Patents

Literature

301results about How to "Prevent oil leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

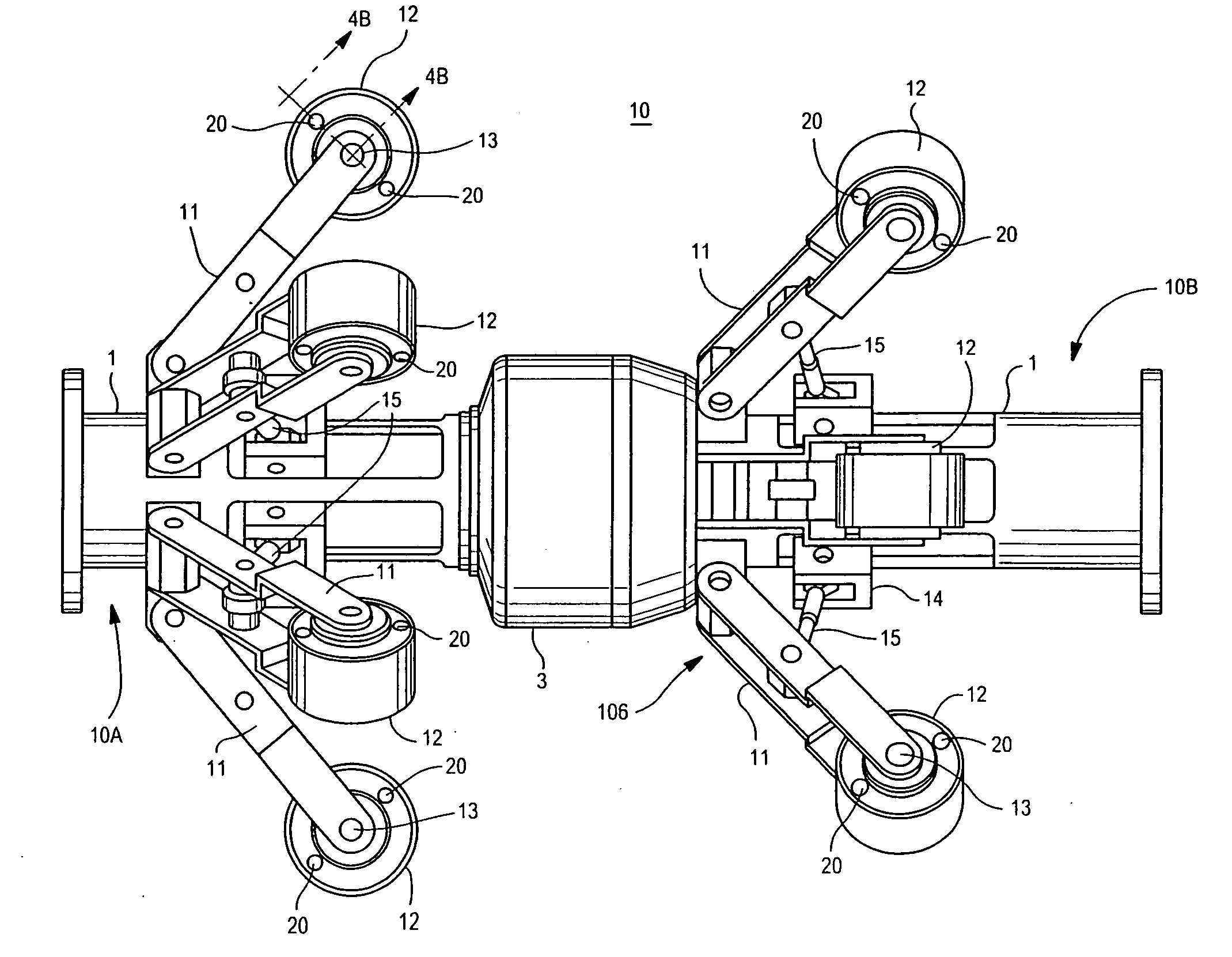

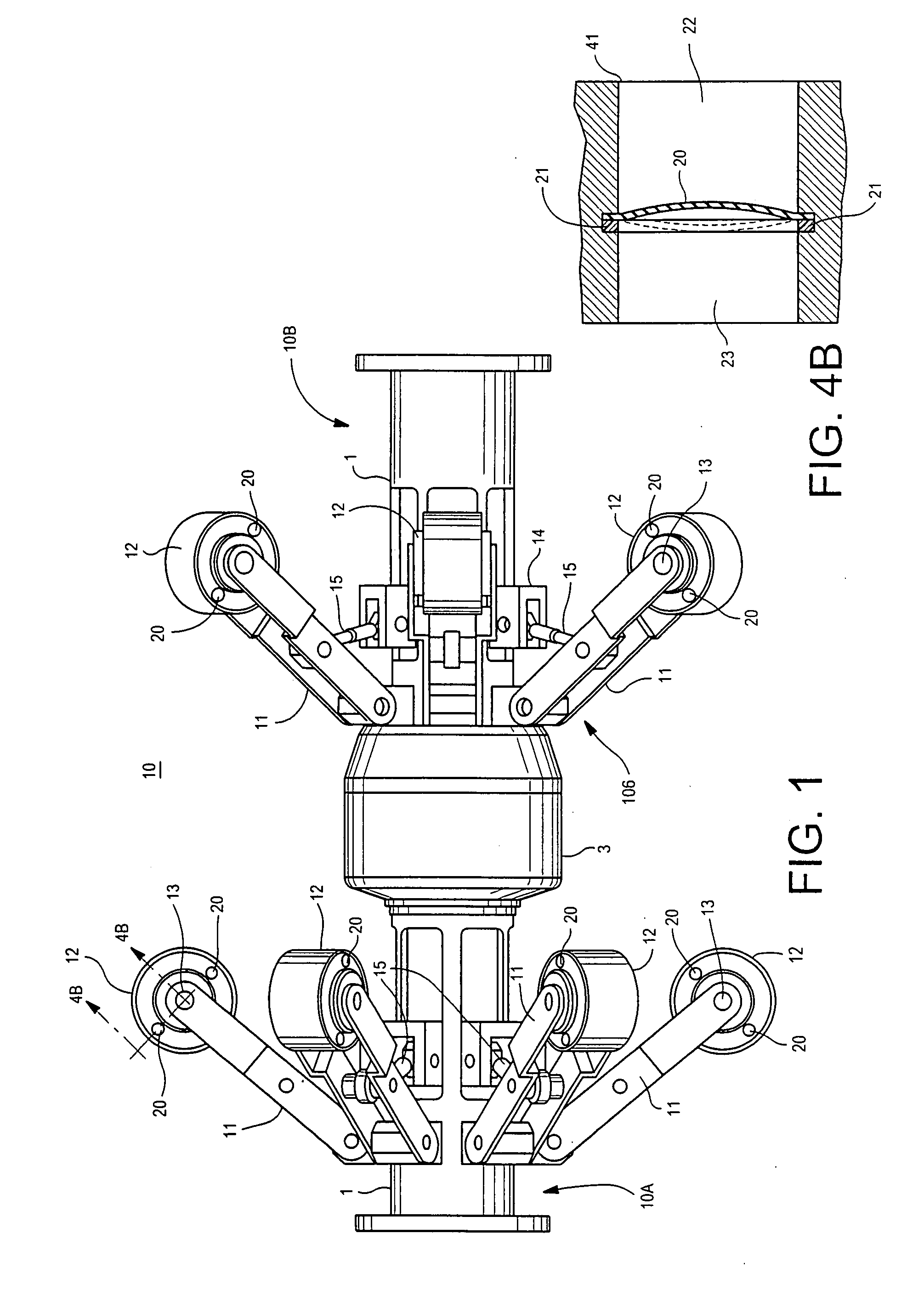

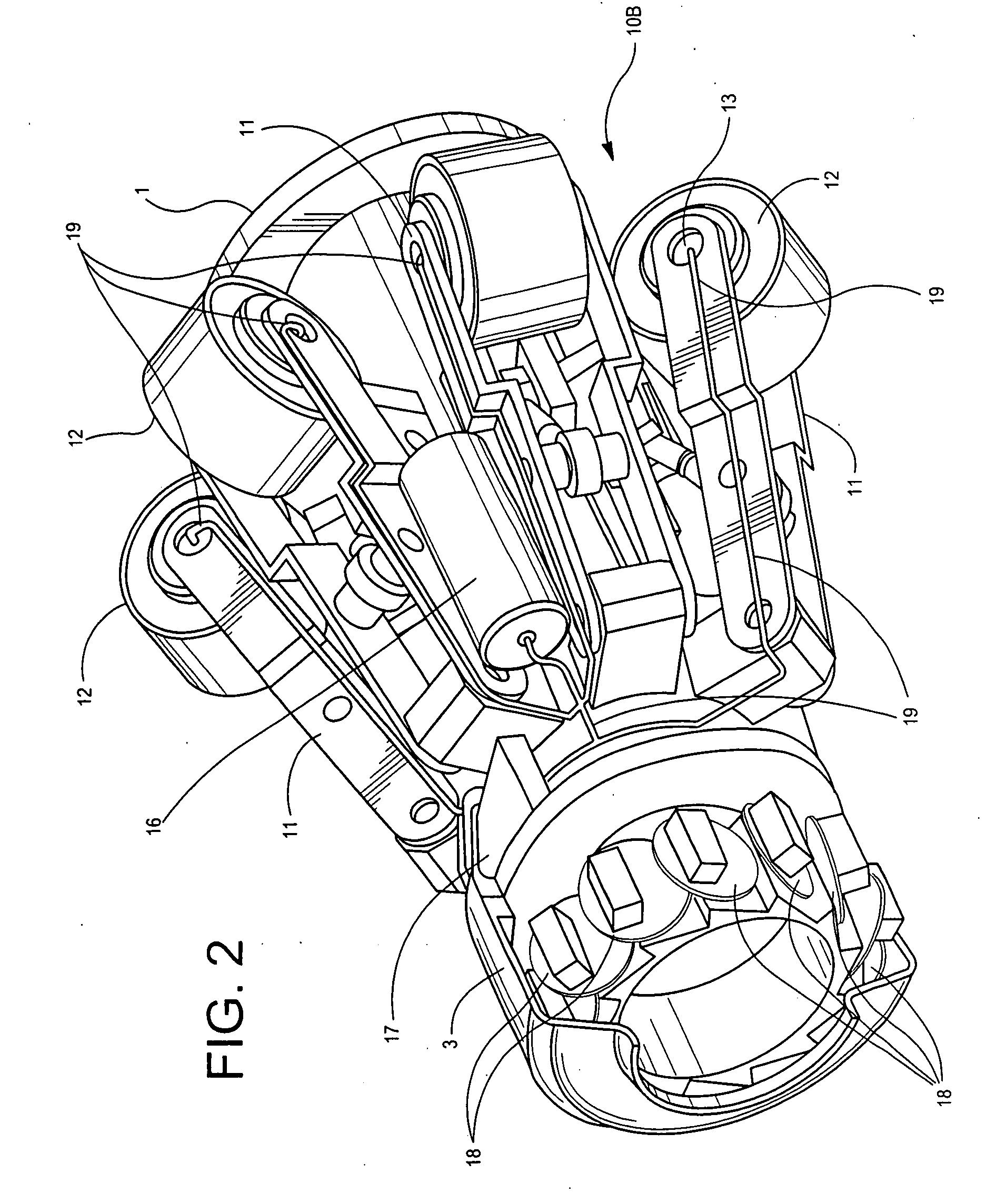

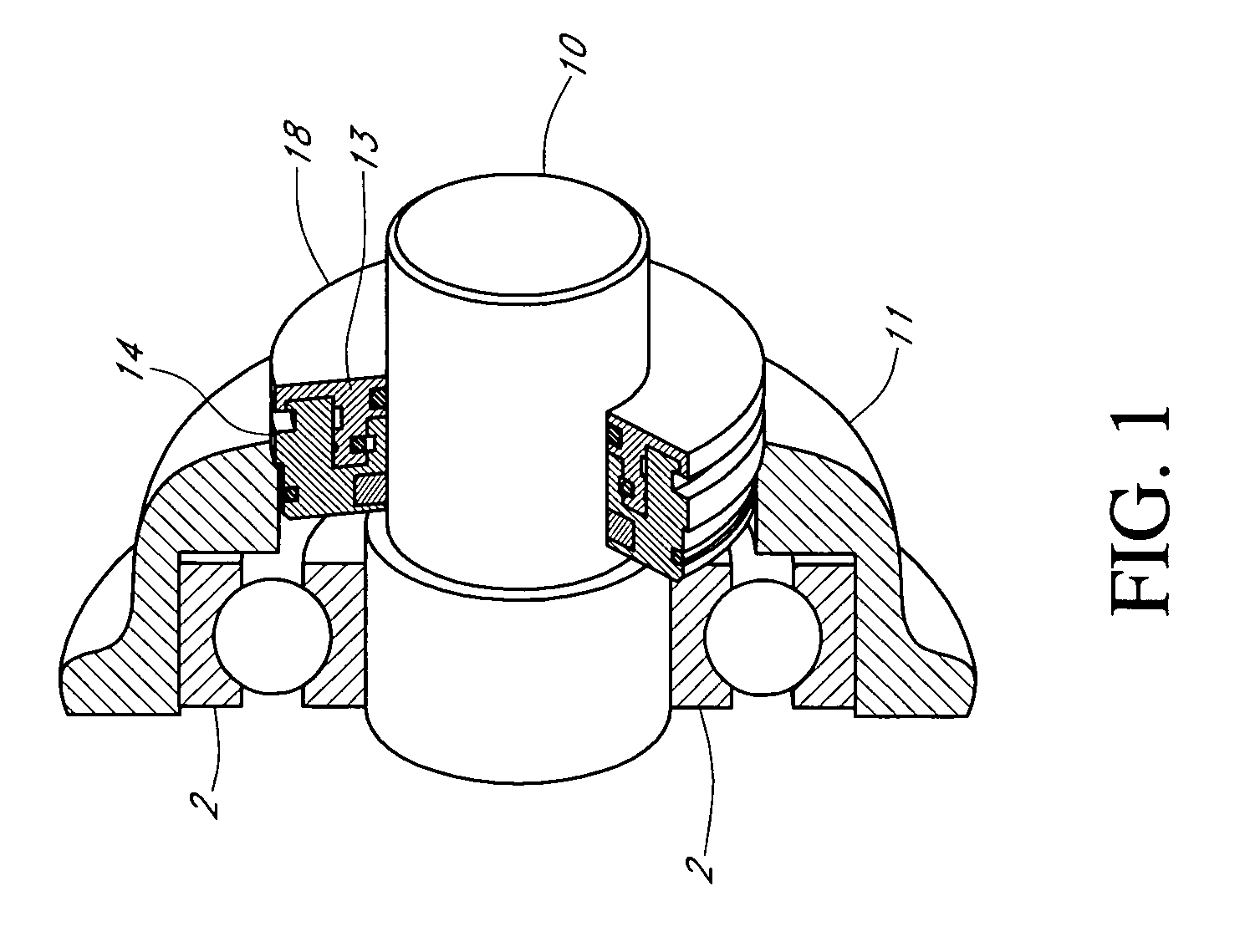

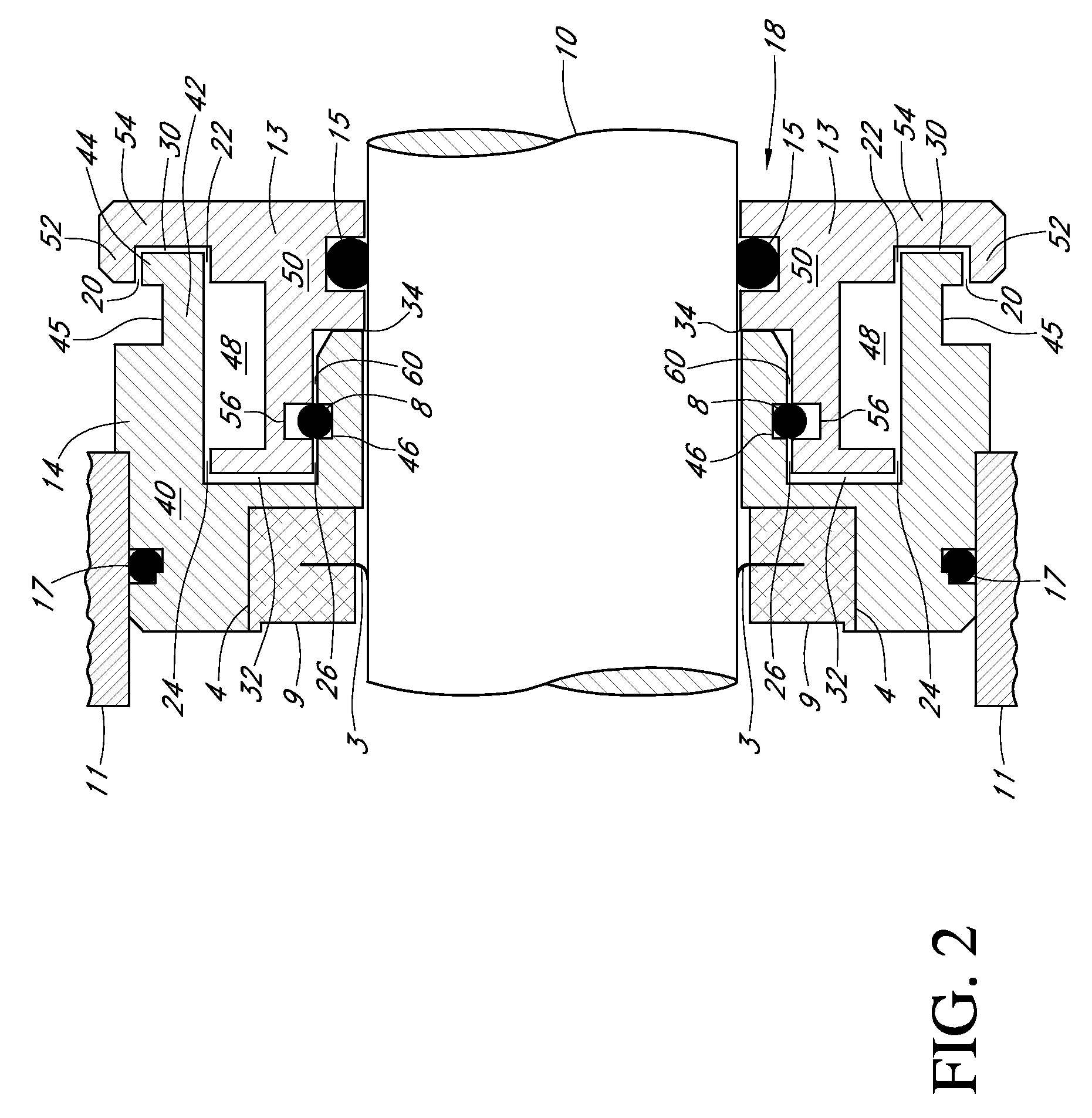

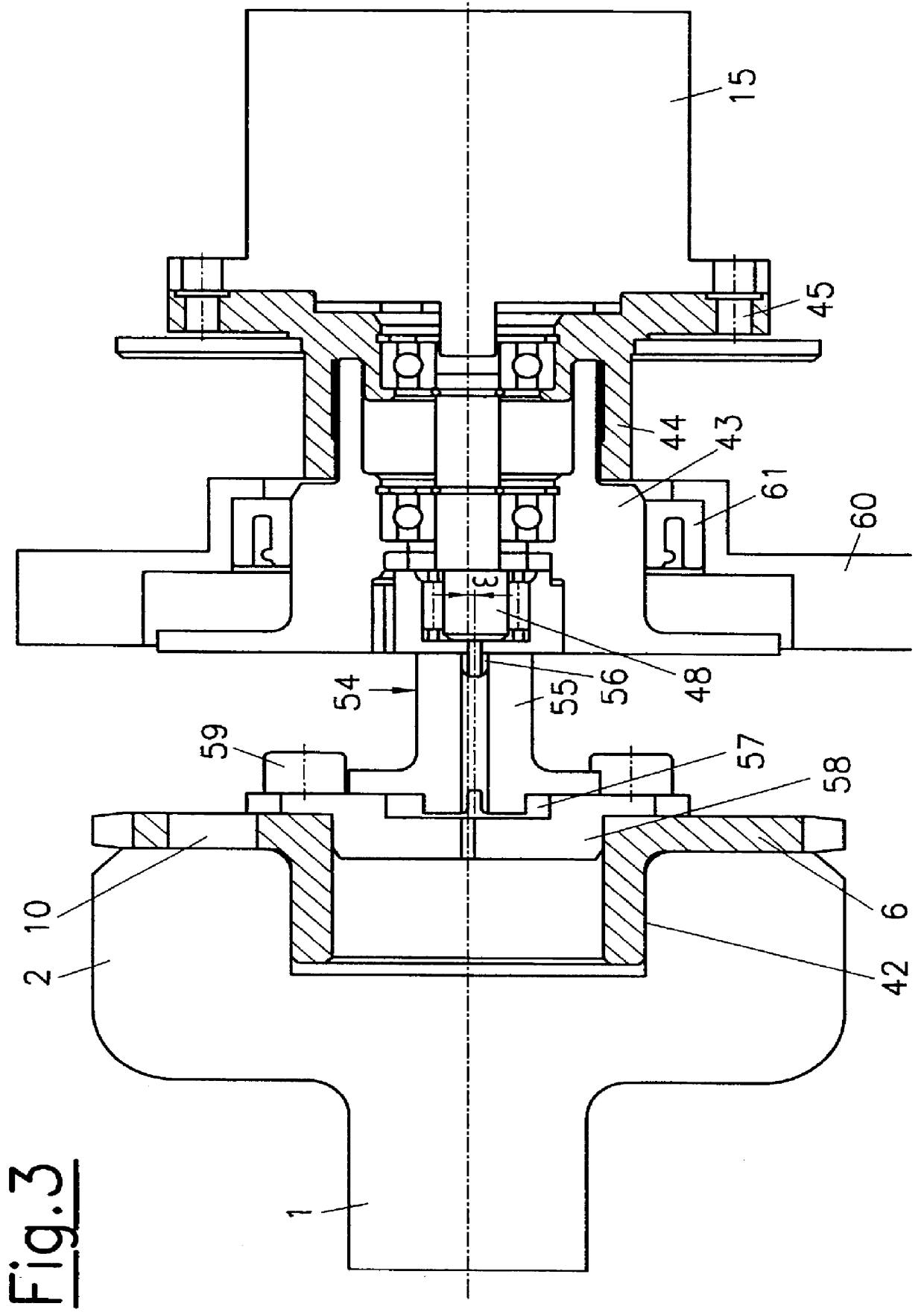

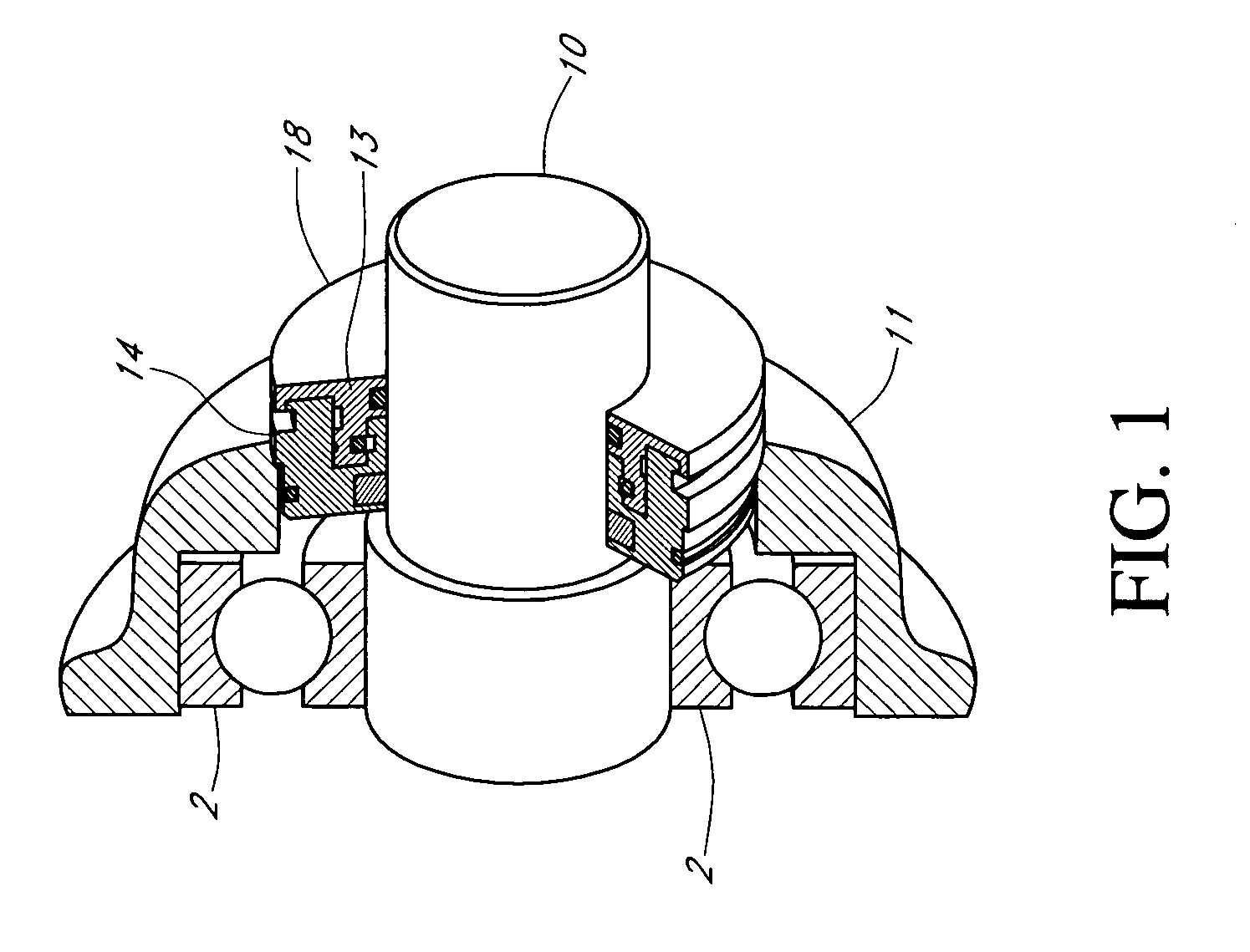

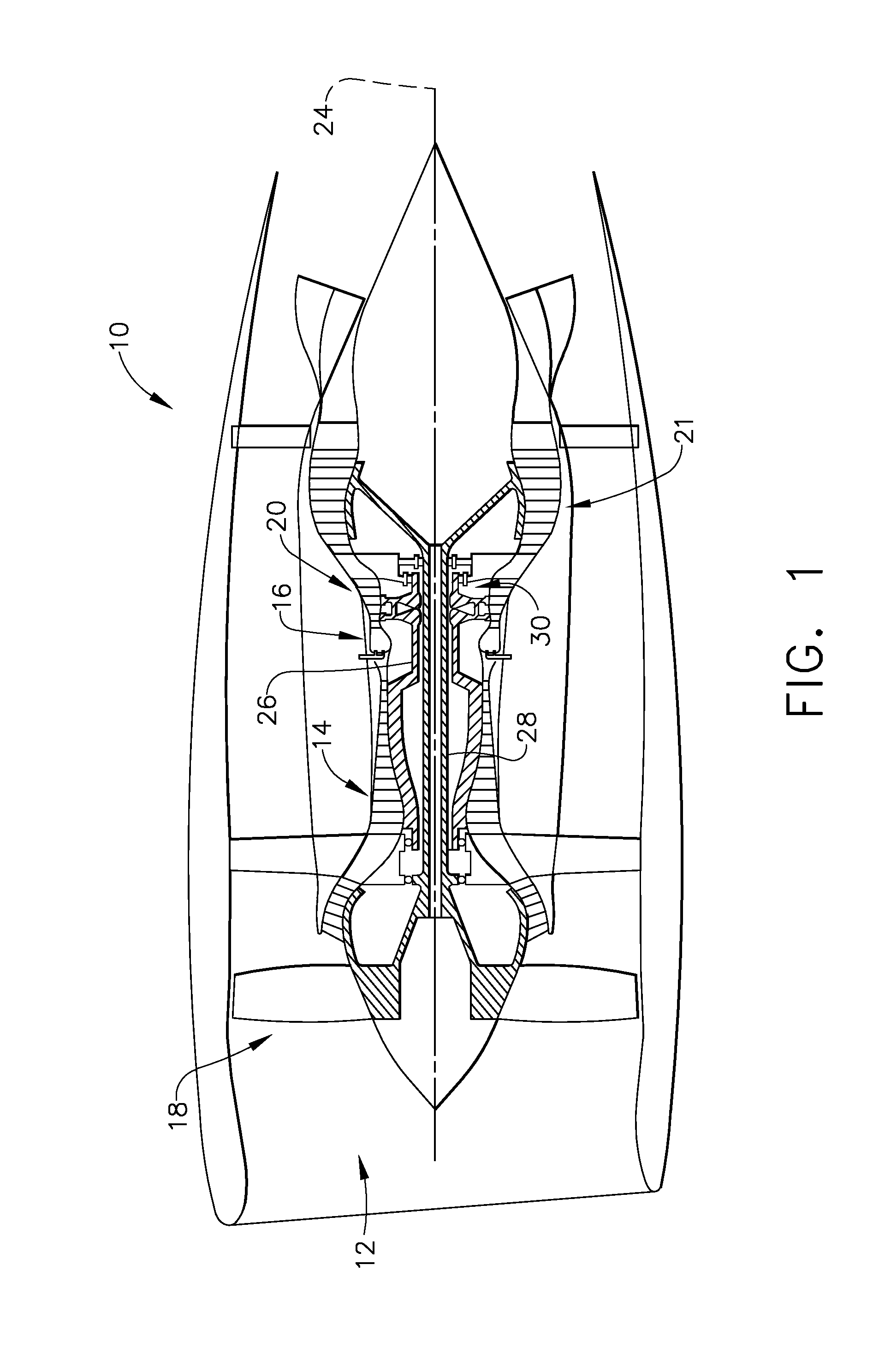

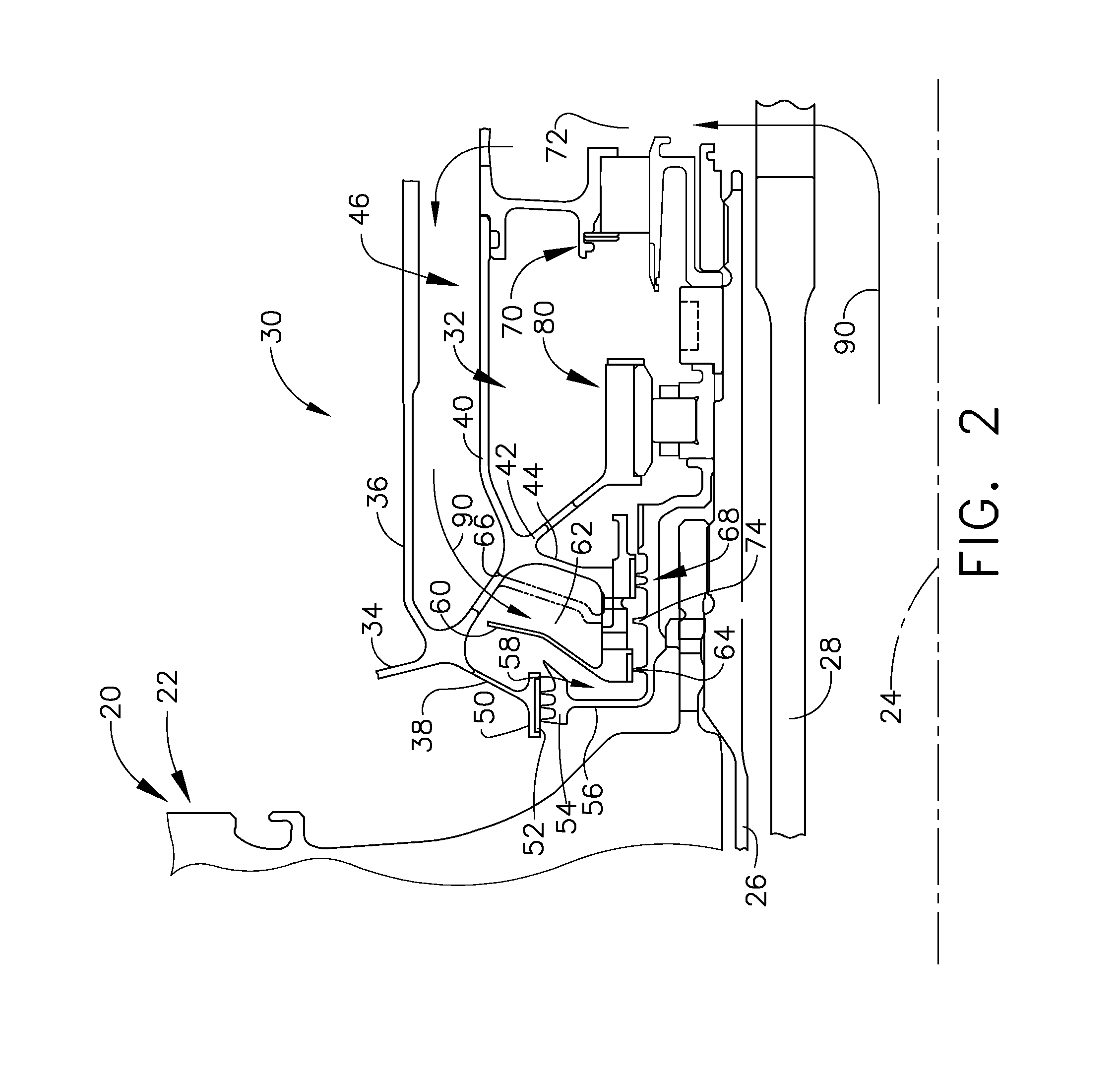

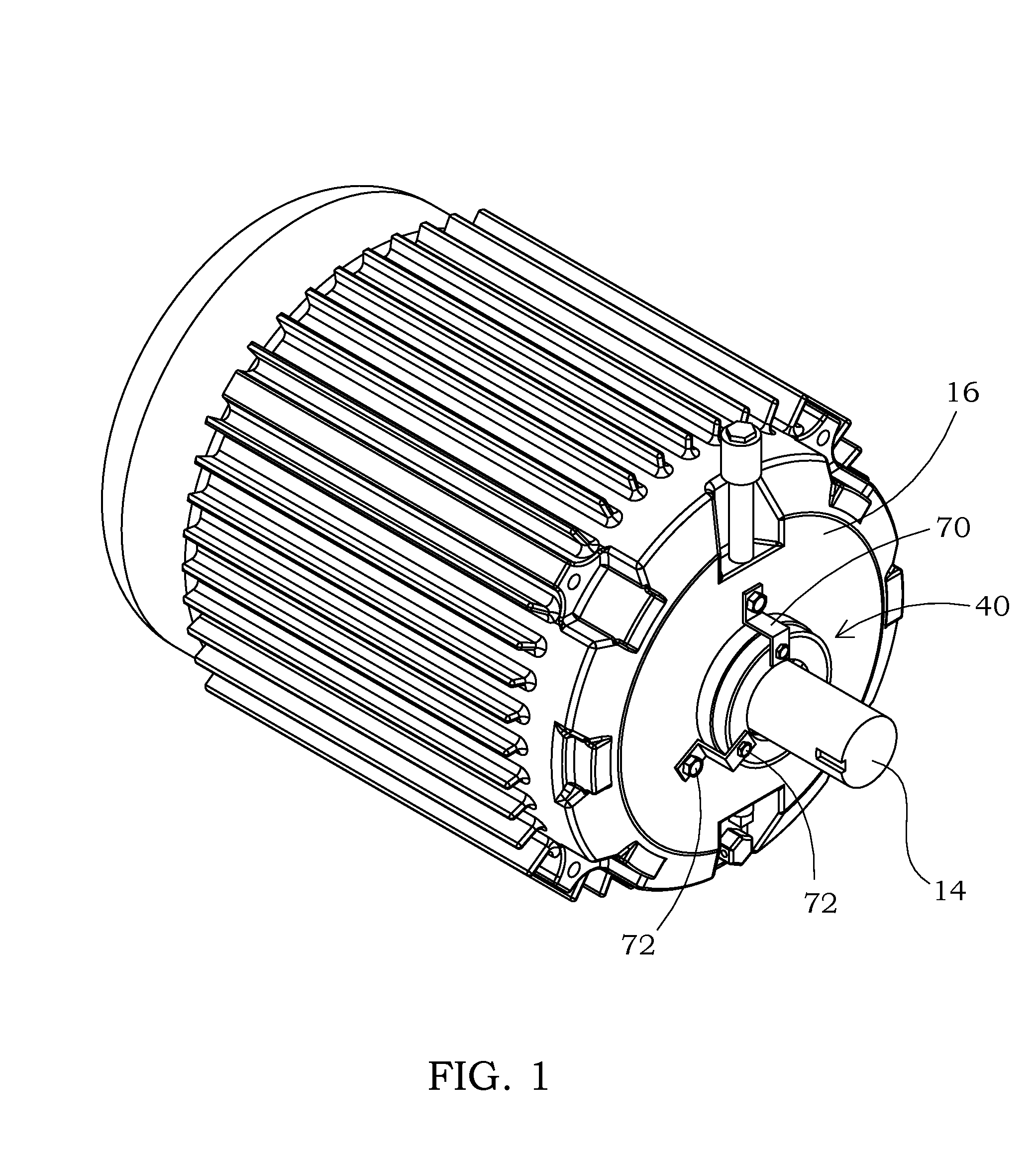

Pressure-balanced electric motor wheel drive for a pipeline tractor

InactiveUS20080245258A1Avoid lostReduce sensitivityRailway tunnelsRailway componentsMotor driveAmbient pressure

