Carbon nanometer tube flat filament, preparation method and preparation device thereof

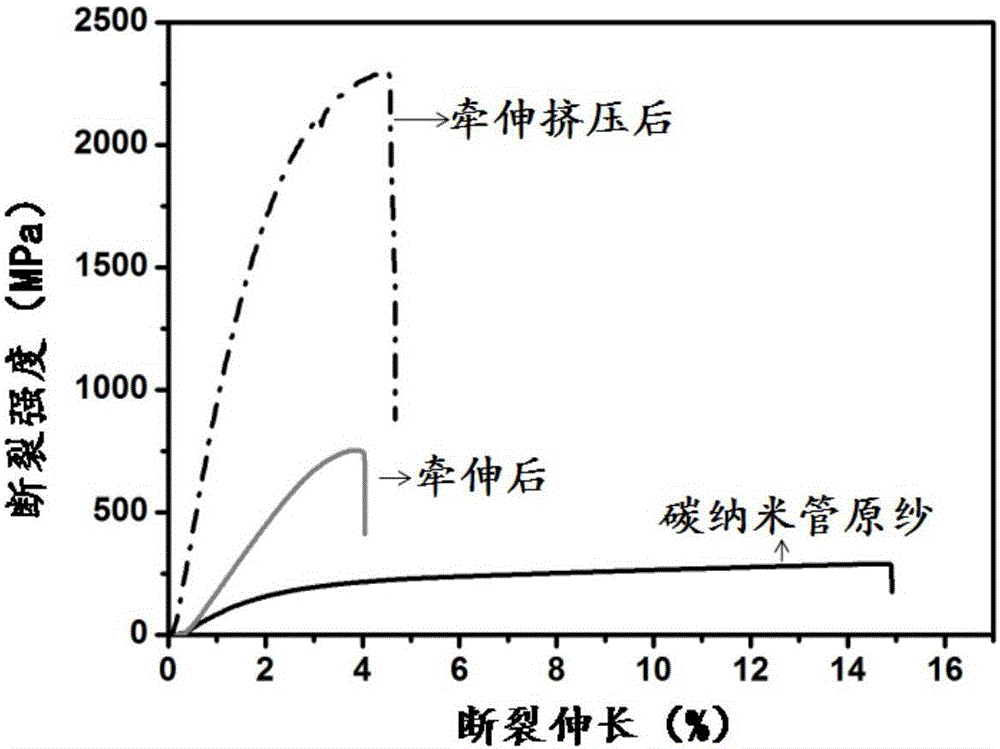

A technology of carbon nanotubes and preparation devices, which is applied in the direction of textiles and papermaking, can solve the problems of difficult processing, etc., and achieve the effects of good mechanics, increased contact area, and improved interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

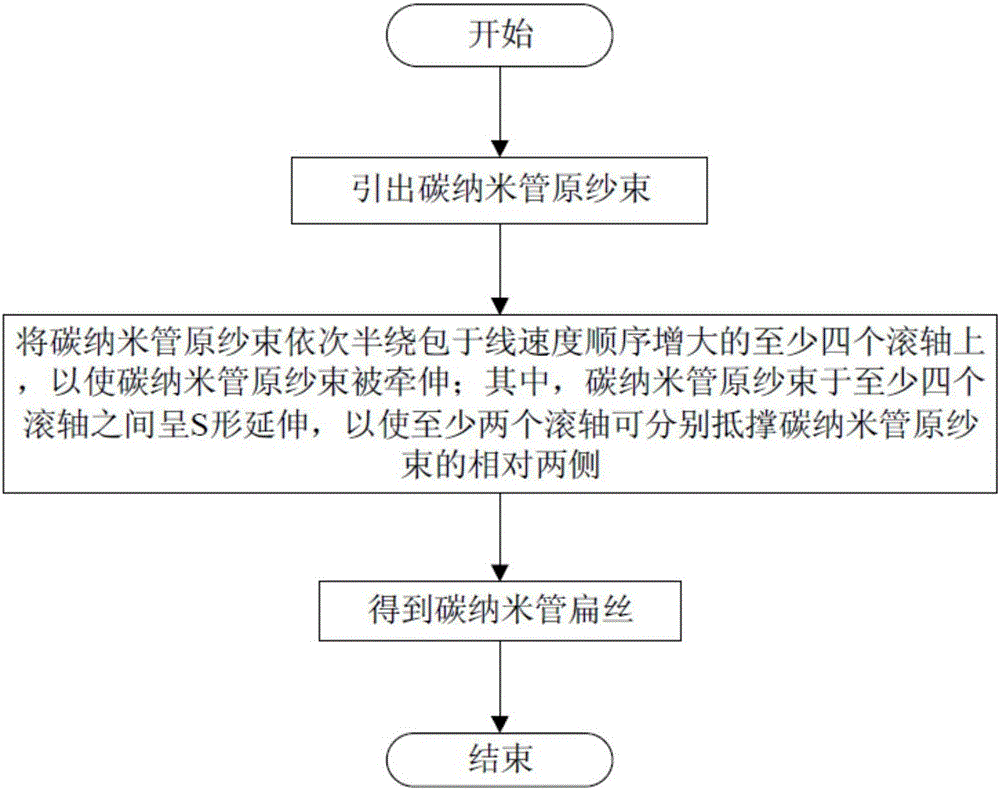

[0046] see figure 1 , one embodiment of the present invention provides a kind of preparation method of carbon nanotube flat wire, and described preparation method comprises steps:

[0047] Draw out the original yarn bundle of carbon nanotubes;

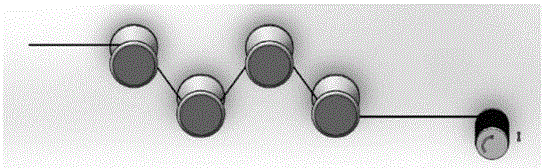

[0048] The carbon nanotube raw yarn bundle is half-wrapped on at least four rollers whose line speed increases sequentially, so that the carbon nanotube raw yarn bundle is drafted; wherein, the carbon nanotube raw yarn bundle is wound on at least four rollers The shafts extend in an S shape, so that at least two rollers can support the opposite sides of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com