Patents

Literature

78results about How to "Reduce axial thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

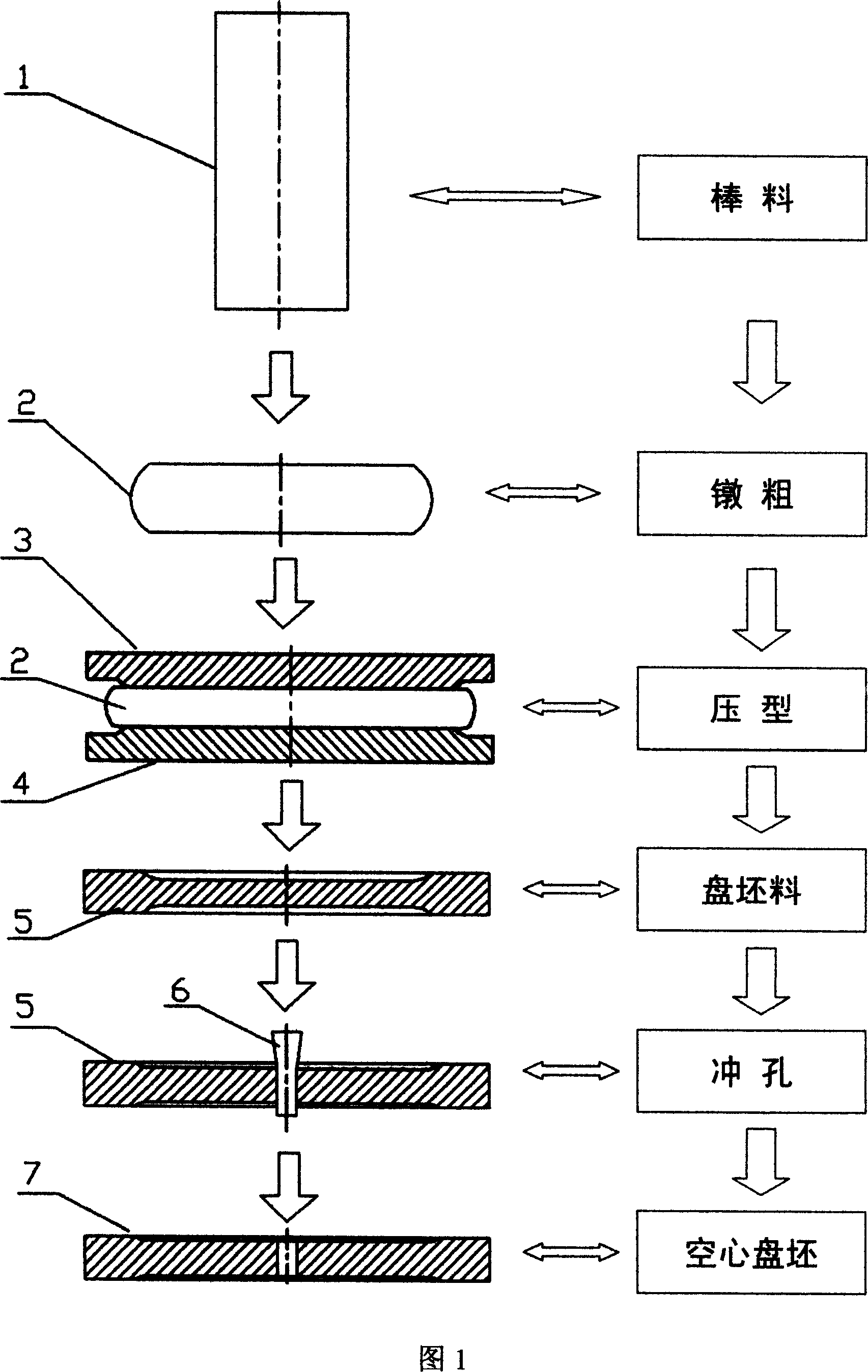

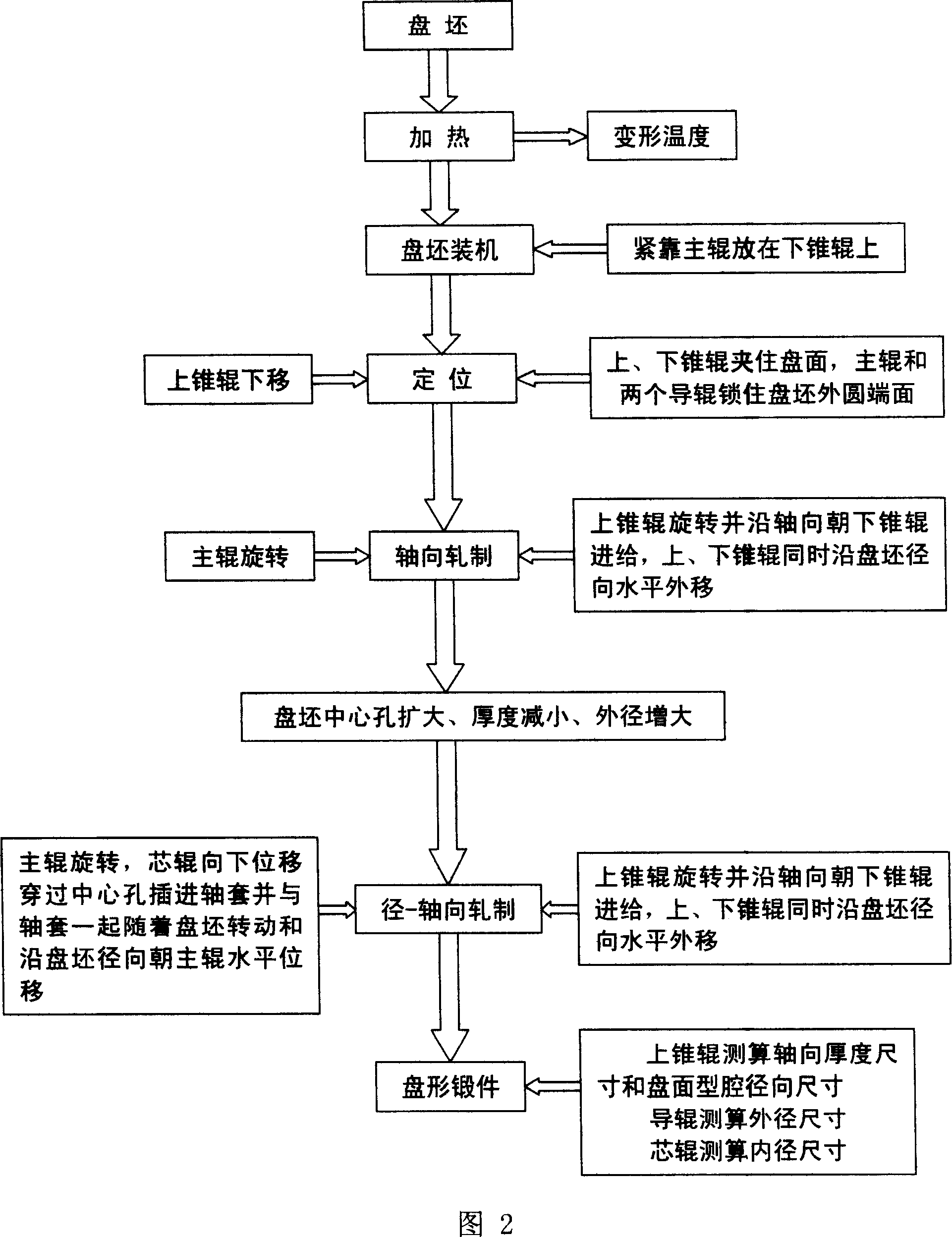

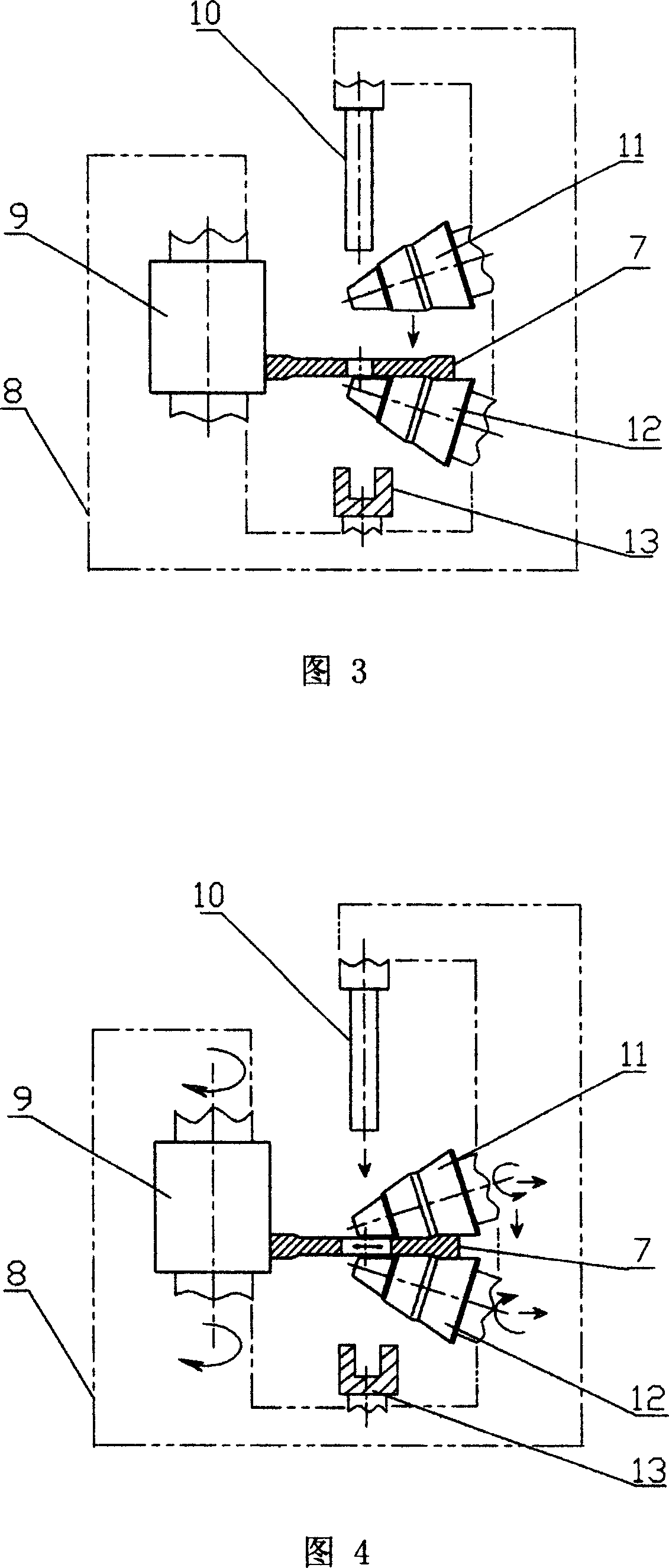

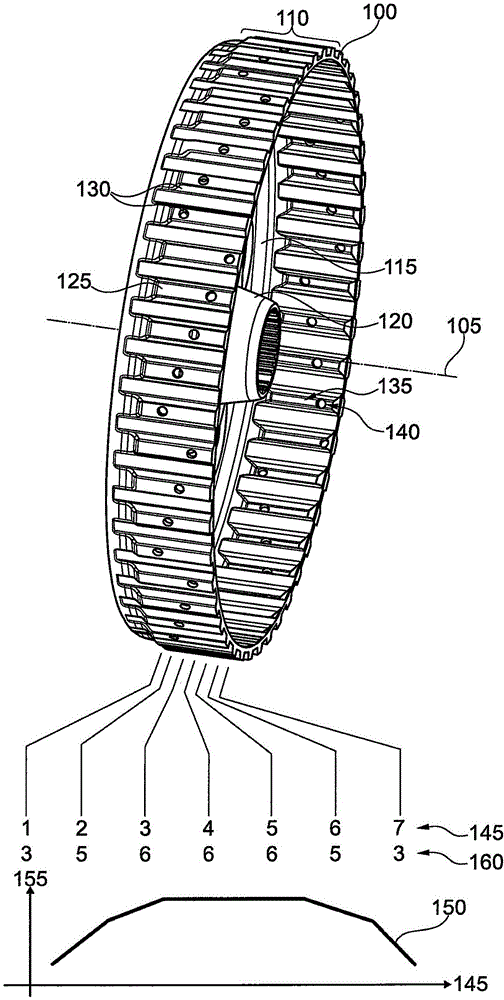

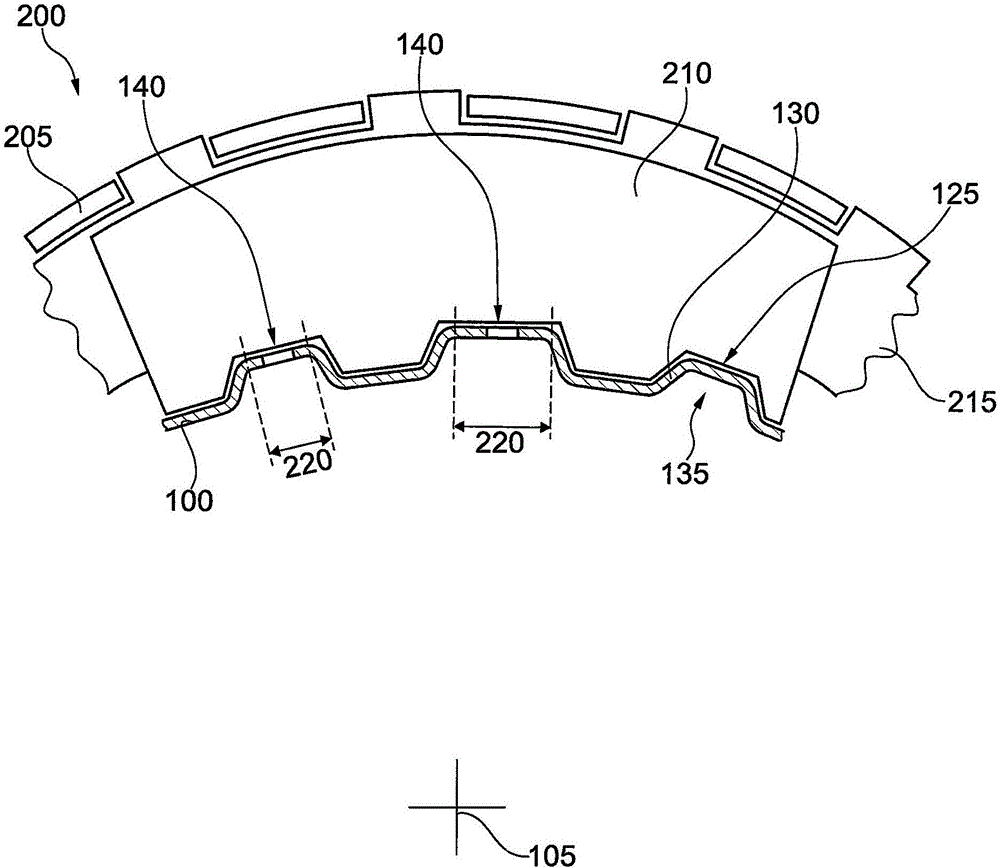

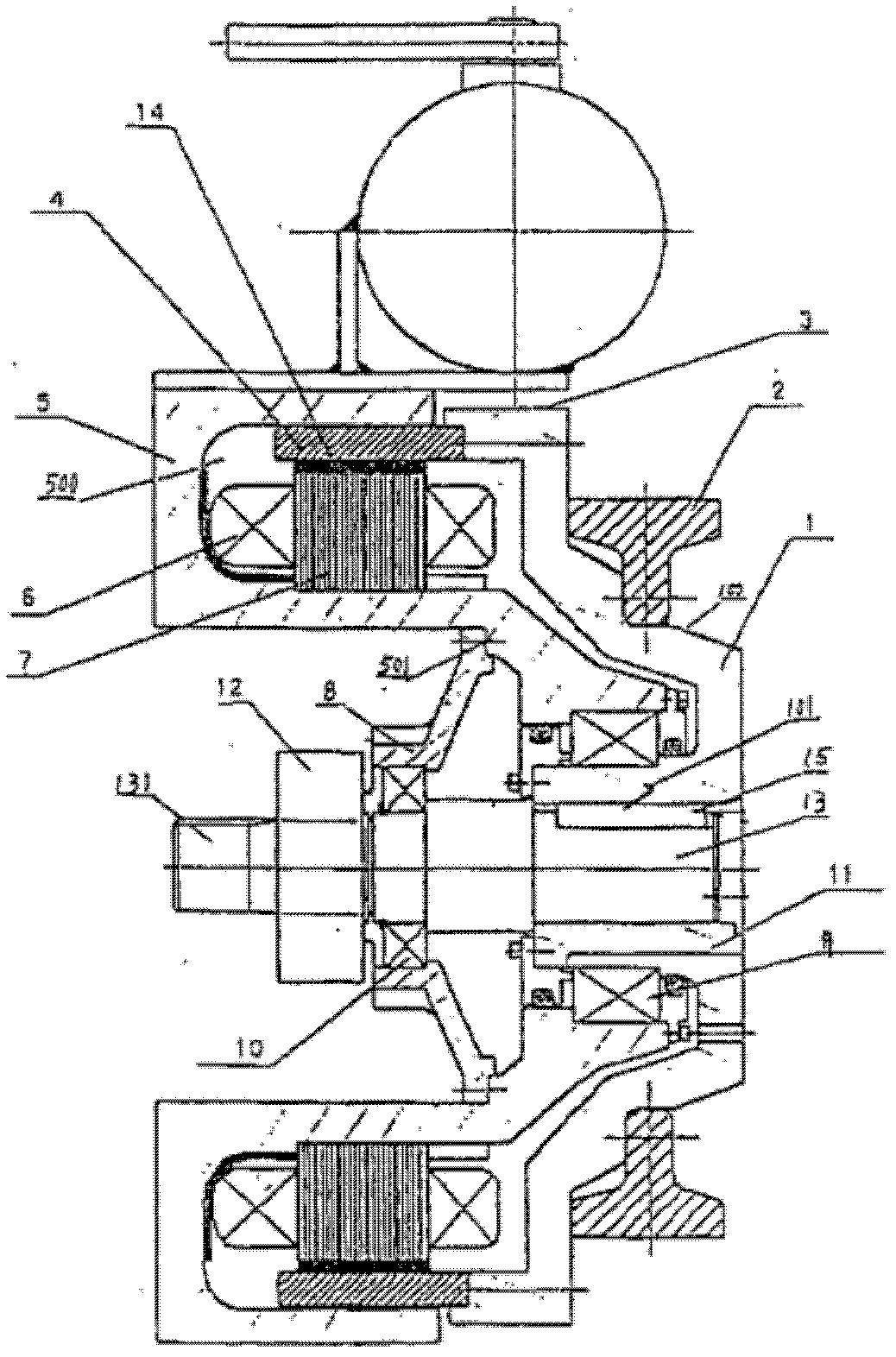

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

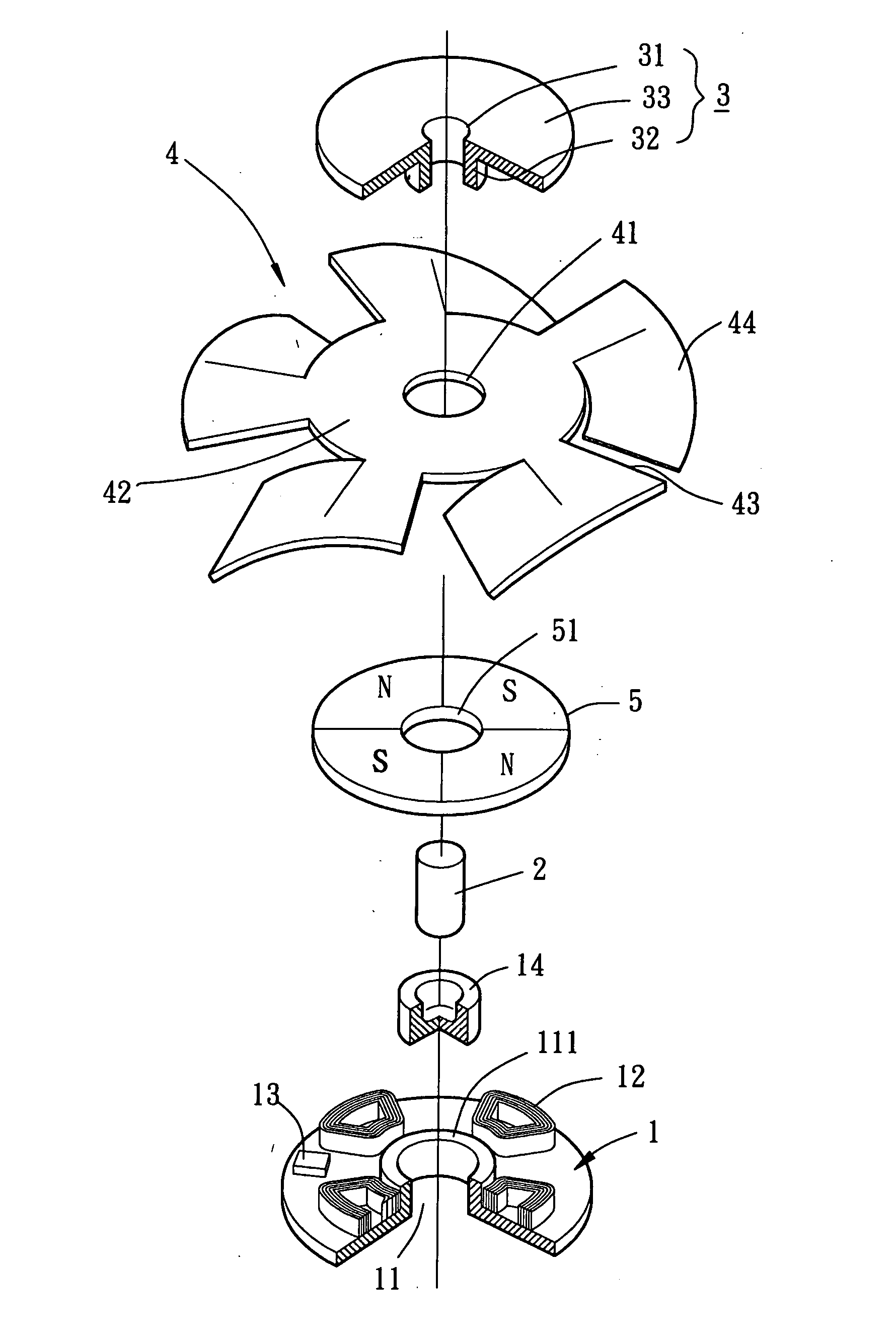

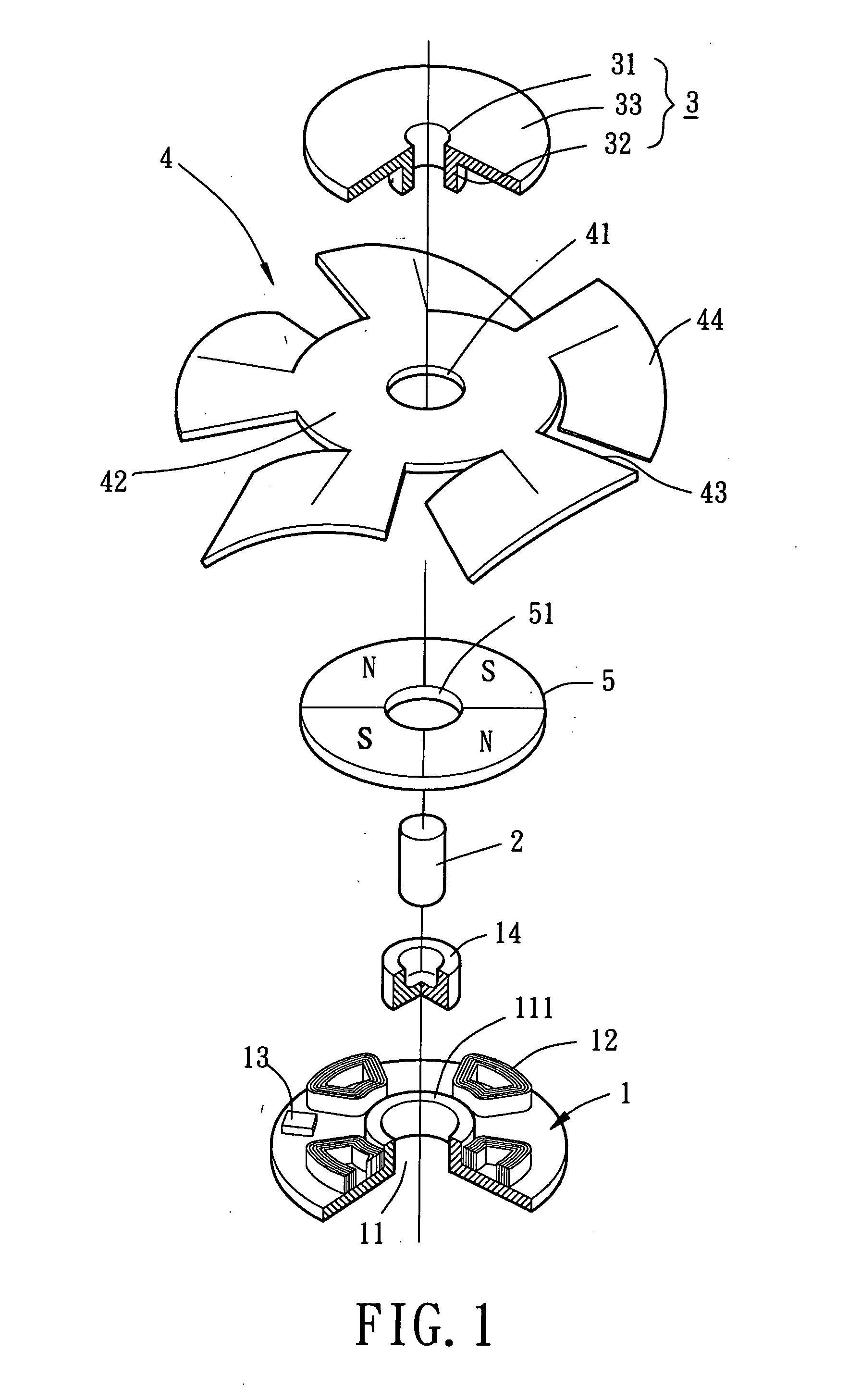

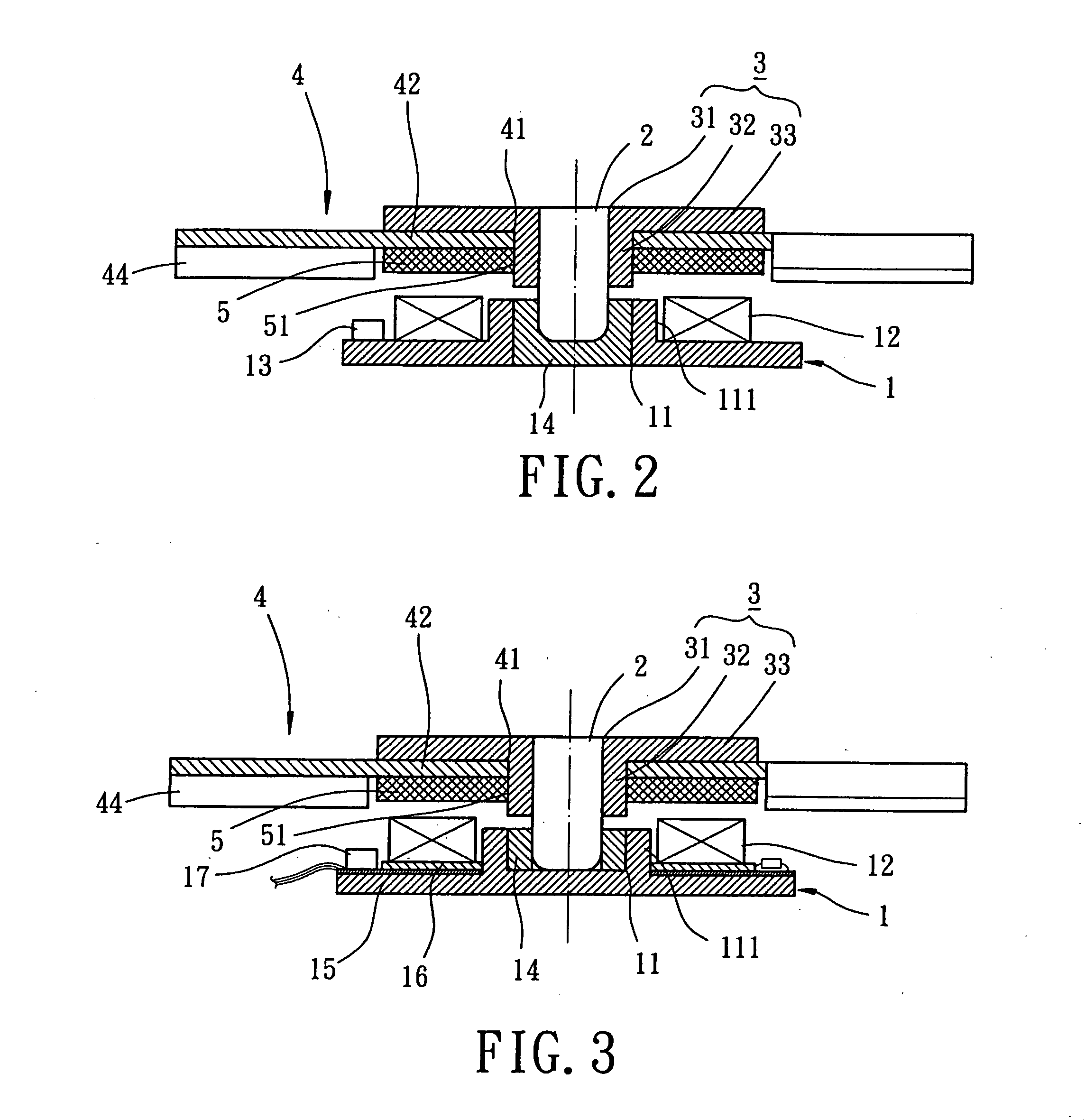

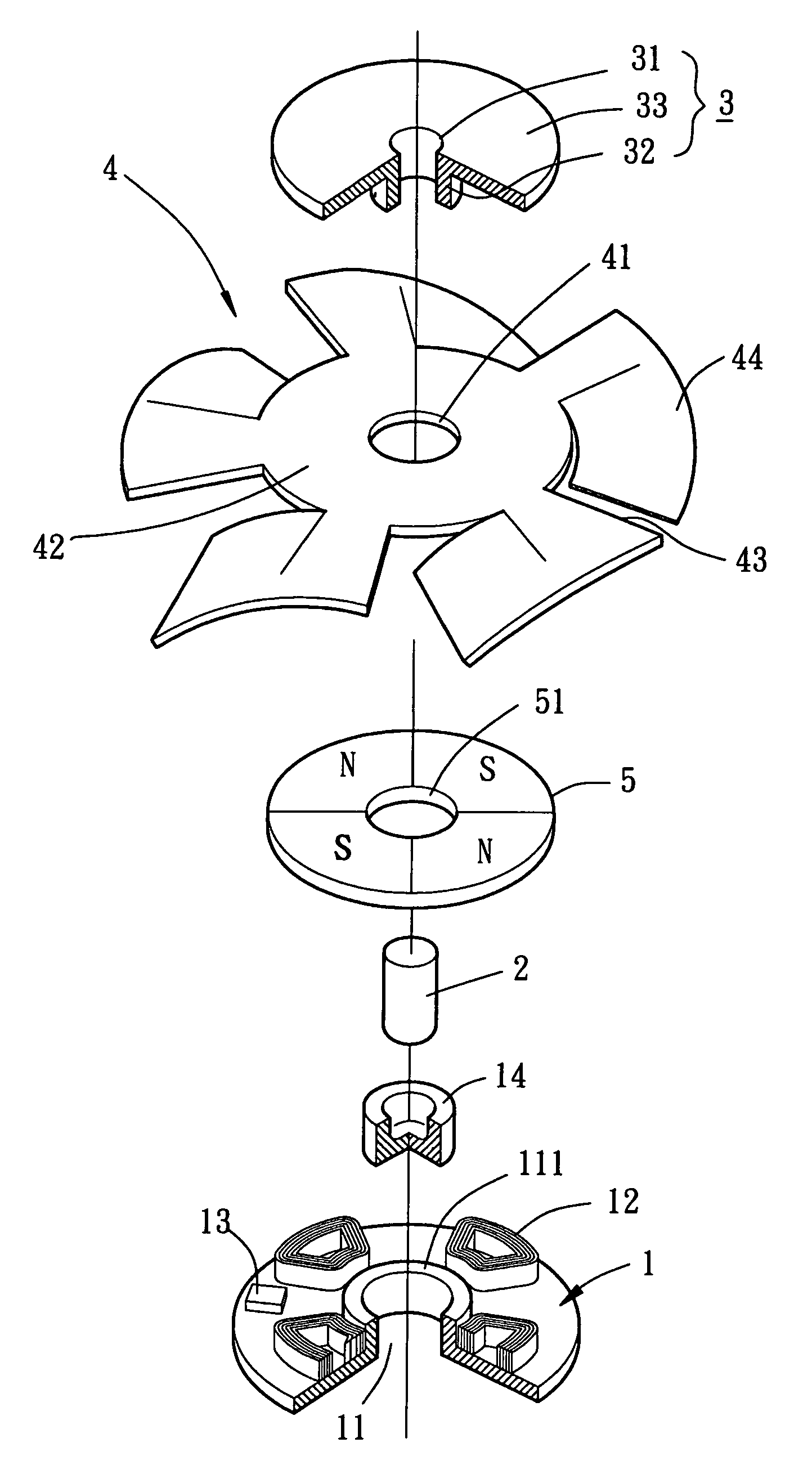

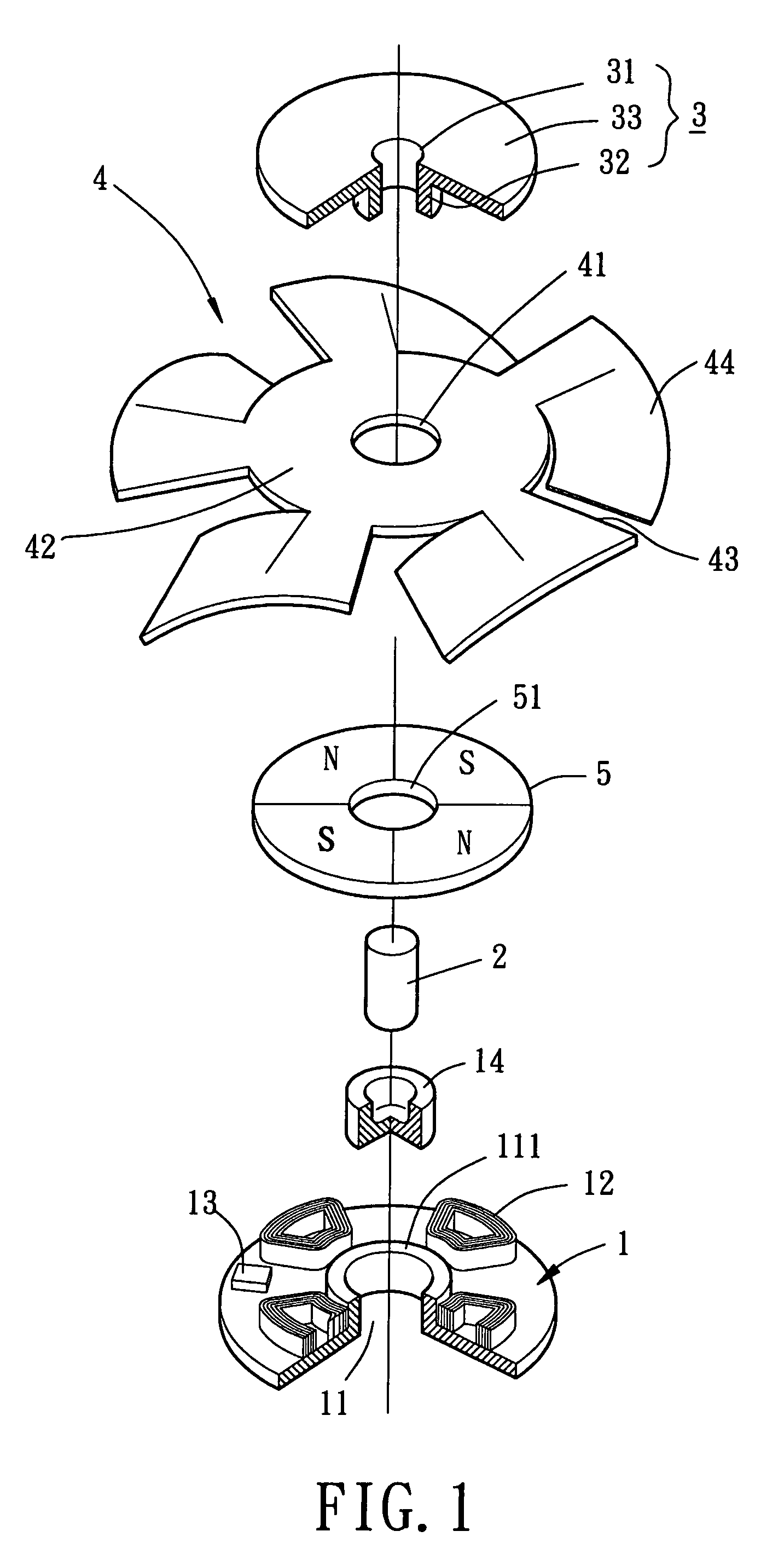