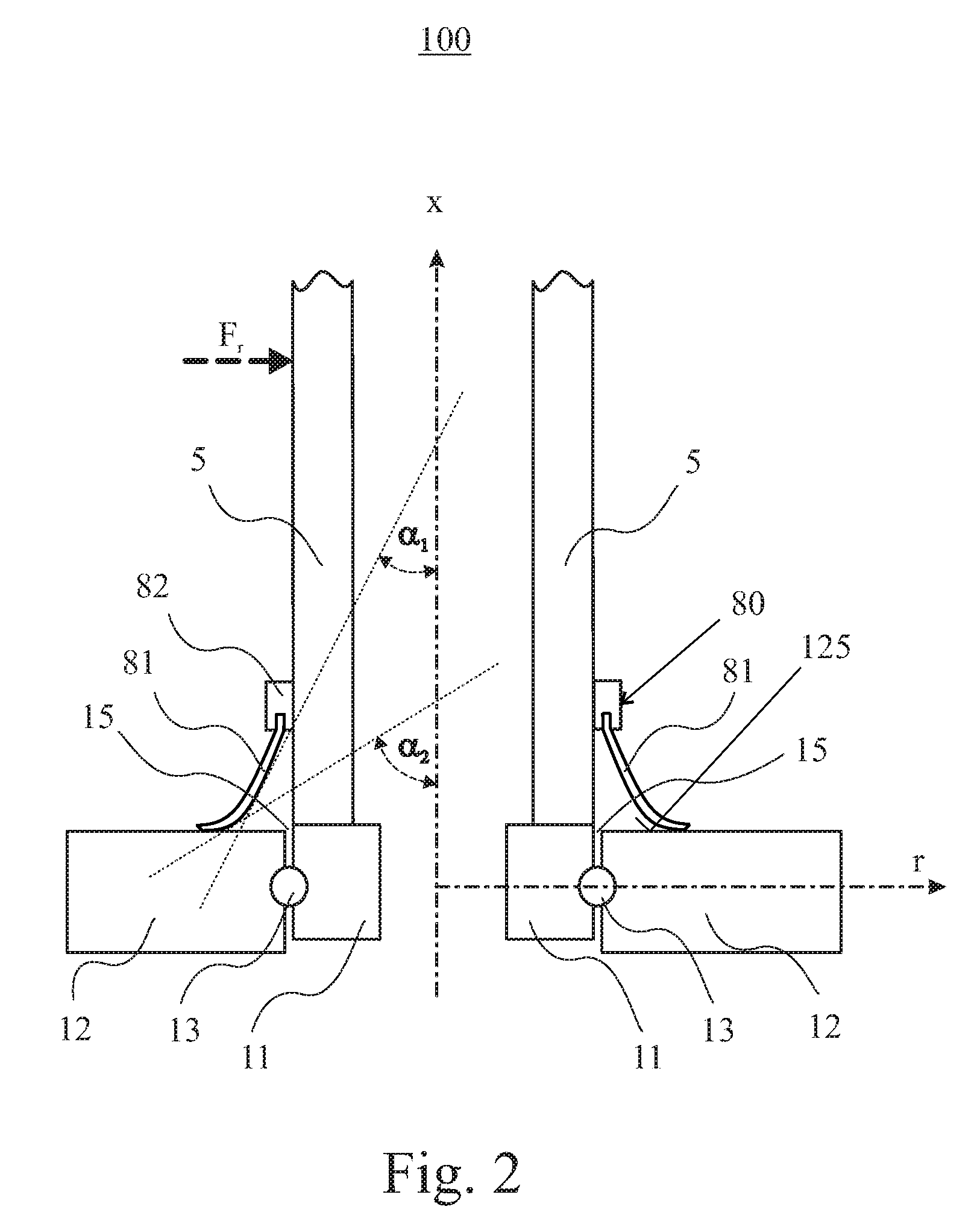

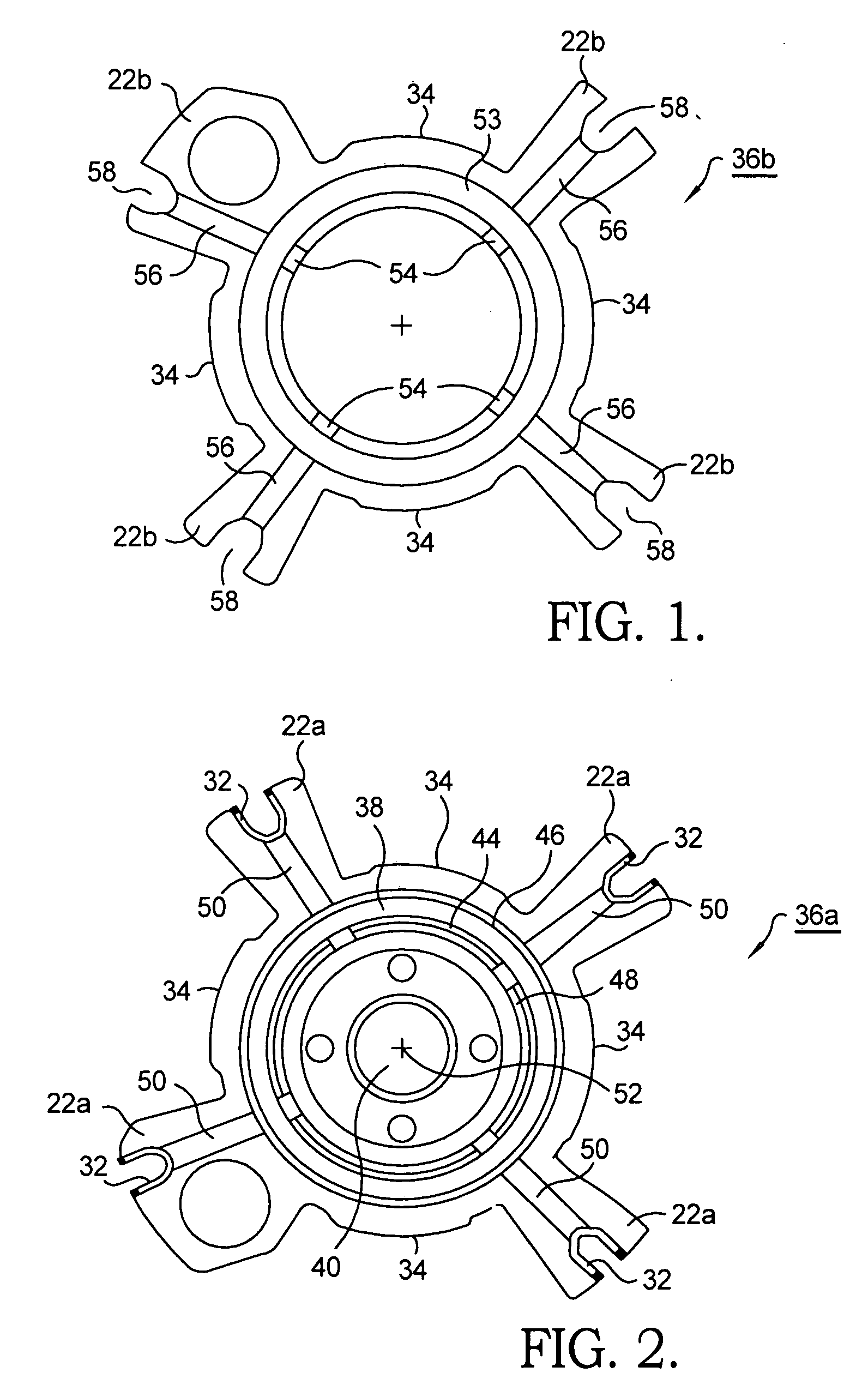

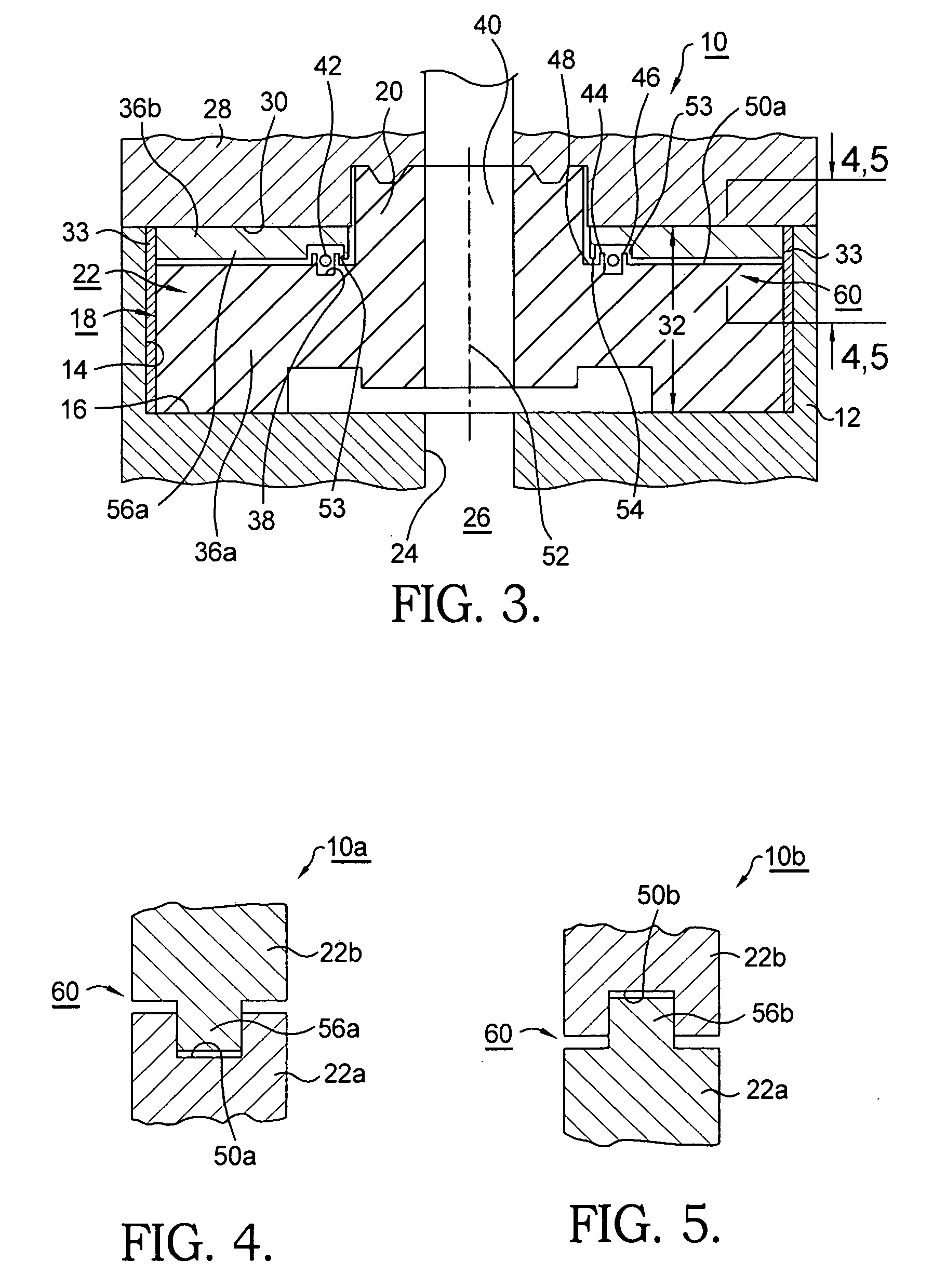

A self-propelled crawler / tractor apparatus is disclosed for traveling through a tubular pipeline while conducting pipeline wall inspection operations and / or towing gear for cleaning, maintenance and the like. The crawler / tractor apparatus is propelled by a plurality of radially positioned motorized traction wheels. Each motorized traction wheel includes a brushless DC electric motor along with clutch, gearbox and other mechanical drive components integrated into a compact self-contained motorized wheel assembly which is sealed and filled with an electrically non-conductive lubricating / cooling oil. The seal integrity at each wheel assembly is maintained against oil leakage and debris ingress by a pressure-balancing mechanism which matches internal oil pressure to the exterior ambient pressure present in the pipeline. The electric motor drive for each traction wheel is individually controlled via an onboard computer to provide a wide range of torque and wheel speeds.

Owner:GENERAL ELECTRIC CO

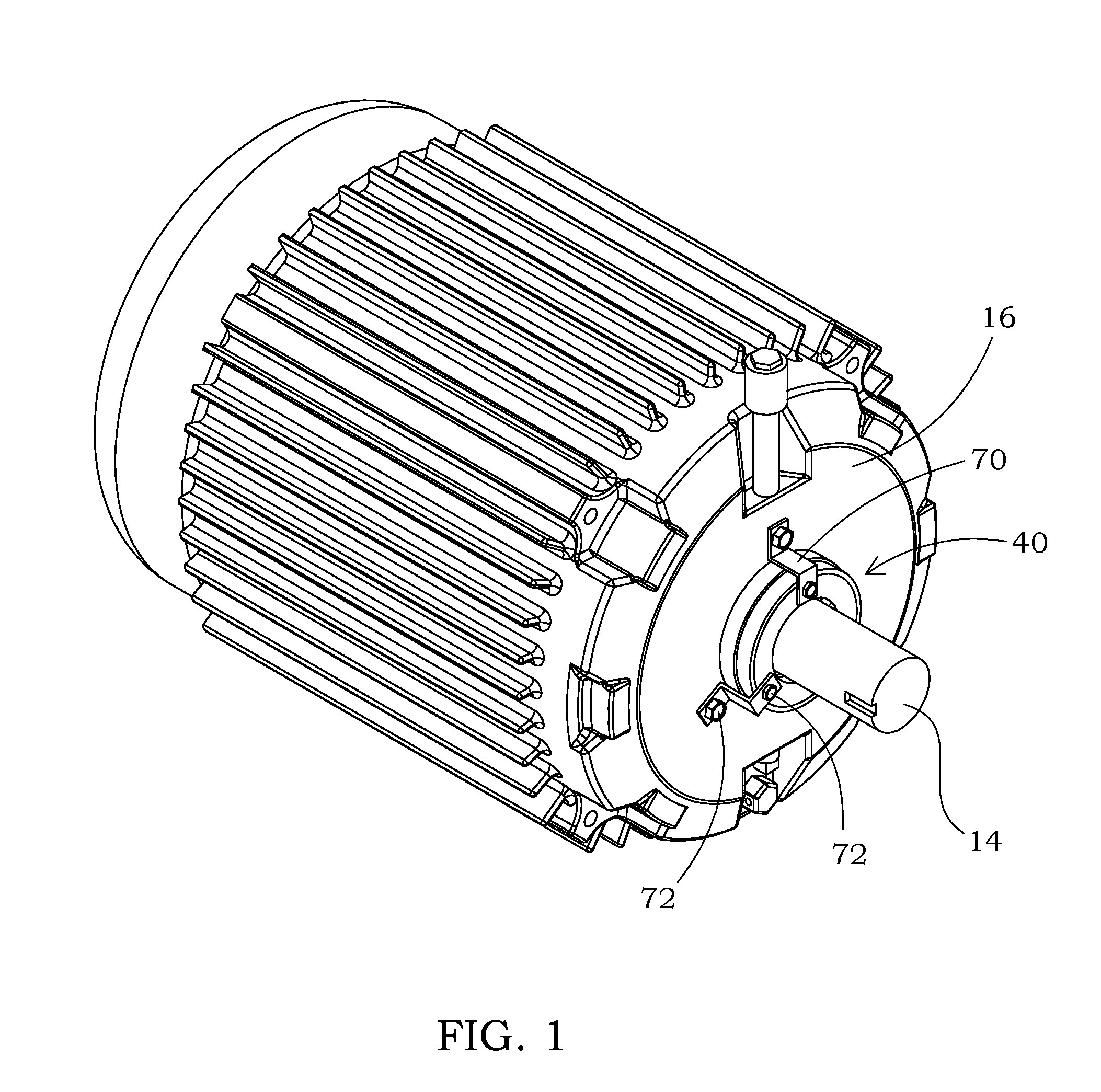

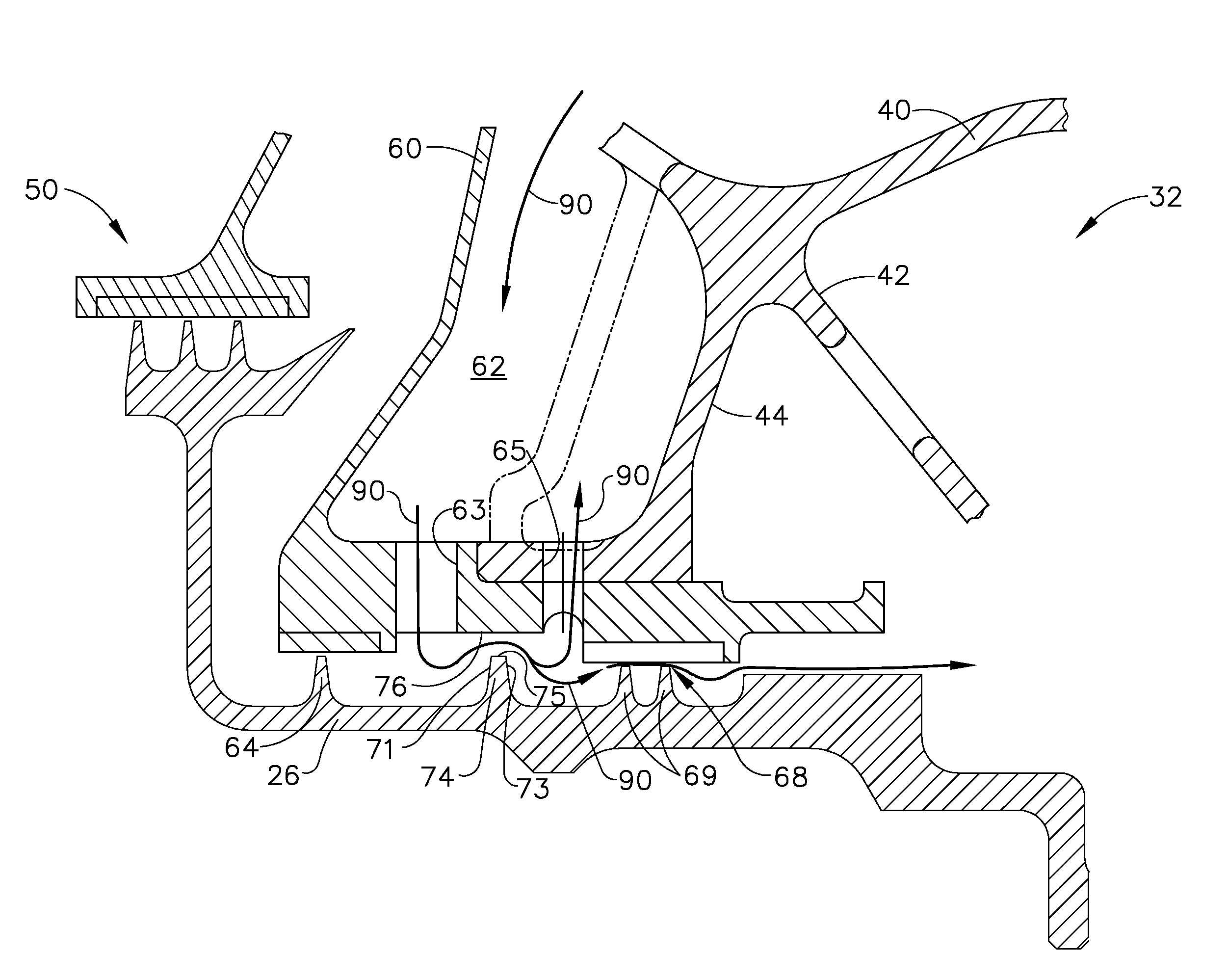

Motor ground seal

InactiveUS7521827B2Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesShock coolingRadial projection

