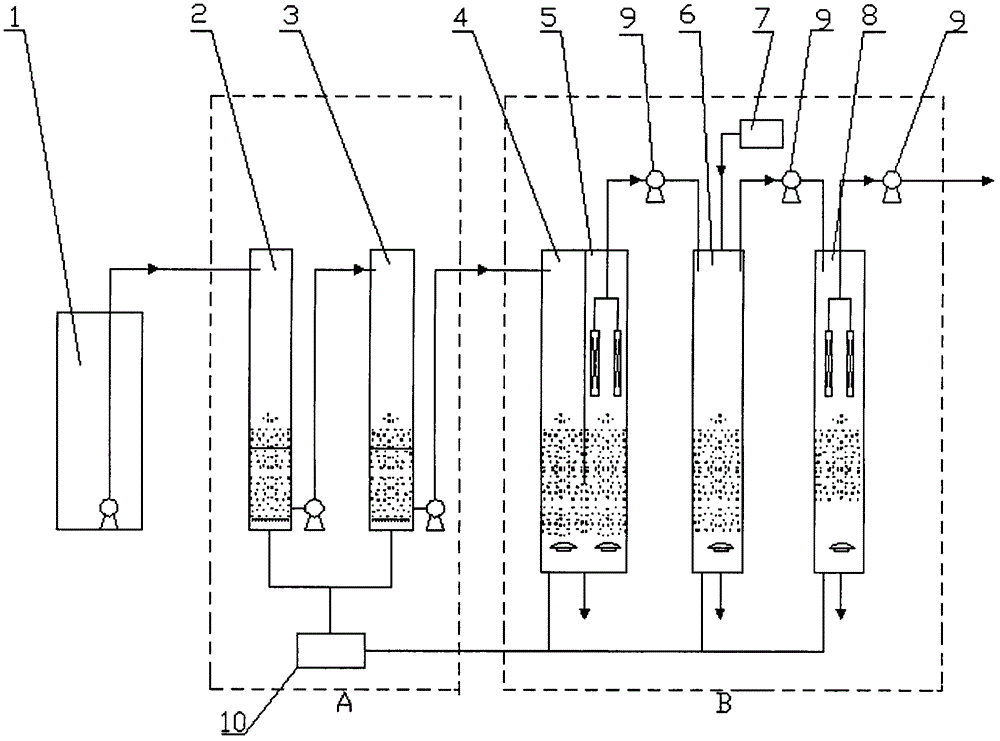

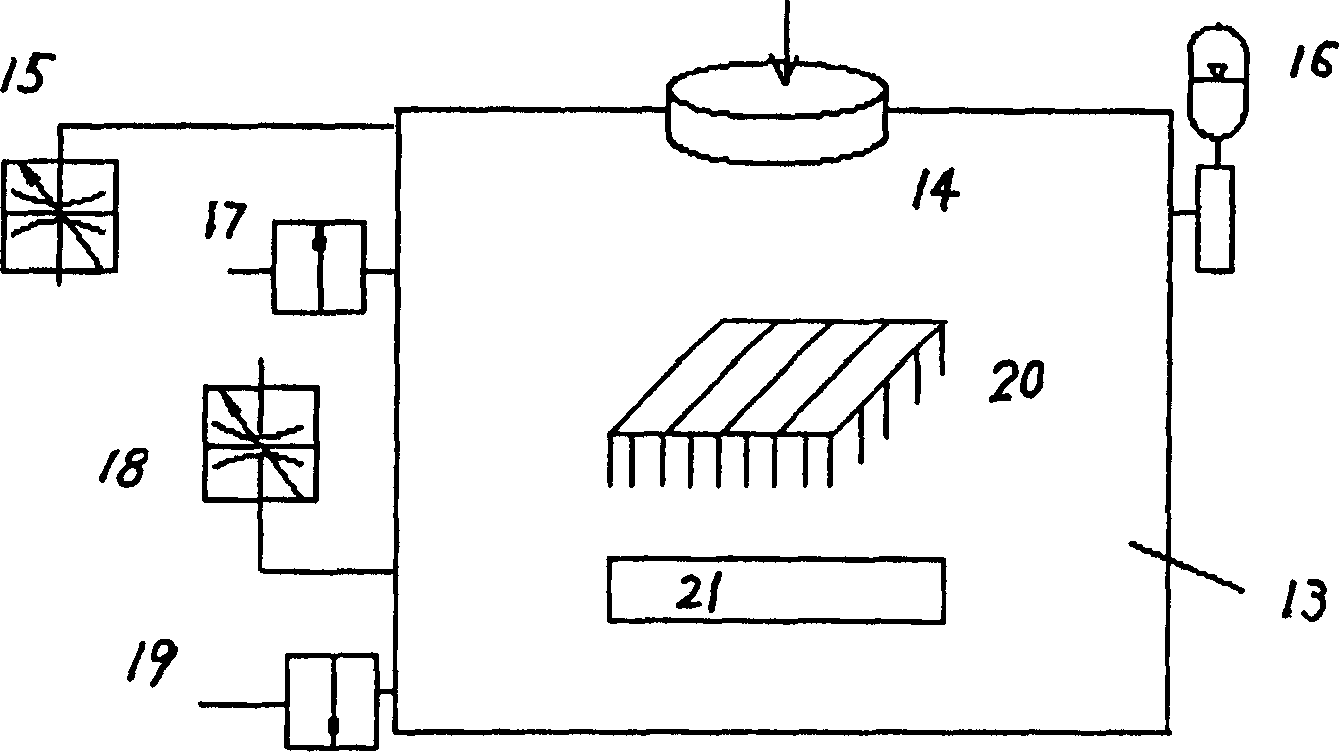

Technology and device for treating percolate from small rubbish transfer station

ActiveCN103145292ALower pHSimple processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationElectrolysisEnvironmental engineering

The invention relates to a technology and a device for treating a percolate from a small rubbish transfer station. The technology realizes combination of two-stage microelectrolysis physicochemical treatment and two-stage MBR biochemical treatment. The technology comprises the following steps of collecting a rubbish percolate by a collection tank, pumping the collected rubbish percolate into a first-stage iron-carbon micro-electrolysis reactor, pumping product water into a second-stage iron-carbon micro-electrolysis reactor, feeding product water obtained by physicochemical treatment orderly into an aeration reactor, a first-stage MBR reactor, an aeration settling pond and a second-stage MBR reactor, carrying out biochemical treatment, and pumping product water obtained by the biochemical treatment out of the device by a metering pump. The technology and the device have advantages of physicochemical and biochemical treatment and realize product water COD less than 1000mg / L in short treatment time. The device has a long service life, low investment and operation costs, and a small floor space, and is a novel rubbish percolate treatment device satisfying transfer station requirements.

Owner:CAPITAL GREINWORTH ENVIRONMENTAL CORP

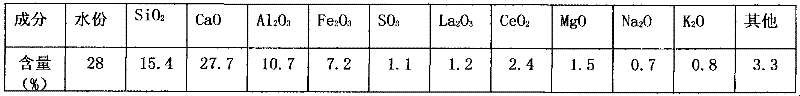

Iron-carbon micro-electrolysis filler and preparing method thereof

The invention relates to an iron-carbon micro-electrolysis filler. The iron-carbon micro-electrolysis filler is prepared from, by weight, 60-80wt% of fine iron powder, 10-25wt% of coal dust, 0.5-2wt%of a binder, 6-10wt% of an additive and 0.2-1wt% of a metal catalyst. The invention further relates to a preparing method of the iron-carbon micro-electrolysis filler. The preparing method comprises the steps that fine iron powder with the sieving particle size as 100 mesh or above and the TFe larger than 70%, the coal dust with 100 mesh, the binder, the additive and the metal catalyst are mixed and stirred according to a proportion to prepare a mixed material; the mixed material is fed into a disc granulator for pelletizing; spherical granules are dried; the dried spherical granules are loaded into a high-temperature-resistance tank for calcining; the spherical iron-carbon micro-electrolysis filler is taken out and packaged after detection. The iron-carbon micro-electrolysis filler has the advantages that the treatment effect is good, the production cost is low, the application range is wide, the treatment reaction speed is high, the effect is stable, and secondary pollution cannot becaused; the biodegradability of wastewater can be improved, the purpose of chemical precipitation for dephosphorization is achieved, settling of sludge is facilitated, and less sludge is generated bythe filler.

