Patents

Literature

134results about How to "Increased preparation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of soft and durable anti-penetrating material

ActiveCN107815870AIncreased durabilityGood flexibilityUltrasonic/sonic fibre treatmentGrip property fibresFiberEngineering

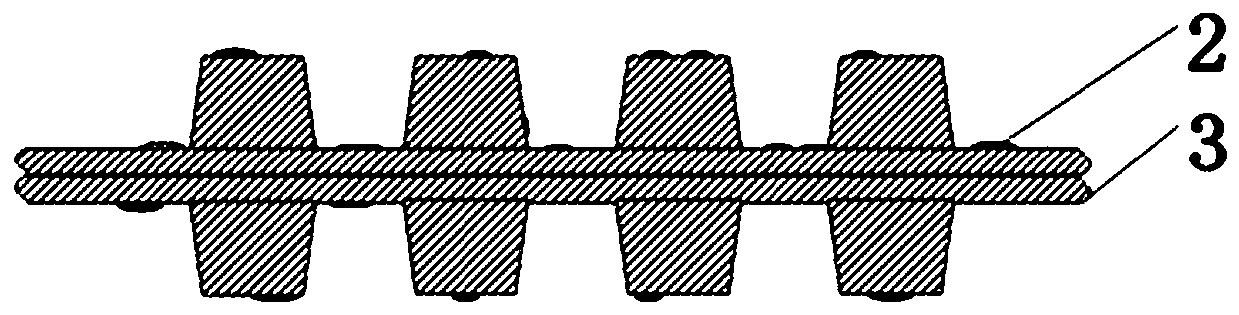

The invention discloses a preparation method of a soft and durable anti-penetrating material. The preparation method is characterized by comprising the following steps: (1) preparing shearing thickening liquid; (2) preparing a high performance fiber fabric with a special tissue structure, namely preparing a fabric from high performance fibers by virtue of a special tissue structure weaving process, putting the fabric into a vacuum drying oven, and drying at 120-150 DEG C for 2-3 hours; and (3) preparing the anti-penetrating material. According to the method, by virtue of reasonable tissue structure configuration on the fabric and plasma treatment on the shearing thickening liquid and the fabric, the shearing thickening liquid and the fabric are adequately compounded, so that the durabilityand flexibility of the anti-penetrating material are improved, and the soft and durable anti-penetrating material suitable for multiple environments of daily protective clothes of military police, armored military equipment, civil and industrial protection and the like is prepared.

Owner:江苏威之盾安防科技有限公司

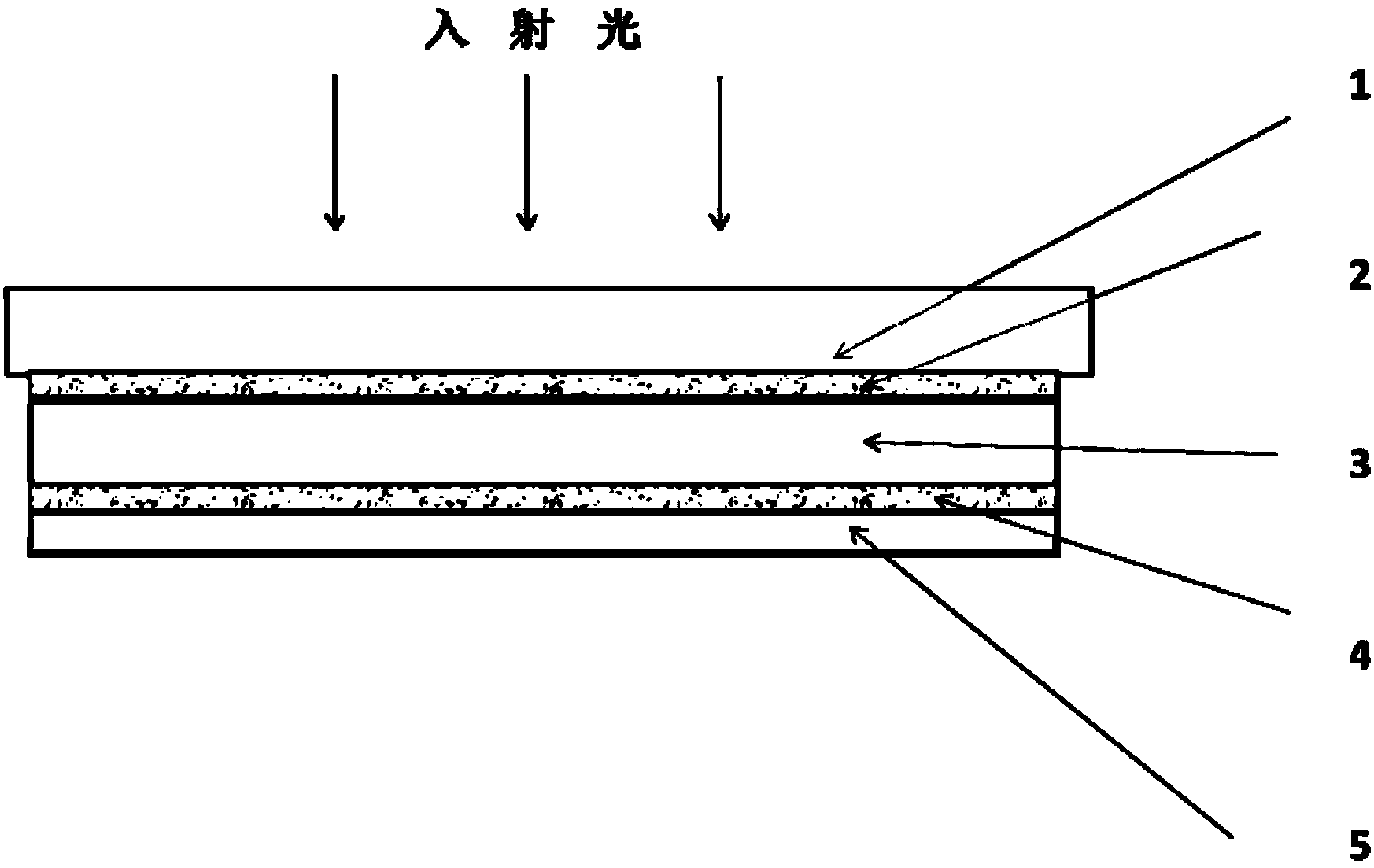

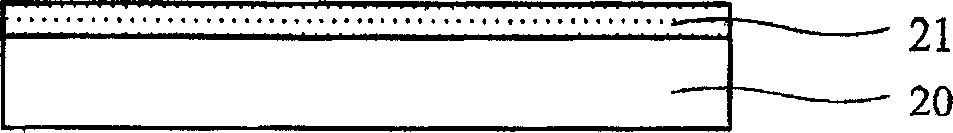

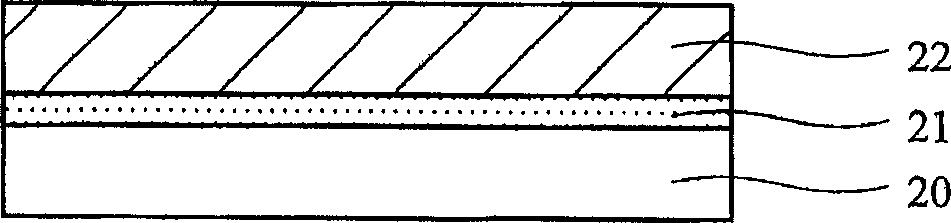

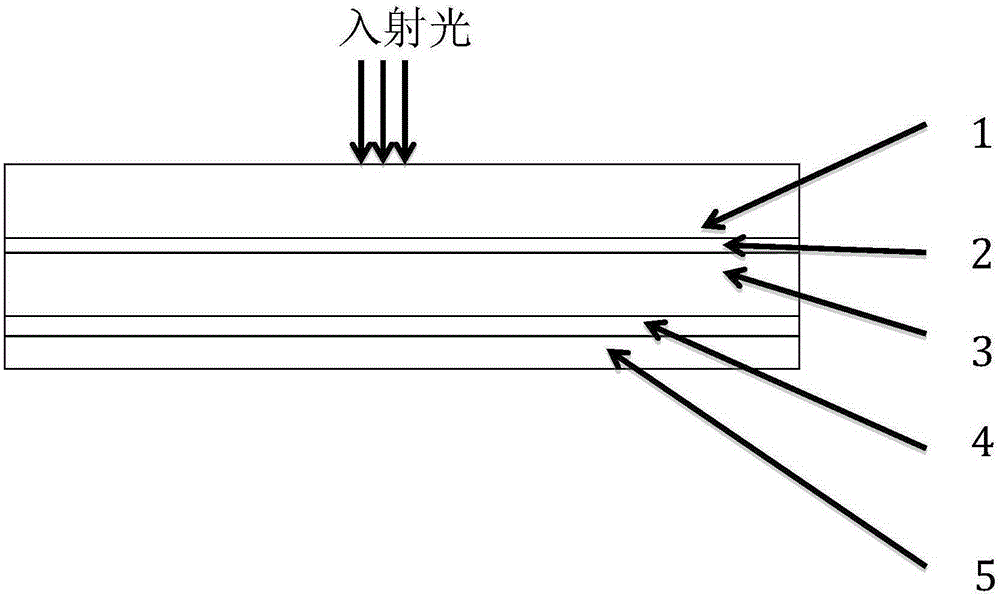

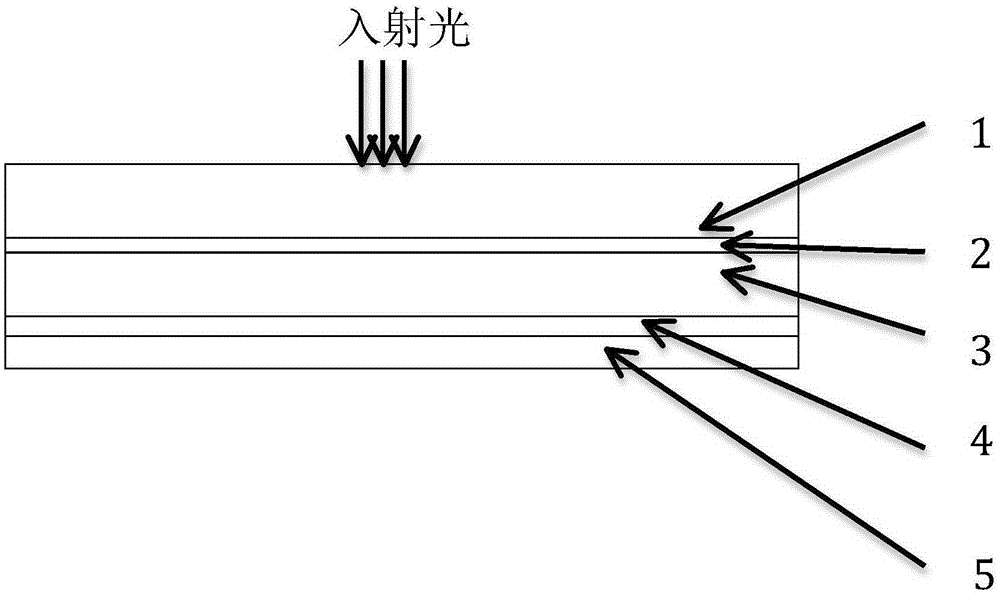

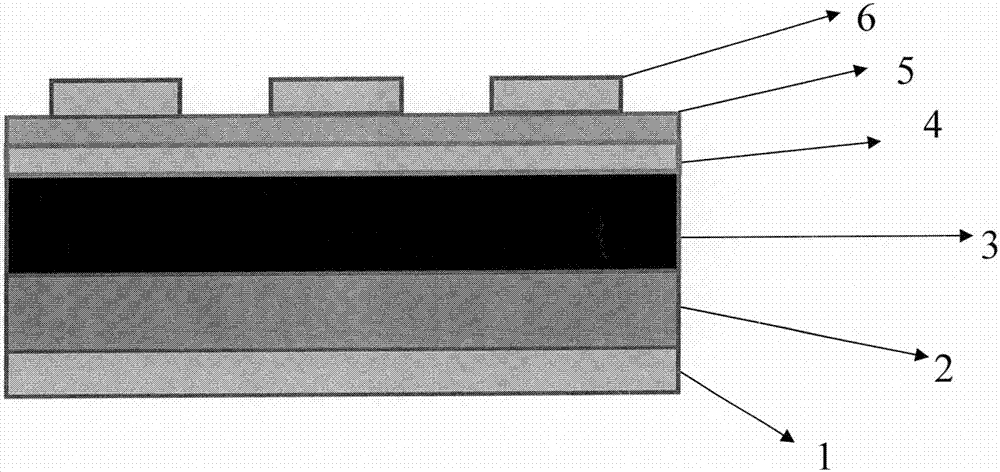

All solid state perovskite microcrystalline silicon composite solar battery and preparation method thereof

ActiveCN104362253AHighlight substantive featuresOvercome stabilitySolid-state devicesSemiconductor/solid-state device manufacturingComposite filmLight energy

The invention discloses an all solid state perovskite microcrystalline silicon composite solar battery and a preparation method thereof, and relates to a semiconductor device specially suitable for converting light energy into electric energy. The all solid state perovskite microcrystalline silicon composite solar battery is composed of a transparent conducting substrate, an oxide semiconductor film layer, a perovskite light absorption layer, a microcrystalline silicon hole transport layer and a back electrode. The preparation method of the all solid state perovskite microcrystalline silicon composite solar battery includes: preparing the perovskite light absorption layer on the transparent conducting substrate coated with an oxide semiconductor film; depositing the microcrystalline silicon hole transport layer on the perovskite light absorption layer so as to form an all solid state perovskite microcrystalline silicon composite film; compositing perovskite light absorption layer material and P type microcrystalline silicon material in matching mode. The all solid state perovskite microcrystalline silicon composite solar battery prepared from the above preparation method simultaneously overcomes the defects that an existing perovskite solar battery is poor in stability and expensive in cost due to the fact that organic hole transport material is used on the existing perovskite solar battery, and the defects that preparation costs are high and photoelectric conversion efficiency is low, caused by low preparation speed of a microcrystalline silicon thin film solar battery.

Owner:HEBEI UNIV OF TECH

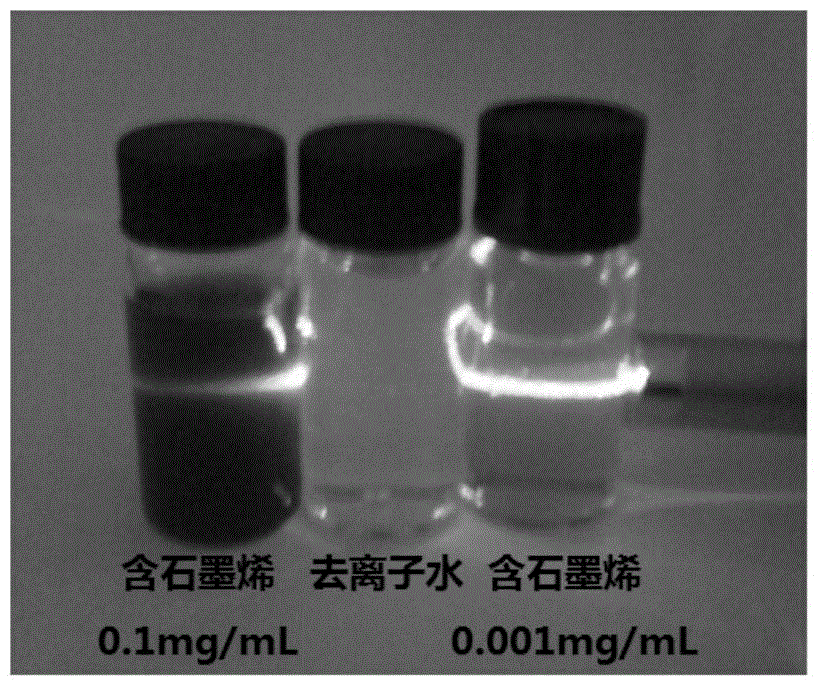

Graphene, graphene colloidal sol, graphene powder and preparation method and preparation device

The invention provides graphene, graphene hydrosol, and graphene powder obtained by drying the graphene hydrosol, wherein the edge of the graphene comprises active groups, and the active groups comprise amino groups. The preparation method of the graphene hydrosol comprises the following steps: (1), performing electrochemical intercalation and exfoliation on graphene to obtain graphene dispersed in electrolyte; the electrolyte after electrochemical intercalation and exfoliation contains both inorganic salt and amino acid; after intercalation, removing free inorganic salt and amino acid compounds from the solution to obtain the graphene hydrosol. According to the graphene, graphene colloidal sol, graphene powder and the preparation method and the preparation device, provided by the invention, the graphene hydrosol is provided, the use of a great deal of an organic solvent in the graphene hydrosol based on the organic solvent is reduced, the stability is good, the preparation method is simple, the operation is easy, the equipment and material requirements are low, the environmental friendliness is achieved, and the industrialization is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

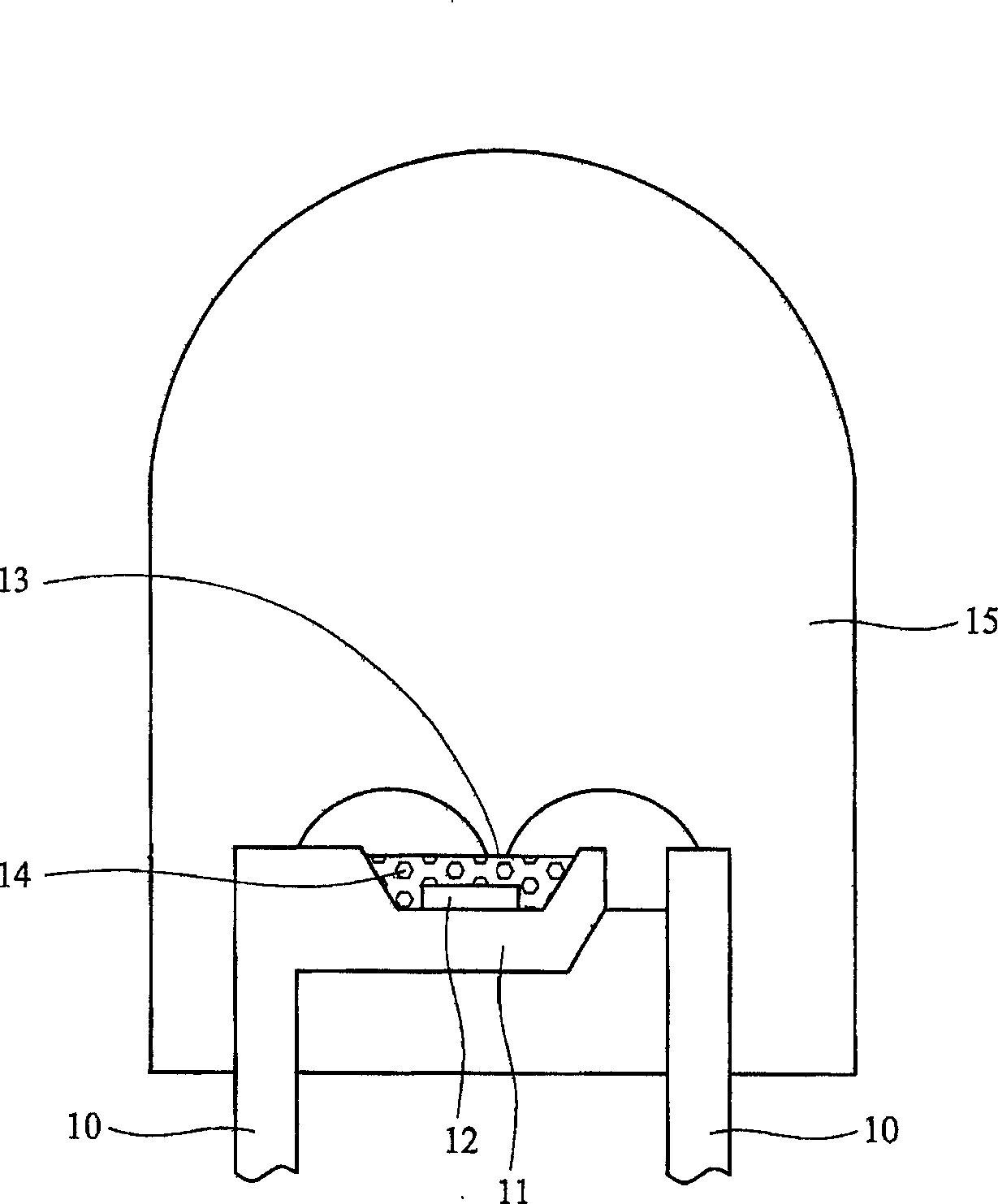

Light-emitting device and making method thereof, making system, packaging device and light emitting source, backlight module and display device

ActiveCN1691359AImprove luminous efficiencyIncreased preparation rateSemiconductor devicesFluorescenceDisplay device

The invention relates to a luminous apparatus and its making method, manufacturing system, sealing device, luminous source, aphototropism module and display device; the said luminous comprises luminous semiconductor device and fluorescence powder layer placed on the optical paths of the luminous semiconductor device, and some parts of the fluorescence powder layer are coagulum without binding agent. The making method comprises: providing miscible liquids with base materials; removing liquids after stewing for a while to reduce the distance of the fluorescence powder to form the coagulum and be on the base materials without binding agent. Also provides a manufacturing system for luminous apparatus, comprising: container, imbedding device, liquids providing device, agitating device and liquids removing device.

Owner:东莞市乐顺光电科技有限公司

Thin film crystalline silicon perovskite heterojunction solar battery and preparation method thereof

ActiveCN105226187AOvercome the disadvantage of low light absorption coefficientReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionHole transport layer

The invention relates to a thin film crystalline silicon perovskite heterojunction solar battery and a preparation method thereof, and relates to a semiconductor device for converting luminous energy into electric energy. The thin film crystalline silicon perovskite heterojunction solar battery includes a transparent conductive substrate, a P-type thin film crystalline silicon hole transport layer, a perovskite light absorption layer, an electron transport layer formed by compact titanium dioxide, and a back electrode, wherein the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer have matched energy levels. The configuration pattern: the P-type thin film crystalline silicon hole transport layer is arranged on the transparent conductive substrate; the perovskite light absorption layer is arranged on the P-type thin film crystalline silicon hole transport layer; the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer form a thin film crystalline silicon perovskite heterojunction; the electron transport layer formed by the compact titanium dioxide is arranged on the perovskite light absorption layer; the back electrode is arranged on the electron transport layer formed by the compact titanium dioxide. According to the invention, the defects that the existing perovskite solar battery is low in stability and high in preparation cost, and a mass of silicon materials are used can be overcame.