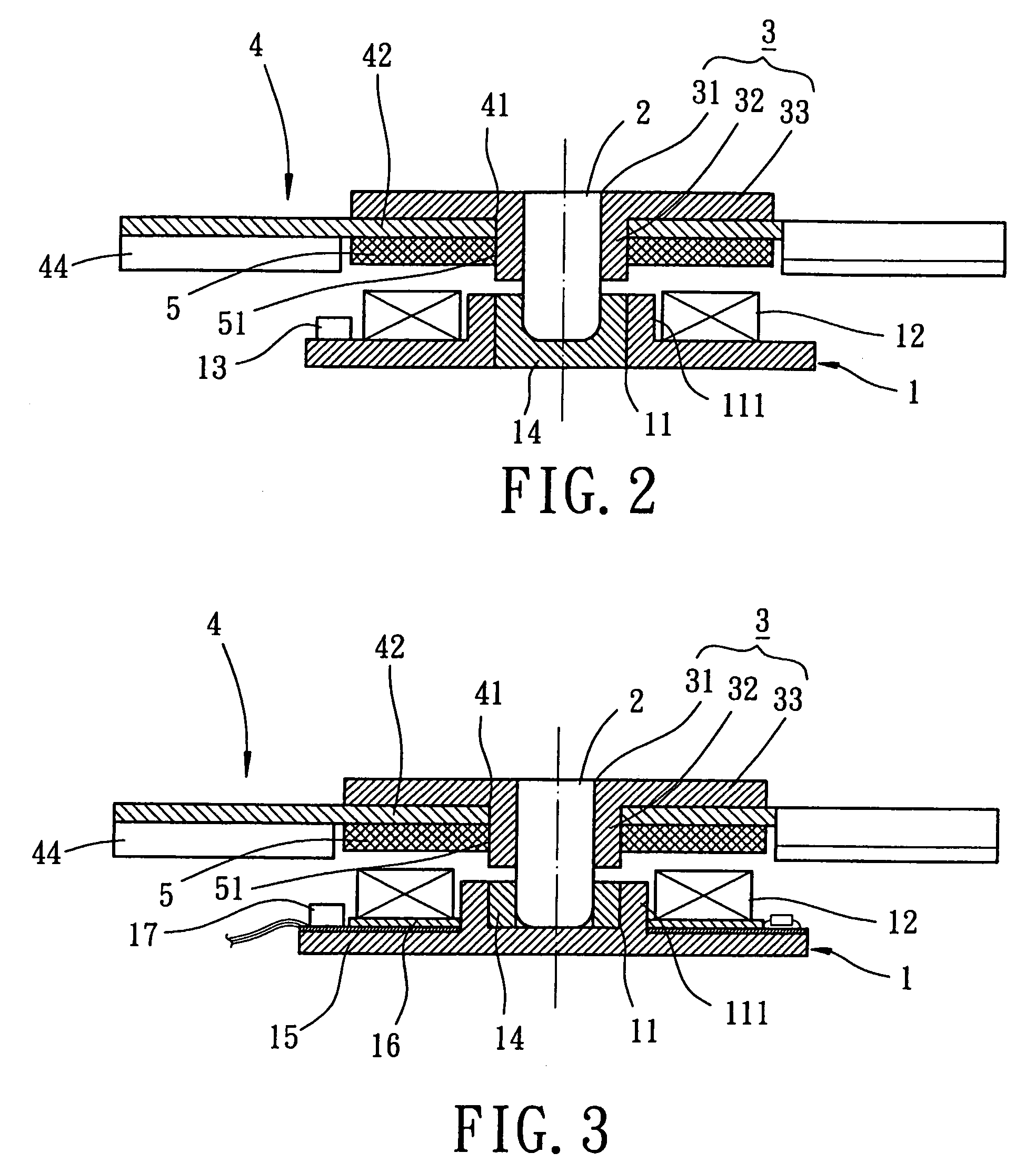

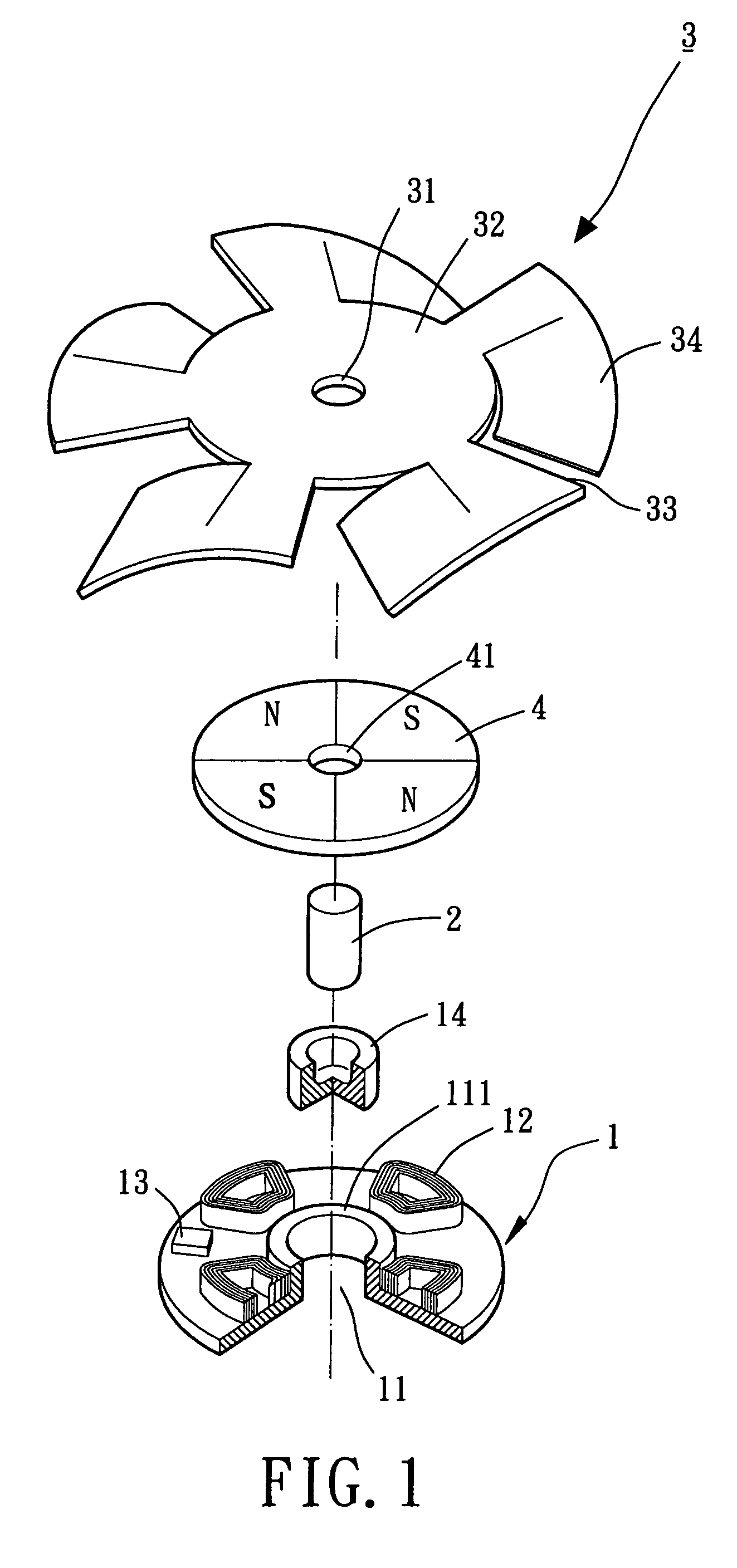

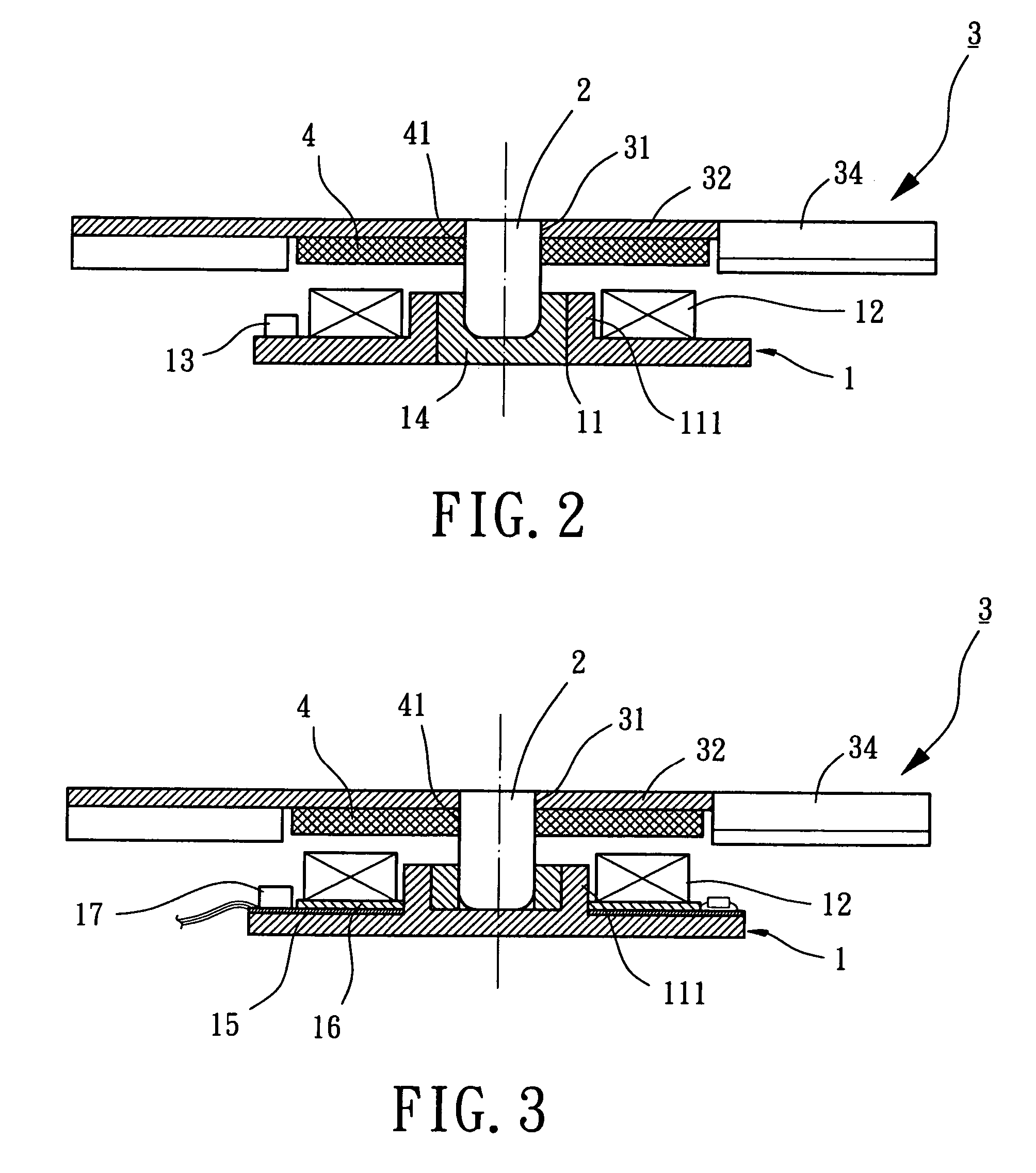

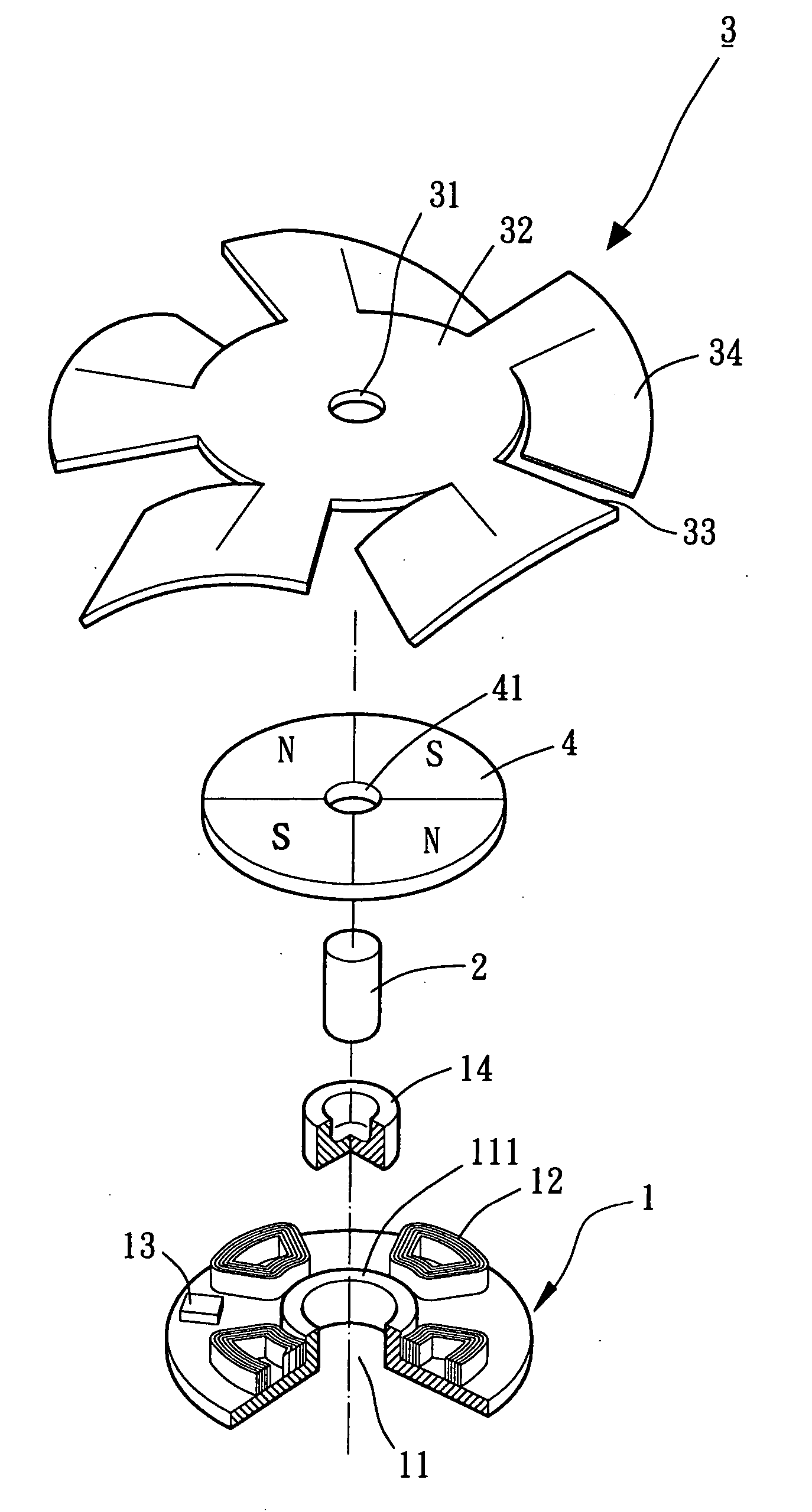

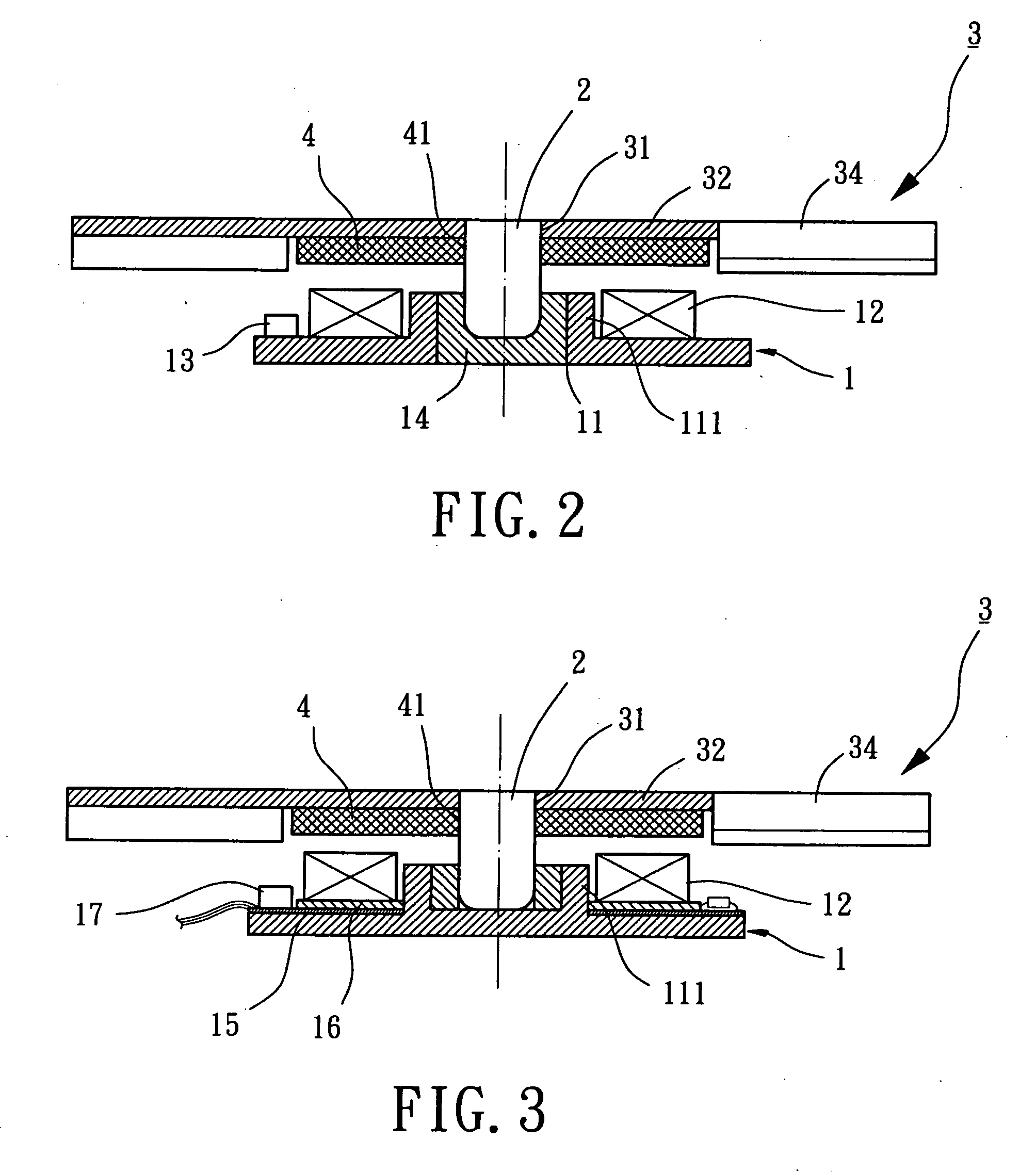

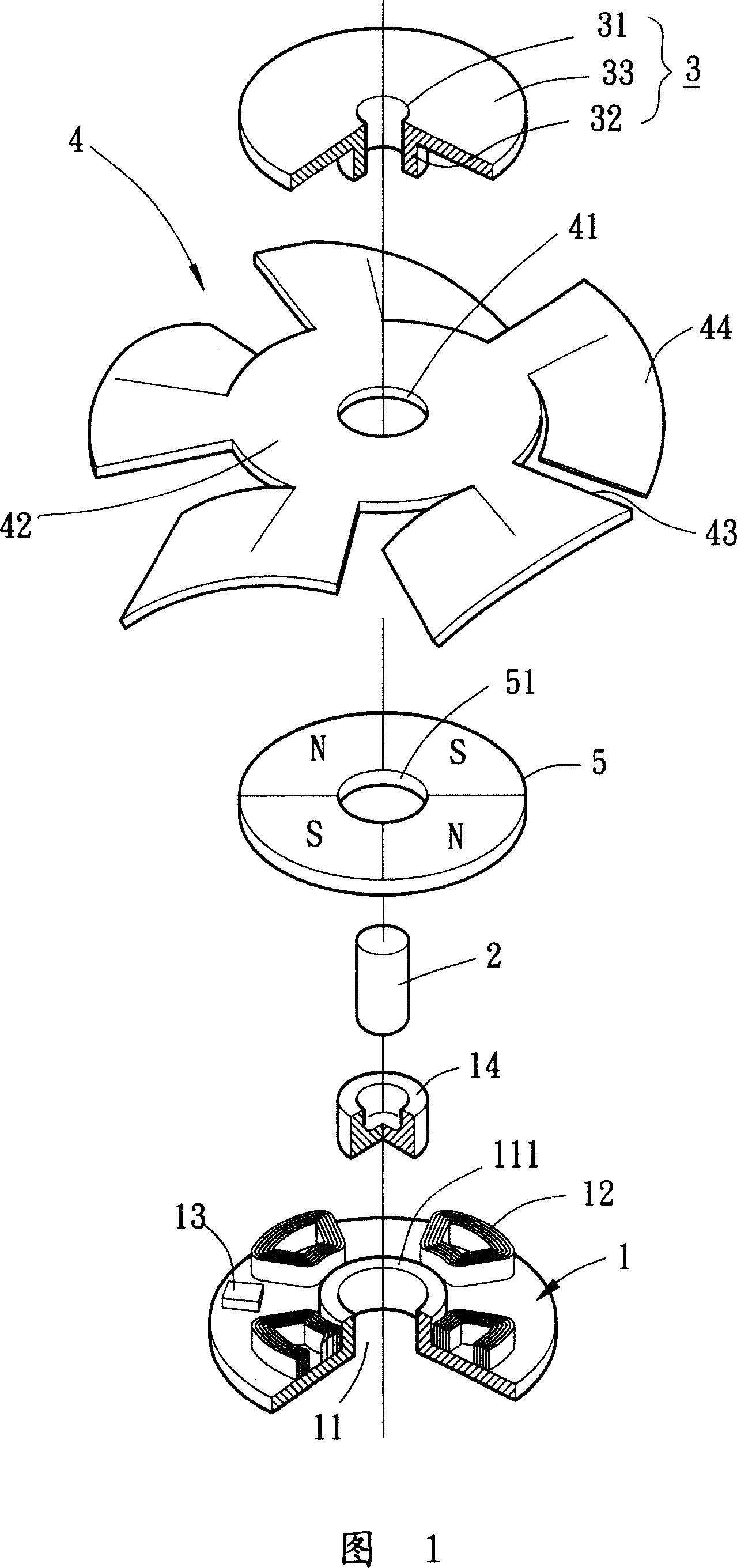

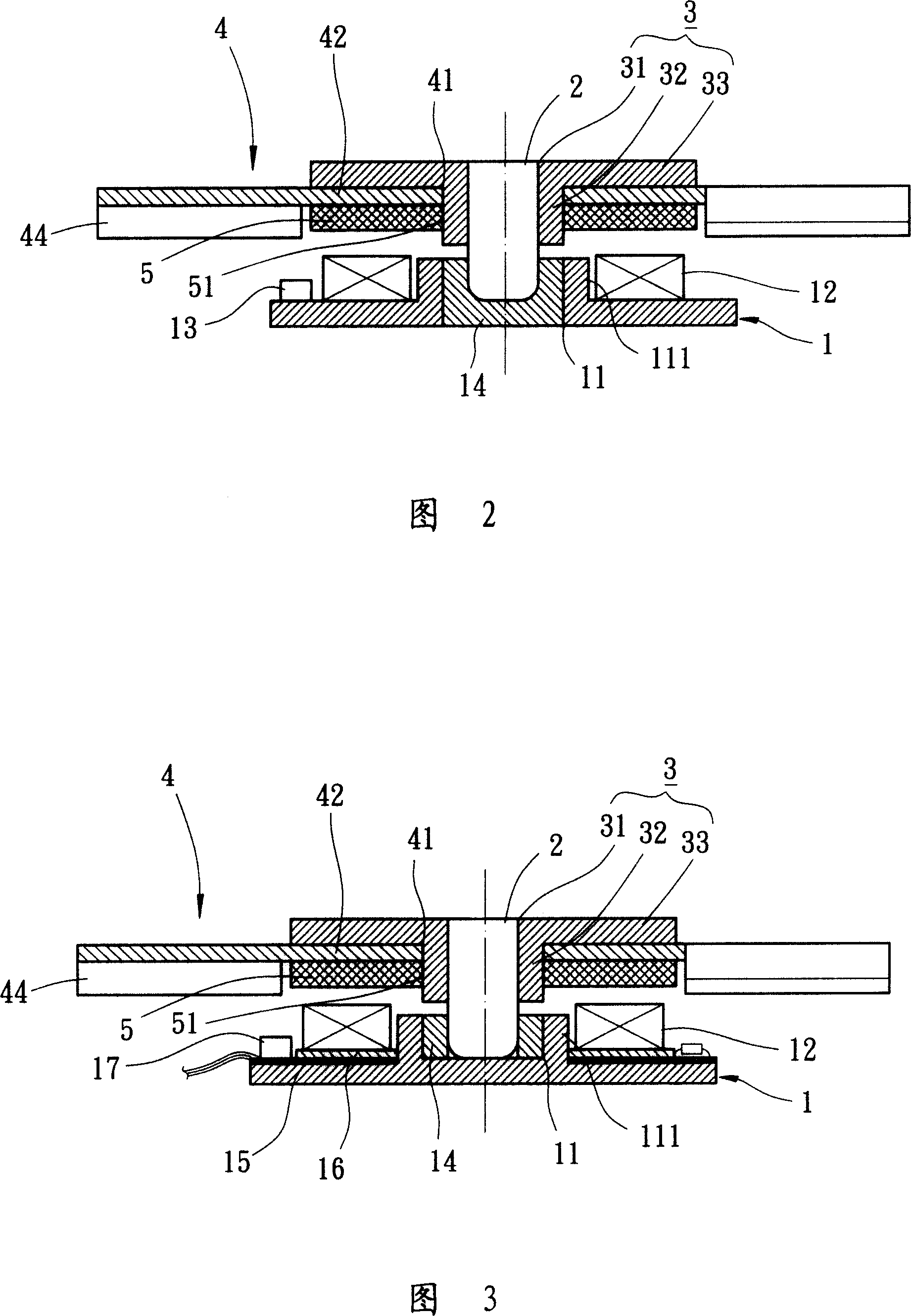

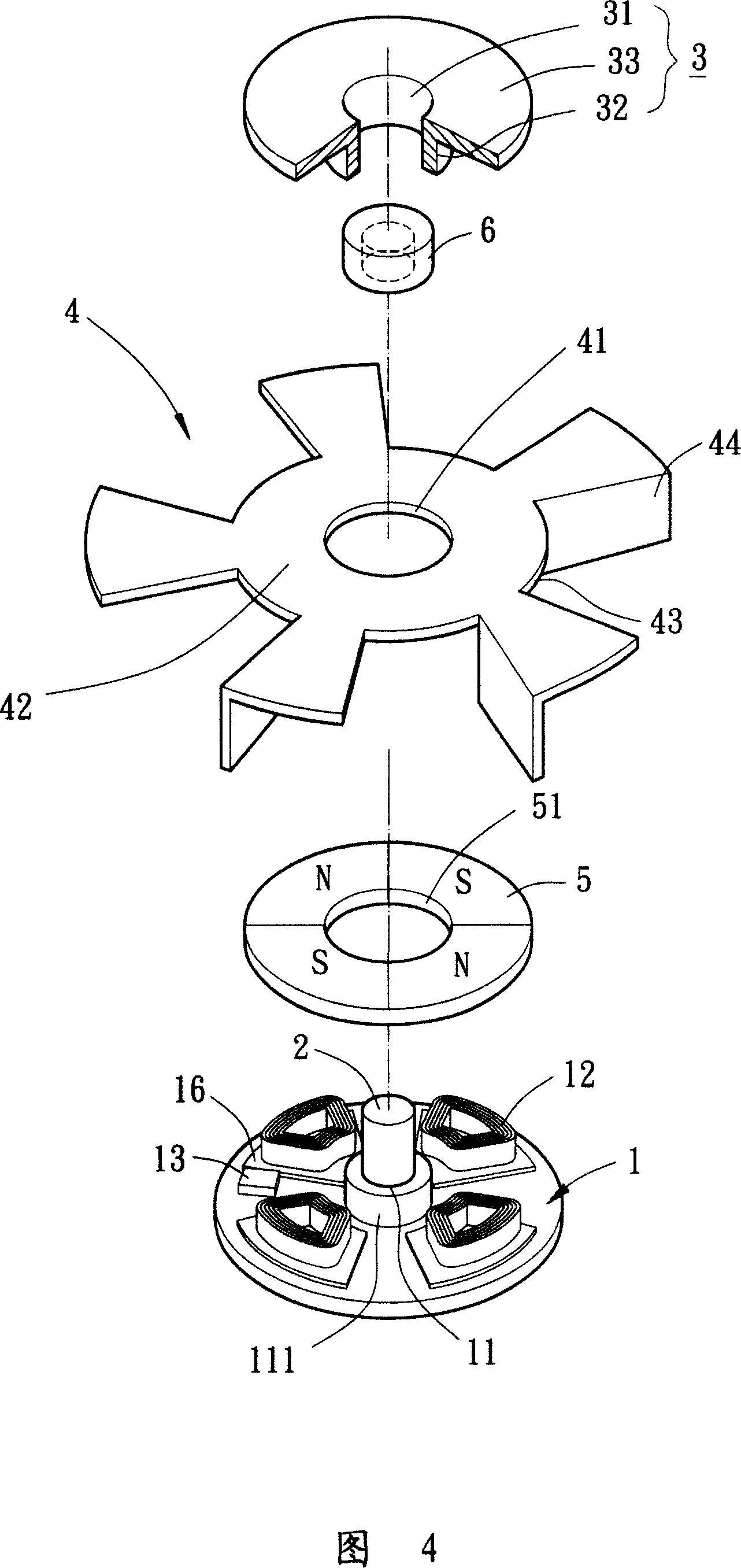

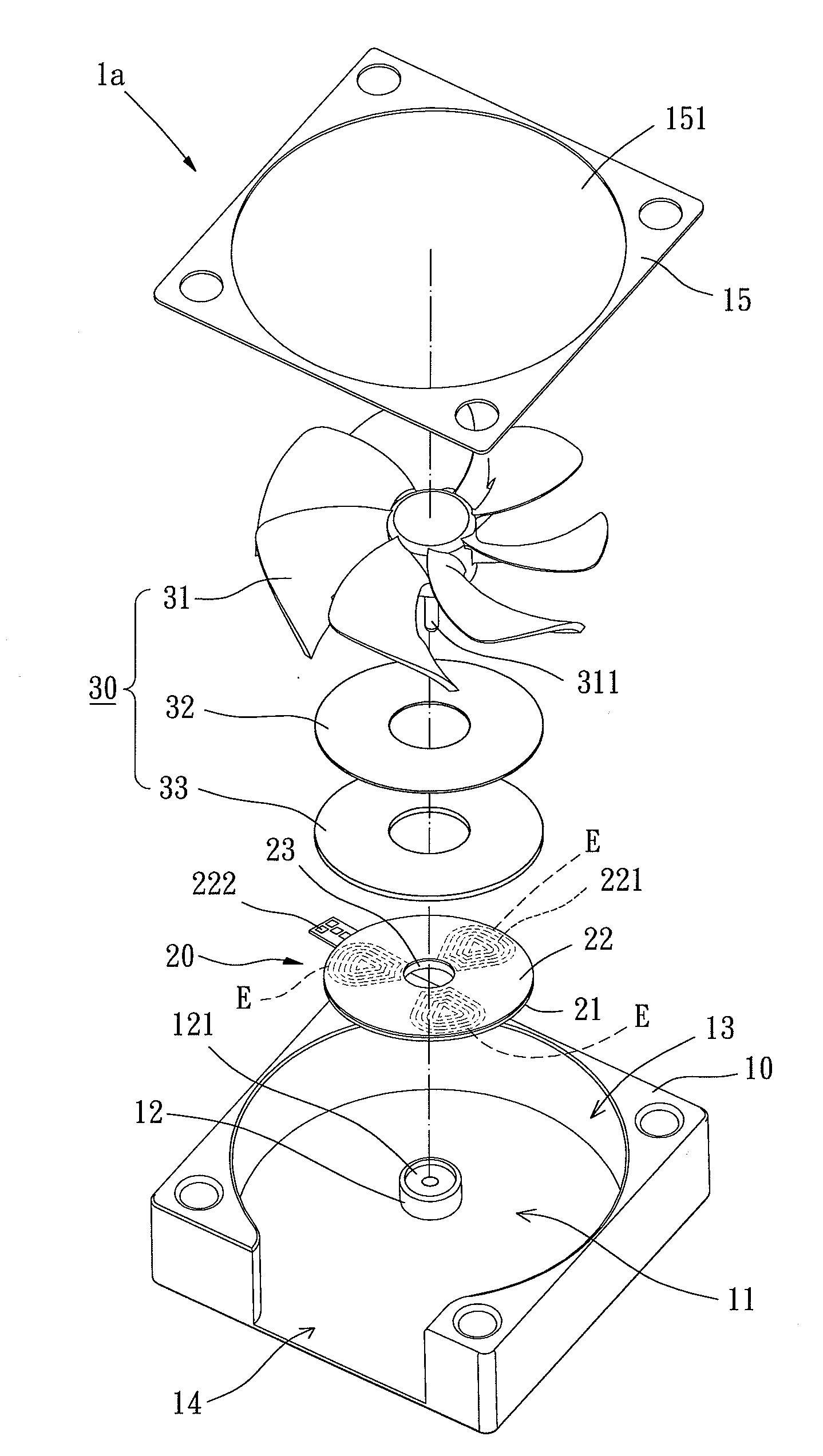

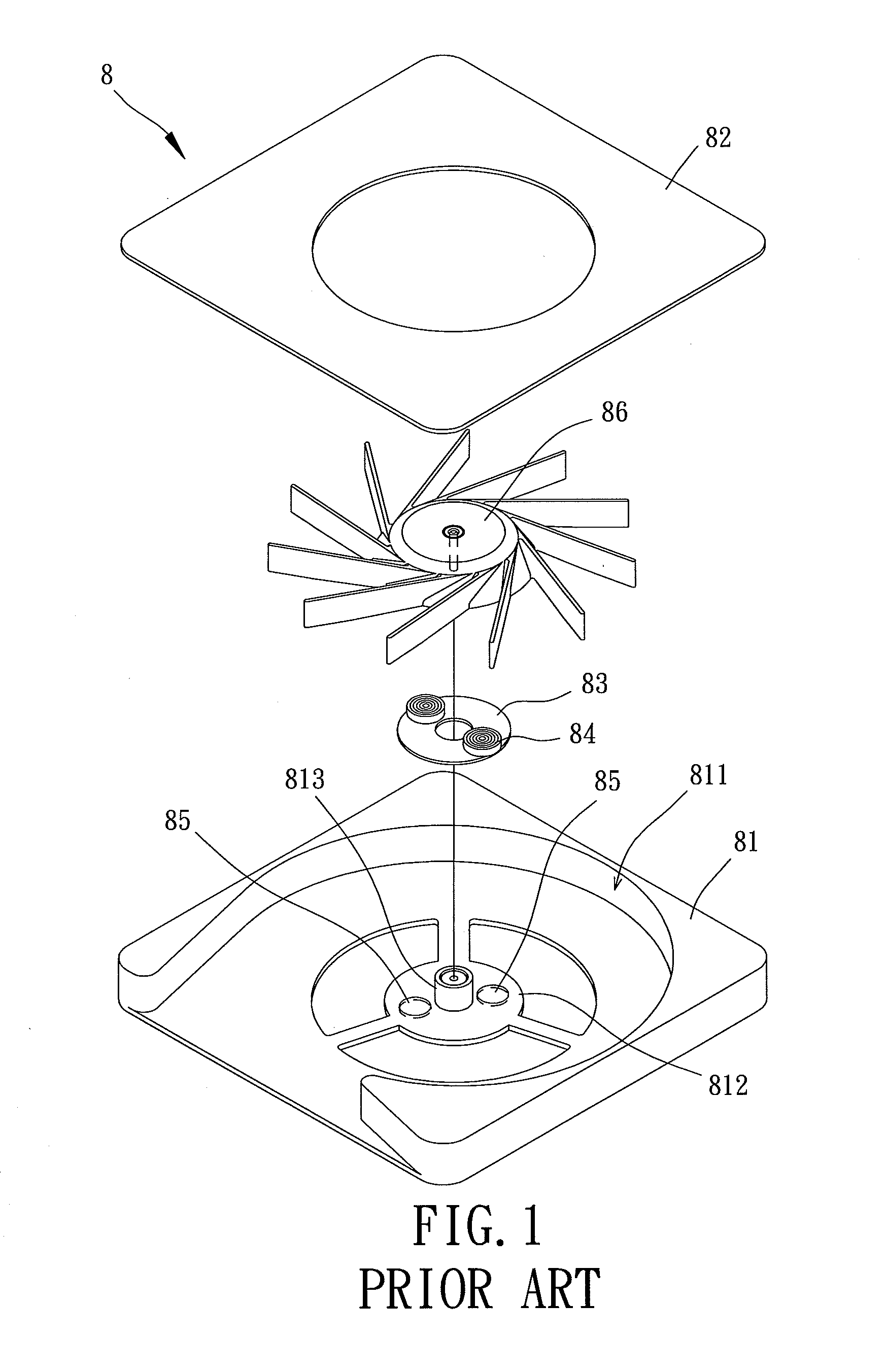

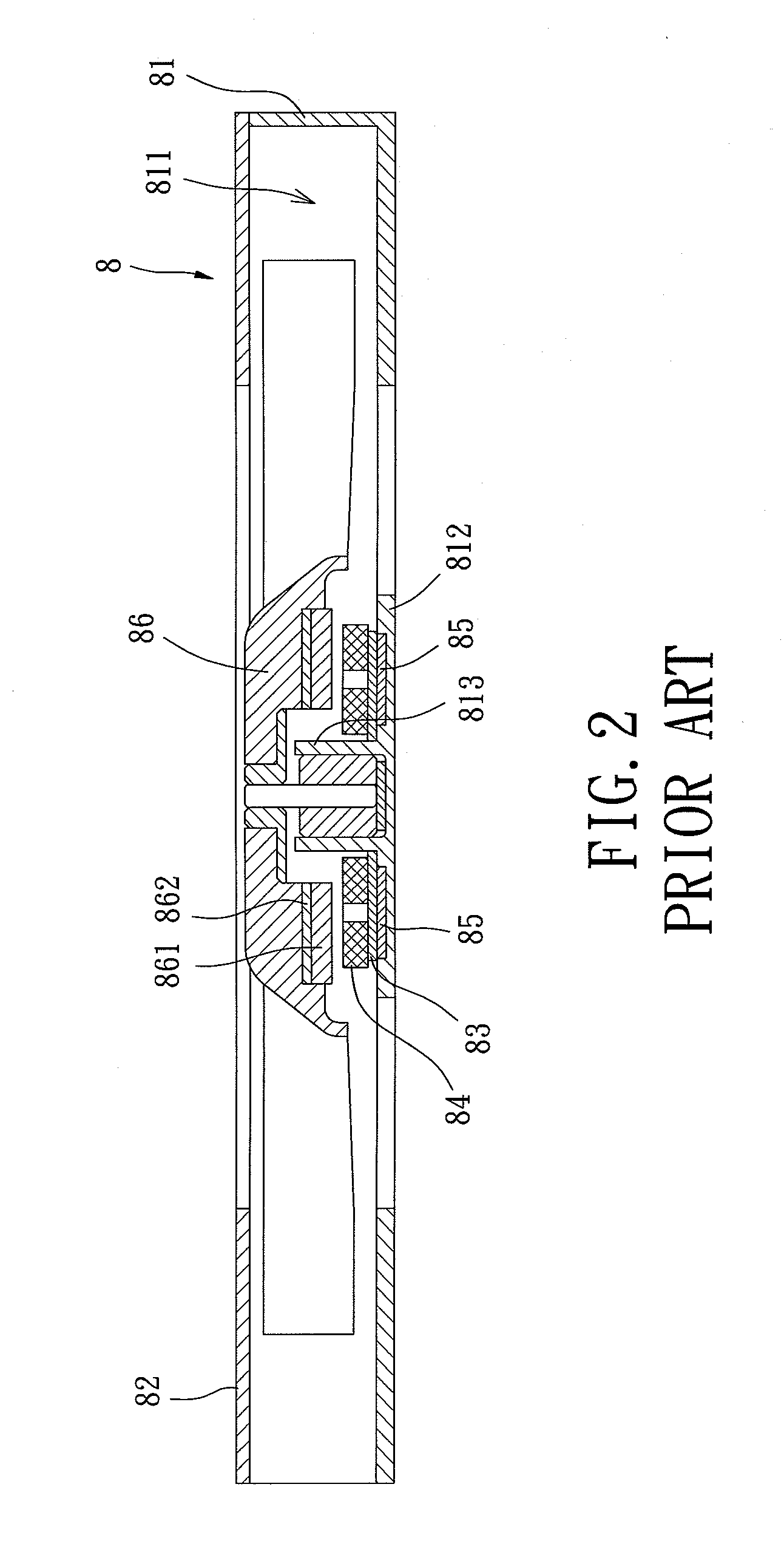

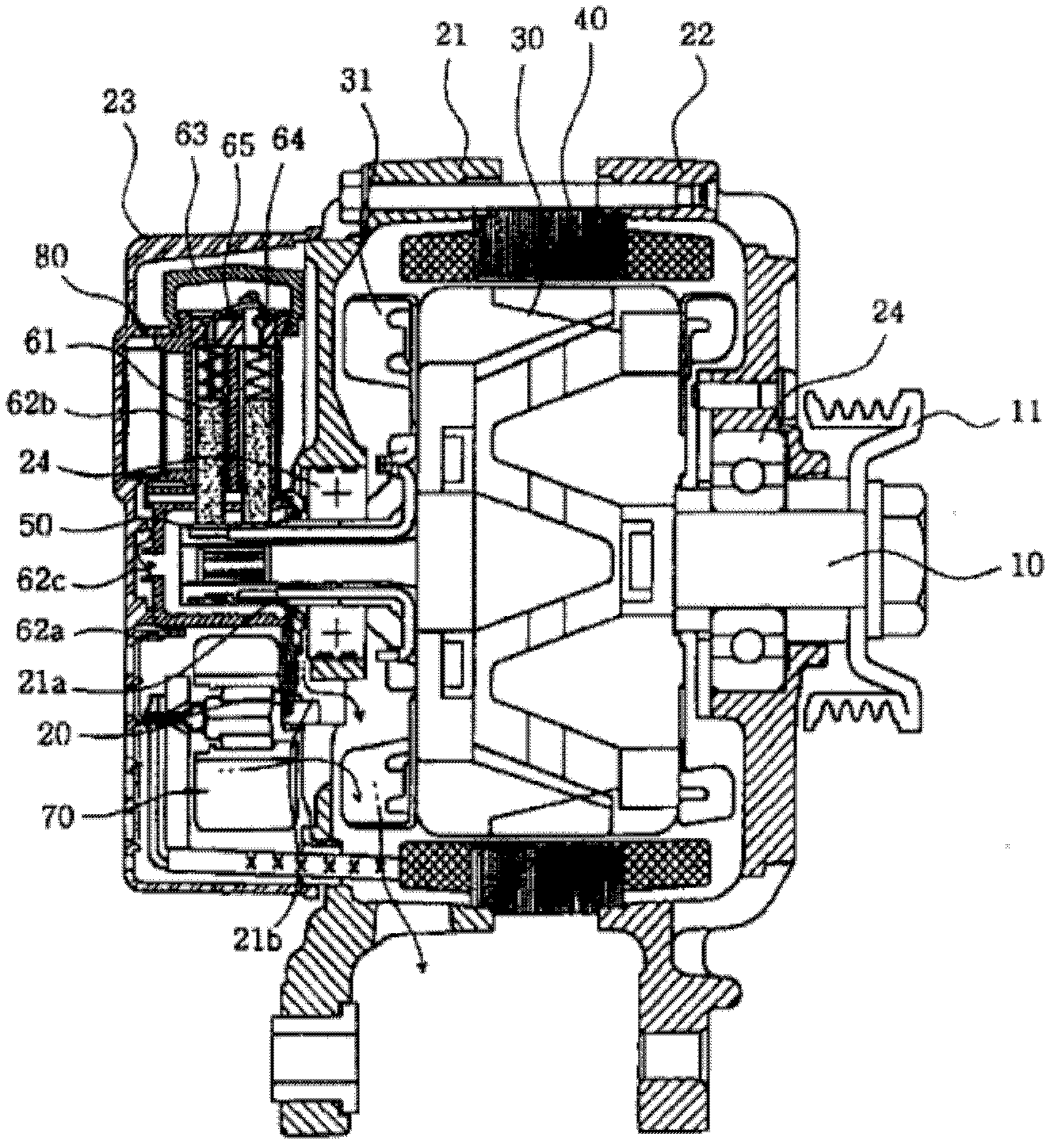

Fan device having an ultra thin-type structure with a minimum air gap for reducing an axial thickness

