Patents

Literature

346 results about "Radial projection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

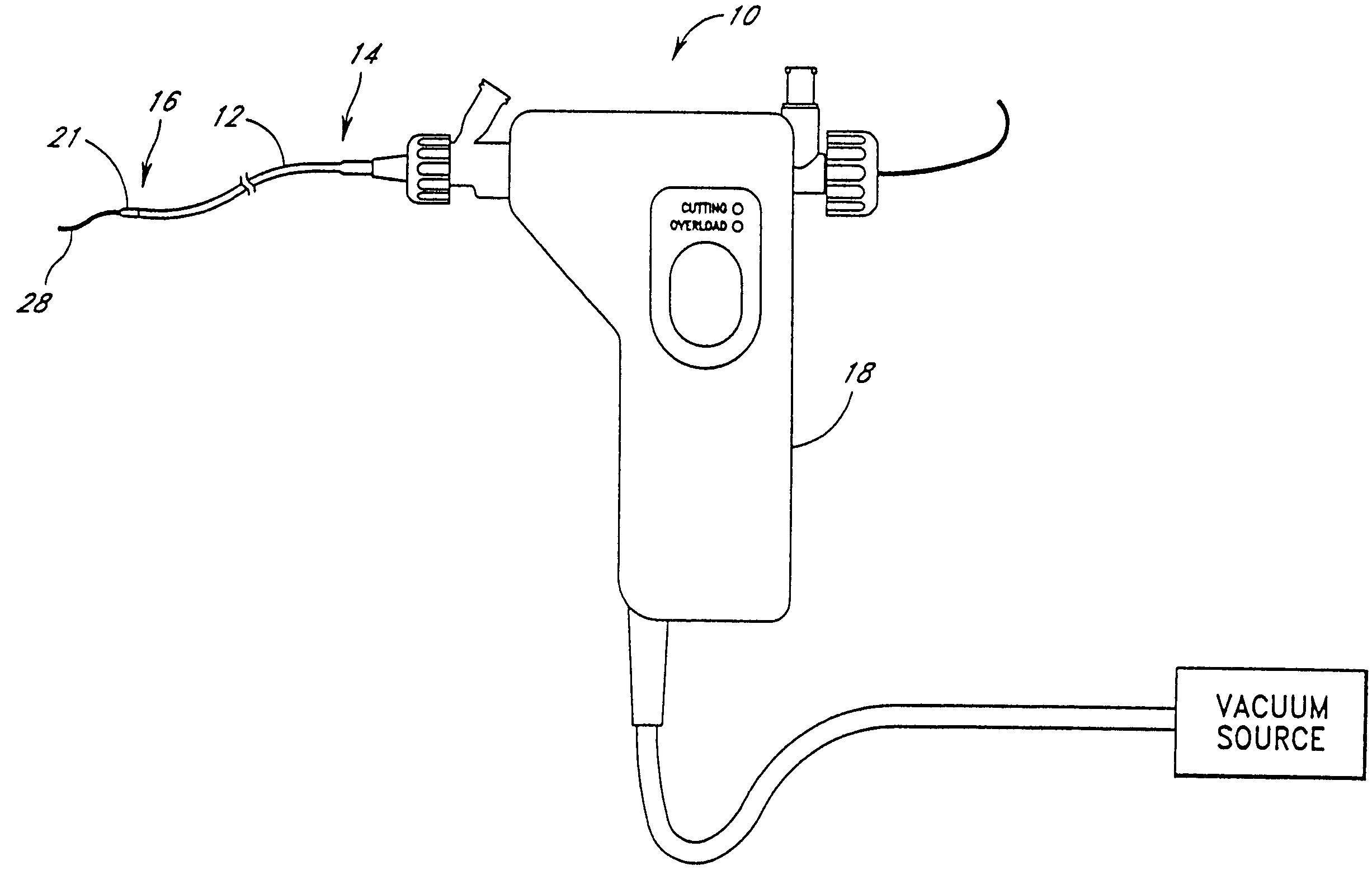

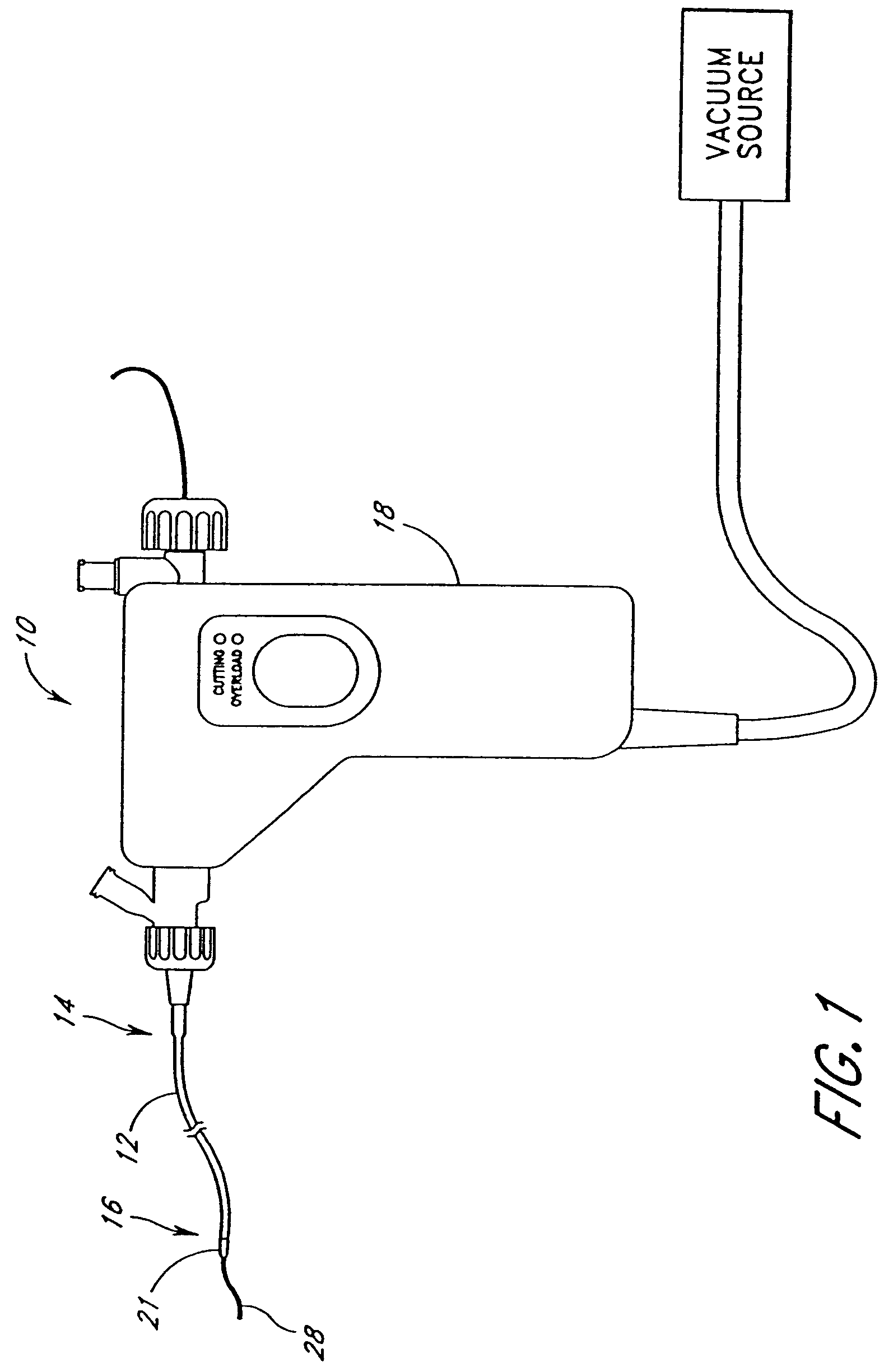

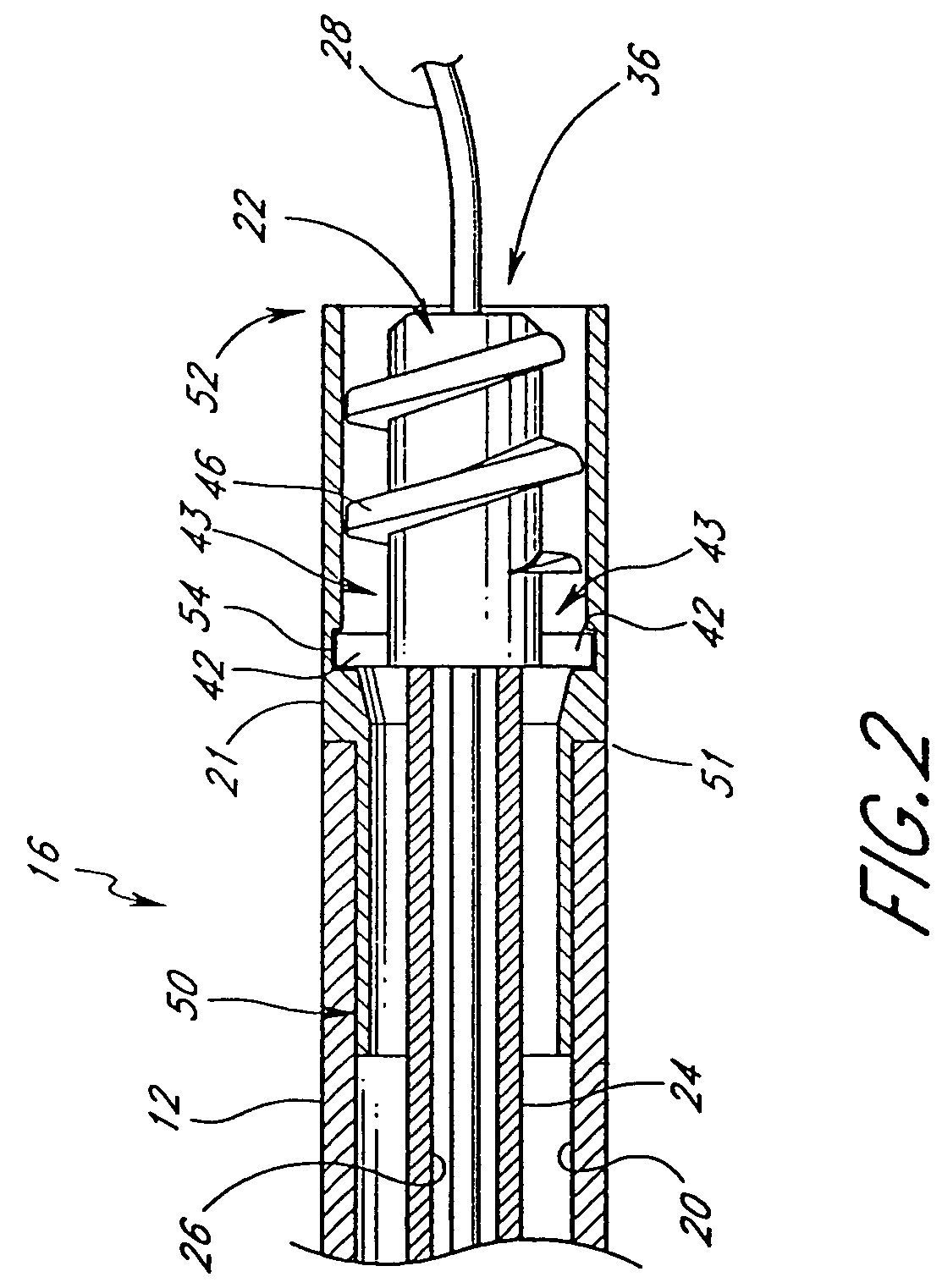

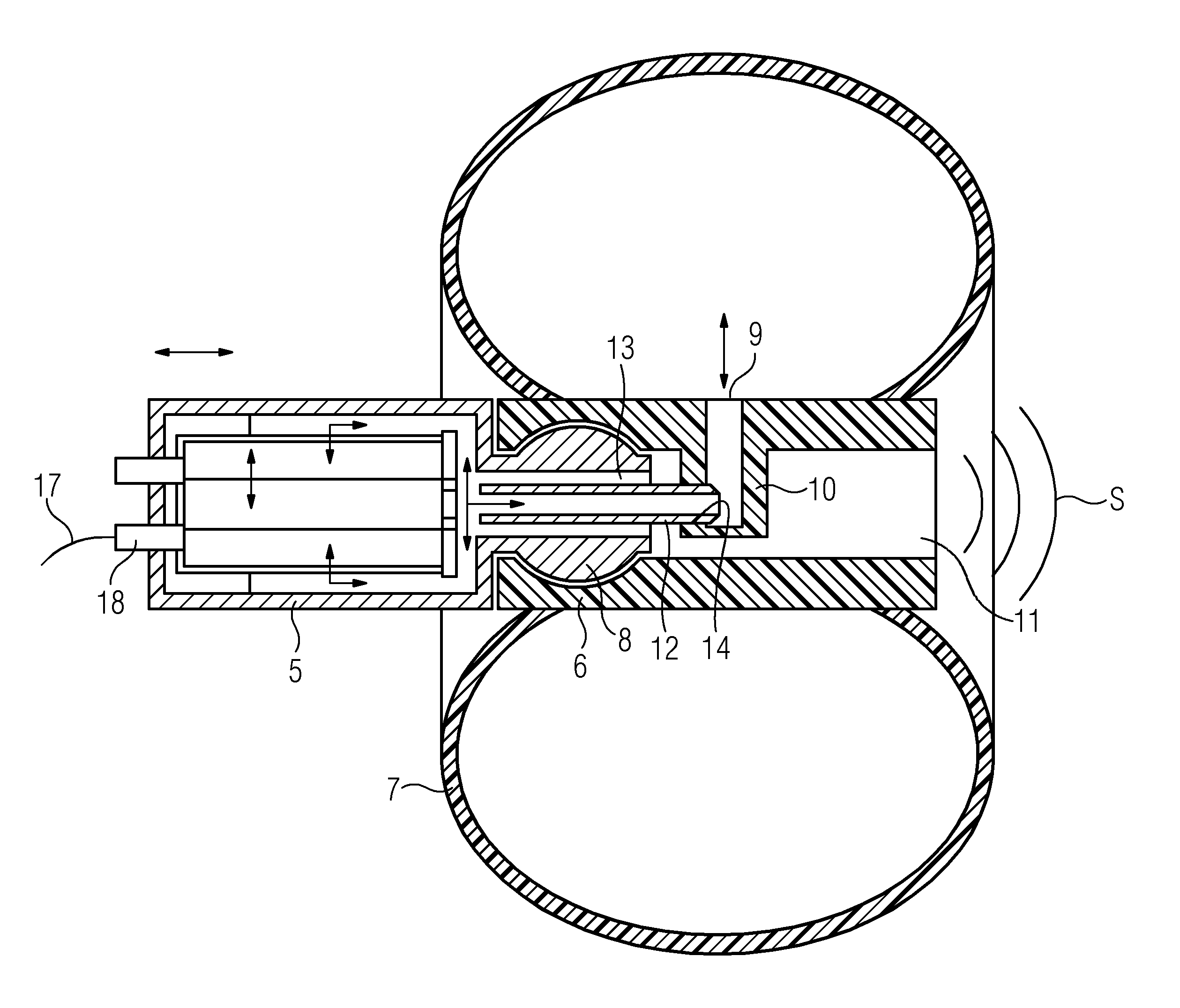

Rotational atherectomy system with stationary cutting elements

An elongate tubular body extends between a rotatable cutter and a control. The cutter is connected to the control with a rotatable element. A vacuum is applied through an annular passage defined between the tubular body and the rotatable element. The cutter has at least one radial projection which cooperates with at least one stationary element on the tubular body to cut material drawn into the tubular body. Material that has been processed by the cutter is aspirated through the tubular body for disposal.

Owner:TYCO HEALTHCARE GRP LP

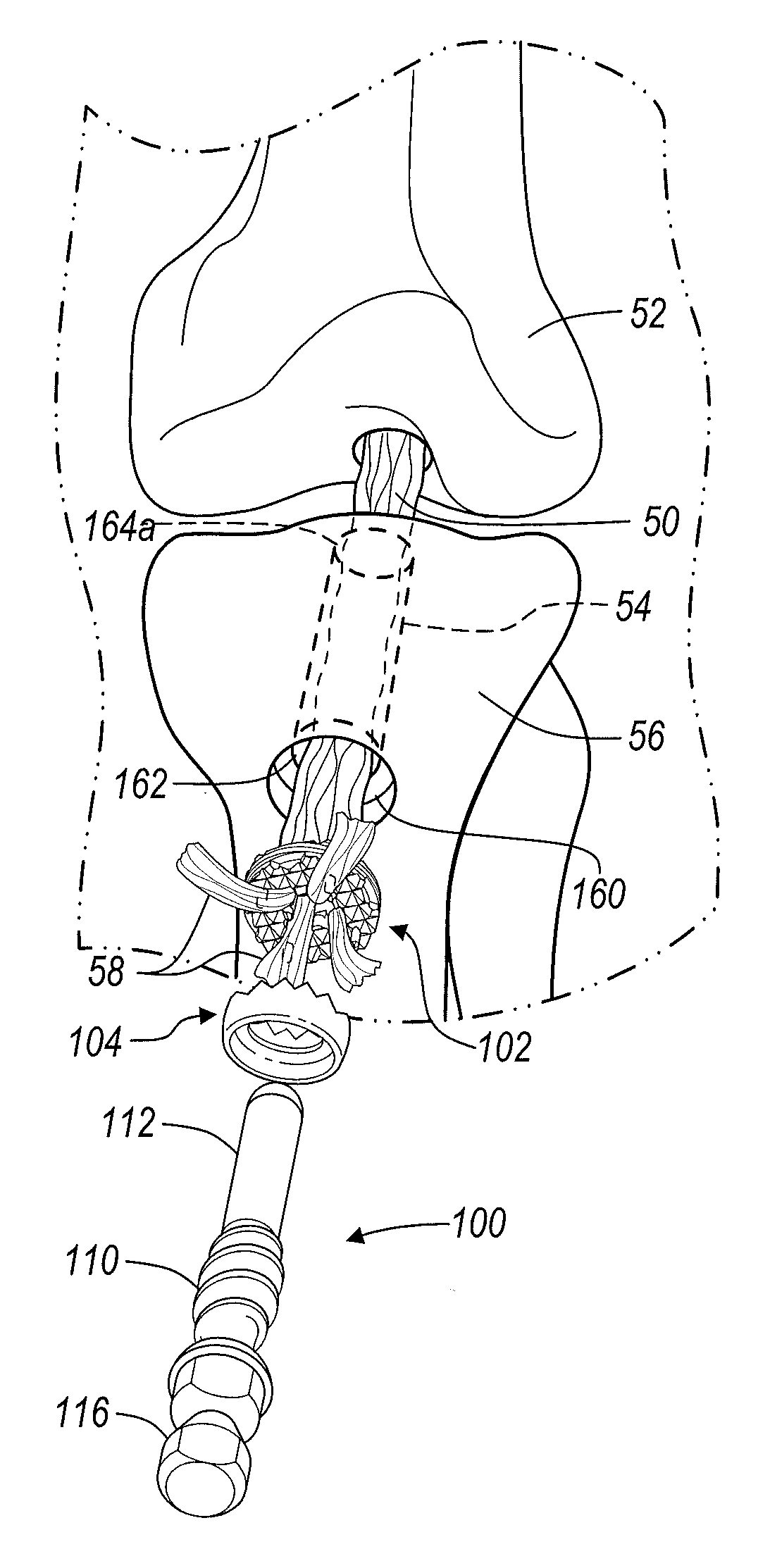

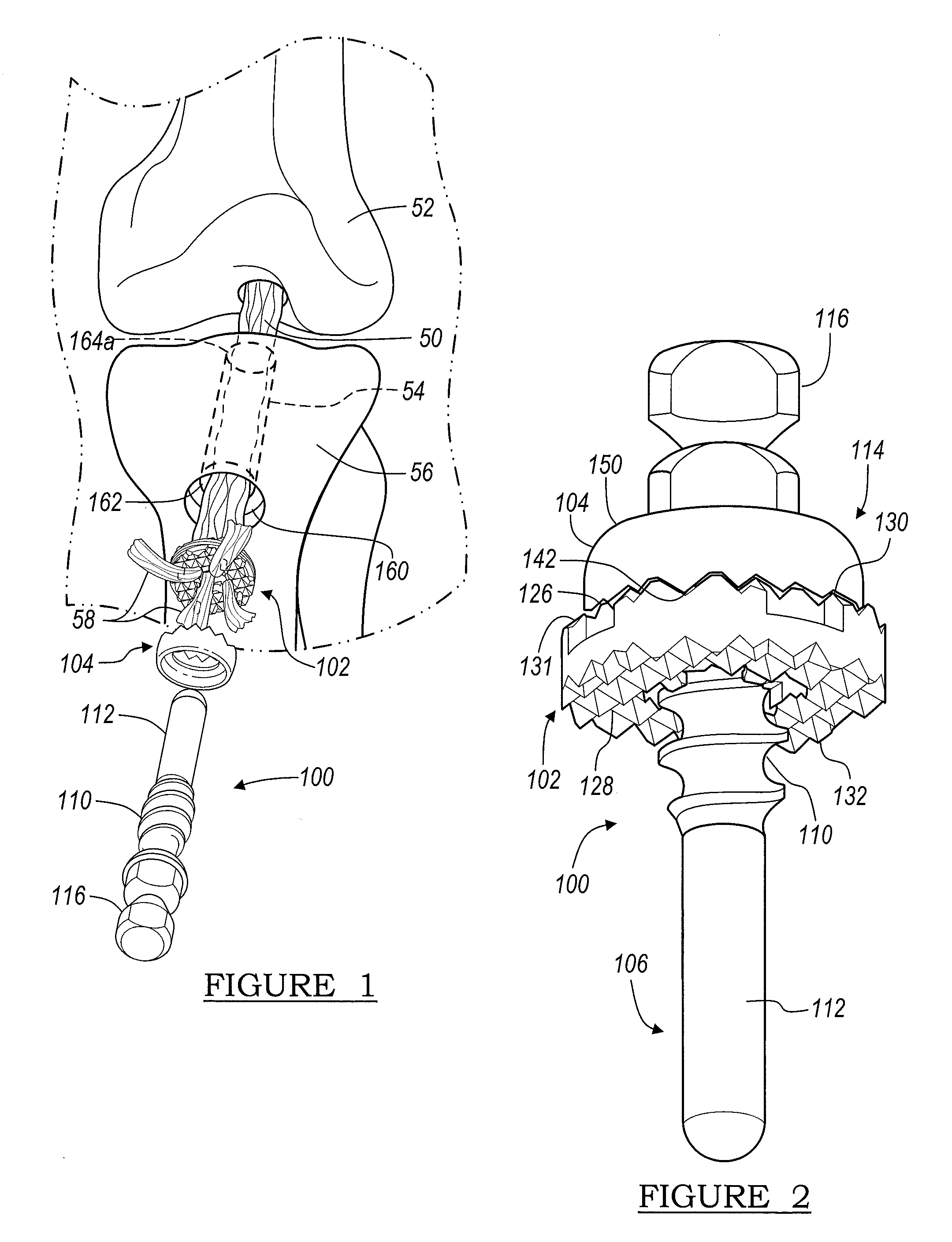

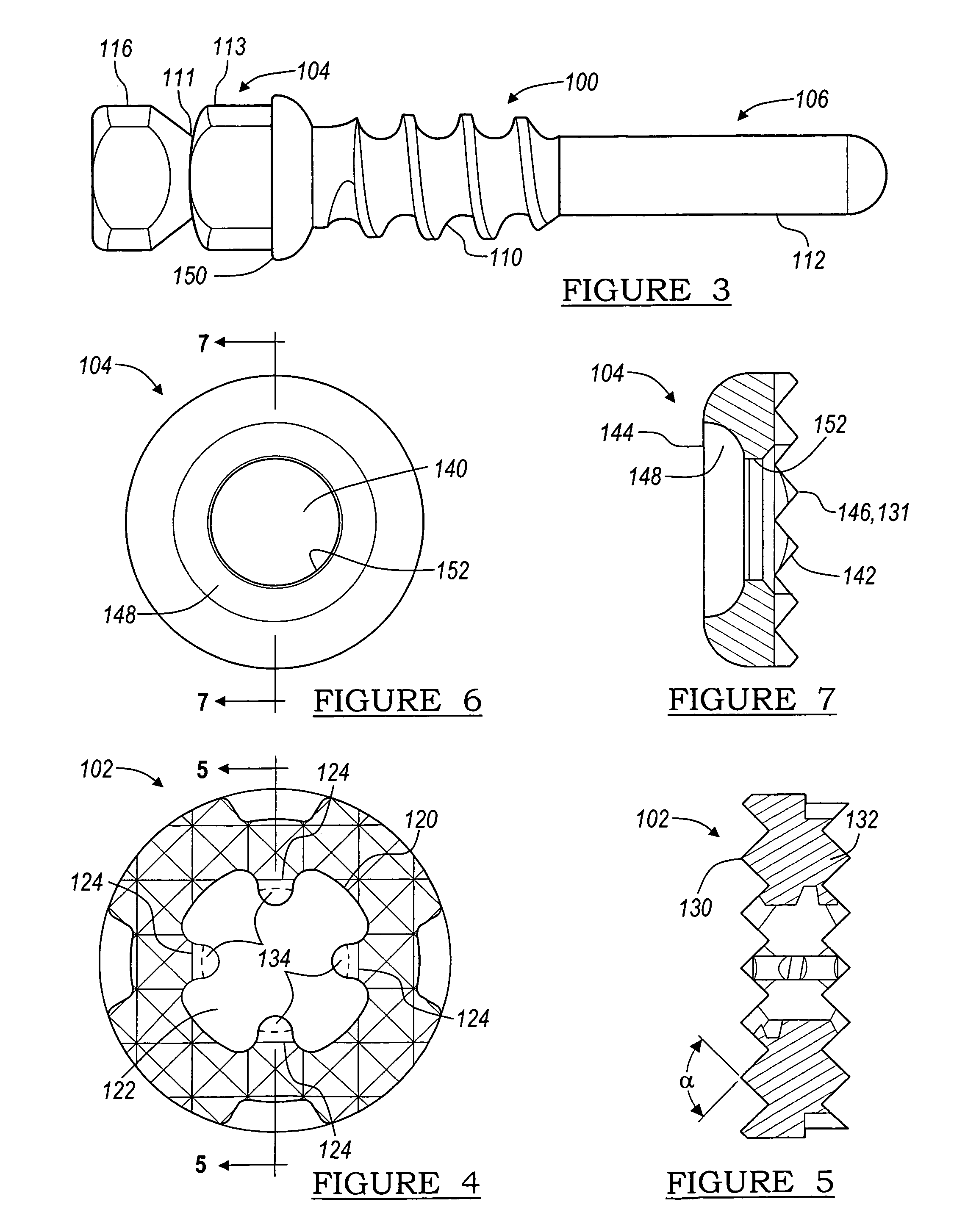

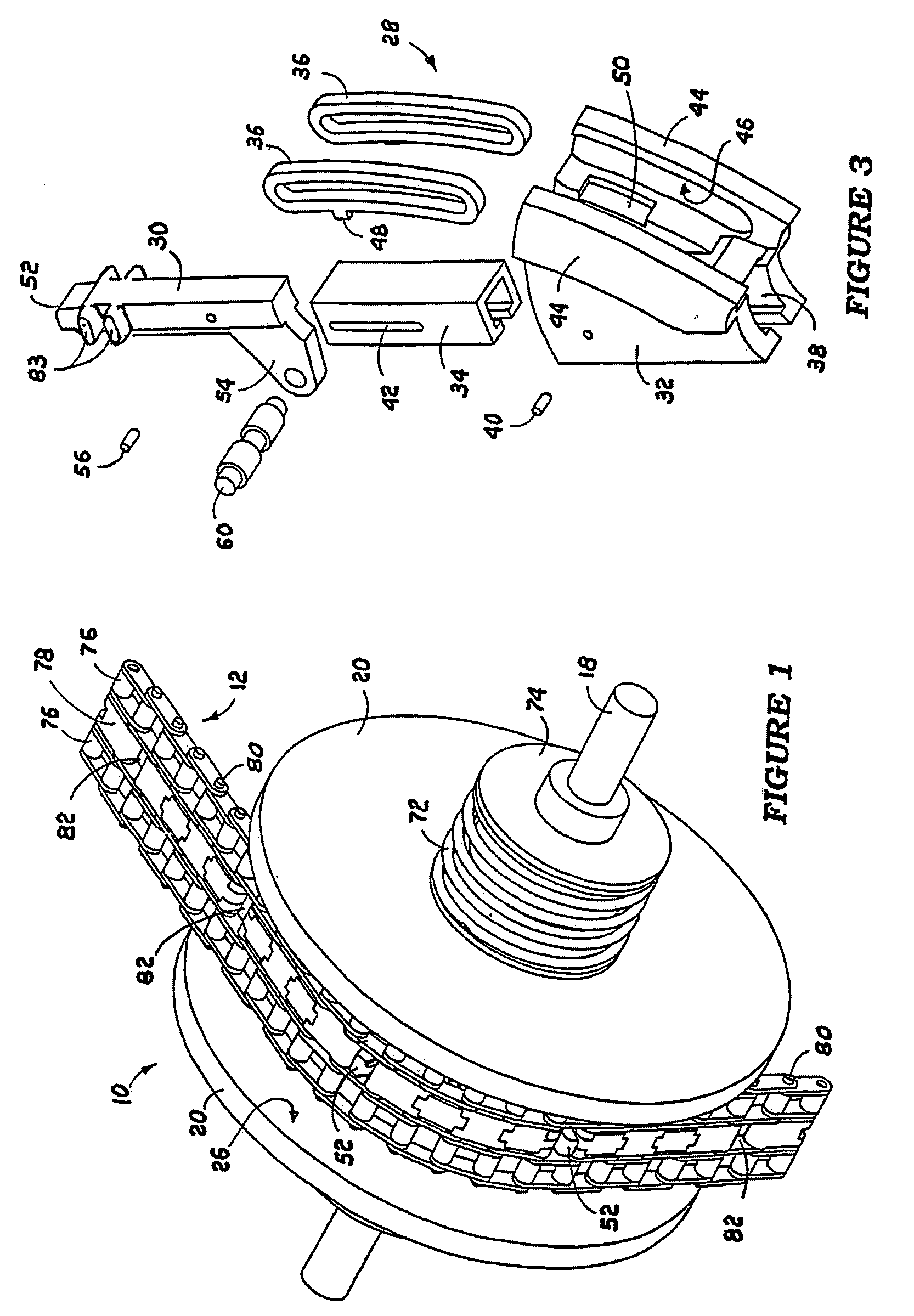

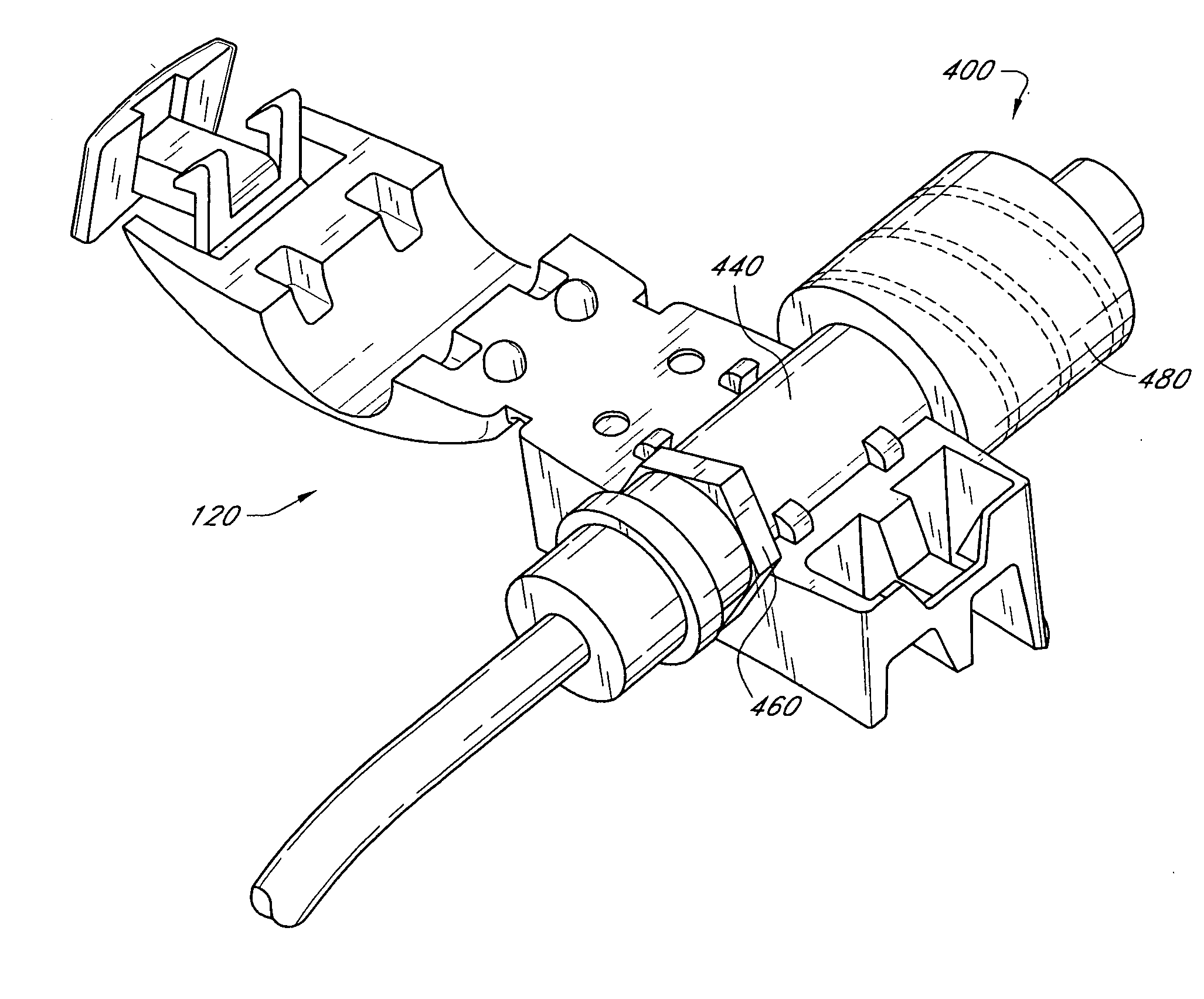

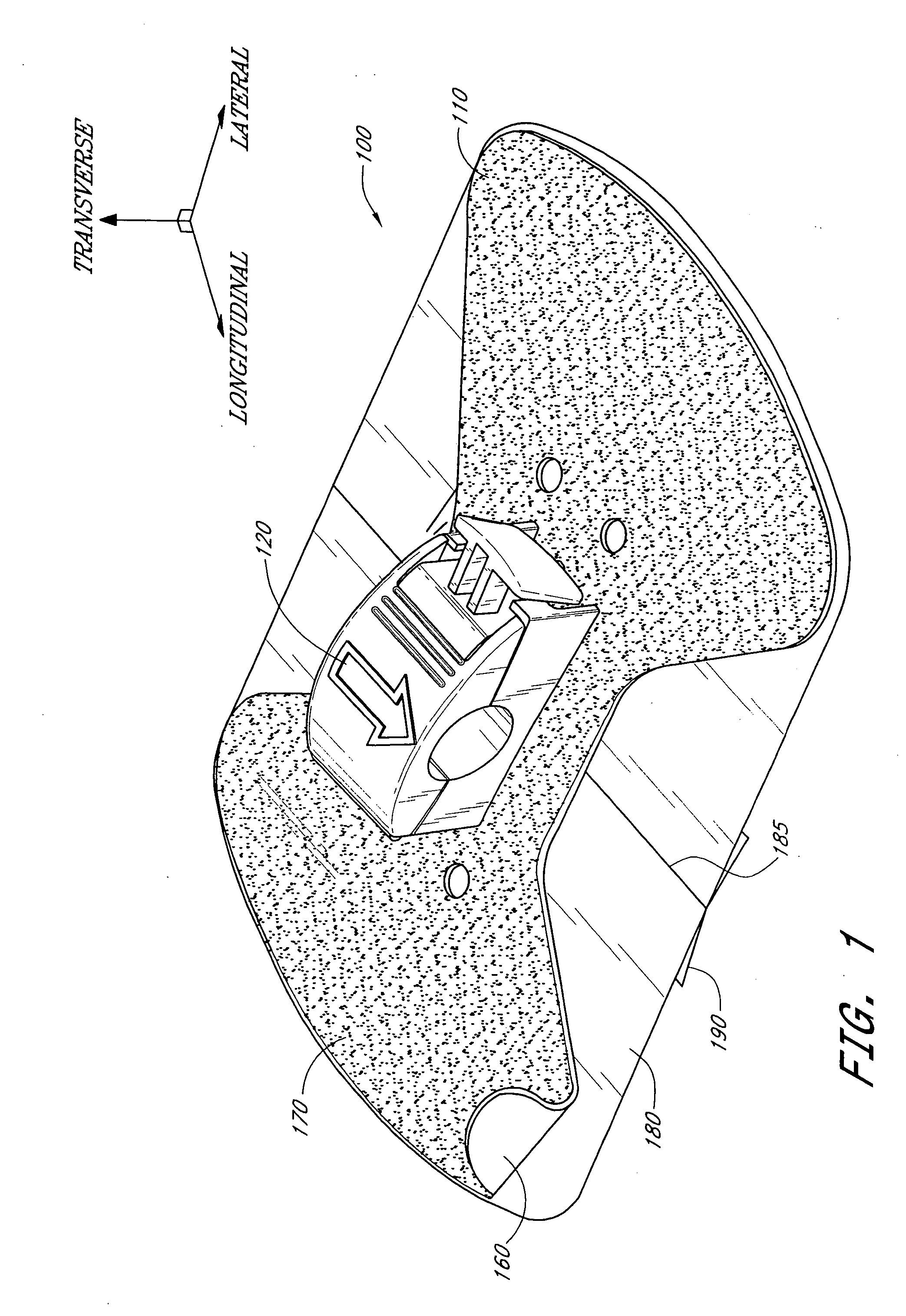

Device and method of fastening a graft to a bone

A device and method for fastening one or more graft strands to a bone. The device may include a first member having a first opening and a second member having a second opening. The first member may include a plurality of radial projections defining recesses, wherein each graft is separately received in a corresponding recess. The device may also include a fastener passing through the first and second openings. The fastener may have a first portion engaging the first member and a second portion received into the bone, such that tightening the fastener against the first member compresses the graft strands between opposing faces of the first and second members.

