Reinforced-concrete draught fan tower

A technology for steel-concrete structures and wind turbine towers, which is applied in the installation/support of wind turbine configuration, wind power generation, sustainable manufacturing/processing, etc. problems, to achieve the effect of improving convenience, saving production time and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

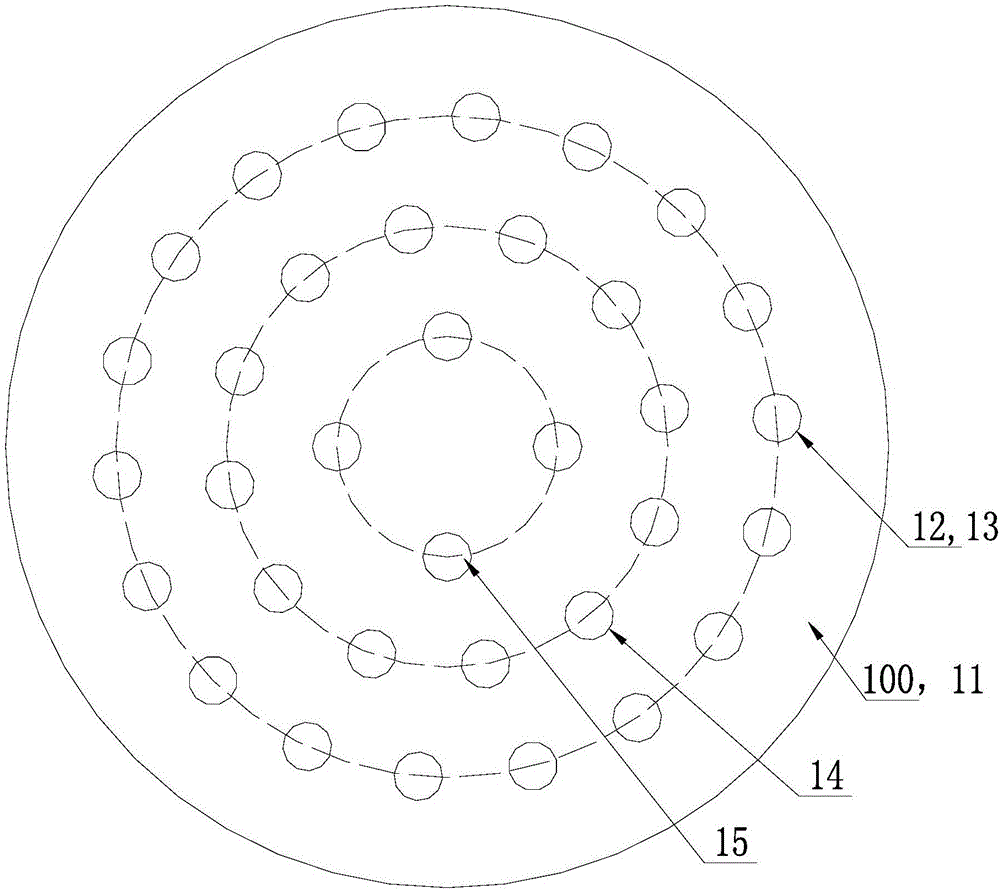

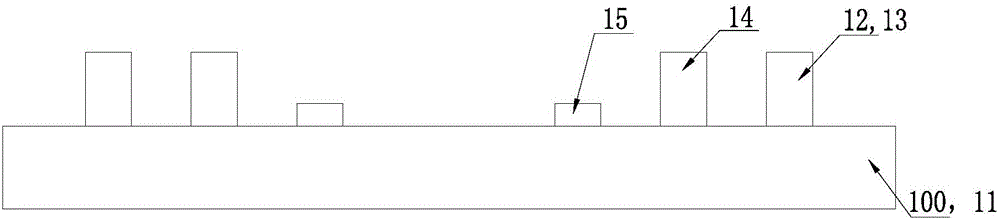

[0052] Such as Figure 5 and Figure 6 As shown, in this embodiment, the concrete tower 300 includes a top plate 39 set at the top and a support platform 200 set at the bottom. The top plate 39 is an annular support platform 200 set along the top of the side wall It is in the shape of a disk covering the bottom of the tower, the top plate 39 is coaxially arranged with the support platform 200, and the two ends of the multiple support steel bars 38 arranged at equal intervals are fixedly connected with the top plate 39 and the support platform 200 respectively to form a The supporting skeleton of the concrete tower 300 .