Owner:HEBEI UNIV OF TECH

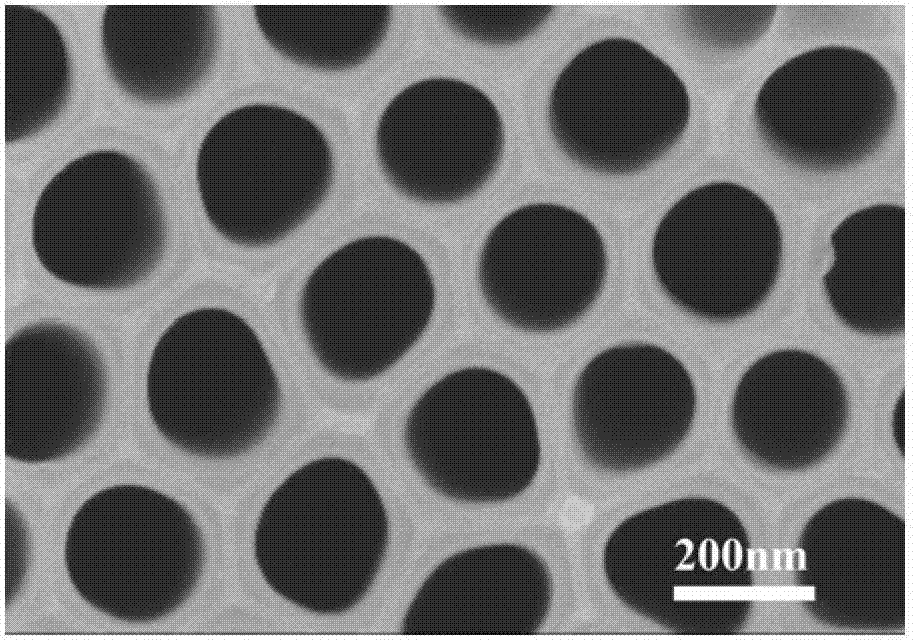

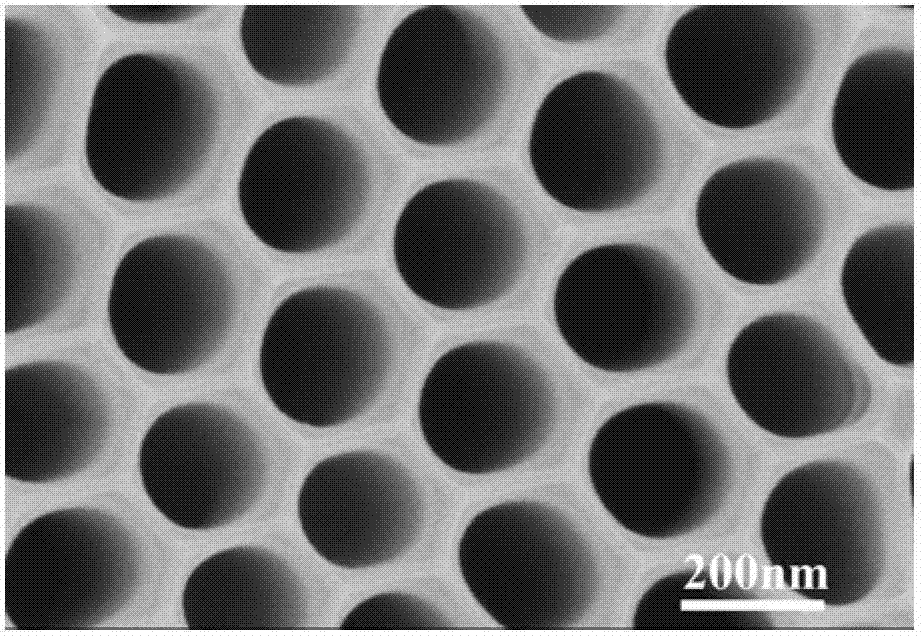

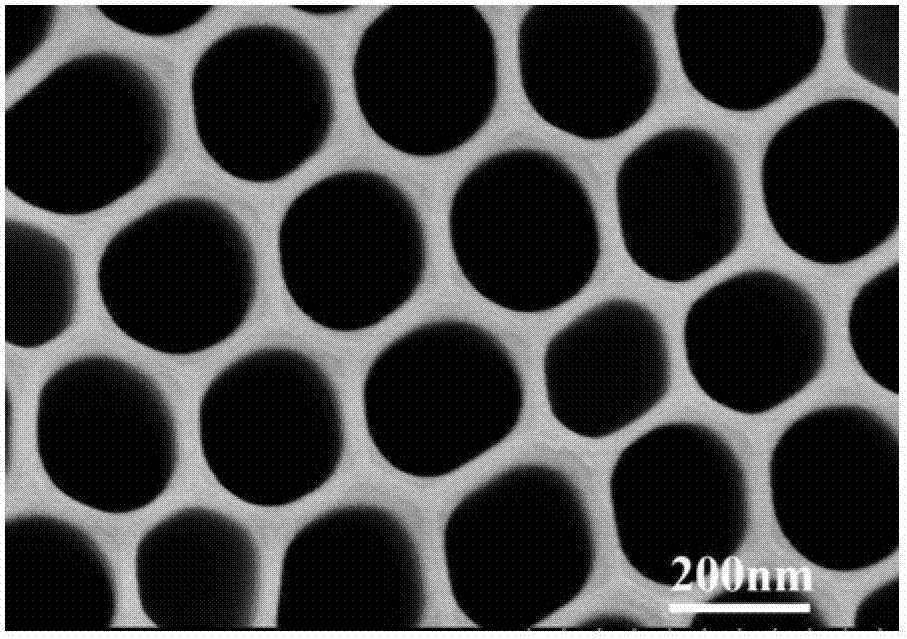

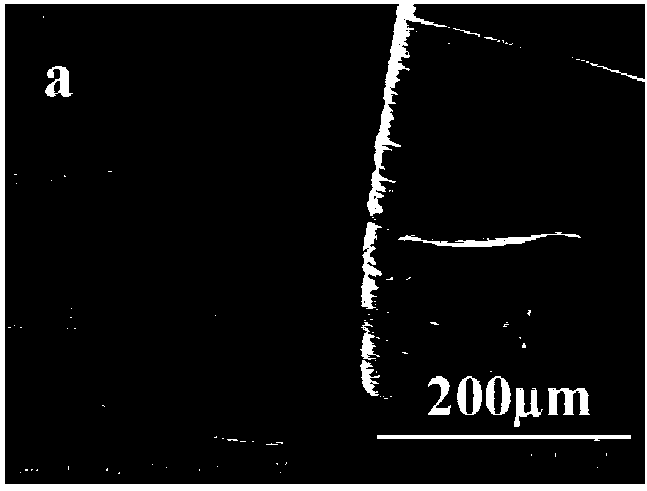

Method for preparing ordered macroporous anodic alumina film by two-step anodic oxidation

InactiveCN103243370AAperture continuously adjustableArranged in orderSurface reaction electrolytic coatingIce waterPhosphoric acid

The invention relates to a method for preparing an ordered macroporous anodic alumina film by two-step anodic oxidation. The method comprises the following steps of: carrying out hard anodizing on aluminum which is subjected to high temperature annealing, ultrasound deoiling and electrochemical polishing treatments in modified oxalic acid electrolyte, so as to obtain a porous anodic alumina film; removing an irregular porous alumina layer which is formed after first anodic oxidation by using a mixed solution of chromic acid and phosphoric acid; then carrying out second anodic oxidation, namely carrying out mild anodic oxidation on the aluminum sheet with the alumina film removed in the modified phosphate electrolyte in a constant voltage manner, wherein the voltage in the second anodic oxidation is completely the same as the voltage in the first anodic oxidation; and finally chambering the test sample subjected to anodic oxidation in a phosphoric acid solution to obtain the ordered macroporous anodic alumina film. The preparation method is carried out under an ice-water bath condition without the requirement on a very low temperature or a high voltage; the cost of used raw materials is low; and equipment is simple and is convenient to operate and easy to control, and therefore the method has a bright application prospect in the modern industry and high and new technology field.

Owner:DONGHUA UNIV

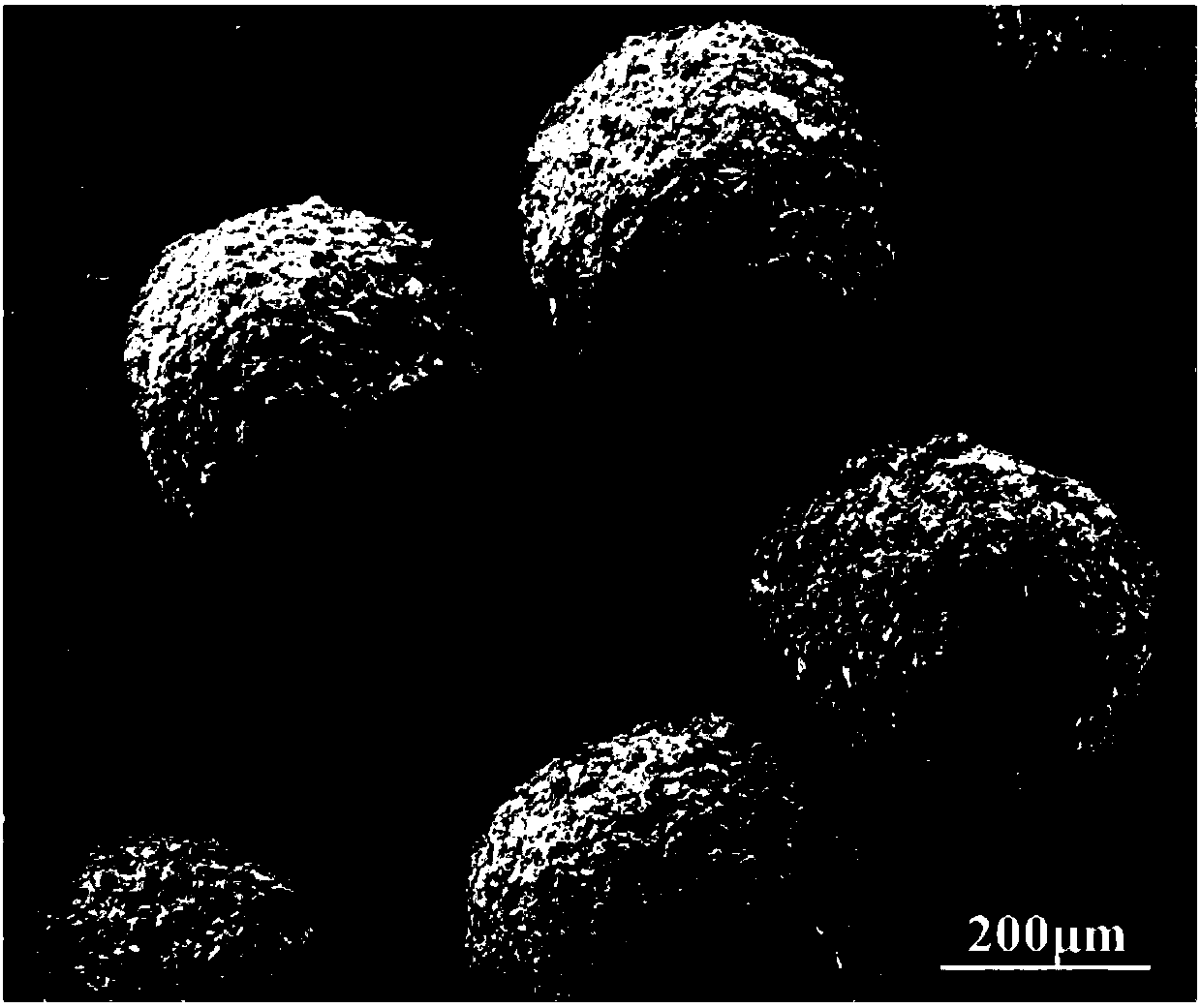

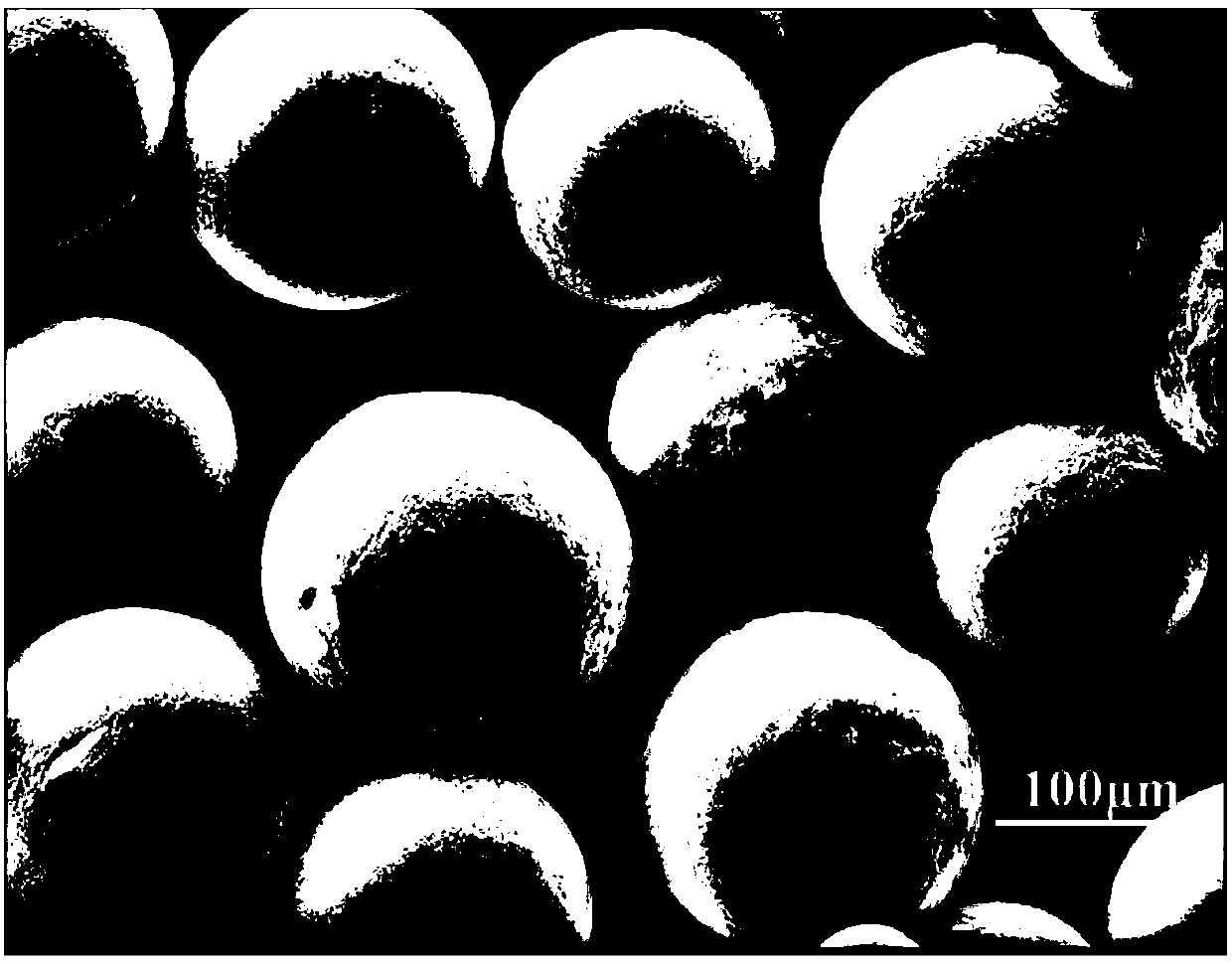

Preparation method of spherical powder of refractory material

The invention discloses a preparation method of spherical powder of a refractory material. The method includes the steps that firstly, raw material powder of the refractory material and an adhering agent are mixed uniformly, then pelleting is performed, and prefabricated granules are obtained; secondly, the prefabricated granules are subjected to vacuum sintering or hydrogen atmosphere protectingsintering, and a prefabricated granule blank body is obtained; and thirdly, the prefabricated granule blank body is contained into a quantitative powder feeding device of a plasma device, and is fed into a high temperature area of a plasma generating device through a conveying pipeline under the gas effect to be molten and shrink so as to generate a compact sphere, then the compact sphere falls into a collecting tank, and the spherical powder of the refractory material is obtained. According to the preparation method of the spherical powder of the refractory material, the raw material powder of the refractory material is sintered after being subjected to pelleting, then plasma is adopted, the raw material powder of the refractory material is made to be molten rapidly, the spherical powderis generated through fast shrinking and nodulizing, the sphericity degree of the powder is improved, and generation of satellite powder and hollow powder is avoided, and finally the compact and uniform spherical powder, smooth and clean in surface and high in sphericity degree, of the refractory material is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

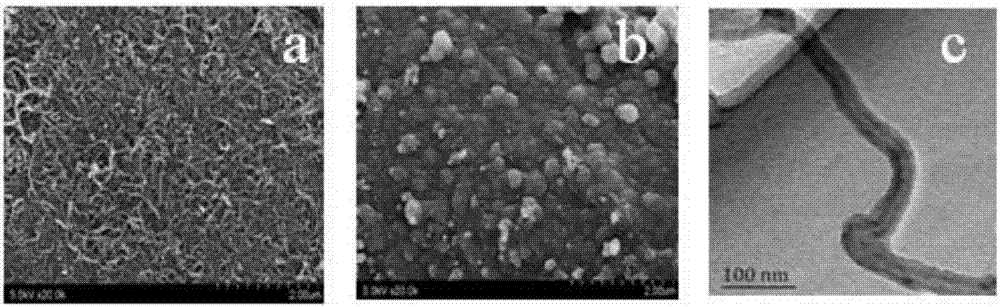

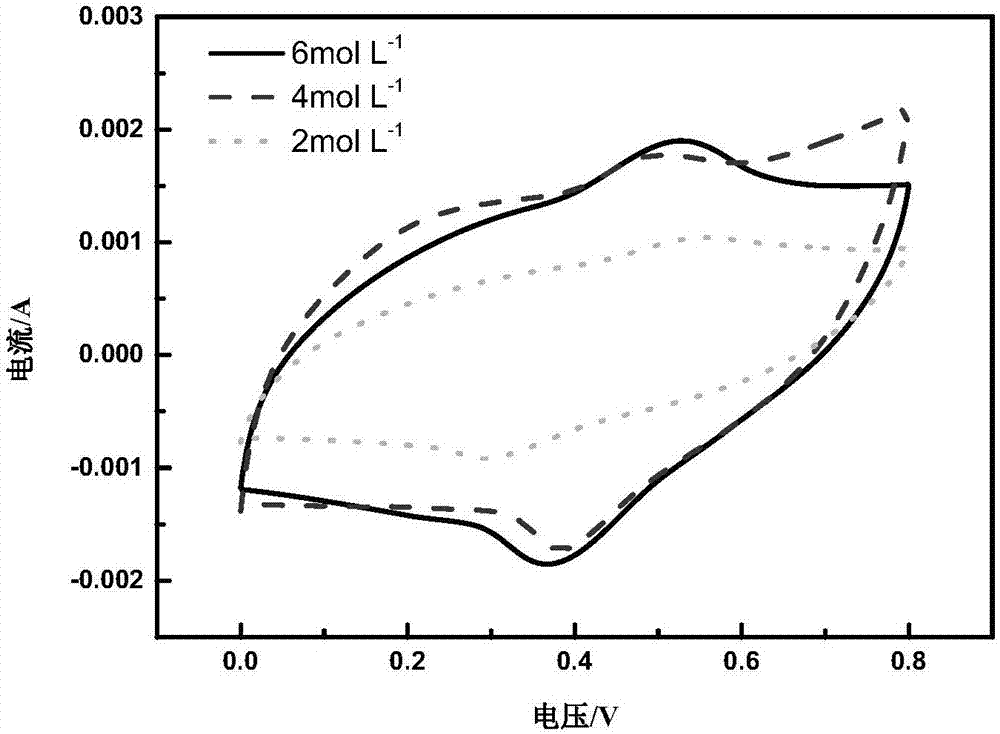

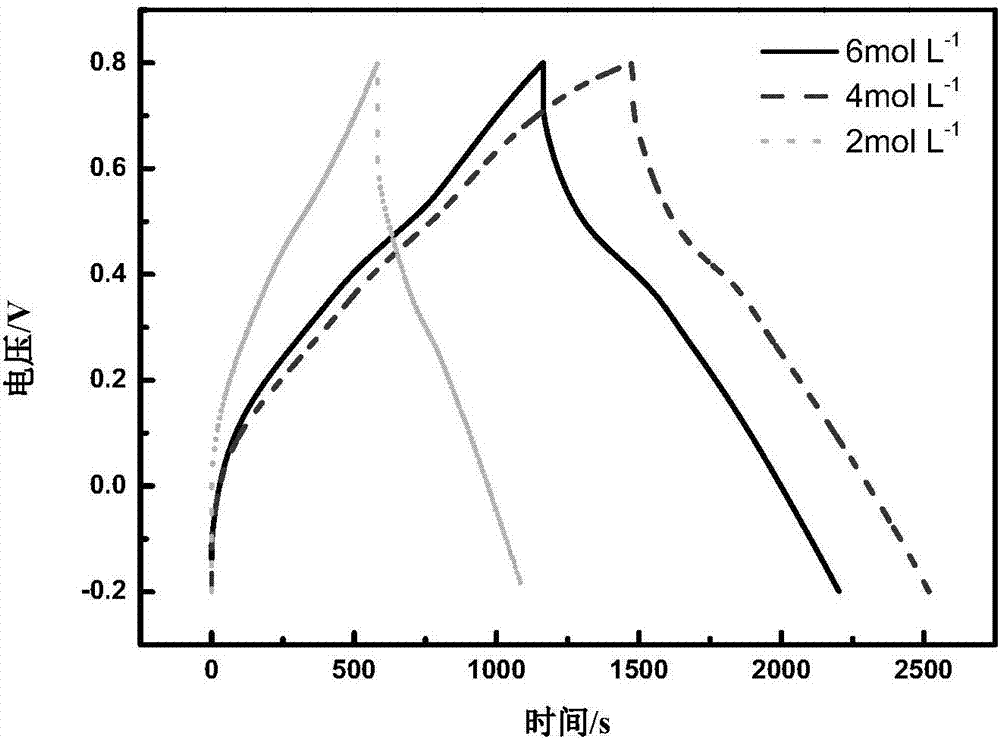

Polyaniline/carbon nanotube/cotton fabric composite flexible electrode with high specific capacitance, and preparation and application thereof

InactiveCN106971865AImprove efficiencyImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceChemical plating

The invention relates to a polyaniline / carbon nanotube / cotton fabric composite flexible electrode with high specific capacitance, and preparation and application thereof. The preparation comprises the steps: enabling a carbon nanotube to be carried by cotton fabric, carrying out the chemical plating of polyaniline, and obtaining a polyaniline / carbon nanotube / cotton fabric compound; adding a carboxylation carbon nanotube to deionized water, adding sodium dodecyl benzene sulfonate, carrying out the stirring, supersonic and dispersing operation, and obtaining carbon nanotube dispersion liquid; enabling the cotton fabric to be immersed in the carbon nanotube dispersion liquid for processing, then taking out the cotton fabric for drying, washing and airing under the room temperature, obtaining a carbon nanotube / cotton fabric compound, enabling the carbon nanotube / cotton fabric compound to be immersed in mixed liquid of hydrochloric acid and phenylamine for 0.5-1.5 hour, adding ammonium persulfate solution, carrying out the polymerization reaction, washing and airing under the room temperature, and obtaining the electrode. The electrode prepared through the above method is light in weight and is flexible, and the method is high in efficiency. All materials used in an experiment are commercial products, thereby greatly improving the preparation feasibility and industrialization. The method is very good in prospect.