Owner:BIOMET MFG CORP

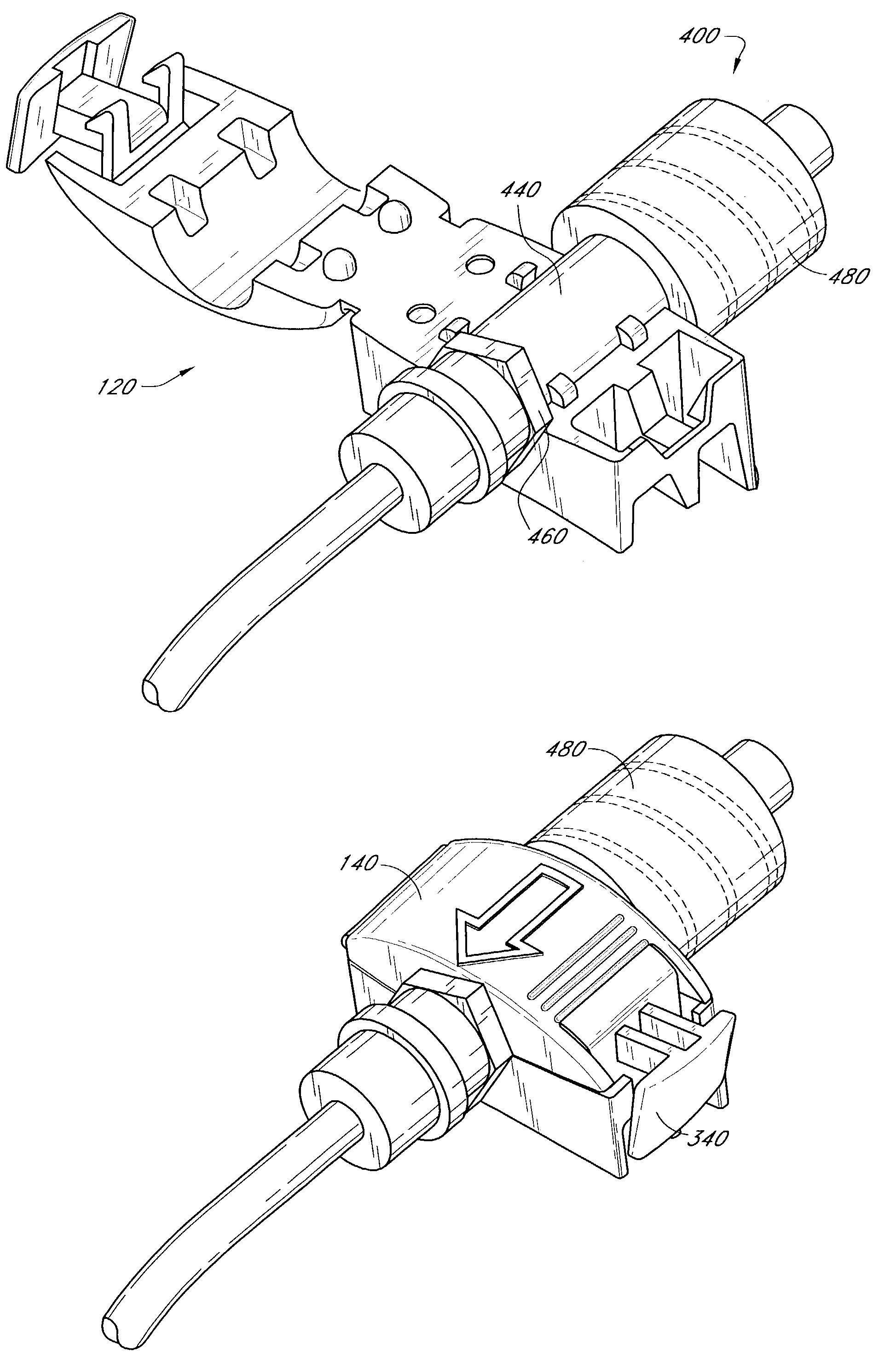

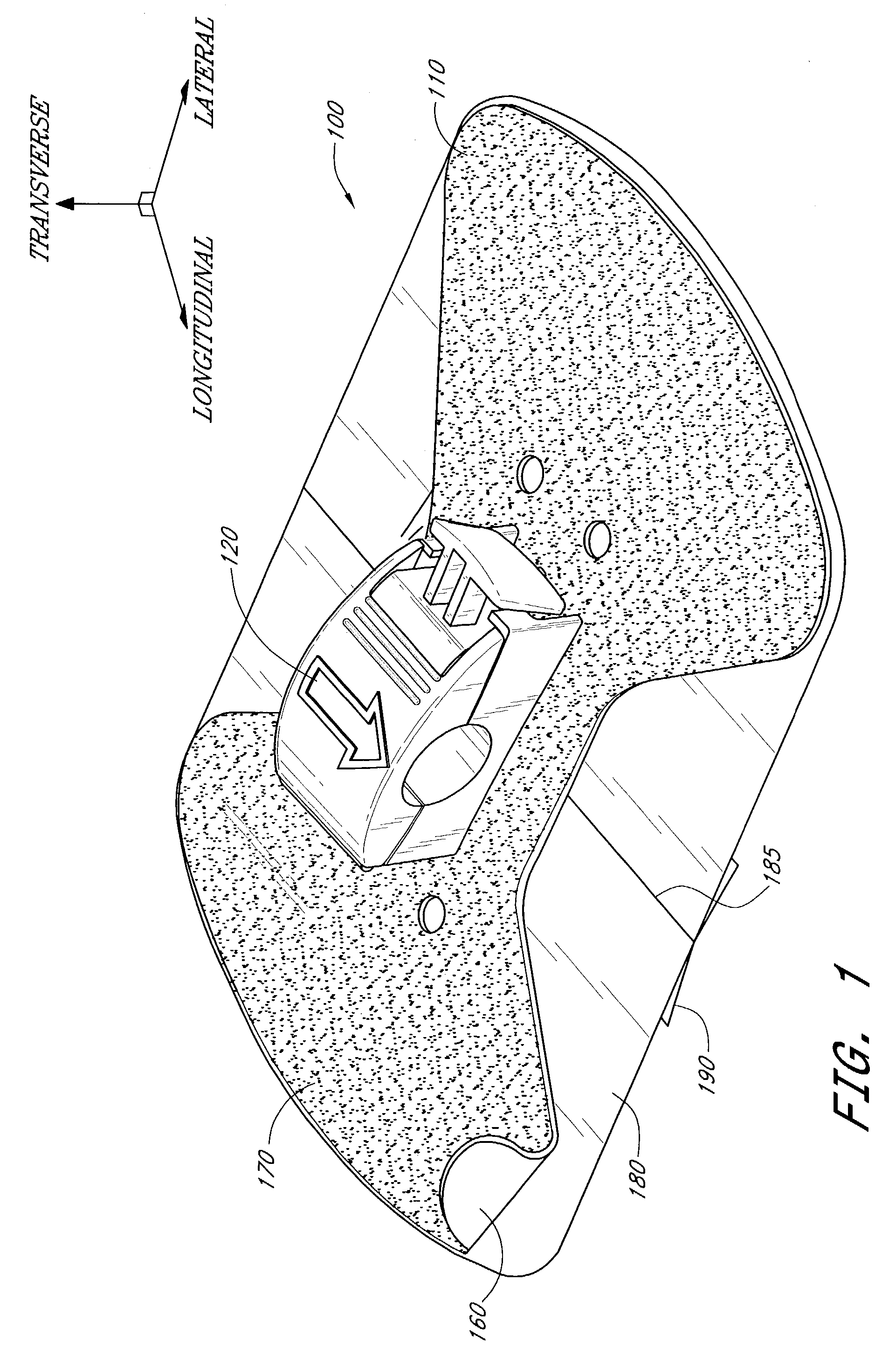

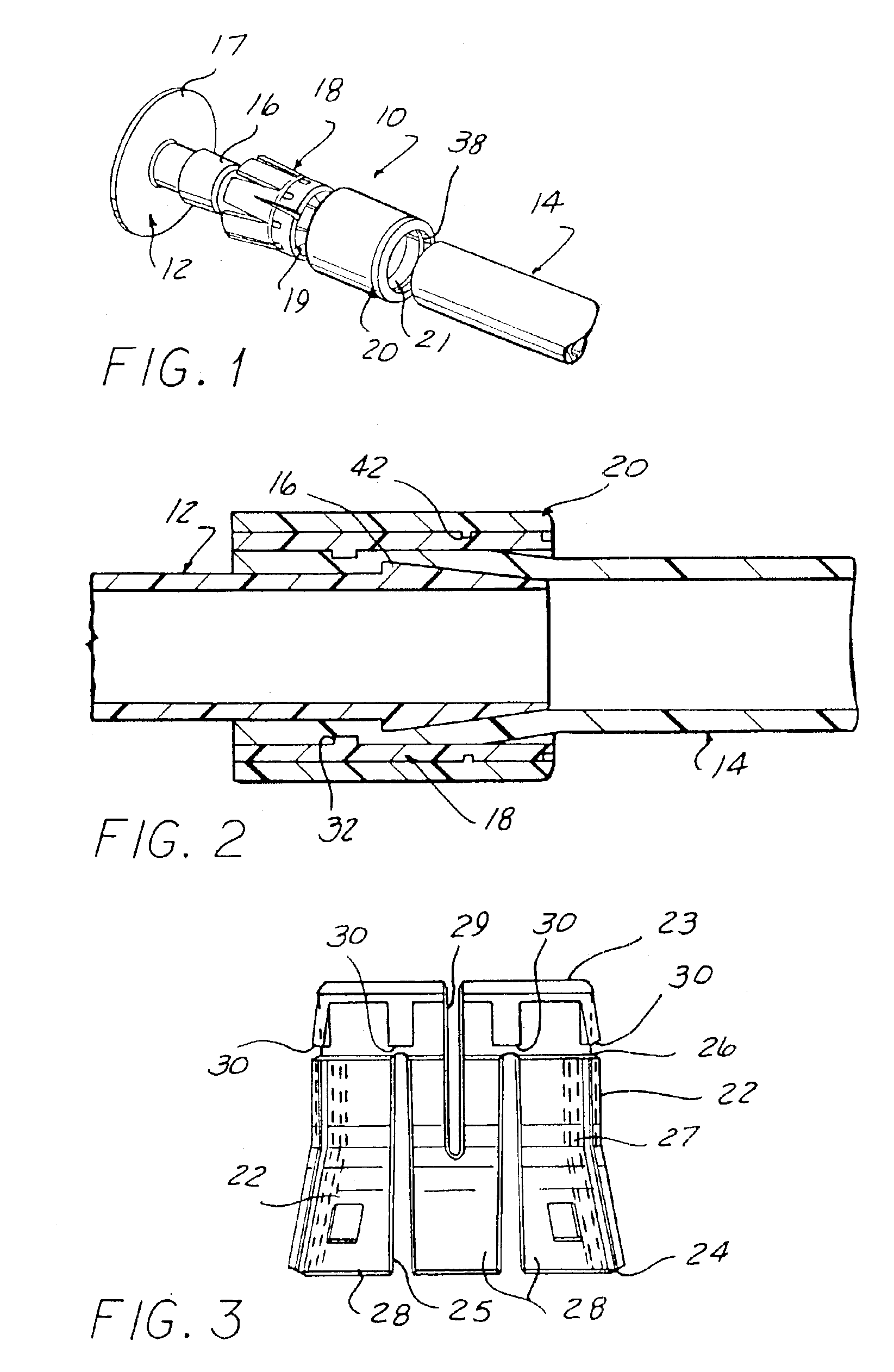

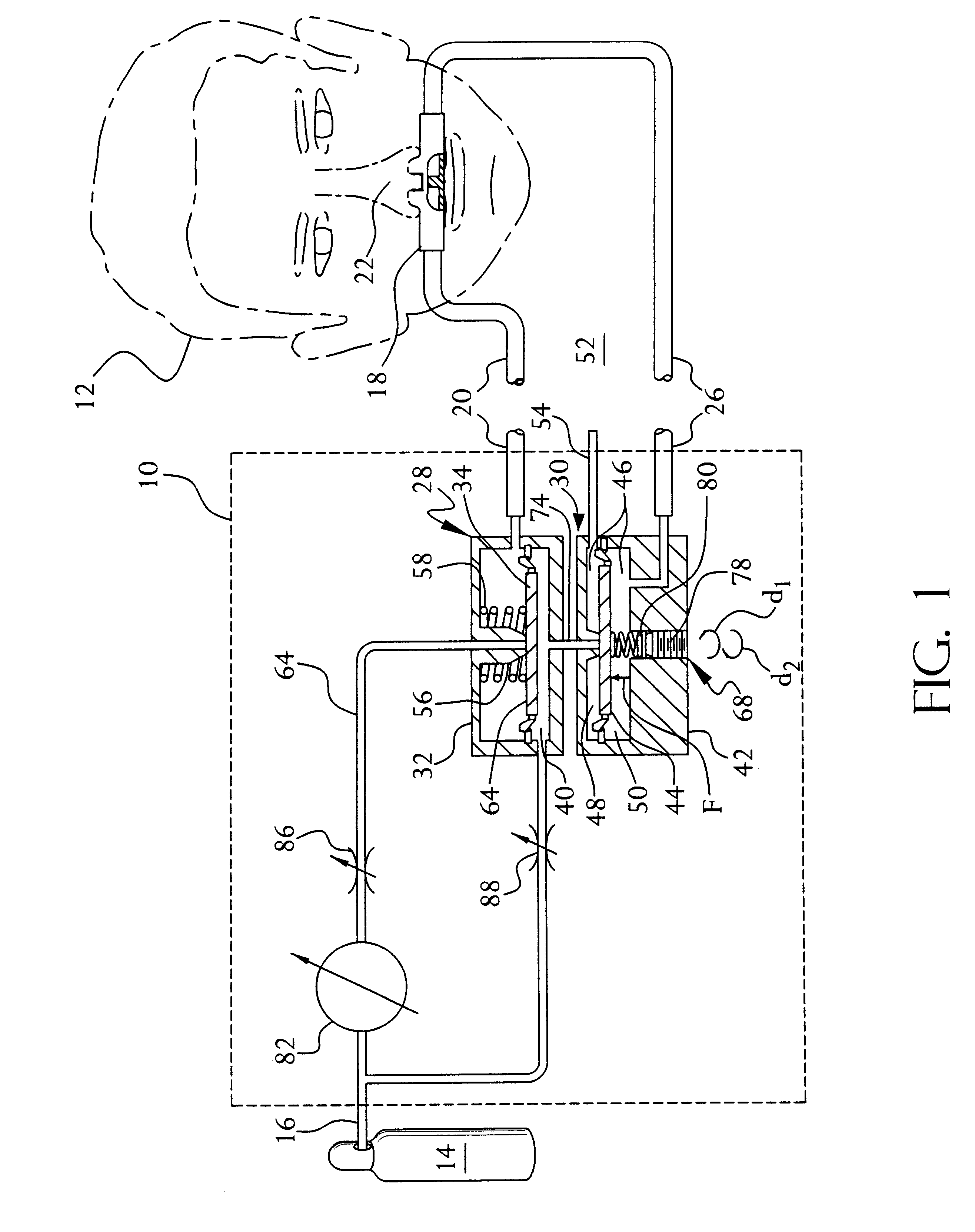

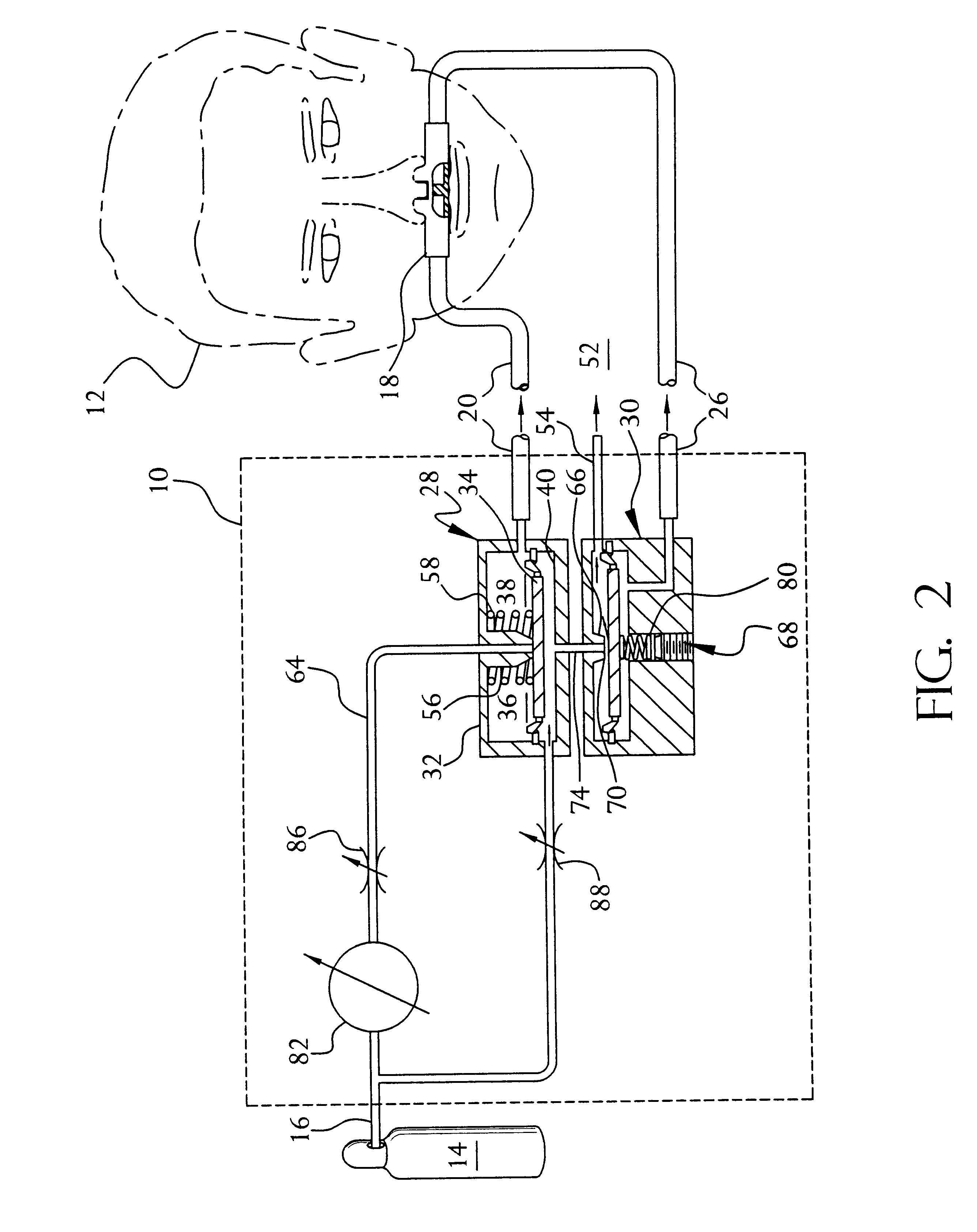

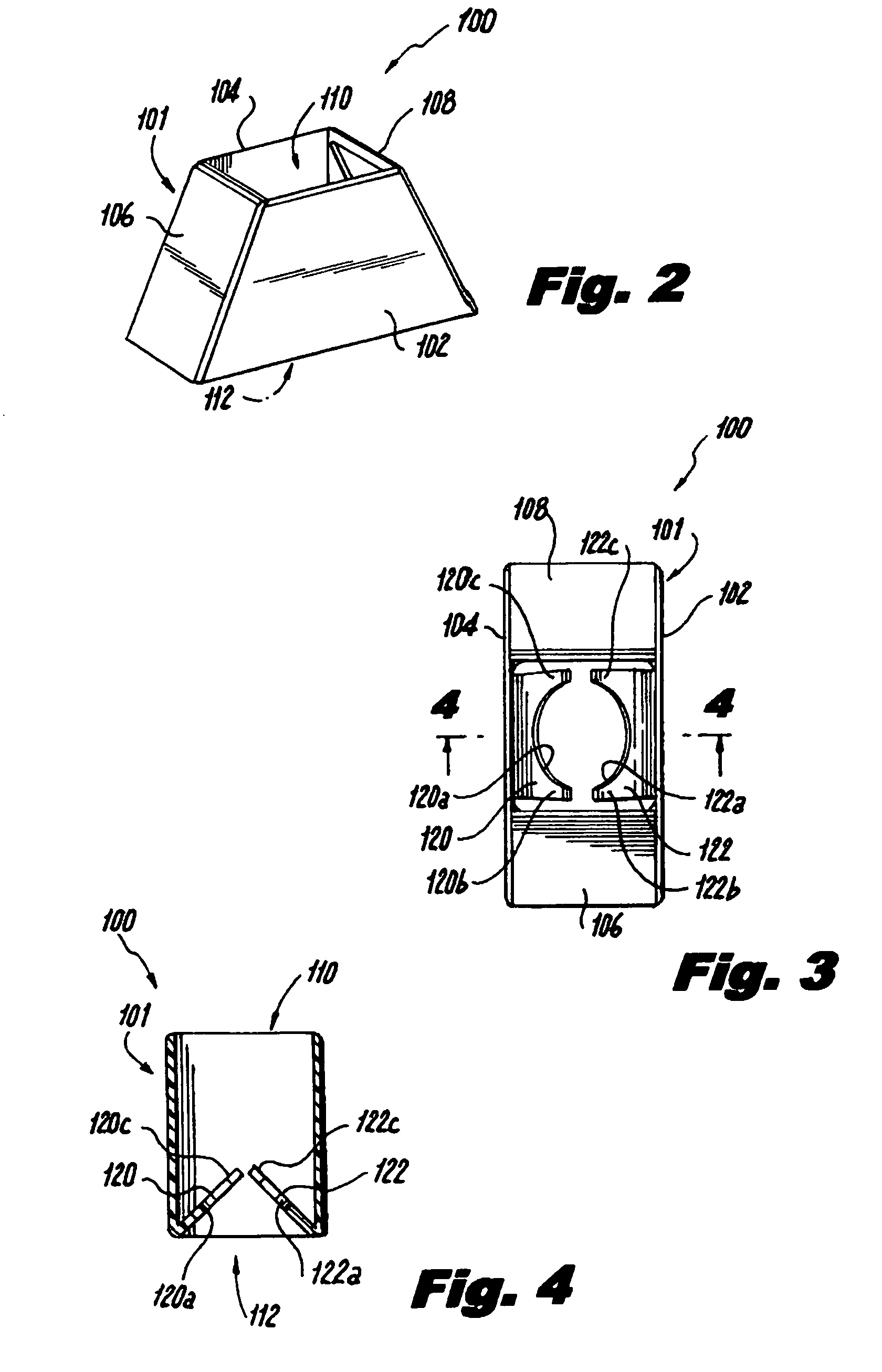

Medical line securement device

ActiveUS7223256B2Prevent axial movementCatheterInfusion needlesCATHETER ADAPTERBiomedical engineering

A medical line securement device holds a medical article such as a connector fitting for a catheter or a catheter adaptor in position upon the body of a patient and inhibits axial motion of the medical article. The securement device includes a retainer with a base and a cover. The cover is hinged to the base such that it may be moved between an open and closed position. The base and cover each have a groove which cooperate when the cover is in the closed position to form a channel through the retainer. The medical article includes an elongated body which is received within the groove of the retainer, the elongated body lying between at least a pair of regions of larger radius of the medical article. By receiving the portion of the elongated body of the medical article between the regions of larger radius, axial motion of the medical article through the groove is inhibited. The retainer may also include one or more slots to receive any radial projections of the medical article within the retainer.

