Patents

Literature

242 results about "Film density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The density of film refers to the amount of light a negative transmits. The denser or more blocked from light the sections of a negative are, the darker they will be in print. This is called negative film density.

Method of controlling the film properties of a CVD-deposited silicon nitride film

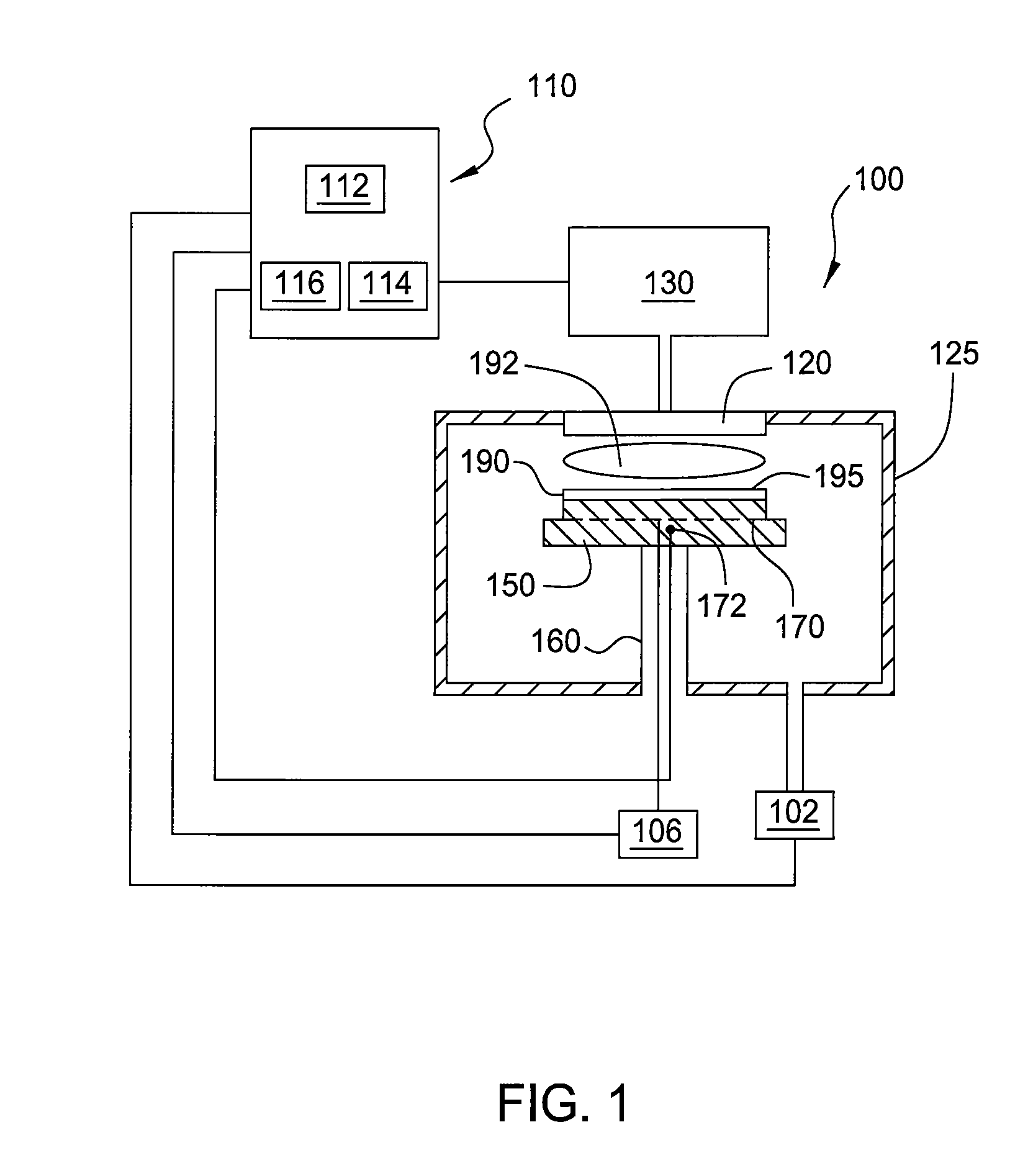

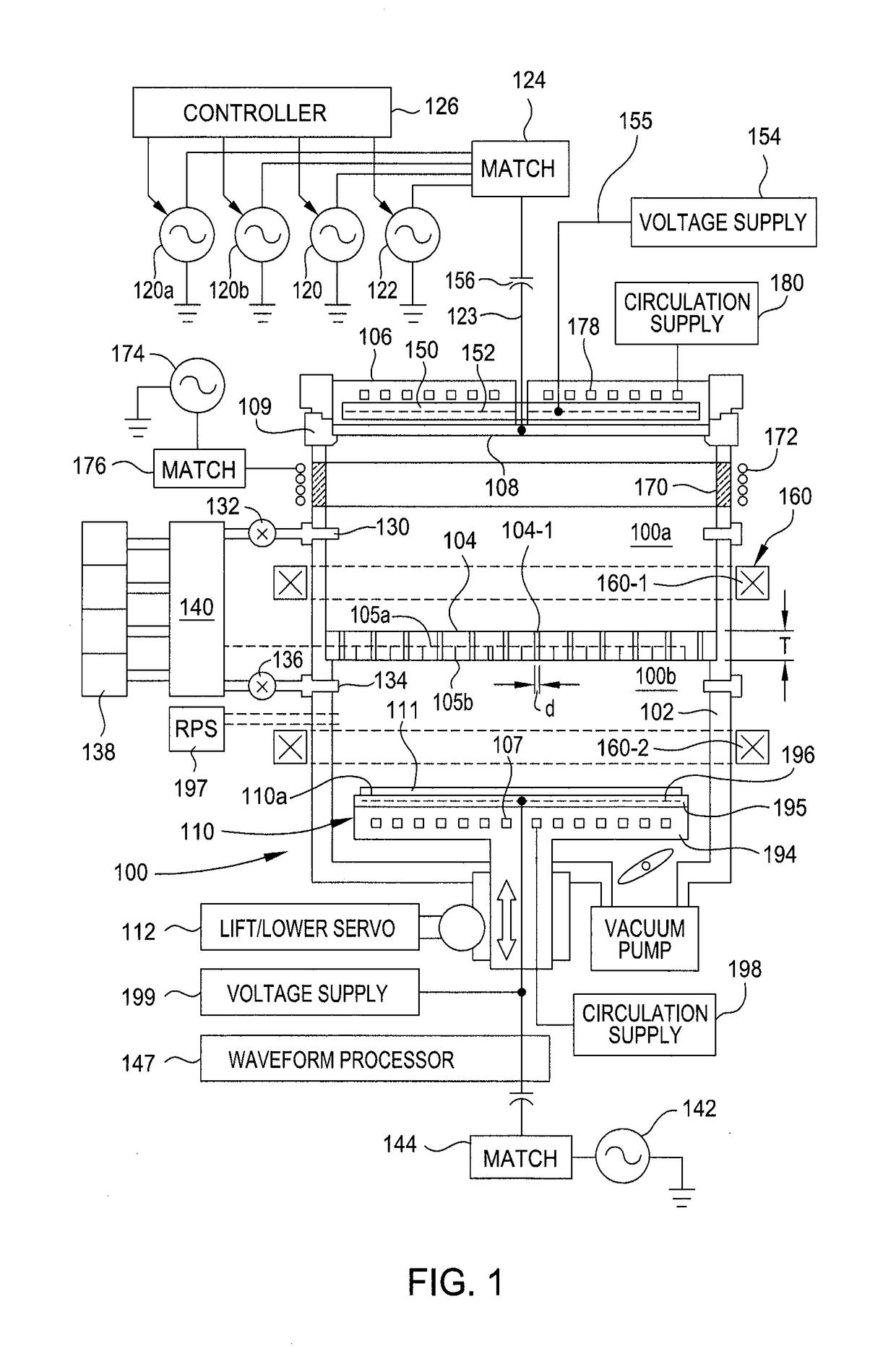

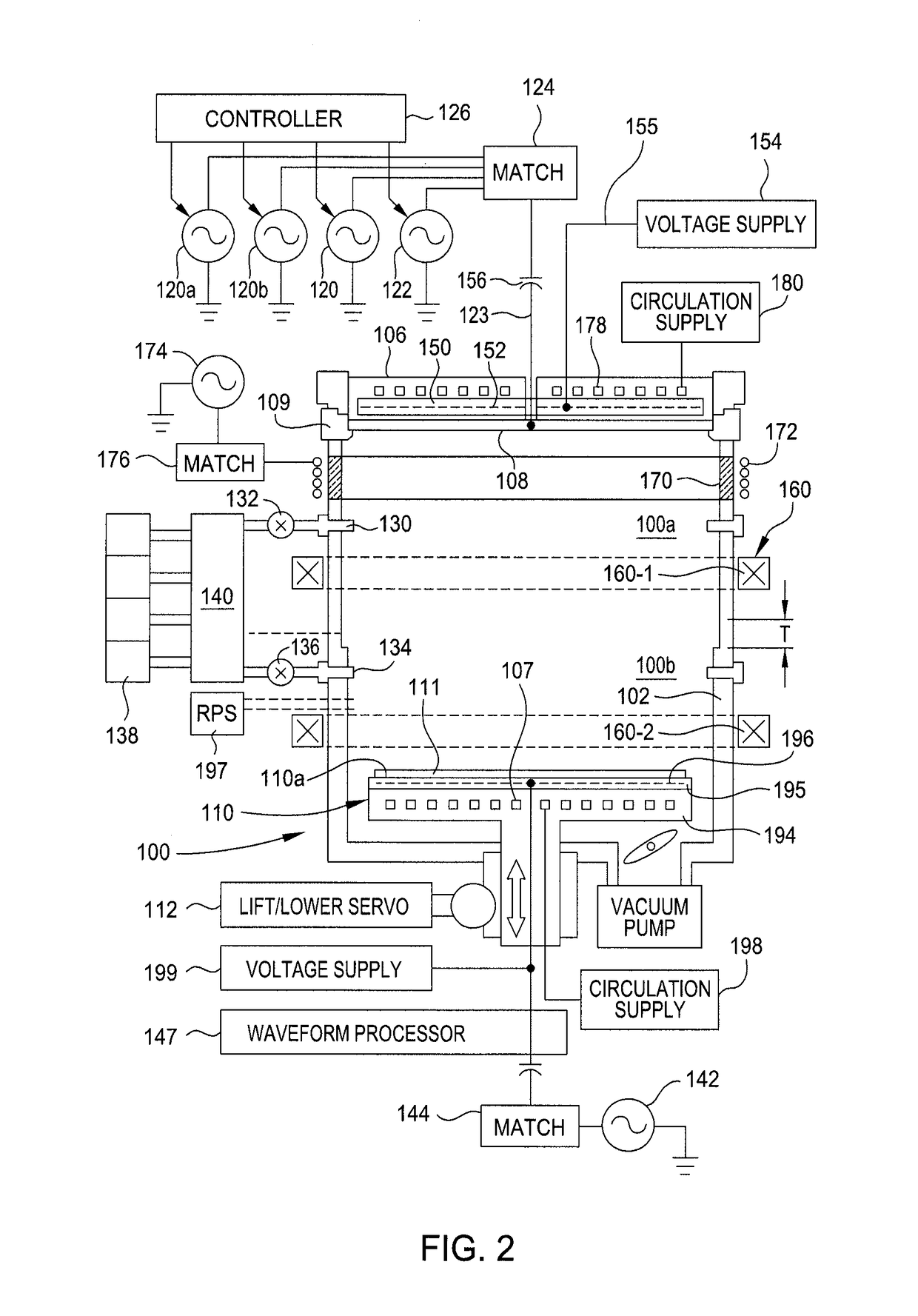

InactiveUS20060019502A1Increase wet etch rateEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas composition

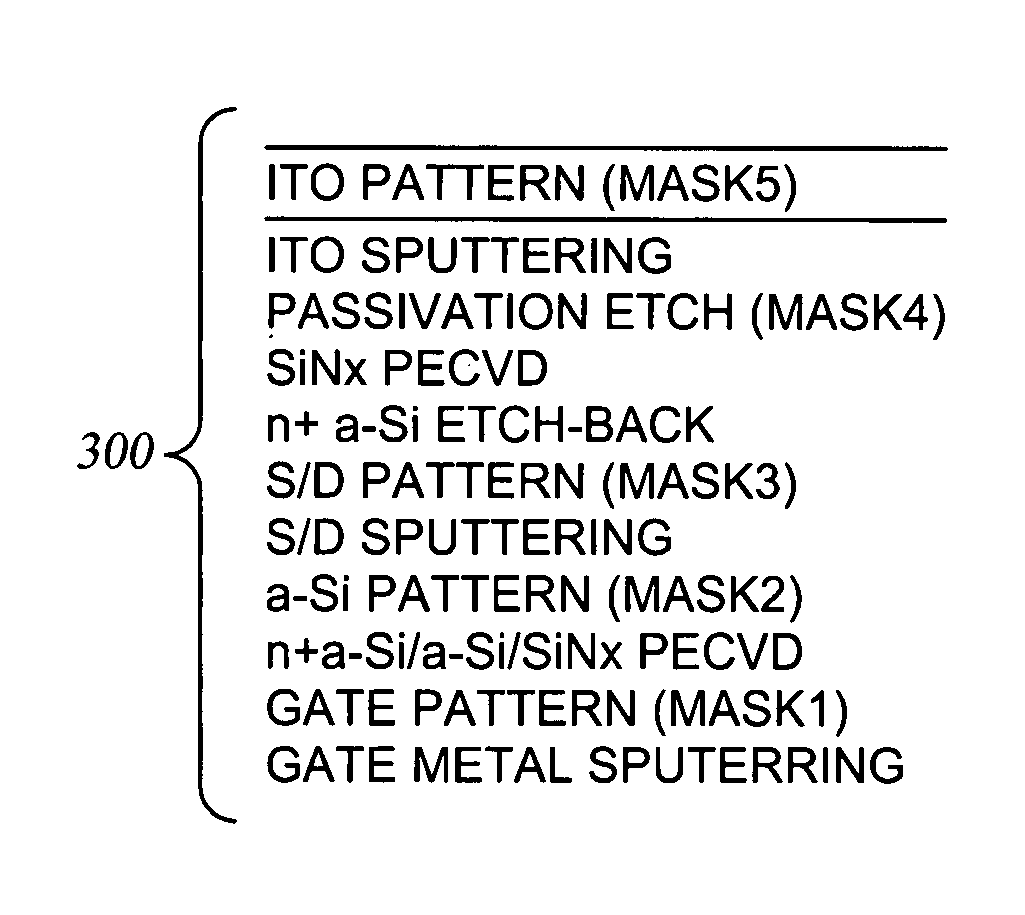

We have discovered that adding H2 to a precursor gas composition including SiH4, NH3, and N2 is effective at improving the wet etch rate and the wet etch rate uniformity across the substrate surface of a-SiNx:H films which are deposited on a substrate by PECVD. Wet etch rate is an indication of film density. Typically, the lower the wet etch rate, the denser the film. The addition of H2 to the SiH4 / NH3 / N2 precursor gas composition did not significantly increase the variation in deposited film thickness across the surface of the substrate. The a-SiNx:H films described herein are particularly useful as TFT gate dielectrics in the production of flat panel displays. The uniformity of the film across the substrate enables the production of flat panel displays having surface areas of 25,000 cm2 and larger.