Owner:DONGHUA UNIV

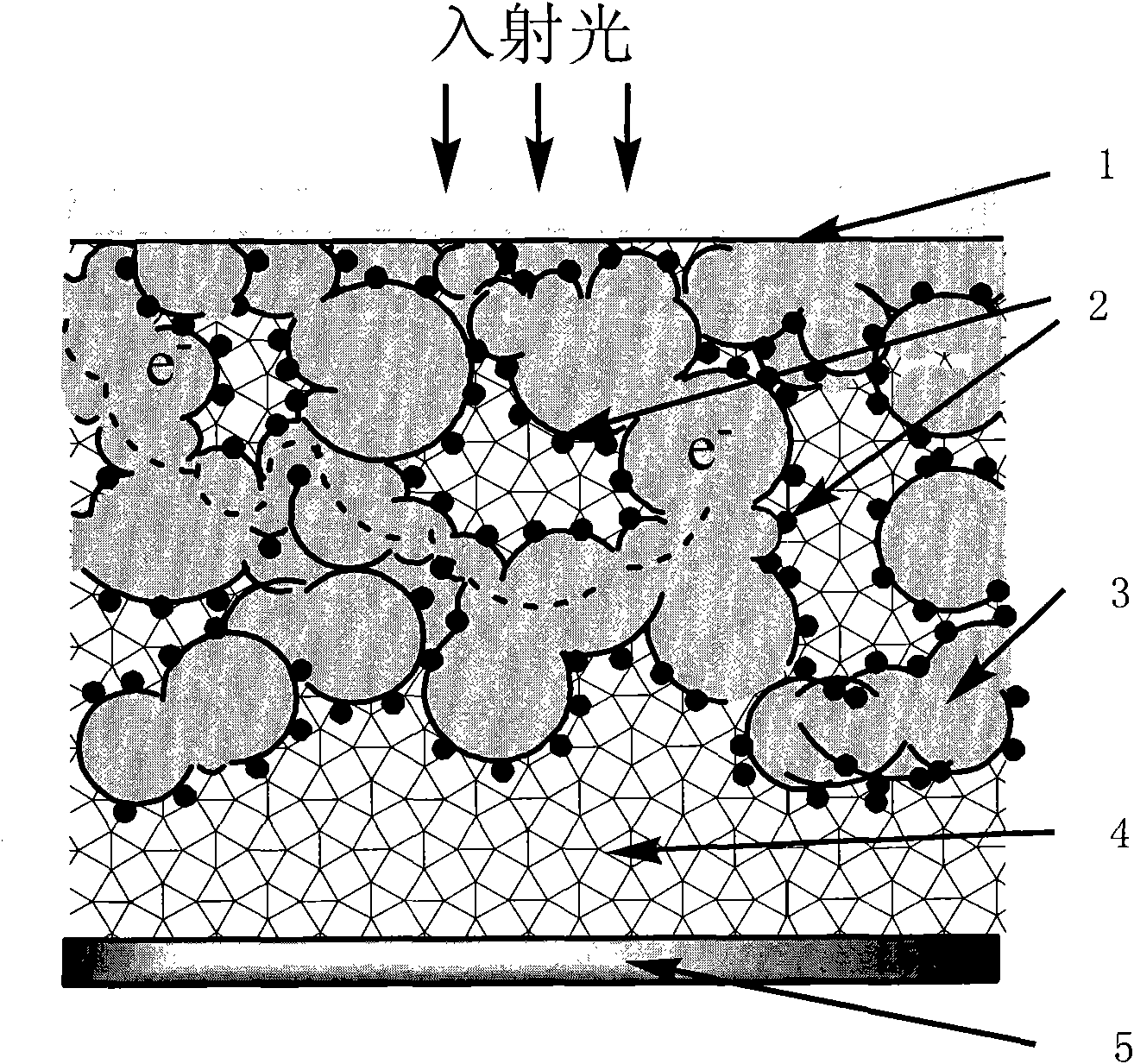

Solid dye-sensitized nanocrystal/microcrystal silicon composite film solar cell and preparation method thereof

InactiveCN101872685AHighlight substantive featuresOvercome the disadvantage of high preparation costLight-sensitive devicesFinal product manufactureComposite filmLight energy

The invention discloses a solid dye-sensitized nanocrystal / microcrystal silicon composite film solar cell and a preparation method thereof, and relates to a special semiconductor device for converting light energy into electric energy. The solid dye-sensitized nanocrystal / microcrystal silicon composite film solar cell is composed of a transparent conducting substrate, a dye-sensitized nanocrystal porous film, a porous membrane, a microcrystal silicon hole transport layer and a back electrode, wherein the dye-sensitized nanocrystal porous film is coated on the transparent conducting substrate; the microcrystal silicon hole transport layer is settled on the dye-sensitized nanocrystal porous film to form the solid dye-sensitized nanocrystal / microcrystal silicon porous film; and an aluminum or copper film is plated on the solid dye-sensitized nanocrystal / microcrystal silicon porous film to form the back electrode. In the invention, the dye-sensitized nanocrystal and the microcrystal silicon composite film are matched and compounded to prepare the solid dye-sensitized nanocrystal / microcrystal silicon composite film solar cell. The invention overcomes the defect of poor liquid stability in the traditional dye-sensitized solar cell and the defects of low preparation rate and high preparation cost in the prior microcrystal silicon film solar cell.

Owner:HEBEI UNIV OF TECH

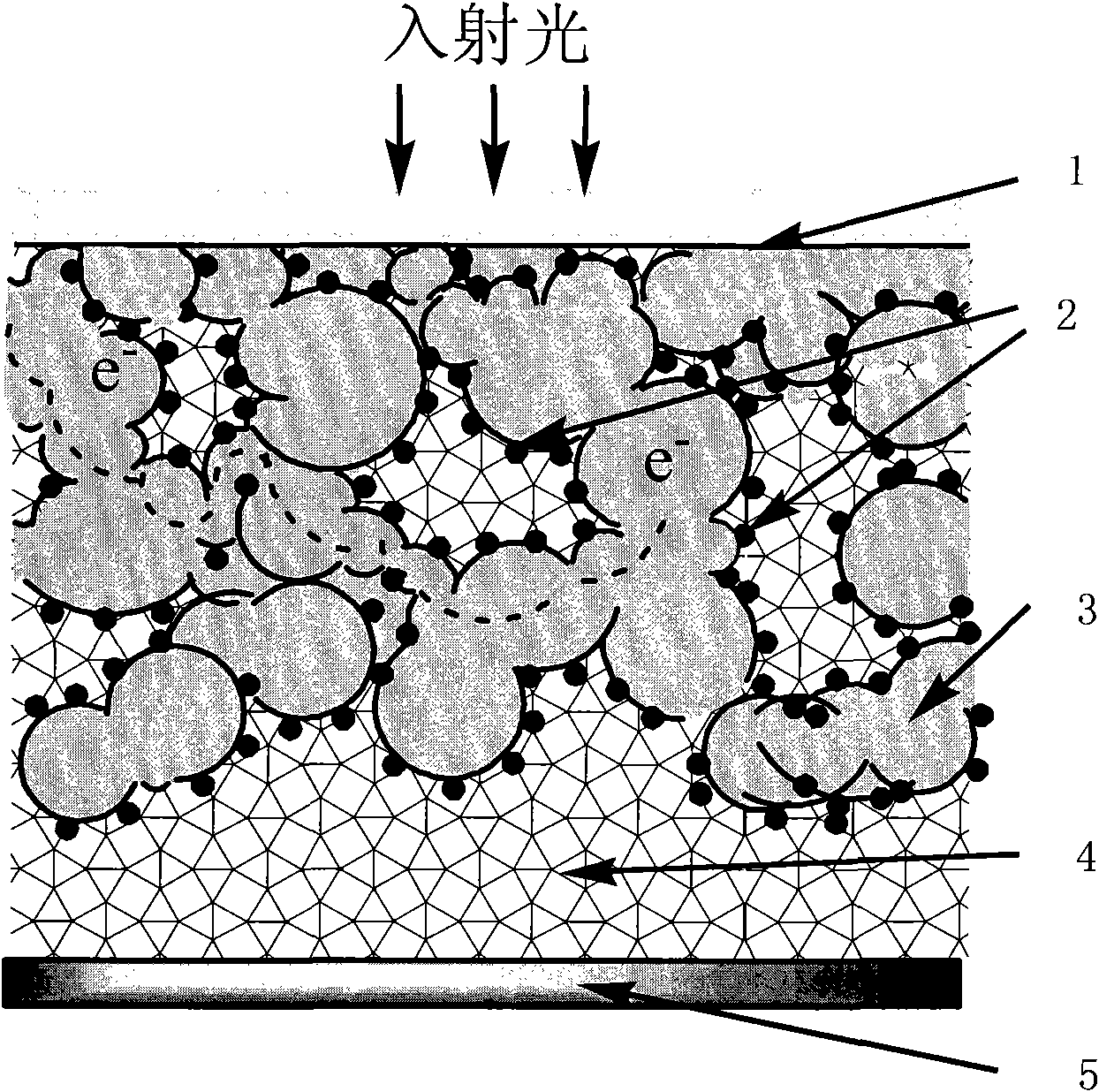

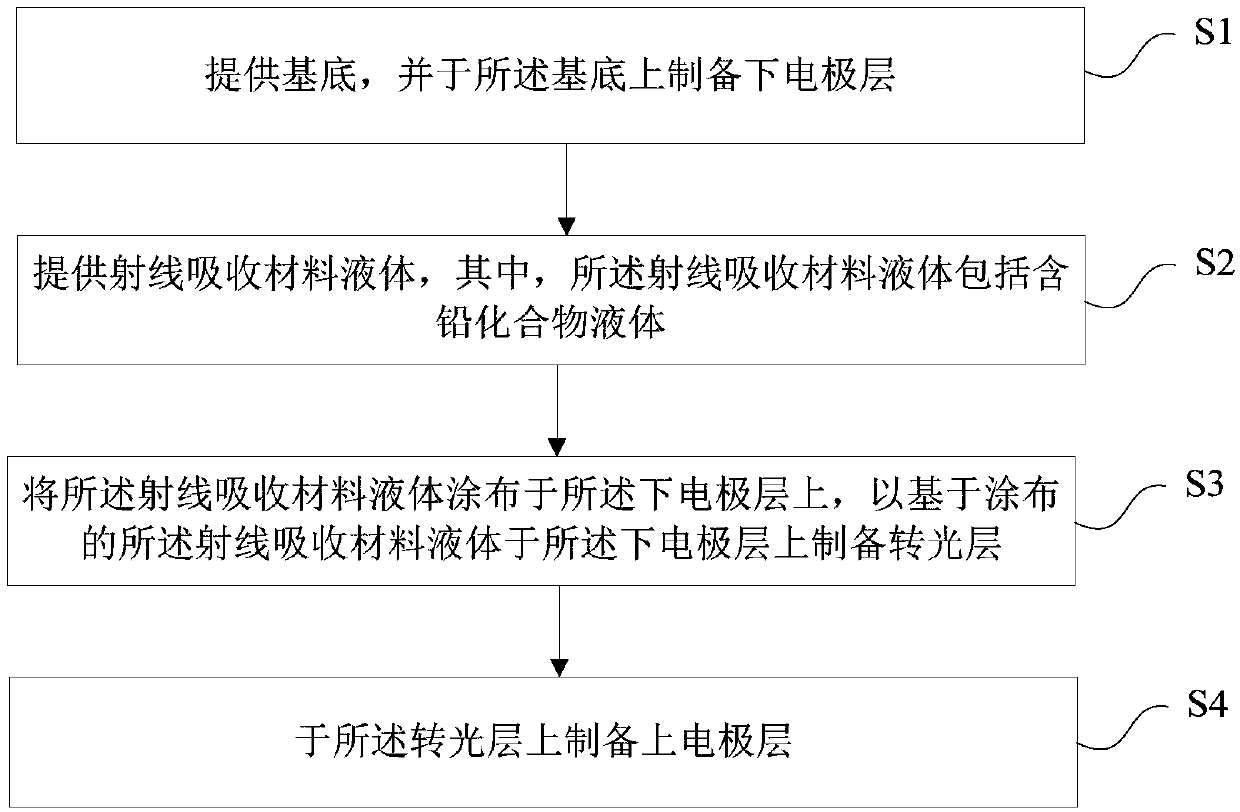

A flat panel detector structure and a preparing method thereof

ActiveCN109585477AImprove noiseHigh sensitivityMaterial analysis using wave/particle radiationSolid-state devicesFlat panel detectorChemical composition

The invention provides a flat panel detector structure and a preparing method thereof. The preparing method comprises the steps of providing a substrate and preparing a lower electrode layer on the substrate; providing a radiation absorbing material liquid, wherein the radiation absorbing material liquid comprises a lead-containing compound liquid; and coating the radiation absorbing material liquid on a lower electrode layer to prepare a light-converting layer on the lower electrode layer based on the coated radiation absorbing material liquid; and preparing an upper electrode layer on the light-converting layer. The structure and method of the invention improve the materials of the existing light-converting layer, improve the radiation absorption capability of the light-converting layer,reduce the thickness of the light-converting layer, design the forming method of the light-converting layer and solve the problem in forming a polycrystalline structure. Furthermore, the chemical composition and phase uniformity of the device are improved; the uniformity of the image is raised; the effective utilization of raw materials is raised; the process equipment is simplified; the structure of the detector is designed; the problem of leakage current is mitigated; the noise of detector is reduced; the sensitivity and the contrast ratio are raised; the electrode materials of the detectorare improved; and the cost is reduced.

Owner:IRAY IMAGE TECH TAICANG CO LTD

Method for preparing porous ceramic/metal bicontinuous phase composite material composed of adjustable matrix phase and reinforcing phase

The invention discloses a method for preparing a porous ceramic / metal bicontinuous phase composite material composed of an adjustable matrix phase and a reinforcing phase. The method comprises the following steps: by using one or more of metal powder and alloy powder as matrix powder, adding non-metal powder 1 promoting alloy generation or serving as an alloy component or perfecting a porous ceramic material and metal wettability, adding non-metal powder 2, and uniformly mixing to serve as filling powder; by using porous ceramic as the reinforcing phase, putting the porous ceramic in a container, pouring the filling powder in the porous ceramic, continuously rotating and vibrating or carrying out low pressure pressing to fully fill the powder in the porous ceramic pores, and pouring a proper amount of filling powder on the porous ceramic with fully filled filling powder; then, maintaining the temperature for a period under a protective atmosphere, and naturally cooling to the room temperature to obtain the porous ceramic / metal bicontinuous phase composite material composed of the adjustable matrix phase and the reinforcing phase.

Owner:SHANGHAI INST OF TECH

Thin film crystal silicon perovskite heterojunction solar cell manufacturing method

InactiveCN105244442AHighlight substantive featuresLow costFinal product manufactureSolid-state devicesHeterojunctionSolar cell

The invention discloses a thin film crystal silicon perovskite heterojunction solar cell manufacturing method, which relates to a semiconductor device manufacturing method particularly suitable for converting optical energy into electric energy, and is a manufacturing method based on an excimer laser crystallization method. The method of the invention comprises steps: the excimer laser crystallization method is used for manufacturing a P-type thin film crystal silicon layer on a transparent conductive substrate, spin coating of a perovskite light absorption layer is carried out on the P-type thin film crystal silicon layer, an electron transport layer formed by dense titanium dioxide is manufactured on the perovskite light absorption layer, a back electrode is manufactured on the electron transport layer formed by the dense titanium dioxide, and finally, a thin film crystal silicon perovskite heterojunction solar cell composed of the transparent conductive substrate, the P-type thin film crystal silicon layer, the perovskite light absorption layer, the electron transport layer formed by the dense titanium dioxide and the back electrode is manufactured. Defects that the layer transfer technique used in the prior art has multiple steps and is complicated, the obtained thin film crystal silicon has a small size, the finished product rate is low, and the thickness of the thin film crystal silicon can not be over thin can be overcome.

Owner:HEBEI UNIV OF TECH

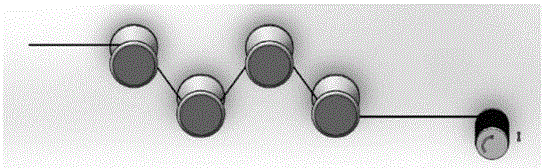

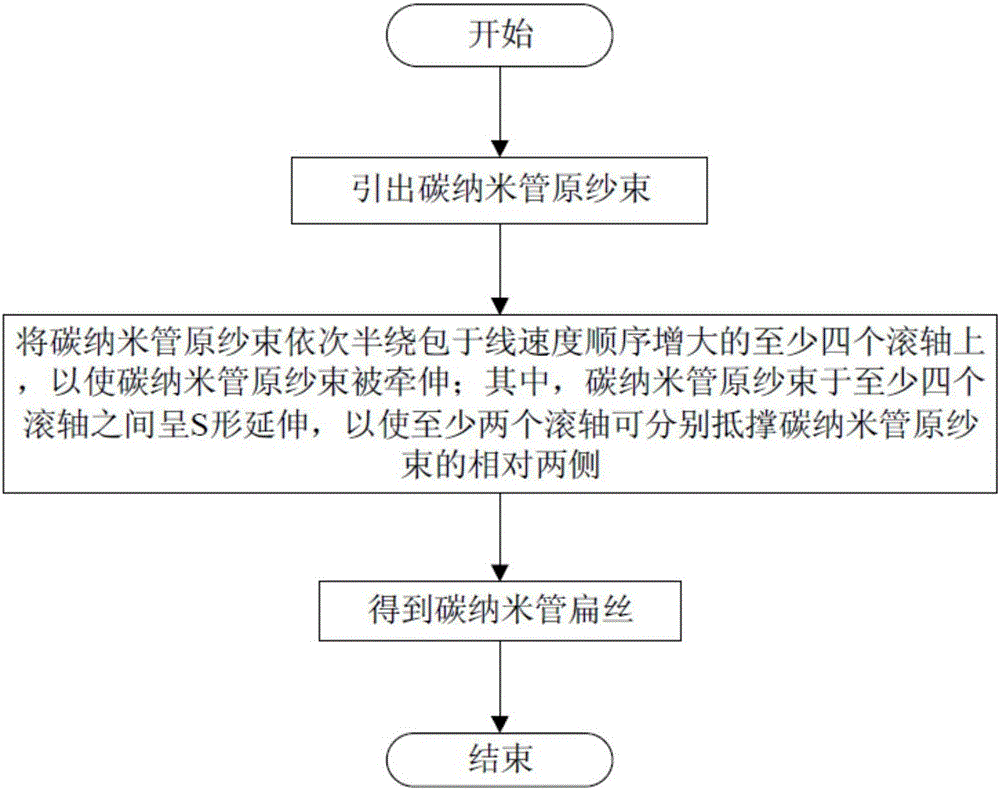

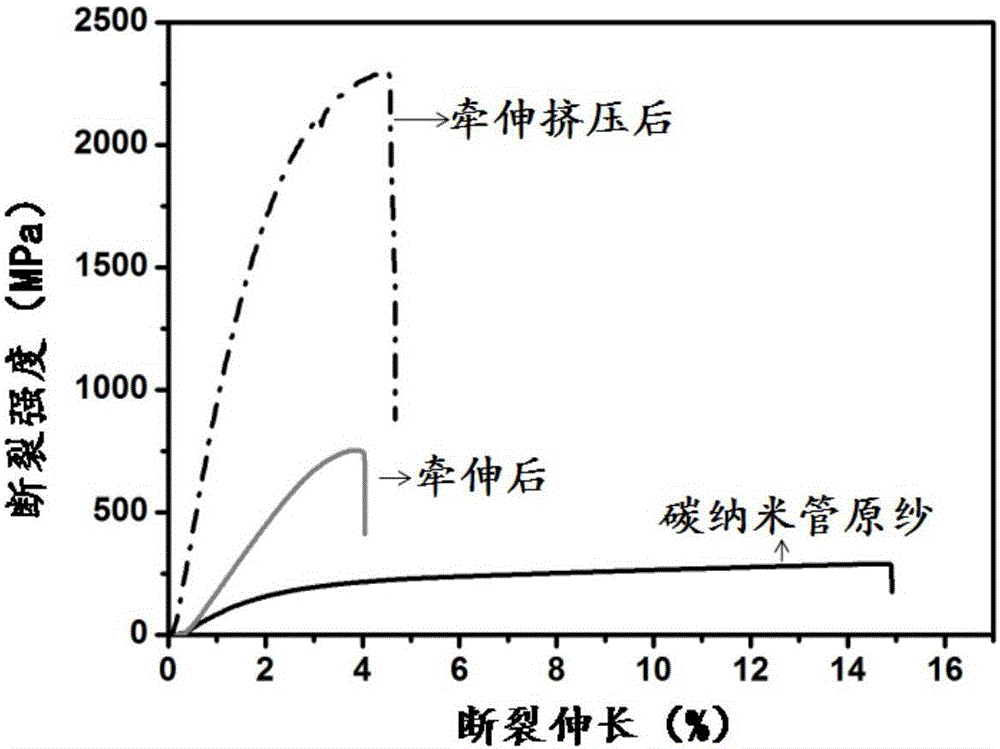

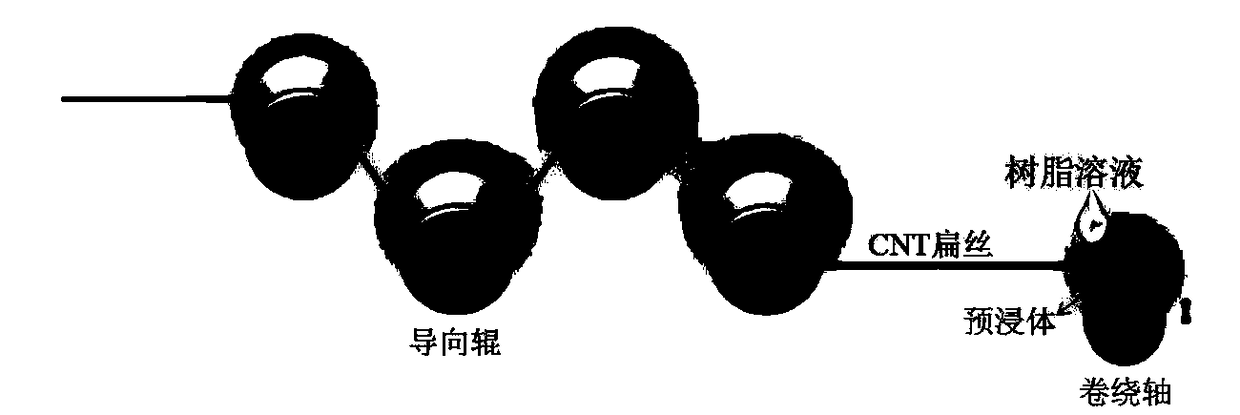

Carbon nanometer tube flat filament, preparation method and preparation device thereof

InactiveCN106381592AIncreased preparation rateHigh degree of bindingTextiles and paperYarnCarbon nanotube

The invention discloses a carbon nanometer tube flat filament, a preparation method and a preparation device thereof. The preparation method for the carbon nanometer tube flat filament comprises the following steps: drawing out a carbon nanometer tube base yarn beam; successively semi-lapping the carbon nanometer tube base yarn beam on at least four rollers at sequentially increasing linear velocity, thereby drawing the carbon nanometer tube base yarn beam; stretching the carbon nanometer tube base yarn beam in S form among at least four rollers and respectively resisting at least two rollers against the two opposite sides of the carbon nanometer tube base yarn beam, thereby obtaining the carbon nanometer tube flat filament. Compared with the prior art, the preparation method has the advantages that the preparation rate of the carbon nanometer tube flat filament is greatly increased through a gradual stretching method; the carbon nanometer tubes in the carbon nanometer tube flat filament are arrayed in an oriented way along the axial direction of the flat filament; the directional problem in a use process can be reduced; the carbon nanometer tube flat filament is flat; the combination degree between the carbon nanometer tubes in the carbon nanometer tube flat filament is higher and the density is increased; the contact area between the carbon nanometer tube flat filament and the carbon nanometer tube flat filament or the resin in the use process is increased; the interface bonding performance is increased.

