Method of preparing calcium fluoride

A calcium fluoride and calcium salt technology, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problems of low production rate, uneconomical, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the features of the present invention, a preferred embodiment is listed below and described in conjunction with the drawings, wherein:

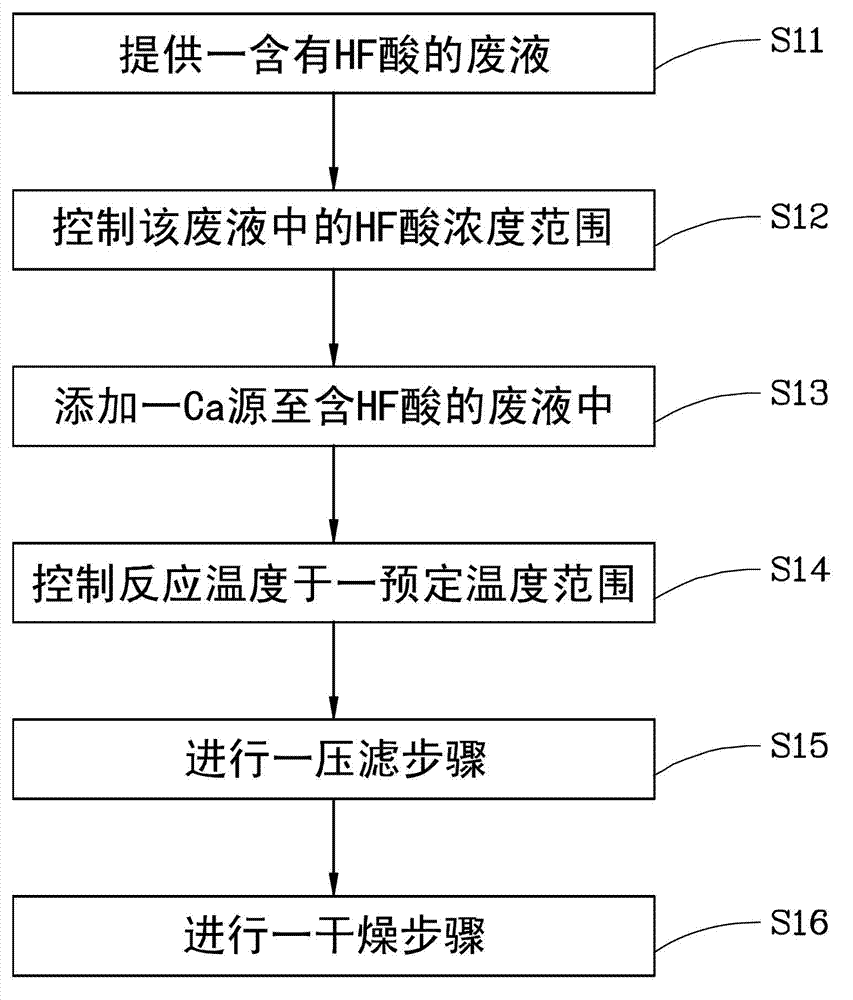

[0014] figure 1 It is a flowchart of a method for preparing calcium fluoride in a preferred embodiment of the present invention; and

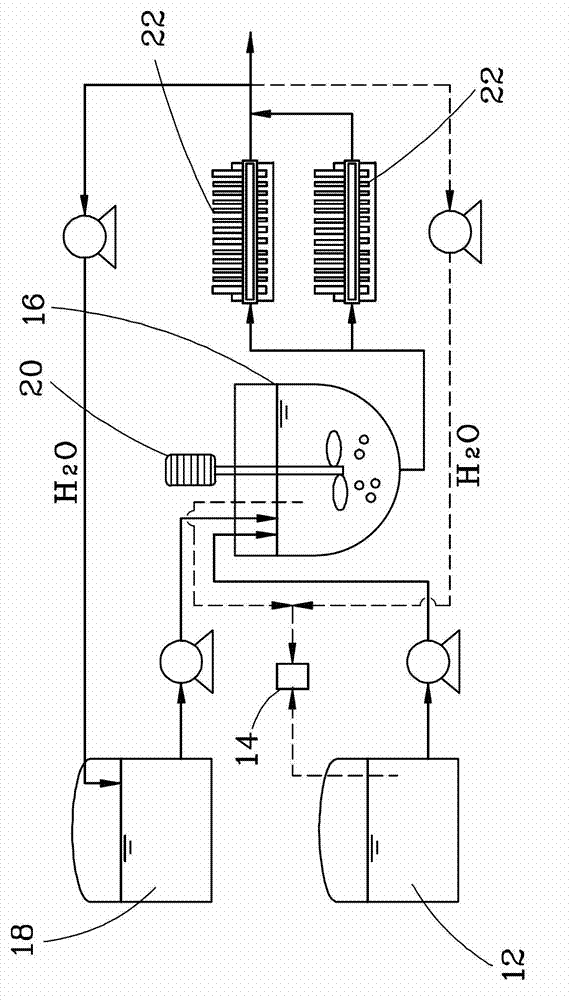

[0015] figure 2 It is a process schematic diagram of a calcium fluoride preparation method in a preferred embodiment of the present invention.

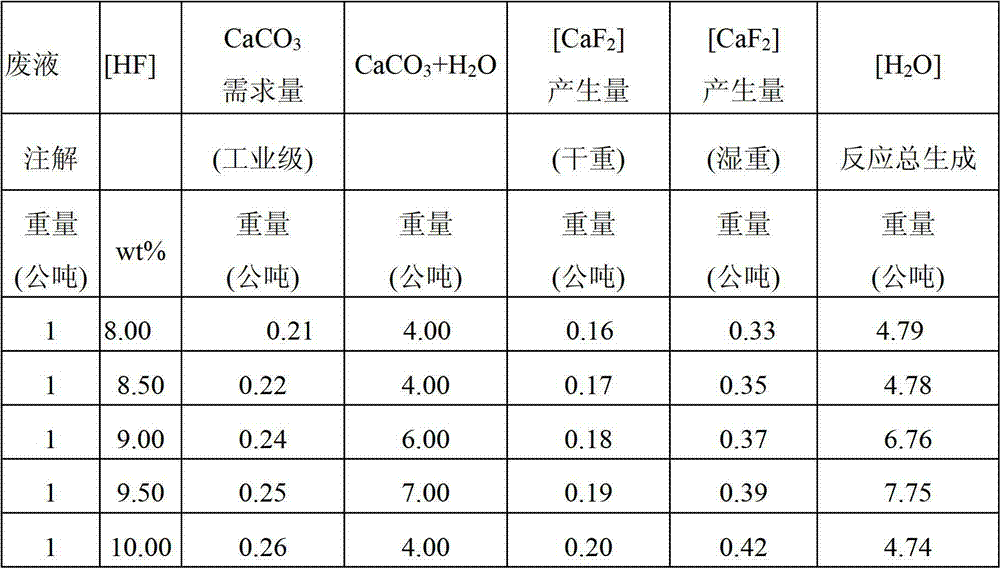

[0016] The waste liquids formed by different industries and different processes usually contain different concentrations of HF acid, the concentration can range from 3wt% to 49wt%, and some of these waste liquids may also contain impurities such as nitric acid and / or sulfuric acid, or even Fluorosilicide. The present invention is to provide a method for preparing calcium fluoride, which has simple manufacturing process, low cost, and CaF 2 The preparation rate is high, and the prepared CaF 2 It has extremely high and stable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com