High-power bipolar pulse formation circuit integrated with high-voltage burst pulse preionization

A bipolar pulse and short pulse technology, which is applied in the direction of electric pulse generator circuit, plasma, and energy storage components to generate pulses, etc., can solve the problems of inability to adapt to changes in plasma load impedance characteristics, large power supply volume, and particle deposition rate. Low-level problems, to achieve the effect of improving power supply efficiency and target sputtering coating efficiency, solving the large volume of power supply, and reducing the volume of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

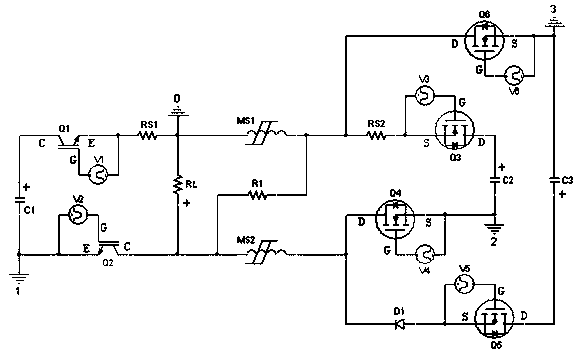

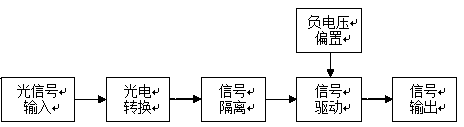

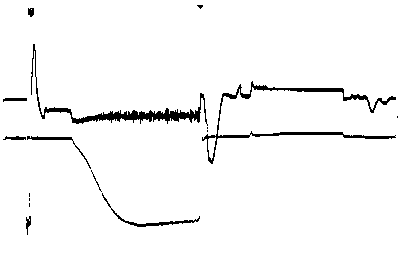

[0021] Such as figure 1 As shown, an integrated high-power bipolar pulse forming circuit integrating high-voltage short-pulse pre-ionization is composed of a negative-polarity high-voltage short-pulse pre-ionization pulse-forming network, a high-power negative-polarity main pulse network and a positive-polarity pulse-forming network. The negative polarity high-voltage short pulse pre-ionization pulse forming network is mainly composed of energy storage capacitor C1, IGBT switch tube Q1, IGBT switch tube Q2, and current limiting circuit RS1 load RL. When the driving signals V1 and V2 are at high level at the same time, the switch tube Q1 , Q2 are turned on at the same time, the energy storage capacitor C1 forms a discharge circuit through the switch tubes Q1, Q2, the current limiting resistor R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com