[0053] In this embodiment, the distances between the upper end of each supporting steel bar 38 and the center of the top plate 39 are equal, and the distance between the lower end and the center of the supporting platform 200 is equal, and the horizontal distance between the lower end of the supporting steel bar 38 and the axis of the tower is greater than t...

Embodiment 2

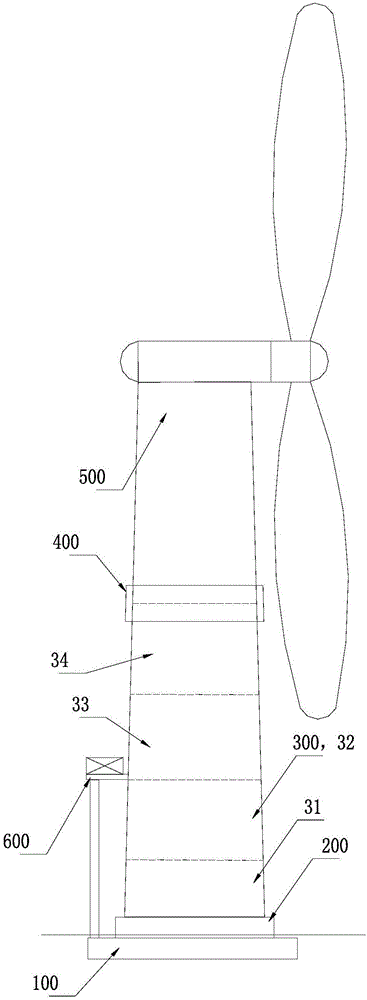

[0060] Such as figure 1 As shown, in this embodiment, the concrete tower 300 includes multiple sections of concrete towers poured sequentially from bottom to top, and each concrete tower section is a cylindrical structure arranged along the supporting frame to form the concrete tower 300 side wall of the tower. Preferably, the concrete tower tube 300 in this embodiment is divided into four sections for pouring in different batches, which are respectively from bottom to top, the first concrete tower section 31, the second concrete tower section 32, and the third concrete tower section The barrel section 33 and the fourth concrete tower section 34.

[0061] Such as Figure 6 to Figure 8 and Figure 12 As shown, in this embodiment, a plurality of prestressed steel bars 1 are arranged in the side wall of the concrete tower 300, and each prestressed steel bar 1 is arranged at equal intervals with respect to the axis of the tower; The grid-shaped steel bar group 21 forming the s...

Embodiment 3

[0070] Such as Figure 9 As shown, in this embodiment, the concrete tower 300 is formed by splicing a plurality of arc-shaped concrete tower sections 30; both sides of the concrete tower section 30 are respectively provided with Connected mother-in-law spelling strips. Therefore, the concrete tower 300 itself can be constructed by splicing and installing multi-segment concrete tower sections 30, so that the concrete tower 300 itself can realize the manufacturing process of pouring in batches and rapid assembly in the later stage, greatly speeding up the production of concrete The manufacturing speed of the tower tube 300 reduces the manufacturing difficulty.

[0071]In this embodiment, the left side of each concrete tower section 30 is respectively provided with a sub-strip, and the right side is respectively provided with a mother-strip, and the said mother-strip and the sub-strip are arranged in cooperation; the said sub-strip It is composed of protruding ribs 35 with a "T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com