Owner:VENETEC INT INC

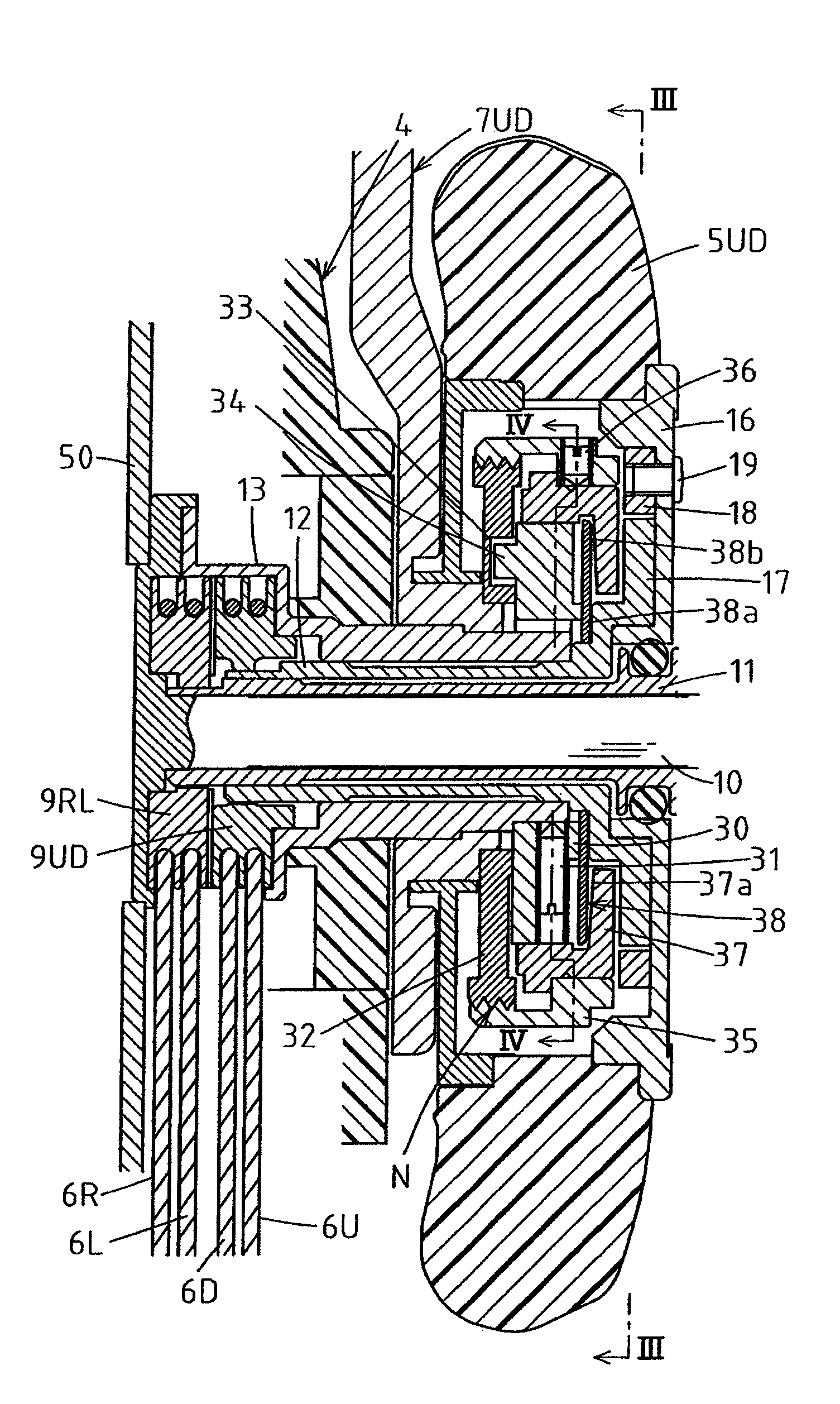

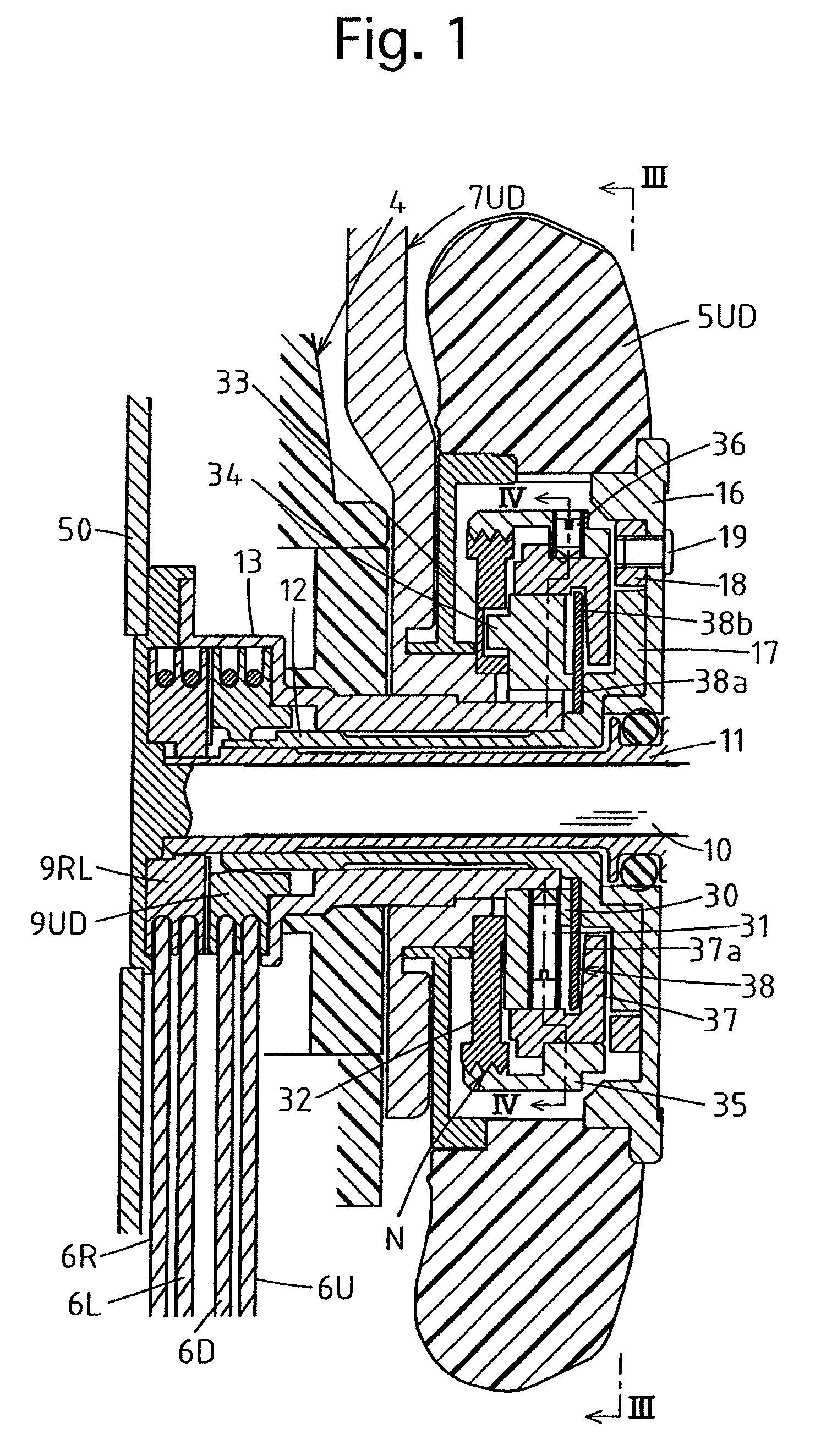

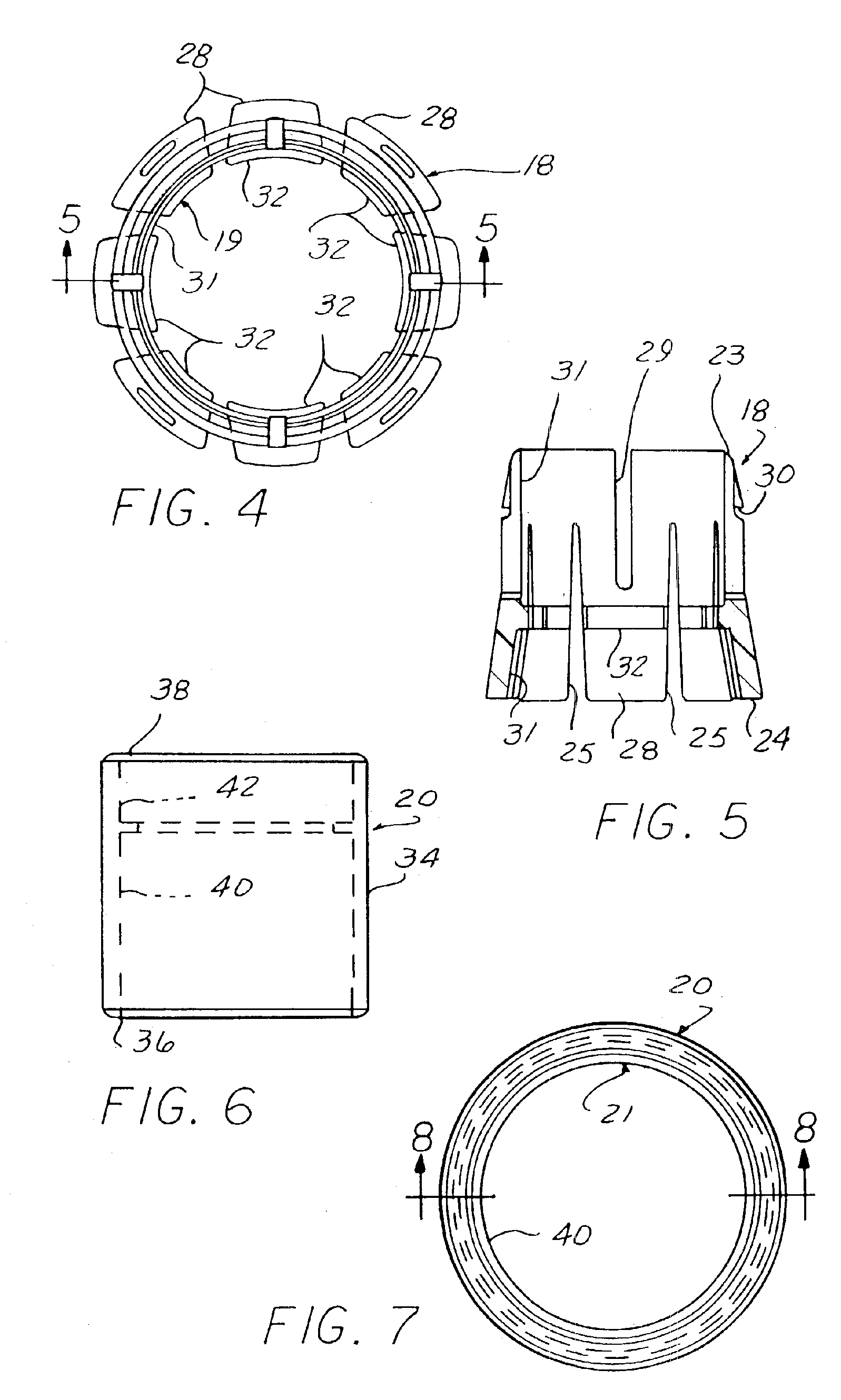

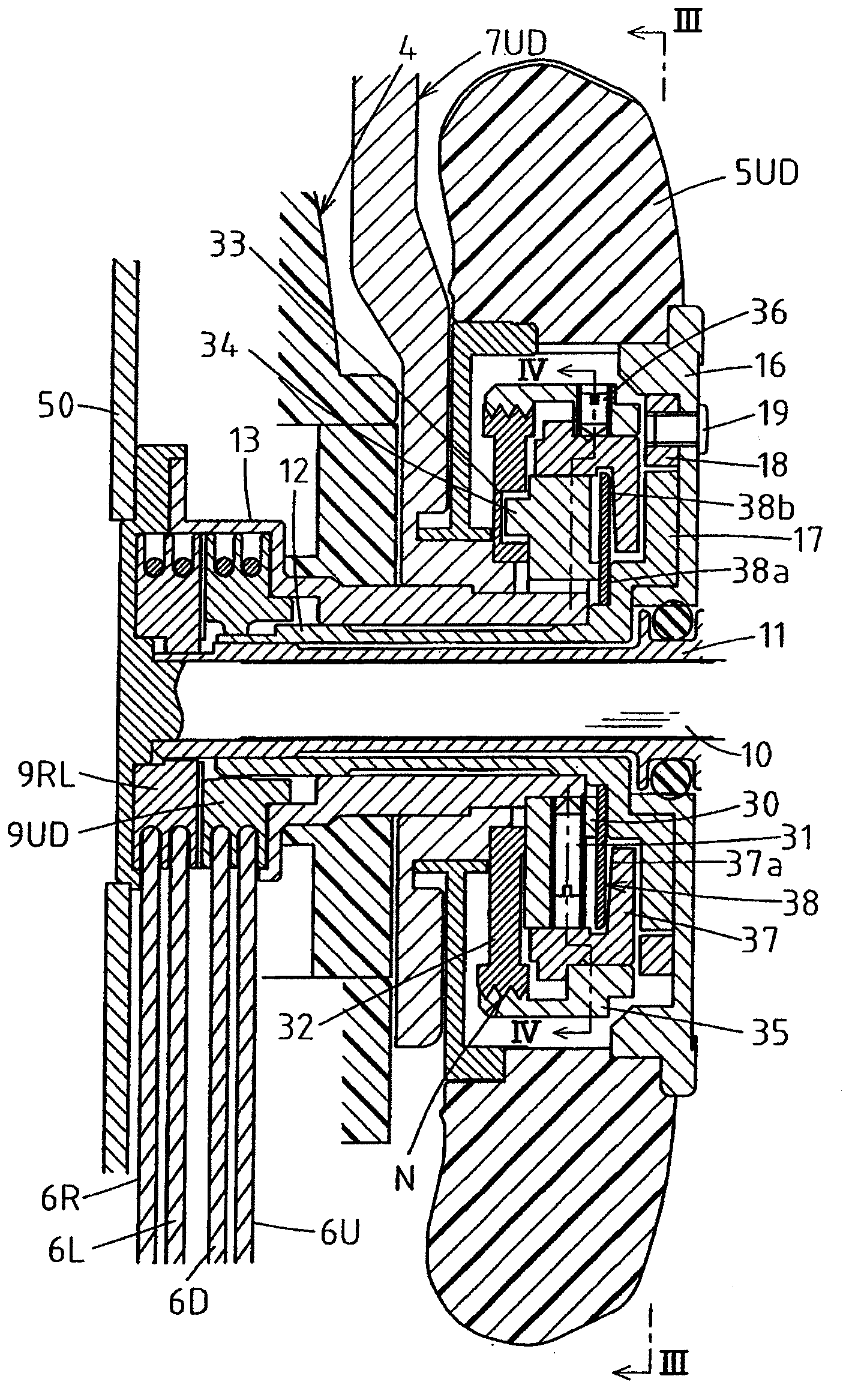

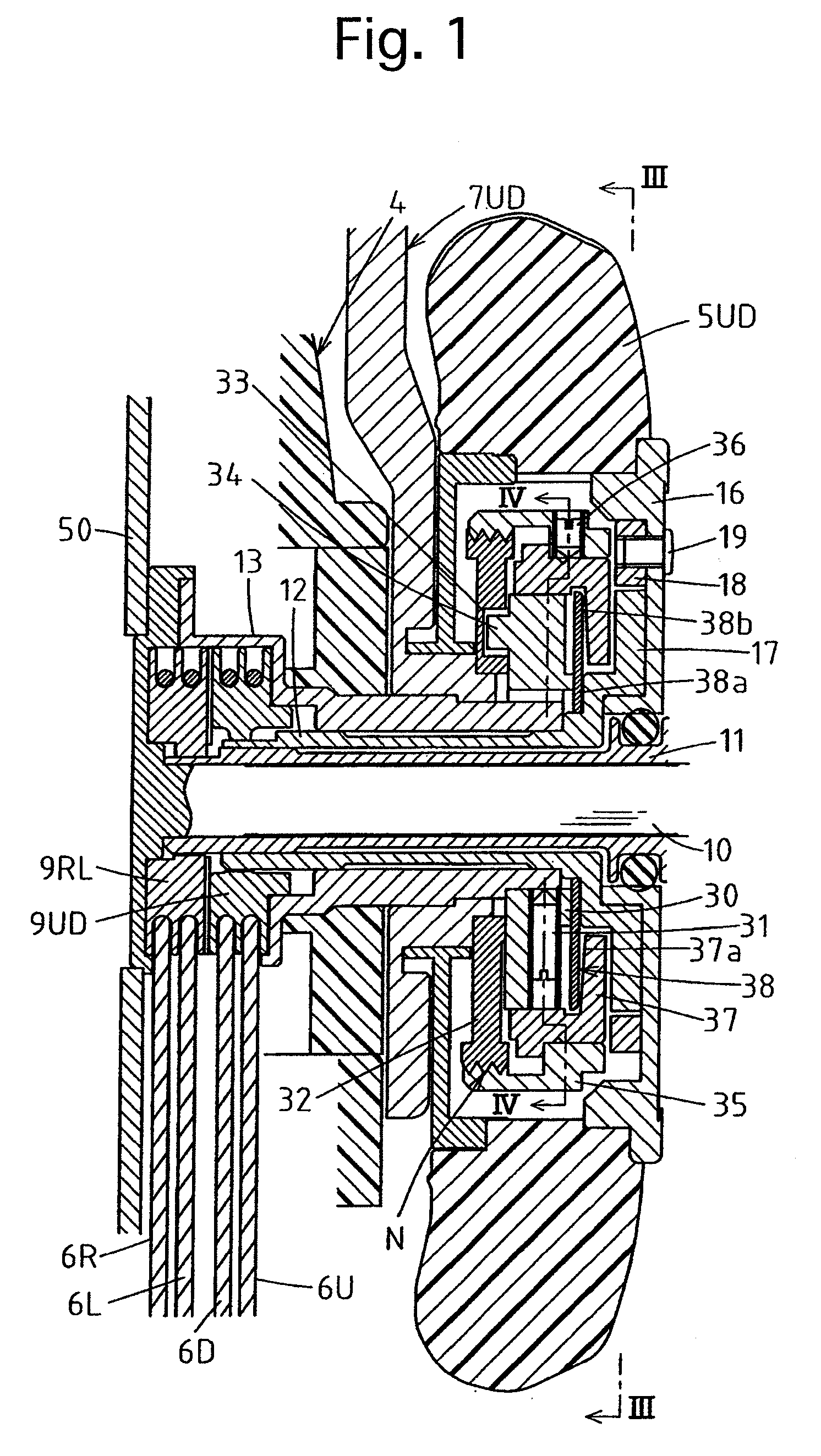

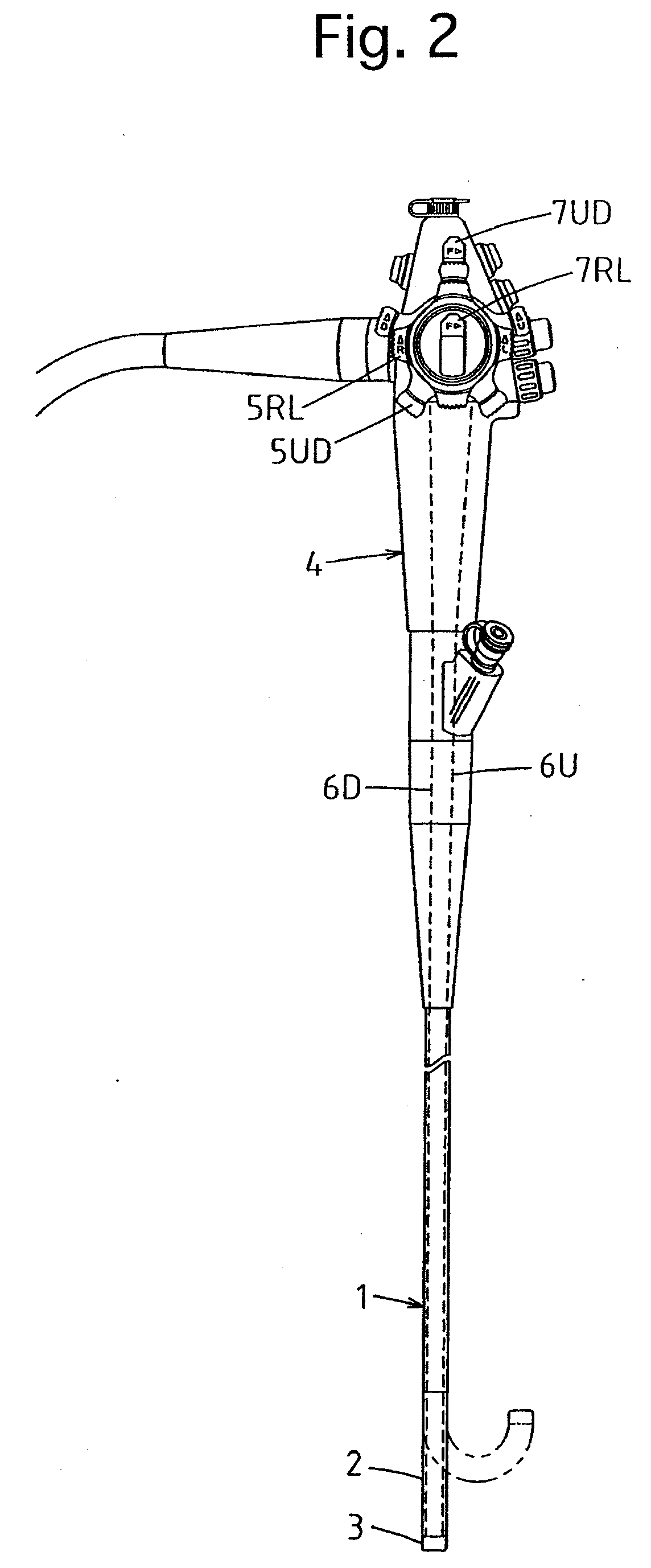

Bent state holding mechanism of an endoscope

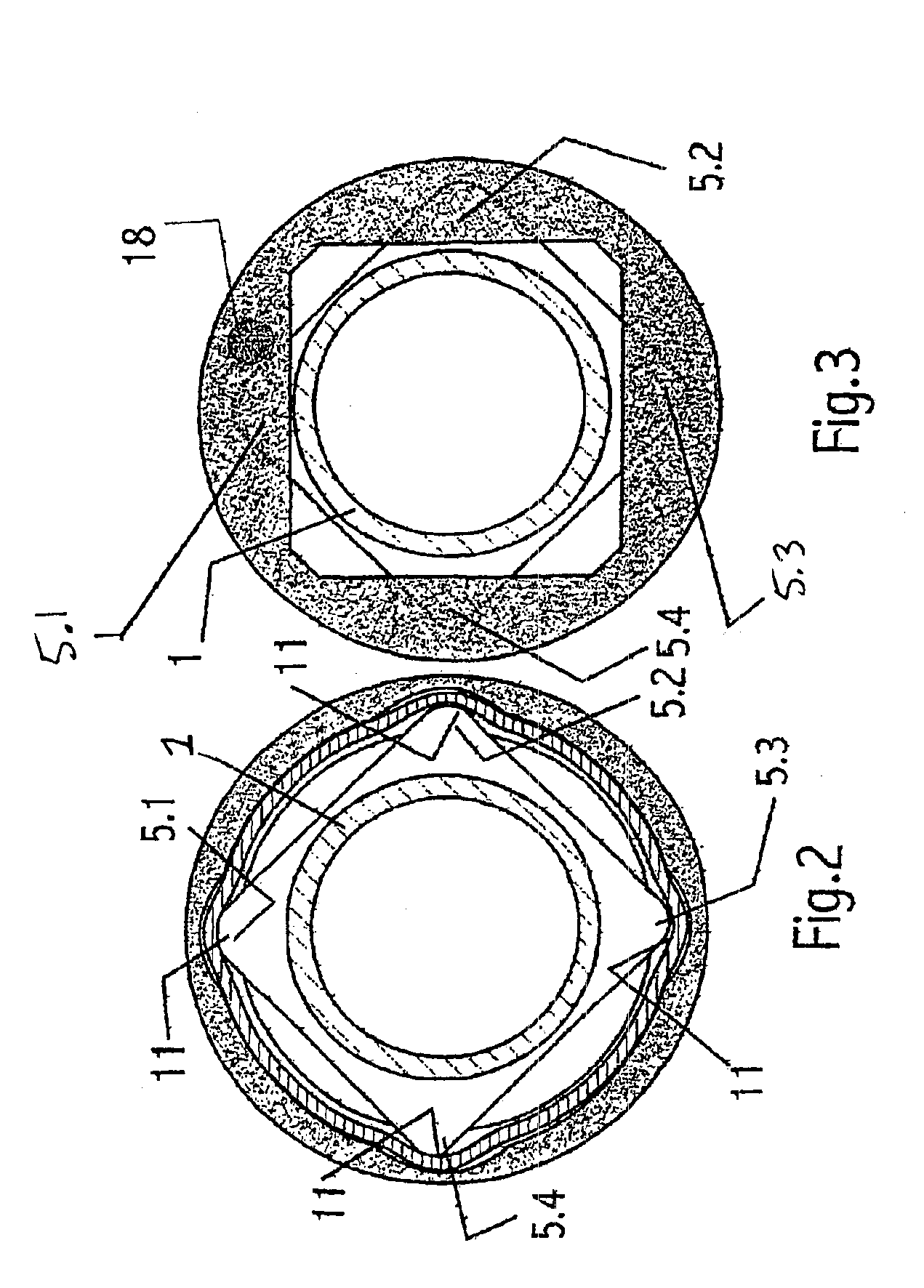

A bent state holding mechanism for an endoscope which includes a control portion and an insertion portion extending therefrom, the insertion portion having a bendable portion at a distal end thereof, including a bendable portion control mechanism provided on the control portion, which is operated to bend the bendable portion, and at least two frictional resistance producing members which rotate relative to each other upon operation of the bendable portion control mechanism, to exert a frictional resistance for holding the bendable portion at any operated position. The two frictional resistance producing members include a radial plate spring made of resilient metal which includes a ring portion and a plurality of radial projections which project radially outwards from the ring portion; and an annular friction member having a pressure surface which is brought to be pressed obliquely against flat surfaces of the plurality of radial projections.

Owner:HOYA CORP

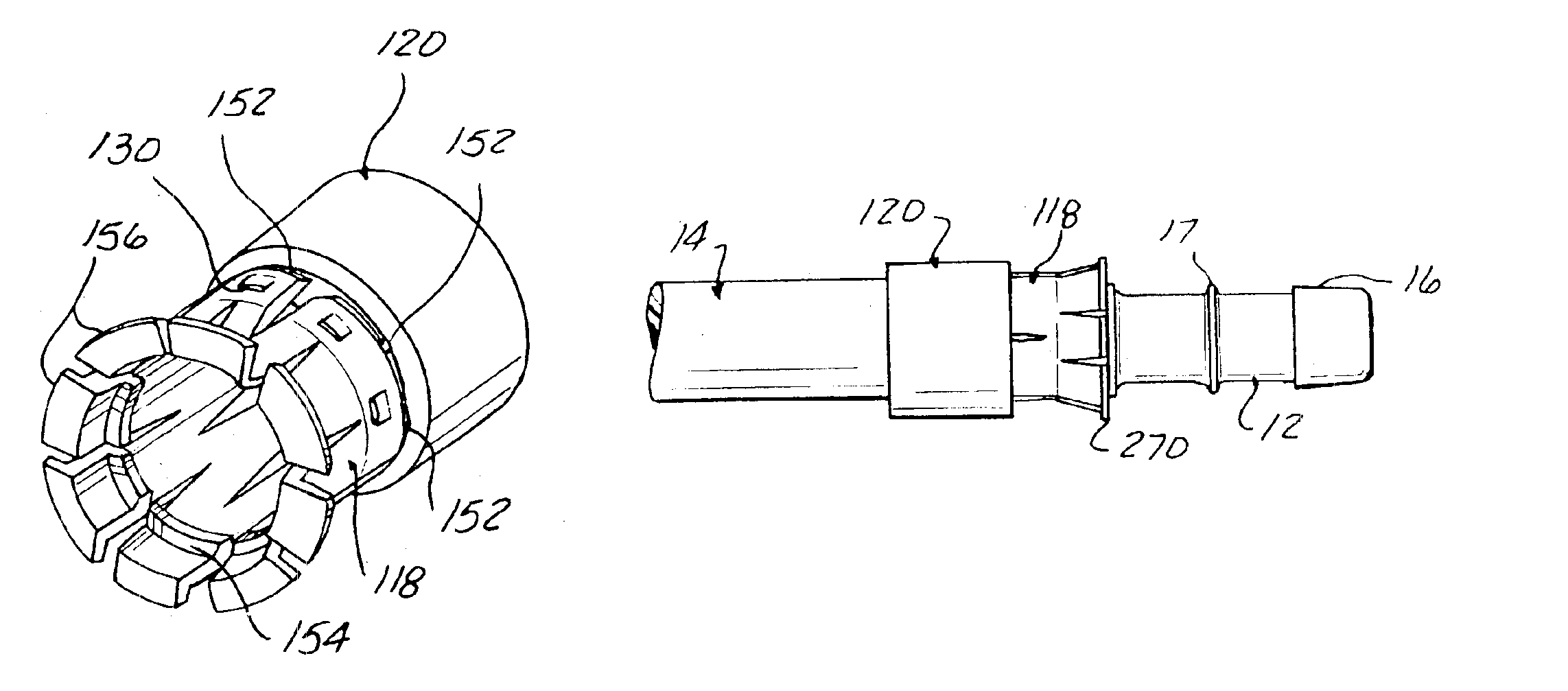

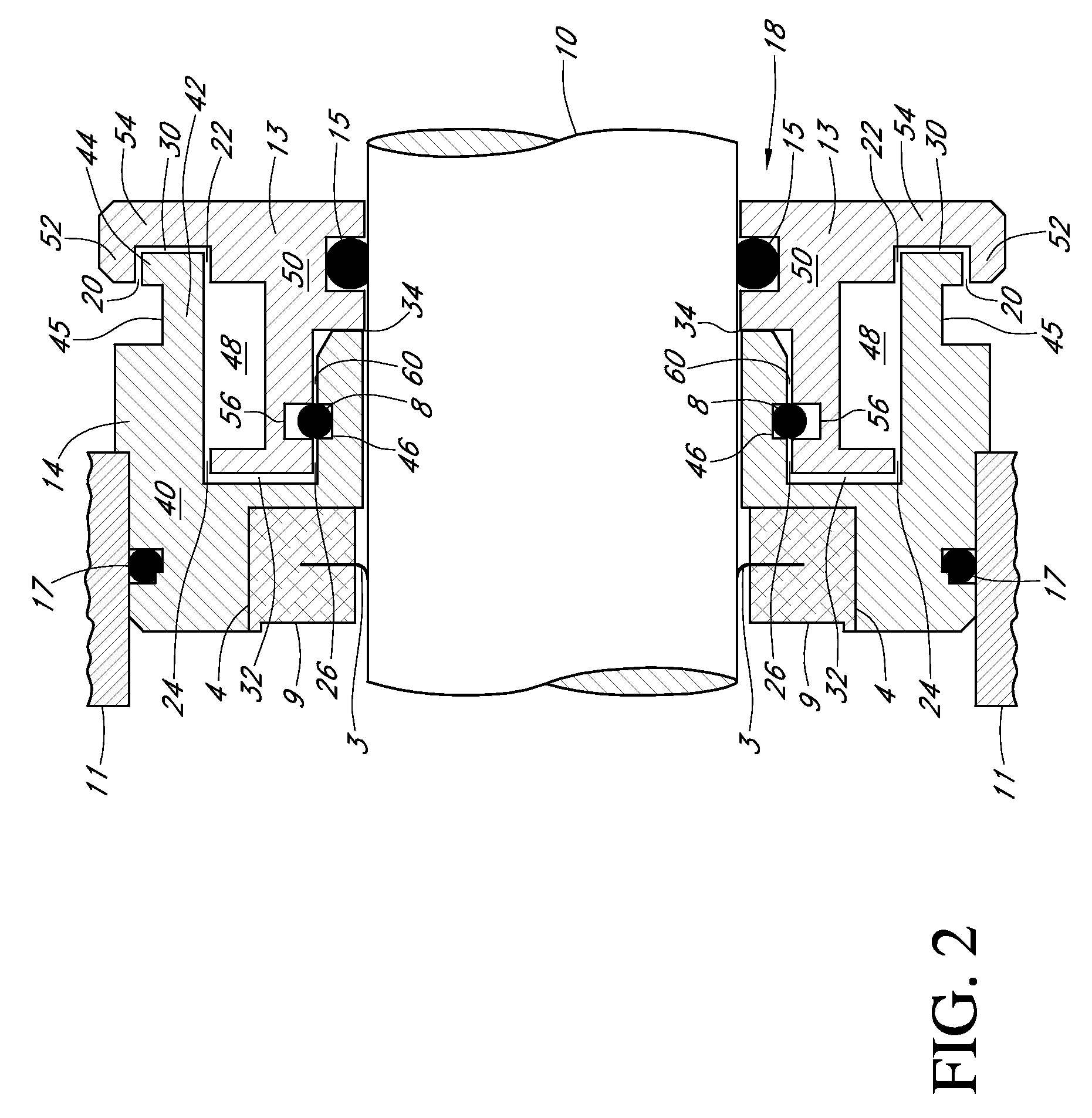

Barb clamp

ActiveUS7090257B2Reduce intensityImprove retentionRespiratorsSleeve/socket jointsBiomedical engineeringRadial projection

A plastic barb clamp provides leakproof connection of a flexible tube in a barb fitting. The barb clamp includes a collet and a sleeve. The barb clamp is configured to fit snugly within the tube. The collet is slid over the tube. Annular retainers on the interior surface of the collet fit tightly around the tube and under an expanded portion of the barb fitting. The sleeve is then slid over the collet. As the sleeve moves over the collet, tangs on the collet are pushed radially inwardly into the tube and barb fitting. The exterior surface of the collet has radial projections or expanded diameter portions for locking with the sleeve. The sleeve has an annular projection or a reduced diameter portion on the interior surface of the sleeve to correspond to the exterior surface of the collet to provide a secure lock between the collet and sleeve. To properly orientate the sleeve relative to the collet, the sleeve and collet can be molded as one piece, wherein the sleeve and collet are connected by thin, frangible pieces of plastic.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

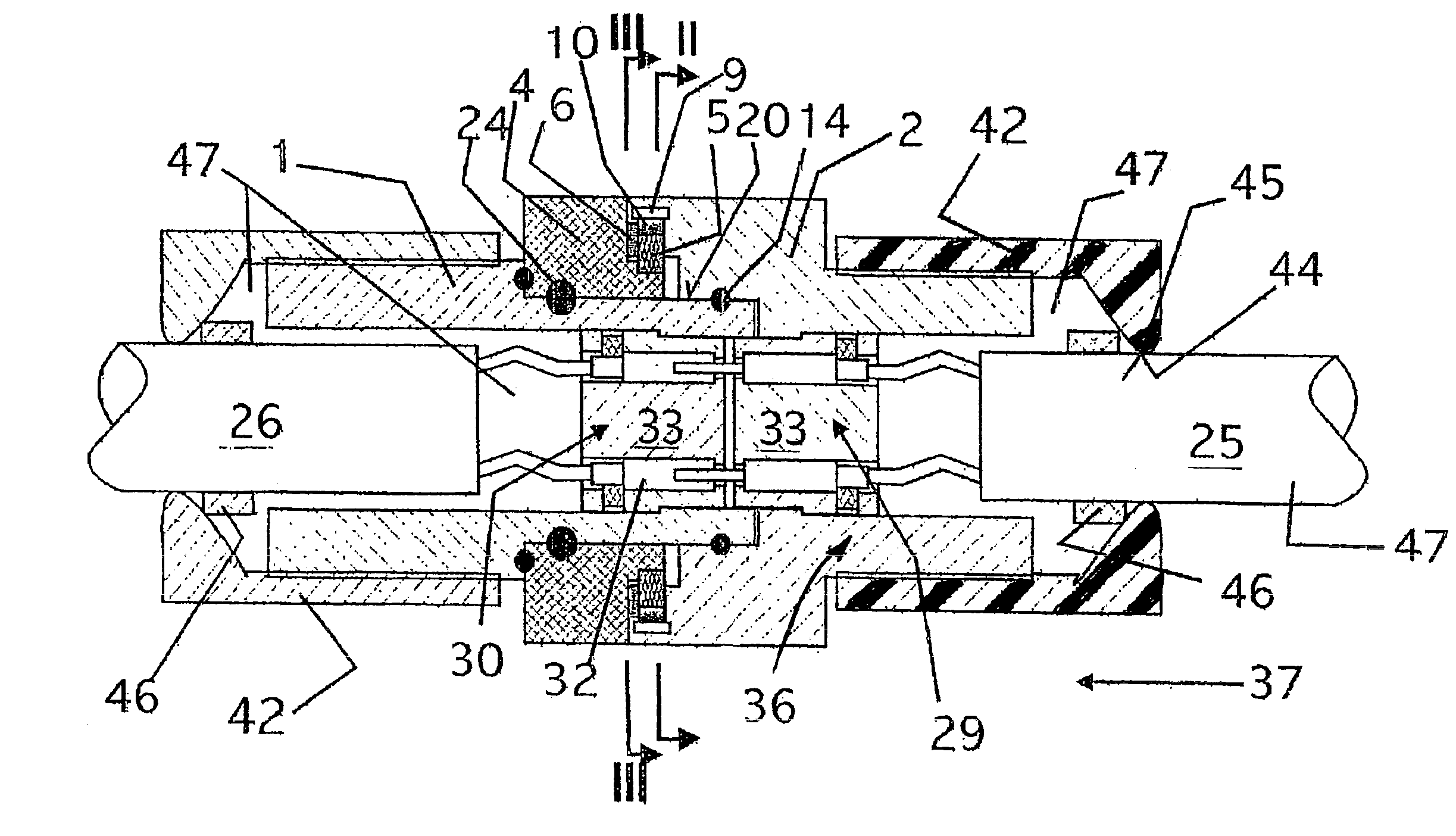

Coupling for explosion-proof connection of two electric line ends

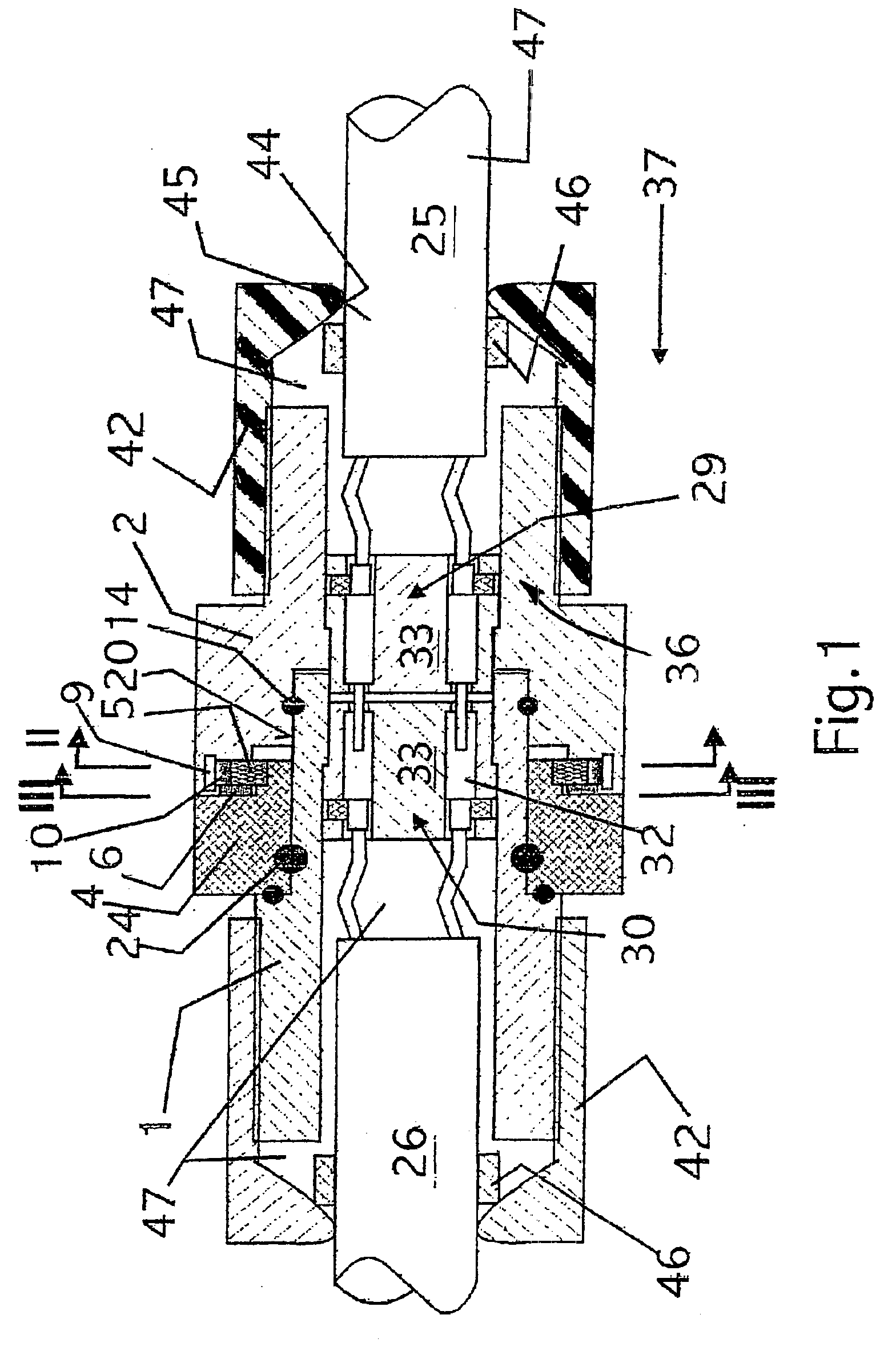

InactiveUS6877277B2Reliable wayWithout incurring riskSecuring/insulating coupling contact membersCouplings bases/casesElectric lightCoupling

For an explosion-proof connection of two electric line ends (25, 26), the contact elements (27, 28) are accommodated in two tubes (1, 2), which can be joined in an explosion-proof manner. Each of the plug-in contact parts is axially secured in its tube by a radial projection (41) in the direction toward the end facing the other tube. At its line end, each of the tubes is closed by an end cap (42), which sealingly surrounds with a narrow outlet (44) the electric lines, including an insulation (43). The tube, in which the plug-in contact part with the contact pins is axially secured, extends beyond the tip of the contact pins, and has there an enlarged diameter, with which it surrounds the other tube (inner tube 1,3) with a narrow cylindrical gap (sealing gap 20).

Owner:TIEFENBACH BERGBAUTECHN

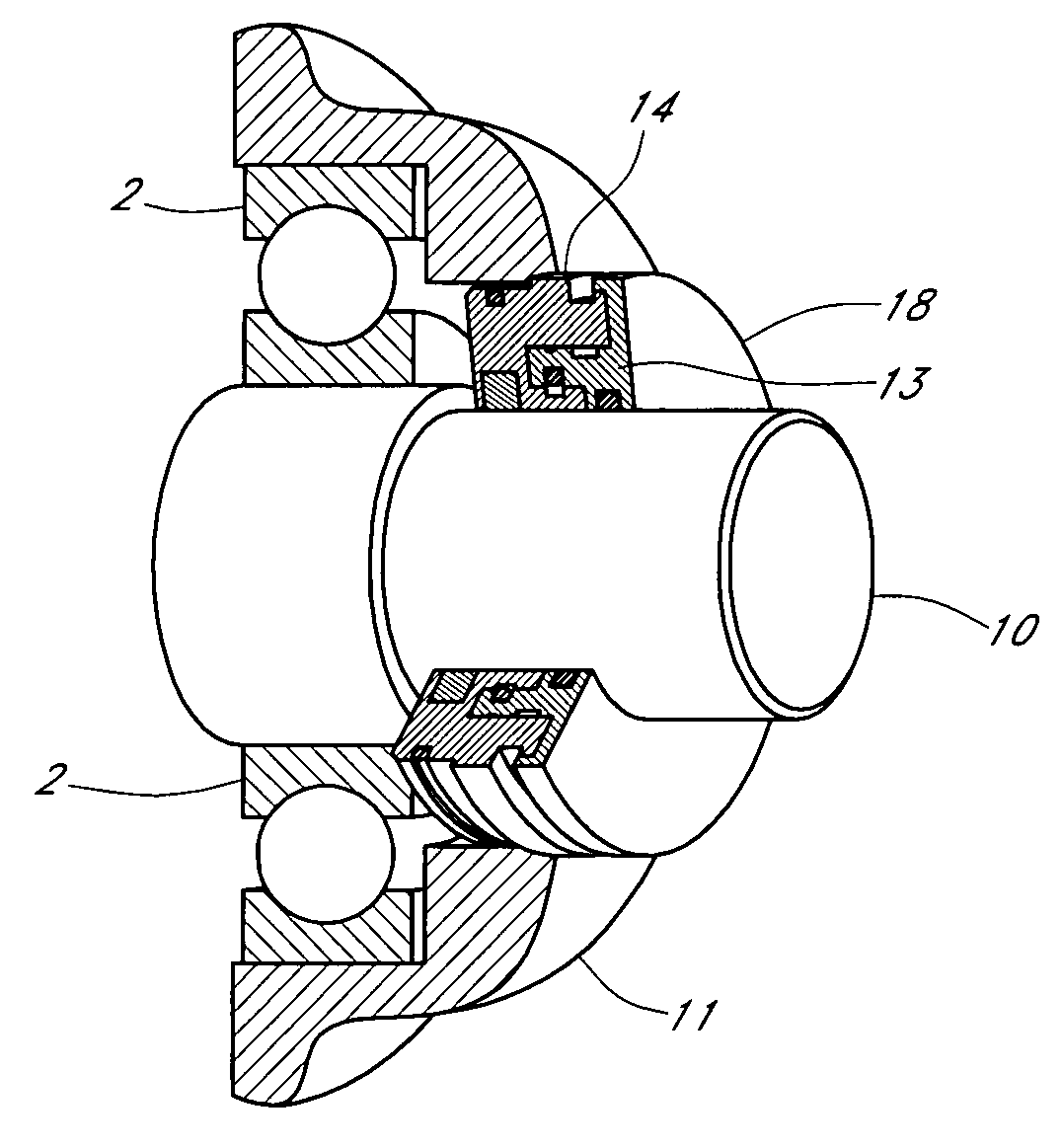

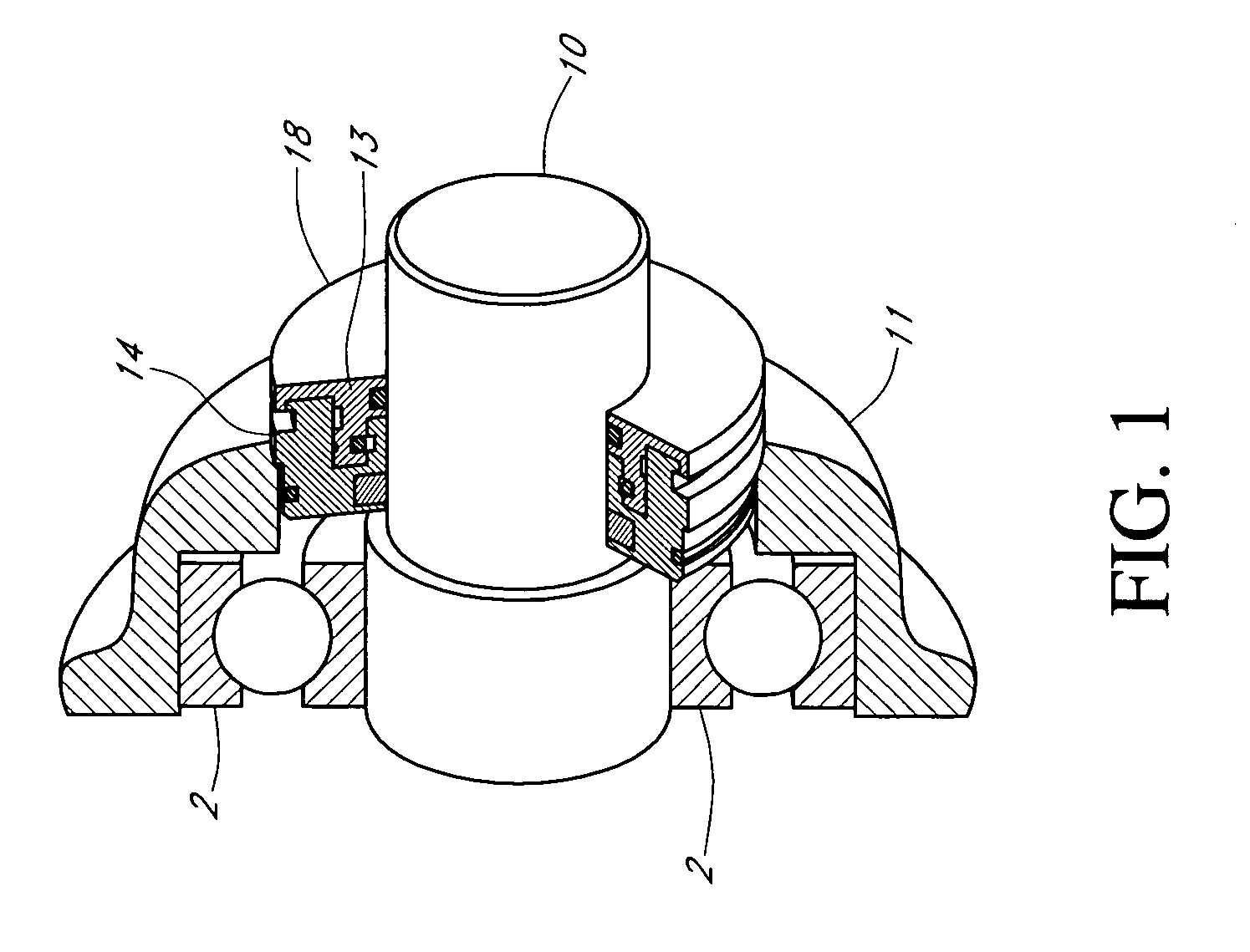

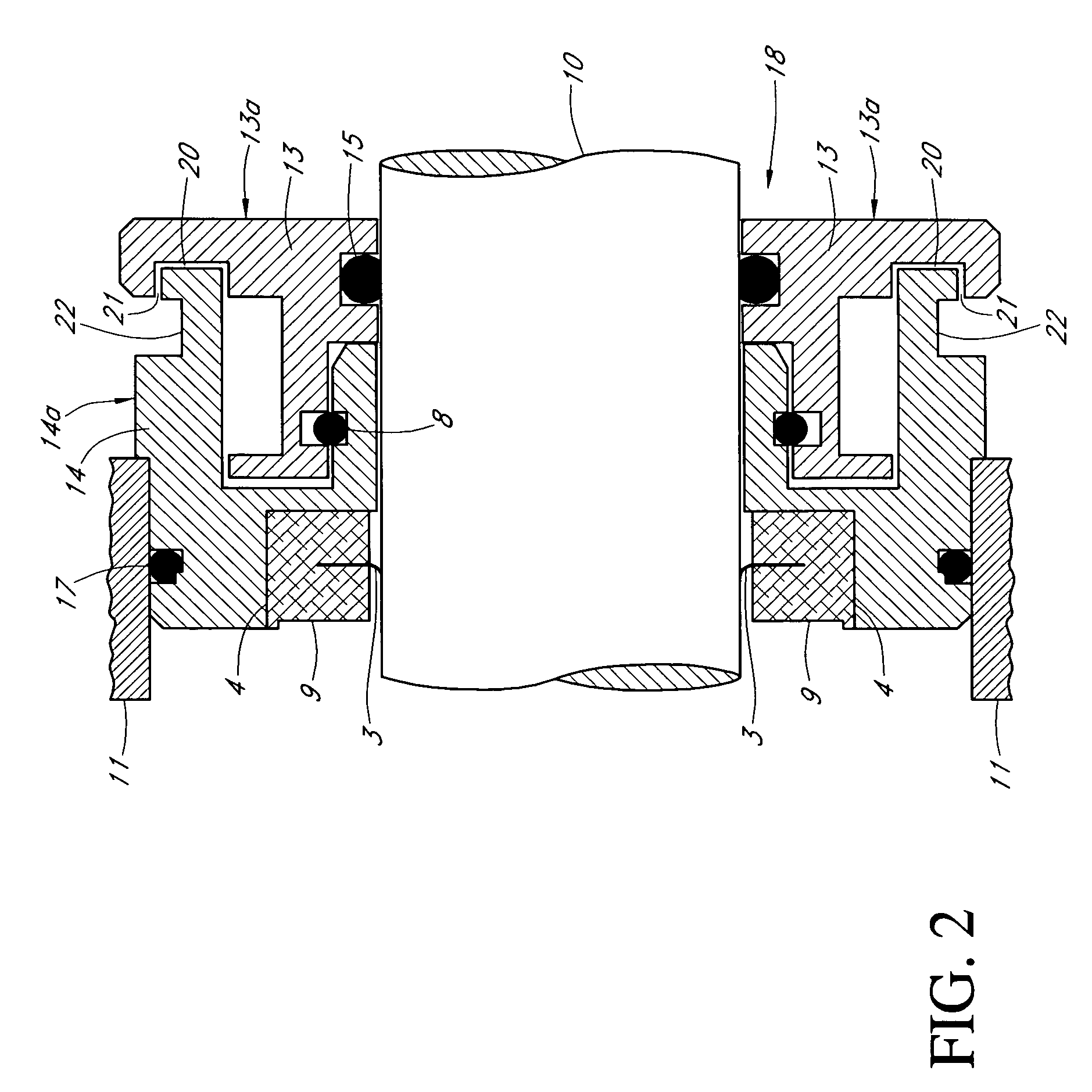

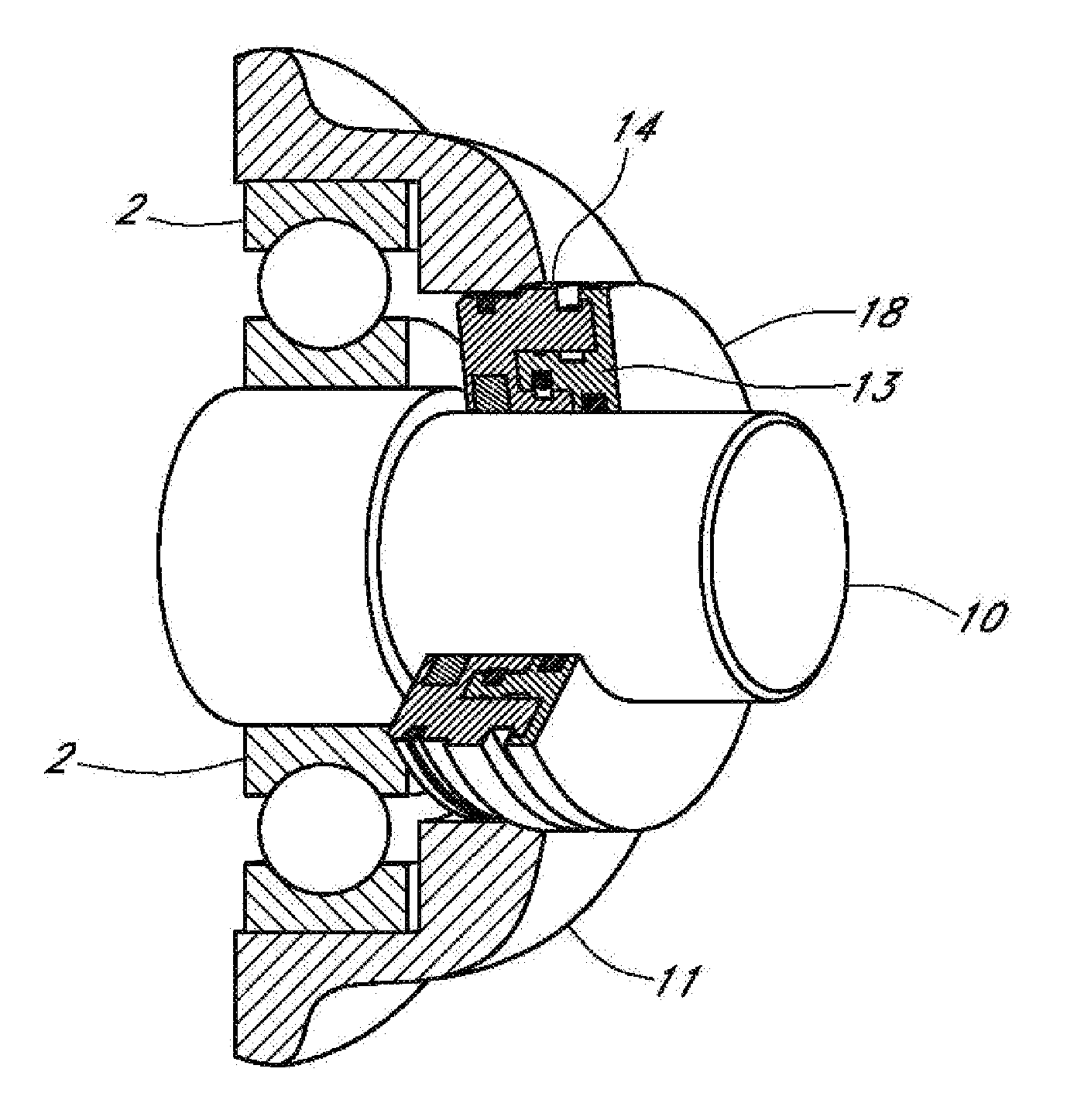

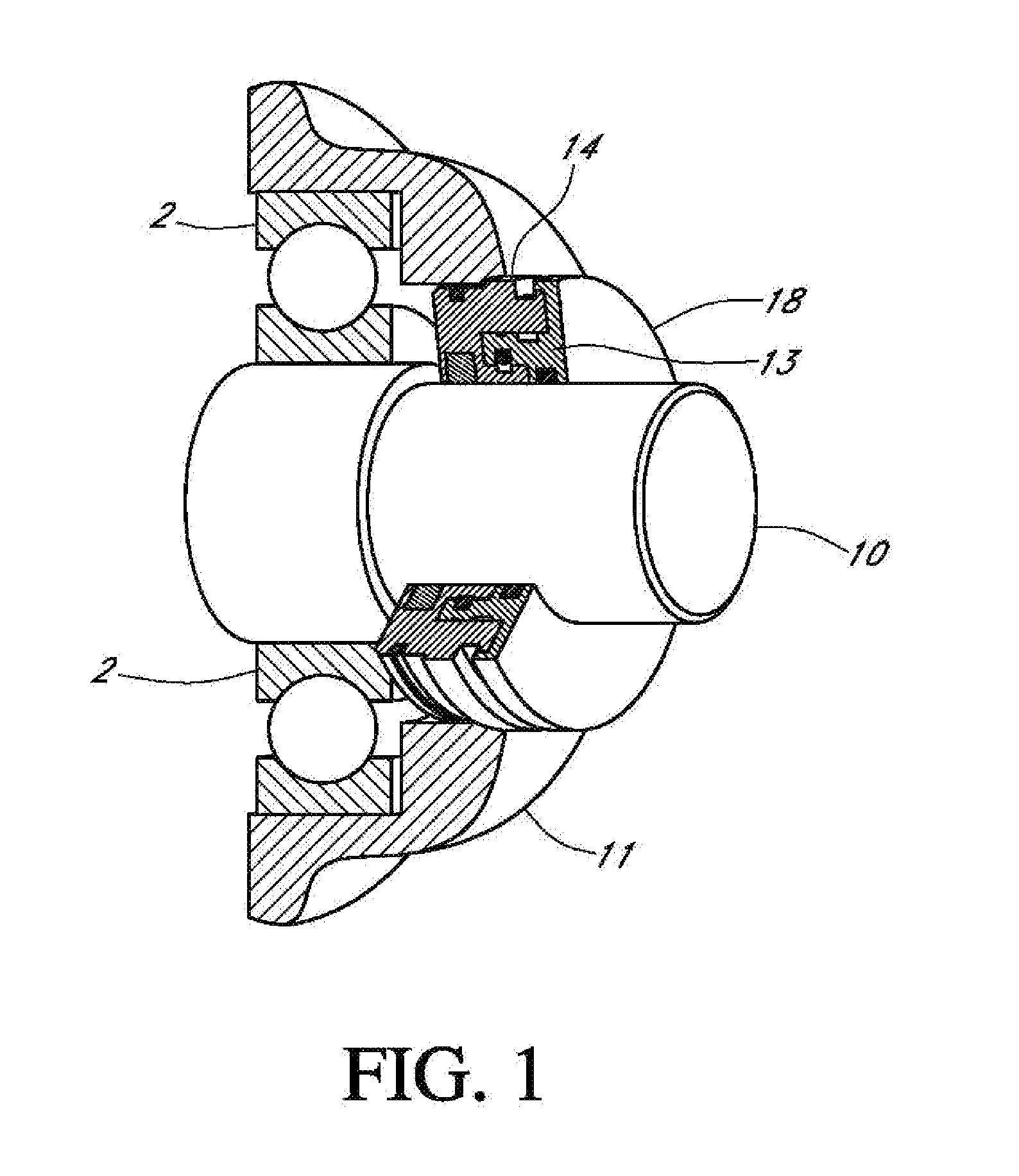

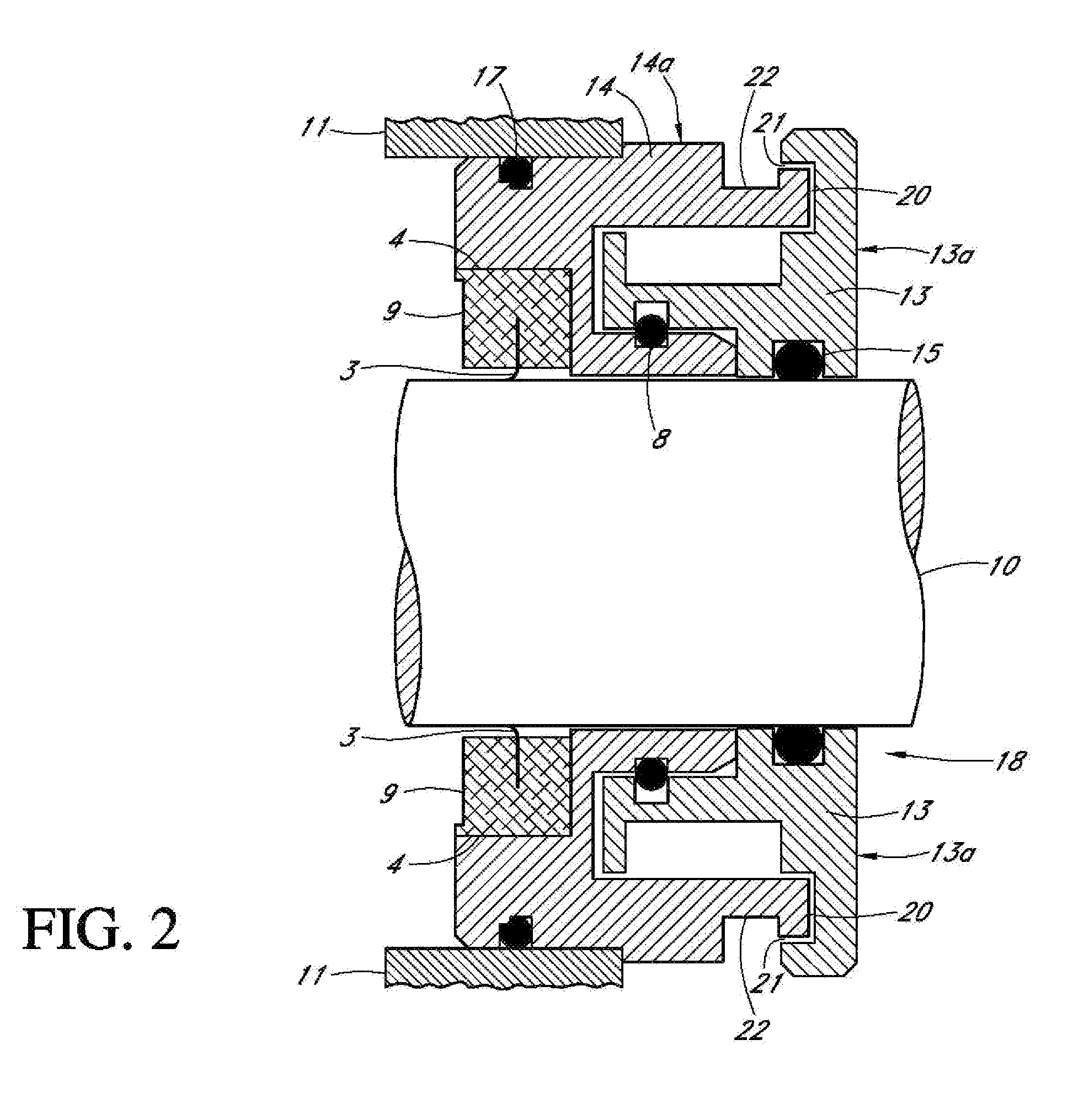

Motor ground seal

InactiveUS7521827B2Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesShock coolingRadial projection