Owner:SUZHOU CREATIVE CARBON NANOTECH

A waterborne coating composition used for exterior walls of buildings and a preparing method thereof

InactiveCN107353802AImprove waterproof performanceHigh tensile strengthPolyurea/polyurethane coatingsPliabilityMechanical property

The invention discloses a water-based paint composition for building exterior walls and a preparation method thereof, comprising the following raw materials in parts by weight: 30-35 parts of water-based polyurethane emulsion, 25-29 parts of polyacrylate, 26-31 parts of isocyanate, polyether 25‑30 parts, 16‑20 parts of sodium methyl silicate, 11‑14 parts of sodium carbonate, 10‑15 parts of talc powder, 11‑16 parts of mica powder, 12‑17 parts of titanium dioxide, 8‑12 parts of sodium tripolyphosphate 9-13 parts of polyoxyethylene fatty acid ester, 7-11 parts of sodium polyacrylate, 6-10 parts of tricresyl phosphate, 5-9 parts of ethylene glycol butyl ether, 4-8 parts of tetrachloroisophthalonitrile , 3-7 parts of ethylene glycol, 5-8 parts of terpineol, 30-34 parts of deionized water; including the following steps: S1: water-based polyurethane emulsion, polyacrylate, isocyanate, polyether, sodium methyl silicate and deionized water in a blender. The invention has excellent waterproof performance, high tensile strength and good flexibility, and also has excellent mechanical properties, low cost, high yield and no pollution to the environment.

Owner:天津市金三鑫水性涂料科技有限公司

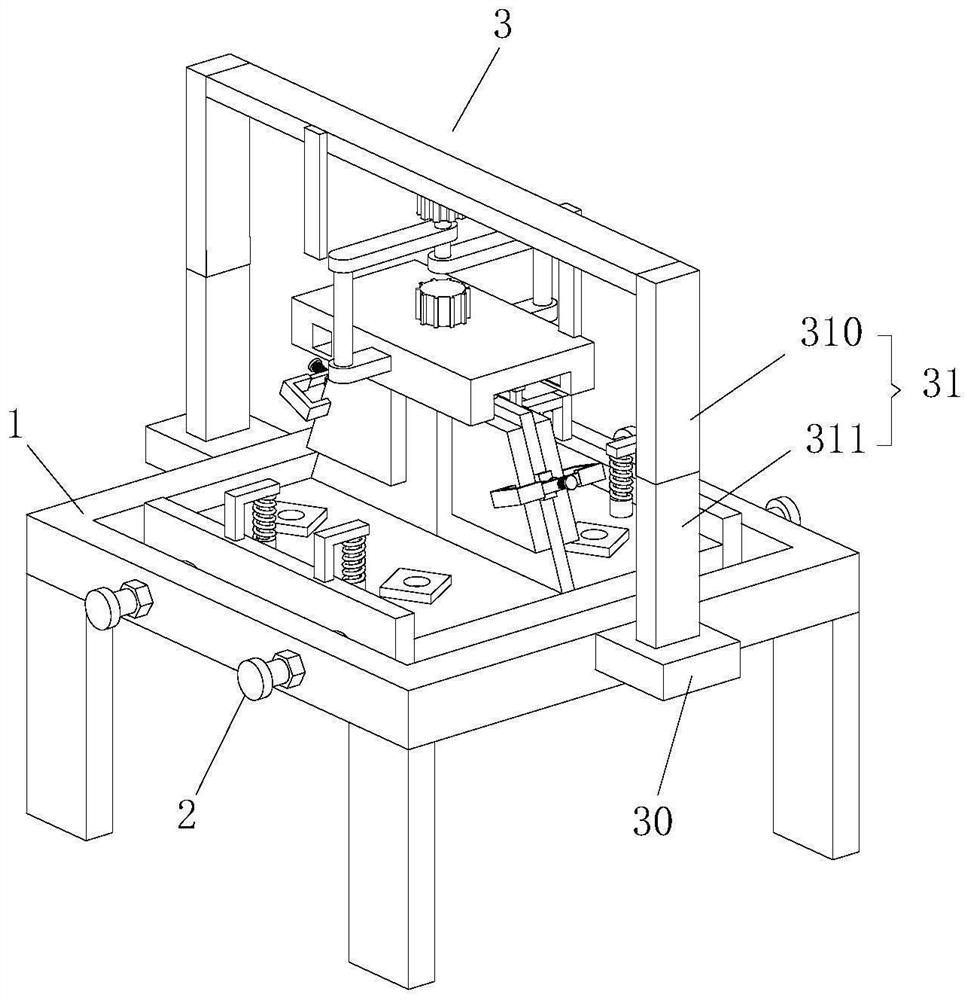

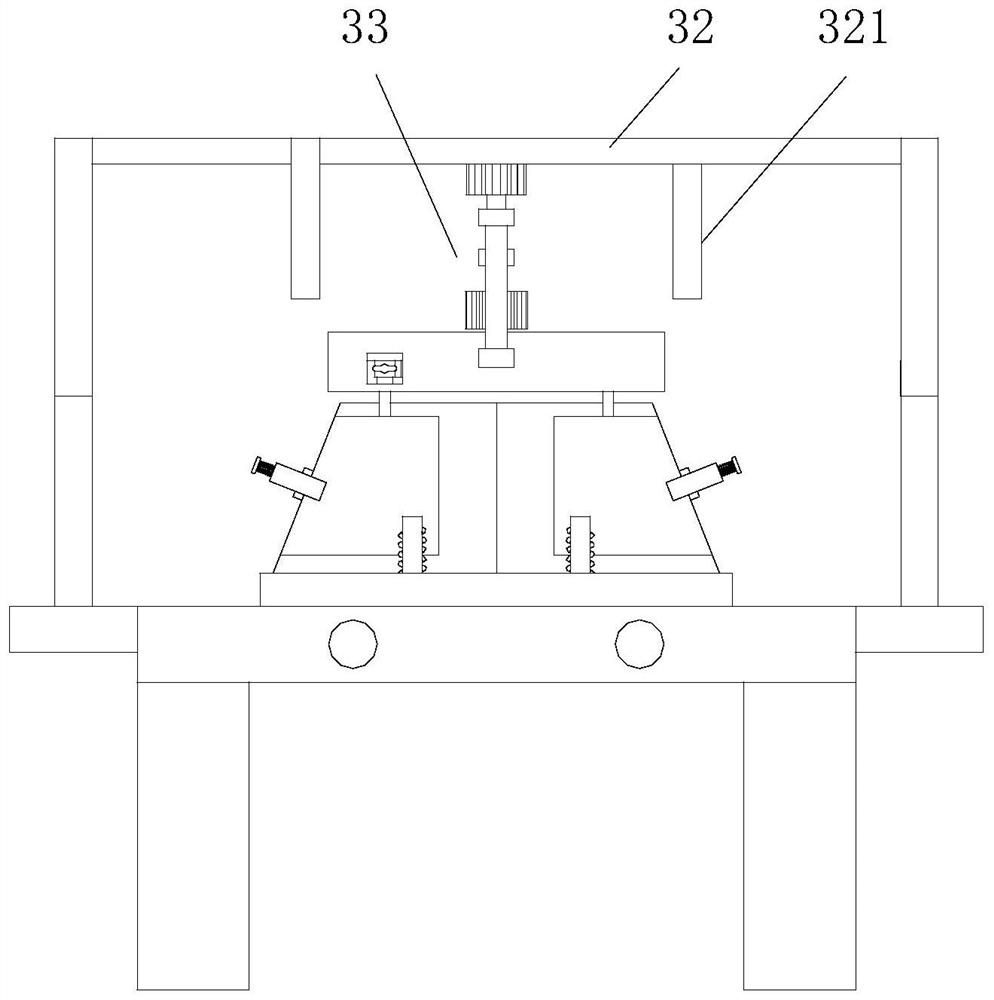

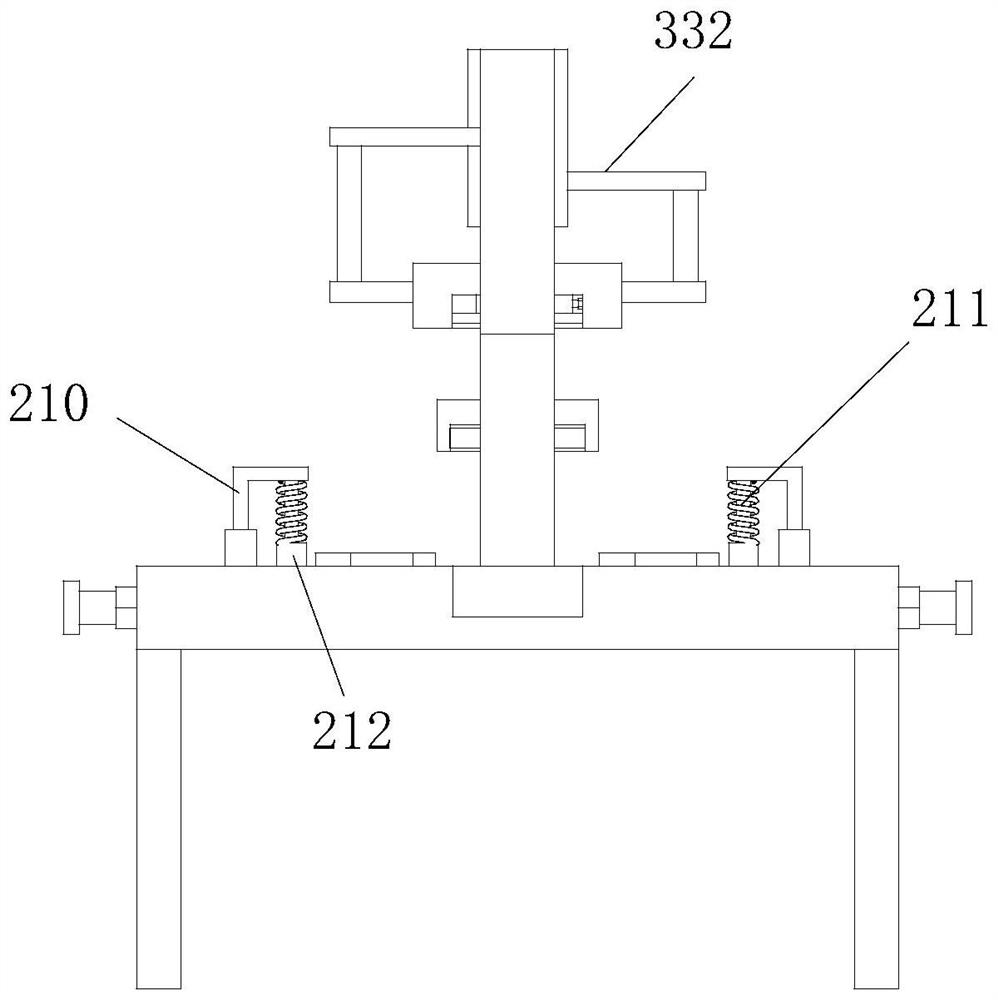

Steel structure manufacturing and machining system

ActiveCN113210915AAchieve fixationAdjustable distanceWelding/cutting auxillary devicesAuxillary welding devicesMachineMachining system

The invention relates to a steel structure manufacturing and machining system. The steel structure manufacturing and machining system comprises a workbench, a limiting device and a clamping and aligning device, the workbench is connected with the existing ground, the limiting device is arranged on the workbench, and the clamping and aligning device is arranged above the limiting device. A limiting bolt can push a limiting plate by rotating the limiting bolt, the front end and the rear end of a square base are clamped and limited, so that the square base is fixed, and the square base is prevented from deviating in the welding manufacturing and machining process; and meanwhile, the distance between limiting plates can be adjusted by adjusting the limiting bolt, so that the machine can fix bases of different sizes, and connecting supports of different specifications can be manufactured.

Owner:山东瑞驰钢结构有限公司

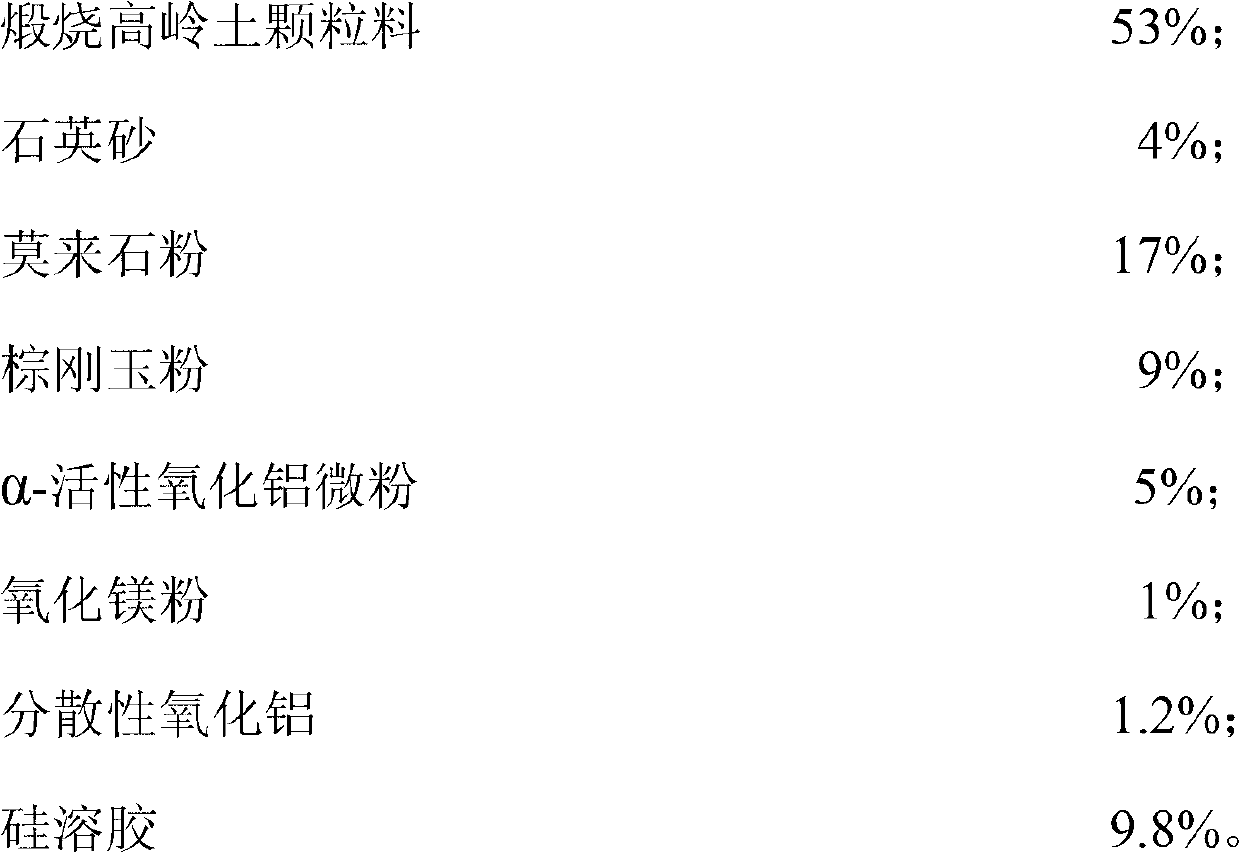

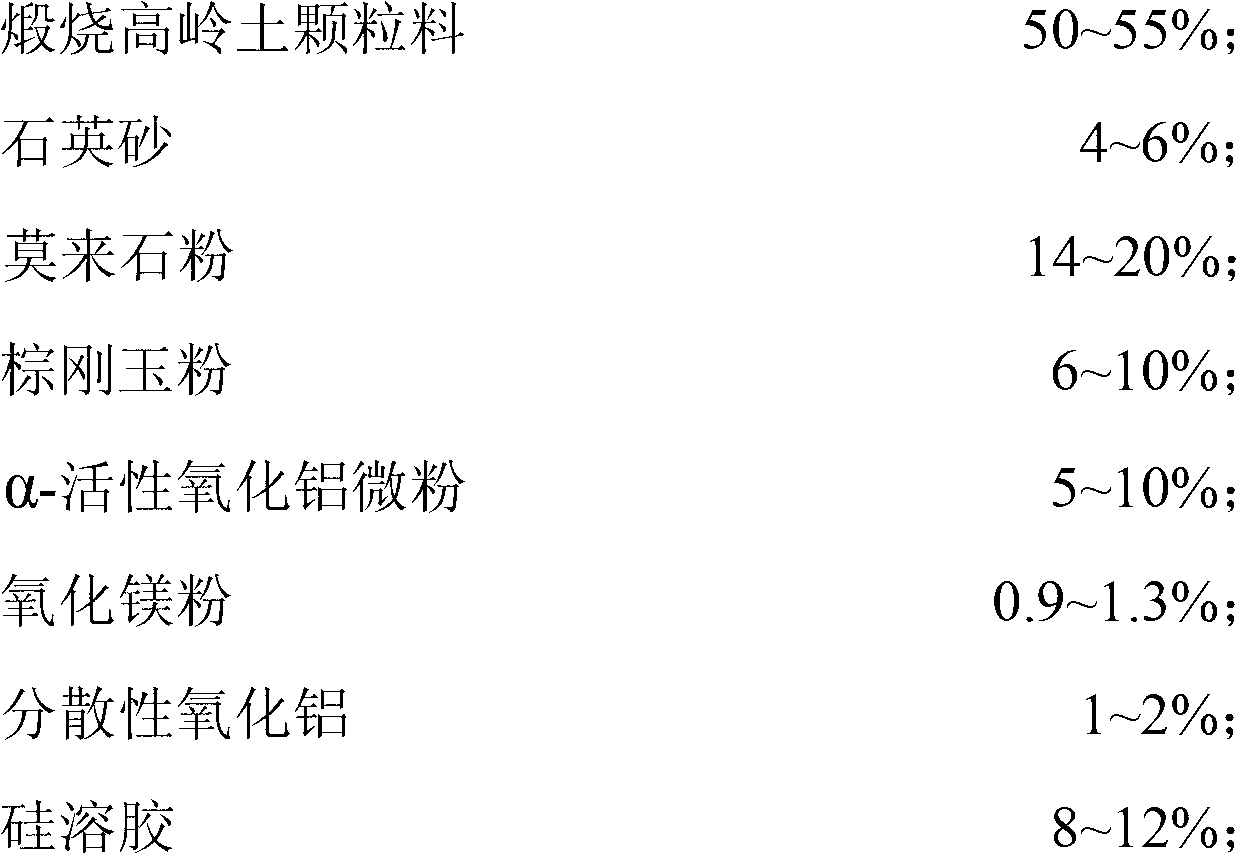

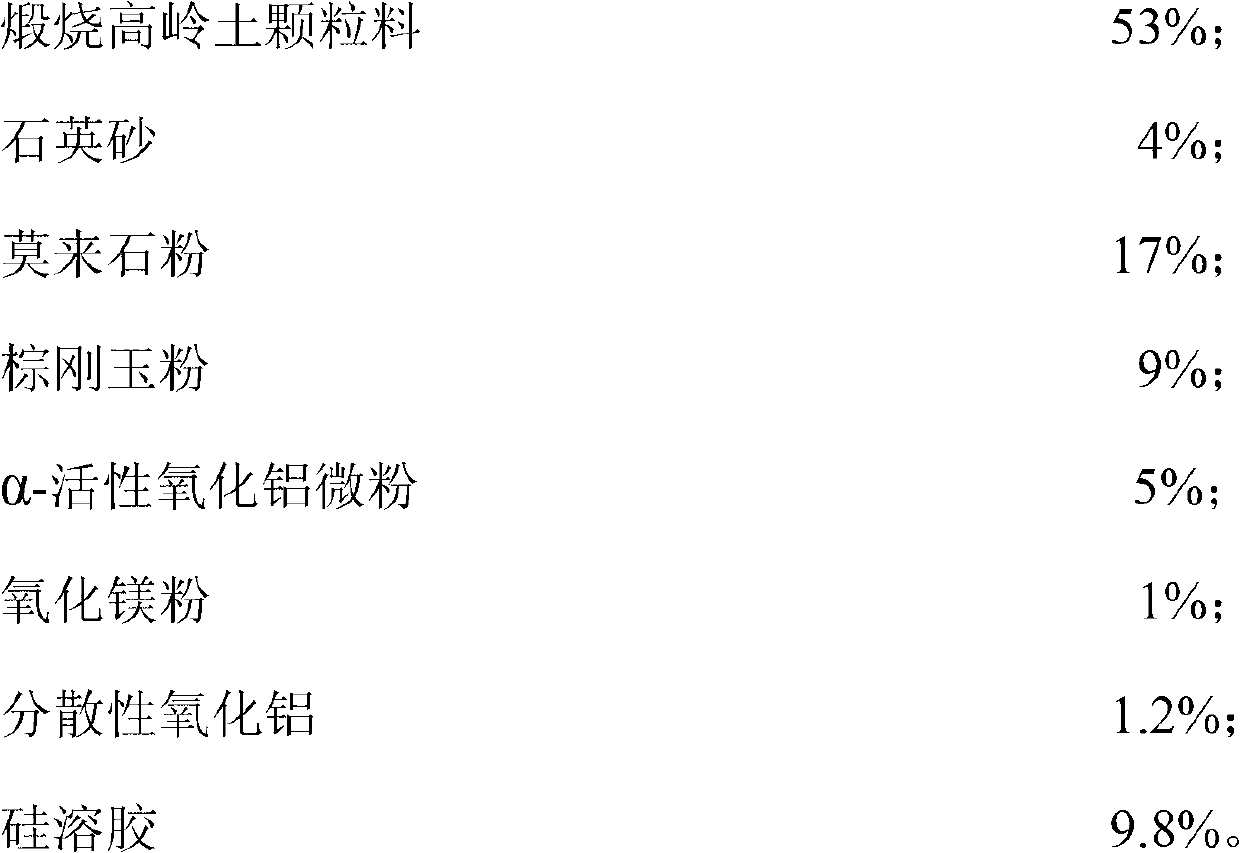

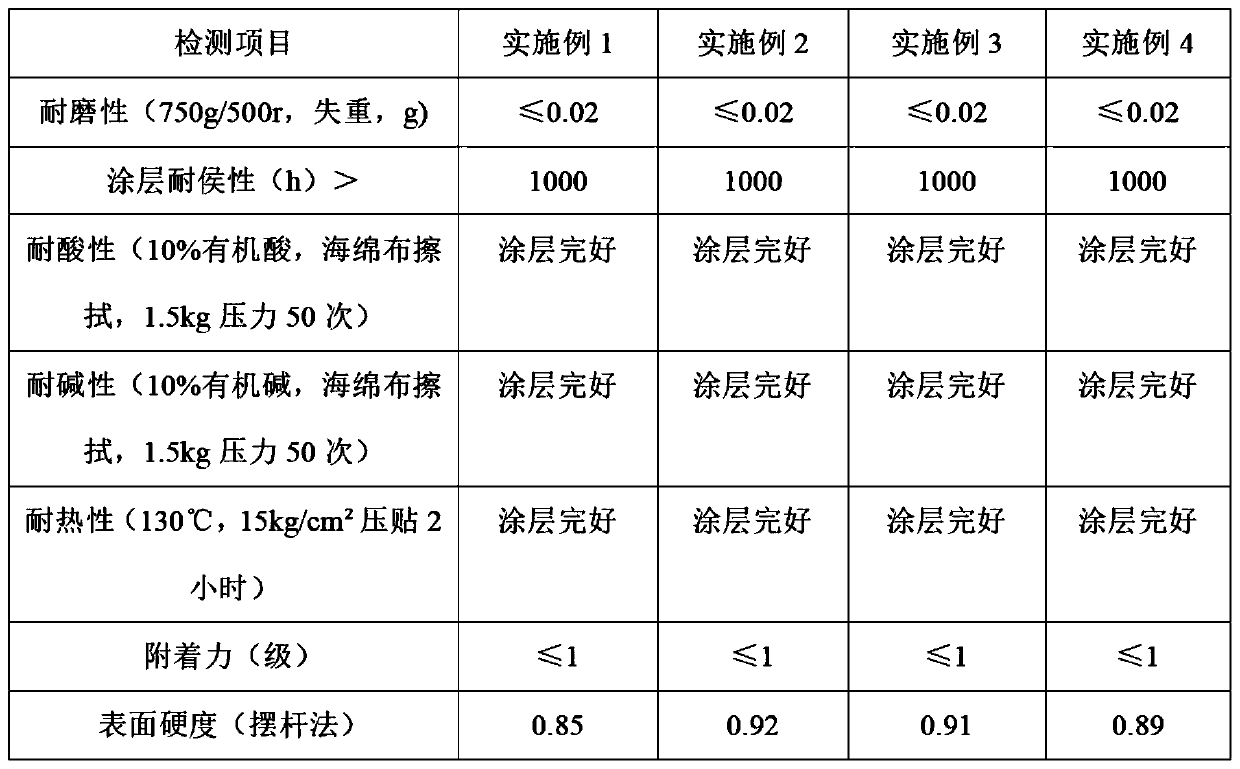

Energy-efficient sol combined mullite castable used for blast furnace air supply branch pipe inner liner

The invention discloses an energy-efficient sol combined mullite castable used for a blast furnace air supply branch pipe inner liner, which belongs to the refractory material technical field. The energy-efficient sol combined mullite castable used for the blast furnace air supply branch pipe inner liner comprises the following raw materials by weight: 50-55% of calcining kaolin granules, 4-6% of quartz sand, 14-20% of mullite powder, 6-10% of brown lapis amiridis, 5-10% of alpha-active alumina micro powder, 0.9-1.3% of magnesium oxide powder, 1-2% of dispersible alumina and 8-12% of silica sol. The energy-efficient sol combined mullite castable has the advantages of excellent physical and chemical performances, low cost, good application property and short making period, and is the high-quality inner liner material adapted to operation and making condition of the blast furnace air supply branch pipe.

