Electric connection mechanism used for plug-in circuit breaker

A plug-in, circuit breaker technology, applied in the direction of protective switch terminals/connections, electrical components, pull-out switch cabinets, etc., can solve problems such as inability to form surface contact and fit, machining accuracy errors, and reduced electrical conductivity, etc., to achieve excellent loading Flow capacity, obvious effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention proposes an electrical connection mechanism for a plug-in circuit breaker, aiming at the requirements of the electrical connection structure between the body of the withdrawable circuit breaker and the drawer seat.

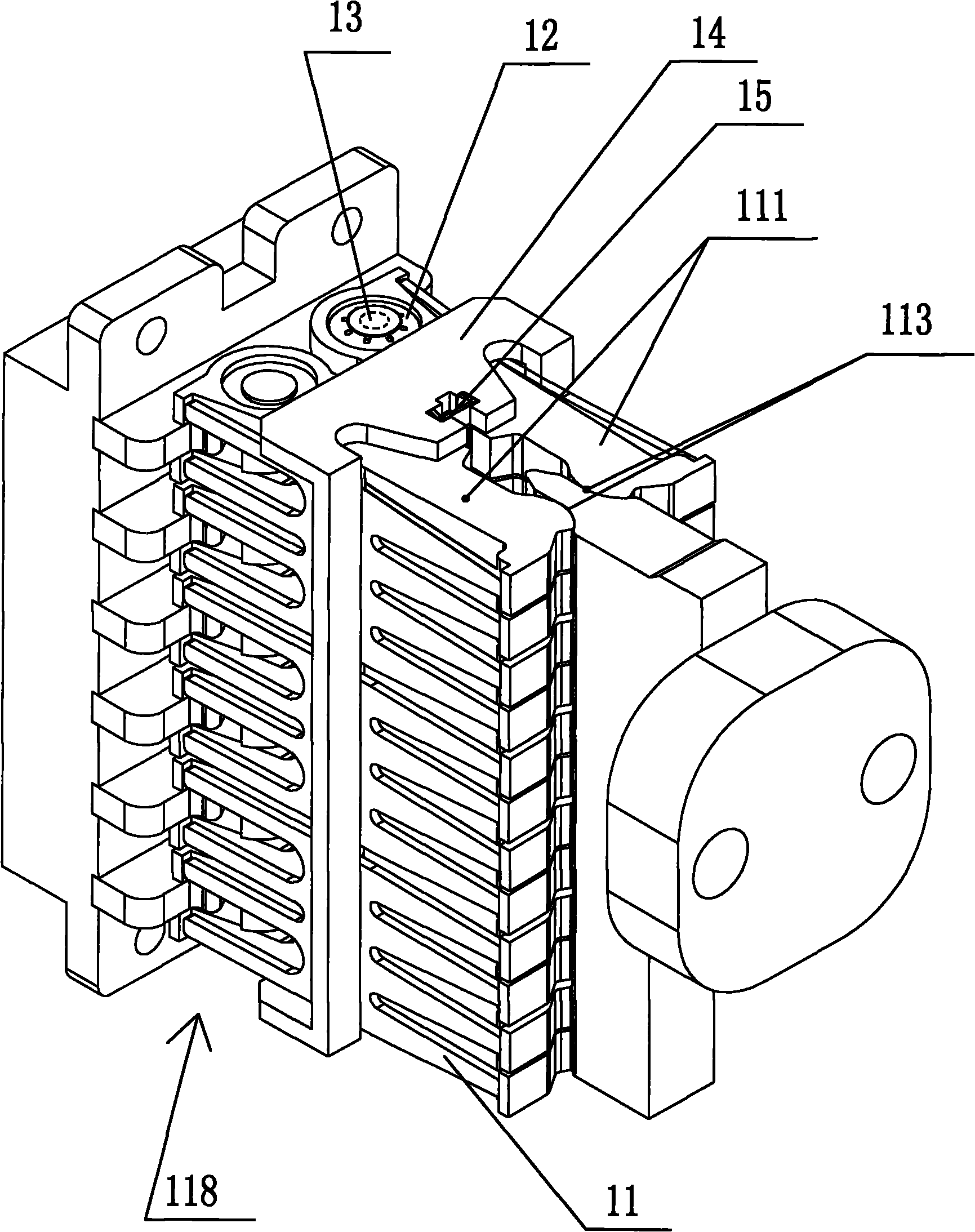

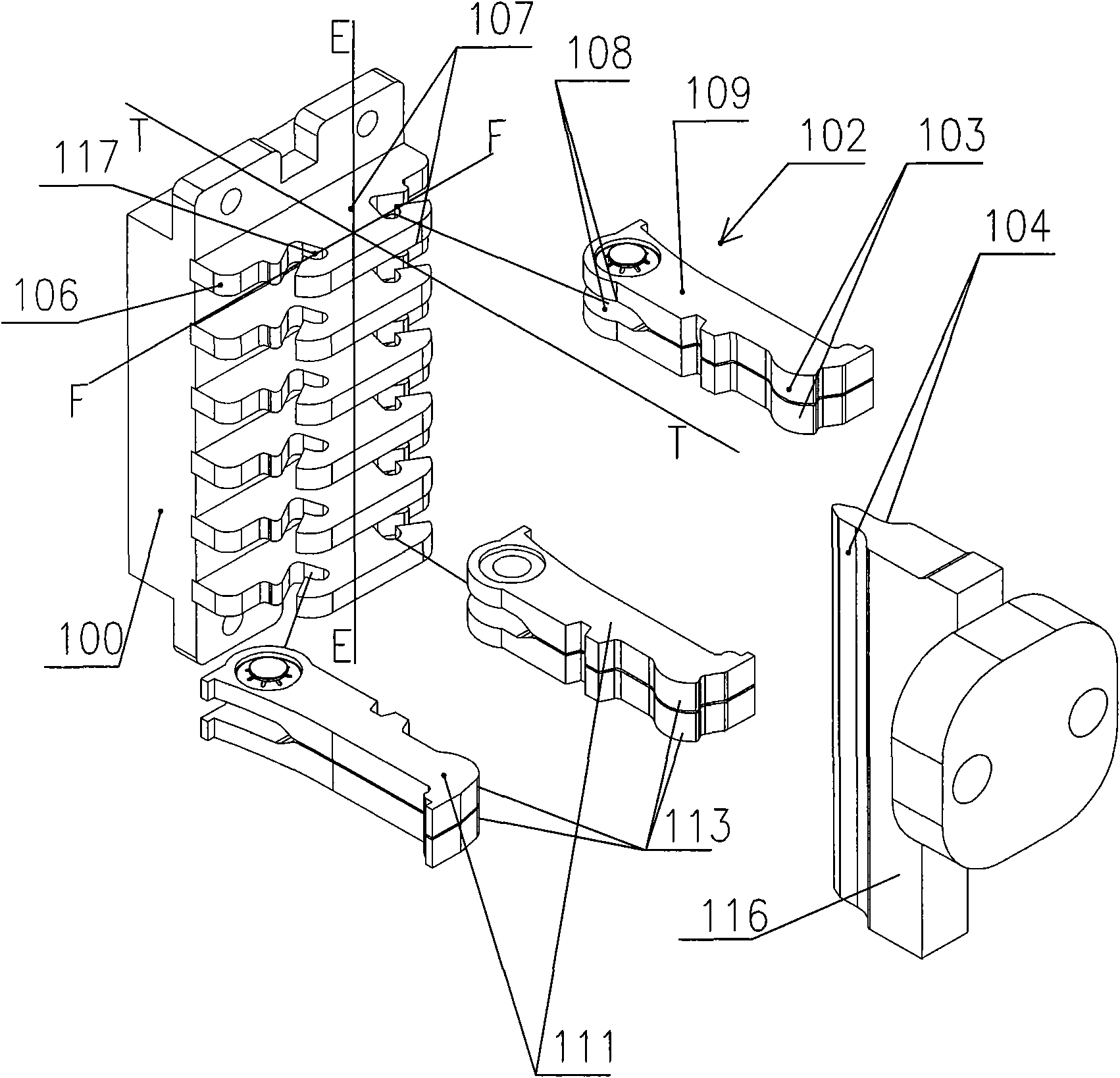

[0038] Such as figure 1 , figure 2 As shown, the electrical connection mechanism 118 includes a fixed terminal 100, a blade 116, a plug-in chuck for connecting the fixed terminal and the blade, and an elastic element 11 for pressing the plug-in chuck. in:

[0039] The fixed terminal 100 has at least one protruding portion 106 extending forward of the axis T-T parallel to the direction of insertion and extraction, and the left and right sides of the middle of the protruding portion 106 are provided with installation guide grooves 117 for connecting with the plug-in chuck. The upper and lower surfaces of the free end of the protruding portion 106 are contact surfaces 107 , both of which are flat or arcuate, and whose normal direction E-E is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com