Owner:INPRO INC

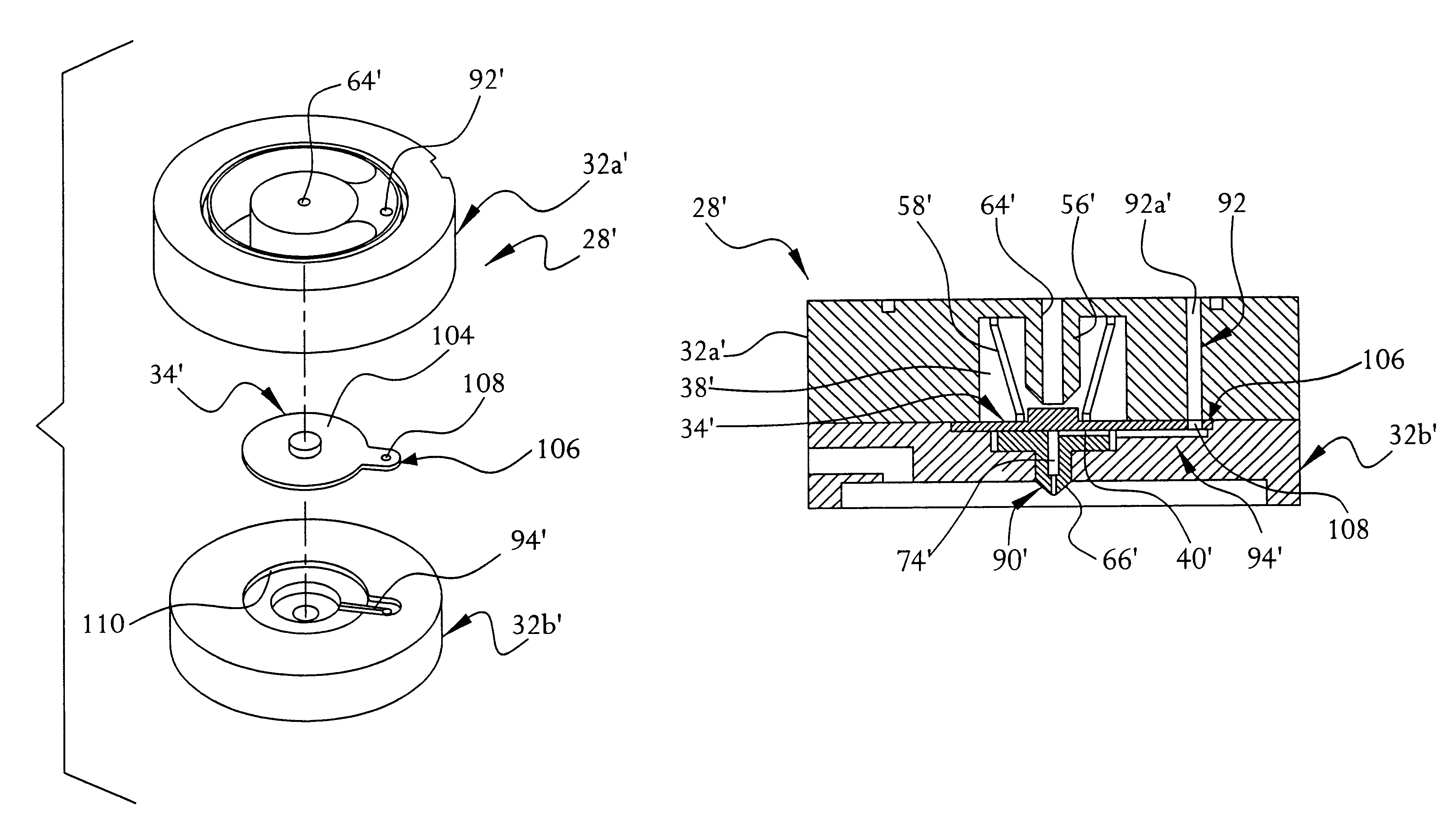

Supply valve and diaphragm for a pneumatically-operated gas demand apparatus

InactiveUS6318366B1Reduce wasteSimple designEngine diaphragmsRespiratory masksVALVE PORTRadial projection

A supply valve for a pneumatically-operated gas demand apparatus or an intermittent gas delivery device disposed between a source of pressurized respiratory gas and a patient. The valve includes first and second housing parts defining a chamber and having first and second cooperating fluid passageways. A flexible diaphragm member is disposed in the chamber. The diaphragm member includes a central sealing portion and a radial projection integral with the central sealing portion for enabling fluid communication between the first and second fluid passageways and for sealing the first and second passageways against leakage.

Owner:SALTER LABS LLC

Motor ground seal

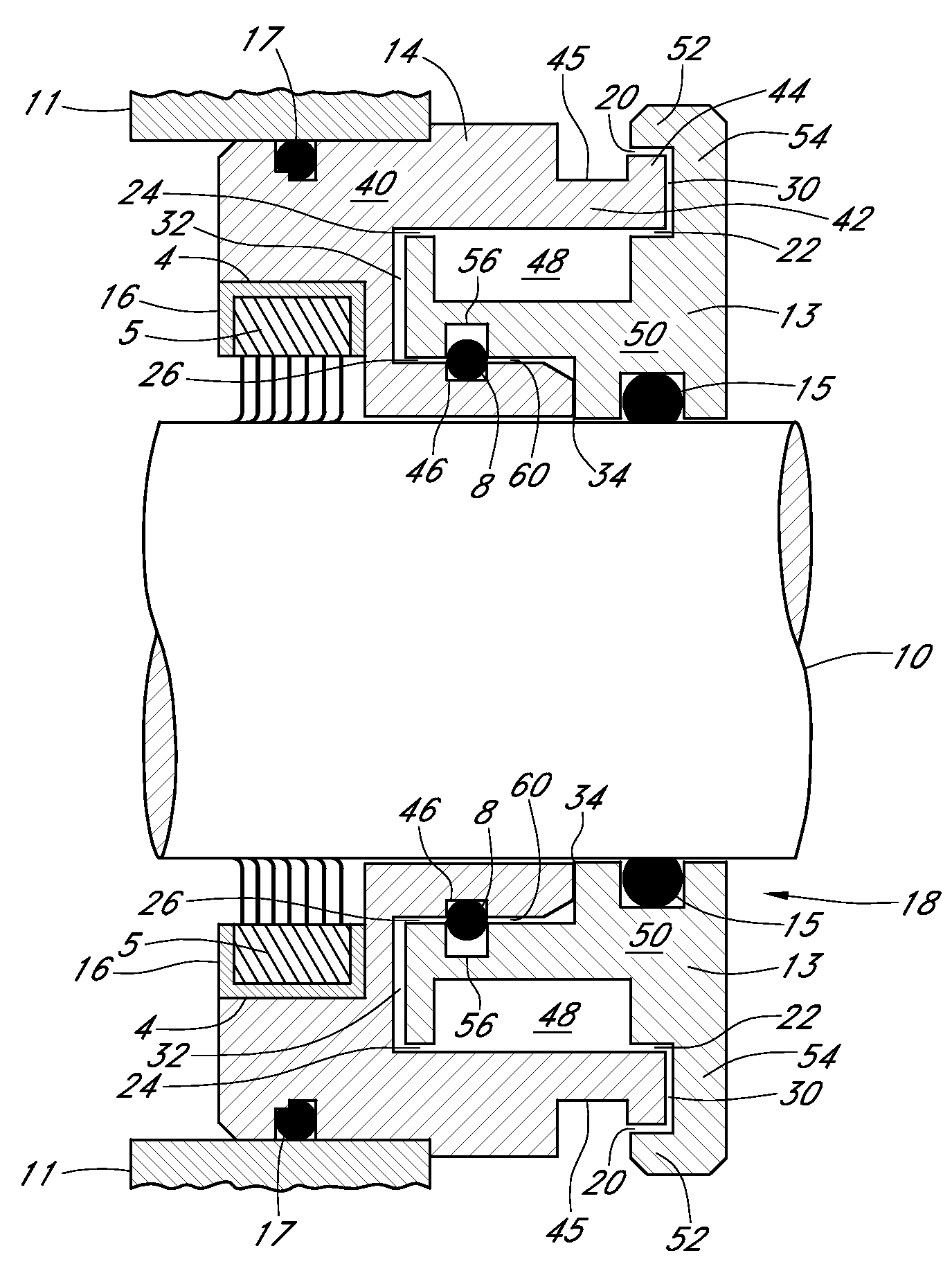

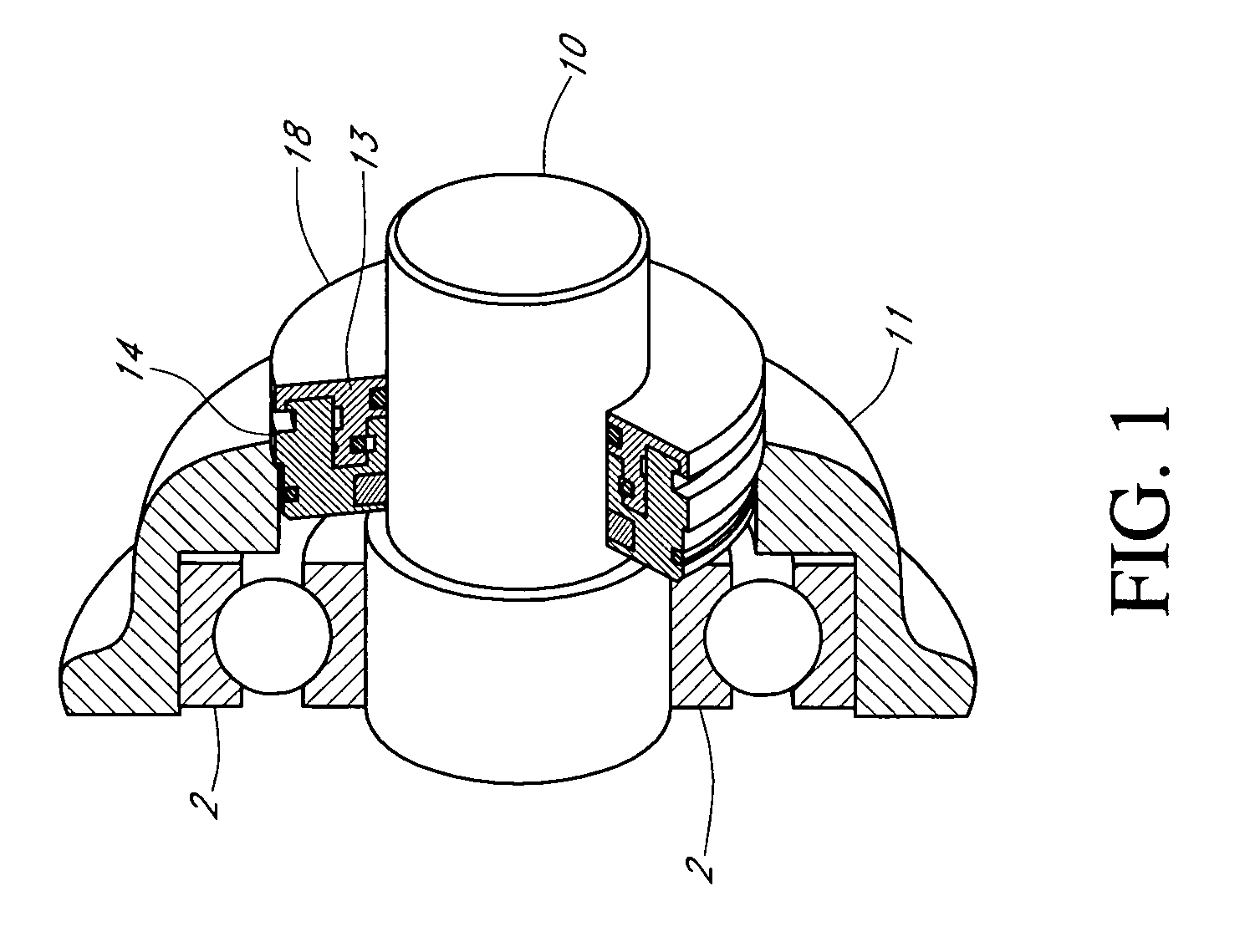

InactiveUS20070138748A1Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesEngineeringRelative motion

A shaft seal assembly is disclosed having a stator including a main body and axial and radial projections therefrom. The rotor is radially extended and encompasses the axial and radial projections from said stator. A passageway formed between the radial projection of stator and rotor results in an axial passageway having its opening facing rearwardly from the rotor and away from the source of impinging coolant and / or contaminant. A concentric circumferential receptor groove in the stator facing the housing allows insertion of conductive means for transmission of electrostatic charge away from the shaft through the shaft seal assembly to the housing and ground. The receptor groove is opposite the axial passageway and provides for both a substantially lower contaminant environment and improved engagement with conductive means. The dimension of interface gap between the rotor and the radial projection from the stator, which the access to the shaft of any impinging material is fixed at a predetermined value and does not vary with the relative movement between the rotor and the stator. The shaft seal assembly provides improved rejection or warding off of contaminants from ingress into the labyrinths and ultimately restrains attack of the bearing environment as well as substantial elimination of bearing current and attendant bearing fluting or frosting.

Owner:INPRO INC

Motor Grounding Seal

InactiveUS20110204734A1Prevent oil leakageAvoid pollutionEngine sealsAssociation with grounding devicesCoolantRadial projection

A shaft seal assembly is disclosed having a stator including a main body and axial and radial projections therefrom. The rotor may be radially extended to encompass the axial and radial projections from said stator. A passageway formed between the radial projection of stator and rotor results in an axial passageway having its opening facing rearwardly from the rotor and away from the source of impinging coolant and / or contaminant. A concentric circumferential receptor groove in the stator facing the housing allows insertion of a conductive insert for transmission of electrostatic charge away from the shaft through the shaft seal assembly to the housing and ground. The receptor groove is opposite the axial passageway and provides for both a substantially lower contaminant environment and improved engagement with the conductive insert.

Owner:ORLOWSKI DAVID C +1

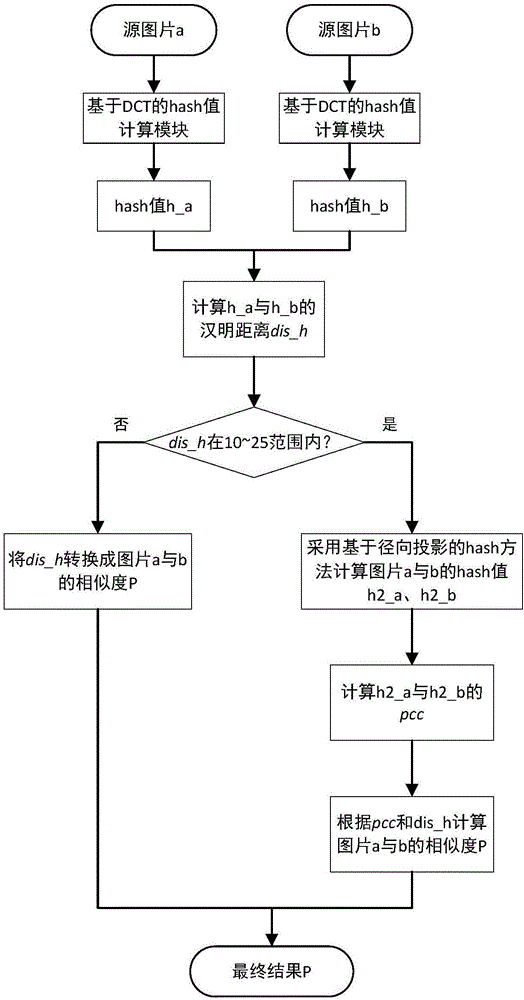

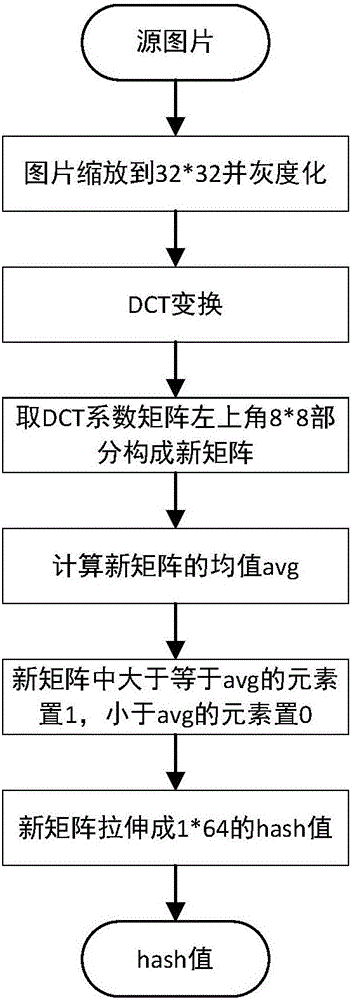

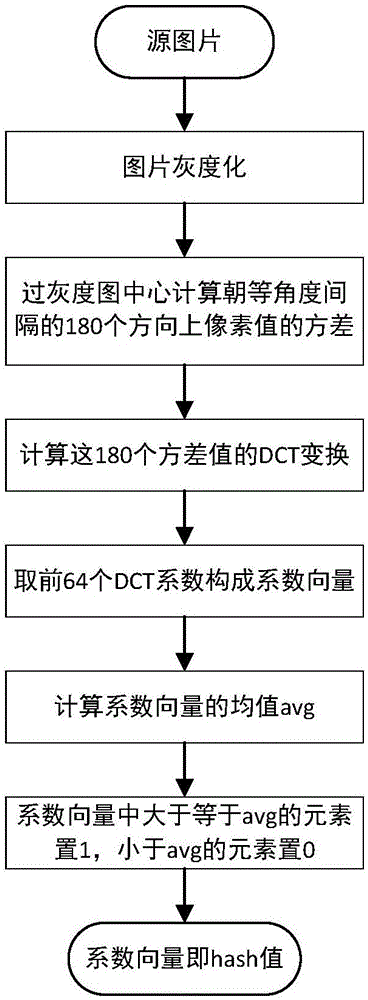

Picture similarity calculation method

ActiveCN106650829AImprove accuracyReduce calculation speedCharacter and pattern recognitionCorrelation coefficientHamming distance

The invention discloses a picture similarity calculation method, comprising the steps of: (1) calculating hash values of two pictures to be compared by using a hash method based on DCT (Discrete Cosine Transformation); (2) calculating the Hamming distance dis-h between the two hash values; (3) if the Hamming distance is not in a set range, directly calculating the similarity of the two pictures via a formula; (4) if the Hamming distance is in the set range, calculating a hash value by using a hash method based on radial projection; and (5) calculating a Pearson's correlation coefficient of the hash value obtained last step, and calculating the similarity of the two pictures in combination with the Hamming distance obtained in step 2. The method has certain robustness for image rotation, avoids the influence caused by gamma correction or color histogram adjustment, and improves the accuracy of picture similarity results.

Owner:SOUTH CHINA UNIV OF TECH

Bent state holding mechanism of an endoscope

A bent state holding mechanism for an endoscope which includes a control portion and an insertion portion extending therefrom, the insertion portion having a bendable portion at a distal end thereof, including a bendable portion control mechanism provided on the control portion, which is operated to bend the bendable portion, and at least two frictional resistance producing members which rotate relative to each other upon operation of the bendable portion control mechanism, to exert a frictional resistance for holding the bendable portion at any operated position. The two frictional resistance producing members include a radial plate spring made of resilient metal which includes a ring portion and a plurality of radial projections which project radially outwards from the ring portion; and an annular friction member having a pressure surface which is brought to be pressed obliquely against flat surfaces of the plurality of radial projections.

Owner:HOYA CORP

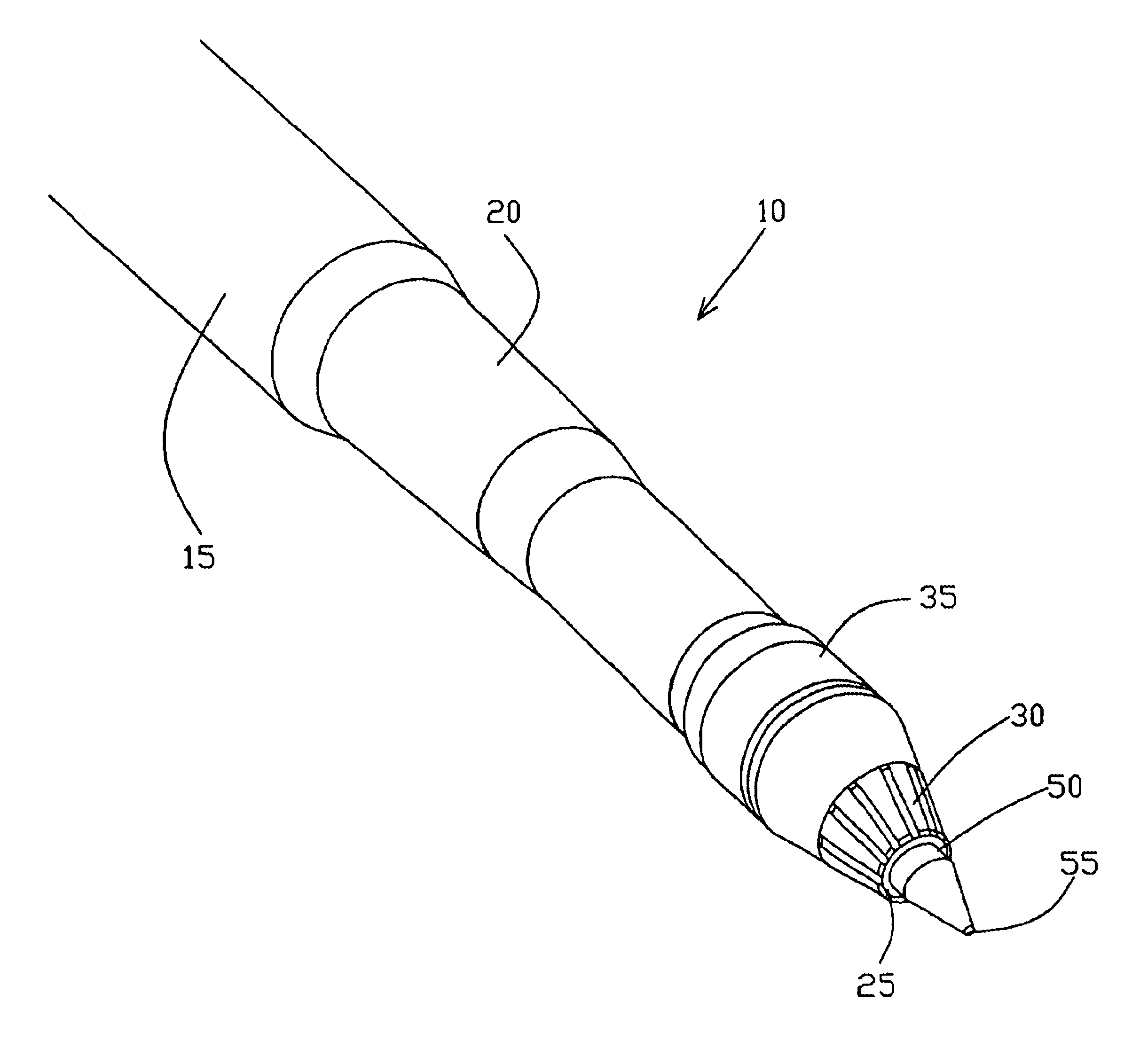

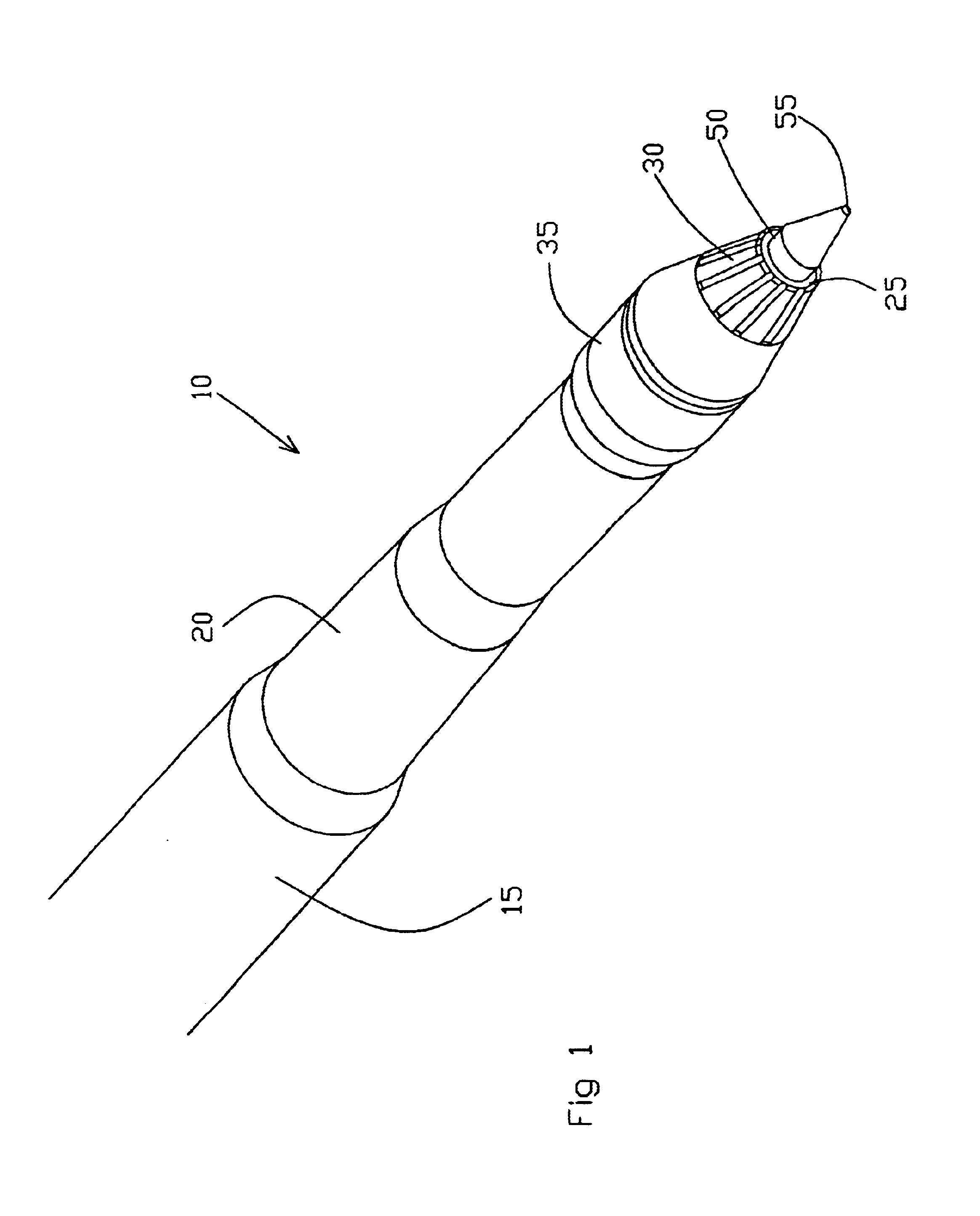

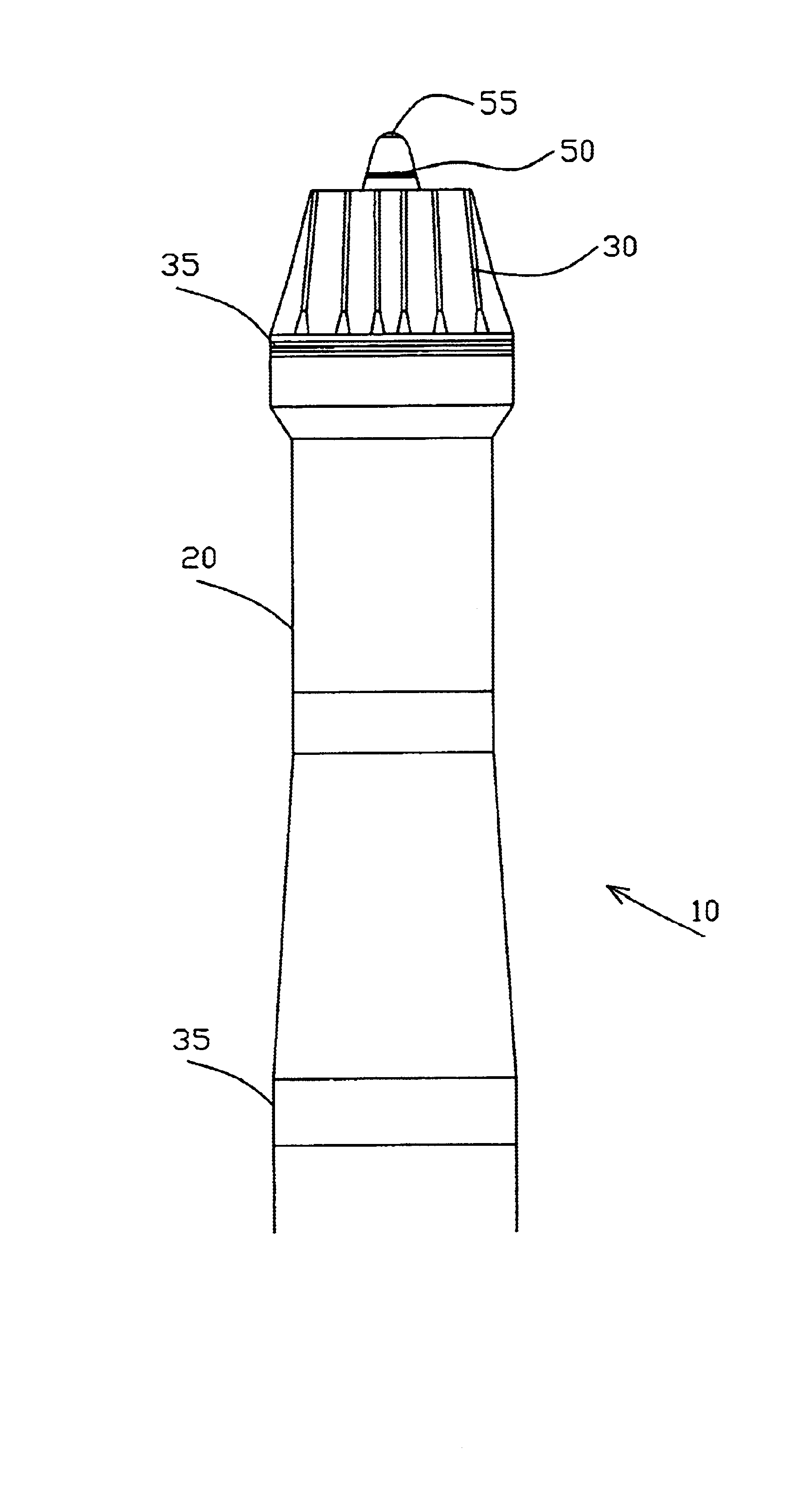

Digitizer pen

InactiveUS6876356B2Easy extractionTransmission systemsCathode-ray tube indicatorsUltrasonic sensorTransducer

A digitizer pen system including: a pen having an elongated body terminating in a writing tip and at least one ultrasound transducer deployed adjacent to the writing tip. The digitizer pen also includes a writing element removably inserted into the writing tip. The writing element has an end protruding from the writing tip. The digitizer pen also includes an extraction tool including a plurality of flexible leaves deployed around a central position. The flexible leaves are spaced such that, when the extraction tool is pressed onto the protruding end of the writing element, the flexible leaves grip the protruding end so as to facilitate extraction of the writing element. The elongated body has a main grip surface. The elongated body includes at least one radial projection located between the ultrasound transducer and the main grip surface.

