Alkali metal doping method in large-scale production of CIGS (copper, indium, gallium, selenium) thin-film solar cell

A technology for solar cells and copper indium gallium selenide, which is applied in the field of solar cells, can solve problems such as the inability to effectively improve the photoelectric conversion efficiency of copper indium gallium selenide cells, and achieves low device and production process costs, improved filling factor, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

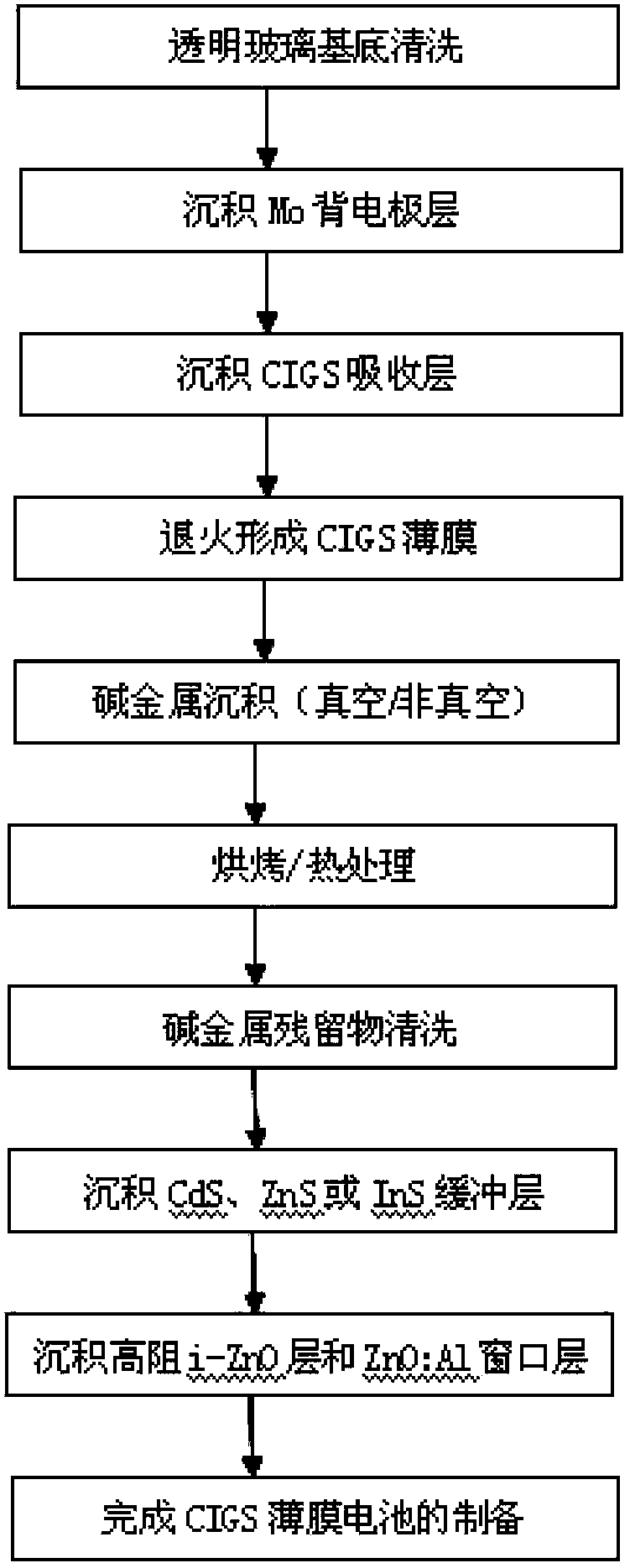

[0039] Such as figure 1 Shown, illustrate the flowchart of the alkali metal doping method in a kind of thin film material according to an embodiment of the present invention, comprise following process:

[0040]1. Cleaning is used to provide transparent glass as a substrate;

[0041] 2. Utilize the sputtering process to cover the back electrode Mo layer on the above-mentioned transparent glass substrate;

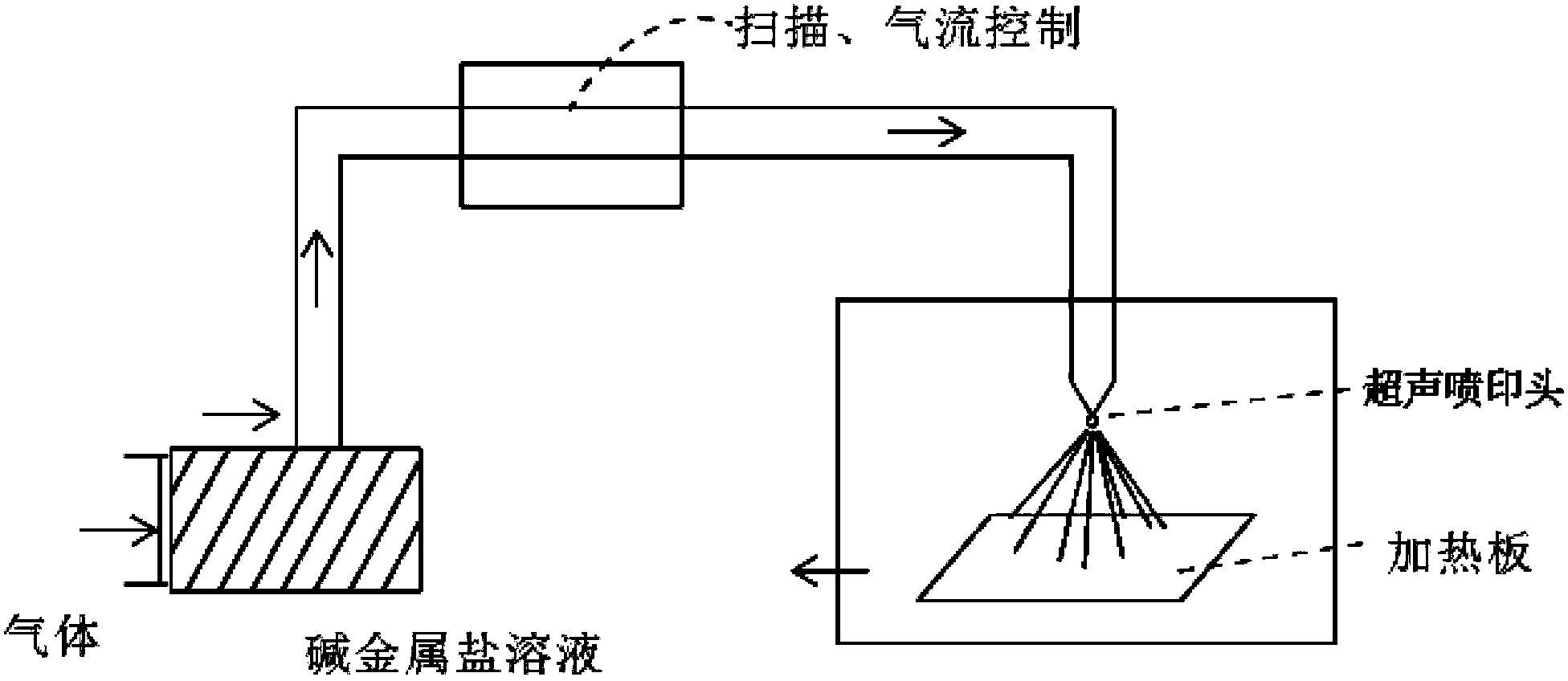

[0042] 3. Use the spraying process to spray the CIGS precursor on the basis of the previous steps, thereby depositing and forming a light-absorbing layer including c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com