Owner:APPLIED MATERIALS INC

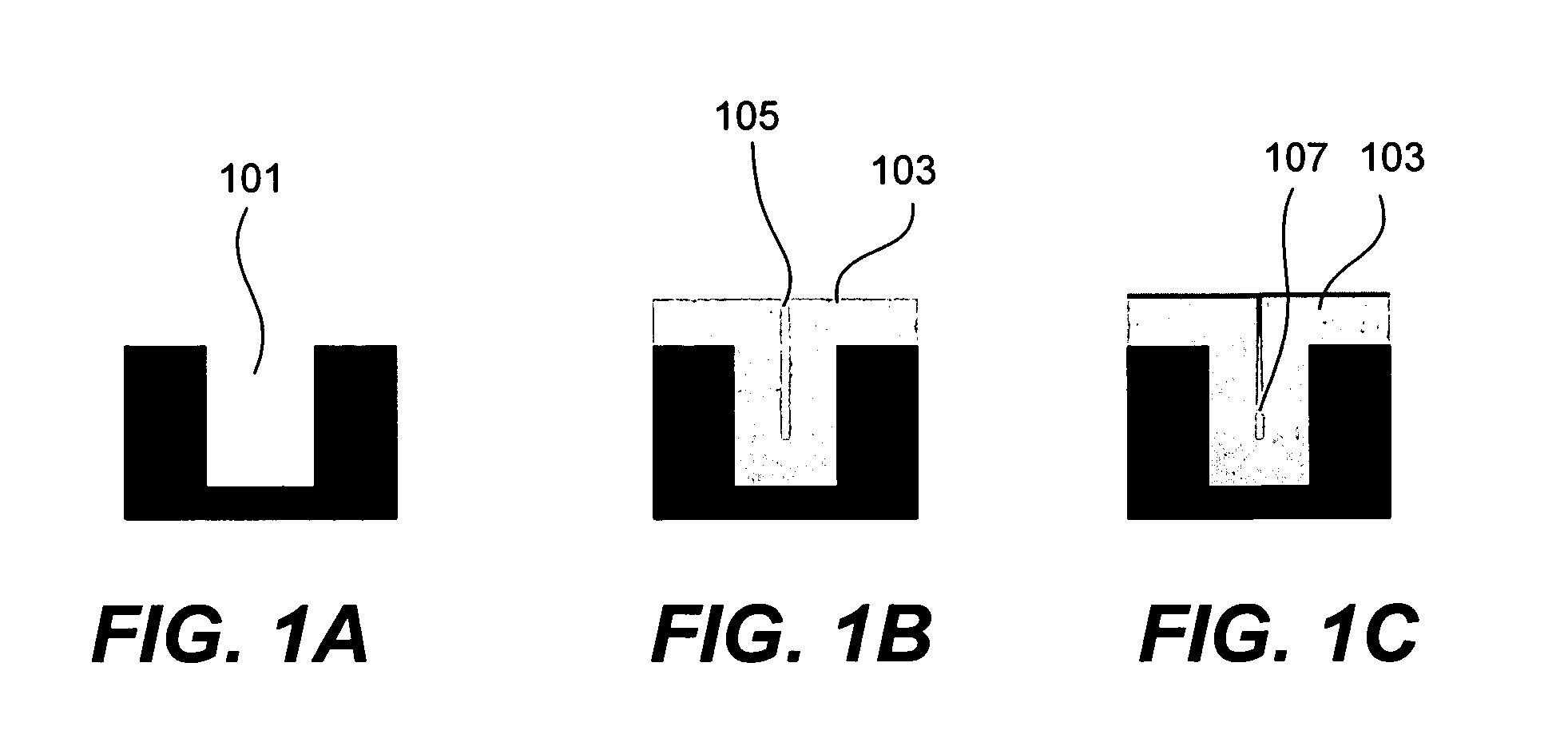

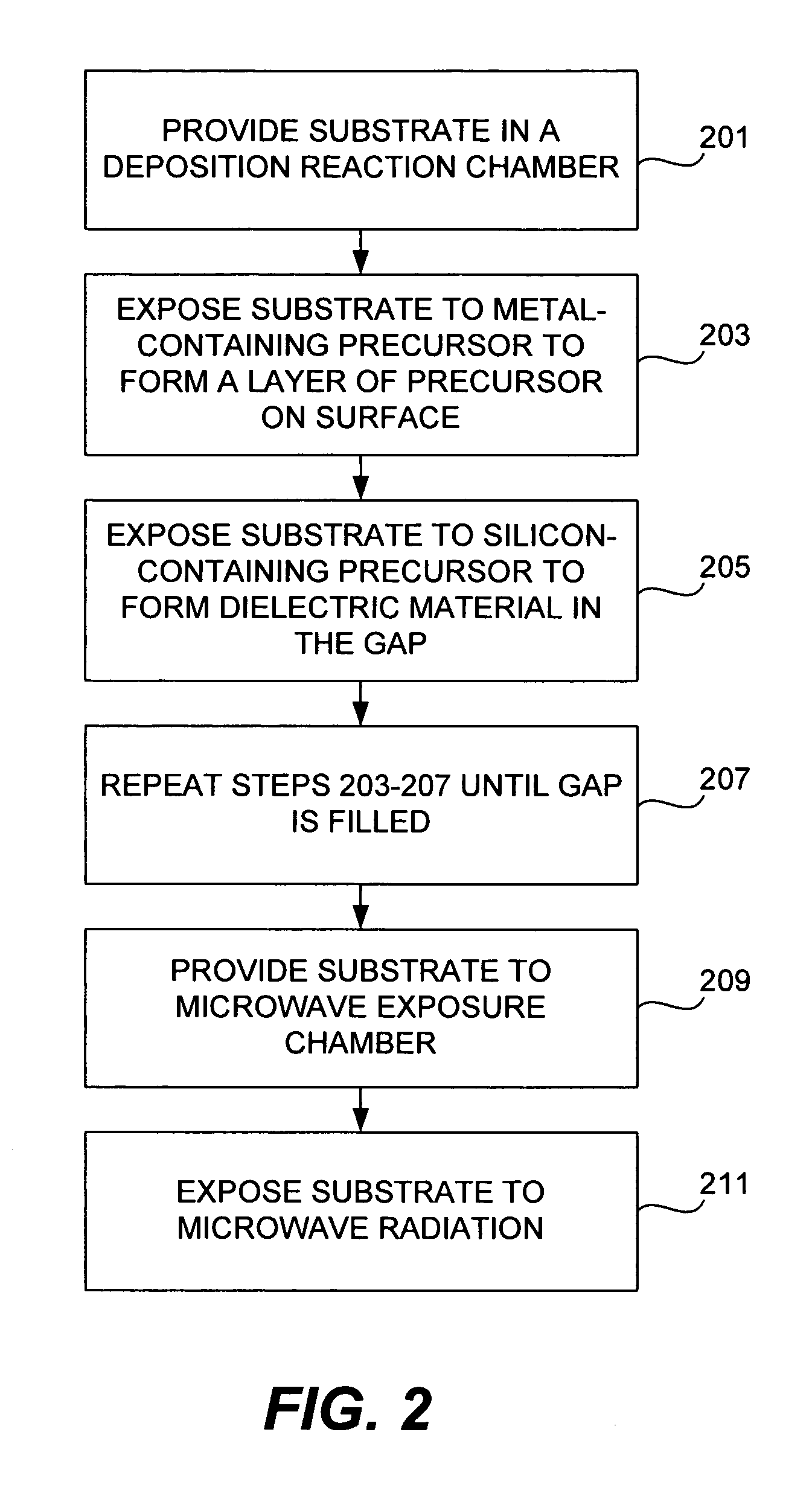

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

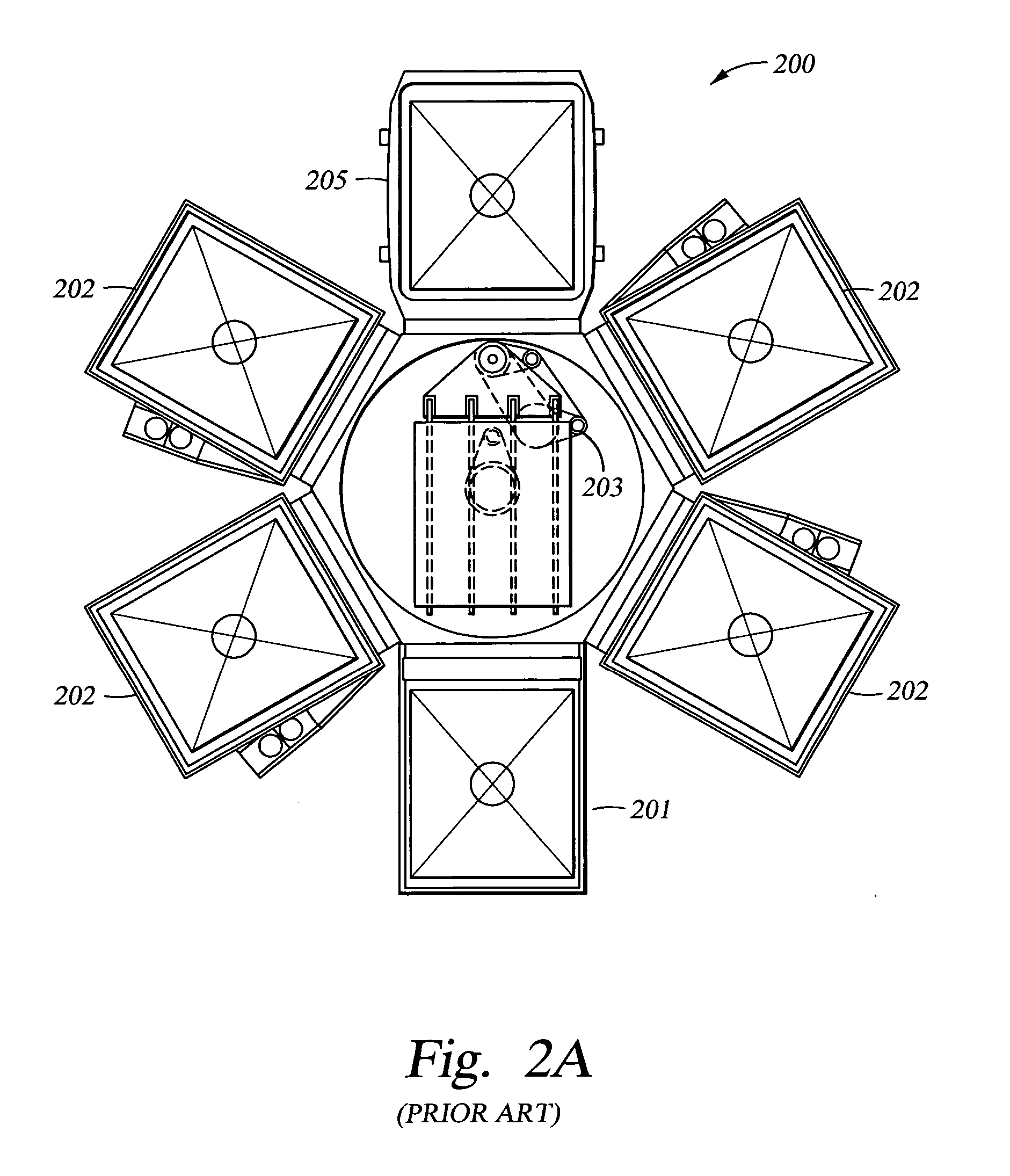

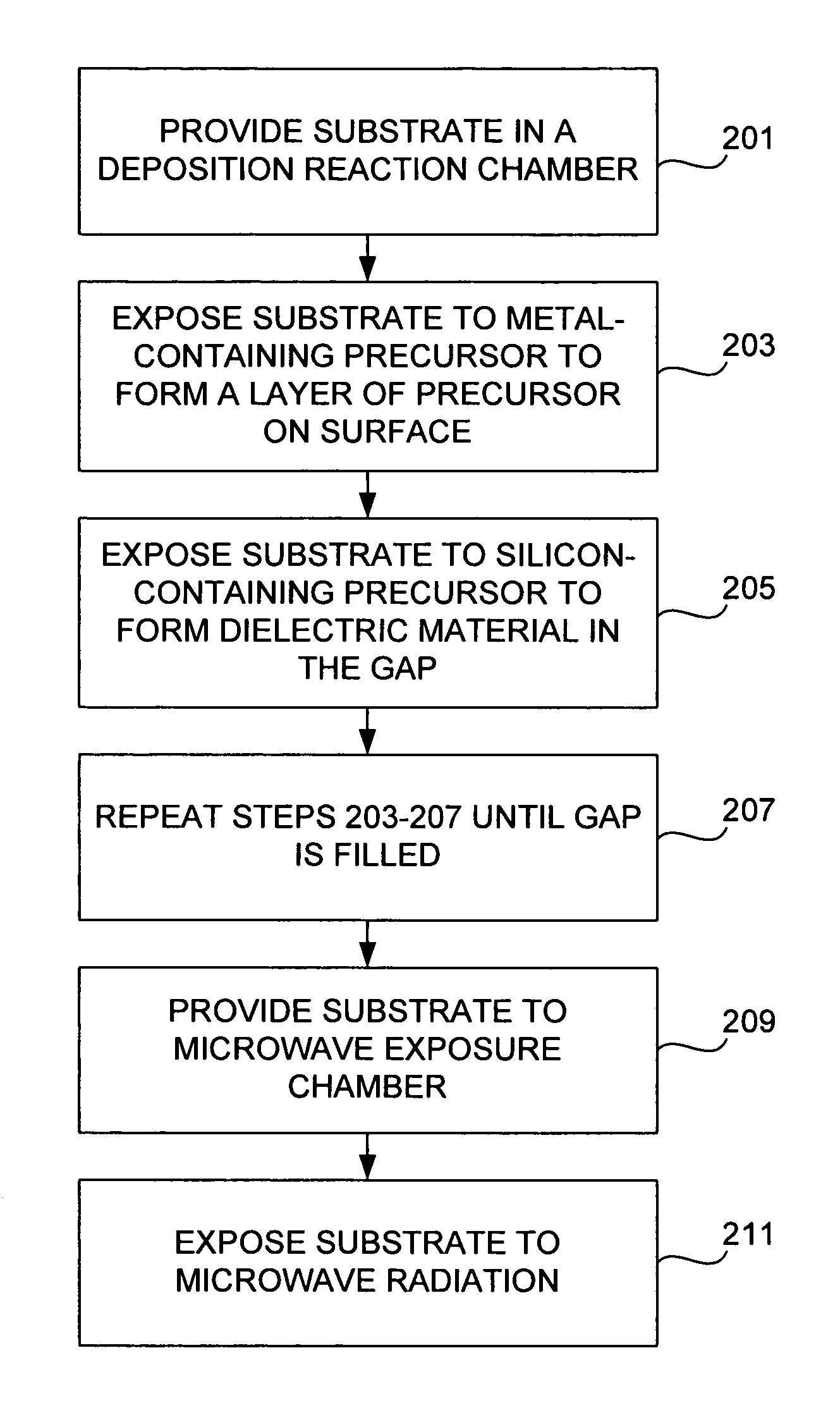

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

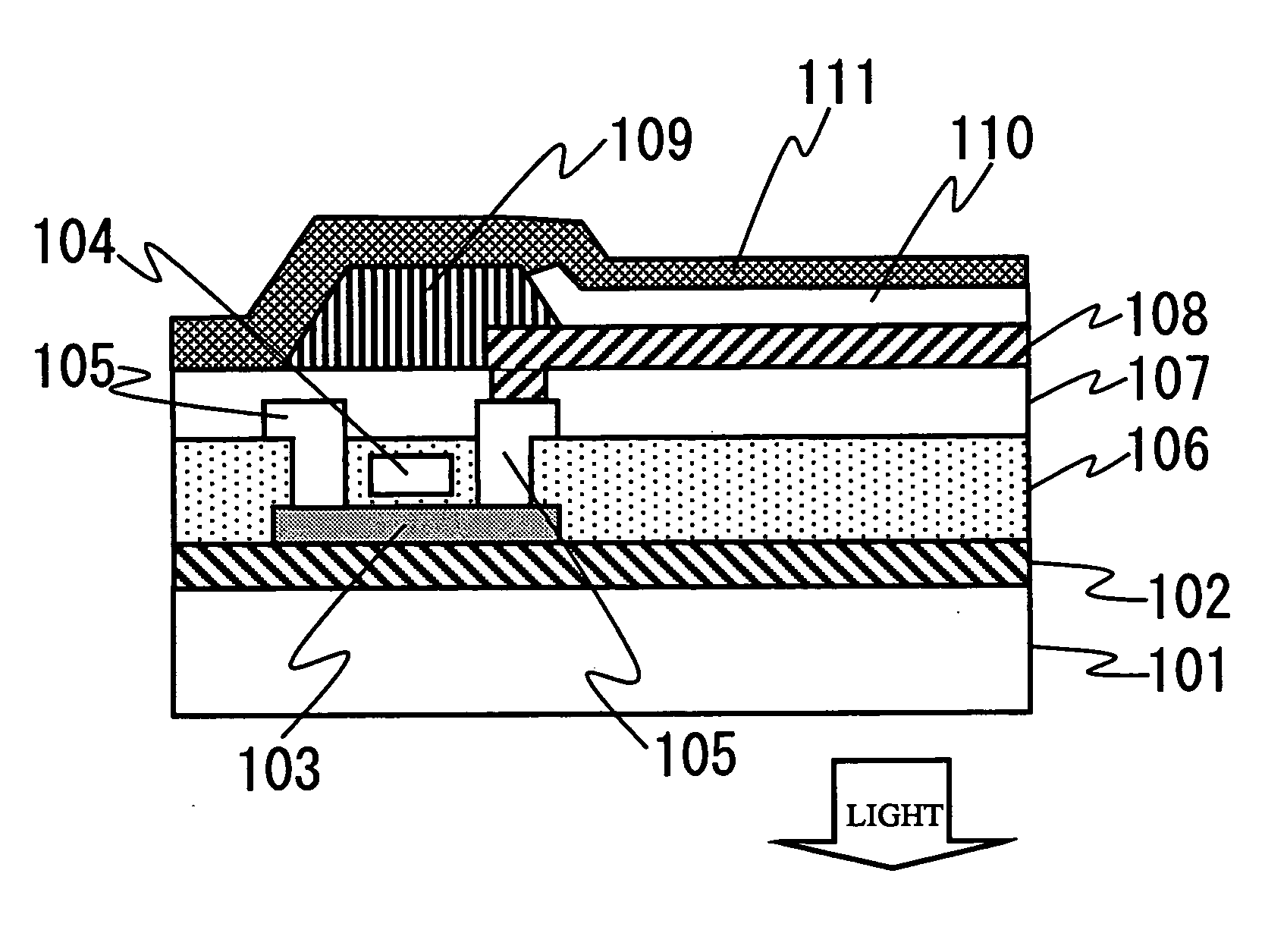

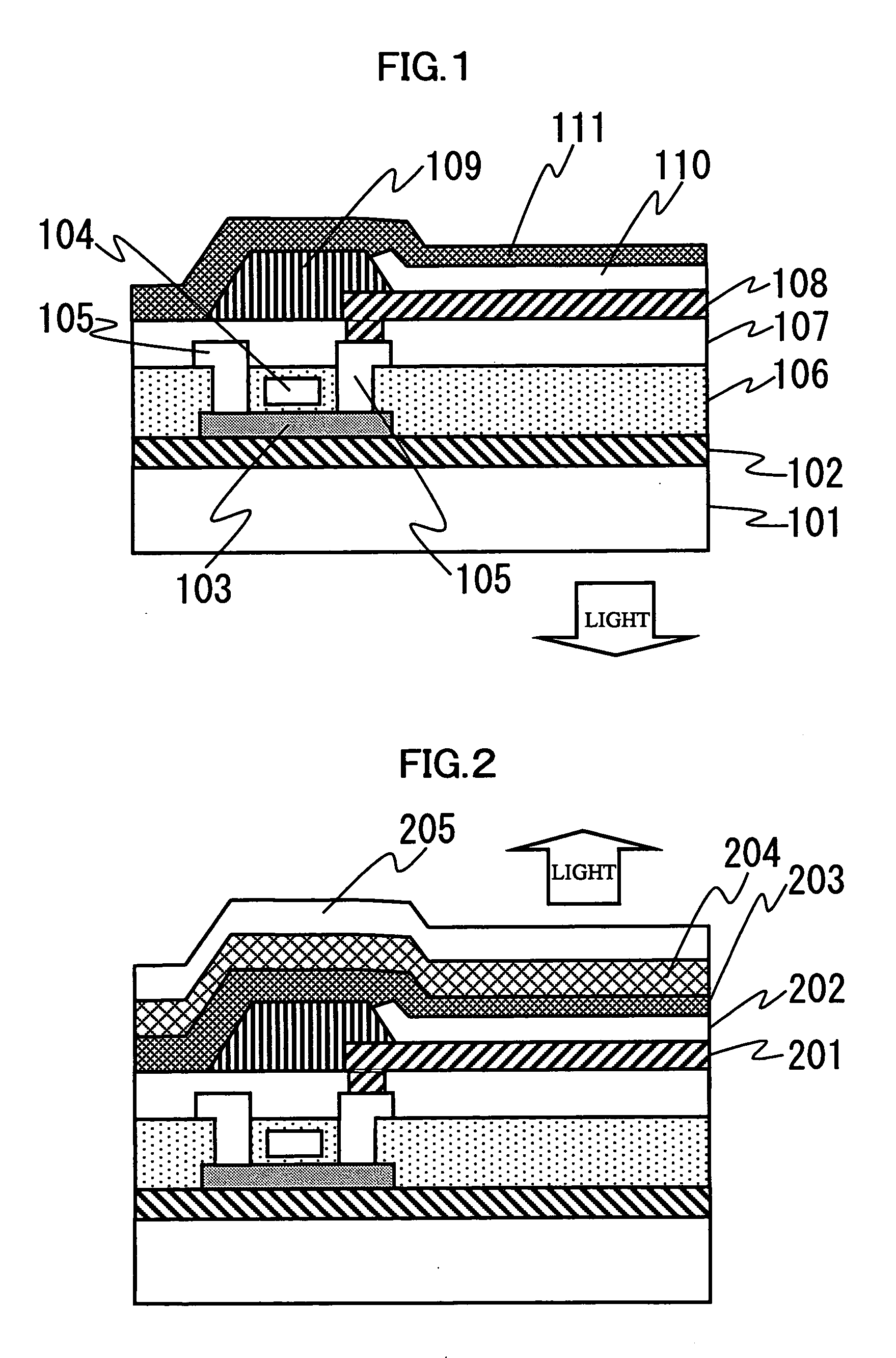

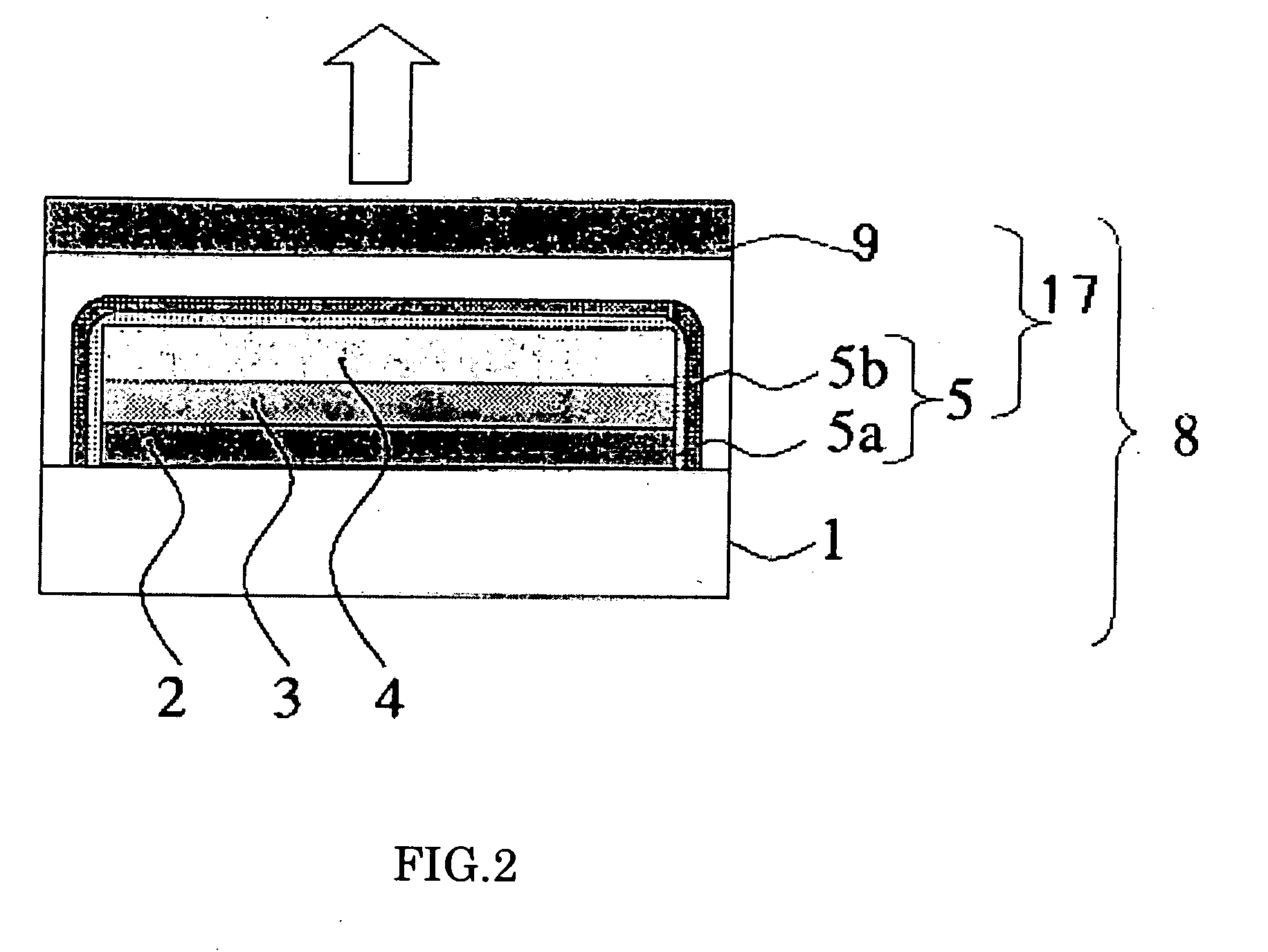

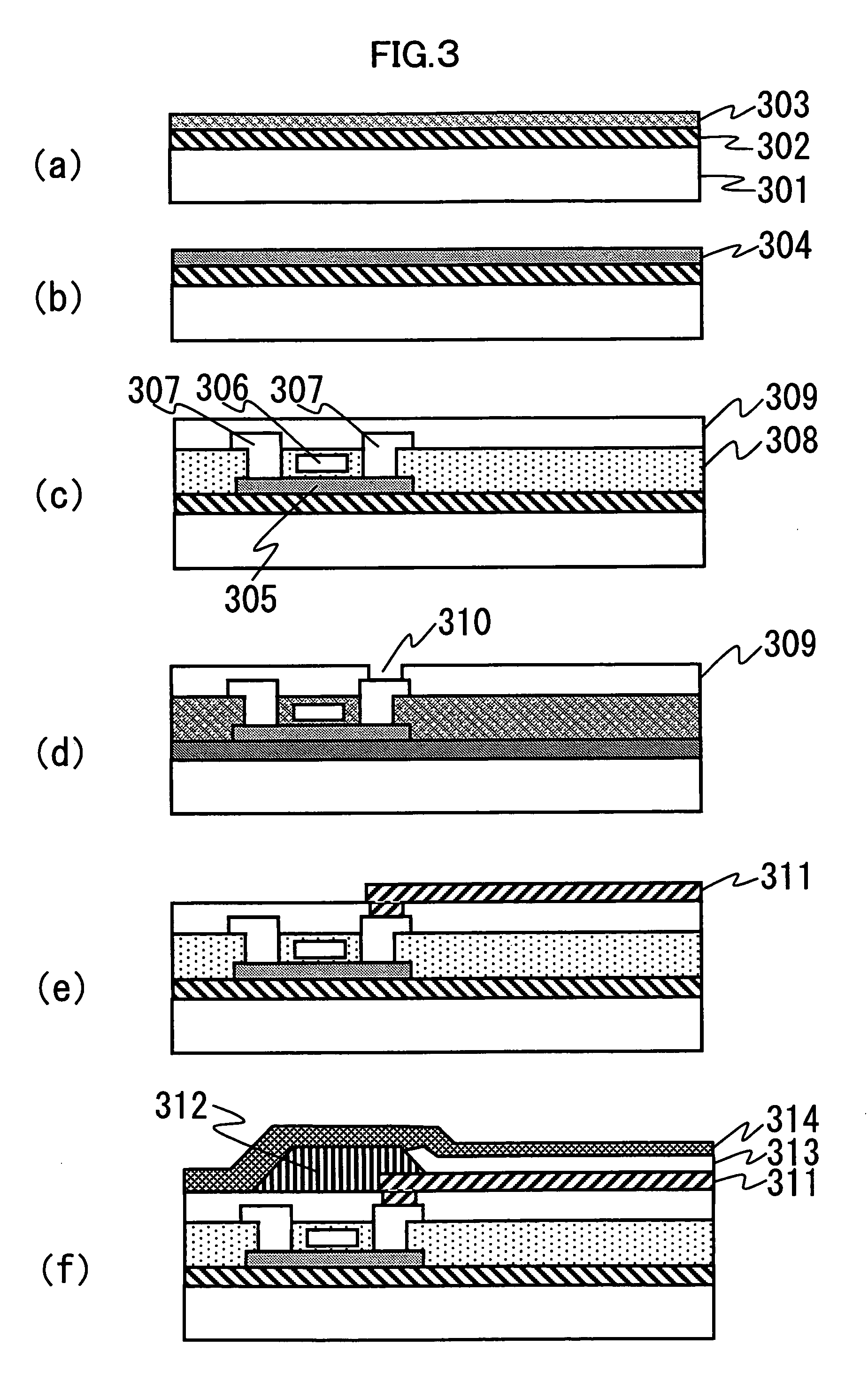

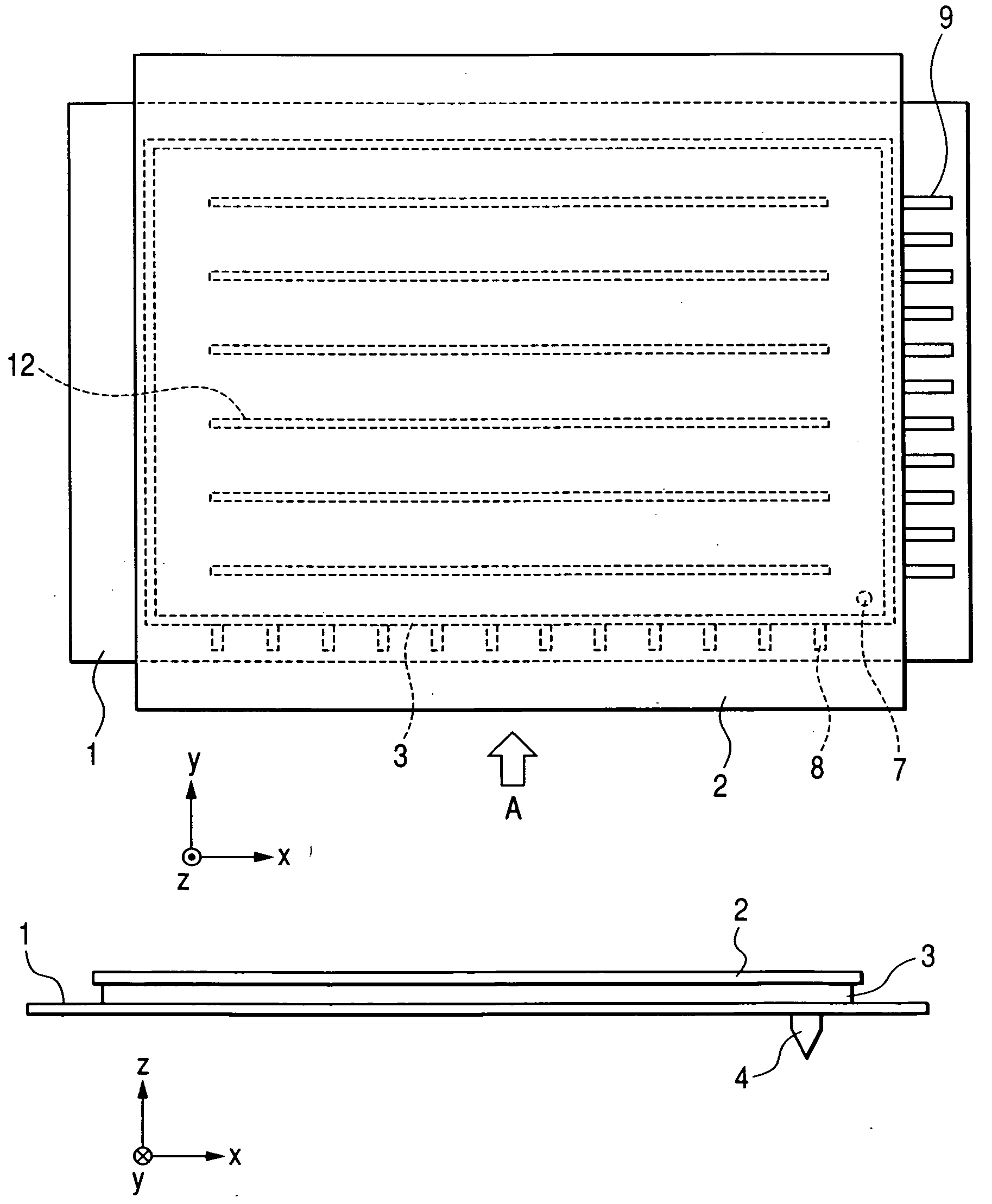

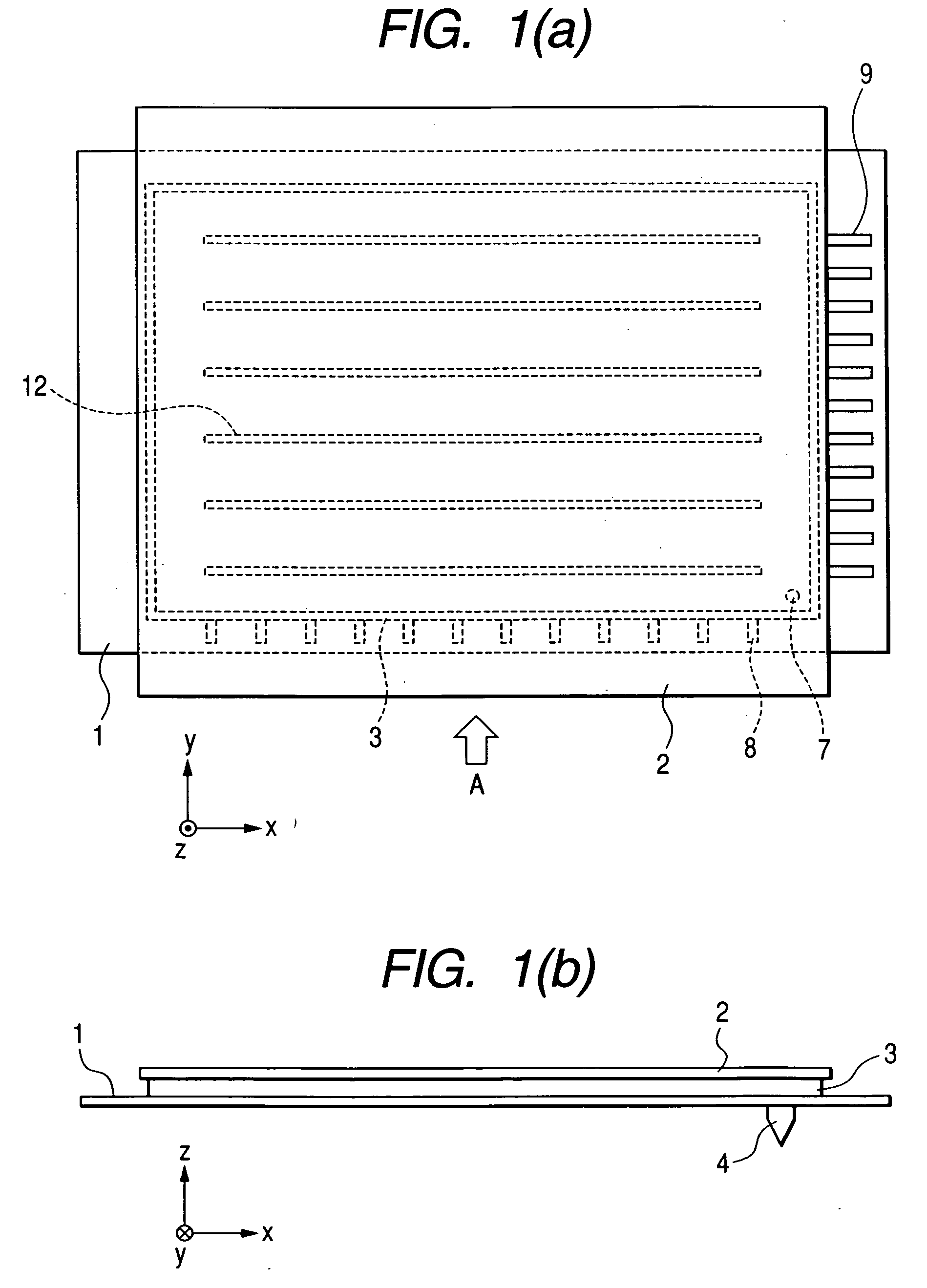

Organic light emitting diode display and method for manufacturing the same

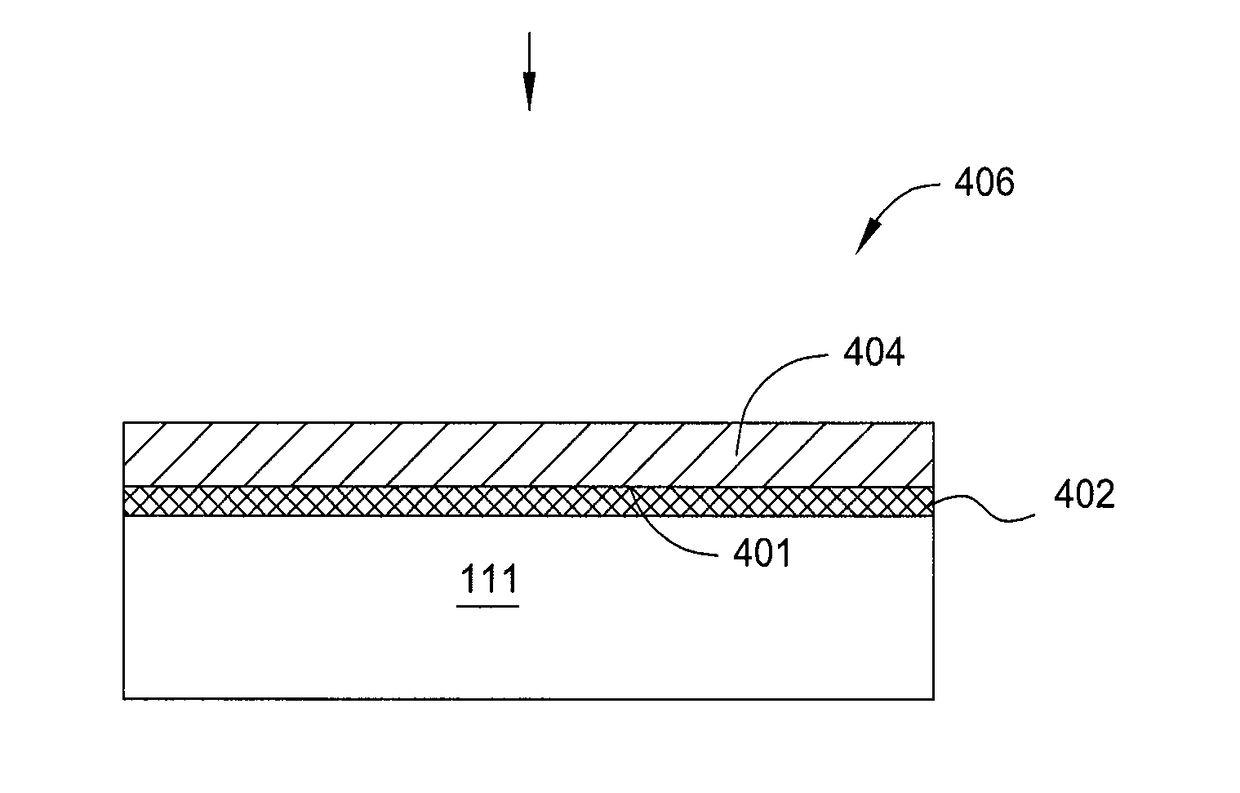

ActiveUS20050156520A1Decreasing density of filmCoefficient loweredDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixRefractive index

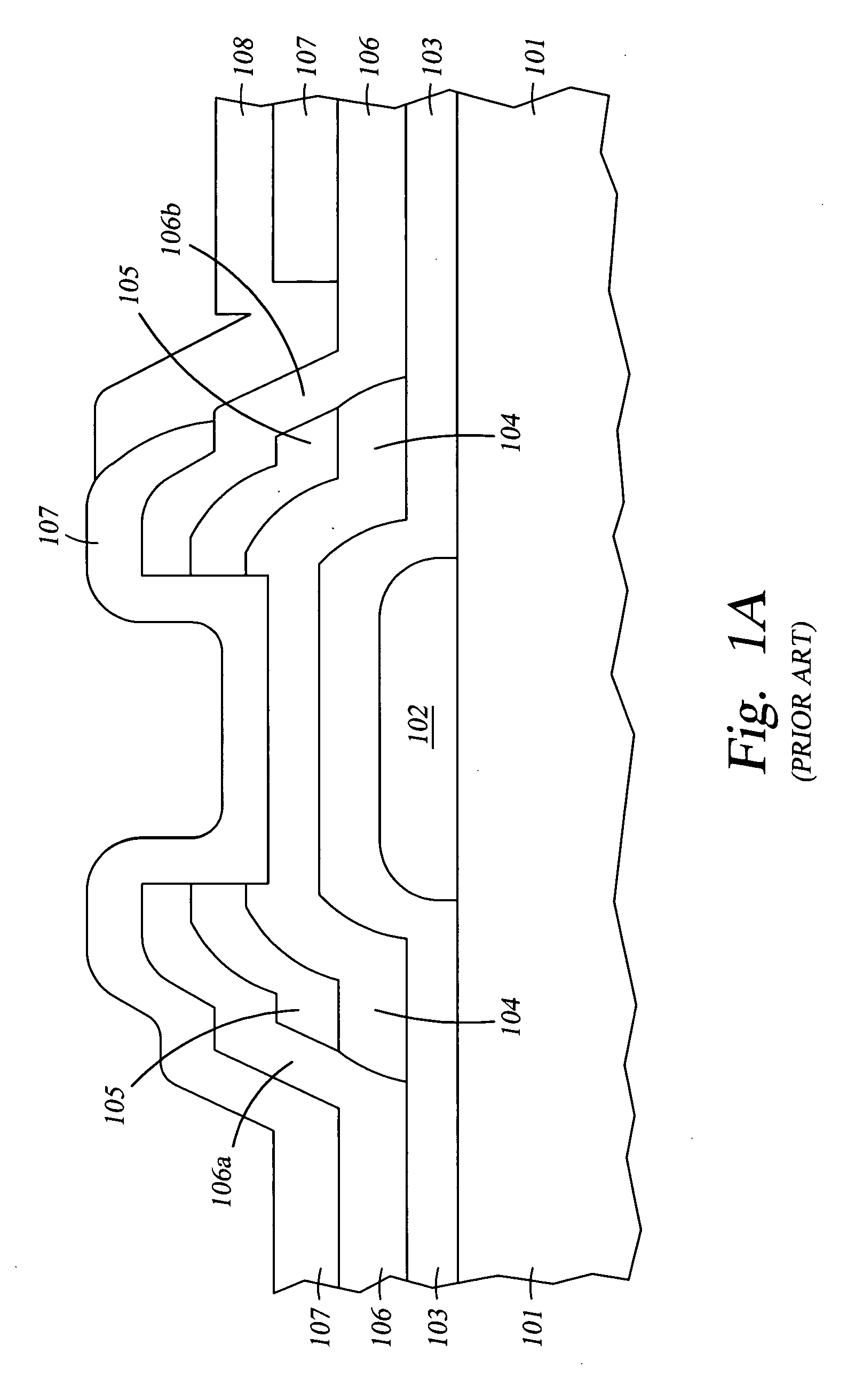

An active matrix type organic light emitting diode display serving as a bottom emission type device coupling out emission of an organic electroluminescence layer from a substrate where thin film transistors are formed or as a top emission type device coupling out the emission on the opposite side to the substrate. In a suitable layer (102, 106, 107) in each device, an insulating film containing SiO is formed. The insulating film is porous with nano pores in the film. The porous insulating film is controlled as to film density, film refractive index, nano pore diameter in film, average nano pore diameter in film and maximum nano pore diameter in film so that the refractive index is lower than that of a transparent electrode or a transparent substrate of the display holding the organic electroluminescence layer therebetween, and nano pores are present in the film. Light scattering effect can be obtained so that emission from the organic electroluminescence layer (110) can be coupled out to the outside efficiently.

Owner:SAMSUNG DISPLAY CO LTD +1

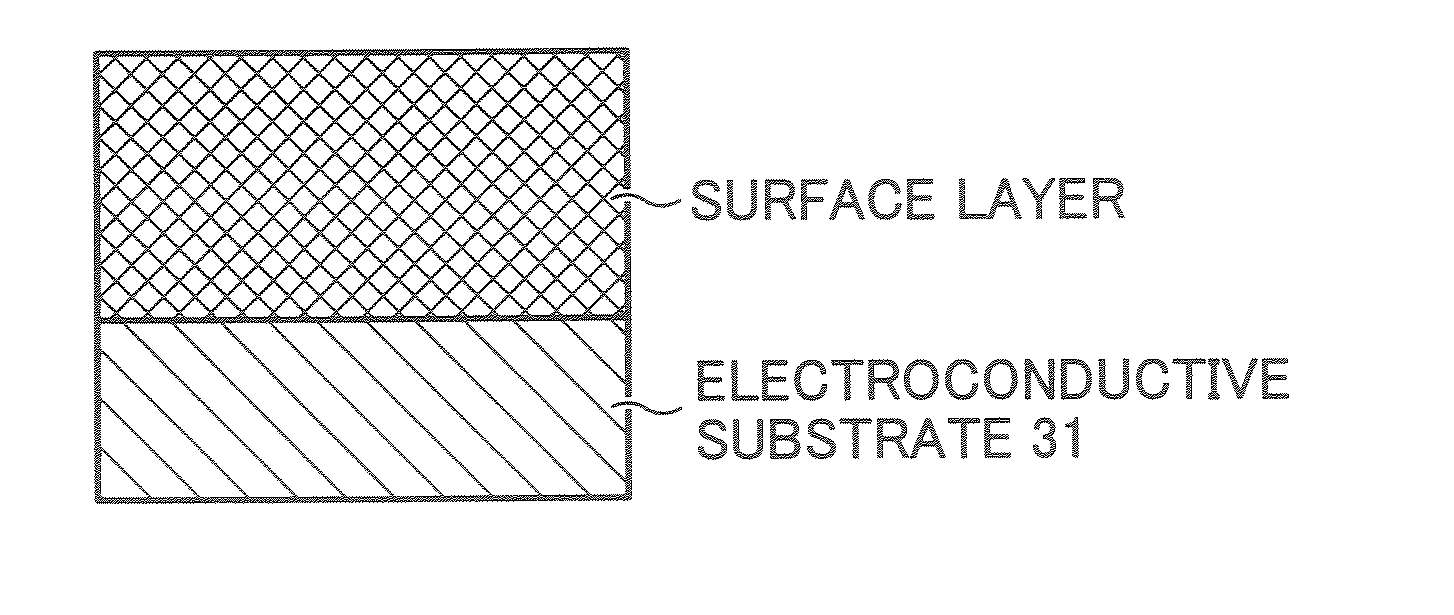

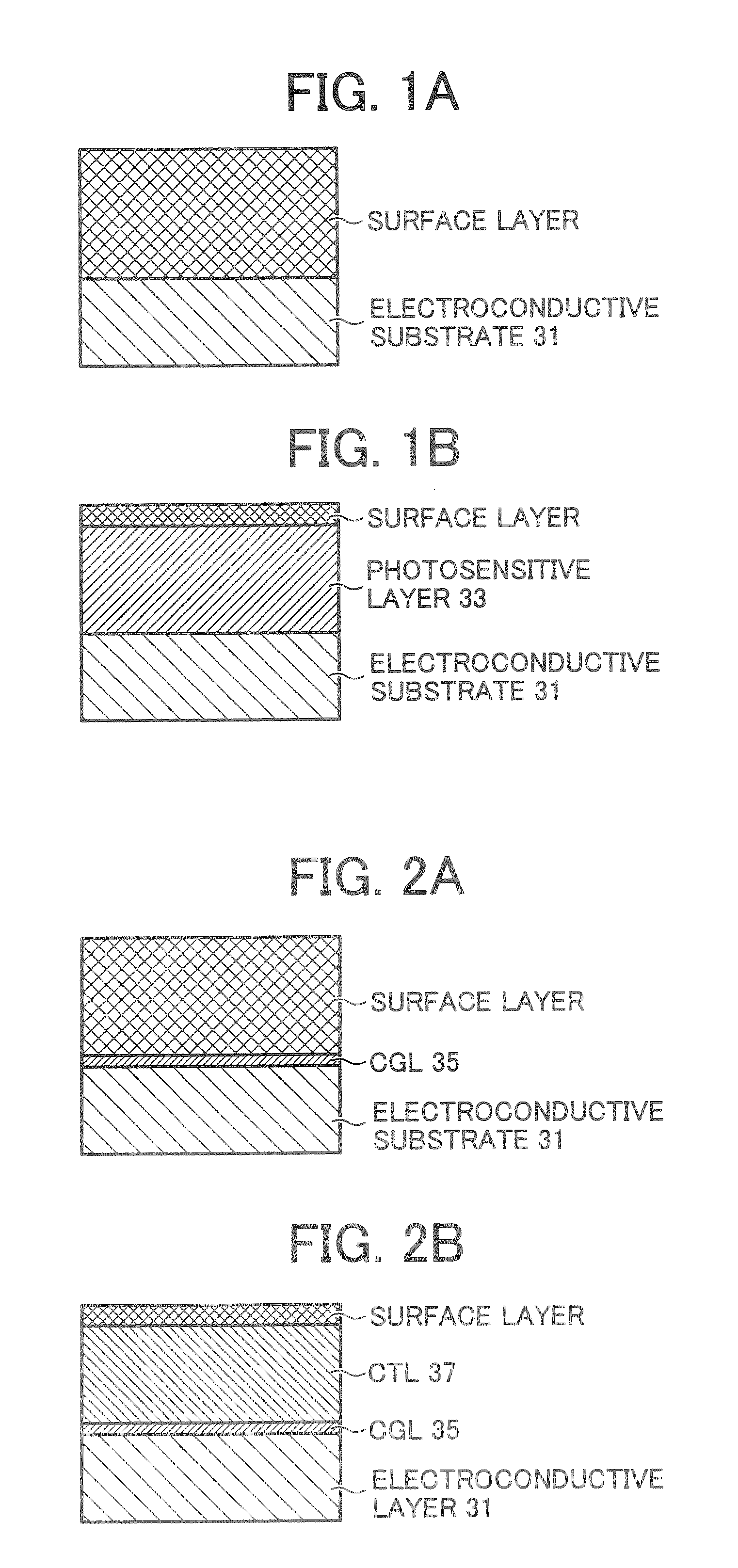

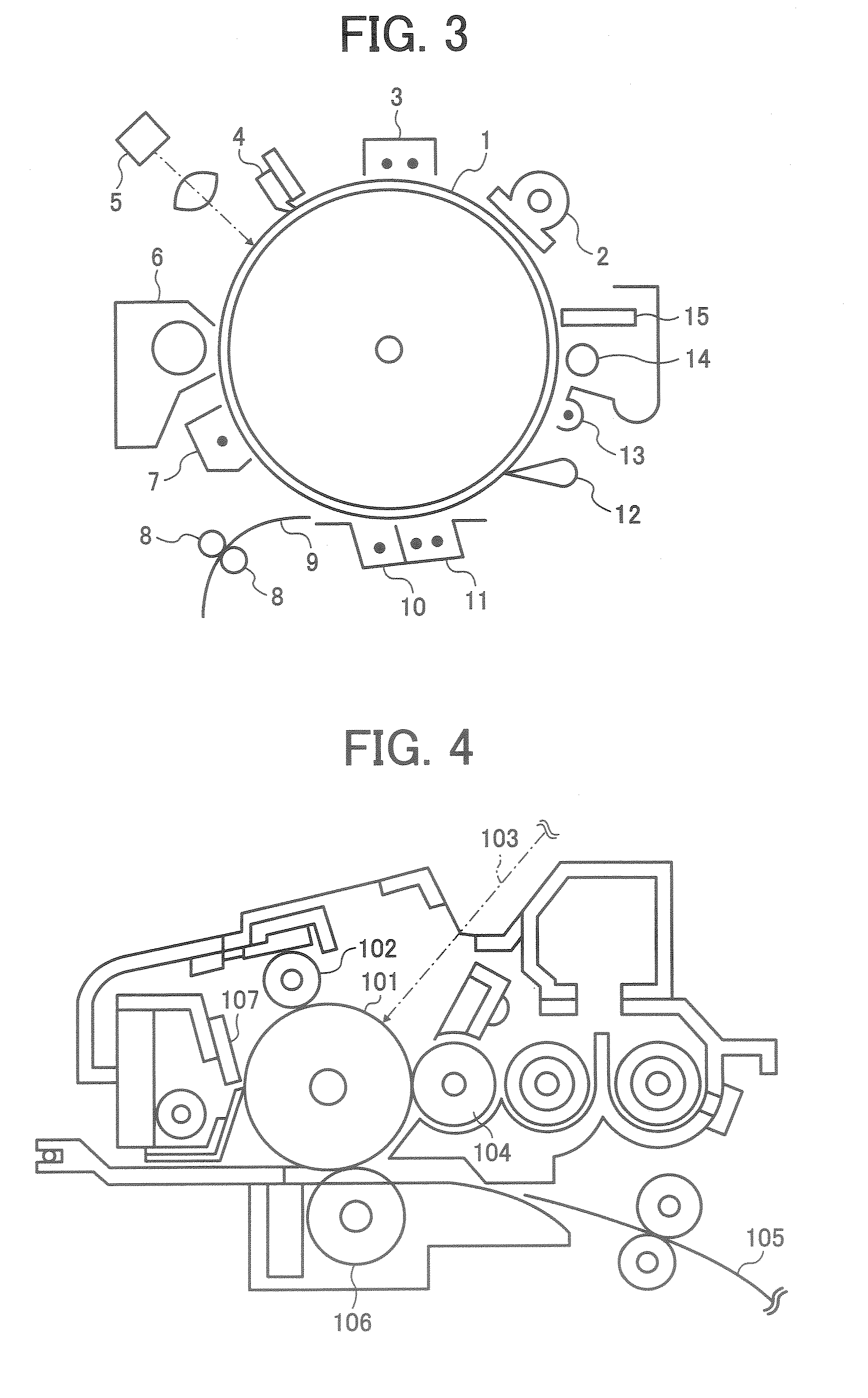

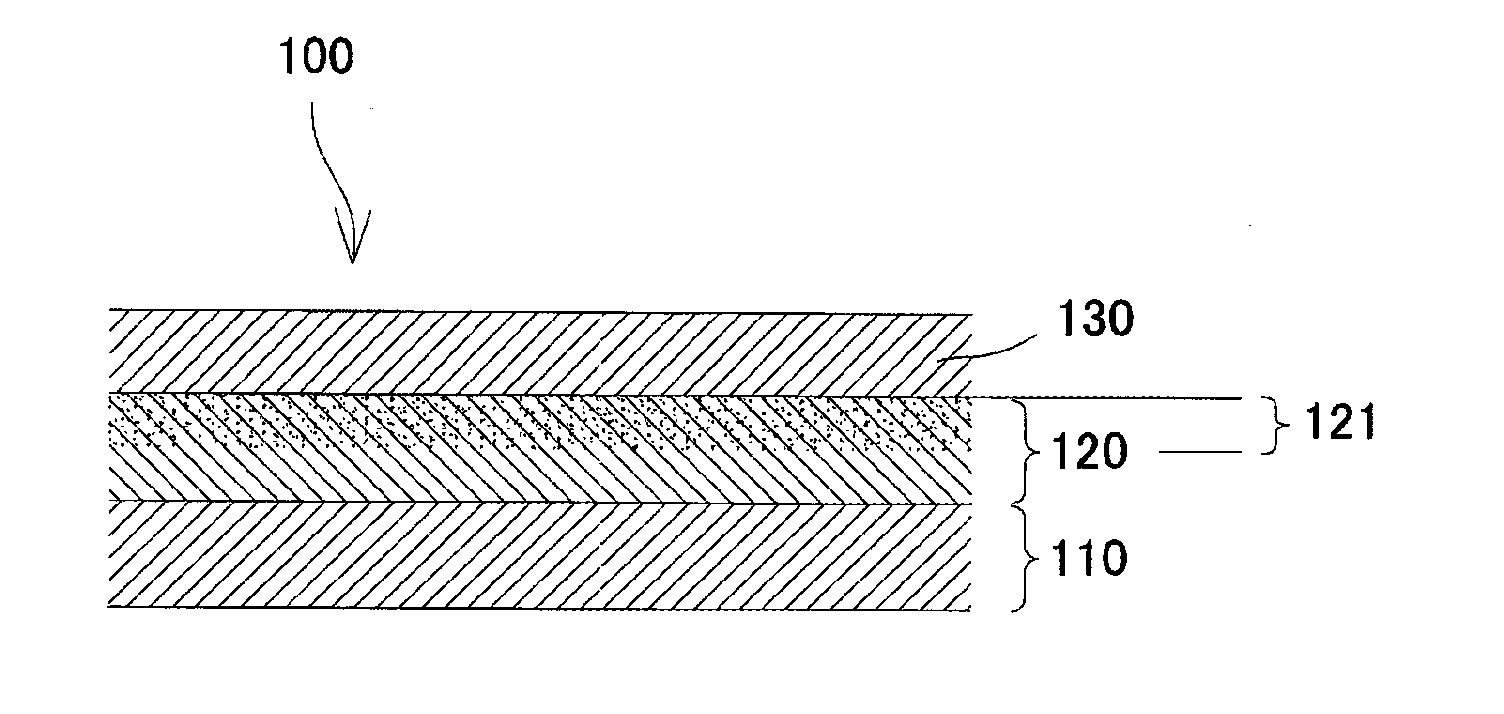

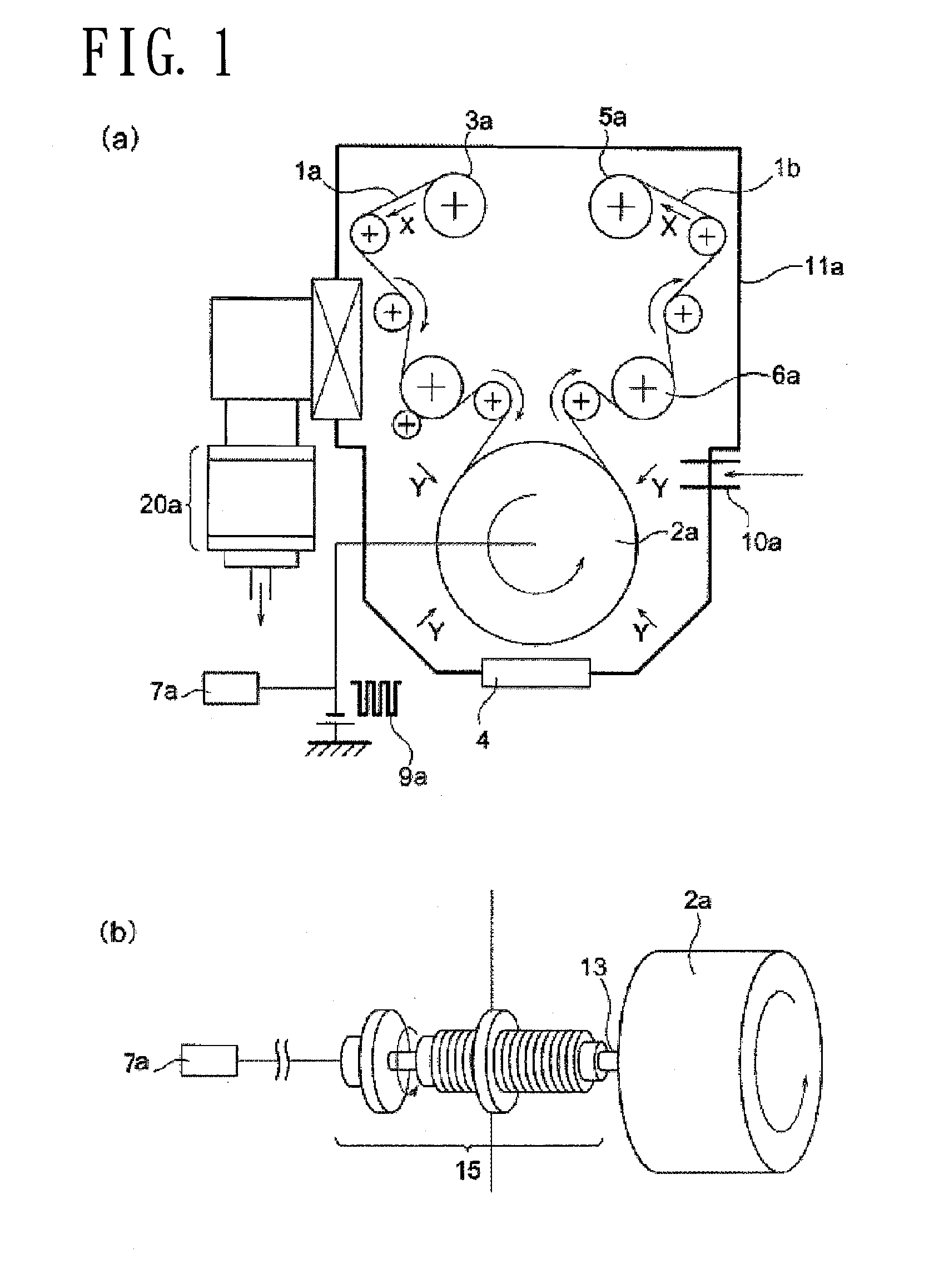

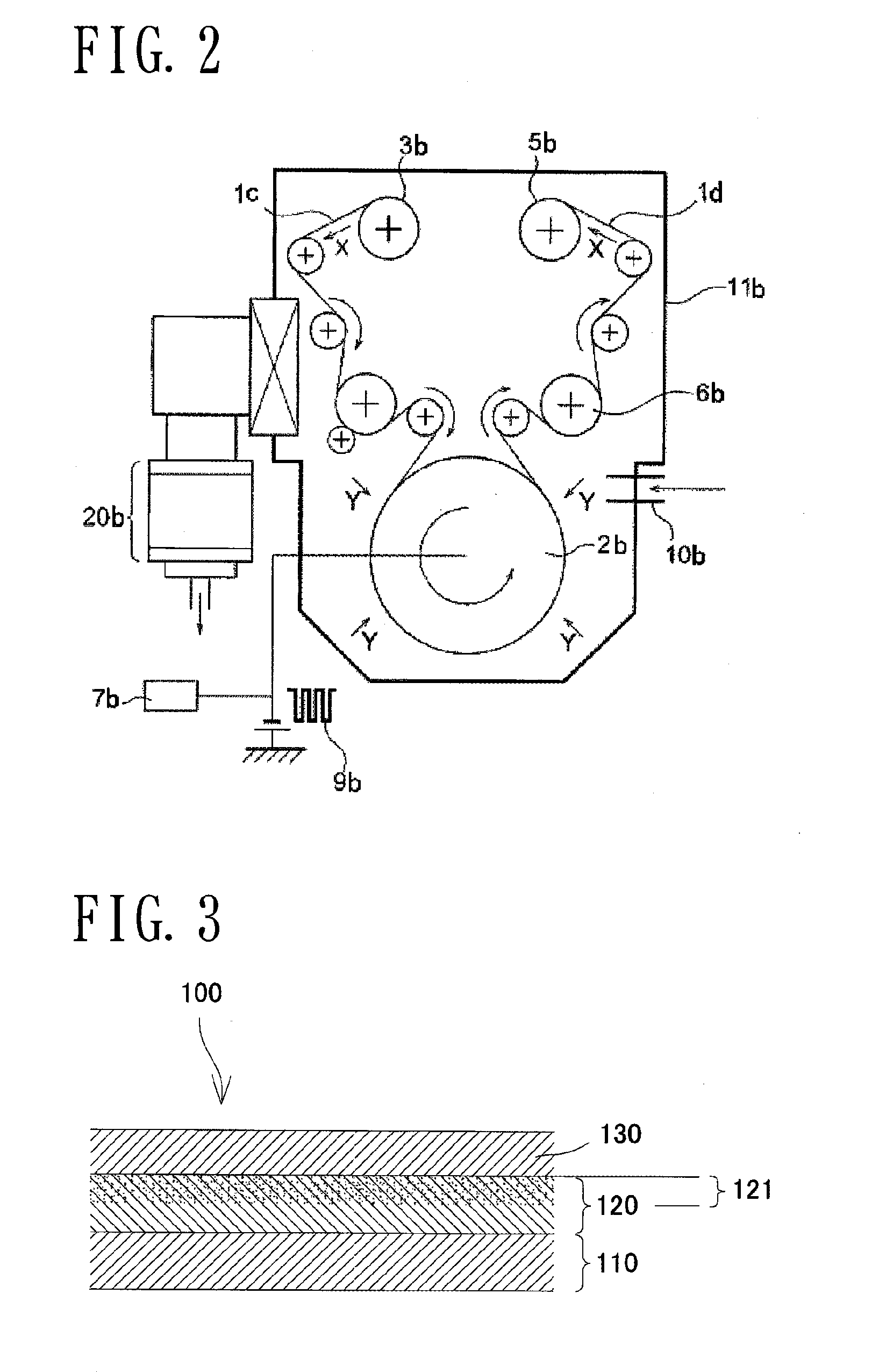

Electrophotographic photoreceptor and method of preparing the photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the photoreceptor

InactiveUS20070212627A1Increased durabilityElectrically stableElectrographic process apparatusCorona dischargeImage formationPhotochemistry

An electrophotographic photoreceptor formed of an electroconductive substrate and a photosensitive layer located overlying the electroconductive substrate, wherein the photosensitive layer contains units obtained from a tri- or more functional radical polymerizable monomer having no charge transport structure and a radical polymerizable compound having a charge transport structure and the photosensitive layer has a layer film density of from 1.0 to 1.4 g / cm3.