Owner:PEGASUS TECH LTD

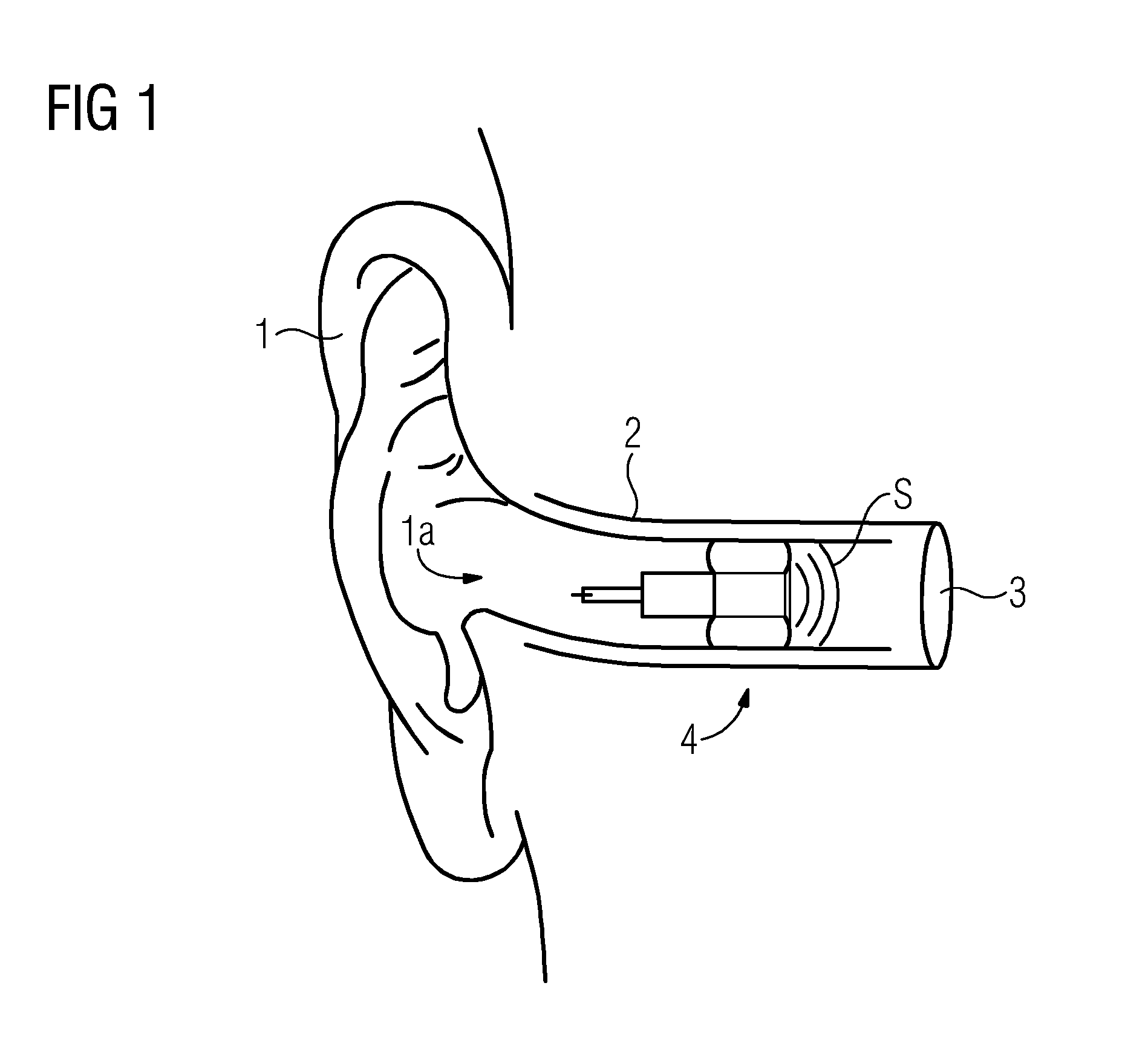

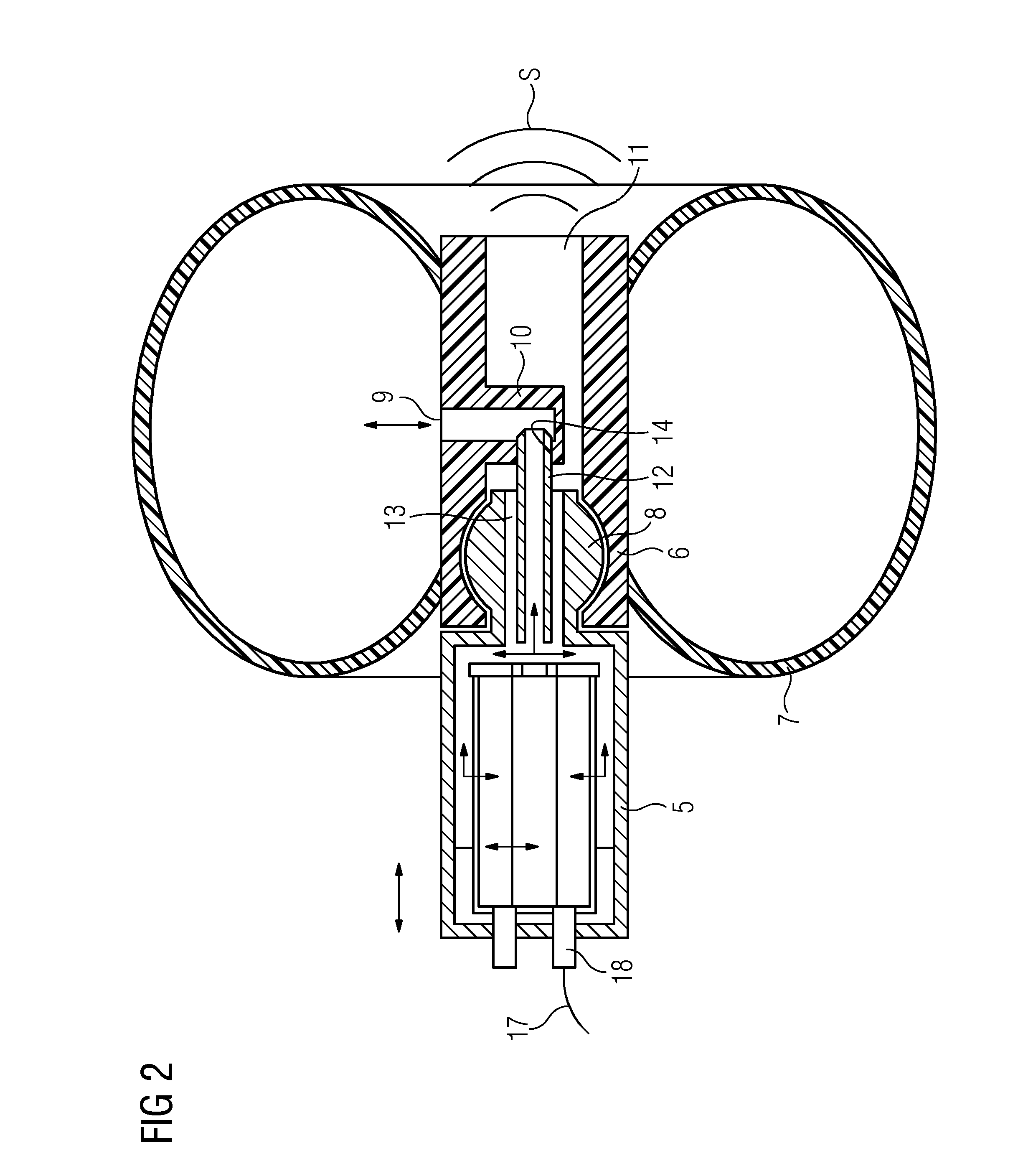

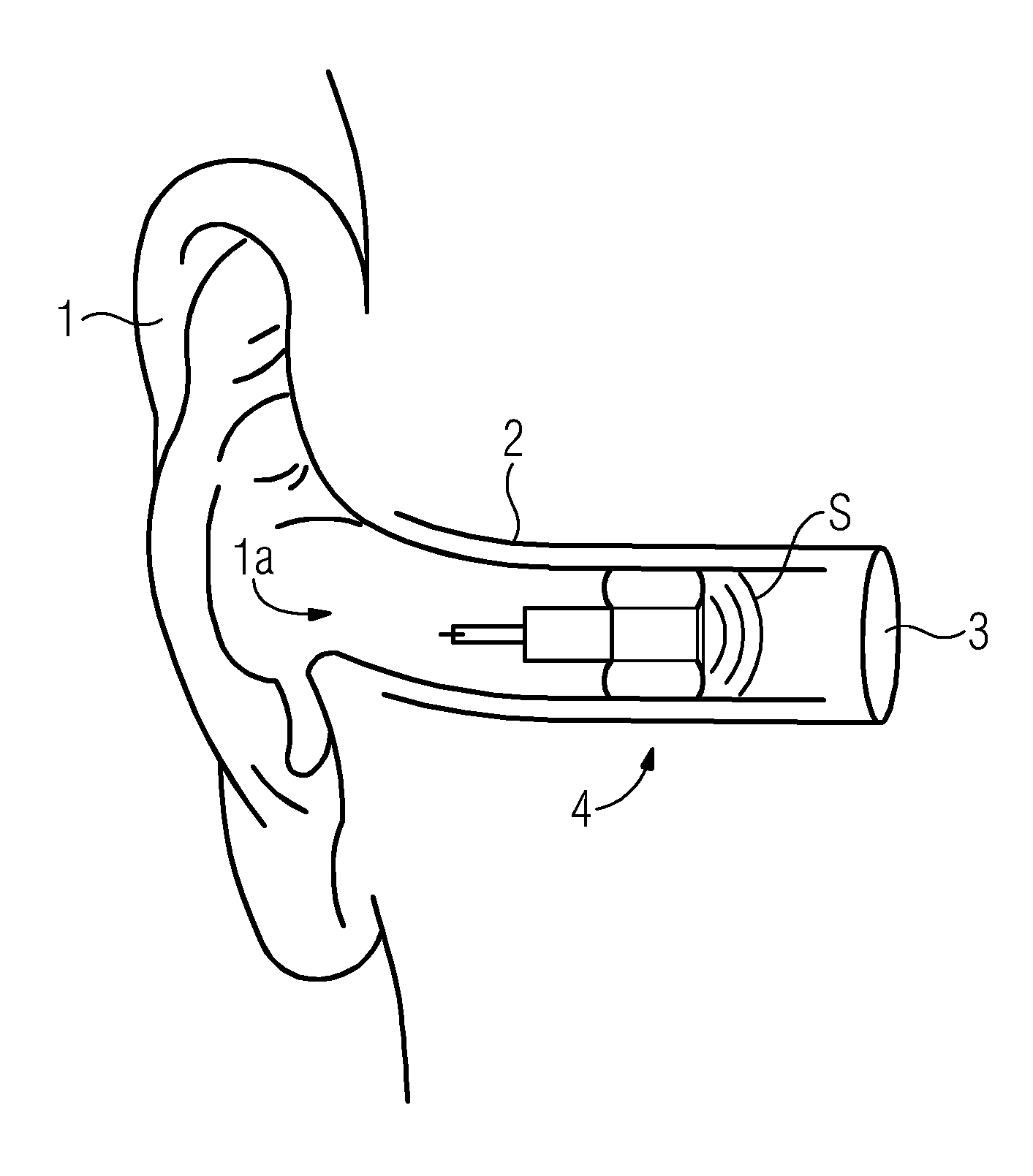

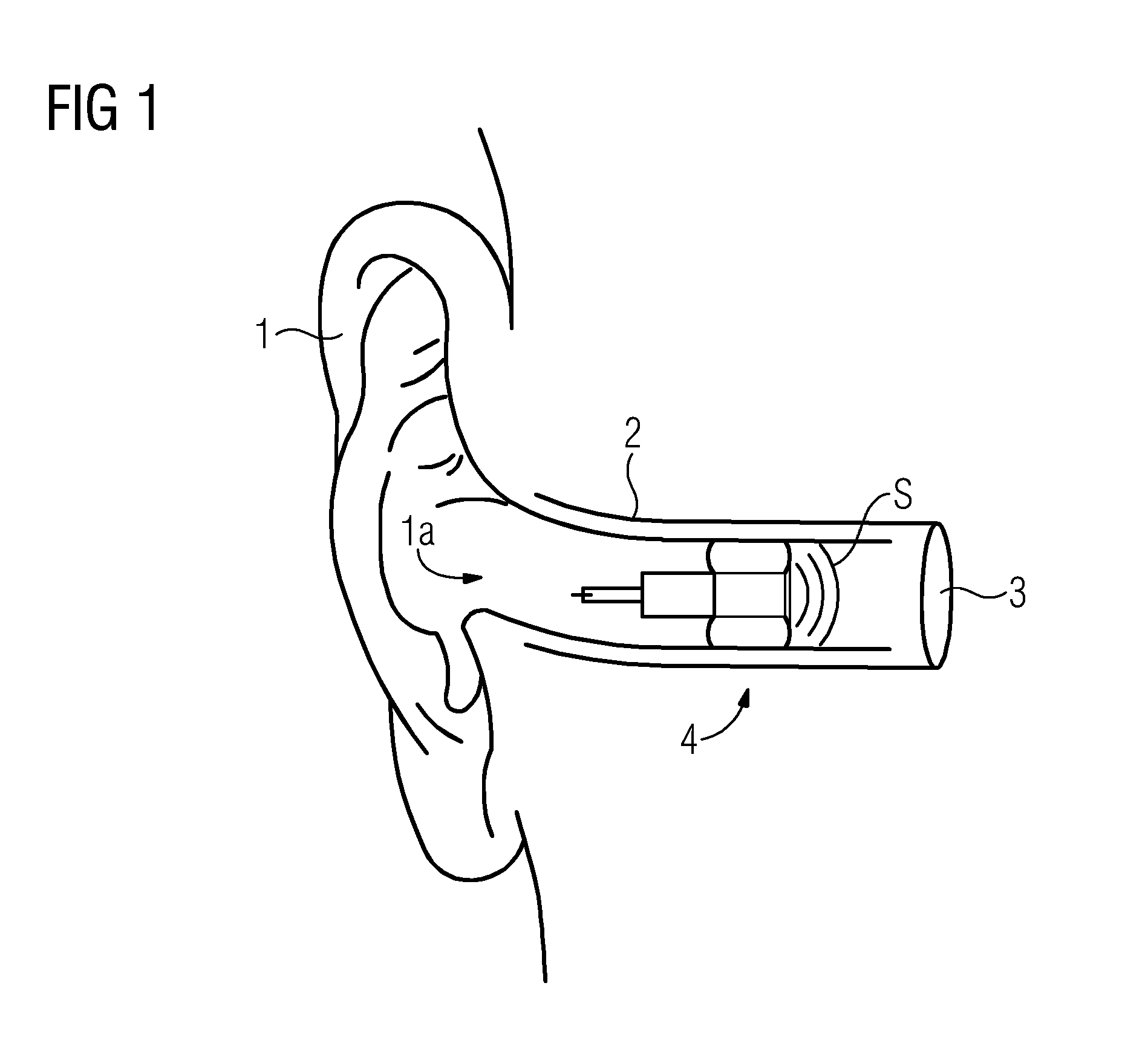

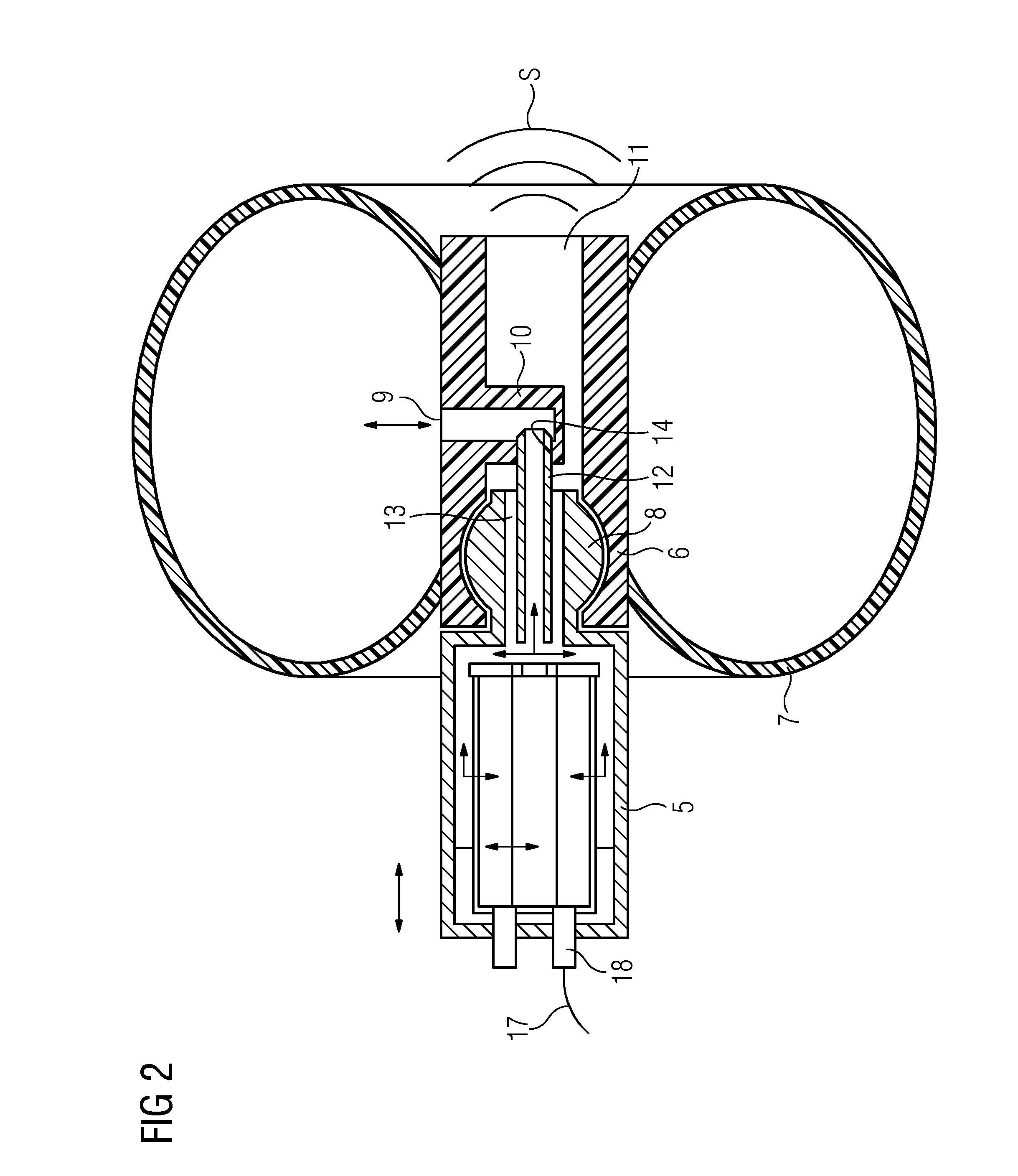

Inflatable ear mold connection system

InactiveUS8548181B2Easy to assemblePlace safeIntra aural earpiecesHearing aids housingExternal Auditory CanalsEngineering

Owner:SIVANTOS PTE LTD

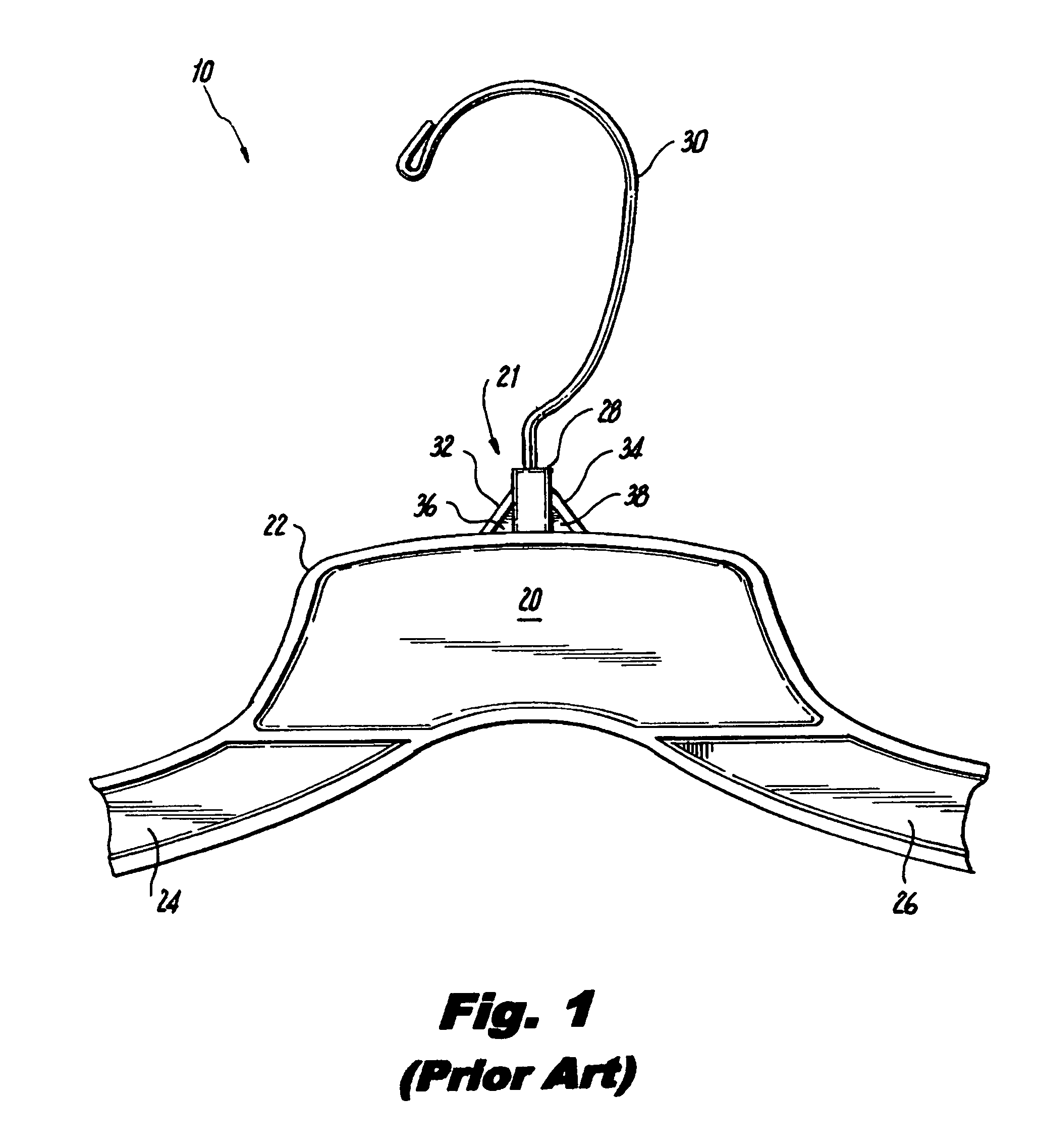

Lower neck indicator for wire hook hangers

In a lower neck sizer for a garment hanger and a combination turnable wire hook hanger and lower neck sizer, the lower neck sizer includes a body dimensioned to generally surround a cylindrical projection and the support flanges adjacent to the body flange of the hanger, and an inwardly extending tab secured to the sizer body configured to engage the hanger at the lower neck region to resist removal. The inwardly extending tab may have a relief to accommodate a cylindrical projection of the hanger and a finger directed towards the intersection between a support flanges and the cylindrical projection. Alternately, the inwardly extending tab may have an upward surface located to engage the body flange. The lower neck sizer may include a downward extension, the inwardly extending tab being carried by the downward extension. Alternately, the inwardly extending tab may include a plurality of substantially radial projections located at an upper surface of the lower neck sizer, and dimensioned to engage the wire hook. The lower neck sizer can have a discontinuity traversing the height of the body to facilitate mounting on the hanger.

Owner:PROSPERITY PROD HK LTD

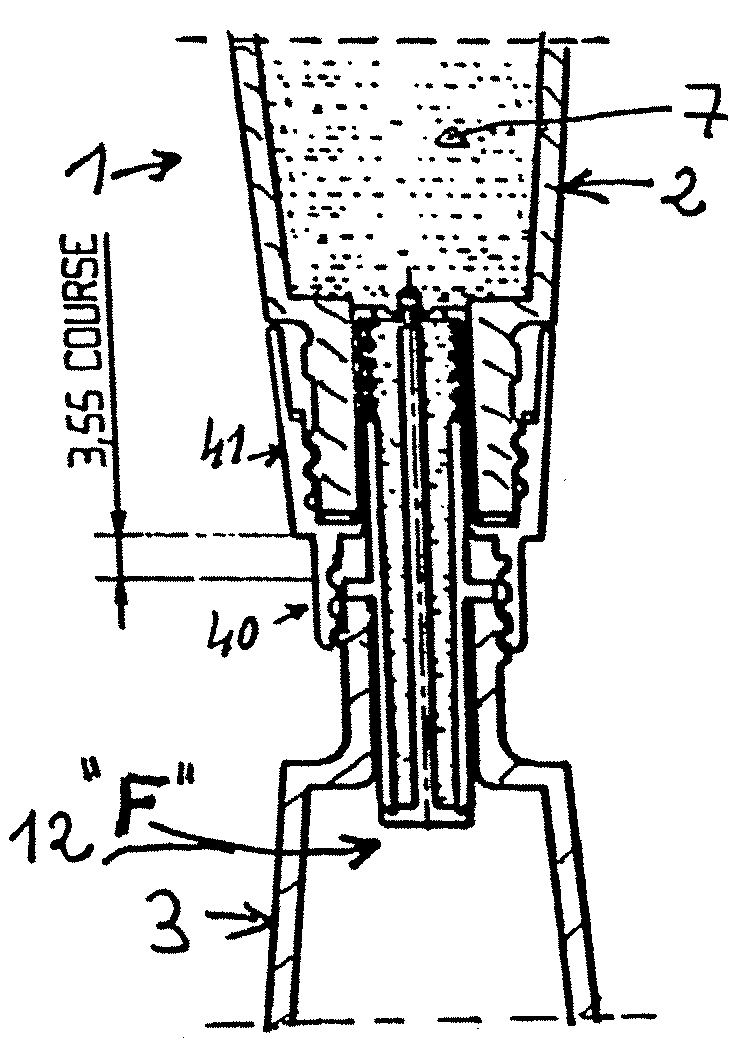

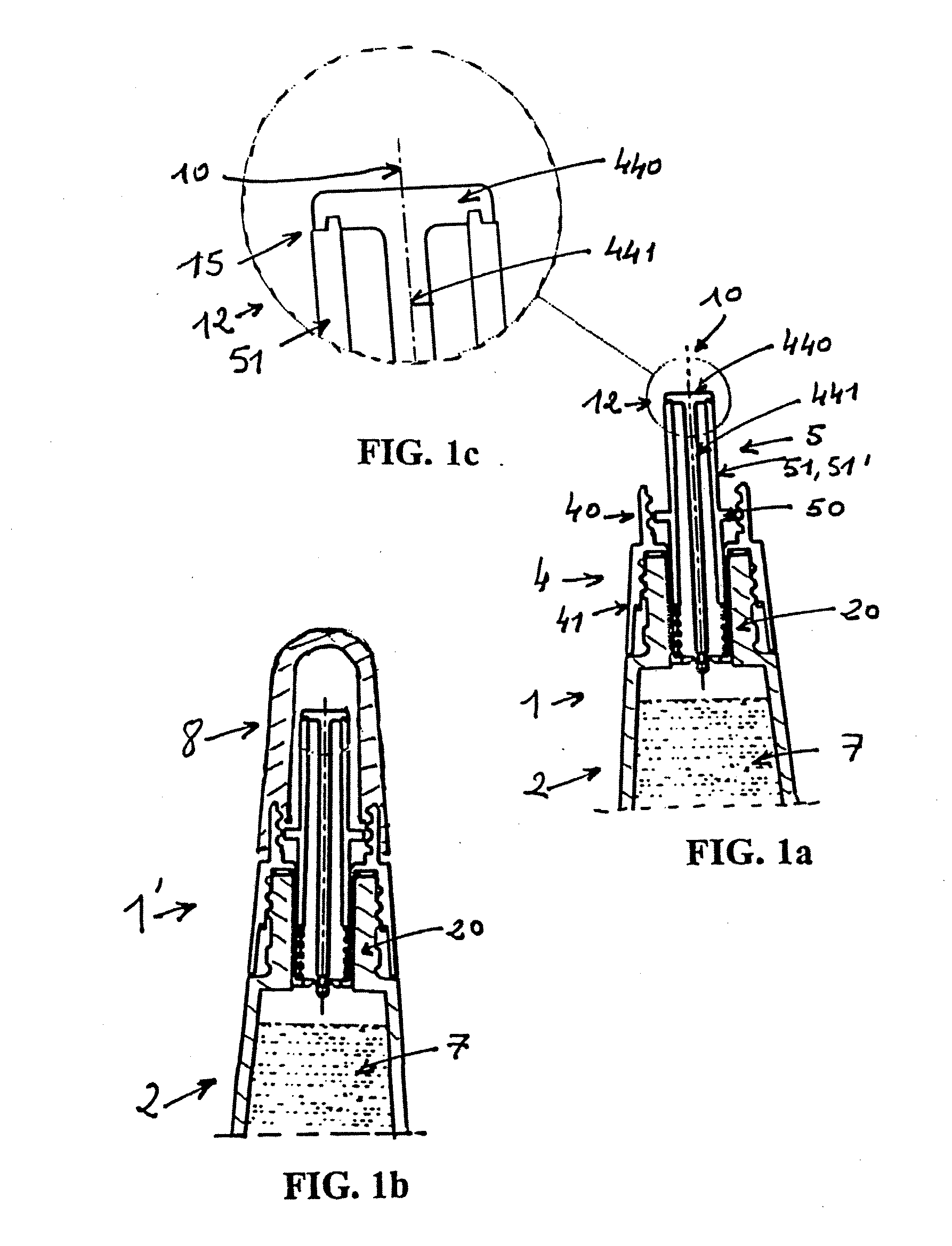

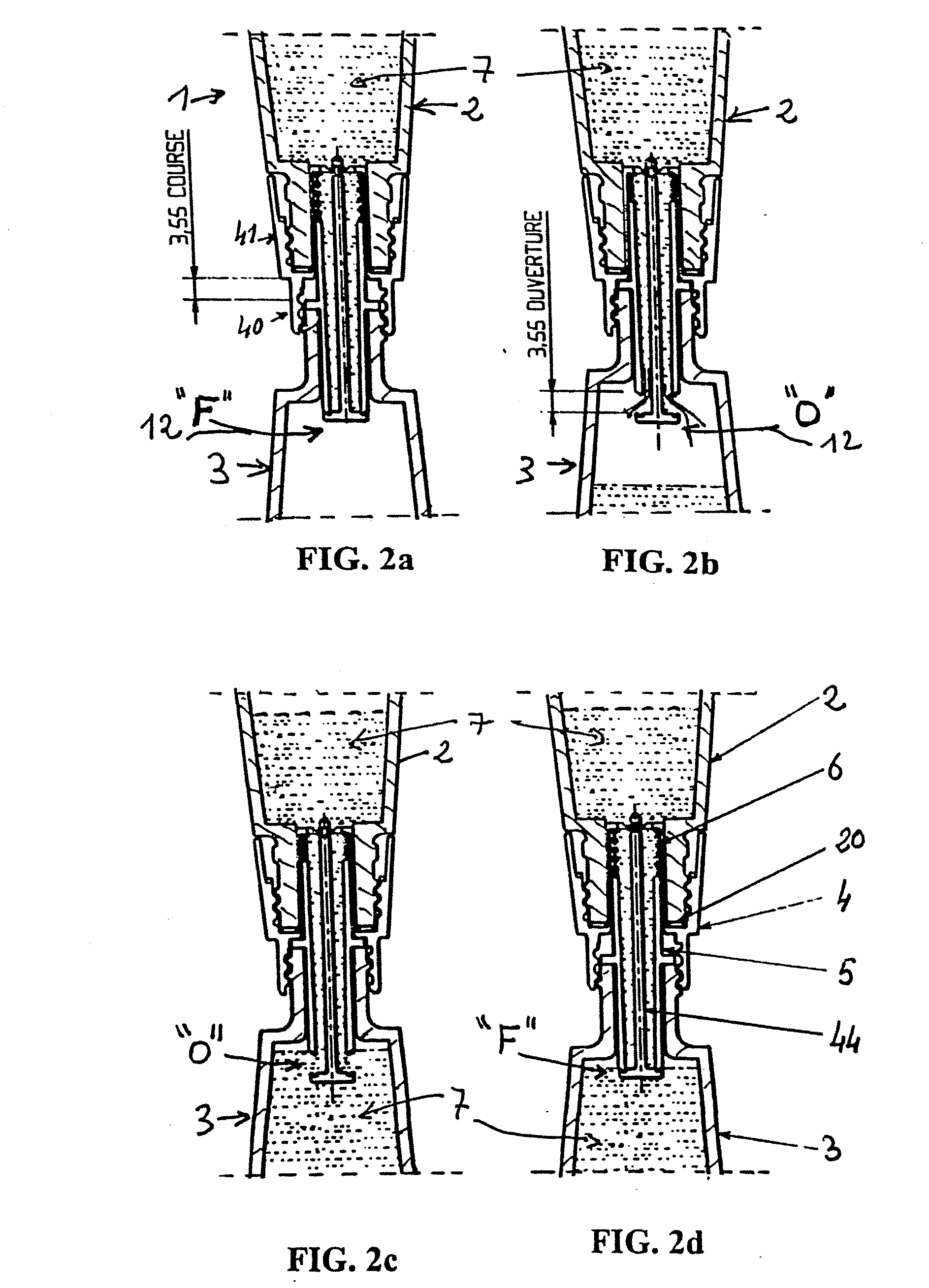

Refill device for dispensing a cosmetic product

A device for refilling a first container, fitted with a threaded first neck and a vaporization head, includes a second container for a liquid, a connection component including a first bearing plate for engaging the first neck and a second bearing plate engaging the second container, a median wall including a central orifice, and a means of closing the second container or the central orifice. The connection component engages an axially movable component capable of sliding inside the connection component, to form a valve, the movable component being able to move, under the action of an axial constraint, from a closed position “F” to an open position “O”, or, under the action of a spring, from the position “O” to the position “F”. The movable component includes a radial projection for engaging the first neck so that the first neck exerts an axial constraint on the radial projection.

Owner:ALCAN PACKAGING BEAUTY SERVICES

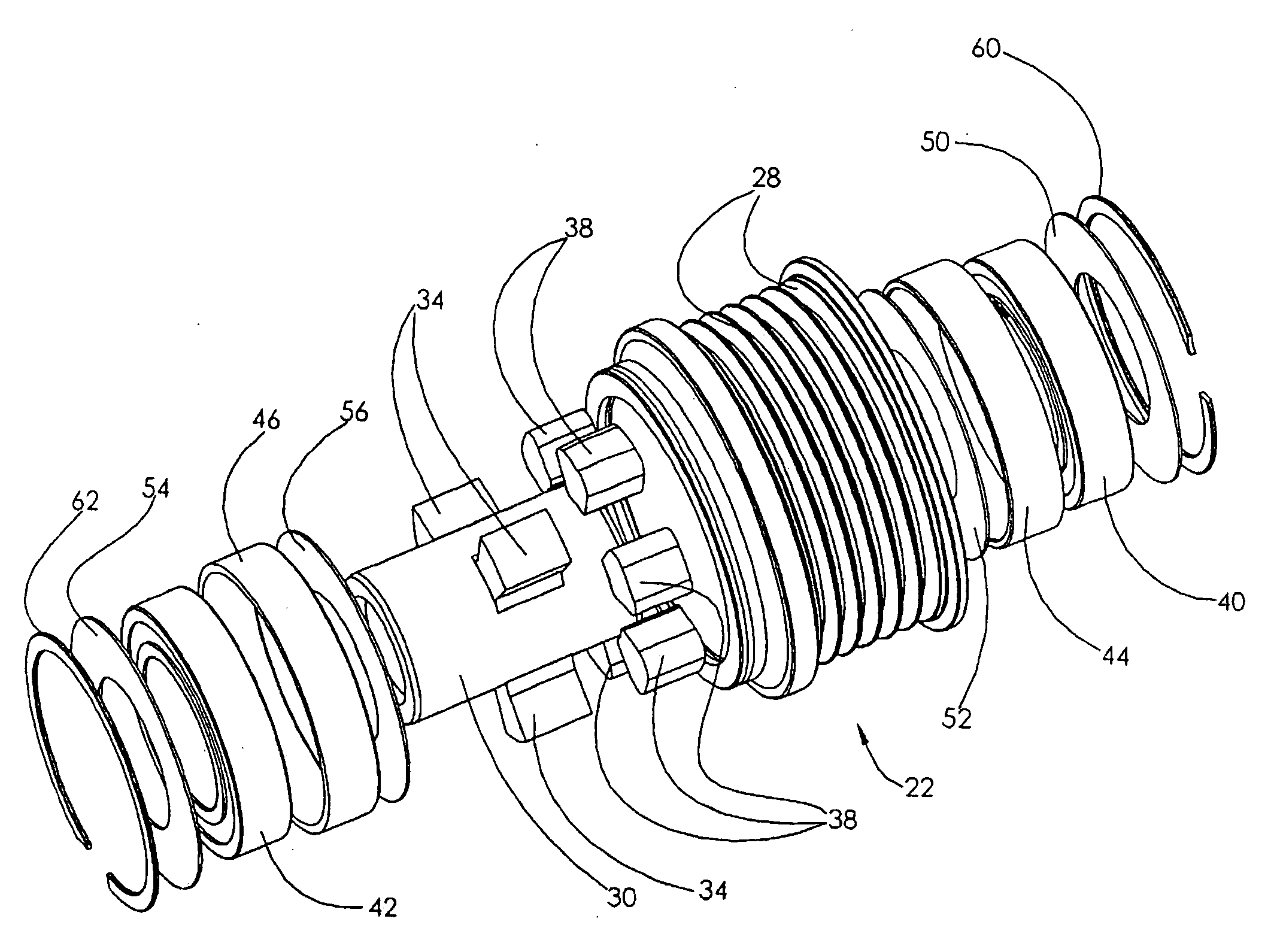

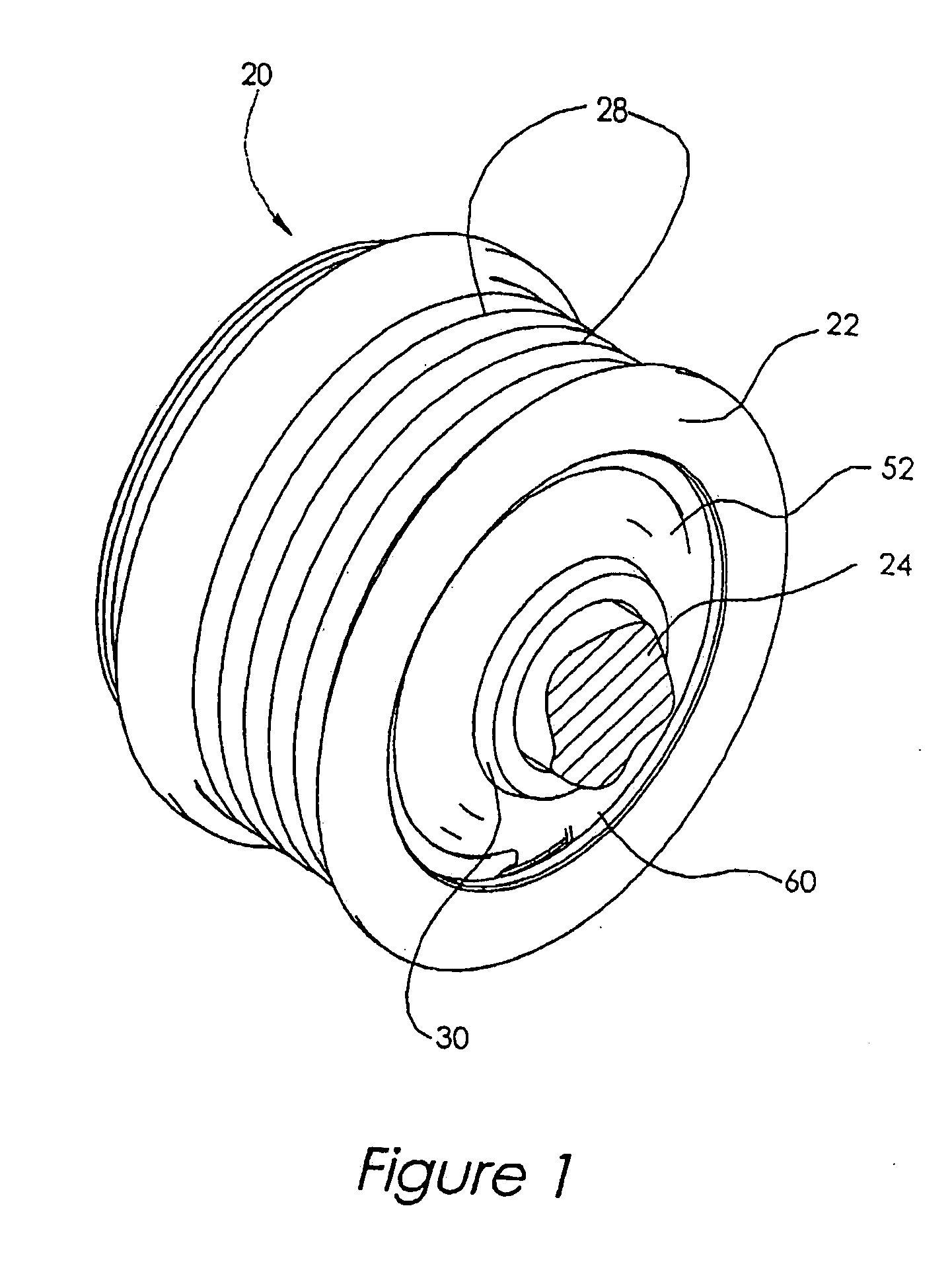

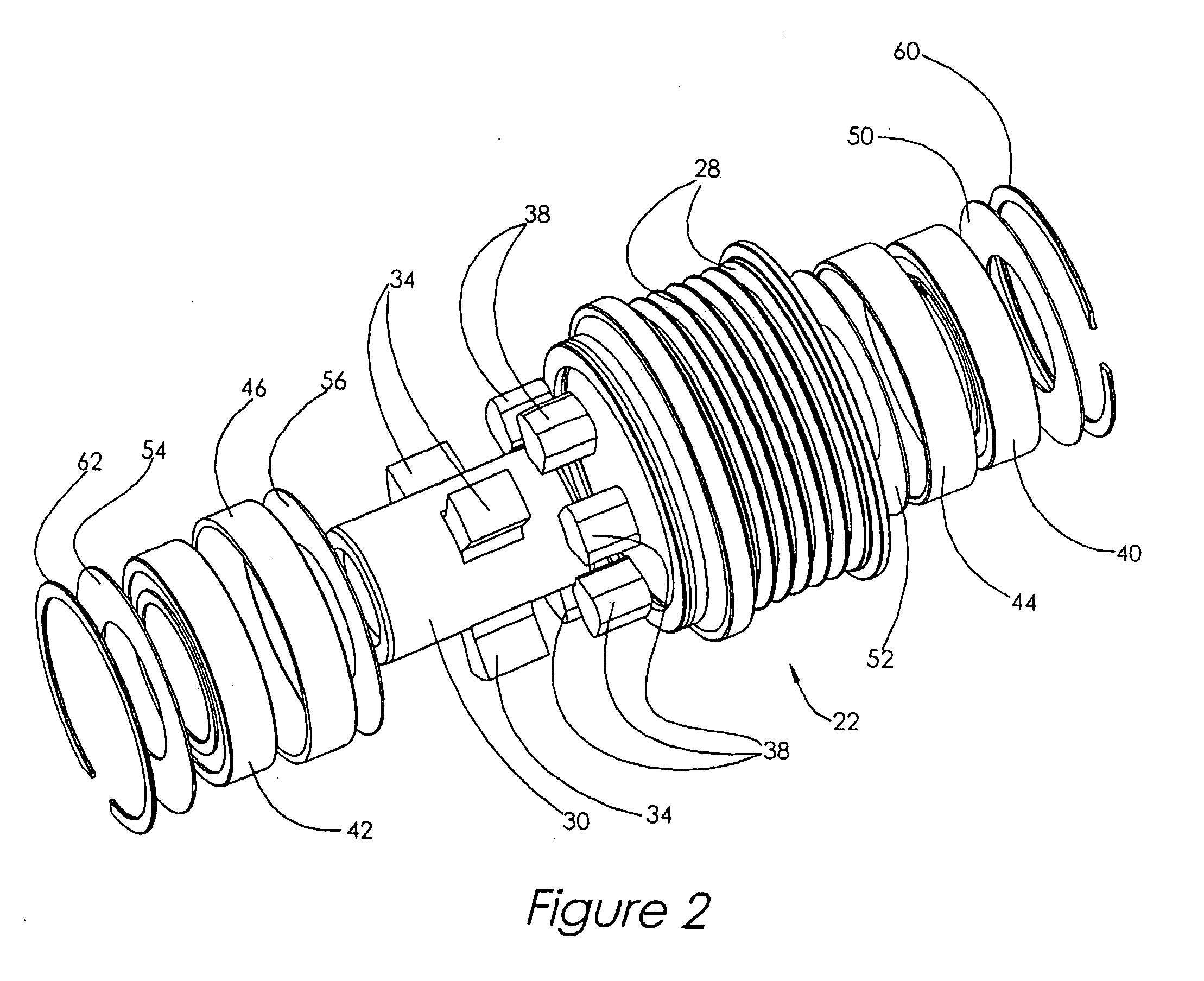

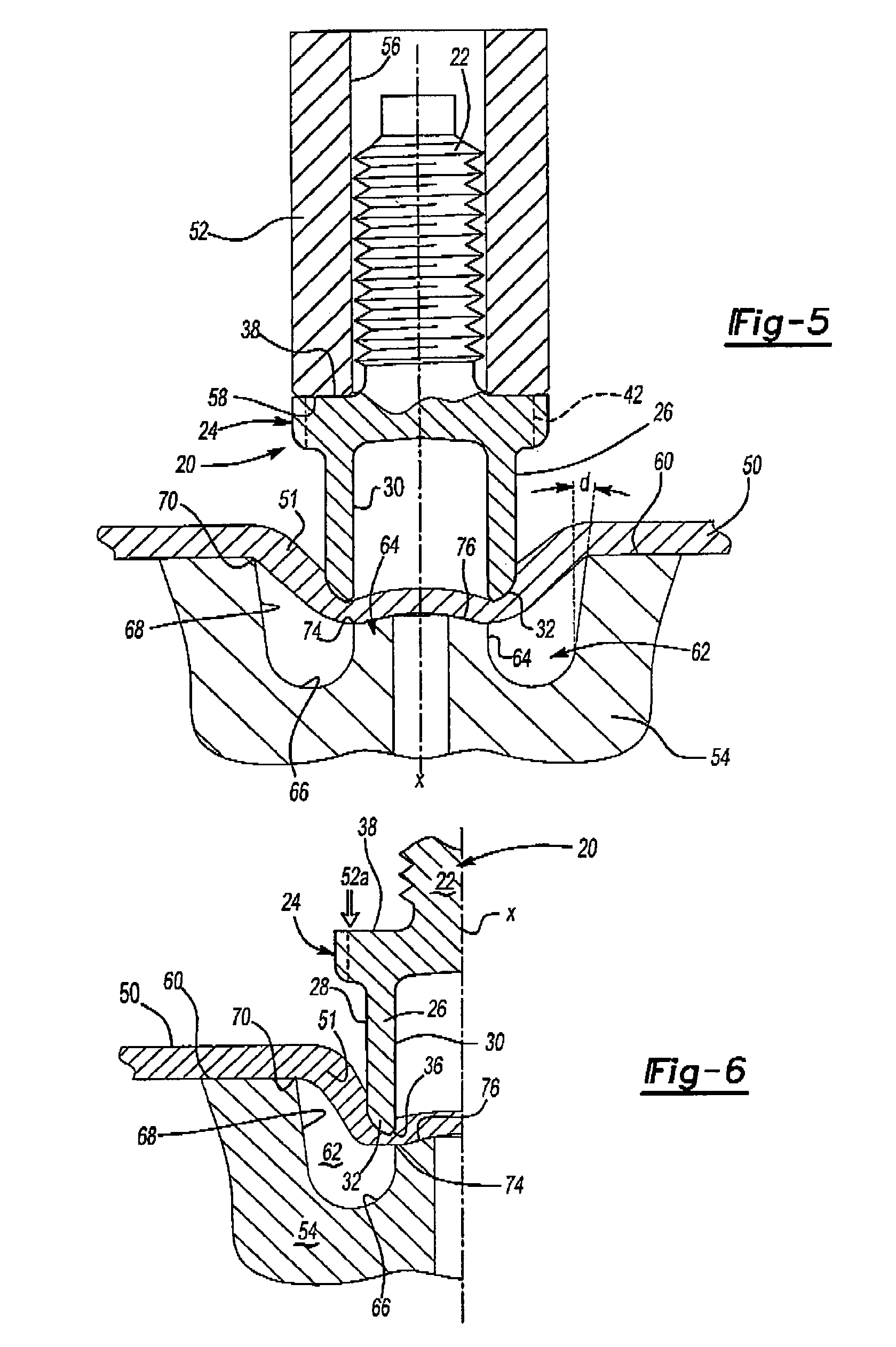

Polymer spring controlled pulley assembly for rotary devices

InactiveUS20100255943A1Shorten speedReduce the impactYielding couplingPortable liftingAlternatorAngular rotation

A drive system for a rotary device, such as an automotive alternator compensates for and reduces the effect of sudden bidirectional rotational velocity variations of the pulley caused by sudden acceleration and deceleration of an internal combustion engine without using a one-way clutch. The drive system comprises a pulley comprising a tubular barrel having a plurality of radial projections extending inwardly from its inner surface, and a cylindrical hub that is journaled within the pulley and connected to the alternator shaft. The hub has a plurality of radial projections extending outwardly from its outer circumference which are interleaved between the pulley projections. A plurality of solid resilient polymer spring members are disposed in the cavity spaces between the projections. Upon sudden acceleration or deceleration of the pulley, it rotates angularly relative to the hub and shaft to resiliently compress the polymer spring members, which exert a counter restoring force to eliminate the relative angular rotation.