InactiveUS20070114869A1Reduce axial thicknessSimple structureAssociation with control/drive circuitsMagnetic circuit rotating partsImpellerMagnetic poles

A fan device includes a base plate, a flat-type impeller, an assembling member, a magnet sheet and a shaft member. The base plate includes an axial hole and at least one stator coil arranged thereon. The flat-type impeller is formed with an annular supporting plate and bent vanes while the assembling member is formed with an assembling hole and an upraised flange. The magnet sheet provides with at least one pair of alternatively opposite magnetic poles (i.e. north pole and south pole). A first distal end of the shaft member is extended through the flat-type impeller and inserted into the assembling hole of the assembling member while a second distal end of the shaft member is inserted into the axial hole of the base plate. The flat-type impeller is positioned and sandwiched in between the assembling member and the magnet sheet so as to constitute a thin-type structure.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

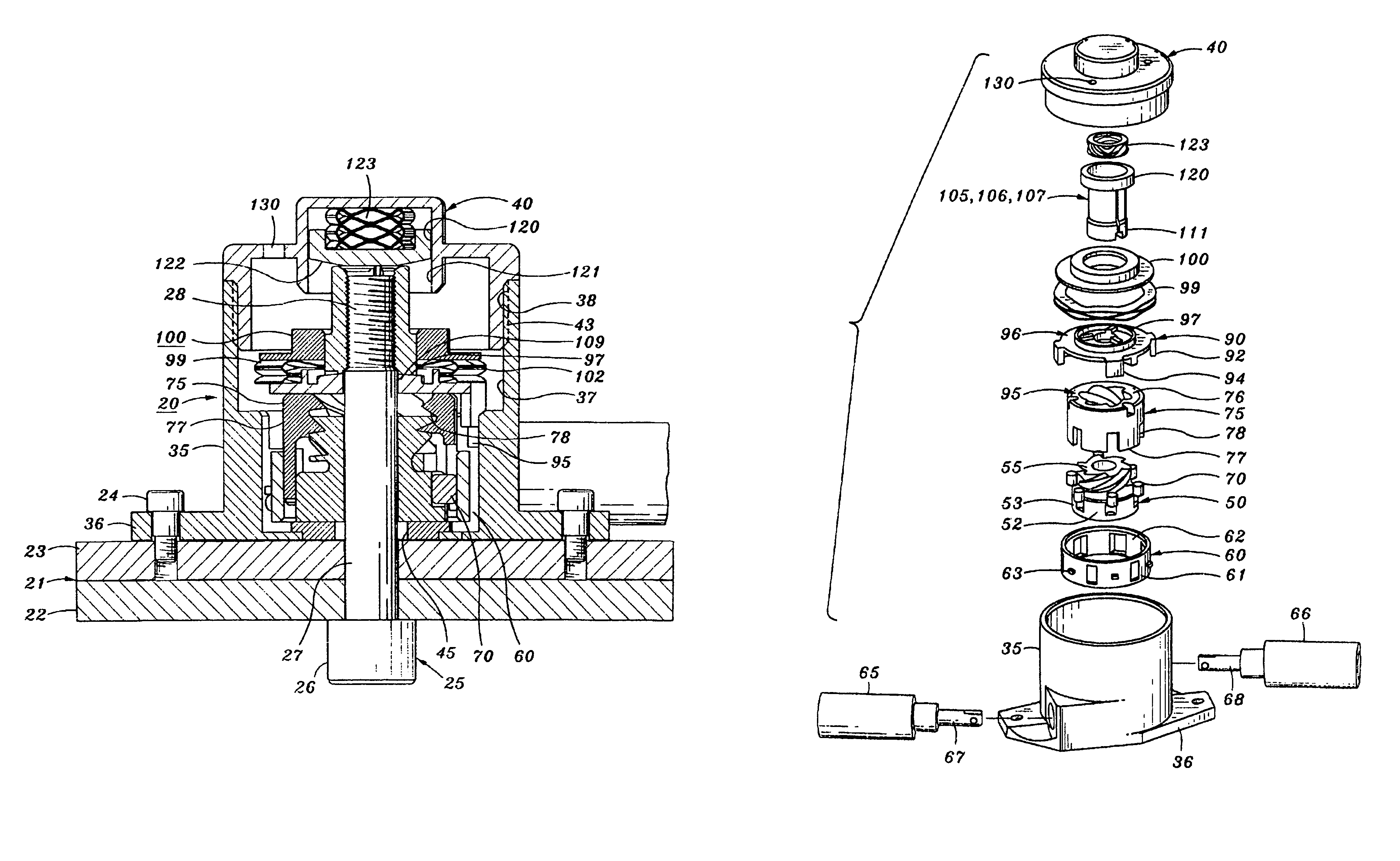

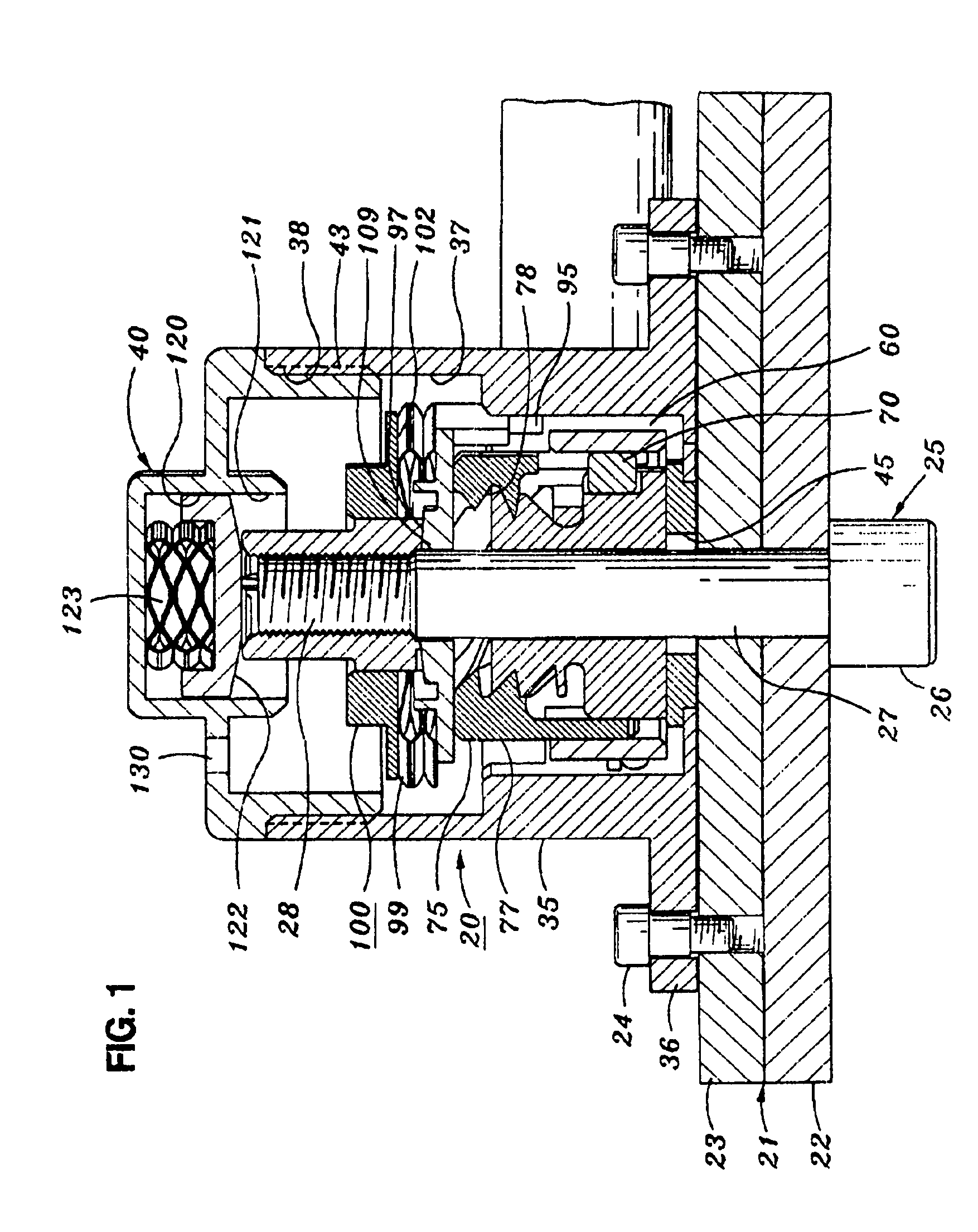

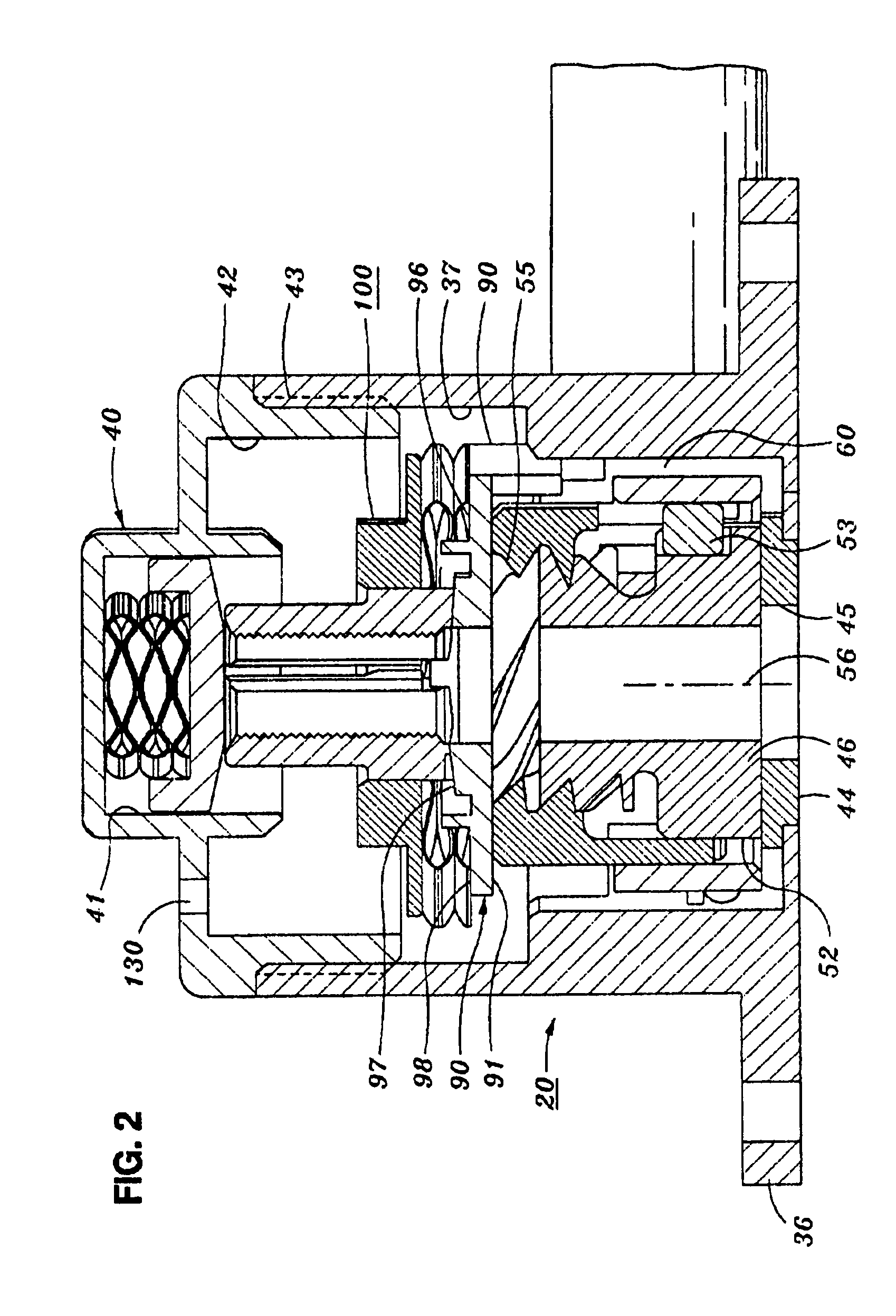

Non-pyrolytically actuated reduced-shock separation fastener

InactiveUS20050084364A1Reduce axial thicknessRelieve the axial tensile preloadCosmonautic vehiclesNutsEngineeringNuts and bolts

A separable fastener for holding two objects together with the use of a bolt threaded into the fastener. The necessary inherent axial tension in the bolt / fastener system is accommodated by a relief element which relieves at least some of the stored tension before the nut separates, thereby reducing the physical shock on the assembly. The energy needed to separate the nut and bolt is entirely contained within the system so that pyrotechnic devices are unnecessary for the purpose.

Owner:HI SHEAR TECH

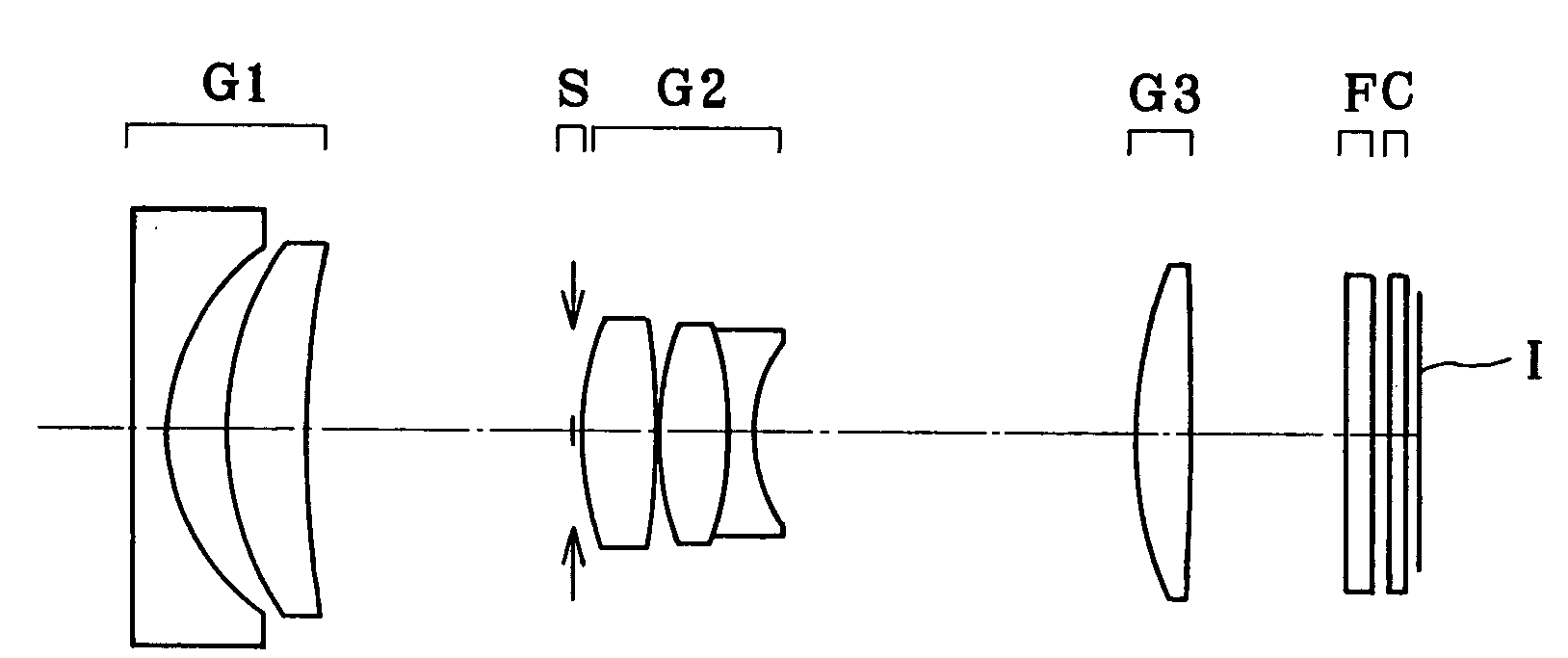

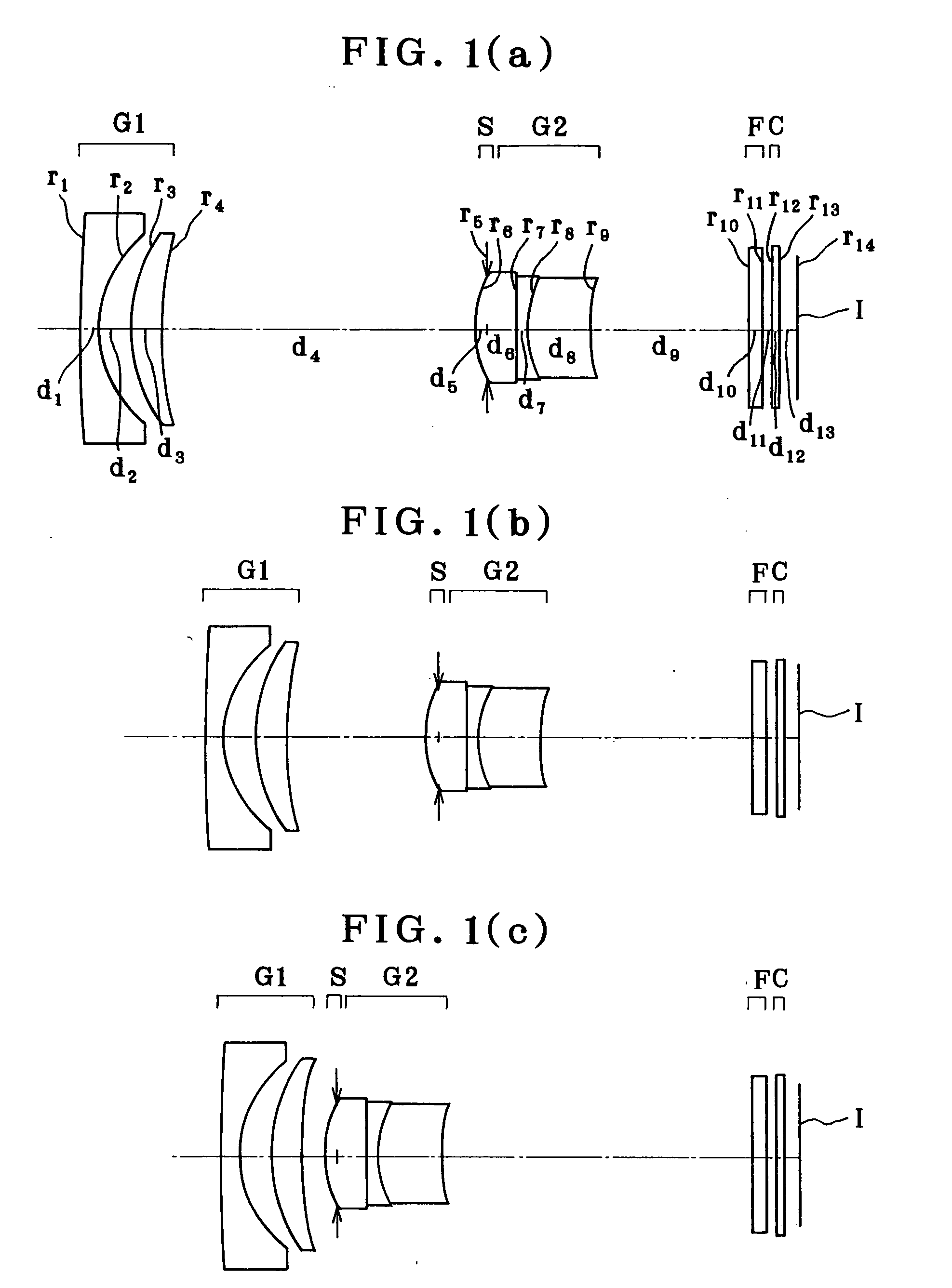

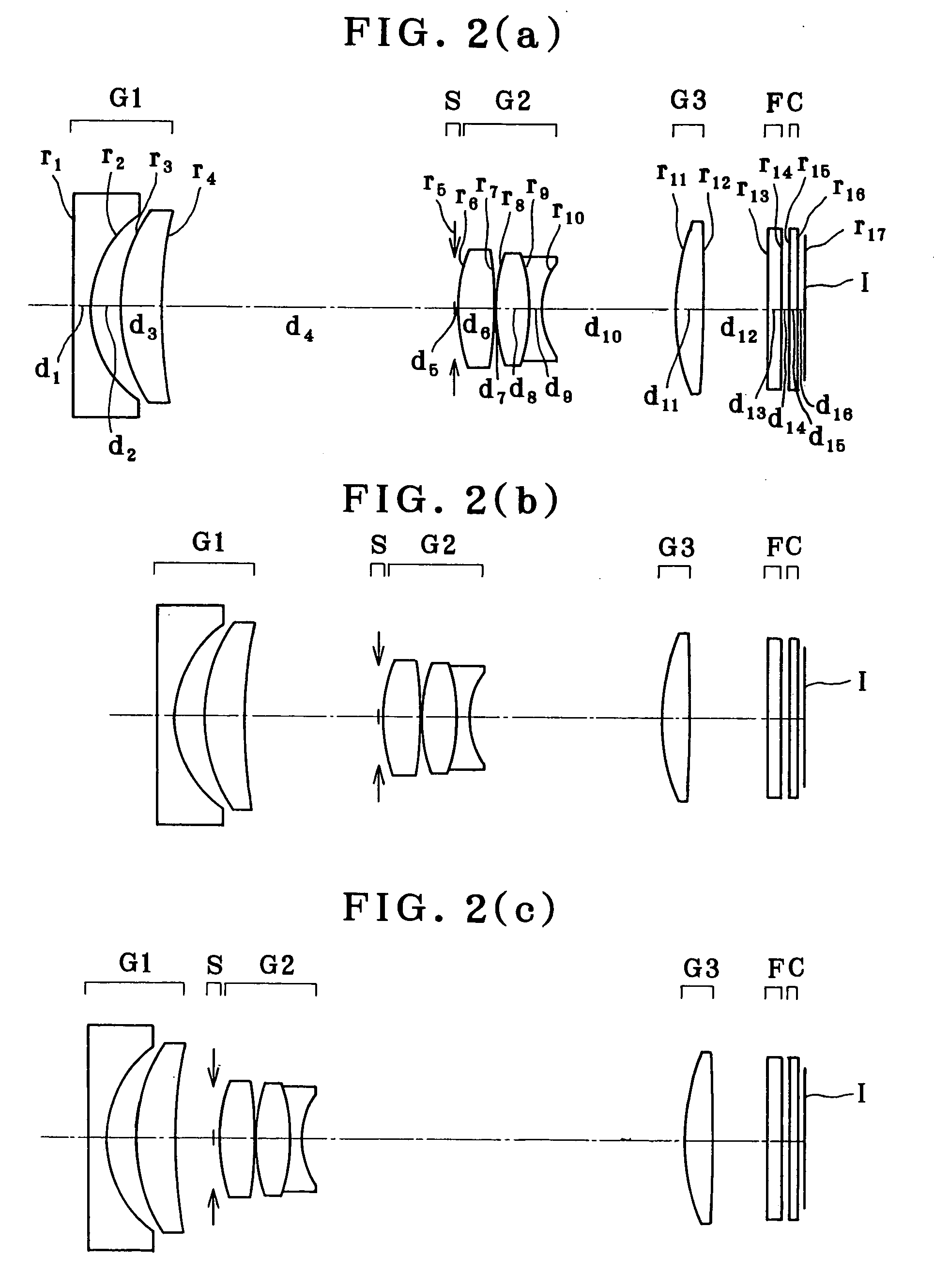

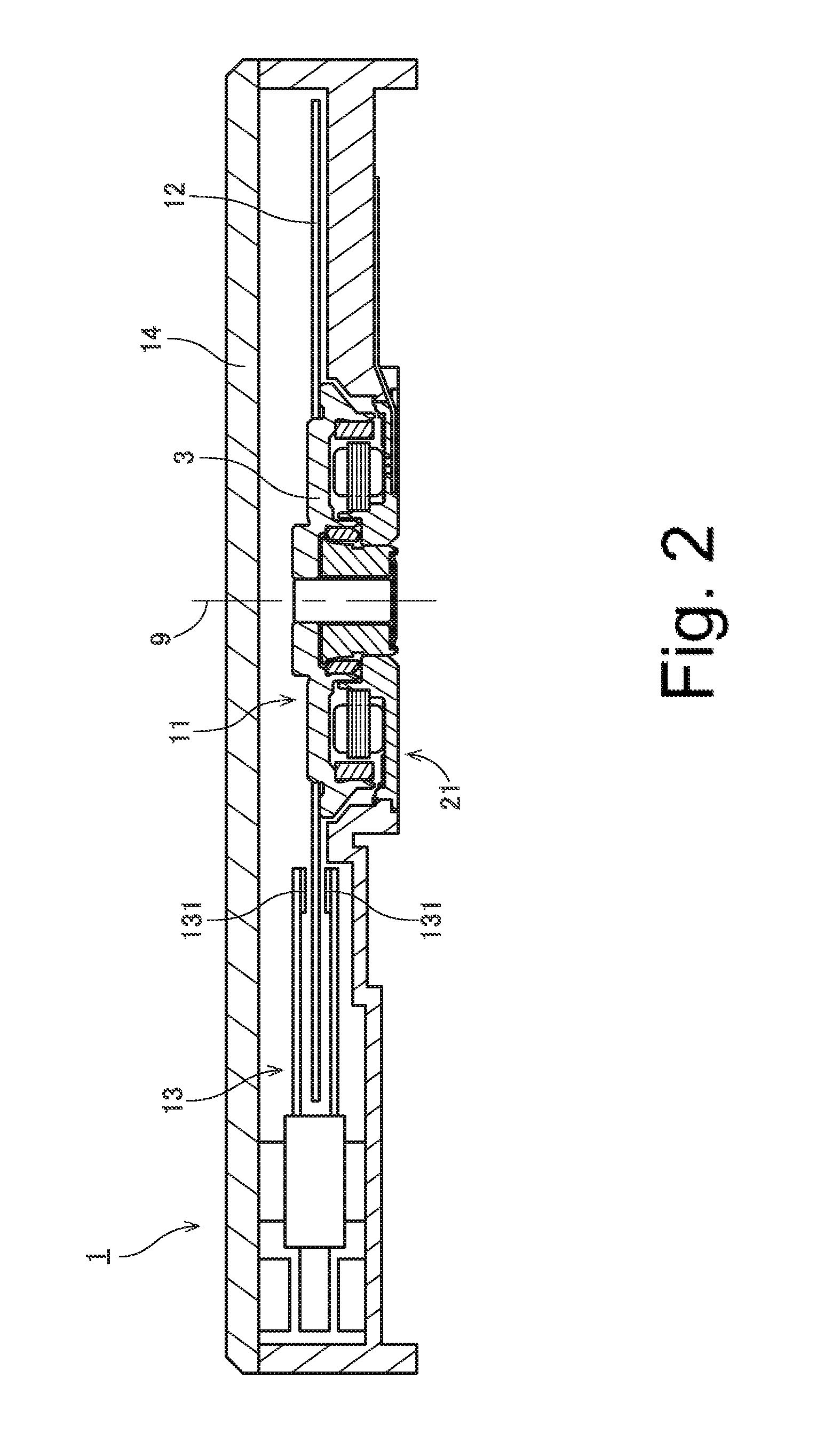

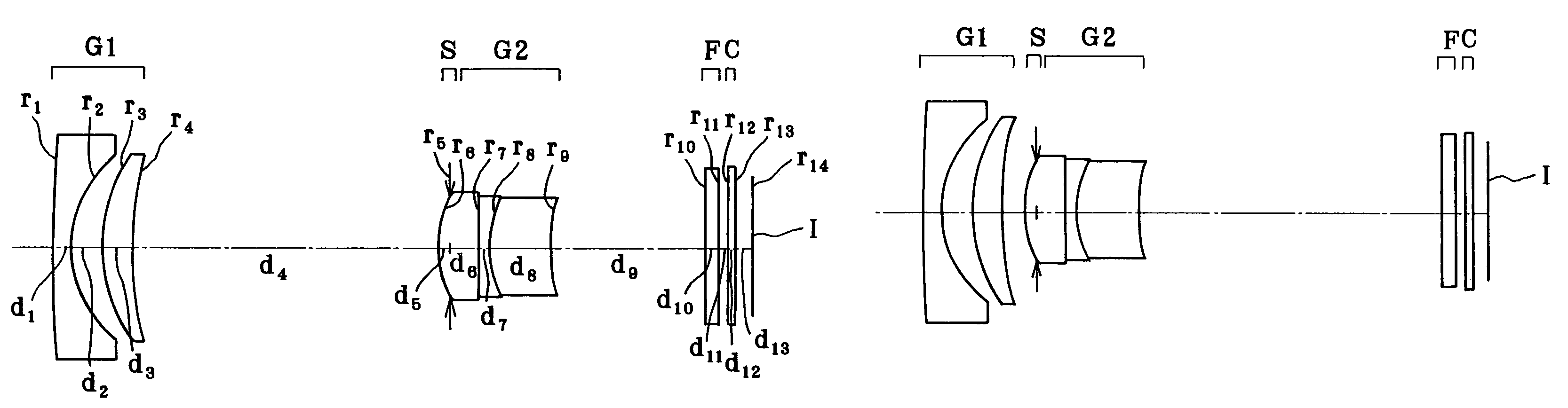

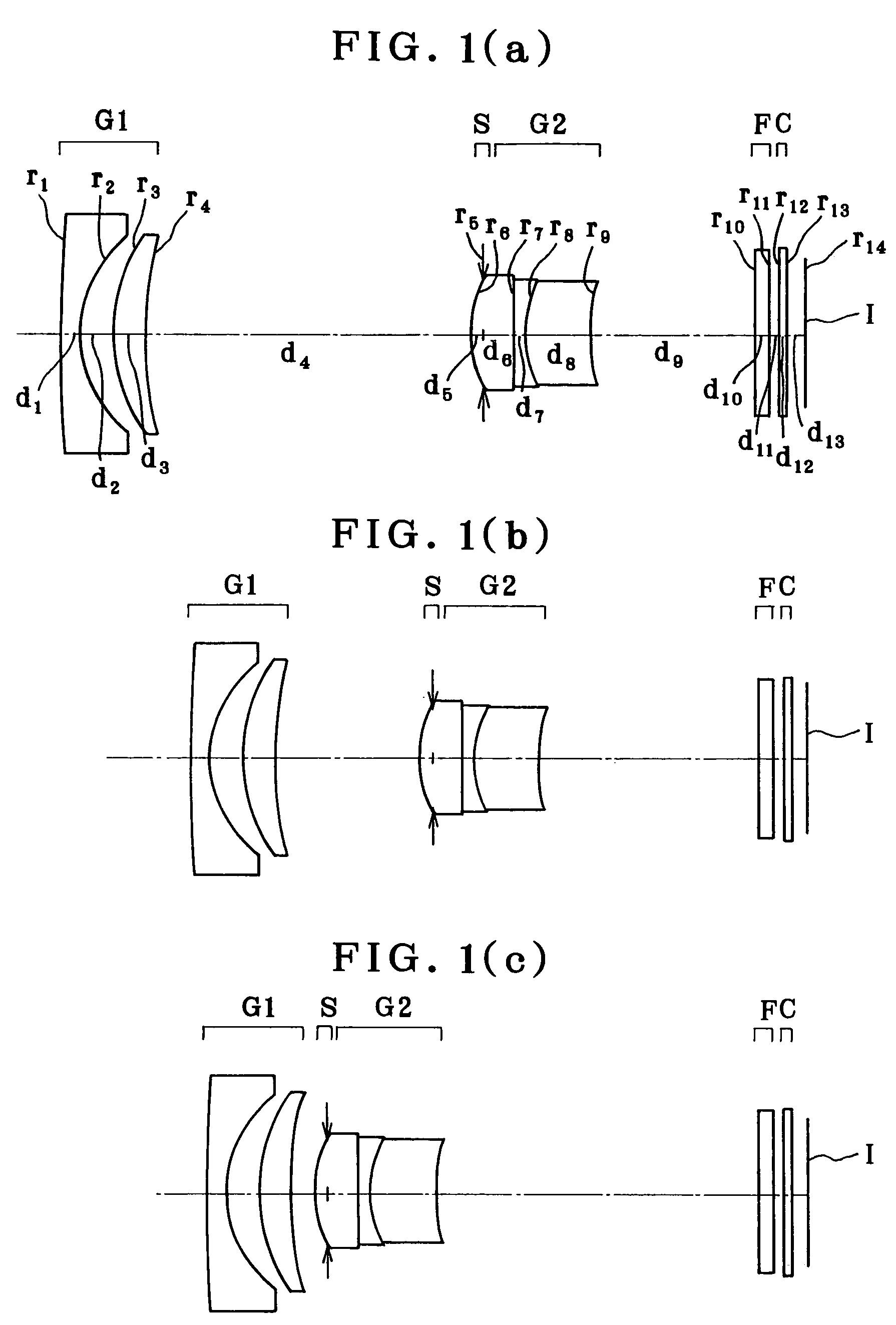

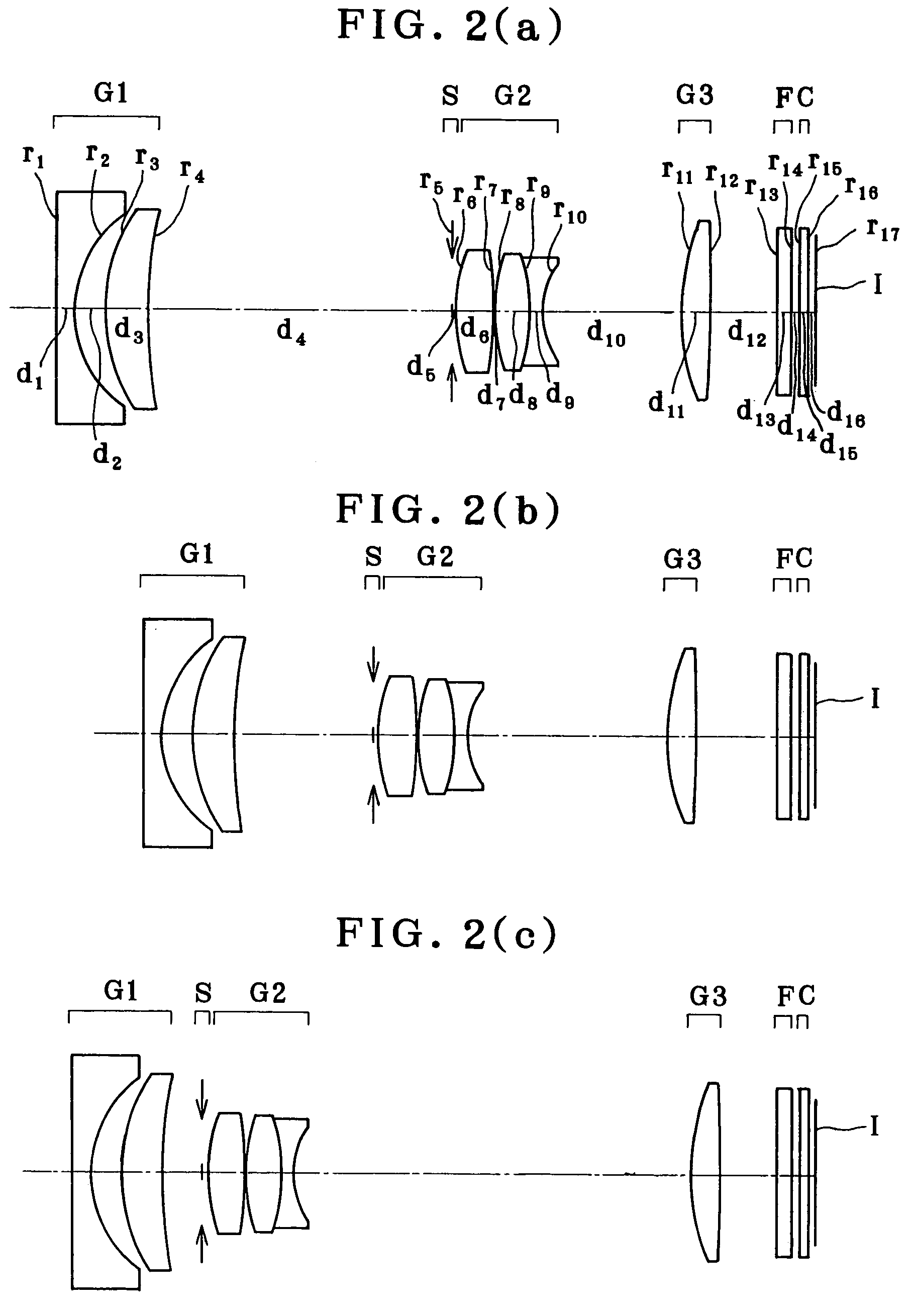

Zoom lens and imaging system incorporating it

InactiveUS20060152815A1Improve balanceReduce thicknessOptical elementsRefractive indexImage formation

The invention relates to a small-format yet high-performance two units or three units type zoom lens with a negative unit at the front, which has a zoom ratio of about 3, an angle of view of as wide as 60° at the wide-angle end and high image-formation capability, and is much less susceptible to chromatic blurring, with a compact lens barrel. The zoom lens comprises a first lens unit G1 of negative refracting power and a second lens unit G2 of positive power, wherein zooming is implemented by varying the space between the lens units. The first lens unit G1 is made up of one negative lens L11 and one positive lens L12, two in all, and satisfies specific conditions with respect to their refractive index and Abbe constant.

