Microelectrolysis filler and use method thereof

A technology of micro-electrolysis and raw materials, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve troublesome operation and management, unreasonable structure of micro-electrolysis device, inability to continuously treat wastewater, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Describe content of the present invention in detail below in conjunction with embodiment:

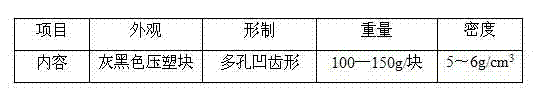

[0045] 1. Preparation of porous concave tooth-shaped monomer micro-electrolytic filler

[0046] 1) Main ingredients of raw materials:

[0047] Iron powder: content 70-80%, 60-80 mesh;

[0048] Inert carbon powder: content 20-25%, 80-100 mesh;

[0049] Binder: the content is 1-3%, the main components are silicon dioxide and silicate, and the mass ratio is 2:5;

[0050] Surfactant A10: content 0.1-0.3%;

[0051] Trace metal powder: 0.1-0.3%, mainly molybdenum powder and chromium powder with a mass ratio of 1:1.

[0052] 2) Processing of porous micro-electrolytic filler

[0053] Processing steps: screening---mixing---pressing---sintering---cooling

[0054] (a) Raw material screening: remove impurities and screen various raw materials as required;

[0055] (b) Mixing: Add the screened raw materials into the mixer, and the mixing time is 1.5 hours;

[0056] (c) Compression: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com