Owner:CT DRIVES LLC A LIMITED LIABILITY COMPANY OF THE STATE OF CALIFORNIA

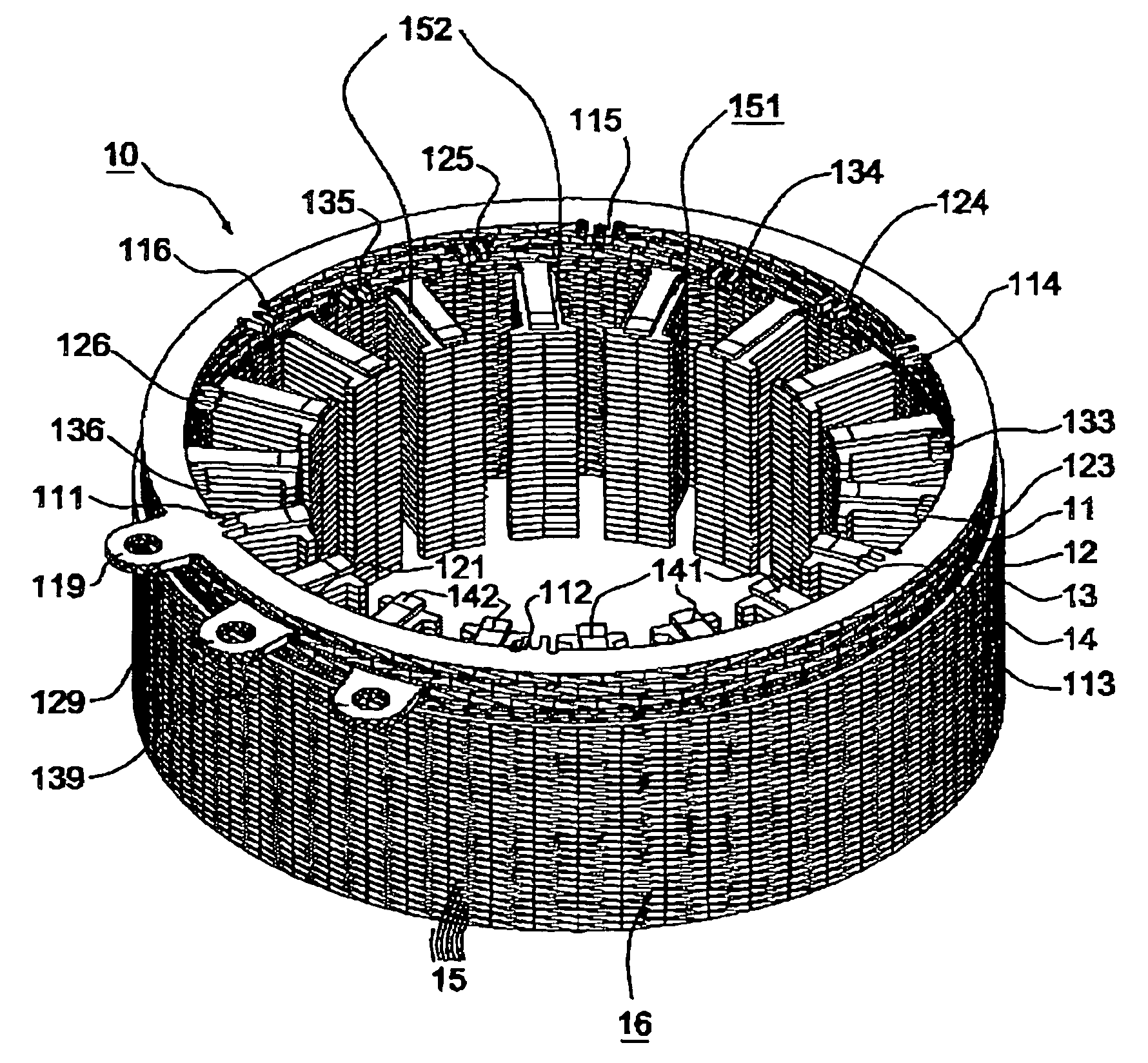

Electric motor

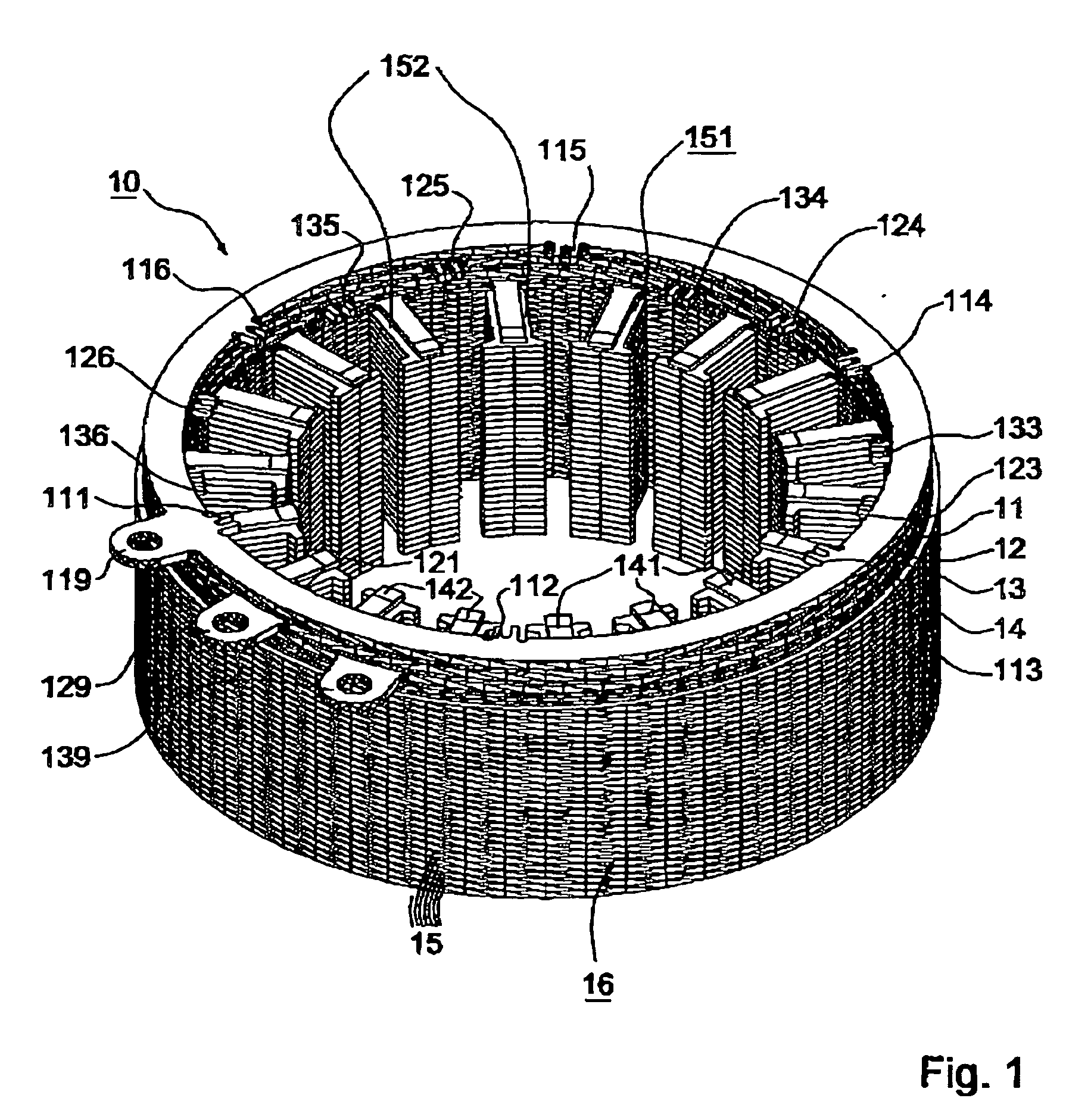

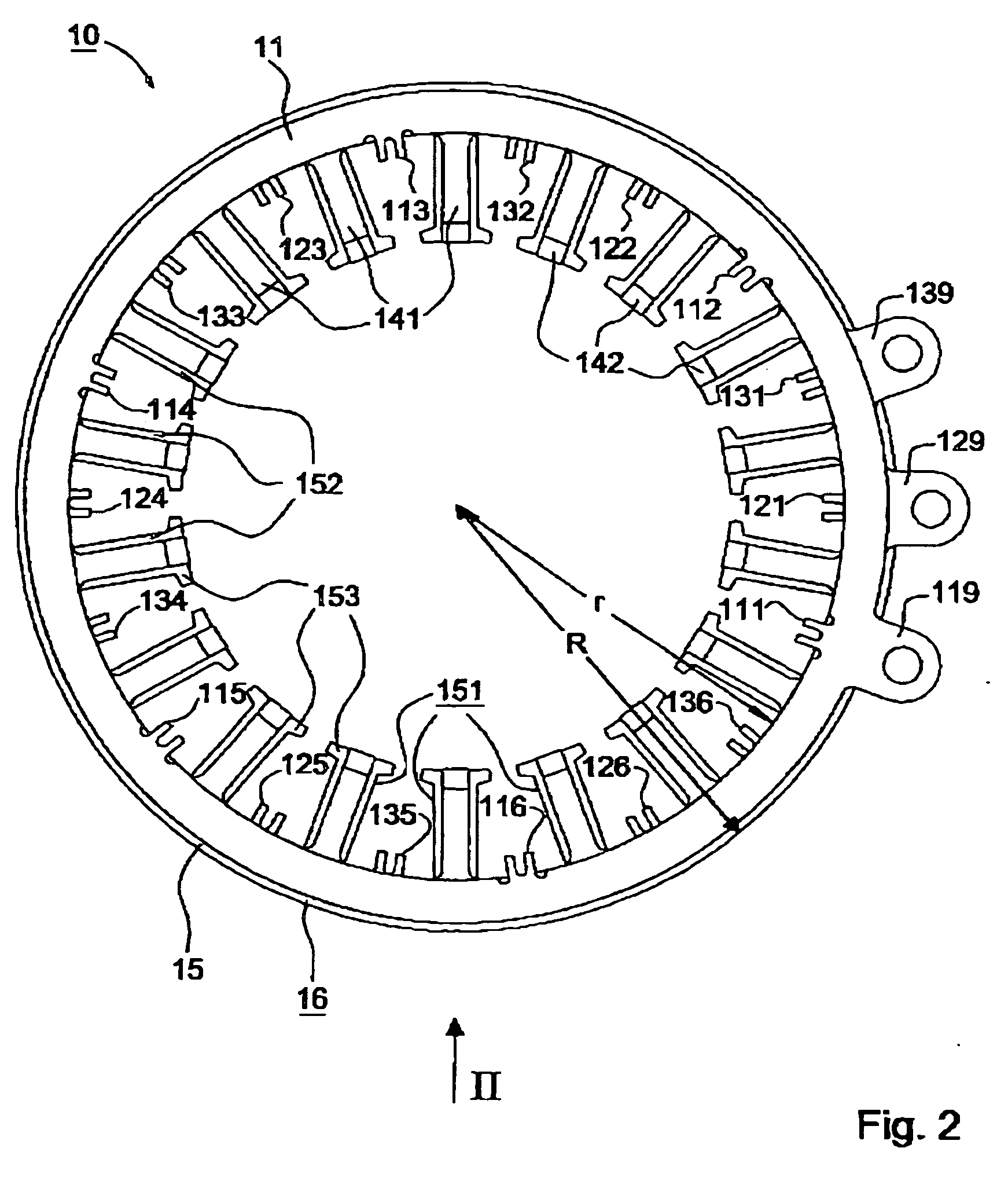

InactiveUS20050023910A1Space minimizationImprove the level ofWindingsMagnetic circuitSize ratioConductor Coil

A compact electric motor has a rotor, and a stator (10) having a alotted lamination stack (16) defining slots separated by teeth, said teeth having tooth heads (153). Partial windings (17) are arranged in said. On at least one axial end of said lamination stack, jumper rings (11, 12, 13) and a neutral ring (14) are arranged. The latter has a plurality of inwardly extending radial projections (141) having free ends (142) adapted for connection to ends (171) of said partial windings (17). Connection of partial windings (17) in parallel provides a favorable power / size ratio and substantial pour output, even with low operating voltage.

Owner:EBM PAPST ST GEORGEN & -

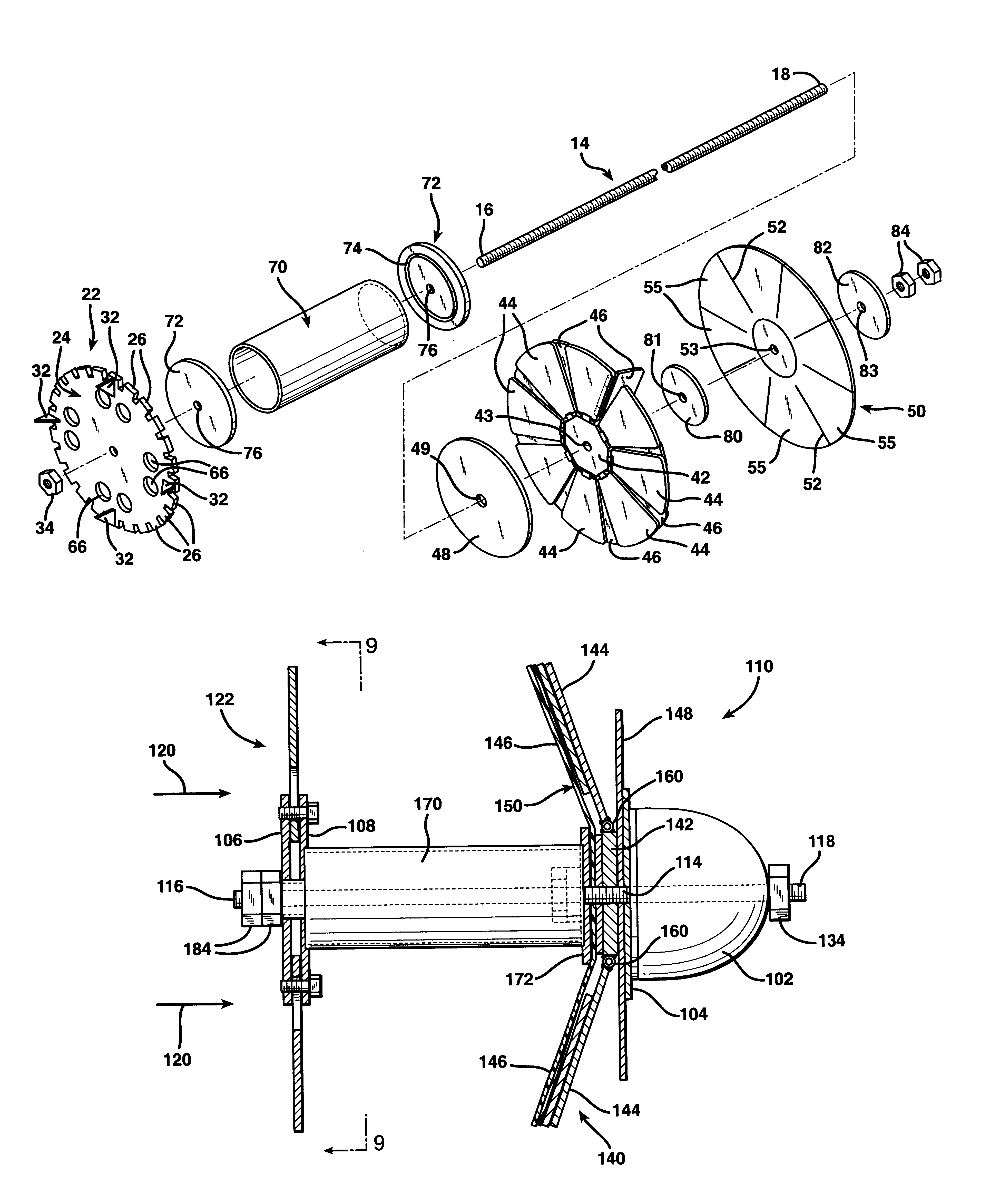

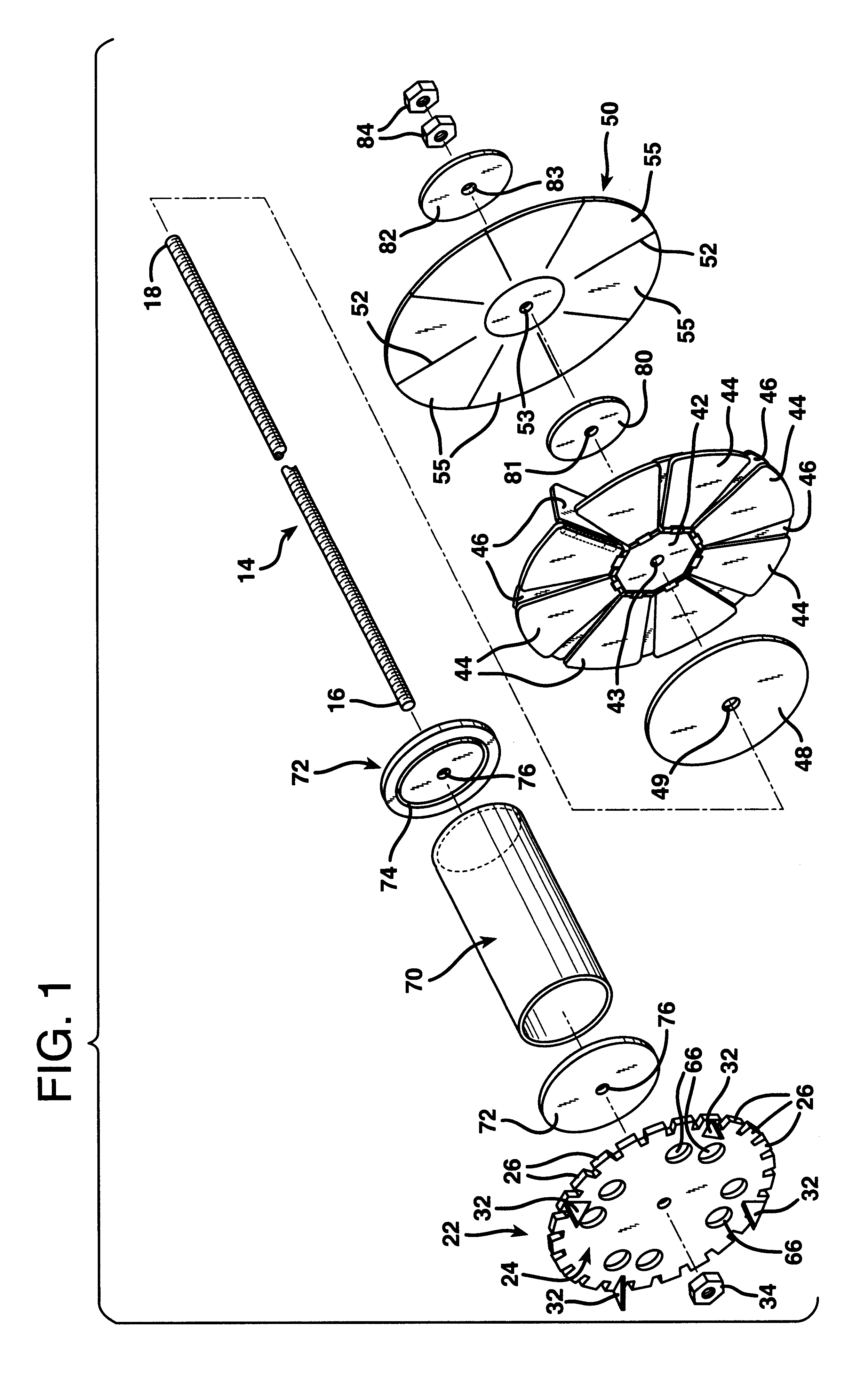

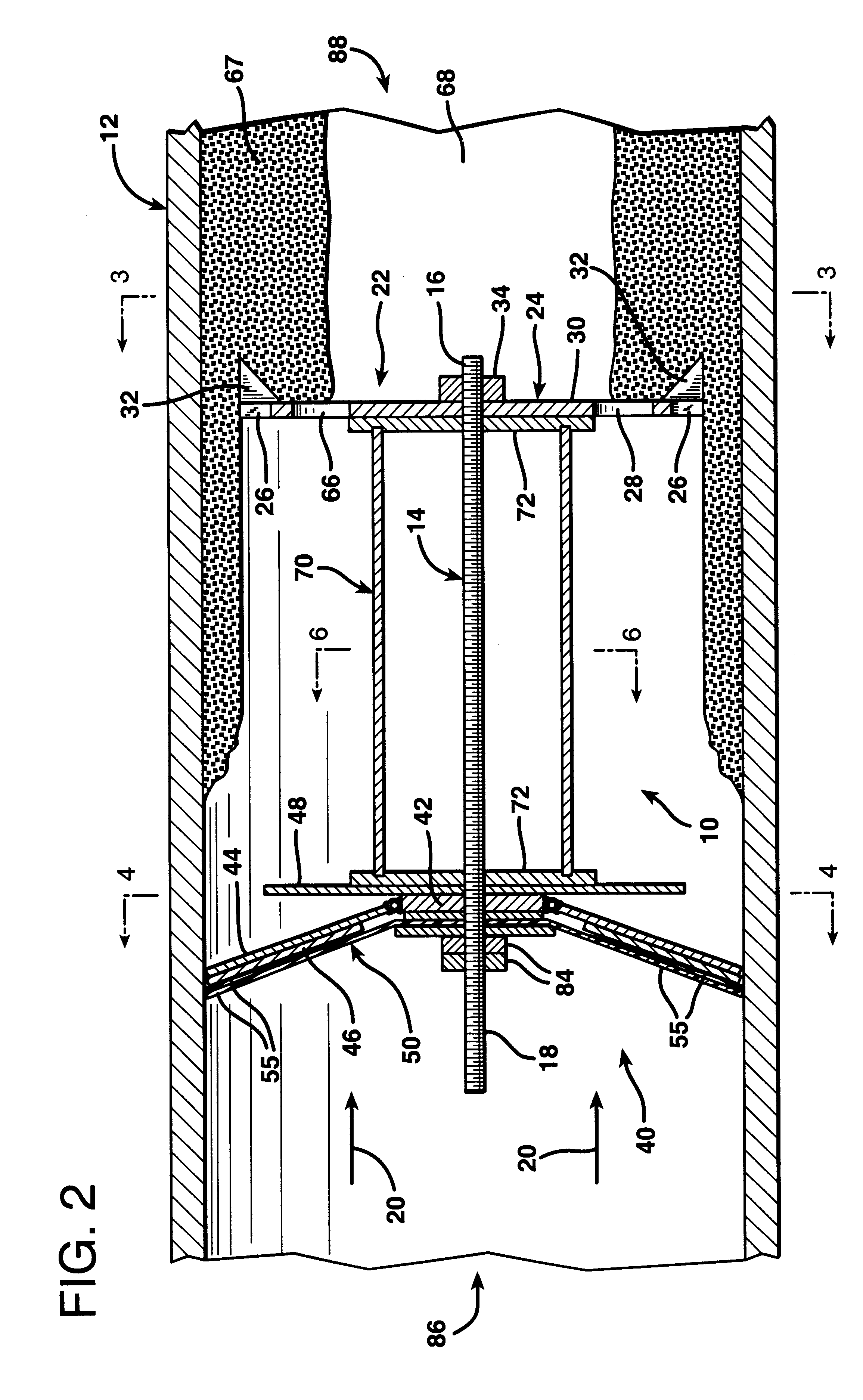

Pipeline cleaning tool and a method of cleaning pipelines

A pipeline cleaning tool is constructed with an elongated support mechanism having a rigid cutting unit mounted at one end and a folding propulsion assembly mounted at the other end. The propulsion assembly includes a system of folding sector panels that are hinged to a central hub for rotation relative thereto about tangential axes of rotation. A separate expansion flap is secured to each sector panel for rotation relative thereto about a radially oriented axis of rotation by a hinged connection to one radial side edge. Each expansion flap partially overlaps the upstream face of the sector panel immediately adjacent to that upon which it is mounted. The area of overlap is controlled by the extent to which the sector panels of the propulsion unit are folded back toward the supporting shaft. The greater the extent of folding, the greater will be the area of overlap of each expansion flap upon the upstream face of an adjacent sector panel. A disc-shaped backing seal is employed immediately adjacent the sector panels and the expansion flaps against the upstream faces thereof. A pressure differential is thereby formed across the propulsion unit which propels the cleaning tool along a section of pipeline to be cleaned. Radially projecting teeth and, in some cases, longitudinally projecting blades, slice through and break up accumulated clogging material that adheres to the inside of the pipeline wall as the pipeline cleaning unit is forced through the pipeline by pressure against the upstream side of the propulsion unit. The distance of radial projection of the teeth of the cutting unit may be made adjustable.