Owner:INPRO INC

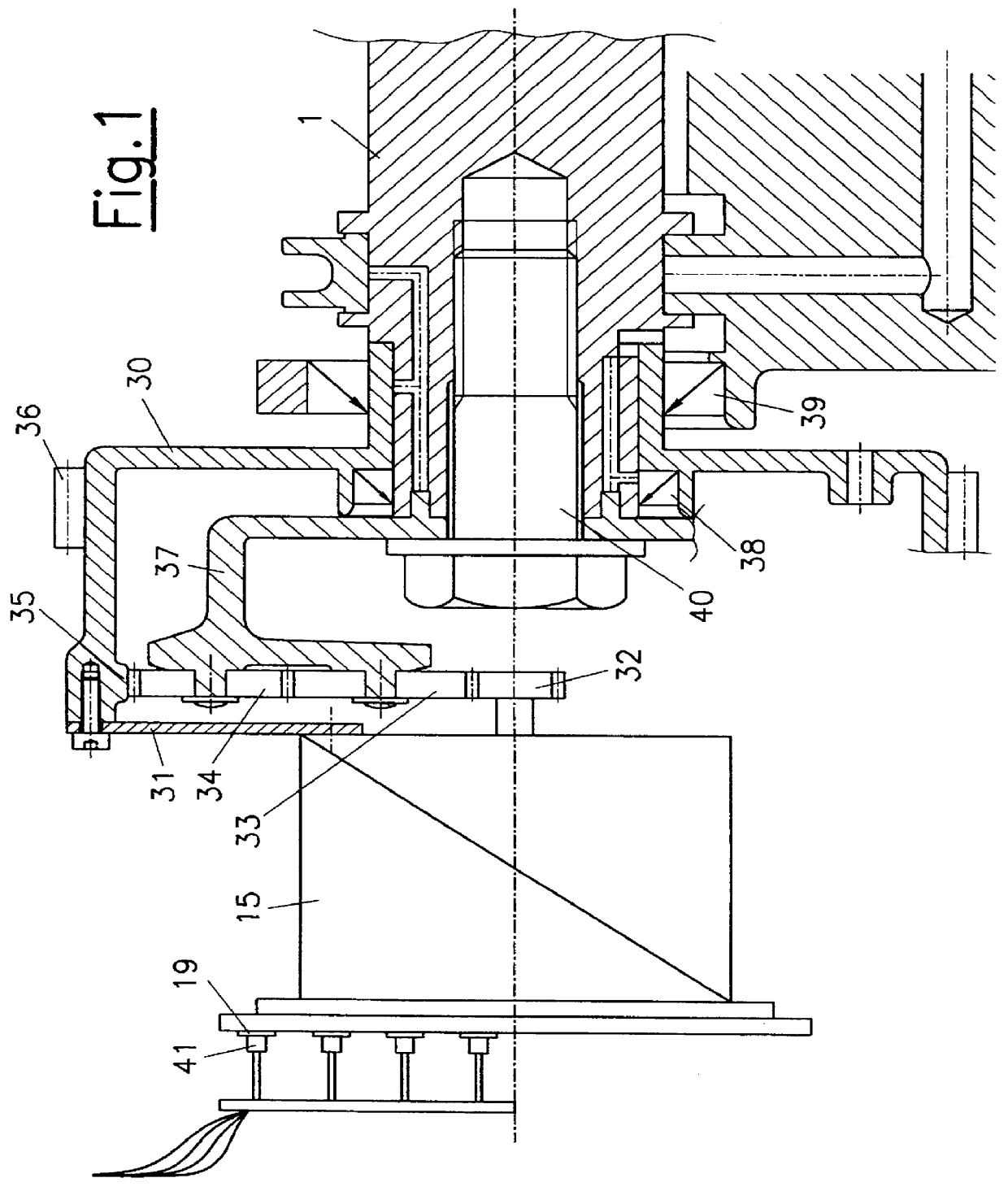

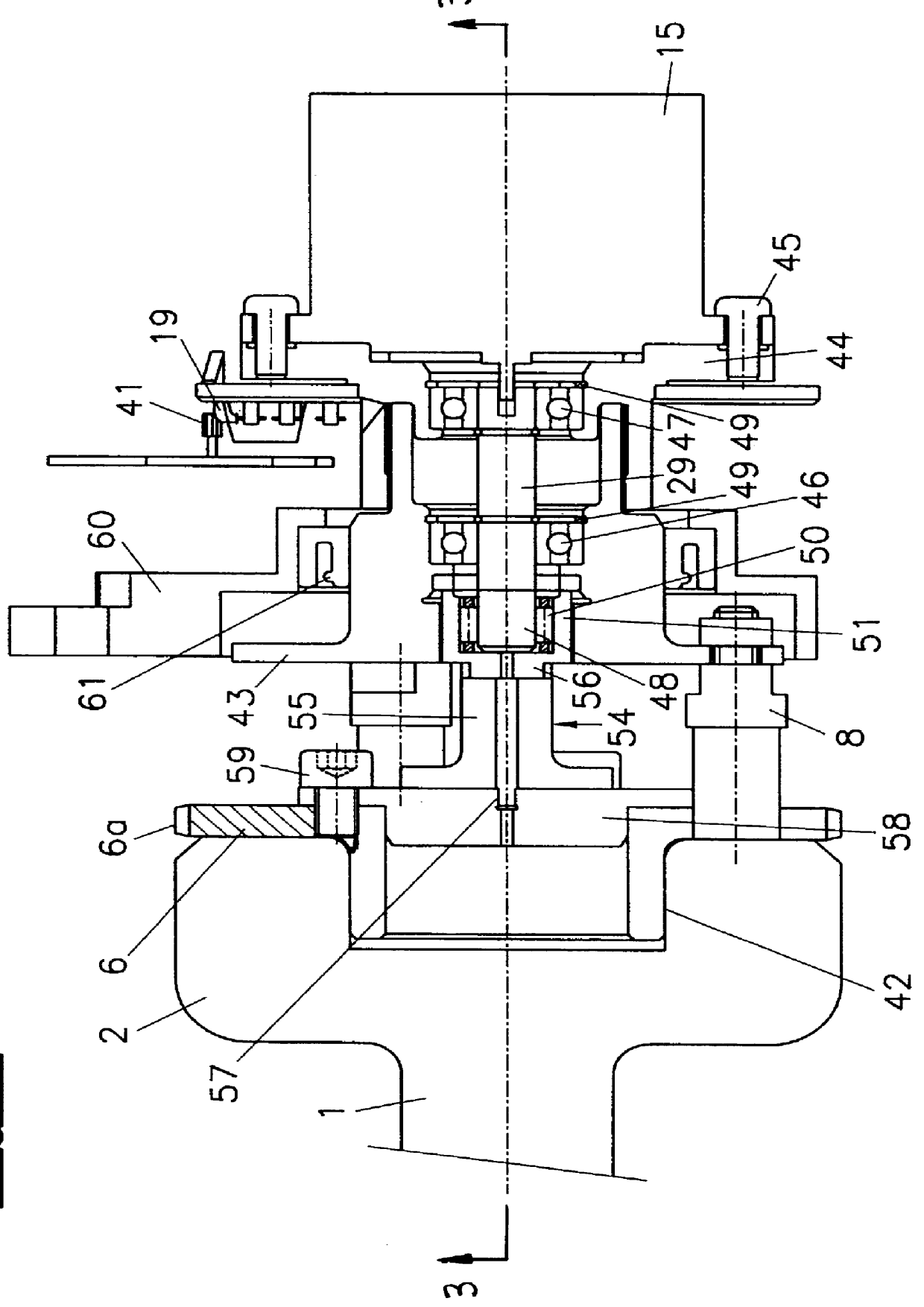

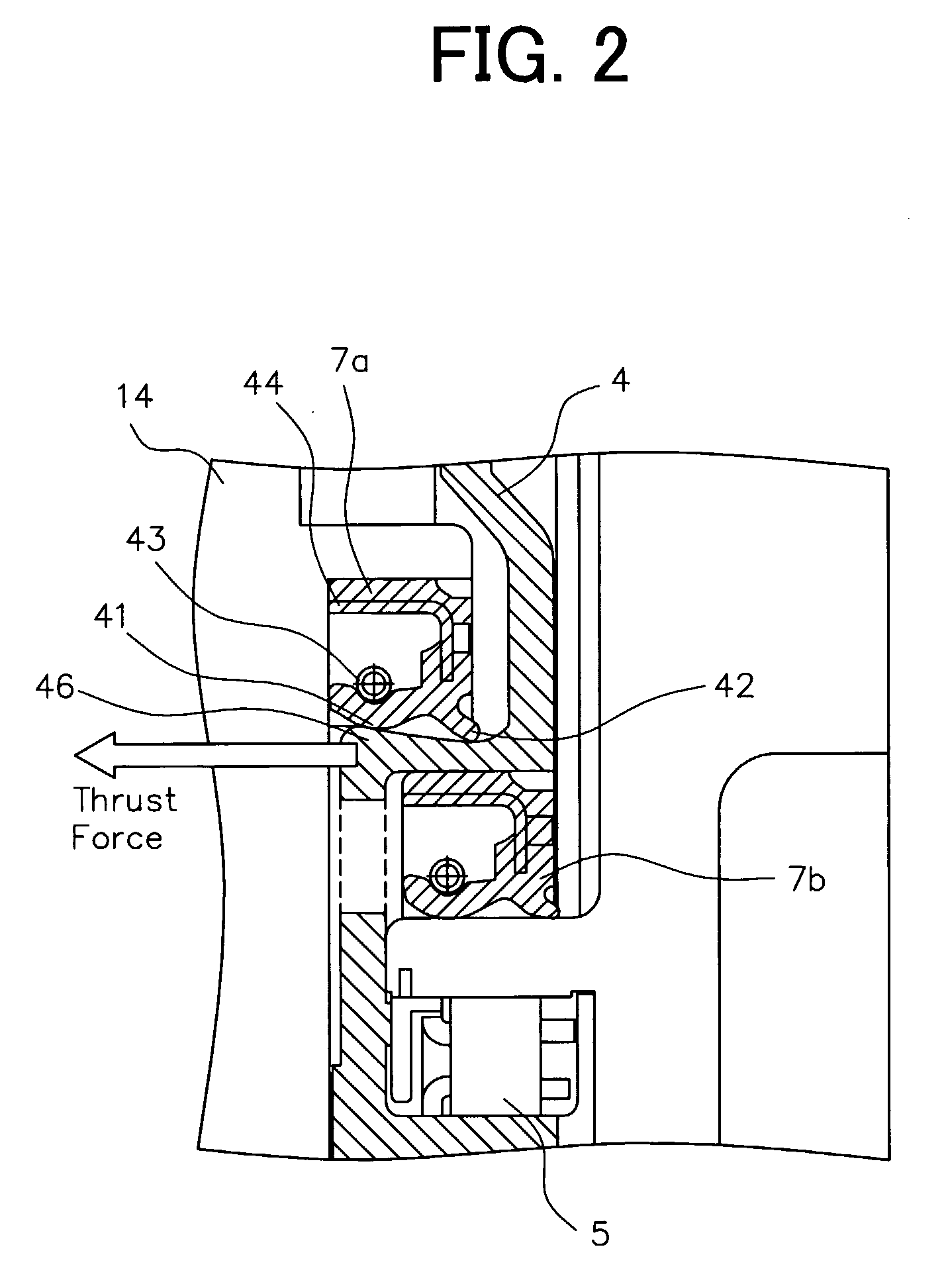

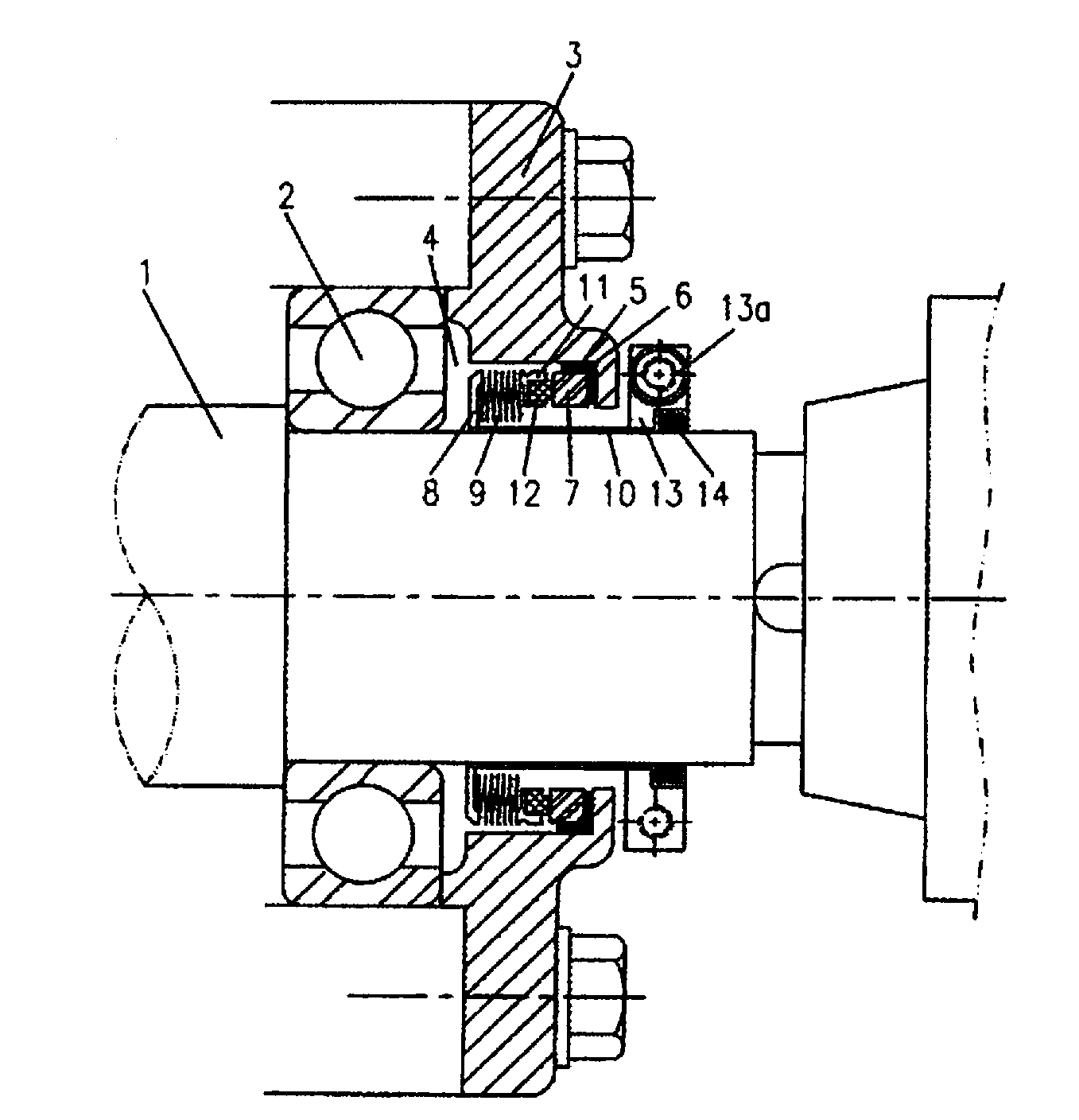

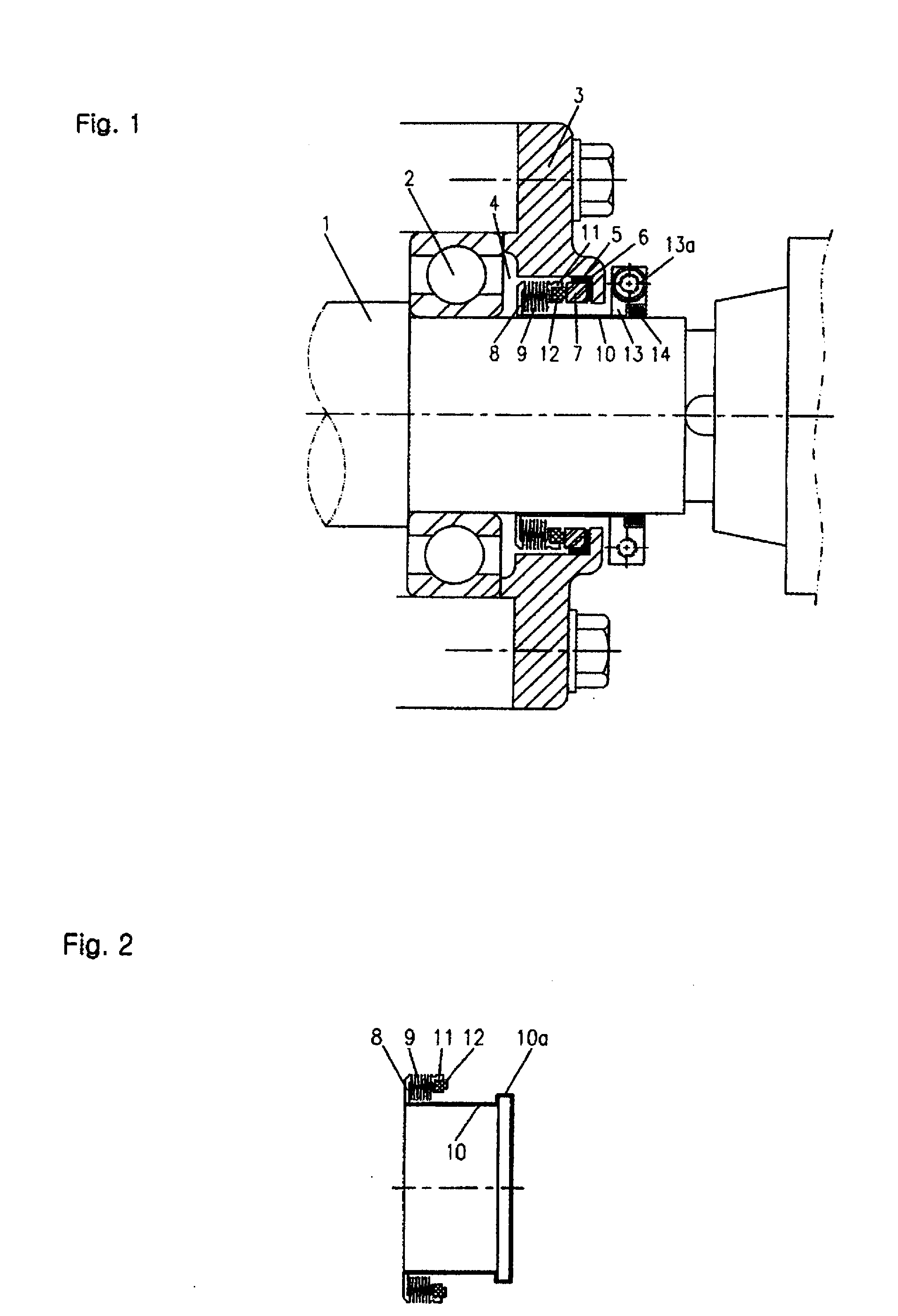

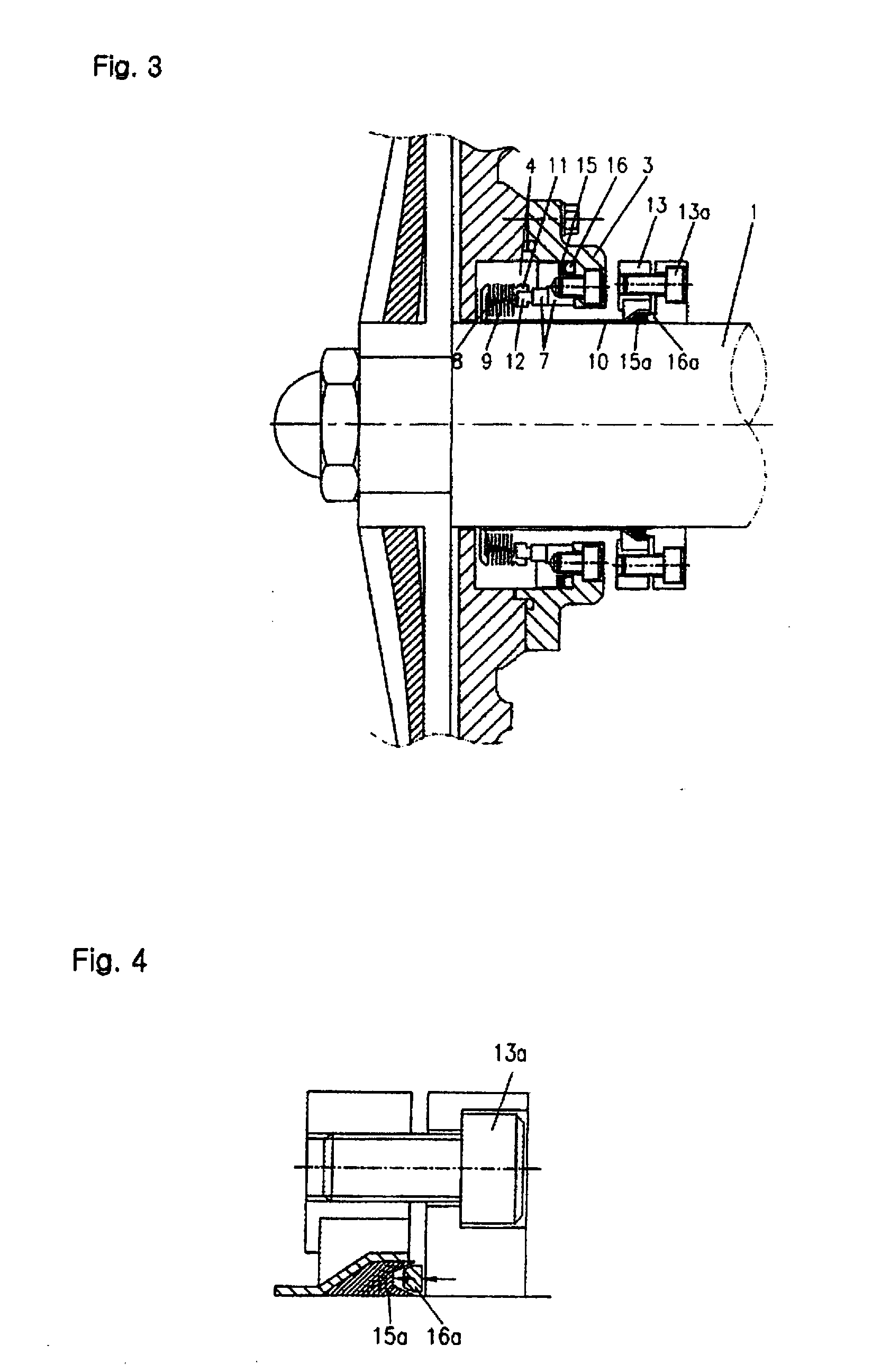

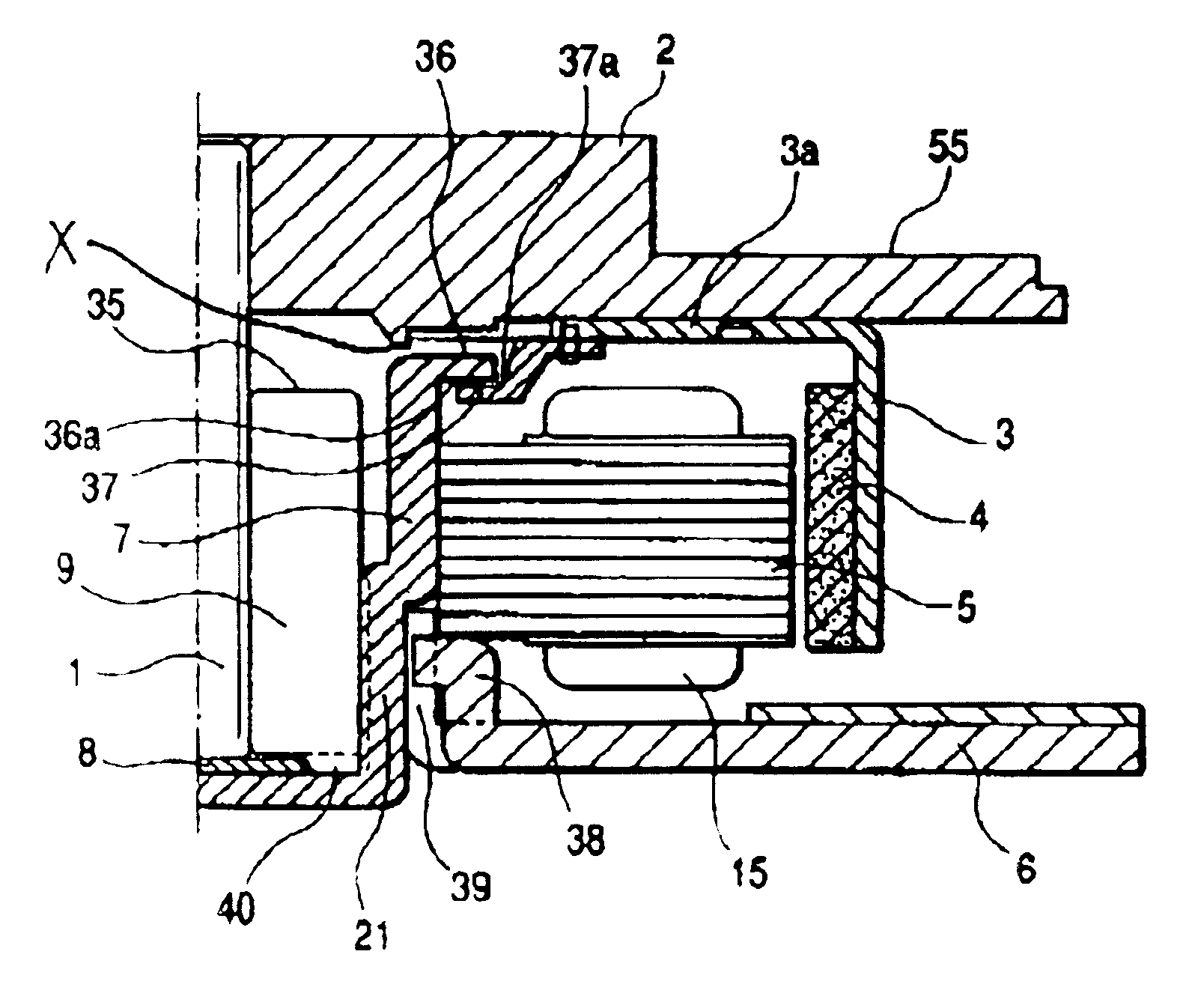

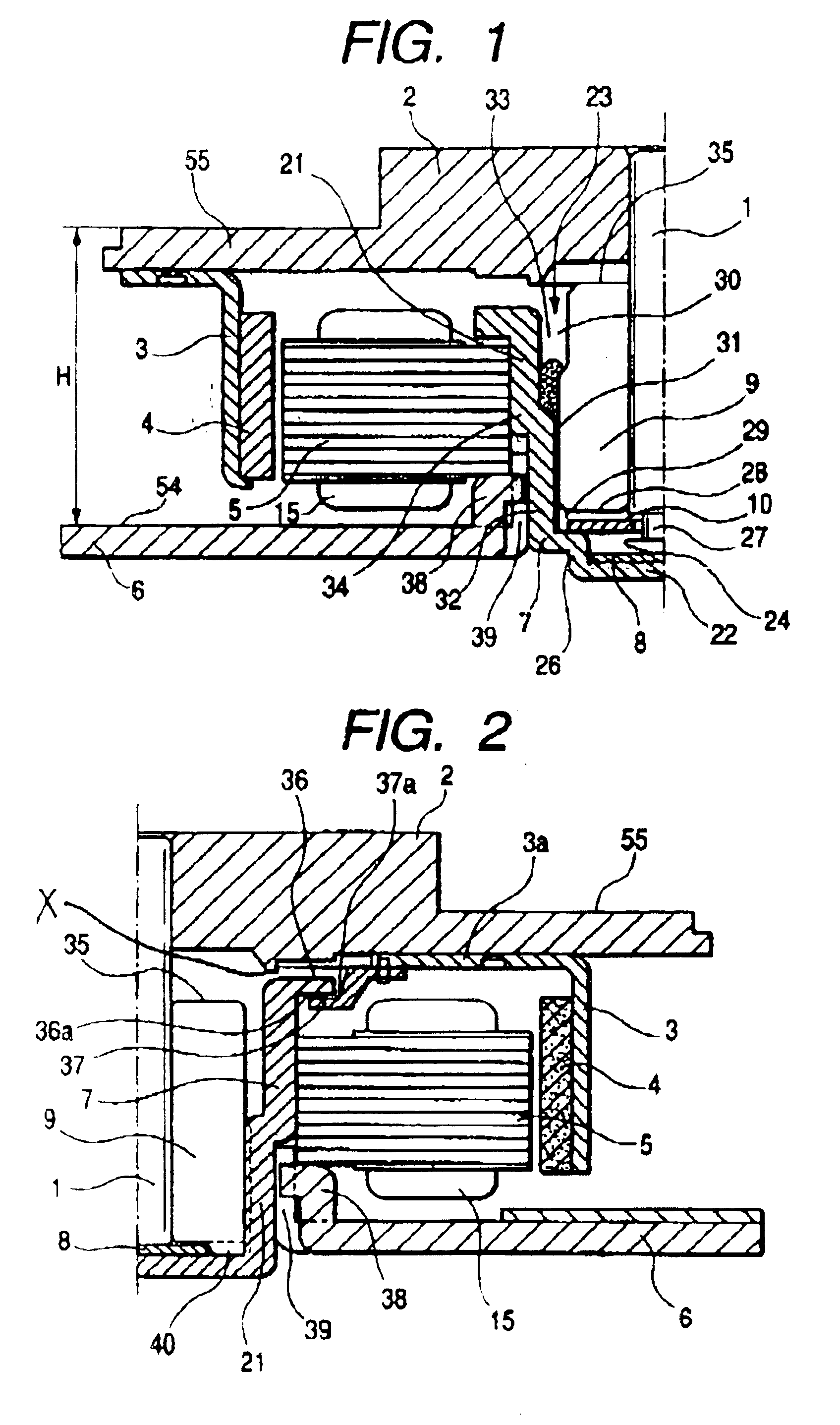

Device for adjusting the phase angle of a camshaft of an internal combustion engine

InactiveUS6138622ASimple designSmall sizeValve drivesMachines/enginesGear wheelExternal combustion engine

A device for adjusting the phase angle of a camshaft of an internal combustion engine includes an adjusting mechanism which is operated by an electric motor, the latter being rigidly connected to the camshaft or the camshaft drive gear. Reliable adjustment is obtained in a simple manner by providing the adjusting mechanism as a planetary gear set.

Owner:TCG UNITECH AKTIENGES

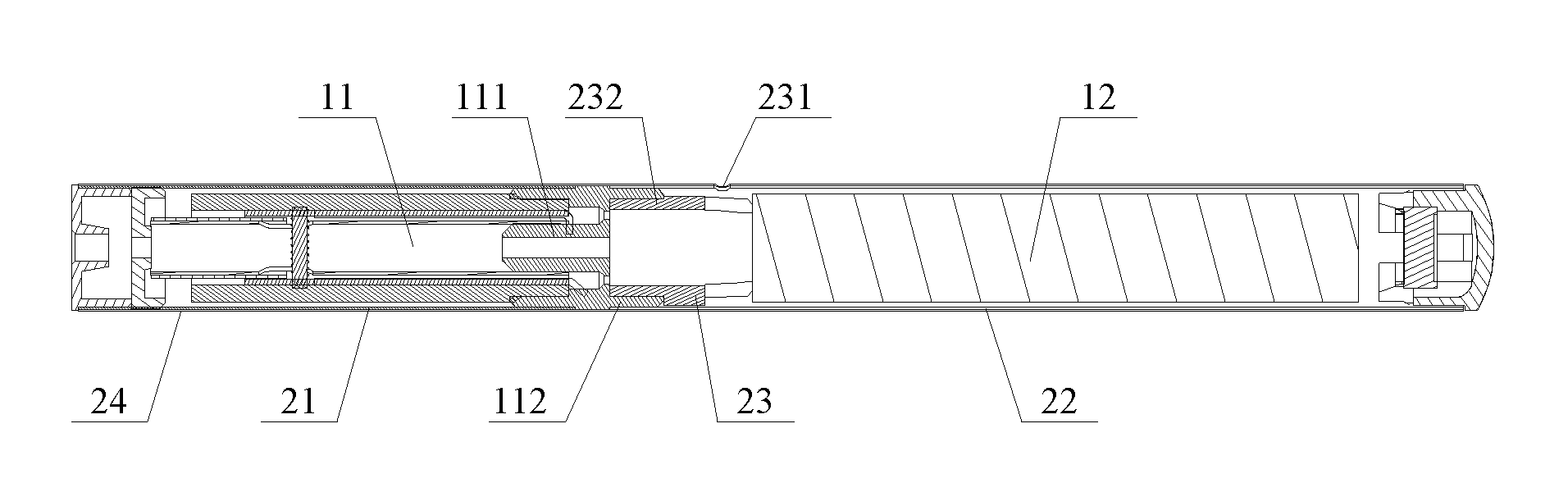

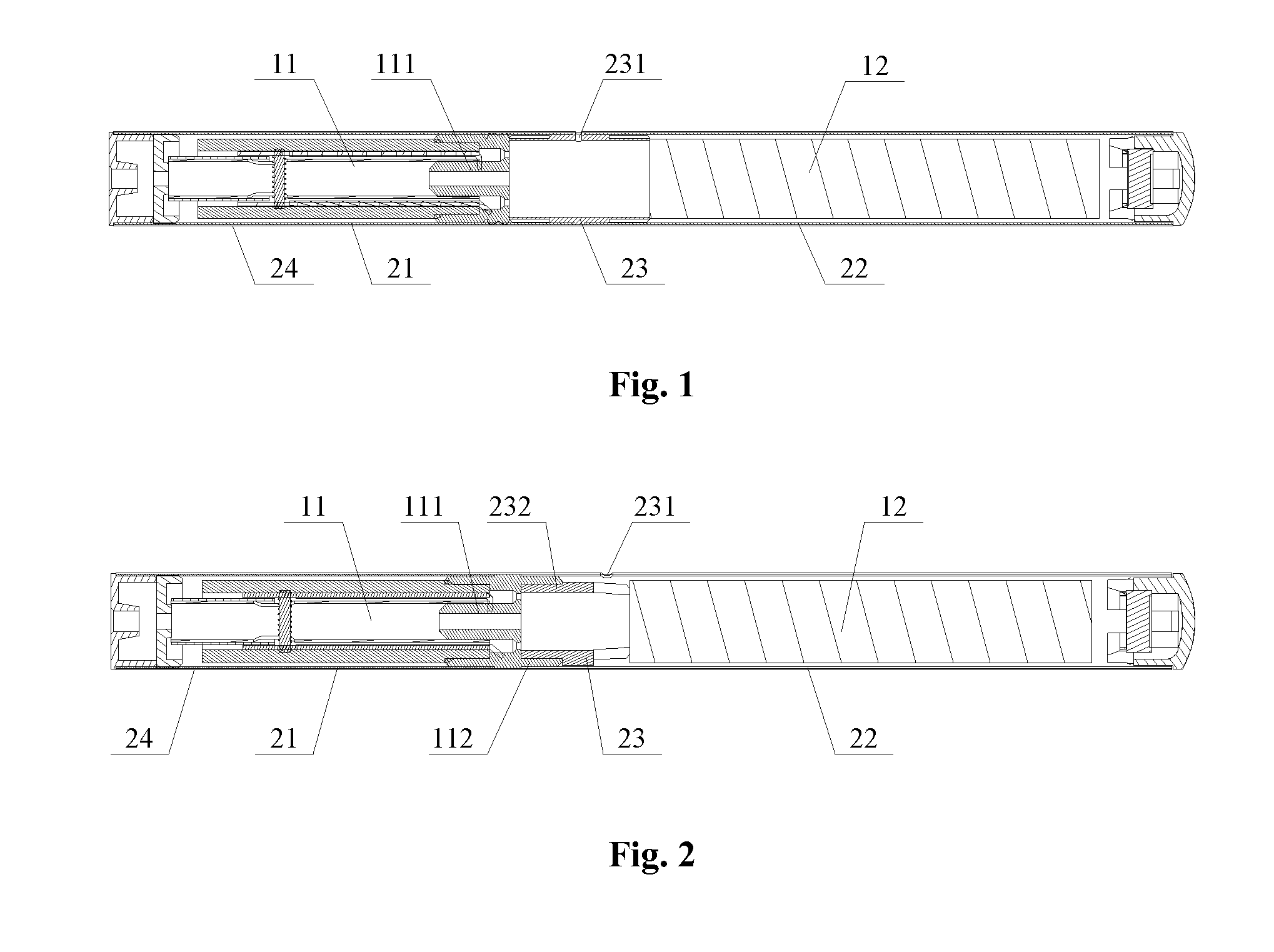

Electronic cigarette

InactiveUS20160242463A1Prevent oil leakageAssembly structure is stable and reliableTobacco devicesCell component detailsElectrical batteryEngineering

An electronic cigarette, in which an atomizer assembly protective cartridge is provided outside of the atomizer assembly, and a battery assembly protective cartridge is provided outside of the battery assembly. An atomizing seat fitted with the holder is provided at an inner end of the atomizer assembly. At least a coating layer is provided outside of the atomizer assembly protective cartridge, the holder and the battery assembly protective cartridge, and enables connection between the atomizer assembly protective cartridge, the holder and the battery assembly protective cartridge. In the overall process of assembling the electronic cigarette, since there is no pushing or squeezing action between the atomizer assembly and the battery assembly, it is possible to effectively avoid oil leakage caused by an inclination and a deformation of the atomizing seat under uneven force is effectively avoided.

Owner:HUIZHOU KIMREE TECH

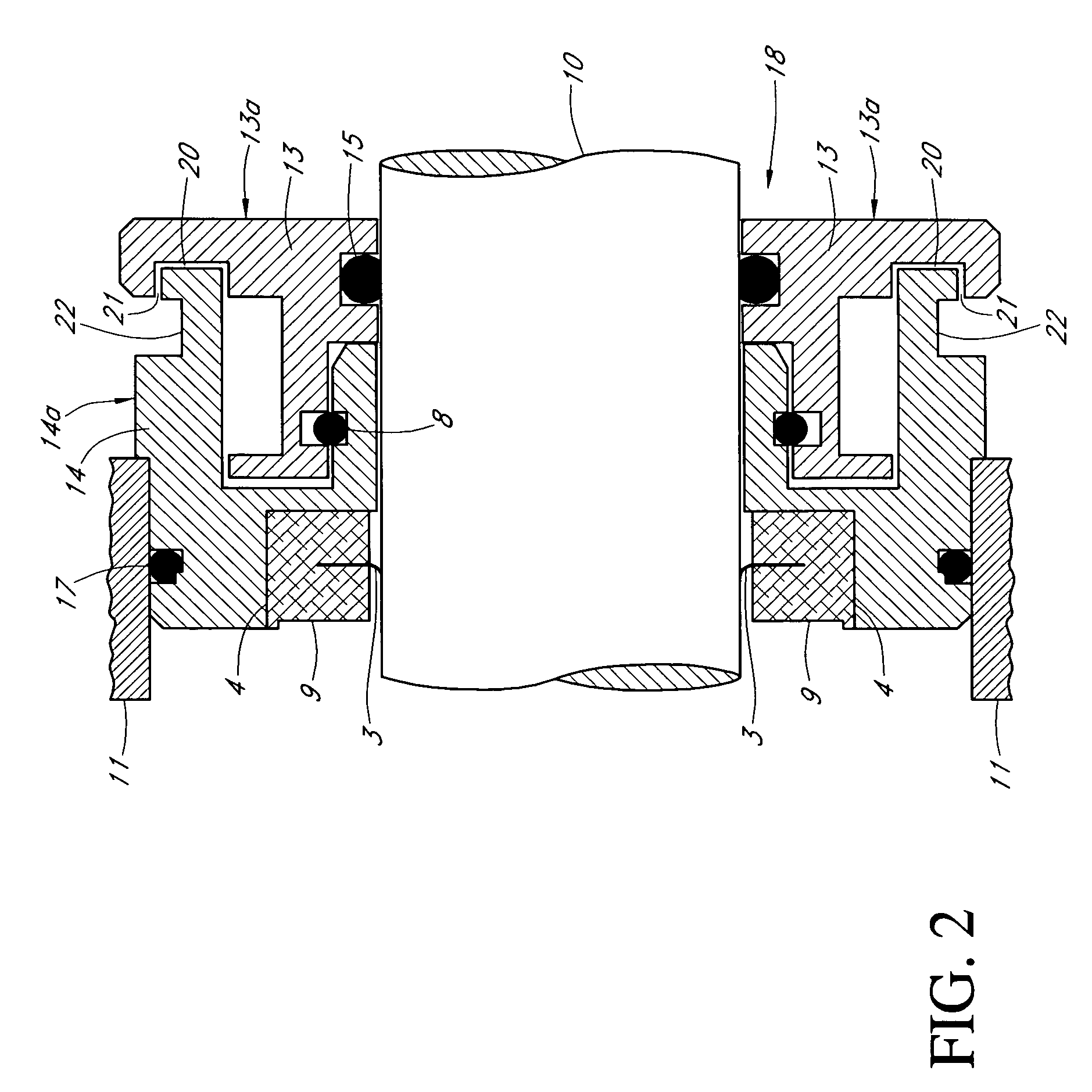

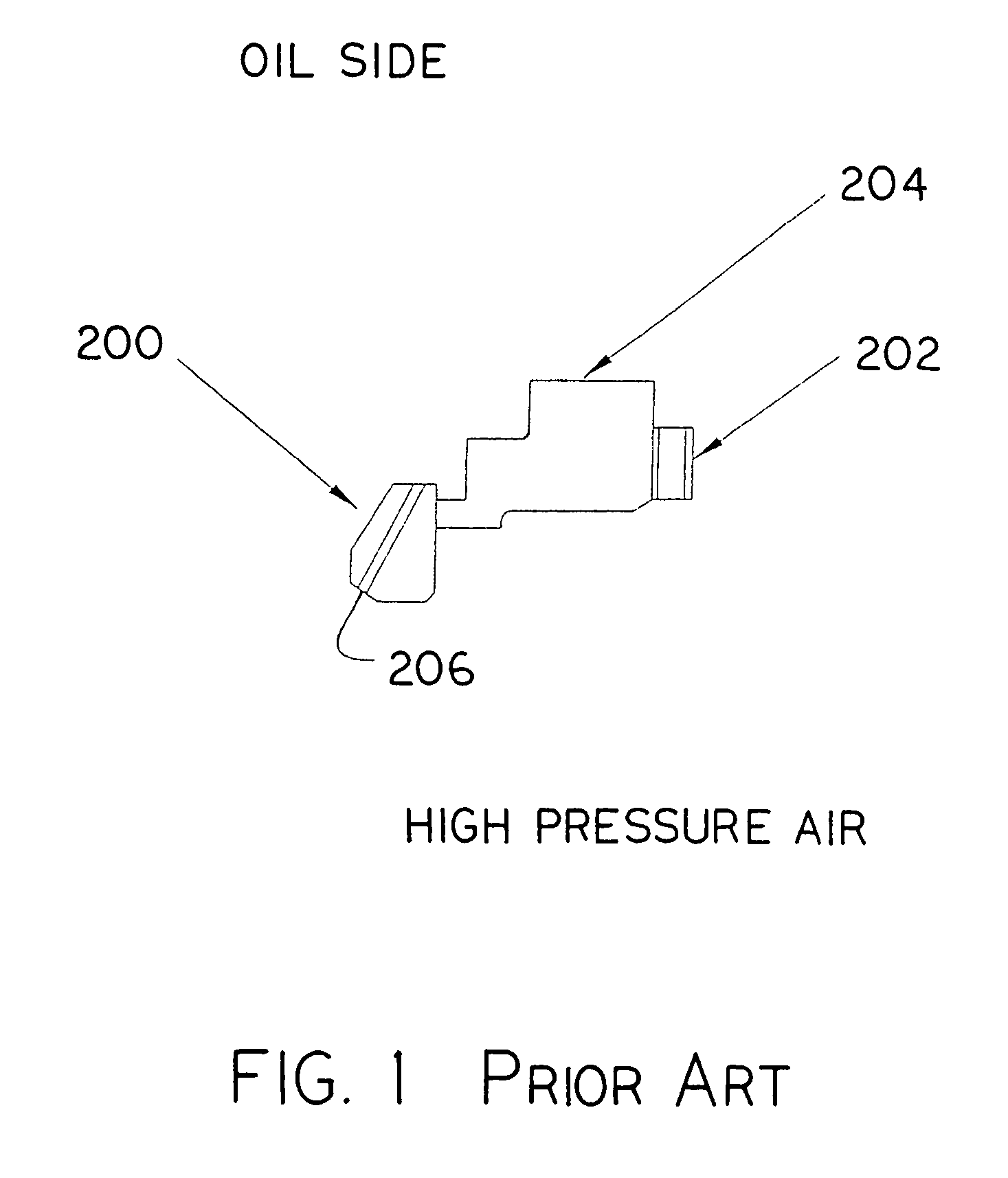

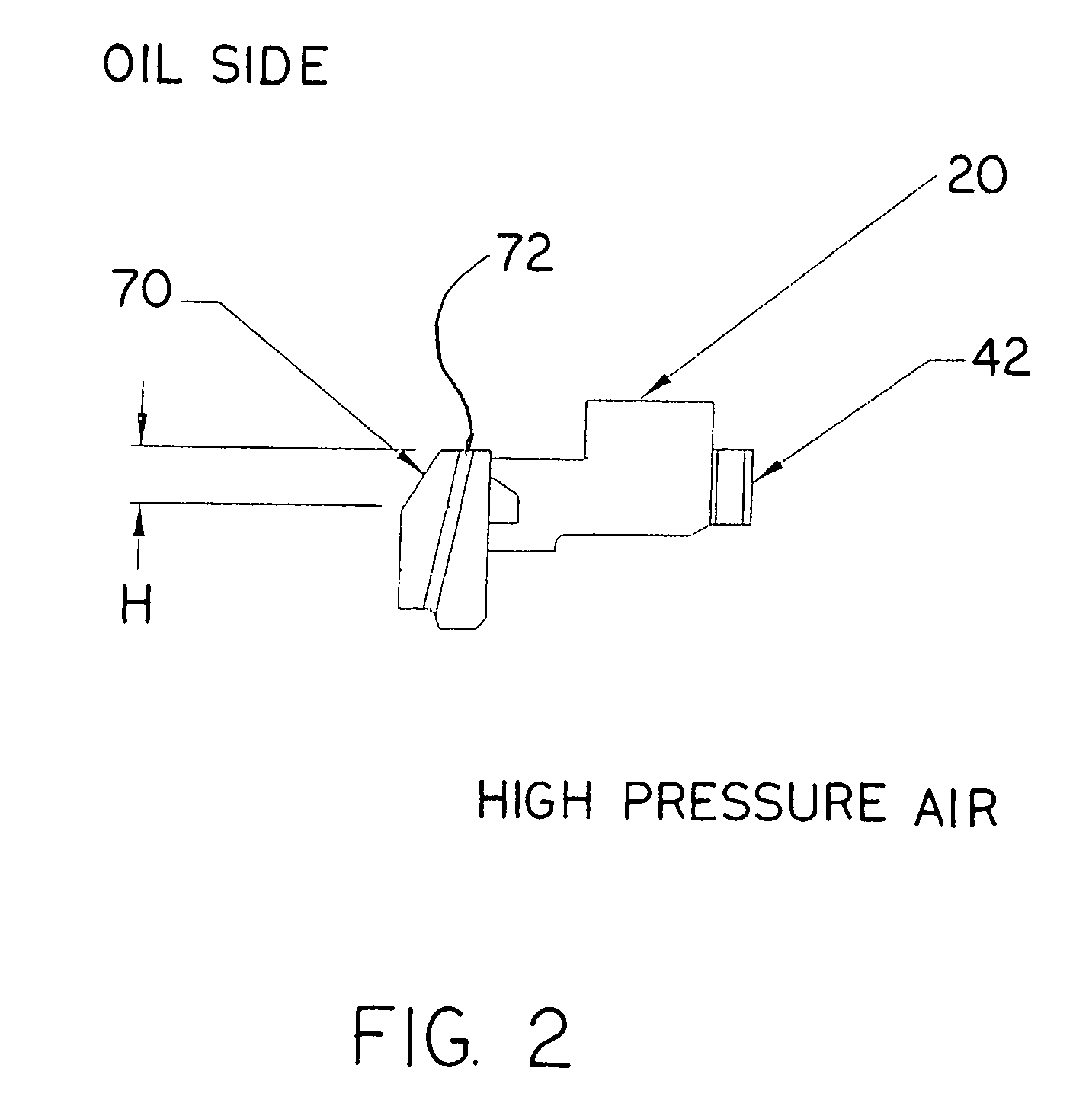

Motor ground seal

InactiveUS20070138748A1Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesEngineeringRelative motion

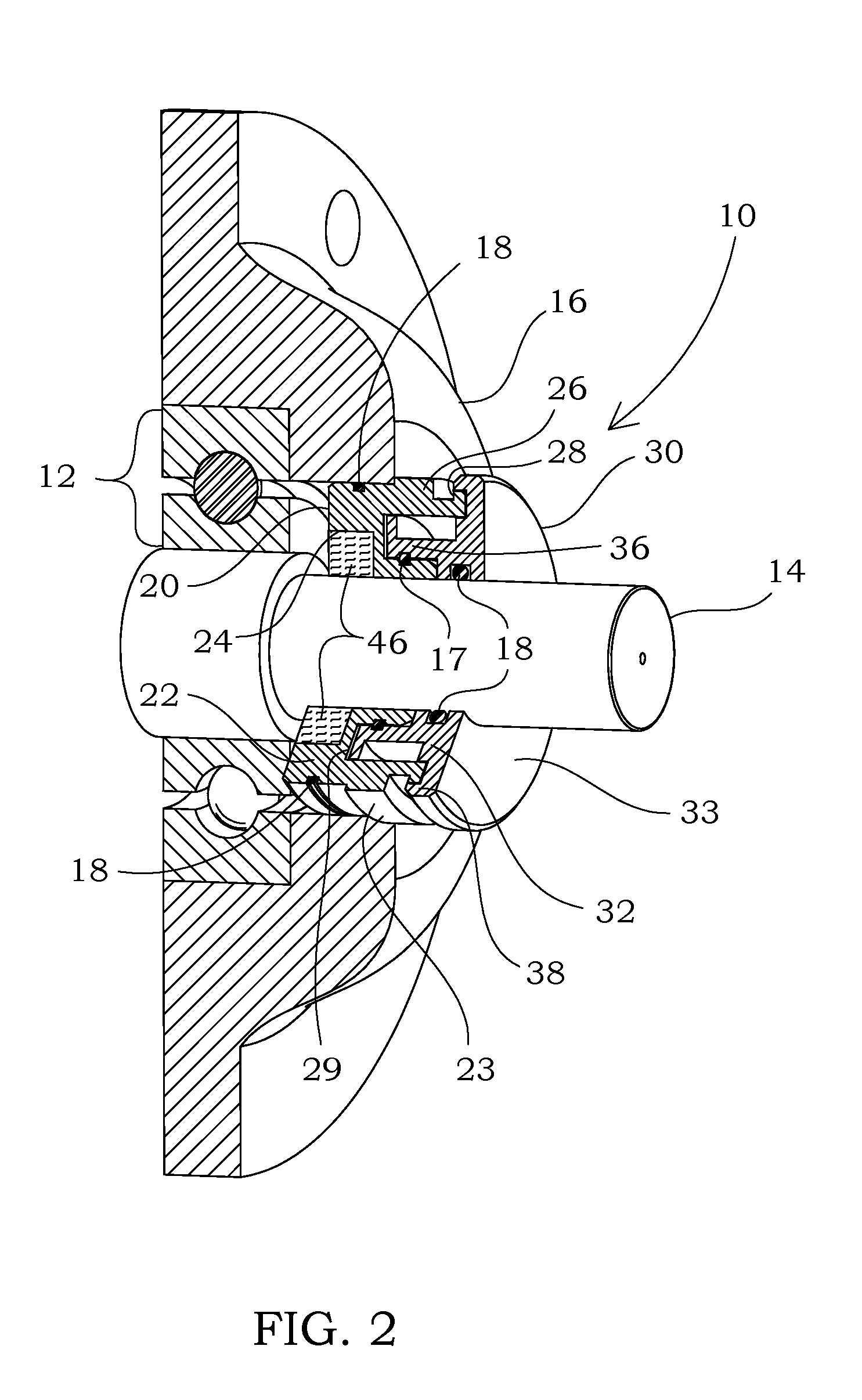

A shaft seal assembly is disclosed having a stator including a main body and axial and radial projections therefrom. The rotor is radially extended and encompasses the axial and radial projections from said stator. A passageway formed between the radial projection of stator and rotor results in an axial passageway having its opening facing rearwardly from the rotor and away from the source of impinging coolant and / or contaminant. A concentric circumferential receptor groove in the stator facing the housing allows insertion of conductive means for transmission of electrostatic charge away from the shaft through the shaft seal assembly to the housing and ground. The receptor groove is opposite the axial passageway and provides for both a substantially lower contaminant environment and improved engagement with conductive means. The dimension of interface gap between the rotor and the radial projection from the stator, which the access to the shaft of any impinging material is fixed at a predetermined value and does not vary with the relative movement between the rotor and the stator. The shaft seal assembly provides improved rejection or warding off of contaminants from ingress into the labyrinths and ultimately restrains attack of the bearing environment as well as substantial elimination of bearing current and attendant bearing fluting or frosting.

Owner:INPRO INC

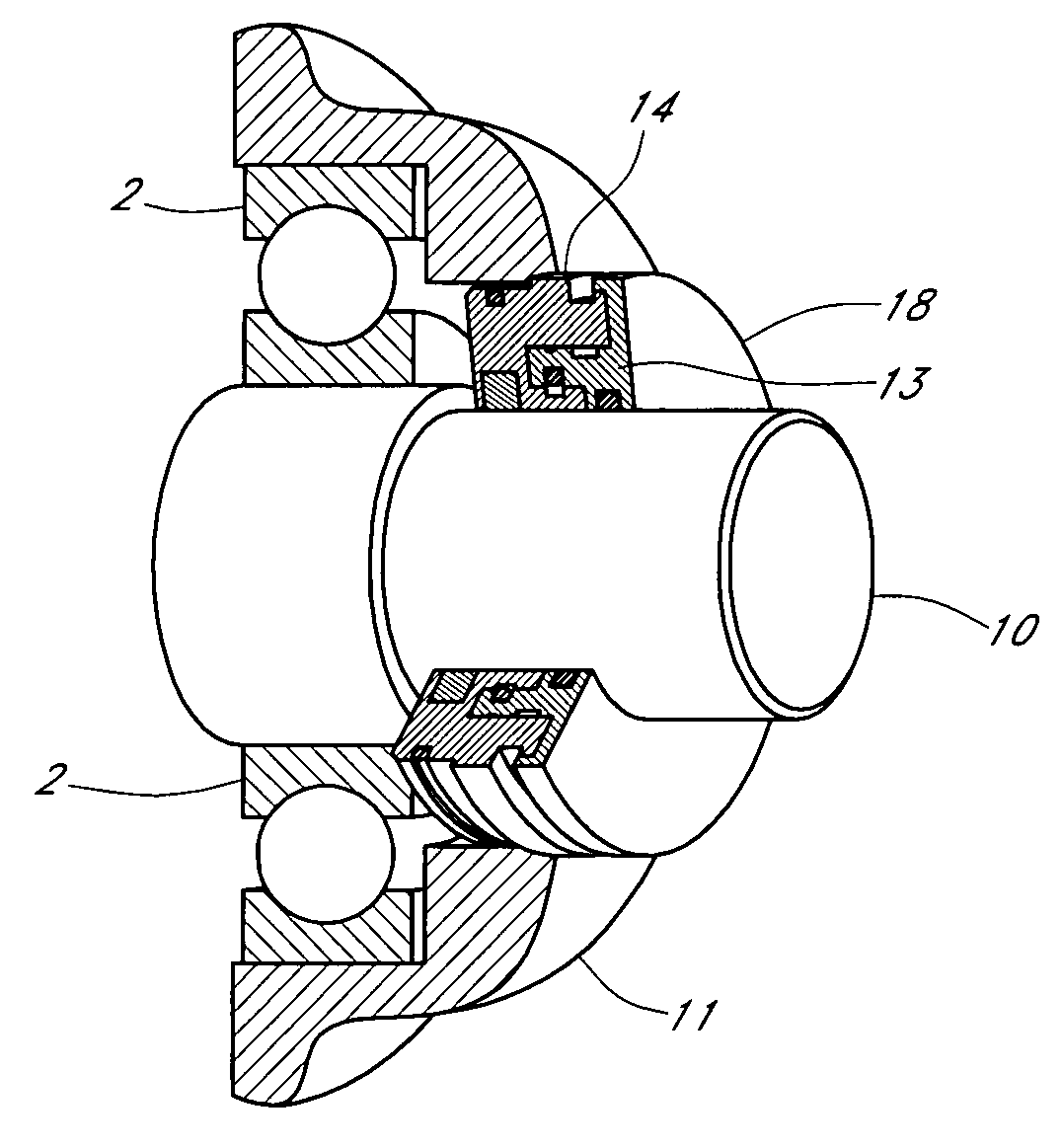

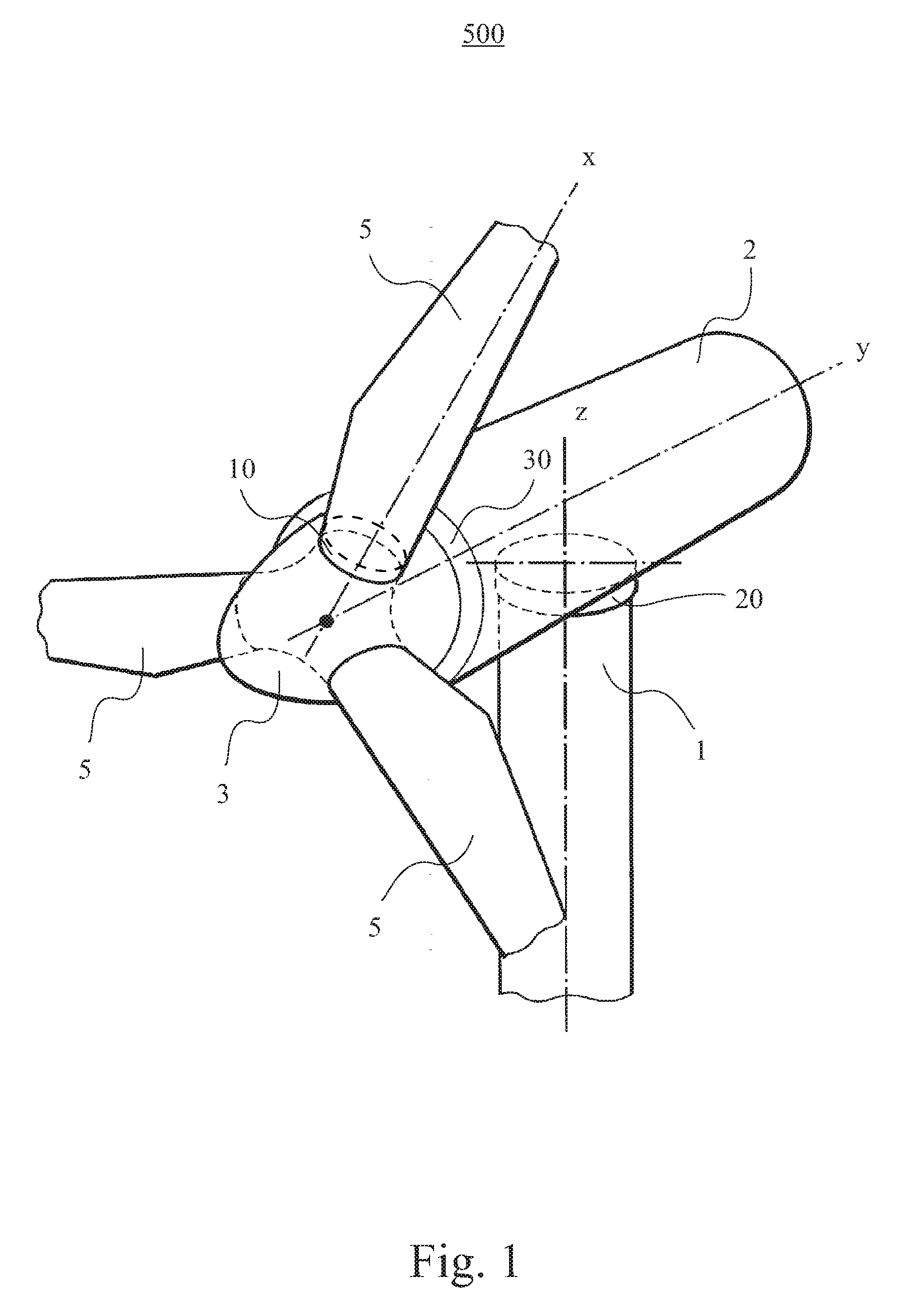

Seal arrangement and a brush seal for a wind turbine

A seal arrangement for sealing a bearing comprising a first component and a second component which are rotatably movable with respect to each other is provided. The seal arrangement includes brush seal having an annular brush body carried by the first component and a bundle of resiliently bendable bristles. The brush seal is adapted to maintain a sealing condition when the first and second component are moved relative to each other in a non-rotational manner. Further, a brush seal and a wind turbine having a brush seal are provided.