Owner:RICOH KK

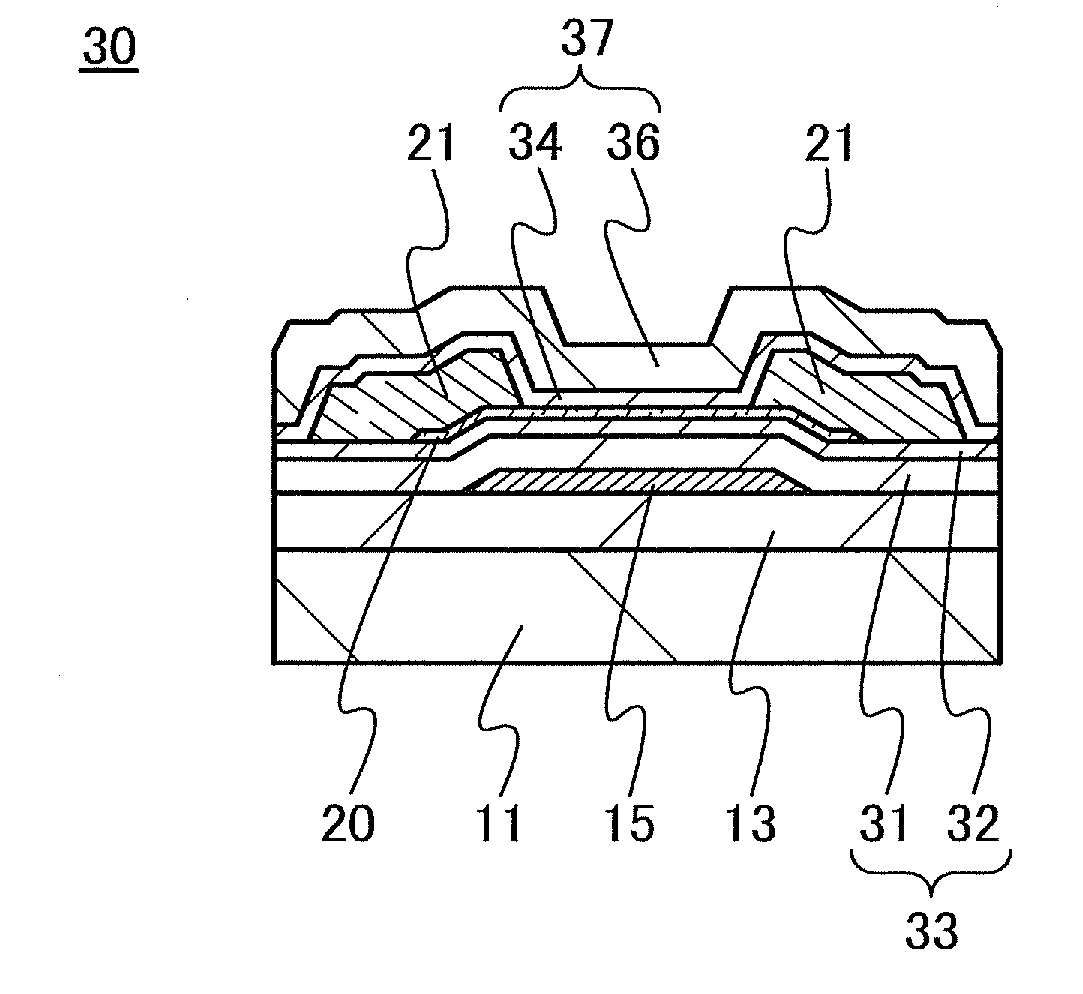

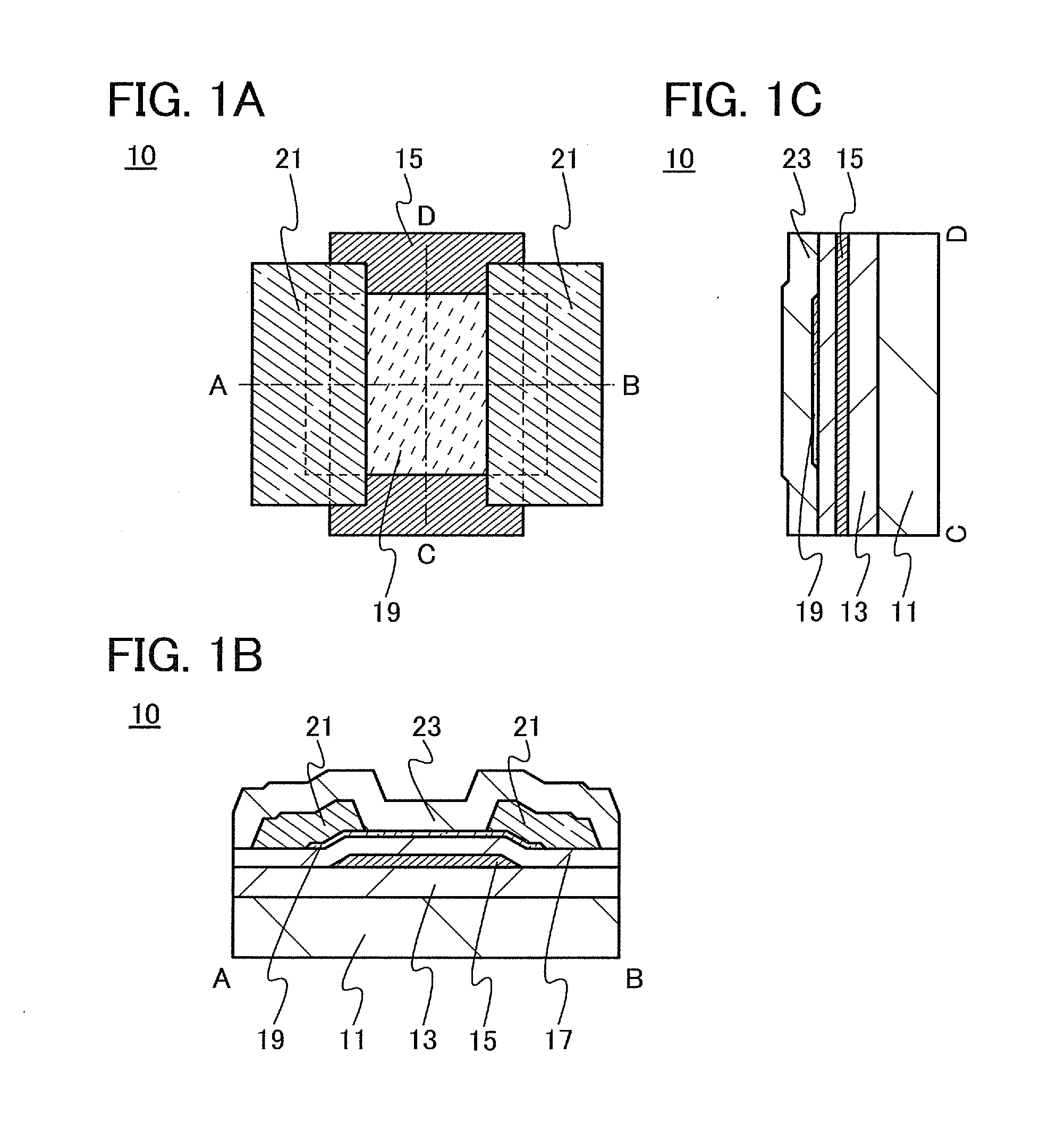

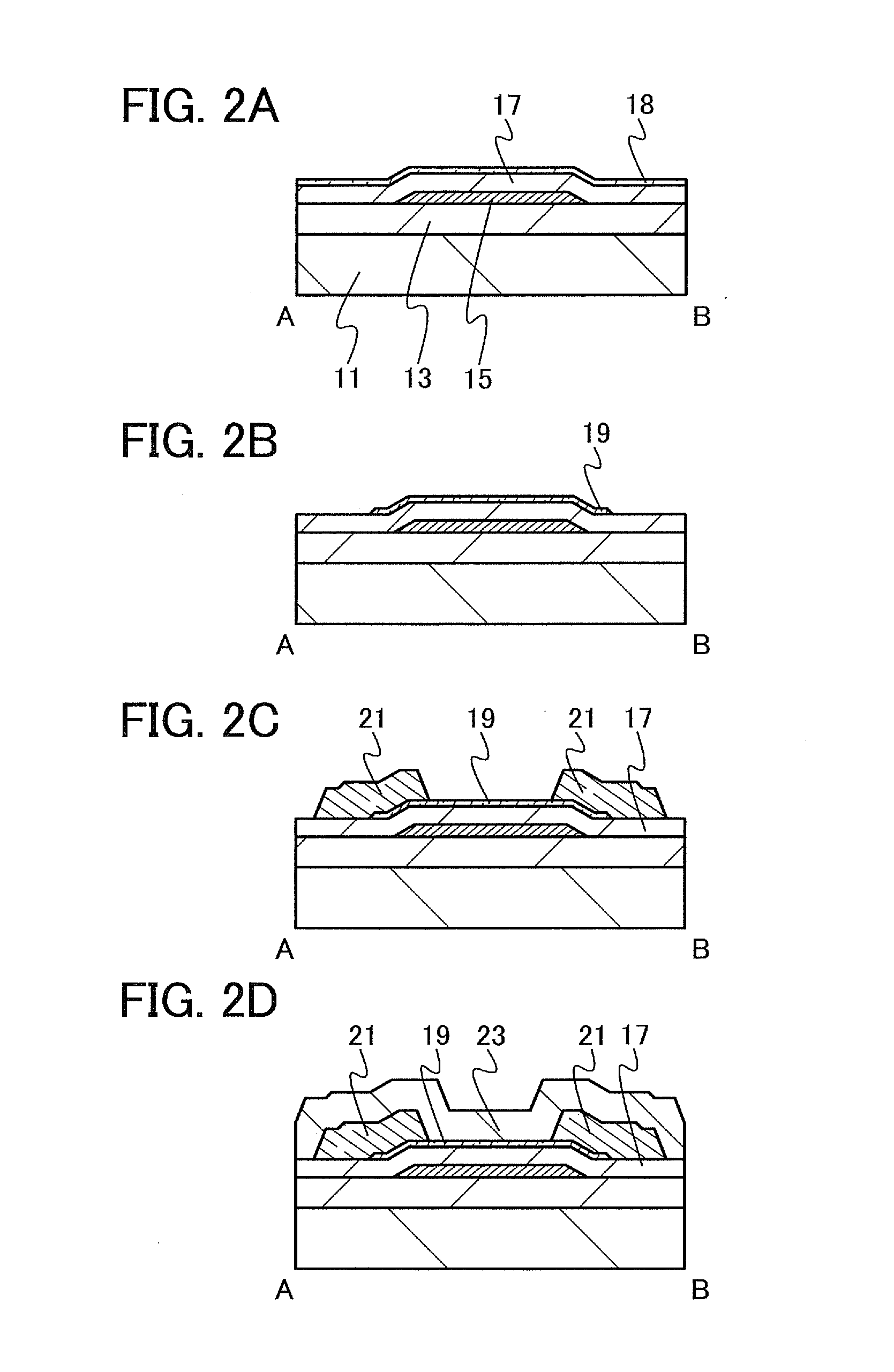

Semiconductor device

ActiveUS20130270550A1Excellent electrical propertiesIncrease film densityTransistorSolid-state devicesElectronPhysics

Electric characteristics of a semiconductor device using an oxide semiconductor are improved. Further, a highly reliable semiconductor device in which a variation in electric characteristics with time or a variation in electric characteristics due to a gate BT stress test with light irradiation is small is manufactured. A transistor includes a gate electrode, an oxide semiconductor film overlapping with part of the gate electrode with a gate insulating film therebetween, and a pair of electrodes in contact with the oxide semiconductor film. The gate insulating film is an insulating film whose film density is higher than or equal to 2.26 g / cm3 and lower than or equal to 2.63 g / cm3 and whose spin density of a signal with a g value of 2.001 is 2×1015 spins / cm3 or less in electron spin resonance.

Owner:SEMICON ENERGY LAB CO LTD

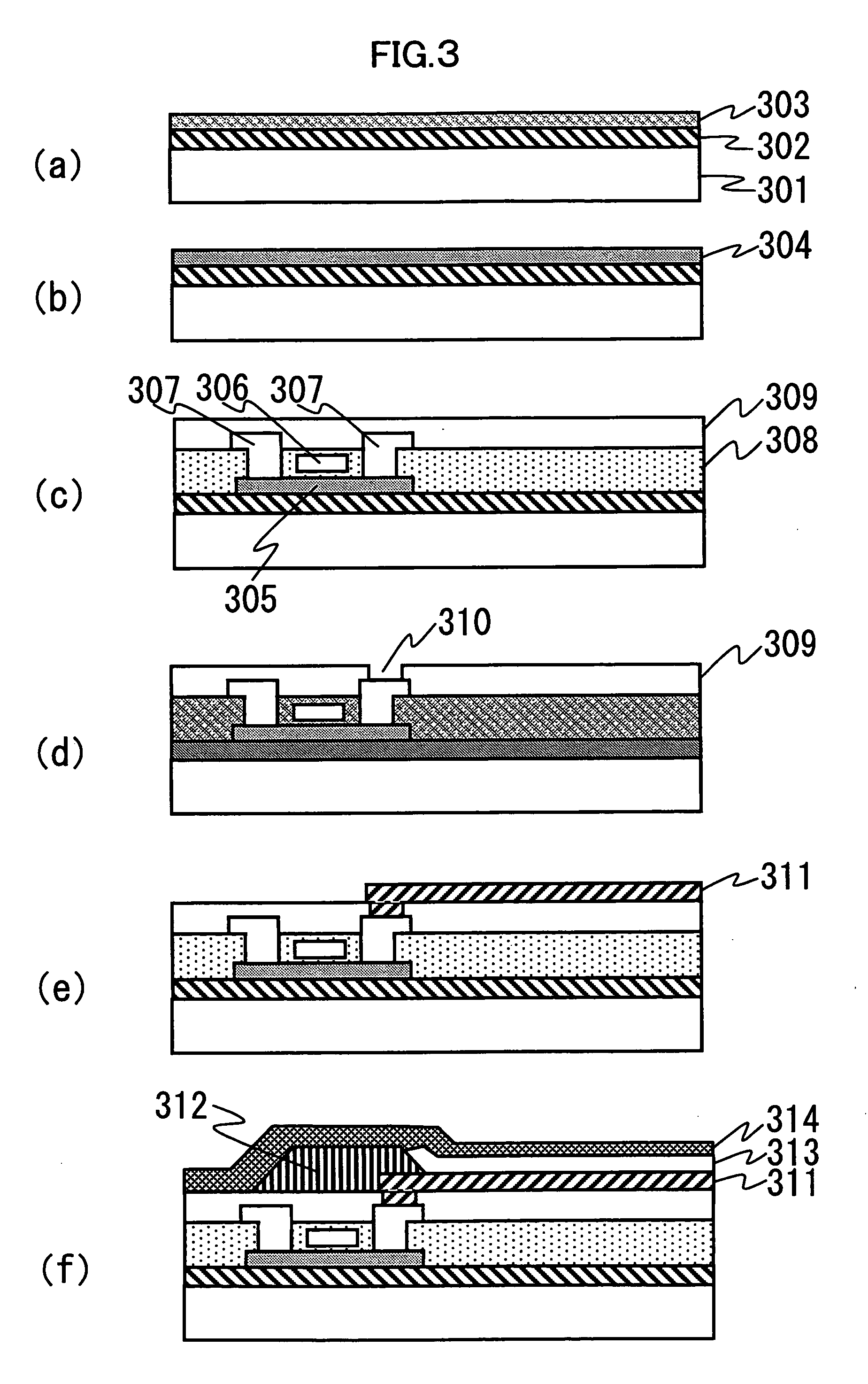

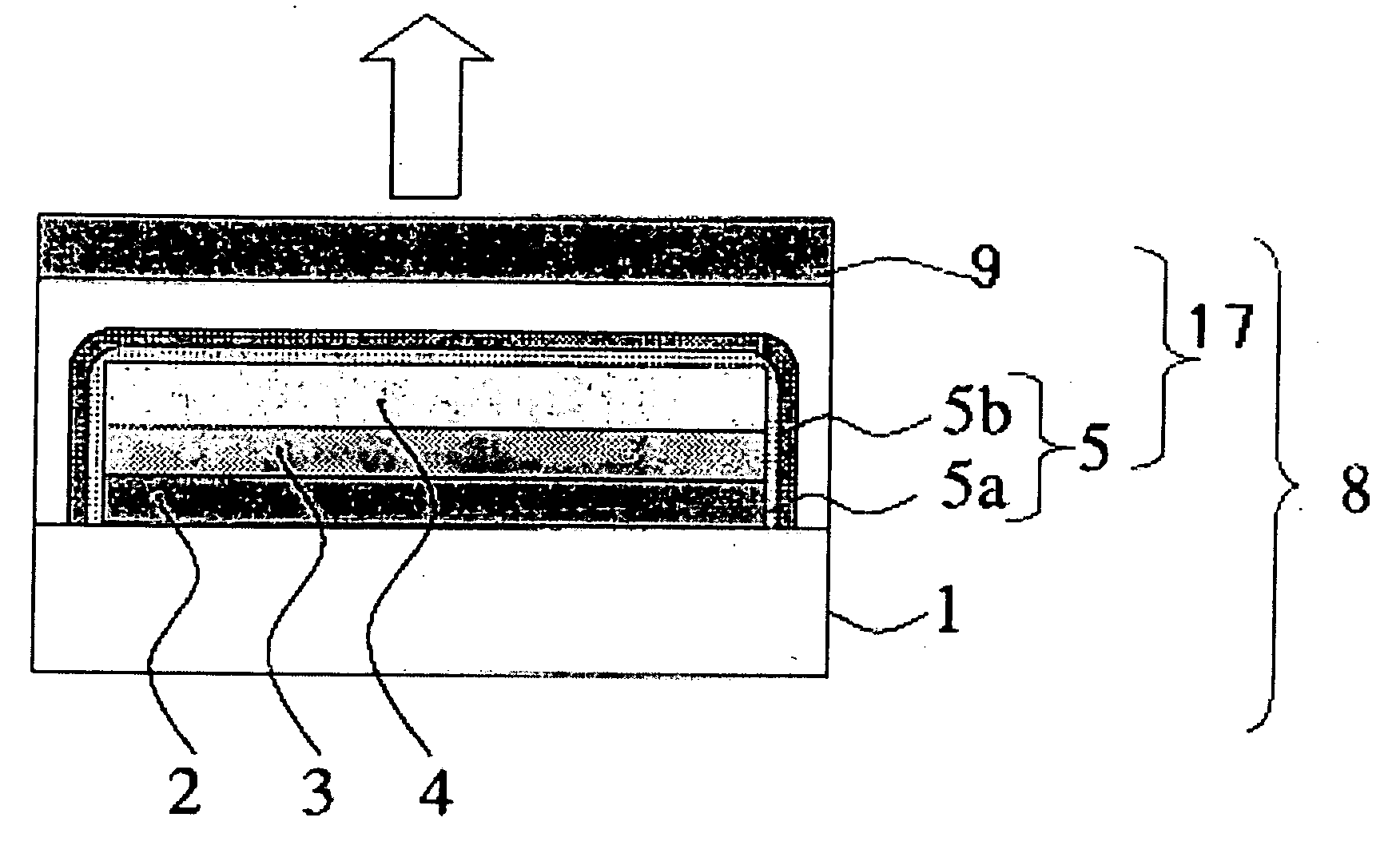

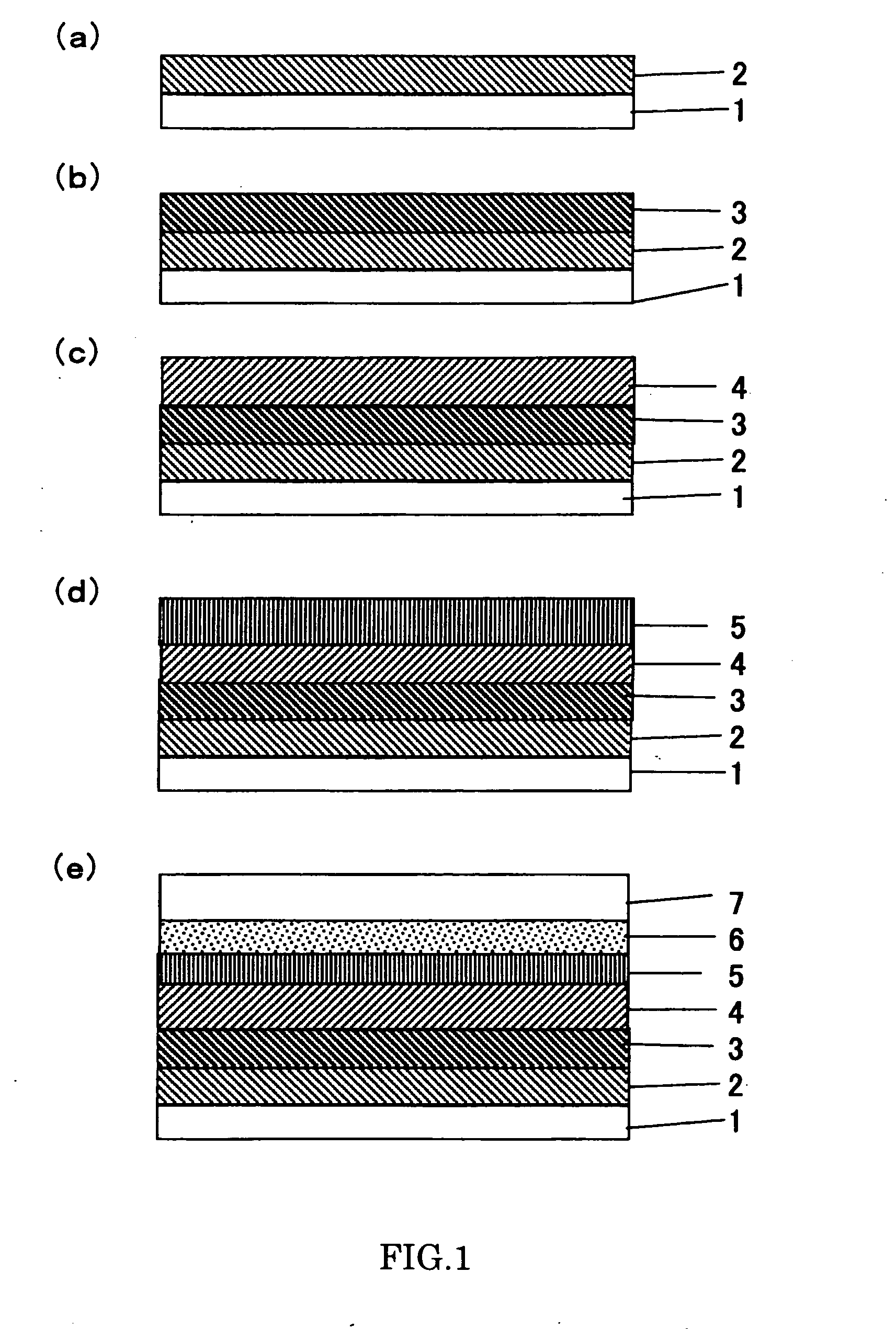

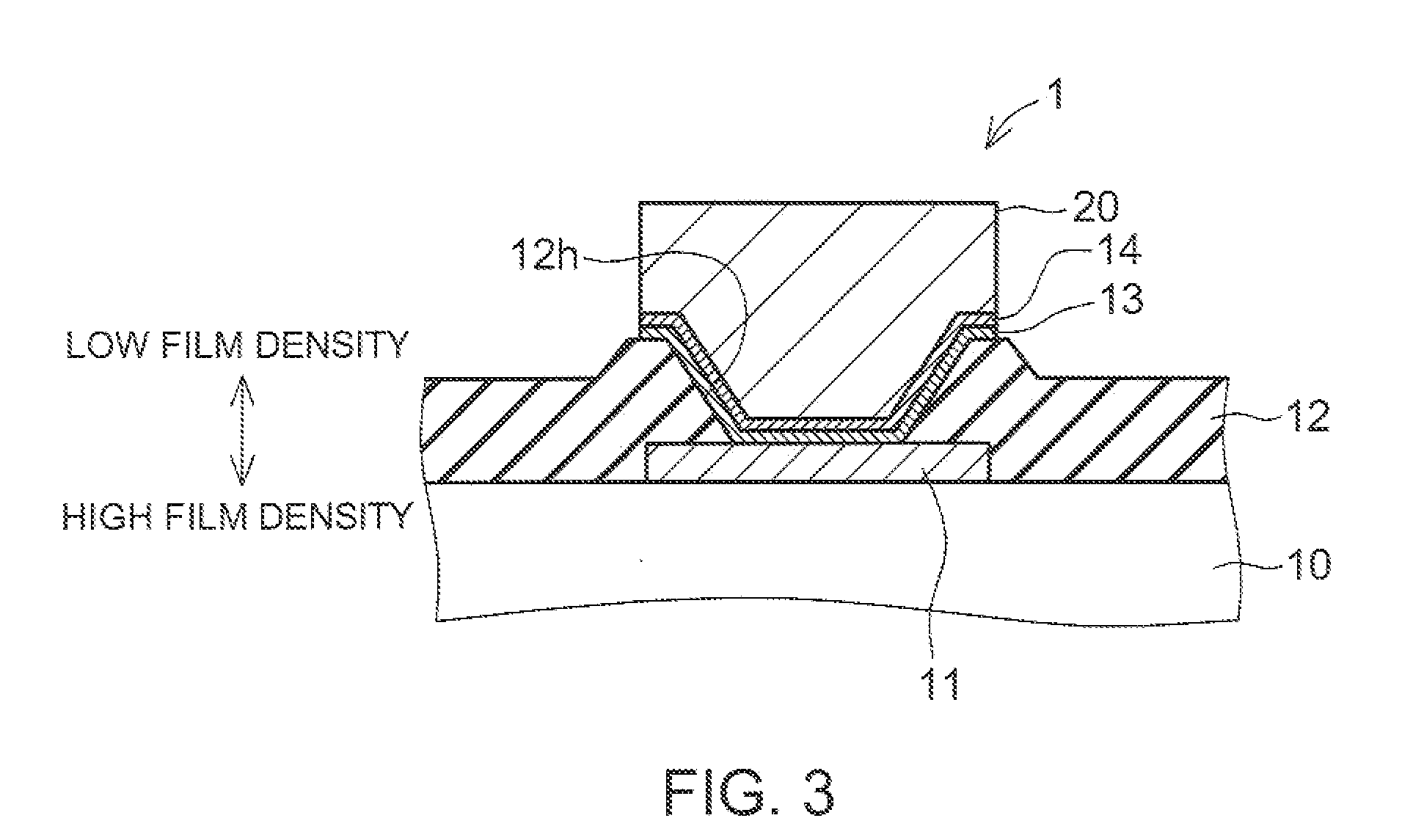

Organic electroluminescent element and the manufacturing method

InactiveUS20070164666A1Discharge tube luminescnet screensLamp detailsOptoelectronicsOrganic electroluminescence

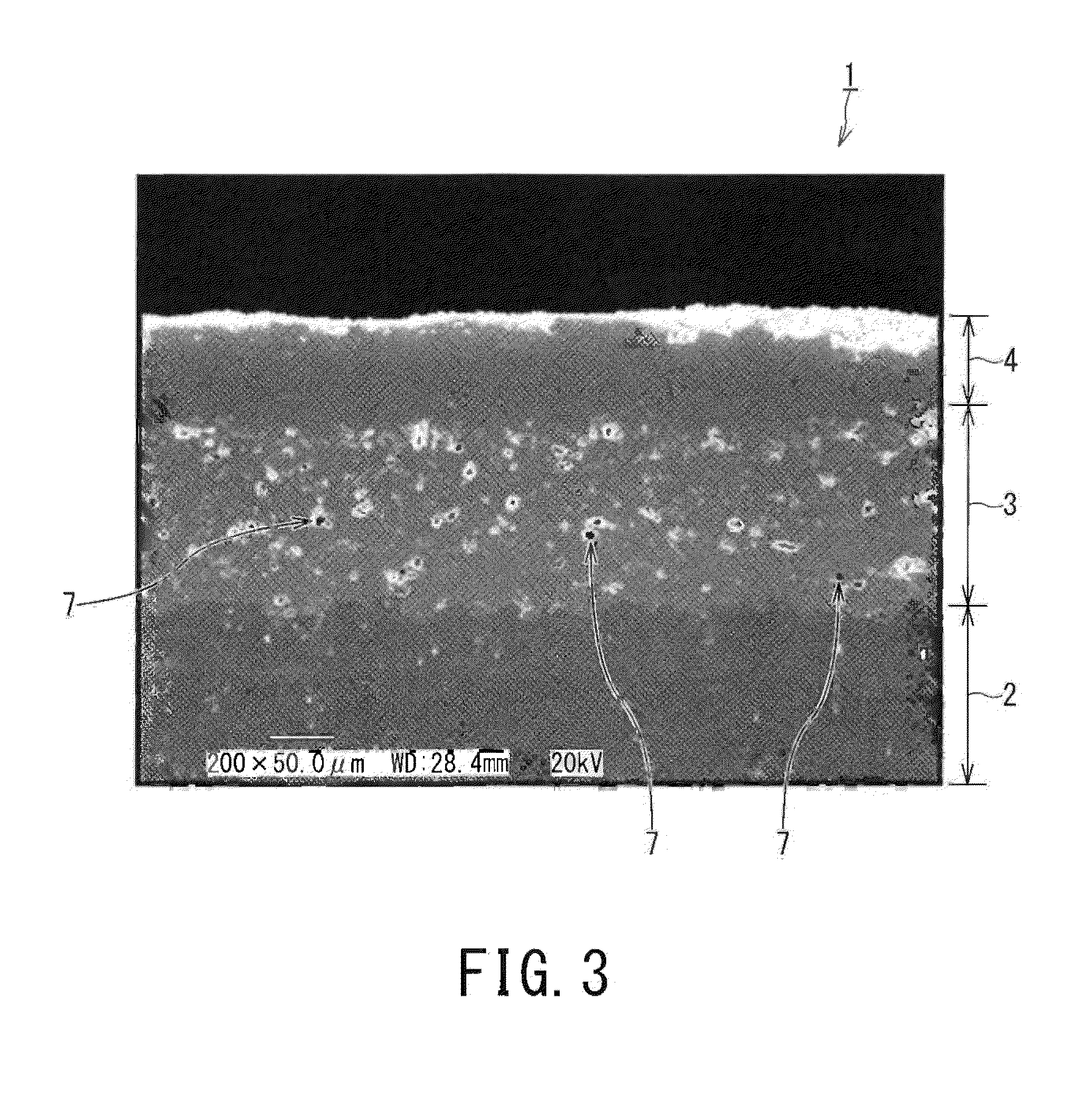

One embodiment of an organic electroluminescent element of present invention includes a substrate, a first electrode on the substrate, an organic luminescent medium layer including an organic luminescent layer on the first electrode, a second electrode on the organic luminescent medium layer and barrier film formed on the second electrode. The organic luminescent medium layer is sandwiched between the first electrode and the second electrode. Film density of the barrier film changes in thickness direction.