Owner:OLYMPUS CORP

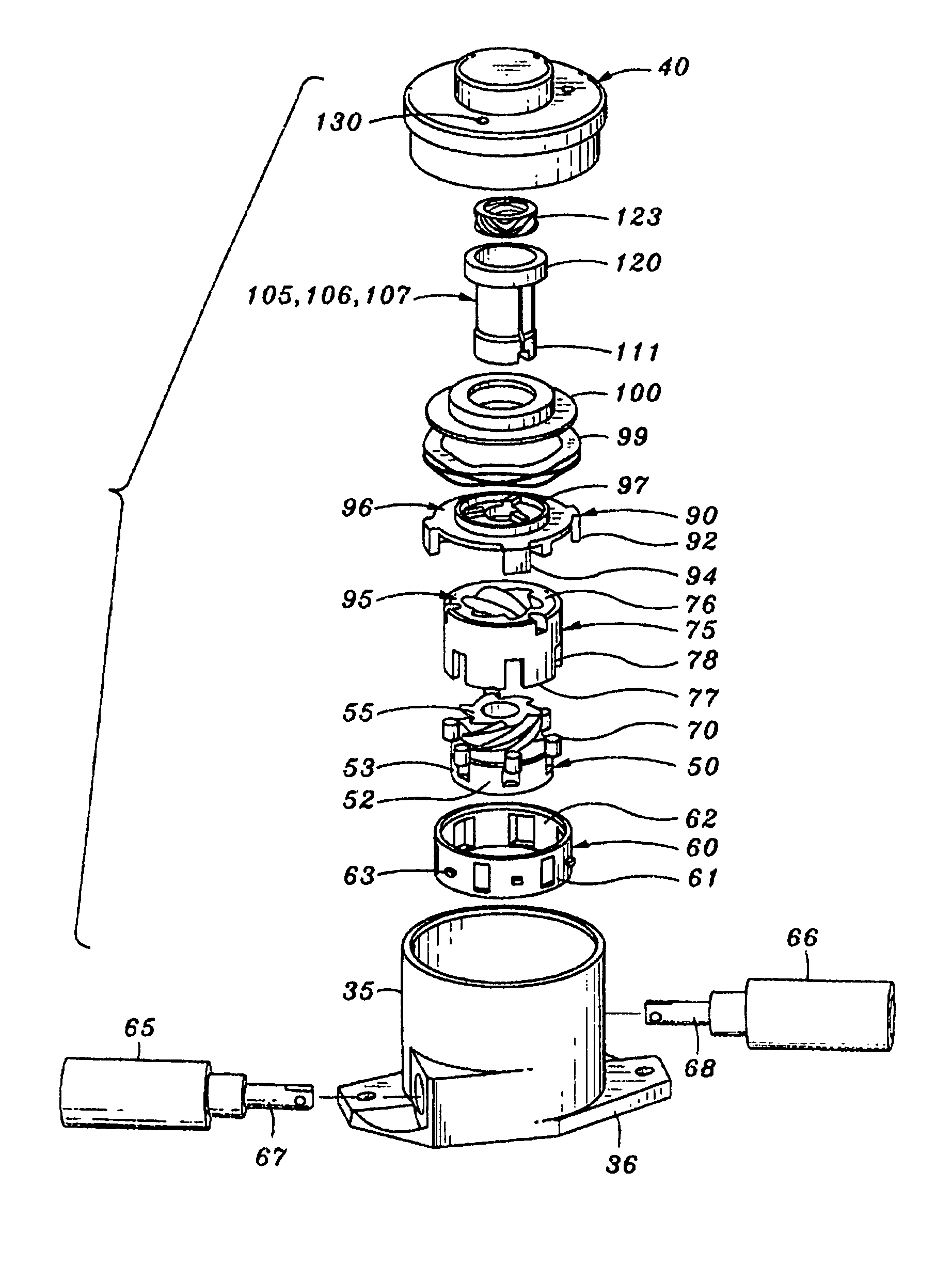

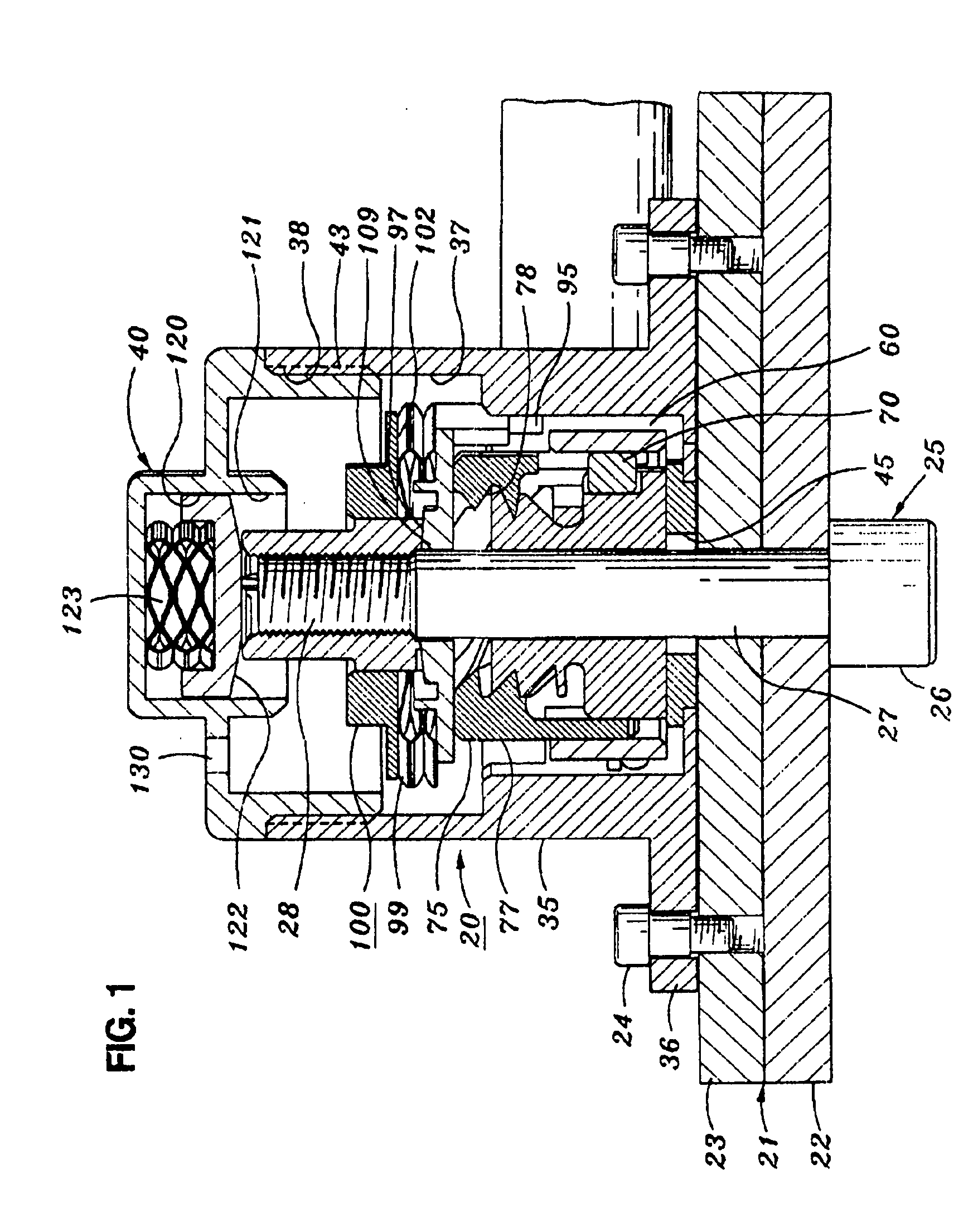

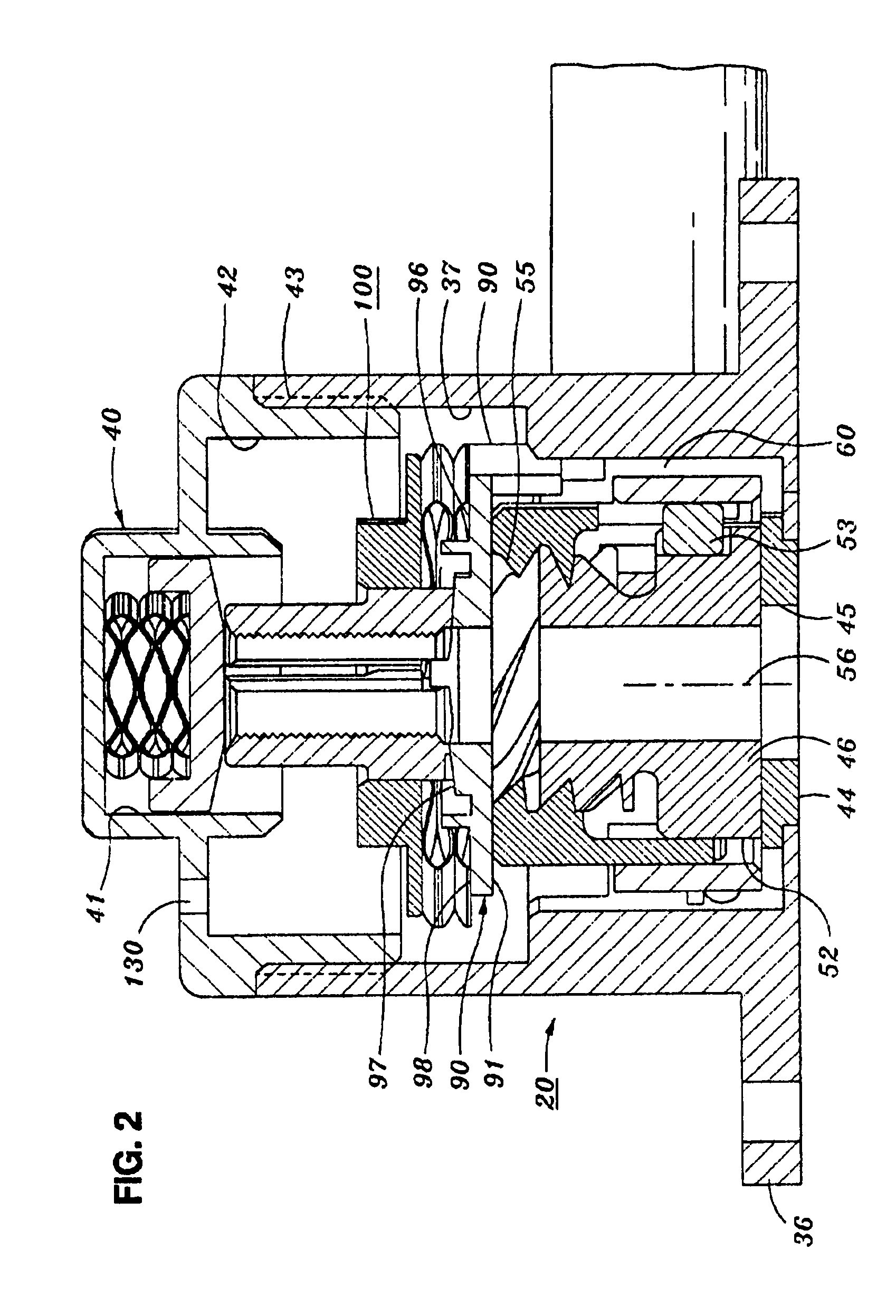

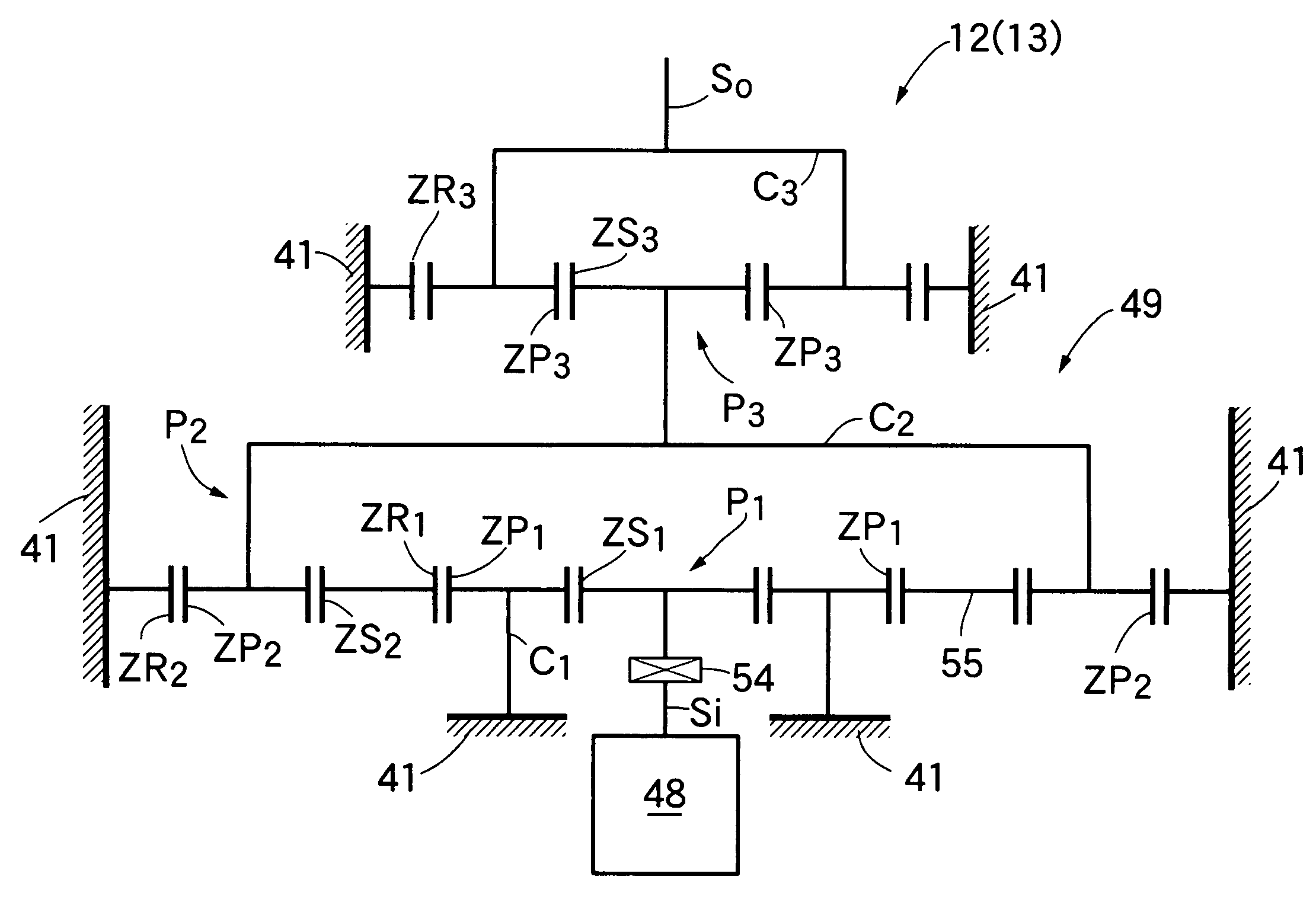

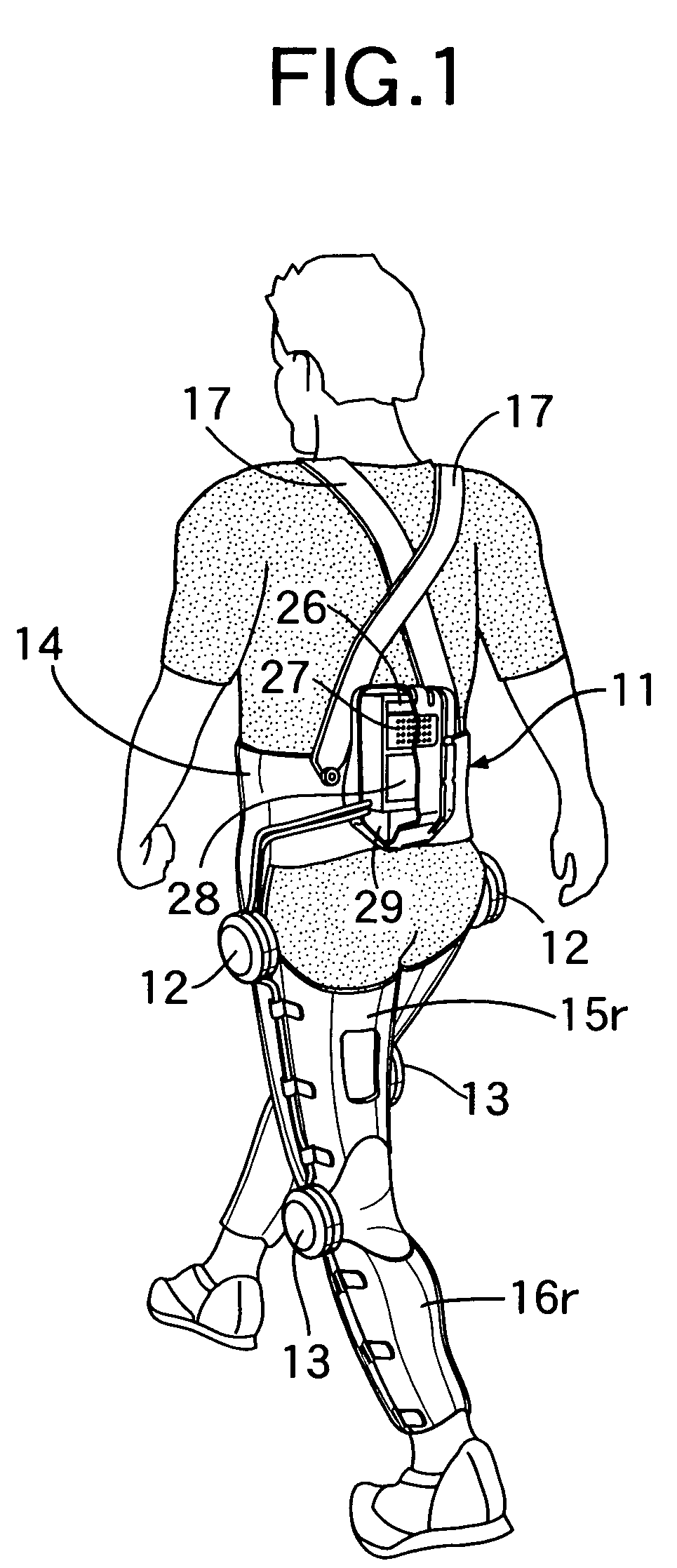

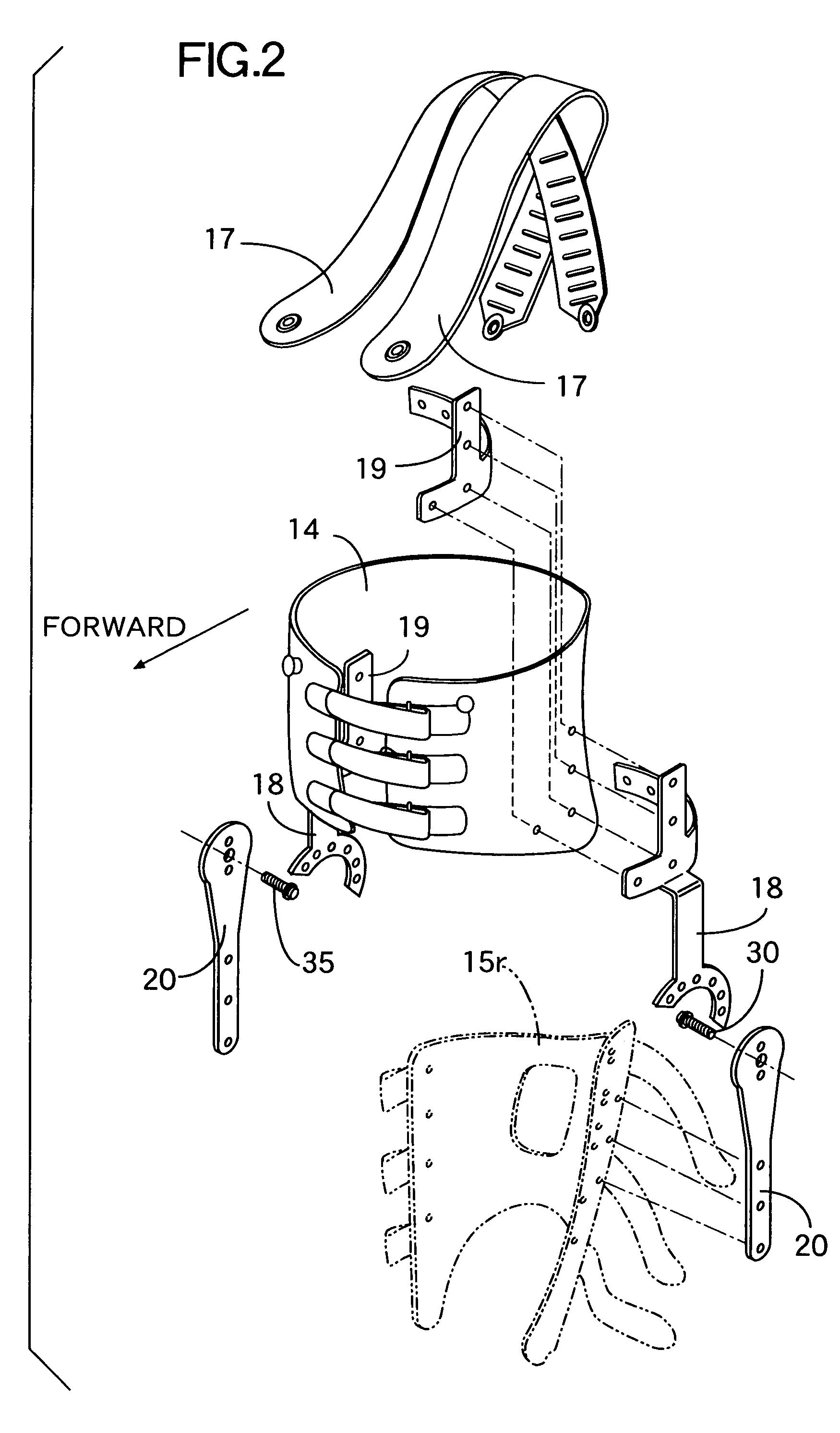

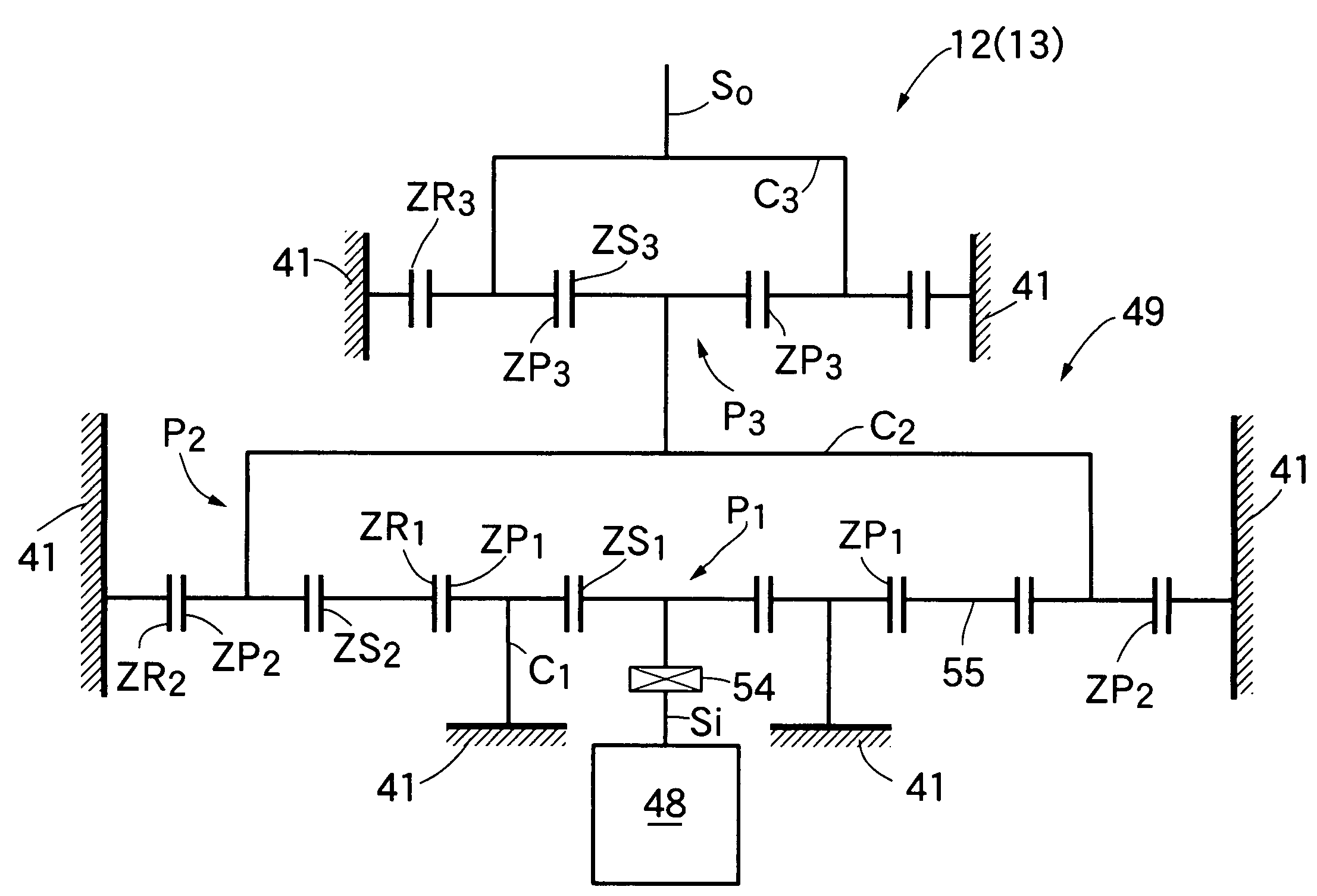

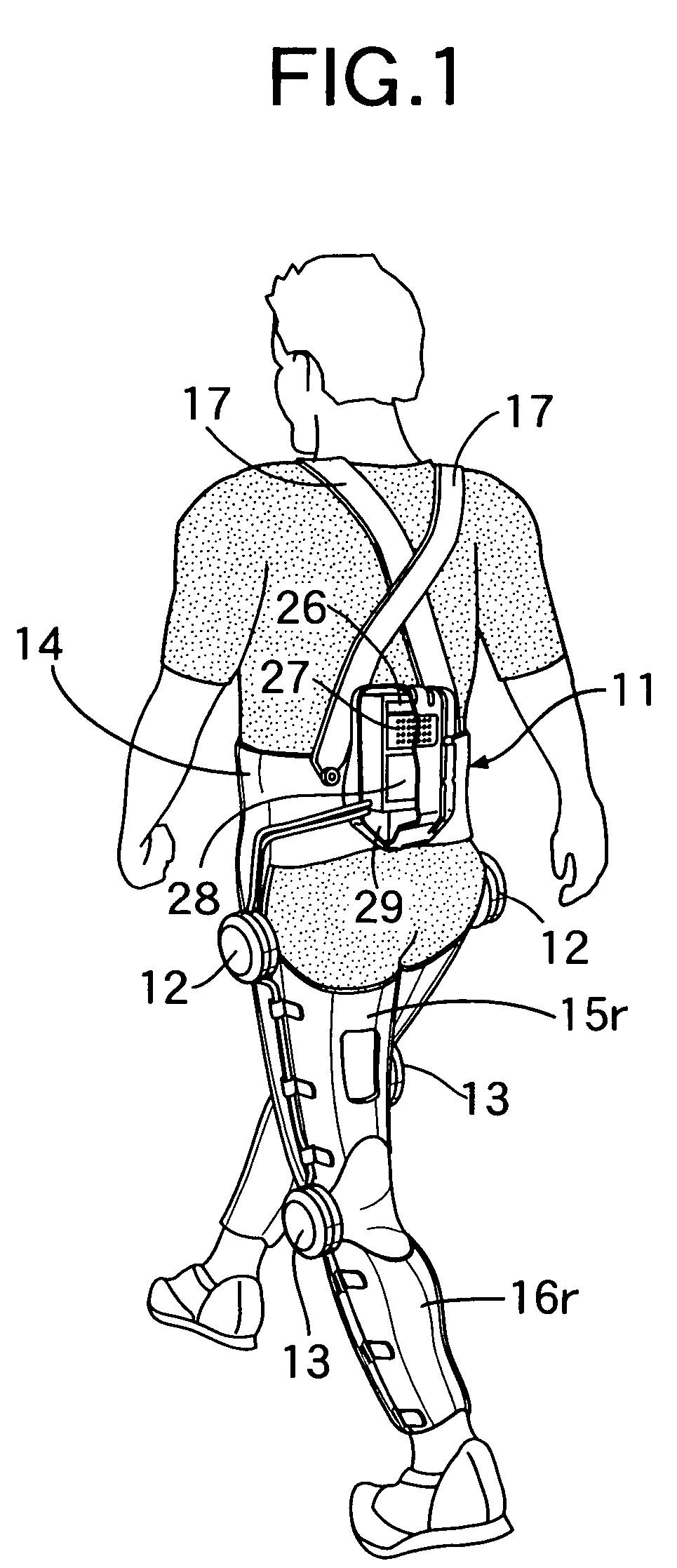

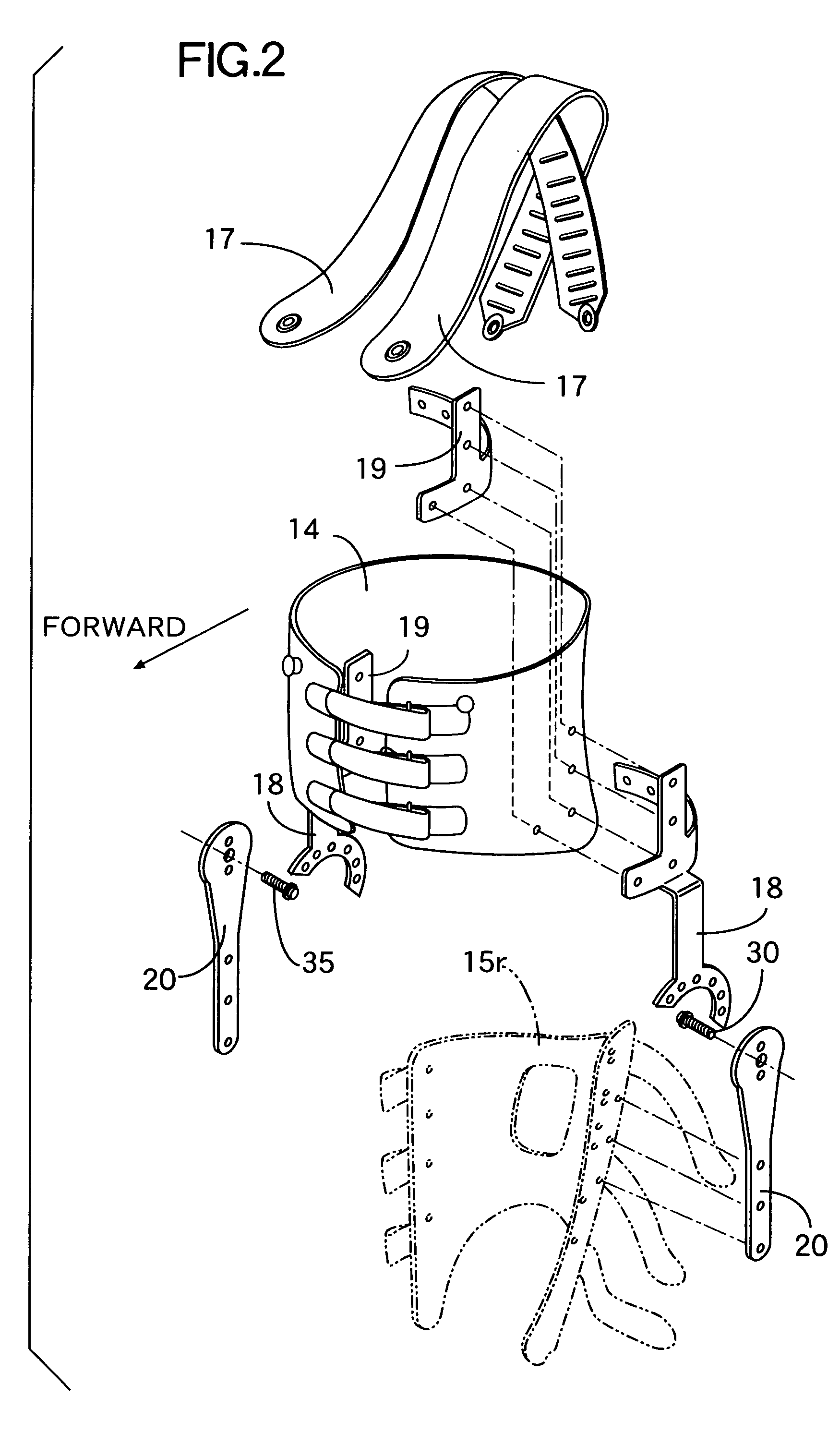

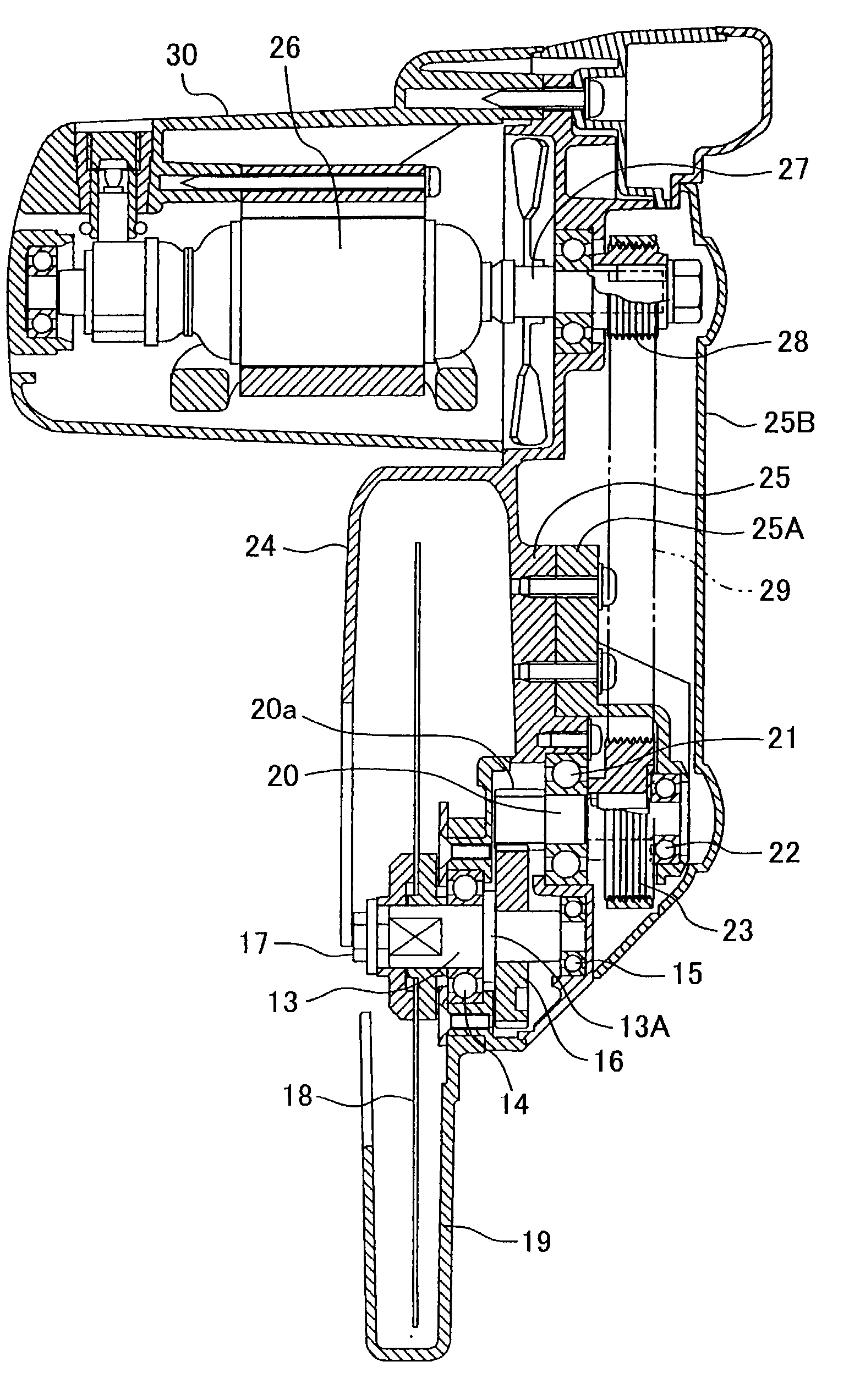

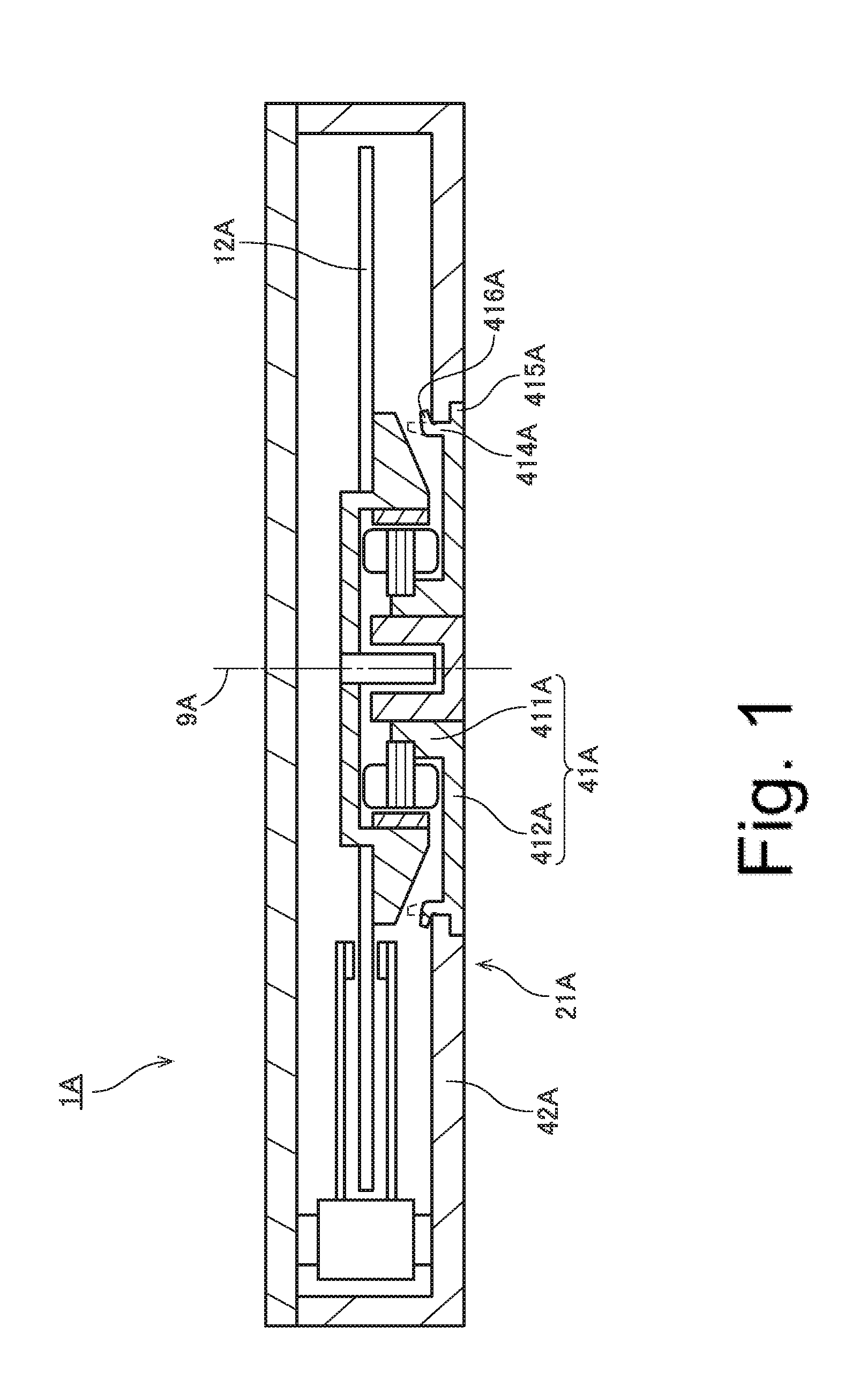

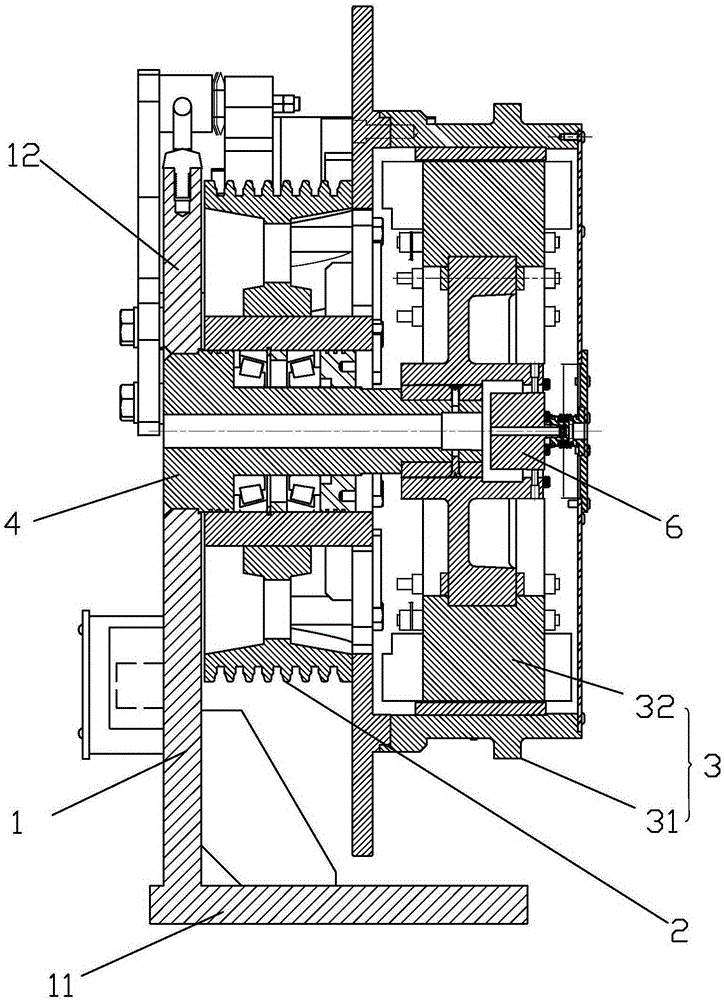

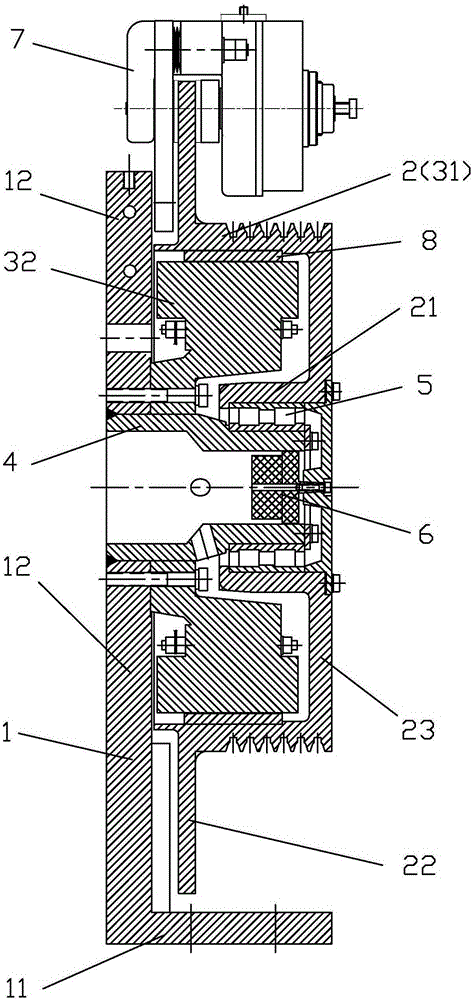

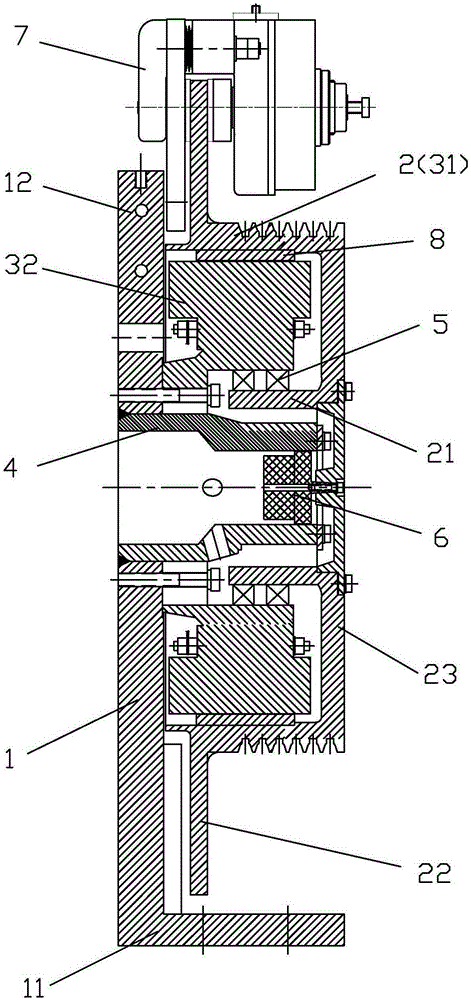

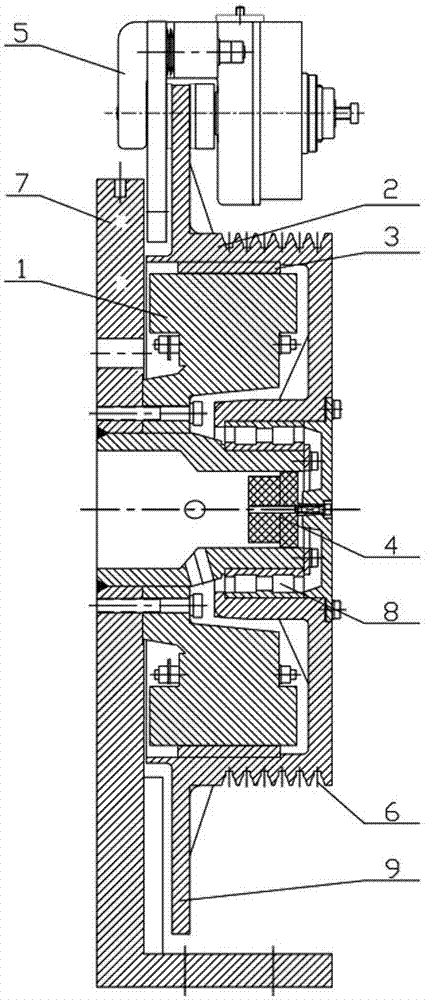

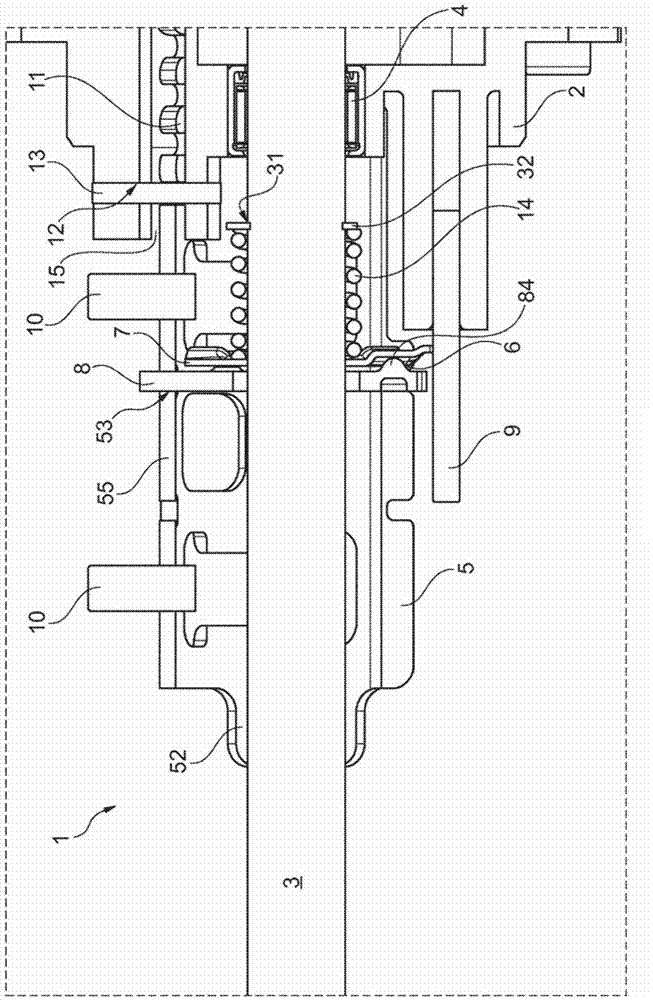

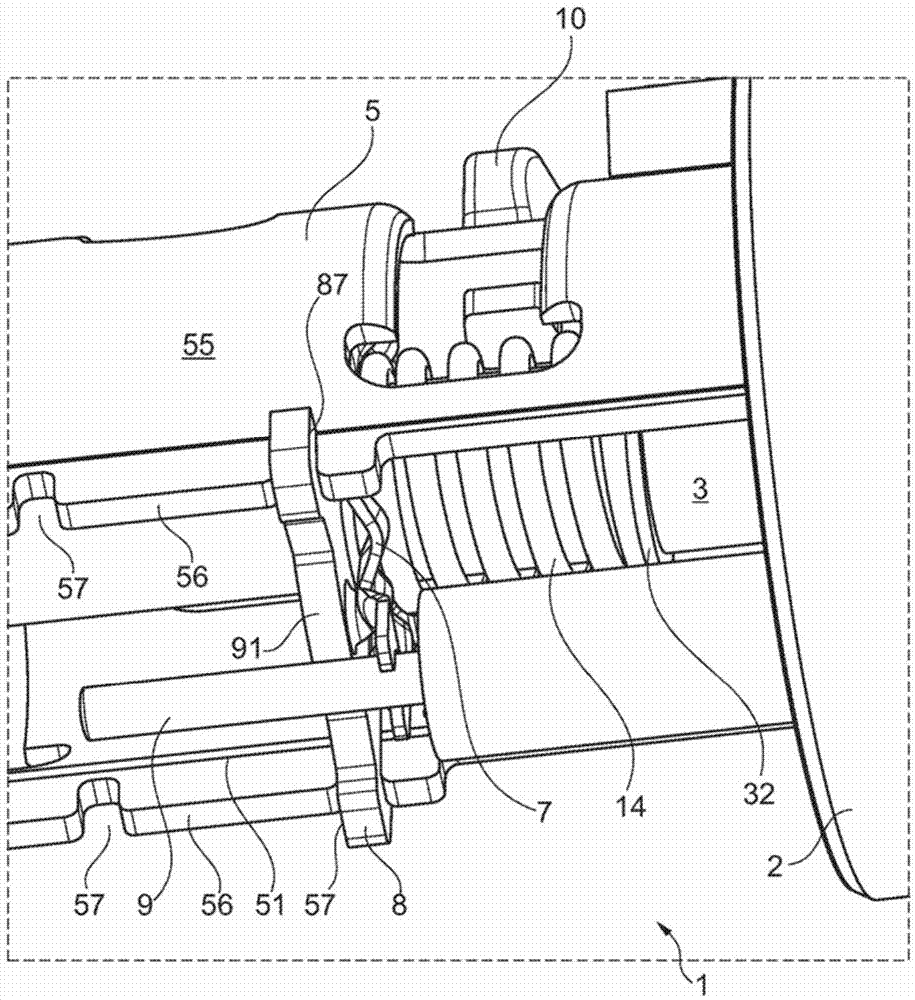

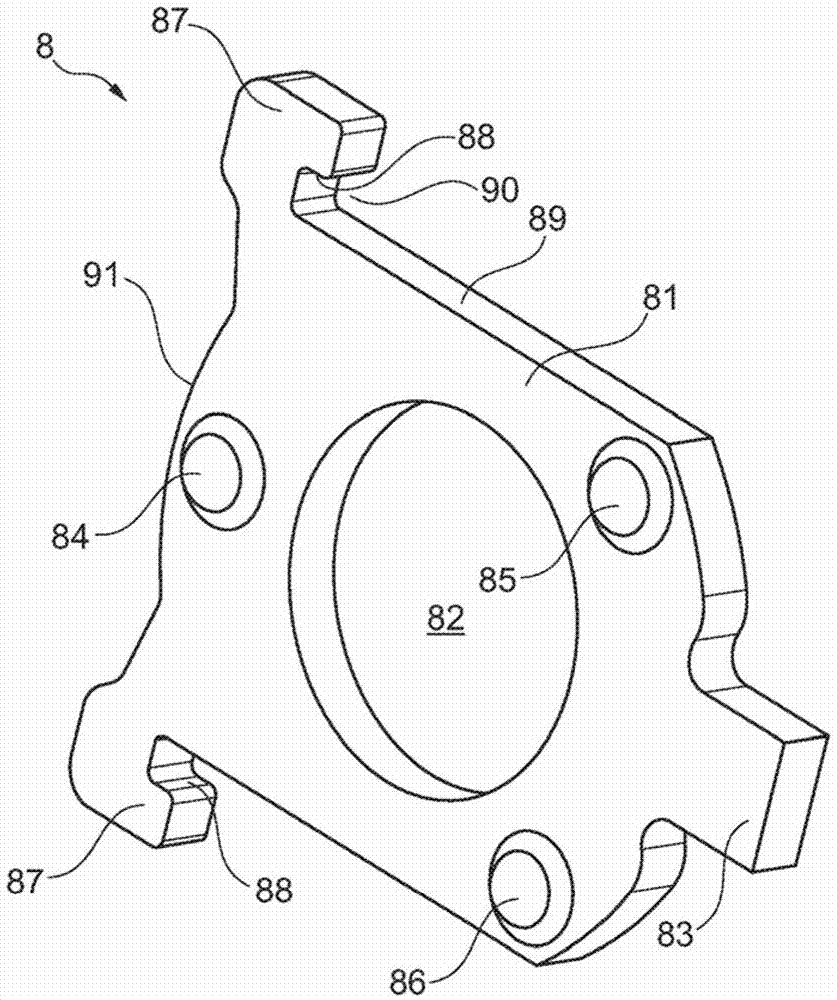

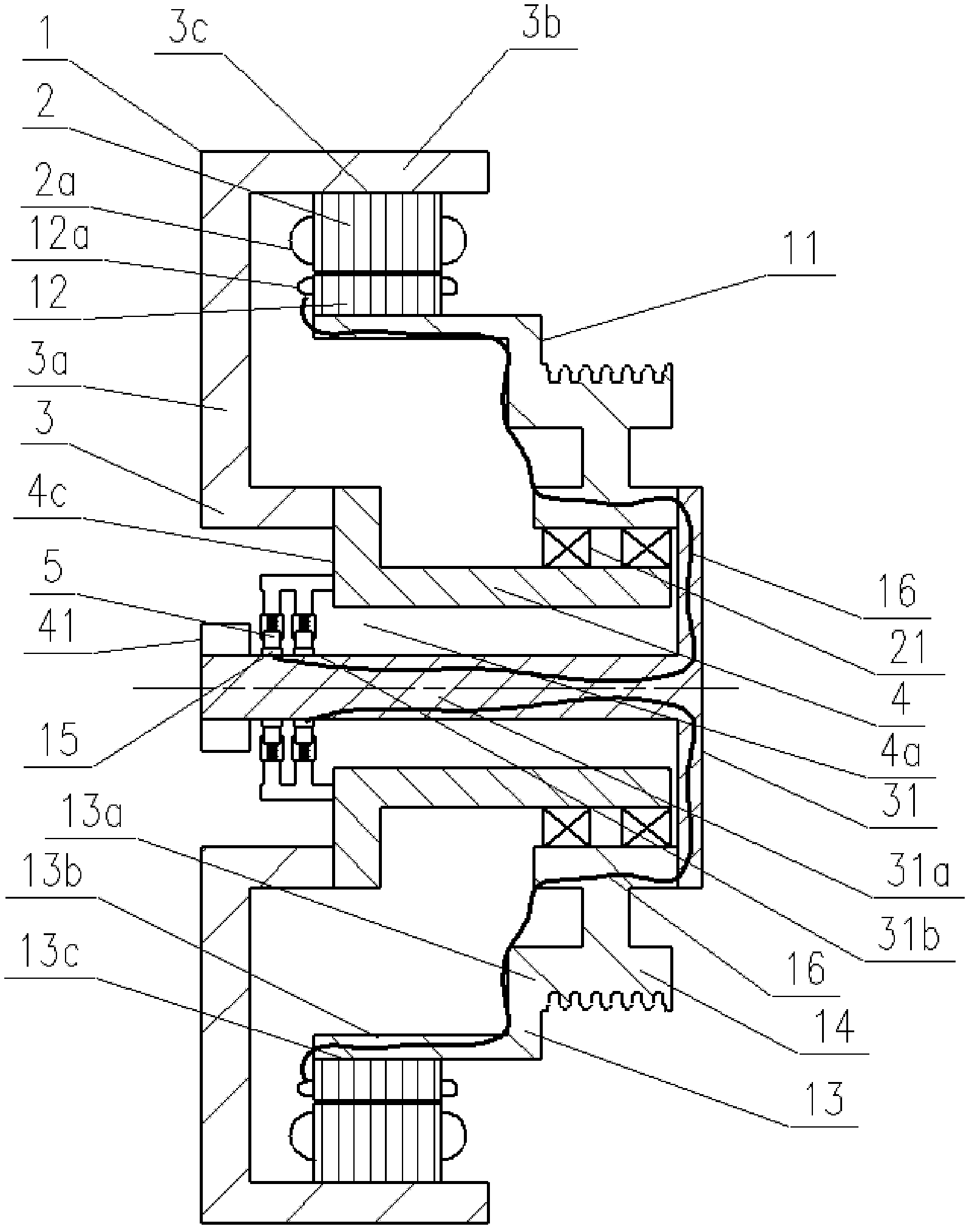

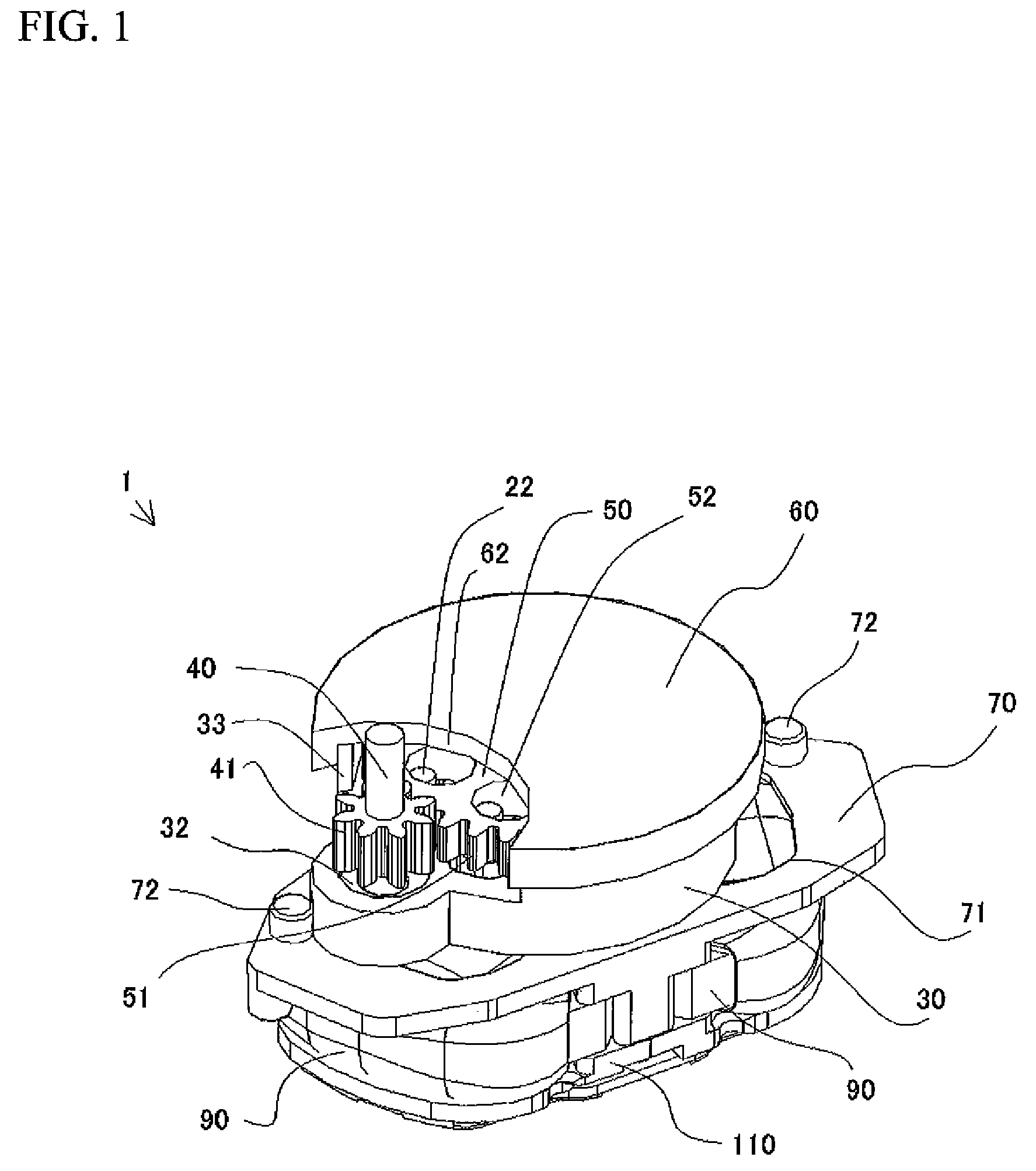

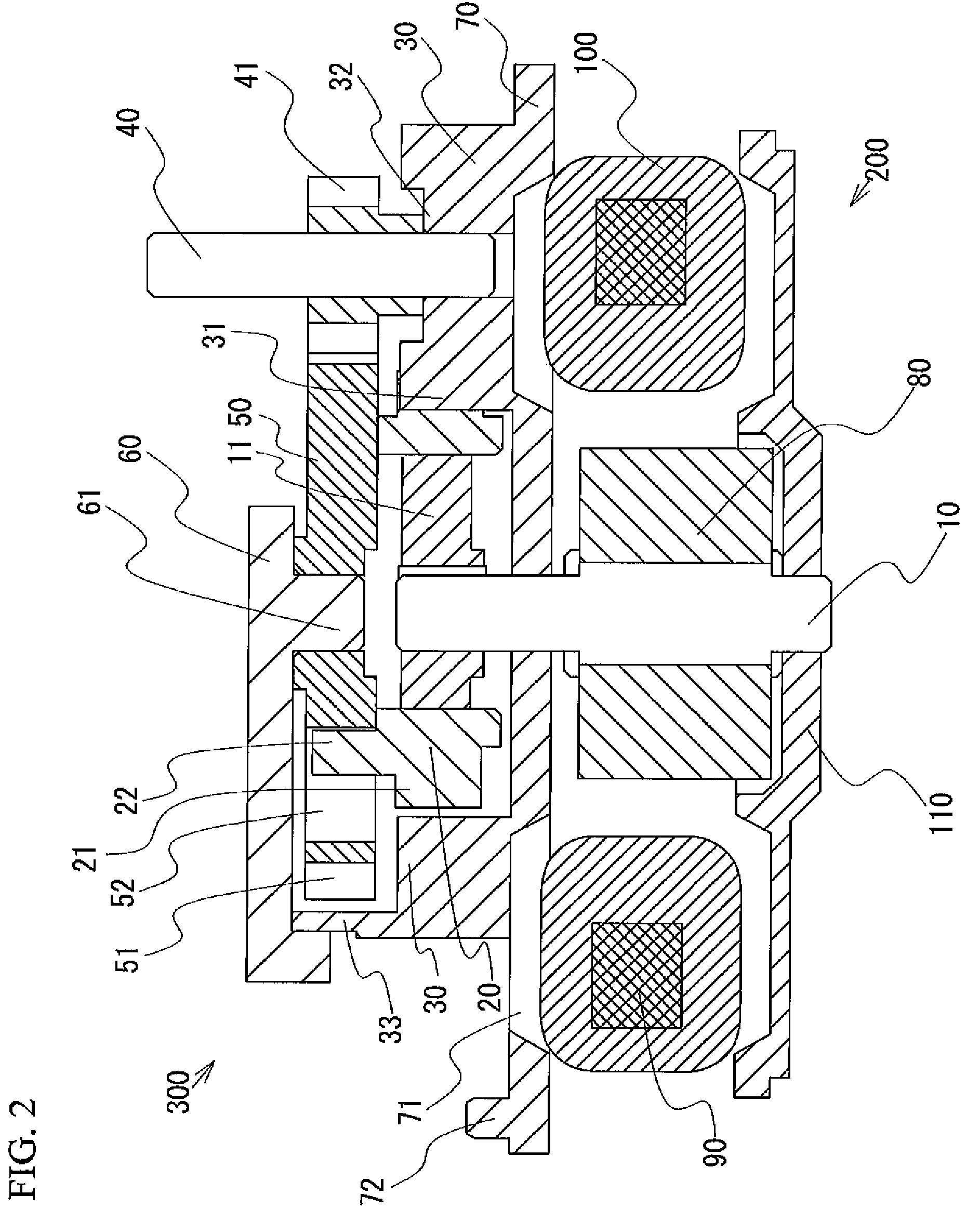

Speed reducer for walk assist apparatus

InactiveUS7404782B2Shorten speedReduce axial thicknessChiropractic devicesWalking aidsThree stageReduction drive

A reduction gear (49) for a walking assistance system is provided that includes first to third planetary gear mechanisms (P1 to P3) between an input shaft (Si) connected to a motor (48) and an output shaft (So), the second planetary gear mechanism (P2) being disposed radially outside the first planetary gear mechanism (P1) connected to the input shaft (Si), and the third planetary gear mechanism (P3) being disposed outside, in the direction of an axis L, the first planetary gear mechanism (P1). It is therefore possible, while reducing the speed of rotation of the input shaft (Si) in three stages by the first to the third planetary gear mechanisms (P1 to P3) and transmitting the rotation to the output shaft (So), to reduce the thickness of the reduction gear (49) compared with a case in which the first to the third planetary gear mechanisms (P1 to P3) are disposed so as to be stacked in the direction of the axis (L), thereby improving the appearance when a user is fitted with the walking assistance system.

Owner:HONDA MOTOR CO LTD

Non-pyrolytically actuated reduced-shock separation fastener

InactiveUS7001127B2Reduce axial thicknessRelieve the axial tensile preloadCosmonautic vehiclesNutsEngineeringScrew thread

A separable fastener for holding two objects together with the use of a bolt threaded into the fastener. The necessary inherent axial tension in the bolt / fastener system is accommodated by a relief element which relieves at least some of the stored tension before the nut separates, thereby reducing the physical shock on the assembly. The energy needed to separate the nut and bolt is entirely contained within the system so that pyrotechnic devices are unnecessary for the purpose.