Owner:GENERAL ELECTRIC CO +1

Method and device for minimizing oil consumption in a gas turbine engine

InactiveUS6877950B2Oil consumption is minimizedHigh densityEngine sealsPump componentsEngineeringProduct gas

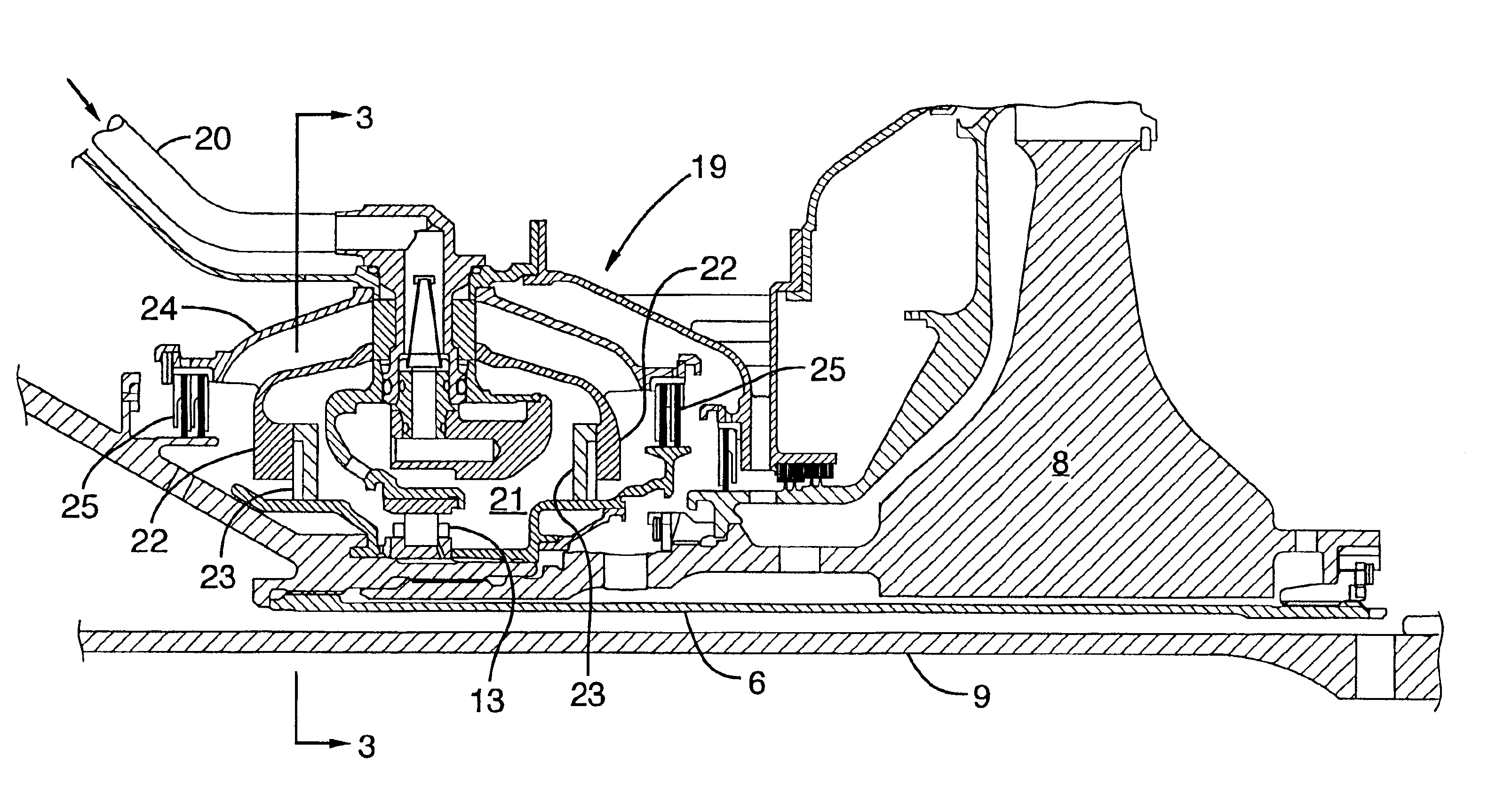

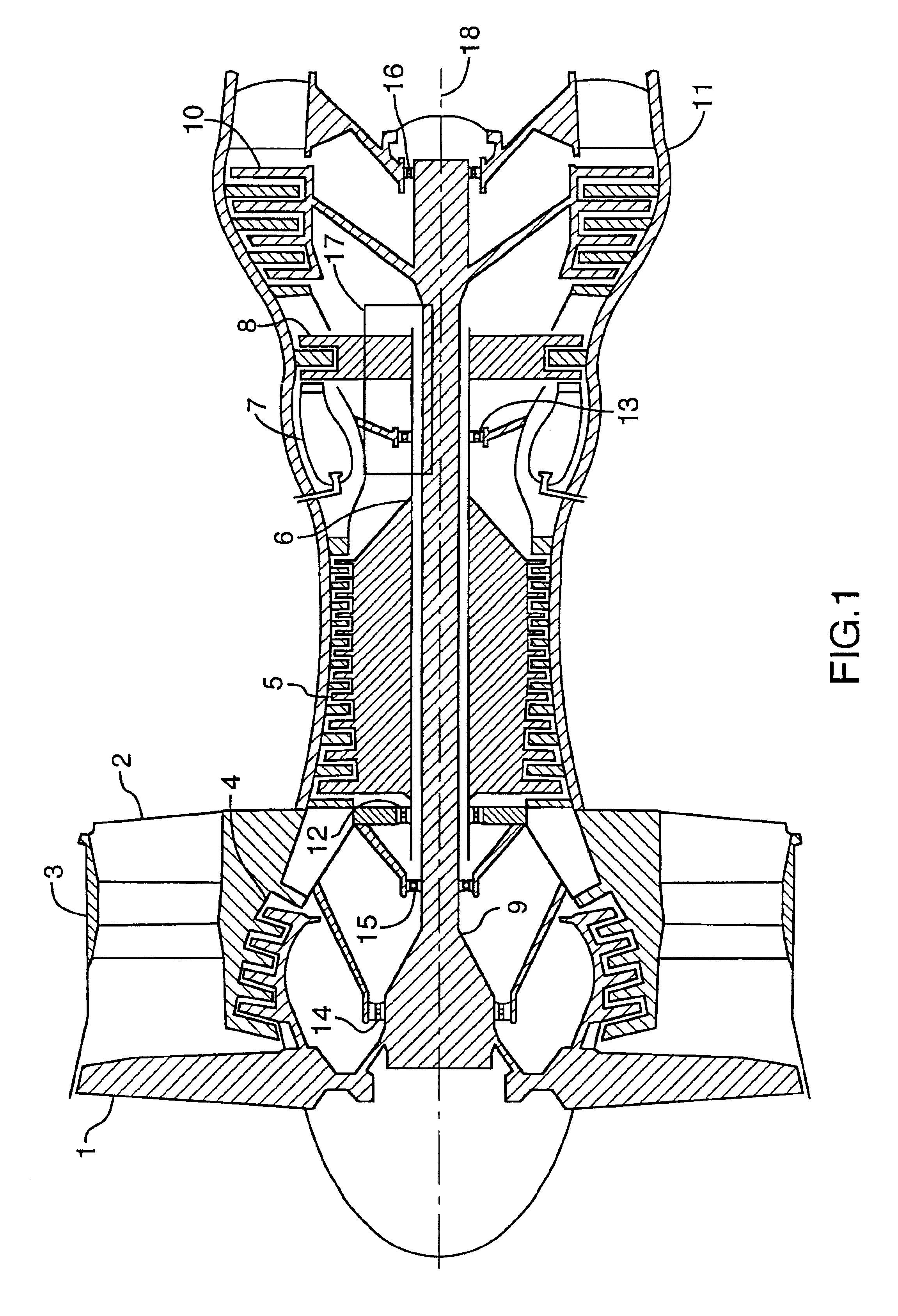

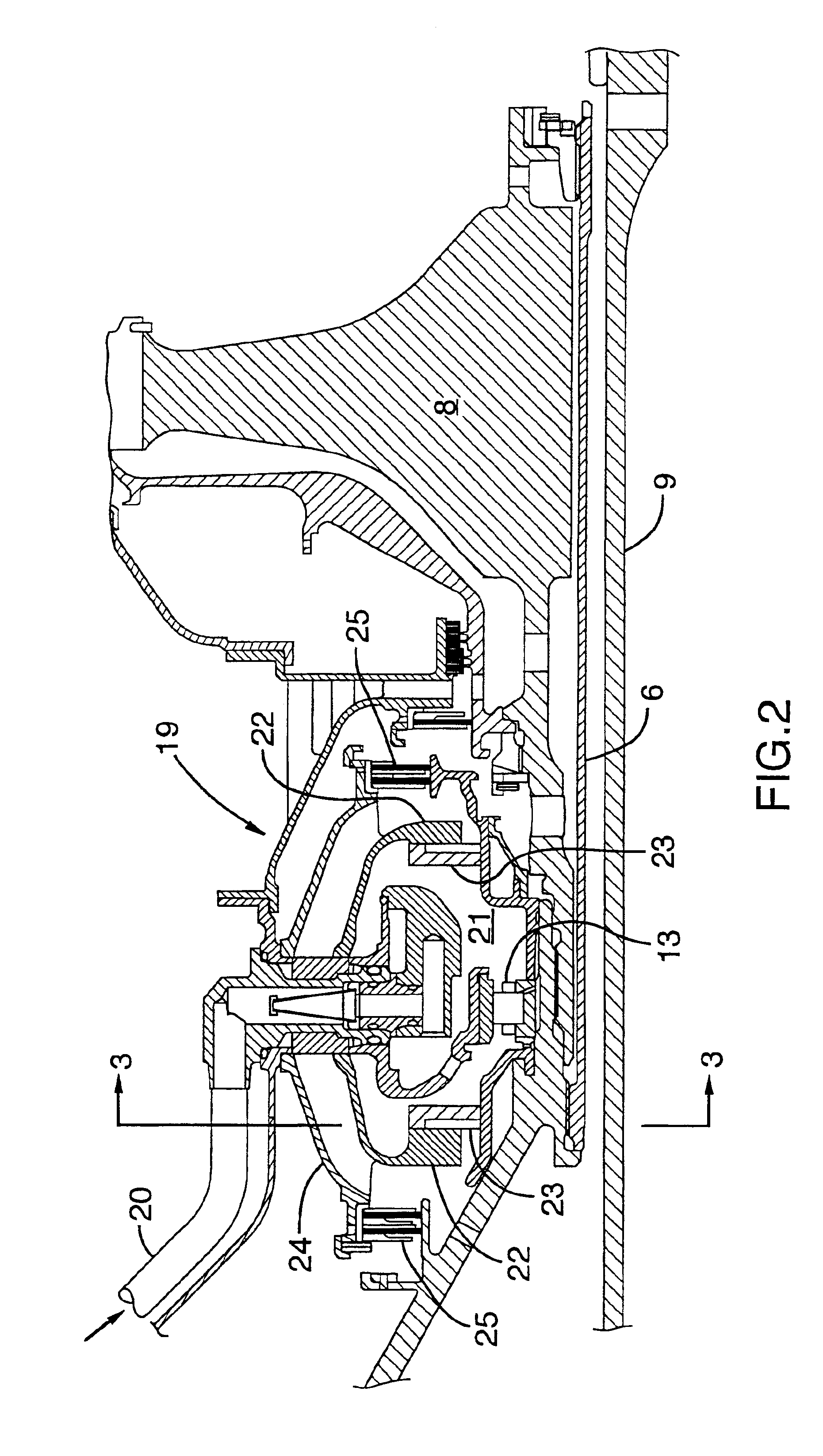

A method of minimizing oil consumption in a gas turbine engine, by avoiding reliance on air intake into the engine oil circuit for bearing chamber oil sealing purposes. The engine oil circuit has bearing chambers with hydropad seals between the shaft and bearing chamber. During engine operation the ring rotates to cast oil radially outwardly from the shaft axis toward the outer periphery of the bearing chamber under centrifugal force, independent of any gas pressure differential across the sealing surfaces of the hydropad seal.

Owner:PRATT & WHITNEY CANADA CORP

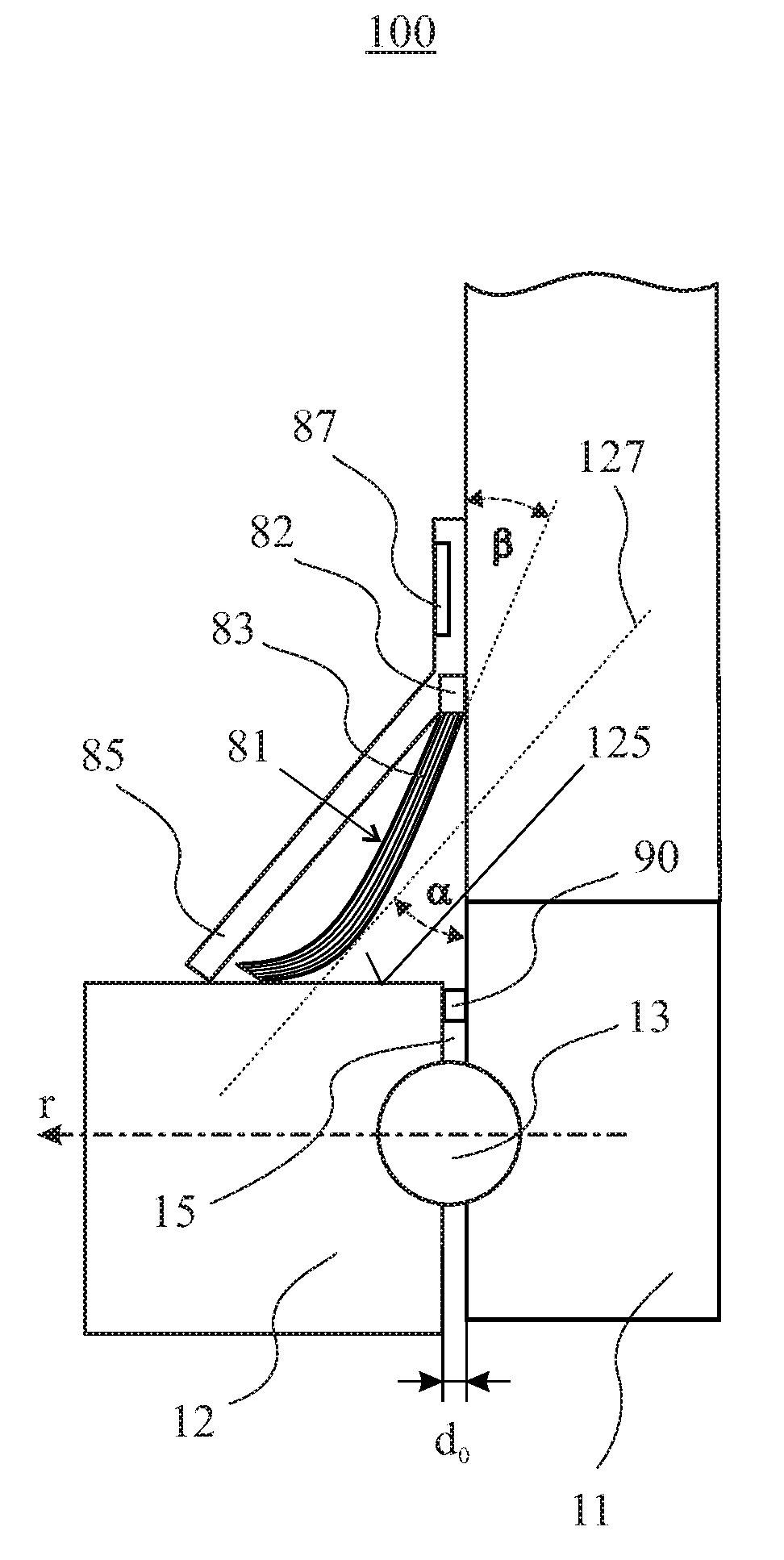

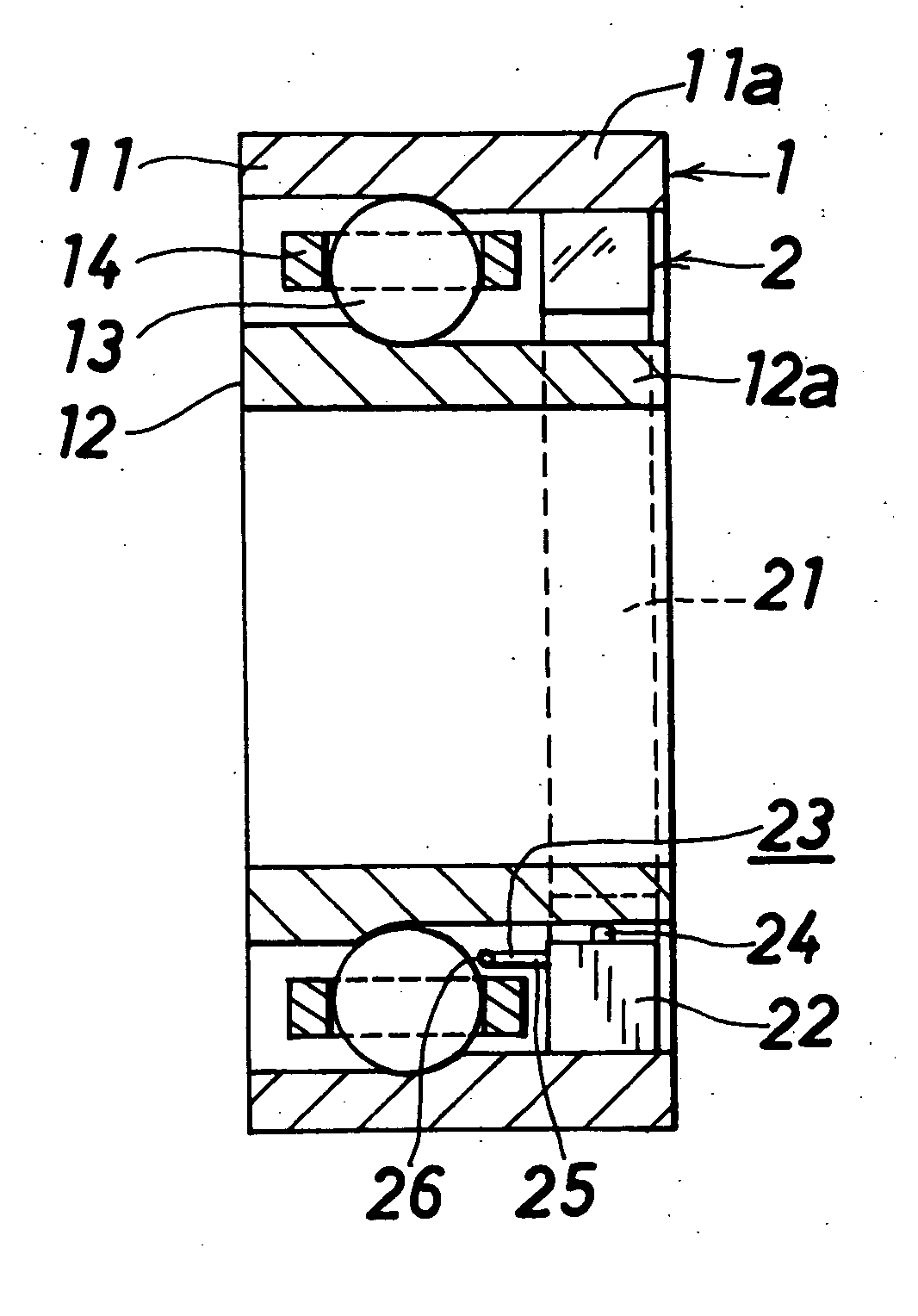

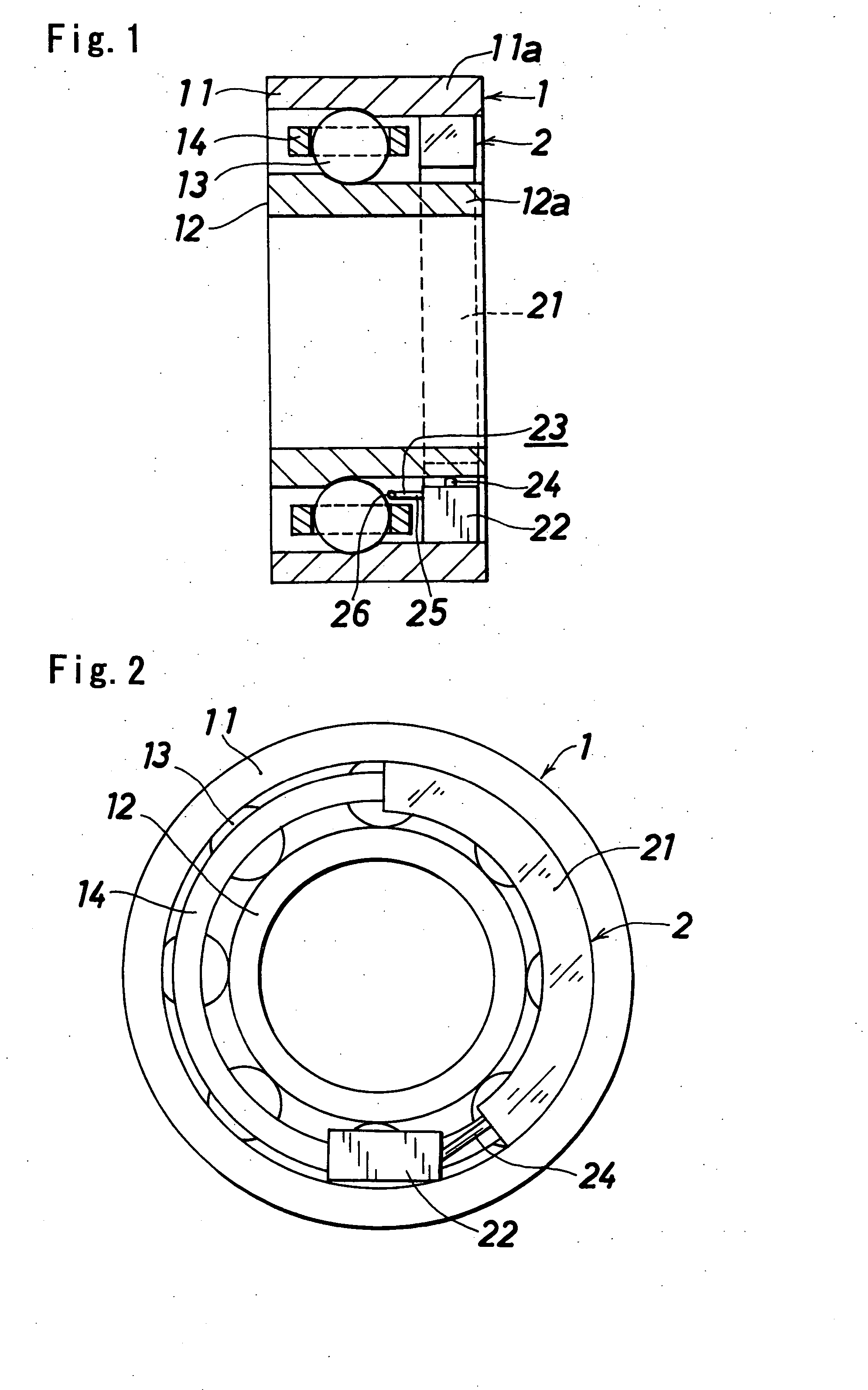

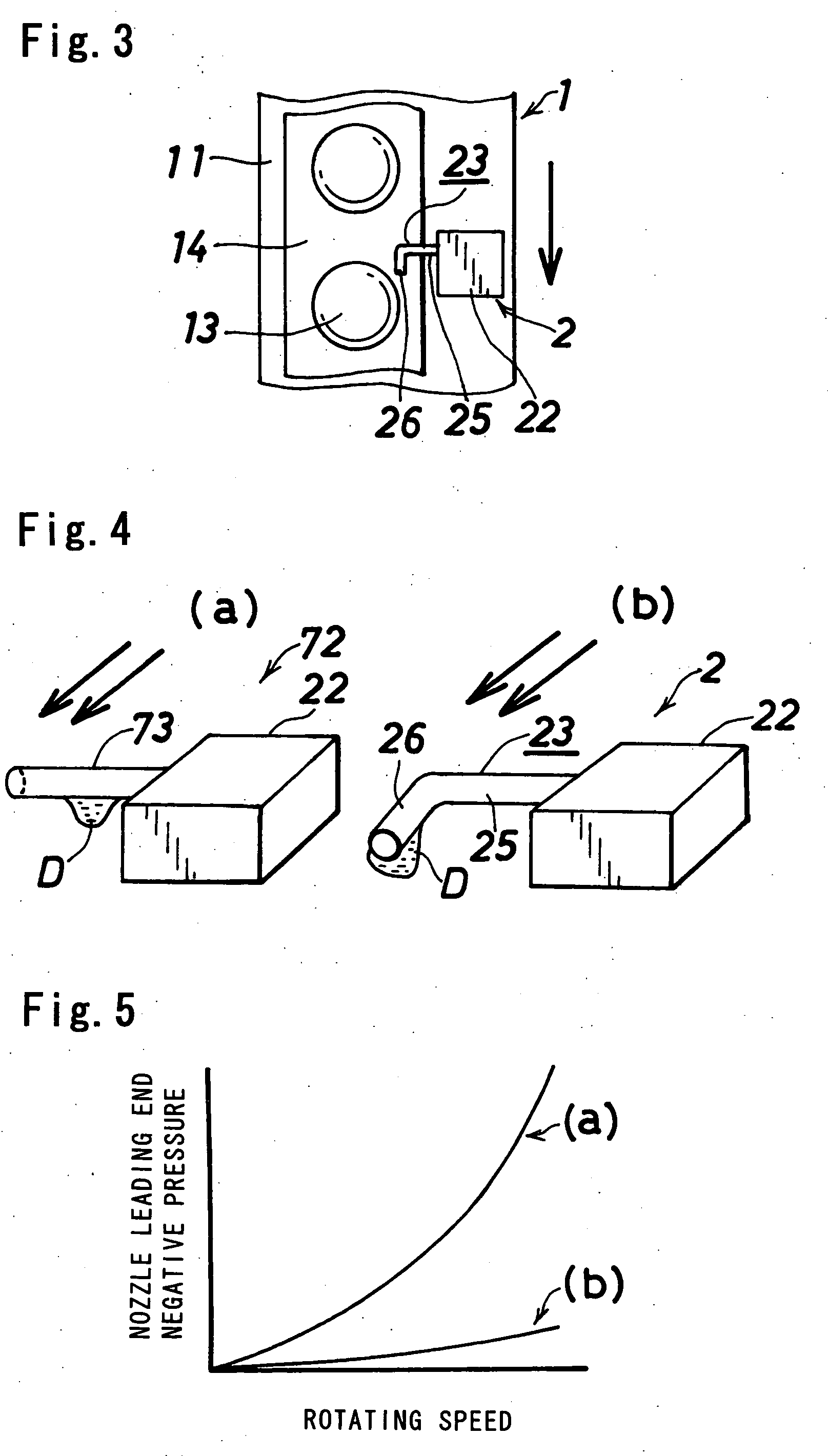

Rolling bearing apparatus

InactiveUS20070071382A1Reduce maintenance frequencyReduce noiseRolling contact bearingsDrip or splash lubricationRolling-element bearingCentre of rotation

An oil supply unit provided in a rolling bearing apparatus has a lubricating oil discharge nozzle in which an opening is faced to a cage portion of the rolling bearing. An opening direction of the nozzle is inclined to a rotating direction with respect to a direction of a center axis of rotation.

Owner:JTEKT CORP

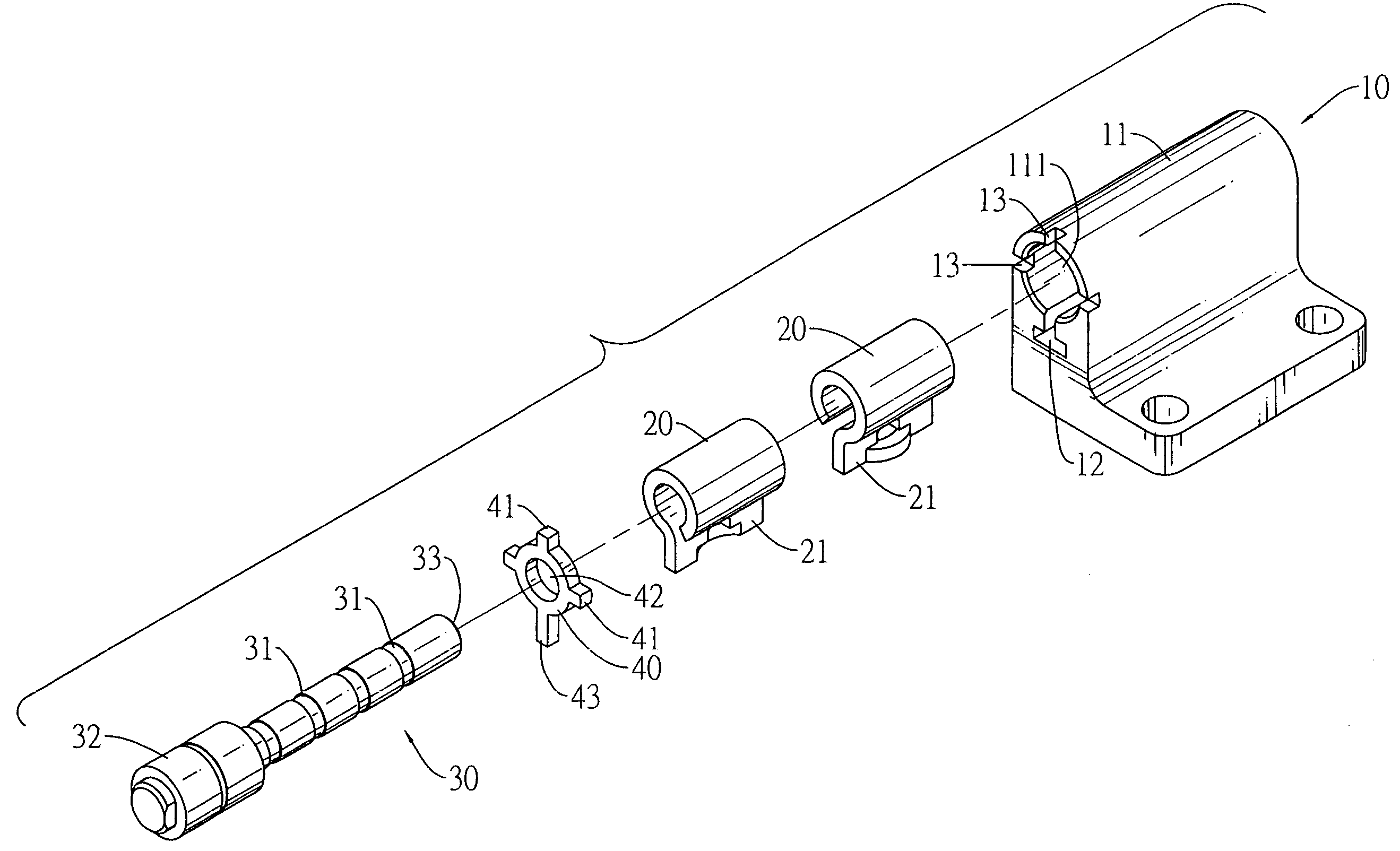

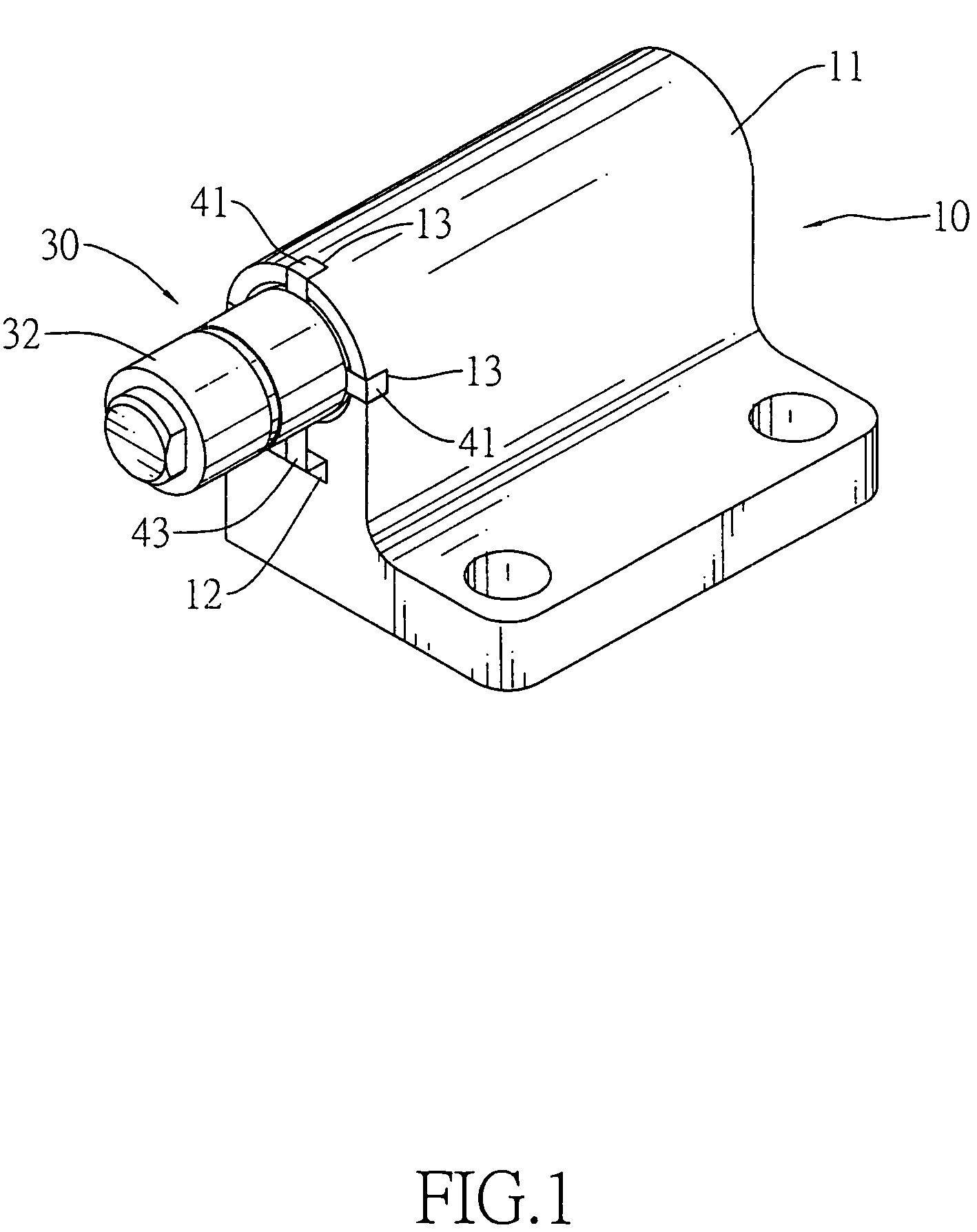

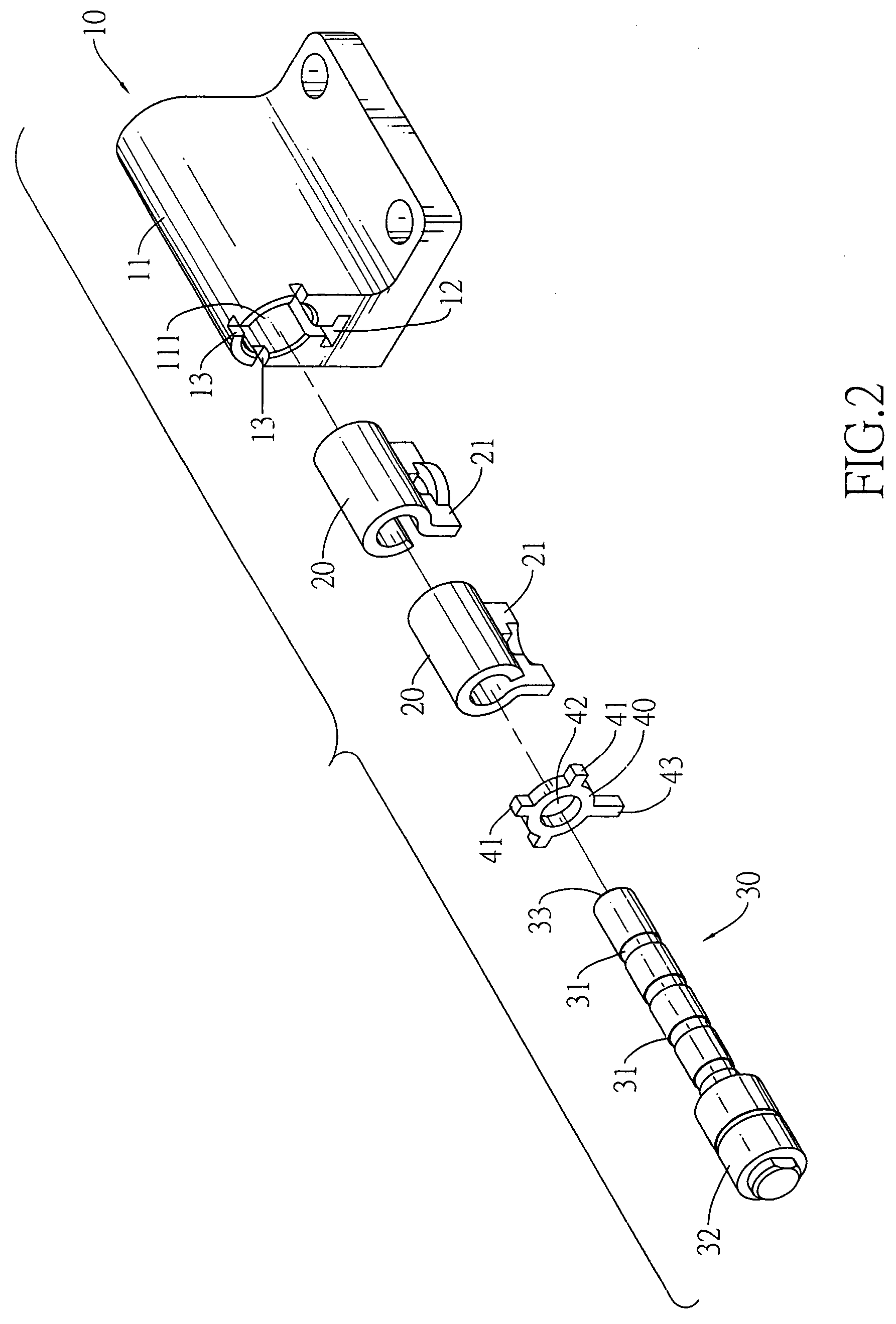

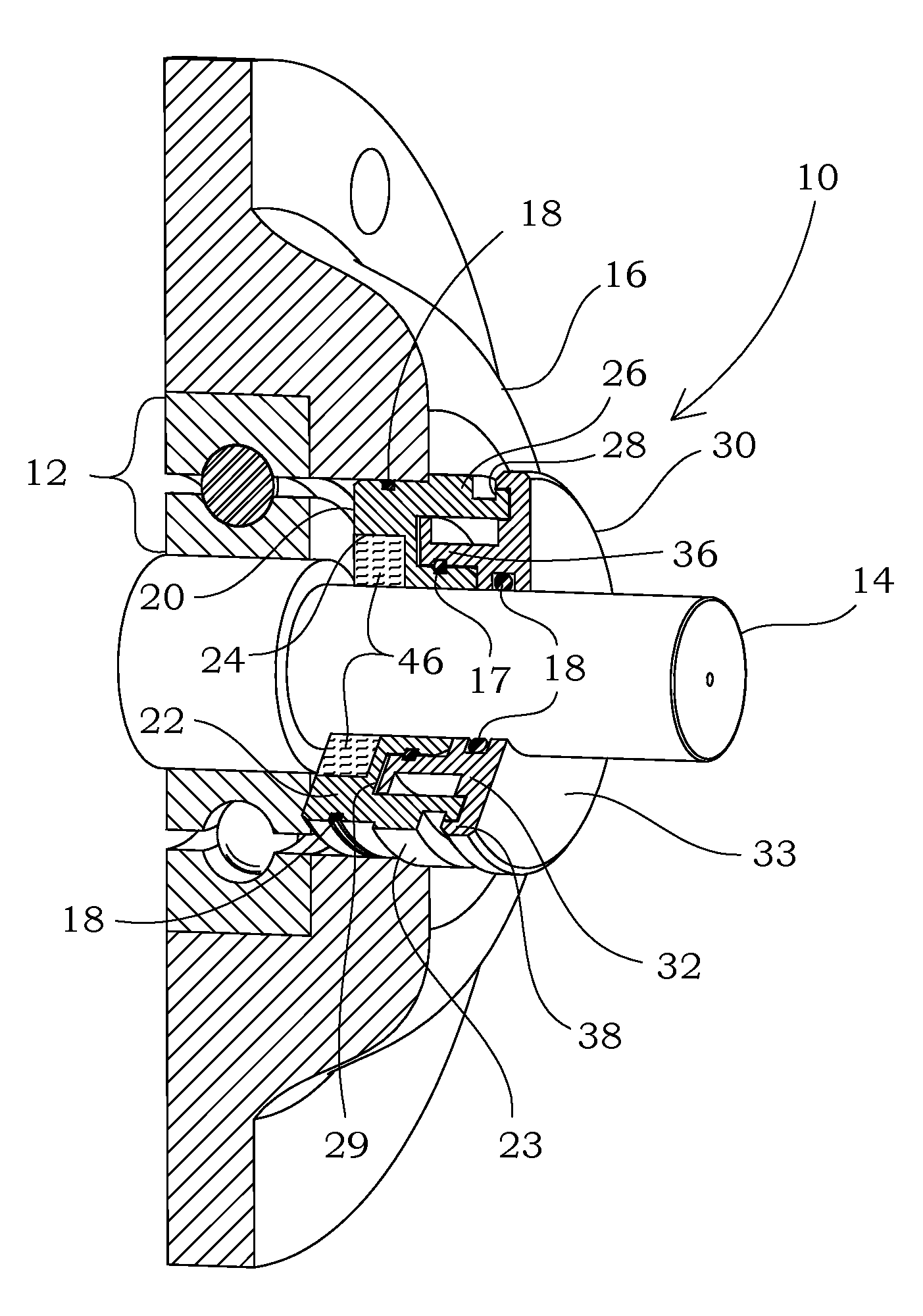

Hinge

InactiveUS7451523B2Prevent oil leakageWing fastenersDetails for portable computersEngineeringMechanical engineering

A hinge has a stationary bracket having multiple limiting slots, two resilient spacers, a pintle having a bar and an enlarged head, a stop element mounted in the pintle between the enlarged head and the resilient spacers and having multiple limiting tabs corresponding to and mounted in the limiting slots in the stationary bracket to make the limiting tab and the pintle to seal the opening and a keyhole provided the pintle to mount in and having an inner diameter being not bigger than an outer diameter of the bar to provide a tightness between the keyhole and the pintle. So the pintle is sturdy in the sleeve and the oil would not leak out of the sleeve.