Owner:马步真

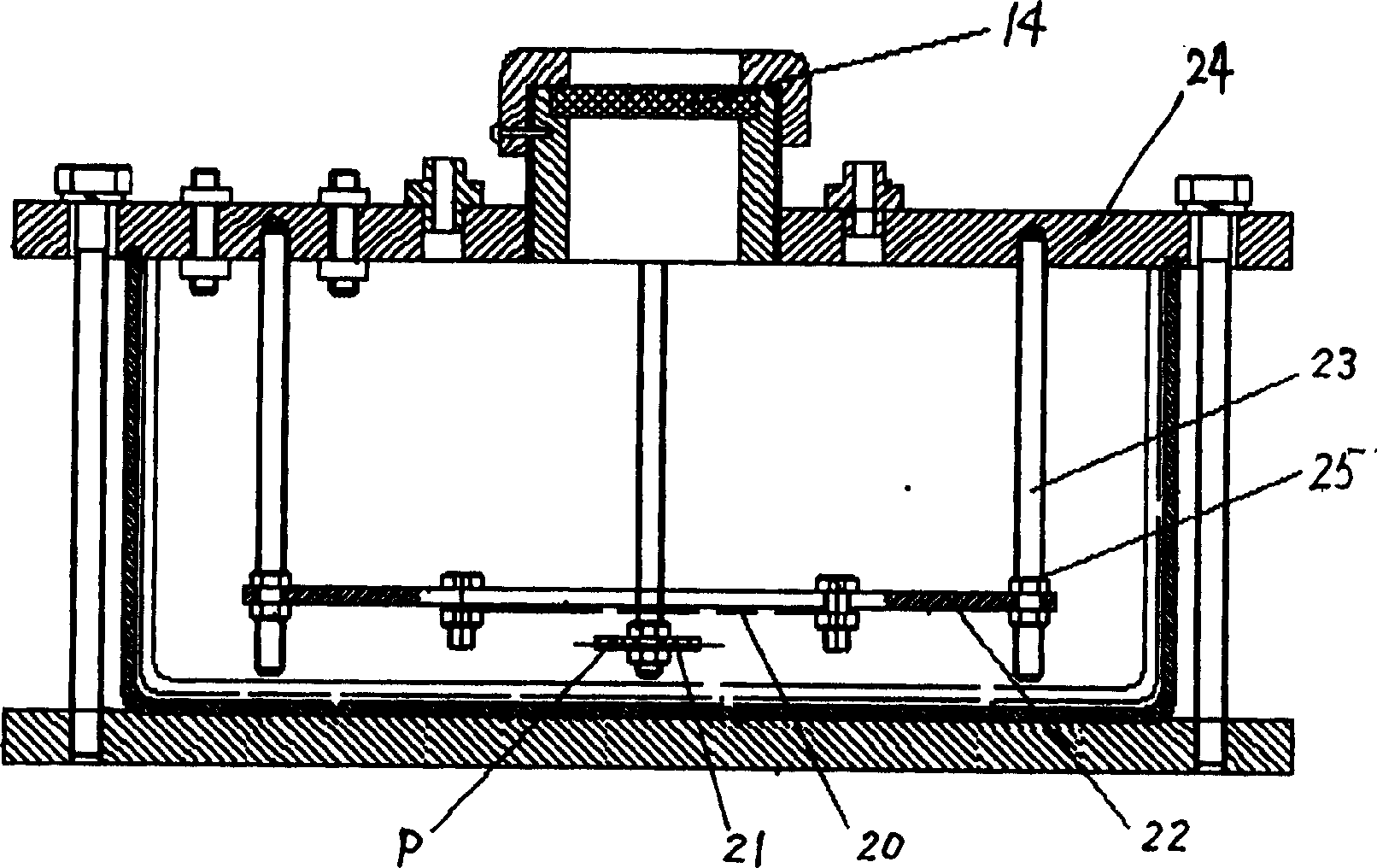

Quasi-molecule laser electrochemical microstructure manufacturing method and equipment

InactiveCN1259598CEliminate damageAspect ratio heightPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrochemical responseShielding gas

The present invention belongs to the field of micro-manufacturing. Aiming at the shortcomings of traditional methods, excimer laser, integrated circuit plate-making lithography, electrochemistry and scanning probe microscopic technology are fused into a new processing method. The steps are: (1) first prepare a microscopic probe Needle array; (2) Fix the substrate between the plate electrode and the microprobe array, generate negative pressure, and inject protective gas; (3) Apply voltage between the electrodes after injecting the electrolyte solution, and at the same time pass through the excimer laser The electrochemical reaction is controlled to complete the machining process. The corresponding device is equipped with an electrochemical reaction chamber on the workbench of the laser microprocessing machine, which includes a laser pneumatic window, a protective gas inlet, a vacuum pump interface, an electrolyte solution inlet, a microprobe array, a flat electrode, an auxiliary electrochemical reaction gas inlet, and a waste outlet. . The invention can obtain a microstructure with an aspect ratio of 5-50 and a characteristic size of 1-50 microns on metal and semiconductor substrates, and has wide applications in the fields of environmental protection, textiles, papermaking, energy, information and national defense.

