Method for fabricating solar cell

A solar cell and manufacturing method technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the open voltage and conversion efficiency of solar cells, reducing the utilization rate of sunlight, serious light absorption, etc., to solve passivation and light absorption. , Improve open circuit voltage and conversion efficiency, reduce the effect of minority carrier recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] refer to Figure 1-Figure 6 , to introduce the manufacturing method of this embodiment.

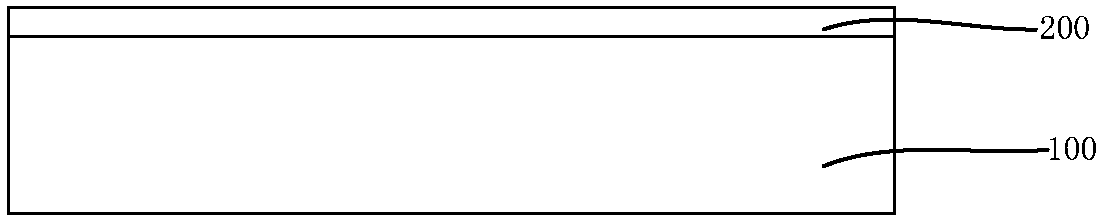

[0048] refer to figure 1 , forming an oxide layer 200 on the front surface of the substrate 100 of the first conductivity type, for example, an n-type silicon wafer.

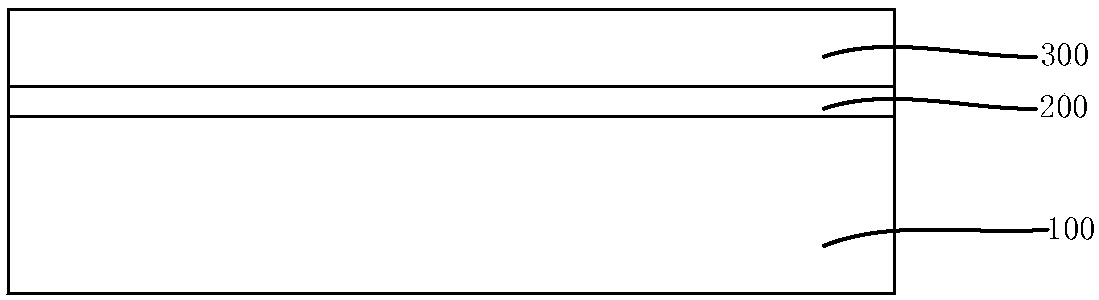

[0049] refer to figure 2 , forming amorphous silicon 300 on the oxide layer 200 .

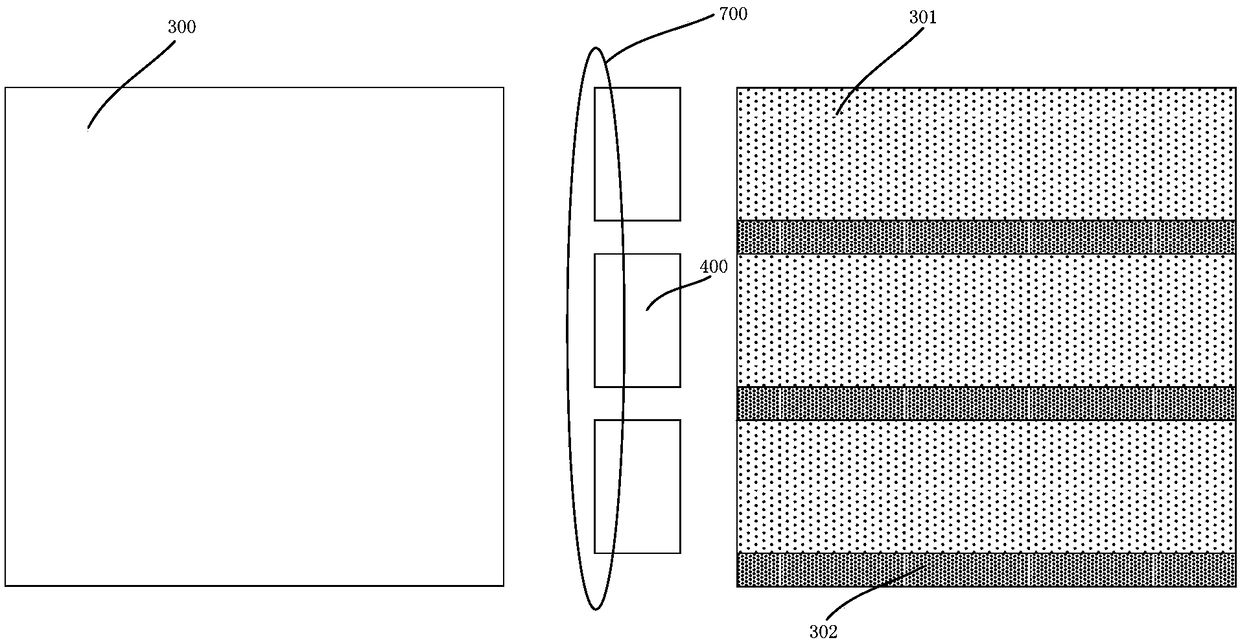

[0050] refer to image 3 with Figure 4 The amorphous silicon is selectively doped with a doping element of the second conductivity type to form a heavily doped region 302 and a lightly doped region 301 (both the heavily doped region and the lightly doped region are doped with the second conductivity type element. Miscellaneous), such as p-type doping, implanting boron ions. Specifically, a barrier layer 400 with a hollow area is set between the workpiece to be processed and the beam 700, and the beam and the barrier layer partially overlap, so that the workpiece (the workpiece here is figure 2 structure) moving from left to ...

Embodiment 2

[0054] The principle of embodiment 2 is the same as that of embodiment 1, the difference is:

[0055] refer to Figure 7-Figure 11 , before forming the oxide layer, a second conductivity type doped layer 600, such as a p-type doped layer, is firstly formed in the front surface of the first conductivity type substrate 100, such as an n-type silicon wafer. Doping can be achieved by existing means, such as boron diffusion or boron ion implantation. Then the oxide layer 200 is formed on the doped layer 600 of the second conductivity type.

[0056] refer to Figure 8-Figure 11 , polysilicon 300 is formed on the oxide layer 200, and then a heavily boron-doped region 302 and a lightly boron-doped region 302 are formed in the polysilicon through a barrier layer provided with a hollow area combined with ion implantation (implantation of a second conductivity type dopant element, such as boron element). impurity region 301, and heat-treat the ion-implanted structure.

[0057] The su...

Embodiment 3

[0059] The principle of embodiment 3 is the same as that of embodiment 2, the difference is:

[0060] refer to Figure 12 In this embodiment, only the heavily doped region 302 remains, the lightly doped polysilicon is completely etched away, and electrodes are formed on the heavily doped region. Refer to Example 2 for the remaining steps.

[0061] In the present invention, light and heavy doping of polysilicon can form a carrier selective electrode and reduce the recombination of metal and silicon contacts. Since the doped regions of different doses in polysilicon have different tolerances to alkaline reagents, selective etching can be formed, thereby forming thicker polysilicon under the metal contact, and forming thinner polysilicon in the light-receiving part. Thus, the contradiction between passivation and light absorption is solved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com