Owner:SHIN ZU SHING

Current Diverter Ring

InactiveUS20100187946A1Prevent oil leakageImprove sealingRotary current collectorAssociation with grounding devicesShunt DeviceEngineering

The current diverter rings and bearing isolators serve to dissipate an electrical charge from a rotating piece of equipment to ground, such as from a motor shaft to a motor housing. The current diverter ring includes a body and a first and second wall protruding therefrom, which walls form an annular channel. The body may be affixed to a shaft, a motor housing, a bearing isolator, or other structure. In a first embodiment, a plurality of conductive segments is fixedly positioned within the annular channel to conduct electrical charges from the shaft to the motor housing. In a second embodiment, conductive segments are positioned between an inner and an outer body. The bearing isolator may incorporate an annular channel for retention of conductive segments within the stator of the bearing isolator or it may be fashioned with a receptor groove into which a current diverter ring may be mounted.

Owner:INPRO INC

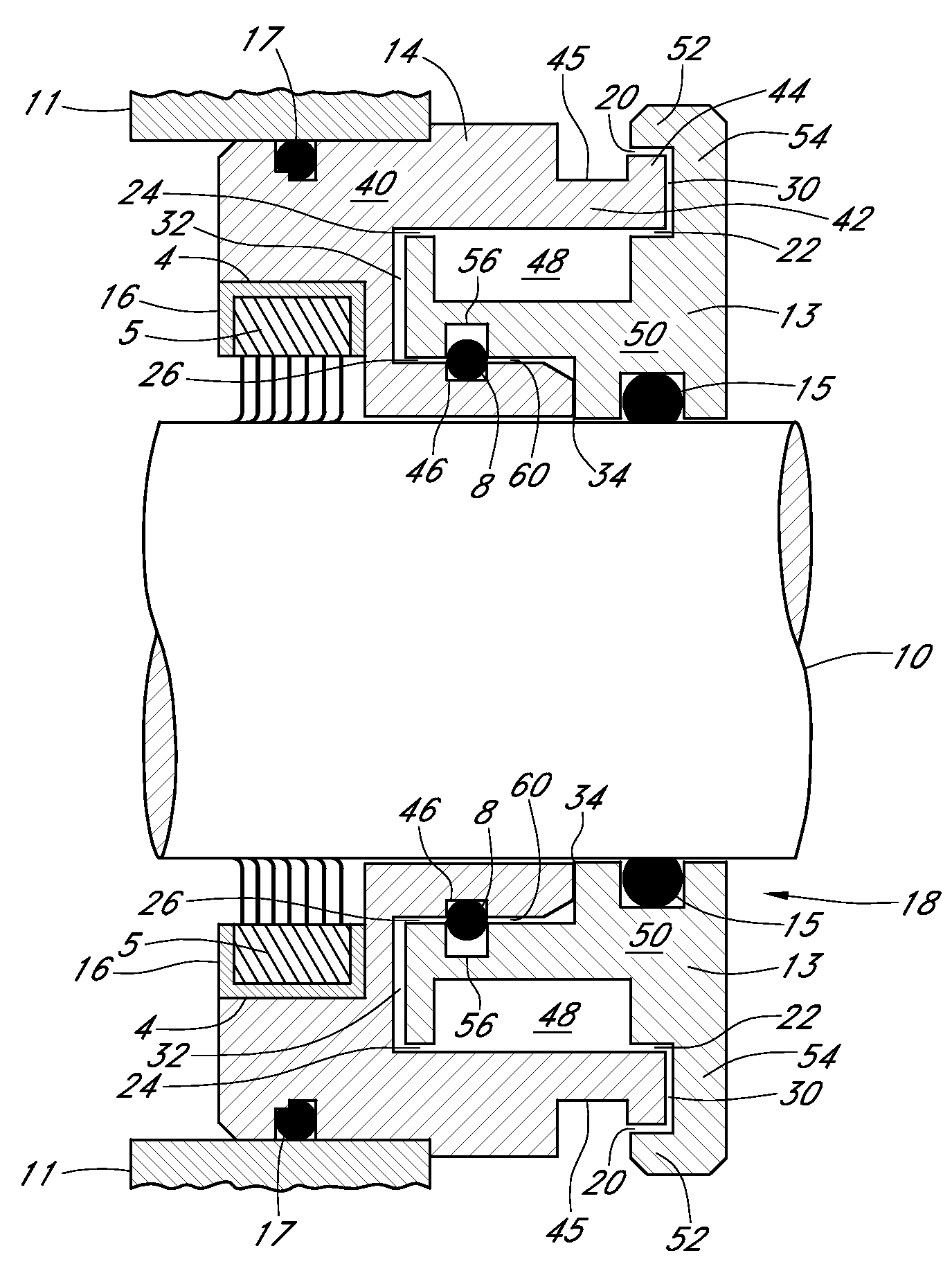

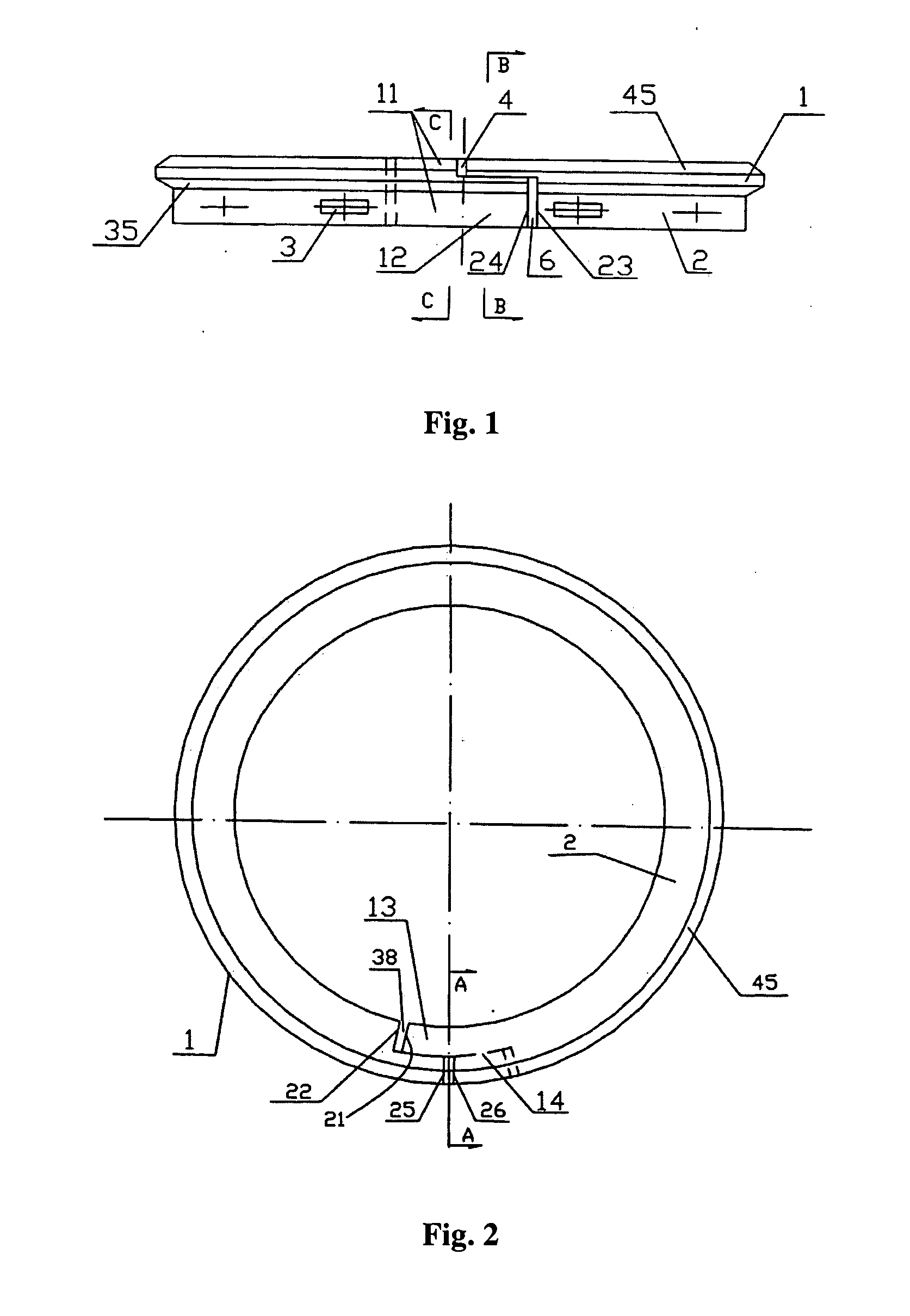

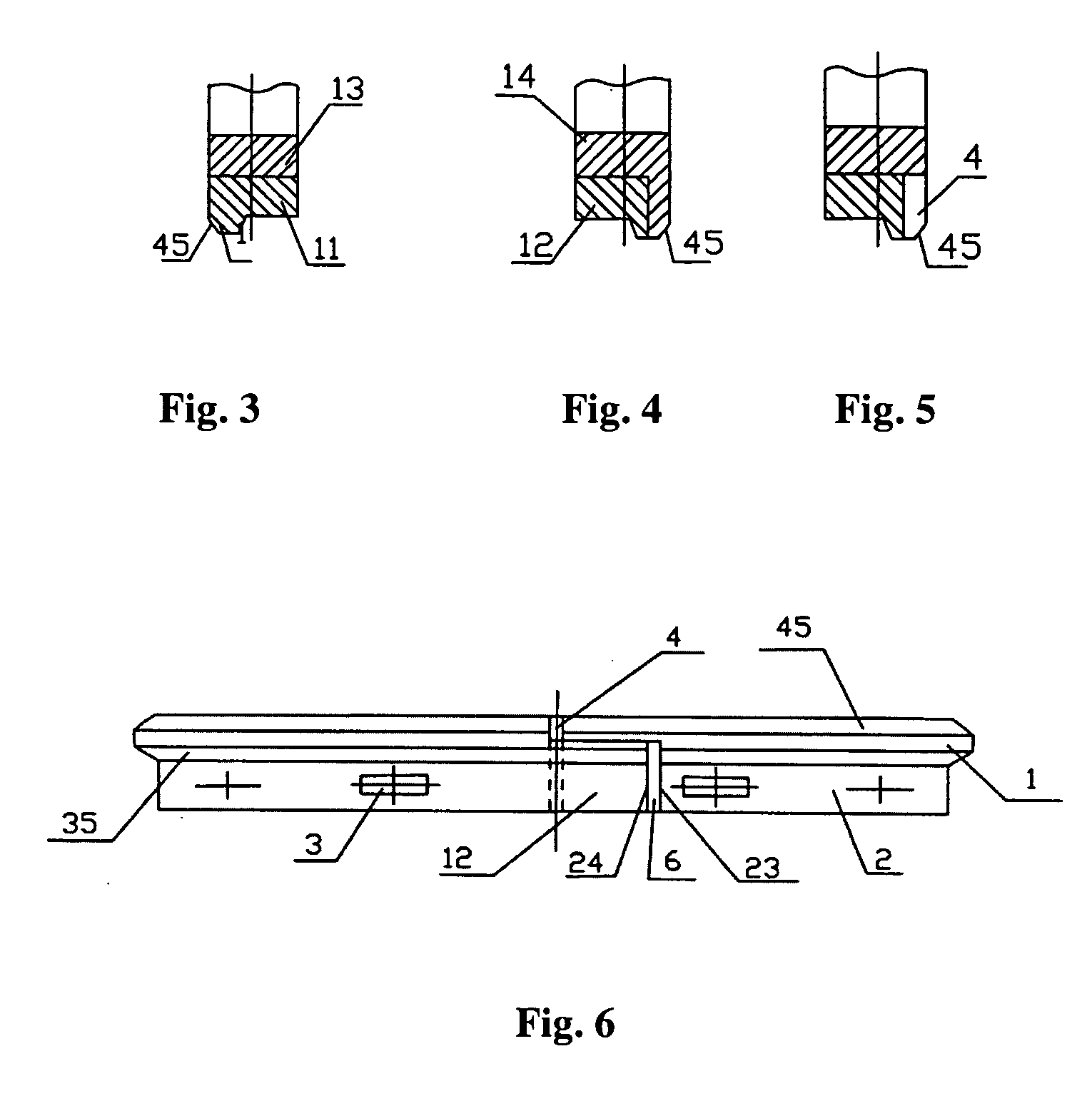

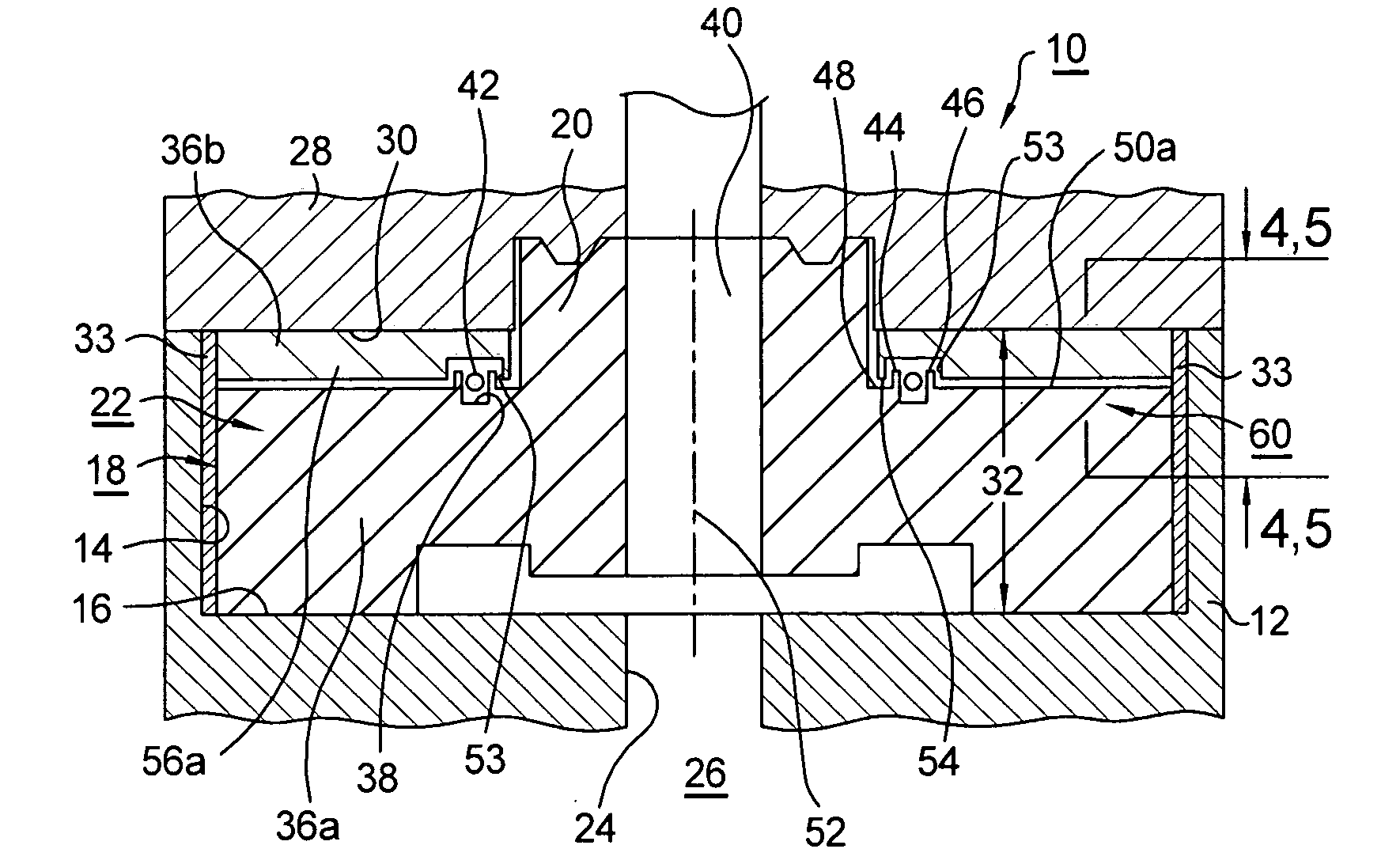

Windback labyrinth seal that accommodates a pressure differential for rotating shafts

InactiveUS6932350B1Prevent oil leakageAvoid pressure dropEngine sealsLeakage preventionLeading edgeDifferential pressure

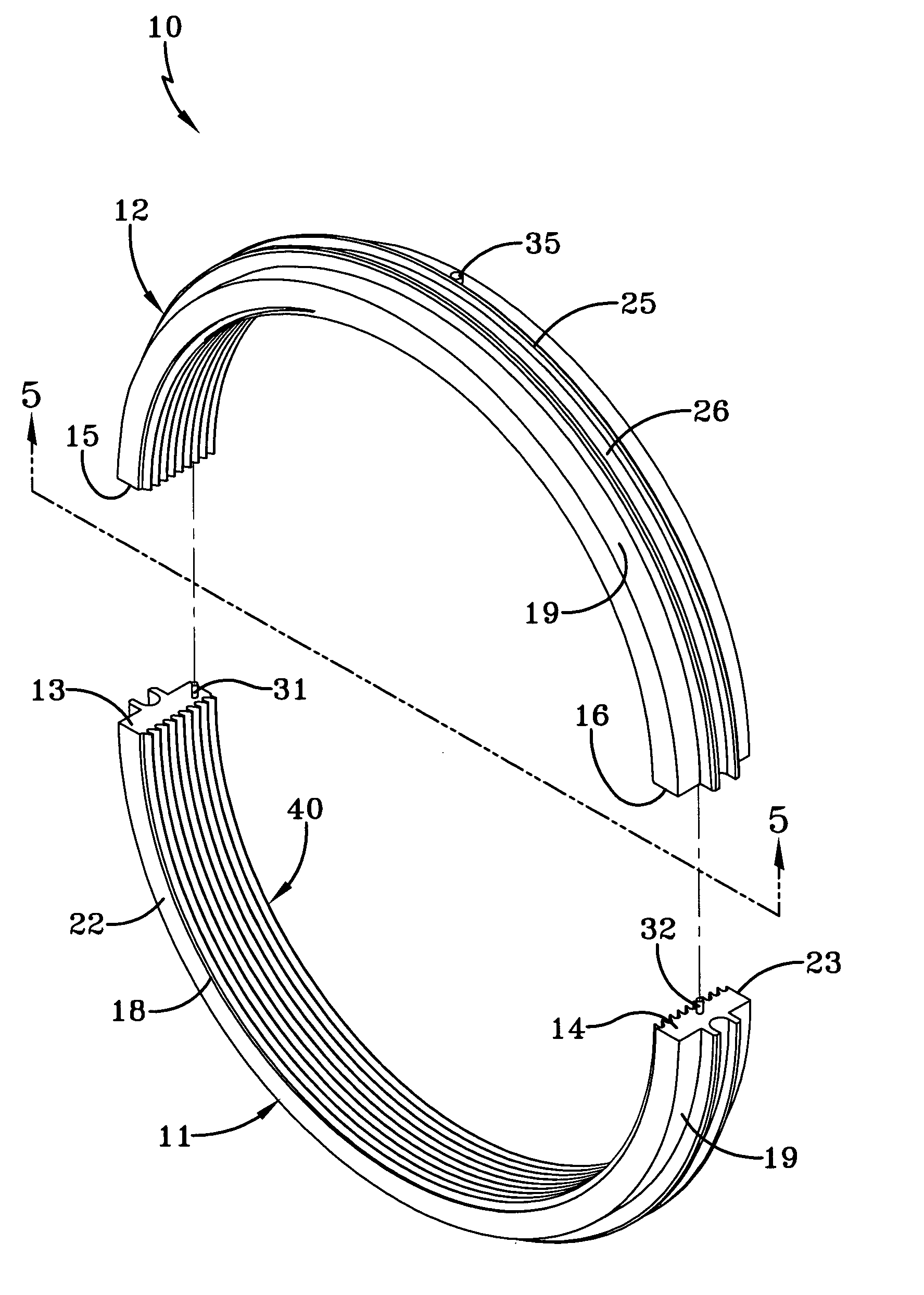

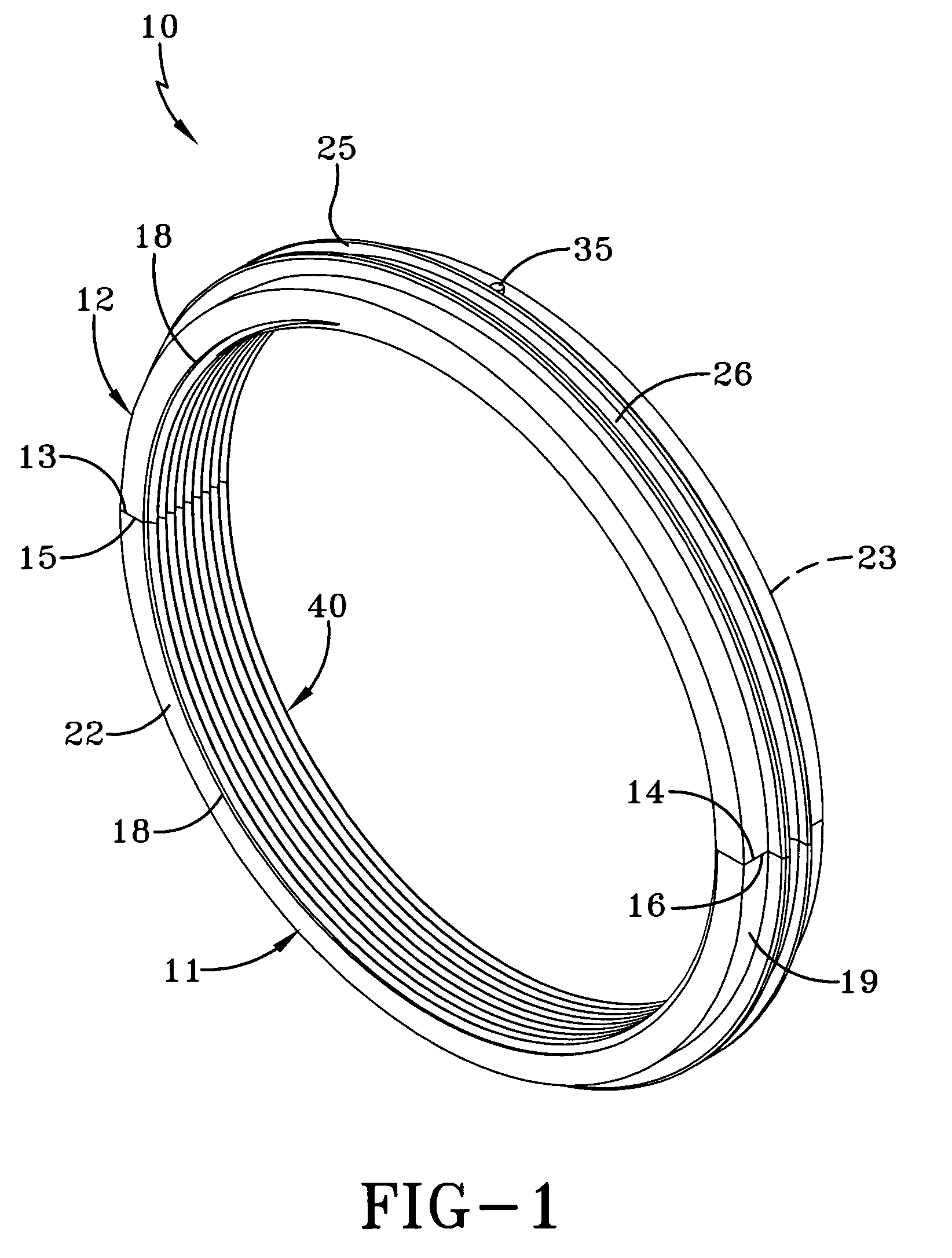

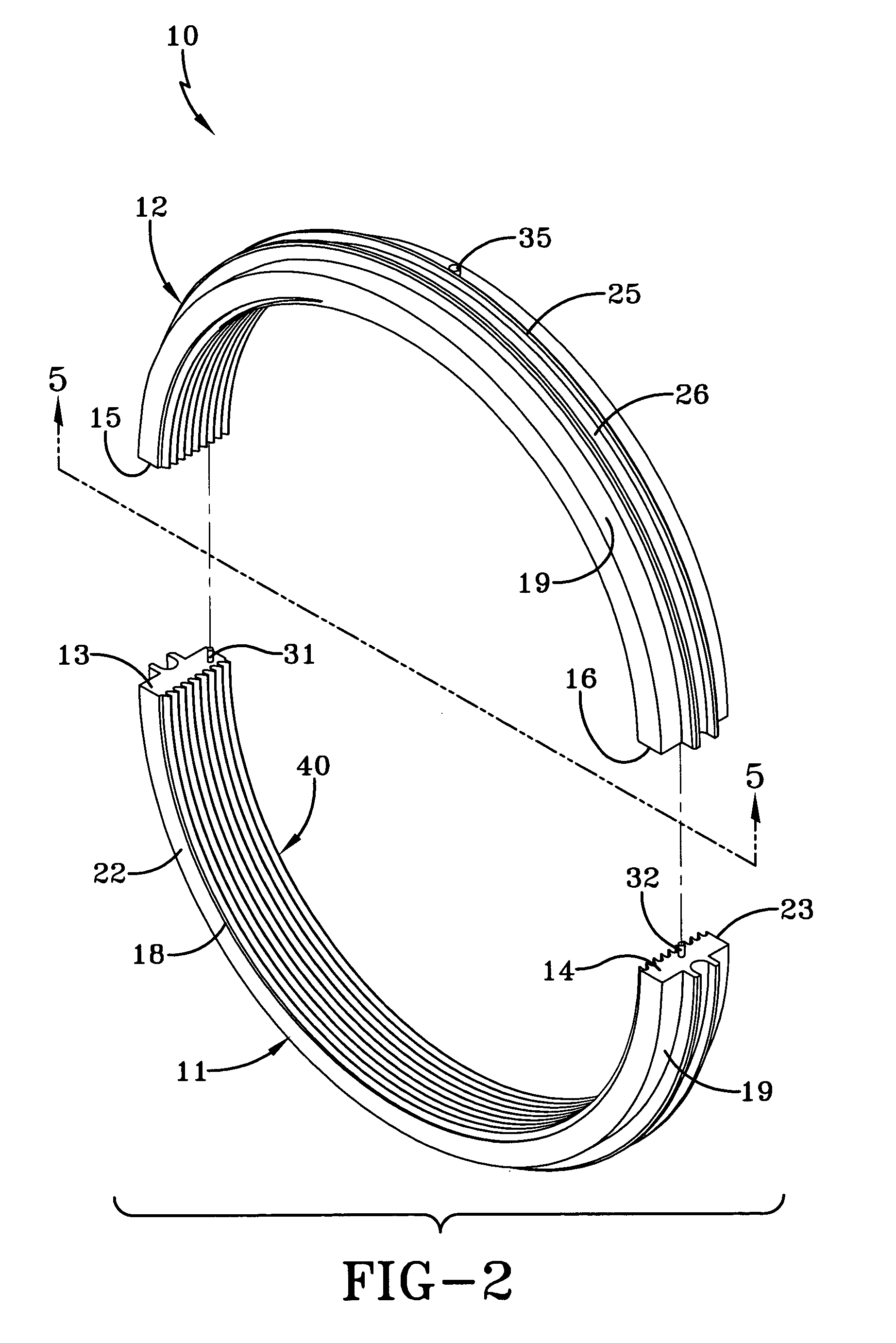

A segmented labyrinth seal (10) having a windback configuration formed around a rotatable shaft for preventing leakage of oil from a bearing housing having a first face (22) and a second face (23). An exterior cylindrical surface (19) and an interior cylindrical surface (18) extend between the first face (22) and the second face (23). A thread pattern (40) provided on the interior cylindrical surface (18) providing the windback configuration, and configured in a right-hand direction or a left-hand direction. A plurality of profiled teeth (41) form the thread pattern (40) and have first sides (43), second sides (44), and connecting sides (45) extending between the first sides (43) and the second sides (44). Leading edges (47) are formed where the first sides (43) join the connecting sides (45), and trailing edges (48) are formed where the second sides (44) join the connecting sides (45). The first sides (43) and the second sides (44) are slanted toward the first face (22). A pressure drop is taken over the plurality of profiled teeth (41). A channel (C) tracing the thread pattern (40) is formed between the first sides (43) and the second sides (44) of adjacent teeth of the plurality of profiled teeth (41), the channel being adapted to capture the oil from the bearing housing, and returning the oil to the bearing housing without the need for axial drain holes.

Owner:HYUNDAI IDEAL ELECTRIC

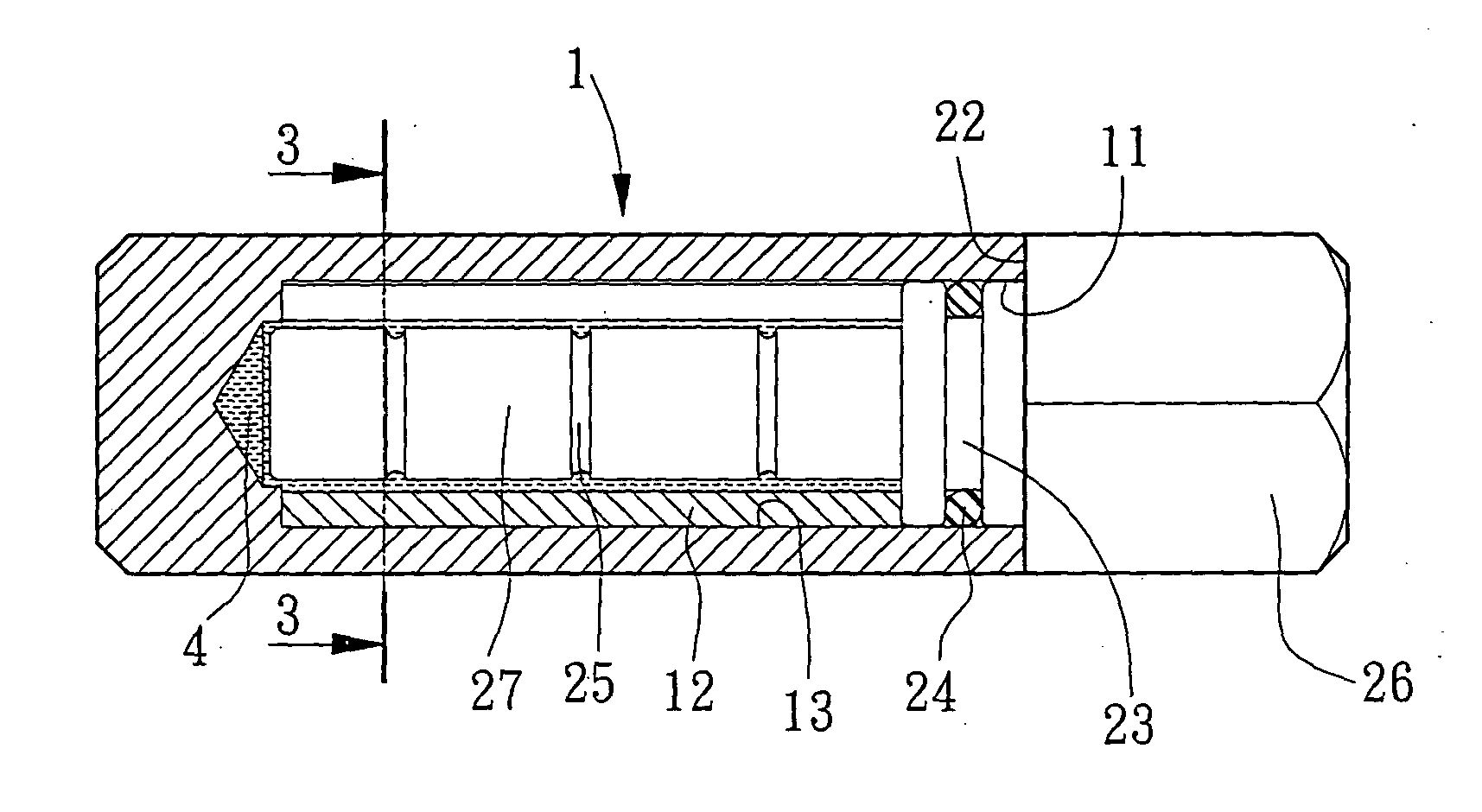

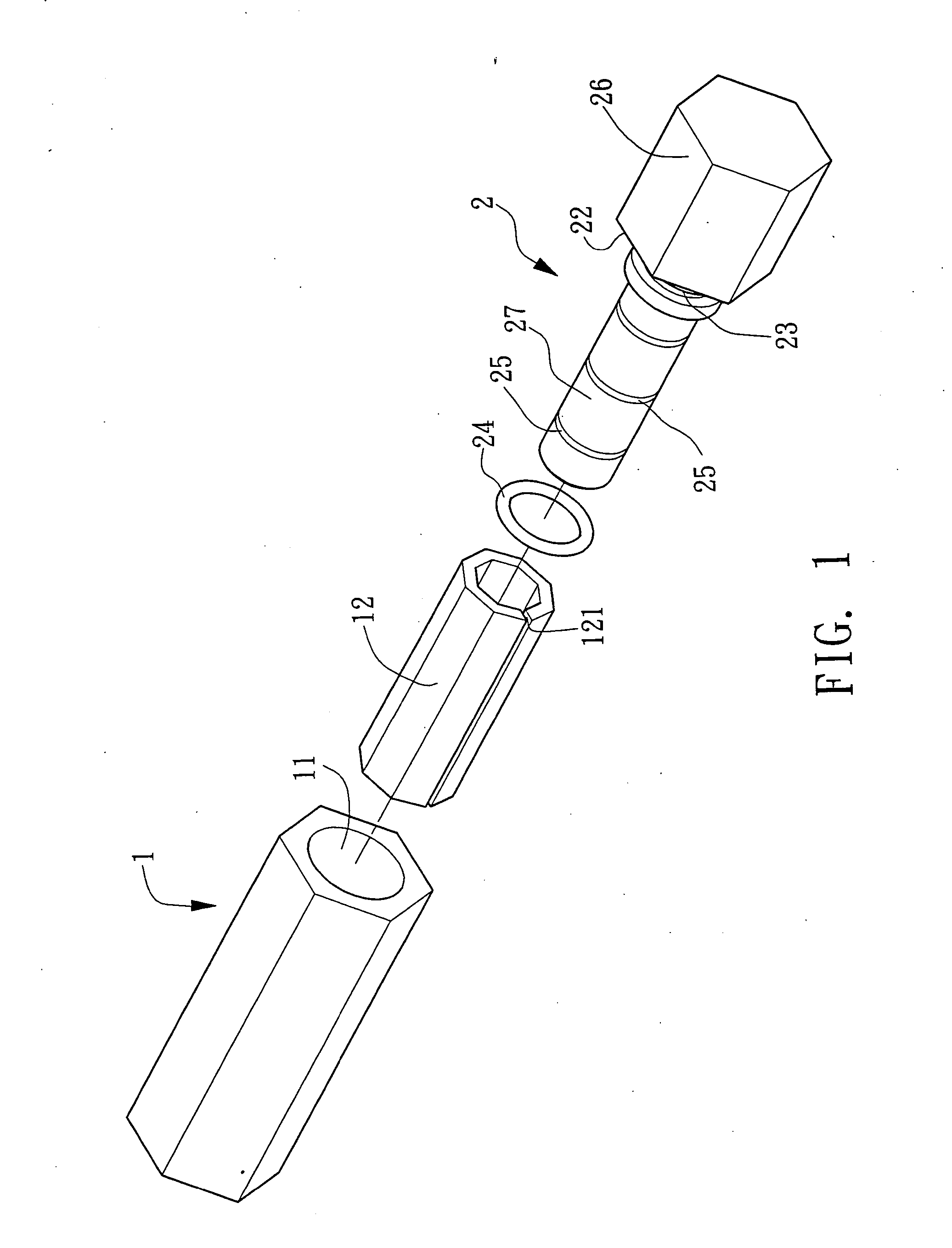

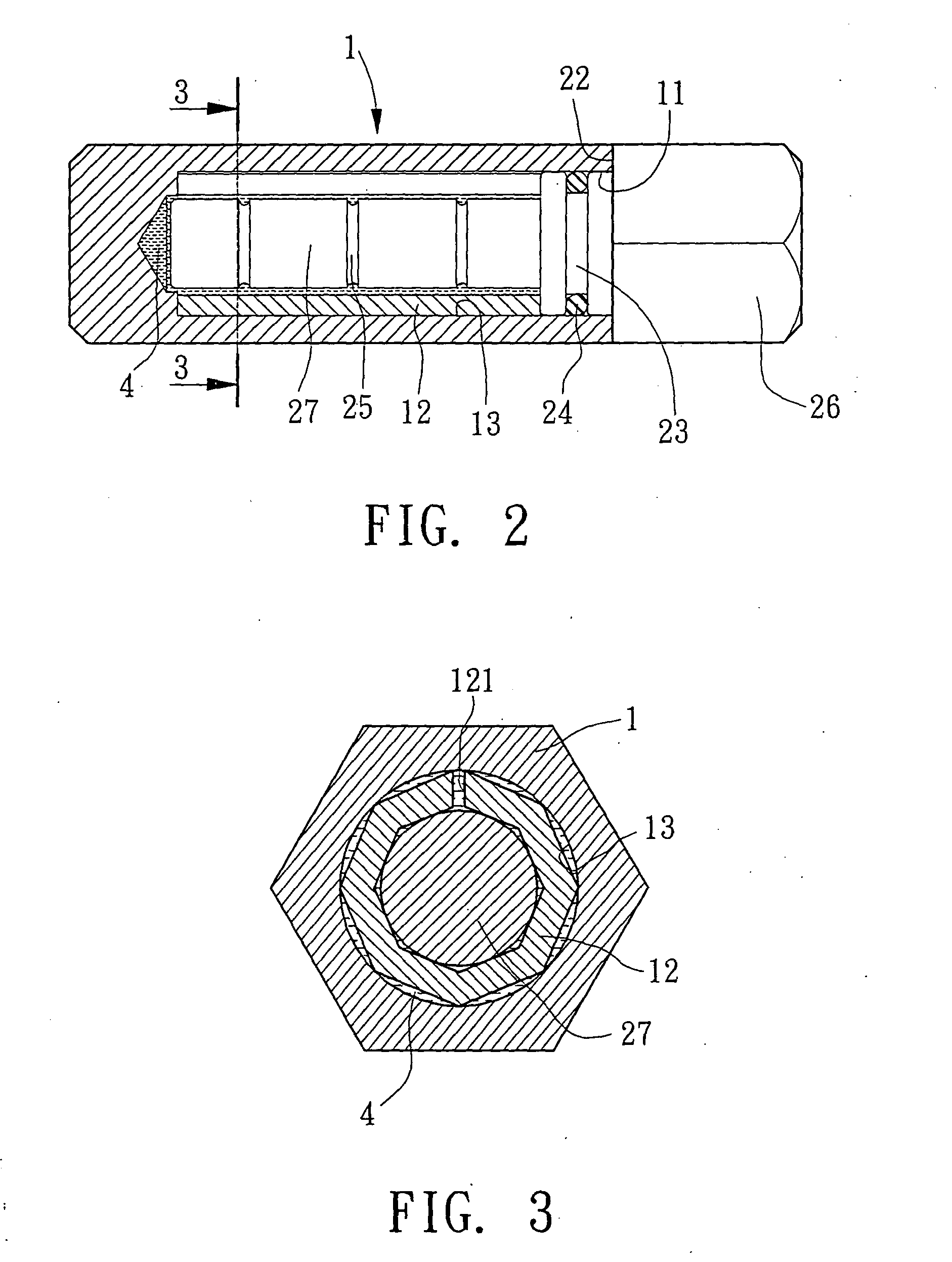

Hinge

InactiveUS20050034274A1Improve hingePrevent oil leakageWing fastenersDetails for portable computersEngineeringLubricant

A hinge includes a cylinder having a close end and an open end longitudinally opposite to the close end of the cylinder. A polygonal sleeve is fixedly received in the cylinder. The polygonal sleeve has multiple edges abutting against an inner periphery of the cylinder. A pivot axle is partially pivotally received in the sleeve. A sealant is mounted around the pivotally for tightly closing the open end of the cylinder to prevent the lubricant in the hinge from leaking.