Owner:HUAZHONG UNIV OF SCI & TECH

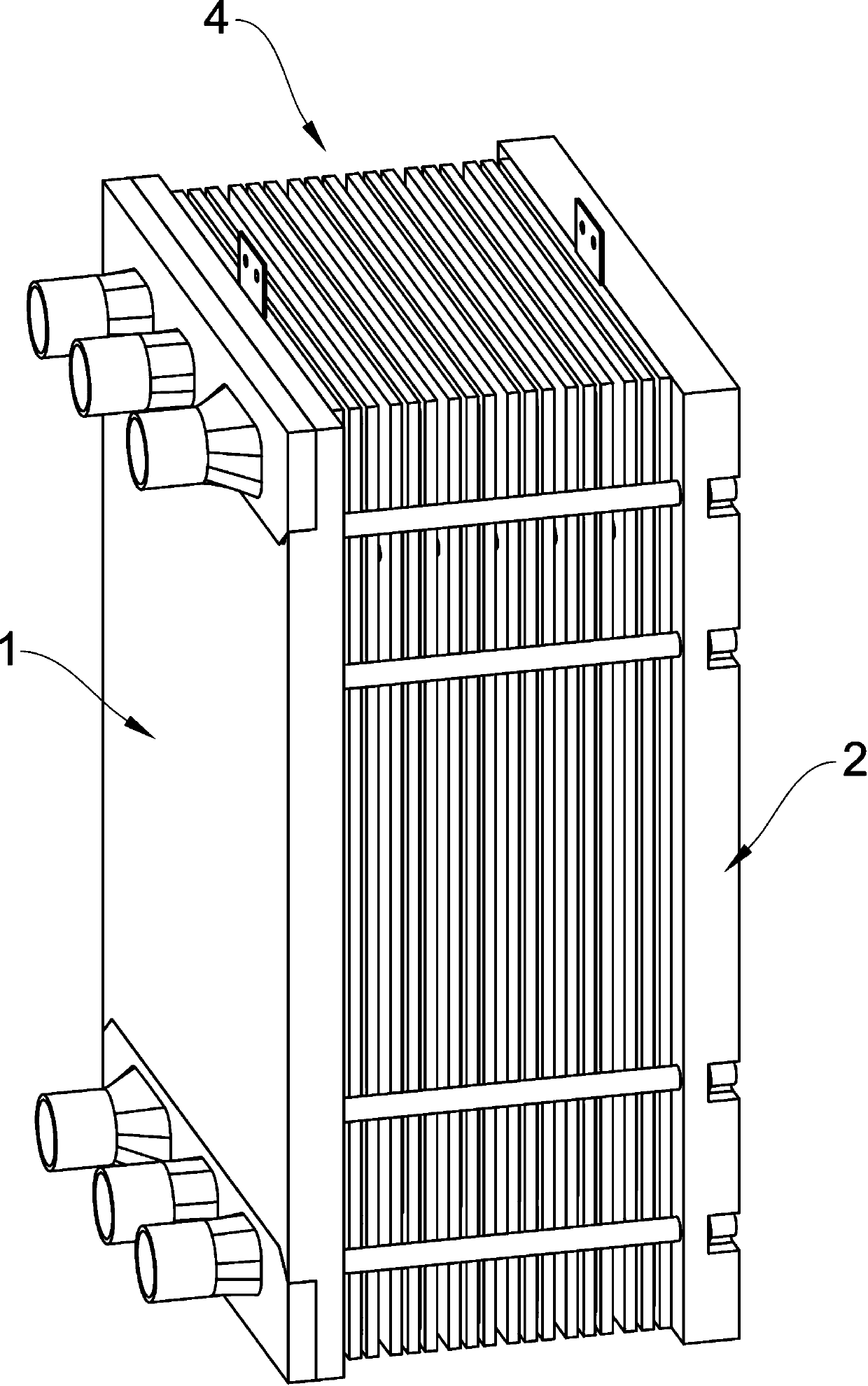

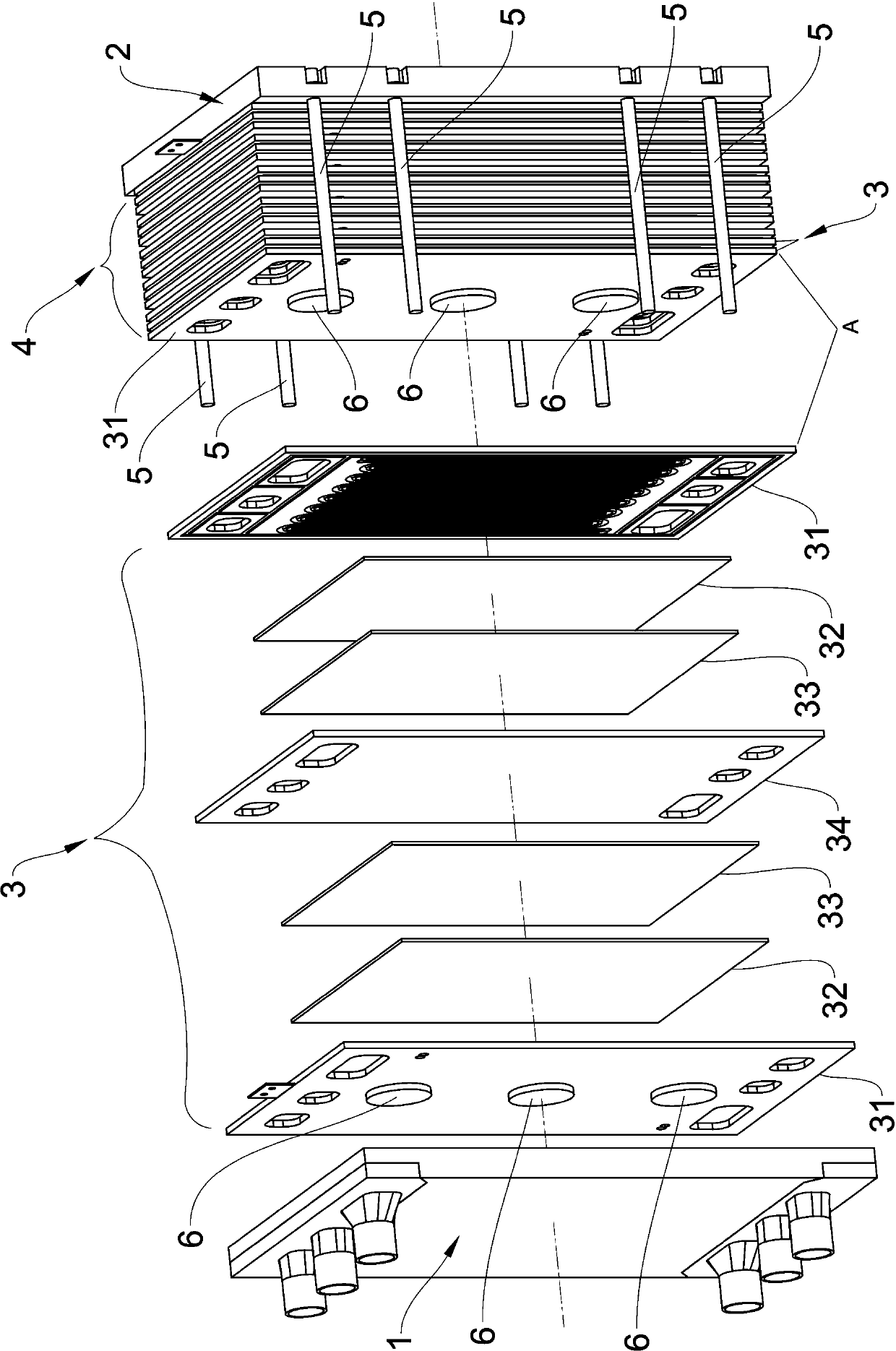

Ultrasonic fuel cell

The invention relates to an ultrasonic fuel cell, which includes a front end plate, a rear end plate, an electric pile formed by stacking up and combining a plurality of single batteries in series, and a screw rod. The electric pile is arranged between the front end plate and the rear end plate and is fastened and fixed by the screw rod. Each single battery is formed by stacking a bipolar plate, carbon paper / carbon cloth, a catalyst sheet layer, a proton exchange membrane, a catalyst sheet layer, carbon paper / carbon cloth and a bipolar plate in sequence. A plurality of ultrasonic transducers are arranged on the outer side of the single battery and positioned on the back surface of the bipolar plate. Each ultrasonic transducer is connected with an electric wire. High-frequency ultrasonic vibration is generated when the ultrasonic transducer works. In this way, impurities generated in the fuel reaction process are prevented from precipitating on the fluid channel, the carbon paper / carboncloth, the catalyst sheet layer, the proton exchange membrane and the like to cause blockage. The passivation of the fuel cell is greatly delayed. The electric energy conversion efficiency of the fuel cell is improved. The service life and the reliability of the fuel cell are greatly prolonged.

Owner:彭志军

Calcium carbide used as water phosphorus removal filter material and preparation method thereof

ActiveCN106219692ASolving Passivation ProblemsSolve the cost problemEnergy based wastewater treatmentWater/sewage treatment apparatusUranium carbideMixed materials

The invention relates to calcium carbide used as a water phosphorus removal filter material and a preparation method of the calcium carbide. The calcium carbide is prepared from, by volume, 0.5-30% of metal materials, 0.5-80% of binding agent, 1-40% of activating agent and 0.5-15% of catalyst. The preparation method of the filter material comprises the steps that the components of the filter material are subjected to micronization and nanocrystallization treatment, and the fineness of the components is not smaller than 300 mesh after micronization and nanocrystallization treatment; the components subjected to micronization and nanocrystallization treatment are mixed to be uniform; the evenly-mixed material is subjected to sintering-free extrusion (hydraulic) molding; the molded product is maintained, dried and packaged. Compared with the prior art, the problems of metal passivation, high cost and lack of timeliness in phosphorus removal methods are well solved.