Owner:HI SHEAR TECH

Speed reducer for walk assist apparatus

InactiveUS20060142105A1Shorten speedReduce axial thicknessChiropractic devicesWalking aidsThree stageReduction drive

A reduction gear (49) for a walking assistance system is provided that includes first to third planetary gear mechanisms (P1 to P3) between an input shaft (Si) connected to a motor (48) and an output shaft (So), the second planetary gear mechanism (P2) being disposed radially outside the first planetary gear mechanism (P1) connected to the input shaft (Si), and the third planetary gear mechanism (P3) being disposed outside, in the direction of an axis L, the first planetary gear mechanism (P1). It is therefore possible, while reducing the speed of rotation of the input shaft (Si) in three stages by the first to the third planetary gear mechanisms (P1 to P3) and transmitting the rotation to the output shaft (So), to reduce the thickness of the reduction gear (49) compared with a case in which the first to the third planetary gear mechanisms (P1 to P3) are disposed so as to be stacked in the direction of the axis (L), thereby improving the appearance when a user is fitted with the walking assistance system.

Owner:HONDA MOTOR CO LTD

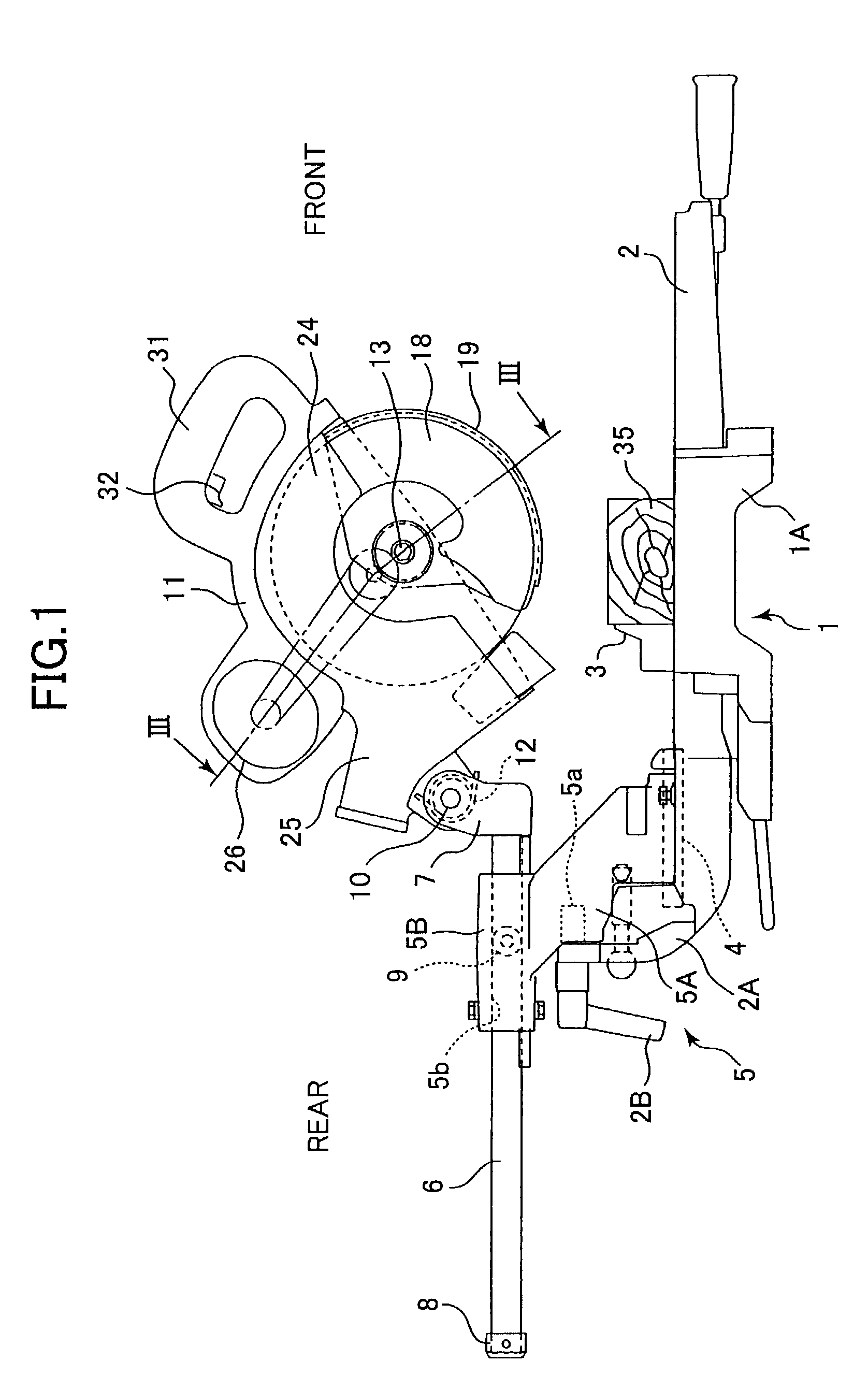

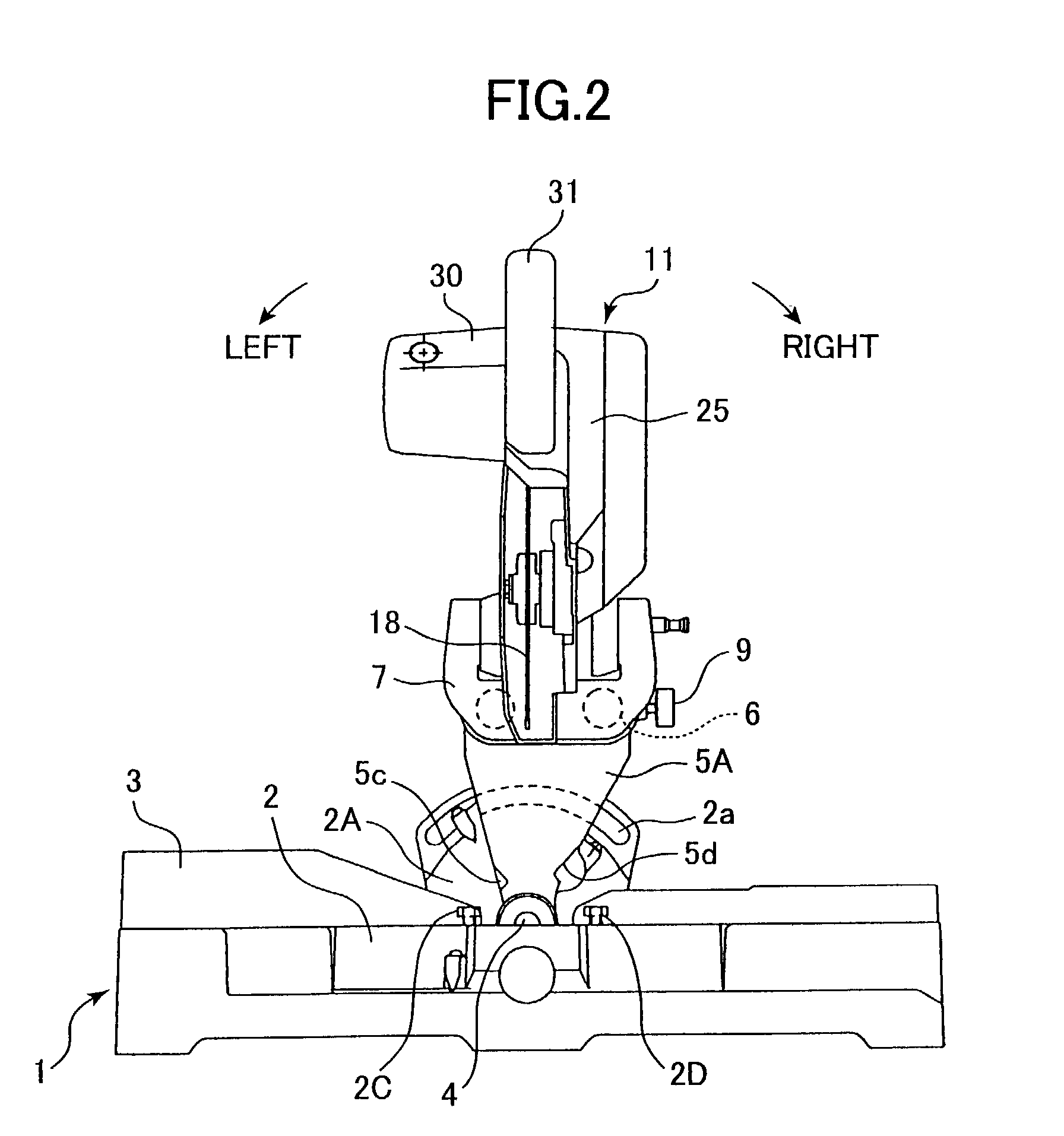

Miter saw with laterally tiltable circular saw blade

InactiveUS6971298B2Reduce axial thicknessIncrease effective cutting lengthMetal sawing devicesMetal sawing accessoriesGear wheelMedial axis

A miter saw including a base portion and a main body portion laterally tiltable and vertically pivotable. The main body portion includes a circular saw blade whose one side is provided with a power transmission mechanism. The mechanism includes a motor shaft pulley fixed to a motor shaft of a motor, a saw blade shaft extending in parallel with the motor shaft and an intermediate shaft extending in parallel with the saw blade shaft and positioned between the motor shaft and the saw blade shaft. On the saw blade shaft, a first saw blade shaft bearing, a flanged abutment portion, a gear and a second saw blade shaft bearing are arrayed in an order from the circular saw blade. On the intermediate shaft, a pinion meshedly engaged with the gear, a first intermediate shaft bearing in alignment with the second saw blade shaft bearing, an intermediate shaft pulley in alignment with the motor shaft pulley and a second intermediate shaft bearing are arrayed in this order from the circular saw blade. The gear and the pinion are positioned closest to the circular saw blade, which permits an axial thickness of the abutment portion to be reduced for reducing entire axial thickness of the power transmission mechanism.

