Preparation method of nitrate nitrogen-removed nano-iron-carbon micro-electrolysis material

A technology of iron-carbon micro-electrolysis and nitrate nitrogen, which is applied in the fields of chemical instruments and methods, water pollutants, water/sewage treatment, etc., and can solve the problems of increased difficulty in packing replacement, reduced effect of iron bed treatment, and deterioration of wastewater flow state, etc. problem, to achieve the effect of enhancing suspension, strong reducibility, and enhanced reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

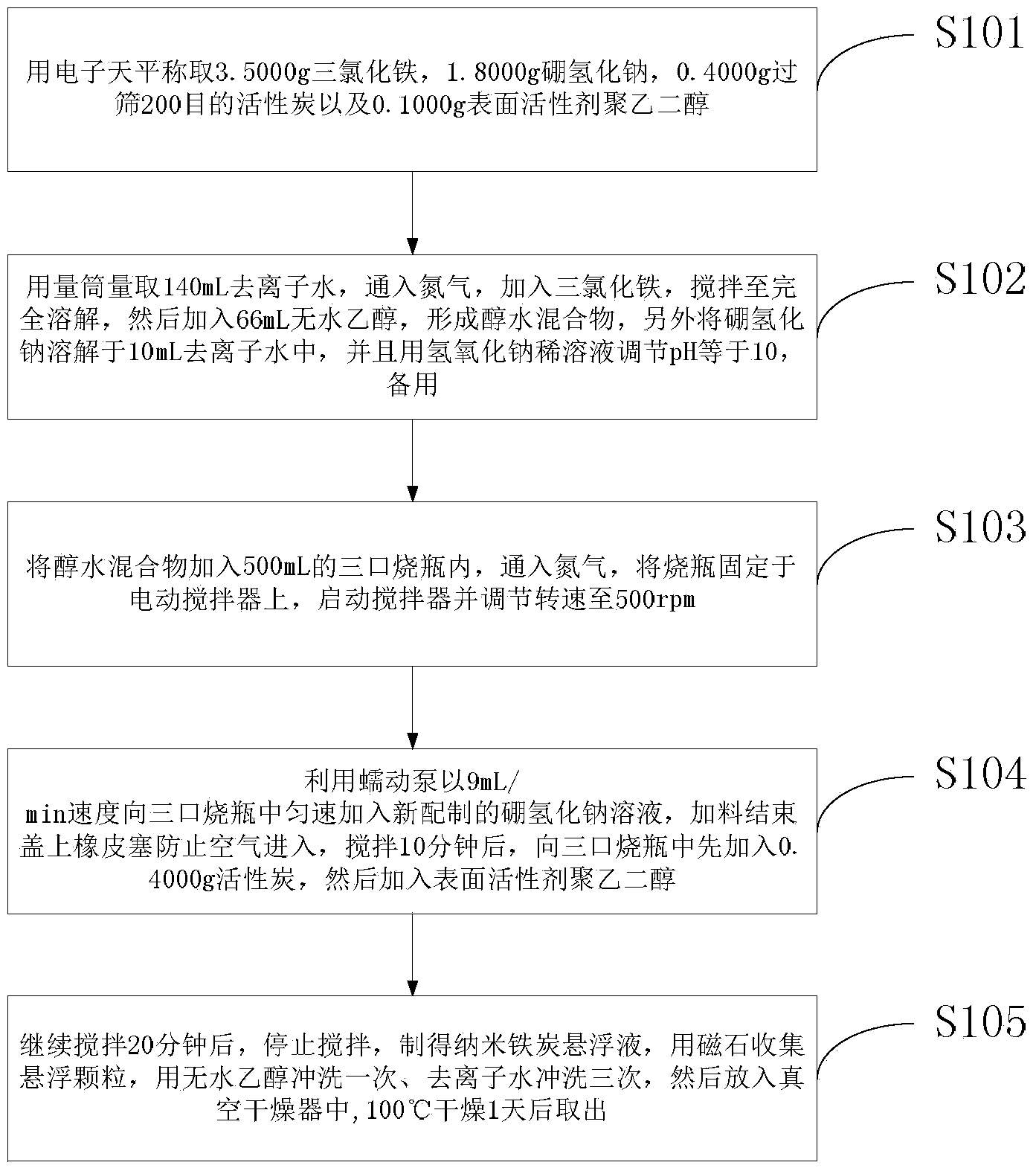

[0026] figure 1 The flow chart of the preparation method of nano-iron carbon is shown, and as shown in the figure, a preparation method of nano-iron carbon includes the following steps:

[0027] S101: Weigh 3.5000g of ferric chloride, 1.8000g of sodium borohydride, 0.4000g of 200-mesh activated carbon and 0.1000g of surfactant polyethylene glycol with an electronic balance;

[0028] S102: Measure 140mL of deionized water with a measuring cylinder, inject nitrogen gas, add ferric chloride, stir until completely dissolved, then add 66mL of absolute ethanol to form an alcohol-water mixture, and diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com