Owner:上海润溪环保科技有限公司

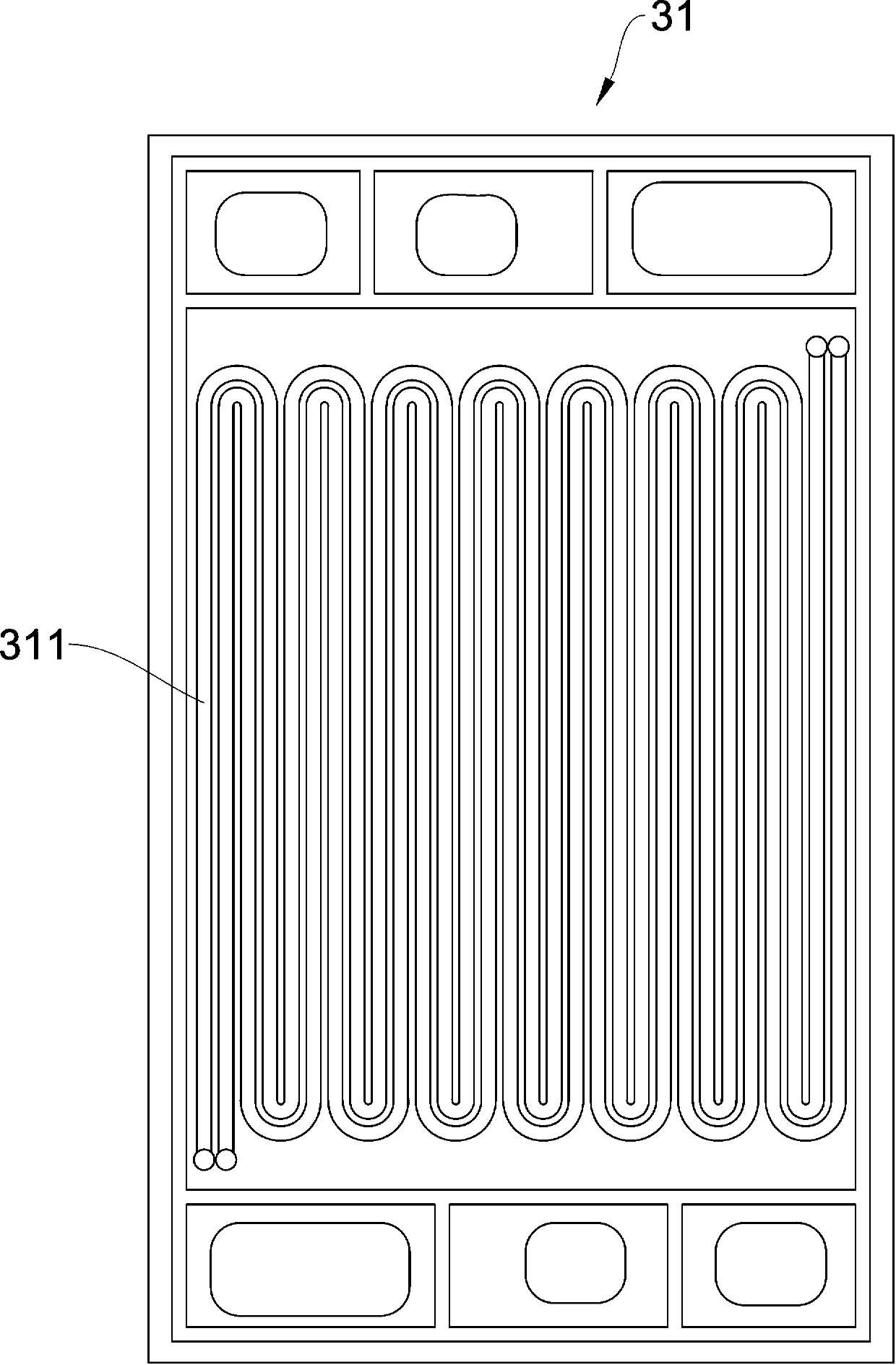

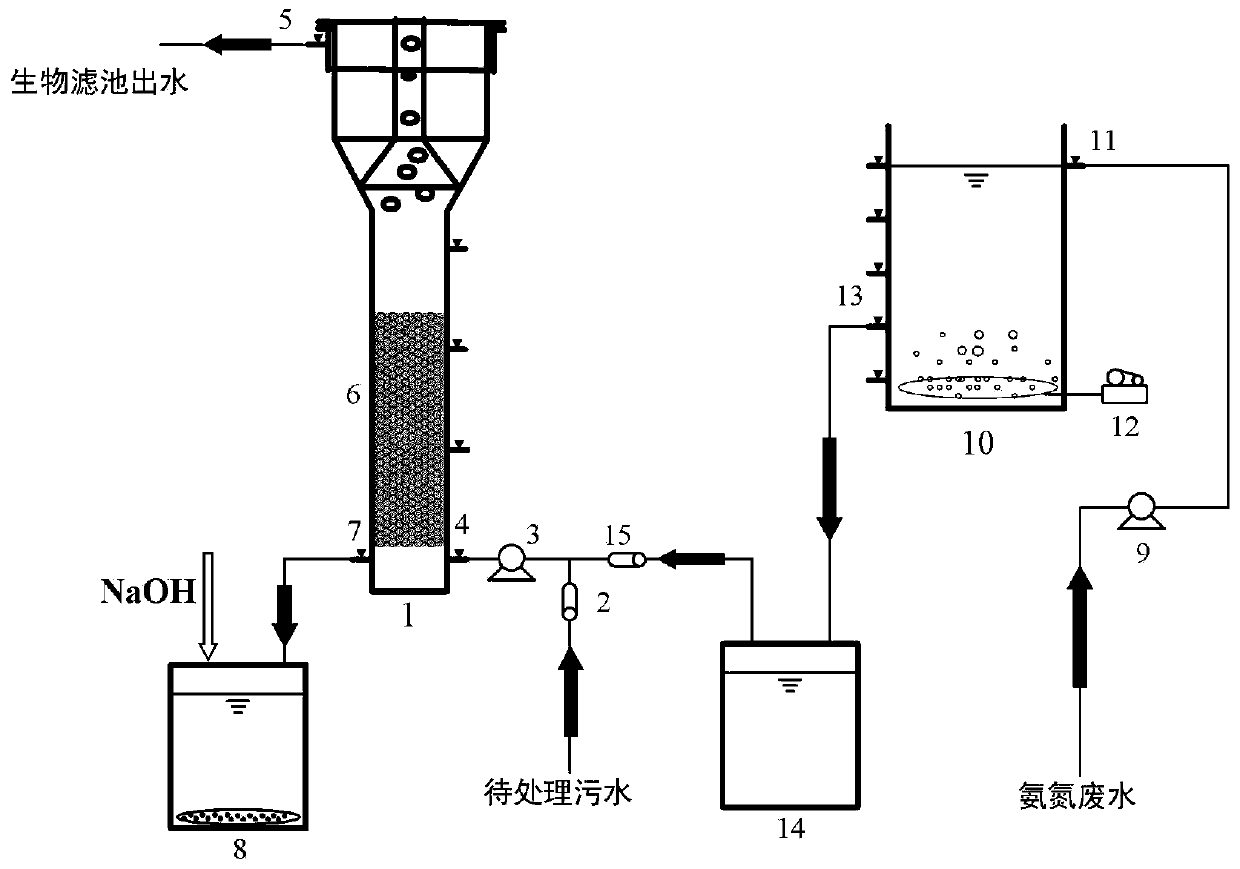

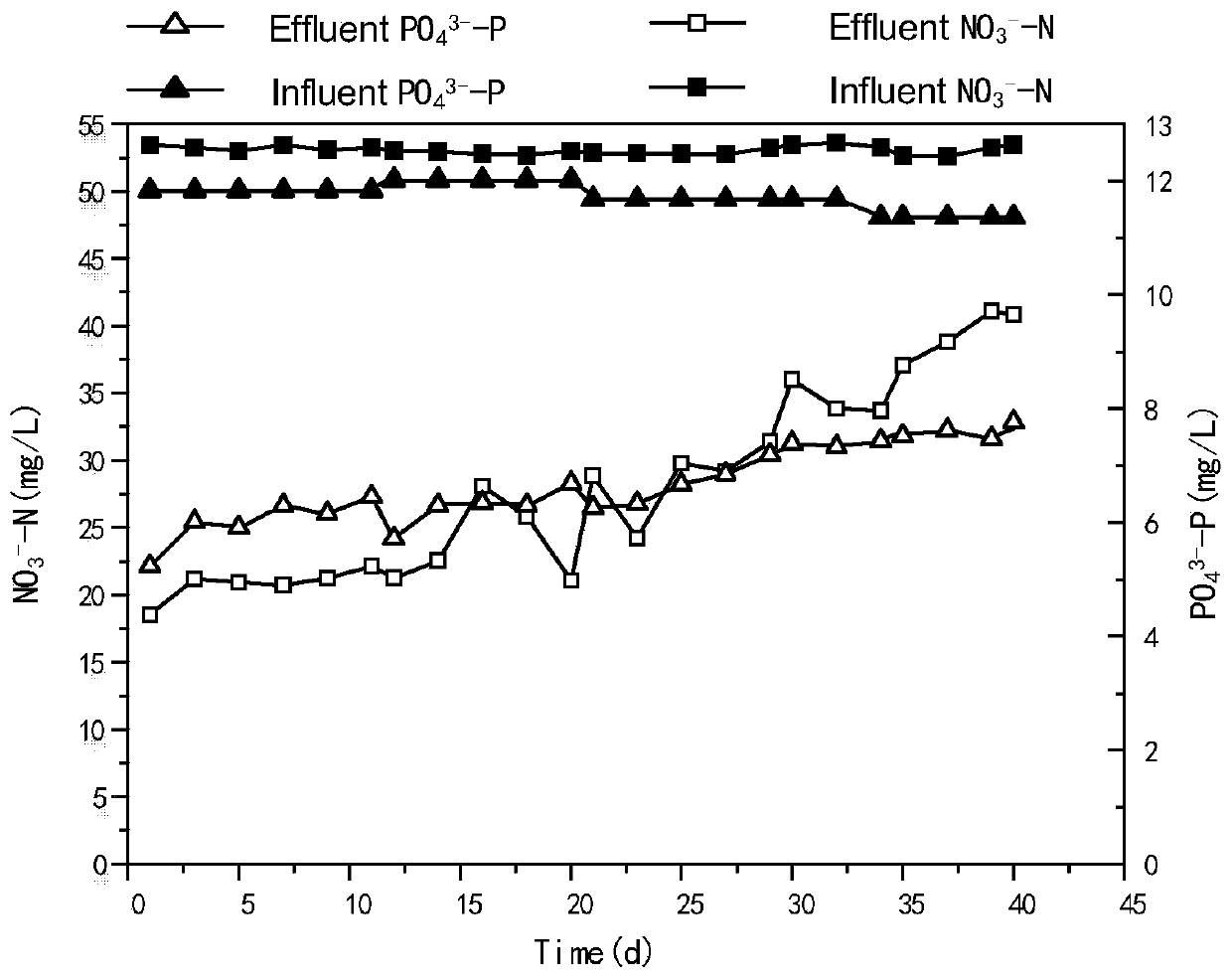

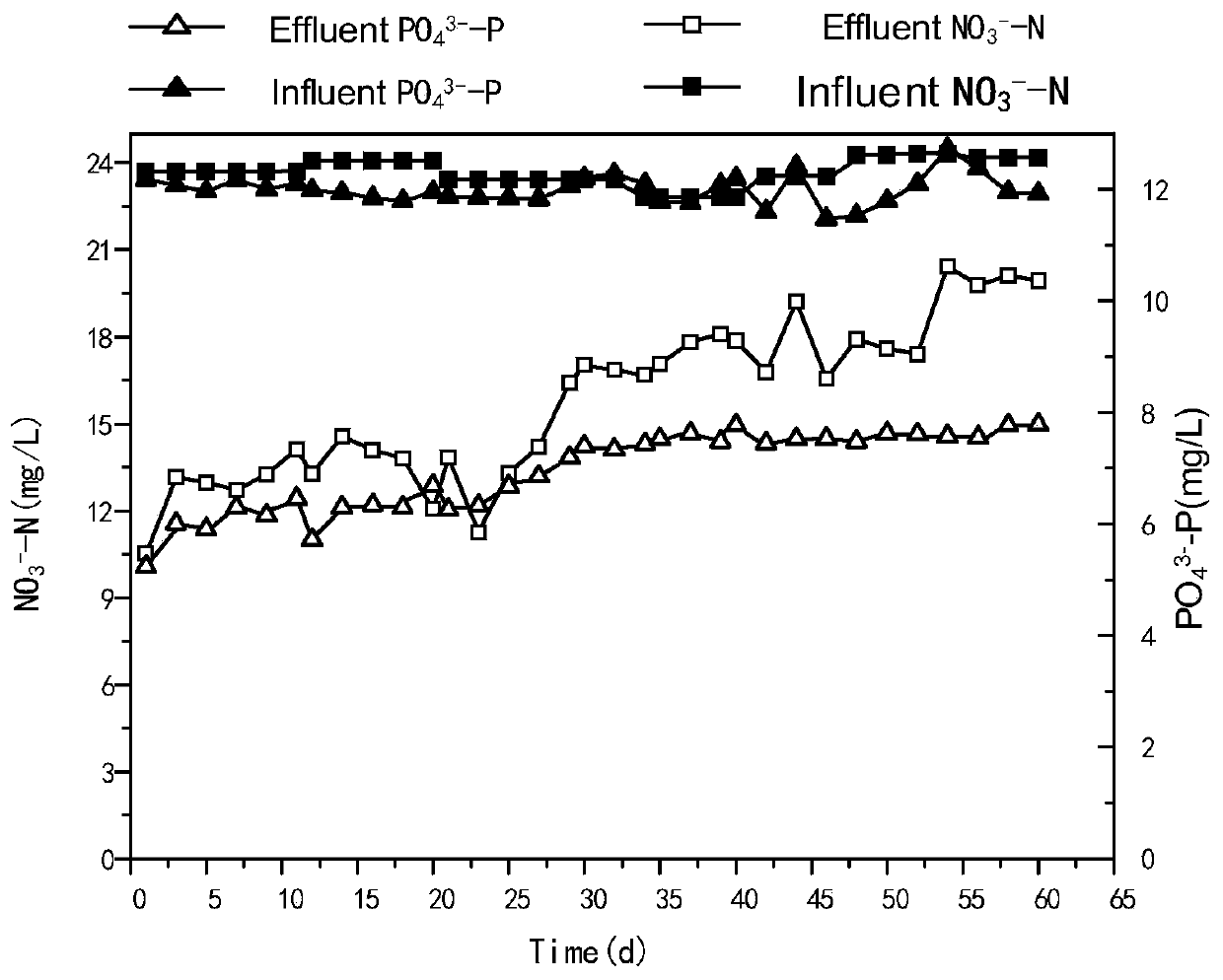

Nitrogen and phosphorus removal water treatment device and treatment method thereof

ActiveCN111018132ASolving Passivation ProblemsEfficient recyclingWater treatment compoundsWater contaminantsActivated sludgeAmmoniacal nitrogen

The invention discloses a nitrogen and phosphorus removal water treatment device and a method for applying the nitrogen and phosphorus removal water treatment device for advanced nitrogen and phosphorus removal of sewage. The device comprises a biological filter tank and a nitration reaction tank, the biological filter is filled with pyrite filler, and a microbial film is attached to the surface of the pyrite filler; wherein the biological filter is provided with a water inlet, a water outlet I and a water outlet II, the water inlet of the biological filter is communicated with two water inletbranches, the first water inlet branch inputs sewage to-be-treated into the biological filter through a water inlet pump I, and the second water inlet branch is communicated with the nitration reaction liquid storage tank through the water inlet pump I and is used for washing the filler in the filter. The sewage is discharged from the water outlet I after being treated by the biological filter, and the biological filter is communicated with the flushing fluid recovery tank through the water outlet II; the nitration reaction tank is provided with a water inlet and a water outlet, ammonia nitrogen wastewater is input