Owner:TOPPAN PRINTING CO LTD

Organic light emitting diode display with insulating film which contains SiO

ActiveUS7301274B2Lower refractive indexIncrease brightnessDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixDisplay device

Owner:SAMSUNG DISPLAY CO LTD +1

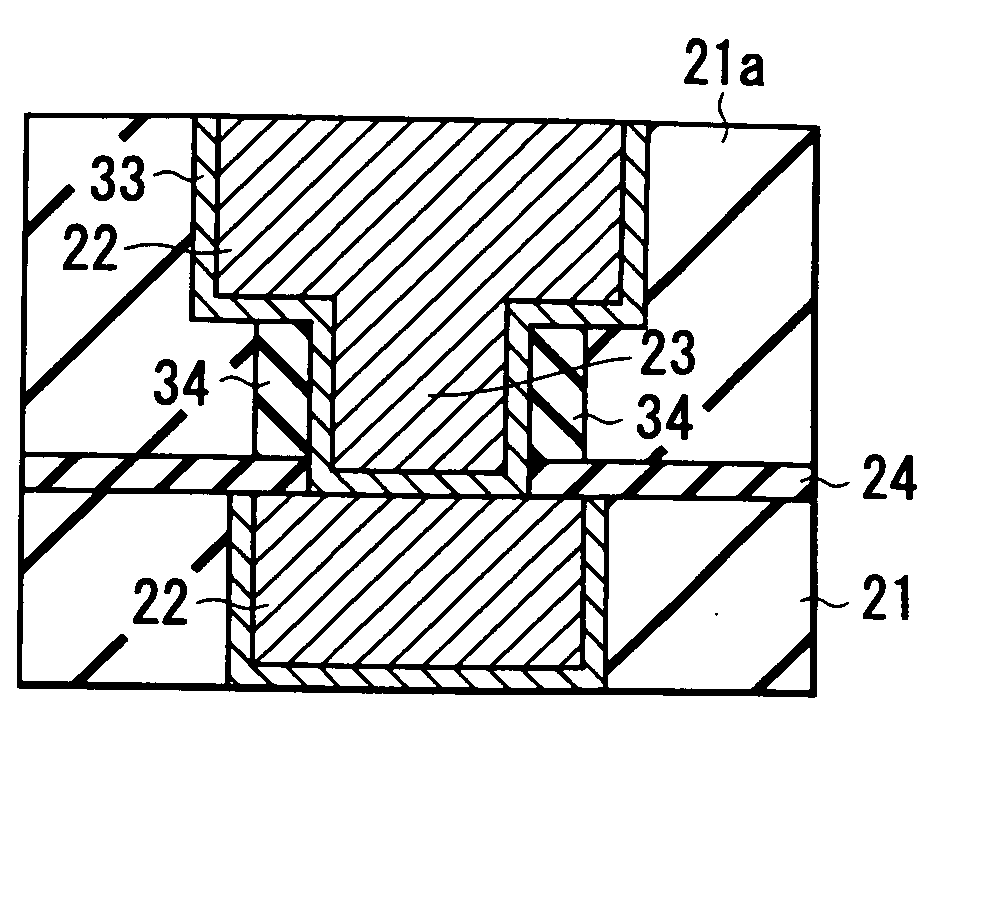

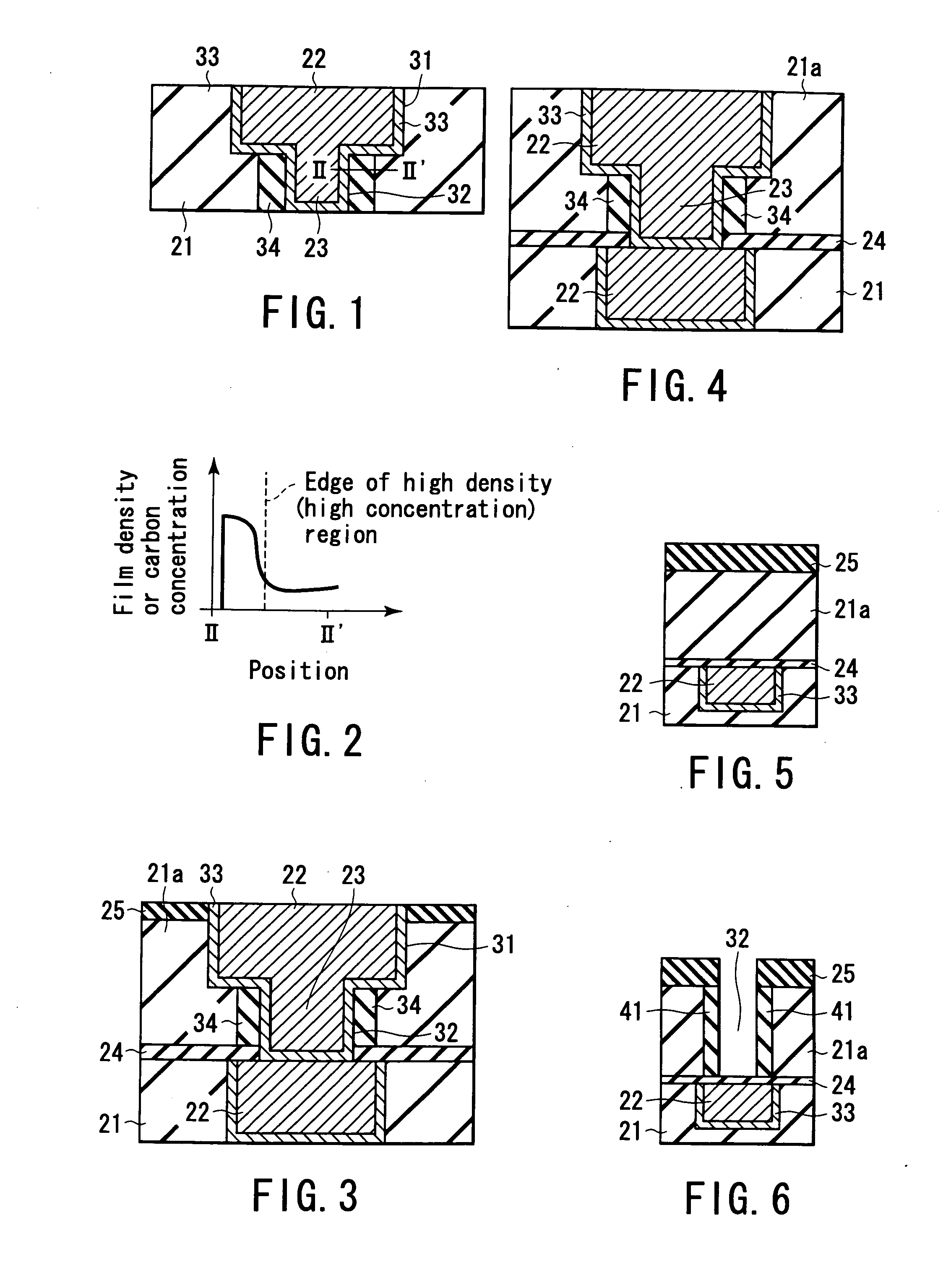

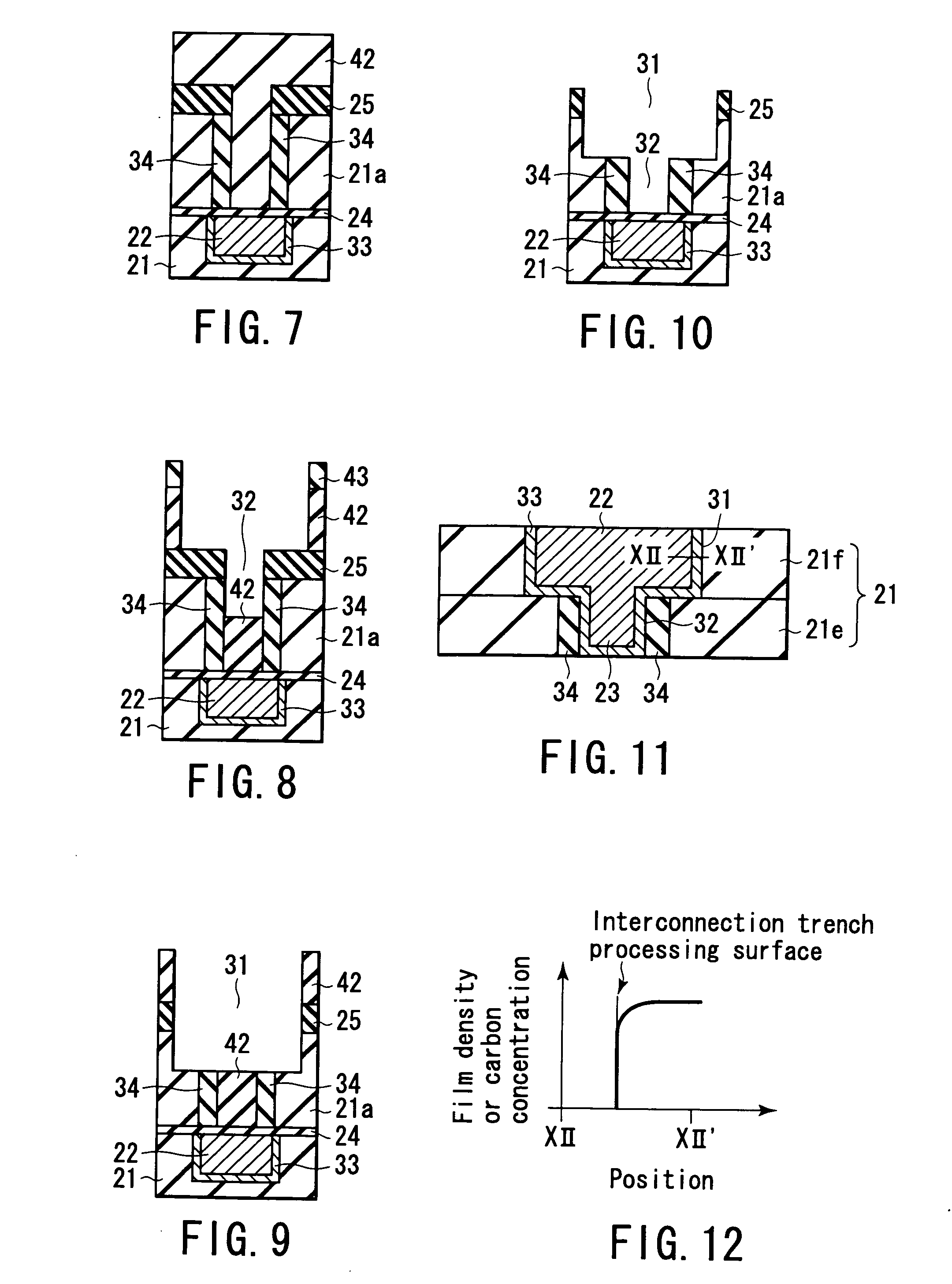

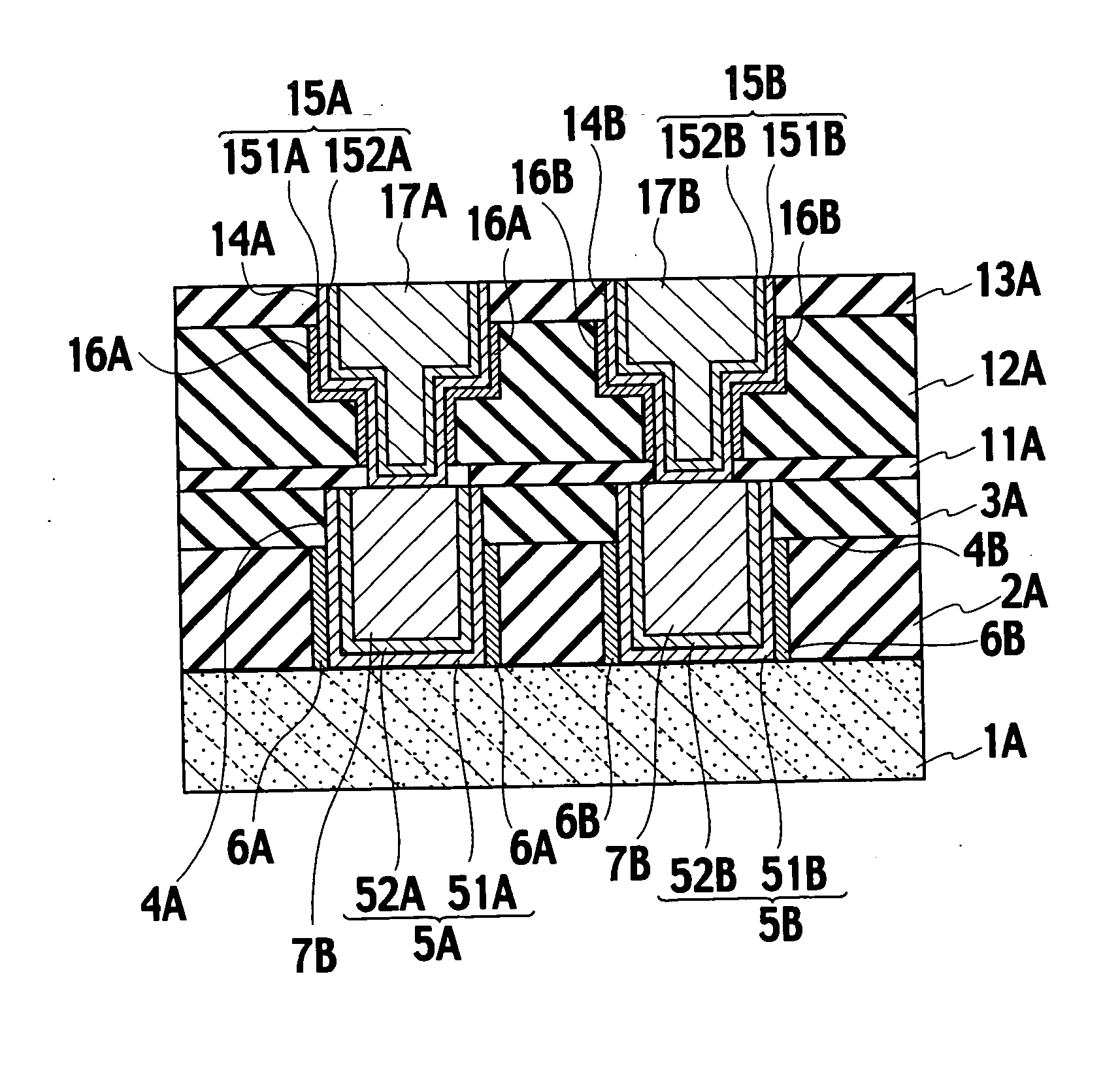

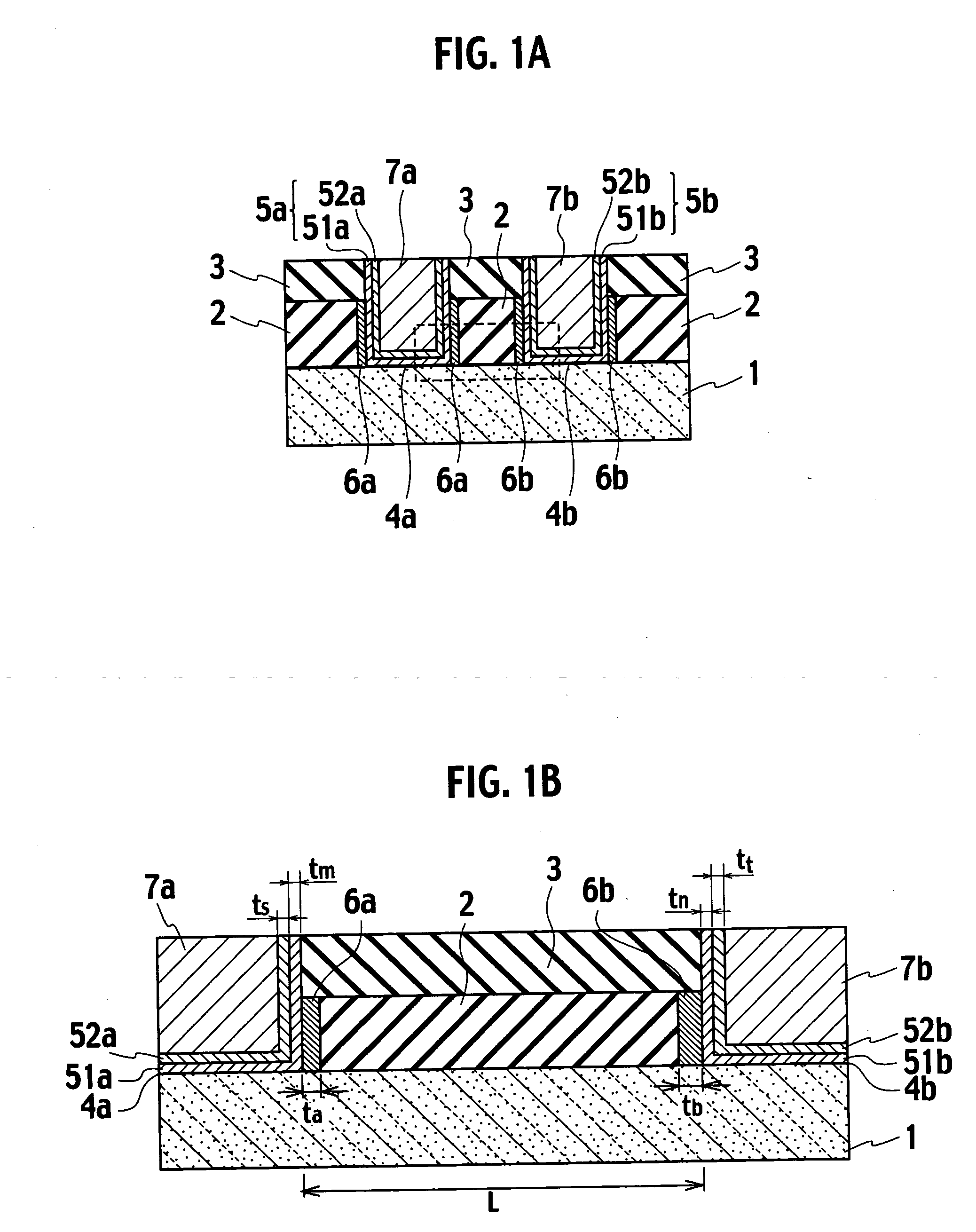

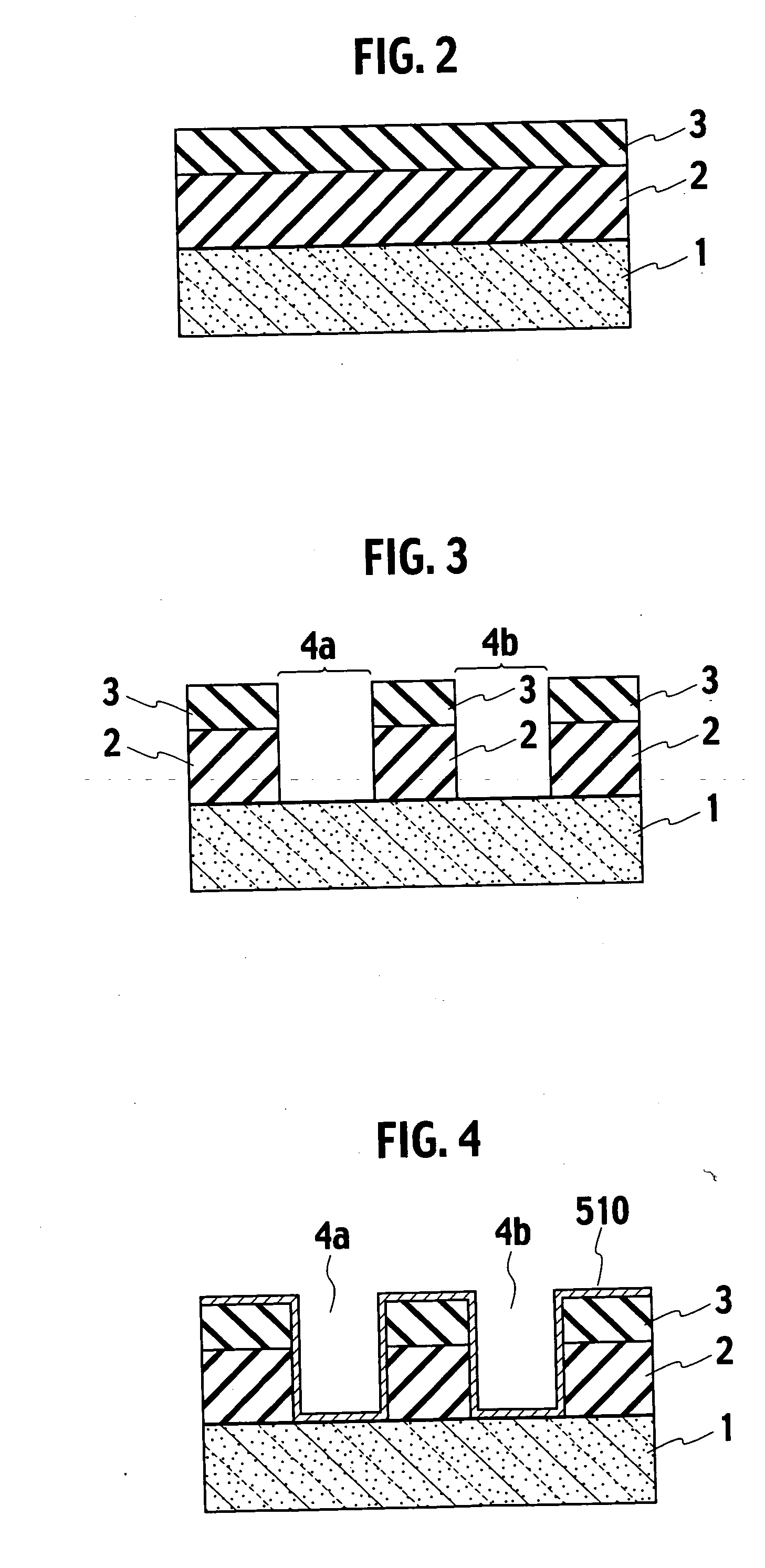

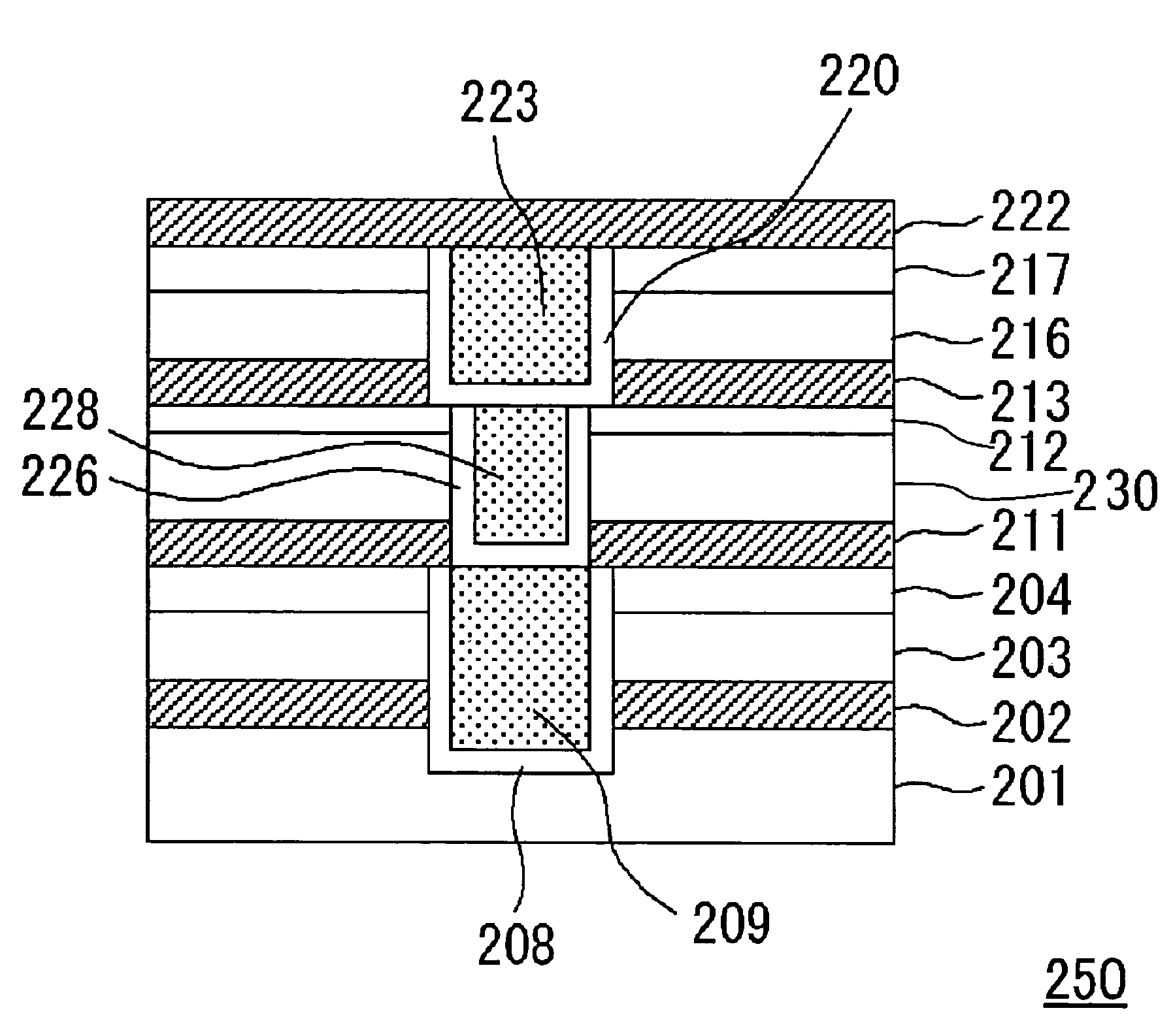

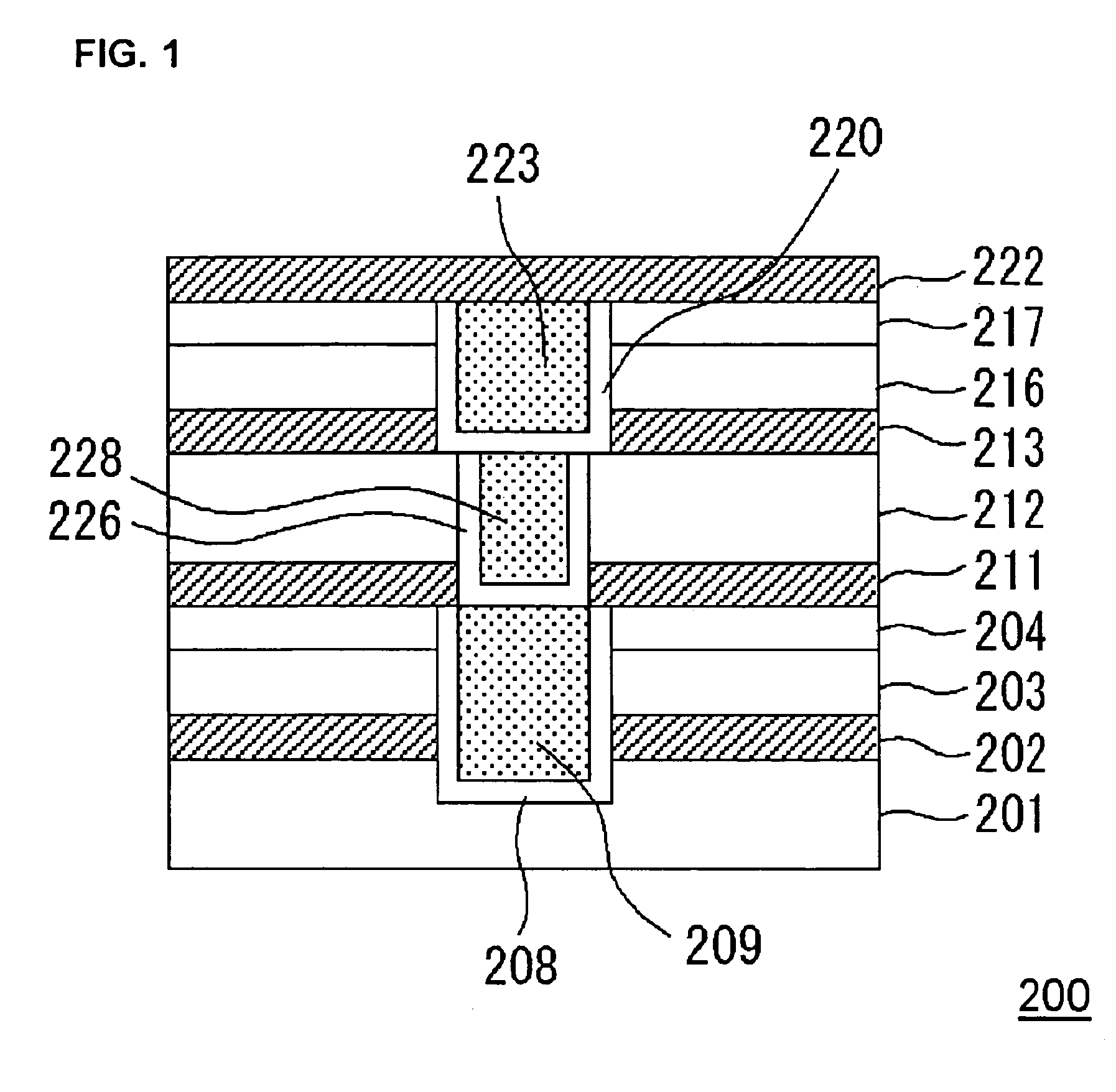

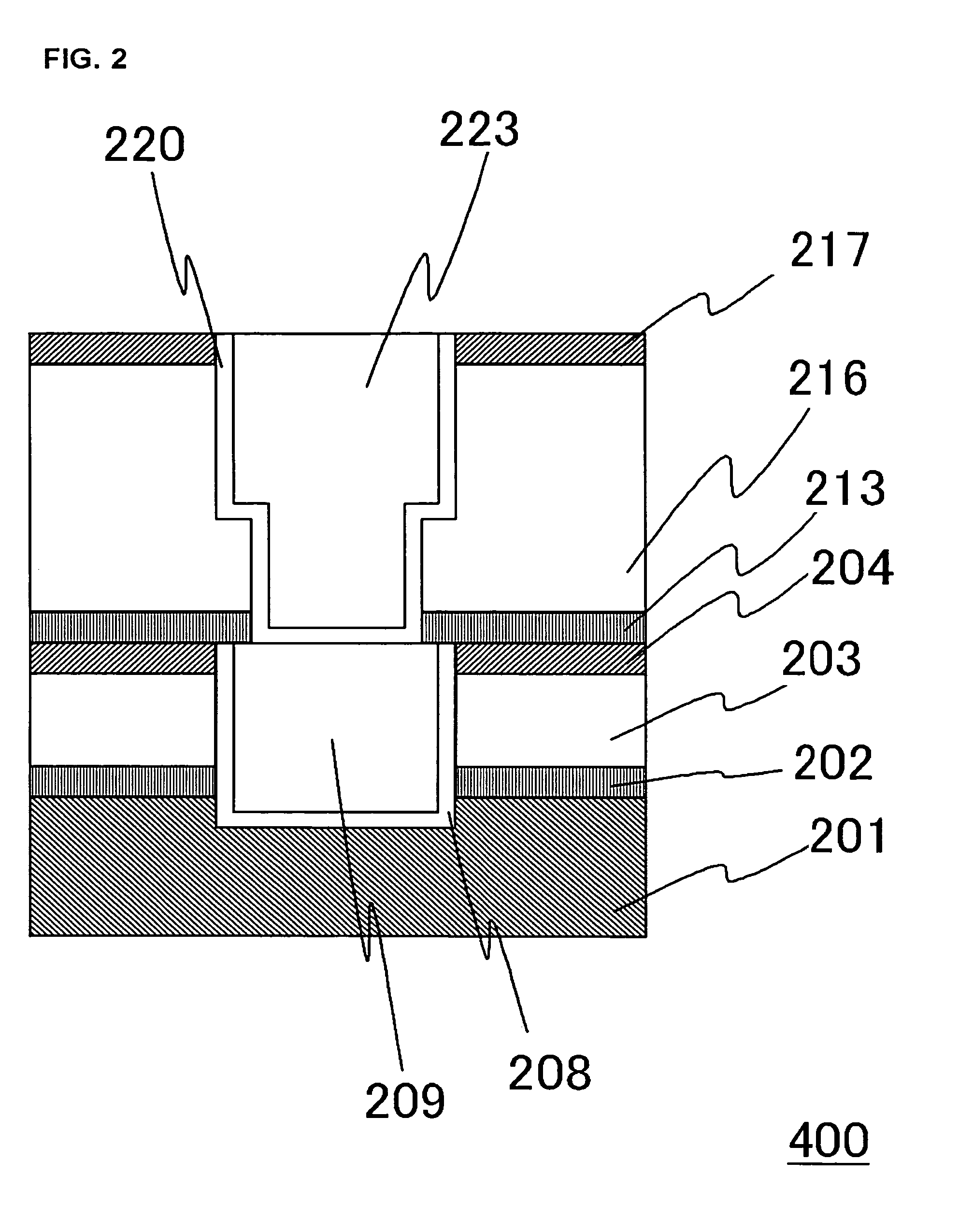

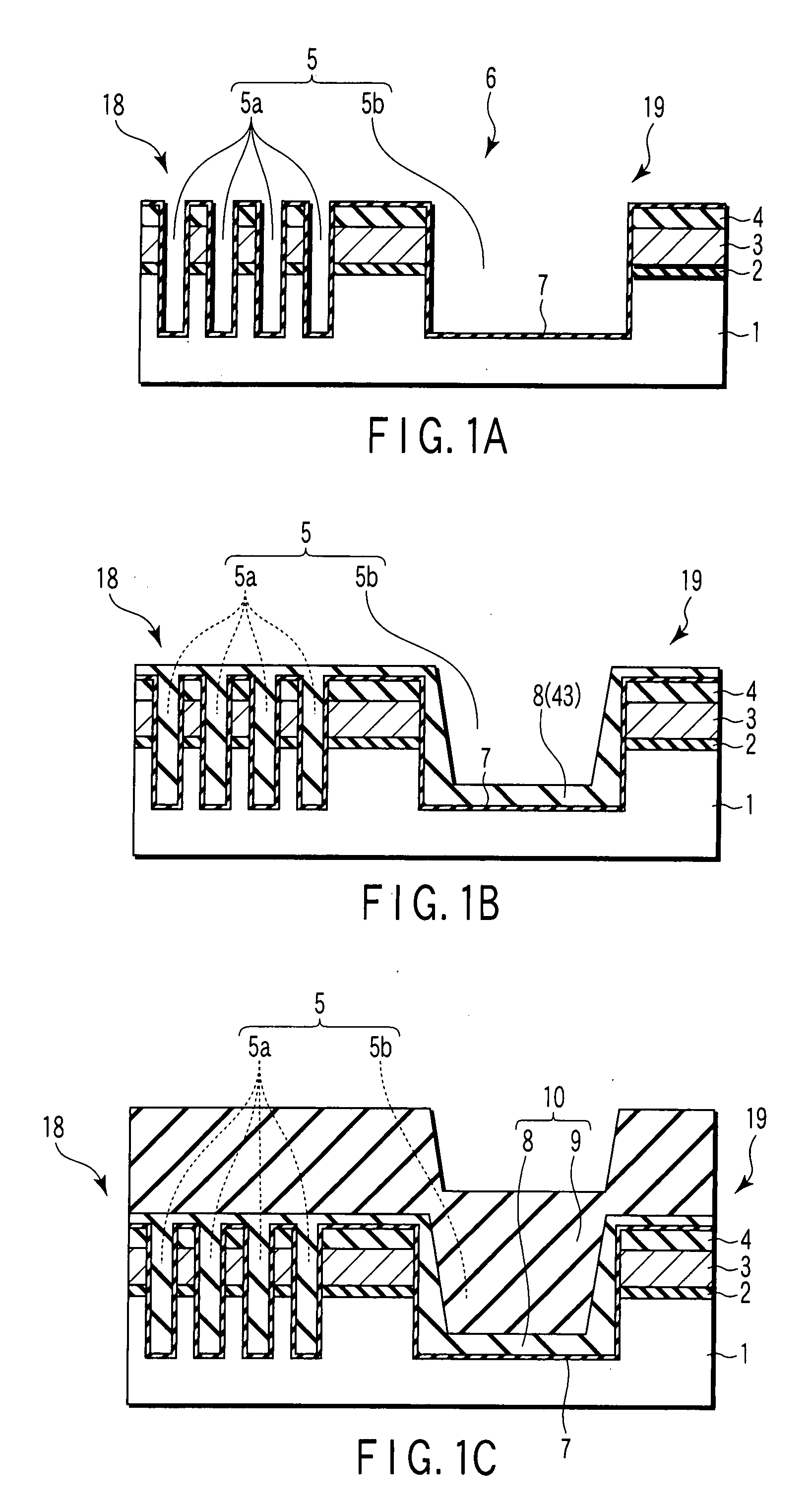

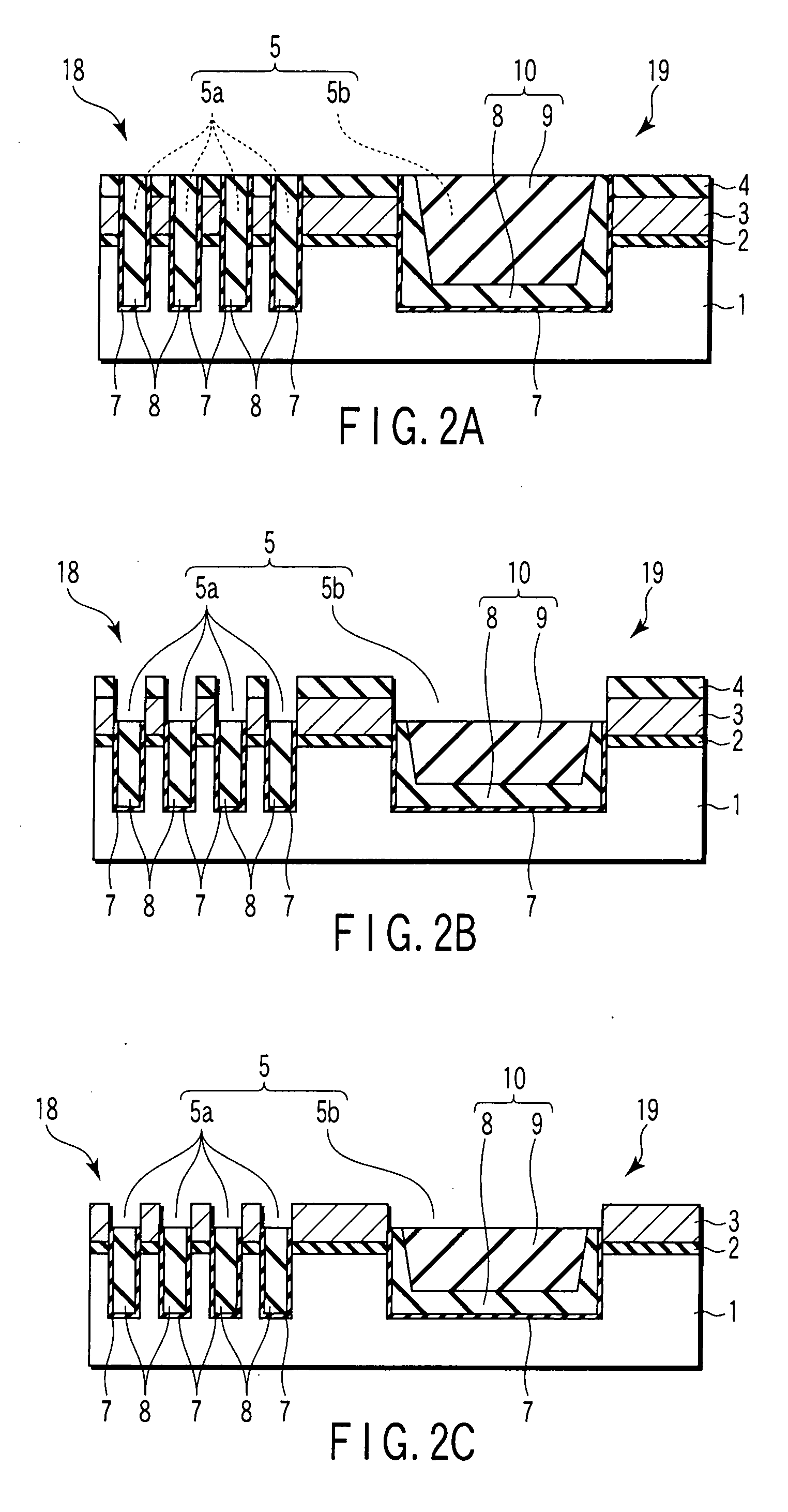

Semiconductor device and method of manufacturing the same

ActiveUS20050151266A1Increase film densitySemiconductor/solid-state device detailsSolid-state devicesDielectricHigh density

An insulating film having dielectric constant not greater than 2.7 is provided above a semiconductor substrate. A via comprises a conductive material, which is provided in a via hole formed in the insulating film. A first interconnection comprises a conductive material, which is provided in an interconnection trench formed on the via in the insulating film. A first high-density region is formed in the insulating film, and has a cylindrical shape surrounding the via, an inner surface common to the boundary of the via hole, and a film density higher than the insulating film.