Owner:中冶武汉冶金建筑研究院有限公司

Polyurethane coating layer for aircraft organic glass, and preparation method thereof

ActiveCN110093099AImprove wear resistanceWithstand shockTransportation and packagingMixersAntioxidantUltraviolet

The invention discloses a polyurethane coating layer for aircraft organic glass, and a preparation method thereof, and belongs to the technical field of polyurethane coating layers. The polyurethane coating layer for aircraft organic glass is prepared by mixing raw materials to form a solution, spraying the solution and curing the solution, and the raw materials of the solution comprise 10-15% ofan isocyanate, 3-5% of a diol, 15-20% of a triol, 0.0005% of a catalyst, 0.015% of an antistatic agent, 0.035% of a surfactant, 0.5% of an antioxidant, 1% of an ultraviolet absorber, 0.3% of a leveling agent and 50-70% of an organic solvent. The preparation method of the solution comprises the following steps: 1, adding the isocyanate, the diol, the surfactant and the antistatic agent into a flask. The coating layer has good wear resistance, makes the thickness of a dry film reach 76 [mu]m, has the advantages of high elongation at break, god resistance to impact of raindrops, and excellent weather resistance, and can greatly enhance the wear resistance of aircraft organic glass and prolong the service life of the aircraft organic glass.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

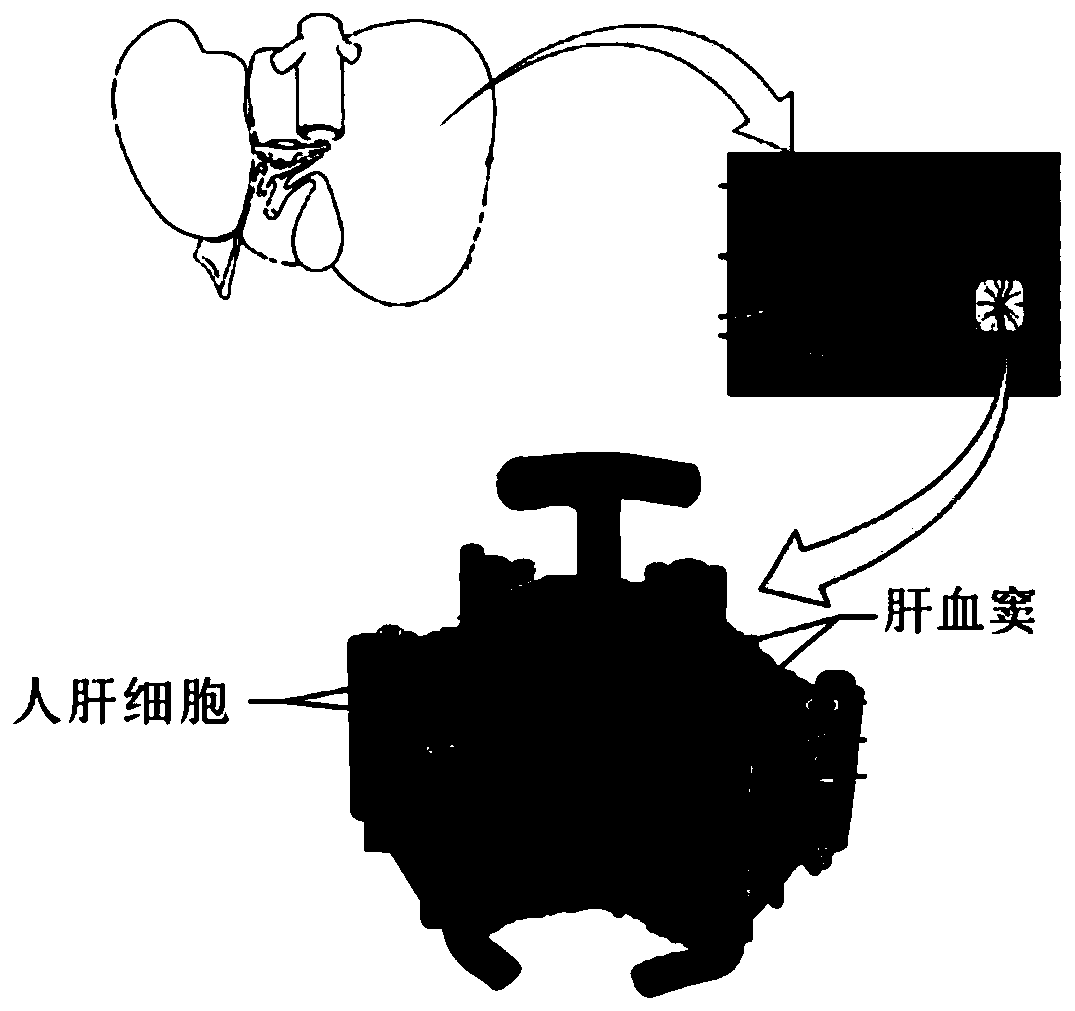

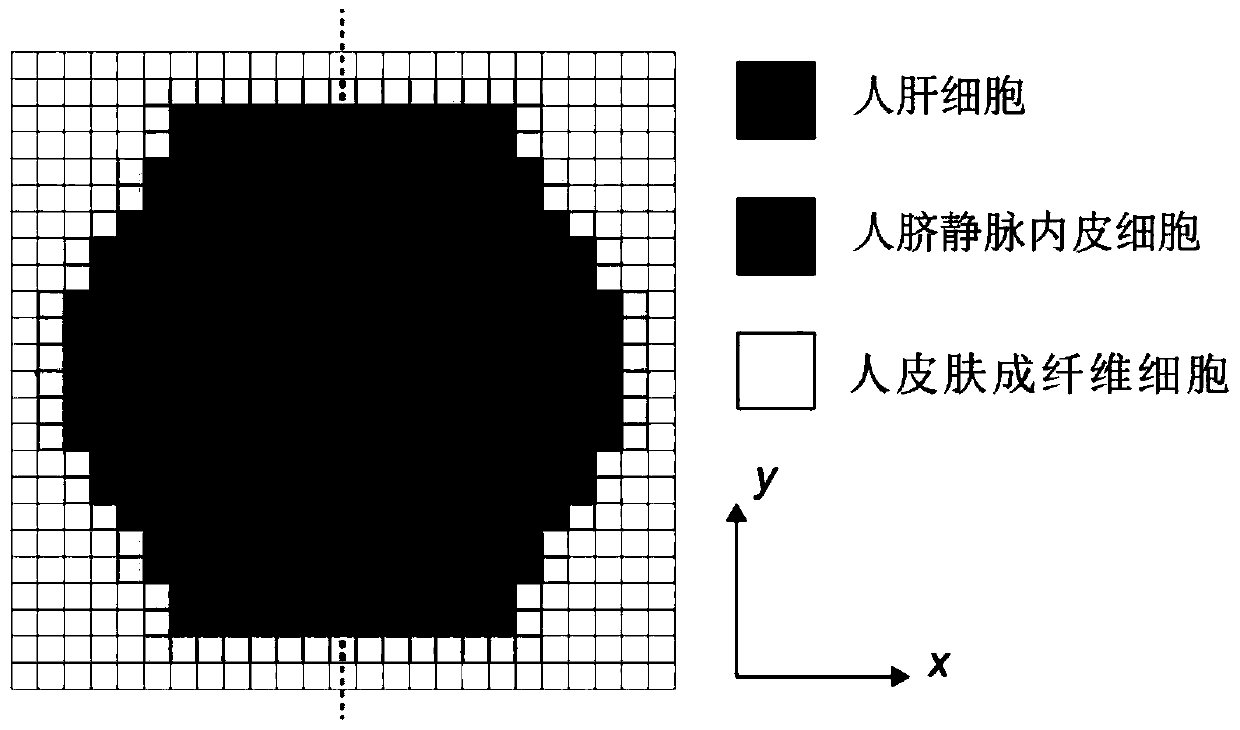

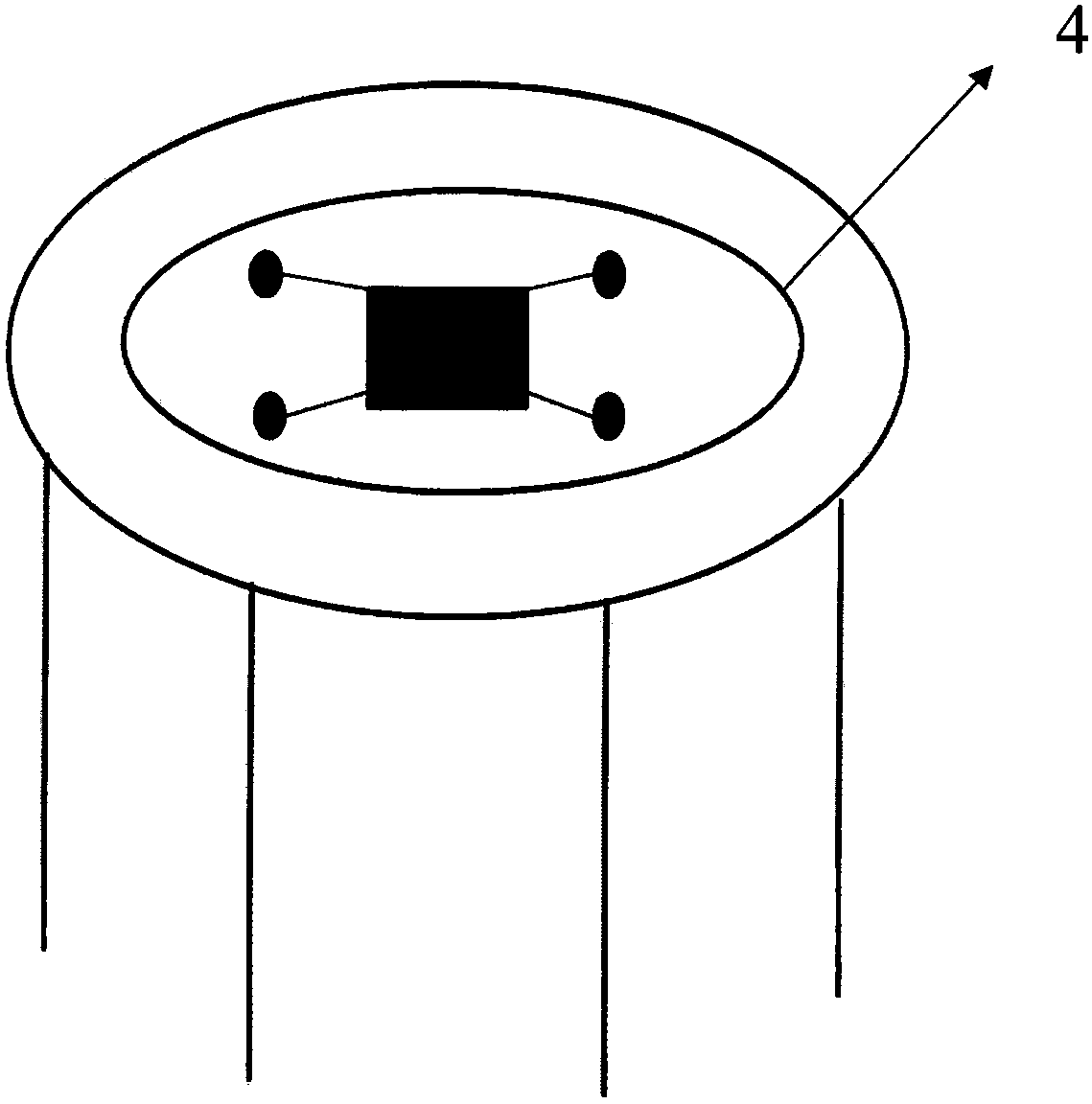

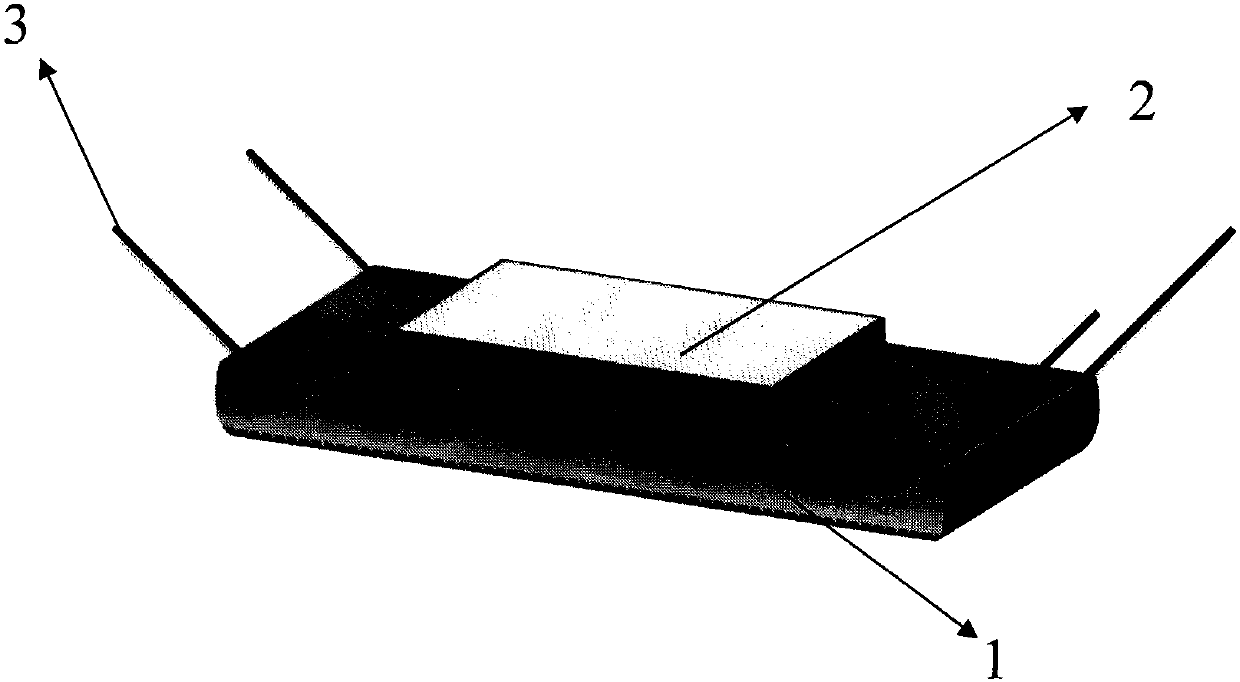

3D voxel printing device based on cell soft spheres and method thereof

ActiveCN111269834AReduce hardnessEfficient reductionAdditive manufacturing apparatusHepatocytesCellular MicroenvironmentTissue architecture

The invention discloses a 3D voxel printing device based on cell soft spheres and a method thereof. The device comprises a water phase input part, an oil phase input part and a microfluidic microtube,wherein the water phase input part inputs an extracellular matrix material loaded with cells, namely bio-ink, into the microfluidic microtube; and the oil phase input part synchronously inputs a low-viscosity and low-boiling-point oil phase meeting set requirements into the microfluidic microtube. The extracellular matrix material loaded with the cells is separated into monodisperse microdropletsembedded with the cells through an oil phase, the microdroplets are gelled into cell soft spheres in the flowing process in the microtube, the cell soft spheres are sequentially shot onto a substrateby utilizing rapid expansion and volatilization of the oil phase at an outlet of the microfluidic microtube, and the cell soft spheres are adhered together through an incompletely gelled ink material. An in-vitro model capable of highly reducing the human organ or tissue structure and the cell microenvironment can be printed under the condition that a printing material does not contain a biological inert material for assistance.

Owner:杭州济扶科技有限公司

Building external wall temperature-change-resistant anti-oxidative color coating

InactiveCN106381045AHigh tensile strengthGood flexibilityPolyurea/polyurethane coatingsAluminium hydroxidePOLYOXYETHYLENE ETHER

The invention discloses a building external wall temperature-change-resistant anti-oxidative color coating, which is prepared from the following raw materials in parts by weight: 20 to 25 parts of carboxylic waterborne polyurethane, 19 to 24 parts of pure silicon resin emulsion, 11 to 16 parts of cobalt blue, 10 to 15 parts of mill base, 8 to 12 parts of bentonite, 7 to 11 parts of mica powder, 6 to 10 parts of kaolin, 5 to 9 parts of talcum powder, 12 to 14 parts of sodium carbonate, 9 to 11 parts of sodium tripolyphosphate, 10 to 12 parts of polyoxyethylene aliphatic ester, 8 to 10 parts of sodium polyacrylate, 13 to 16 parts of sheet zinc powder, 7 to 11 parts of aluminum hydroxide, 5 to 8 parts of silicon nitride, and 30 to 35 parts of deionized water. A preparation method comprises the following steps of S1, adding the carboxylic waterborne polyurethane, the pure siliconresin emulsion, the cobalt blue, the mill base and the deionized water into a stirrer, and stirring with the stirring speed of 30 to 40rpm for 20 to 30min at the temperature of 40 to 50 DEG C; S2, adding the sheet zinc powder, the aluminum hydroxide and the silicon nitride for stirring with the stirring speed of 100 to 150rpm for 5 to 10min. The building external wall temperature-change-resistant anti-oxidativecolor coating provided by the invention has excellent temperature alternating resistance and oxidation resistance, has high tensile strength and favorable flexibility, and is simple in preparation process, convenient to use, and low in cost.

Owner:CHENGDU PUJIANG KEXIAN TECH

Chemical sensor simultaneously having light sensitivity and gas sensitivity

InactiveCN107807157AWide range of usesHigh light sensitivityMaterial electrochemical variablesElectrical resistance and conductanceGas detector

The present invention provides a chemical sensor simultaneously having light sensitivity and gas sensitivity, and relates to a semiconductor device specially adapted for various gases and illuminationdetection. The chemical sensor comprises the sensitive layer of a chemical sensor, a planar Au plating ceramic substrate, a leading wire and a gas sensor base, wherein the sensitive layer of the chemical sensor is a thin film layer obtained by doping a CH3NH3PbI3 perovskite precursor liquid and WO3 nanometer powder, and a heating layer made of a special material and a Au plating electrode are arranged on the planar ceramic sheet. According to the present invention, by preparing the CH3NH3PbI3 perovskite precursor liquid and WO3 nanometer powder mixing chemical sensor, the gas sensitivity of the sensor is improved, the sensitivity to gases is improved, the chemical sensor has good sensitivity to light, and the resistance of the sensor is reduced in the case of strong illumination so as toimprove the sensitivity to gases.