into the nitration reaction tank through the water inlet pump II, the water outlet of the nitration reaction tank is communicated with the nitration reaction liquid storage tank, and activated sludge is inoculated in the nitration reaction tank and aerated through an air pump.

Owner:NANJING UNIV

Method for fabricating solar cell

ActiveCN108831953AIncrease the open circuit voltageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationAmorphous siliconSolar cell

The invention discloses a method for fabricating a solar cell, comprising a step S1 of forming an oxide layer on the surface of a first conductive type of substrate; a step S2 of forming polycrystalline silicon or amorphous silicon on the oxide layer; a step S3 of selectively doping the polycrystalline silicon or amorphous silicon with a second conductive type of doping element to form a heavily doped region and a lightly doped region; a step S4 of subjecting the structure obtained in the step S3 to heat treatment in order to convert the amorphous silicon into the polycrystalline silicon; a step S5 of selectively etching the polycrystalline silicon obtained in the step S4 with an alkaline reagent; and a step S6 of forming an electrode in the heavily doped region. The method forms the metalon the thick polycrystalline silicon by selectively doping the polycrystalline silicon, thereby reducing the recombination at a metal and semiconductor contact position. Further, the thin polycrystalline silicon is used for light transmission so as to achieve a passivation effect and light transmission balance.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