Owner:KIOXIA CORP

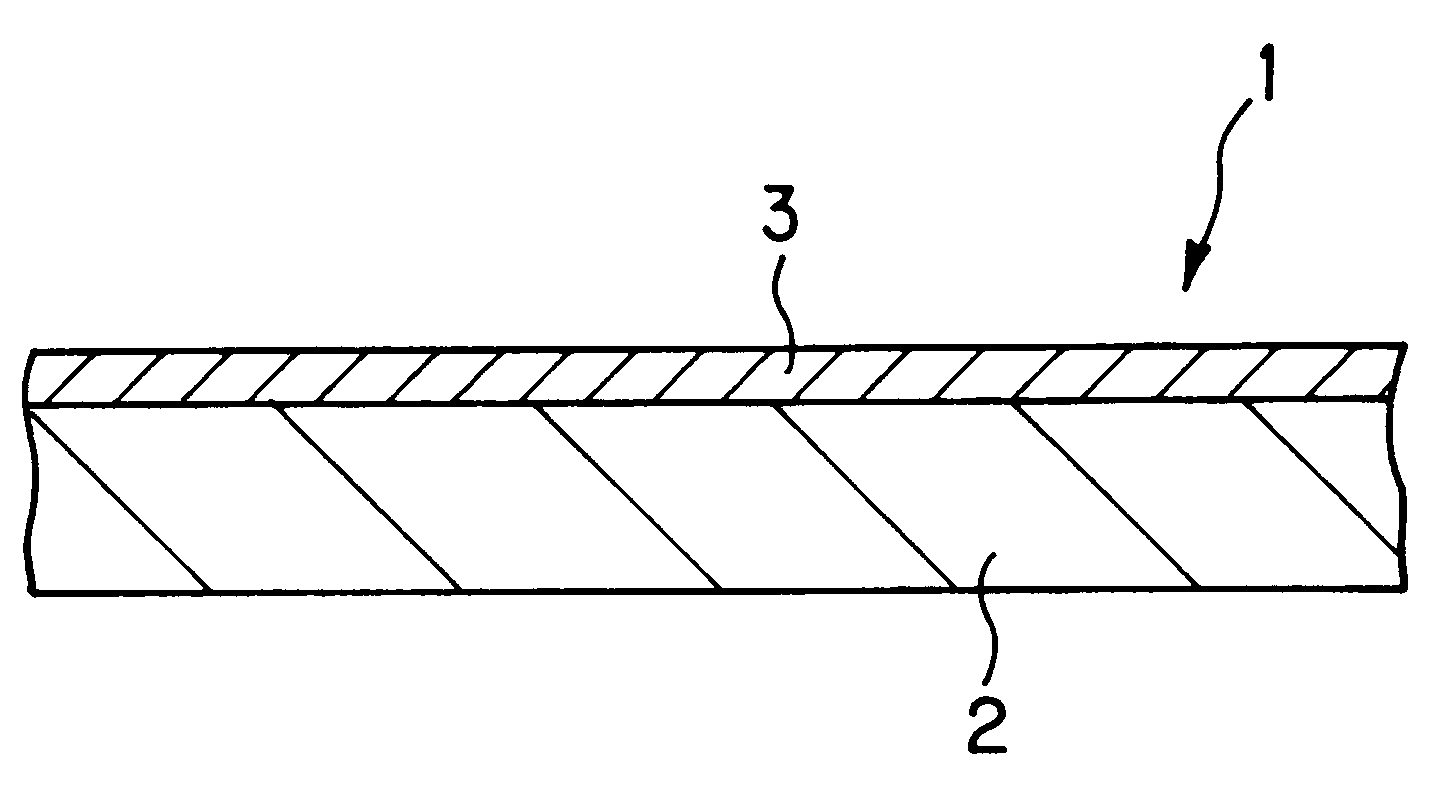

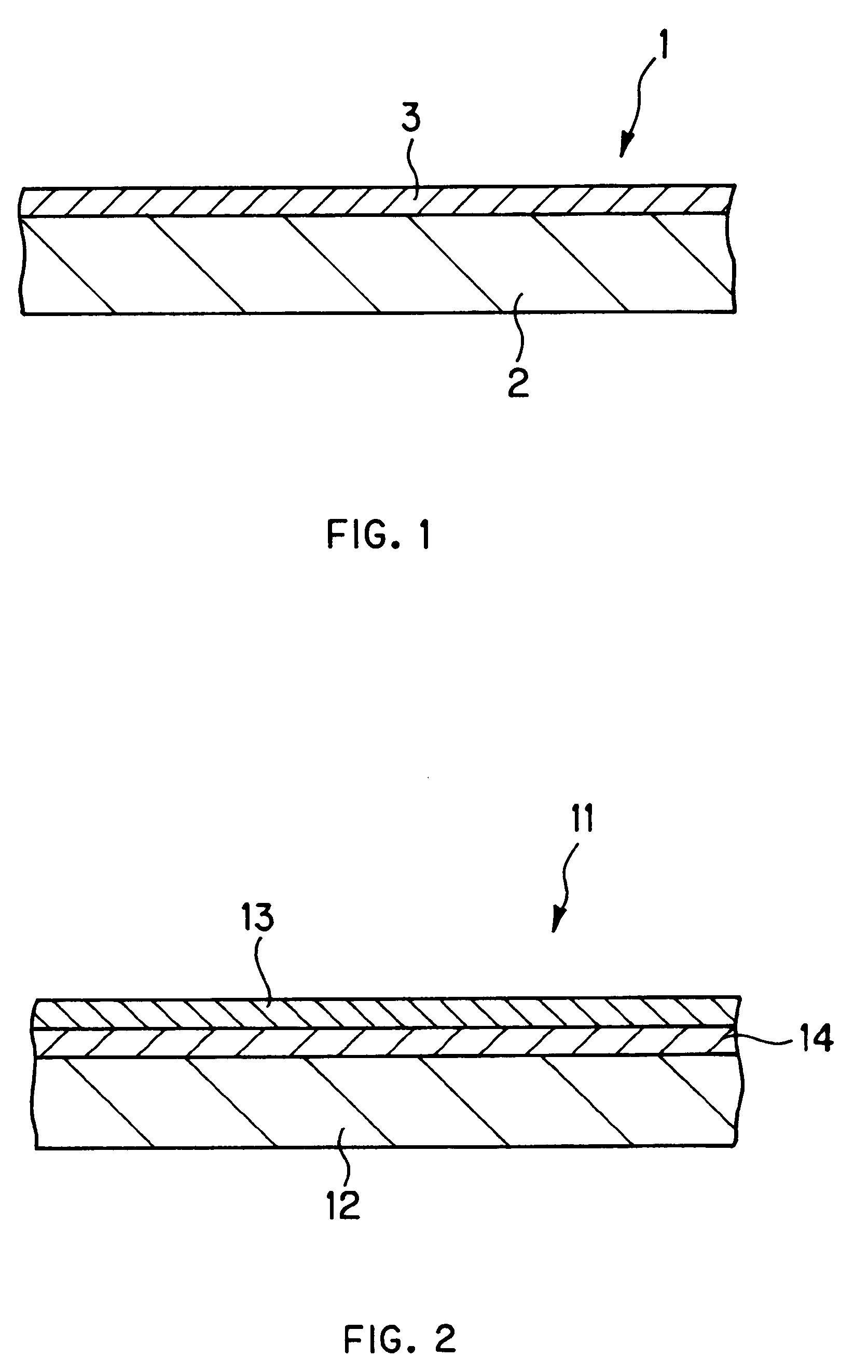

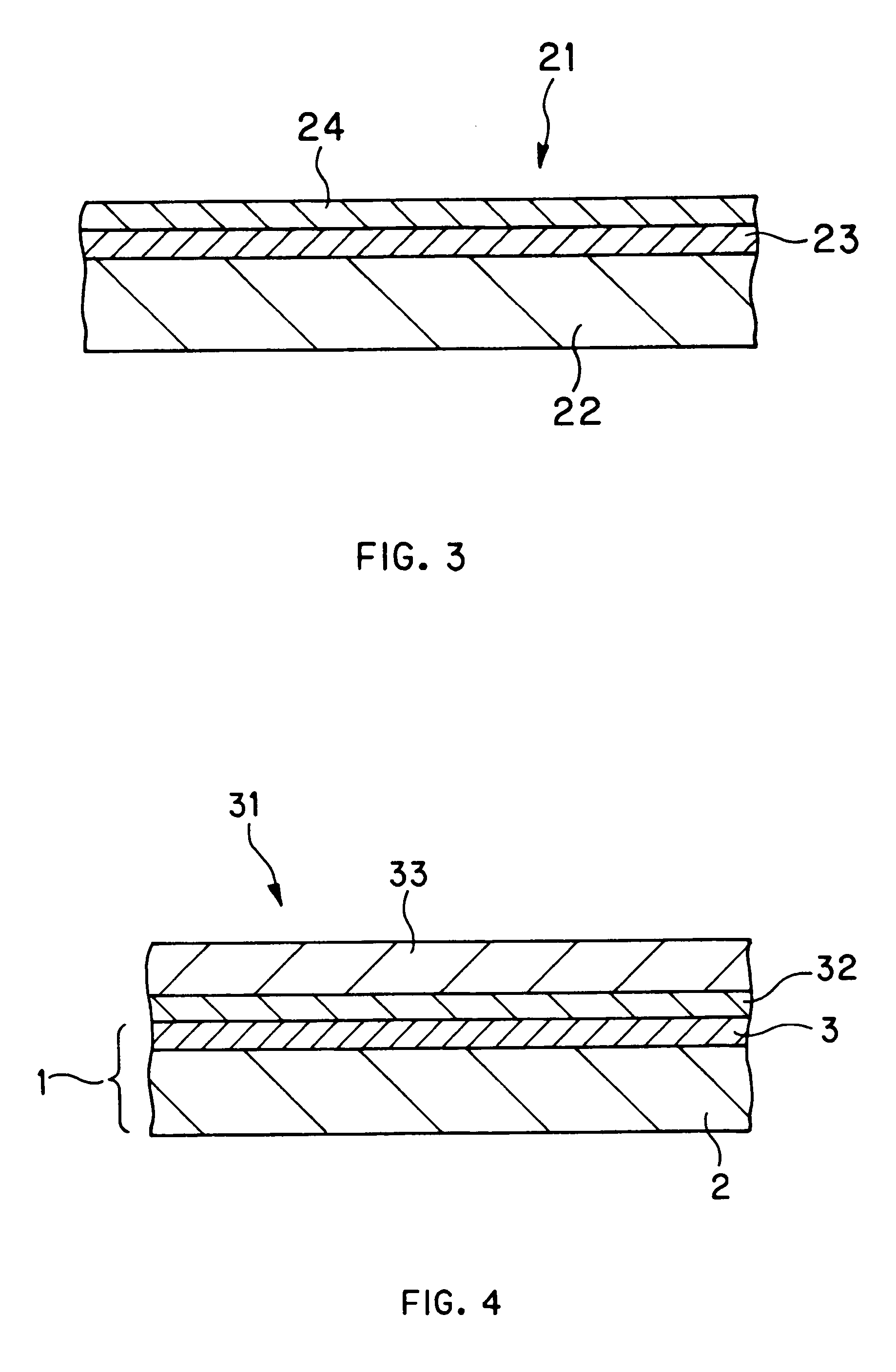

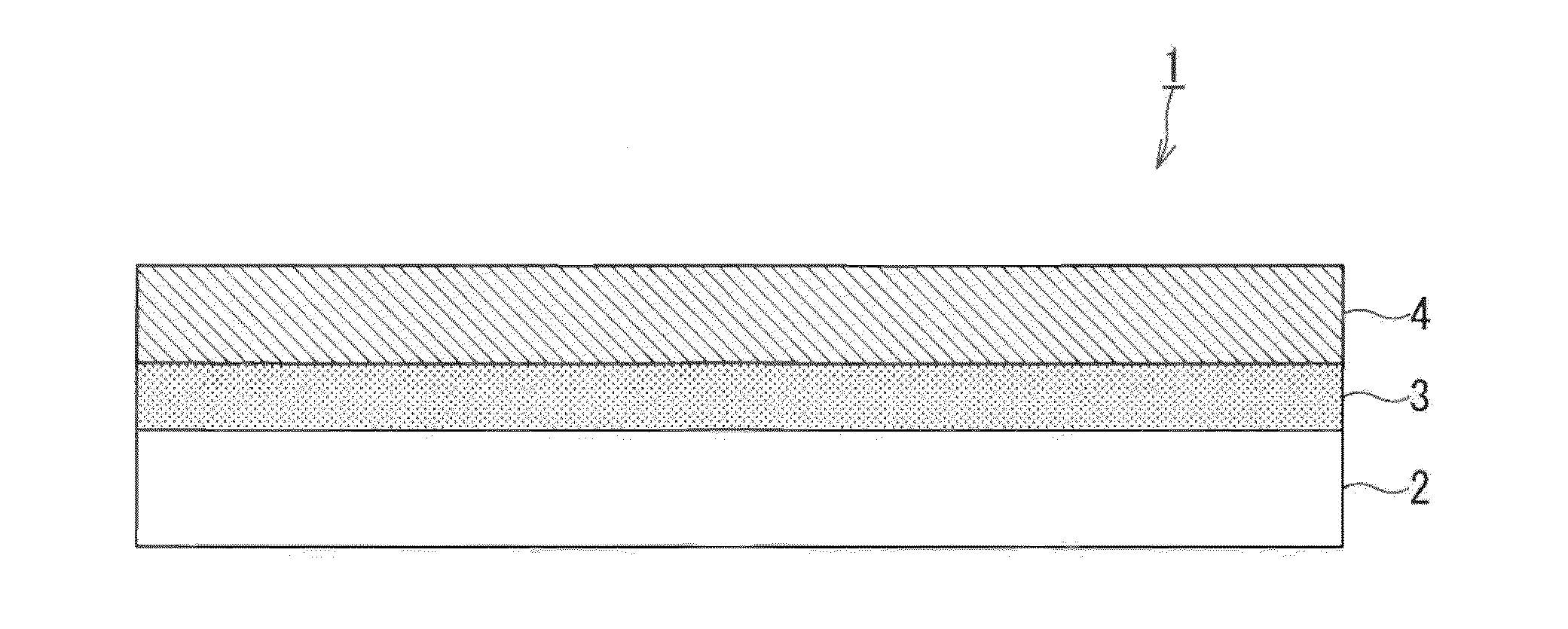

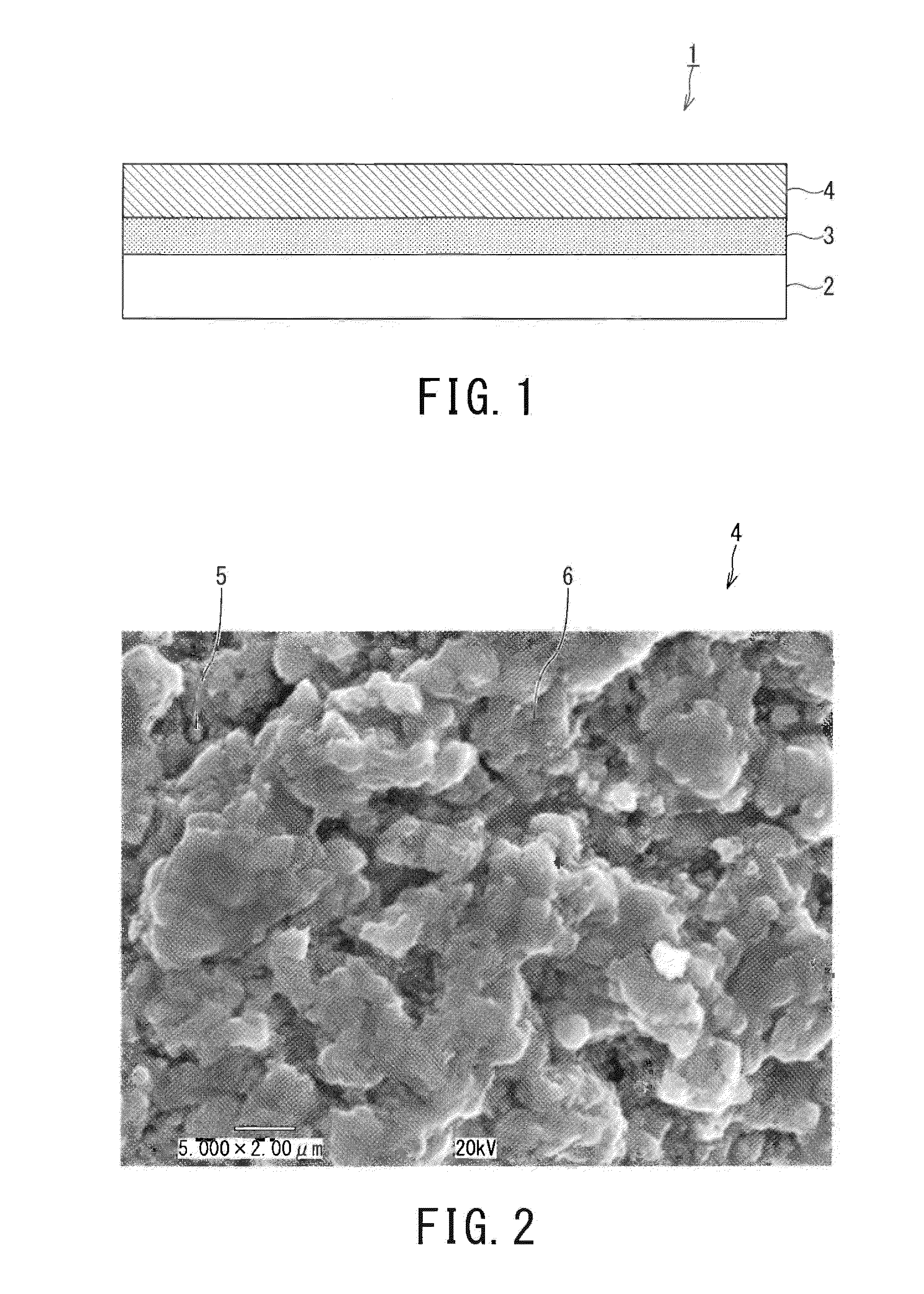

Barrier film and laminated material, container for wrapping and image display medium using the same, and manufacturing method for barrier film

ActiveUS7651594B2Improve barrier propertiesHigh transparencyVacuum evaporation coatingSputtering coatingInfraredSilicon oxide

An object of the present invention is to provide a barrier film having the extremely high barrier property and the better transparency, a method for manufacturing the same, and a laminated material, a container for wrapping and an image displaying medium using the barrier film. According to the present invention, there is provided a barrier film provided with a barrier layer on at least one surface of a substrate film, wherein the barrier layer is a silicon oxide film having an atomic ratio in a range of Si:O:C=100:140 to 170:20 to 40, peak position of infrared-ray absorption due to Si—O—Si stretching vibration between 1060 to 1090 cm−1, a film density in a range of 2.6 to 2.8 g / cm3, and a distance between grains of 30 nm or shorter. Still more, there is provided a barrier film provided with a barrier layer on at least one surface of a substrate film, has a composition wherein the barrier layer is a silicon oxi-nitride film, and the silicon oxi-nitride film has an atomic ratio in a range of Si:O:N:C=100:60 to 90:60 to 90:20 to 40, a maximum peak of infrared-ray absorption due to Si—O stretching vibration and Si—N stretching vibration is in a range of 820 to 930 cm−1, a film density is in a range of 2.9 to 3.2 g / cm3, and a distance between grains is 30 nm or shorter.

Owner:DAI NIPPON PRINTING CO LTD

Semiconductor device and a method of fabricating a semiconductor device

InactiveUS20060154464A1Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A semiconductor device includes a semiconductor substrate; a porous low k dielectric disposed on the semiconductor substrate having a plurality of trenches therein, the porous low k dielectric having an effective dielectric constant of 3.0 or less; a plurality of barrier layers provided on each surface of the trenches, each of the barrier layers including a plurality of films having different film densities; a plurality of metal diffused regions provided in the porous low k dielectric and contacting the barrier layers; and a first conductor embedded in one of the trenches in contact with one of the barrier layer.

Owner:KK TOSHIBA

Component for plasma processing apparatus and method for manufacturing component for plasma processing apparatus

ActiveUS20150152540A1Improve plasma resistanceSuppress generation of particleLiquid surface applicatorsMolten spray coatingEngineeringGrain boundary

Owner:KK TOSHIBA +1

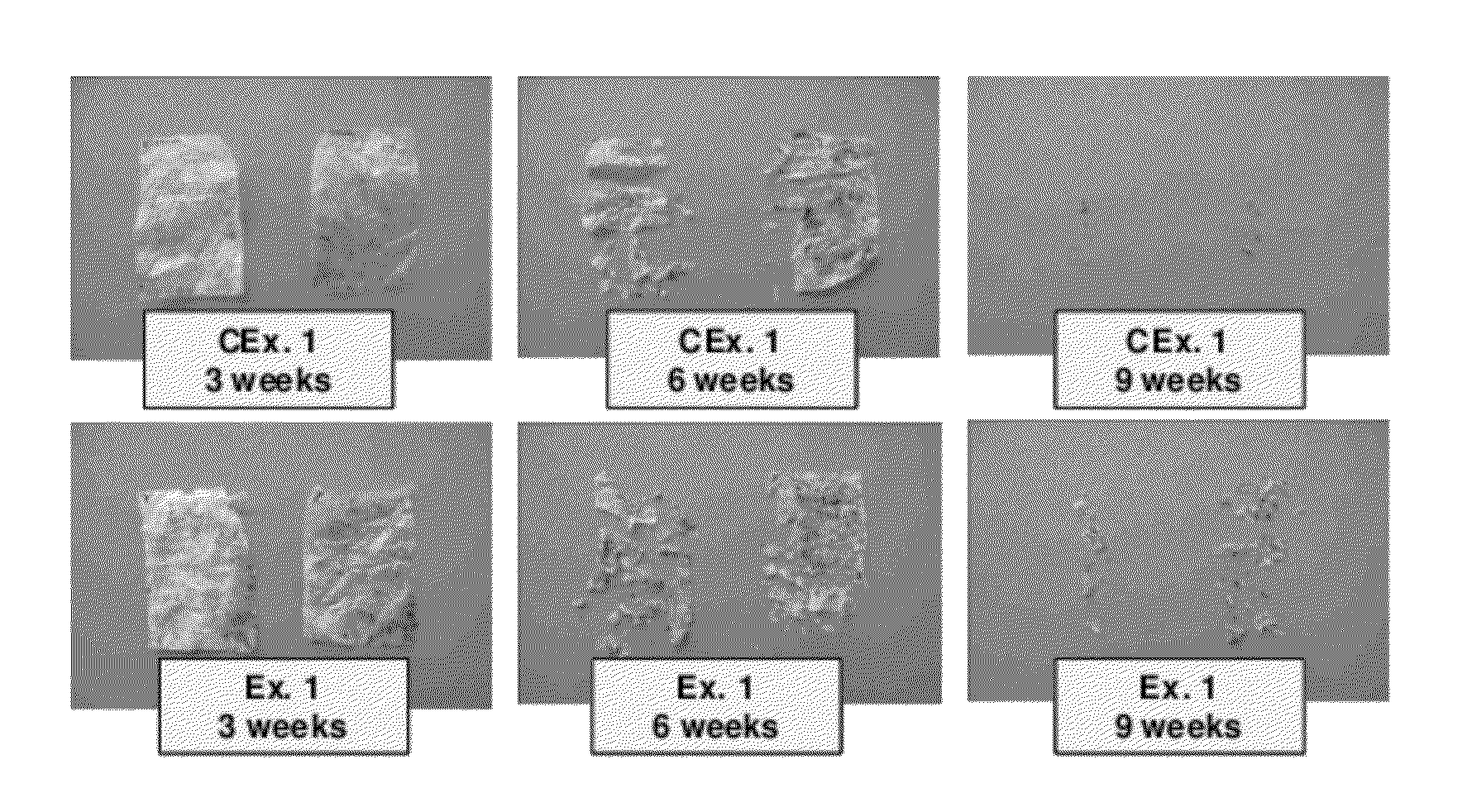

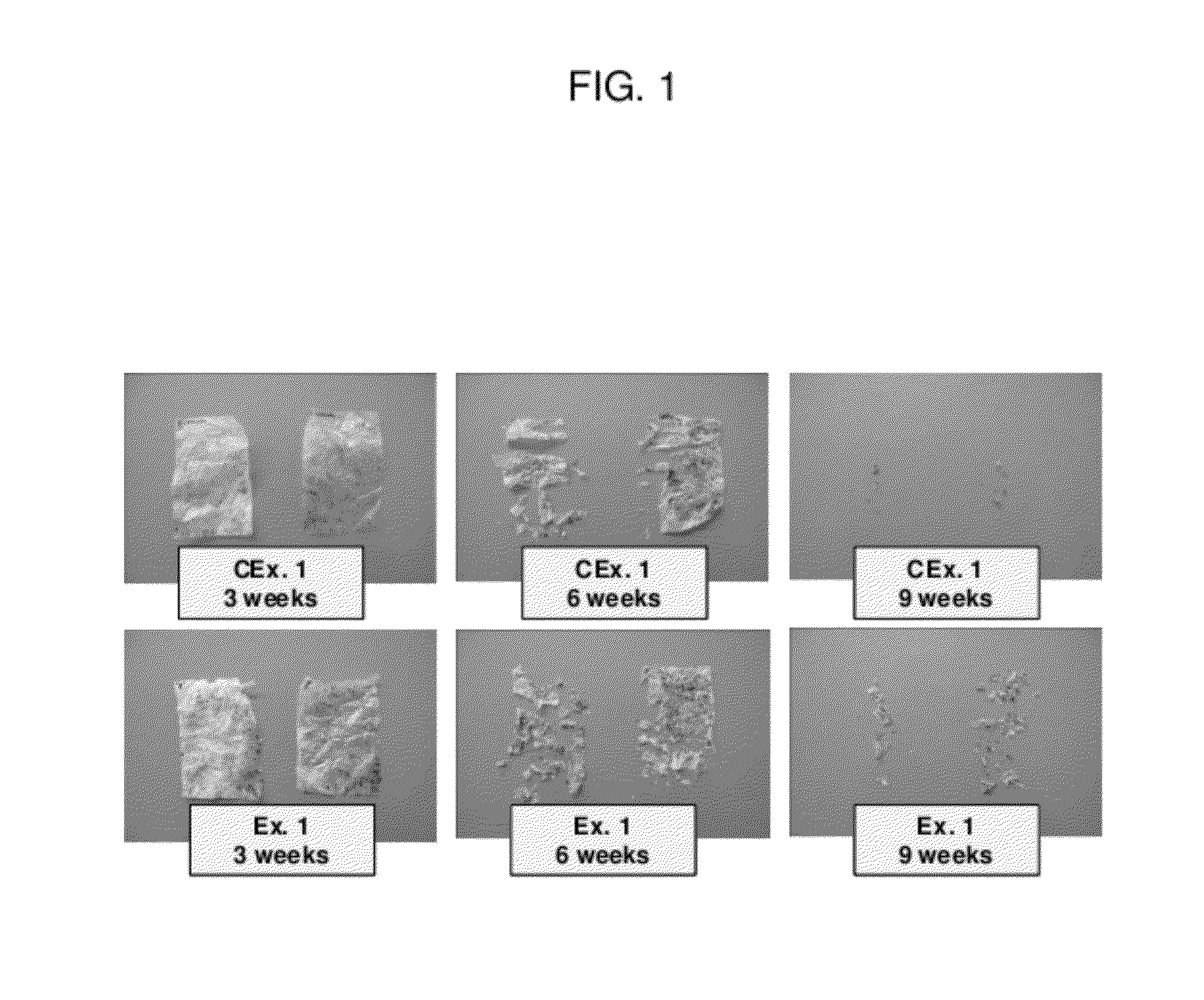

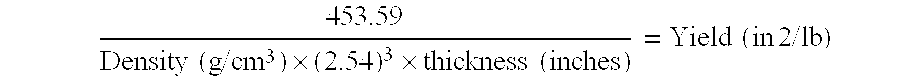

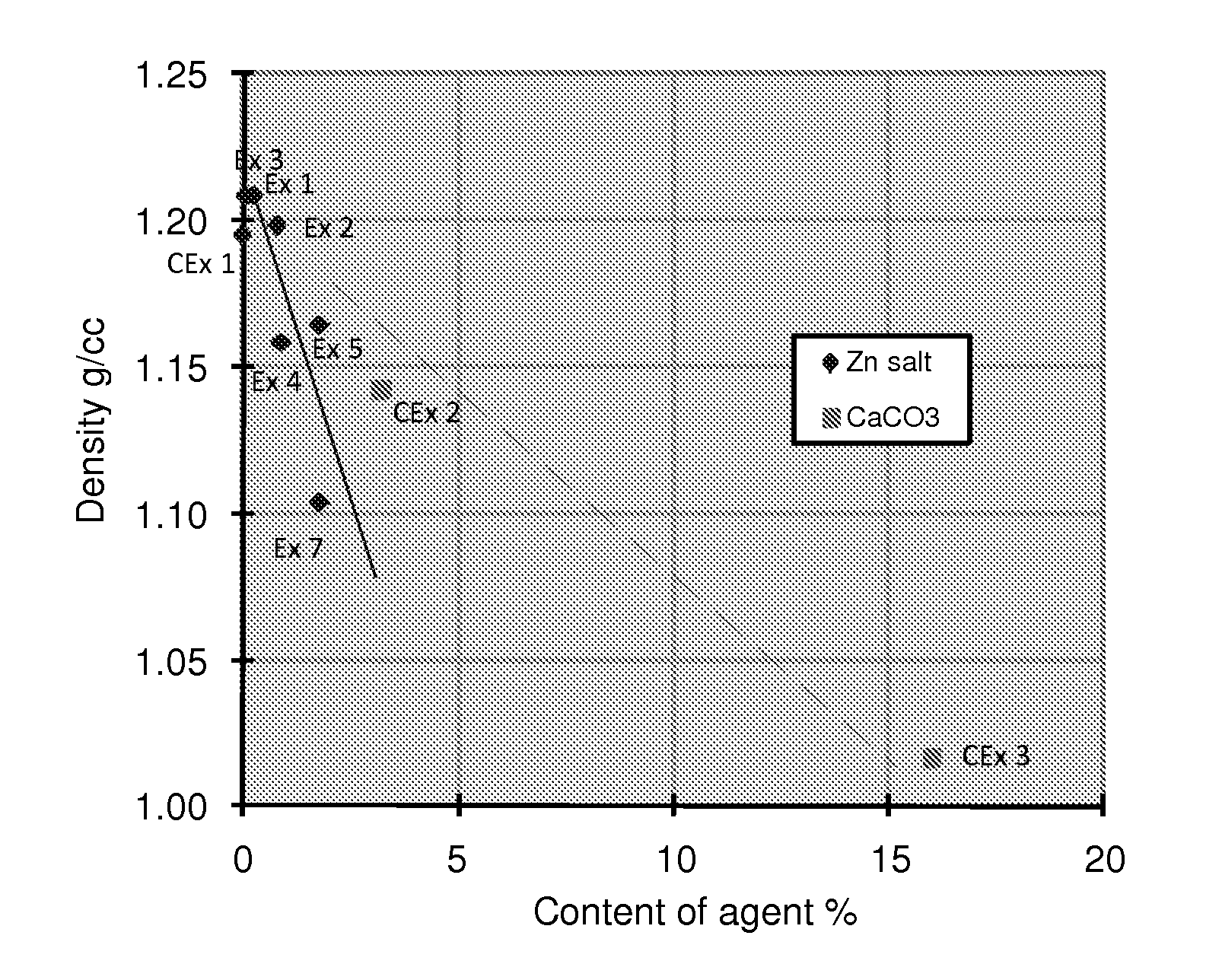

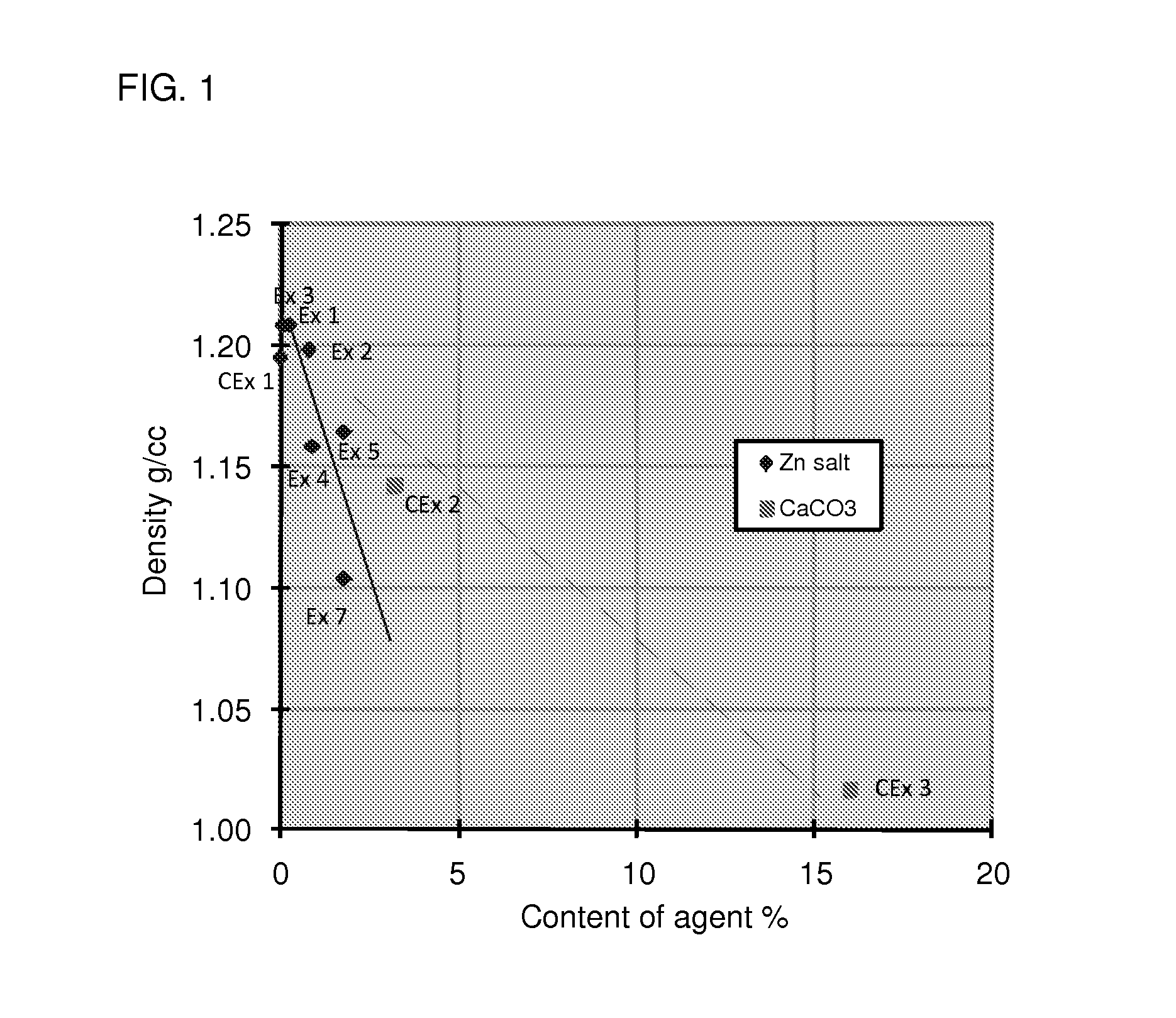

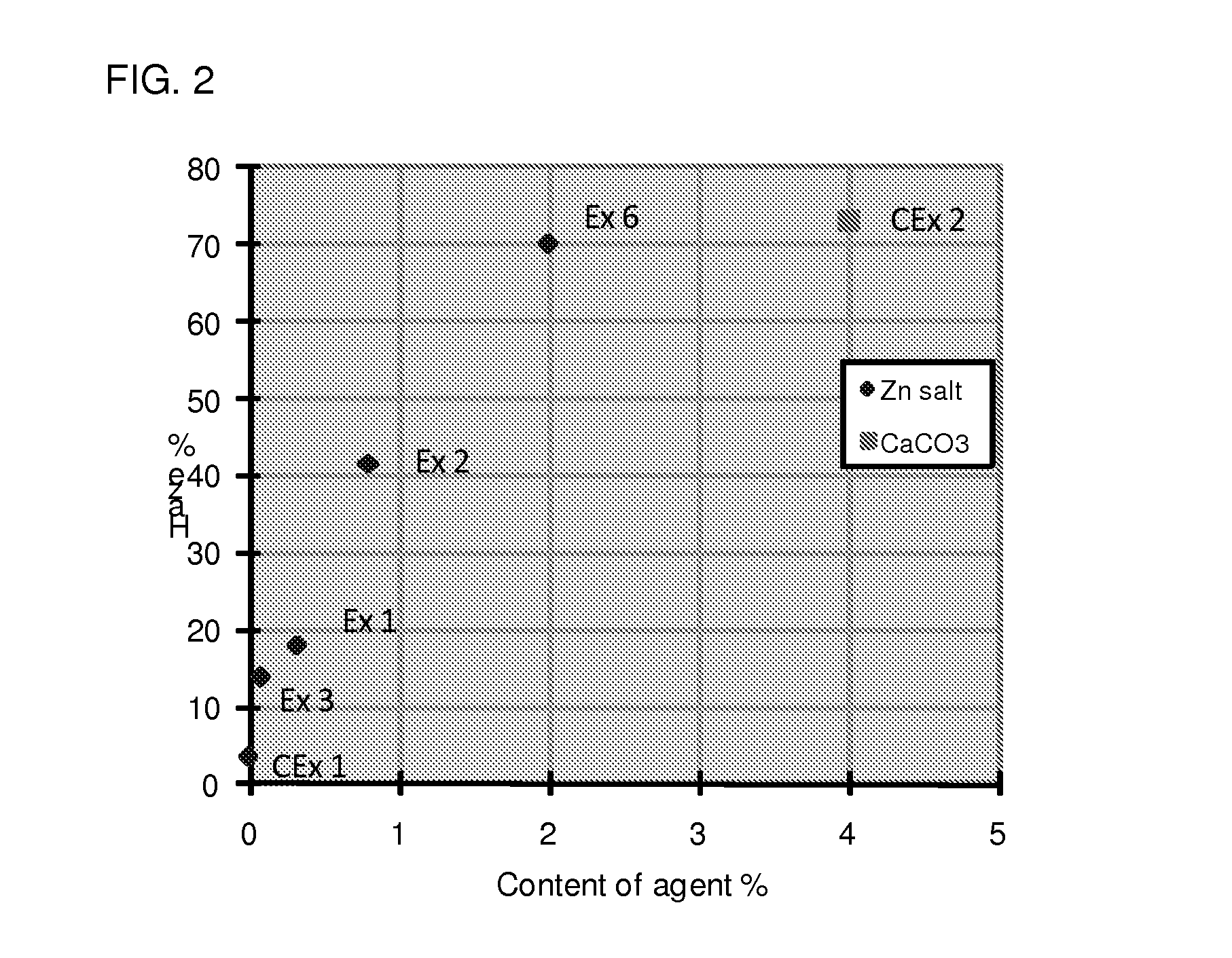

Biaxially oriented cavitated polylactic acid film

InactiveUS20120141766A1Low costRemain biodegradableSynthetic resin layered productsVacuum evaporation coatingPolystyreneMaterials science

Disclosed are biaxially oriented laminate films including a core layer including a blend of crystalline polylactic acid polymer and crystalline polystyrene. The films are biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the crystalline polystyrene such that a white opaque cavitated appearance and lower film densities are obtained. The laminate films may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