Owner:HEBEI UNIV OF TECH

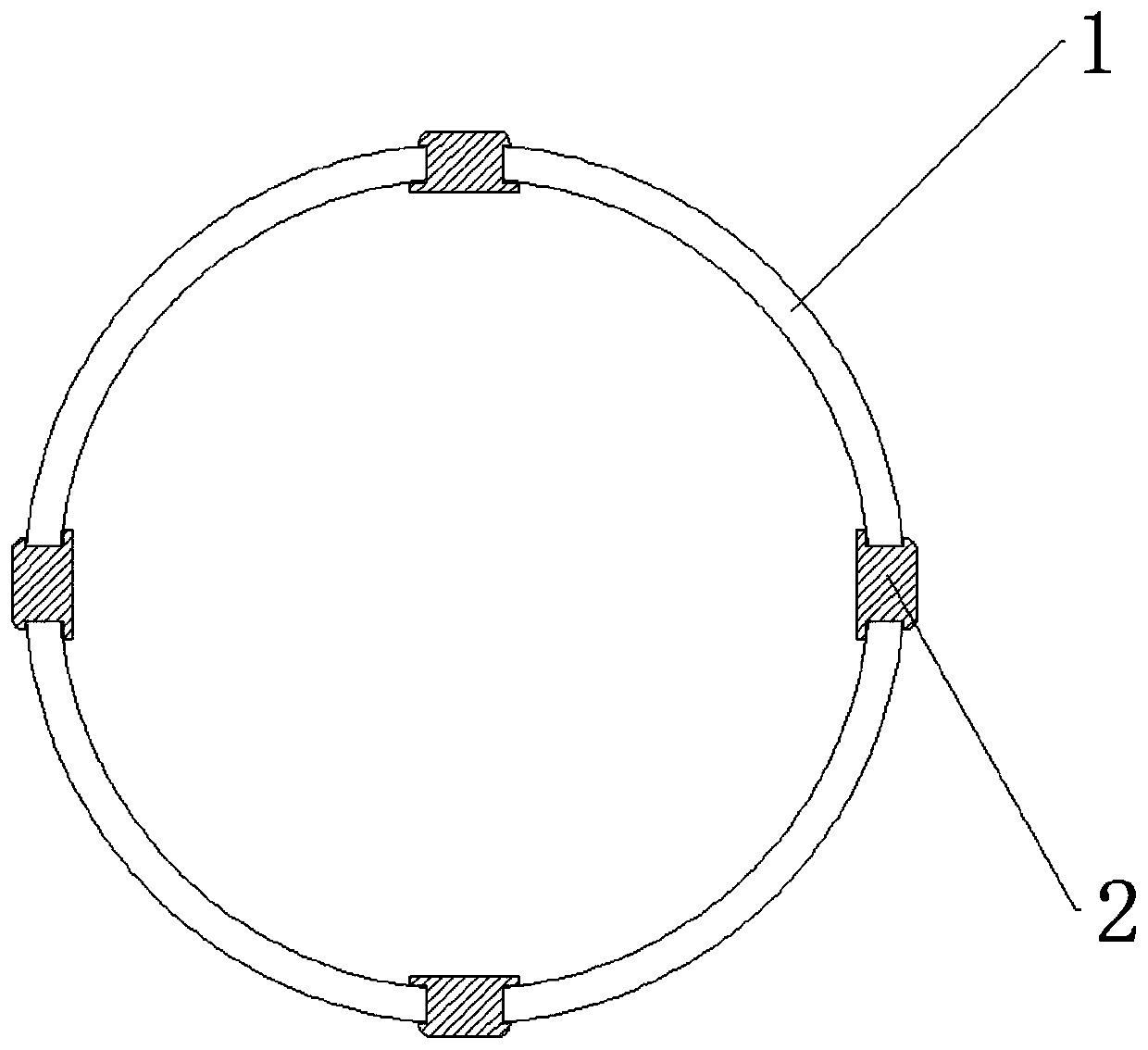

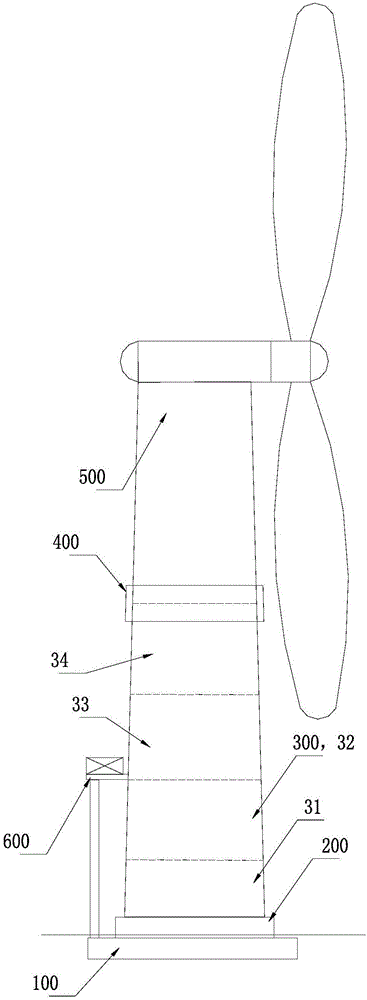

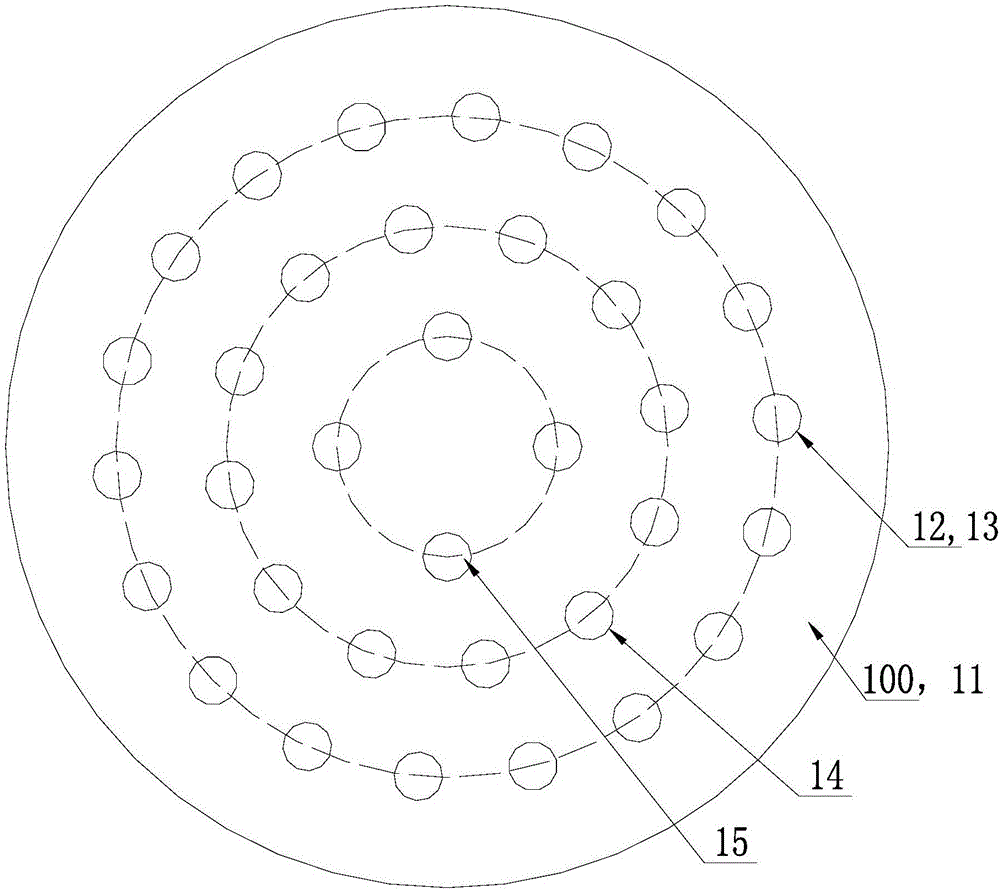

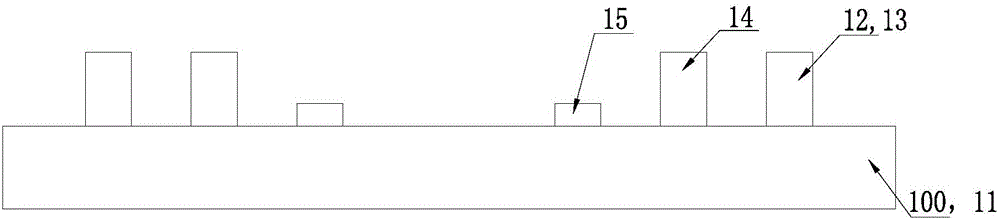

Reinforced-concrete draught fan tower

InactiveCN105715462AIncrease manufacturing rateReduce manufacturing difficultyFinal product manufactureWind motor supports/mountsRebarWind force

The invention relates to a reinforced-concrete draught fan tower. The reinforced-concrete draught fan tower comprises a pile foundation, a supporting platform, a concrete tower body and a steel tower body, wherein the pile foundation, the supporting platform, the concrete tower body and the steel tower body are sequentially arranged from bottom to top. The pile foundation is pre-buried underground, the supporting platform laid on the pile foundation is arranged at the bottom of the concrete tower body, the supporting platform and the pile foundation are integrally formed through pouring, and the top of the concrete tower body is coaxially and fixedly connected with the bottom of the steel tower body through a connecting part. The upper ends and the lower ends of prestressed steel bars penetrating through the side wall of the concrete tower body are fixed to the connecting part and the supporting platform correspondingly through anchors. Due to the arrangement, the draught fan tower which is overall high is divided into the concrete tower body and the steel tower body, so that the overall manufacturing cost of a draught fan is lowered; meanwhile, the upper ends and the lower ends of the prestressed steel bars penetrating into the concrete tower body are fixed through the anchors correspondingly, so that the prestressed steel bars are in a tensioned state, wind resistance and vibration reduction are provided for concrete steel bars, and shaking caused by pneumatic vibration of the tower is buffered.

Owner:DATANG HUBEI NEW ENERGY CO LTD

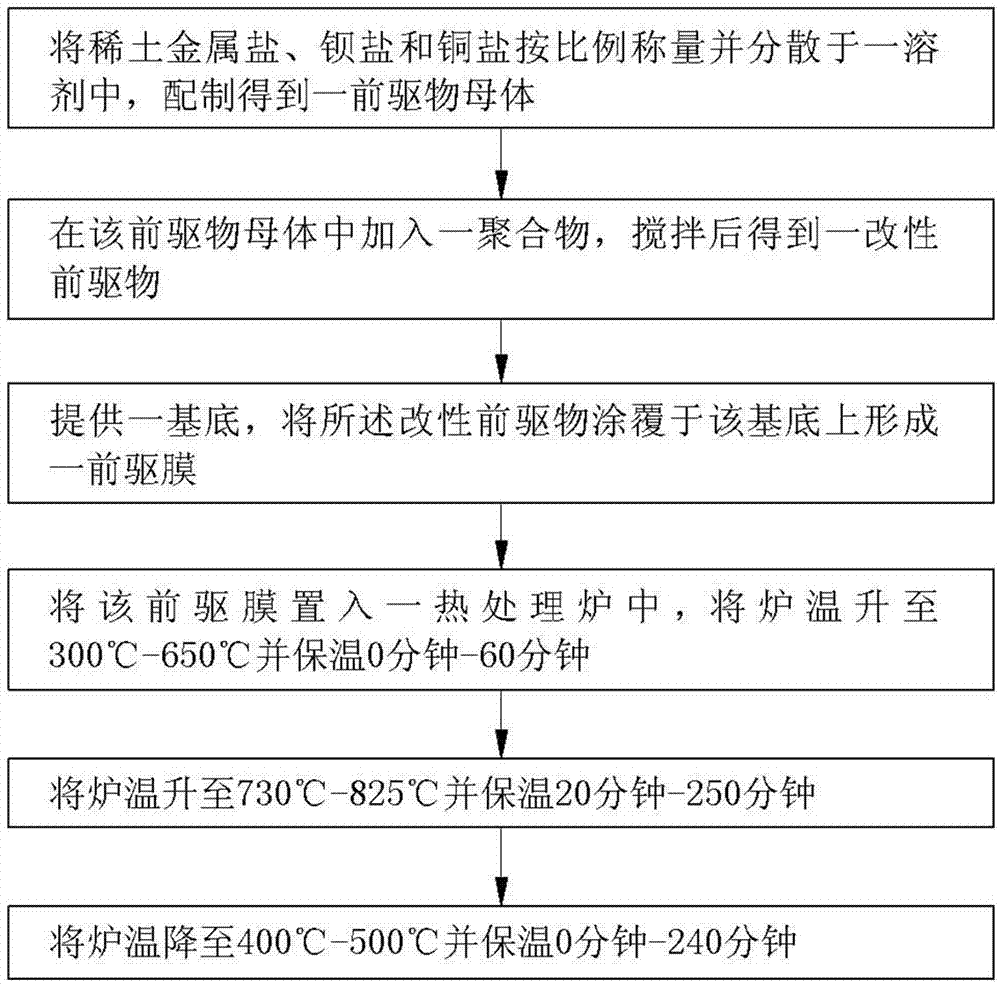

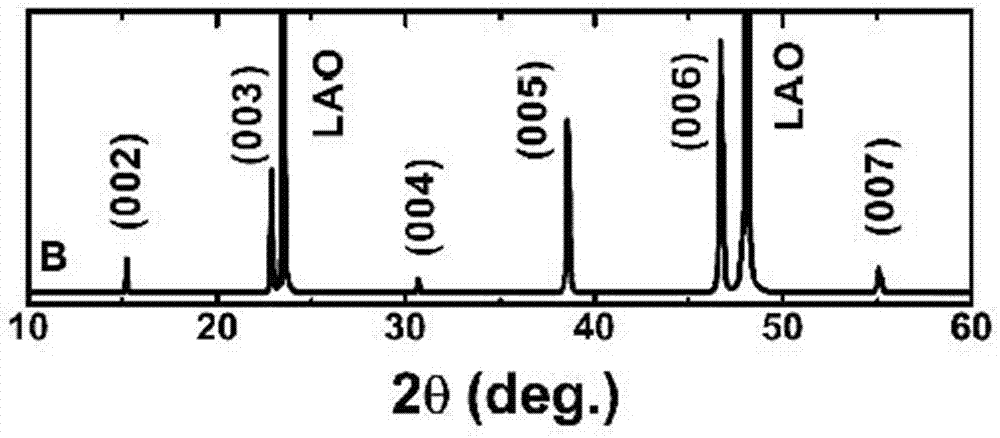

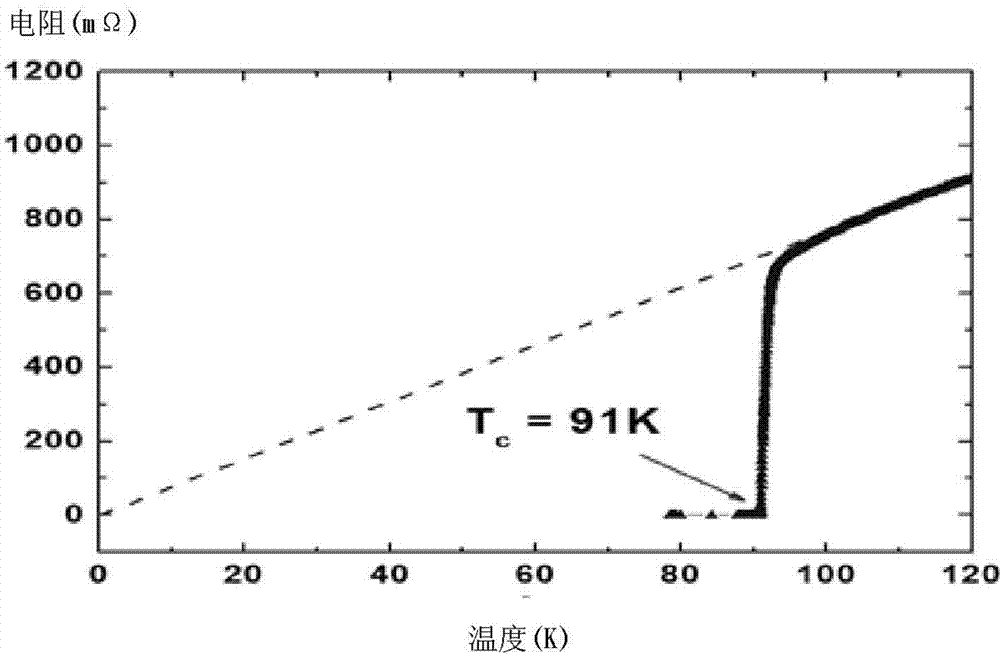

Preparation method of high temperature superconducting film

ActiveCN103086722AImprove diffusion abilityImprove mechanical propertiesFurnace temperatureHigh-temperature superconductivity

The invention relates to a preparation method of a high temperature superconducting film. The preparation method comprises the specific steps of weighting rear earth metal salt, barium salt and copper salt according to a proportion and dispersing in a solvent so as to prepare and obtain a precursor parent; adding a polymer to the precursor parent and stirring so as to obtain a modified precursor; providing a substrate and coating the modified precursor on the substrate so as to form a precursor film; placing the precursor film in a thermal treatment furnace, raising the furnace temperature to 300 DEG C-650 DEG C rapidly and holding the temperature for 0-60 minutes; raising the furnace temperature to 730 DEG C-825 DEG C and holding the temperature for 20-250 minutes; and lowering the furnace temperature to 400 DEG C-500 DEG C and holding the temperature for 0-240 minutes. According to the preparation method, not only can the high temperature superconducting film which has a compact and smooth surface and excellent superconductivity be prepared, but also the preparation rate of the high temperature superconducting film can be greatly improved.

Owner:TSINGHUA UNIV +1

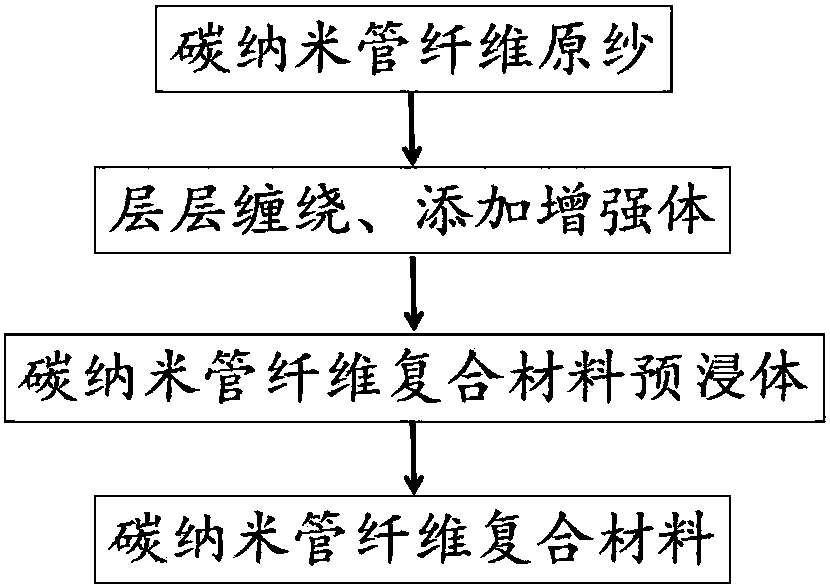

Carbon nanotube fibrous composite material and preparation method thereof

ActiveCN108656652AImprove production efficiencyInterlayer interaction is strongMaterial nanotechnologyLamination ancillary operationsCarbon nanotubeConductor Coil

The invention discloses a carbon nanotube fibrous composite material and a preparation method thereof. The preparation method comprises the following steps: providing one-dimensional carbon nanotube fibers; by a method of layer-by-layer winding, stacking and the like, and adding reinforcing bodies, enabling the carbon nanotube fibers to be in stacked arrangement layer by layer so as to form a carbon nanotube fibrous composite material prepreg body with a layered composite structure; and performing forming treatment on the carbon nanotube fibrous composite material prepreg body, thereby obtaining the carbon nanotube fibrous composite material. The preparation method has the beneficial effects that an interlayer arrangement mode is adjusted and controlled by adjusting and controlling the adopted arrangement parameters of the carbon nanotube fibers, interpenetration of the carbon nanotube fibers in a plurality of layers is realized, and the obtained carbon nanotube fibrous composite material has the advantages of strong interlayer action, convenience for forming, convenience for dimension design, high preparation efficiency and the like, can exert the advantage of the mechanical properties of the carbon nanotube fibers and also can maintain the electric and thermal properties of the carbon nanotube fibers.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