Owner:WU CHING SUNG

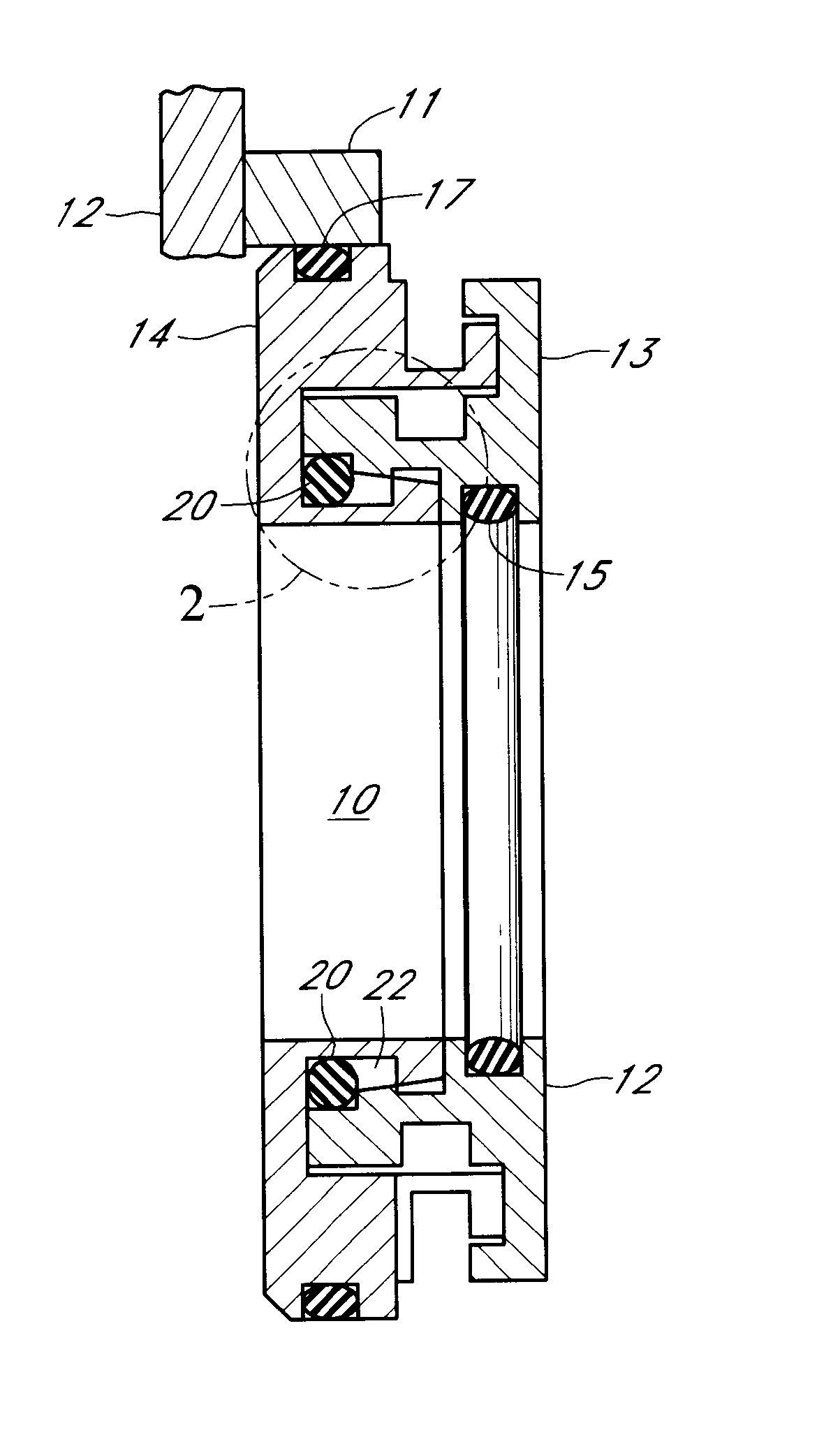

Snap together bearing isolator

The assembly includes rotor and stator elements each having an inclined plane or surface juxtaposed to each other. This is a metallic assembly and the rotor and stator also have juxtaposed cavities. The stator cavity being of sufficient size to accommodate a sealing member. The inclined surfaces are flexed with the inclined plane or surface of the rotor forced over the inclined plane or surface of the stator to lock the rotor and stator together with the sealing member enclosed between the rotor and stator. The sealing member does not rotate with the stator. The seal contains at least one labyrinth formed with the rotor and stator, are adjacent each other and lock together.

Owner:INPRO INC

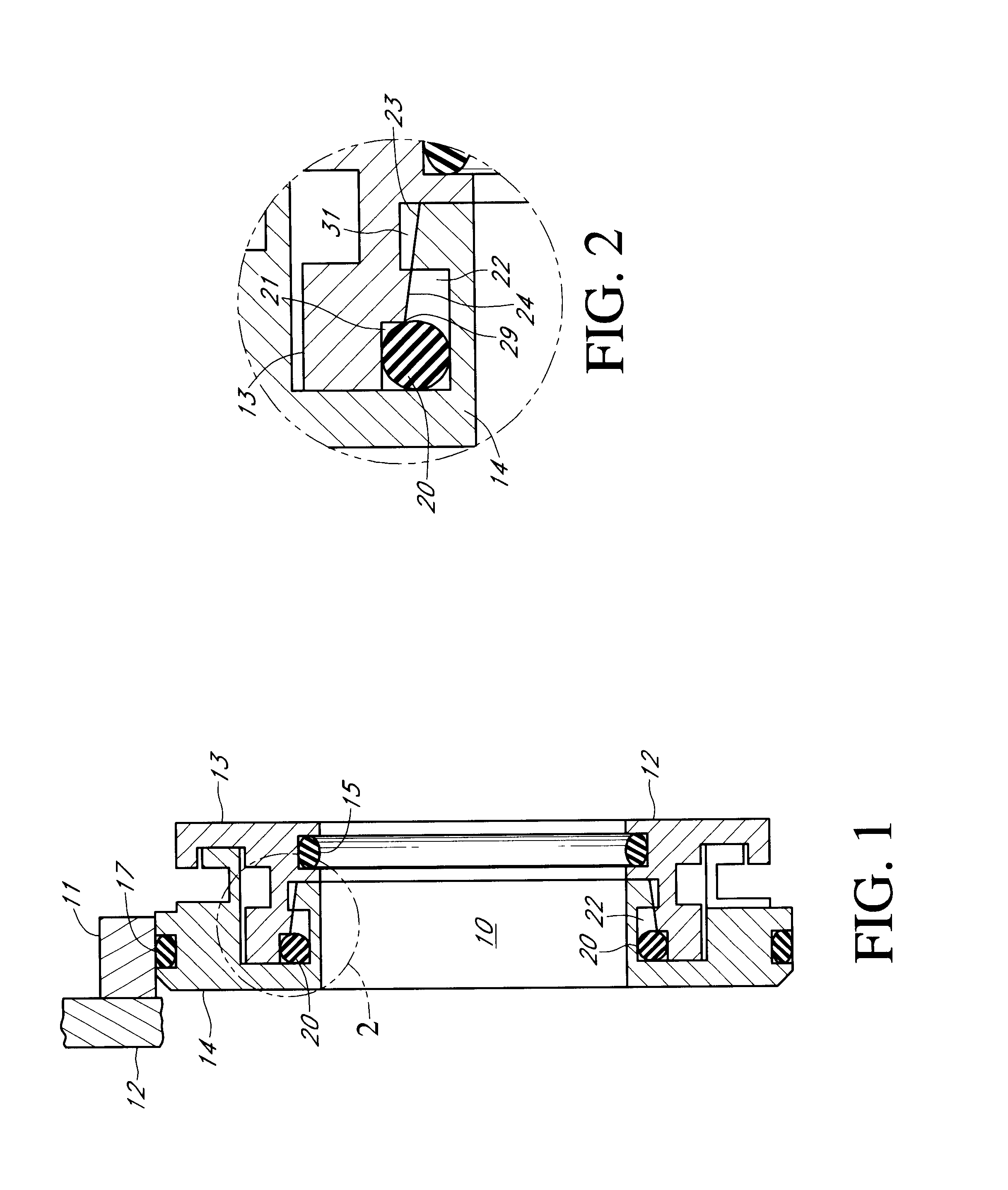

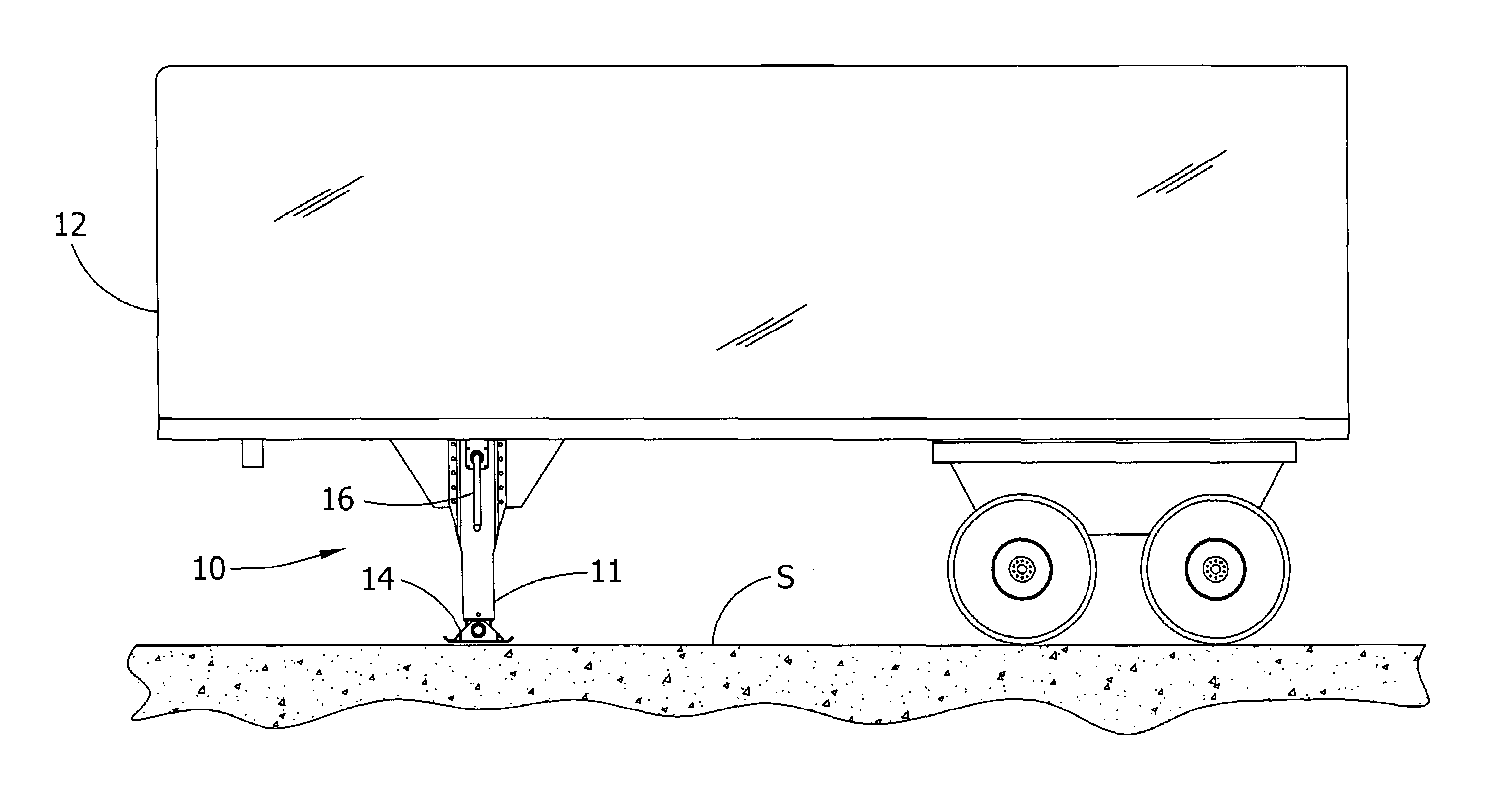

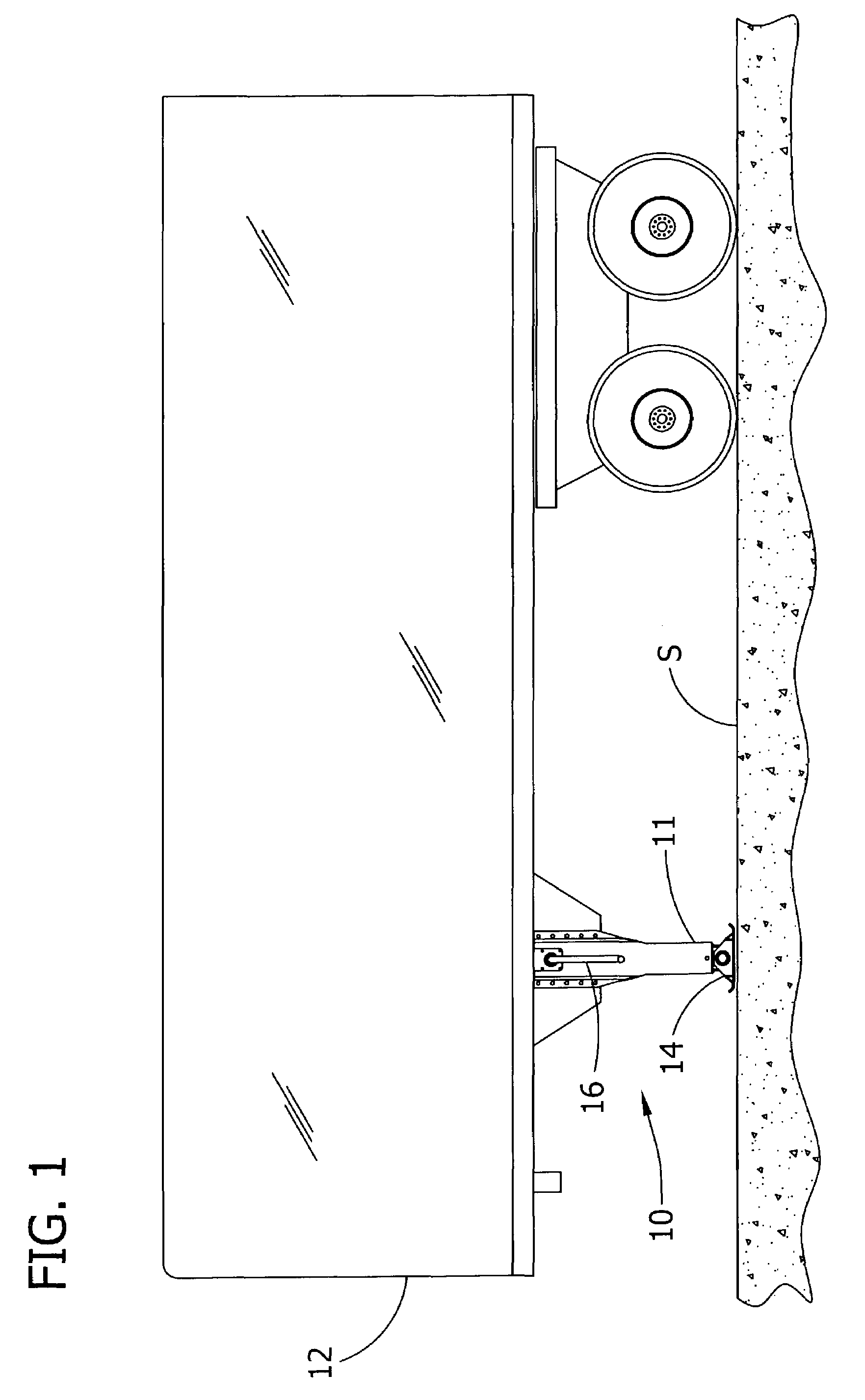

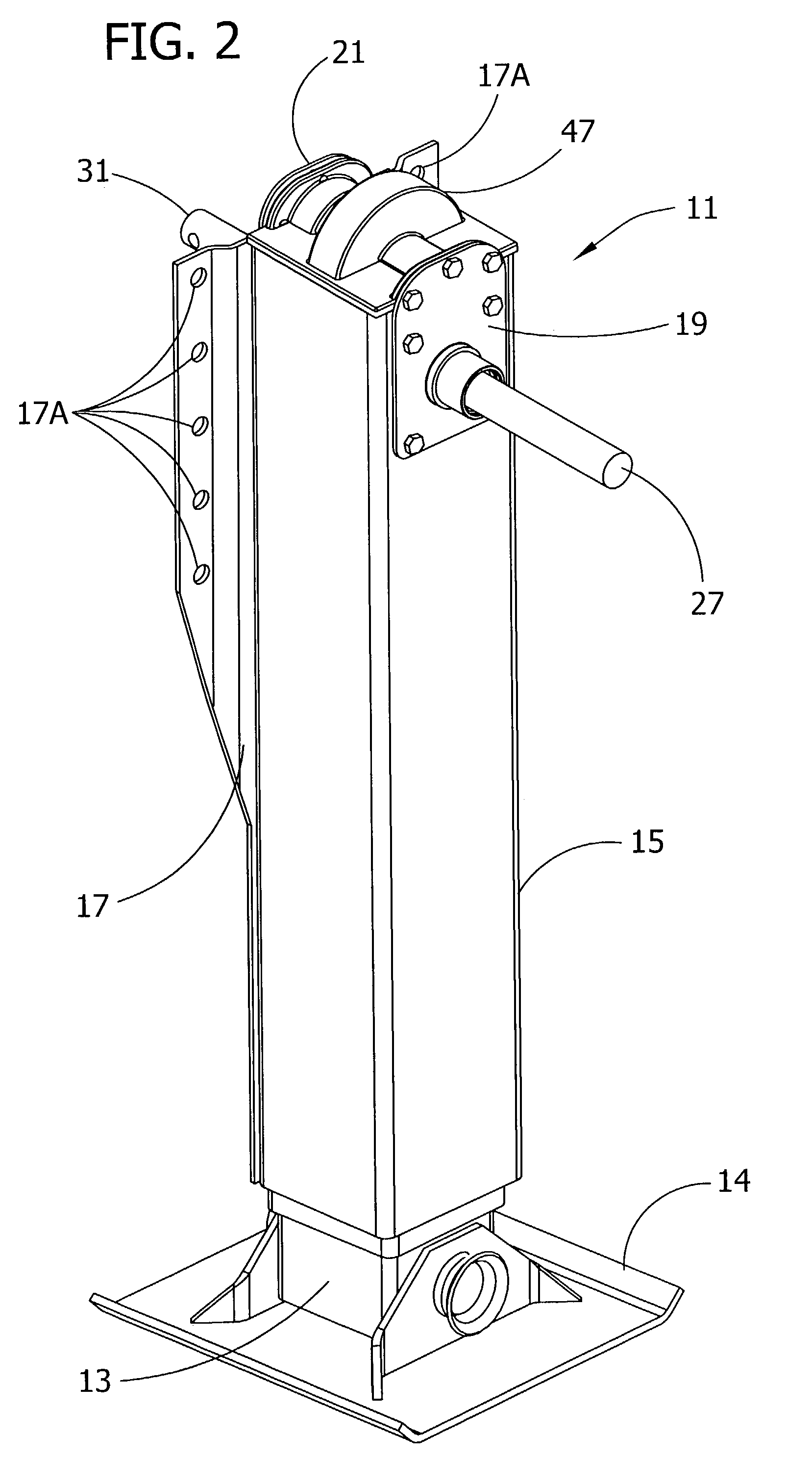

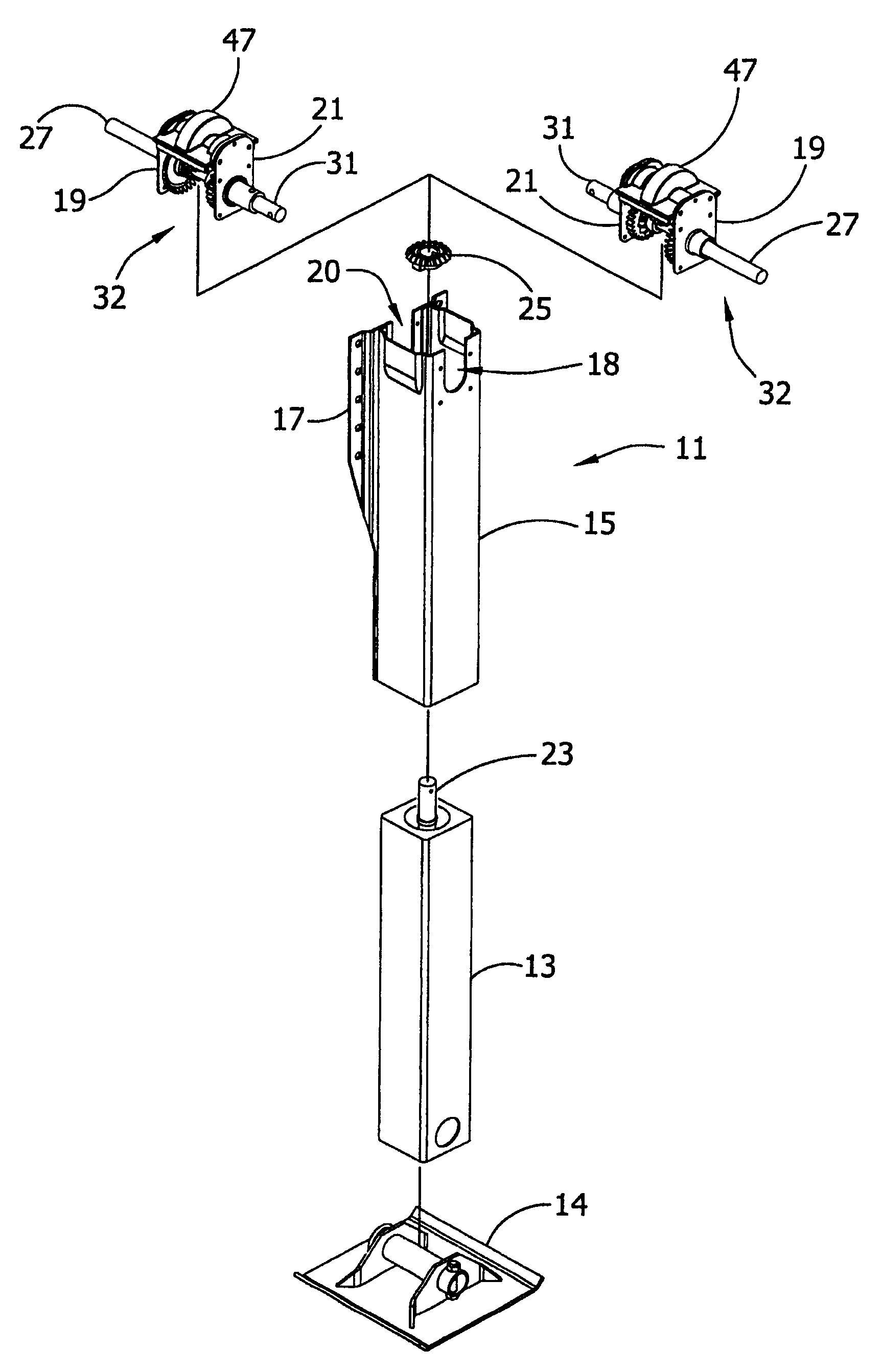

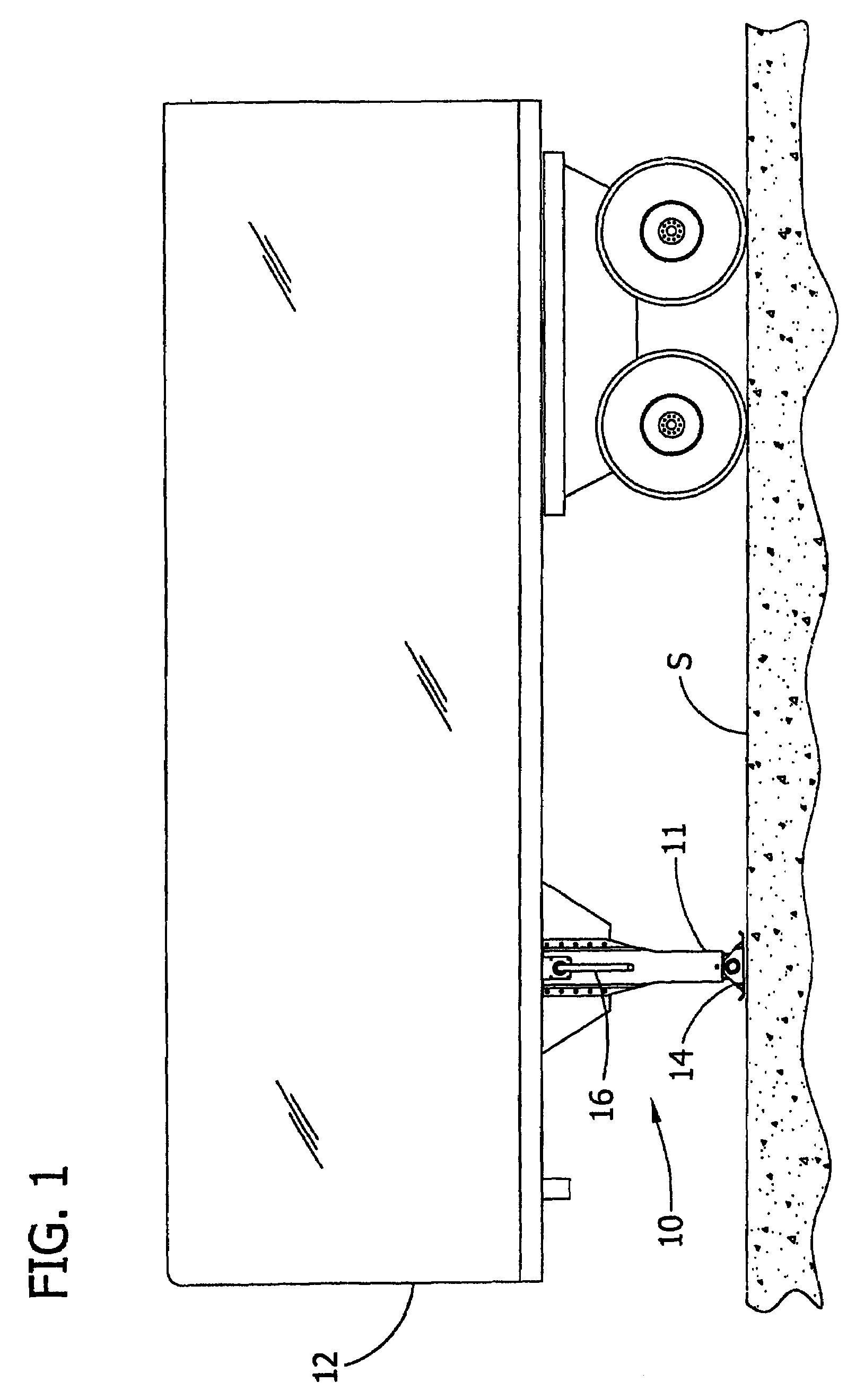

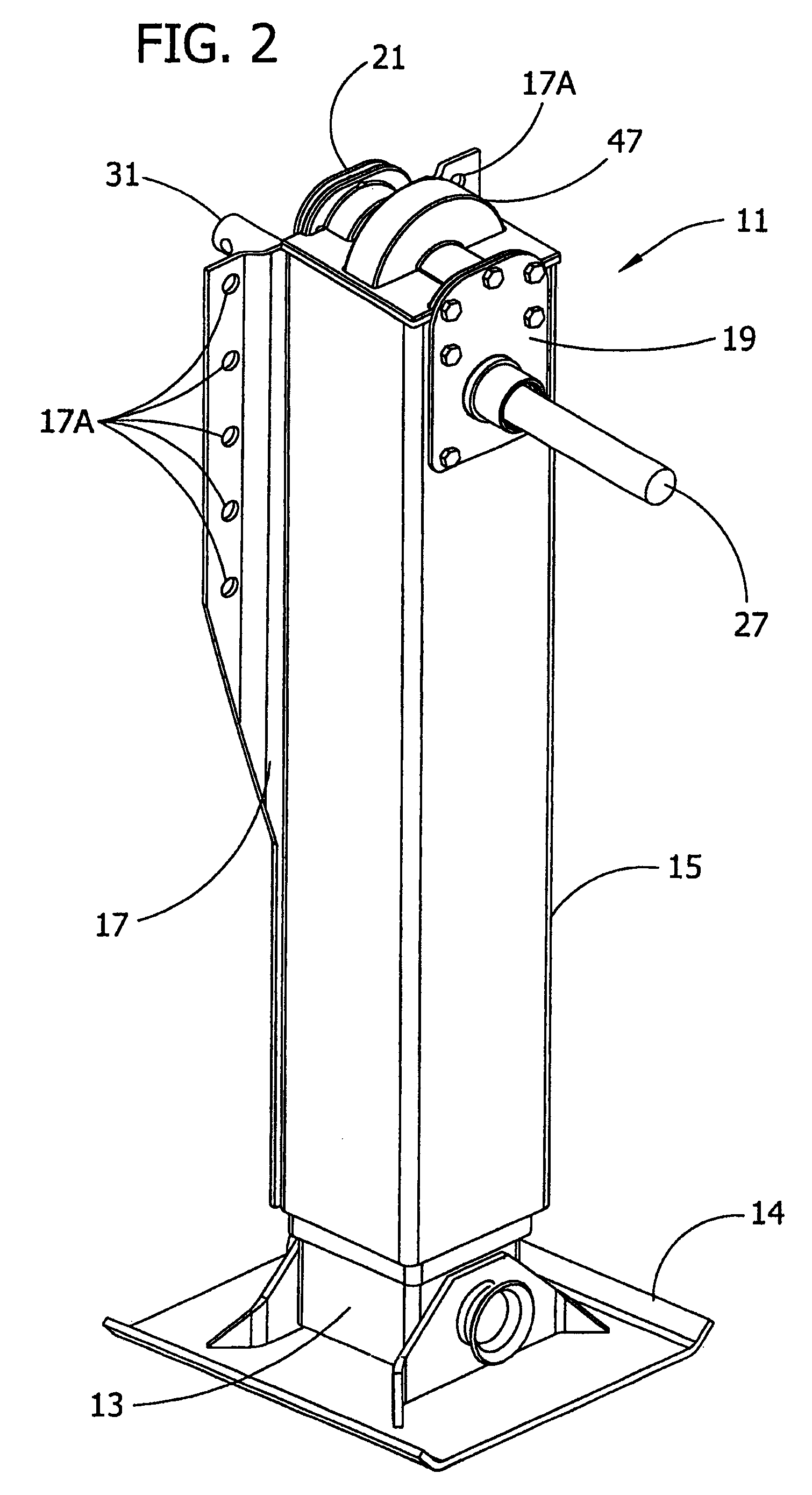

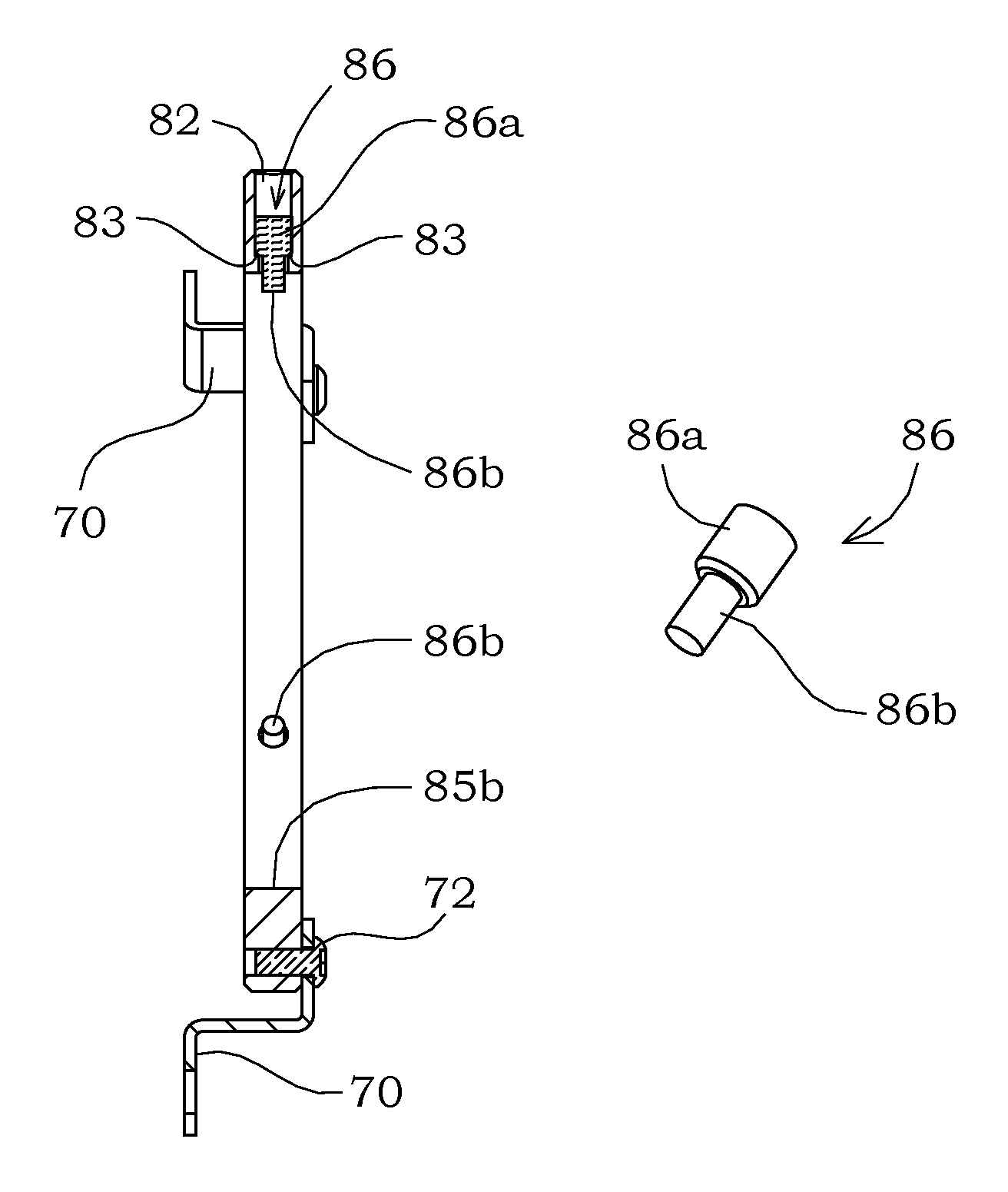

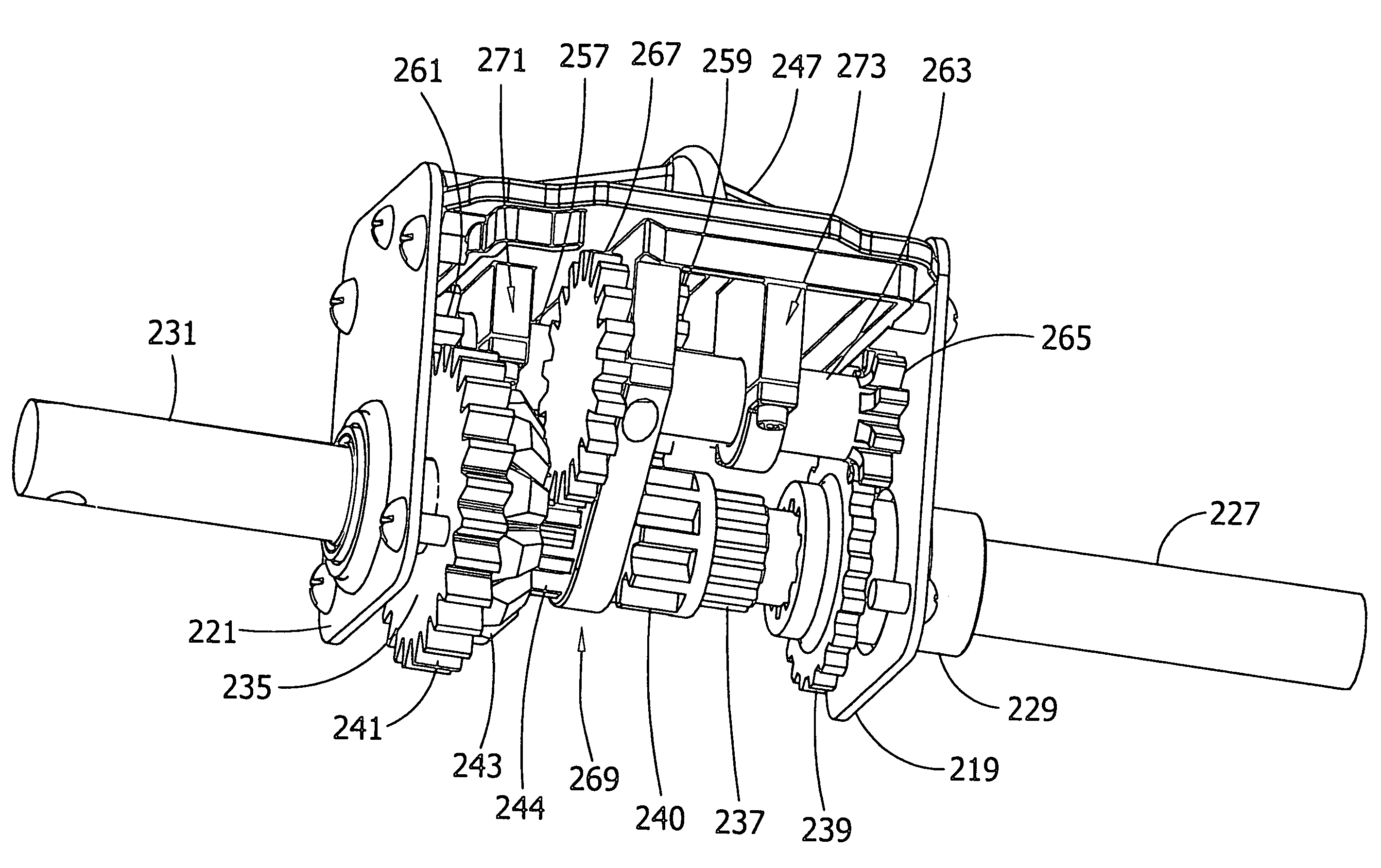

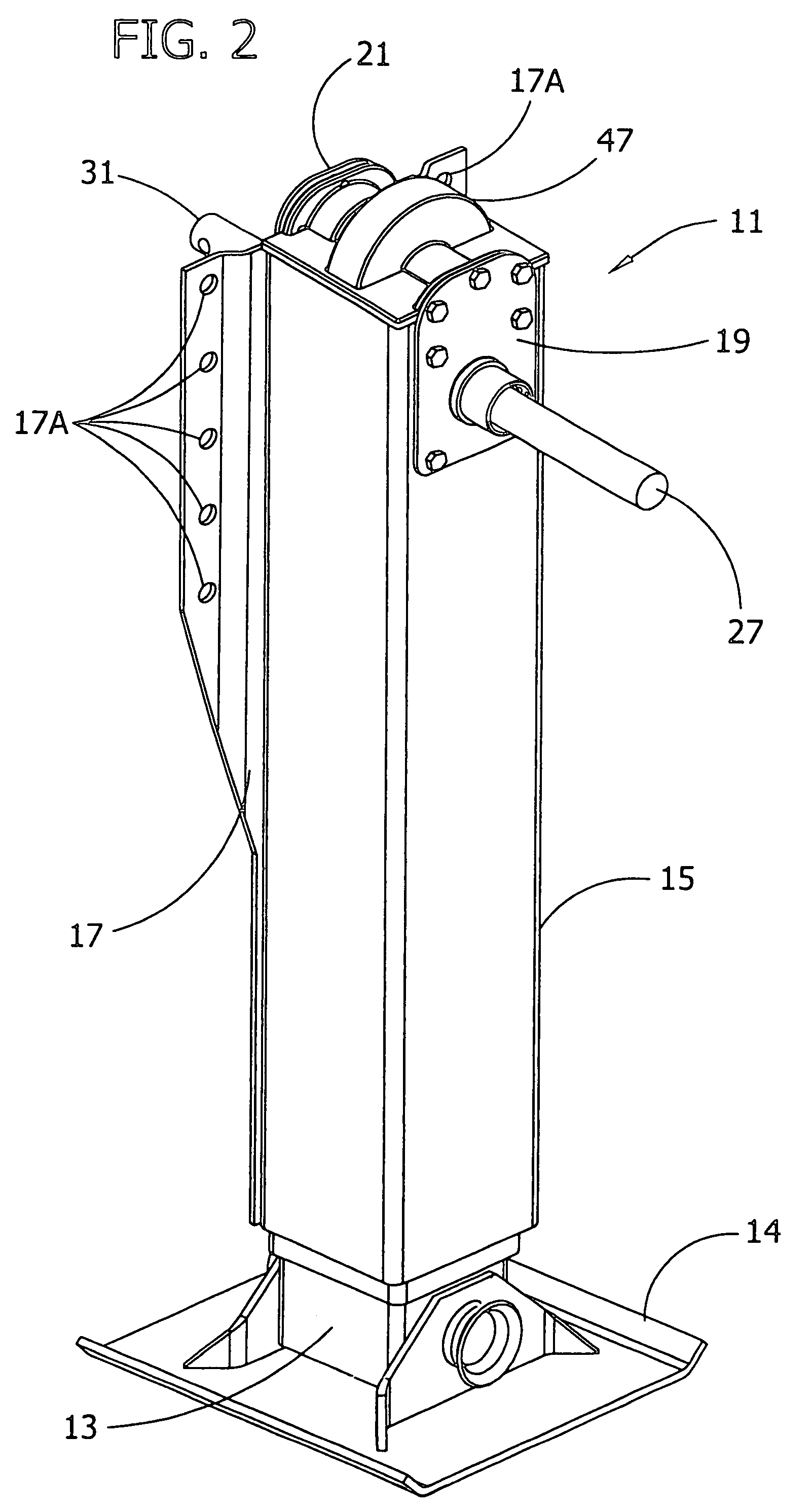

Landing gear and method of assembly

ActiveUS7055859B2Simplify constructionEfficiently assembleVehicle fittings for liftingToothed gearingsLanding gearGear wheel

Landing gear for selectively supporting a semitrailer and a method of assembly of the landing gear is provided. The landing gear includes a leg having an upper section and a lower section telescopingly received in the upper section. A lead screw extends and retracts the upper and lower sections relative to each other upon rotation thereof. An input shaft applies a torque to the lead screw to drive rotation thereof, the input shaft being rotatable about a rotation axis and movable in translation along the rotation axis for shifting between a first position for low gear operation and a second position for high gear operation. An output shaft, axially aligned with the input shaft, has an output gear for transmitting torque to the lead screw. A gearing subassembly is received in the upper leg section and is configured to augment lift when the input shaft is in the first position and augment speed in the second position.