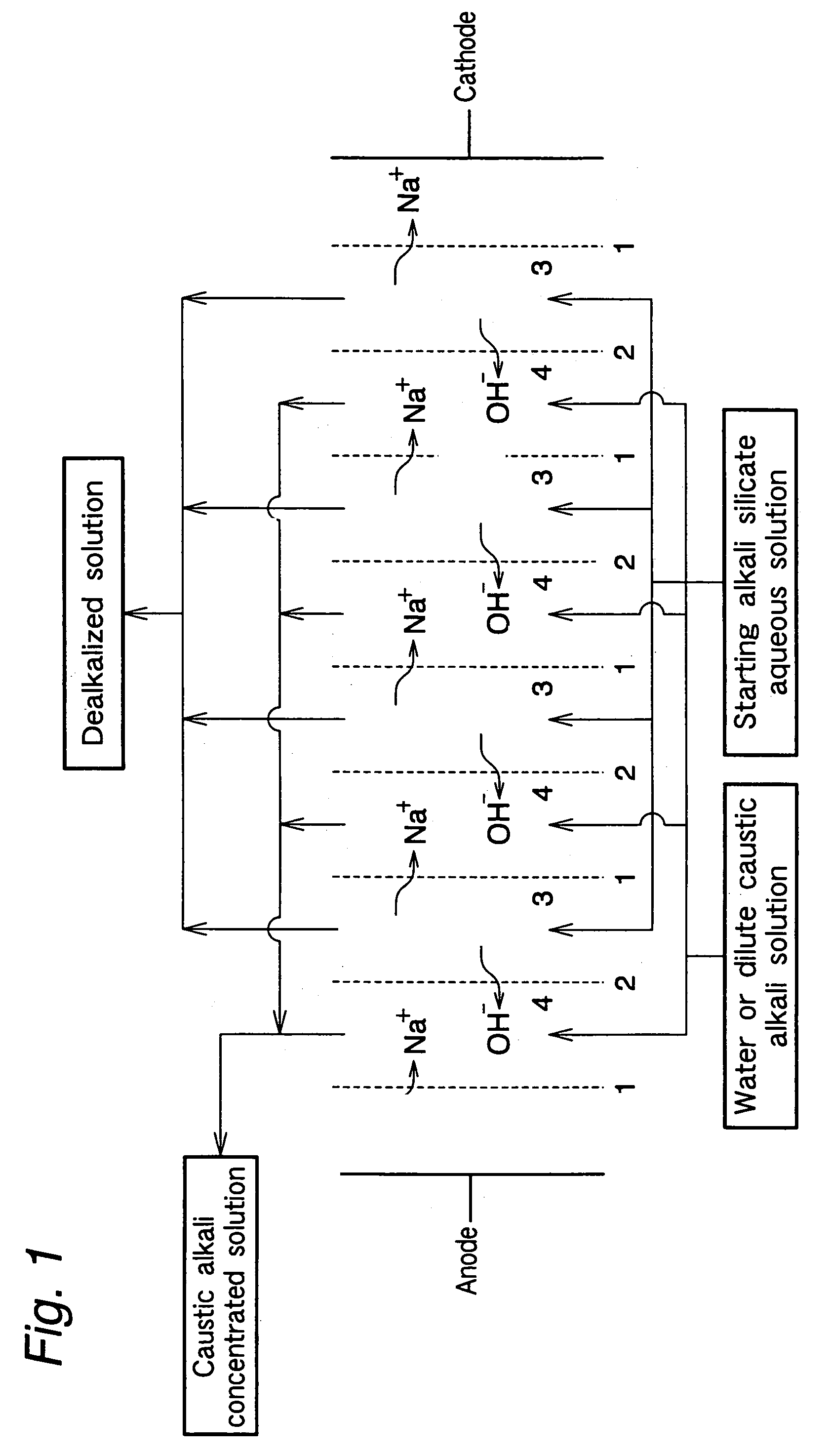

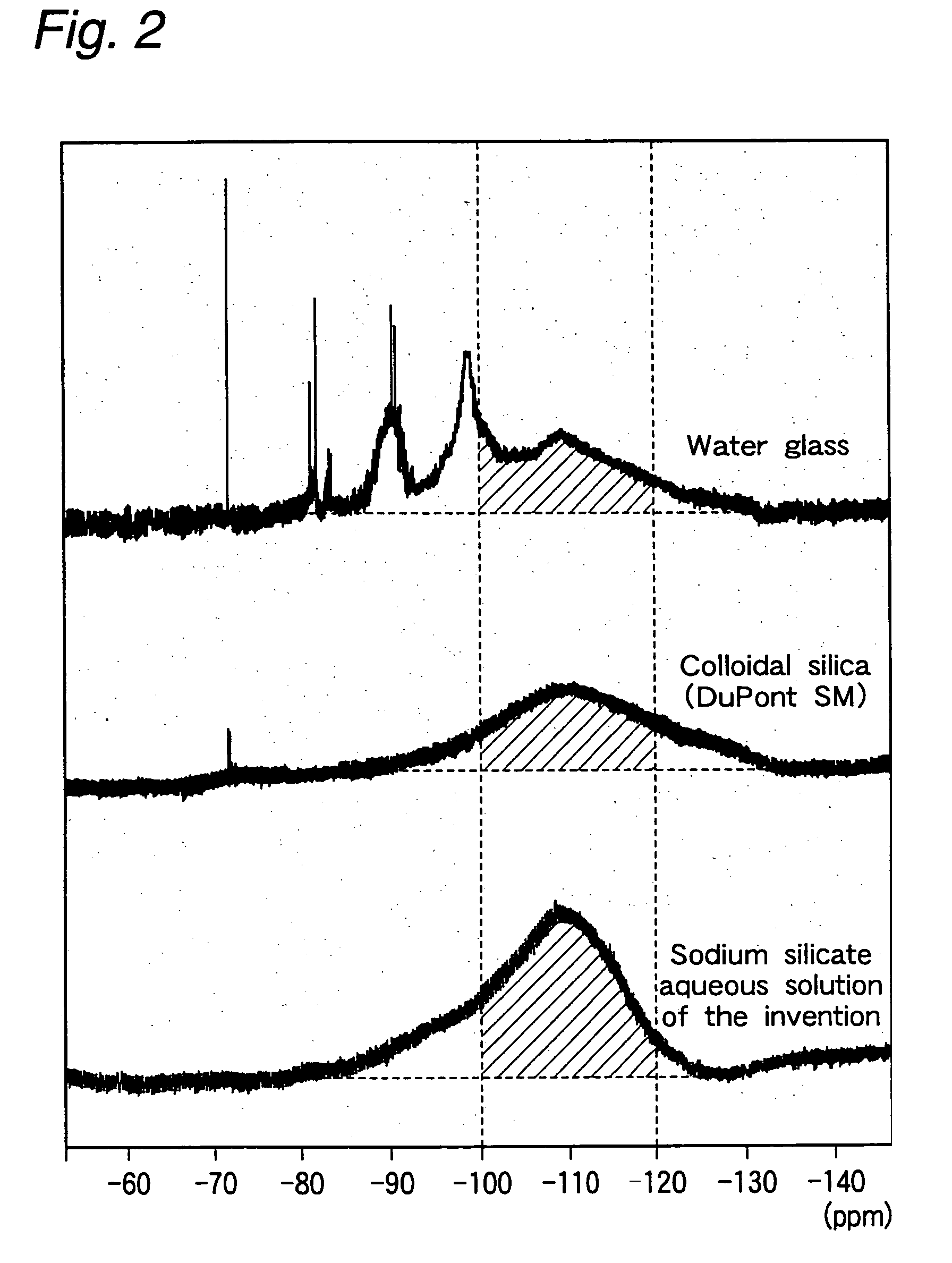

Coating material composition having photocatalytic activity

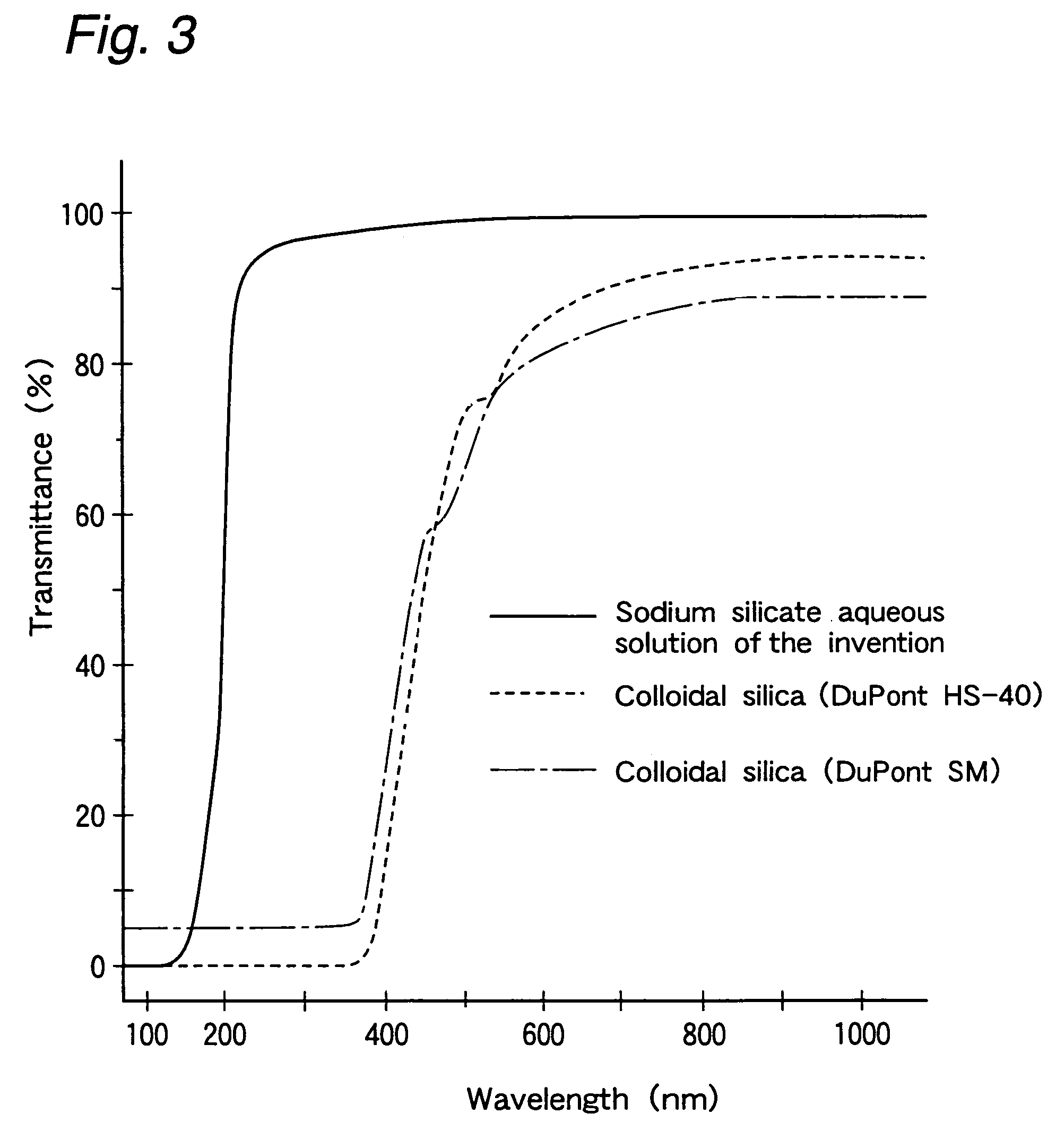

ActiveUS20040116577A1High strengthImprove adhesionPhysical/chemical process catalystsAlkali metal silicate coatingsChemical compositionRefractive index

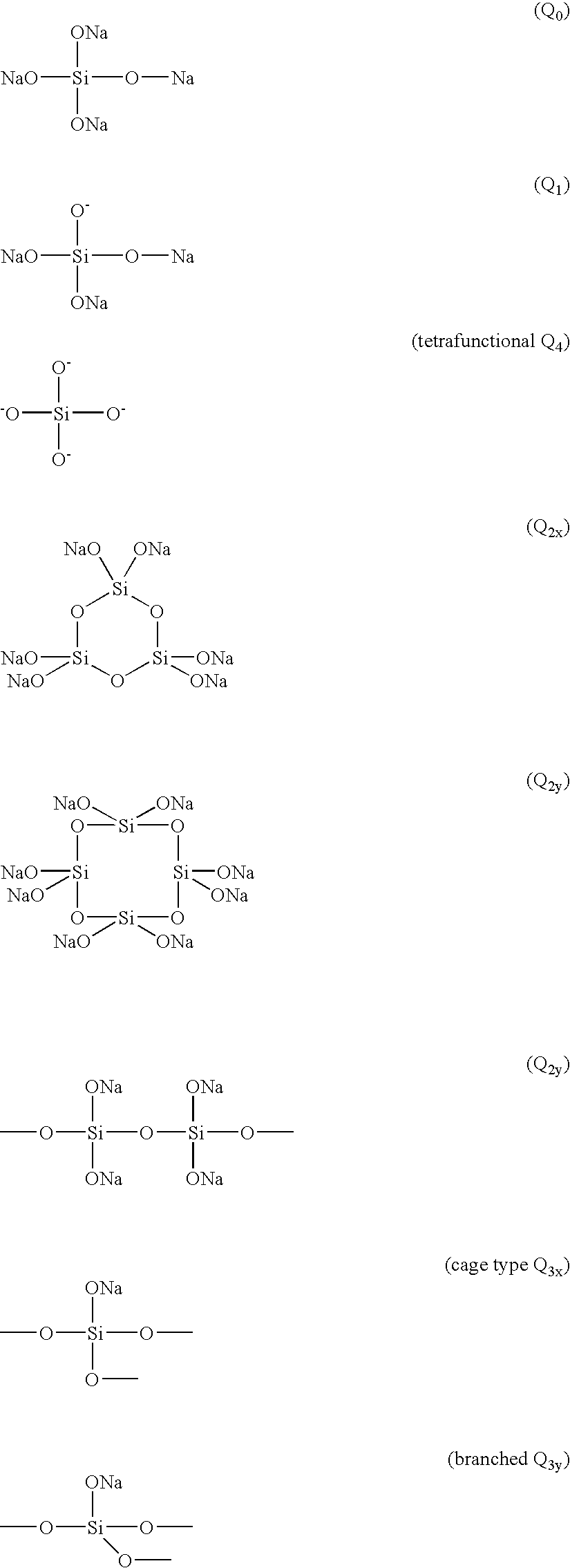

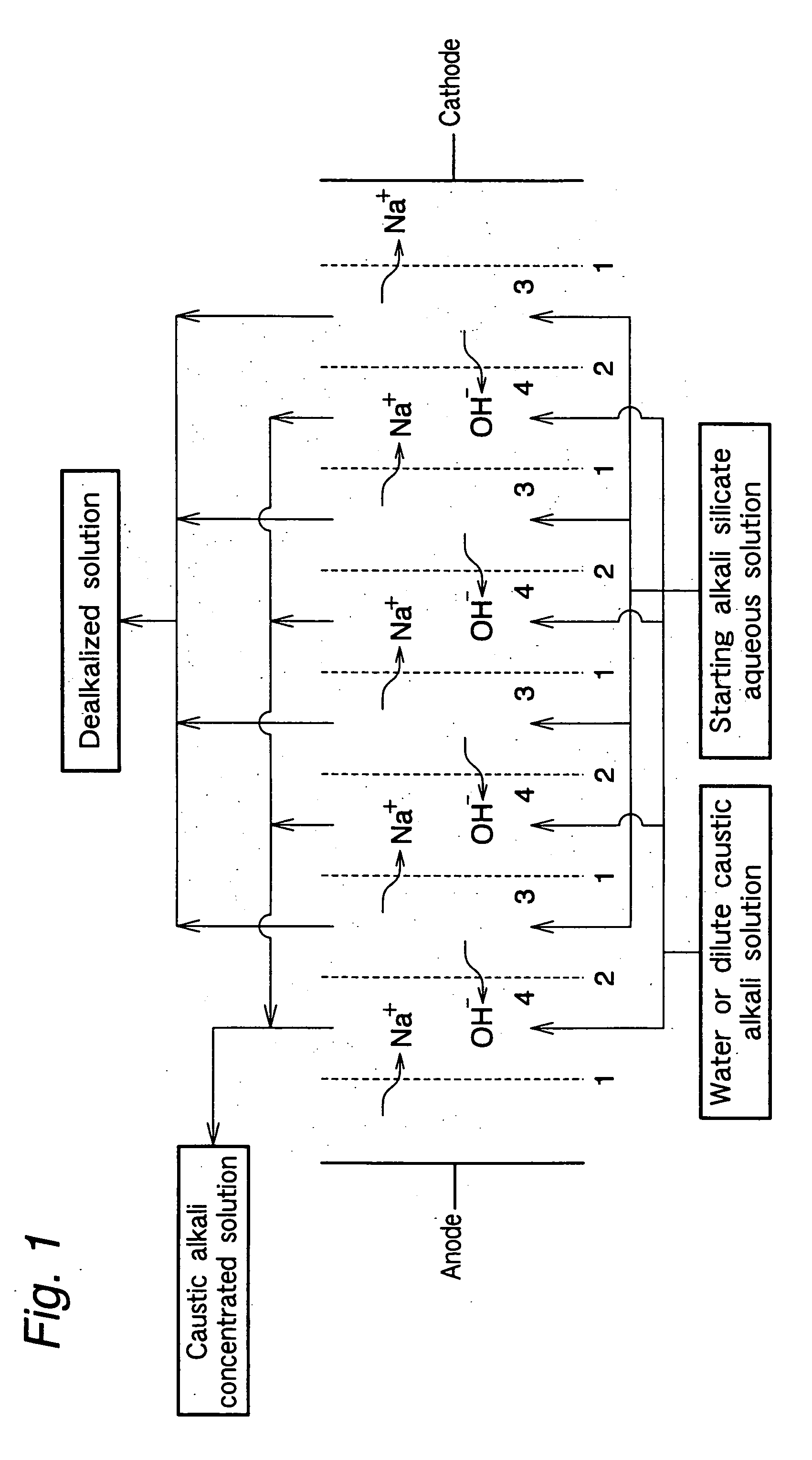

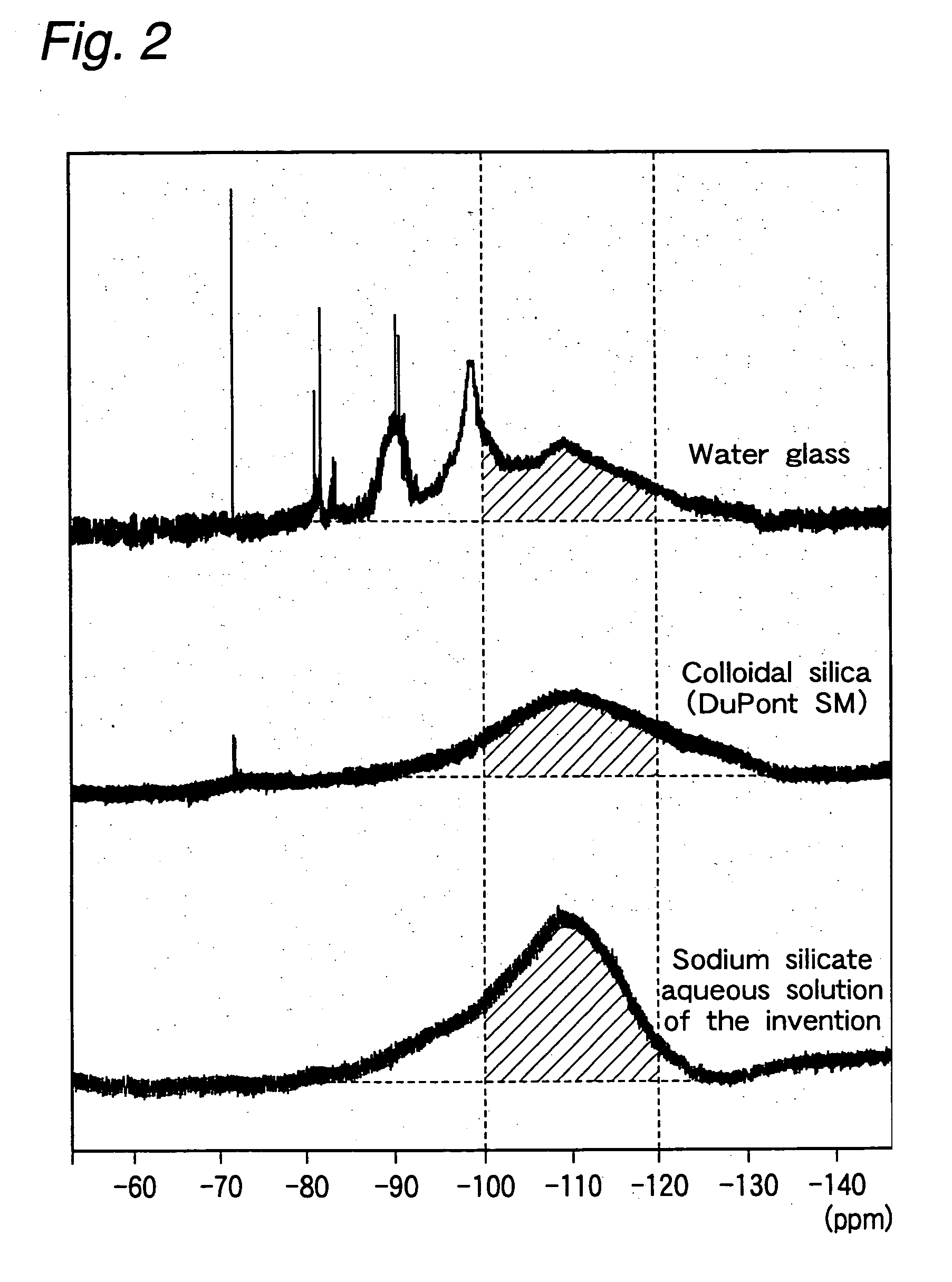

Disclosed herein is a photocatalytic coating composition that enables control of refractive index, film density and hydrophilicity and gives a film with improved strength and adhesion. The photocatalytic coating composition comprises: (1) an alkali silicate aqueous solution having: (A) a molar ratio of silicon to an alkali (SiO2 / (A2O+B) (A: alkali metal, B: NH3)) in the range of 4 to 30; and (B) a silicon concentration in terms of oxide (SiO2 concentration) in the range of 6.8 to 30% by weight; and (2) a photocatalytic compound.

Owner:TOSOSANGYO

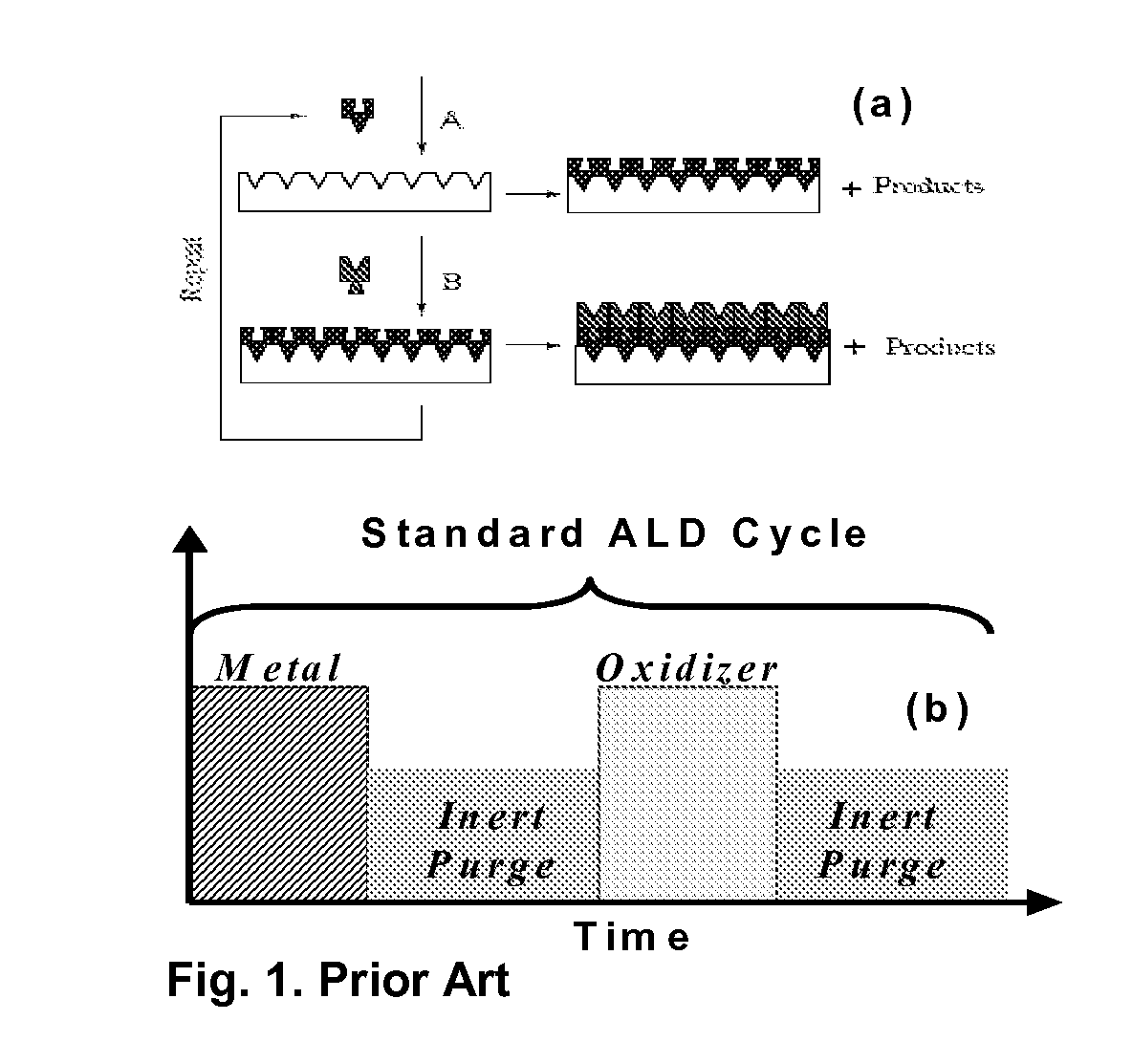

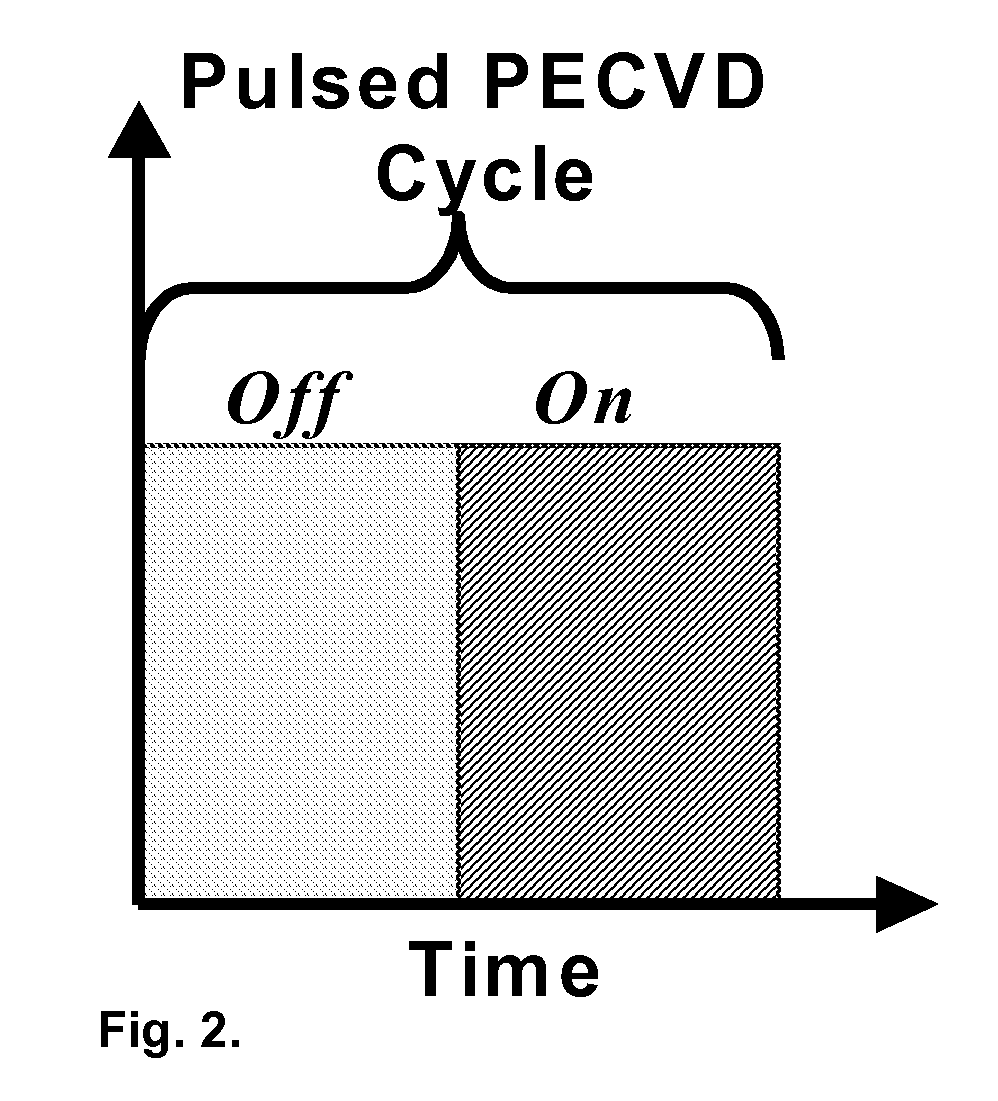

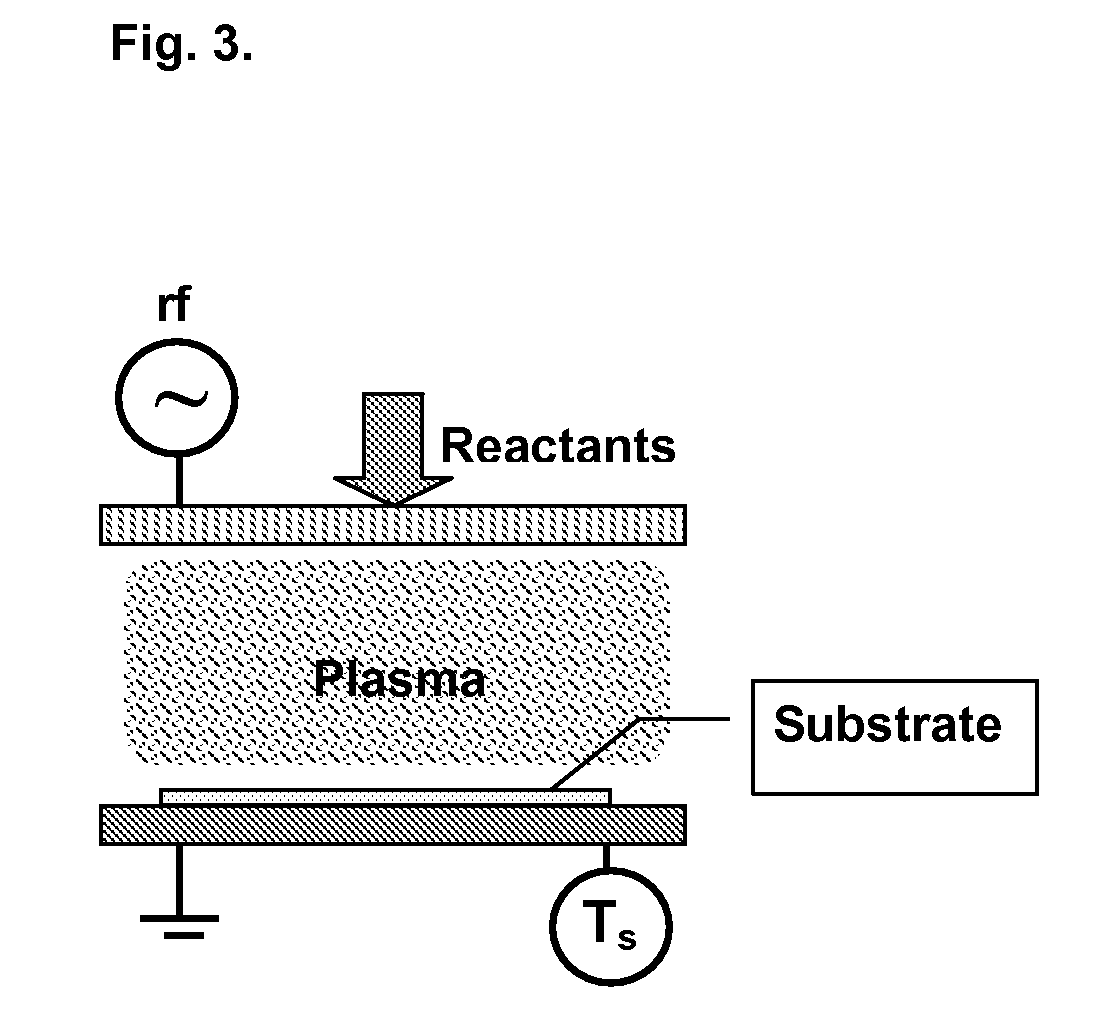

Self-Limiting Thin Film Synthesis Achieved by Pulsed Plasma-Enhanced Chemical Vapor Deposition

InactiveUS20080199632A1Improve throughputIncrease deposition rateChemical vapor deposition coatingPlasma techniqueSelf limitingFourier transform infrared spectroscopy

Ta2O5 and Al2O3 thin films were fabricated by pulsed plasma-enhanced chemical vapor deposition (PECVD) with simultaneous delivery of O2 and the metal precursor. By appropriately controlling the gas-phase environment self-limiting deposition at controllable rates (˜1 Å / pulse) was obtained. The process was insensitive to substrate temperature, with a constant deposition rate observed from 90-350° C. As-deposited Ta2O5 films under these conditions displayed good dielectric properties. Performance improvements correlate strongly with film density and composition as measured by spectroscopic ellipsometry and Fourier transform infrared spectroscopy. Pulsed PECVD eliminates the need for gas actuation and inert purge steps required by atomic layer deposition.

Owner:COLORADO SCHOOL OF MINES

Coating material composition having photocatalytic activity

InactiveUS7297206B2Physical/chemical process catalystsAlkali metal silicate coatingsRefractive indexAqueous solution

Disclosed herein is a photocatalytic coating composition that enables control of refractive index, film density and hydrophilicity and gives a film with improved strength and adhesion. The photocatalytic coating composition comprises: (1) an alkali silicate aqueous solution having: (A) a molar ratio of silicon to an alkali (SiO2 / (A2O+B) (A: alkali metal, B: NH3)) in the range of 4 to 30; and (B) a silicon concentration in terms of oxide (SiO2 concentration) in the range of 6.8 to 30% by weight; and (2) a photocatalytic compound.

Owner:TOSOSANGYO

Thermal annealing for Cu seed layer enhancement

InactiveUS6998337B1Low resistance CuReduce voidsSolid-state devicesSemiconductor/solid-state device manufacturingAdamiteReducing atmosphere

Semiconductor devices with highly reliable Cu interconnects exhibiting reduced resistance are formed by sequentially depositing a seed layer by PVD, depositing a conformal seed layer enhancement film by electroplating, and then thermal annealing the seed layer enhancement film in an inert or reducing atmosphere to expel impurities, enhance film conductivity, reduce film stress, increase film density, and reduce film roughness. Embodiments include single and dual Cu damascene techniques formed in dielectric layers having a dielectric constant no greater than about 3.9.

Owner:ADVANCED MICRO DEVICES INC

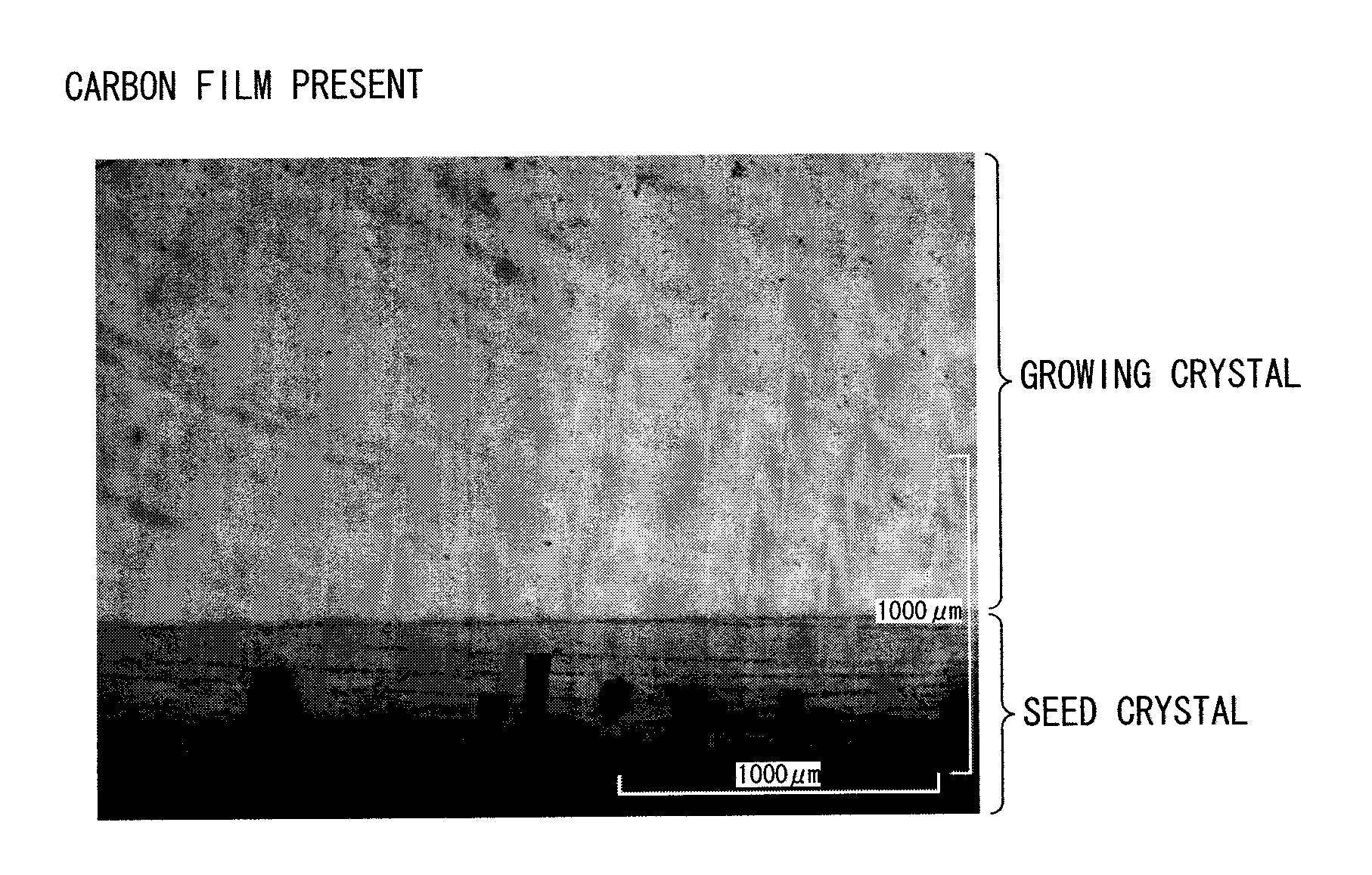

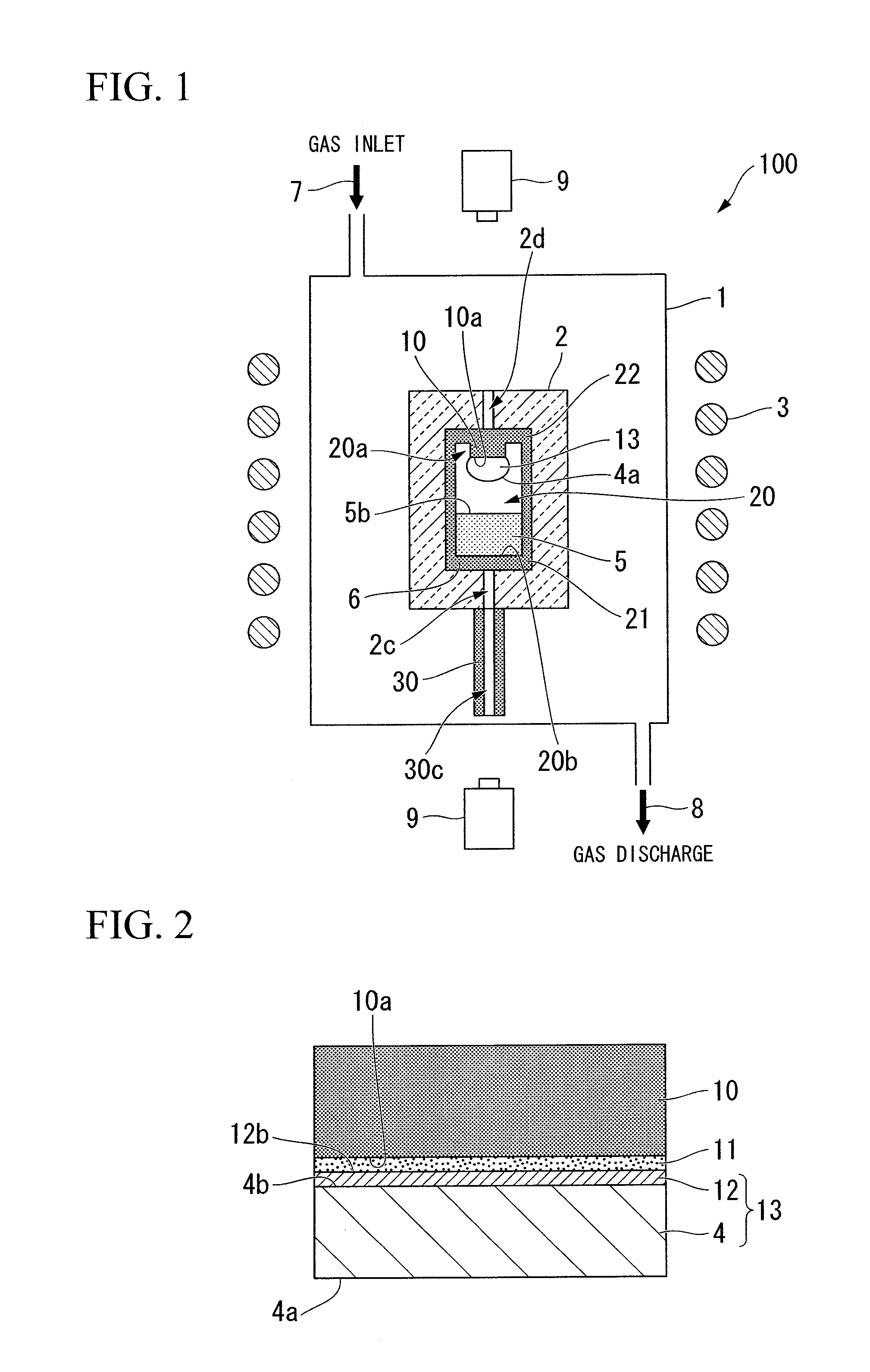

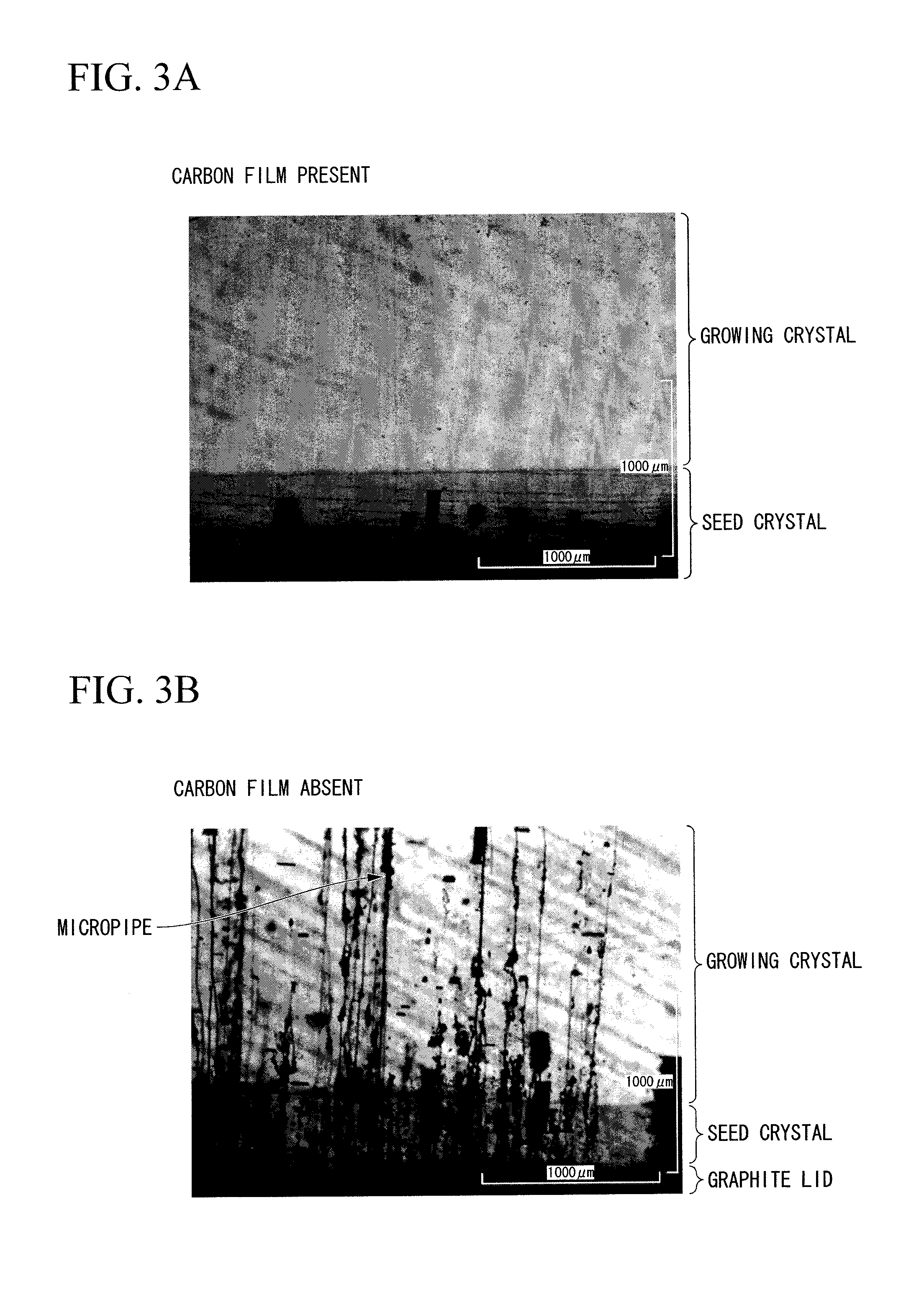

Seed crystal for silicon carbide single crystal growth, method for producing the seed crystal, silicon carbide single crystal, and method for producing the single crystal

InactiveUS20110111171A1Good reproducibilityQuality improvementVacuum evaporation coatingSputtering coatingCarbon filmOptoelectronics

A seed crystal for silicon carbide single crystal growth (13) which is attached to the lid of a graphite crucible charged with a raw material silicon carbide powder. The seed crystal includes a seed crystal (4) formed of silicon carbide having one surface defined as a growth surface (4a) for growing a silicon carbide single crystal by a sublimation method, and a carbon film (12) formed on the surface (4b) opposite to the growth surface of the seed crystal (4). Further, the film density of the carbon film (12) is 1.2 g / cm3 to 3.3 g / cm3.