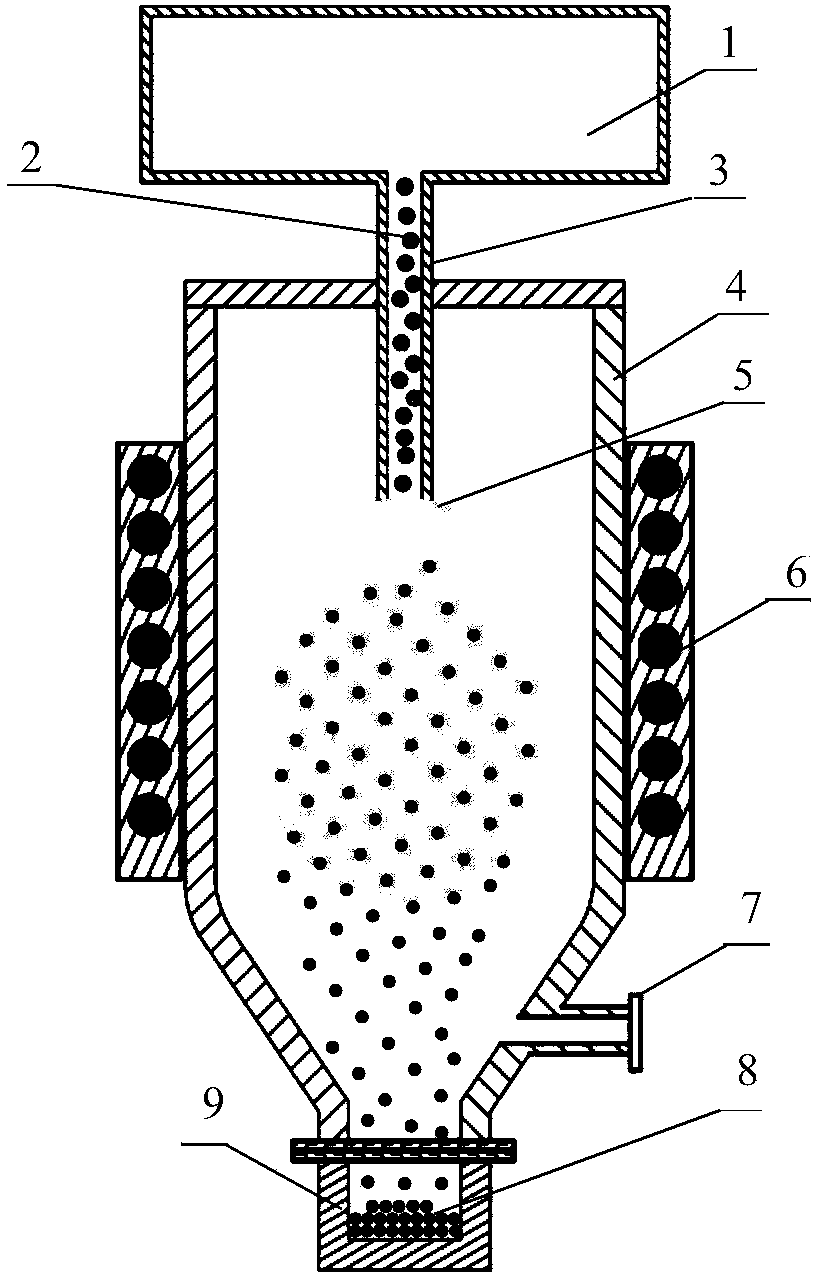

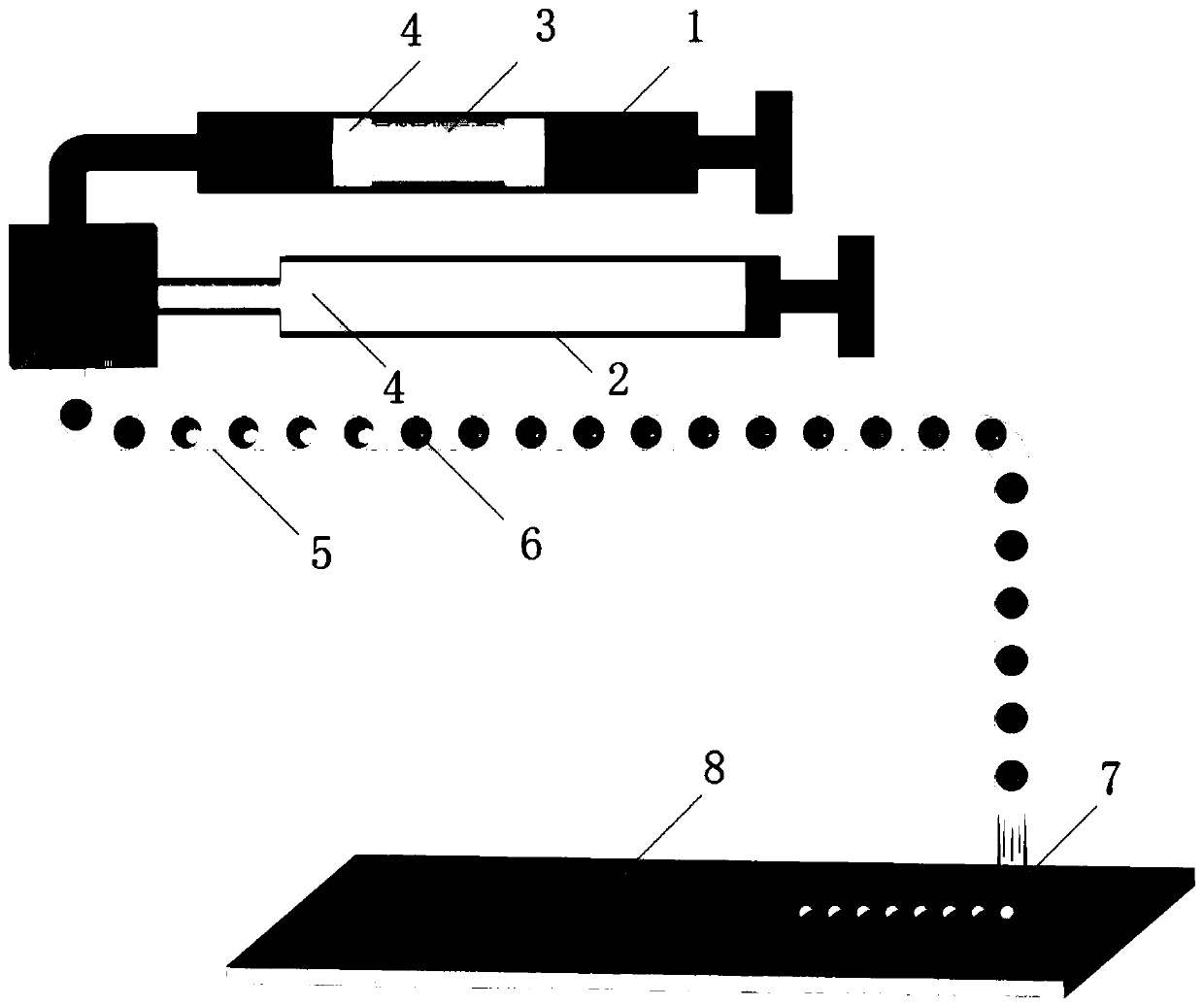

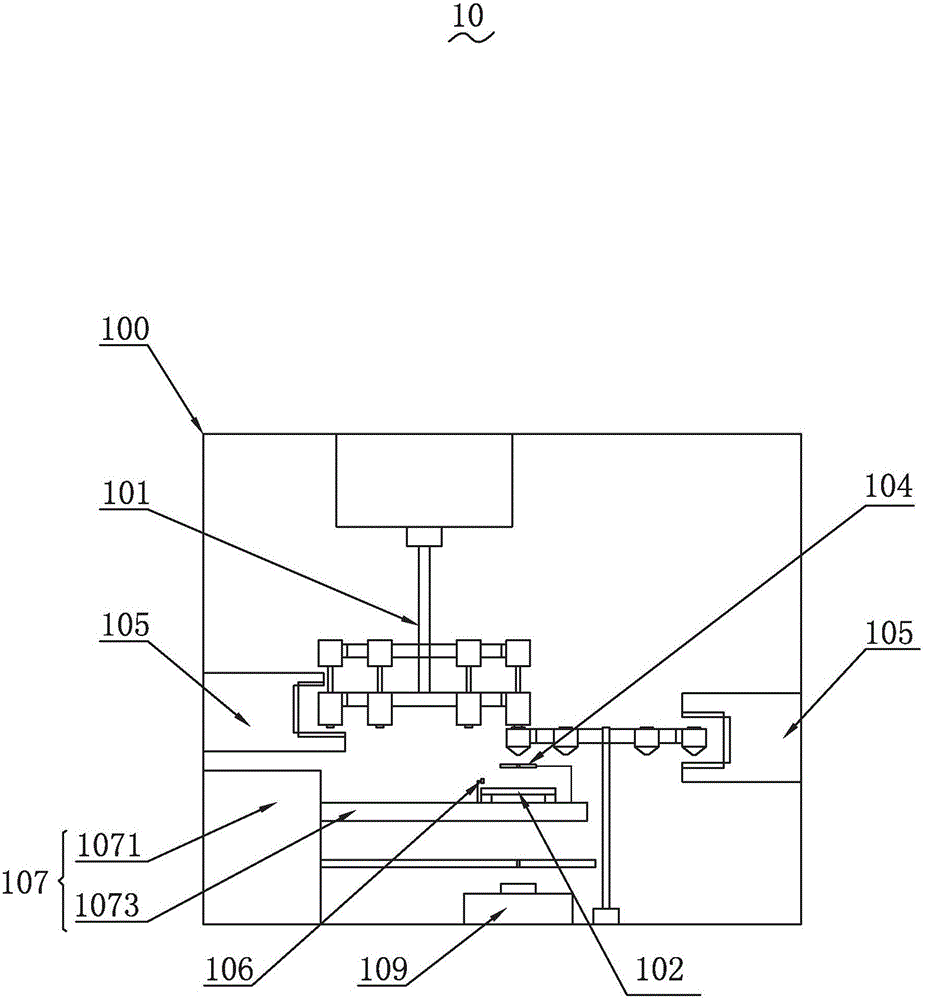

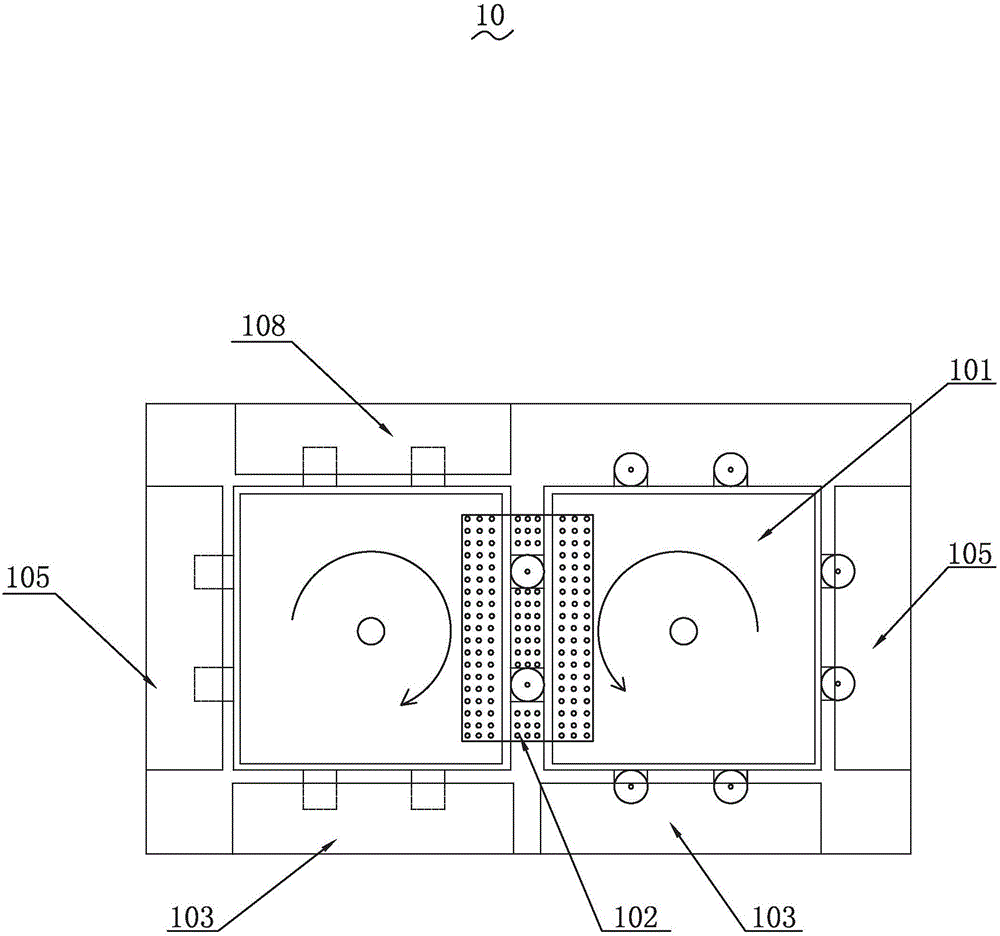

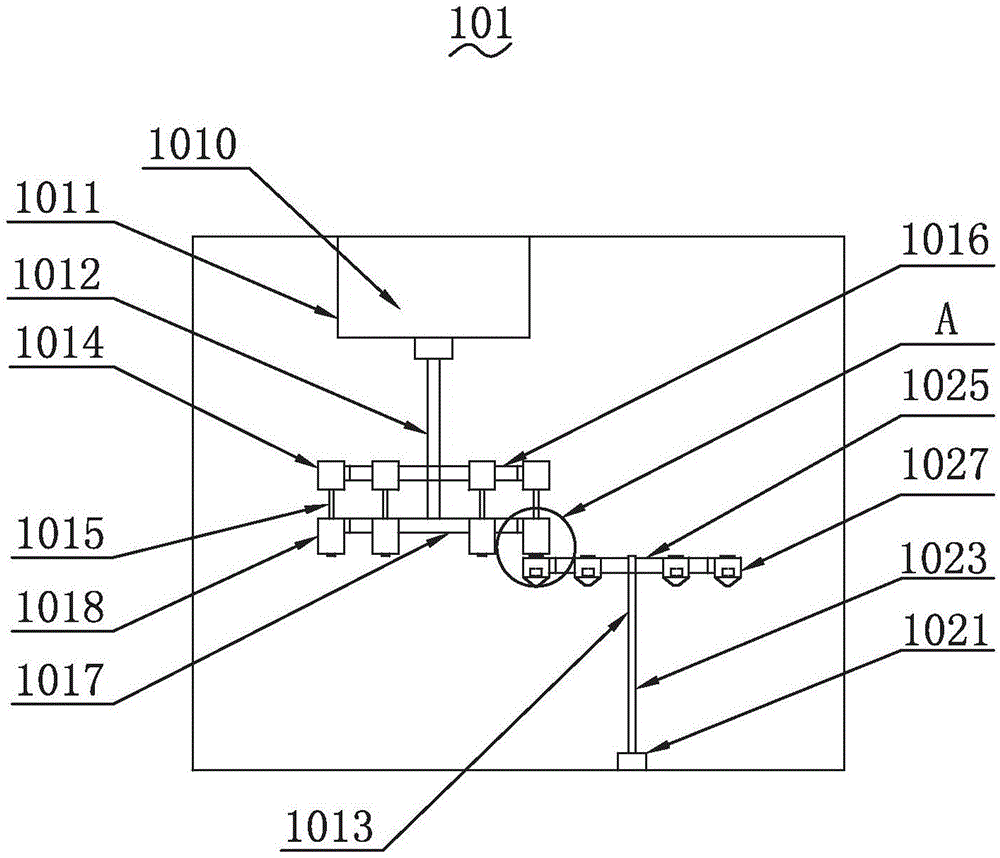

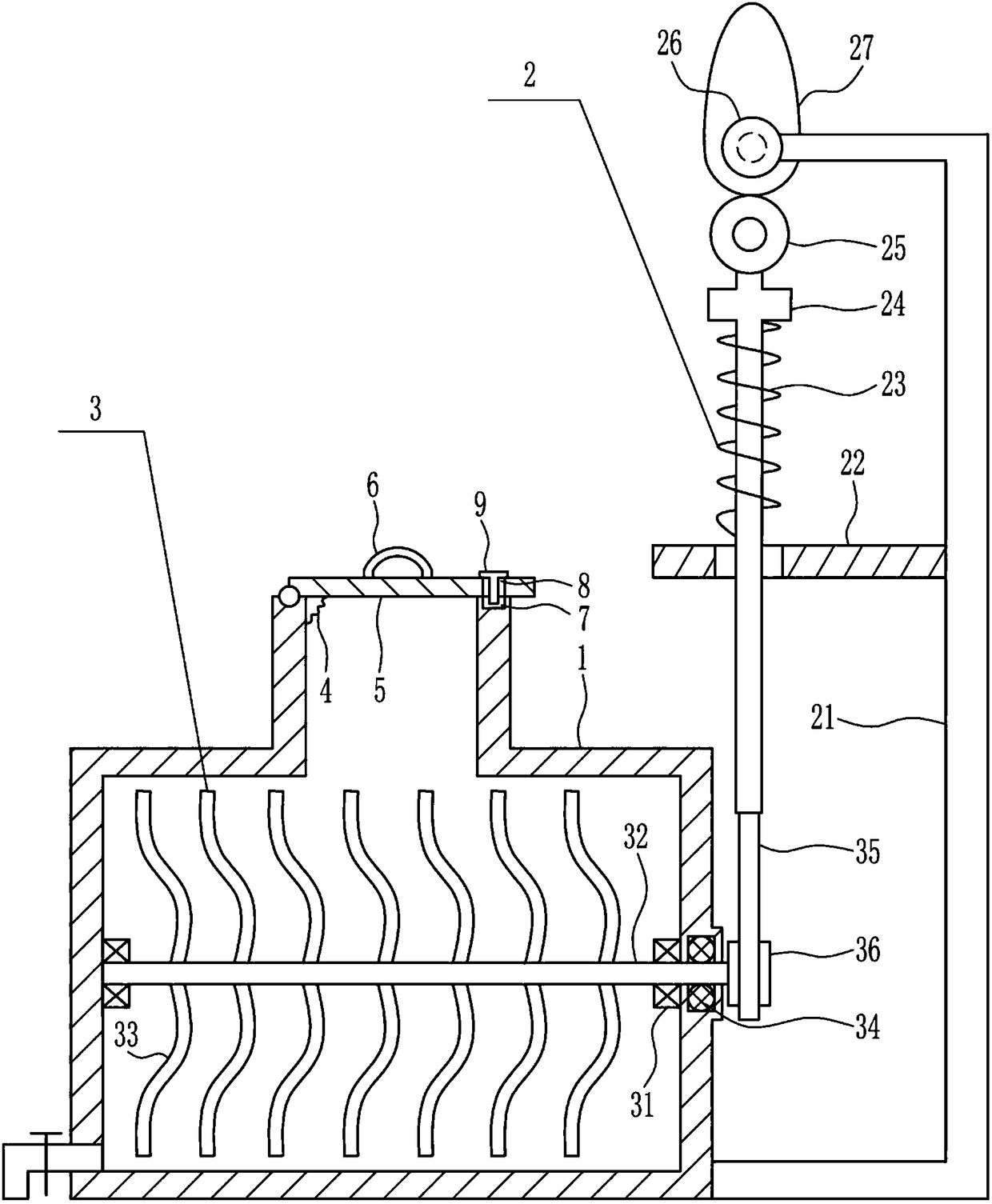

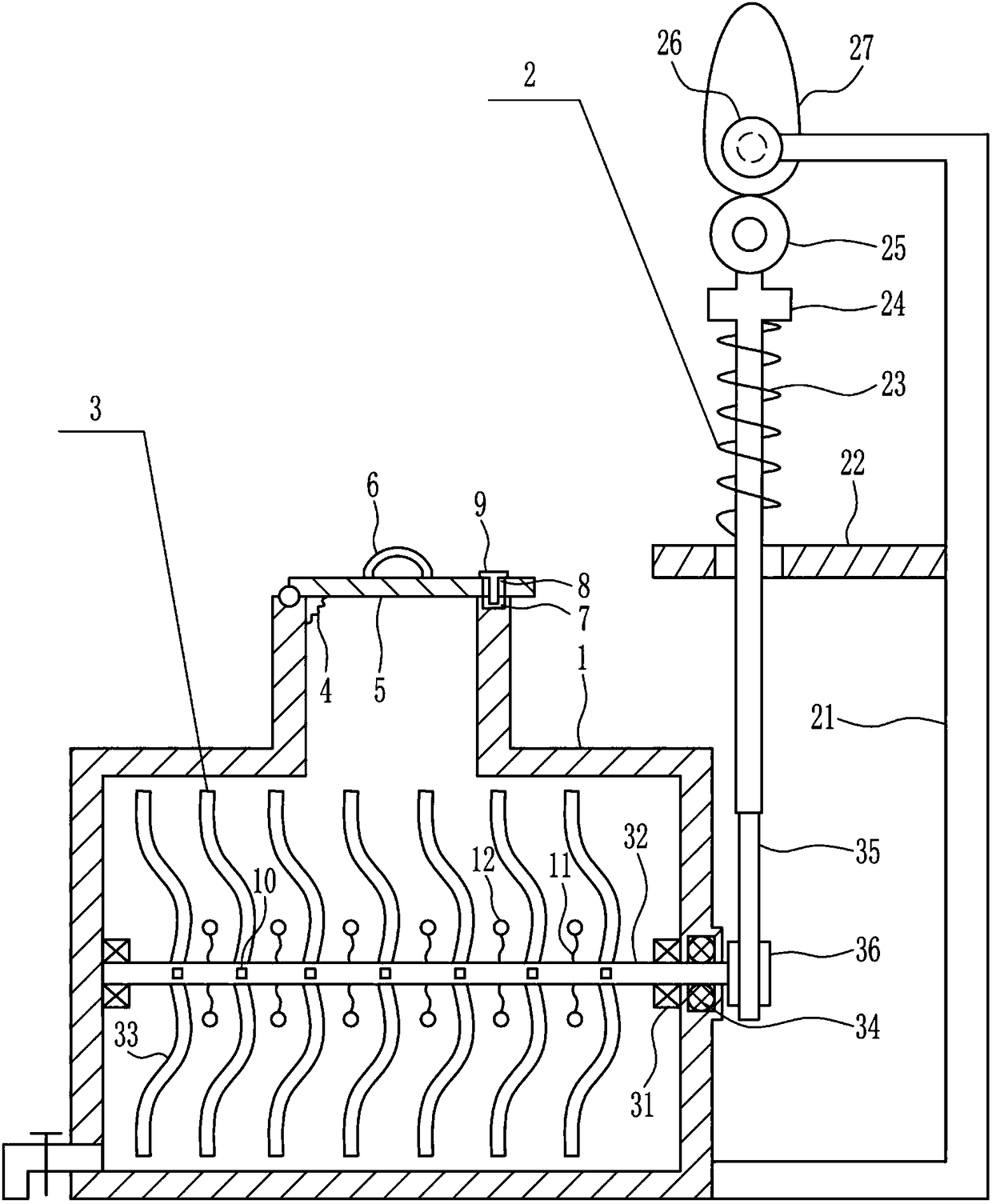

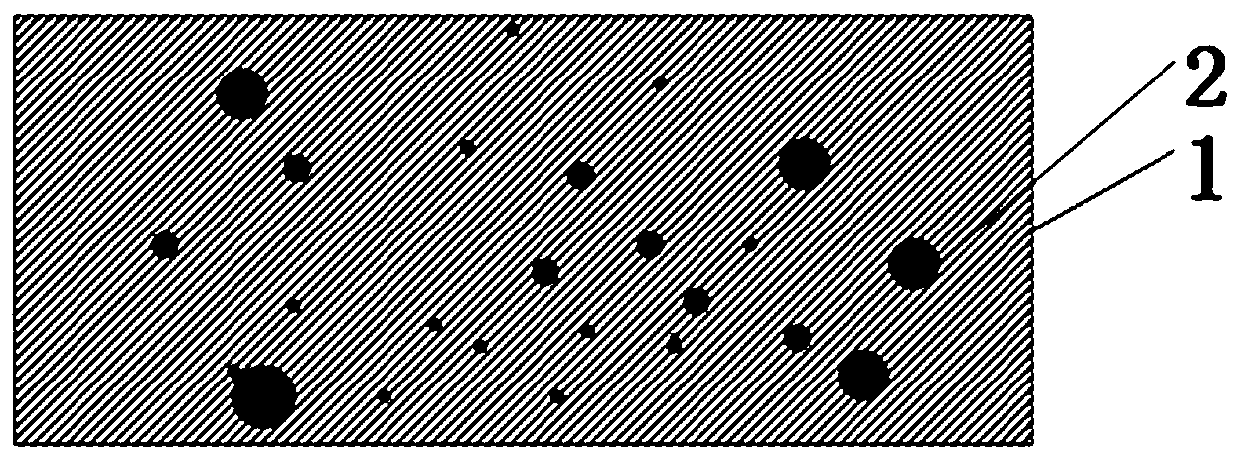

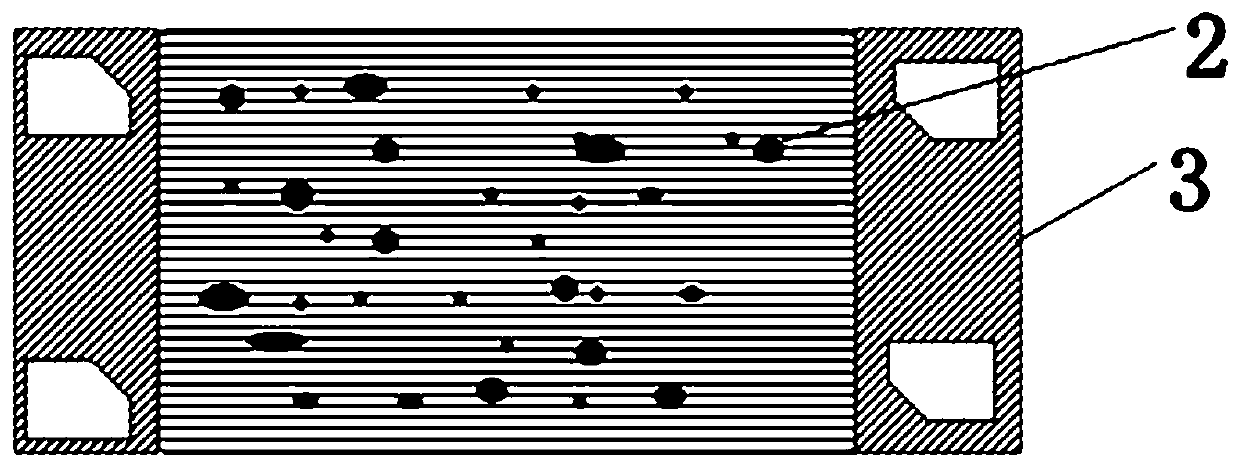

Ultrasonic atomization pyrolysis spray coating device and utilization method thereof

ActiveCN105772290AIncreased preparation rateGuaranteed purityLiquid surface applicatorsLiquid spraying apparatusSpray coatingUltrasonic atomization

The invention relates to an ultrasonic atomization pyrolysis spray coating device which comprises a substrate and a rotating mechanism, wherein the substrate is used for placing a plurality of groups of samples to be subjected to spray coating; the rotating mechanism comprises a first rotating mechanism and a second rotating mechanism; the first rotating mechanism is provided with liquid mixing devices; the liquid mixing devices accommodate a solution to be sprayed; the second rotating mechanism is provided with atomization nozzles; and the first rotating mechanism and the second rotating mechanism periodically rotate and can synchronously reach a spray coating zone above the substrate to cooperate with each other to perform spray coating on the samples to be subjected to spray coating on the substrate. The invention further provides a utilization method of the ultrasonic atomization pyrolysis spray coating device. The utilization method comprises the steps that the ultrasonic atomization pyrolysis spray coating device is provided, and the plurality of groups of samples to be subjected to spray coating are placed on the substrate; the first rotating mechanism and the second rotating mechanism are periodically rotated; and when the first rotating mechanism and the second rotating mechanism synchronously reach the spray coating zone above the substrate, the liquid mixing devices of the first rotating mechanism and the atomization nozzles of the second rotating mechanism cooperate to perform spray coating on the samples on the substrate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