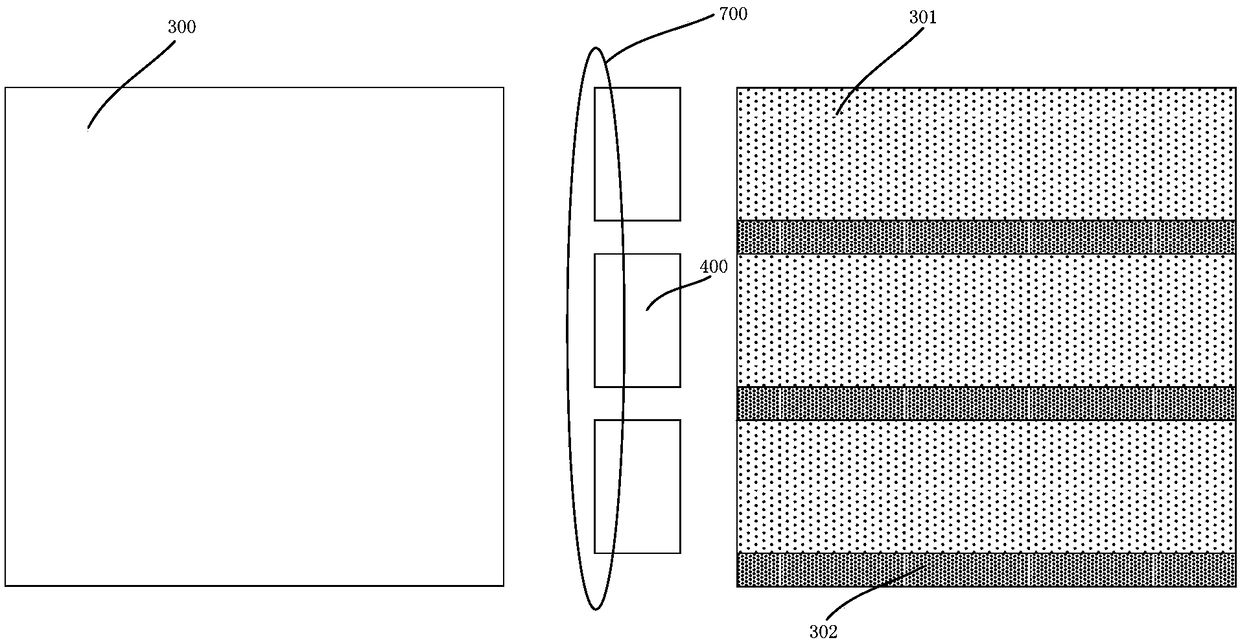

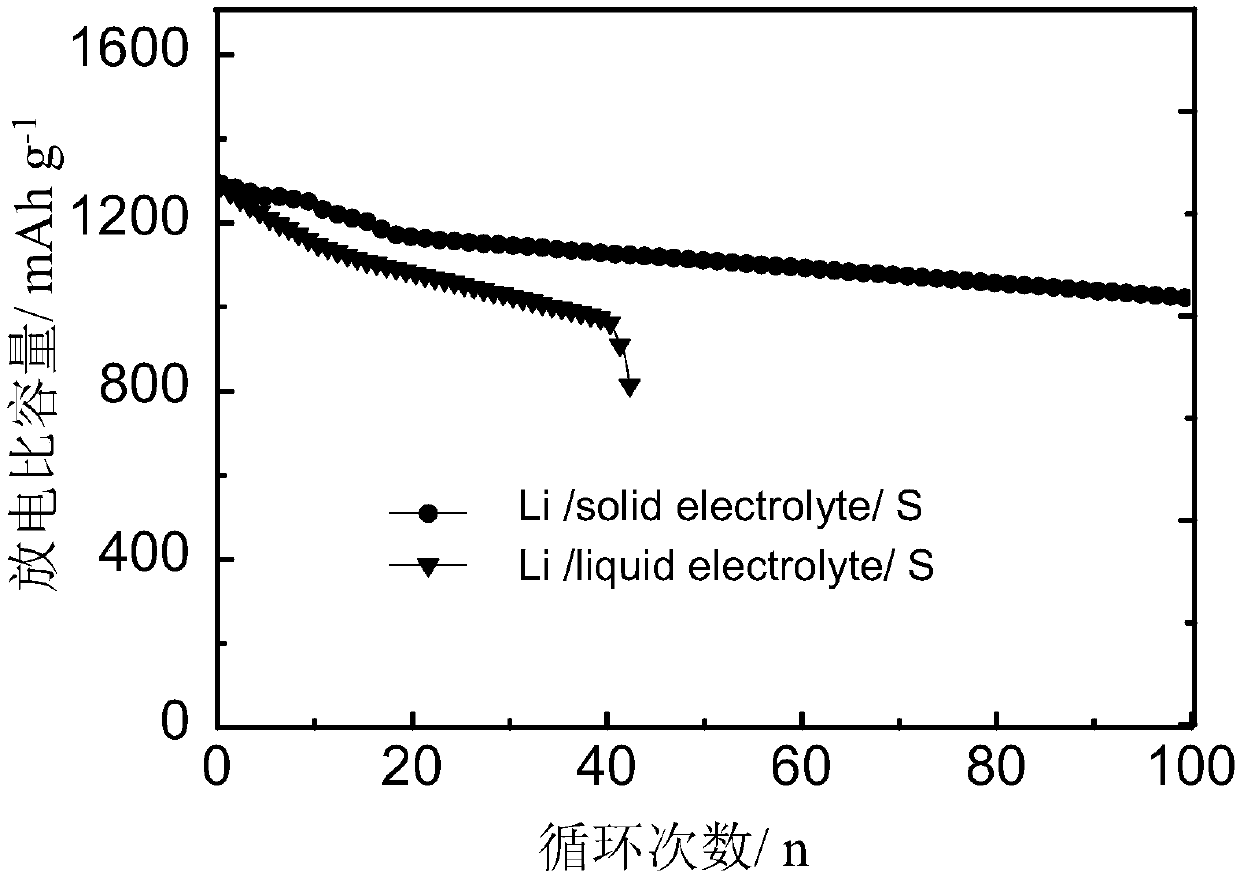

Double-layer solid electrolyte composite membrane mainly composed of polyacrylonitrile and preparation method and application thereof

ActiveCN109524719ASolving Lithium Passivation ProblemsImprove electrochemical performanceSolid electrolytesFinal product manufactureN dimethylformamideLithium–sulfur battery

The invention discloses a double-layer solid electrolyte composite membrane mainly composed of polyacrylonitrile, a preparation method thereof and application of the double-layer solid electrolyte composite membrane as an electrolyte in preparation of a lithium-sulfur gel electrolyte battery. The preparation method comprises the following steps of: dissolving PAN (polyacrylonitrile), PEO (polyoxyethylene) and LATP (Li1.3Al0.3Ti1.7(PO3)4) in DMF (N,N-dimethylformamide), stirring, then applying a mixture on a glass plate in a scraping manner by using a scraping knife, and drying to obtain a first layer of electrolyte; dissolving the PAN and the LATP in the DMF, stirring, then applying a mixture on the first layer of electrolyte in a scraping manner by using the scraping knife to obtain a second layer of electrolyte; and carrying out vacuum drying to obtain the double-layer solid electrolyte composite membrane mainly composed of the polyacrylonitrile. The obtained material is directly sliced to serve as the electrolyte of the lithium-sulfur battery. The method has simple preparation process, large yield and low cost, can be used for large-scale production, and facilitates the realization of industrialization. The double-layer solid electrolyte composite membrane prepared by the method is applied in the lithium-sulfur total battery, can suppress the shuttling effect, improves the battery capacity, and has a good cycle performance.

