Manufacturing method of circuit board

A production method and circuit board technology, applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of time-consuming, complicated process, waste of copper foil, etc., so as to reduce production cost, speed up production speed, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

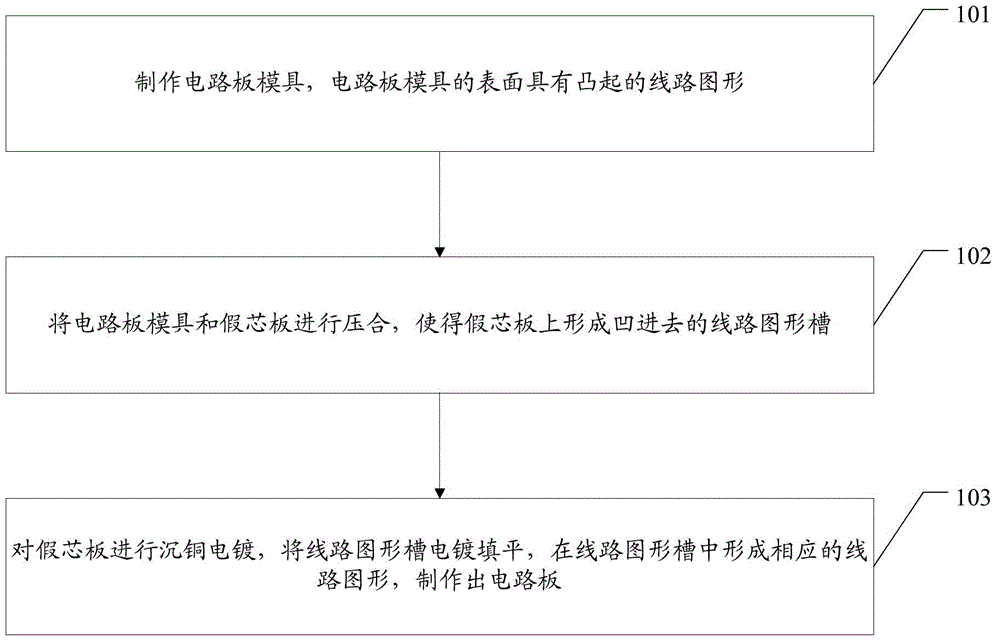

[0023] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a circuit board, which may include:

[0024] 101. Make a circuit board mold, the surface of the circuit board mold has raised circuit graphics;

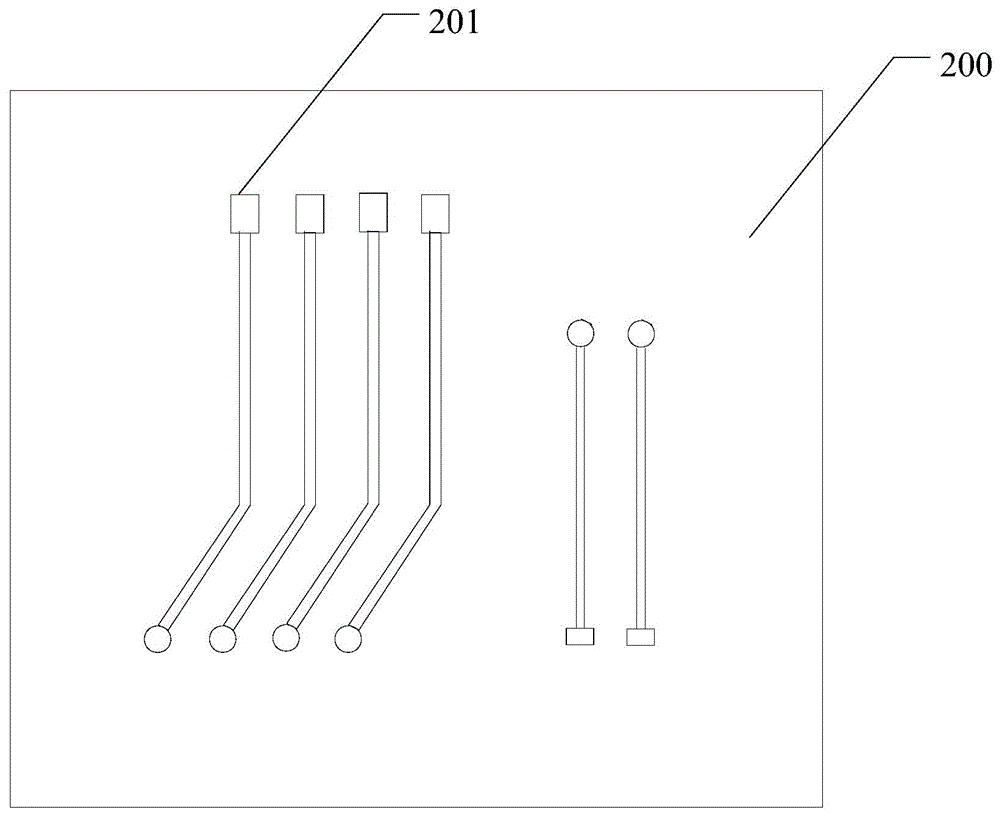

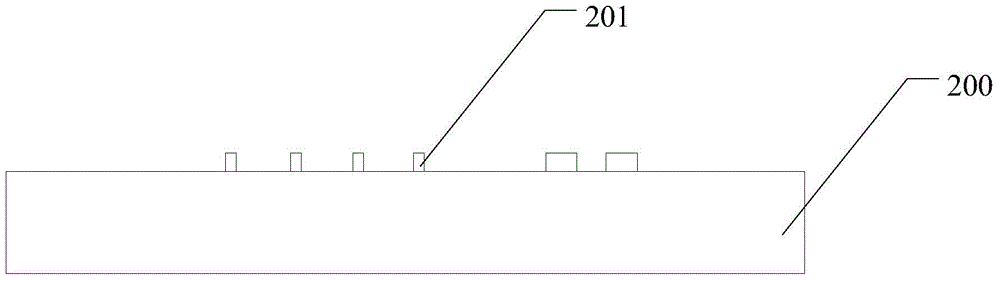

[0025] Please refer to figure 2 and image 3 , are a plan view and a cross-sectional view of the circuit board mold respectively, and the circuit board mold 200 is produced, and the surface of the circuit board mold 200 has a raised circuit pattern 201 .

[0026] Optionally, a circuit board mold 200 is produced, and the surface of the circuit board mold 200 has a raised circuit pattern 201 including:

[0027] The circuit board mold 200 is made of a material that does not stick to resin glue, and the material that does not stick to resin glue is poured according to the circuit pattern 201 of the preset circuit board and iron solution is used to form a raised circuit pattern 201 on the surface of the circuit board mold 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com