Preparation method for total-degradation layer-structured rice seedling-growing tray

A rice seedling raising and layered structure technology, applied in the field of rice seedling raising, can solve the problems that plastic seedling trays cannot be degraded, the degradable seedling raising matrix has poor formability, and paper-based seedling trays cannot realize soilless cultivation, etc., so as to save plastic processing costs , reduce environmental and soil pollution, and save the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: The preparation method of a fully degradable layered rice seedling raising tray in this embodiment is specifically carried out according to the following steps:

[0021] Step 1: Preparation of rice stalk biochar: using dried rice stalks, using muffle furnace equipment, heating to 500 ℃, under oxygen-limited conditions, put the rice stalks in the heat for 1 hour to obtain rice stalk biochar, rice The specific surface area of biochar in rod biochar can reach 350m 2 / g, PH is 9.0;

[0022] In this step, the dried rice straw is put into a muffle furnace and heated to 500°C, which is the optimized charcoal production temperature obtained by pyrolysis of the rice straw at 300-600°C. In this step, preparing biochar from straw and returning it to the field is one of the new ways to effectively utilize crop resources;

[0023] Step 2: Nitriding modification of rice stalk biochar: fully dissolve 35 parts by mass of ammonium nitrate in 100 parts by mass of disti...

Embodiment 1

[0031] Example 1: Using three formulas, a seedling cultivation experiment was carried out with Longdao No. 16 with a sowing amount of 80 g per tray, about 3800 seeds, and three trays with the same formula. Comparative sample: plastic floppy disk + seedling soil and seedling soil. among them:

[0032] Formula 1: 35 parts of nitriding biochar, 35 parts of fungus chaff compost, 30 parts of pulp, 0.5 parts of strong seedling agent;

[0033] Formula 2: 30 parts of nitriding biochar, 40 parts of fungus chaff compost, 30 parts of paper pulp, 0.5 parts of seedling strengthening agent;

[0034] Formulation 3: 30 parts of nitriding biochar, 30 parts of fungus chaff compost, 40 parts of pulp, 0.5 parts of strong seedling agent;

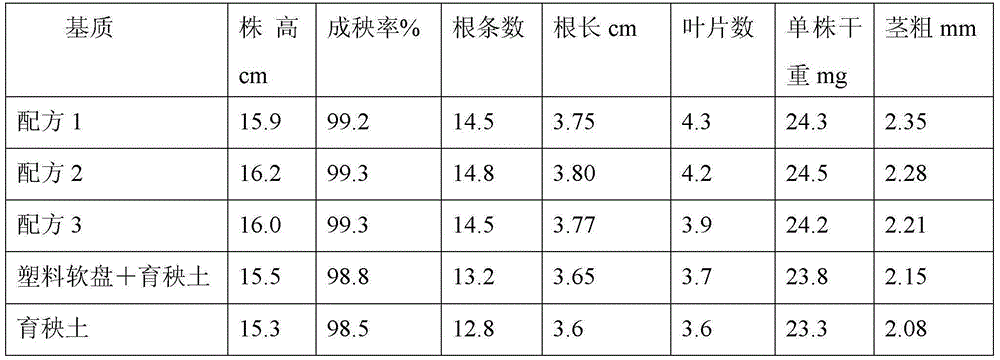

[0035] The experimental results between formula 1, formula 2, formula 3, plastic floppy disk + seedling soil and seedling soil are shown in the following table:

[0036]

[0037] According to the comparison of formula 1, formula 2 and formula 3 with plastic floppy disk ...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the upper fiber mat and the lower fiber mat have the same structure, the initial thickness of the upper fiber mat is 7mm, and the unit area mass is 0.25kg / m 2 . The air permeability of the upper fiber mat and the lower fiber mat with such a structure is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com