Owner:HITACHI KOKI CO LTD

Fan device having an ultra thin-type structure with a minimum air gap for reducing an axial thickness

InactiveUS7456541B2Reduce axial thicknessSimple structureAssociation with control/drive circuitsMagnetic circuit rotating partsImpellerMagnetic poles

A fan device includes a base plate, a flat-type impeller, an assembling member, a magnet sheet and a shaft member. The base plate includes an axial hole and at least one stator coil arranged thereon. The flat-type impeller is formed with an annular supporting plate and bent vanes while the assembling member is formed with an assembling hole and an upraised flange. The magnet sheet provides with at least one pair of alternatively opposite magnetic poles (i.e. north pole and south pole). A first distal end of the shaft member is extended through the flat-type impeller and inserted into the assembling hole of the assembling member while a second distal end of the shaft member is inserted into the axial hole of the base plate. The flat-type impeller is positioned and sandwiched in between the assembling member and the magnet sheet so as to constitute a thin-type structure.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

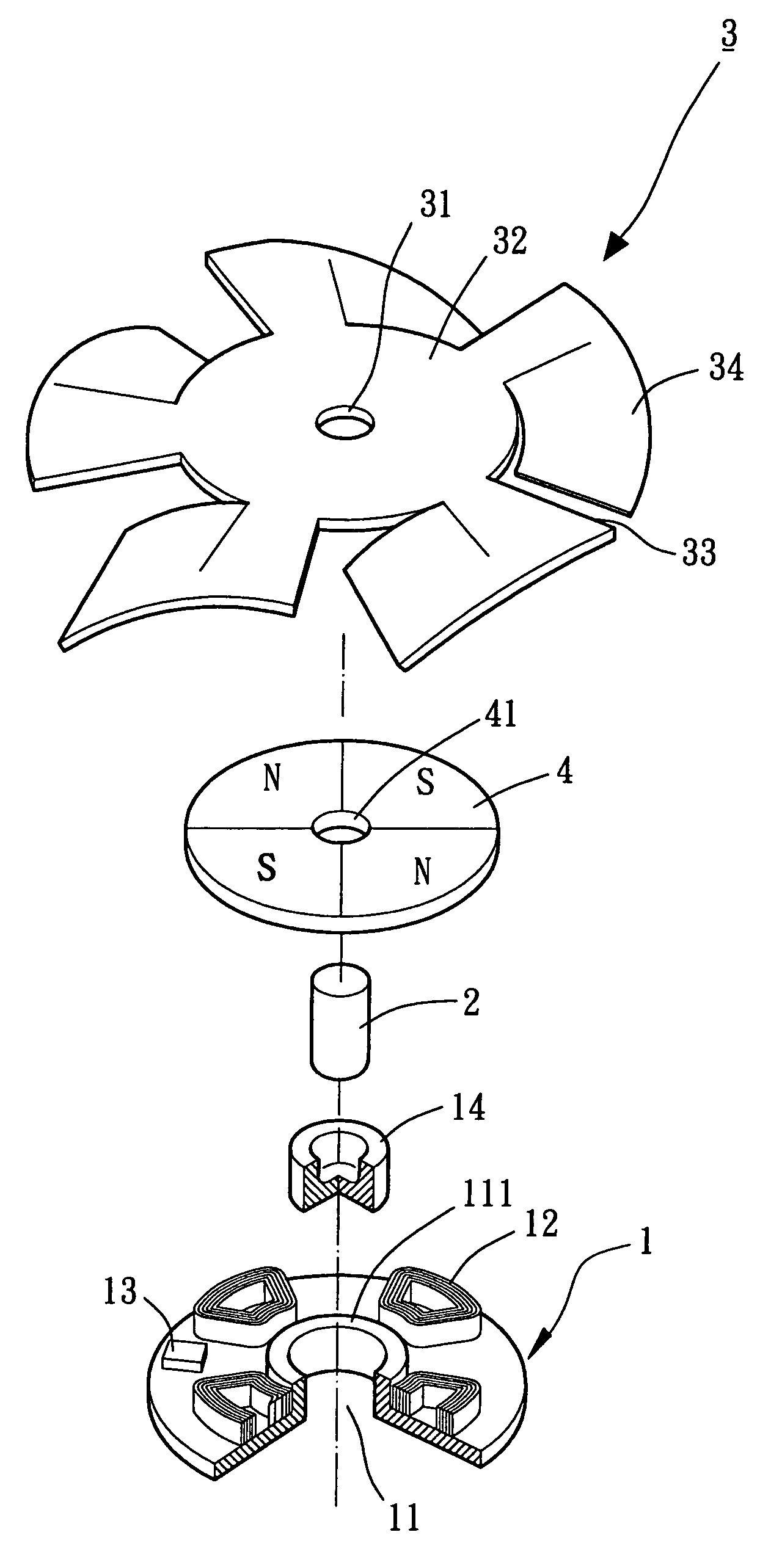

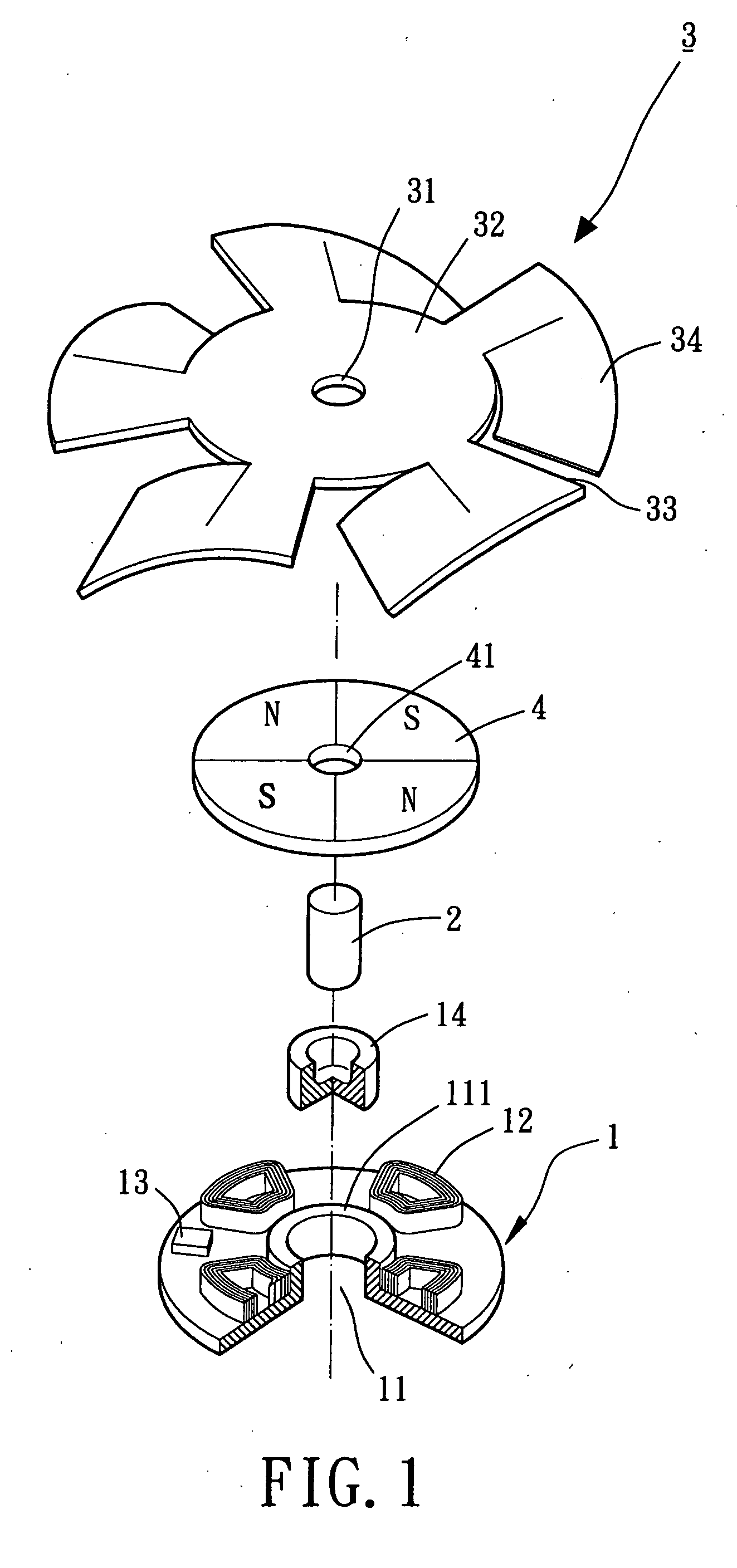

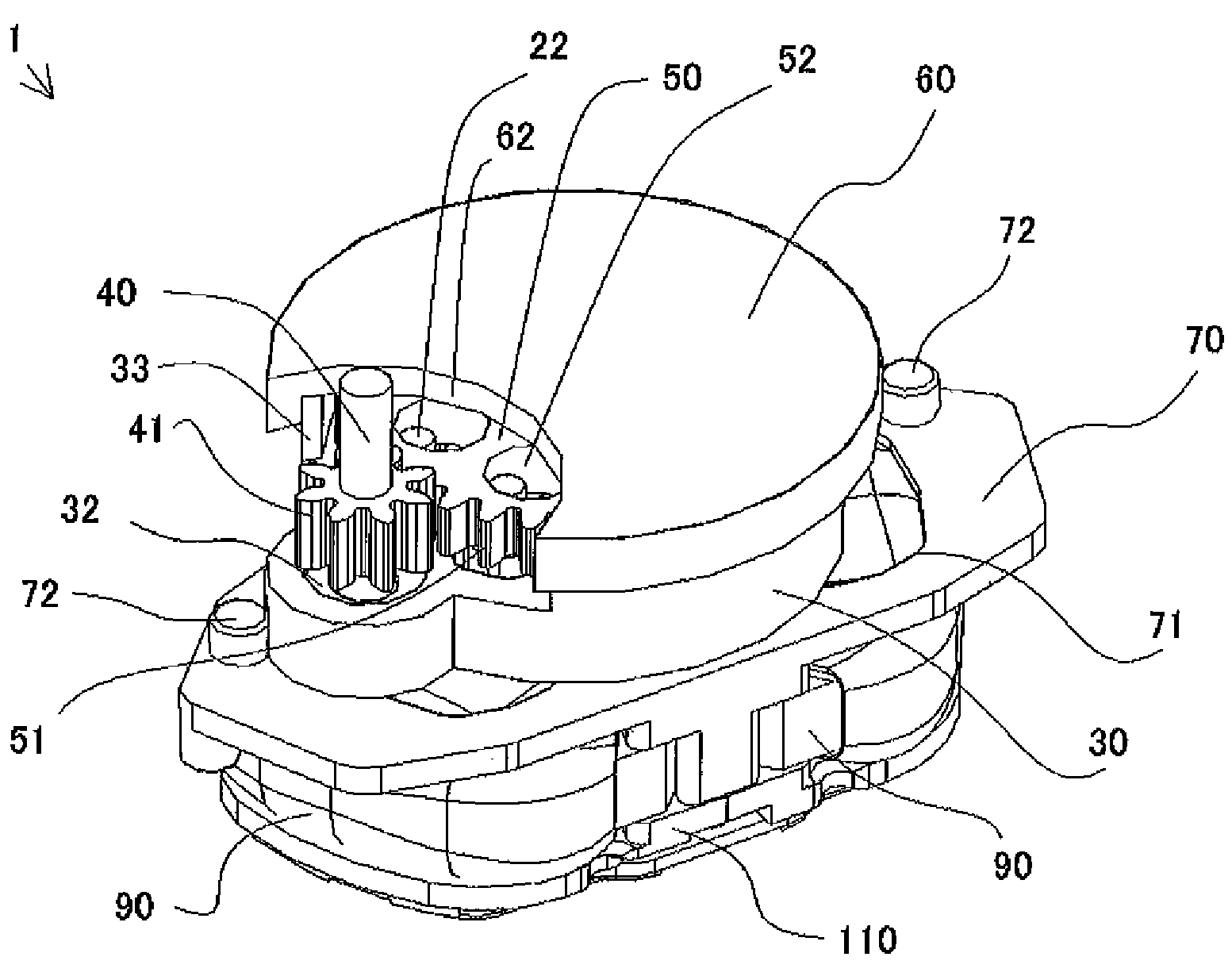

Simplified fan device having a thin-type structure with a minimum air gap for reducing an axial thickness

InactiveUS7474032B2Reduce axial thicknessEasy to installMagnetic circuit rotating partsPump componentsImpellerMagnetic poles

A simplified fan device includes a base plate, a flat-type impeller, a magnet sheet and a shaft member. The base plate includes an axial hole and at least one stator coil arranged thereon. The flat-type impeller is formed with an annular supporting plate, an assembling hole and a series of bent vanes. The magnet sheet provides with a center through hole and at least one pair of alternatively opposite magnetic poles (i.e. north pole and south pole). A first distal end of the shaft member is mounted to one of the assembling hole of the flat-type impeller and the center through hole of the magnet sheet or both. Correspondingly, a second distal end of the shaft member is extended through and rotatably received in a bearing member mounted in the axial hole of the base plate so as to constitute a thin-type structure.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Simplified fan device having a thin-type structure with a minimum air gap for reducing an axial thickness

InactiveUS20070114868A1Reduce axial thicknessEasy to installMagnetic circuit rotating partsPump componentsImpellerStator coil

A simplified fan device includes a base plate, a flat-type impeller, a magnet sheet and a shaft member. The base plate includes an axial hole and at least one stator coil arranged thereon. The flat-type impeller is formed with an annular supporting plate, an assembling hole and a series of bent vanes. The magnet sheet provides with a center through hole and at least one pair of alternatively opposite magnetic poles (i.e. north pole and south pole). A first distal end of the shaft member is mounted to one of the assembling hole of the flat-type impeller and the center through hole of the magnet sheet or both. Correspondingly, a second distal end of the shaft member is extended through and rotatably received in a bearing member mounted in the axial hole of the base plate so as to constitute a thin-type structure.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

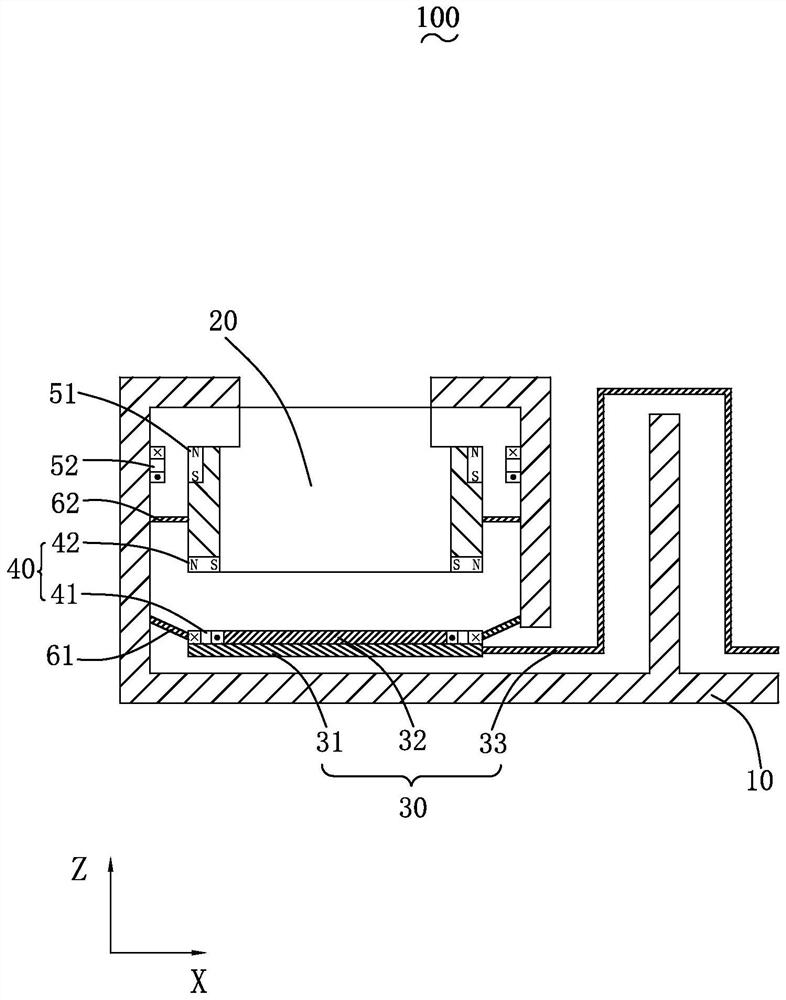

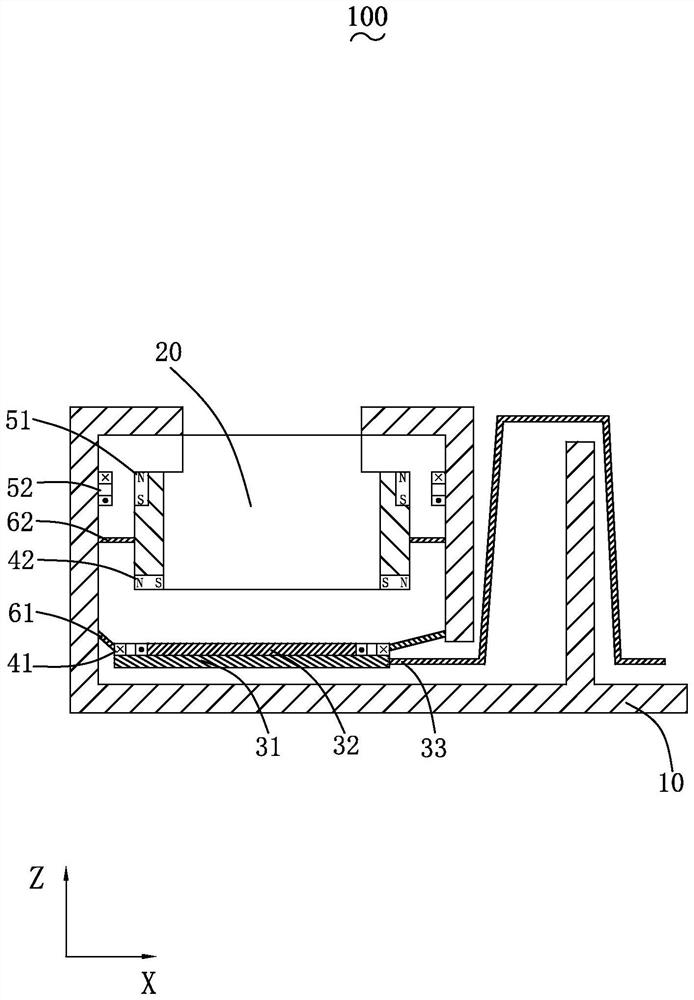

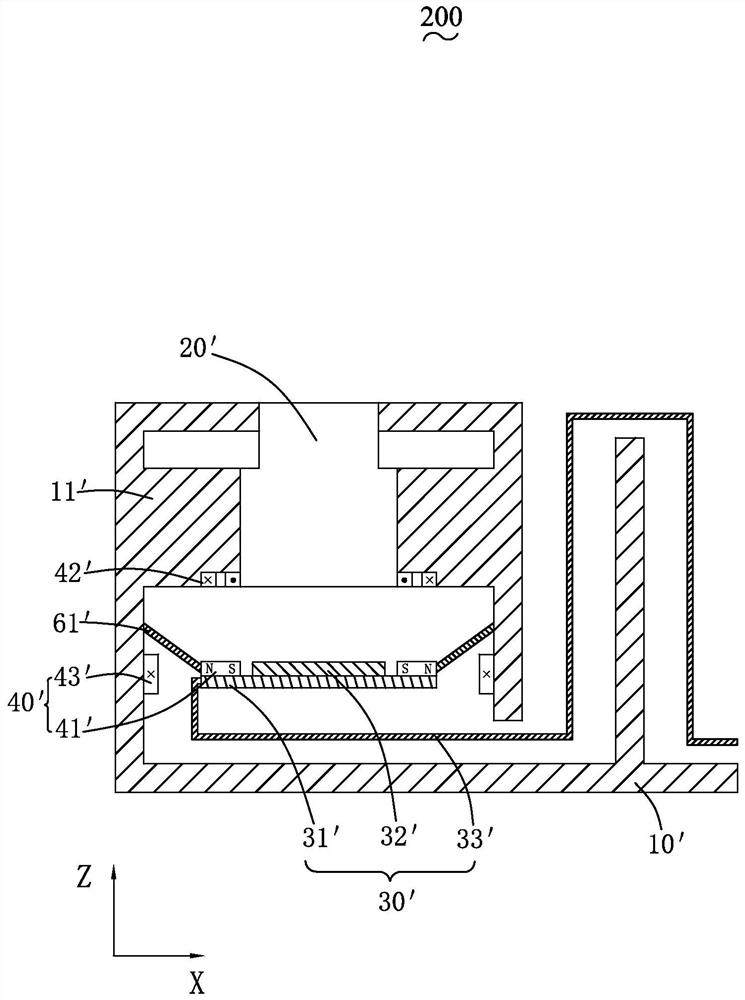

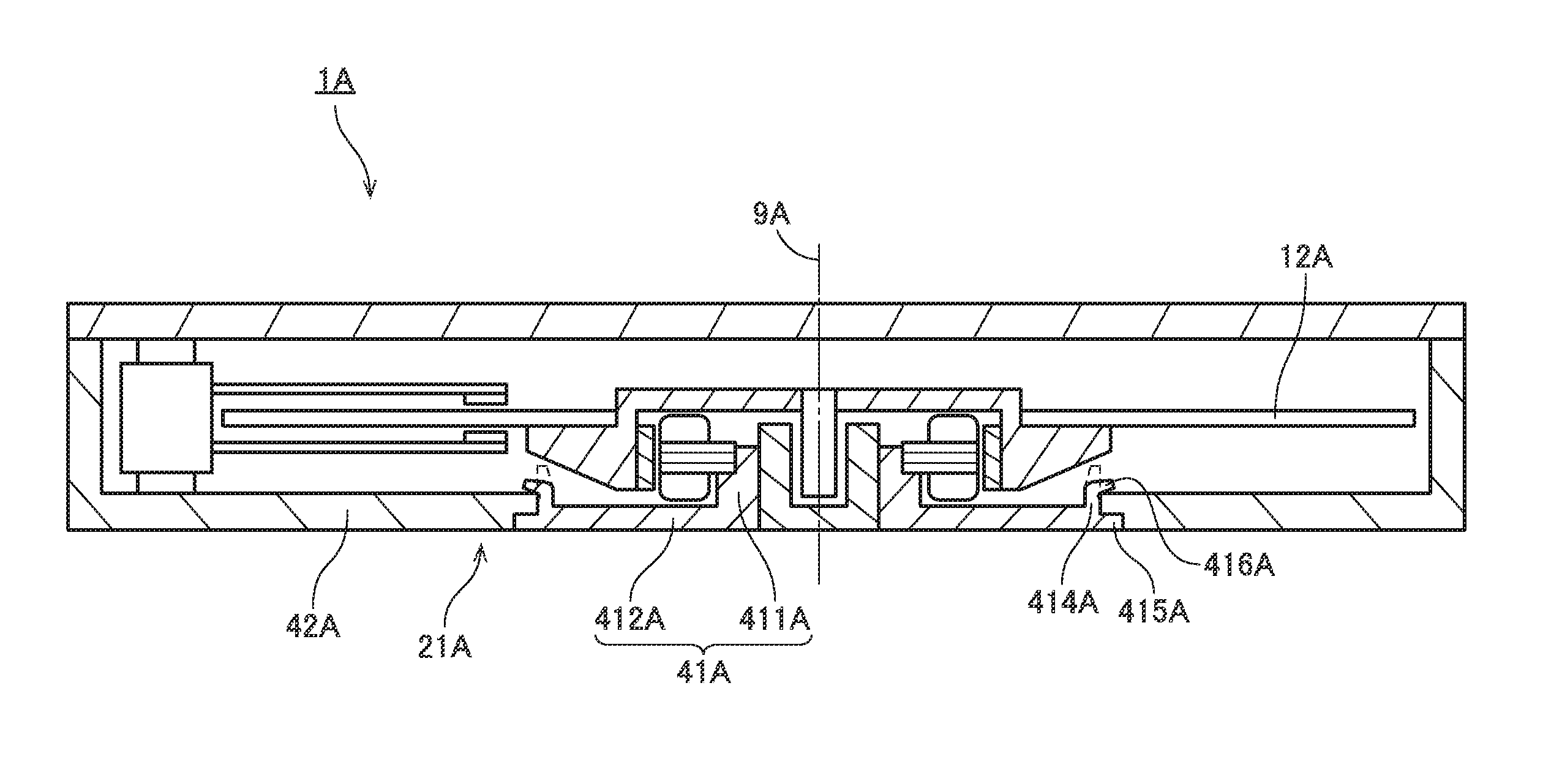

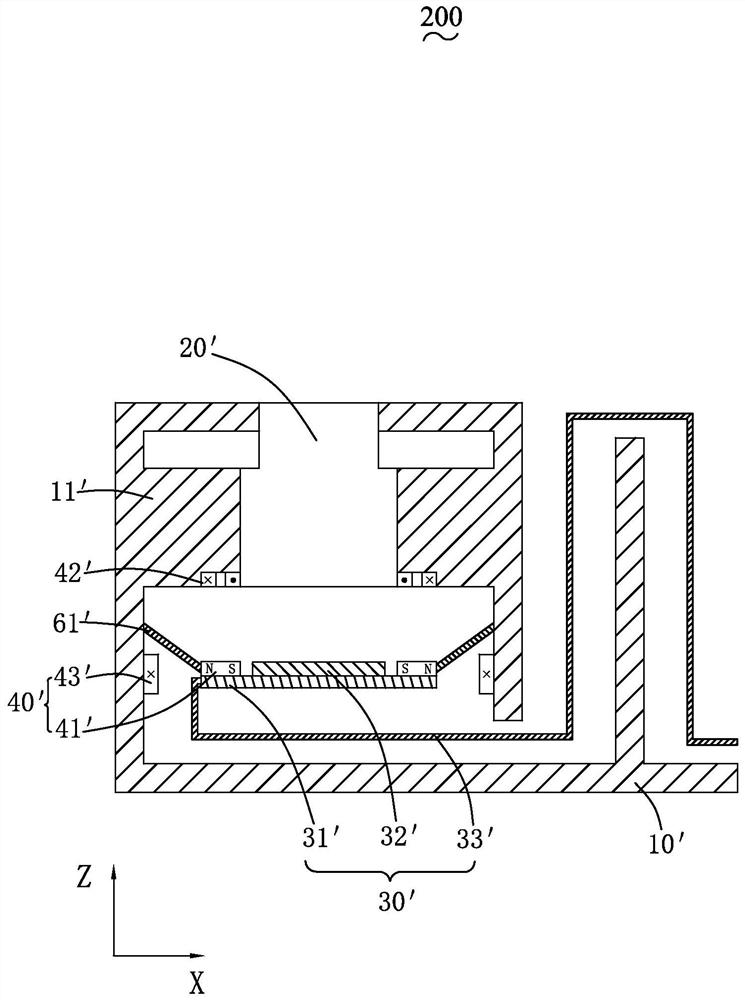

Lens module

InactiveCN111726508AReduce axial thicknessLess room for movementTelevision system detailsColor television detailsOptical axisEngineering

The invention provides a lens module. The lens module comprises a shell with an accommodating space, a lens accommodated in the accommodating space, a sensor assembly and a driving device, wherein thesensor assembly is movably accommodated in the accommodating space and is arranged opposite to the lens in the optical axis direction of the lens, and the driving device drives the sensor assembly tomove in / around the optical axis direction or in the direction vertical to the optical axis relative to the lens. Compared with the prior art, the above lens module increases the degree of freedom ofjitter compensation by moving the image sensor, i.e., compensates the jitter rotating around the optical axis, thereby improving the optical anti-jitter effect. The driving device directly drives theimage sensor to move, the structure is simple, and the occupied space is small; the size of the image sensor is small, and the activity space of the sensor assembly reserved in the shell is small, sothat the size of the shell can be reduced, and the axial thickness of the lens module is reduced.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU

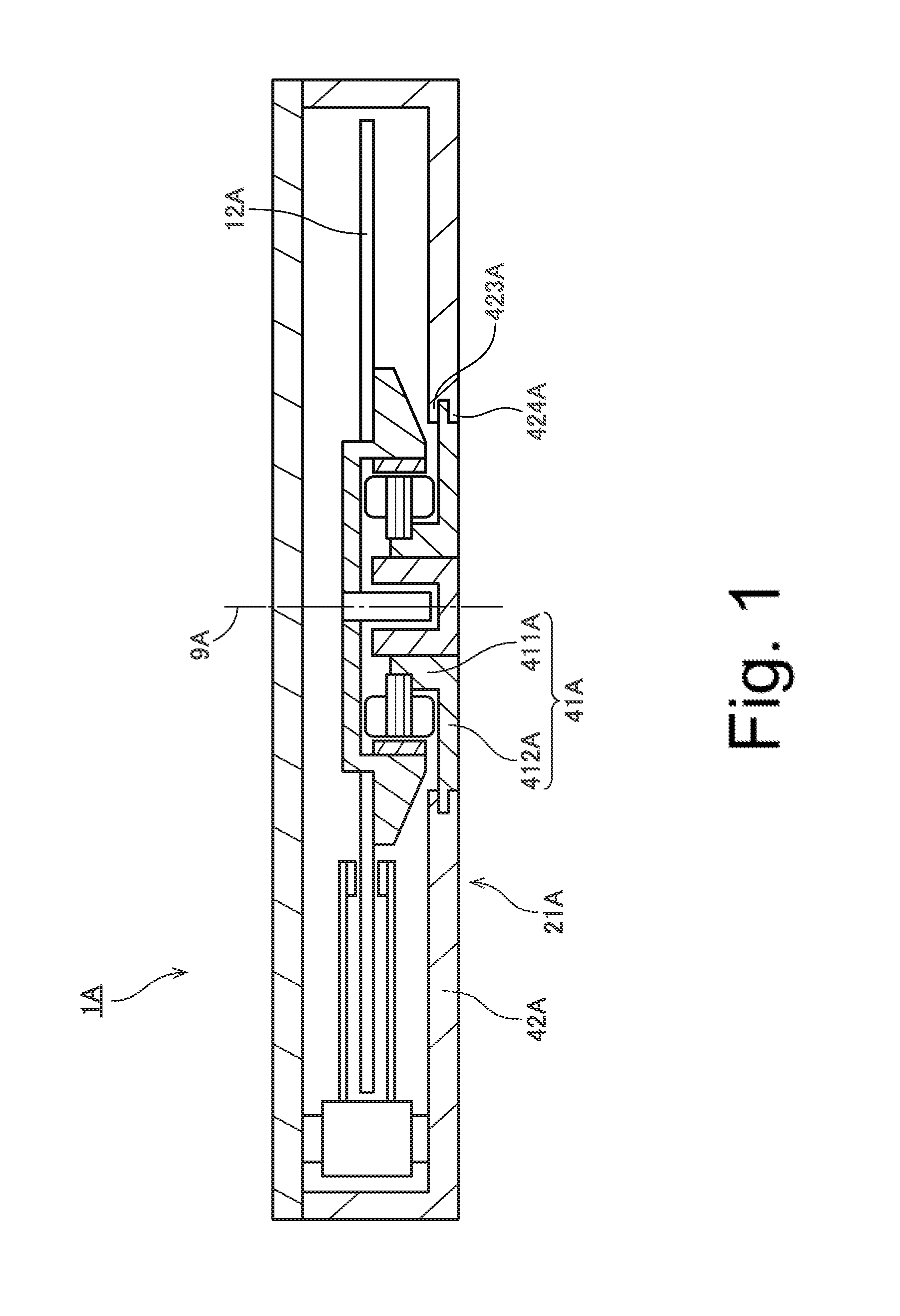

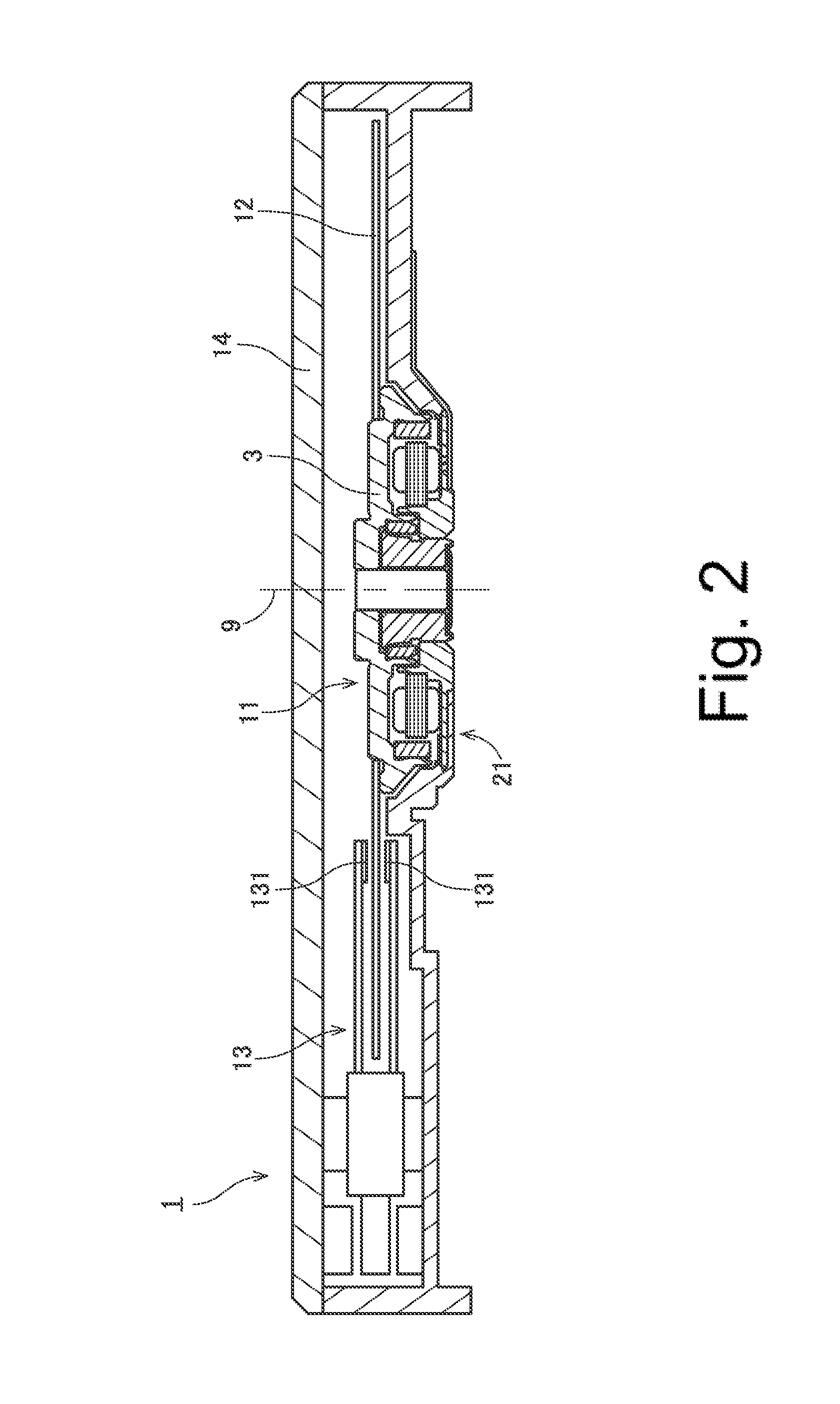

Base plate, base unit, motor and disk drive apparatus

ActiveUS20130335859A1Deterioration of stiffness can be preventedReduce axial thicknessRecord information storageRecord carrier contruction detailsMetallic materialsEngineering

A base plate of a disk drive apparatus includes a motor base disposed around a central axis and a base body portion extending radially outward of the motor base. The motor base is made of a metallic material of a first type. The base body portion is made of a metallic material of a second type. Thus, the axial thickness of a portion of the base plate close to the central axis can be significantly reduced and a reduction in the stiffness of the portion can be prevented. Further, the motor base includes a flange portion and a plastic deforming portion. The flange portion and the plastic deforming portion are respectively in contact with at least a portion of both axial end surfaces of an inner end portion of the base body portion. Thus, extraction of the motor base in the axial direction is prevented.