Owner:SHOWA DENKO KK

Deposition of an amorphous carbon layer with high film density and high etch selectivity

ActiveUS20130302996A1Improve etch selectivityDecent ashabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogen contentPhotochemistry

Embodiments described herein relate to a method for processing a substrate. In one embodiment, the method includes introducing a gas mixture comprising a hydrocarbon source and a diluent gas into a deposition chamber located within a processing system, generating a plasma from the gas mixture in the deposition chamber at a temperature between about 200° C. and about 700° C. to form a low-hydrogen content amorphous carbon layer on the substrate, transferring the substrate into a curing chamber located within the processing system without breaking vacuum, and exposing the substrate to UV radiation within the curing chamber at a curing temperature above about 200° C.

Owner:APPLIED MATERIALS INC

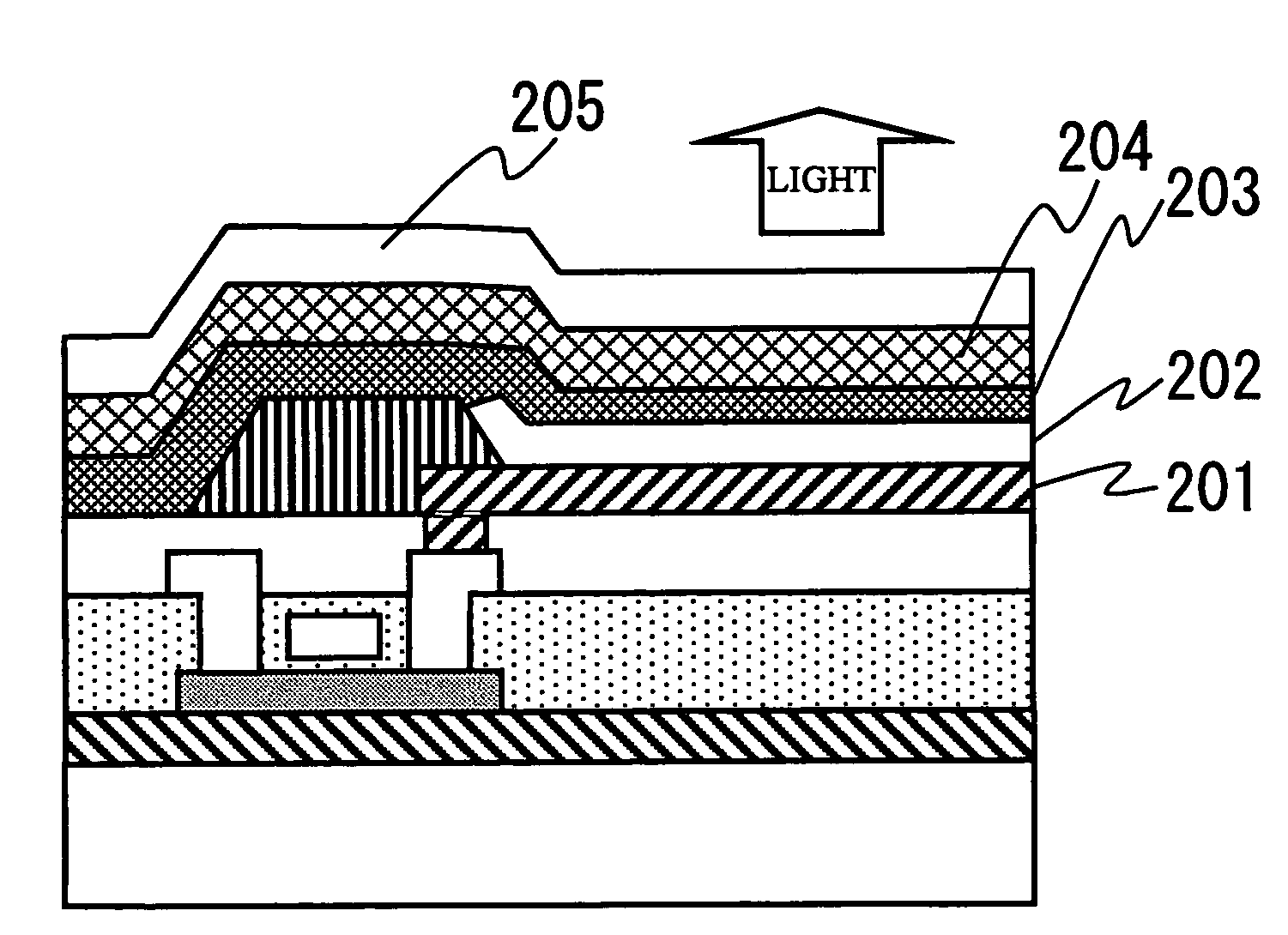

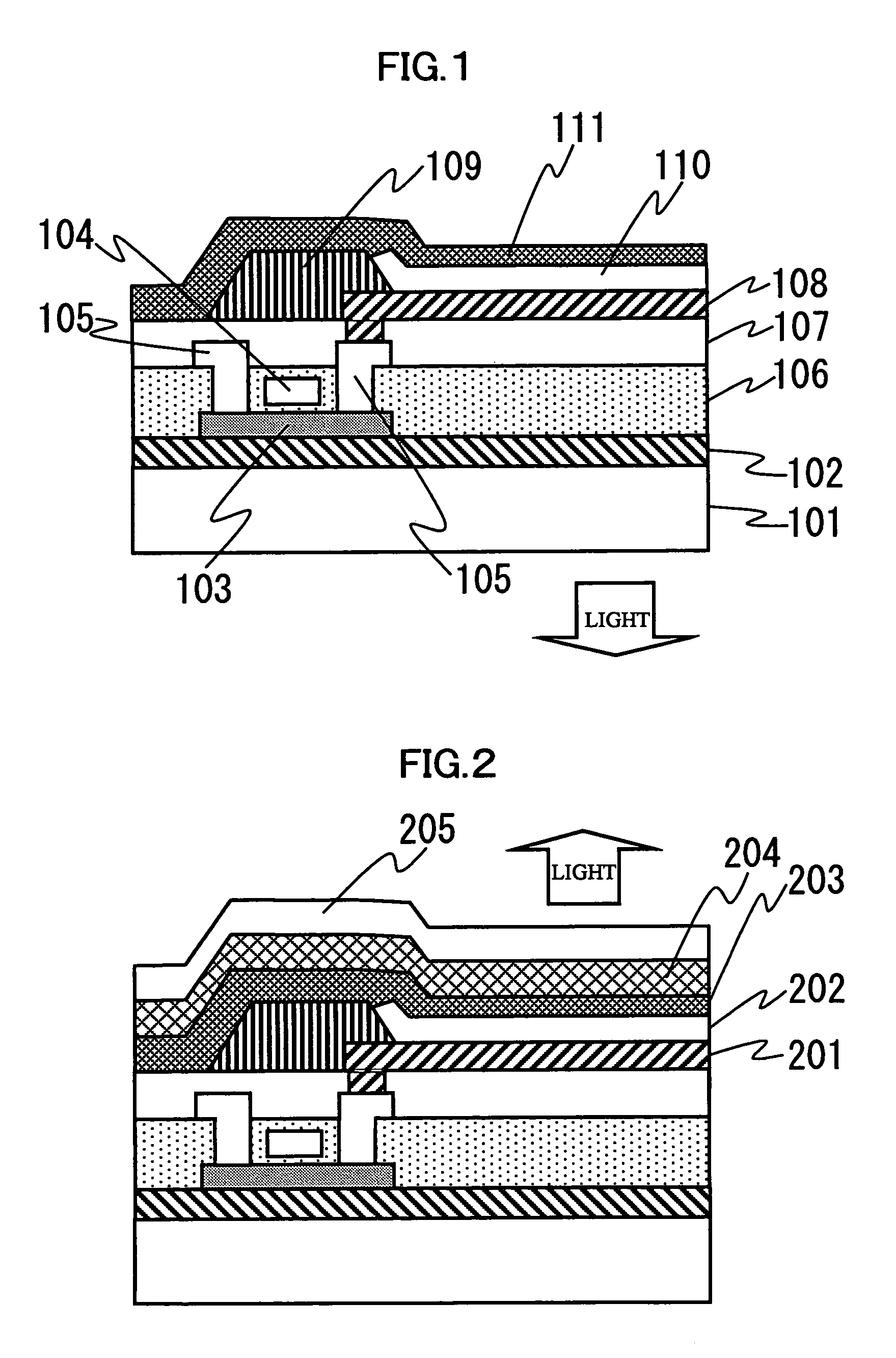

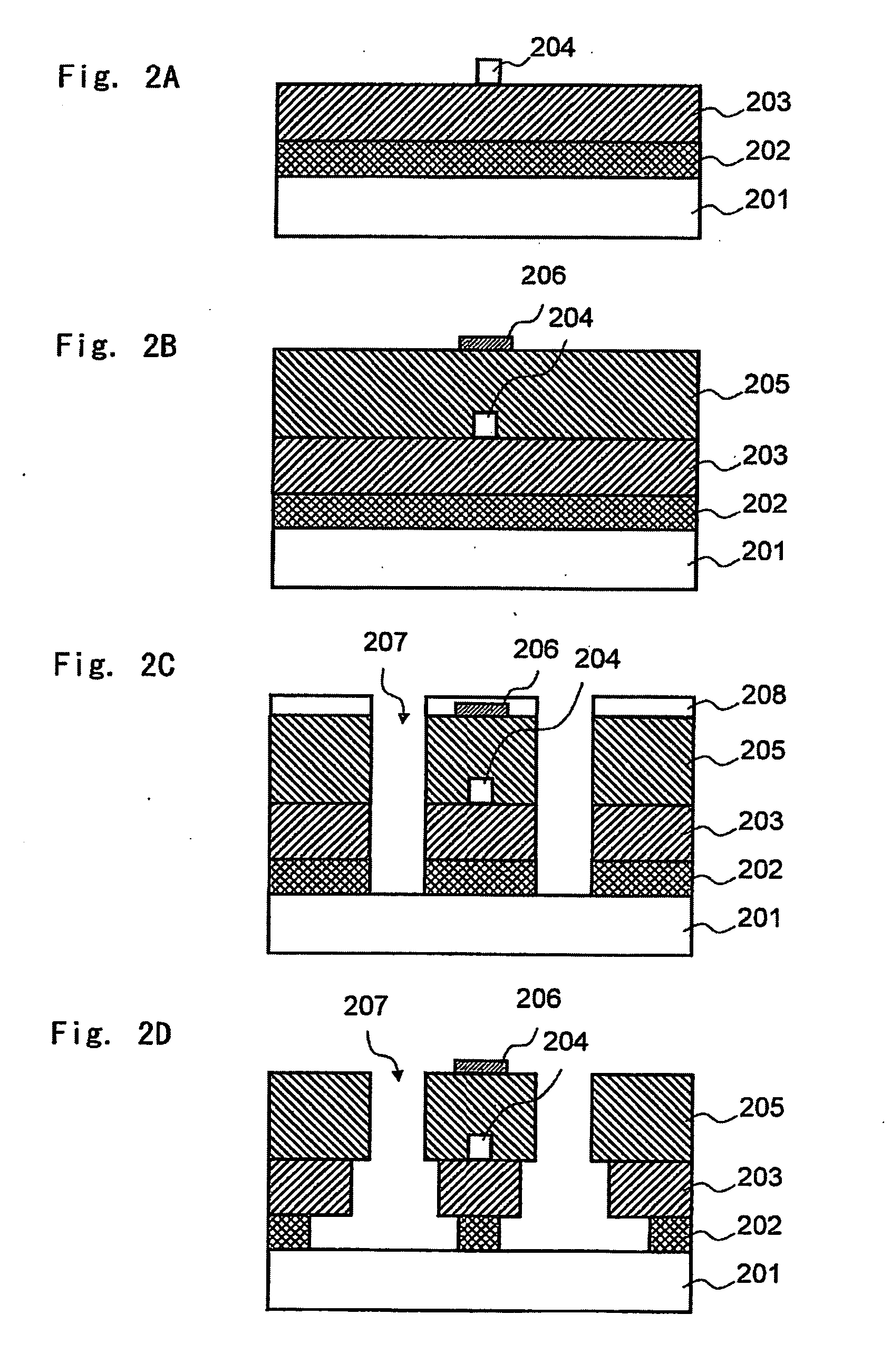

Thermo-optic phase shifter and method for manufacturing same

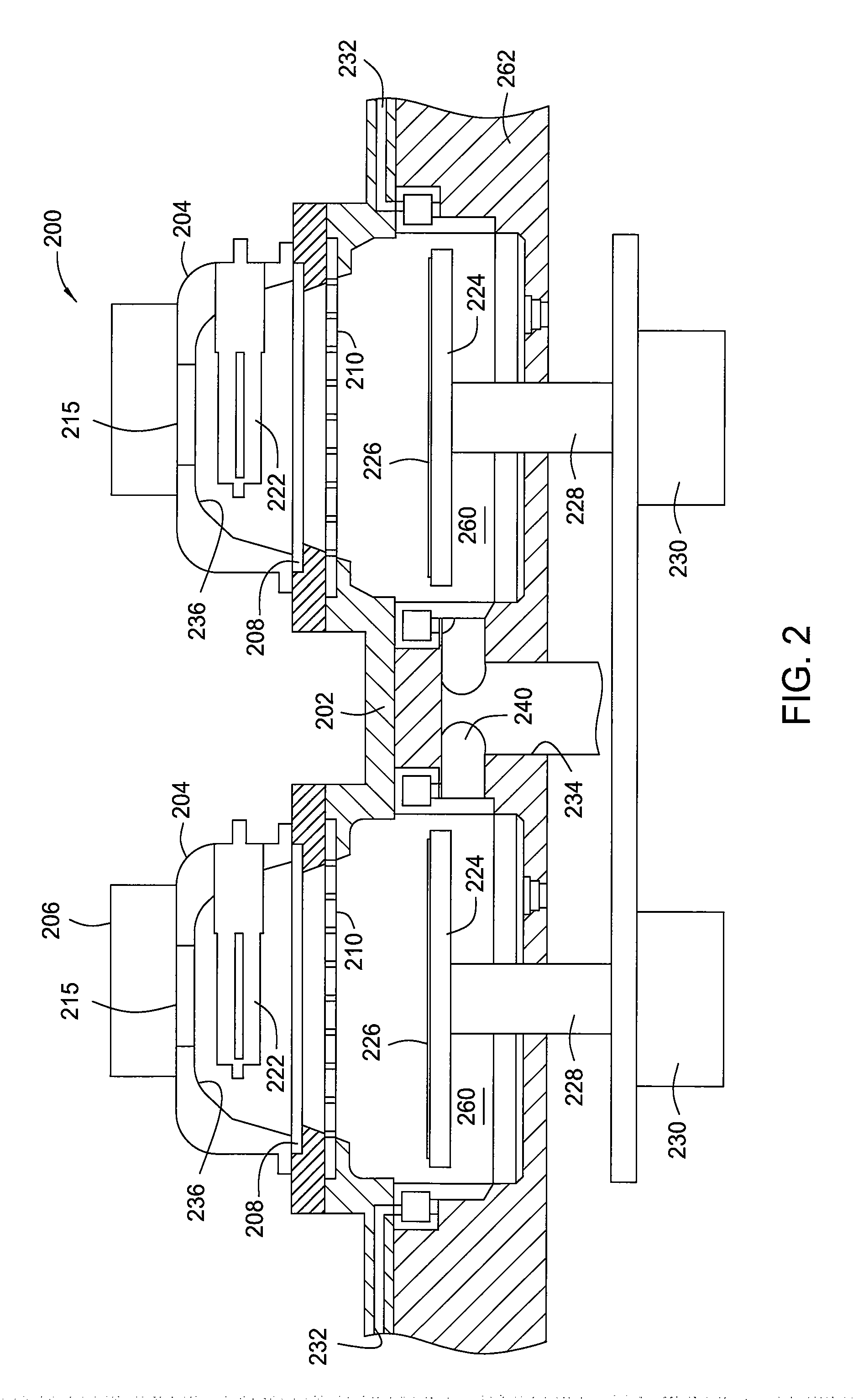

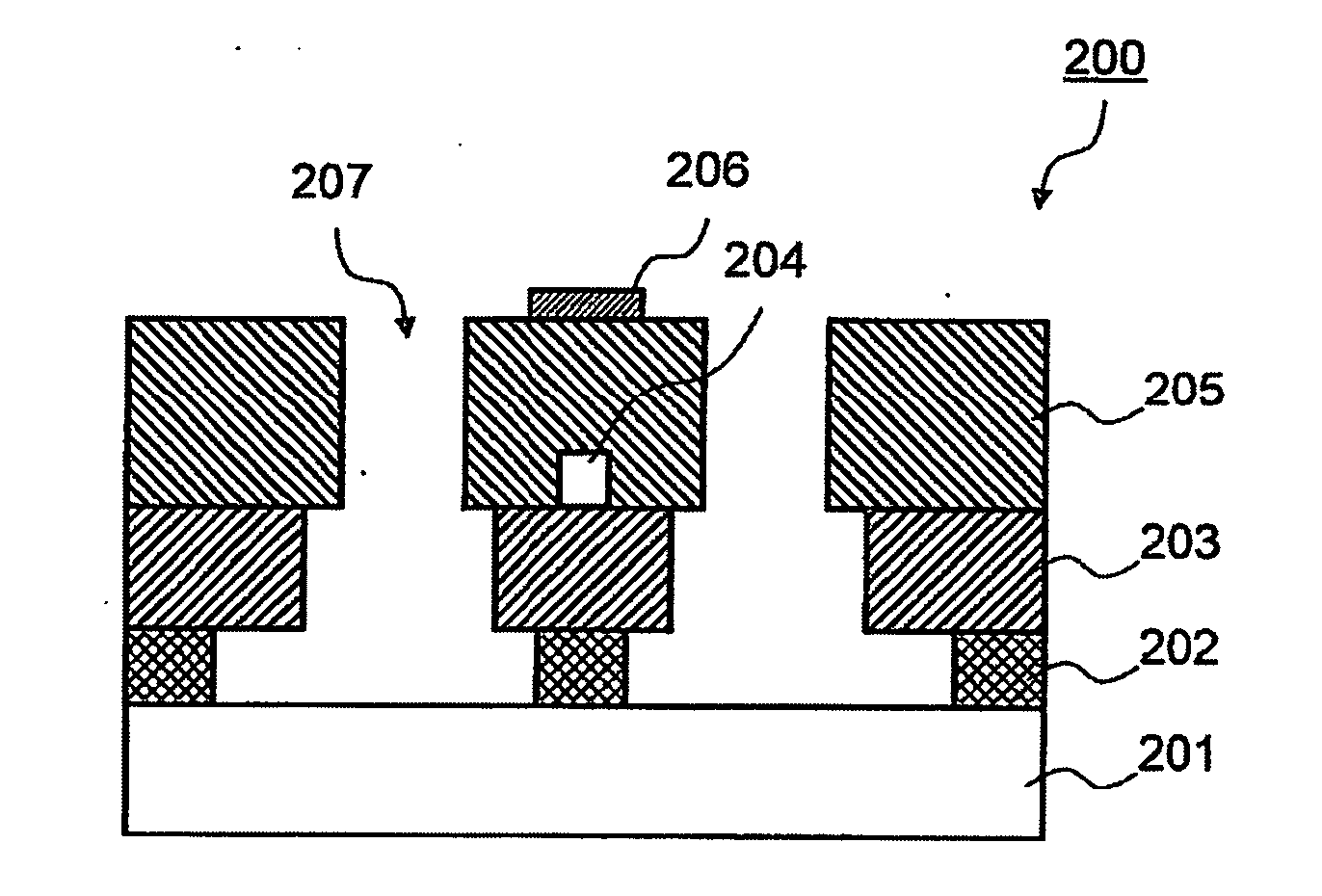

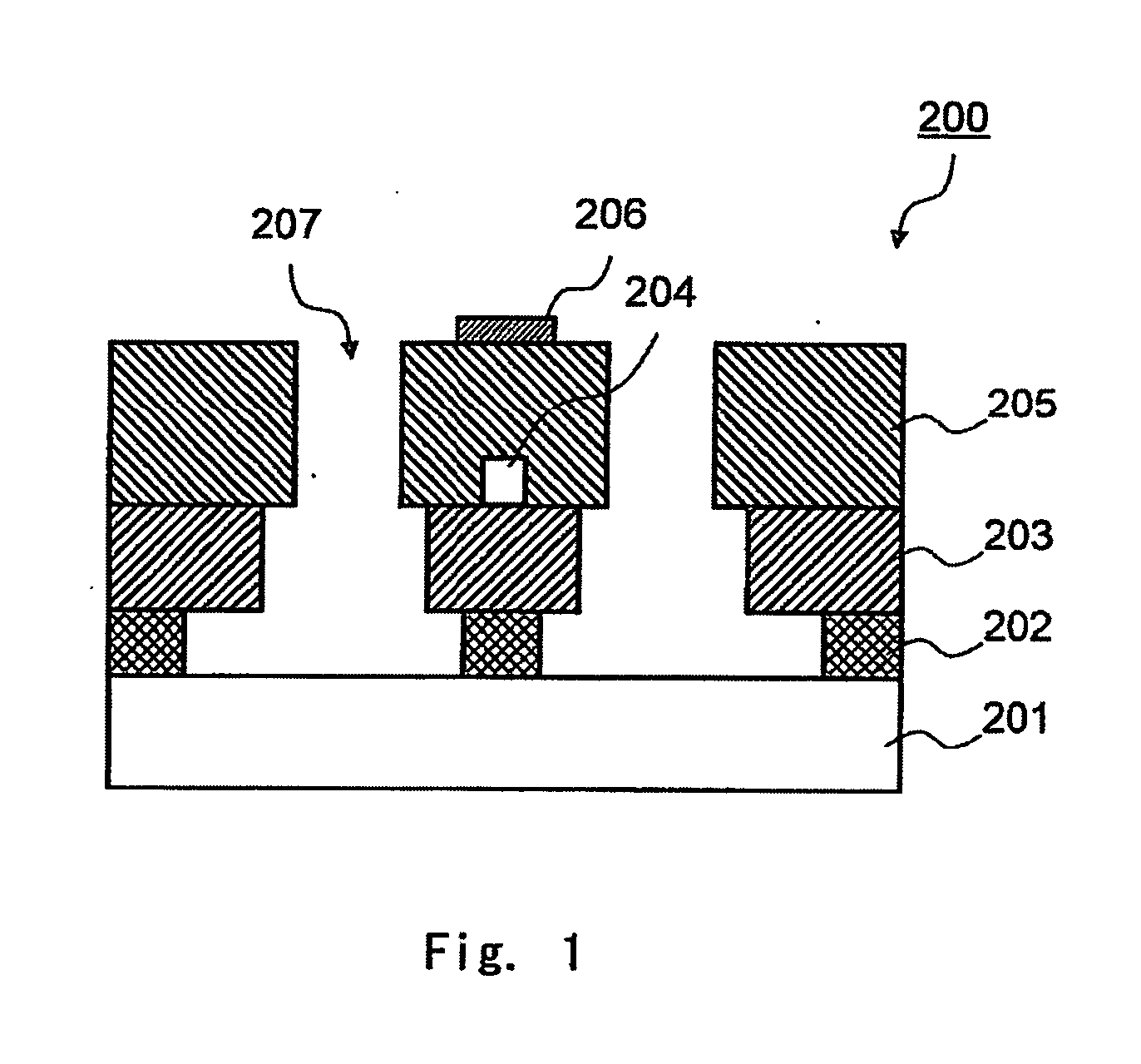

InactiveUS20090297092A1Easy to controlHigh yieldCladded optical fibreVacuum evaporation coatingVolumetric Mass DensityWaveguide

The thermo-optic phase shifter (200) according to an exemplary aspect of the invention includes: a substrate (201); a sacrificial layer (202) formed above the substrate (201); a first cladding layer (203) formed above the sacrificial layer (202) and having a film density higher than that of the sacrificial layer (202); an optical waveguide core (204) formed above the first cladding layer (203); a second cladding layer (205) provided over the first cladding layer (203) to cover the optical waveguide core (204); a heat-generating heater (206) provided to a region of the second cladding layer (205) directly above the optical waveguide core (204); and a groove (207) formed in a side face region of the optical waveguide core (204) and extending from the surface of the second cladding layer (205) to the surface of the substrate (201).

Owner:NEC CORP

Transparent conductive film, process for producing same, and electronic device employing transparent conductive film

InactiveUS20120295120A1Improve conductivityHigh transparencyConductive layers on insulating-supportsVacuum evaporation coatingOxygenElectron

Disclosed is a transparent conductive film, including a substrate and, formed on at least one surface of the substrate, a gas barrier layer and a transparent conductive layer, wherein the gas barrier layer is formed of a material containing at least oxygen atoms, nitrogen atoms, and silicon atoms, and includes a surface layer part which has an oxygen atom fraction of 60 to 75%, a nitrogen atom fraction of 0 to 10%, and a silicon atom fraction of 25 to 35%, each atom fraction being calculated with respect to the total number of the oxygen atoms, nitrogen atoms, and silicon atoms contained in the surface layer part and which has a film density of 2.4 to 4.0 g / cm3.

Owner:LINTEC CORP

Diamond like carbon layer formed by an electron beam plasma process

Methods for forming a diamond like carbon layer with desired film density, mechanical strength and optical film properties are provided. In one embodiment, a method of forming a diamond like carbon layer includes generating an electron beam plasma above a surface of a substrate disposed in a processing chamber, and forming a diamond like carbon layer on the surface of the substrate. The diamond like carbon layer is formed by an electron beam plasma process, wherein the diamond like carbon layer serves as a hardmask layer in an etching process in semiconductor applications. The diamond like carbon layer may be formed by bombarding a carbon containing electrode disposed in a processing chamber to generate a secondary electron beam in a gas mixture containing carbon to a surface of a substrate disposed in the processing chamber, and forming a diamond like carbon layer on the surface of the substrate from elements of the gas mixture.

Owner:APPLIED MATERIALS INC

Biaxially oriented cavitated polylactic acid film

ActiveUS20130122280A1High opacityImprove film yieldLamination ancillary operationsSynthetic resin layered productsMechanical propertyCrystallization

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and a metal salt phosphorus-containing compound nucleating agent which is biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the metal salt phosphorus-containing metal such that a white opaque cavitated appearance and a lower film density and improved mechanical properties are obtained. The laminate film could further have additional layers such as a heat sealable layer disposed on one side of said core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

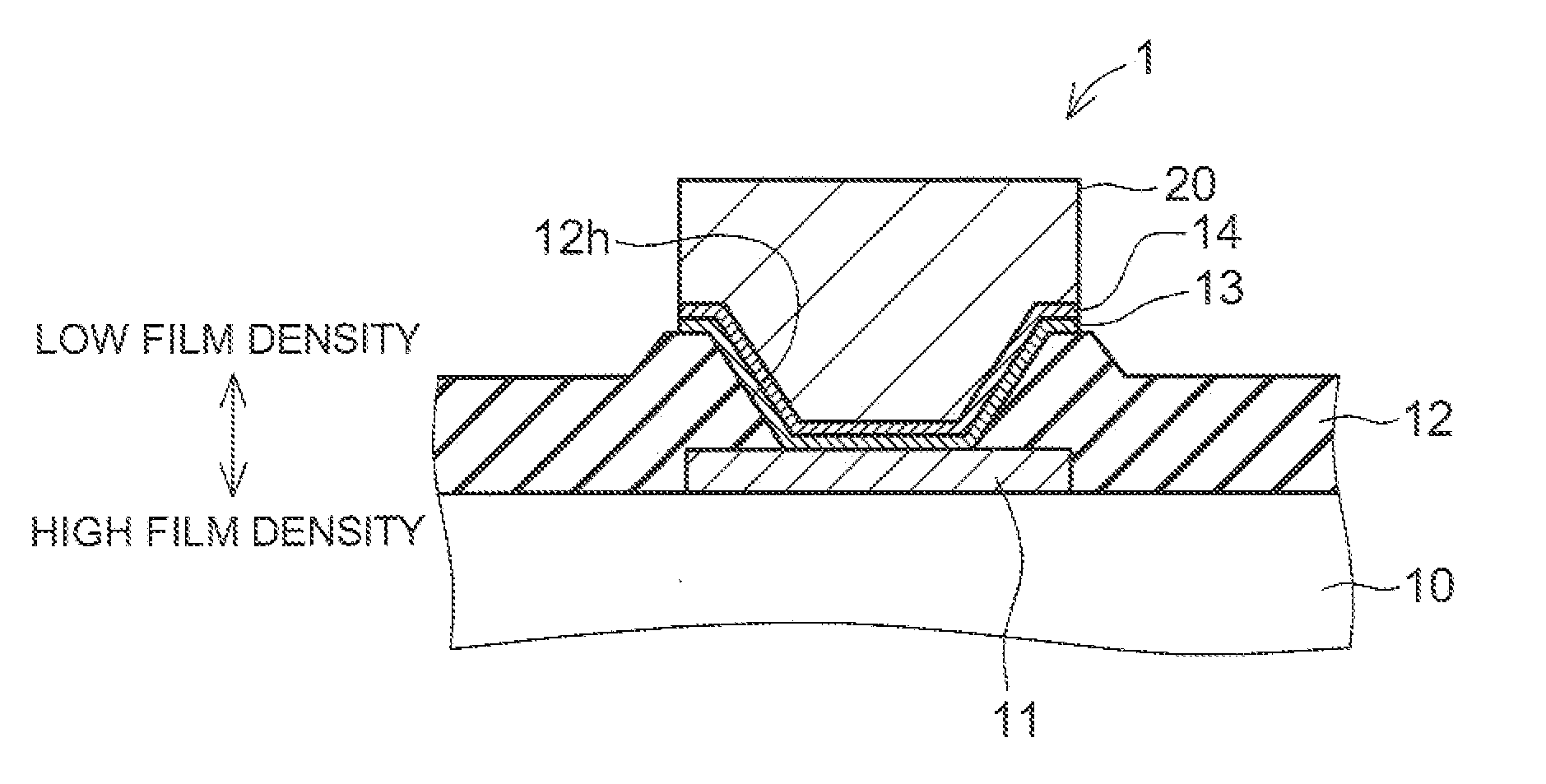

Semiconductor device and method for fabricating the same

InactiveUS20120032338A1Easy to controlReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Disclosed is a semiconductor device which includes a base substrate; a lower electrode formed on a main surface of the base substrate; and an insulating film formed over the lower electrode and the main surface of the base substrate. The insulating film has a contact hole defined by a wall extending upwardly from the top surface of the lower electrode. The insulating film has a film density distribution in which a film density decreases with increasing distance from the main surface of the base substrate in the thickness direction. A width of the contact hole increases as the film density decreases.

Owner:LAPIS SEMICON CO LTD

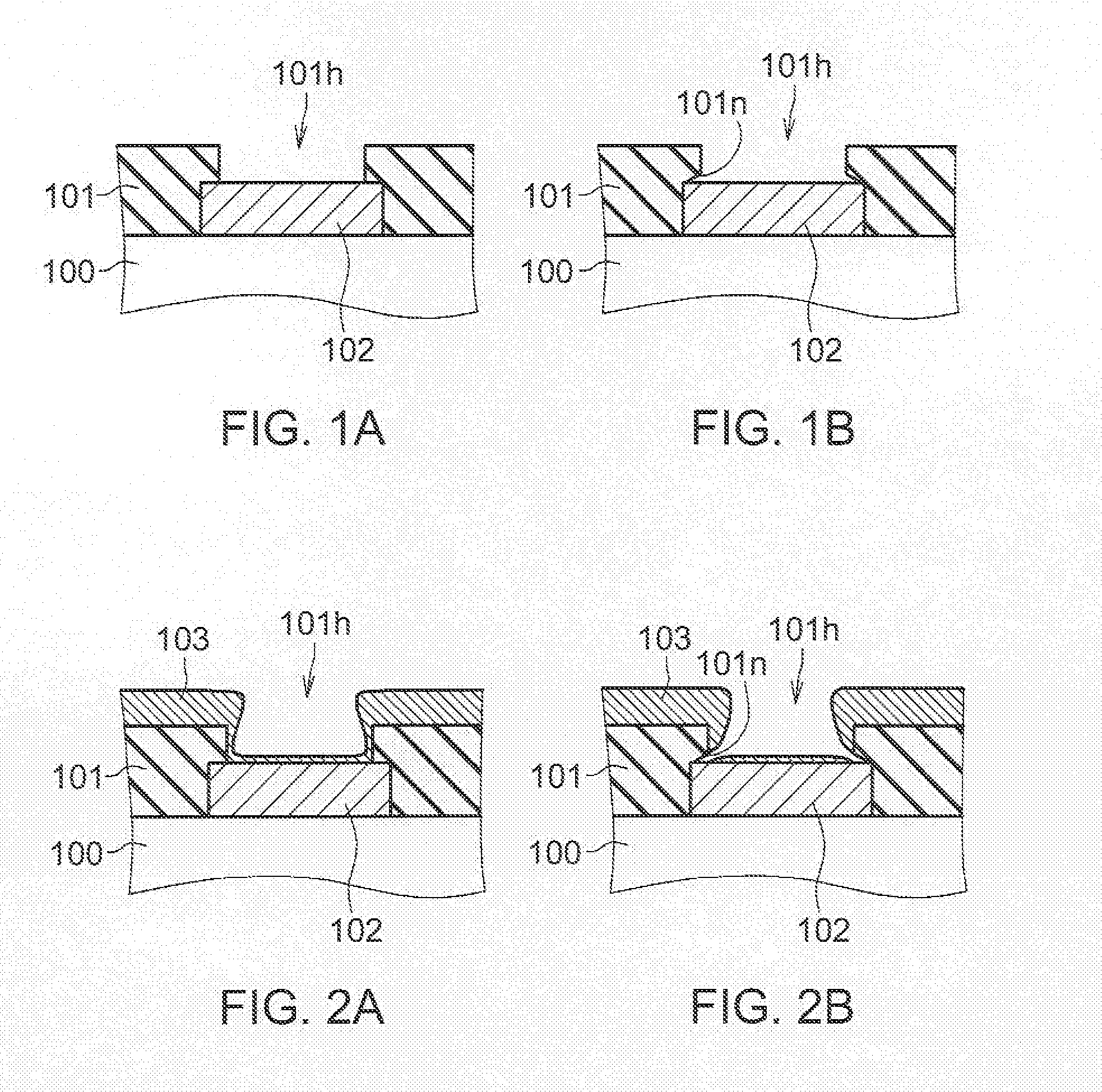

Semiconductor device

InactiveUS7531891B2Improve interlayer adhesionImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesTrimethylsilaneSemiconductor

A semiconductor device having improved adhesiveness between films composing an interlayer insulating film is presented by providing multilayered films in the interlayer insulating films having film density distribution, in which the film density is gradually changes. A SiOC film is deposited to a thickness of 300 nm via a plasma CVD process, in which a flow rate of trimethylsilane gas is stepwise increased. In this case, the film density of the deposited SiOC film is gradually decreased by stepwise increasing the flow rate of trimethylsilane gas. Since trimethylsilane contains methyl group, trimethylsilane has more bulky molecular structure in comparison with monosilane or the like. Thus, the film density is decreased by increasing the amount of trimethylsilane in the reactant gas.

