Preparation method of high temperature superconducting film

A high-temperature superconducting, furnace-temperature technology, applied in the field of preparing high-temperature superconducting films using chemical solution deposition technology, can solve the problems of reducing the production rate of high-temperature superconducting films and long heat treatment time, and achieve excellent superconducting properties and improve mechanical properties , The effect of dense and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for preparing the high-temperature superconducting film provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

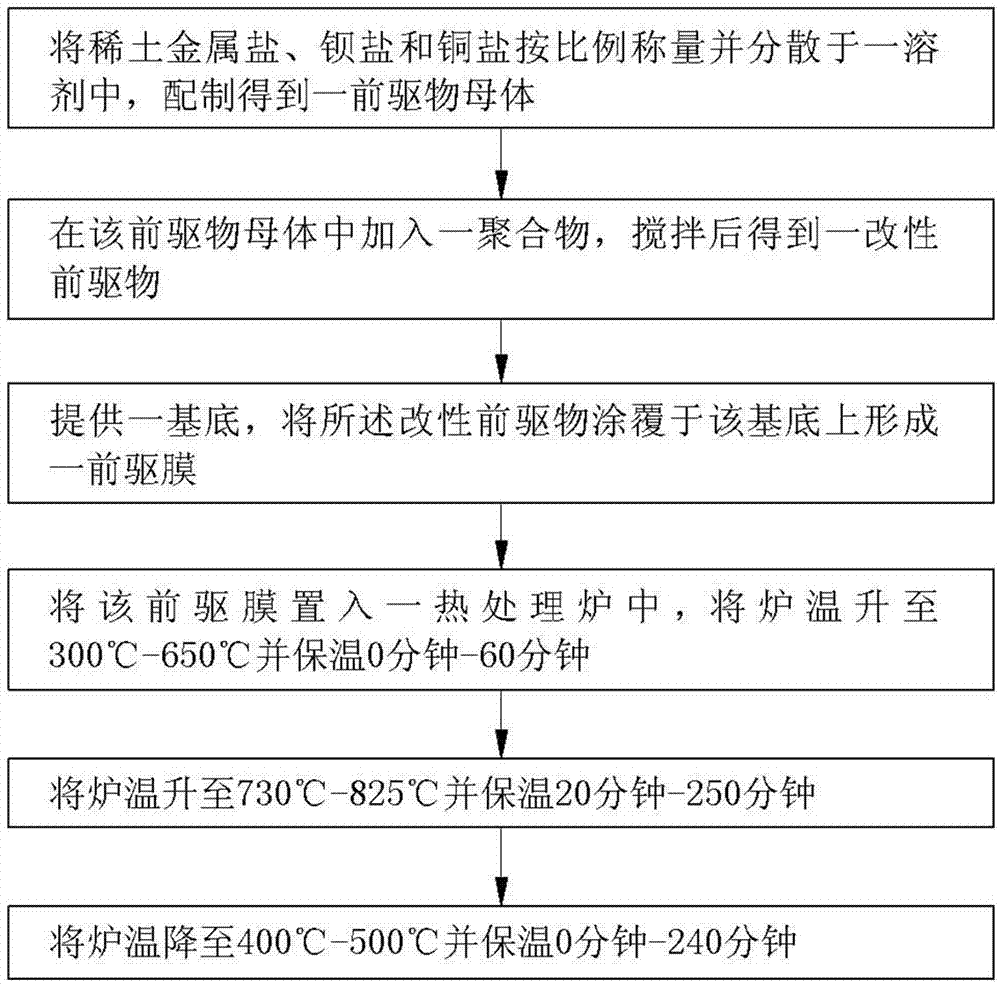

[0019] See figure 1 , an embodiment of the present invention provides a method for preparing a high-temperature superconducting film, which includes the following specific steps:

[0020] (S1) weighing and dispersing rare earth metal salts, barium salts and copper salts in a solvent in proportion to obtain a precursor precursor;

[0021] (S2) adding a polymer to the precursor matrix, and stirring to obtain a modified precursor;

[0022] (S3) providing a substrate, and coating the modified precursor on the substrate to form a precursor film;

[0023] (S4) Put the precursor film into a heat treatment furnace, raise the temperature of the furnace to 300°C-650°C and keep it warm for 0-60 minutes;

[0024] (S5) raising the furnace temperature to 730°C-825°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com