Three-hole integrated 3D biological printing nozzle and method for preparing multi-layer gel

A technology of bioprinting and multi-layer gel, which is applied in the field of bionic materials, can solve the problems of multi-layer structure of bionic natural cartilage and complex preparation process, and achieve the goal of improving the preparation rate, increasing the success rate and recovery rate, and shortening the waiting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

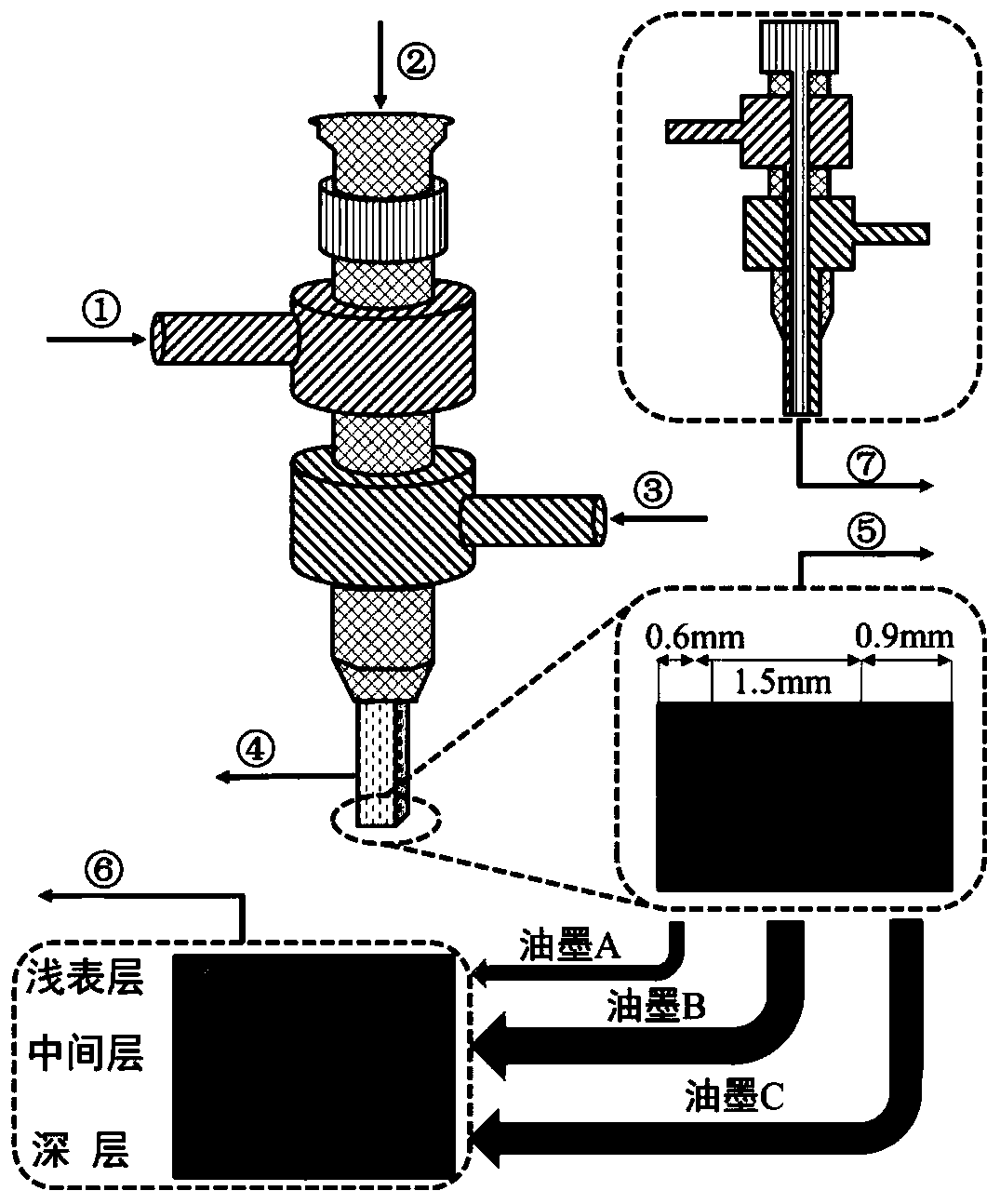

[0032] Embodiment 1: A kind of square three-hole integrated 3D bioprinting nozzle designed by the present invention (such as figure 1 shown); the materials for preparing multilayer gel biomimetic tissue in the present invention include: three composite inks for 3D bioprinting; calcium chloride solution; phosphate buffer.

[0033] The three-hole integrated 3D bioprinting nozzle is mainly divided into seven parts:

[0034] ①Inlet for shallow surface material (bio-ink A);

[0035] ② The feed port of the intermediate layer material (bio-ink B);

[0036] ③ The feed port of the deep layer material (bio-ink C);

[0037] ④ The front view of the "three holes in one" square nozzle;

[0038] ⑤ Cross-sectional view of the "three holes in one" square nozzle;

[0039] ⑥ The internal schematic diagram of the "three holes in one" 3D bioprinting nozzle;

[0040] ⑦ Schematic diagram of the multi-layer gel tissue structure produced by the "three holes in one" 3D bioprinting nozzle.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com