Owner:TNG ENERGY SERVICES

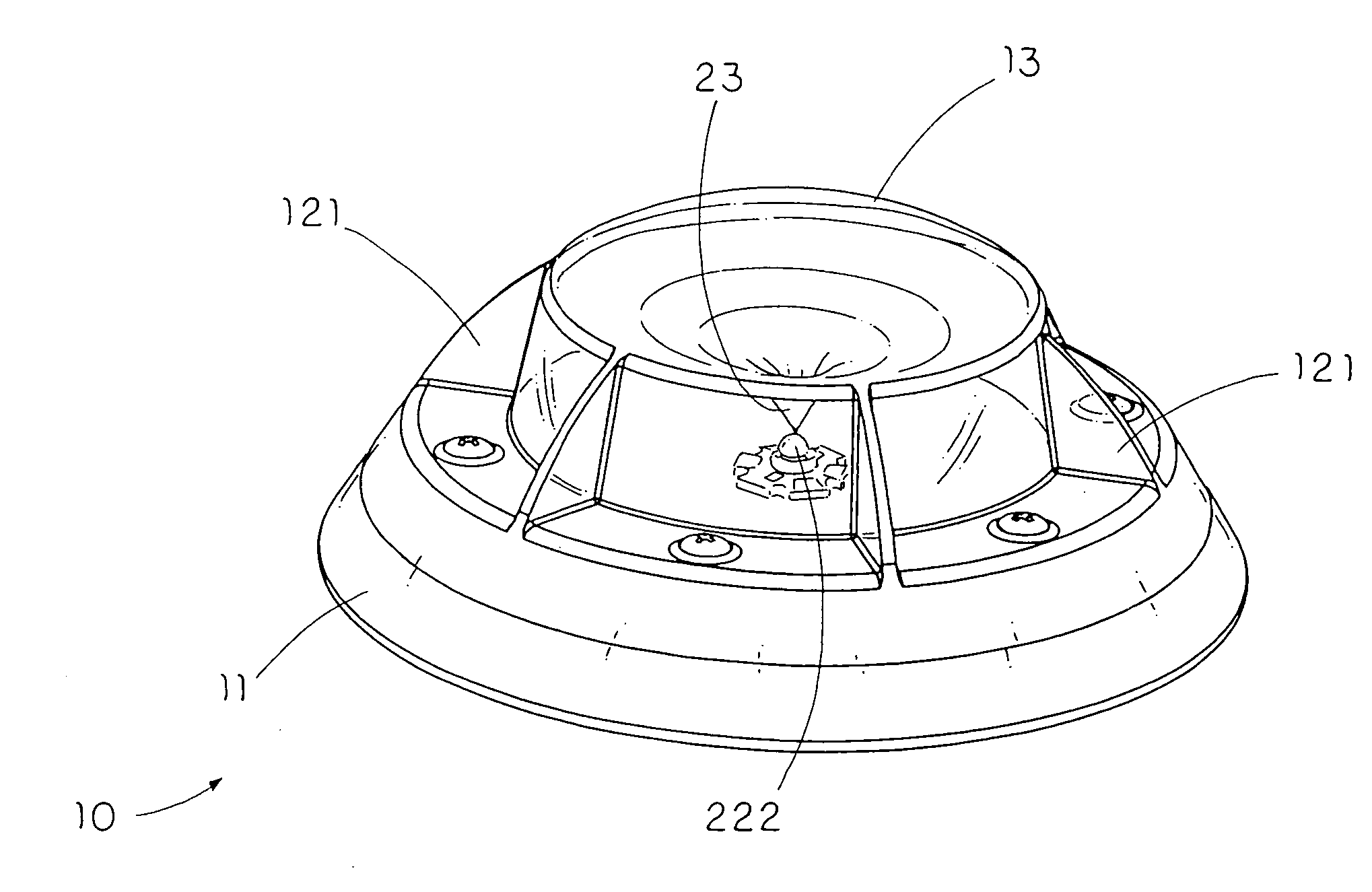

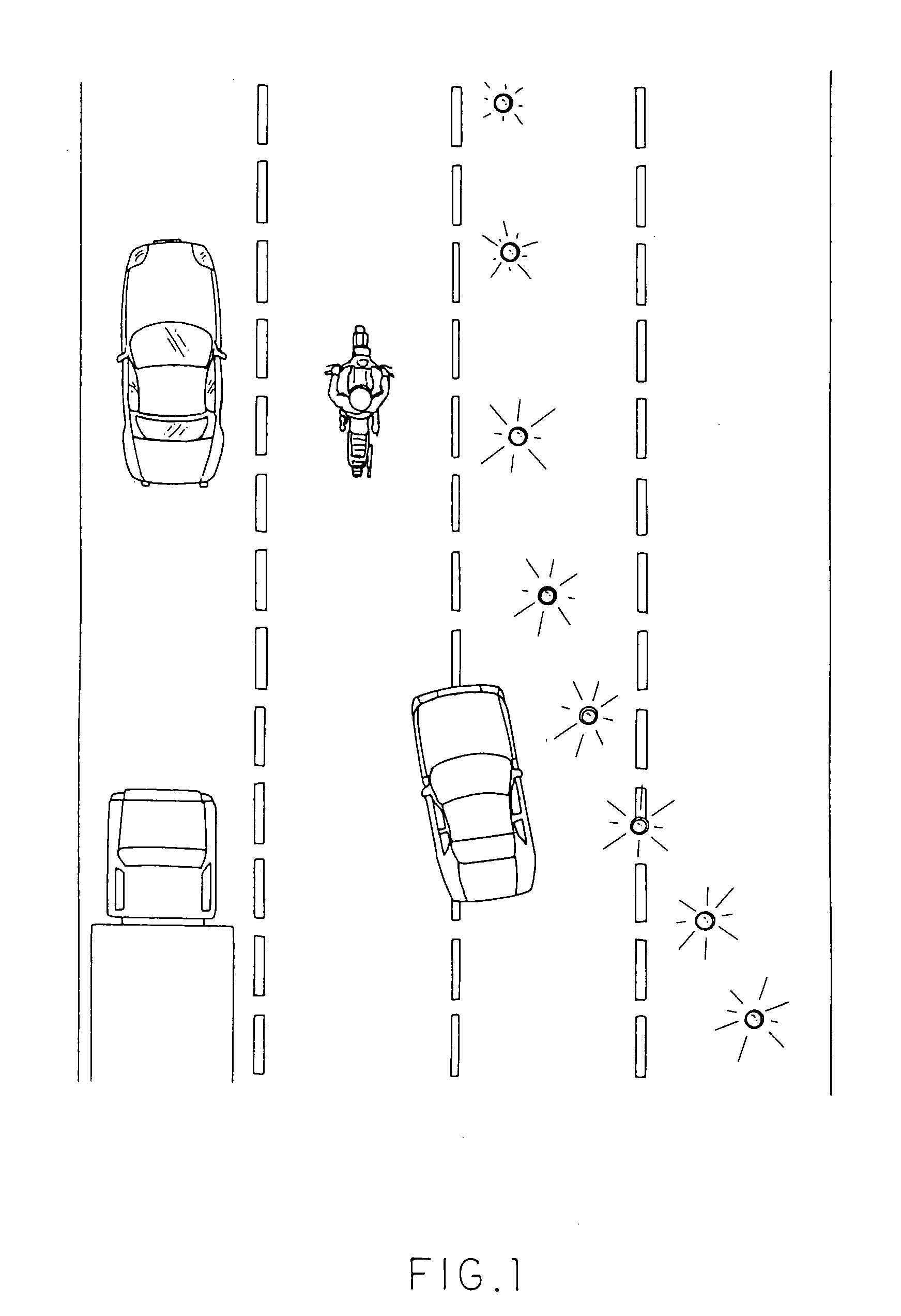

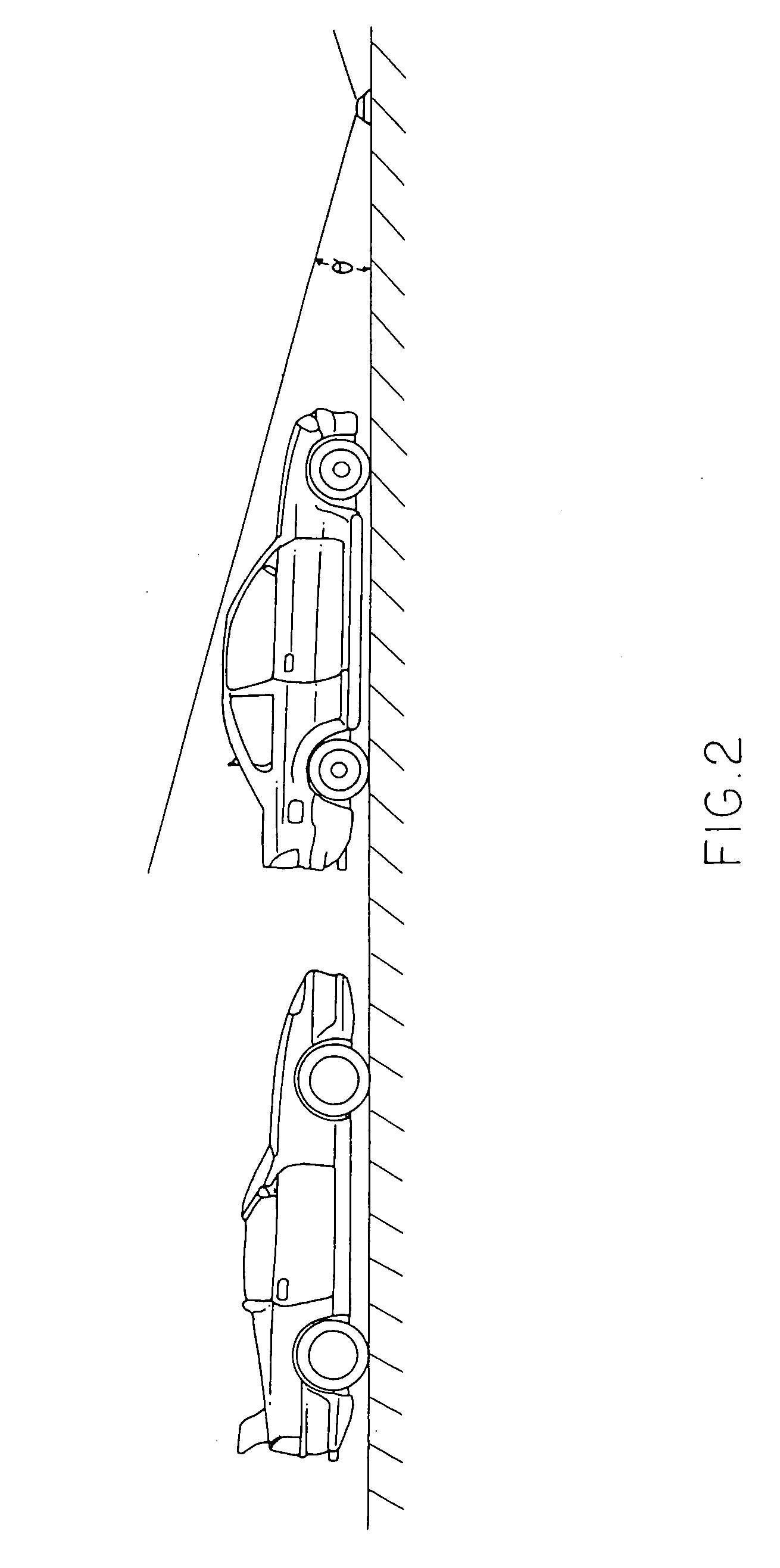

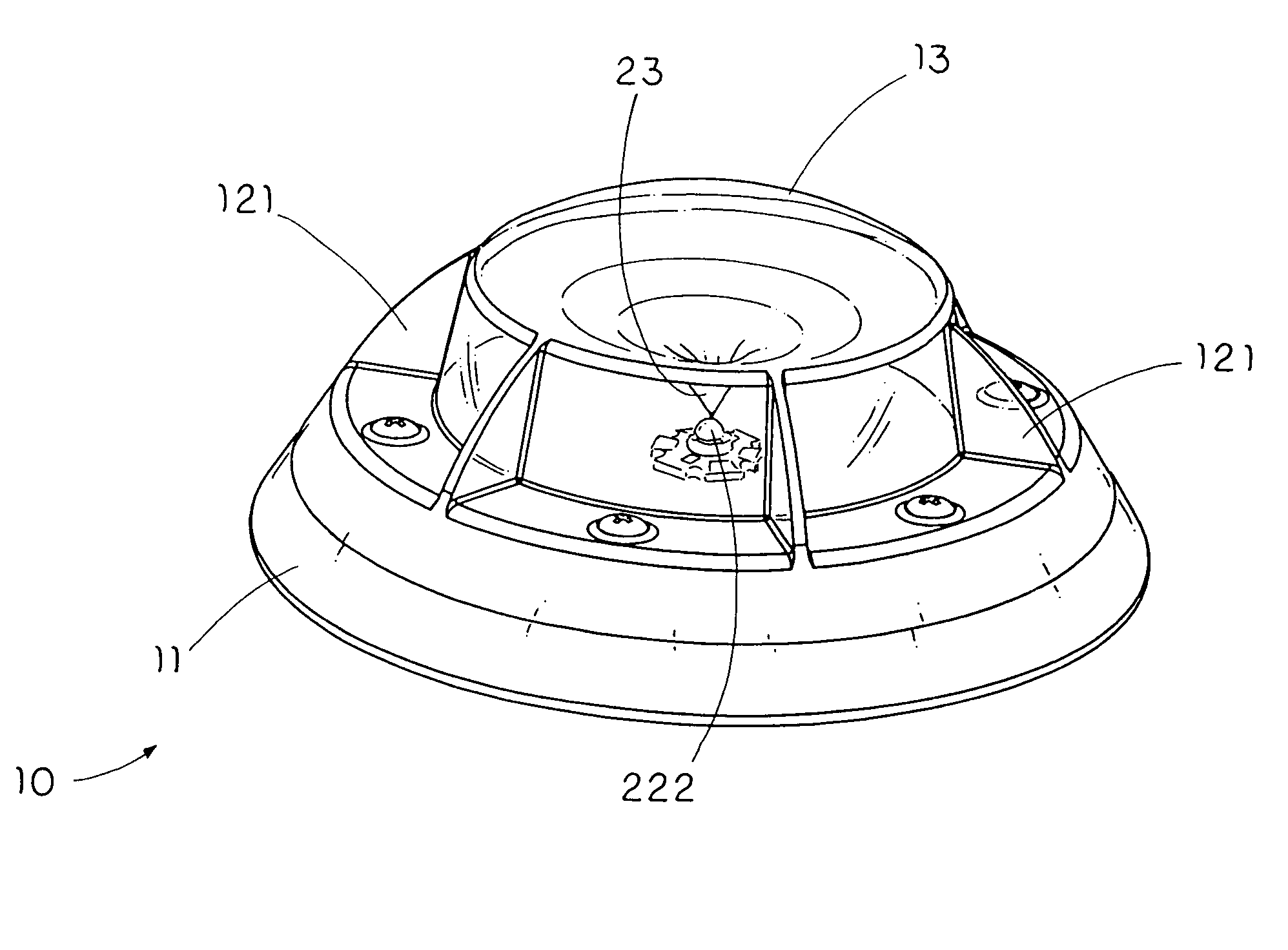

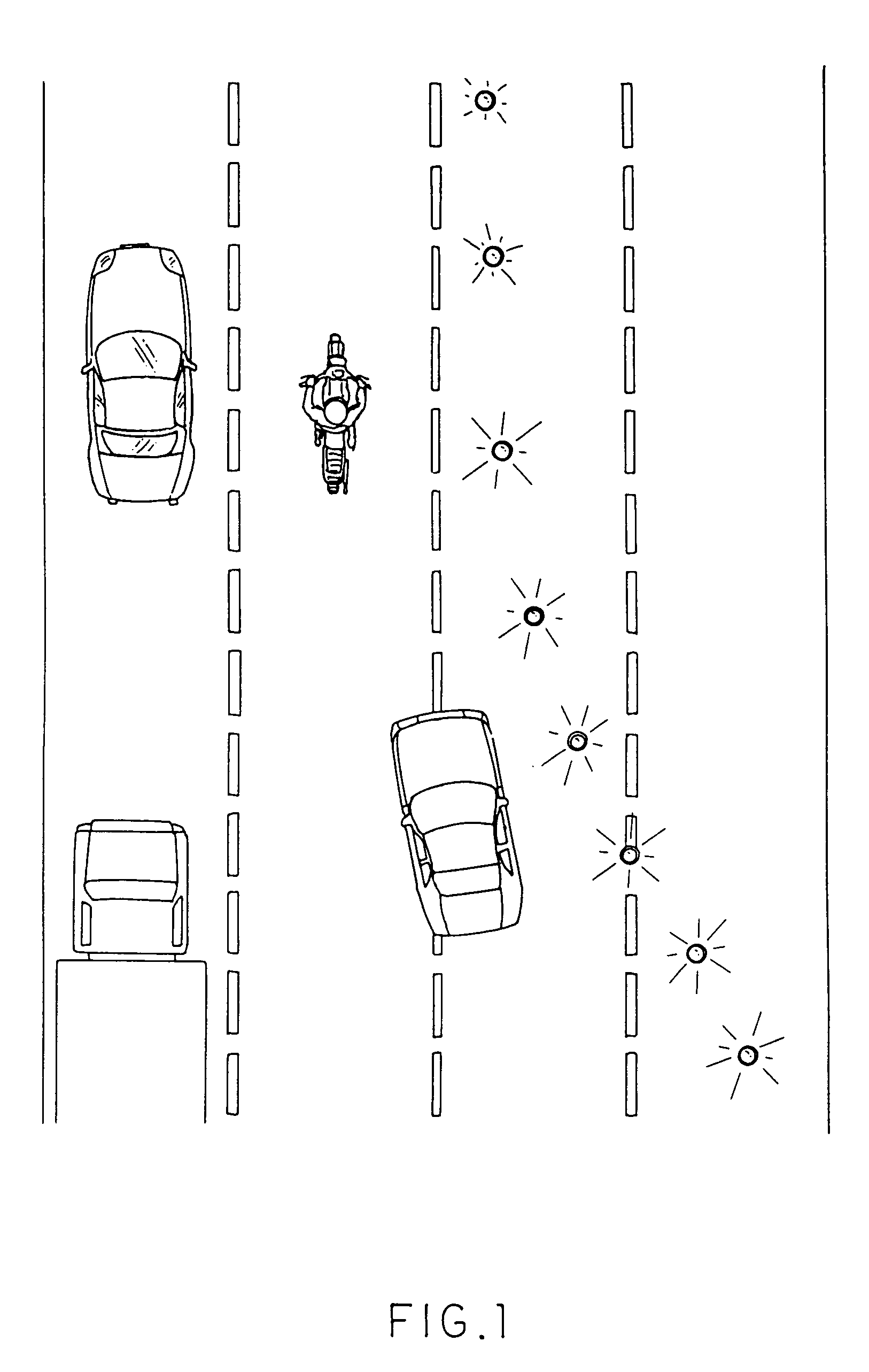

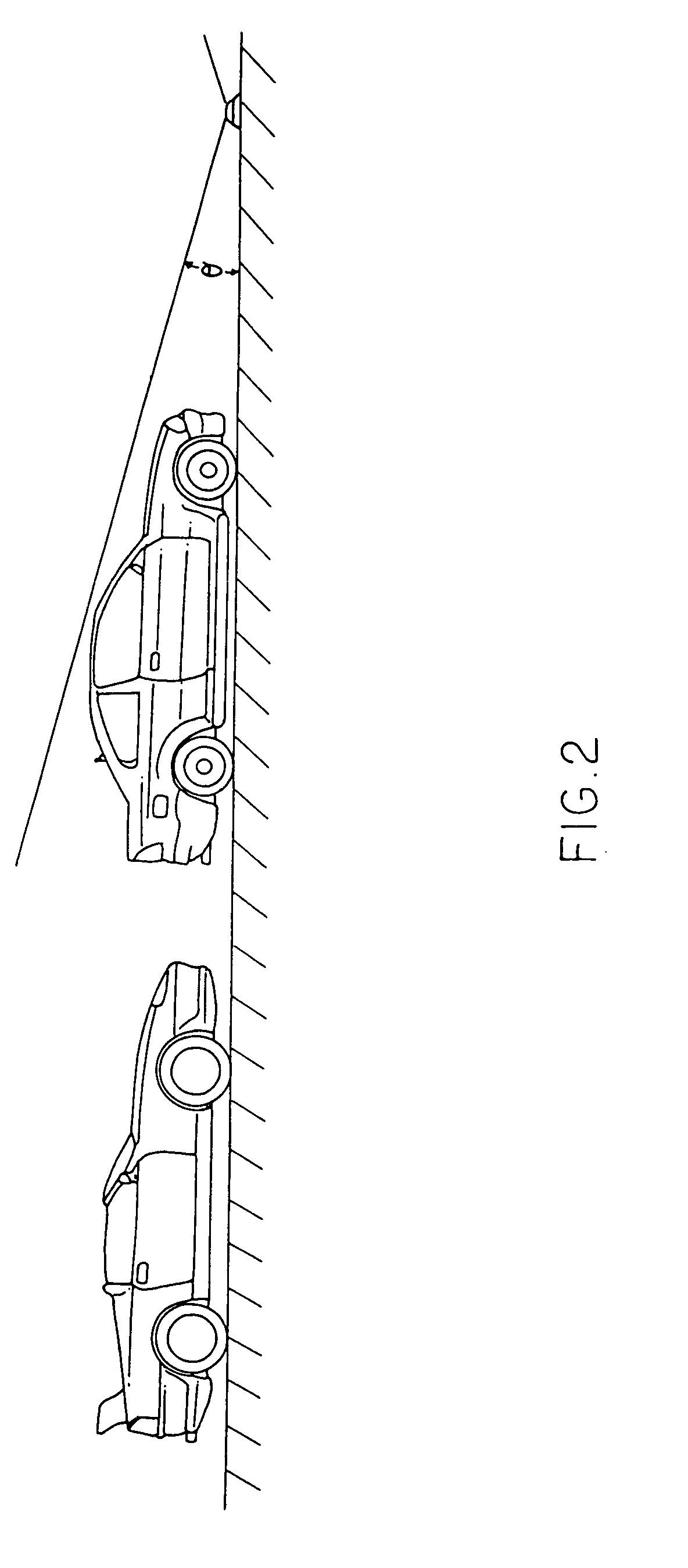

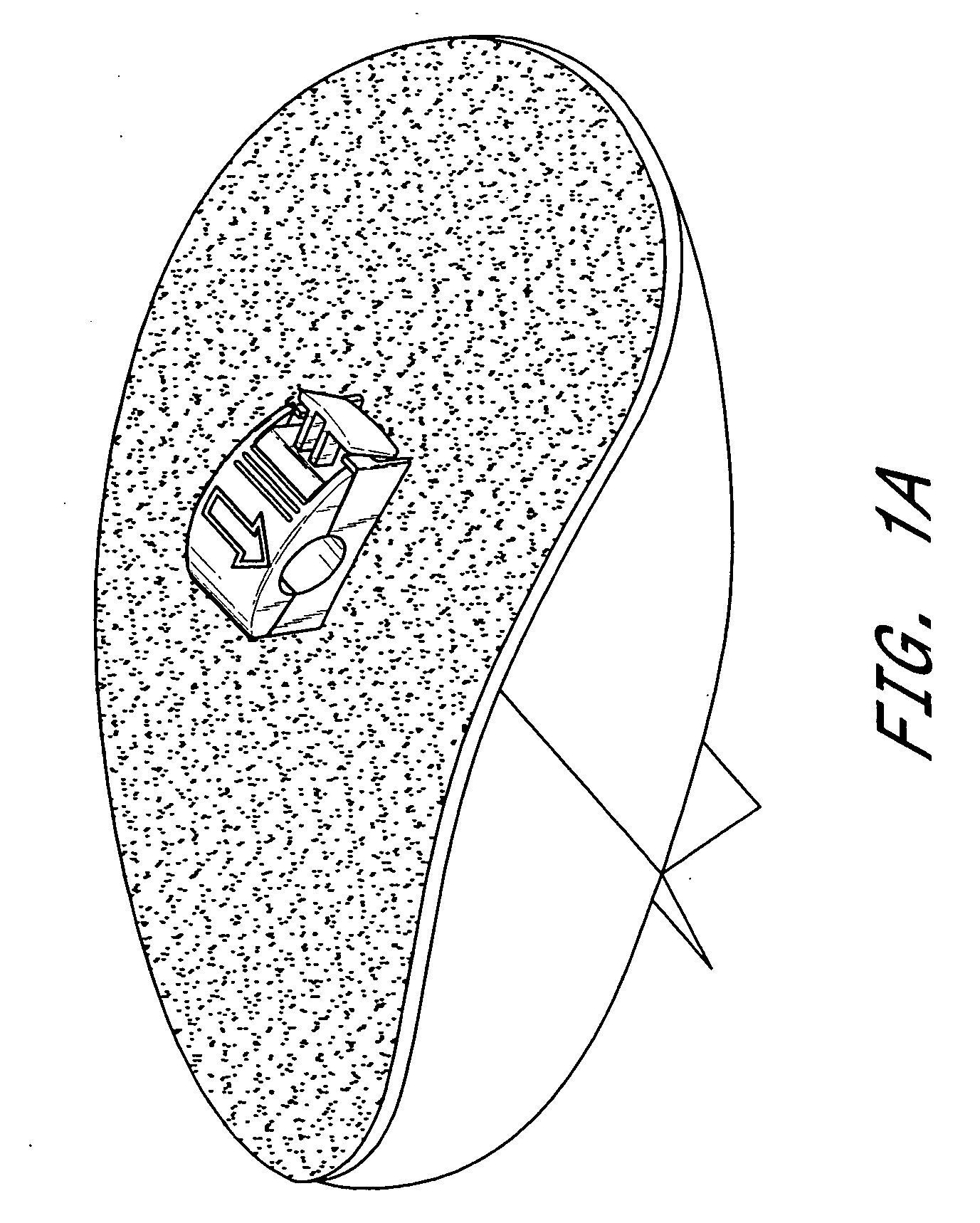

Portable radial projection light source arrangement

InactiveUS20060104054A1Quick to useIncrease awarenessPoint-like light sourceRoad vehicles traffic controlOptoelectronicsLight source

A portable radial projection light source arrangement includes a shelter housing and an illumination unit. The shelter housing includes a protection base having a light source cavity therein, and a supporting frame mounted on the protection base. The illumination unit includes a power source supported in the protection base, a light source disposed in the light source cavity and electrically connected to the power source, and a reflecting member supported at a position coaxially above the light source wherein the reflecting member has a light reflecting surface radially projected from the light source in such a manner that when the light source emits light, the light is radially reflected by the light reflecting surface of the reflecting member to outside.

Owner:COMAN PERRY

Portable radial projection light source arrangement

InactiveUS7111958B2Quick to useIncrease awarenessLighting applicationsPoint-like light sourceLight reflectionRadial projection

A portable radial projection light source arrangement includes a shelter housing and an illumination unit. The shelter housing includes a protection base having a light source cavity therein, and a supporting frame mounted on the protection base. The illumination unit includes a power source supported in the protection base, a light source disposed in the light source cavity and electrically connected to the power source, and a reflecting member supported at a position coaxially above the light source wherein the reflecting member has a light reflecting surface radially projected from the light source in such a manner that when the light source emits light, the light is radially reflected by the light reflecting surface of the reflecting member to outside.

Owner:COMAN PERRY

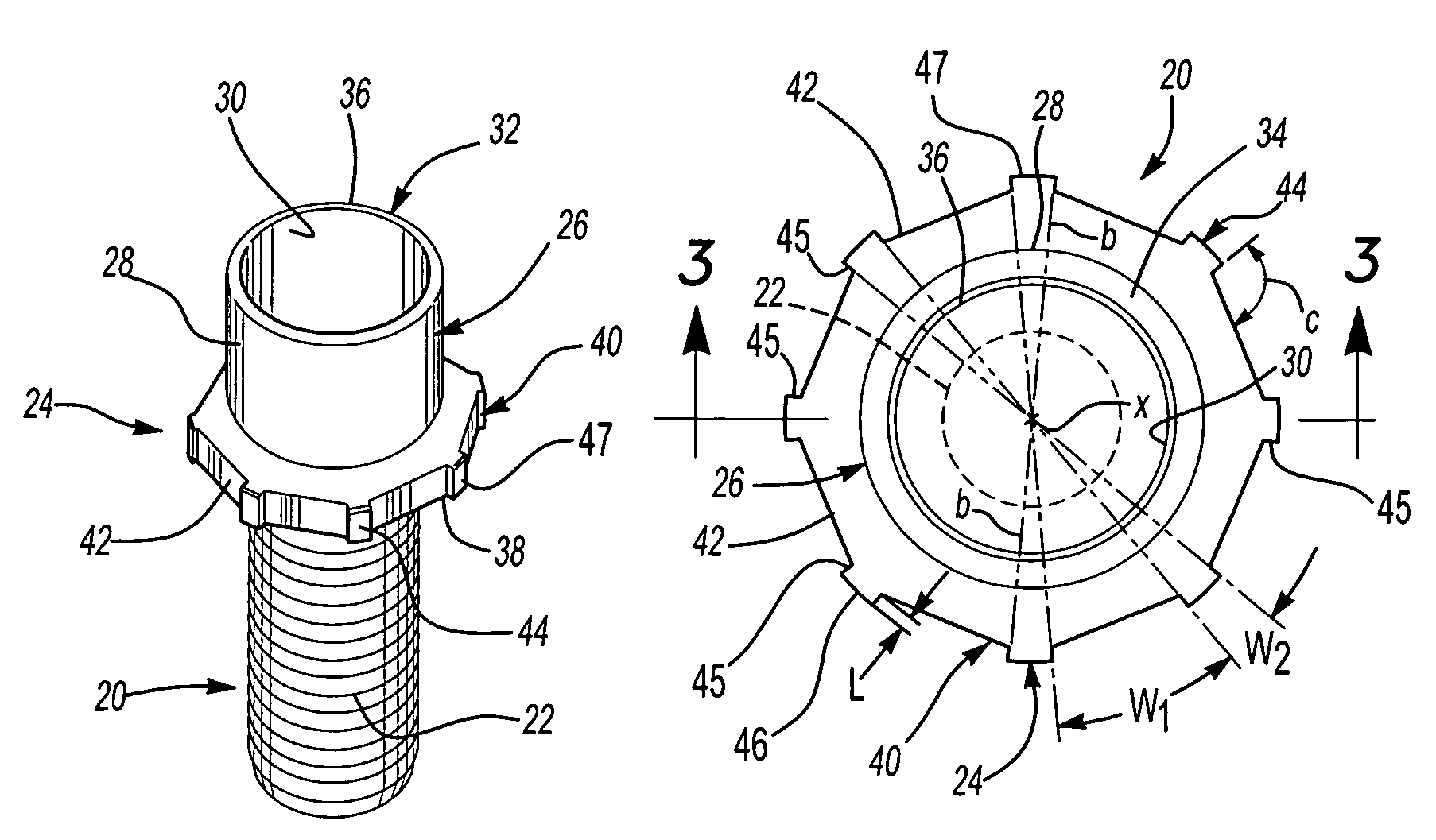

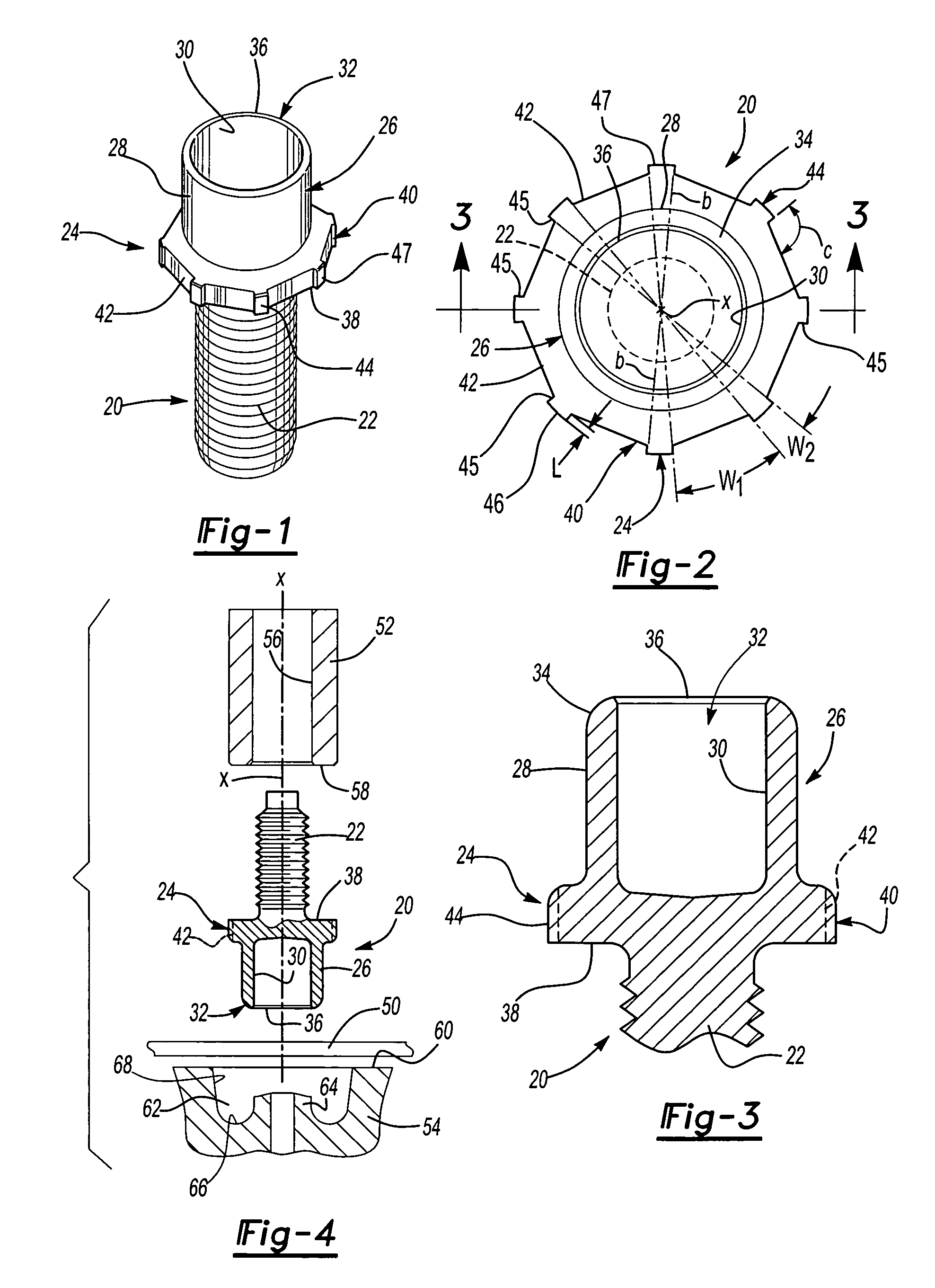

Torque resistant fastening element

A torque resistant self-attaching fastener having a tubular barrel portion and a radial flange portion including a plurality of circumferentially spaced radial projections each having opposed planar generally radial side faces with the outer surface of the radial flange between the radial projections having a greater circumferential width than a circumferential width of the radial projections and a radial length less than the circumferential width. The side faces may be aligned with a radius, the side faces may be parallel or the side faces of adjacent radial projections may be parallel.

Owner:PENN AUTOMOTIVE INC

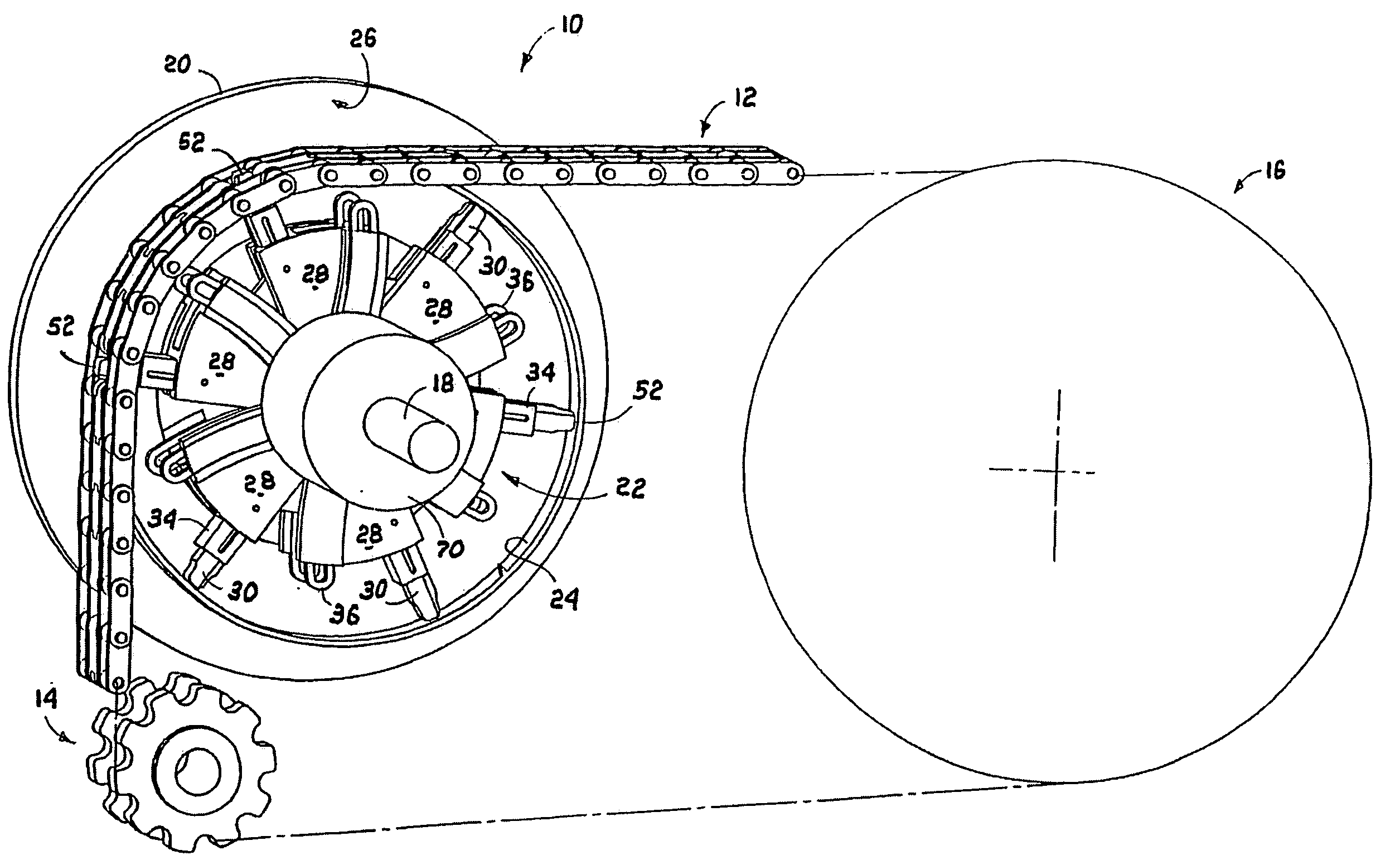

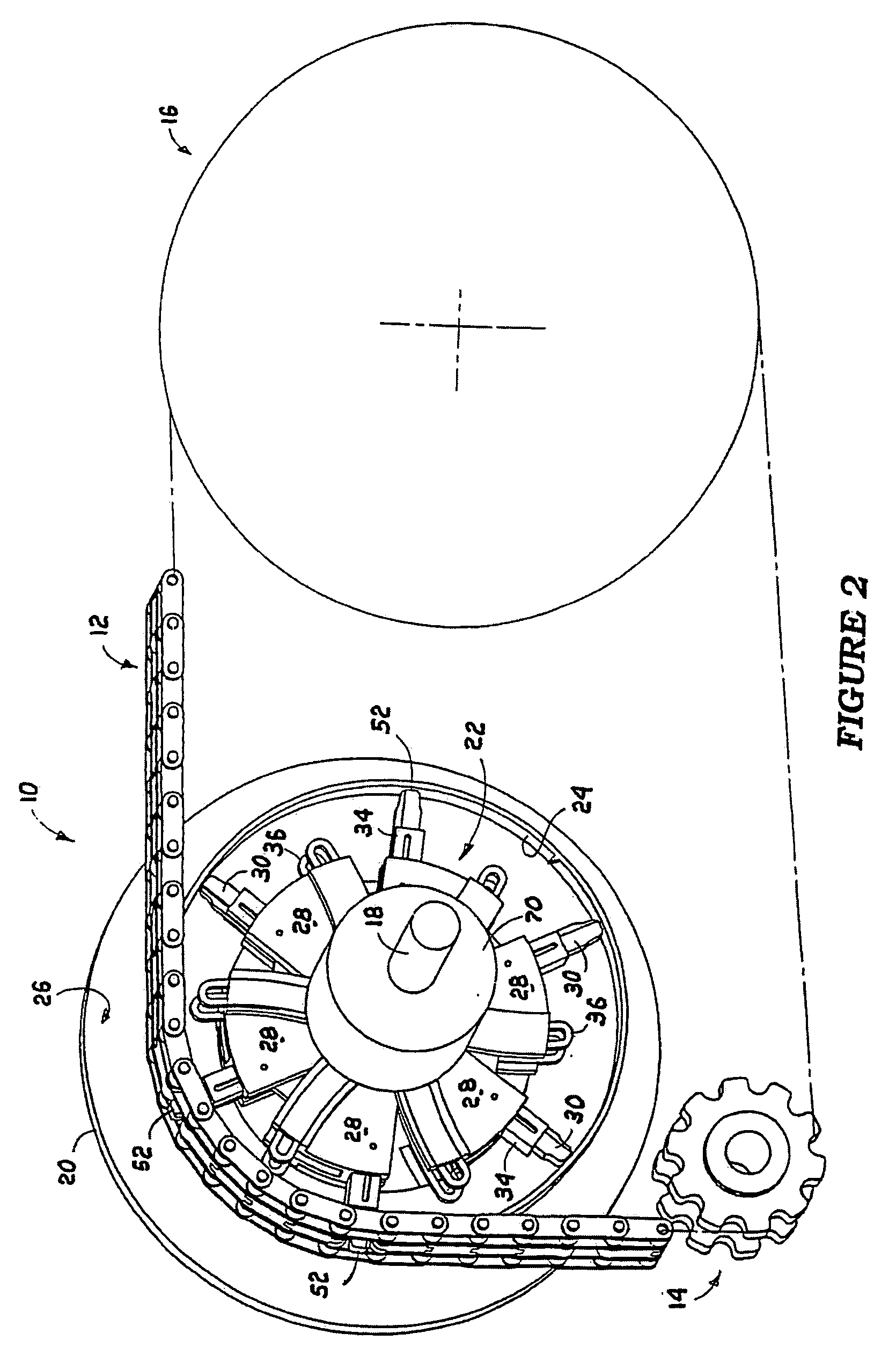

Variable sprocket ivt machine

A variable sprocket IVT machine has a sprocket wheel, on an input shaft, including a plurality of wheel bodies which are independently rotatable on the shaft, a sprocket slidably located in and projecting radially from a sleeve in each wheel body, connecting arrangements, connecting the wheel bodies in the composite wheel, which are adapted to vary the angular disposition between and the degree of radial projection of adjacent sprockets relatively to each other to ensure clean engagement of the sprockets with uniformly spaced apertures in a drive chain which partially surrounds the wheel in a radially movable zone of sprocket engagement, elements for engaging the wheel bodies of the sprockets in the zone with the input shaft and a control arrangement which supports the sprockets not in the zone and which is movable to vary the ratio of rotation of the input shaft relatively to a chain driven output shaft.

Owner:VARIBOX IP

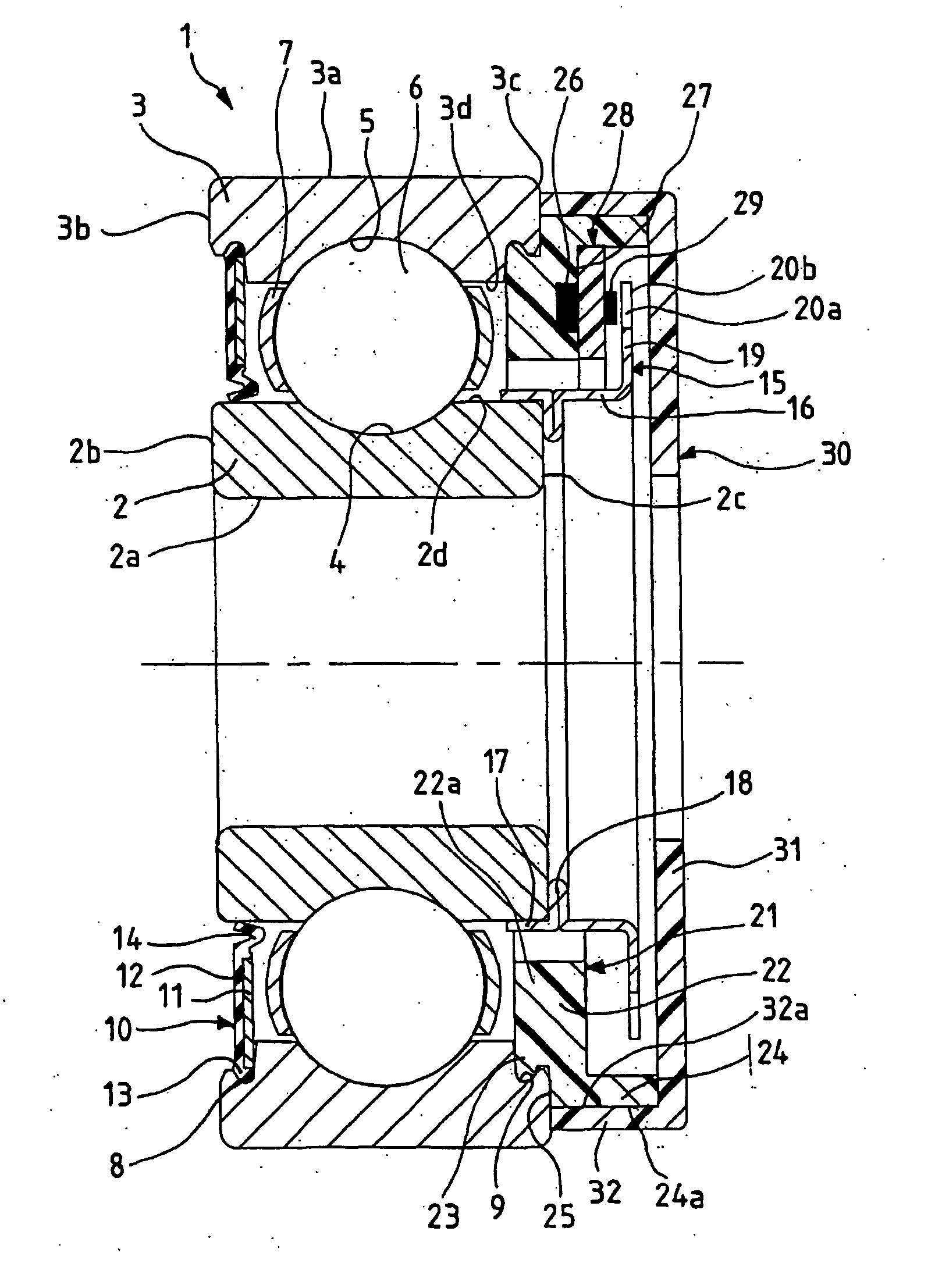

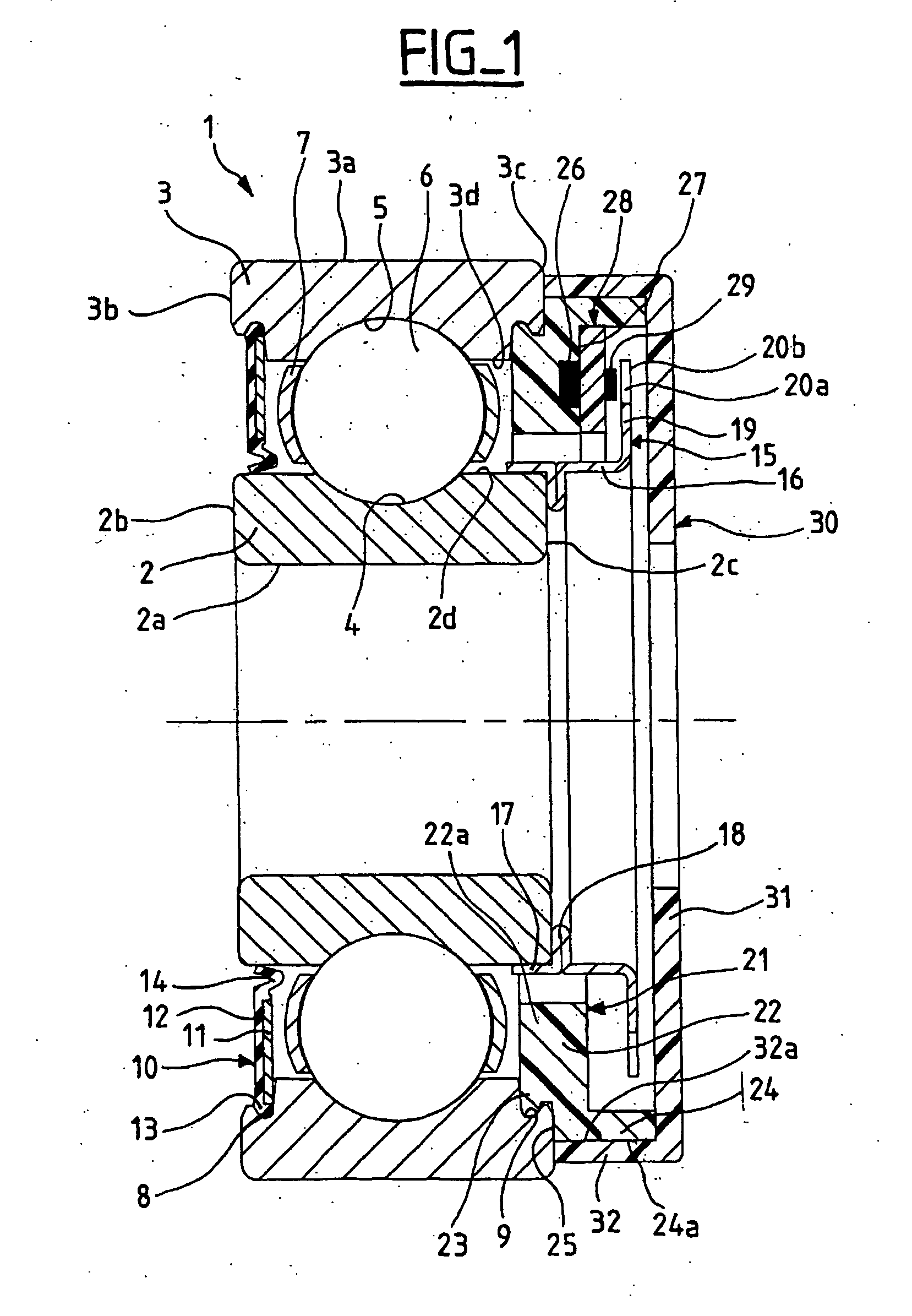

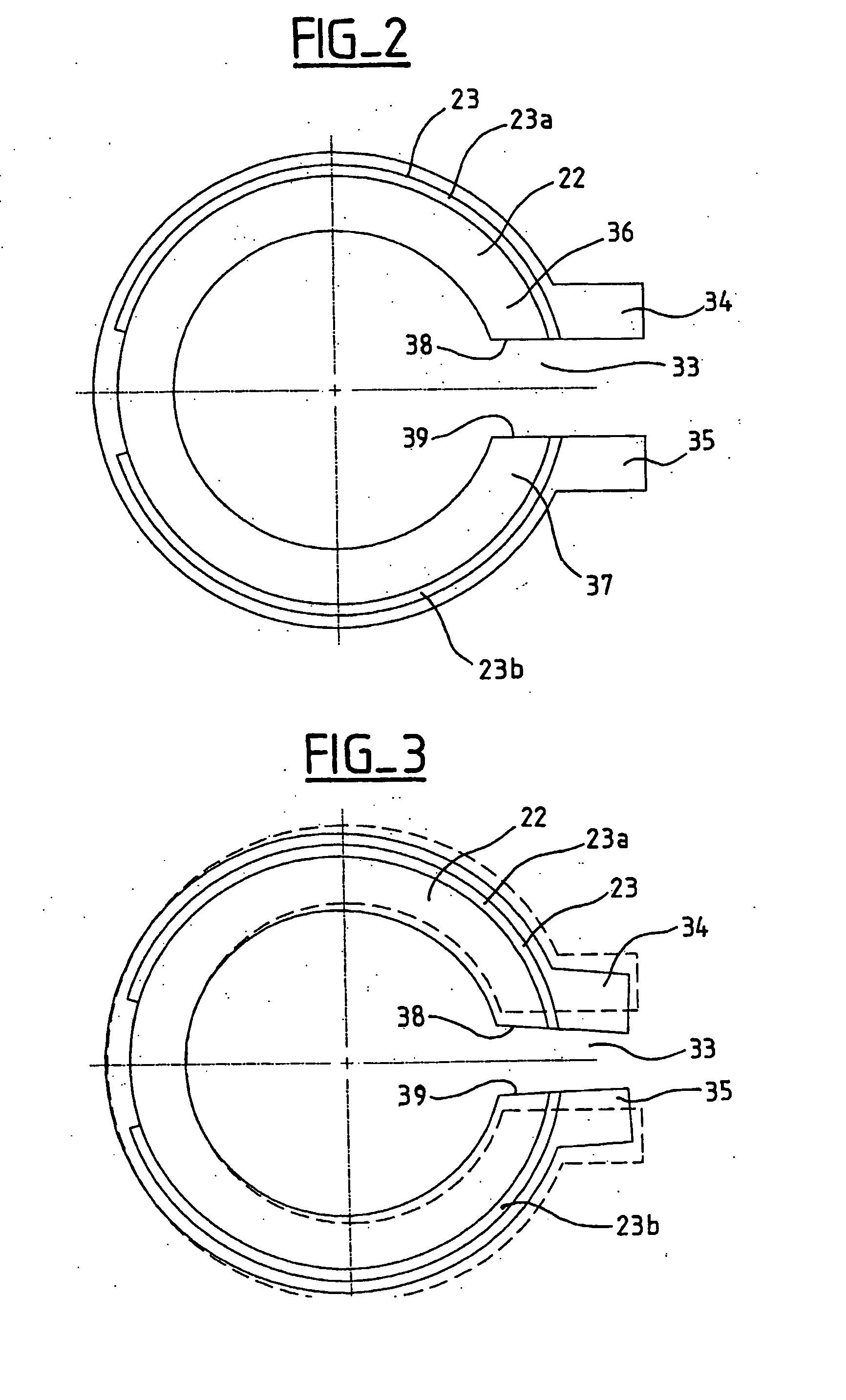

Mounting bracket, rolling bearing and corresponding assembly method

InactiveUS20050235513A1Safe and reliable installationWithout risk of breakingBearing assemblyShaftsBiomedical engineeringRadial projection

A bracket includes a fixing piece on a rotation element (3), said fixing piece comprising a body (22) in the general form of a ring, provided with an annular radial projection (23). The body includes an opening (33) which permits a variation in the diameter of said body (22) on assembly with engagement of the projection (23) in a corresponding groove (9) on the rotation element (3) to give a radial interference fit. A bar (28) prevents a variation in the diameter of the body (22) as above after the assembly thereof.

