A multi-tungsten argon arc heat source, control method and welding device

A control method, tungsten argon arc technology, which is applied in the field of surfacing welding, can solve the problems of low deposition speed and low dilution rate, and achieve the effects of increasing arc energy, increasing deposition rate, and ensuring dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

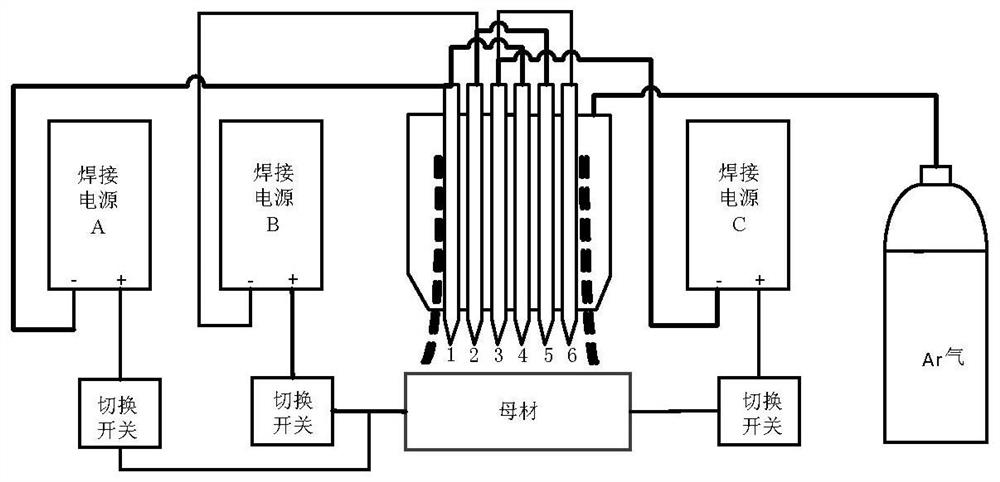

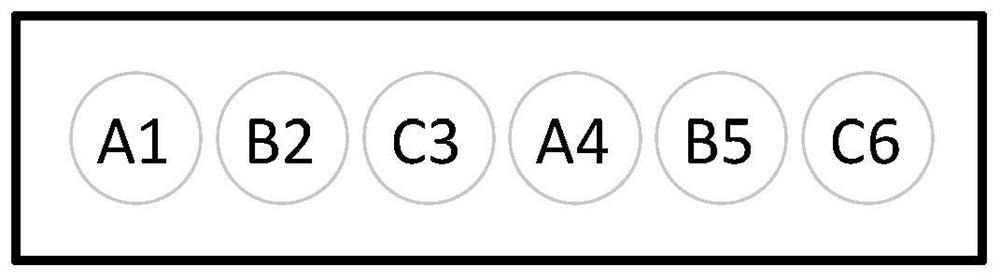

[0039] Embodiment 1: as figure 1 and figure 2 As shown, the heat source in this embodiment includes three welding power sources, three switches, six tungsten electrodes and argon shielding gas; the six tungsten electrodes are arranged in a straight line, represented by numbers 1 to 6 respectively; three power sources are used, Respectively represented by A, B, and C; No. 1 and No. 4 tungsten electrodes are connected to welding power source A, No. 2 and No. 5 tungsten electrodes are connected to welding power source B, No. 3 and No. 6 tungsten electrodes are connected to welding power source C; in this embodiment, tungsten The pole spacing is 1-6mm, the welding current is 30-500A, the switching frequency of the switch is 1-1000Hz, and the distance between the tungsten electrode and the base metal is 2-6mm;

[0040] When the heat source is working, switch the switch to energize the welding circuit of power source A. The arc is first ignited on the No. 1 tungsten electrode, and...

Embodiment 2

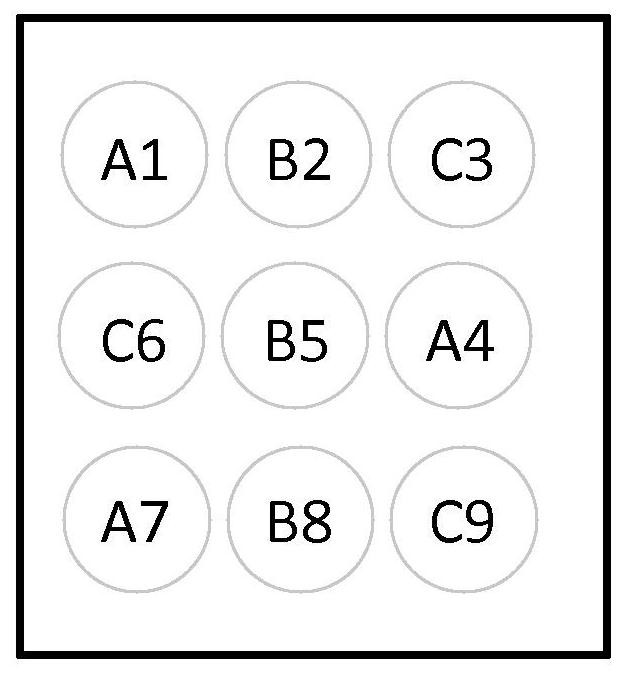

[0041] Embodiment 2: as image 3 As shown, the heat source in this embodiment includes three welding power sources, three switches, nine tungsten electrodes and argon shielding gas; the nine tungsten electrodes are arranged in a 3*3 array, represented by numbers 1 to 9 respectively; A power supply, denoted by A, B, C respectively; No. 1, No. 4 and No. 7 tungsten electrodes are connected to welding power source A, No. 2, No. 5 and No. 8 tungsten electrodes are connected to welding power source B, No. 3, No. 6 and No. 9 The tungsten electrode is connected to the welding power source C; in this embodiment, the distance between the tungsten electrode and the base metal is 1-6mm, the welding current is 30-500A, the switching frequency of the switch is 1-1000Hz, and the distance between the tungsten electrode and the base metal is 2-6mm;

[0042]When the heat source is working, switch the switch to energize the welding circuit of power source A. The arc is first ignited on the No. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com