Preparation method of double-sided lamno3 buffer layer for superconducting tape

A superconducting tape and buffer layer technology, applied in the usage of superconducting elements, superconducting devices, cable/conductor manufacturing, etc., can solve the problem of high surface flatness, achieve high surface flatness, increase deposition rate, and stability sex improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below.

[0029] A kind of double-sided LaMnO for superconducting tape 3 Preparation method of the buffer layer. Specific steps are as follows:

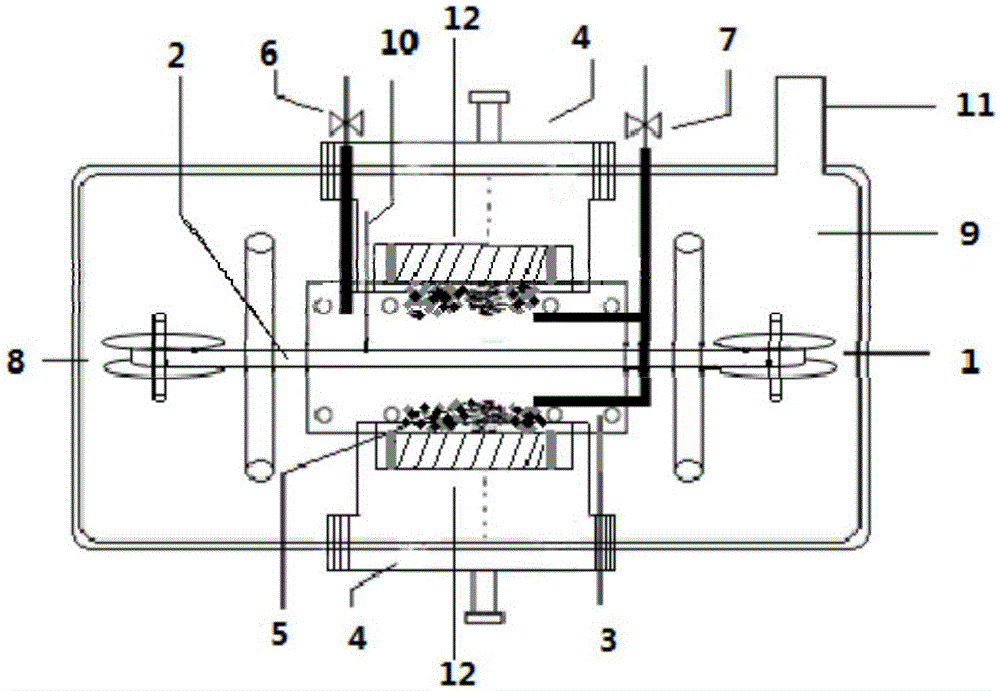

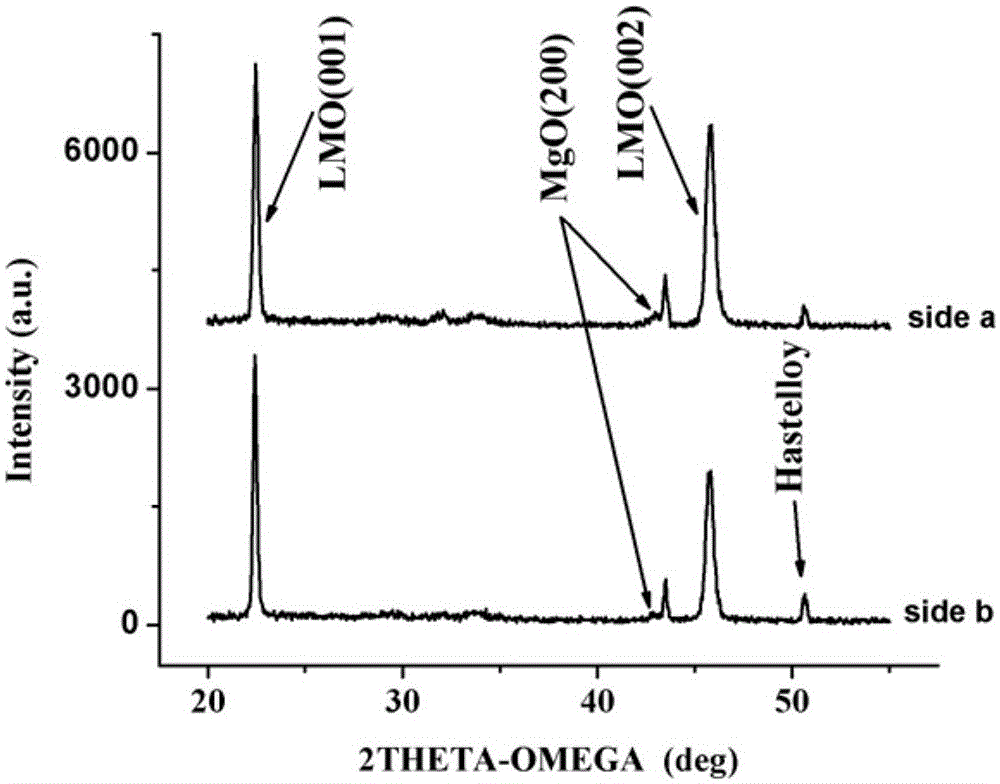

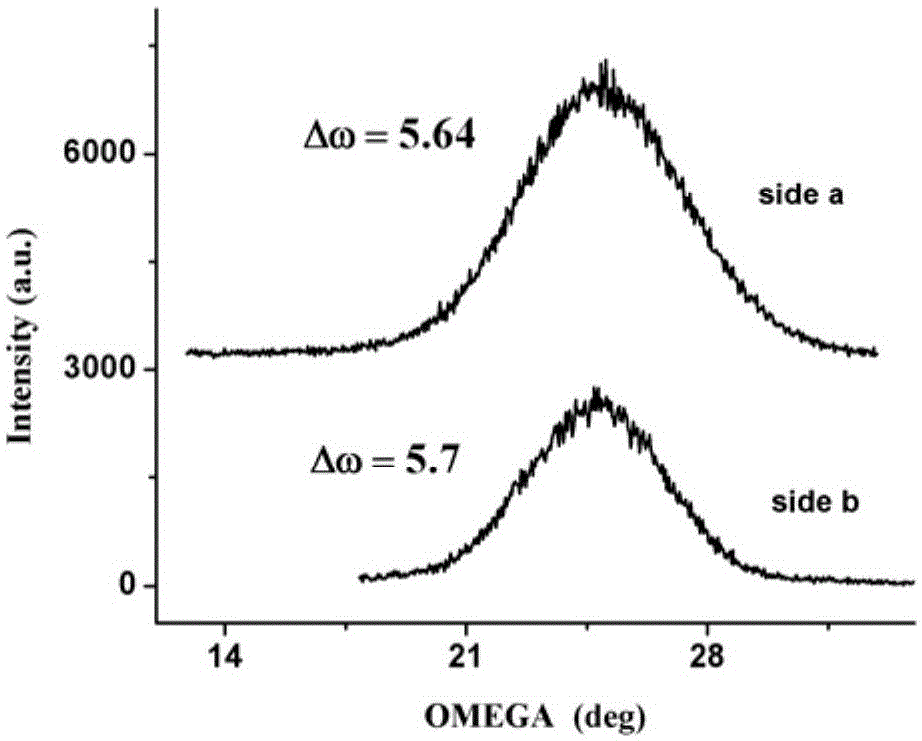

[0030] Step 1: A Hastelloy substrate with a length of 1 m, a width of 10 mm, and a thickness of 0.8 μm coated with yttrium oxide / IBAD-magnesia / homoepitaxial magnesium oxide prepared by double-sided solution planarization was installed on the Between the first turntable 1 and the second turntable 8, the first turntable 1 is driven to move at a constant speed by a stepping motor with a speed controller.

[0031] The second step: place the manganese-lanthanum alloy target (manganese-lanthanum atomic ratio is 1:1) (length is 400 mm, width is 40 mm, thickness is 5 mm) respectively on the target 4, using heating resistance wire 3 pairs of base bands Heating is carried out, and the relative temperature is measured with a thermocouple 10 . The first turntable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com