Acoustic-magnetic coaxial coupling regulation GTAW electric arc welding device and welding method

A technology of coaxial coupling and arc welding, which is applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as coarse structure of components, low arc energy, uneven effect of grain refinement, etc., and achieve uniform structure of components , Increase the arc energy and improve the effect of the molten pool solidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

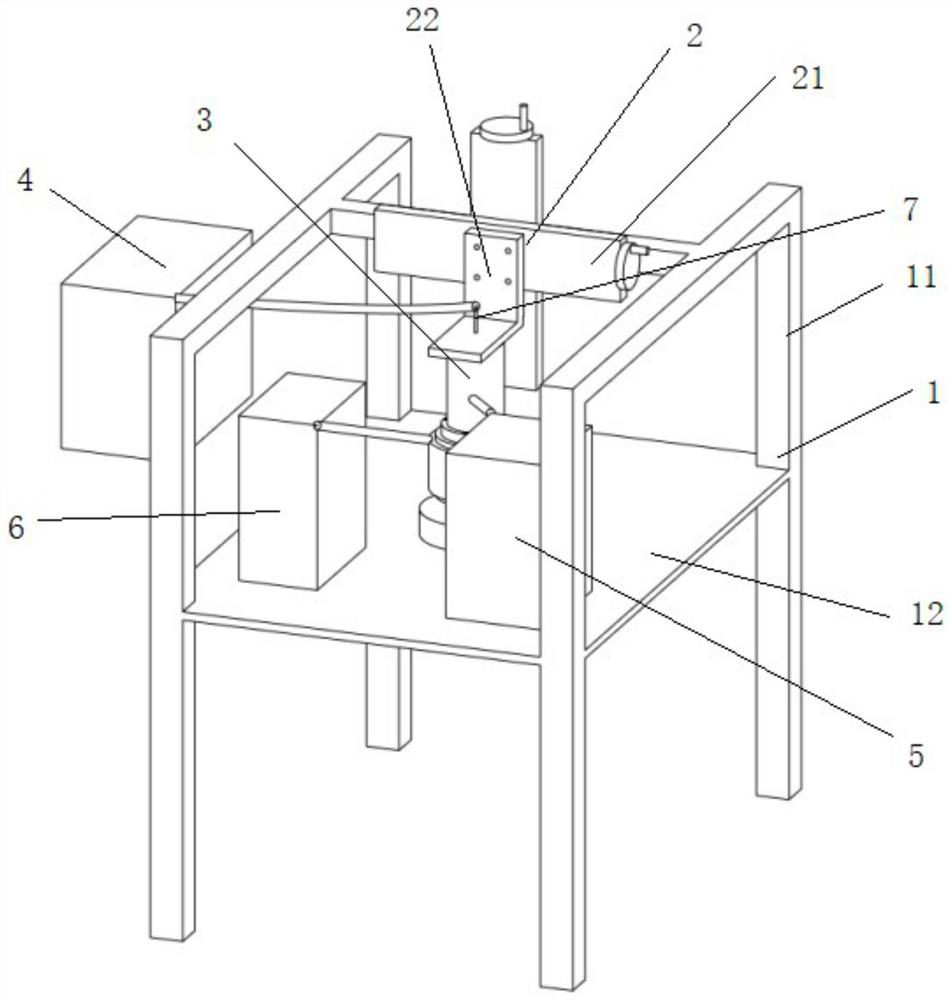

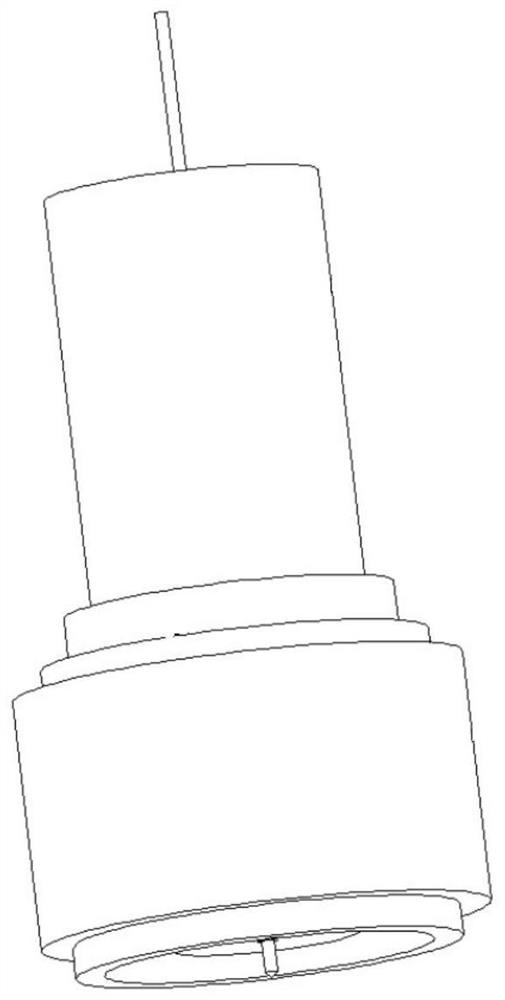

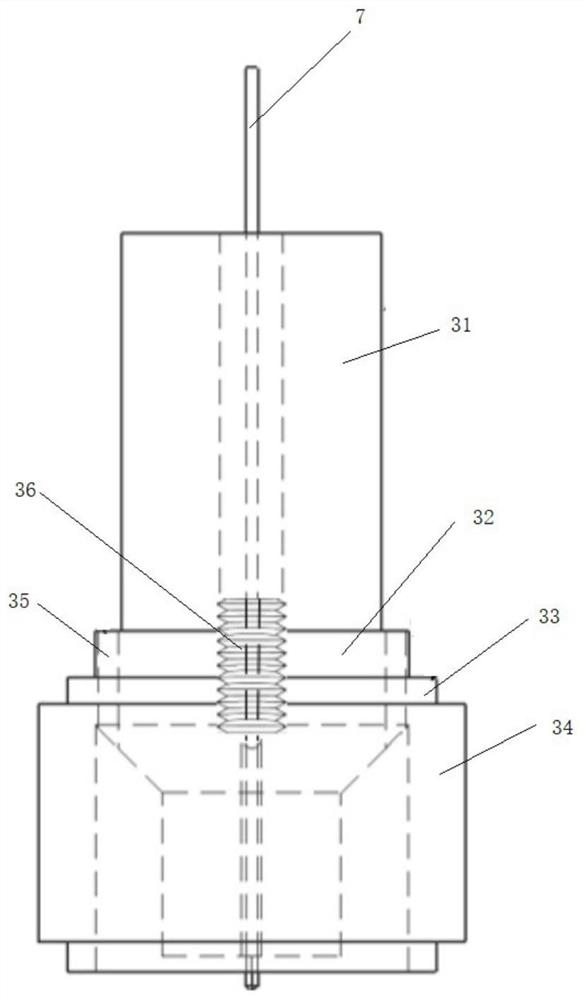

[0033] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of acoustic-magnetic coaxial coupling regulation GTAW arc welding device, it comprises main frame body 1, welding torch control frame 2, acoustic-magnetic coaxial coupling device 3, GTAW welding power supply 4, ultrasonic power supply 5 and AC DC variable frequency power supply 6, wherein the welding torch control frame 2 is fixed on the main frame body 1, the acoustic-magnetic coaxial coupling device 3 realizes position adjustment through the welding torch control frame 2, and the acoustic-magnetic coaxial The coupling device 3 includes an ultrasonic transducer 31, an ultrasonic horn 32, a water cooling device 33 and an electromagnet 34, wherein the ultrasonic transducer 31 and the ultrasonic horn 32 are coaxially fixed end to end, the electromagnet 34, the water cooling device 33 and the The ultrasonic horn 32 is set coaxially from the outside to the inside, the top of the ultrasonic t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com