Owner:NIPPON DENSAN CORP

Zoom lens and imaging system incorporating it

The invention relates to a small-format yet high-performance two units or three units type zoom lens with a negative unit at the front, which has a zoom ratio of about 3, an angle of view of as wide as 60° at the wide-angle end and high image-formation capability, and is much less susceptible to chromatic blurring, with a compact lens barrel. The zoom lens comprises a first lens unit G1 of negative refracting power and a second lens unit G2 of positive power, wherein zooming is implemented by varying the space between the lens units. The first lens unit G1 is made up of one negative lens L11 and one positive lens L12, two in all, and satisfies specific conditions with respect to their refractive index and Abbe constant.

Owner:OLYMPUS CORP

Outer rotor of motor for traction machine

ActiveCN105836583AReduce axial thicknessReduce maintenance costsMechanical energy handlingBuilding liftsMotor driveEngineering

The invention discloses an outer rotor of a motor for a traction machine. The outer rotor comprises a machine seat, a traction wheel arranged on the machine seat, and the motor driving the traction machine to rotate. The machine seat is composed of a bottom plate and a vertical plate, both of which are vertically arranged. The inner end surface of the vertical plate is fixedly provided with a support shaft parallel to the bottom plate. One end of the support shaft is fixed on the vertical plate and the other end of the support plate is suspended. The inner wall of the traction wheel is fixedly provided with a permanent magnet such that the motor rotor and the traction wheel are combined as one. A motor stator is fixed on the vertical plate. The traction wheel has an end surface. The motor stator is positioned between the vertical plate and an end surface. A rotary shaft extends out of the position, facing the support shaft, of the end surface of the traction wheel such that the traction wheel rotates around the support shaft. The rotary shaft is axially overlapped with the support shaft. The outer rotor of the motor for the traction machine has following beneficial effects: by means of the traction wheel, the motor rotor, the rotary shaft of the traction wheel and the support shaft of the machine seat, axial overlap can be achieved. The axial thickness of the traction wheel is shortened so that the ultra-thin design is realized. Cost is reduced and the installation process is simplified. Management and maintenance are conveniently carried out. The final-period maintenance cost of an elevator is decreased.

Owner:曾海平

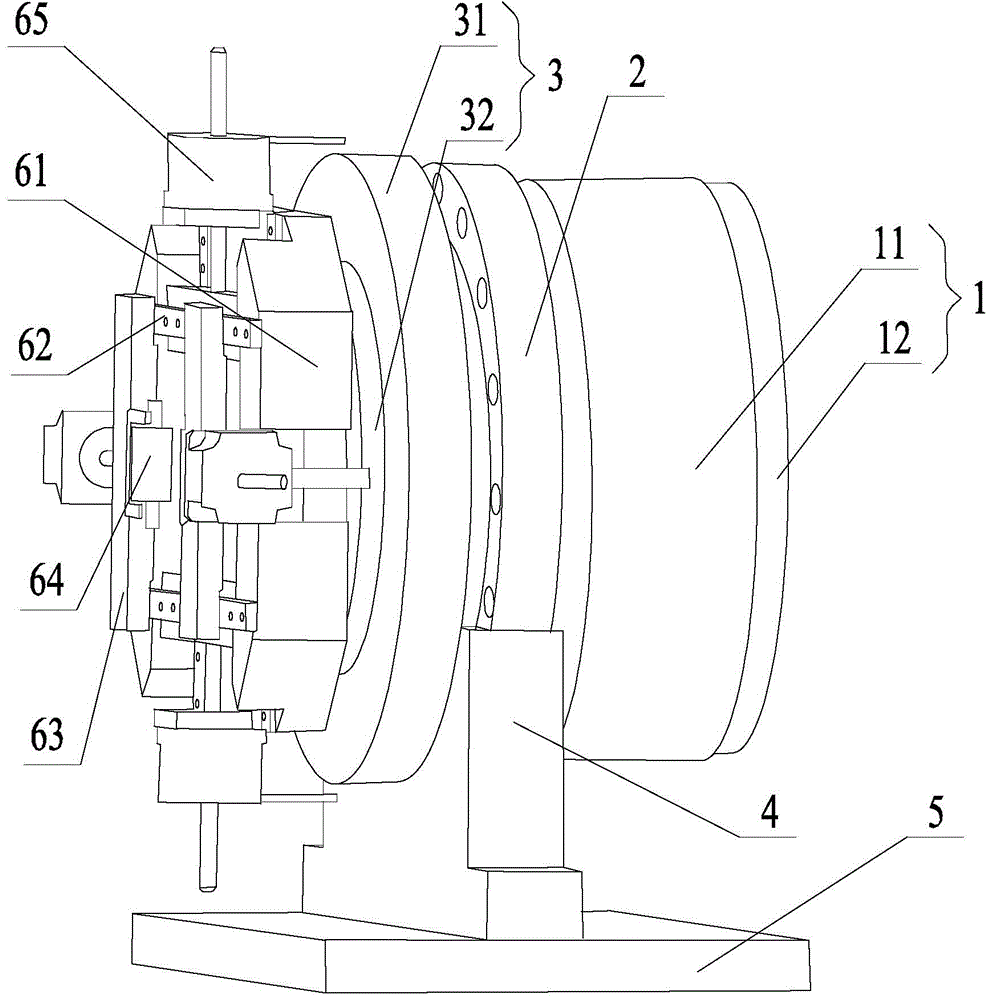

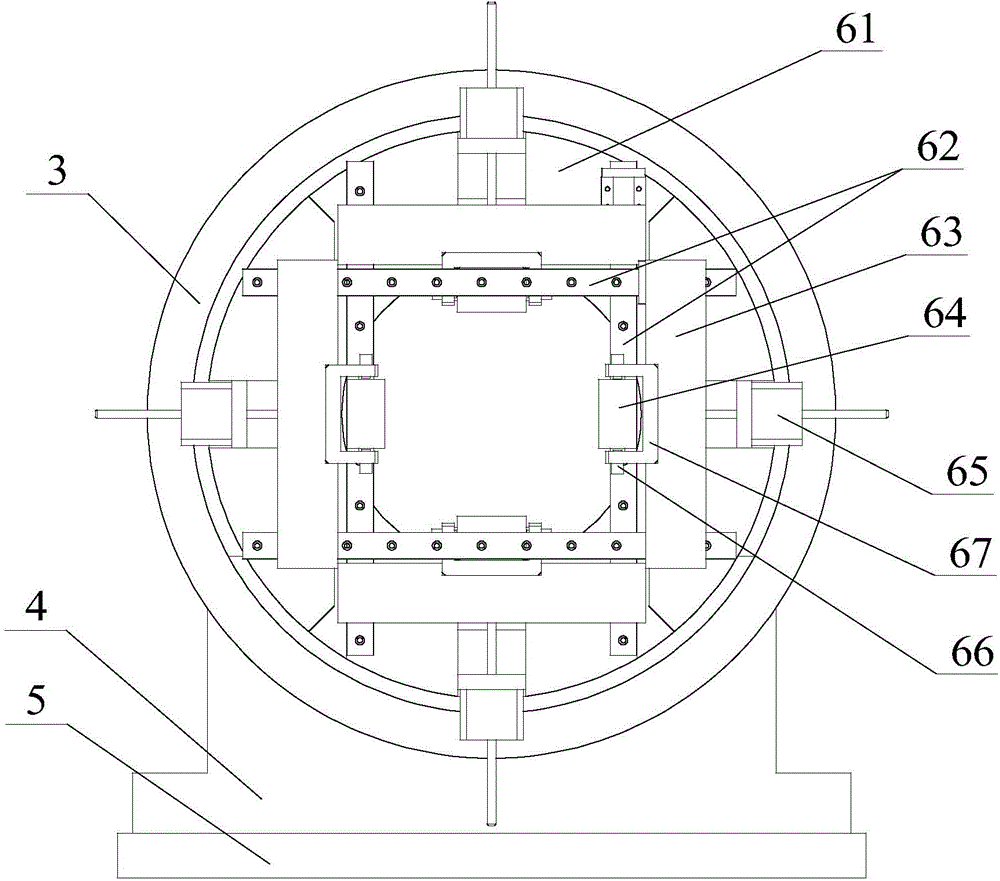

Central support for laser pipe cutting

ActiveCN104014941ASmooth rotationAvoid moment imbalanceWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention relates to the field of laser cutting devices, in particular to a central support for laser pipe cutting. The outer ring of a large-through-hole bearing is fixed to a fixing base. A frameless motor is arranged on one side of the large-through-hole bearing. A slip ring is arranged on the other side of the large-through-hole bearing. A rotor of the frameless motor, the inner ring of the large-through-hole bearing and a rotary slip ring body of the slip ring are connected in sequence and have the same rotation axis. An idler wheel connecting disk is fixed to the rotating slip ring body, and the rotation axes of the idler wheel connecting disk and the rotating slip ring body are identical. Two pairs of parallel guide rails are arranged on the other side of the idler wheel connecting disk, wherein the two pairs of parallel guide rails are perpendicular to each other. Each pair of parallel guide rails is movably provided with two sliding plates. Each sliding plate is provided with an idler wheel. The four idler wheels face the rotation axis of the idler wheel connecting disk. Each idler wheel is connected with a stepping motor. The frameless motor and the stepping motors are connected with an externally arranged controller. By the adoption of the central support for laser pipe cutting, stable and synchronous rotation of the pipes can be achieved; the central support is suitable for supporting various pipes, and the cutting precision is high.

Owner:WUHAN TIANQI LASER EQUIP MFG

Super thin fan

InactiveCN1987113AEasy and reliableReduce axial thicknessPump componentsPump installationsFlangeMagnet

An ultra-thin fan is composed of a base with an axle hole and at least one coil, a blade wheel consisting of an annular plate and multiple curved blades, an assembly elements with an assembling hole and a radial flange, a magnet sheet with at least one pair of N and S poles on its surface, and an axle.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

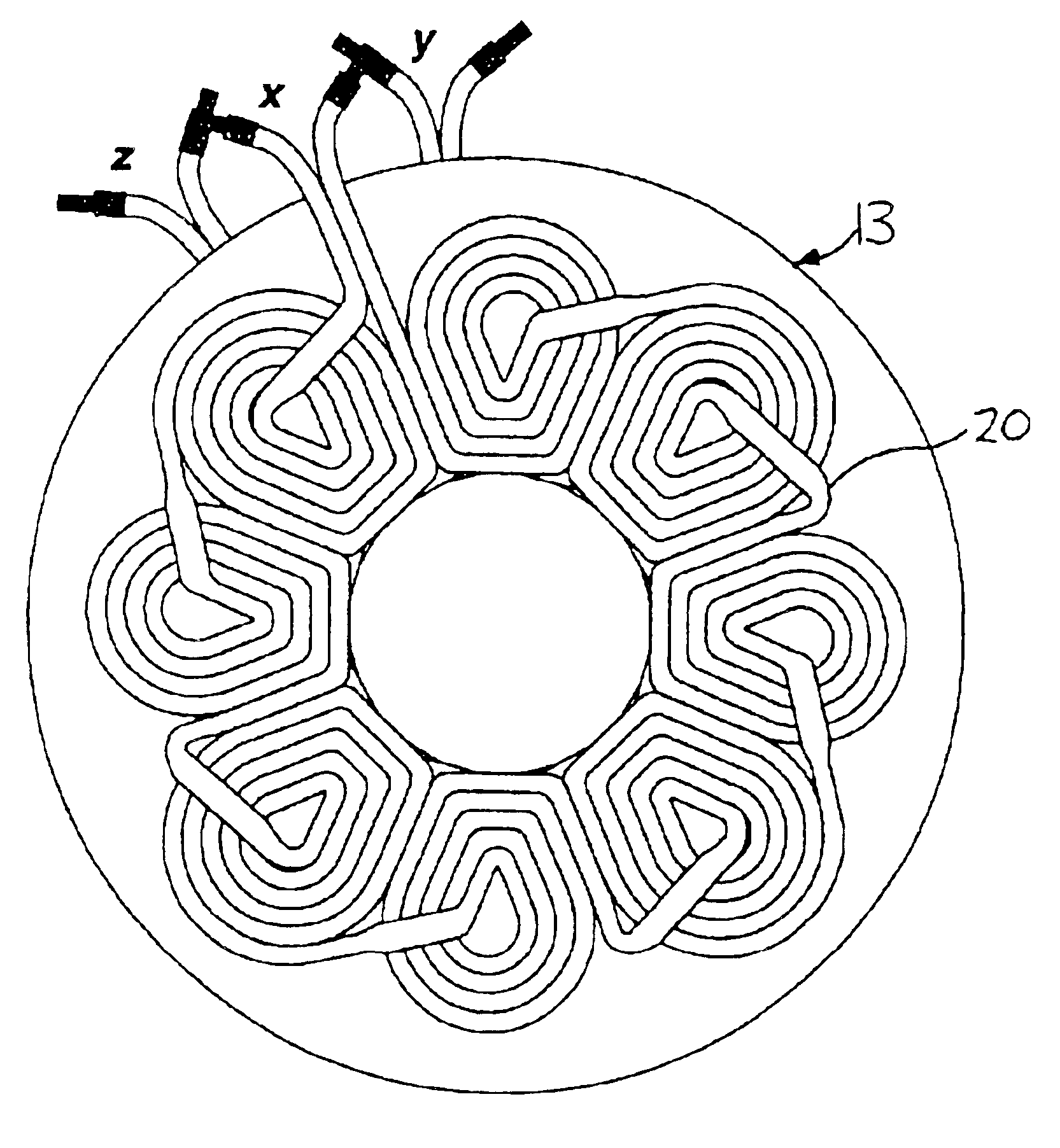

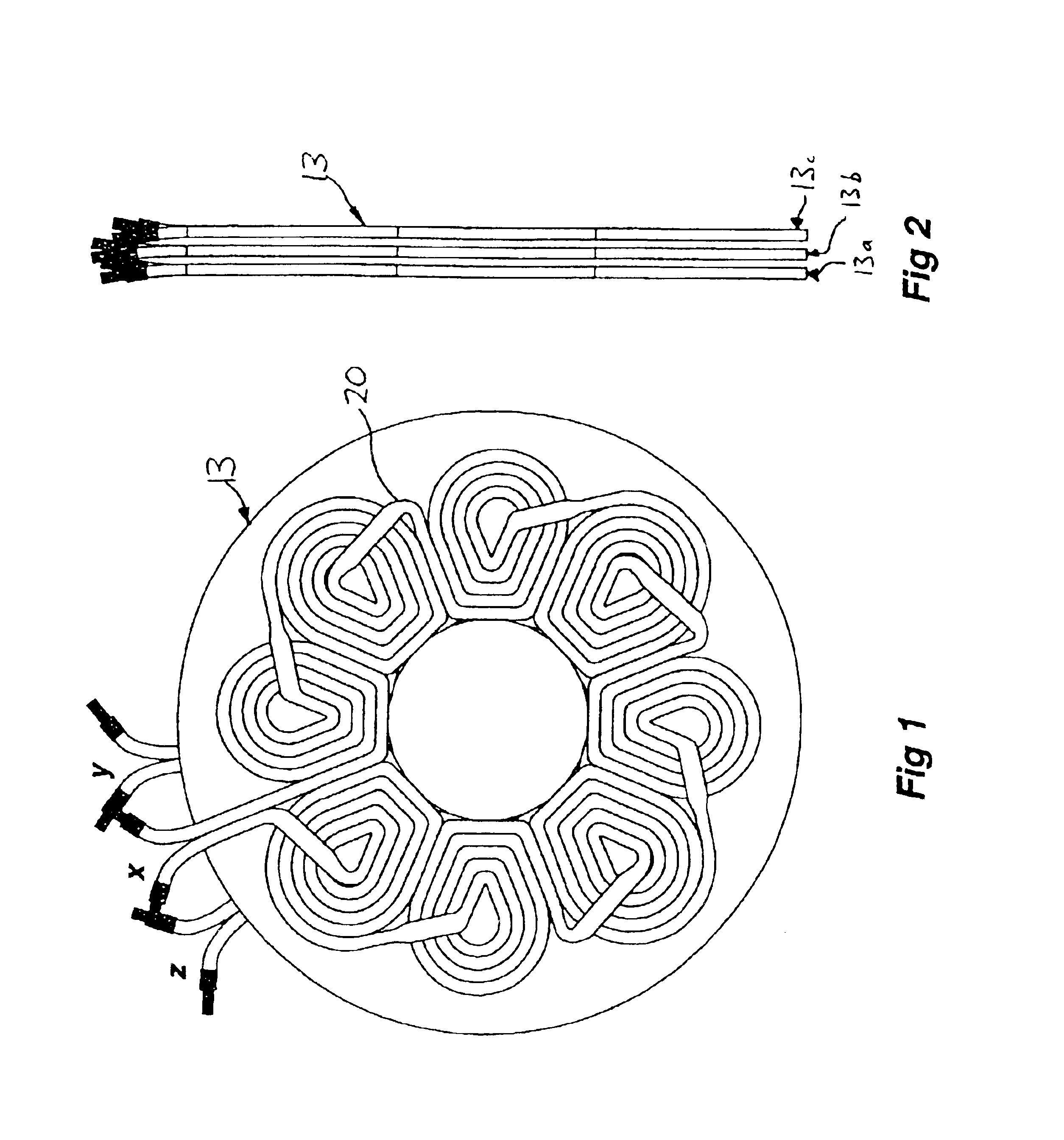

Method of forming a winding disc for an axial field electrical machine

InactiveUS6912773B2Reduce thicknessProvide mechanical strengthWave amplification devicesSynchronous machinesStator coilInterconnection

