Outer rotor of motor for traction machine

A motor traction machine and outer rotor technology, applied in electromechanical devices, mechanical energy control, electrical components, etc., can solve the unfavorable special environment with strict requirements on the thickness of the traction machine, long axial length of the traction machine, management and maintenance costs Advanced problems, to achieve the effect of easy management and maintenance, filling technical gaps, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

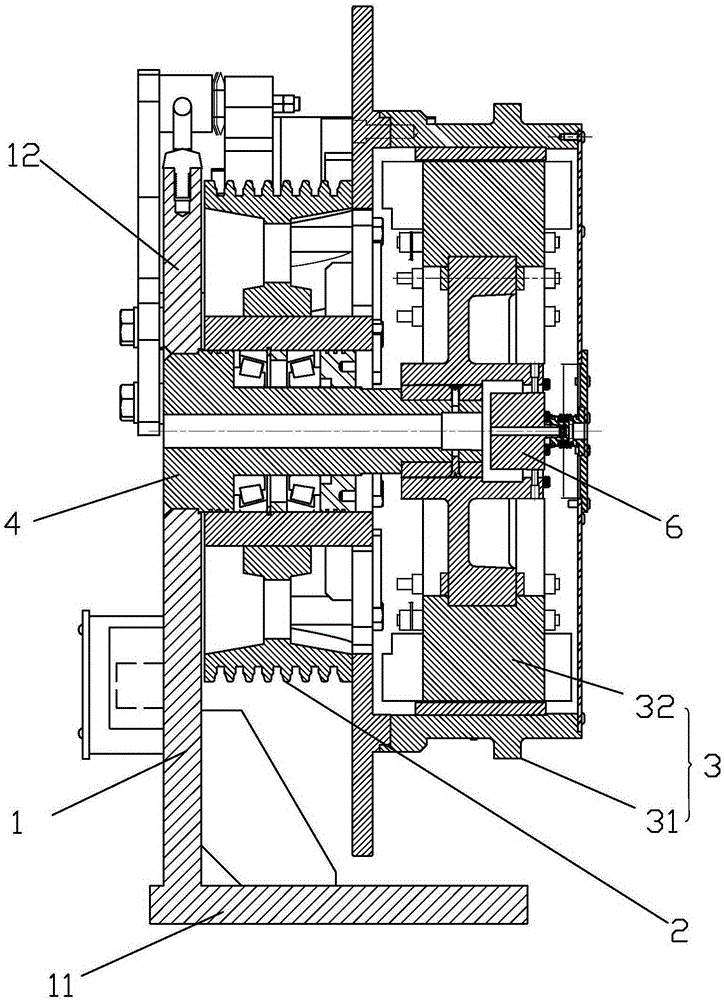

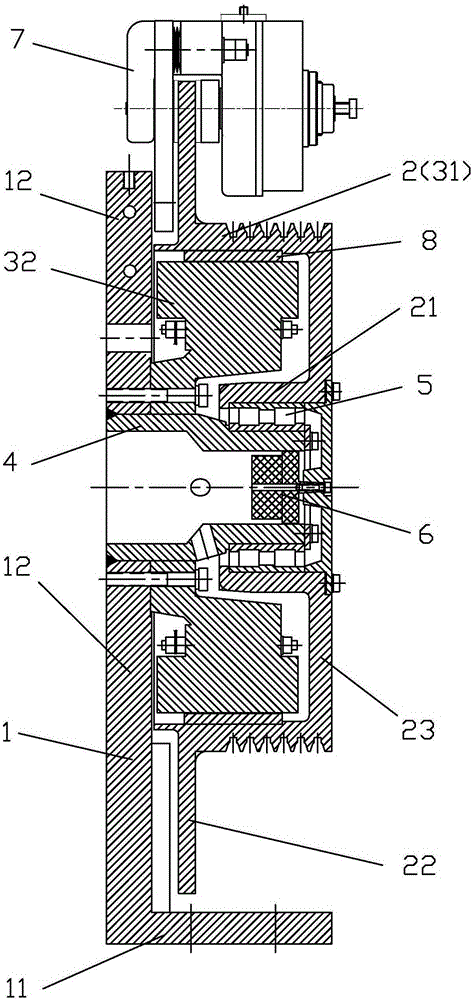

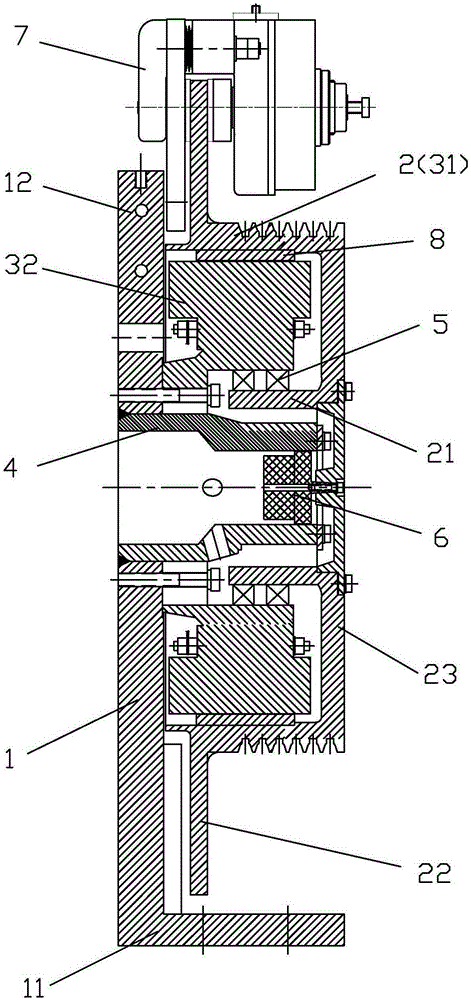

[0016] refer to Figure 2 to Figure 4 , an outer rotor motor traction machine, including a machine base 1, a traction wheel 2 arranged on the machine base 1, and a motor 3 that drives the traction machine to rotate, the said machine base 1 is composed of a bottom plate 11 and a vertical plate 12, the inner end surface of the vertical plate 12 is fixedly provided with a support shaft 4 parallel to the bottom plate 12, one end of which is fixed on the vertical plate 12, and the other end is suspended, and the inner wall of the traction wheel 2 is fixedly provided with a permanent magnet 8 so that The motor rotor 31 and the traction wheel 2 are combined into one, the motor stator 32 is fixed on the vertical plate 12, the traction wheel 2 has an end face 23, the motor stator 32 is located between the vertical plate 12 and the end face 23, and the end face of the traction wheel 23 extends a rotating shaft 21 toward the supporting shaft 4 to make the traction sheave 2 rotate around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com