A heat treatment method for improving the impact toughness of the core of large-section low-alloy high-strength steel forgings

A heat treatment method and impact toughness technology, which is applied in the field of alloy manufacturing, can solve the problems of alloy composition to improve hardenability, poor impact toughness, and carbon equivalent limitation, so as to reduce production costs, reduce production equipment requirements, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

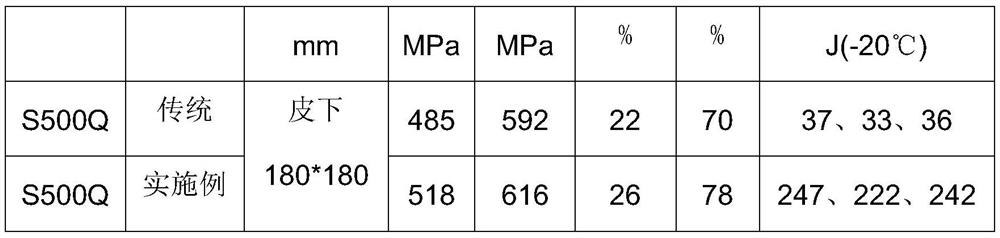

Examples

Embodiment Construction

[0020] The method of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

[0021] The specific preparation steps of the heat treatment method for improving the impact toughness of the core of a large-section low-alloy high-strength steel forging include:

[0022] 1) High-temperature normalizing and tempering: After the forging of S500Q low-alloy high-strength steel, the overall air cooling is below 250°C, normalized at 930-950°C, and tempered at 650-680°C. Steel grain size measurement method, the grain size is better than 6 grades;

[0023] According to the calculation of the phase transition point of the composition (using JmatPro software), through the grain size growth test of the small sample, it is confirmed that the material of the low-alloy high-strength steel can maintain stable and fine grain at 930-950 °C;

[0024] The grain size growth test of the small sample, the steps are: take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com