Owner:TURBO GENSET

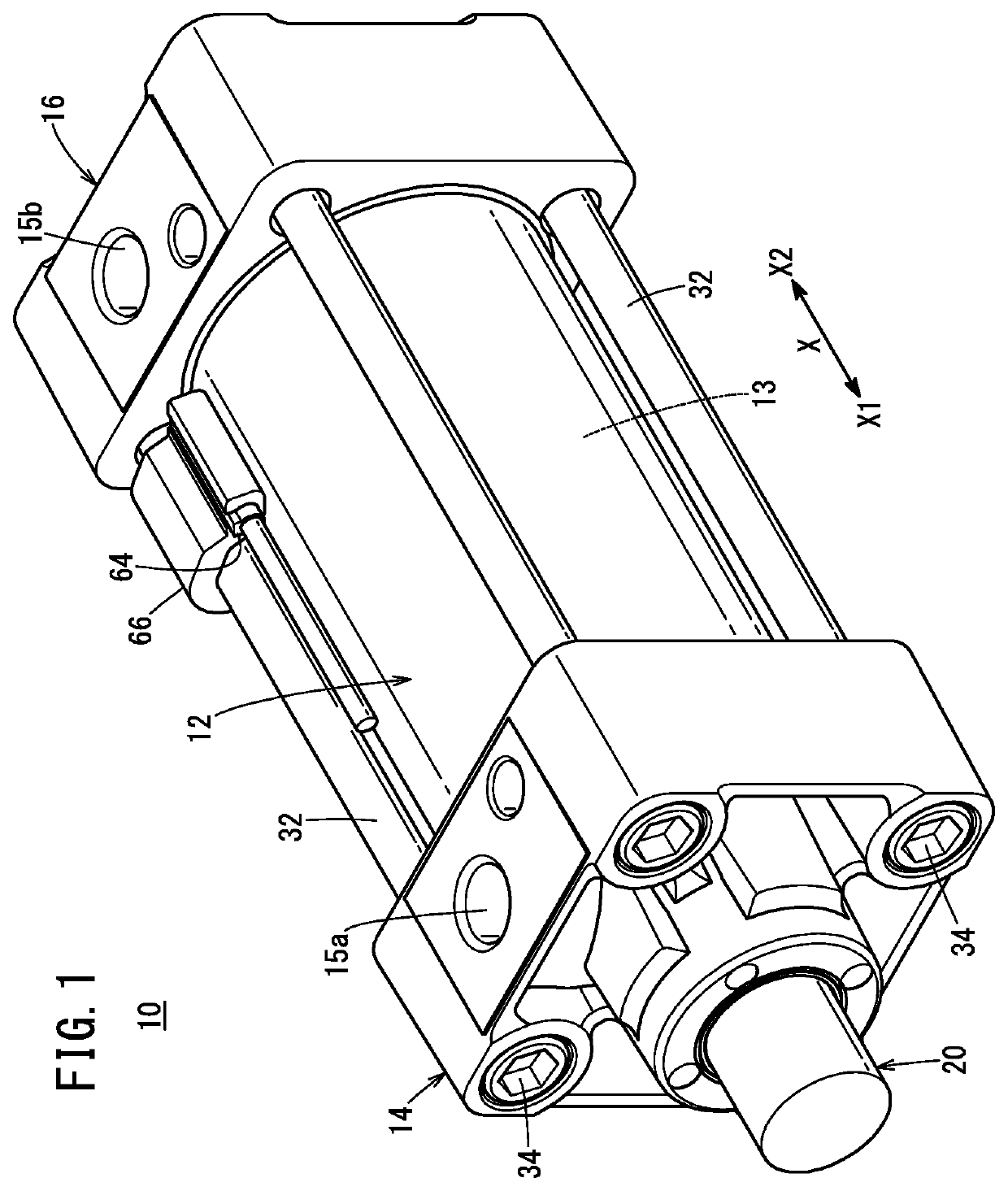

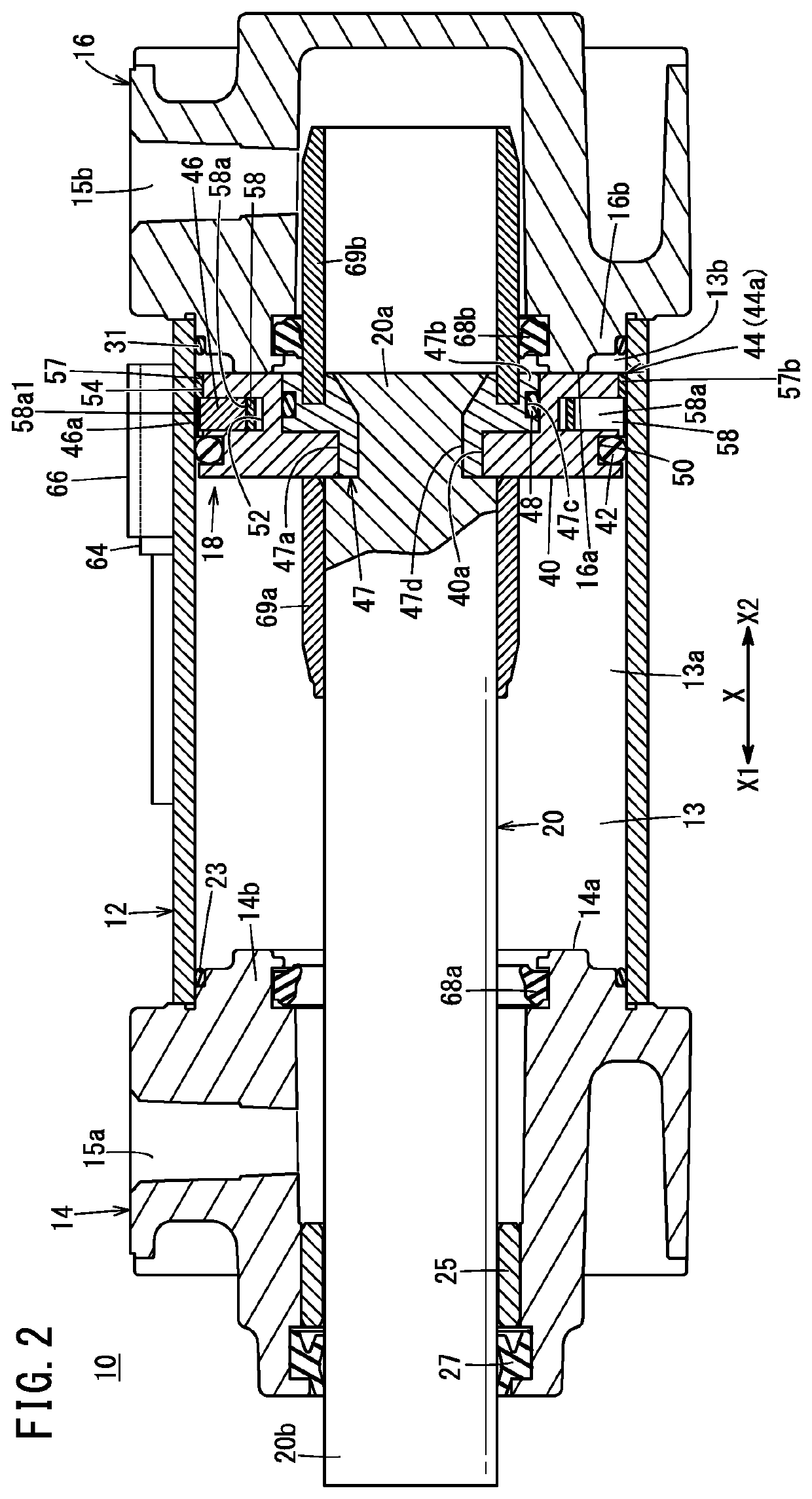

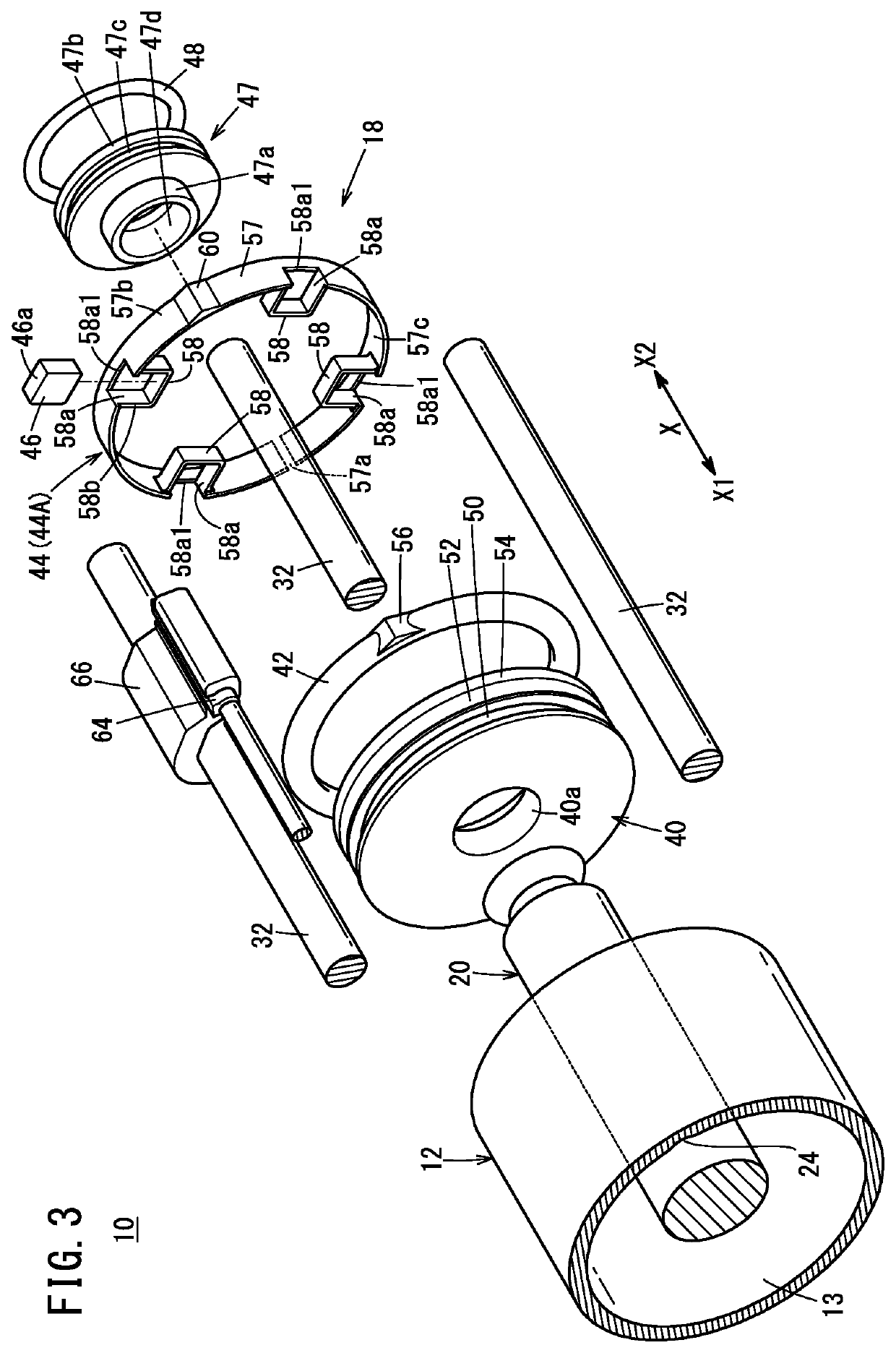

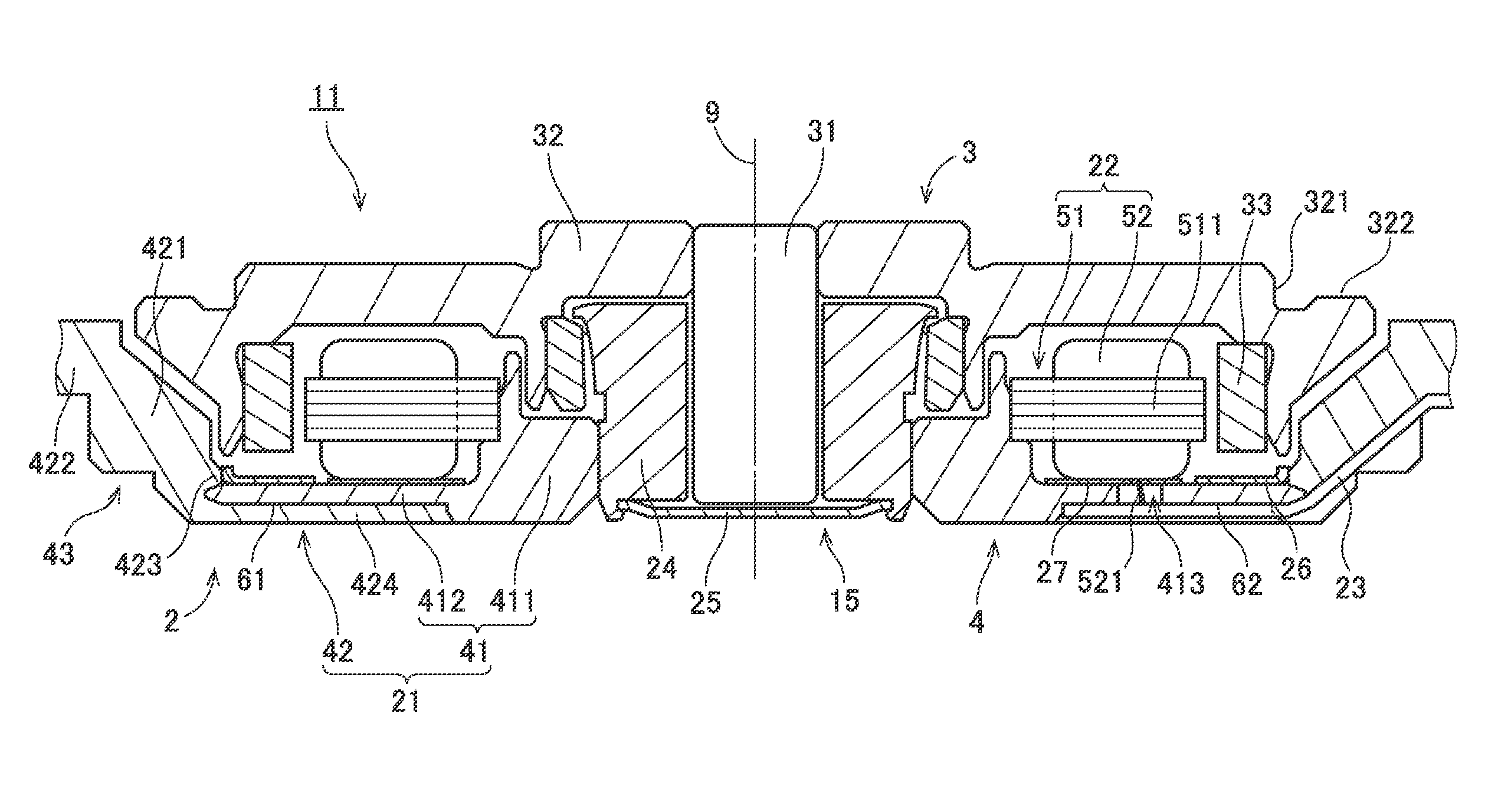

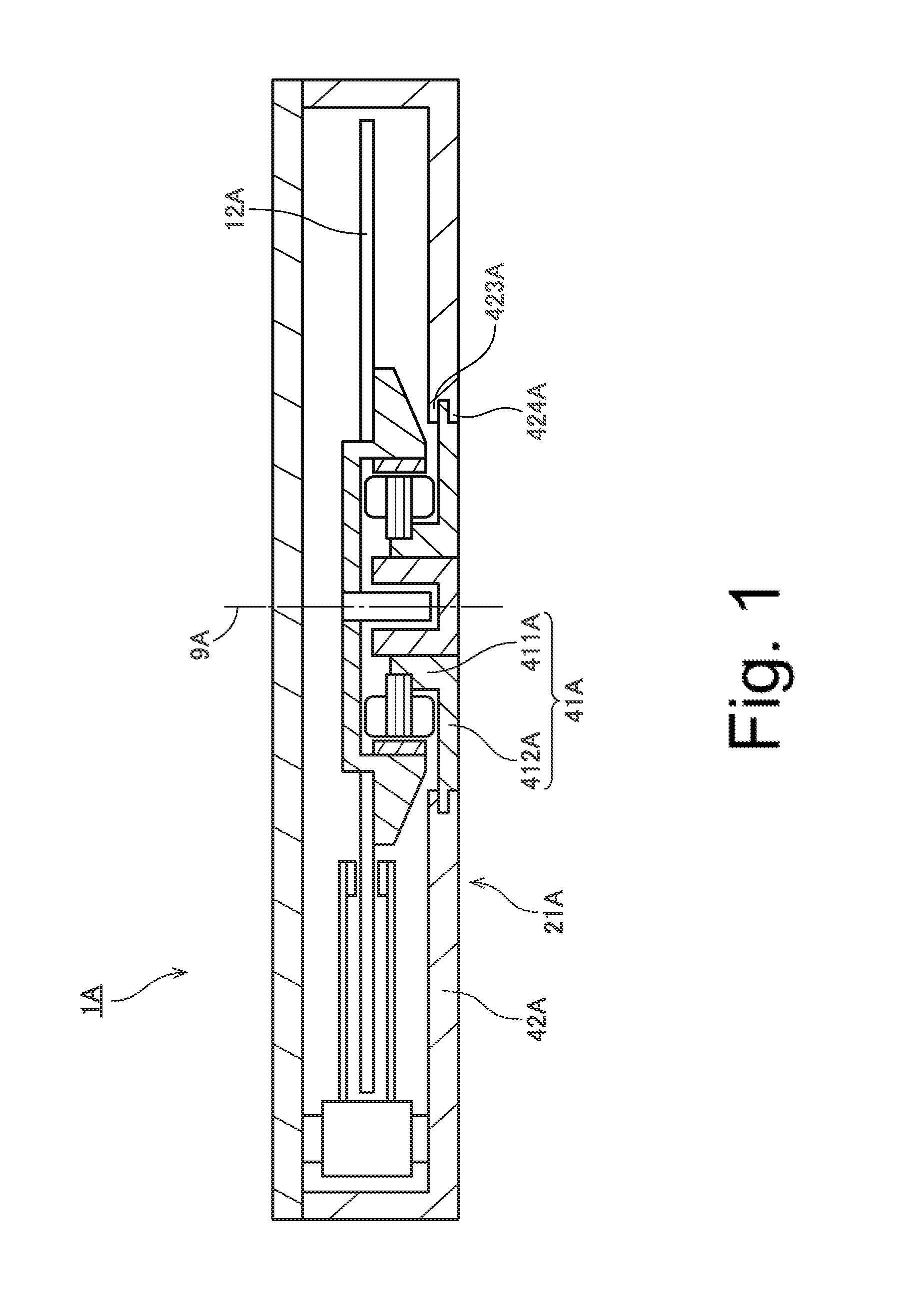

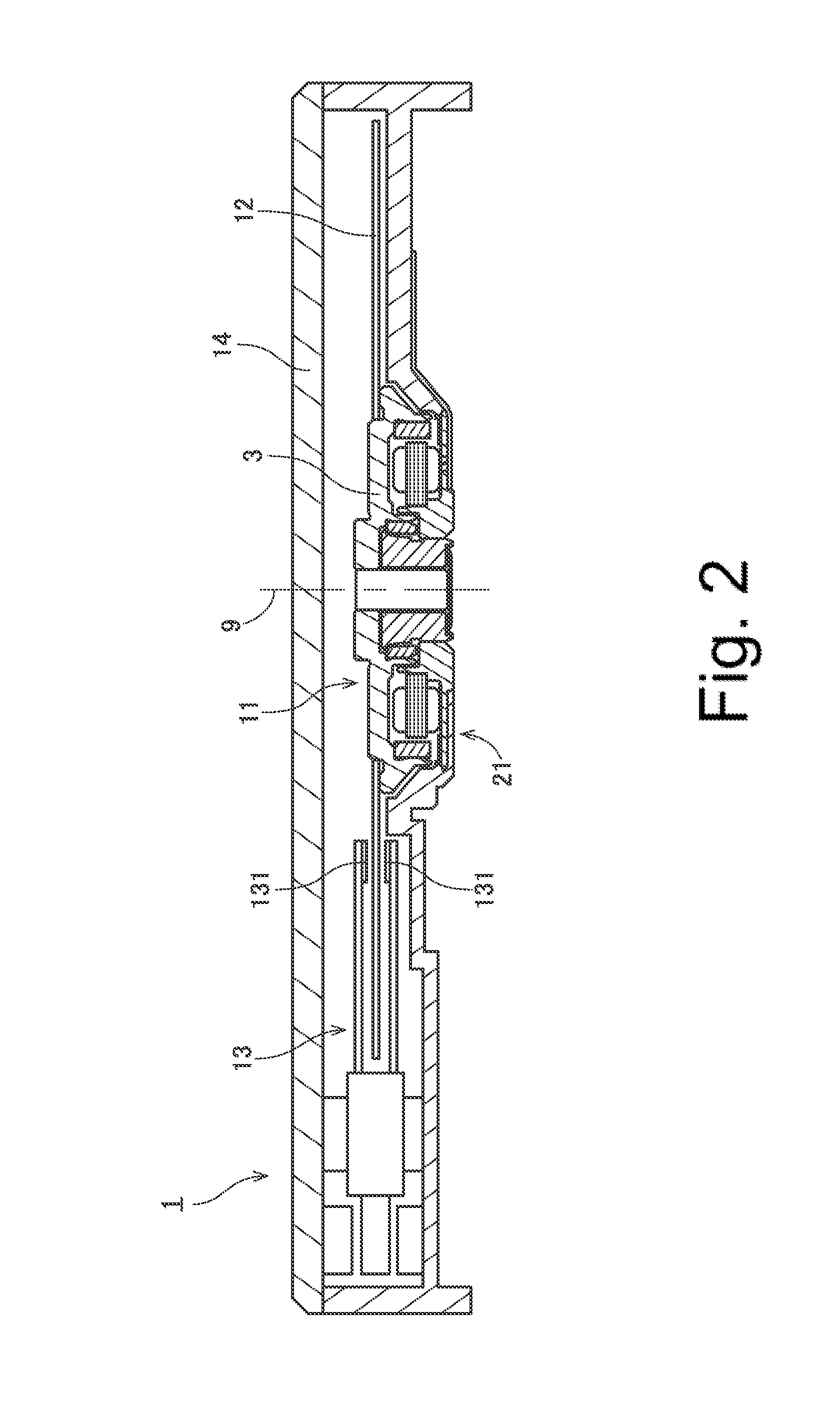

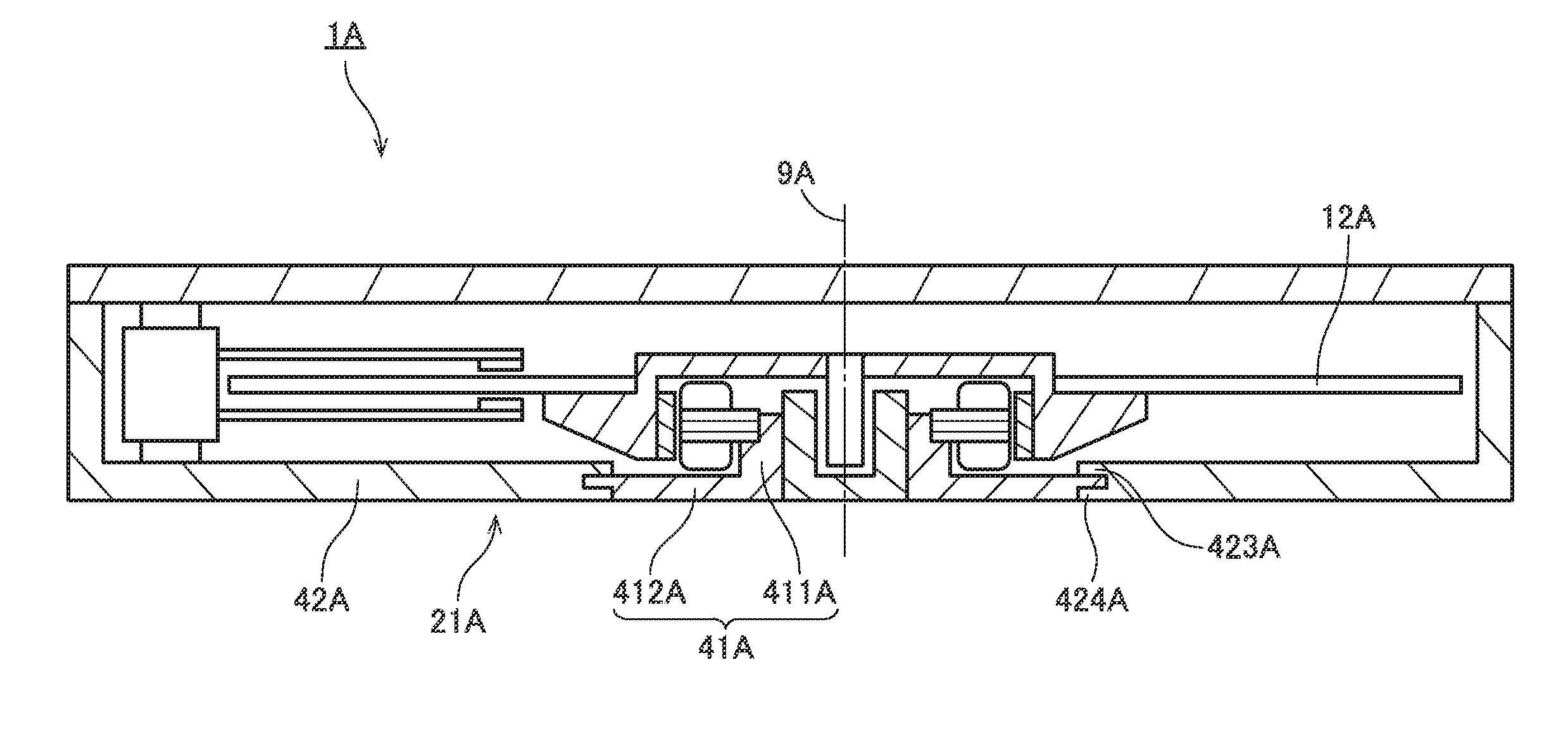

Hydraulic cylinder

ActiveUS20200300276A1Simple processShorten the lengthFluid-pressure actuatorsHydraulic cylinderEngineering

A hydraulic cylinder is provided with a cylinder tube, a piston unit, and a piston rod. The piston unit has a piston body; packing mounted on the piston body; a holding member mounted on the piston body; and a magnet held by a magnet holding part of the holding member. The magnet holding part has a notch that is open on the outer circumferential surface of the holding member.

Owner:SMC CORP

Friction component bracket

ActiveCN106481682AAccurate and sensitive adjustment settingsIncrease or decrease collection areaFriction clutchesCouplingsEngineeringClutch

A friction component bracket for a multi-disc friction clutch comprises a rotation axis; and an axial section with teeth, wherein the tooth has a sidewall that extends in an axial direction and a radial direction and is used for engaging with the friction component in a shape engagement manner, wherein each tooth is provided with a radial projection at radial inside part of the axial section. The radial outer sections of at least some teeth are respectively provided with a channel opening for allowing radial penetration of fluid. Hereon, different teeth have different extension dimensions in the circumferential direction. Different volume flows of fluid are obtained through the channel openings of the teeth.

Owner:SCHAEFFLER TECH AG & CO KG

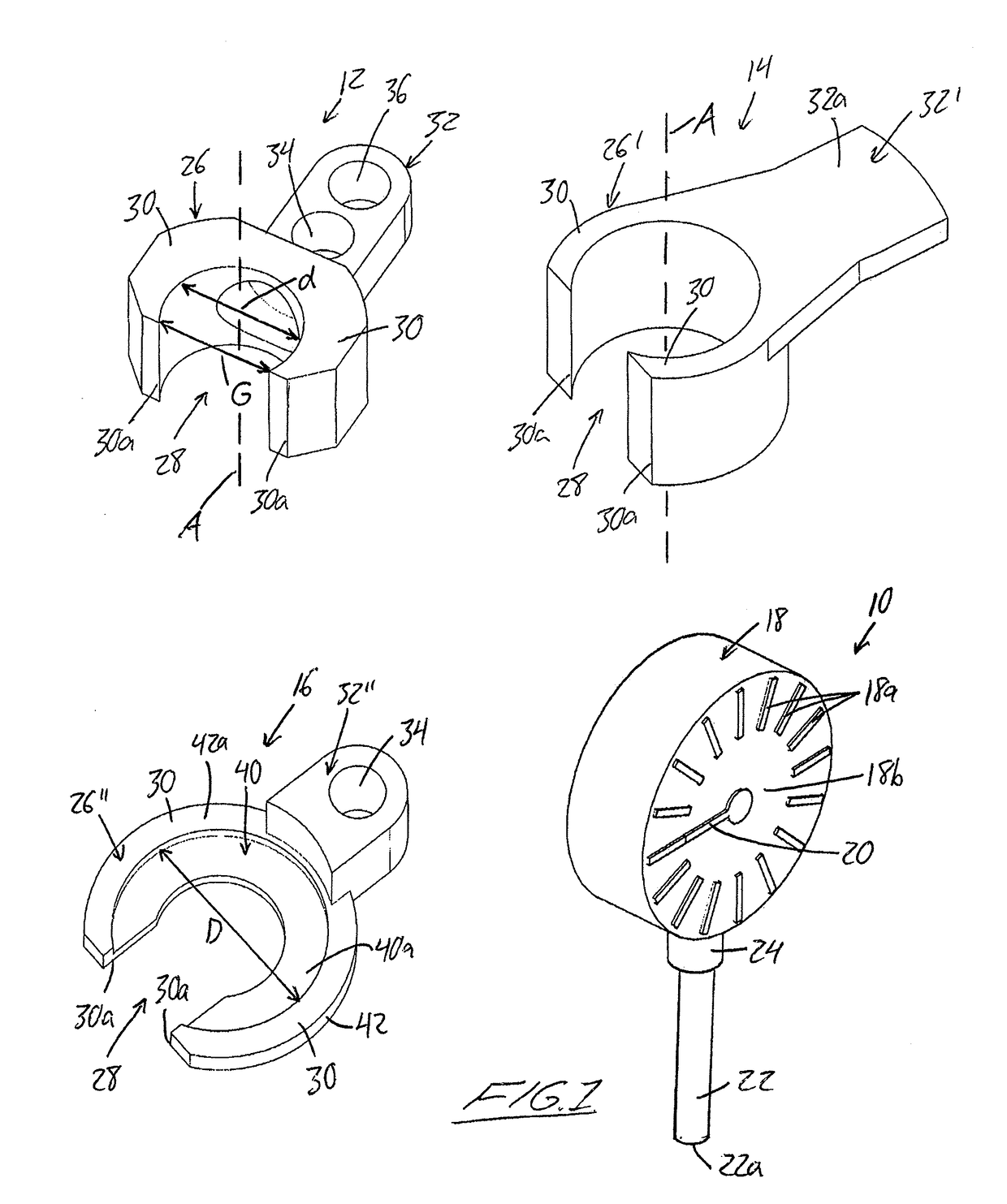

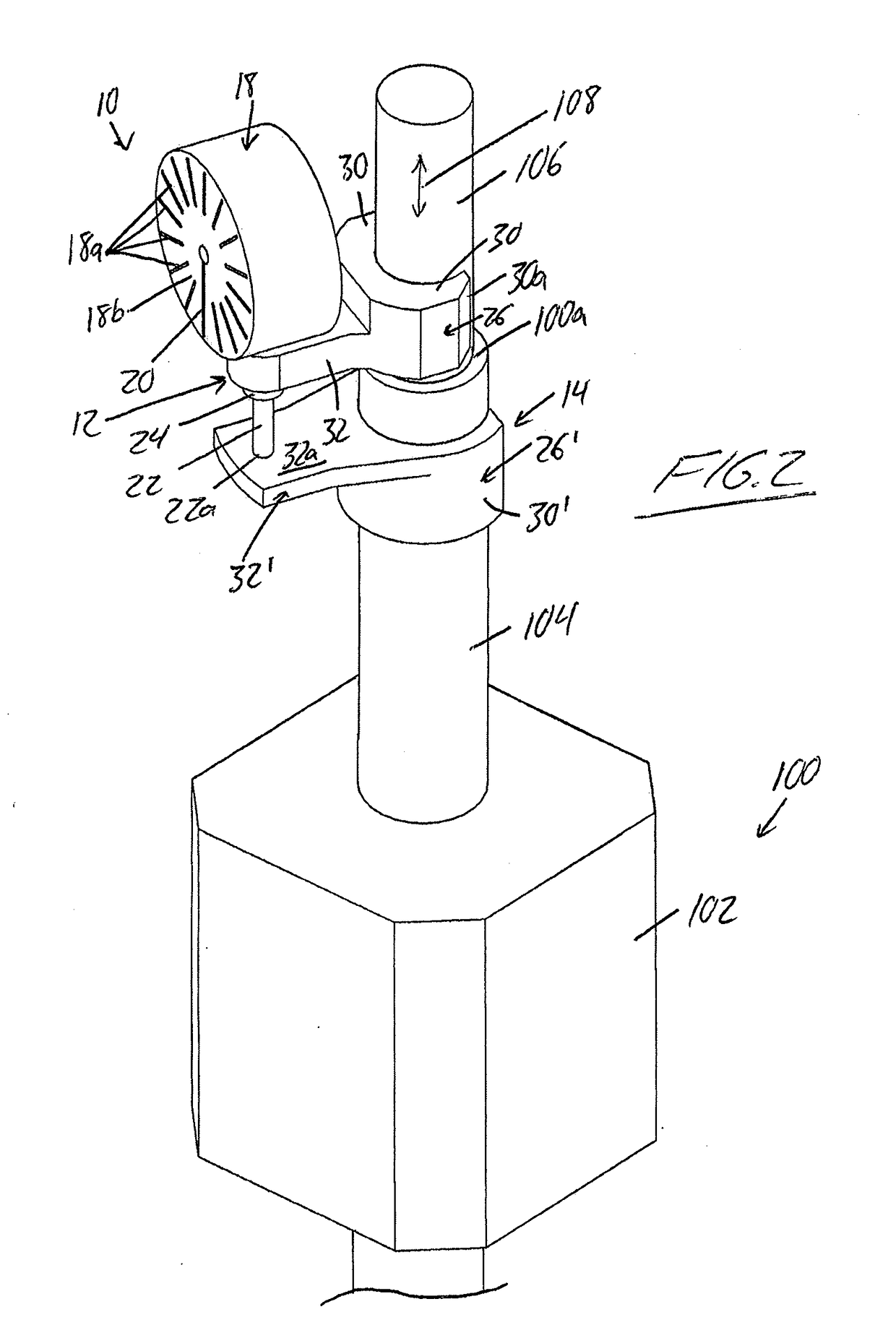

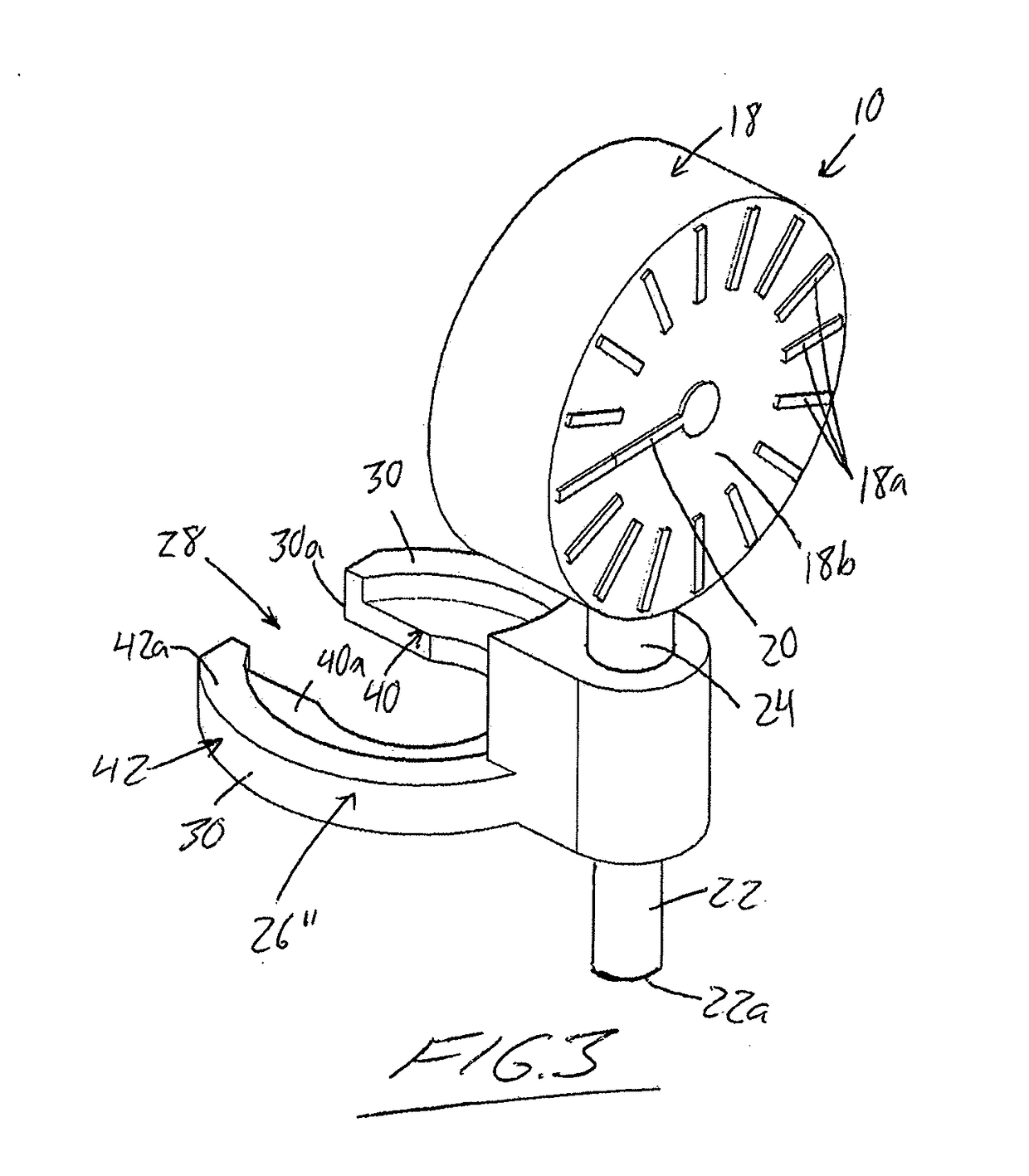

End Play Measurement Apparatus for Linear Actuators

ActiveUS20180364020A1Reduce axial thicknessMechanical clearance measurementsMeasurement deviceLinear actuator

An measurement apparatus for measuring end play of a linear actuator features a dial indicator and a primary mounting clamp. A plunger of the dial indicator is displaceable back and forth to cause an indicator needle to move about a graduated dial to reflect a measurement of said displacement. The primary mounting clamp has a clamp body configured to releasably clamp onto an output rod of said linear actuator, and a dial support body projecting outwardly from said clamp body. The dial support body is configured to the support the dial indicator thereon in a working position in which the plunger reaches axially along the output rod toward a gear housing of said linear actuator to abut against a contact surface carried on a stationary portion of the actuator relative to which the output rod undergoes displacement during operation of said actuator.

Owner:SCHULTZ KENNETH D

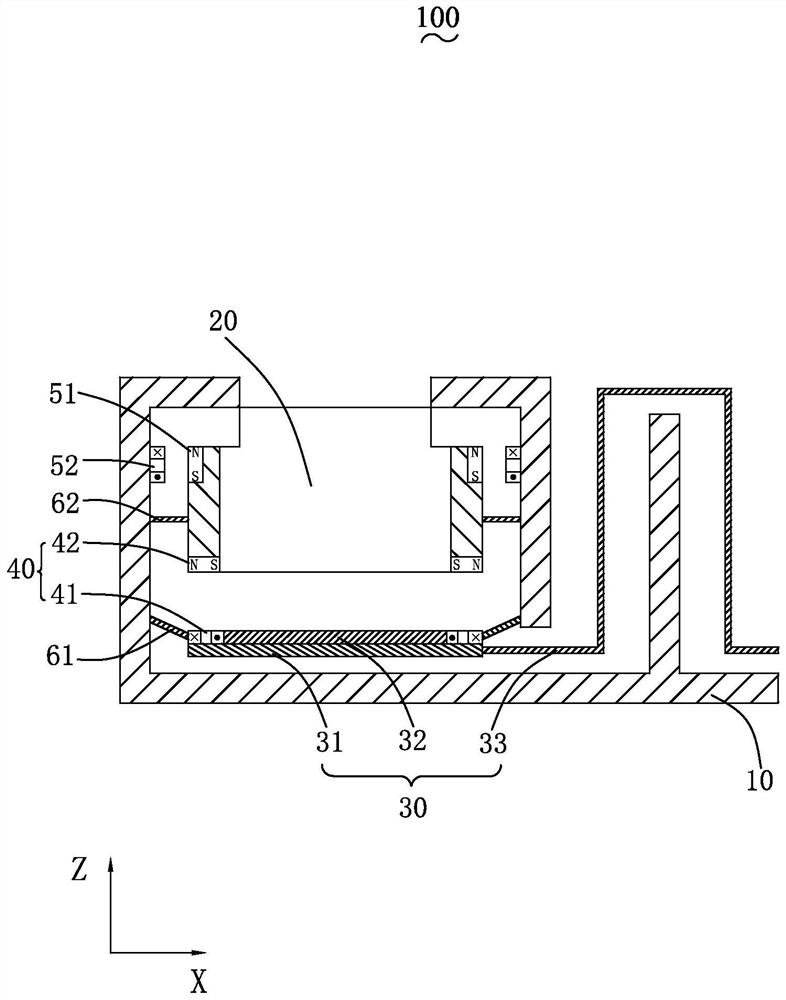

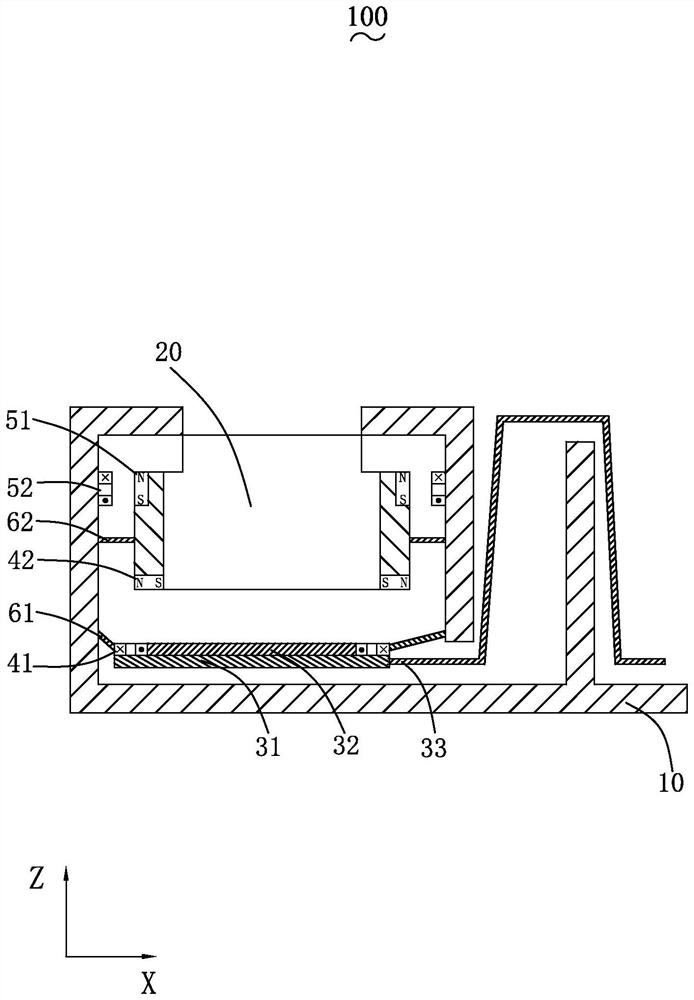

Lens module

InactiveCN111953881AReduce axial thicknessLess room for movementTelevision system detailsColor television detailsOptical axisEngineering

The invention provides a lens module, which comprises a shell with an accommodating space, a lens accommodated in the accommodating space, a sensor assembly and a driving device, and is characterizedin that the sensor assembly is movably accommodated in the accommodating space and is arranged opposite to the lens along the optical axis direction of the lens; the driving device drives the sensor assembly to move relative to the lens along / around the optical axis or along the direction perpendicular to the optical axis. Compared with the prior art, the above lens module increases the degree offreedom of jitter compensation by moving the image sensor, i.e., compensates the jitter rotating around the optical axis, thereby improving the optical anti-jitter effect. The driving device directlydrives the image sensor to move, the structure is simple, and the occupied space is small; the size of the image sensor is small, and the activity space of the sensor assembly reserved in the shell issmall, so that the size of the shell can be reduced, and the axial thickness of the lens module is reduced.

Owner:CHANGZHOU RAYTECH OPTRONICS CO LTD

Outer rotor plane motor traction machine

InactiveCN104843566ANo brake drumAxial space savingMechanical energy handlingStructural associationThree-phaseAlternating current

The invention discloses an outer rotor plane motor traction machine and relates to the technical field of motors. The outer rotor plane motor traction machine comprises a motor stator, a traction sheave, a permanent magnet, an encoder and a disc brake, steel wire rope grooves are formed in the outer surface of the traction sheave, the permanent magnet is attached to the inner side surface of the traction sheave, the motor stator is installed inside a motor shell, symmetric three-phase alternating current coils are wound on the motor stator, the encoder is installed in the middle of a hollow shaft of a motor, a vertical plate is installed at one side of the motor shell, and the disc brake is fixed on the vertical plate. According to the outer rotor plane motor traction machine, the structural design is reasonable, the axial direction space is saved, the axial direction thickness is reduced, the practicability is great, the application range is wide, and the stable operation of an elevator lift car is guaranteed.

Owner:曾海平

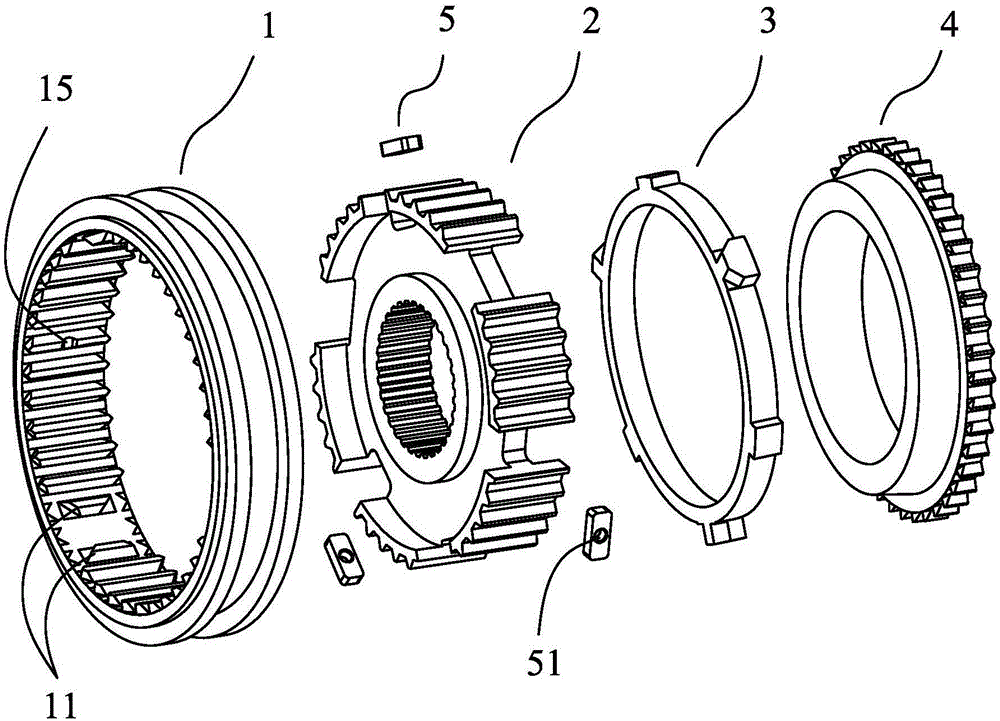

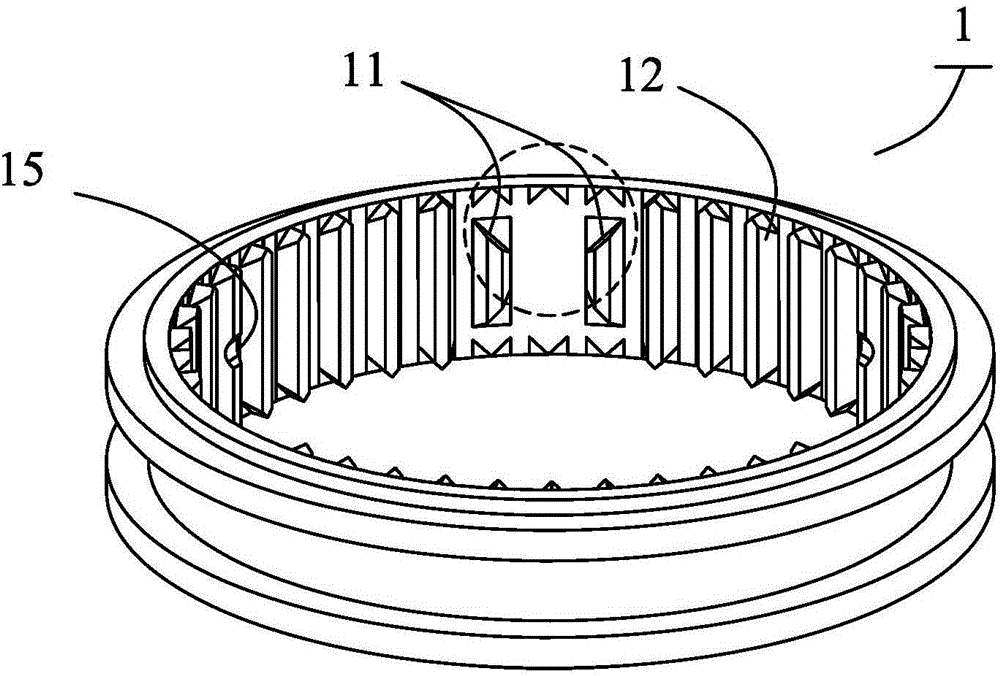

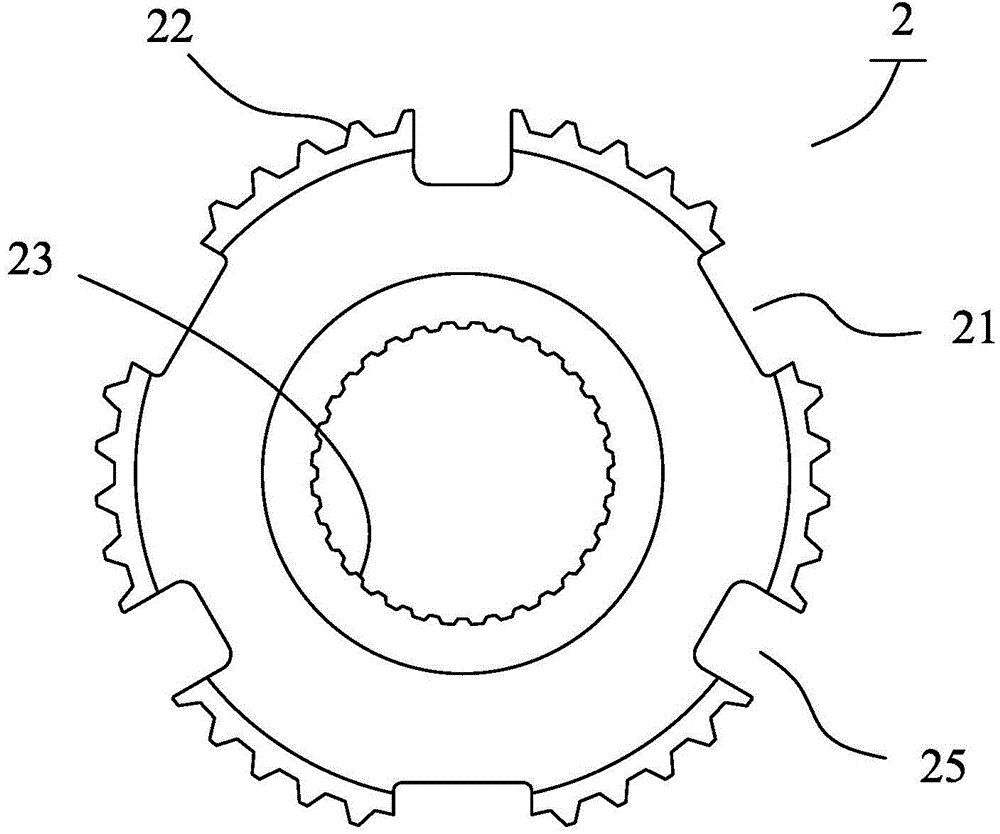

Synchronizer and speed changer

ActiveCN104895950AReduce intensityReduce manufacturing difficultyMechanical actuated clutchesAxial displacementCost Controls

In order to solve the technical problems of longer gear shifting idle stroke, second impact and the like in the prior art, the invention provides a synchronizer and a speed changer. The synchronizer comprises a synchronizer gear sleeve, a synchronizer gear hub, synchronizing rings and combining gears, wherein each synchronizing ring comprises a circular ring body; a locking lug boss is arranged on the outer ring surface of each circular ring body; an axially communicated position avoiding groove is formed in the outer peripheral surface of the synchronizer gear hub; the locking lug boss can move in the axial direction in the corresponding position avoiding groove; one end of the locking lug boss near one side of the synchronizer gear hub is provided with two first locking surfaces; an included angle is formed between the first locking surfaces; the inner peripheral surface of the synchronizer gear sleeve is provided with locking opposite teeth used for locking the locking lug boss; and two second locking surfaces corresponding to the two first locking surfaces are arranged on the end surfaces of the locking opposite teeth. The synchronizer is favorable for cost control; meanwhile, the axial arrangement space of the synchronizer is reduced; the gear shifting secondary impact and the gear shifting noise are reduced; and the scheme is favorable for integral arrangement structure compactness of the speed changer.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Base plate made of materials which have a different young's modulus, base unit, motor, disk drive apparatus and method of manufacturing the base plate

ActiveUS8873196B2Deterioration of stiffness can be preventedReduce axial thicknessAssociation with control/drive circuitsCarrier constructional parts dispositionMetallic materialsYoung's modulus

A base plate of a disk drive apparatus includes a motor base disposed around a central axis and a base body portion extending radially outward of the motor base. The motor base is made of a metallic material of a first type. The base body portion is made of a metallic material of a second type. The base body portion is a casting product in which the motor base is an insert component. An upper protruding portion and a lower protruding portion are defined in one of an outer end portion of a bottom plate portion of the motor base and an inner end portion of the base body portion.

Owner:NIDEC CORP

Base plate, base unit, motor, disk drive apparatus and method of manufacturing the base plate

ActiveUS20130335860A1Deterioration of stiffness can be preventedReduce axial thicknessAssociation with control/drive circuitsRecord information storageMetallic materialsEngineering

A base plate of a disk drive apparatus includes a motor base disposed around a central axis and a base body portion extending radially outward of the motor base. The motor base is made of a metallic material of a first type. The base body portion is made of a metallic material of a second type. The base body portion is a casting product in which the motor base is an insert component. An upper protruding portion and a lower protruding portion are defined in one of an outer end portion of a bottom plate portion of the motor base and an inner end portion of the base body portion.

Owner:NIDEC CORP

Miniature Heat-Dissipating Fan

ActiveUS20100098560A1Reduce thicknessAvoid electromagnetic interferencePiston pumpsPump installationsImpellerElectromagnetic interference

A miniature heat-dissipating fan includes a stator and a rotor. The stator has a first leakage flux absorber, a coil layer arranged on the first leakage flux absorber, and a hole. The coil layer has a plurality of coils and the hole passes through the first leakage flux absorber and the coil layer. The rotor has an impeller, a second leakage flux absorber and a permanent magnet. The second leakage flux absorber and the permanent magnet are attached to a bottom of the impeller, such that the rotor is rotatably coupled to the stator. Consequently, magnetic flux leakage under the stator is prevented to assure that electromagnetic interference will never be caused, and an overall axial thickness of the miniature heat-dissipating fan is reduced by the configuration of the stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Shifting device of a motor vehicle change-speed gearbox

InactiveCN104769337AReduce in quantityCompact structureGearing controlEngineeringMechanical engineering

Owner:SCHAEFFLER TECH AG & CO KG

Traction machine for elevator

InactiveCN102976187ALow costAvoid demagnetizationBuilding liftsSupports/enclosures/casingsElectric powerElectric energy

The invention discloses a traction machine for an elevator. The traction machine for the elevator comprises a motor, a collecting ring assembly, a fixed frame and a rotary frame. The collecting ring assembly comprises a plurality of conducting rings and a plurality of electric brushes. Each electric bush mutually contacts each corresponding conducting ring. The fixed frame comprises a fixed machine seat and a main shaft. The main shaft and the fixed machine seat are connected fixedly with each other. An electric brush installing part is arranged on the fixed frame. The plurality of electric brushes are arranged fixedly on the electric brush installing part. A rotor coil of the motor is connected electrically with the electric conducting ring through an electric conductor. The function of delivering electric power to the rotor coil is achieved by the conducting ring, the electric brushes and the electric conductor. According to the traction machine for the elevator, permanent magnetic steel with high cost is saved and cost of the traction machine is reduced obviously. The electric brushes and the conducting rings are arranged near the hollow portion of the main shaft so that inner space of the traction machine is fully used, the axial thickness of the complete machine is reduced so that the complete machine is thinned and applicable to an elevator with a small motor room or no motor room and the like and with requirement of thin traction machine.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Reduction gear

InactiveUS7686725B2Reduce thicknessReduction gear can be downsizedToothed gearingsDifferential gearingsReduction driveEngineering

A reduction gear includes a reduction mechanism, which includes: an external gear eccentrically rotatable about an input shaft; an internal gear internally meshing with the external gear and having a small number of difference between the teeth of the internal gear and the external gear; a disk for extracting only a rotational component of the external gear; an output shaft; and gears for transmitting the rotational component of the external gear from the disk to the output shaft. The disk, the gears and the output shaft are aligned in a direction perpendicular to an axial direction of the input shaft.

Owner:SEIKO PRECISION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com