Owner:THE HOLLAND GROUP

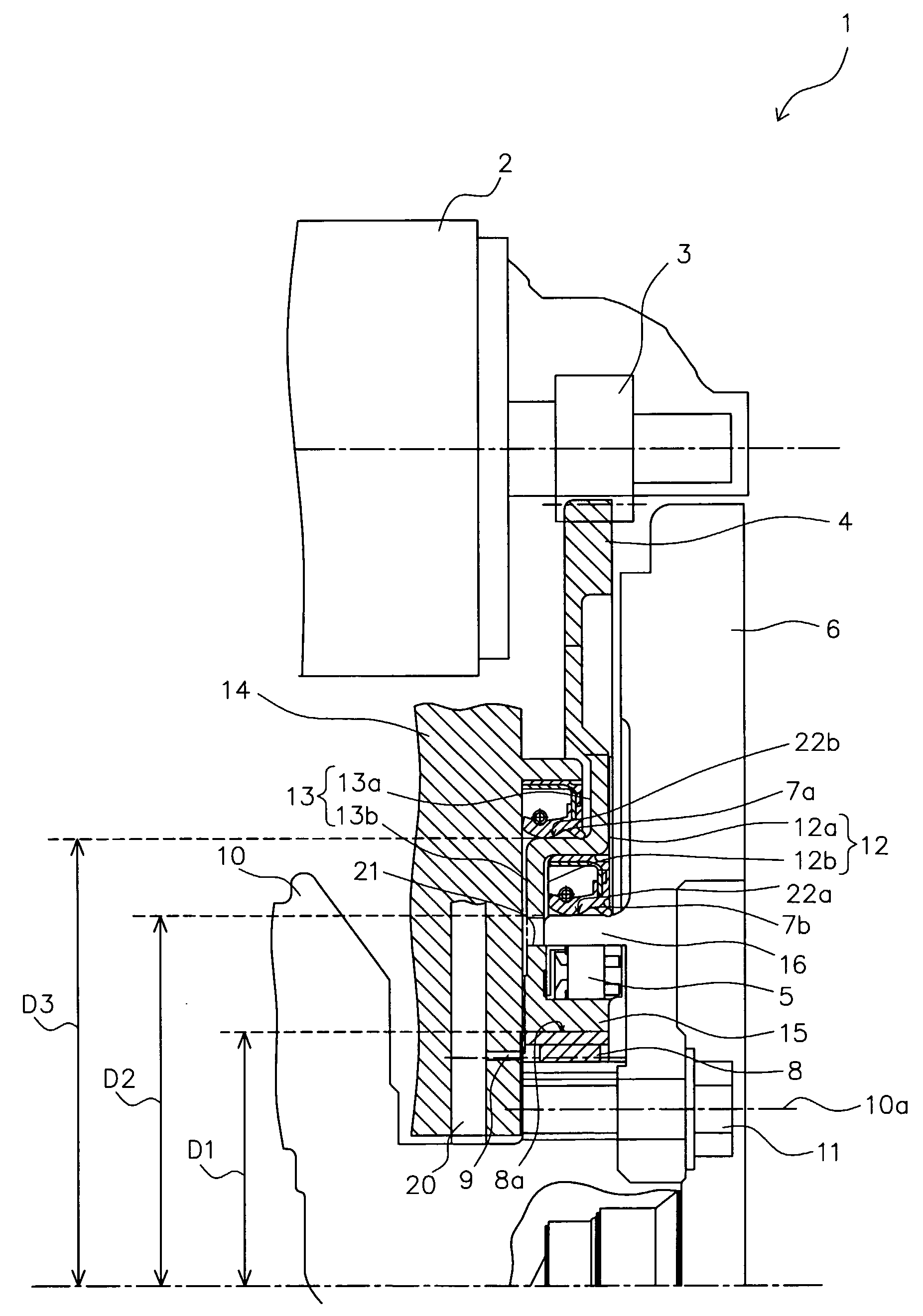

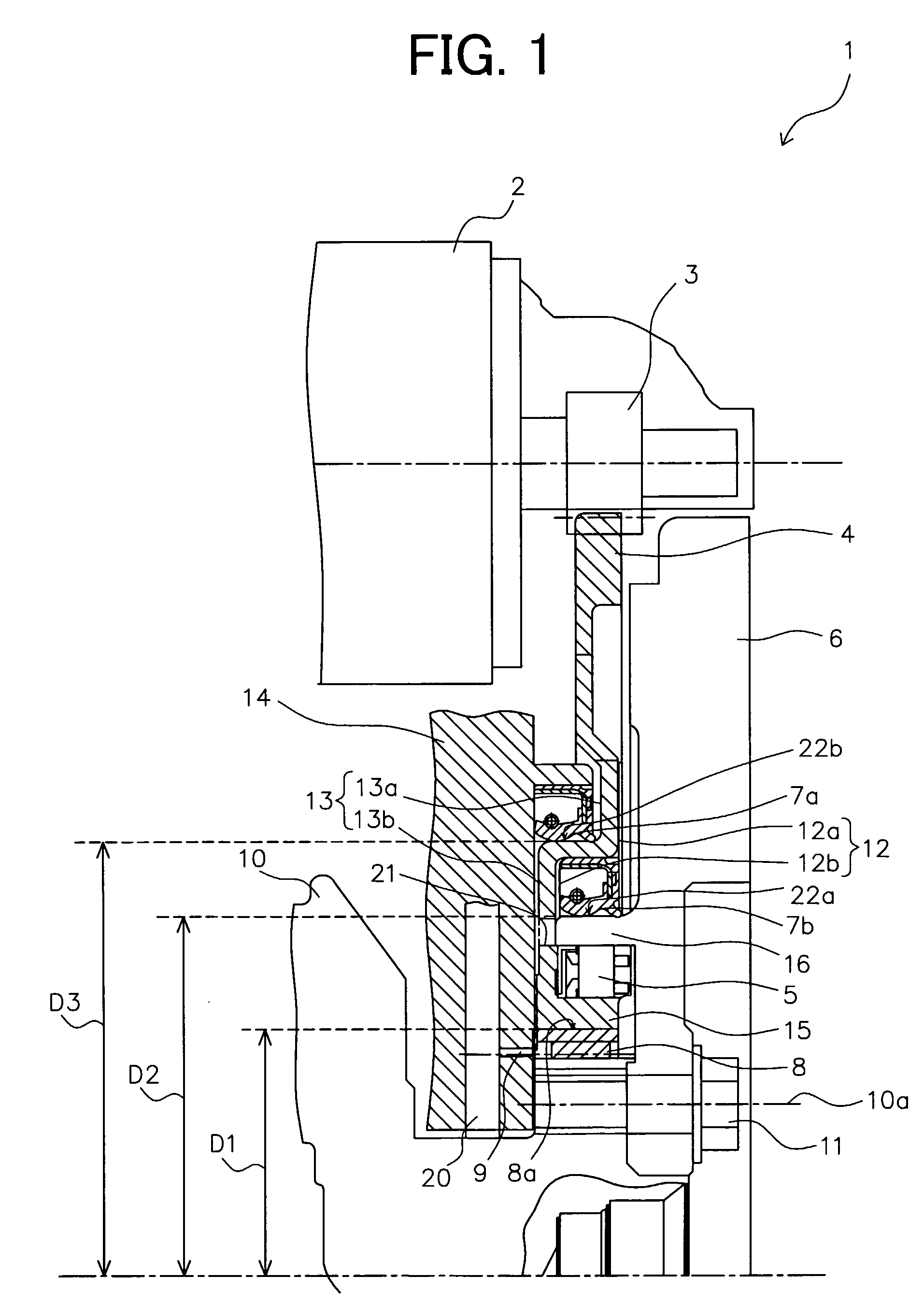

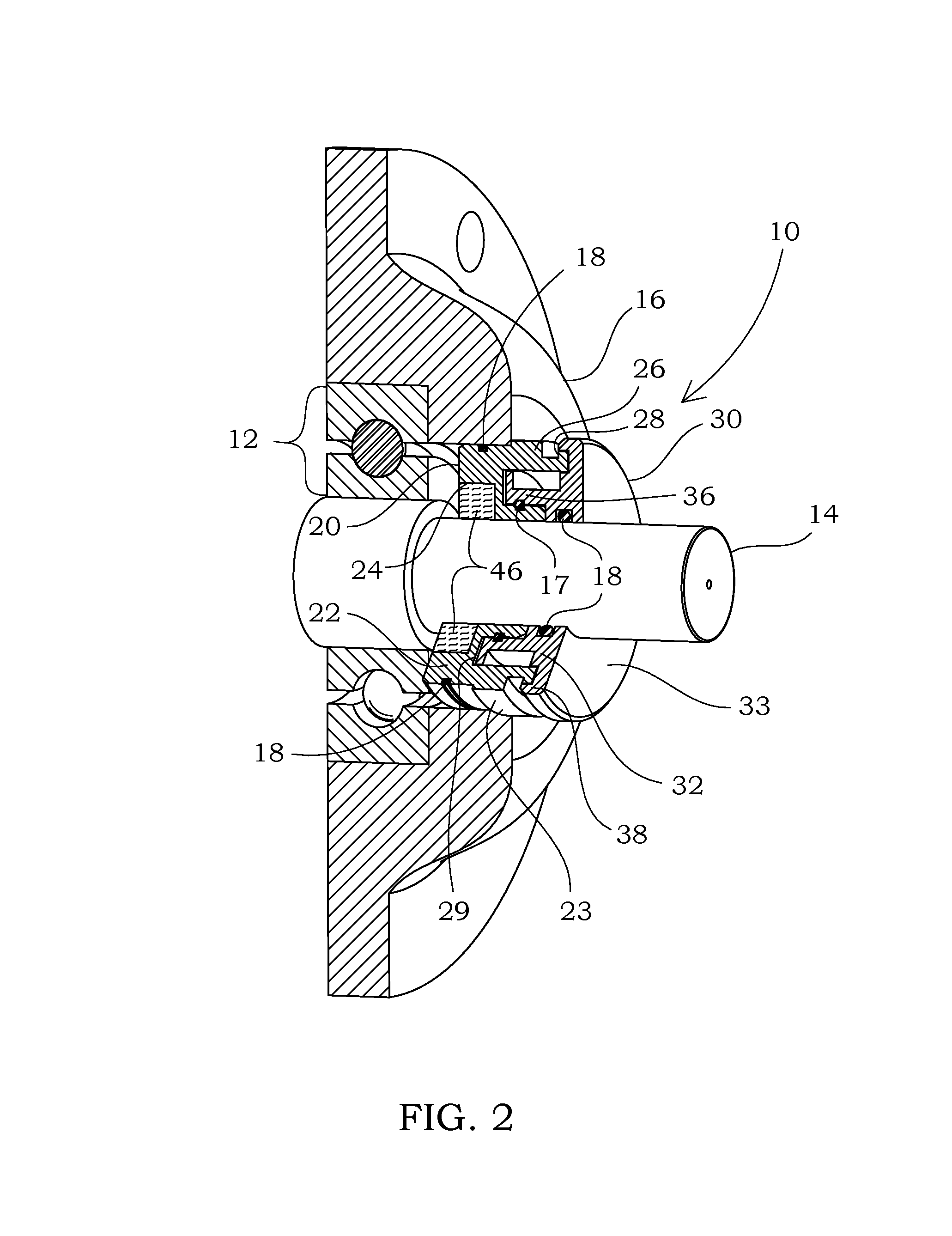

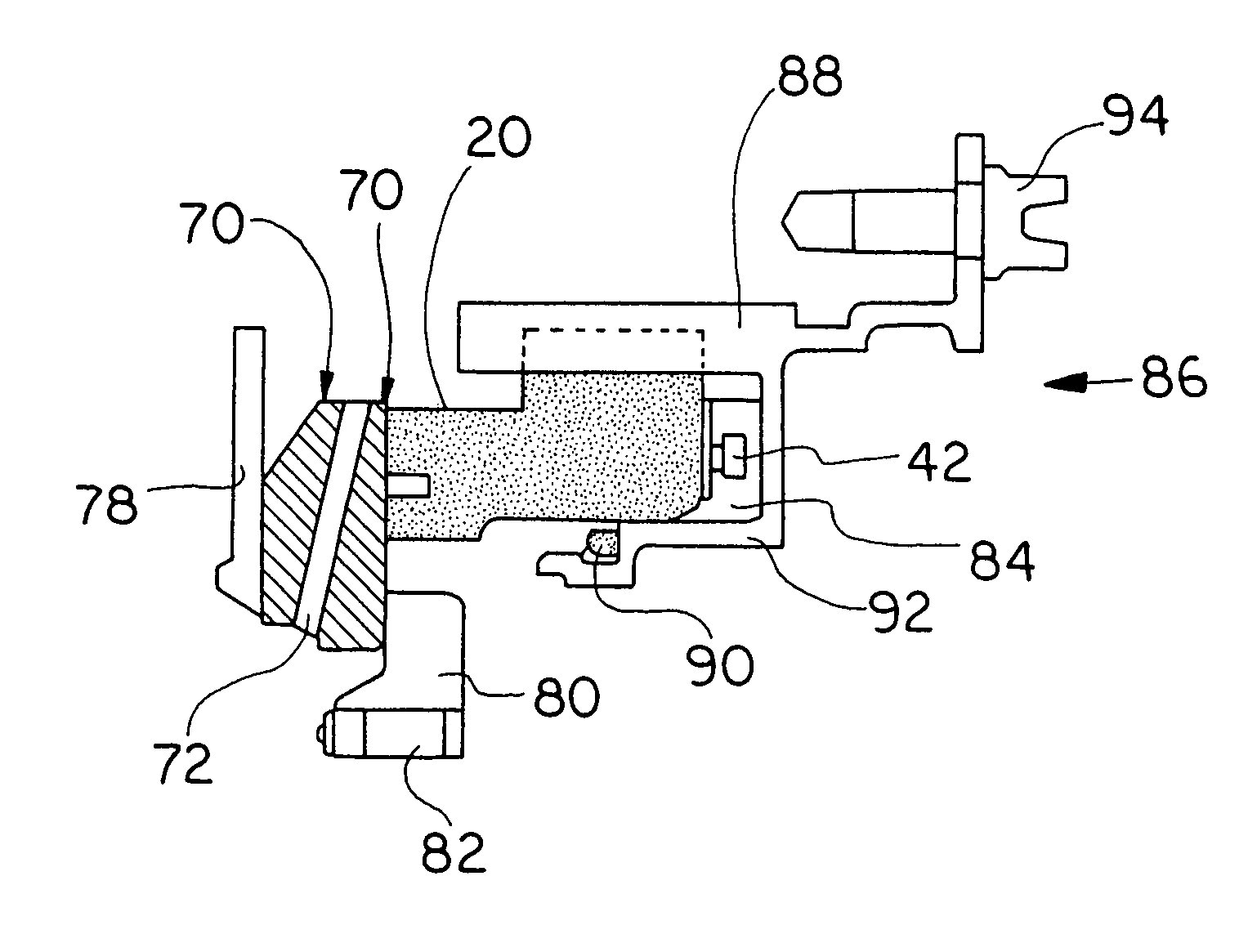

Starting Apparatus

ActiveUS20080121202A1Prevent oil leakageHigh startability and reliabilityPower operated startersMuscle operated startersFreewheelFlywheel

Engine starting apparatus comprising a one way clutch. A first oil seal is located on the outer side of a second oil seal in the radial direction of a ring gear. Upon starting of an engine, the time that the first oil seal is slid on the ring gear is short, and after the start of the engine, the first oil seal is not slid on the ring gear. The second oil seal is located on the inner side of the first oil seal in the radial direction of the ring gear. Therefore, the second oil seal hardly deteriorates even if slid on a flywheel at high speed after the start of the engine. By locating the first and second oil seals at different positions in the radial direction of the ring gear, it is possible to improve the startability and the lifetime of a starting apparatus. At least one oil seal has a taper shape in order to generate a thrust force which forces the ring gear away from the flywheel.

Owner:TOYOTA JIDOSHA KK

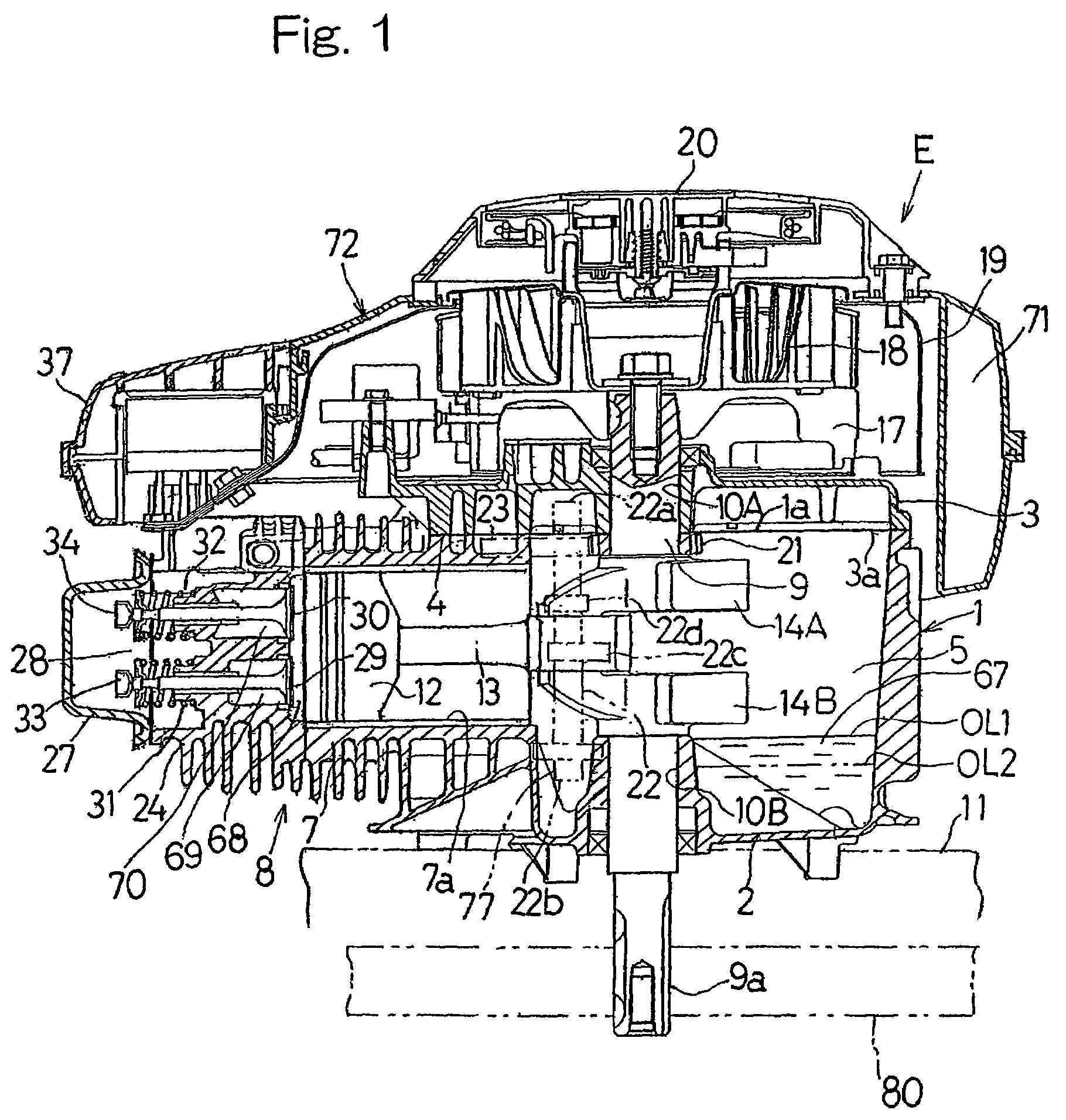

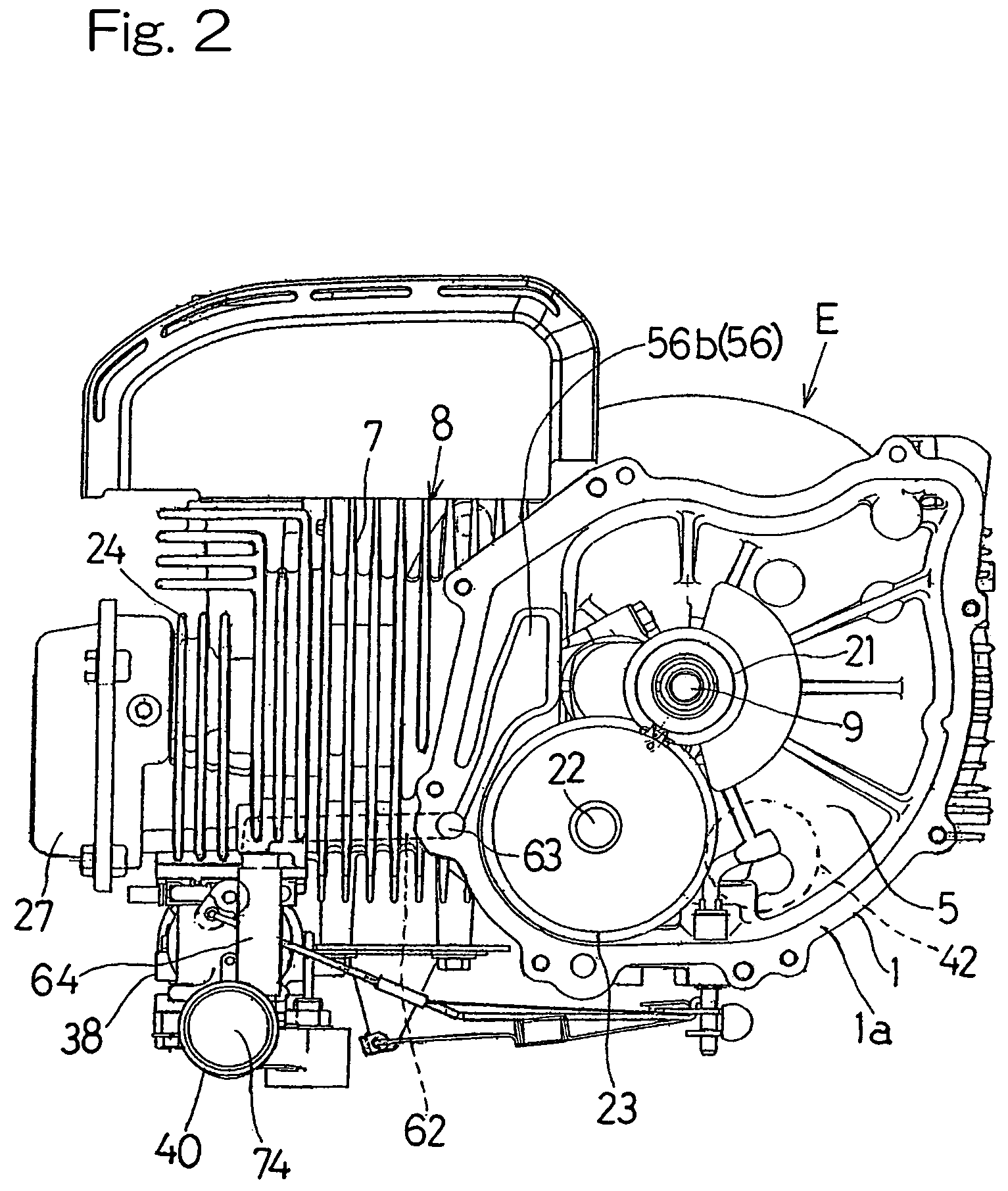

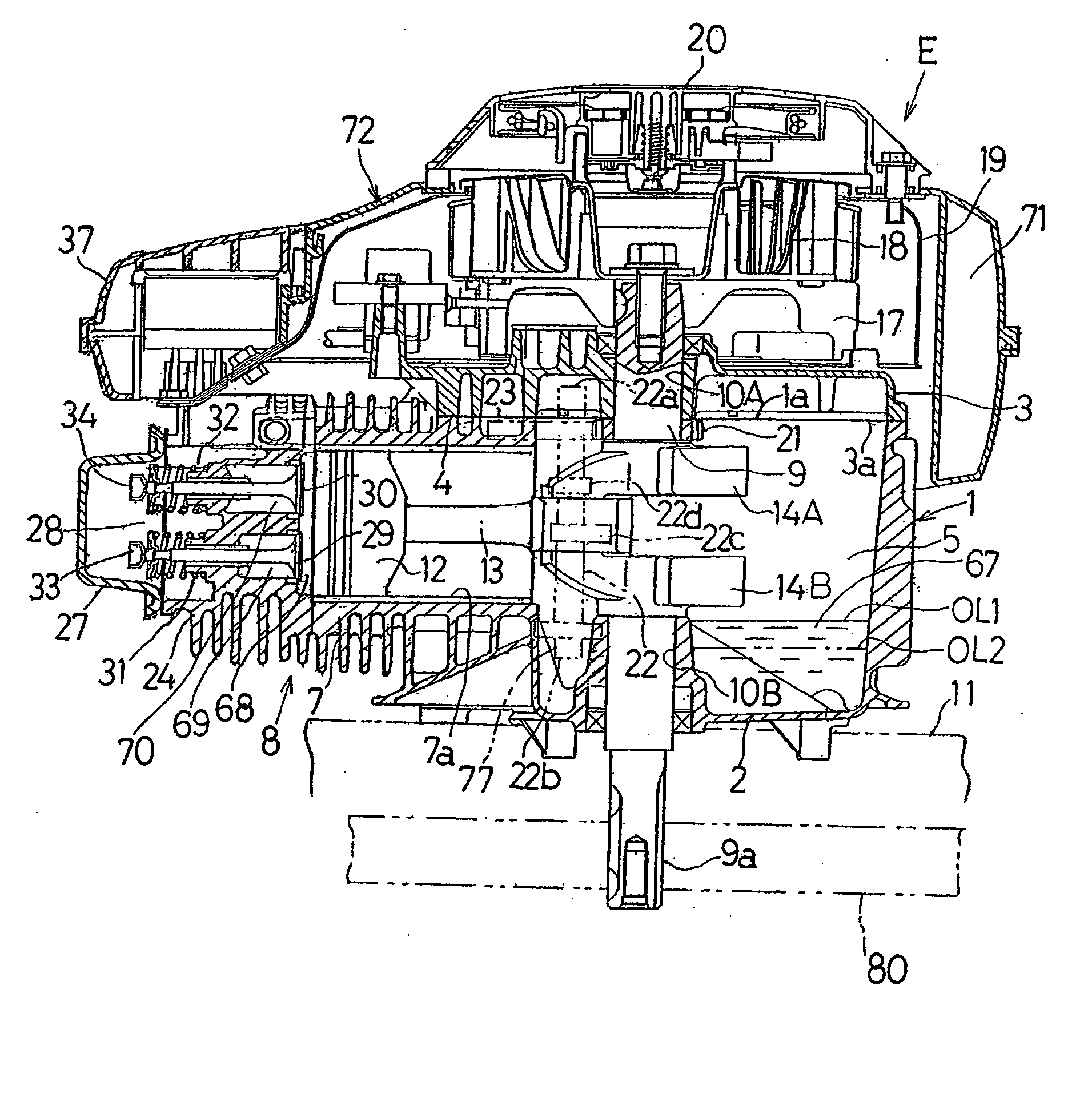

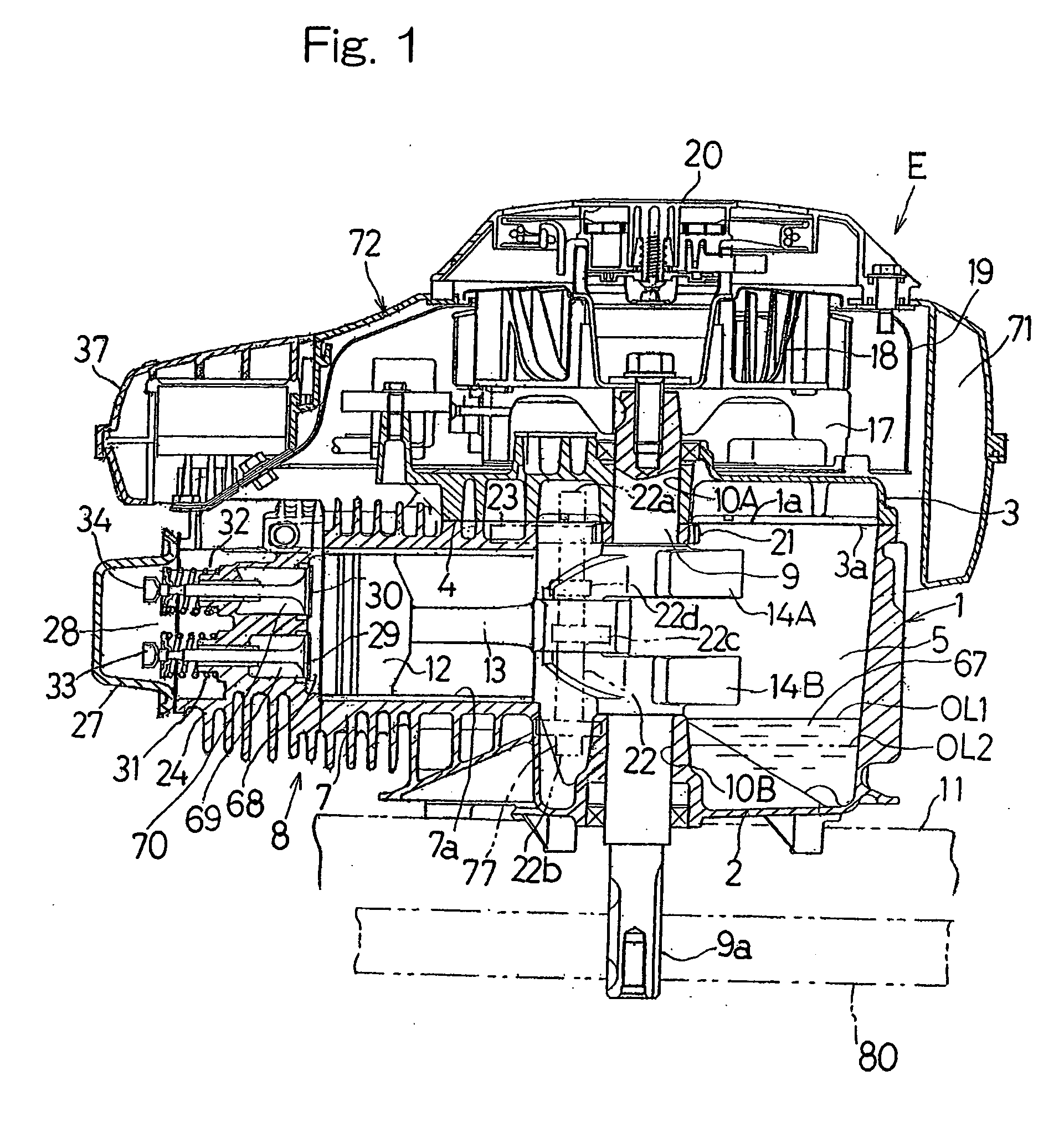

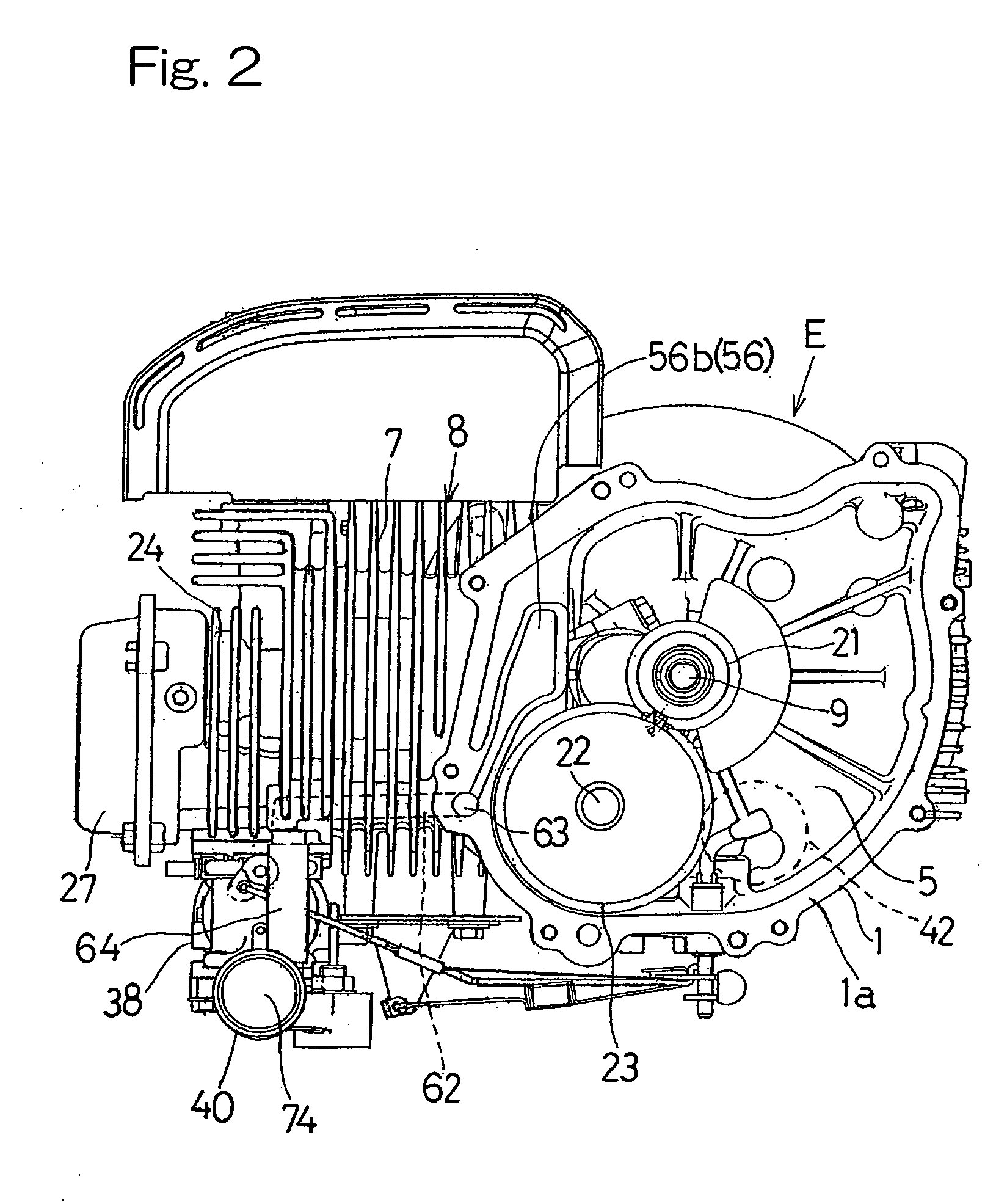

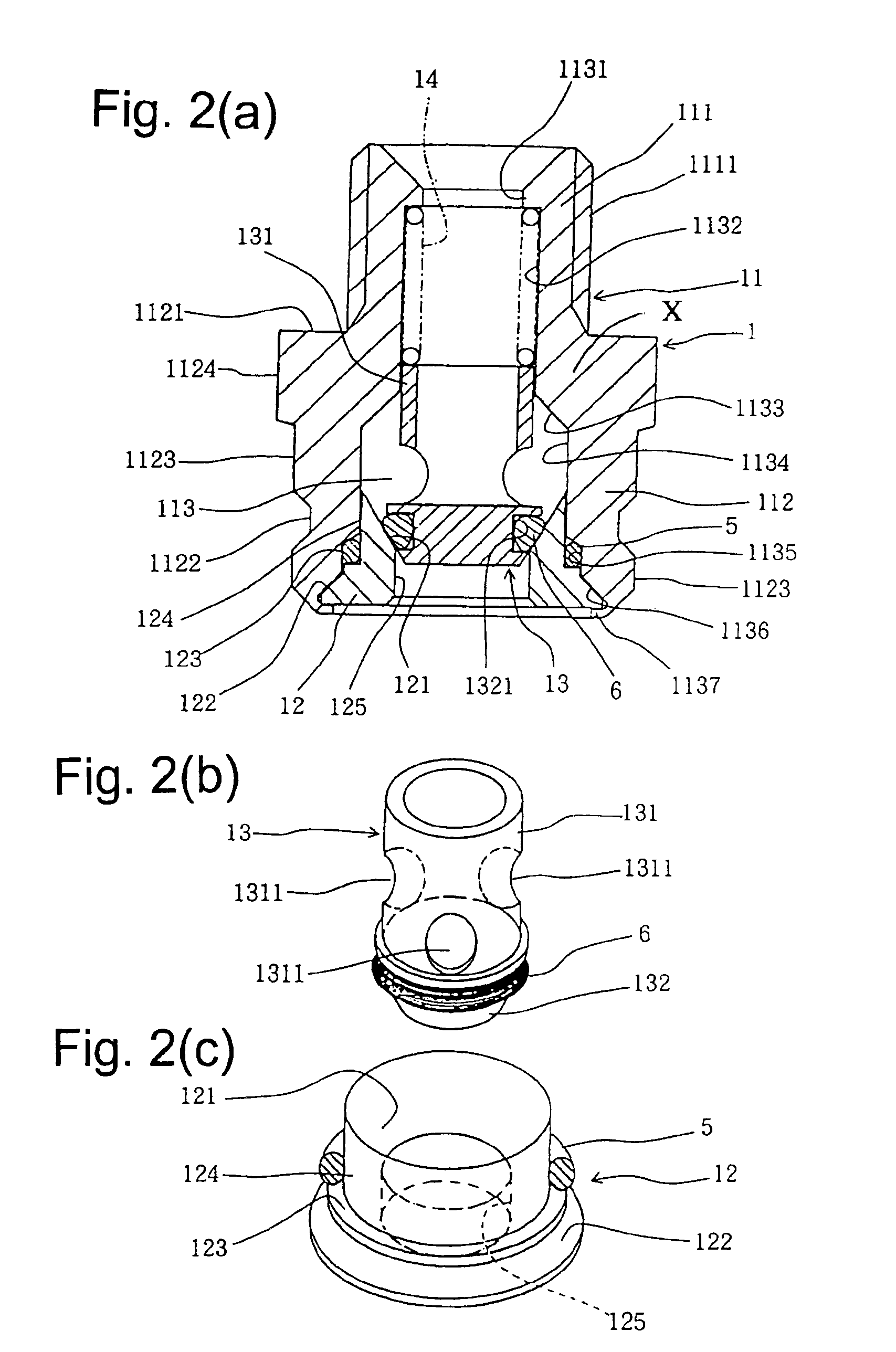

Combustion engine of vertical shaft type

ActiveUS7201132B2Improve installation rigidityEasy maintenanceCasingsCylinder headsCombustionCrankcase

Owner:KAWASAKI MOTORS LTD

Combustion engine of vertical shaft type

ActiveUS20050229893A1Improve installation rigidityEasy maintenanceCasingsLubrication of auxillariesCombustionEngineering

To provide an internal combustion engine of a vertical shaft type, in which leakage of an oil from a crankcase and an oil pan is effectively prevented, which has high mounting rigidity relative to a working machine and, also, which is capable of being easily serviced, the combustion engine includes a vertically extending crankshaft (9) having a pair of upper and lower crank webs (14A and 14B), a crankcase (1) accommodating the crankshaft (9) and including an oil pan (2), and a crankcase cover (3) mounted on an upper surface (1a) of the crankcase (1) to cover the crankcase (1). The upper surface (1a) of the crankcase (1) is positioned above the upper crank web (14A).