Owner:ZHEJIANG UNIV

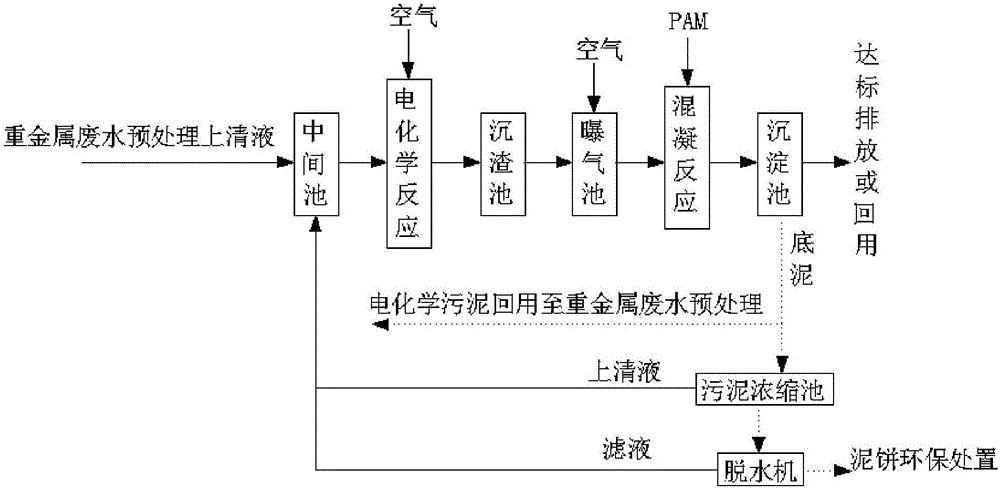

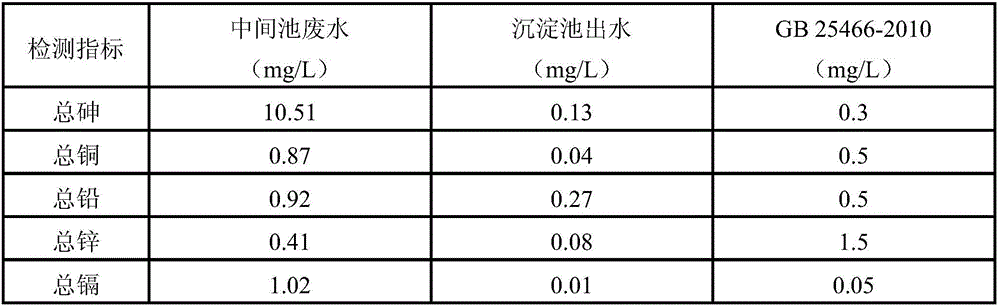

Process method for heavy metal wastewater treatment

InactiveCN106219833AAvoid passivationSolving Passivation ProblemsSludge treatment by de-watering/drying/thickeningWater contaminantsElectrochemical responseChemical reaction

The invention discloses a process method for heavy metal wastewater treatment. The process method comprises the following steps: performing electric-chemical reaction on pretreated heavy metal wastewater clear liquid, performing intermittent aeration in the reaction process, performing settling separation on the obtained product, removing iron-containing solid residues, performing aeration reaction on the obtained turbid liquid, adding a coagulant for coagu-flocculation reaction into the obtained mixed liquid so as to form and settle alum floc, performing solid-liquid separation, recycling or performing up-to-standard discharge on the obtained supernate, and performing aftertreatment on the obtained bottom mud, thereby completing treatment on heavy metal wastewater. The process method disclosed by the invention is good in heavy metal treatment effect, the polar plate passivation problem can be effectively solved, the polar plate utilization rate is high, and the process operation is stable and smooth.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Tab cutting device and method for soft package lithium battery

ActiveCN111129418AAdaptableSolve the technical problems of ear wire drawingFinal product manufactureShearing machinesMechanical engineeringBattery cell

The invention provides a tab cutting device and method for a soft package lithium battery, and relates to the field of lithium battery manufacturing. The device is composed of a cutter driving mechanism, a lower cutter mechanism, an upper cutter mechanism, a CCD mechanism and a bare battery cell feeding mechanism. A lower cutter base comprises a first sliding groove, a second sliding groove, a base, a second linear guide rail, a second left side vertical plate, a second hole, a spring stop block, a first hole and a scraper mounting plate. A knife grinding unit comprises a first dull polish roller, a first buffer piece, a first spring, a first shaft, a second shaft, a second spring, a second buffer piece, a second dull polish roller, a second roller shaft and a first roller shaft. The device has self-adaptive capacity, comprises a cutter self-adaptive welding position, a scraper unit fool-proof leftover material, a knife grinding unit grinding cutter and automatic gap adjustment, and solves the technical problem of tab wiredrawing in a tab cutting procedure in a lithium battery manufacturing process.

Owner:湖南先峰能源科技有限公司

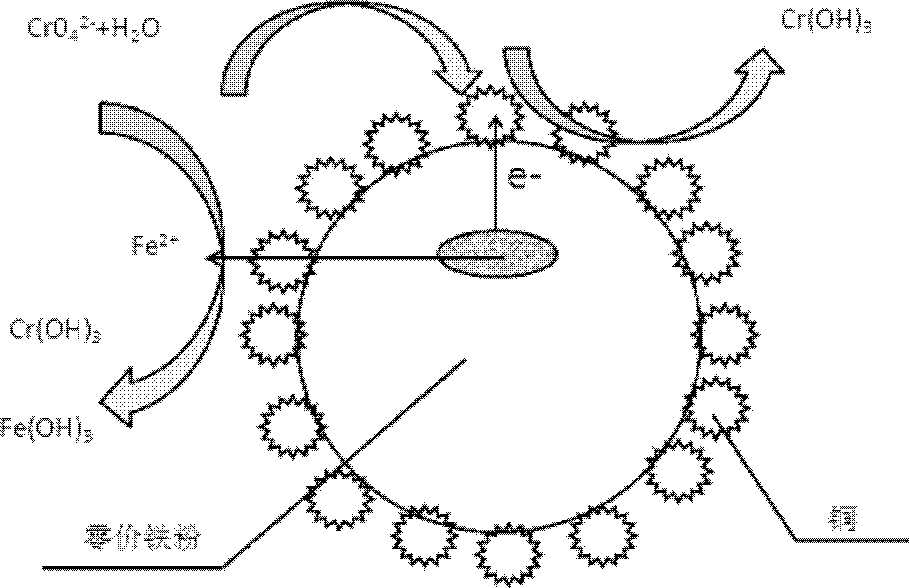

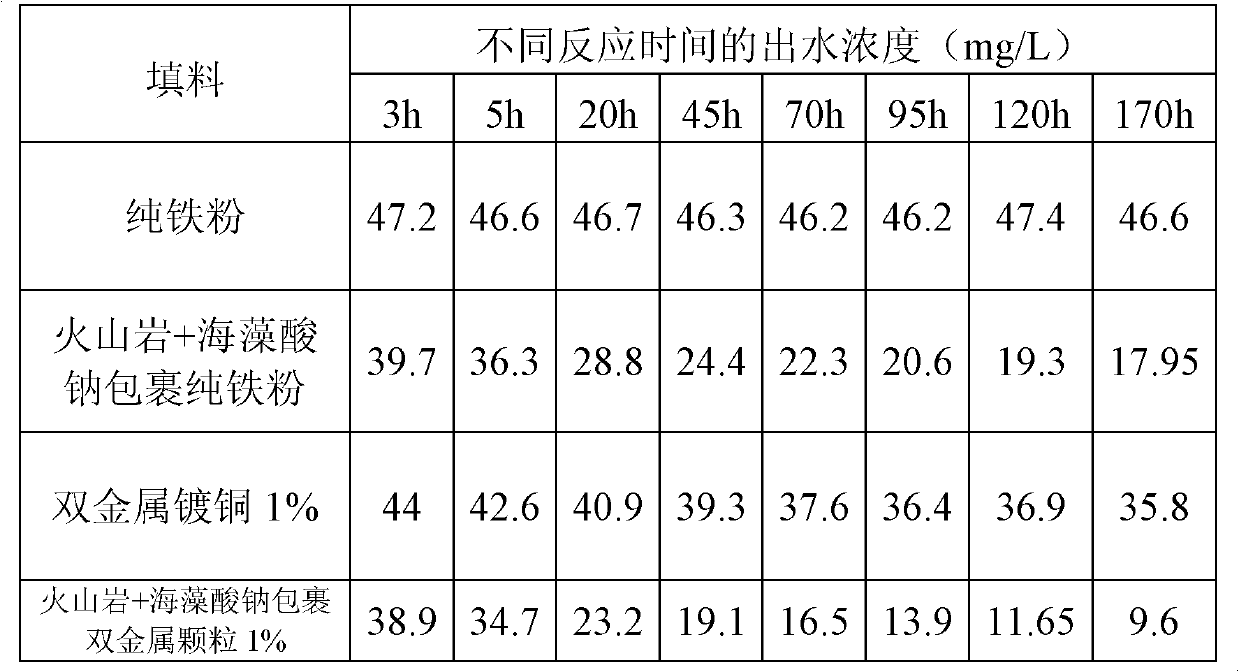

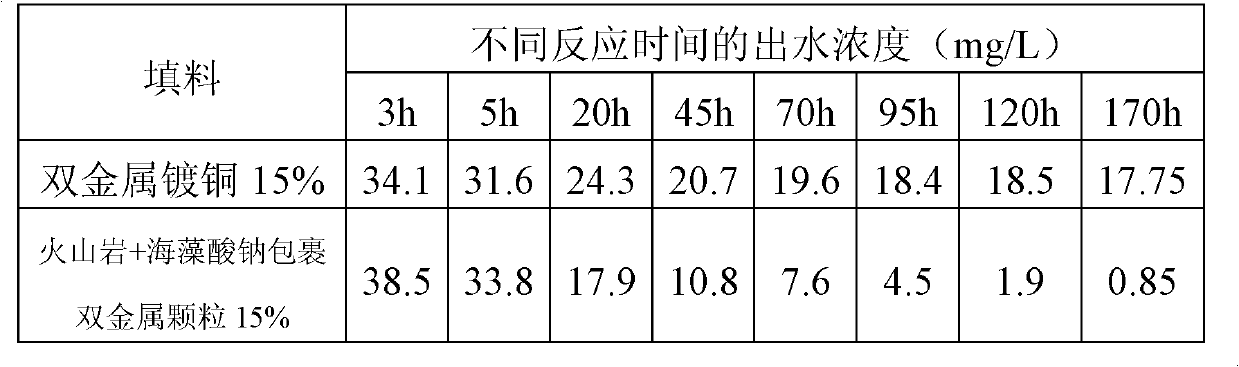

Double-metal macromolecule permeable reactive barrier stuffing material and preparation method thereof