Owner:RENESAS ELECTRONICS CORP

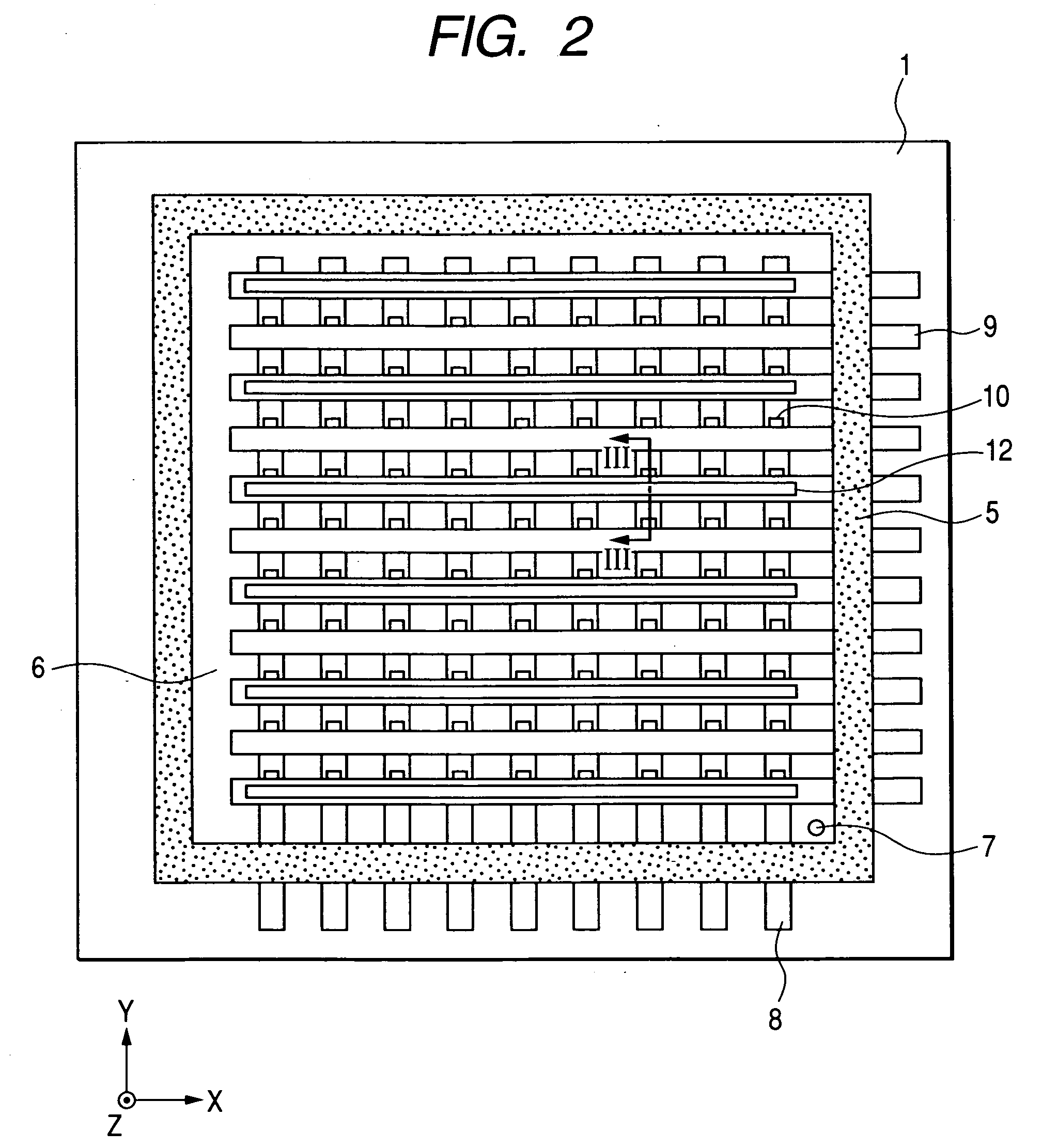

Image display device

InactiveUS20060170329A1Reduce brightnessDischarge tube luminescnet screensCathode ray tubes/electron beam tubesElectron sourcePhosphor

An image display device includes: a front substrate having phosphor layers and a light reflective film succeeding the phosphor layers and composed chiefly of aluminum on an inner surface thereof; a rear substrate having plural electron sources on an inner surface thereof, and disposed to oppose the front substrate with a specified spacing between the front and rear substrates; and a support member which is sandwiched between the front and rear substrates, surrounds a display area formed between the front and rear substrates, and maintains the specified spacing. Two end faces of the support member are hermetically sealed to the front substrate and the rear substrate, respectively, via sealing members. A thickness of the light reflective film is in a range of from 50 nm to 200 nm, and an average film density of the light reflective film is in a range of from 1.6 g / cm3 to 2.6 g / cm3.

Owner:HITACHI DISPLAYS

Manufacturing method for semiconductor device

InactiveUS20080003775A1Increase film densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideSilanol

A manufacturing method for a semiconductor device includes generating on a substrate liquid-phase silanol having fluidity by causing a source gas made of a material containing silicon to react with a source gas made of a material containing oxygen, introducing the silanol into a first recess having an aspect ratio of a predetermined value wholly, and introducing the silanol into a space from a bottom to an intermediate portion in a second recess having an aspect ratio lower than the predetermined value, the first and second recesses are provided in the substrate, burying a silicon oxide film in the first recess and providing the silicon oxide film in the second recess by converting the silanol into the silicon oxide film by dehydrating condensation, and providing a dielectric film having film density higher than that of the silicon oxide film on the silicon oxide film.

Owner:KK TOSHIBA

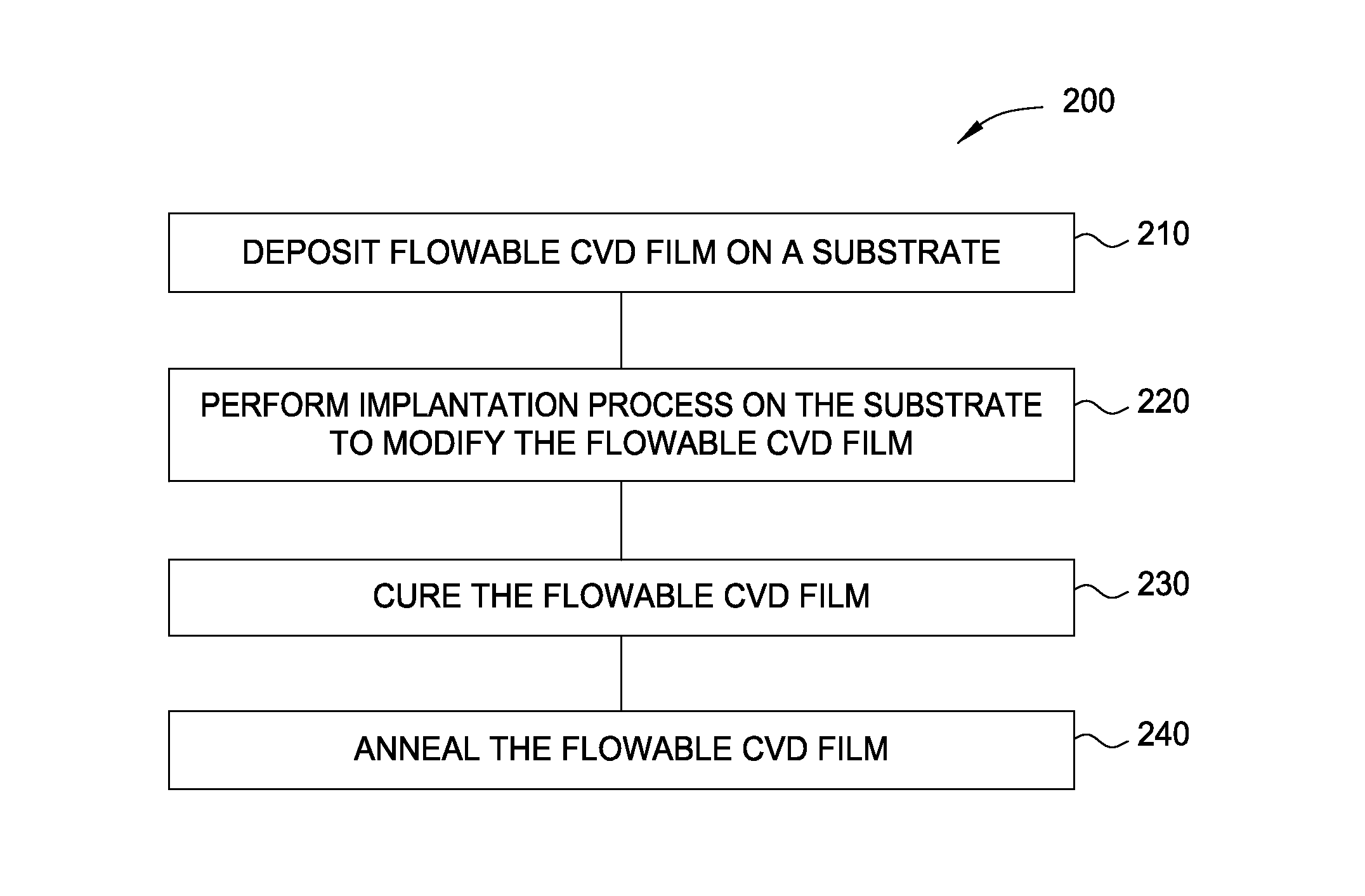

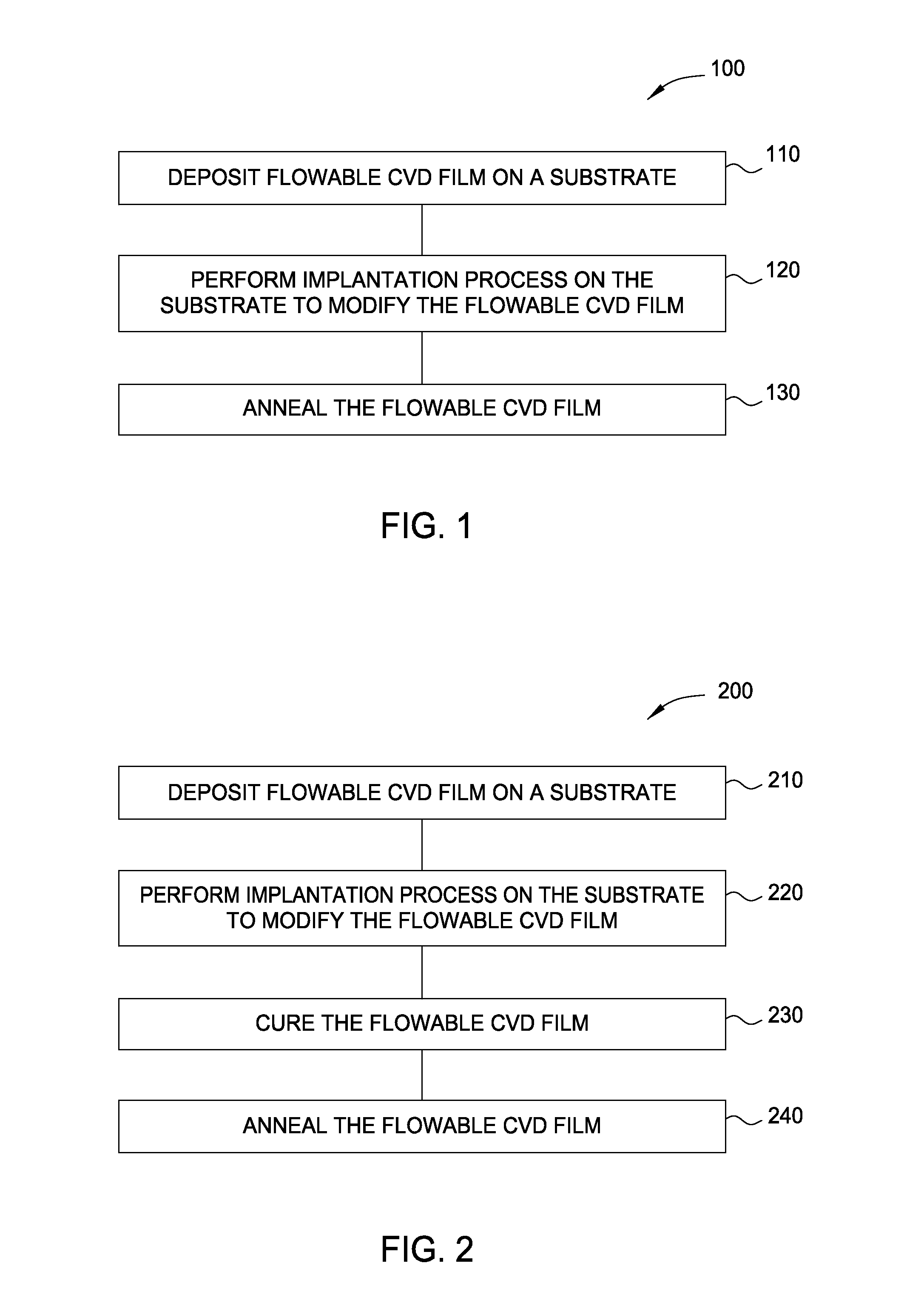

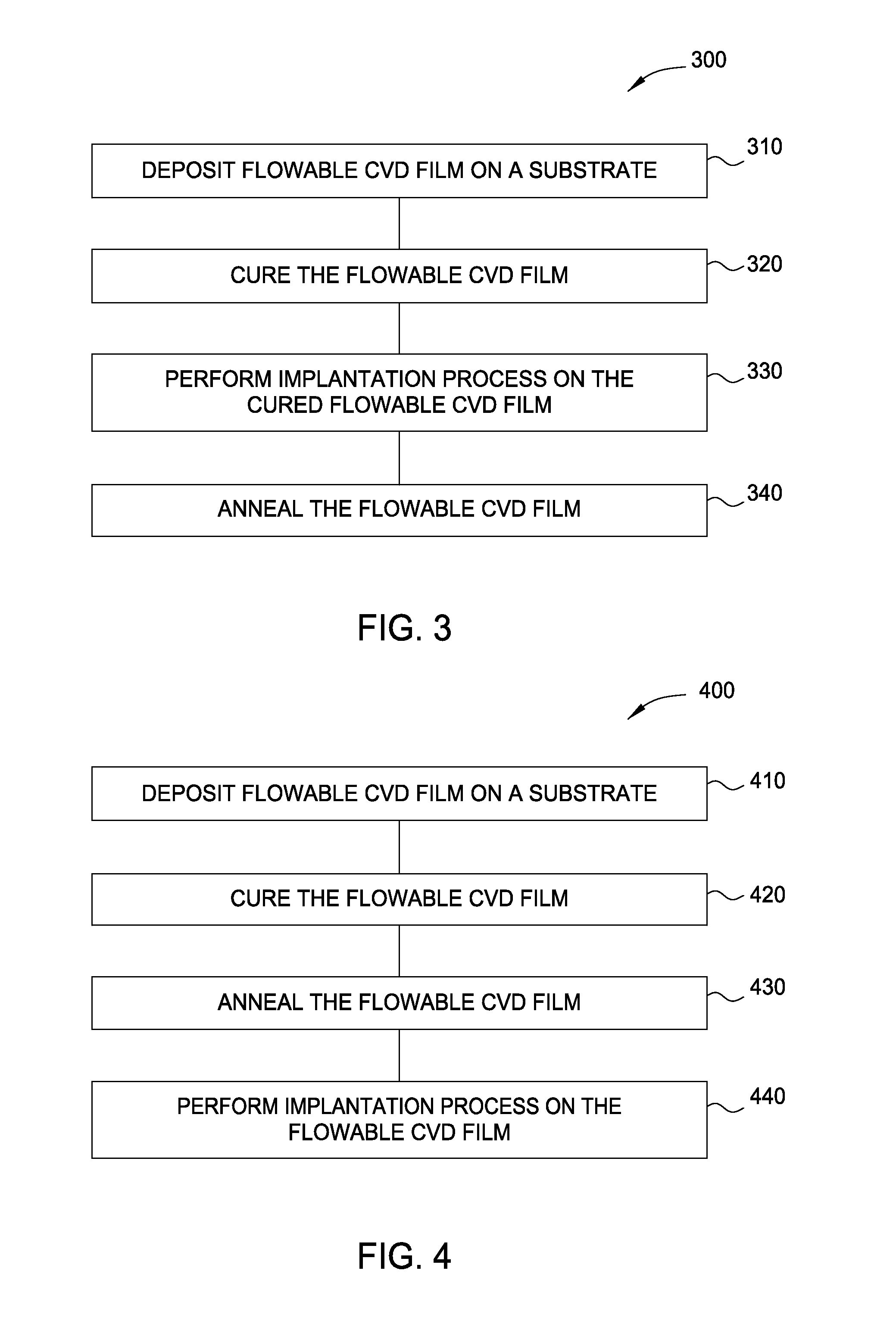

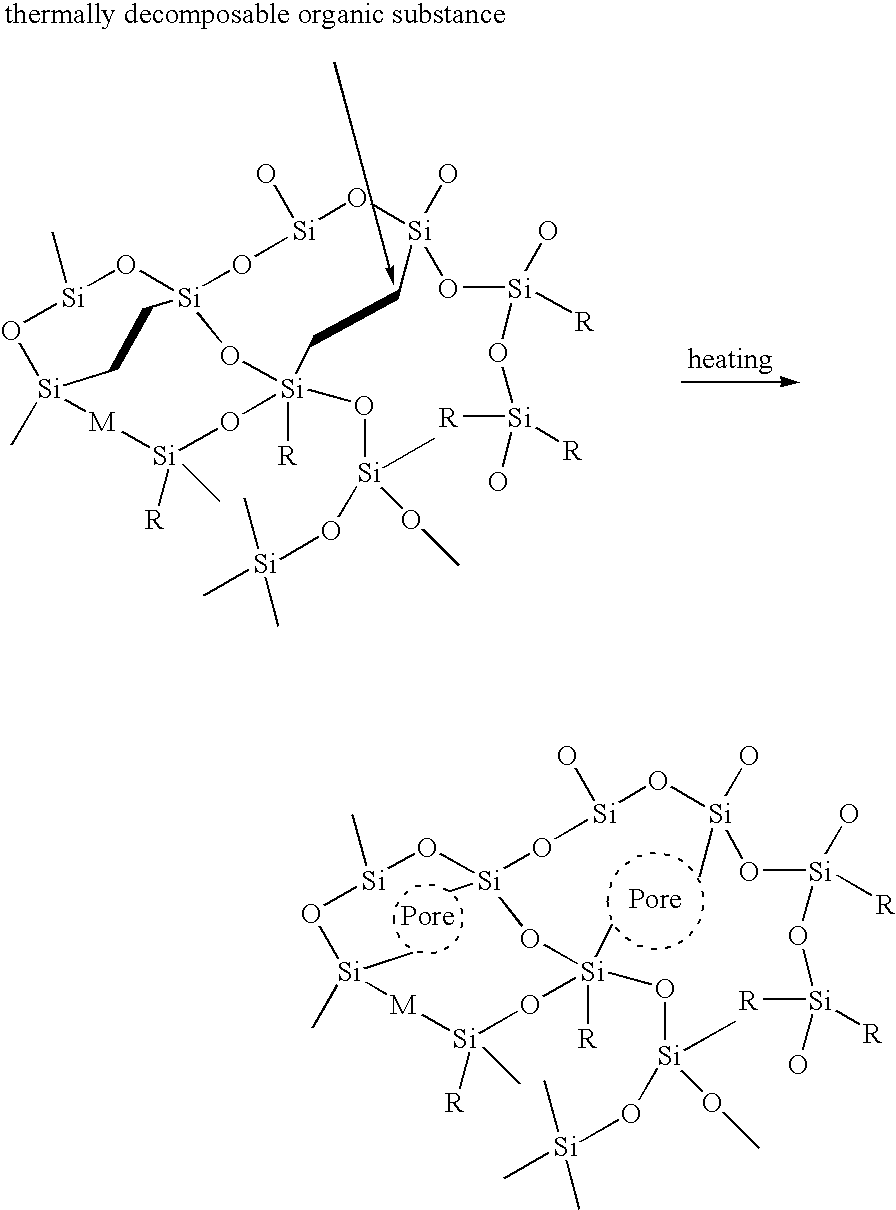

Advanced process flow for high quality fcvd films

ActiveUS20160194758A1Vacuum evaporation coatingSputtering coatingDevice materialVolumetric Mass Density

Embodiments described herein relate to methods for forming flowable chemical vapor deposition (FCVD) films suitable for high aspect ratio gap fill applications. Various process flows described include ion implantation processes utilized to treat a deposited FCVD film to improve dielectric film density and material composition. Ion implantation processes, curing processes, and annealing processes may be utilized in various sequence combinations to form dielectric films having improved densities at temperatures within the thermal budget of device materials. Improved film quality characteristics include reduced film stress and reduced film shrinkage when compared to conventional FCVD film formation processes.

Owner:APPLIED MATERIALS INC

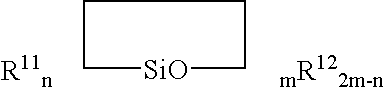

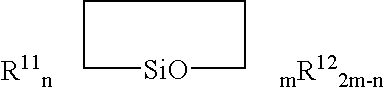

Organic silicate polymer and insulation film comprising the same

InactiveUS20060127587A1Reduce power consumptionReduce crosstalkGroup 4/14 element organic compoundsSemiconductor/solid-state device detailsSilanesDevice material

The present invention relates to a composition for forming a low dielectric insulating film for a semiconductor device, particularly to an organosilicate polymer prepared by mixing a thermally decomposable organic silane compound that is capped with a silane compound at both its ends, and a common silane compound or silane oligomer, and then adding water and a catalyst to conduct hydrolysis and condensation, as well as to a coating composition for an insulating film for a semiconductor device comprising the same, a coating composition for an insulating film for a semiconductor device further comprising a pore-forming organic substance, a method for preparing an insulating film for a semiconductor device by coating the composition and curing, and a semiconductor device comprising a low dielectric insulating film prepared by the method. The organosilicate polymer prepared according to the present invention has superior thermal stability and mechanical strength; an insulating film-forming composition comprising the same can be used for an interlayer insulating film for low dielectric wiring that can contribute to a high speed semiconductor, reduce power consumption, and remarkably decrease cross-talk between metal wiring; and a film obtained by applying the composition to an insulating film has superior coating properties, inhibits phase-separation, can easily control minute pores because organic substances are thermally decomposed to form pores during a curing process, and has superior insulating properties and a remarkably decreased film density.

Owner:LG CHEM LTD

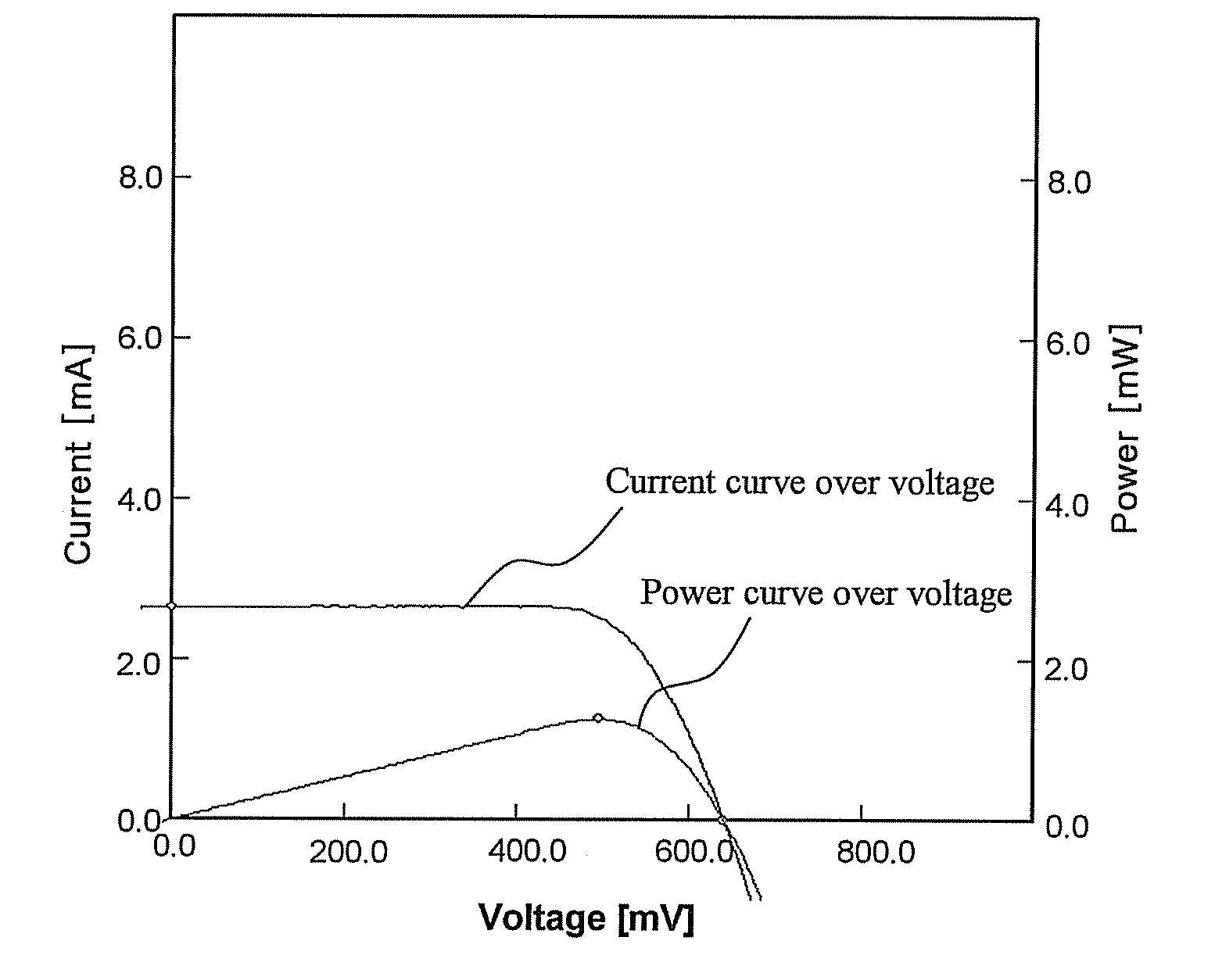

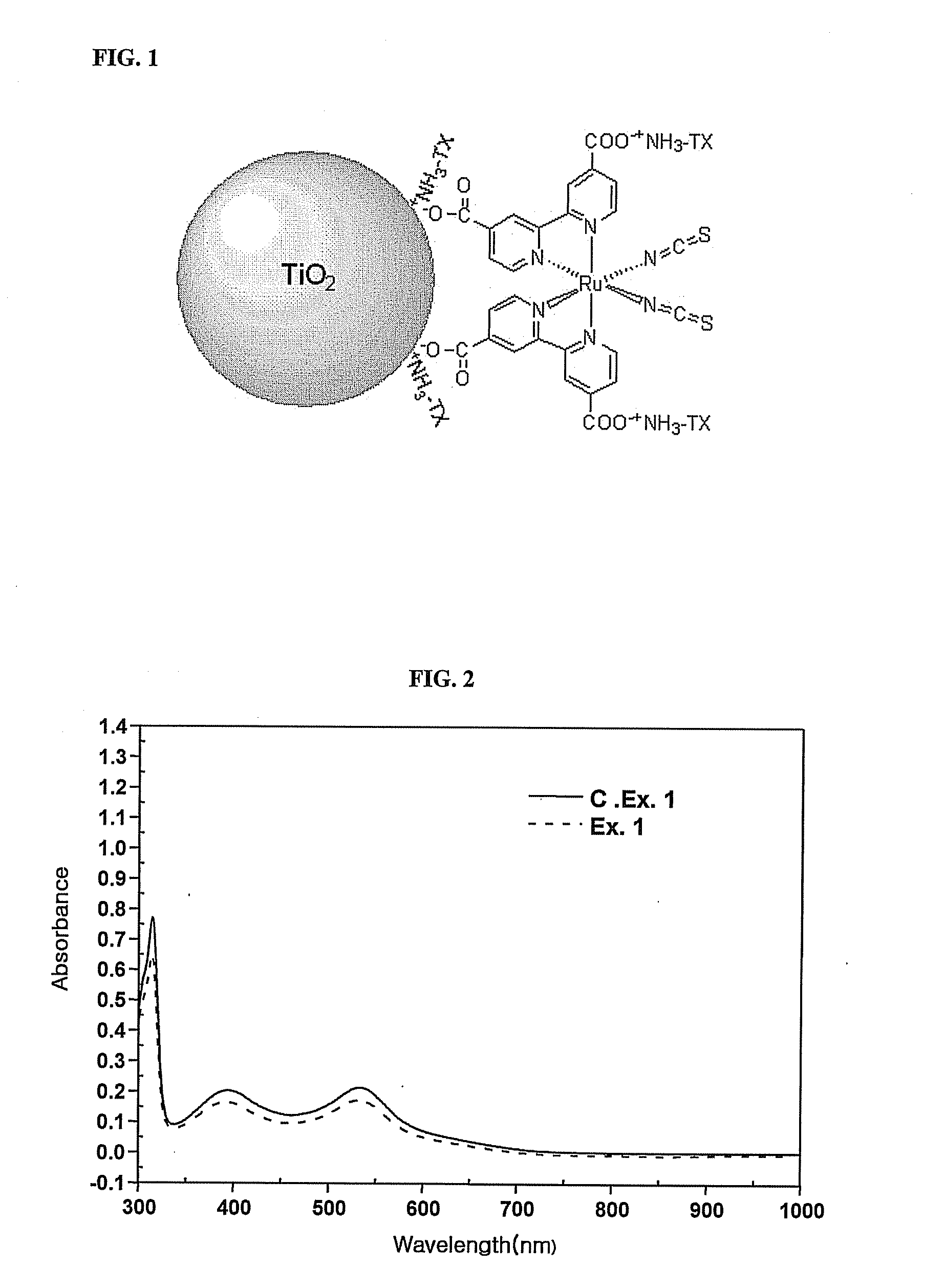

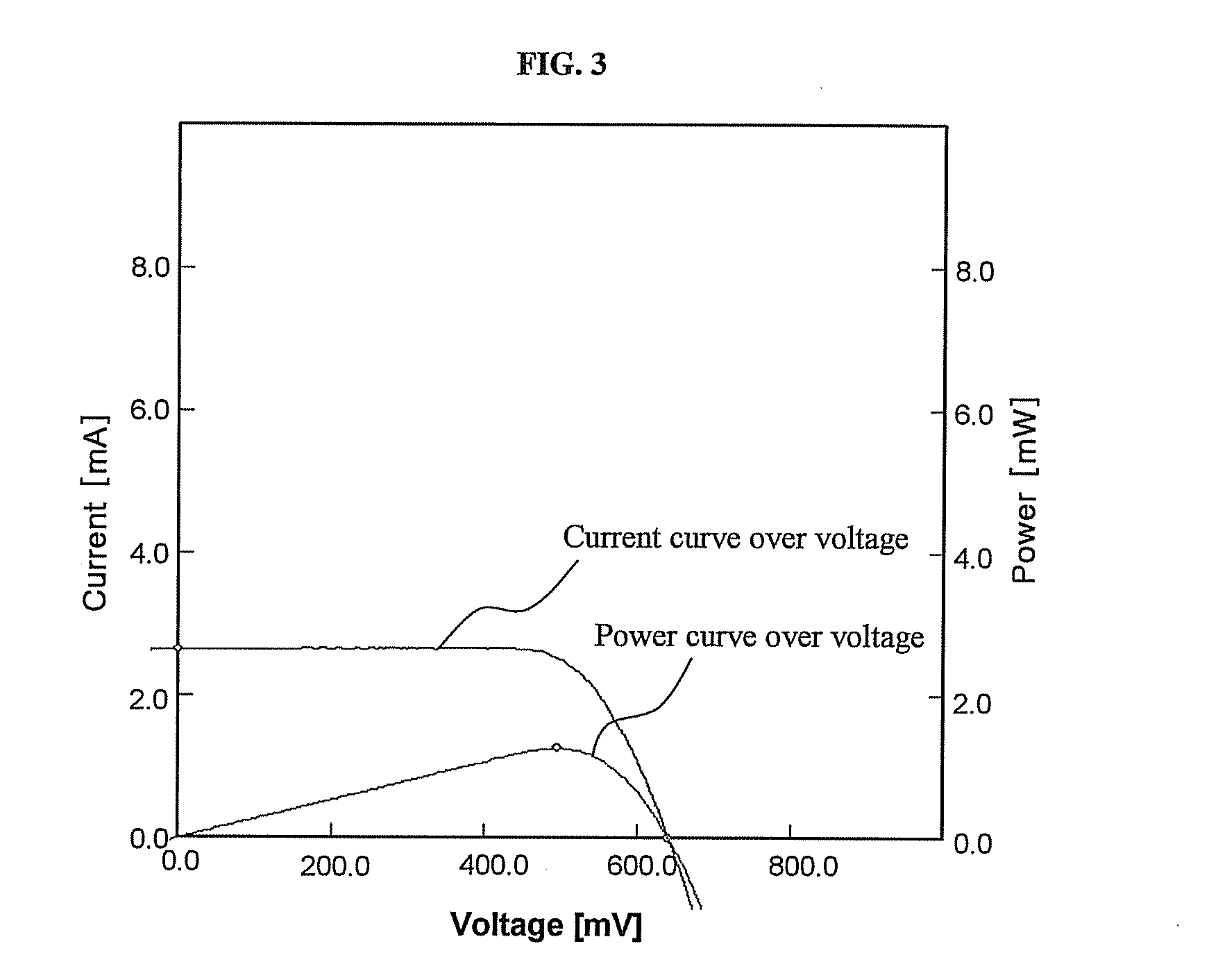

Dye having dispersant function and solar cell comprising the same

InactiveUS20070277871A1Good dispersibilityImprove uniformityRuthenium organic compoundsElectrolytic capacitorsConduction bandSolar cell

Disclosed are a novel dye, having a dispersant functional group to simultaneously exhibit a dye function and a dispersant function, and a dye-sensitized solar cell including the same. According to this invention, the dye may simultaneously manifest a dye function for absorbing light, made possible by being adsorbed on the entire surface of metal oxide particles, to thus produce excited electrons which are then transferred into a conduction band of metal oxide, and a dispersant function for preventing the agglomeration of the particles to thus improve the uniformity of the metal oxide particles in a paste and film density.

Owner:SAMSUNG SDI CO LTD

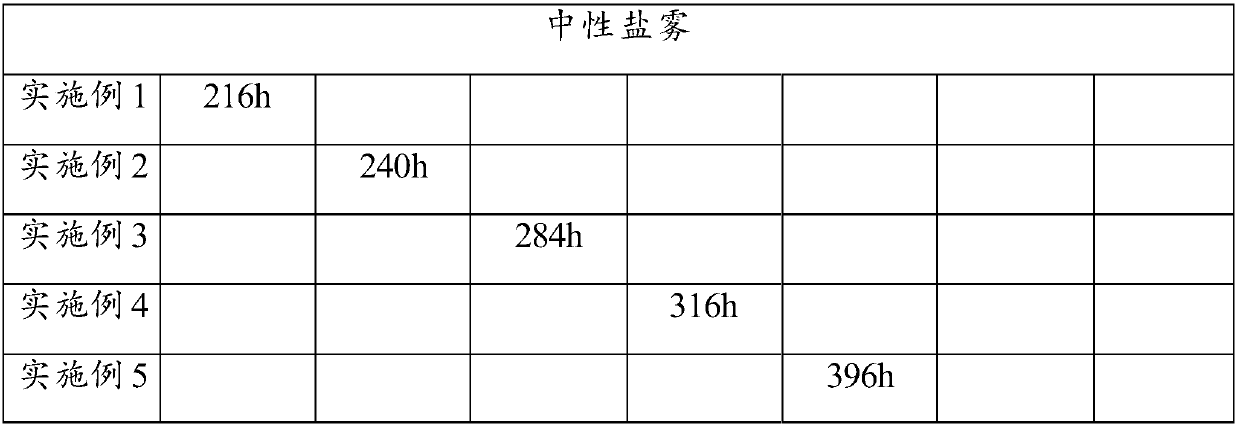

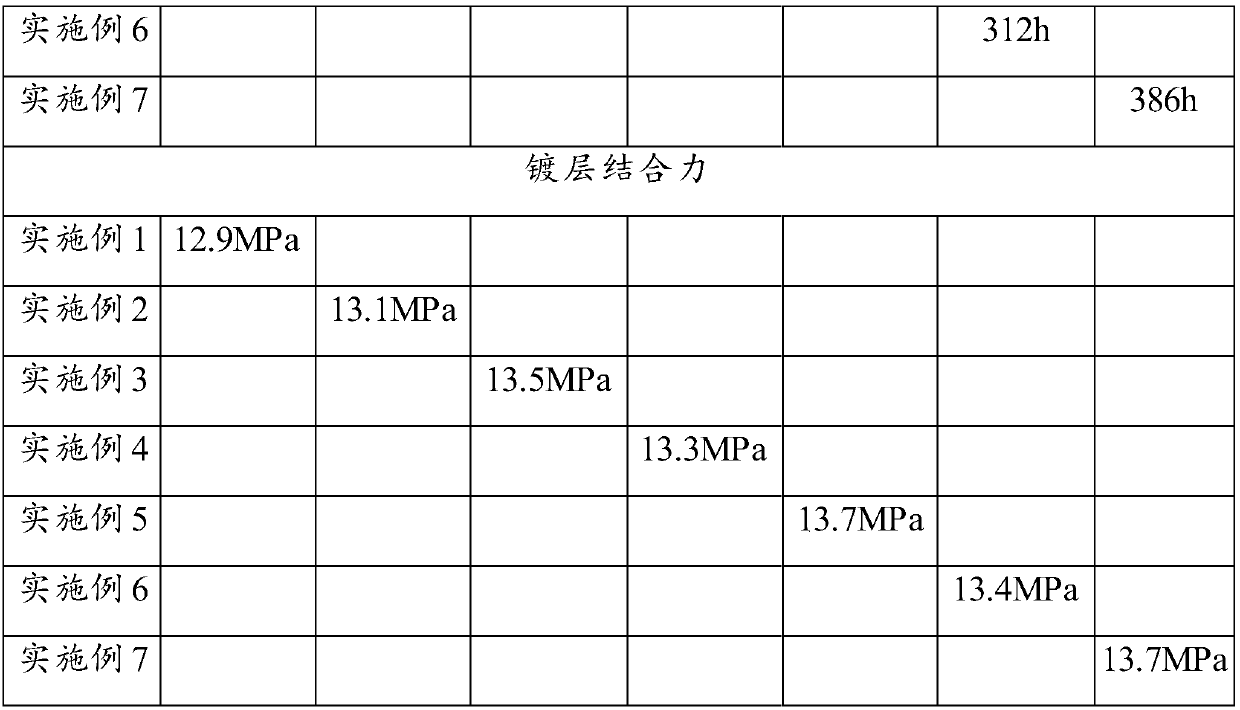

Neodymium iron boron magnet and neodymium iron boron magnet surface plating method

ActiveCN107937879AImprove corrosion resistanceGuaranteed compactnessVacuum evaporation coatingSputtering coatingSputteringMetallurgy

The invention provides a neodymium iron boron magnet with the surface plated with an anti-corrosion layer. The neodymium iron boron magnet comprises a neodymium iron boron magnet body, a multi-arc ionclad layer compounded on the surface of the neodymium iron boron magnet body, and a magnetron sputtering clad layer compounded on the surface of the multi-arc ion clad layer. The invention further provides a method for neodymium iron boron magnet surface plating. Multi-arc ion plating is only adopted in the magnet surface firstly, bottoming flattening is conducted on the magnet surface, the manner of secondary plating through magnetron sputtering is adopted, the multi-arc plating efficiency is high, good film combining and magnetron sputtering film density are effectively combined, the density of the clad layer is improved, the anti-corrosion performance of the film is improved, and the neodymium iron boron magnet with the surface plated with the anti-corrosion layer is obtained. The provided method for neodymium iron boron magnet surface plating, the technology is simple, and the method is suitable for large-scale industry production.

Owner:金力永磁(宁波)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com