Owner:AB SKF

Image detecting method for arc ruler lines of pointer instrument scale

ActiveCN103994786ARealize automatic readingAutomatic readings are accurateIndication of measured valuesHough transformMorphological processing

The invention discloses an automatic detecting method, based on images, for arc scale labels of a pointer instrument. A single digital camera is utilized to construct an image collecting system and carry out calibration, two gauge outfit images are shot under drive signals corresponding to 20% of full scale and 80% of full scale, ruler line areas and scale line areas are achieved through thresholding and morphological processing, a framework is extracted, a candidate ruler disk center is decided on projection through a frame sectioning method, the ruler disk center and the radius of the ruler lines are roughly detected and decided through a hough transform circle, the least square fit is removed and cut by two points to decide the accurate center and the radius of the ruler lines, orientation angles of the scale lines on the ruler lines are decided through a radial projection method to obtain a candidate scale base point, the obtained scale base point is decided and detected through co-domain, and results of two images are combined to obtain a final scale base point set. The detecting method can automatically detect scale positions of arc ruler lines of the pointer instrument, can be applied to automatic calibration and automatic reading of the instrument, improves reading accuracy and reduces labor intensity.

Owner:HUNAN UNIV

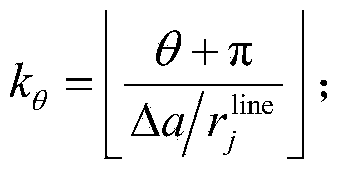

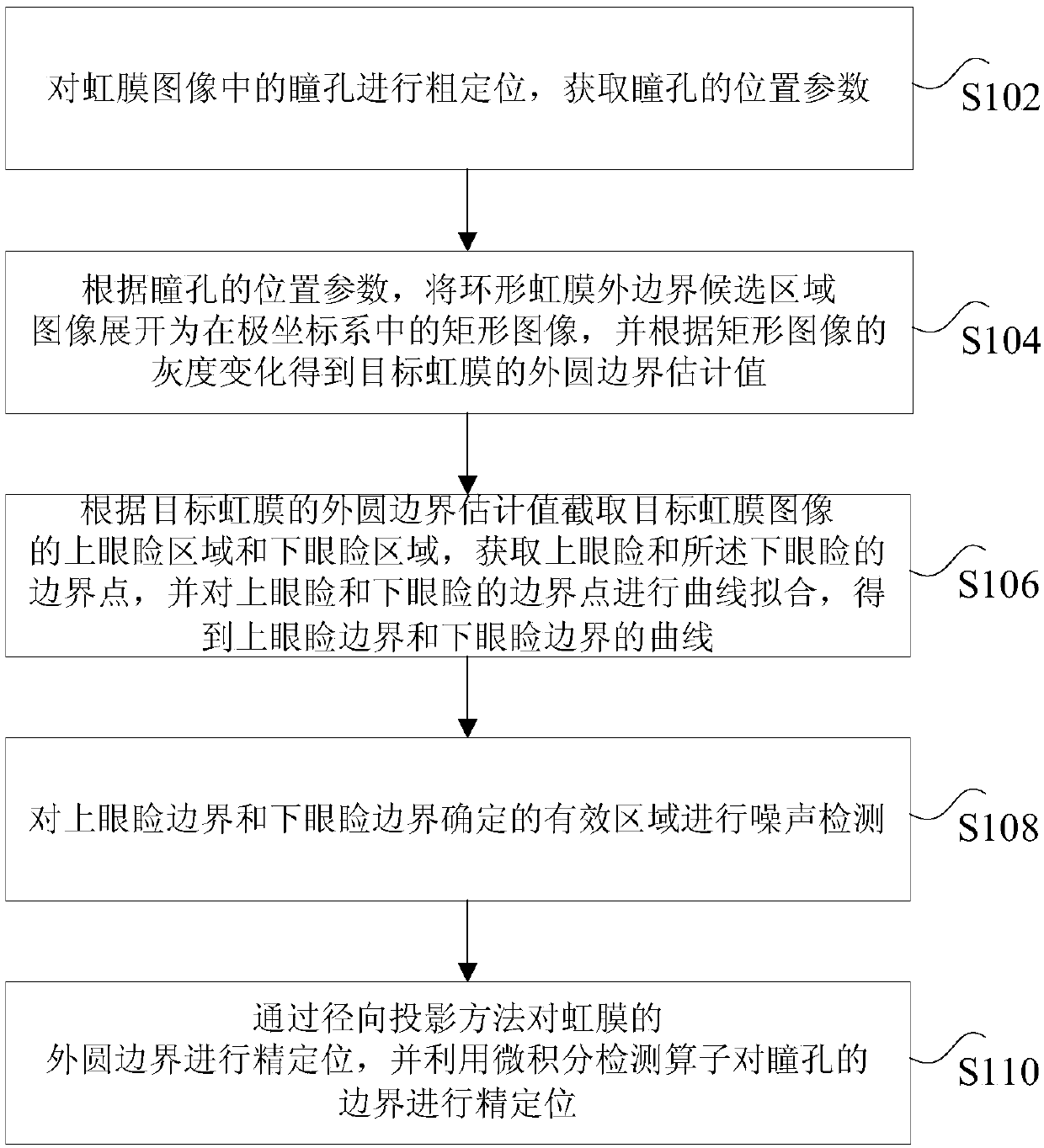

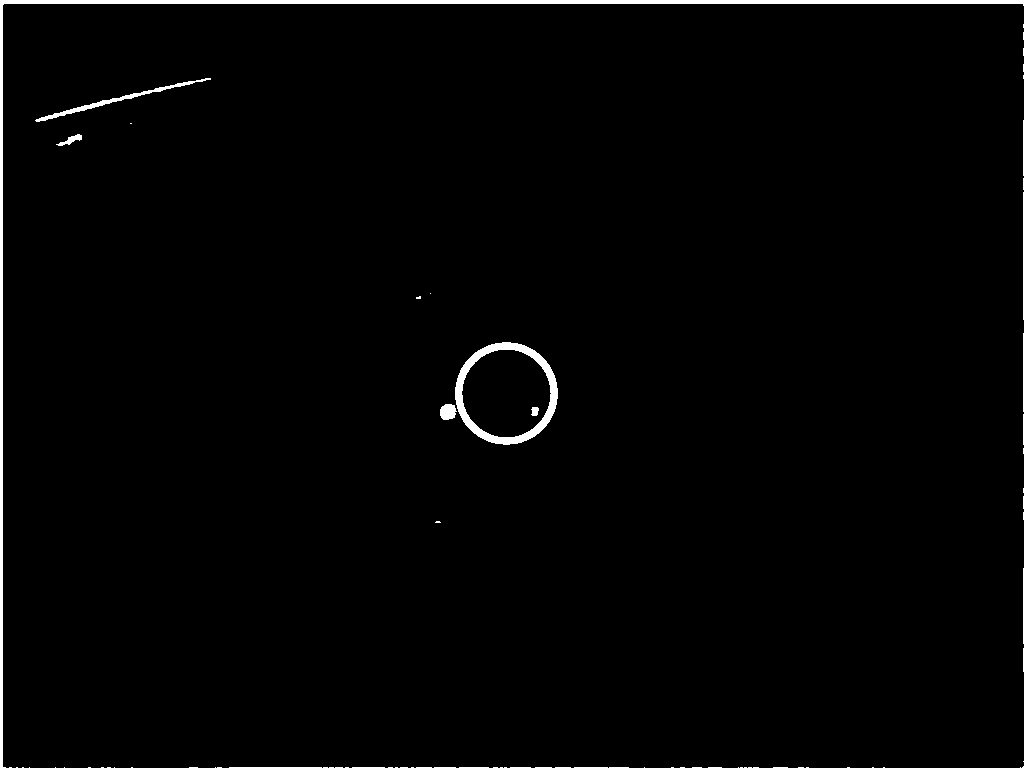

Iris image segmenting method and device

ActiveCN107871322AImprove robustnessImprove stabilityImage enhancementImage analysisEyelidNoise detection

The invention discloses an iris image segmenting method and device. The method includes performing rough positioning on a pupil in an iris image; expanding an image in a candidate area on the outer boundary of an annular iris into a rectangular image in a polar coordinate system and acquiring an excircle boundary estimation value of a target iris according to the gray level change of the rectangular image; intercepting an upper eyelid zone and a lower eyelid zone of the iris image according to the excircle boundary, acquiring boundary points of an upper eyelid and a lower eyelid, performing curve fitting on the boundary points of the upper eyelid and the lower eyelid, and obtaining an upper eyelid boundary curve and a lower eyelid boundary curve; performing noise detection on valid zones determined according to the upper eyelid boundary and a lower eyelid boundary; performing fine positioning on the excircle boundary of the iris through a radial projection method and performing fine positioning on the boundary of the pupil by utilizing a calculus detection operator. The invention solves a problem of low accuracy of low quality iris image segmentation performed by iris image segmenting methods in the prior art.

Owner:BEIJING EYECOOL TECH CO LTD

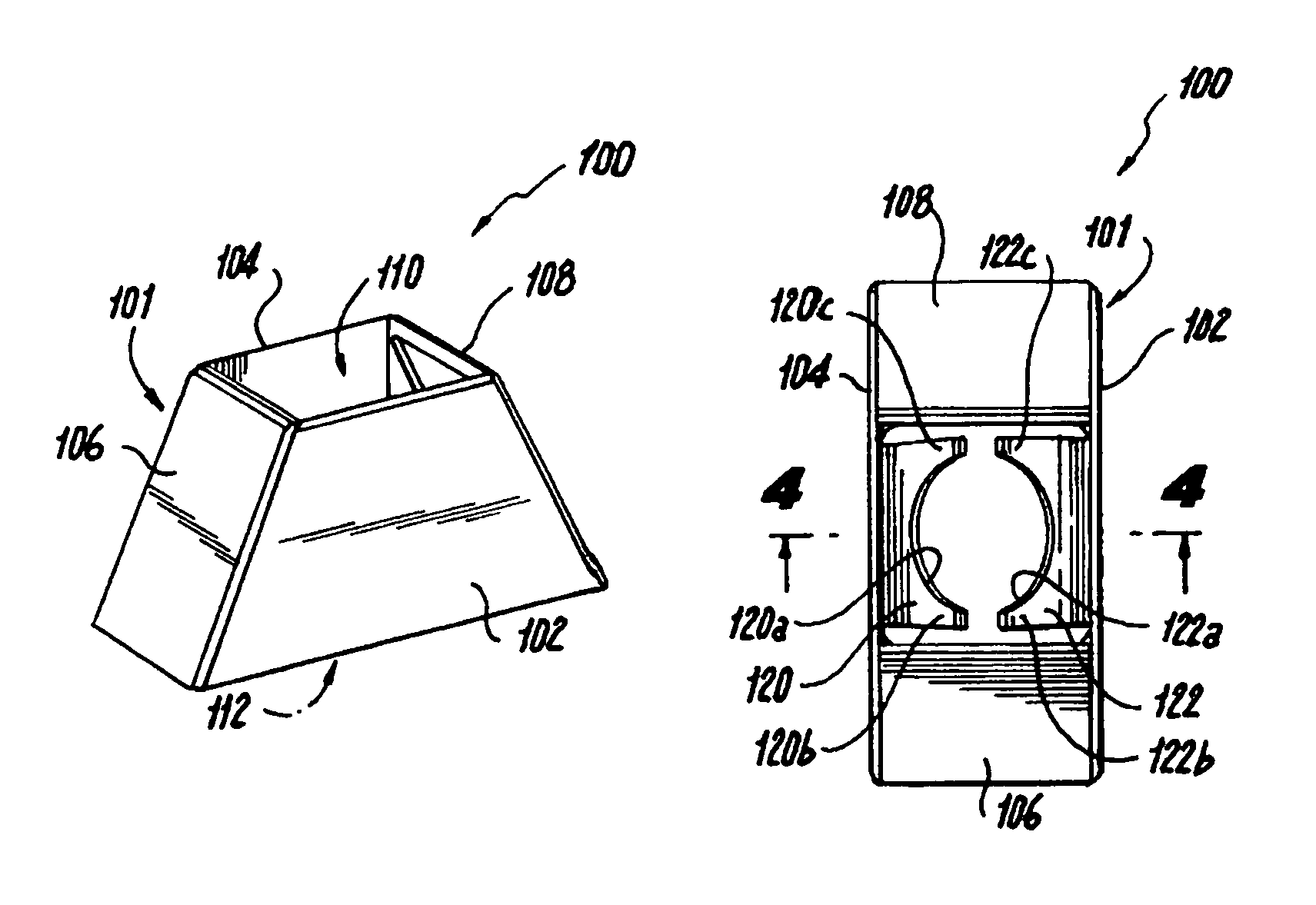

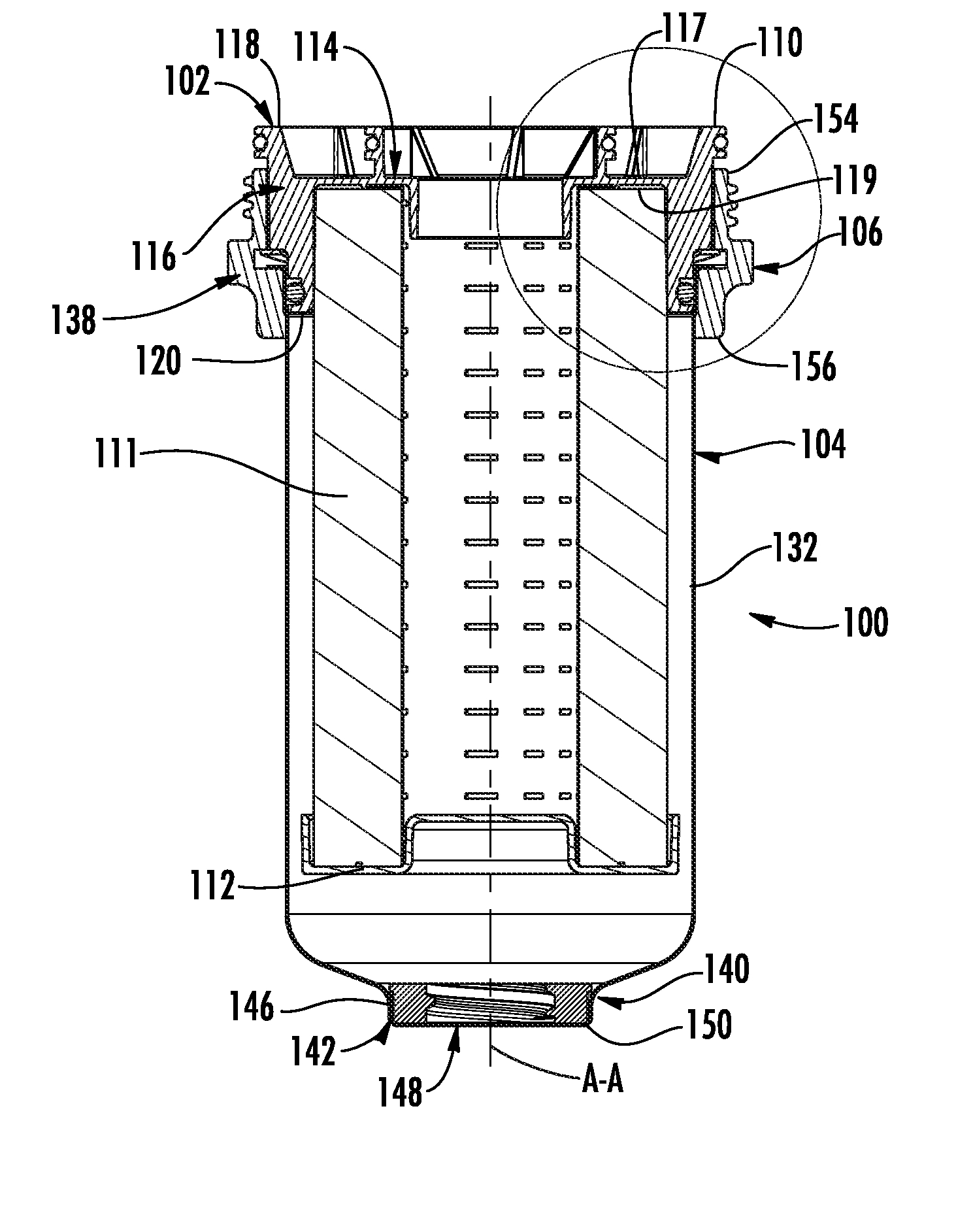

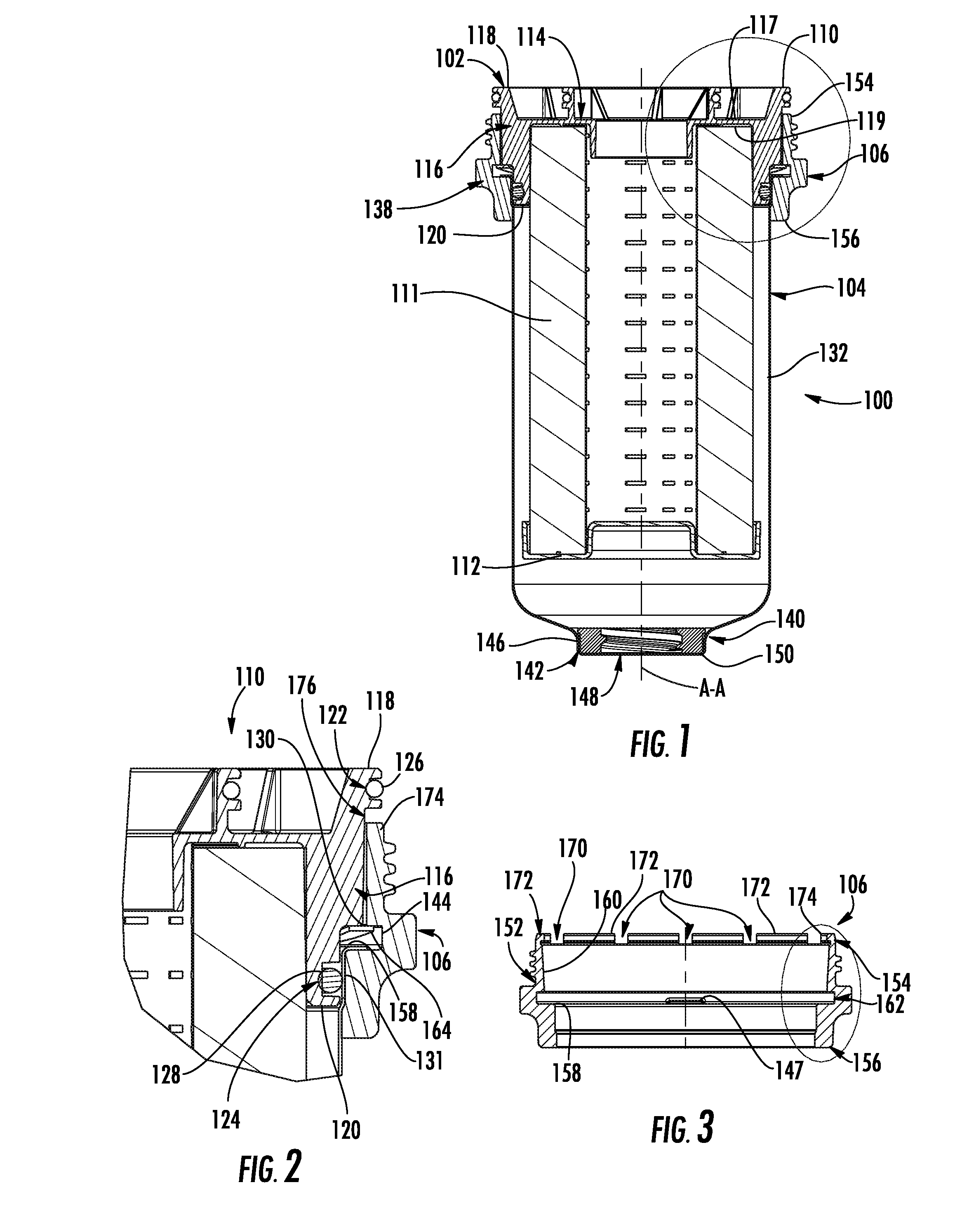

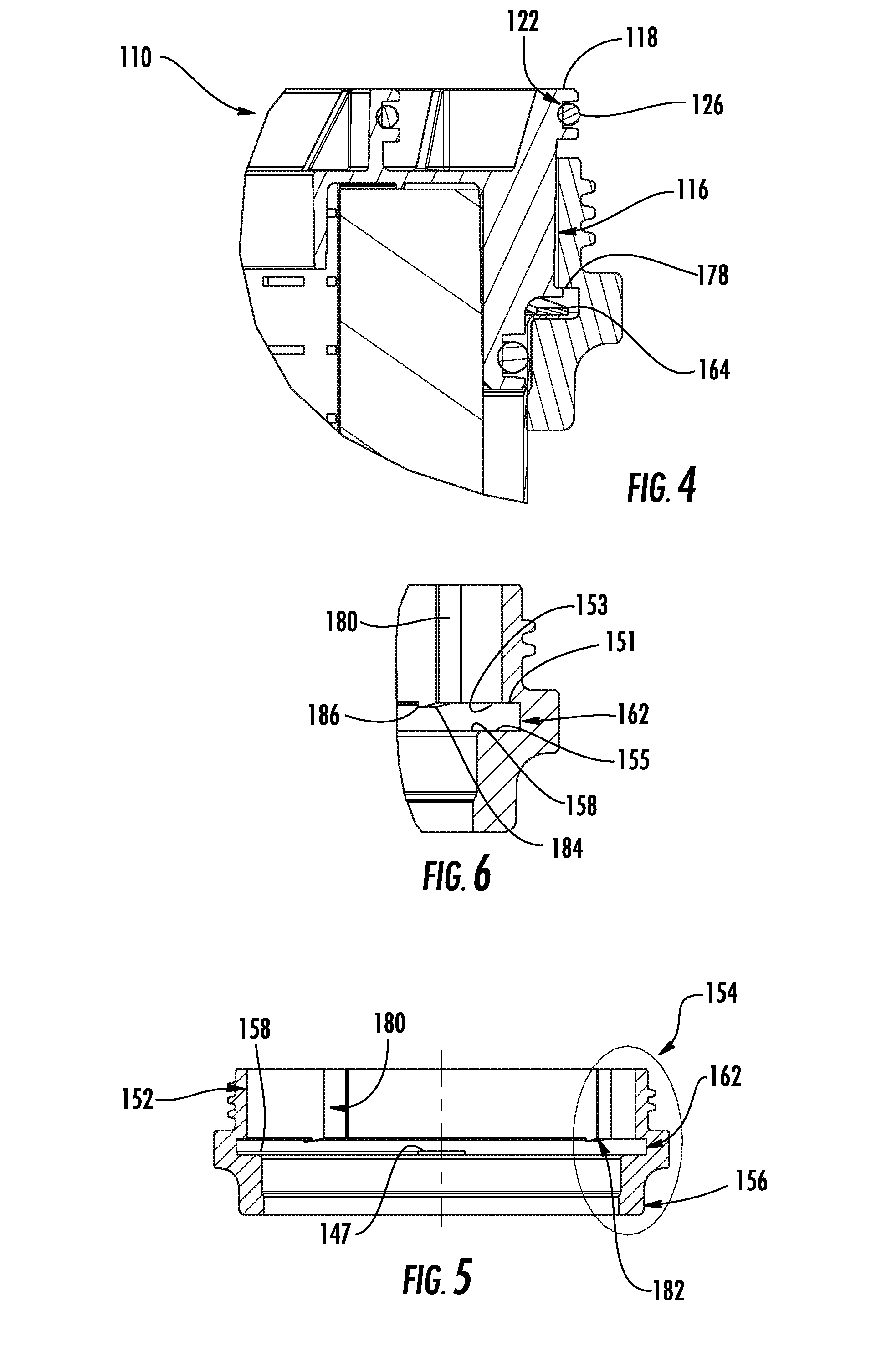

Fuel Filter Cartridge and Method of Construction Thereof

InactiveUS20150090653A1Easy to manufactureImprove sealingDispersed particle filtrationMembrane filtersFilter mediaFuel filter

A filter cartridge has a longitudinal axis and comprises a housing, a filter element, a first collar and a second collar. The housing has a generally cylindrical sidewall and defines an open first end, an axially opposite second end, and a flange projecting radially away from the axis at the first end. The filter element has a ring of filter media circumscribing the axis and extending between first and second end caps. A ledge projects radially from an inner surface of the second collar. The second collar has an annular sidewall having a shoulder projecting from an inner surface. The ledge and the shoulder radially overlap to retain the flange. The first collar may define axially-oriented grooves configured to receive corresponding radial projections of the first end cap, axially securing the filter element within the housing.

Owner:CLARCOR ENGINE MOBILE SOLUTIONS

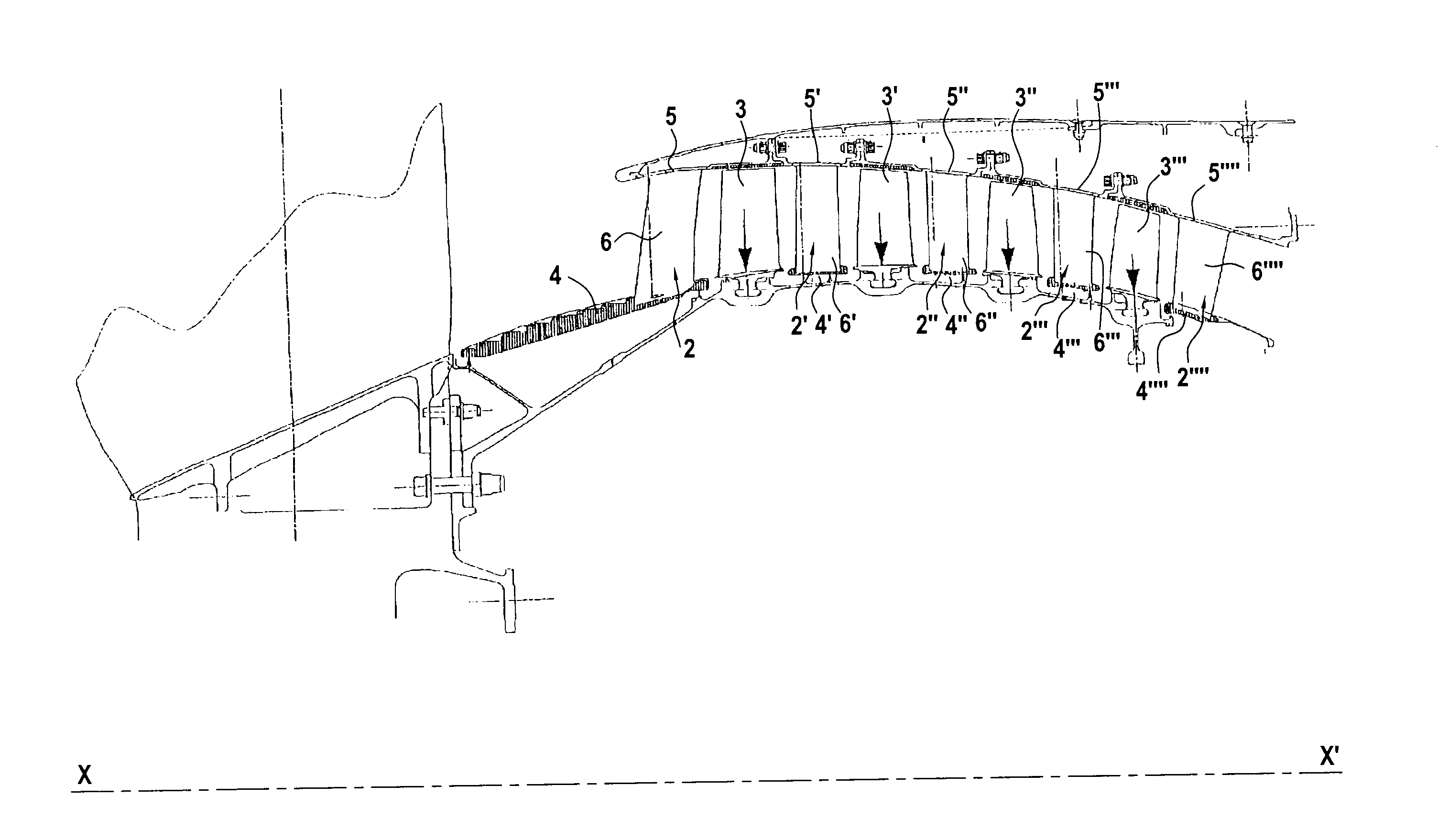

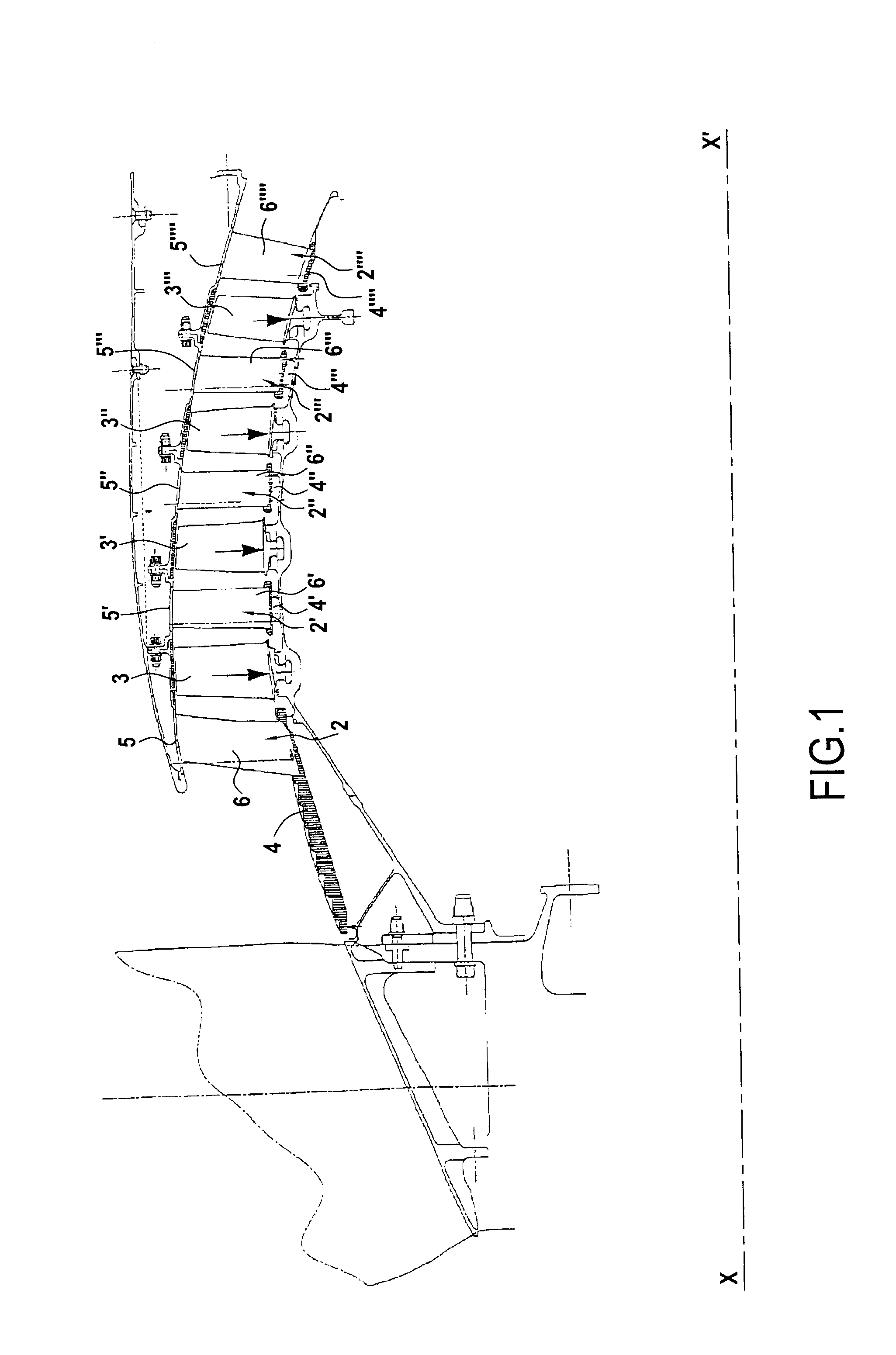

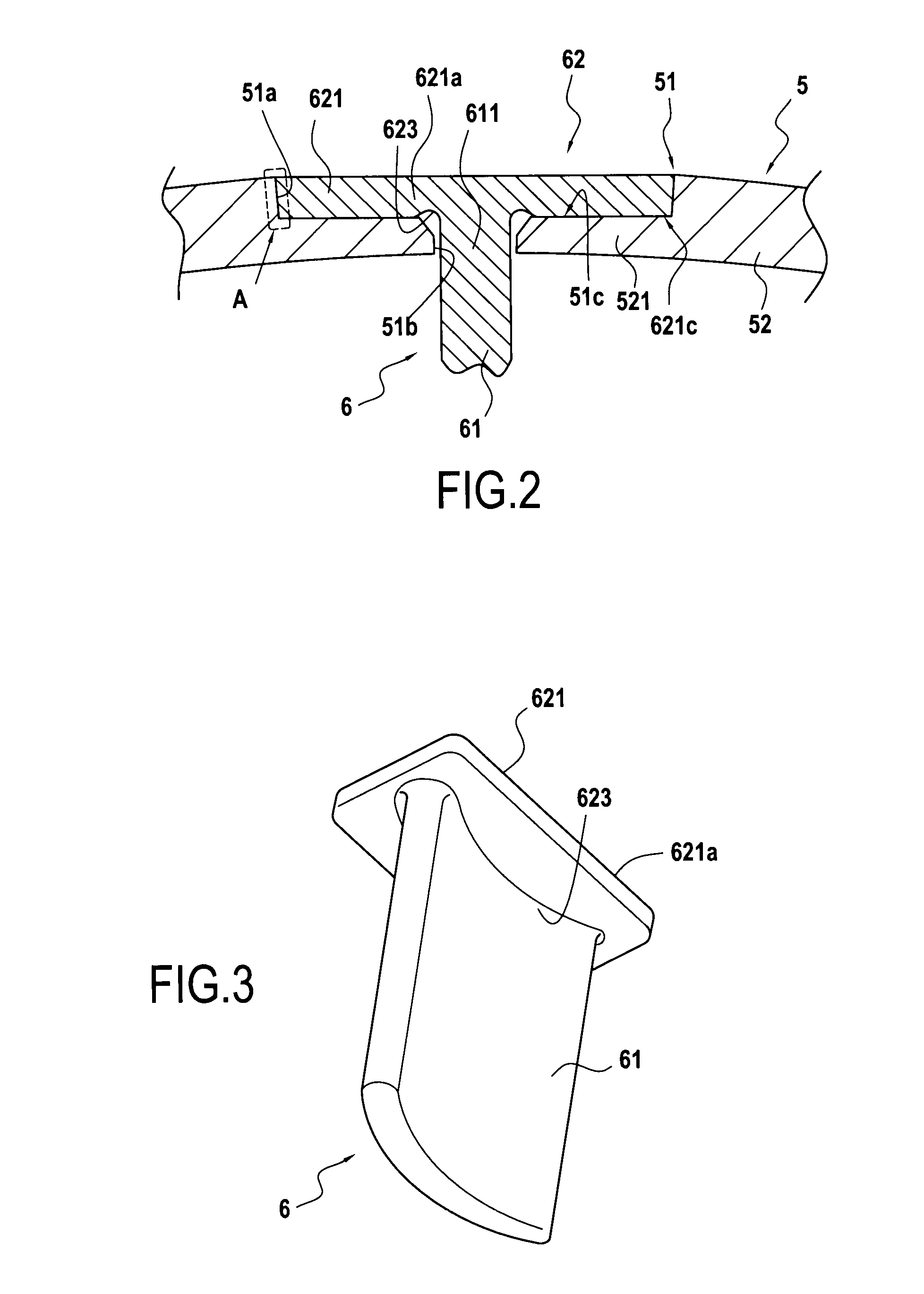

Assembly for a stator stage of a turbomachine, the assembly comprising an outer shroud and at least one stationary vane

InactiveUS20110033285A1Overcomes drawbackAvoid problemsPump componentsStatorsAxial compressorEngineering

The invention relates to an assembly for a stator stage of a turbomachine, the assembly comprising:an outer shroud presenting a series of openings for mounting each stationary vane by welding between the edge of an opening and the outline of the platform of the vane, the outline of the outer segment of an opening surrounding, in radial projection, the outline of the inner segment thereof, the shroud not having any other holes; andat least one stationary vane with its top including a non-pierced platform received in one of said openings prior to the welding step, such that an inside face of the platform bears against a bearing face of the shroud, the outline of the platform presenting a shape that is identical to the shape of the outline of the opening.The invention is applicable to the stator stage of an axial compressor or a turbine of a turbomachine.

Owner:TECHSPACE AERO

Inflatable ear mold connection system

InactiveUS20130101147A1Easy to assembleEasy and simple refurbishmentIntra aural earpiecesHearing aids housingExternal Auditory CanalsEngineering

Owner:SIVANTOS PTE LTD

Medical line securement device

InactiveUS20070088329A1Prevent axial movementCatheterTube connectorsCATHETER ADAPTERBiomedical engineering

A medical line securement device holds a medical article such as a connector fitting for a catheter or a catheter adaptor in position upon the body of a patient and inhibits axial motion of the medical article. The securement device includes a retainer with a base and a cover. The cover is hinged to the base such that it may be moved between an open and closed position. The base and cover each have a groove which cooperate when the cover is in the closed position to form a channel through the retainer. The medical article includes an elongated body which is received within the groove of the retainer, the elongated body lying between at least a pair of regions of larger radius of the medical article. By receiving the portion of the elongated body of the medical article between the regions of larger radius, axial motion of the medical article through the groove is inhibited. The retainer may also include one or more slots to receive any radial projections of the medical article within the retainer.

Owner:VENETEC INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com