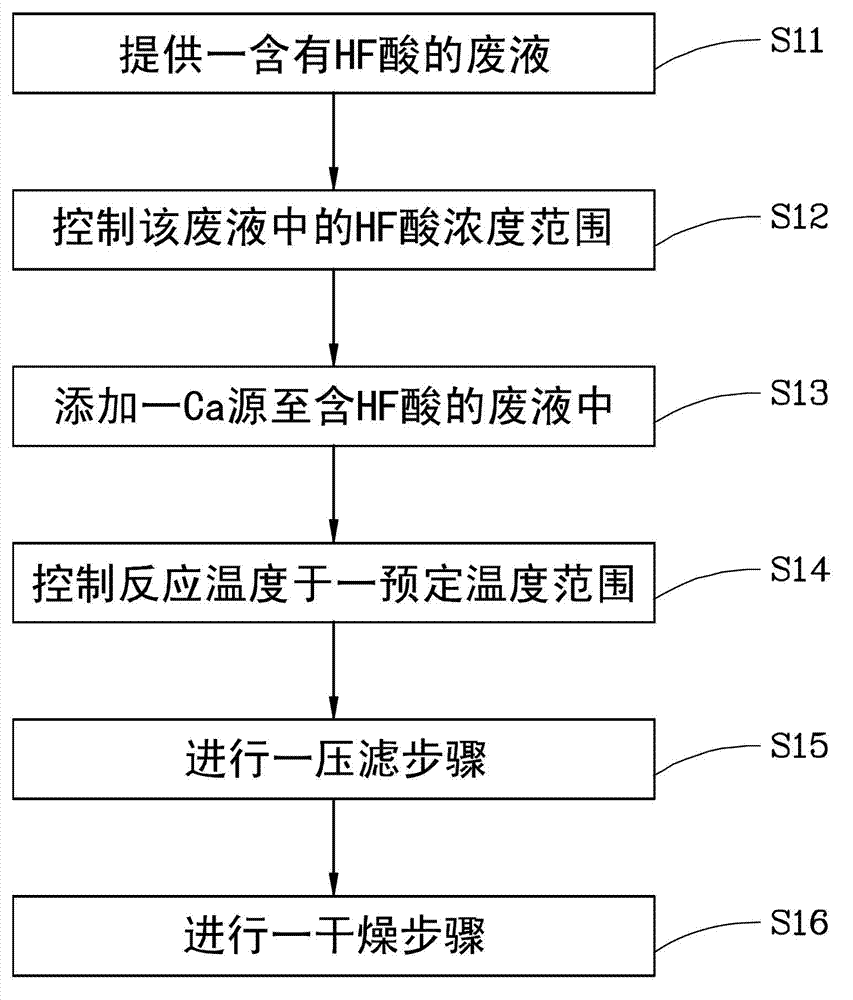

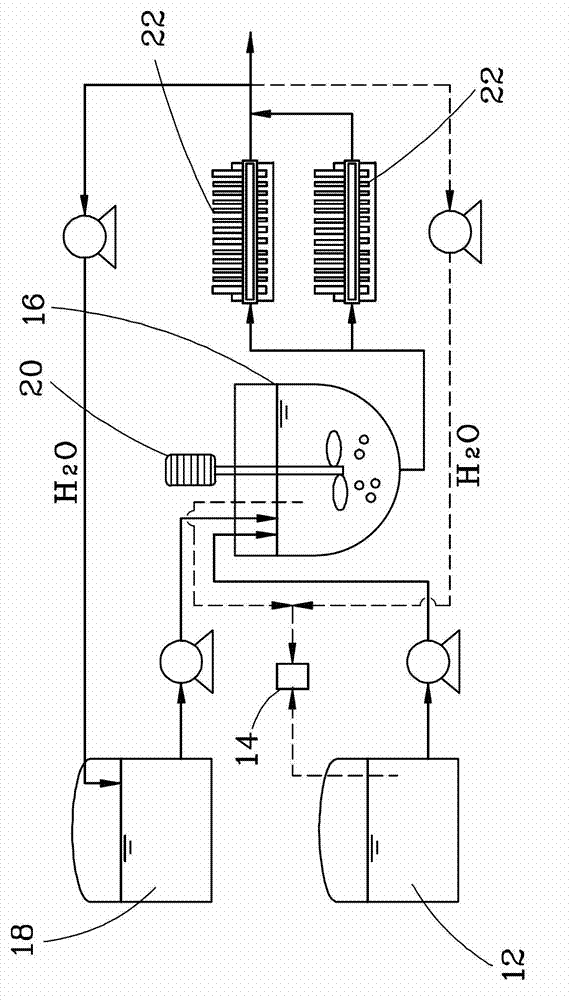

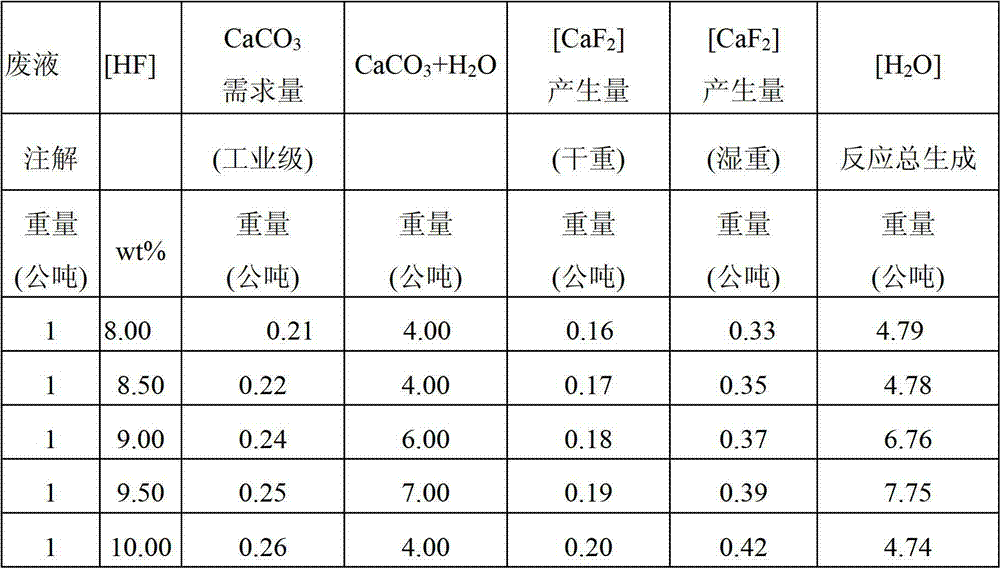

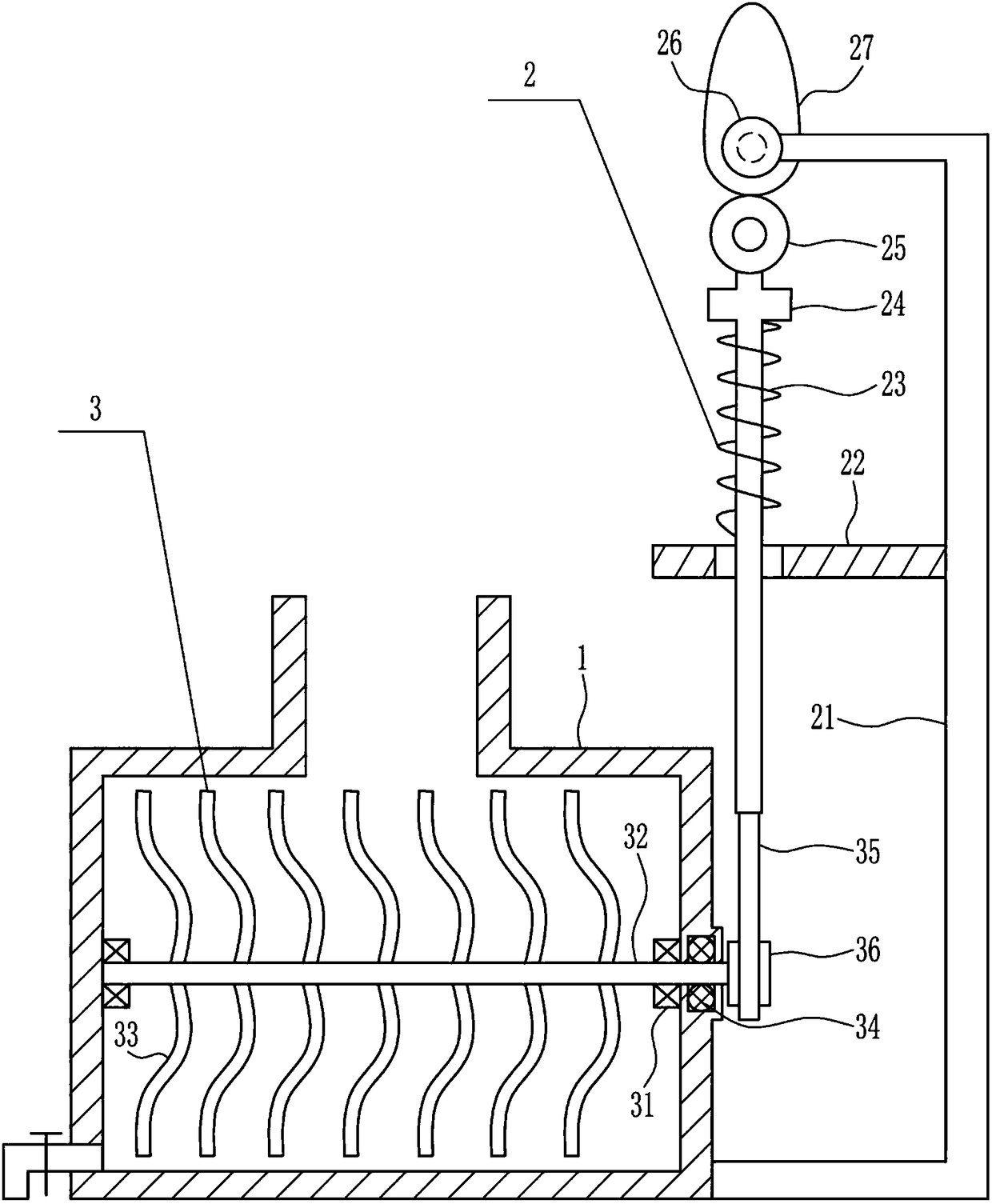

Method of preparing calcium fluoride

InactiveCN103359769ASimple processLow costCalcium/strontium/barium fluoridesReaction temperatureNuclear chemistry

A method of preparing calcium fluoride comprises the following steps: providing a waste solution containing HF acid; controlling the HF content of the waste solution within a predetermined concentration range; adding a Ca source to the waste solution containing HF acid within a predetermined concentration range; and controlling the reaction temperature of Ca and HF acid within a predetermined temperature range to form CaF2. Accordingly, the method of preparing calcium fluoride of this invention has the advantages of simple process, low costs, high CaF2 preparation speed, and high and stable purity and quality of CaF2 prepared thereby.

Owner:吴南明 +1

Traumatic-injury-treating-drug preparing equipment for acupuncture and massage department

InactiveCN108096024AAffect qualityQuality will not affectRotary stirring mixersTransportation and packagingInjury causeMedicine

The invention relates to preparing equipment, in particular to traumatic-injury-treating-drug preparing equipment for the acupuncture and massage department. The traumatic-injury-treating-drug preparing equipment comprises a preparing box and the like and is characterized in that a lifting mechanism is connected to the right wall of the preparing box, and a preparing mechanism is connected into the preparing box and coordinated with the lifting mechanism. The traumatic-injury-treating-drug preparing equipment has the advantages that sufficient preparing is achieved, dust entering, which affects quality, during preparing can be prevented, and preparing capacity can be increased; preparing speed can be increased by the lifting mechanism, and uniform drug preparing can be achieved by the preparing mechanism.

Owner:李刚

Production method of corrosion-resistant high-conductivity fuel cell metal bipolar plate

ActiveCN109768295AShort processAccelerate the process of industrializationFinal product manufactureCollectors/separatorsFuel cellsSurface conductivity

The invention discloses a production method of a corrosion-resistant high-conductivity fuel cell metal bipolar plate. The production method includes the following steps: (1) attaching a conductive material to a metal substrate in the form of spots to obtain a metal substrate A with conductive spots, and then fusing the conductive spots with the metal substrate A into a whole to obtain a metal substrate B; and (2) mechanically punching and forming the metal substrate B to obtain a metal unipolar plate with a flow channel, and bonding the metal unipolar plate to obtain the metal bipolar plate ofthe invention. According to the scheme of the invention, a subsequent surface coating process is not required, the process flow of the fuel cell metal polar plate is shortened, the manufacturing rateof the metal bipolar plate is improved, and the manufacturing cost is reduced; and meanwhile, the corrosion resistance of the substrates and the surface conductivity are fully utilized, the dependence on the surface modification of the metal polar plate is reduced, and the durability in the fuel cell environment can be significantly improved. The method for preparing the fuel cell metal bipolar plate is simple in process and low in cost.

Owner:SHANGHAI ZHIZHEN NEW ENERGY EQUIP CO LTD

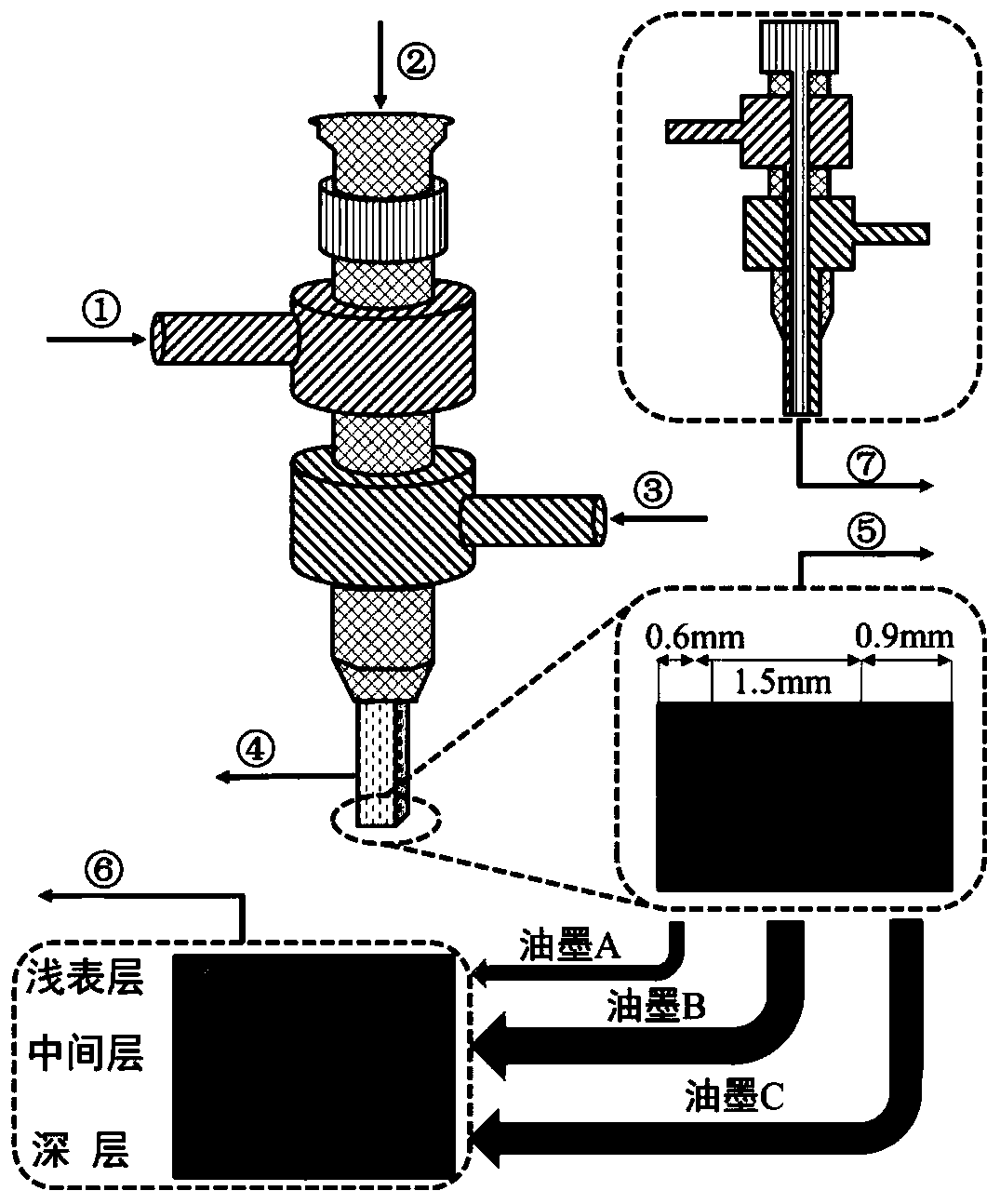

Three-hole integrated 3D biological printing nozzle and method for preparing multi-layer gel

ActiveCN110481023AReduce waiting timeIncrease success rateManufacturing heating elements3D object support structuresSpray nozzleEngineering

The invention discloses a three-hole integrated 3D biological printing nozzle and a method for preparing a multi-layer gel. The three-hole integrated 3D biological printing nozzle comprises a square nozzle at the bottom and three ink bins, wherein the upper part of the square nozzle respectively communicates with the three ink bins; the three ink bins comprises a superficial layer material bin, amiddle layer material bin and a deep layer material bin and are used for storing three composite ink materials; the vertically arranged square nozzle is sleeved with a vertical sleeve; the superficiallayer material bin and the deep layer material bin are sequentially and annularly connected to the sleeve in a sleeving mode; and the lower parts of the three ink bins penetrate through an ink discharging pipe to communicate with the square nozzle at the bottom. According to the three-hole integrated 3D biological printing nozzle and the method for preparing the multi-layer gel, a bionic tissue structure of a three-layer gel material directly printed at one time is similar to the natural tissue in terms of components and structures, the binding capability is good between layers, the 3D biological printing process for directly constructing the multi-layer gel material by one-step method is achieved, the preparation rate of a bionic material is increased, the waiting time of a patient is shortened, and the success rate and the recovery rate of the operation are increased.

Owner:CHINA UNIV OF MINING & TECH

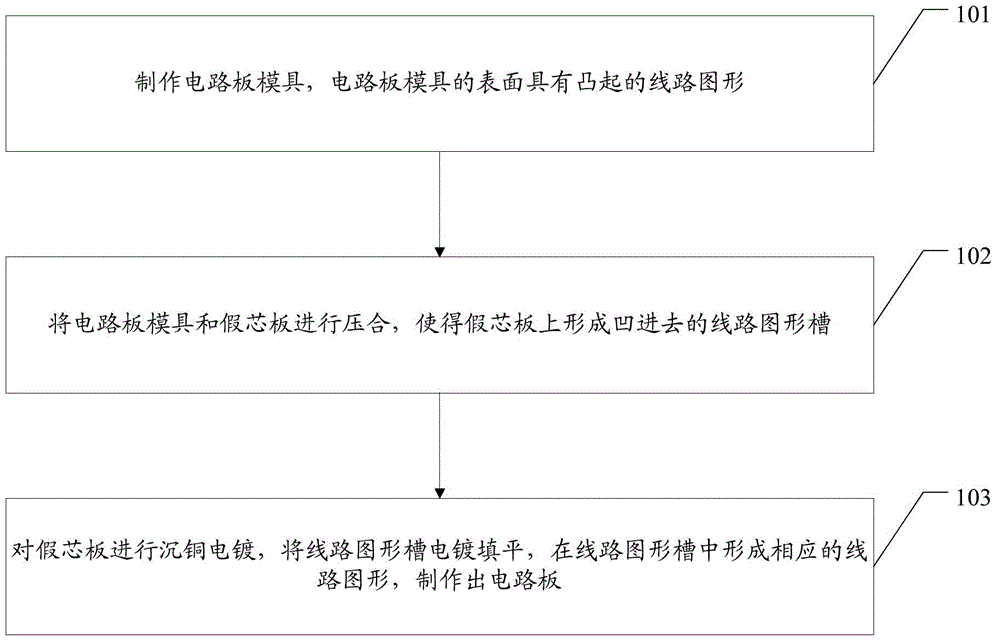

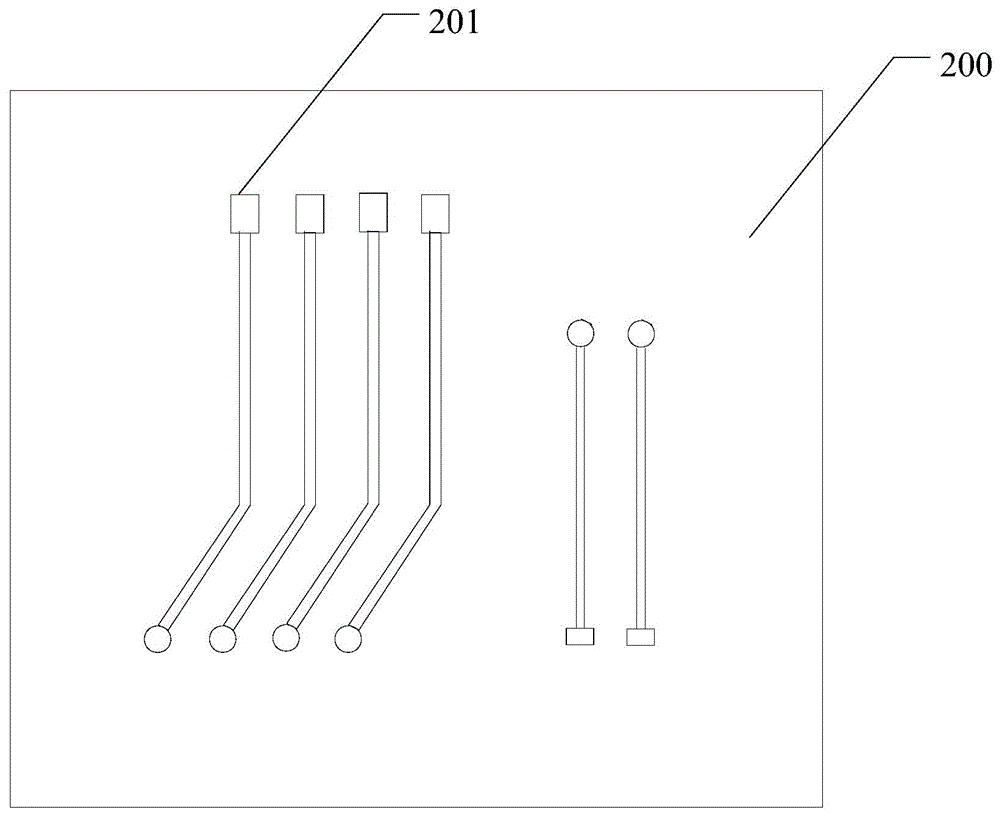

Manufacturing method of circuit board

InactiveCN105472888AIncreased preparation rateReduce manufacturing costPrinted circuit manufactureElectroplatingCopper deposition

The invention discloses a manufacturing method of a circuit board. The method comprises the steps that a circuit board mould is manufactured, and the surface of the circuit board mould is provided with convex line graphs; the circuit board mould and a false core board are laminated so that concave line graph grooves are formed on the false core board; and copper deposition and electroplating are performed on the false core board, the line graph grooves are filled through electroplating, and corresponding line graphs are formed in the line graph grooves so that the circuit board is manufactured. The manufacturing method of the circuit board is used for solving the existing problems of manufacturing of the circuit board in the prior art so that manufacturing rate of the circuit board is accelerated.

Owner:SHENNAN CIRCUITS

Film solar cell with combination of perovskite monocrystalline material and P-type monocrystalline silicon and preparation method thereof

PendingCN106972100AOvercome expensiveAvoid expensive productionSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorAluminium

The present invention provides a film solar cell with the combination of a perovskite monocrystalline material and P-type monocrystalline silicon, and relates to a semiconductor device for converting luminous energy to electric energy. The film solar cell with the combination of the perovskite monocrystalline material and the P-type monocrystalline silicon is formed by a bottom electrode, an N-type oxide semiconductor film, a C<60> electronic film, a perovskite monocrystalline luminous absorption layer, a monocrystalline silicon hole transport layer, and top electrodes, the oxide semiconductor film is an N-type zinc oxide film obtained through magnetron sputtering, the C<60> electronic film is a buffer layer obtained through thermal evaporation, the perovskite monocrystalline is a luminous absorption material with a perovskite structure, the hole transport layer is a P-type monocrystalline silicon material obtained through magnetron sputtering, and the bottom electrode and the top electrodes are films formed by aluminum or silver and obtained through thermal evaporation. According to the film solar cell, the perovskite monocrystalline material is regarded as the luminous absorption layer, the P-type monocrystalline silicon material is regarded as the hole transport layer, and the stable and high-efficiency solar cell is obtained.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com