InactiveCN102671614BSolving Passivation ProblemsSolve the strength problemChemical/physical/physico-chemical processesPollutionMaterials science

The invention relates to a double-metal macromolecule permeable reactive barrier stuffing material, which can effectively remove the pollution of Cr (VI) in underground water. A preparation method of the stuffing material comprises the following steps of: 1) plating metal copper on the surface of zero-valence iron power by a replacement reaction, to prepare the double-metal particles of zero-valence iron power and metal copper; 2) dispersing the double-metal particles into sodium alginate tech grade solution to prepare into a mixed solution, and loading the mixed solution on an inorganic carrier; and 3) adding the product of the step 2) into a CaCl2 solution to be immobilized, to prepare the double-metal macromolecule permeable reactive barrier stuffing material. The product disclosed by the invention is high in strength and permeability, the specific surface area of the zero-valence iron power can be adequately utilized, and the problems of hardening, passivating and blocking generated by the reaction between the zero-valence iron and the Cr (VI), the low use ratio of the iron power and the like can be effectively solved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

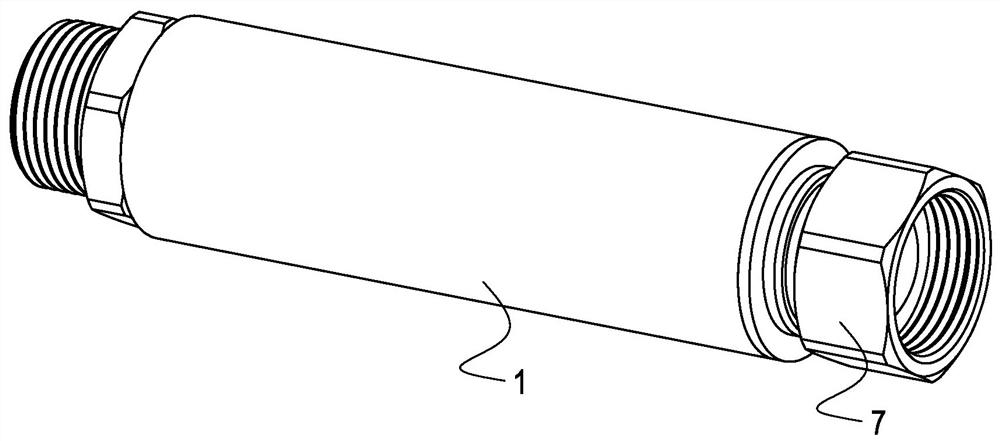

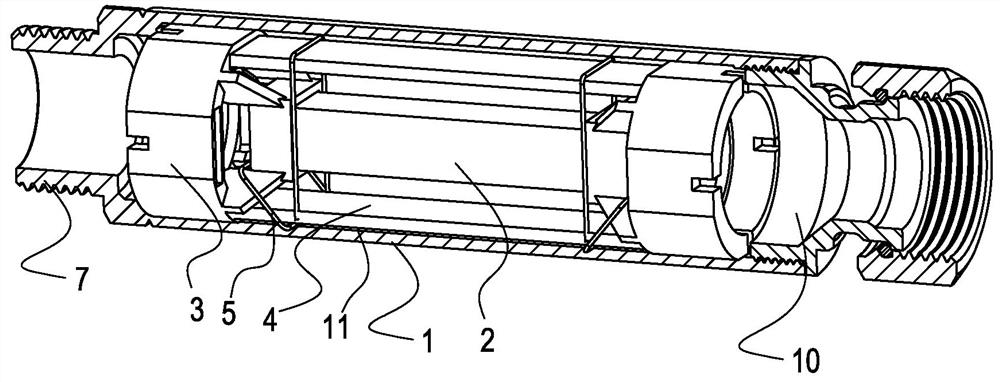

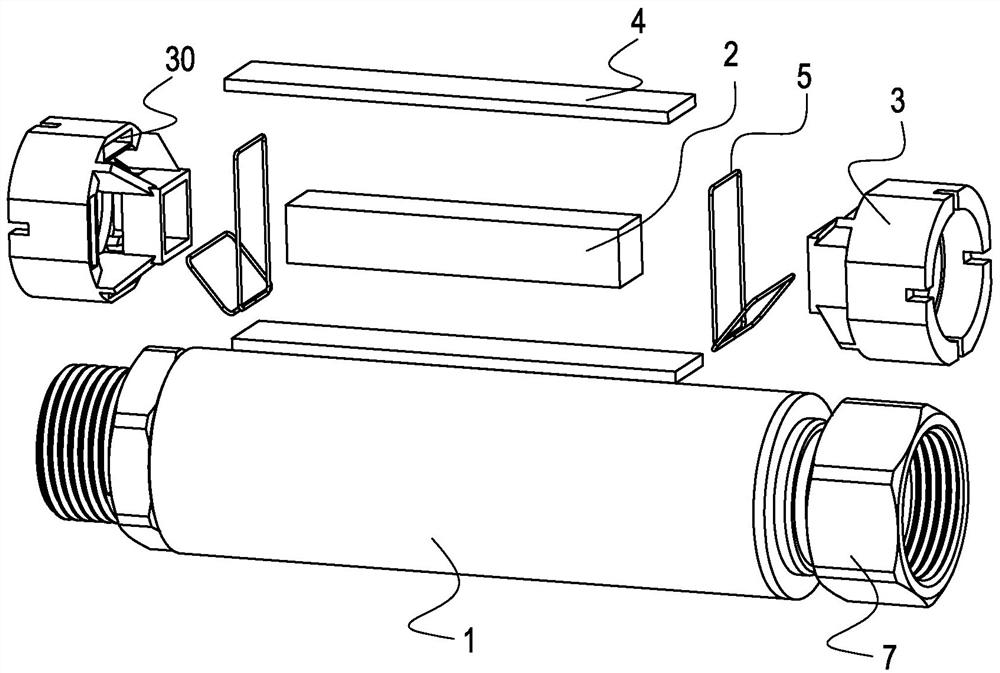

Anti-scaling device for pipeline

ActiveCN112197100ACompact structureDoes not take up spaceWater/sewage treatment by electrochemical methodsWater/sewage treatment by magnetic/electric fieldsEngineeringZinc alloys

The invention relates to an anti-scaling device for a pipeline. A main body of the anti-scaling device for the pipeline is of a tubular structure, and pipeline connecting structures are arranged at the two ends of the main body; a magnetic body is arranged at the central axis position of a tubular inner cavity of the main body, and two ends of the magnetic body are fixed in the tubular inner cavity through fixing bases; temperature-resistant zinc alloy bodies are also fixed on the fixing bases, and gap distances exist between the temperature-resistant zinc alloy bodies and the pipe wall as well as between the temperature-resistant zinc alloy bodies and the magnetic body; and the anti-scaling device is further provided with primary battery anode elements in contact with the temperature-resistant zinc alloy bodies. According to the anti-scaling device, the tubular structure is conveniently connected with the pipeline; the device can be applied to high-temperature environments such as heating; and under dual scale inhibition and scaling, the formation of hard scaling crystals is greatly reduced. The device has the advantages of obvious scale inhibition, environmental protection, no maintenance, long service life, high structural practicability and better market popularization value.

Owner:TAIZHOU BANCHENG HVAC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com