Traction machine for elevator

A technology of traction machines and elevators, which is applied to elevators, electrical components, electromechanical devices, etc. in buildings, and can solve problems such as damaged bearings, short circuits in the internal coils of motors, and increased axial thickness of the whole machine, so as to reduce the axial thickness. Thickness, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

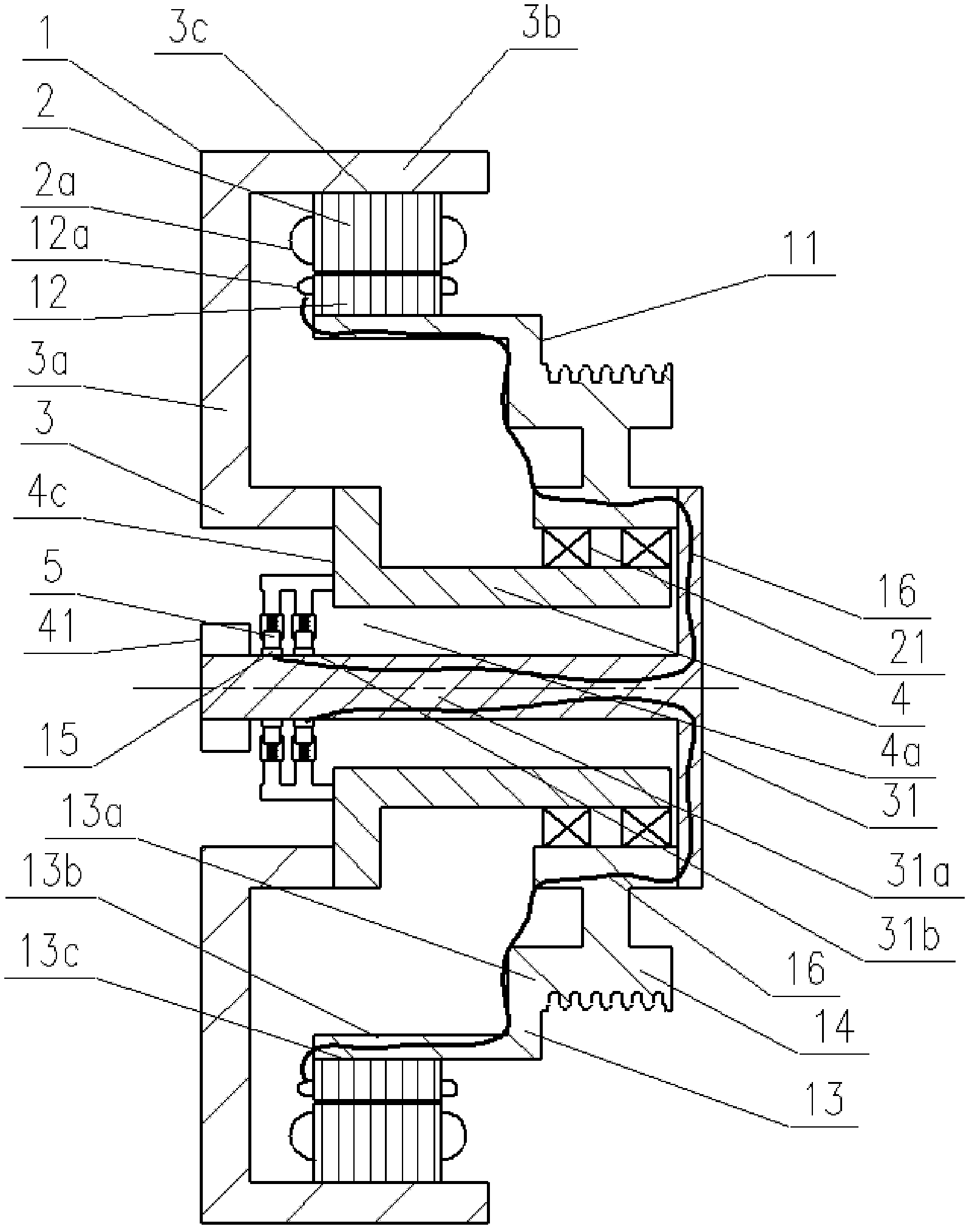

[0044] Such as image 3 Shown is the first embodiment of the elevator traction machine of the present invention, including a motor, a slip ring assembly, a fixed frame 1, and a rotating frame 11;

[0045] The motor comprises a stator 2 provided with a stator coil 2a, a rotor 12 provided with a rotor coil 12a, and the stator 2 is arranged opposite to the rotor 12;

[0046] The slip ring assembly includes a plurality of conductive rings 15 and a plurality of brushes 5, and each brush 5 is in contact with the corresponding conductive ring 15; the slip ring assembly is used to transfer electric energy to the rotor coil 12a;

[0047] The fixed frame 1 includes a fixed machine base 3 and a main shaft 4, the main shaft 4 and the fixed machine base 3 are split structures, and the main shaft 4 is fixedly connected to the fixed machine base 3;

[0048] The fixed base 3 has a hollow disc-shaped extension 3a extending radially outward, a cylindrical portion 3b bent from the extension 3a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com