Owner:KAWASAKI MOTORS LTD

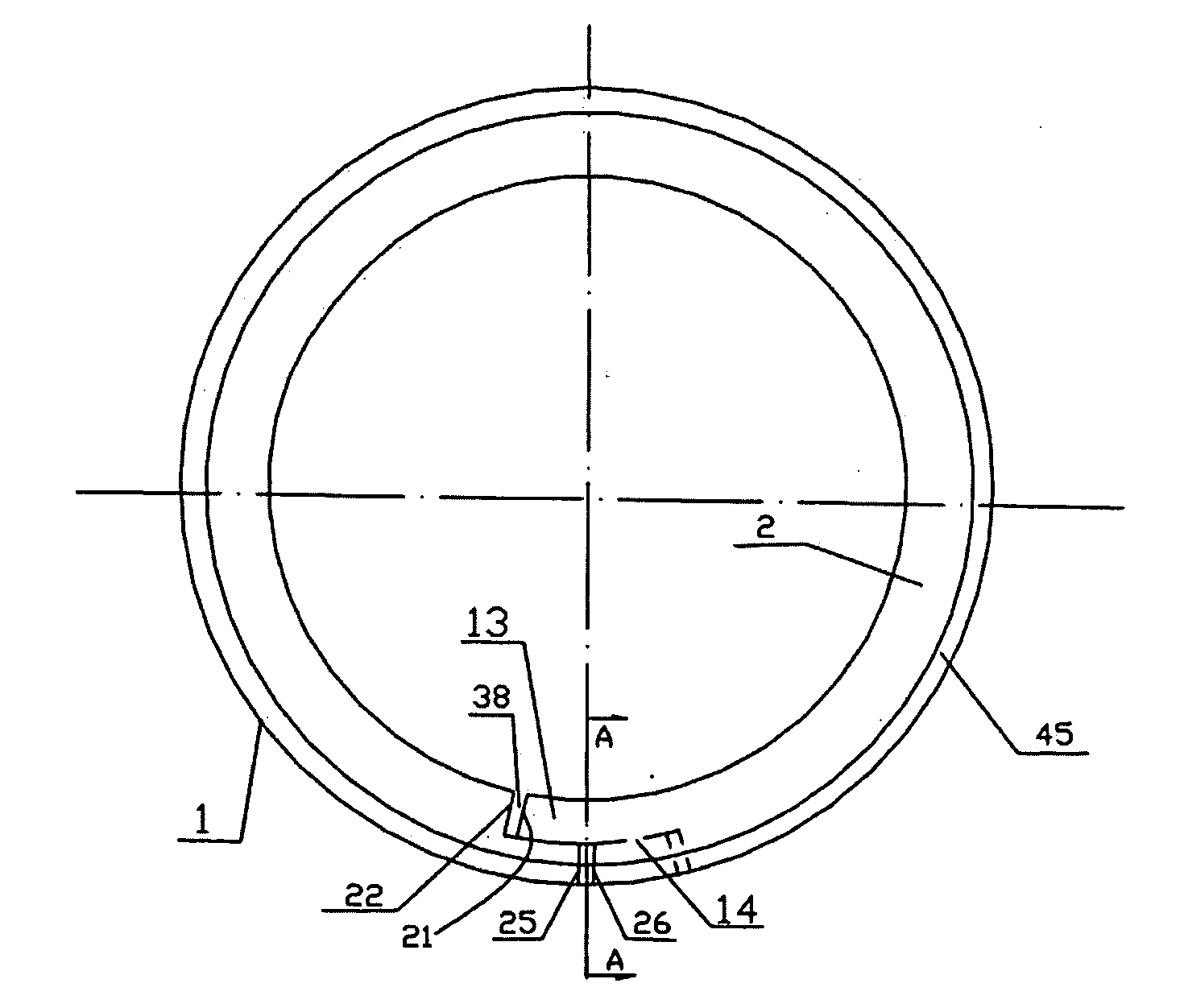

Oil sealing ring

InactiveUS20080252019A1Prevent leakagePrevent oil leakagePiston ringsBraking action transmissionGas compressorInternal combustion engine

An oil ring, particularly disposed in an oil ring outer-groove of a piston in an internal combustion engine or an air compressor, comprising a base ring (2) having a split, and an annular flange (1) radially-protruding outwards and disposed on outer circumferential surface of the base ring (2).

Owner:YU XIUMING

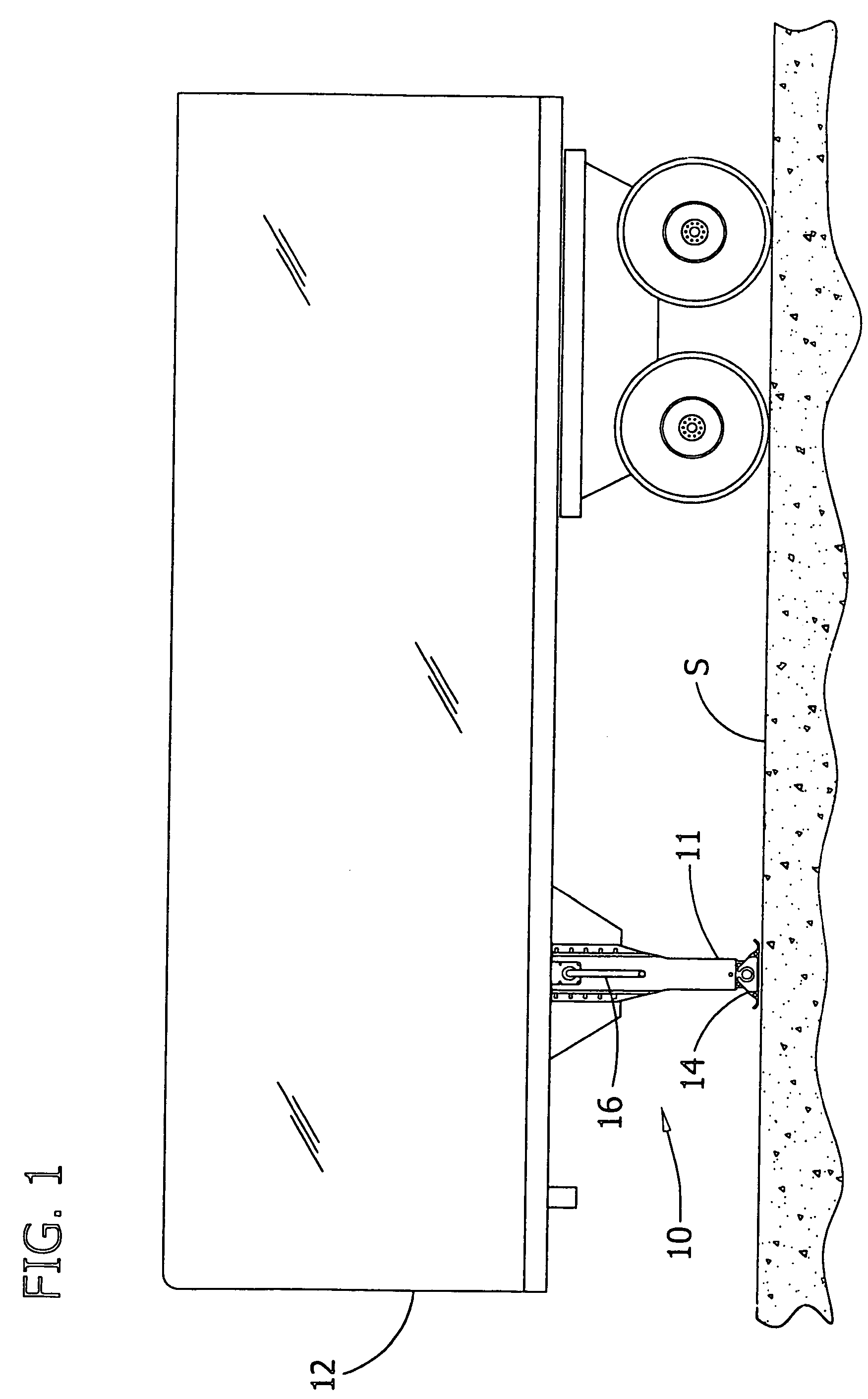

Landing gear and method of assembly

ActiveUS8051545B2Easy constructionPrevent oil leakageVehicle fittings for lifting and manoeuvringVehicle fittings for liftingLanding gear

Landing gear for selectively supporting a semitrailer and a method of assembly of the landing gear is provided. The landing gear includes a leg having an upper section and a lower section telescopingly received in the upper section. A lead screw extends and retracts the upper and lower sections relative to each other upon rotation thereof. An input shaft applies a torque to the lead screw to drive rotation thereof, the input shaft being rotatable about a rotation axis and movable in translation along the rotation axis for shifting between a first position for low gear operation and a second position for high gear operation. An output shaft, axially aligned with the input shaft, has an output gear for transmitting torque to the lead screw. A gearing subassembly is received in the upper leg section and is configured to augment lift when the input shaft is in the first position and augment speed in the second position.

Owner:SAF HOLLAND INC (US)

Wide discourager tooth

Owner:GENERAL ELECTRIC CO

Oil drain plug of engine

InactiveUS6902038B2Prevent oil leakageImprove productivityCrankshaftsValve arrangementsCoil springEngineering

A new type of plug incorporating a normally closed valve for draining oil from an oil pan of a car engine, wherein the normally closed valve is incorporated in a through hole provided as an oil draining path in a bolt type member fixed to the oil pan, an oil draining dedicated jig is assembled to the plug so as to open the normally closed valve in order to drain the oil contained in the oil pan by sucking it with a negative pressure, a movable valve disc member installed in the through hole is installed so that it is engaged with a valve seat provided near the outer end part of the through hole by a coiled spring so as to form the normally closed valve, and the tip end of the plug is made flush generally with the internal surface of the oil pan so as to prevent any structure from projecting toward the inside.

Owner:TAKAHARA TAMOTSU +1

Current diverter ring

ActiveUS8604653B2Prevent oil leakageImprove sealingRotary current collectorAssociation with grounding devicesShunt DeviceEngineering

The current diverter rings and bearing isolators serve to dissipate an electrical charge from a rotating piece of equipment to ground, such as from a motor shaft to a motor housing. One embodiment of the current diverter ring includes an inner body and an outer body configured to clamp at least one conductive segment between them. In the preferred embodiments of the current diverter ring, the conductive segments are positioned in radial channels. The outer body may be affixed to a shaft, a motor housing, a bearing isolator, or other structure. The bearing isolator may incorporate a retention chamber for holding conductive segments within the stator of the bearing isolator, or the bearing isolator may be fashioned with a receptor groove into which a current diverter ring may be mounted.

Owner:INPRO INC

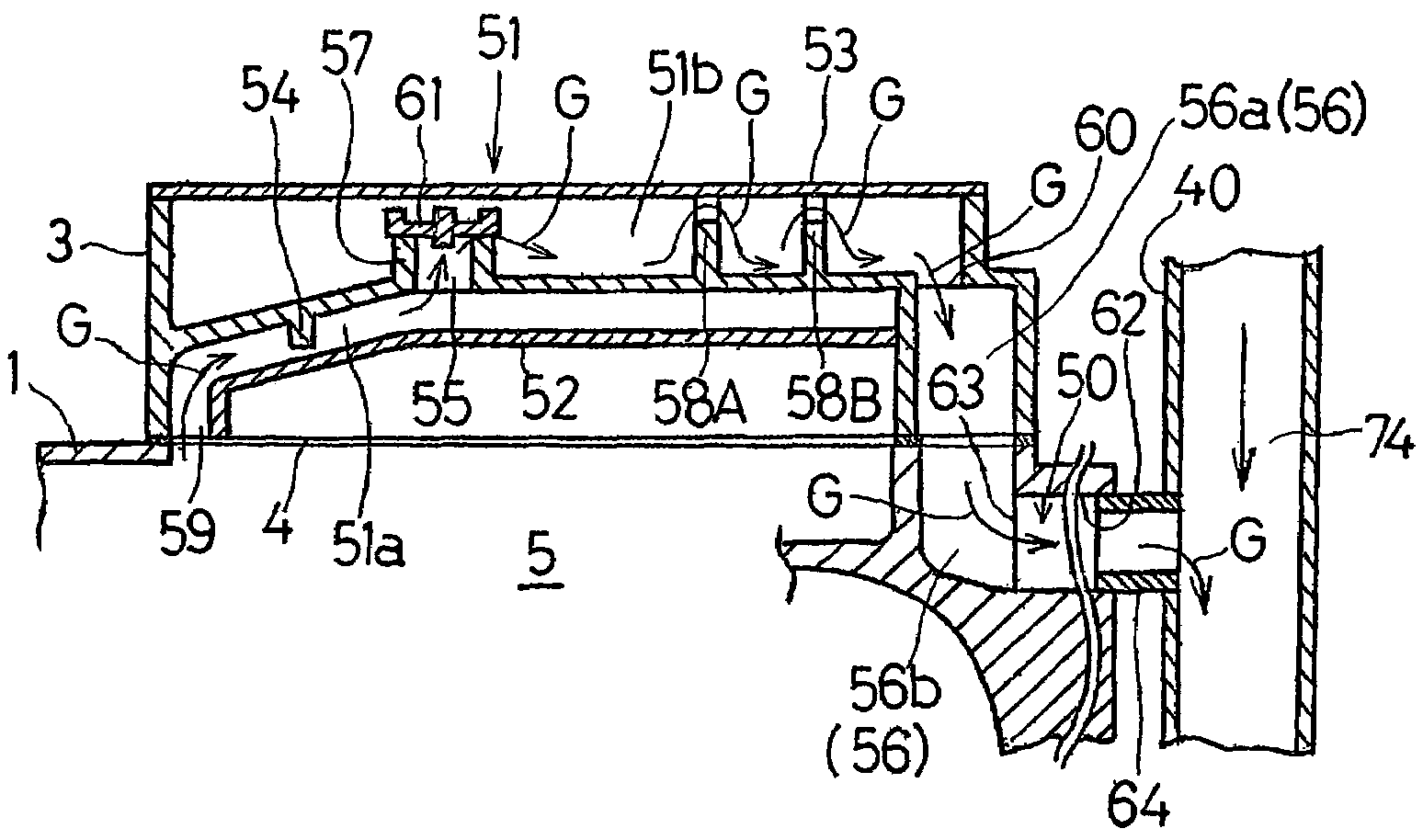

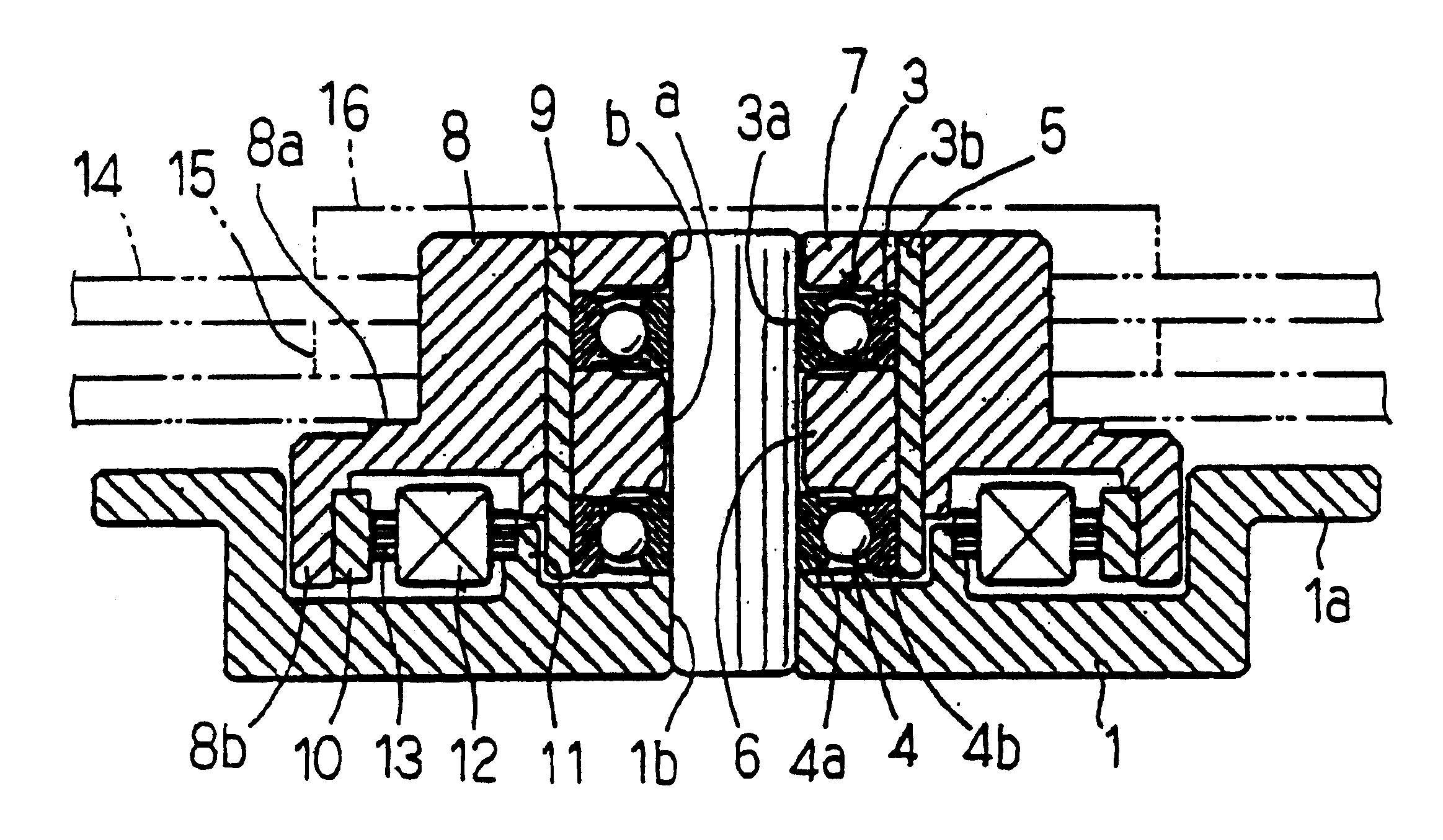

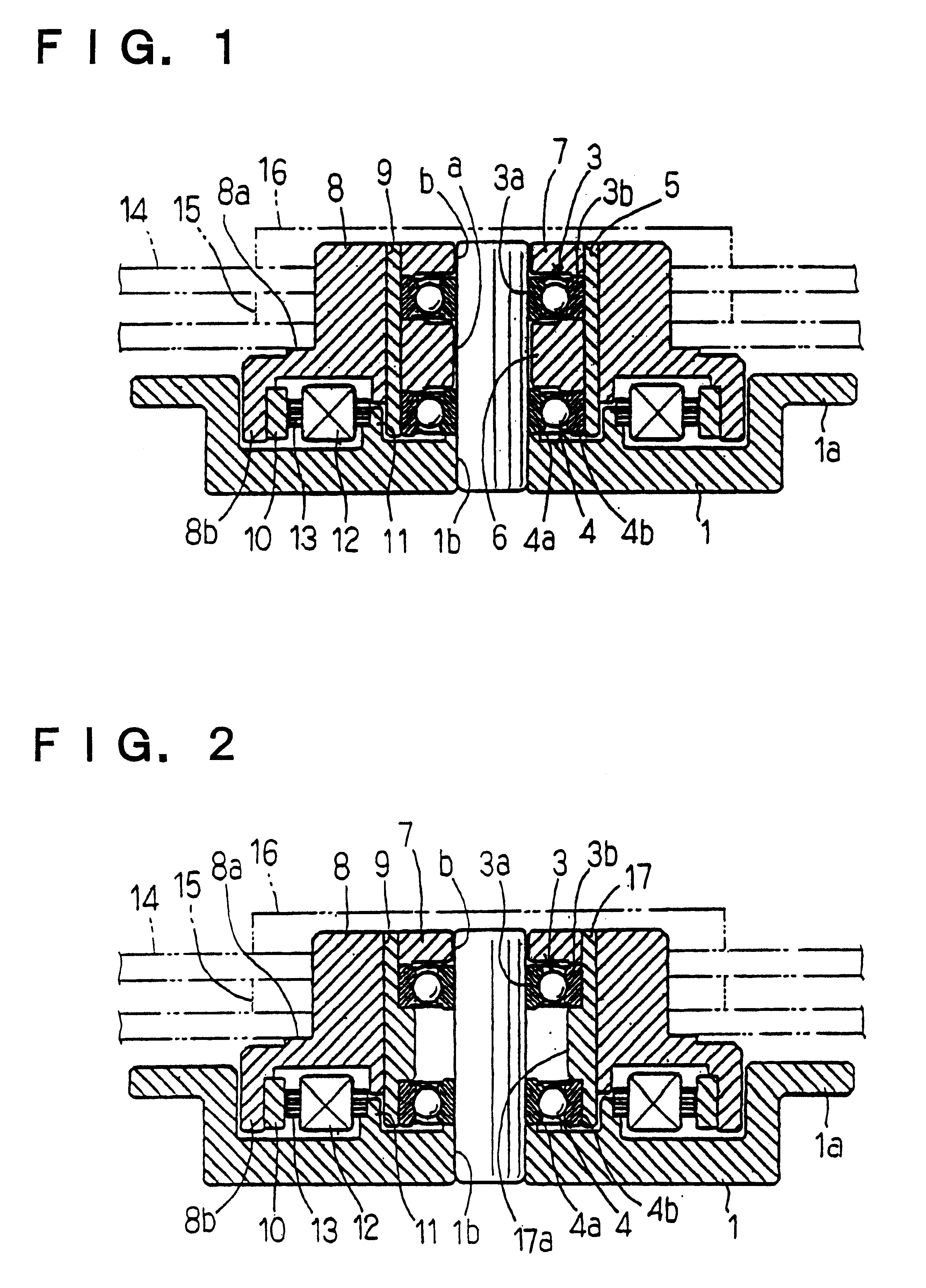

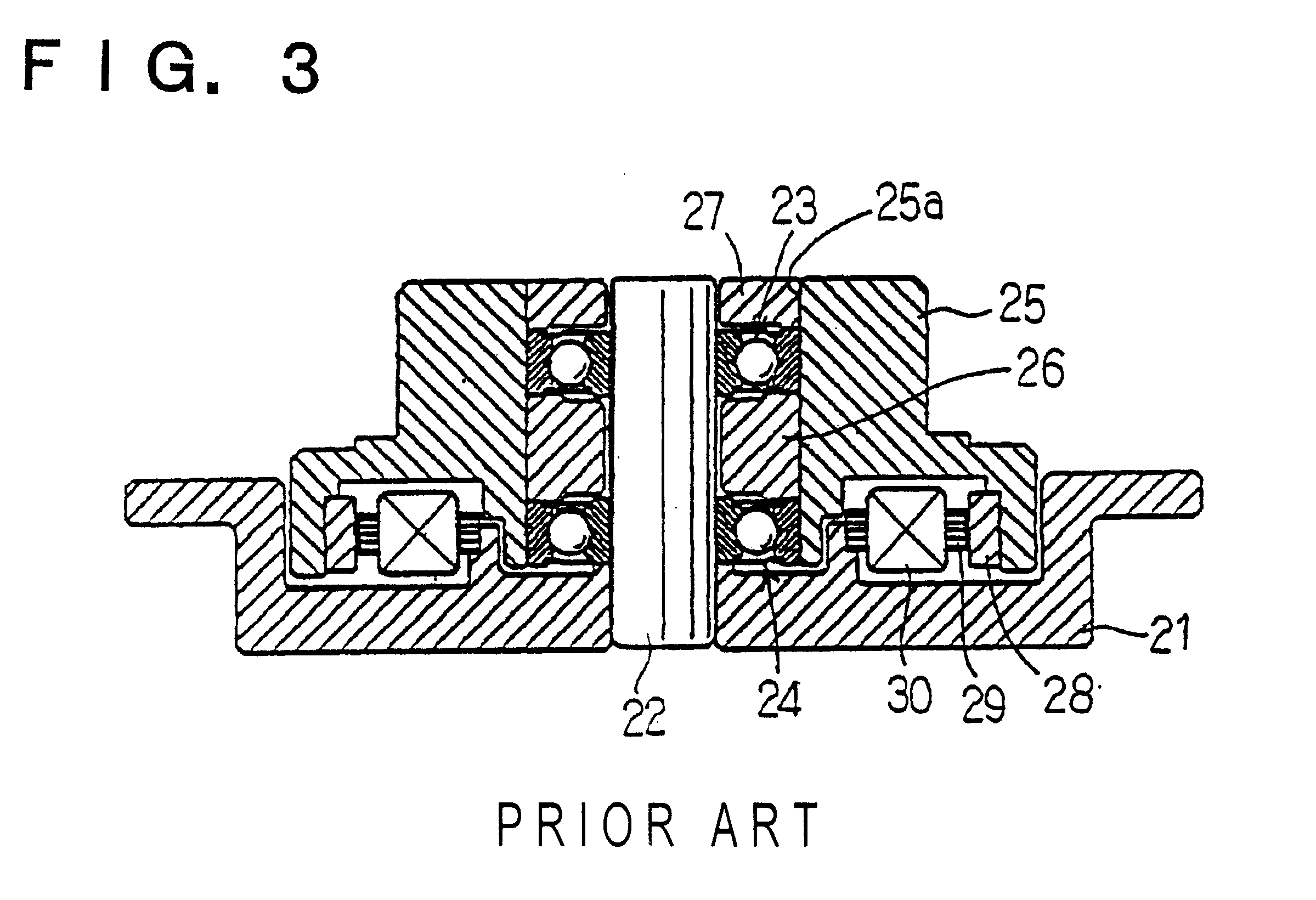

Spindle motor

The object of the present invention is to provide a spindle motor of high accuracy of rotation irrespective of the temperature differential for driving the hard disk or disks of the hard disk drive device.A spindle motor including a shaft secured on a base to extend vertically therefrom, and a rotor hub journalled rotatably around the shaft through a plurality of anti-friction bearings each of which has outer and inner races and rotational bodies disposed between races, characterized in that a cylindrical sleeve having a through bore is disposed between outer peripheral surface of each anti-friction bearing and an inner peripheral surface of a central bore provided through the rotor hub, the sleeve and the outer races of the anti-friction bearings are made of the ferrous metal material of substantially the same coefficient of expansion, and the inner races of anti-friction bearings and the shaft are also made of the ferrous metal material of substantially the same coefficient of expansion.

Owner:MINEBEA CO LTD

Reverse pressure double dam face seal

ActiveUS7780399B1Enhance drawing clarityIncrease pressureEngine sealsPump componentsEngineeringHigh pressure

A double dam reverse pressure face seal assembly for use in the turbomachine having a tunnel extending through the machine for high pressure air passage therein during normal machine operating has a mating ring positioned annularly respecting the tunnel for flow of lubricating oil generally outwardly through passageways in the ring and a sealing member biased against an interface surface of the mating ring, the sealing member including a first dam presenting a first contact face to the interface surface of the mating ring, a second dam integral with an outboard of the first dam, presenting a second contact face to the interface surface of the mating ring and a channel between the first and second dams for annularly downward flow of oil leaking inwardly past the second dam towards a channel exit.

Owner:STEIN SEAL

Landing gear and method of assembly

InactiveUS7380825B2Easy constructionPrevent oil leakageMechanical apparatusVehicle fittings for lifting and manoeuvringGear wheelLanding gear

Landing gear for selectively supporting a semitrailer and a method of assembly of the landing gear is provided. The landing gear includes a leg having an upper section and a lower section telescopingly received in the upper section. A lead screw extends and retracts the upper and lower sections relative to each other upon rotation thereof. An input shaft applies a torque to the lead screw to drive rotation thereof, the input shaft being rotatable about a rotation axis and movable in translation along the rotation axis for shifting between a first position for low gear operation and a second position for high gear operation. An output shaft, axially aligned with the input shaft, has an output gear for transmitting torque to the lead screw. A gearing subassembly is received in the upper leg section and is configured to augment lift when the input shaft is in the first position and augment speed in the second position.

Owner:SAF HOLLAND INC

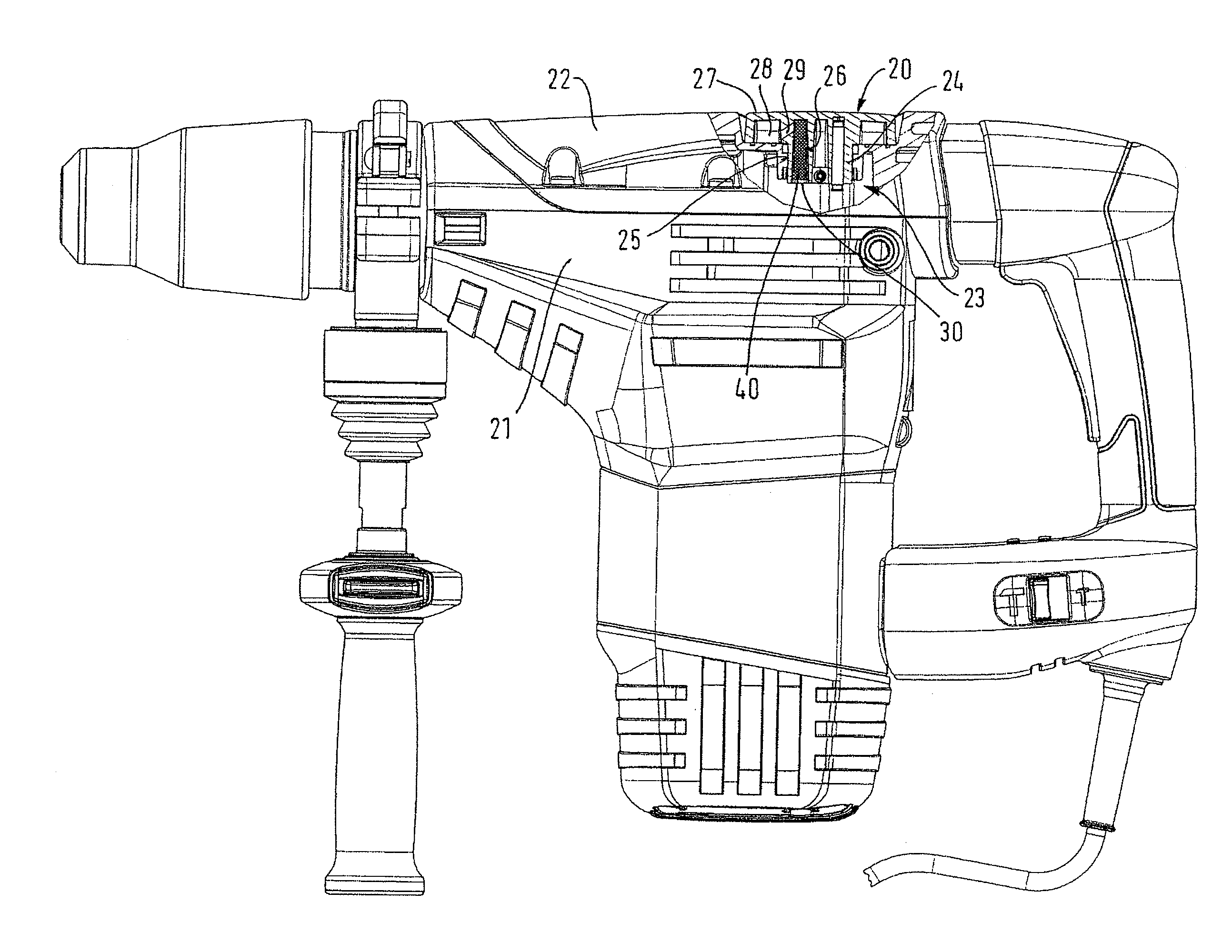

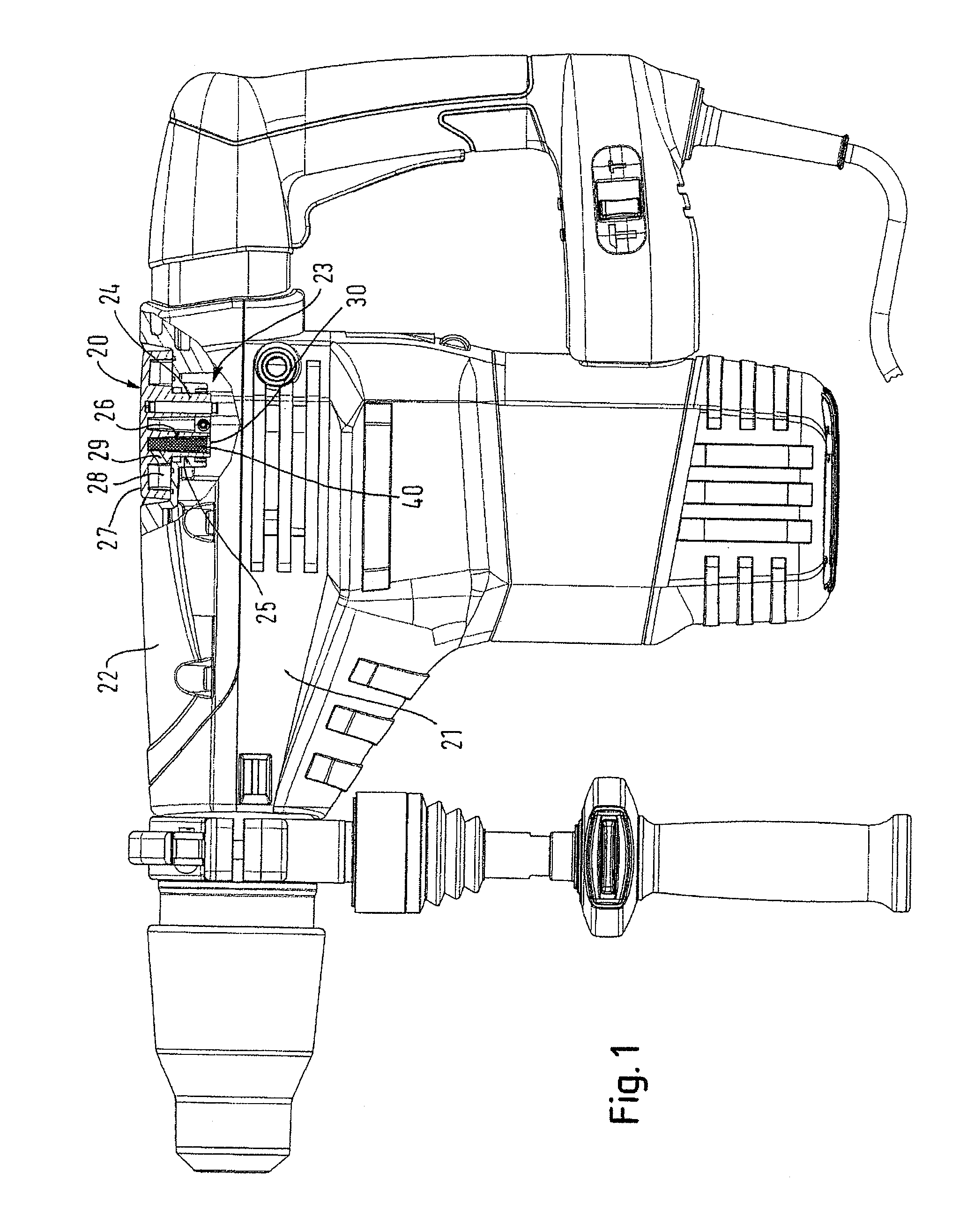

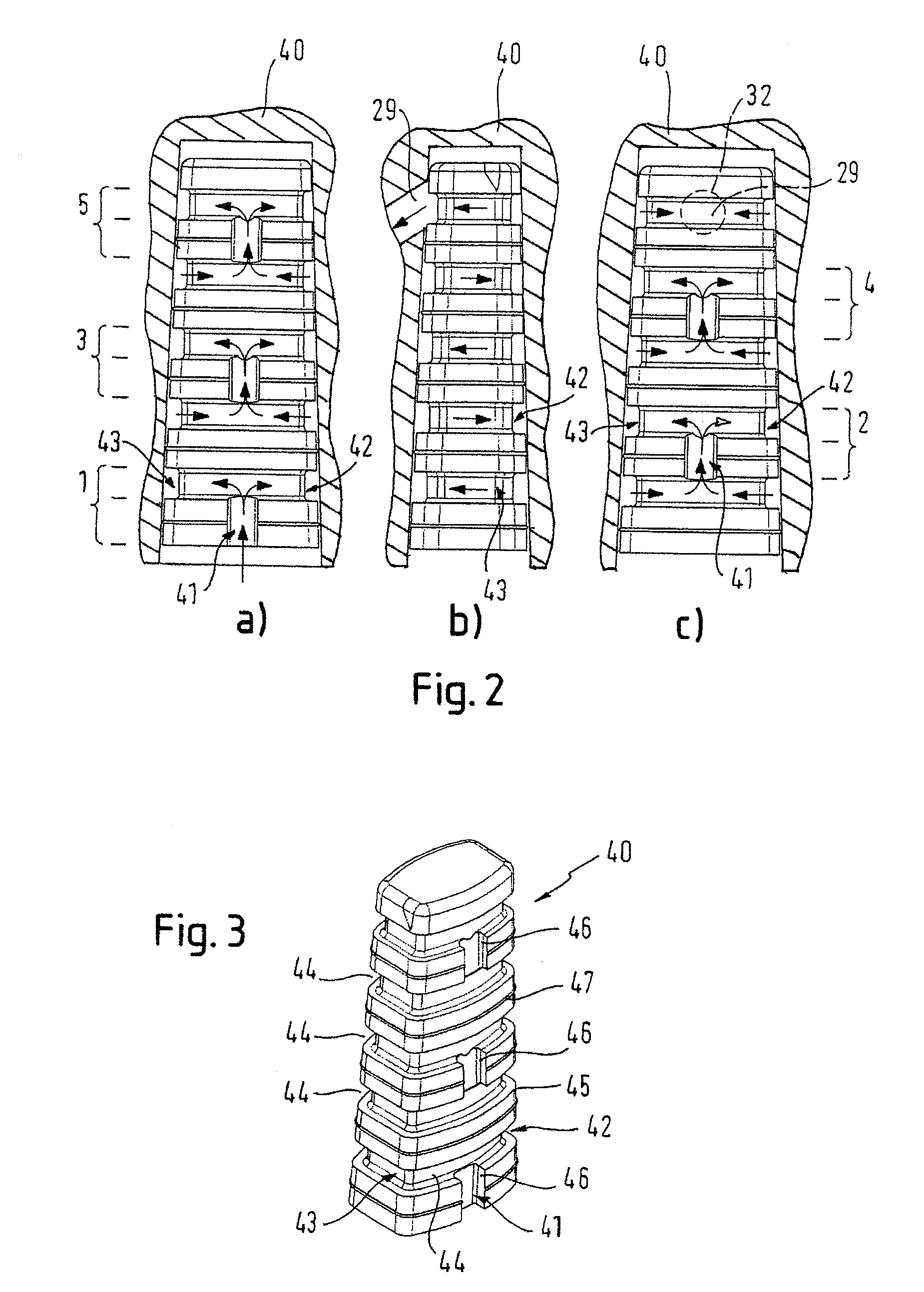

Power tool having a transmission vent

A power tool, such as a hammer drill and / or a chiseling hammer, includes a lubricated transmission arranged in a sealed transmission box. The transmission box is in fluid connection with the atmosphere via a venting channel. A sealing element is arranged in the venting channel. The sealing element cooperates with the venting channel to create a meandering pathway for air to pass through the venting channel so that leakage of lubricant between the sealing element and the venting channel is at least substantially prevented.

Owner:AEG ELECTRIC TOOLS

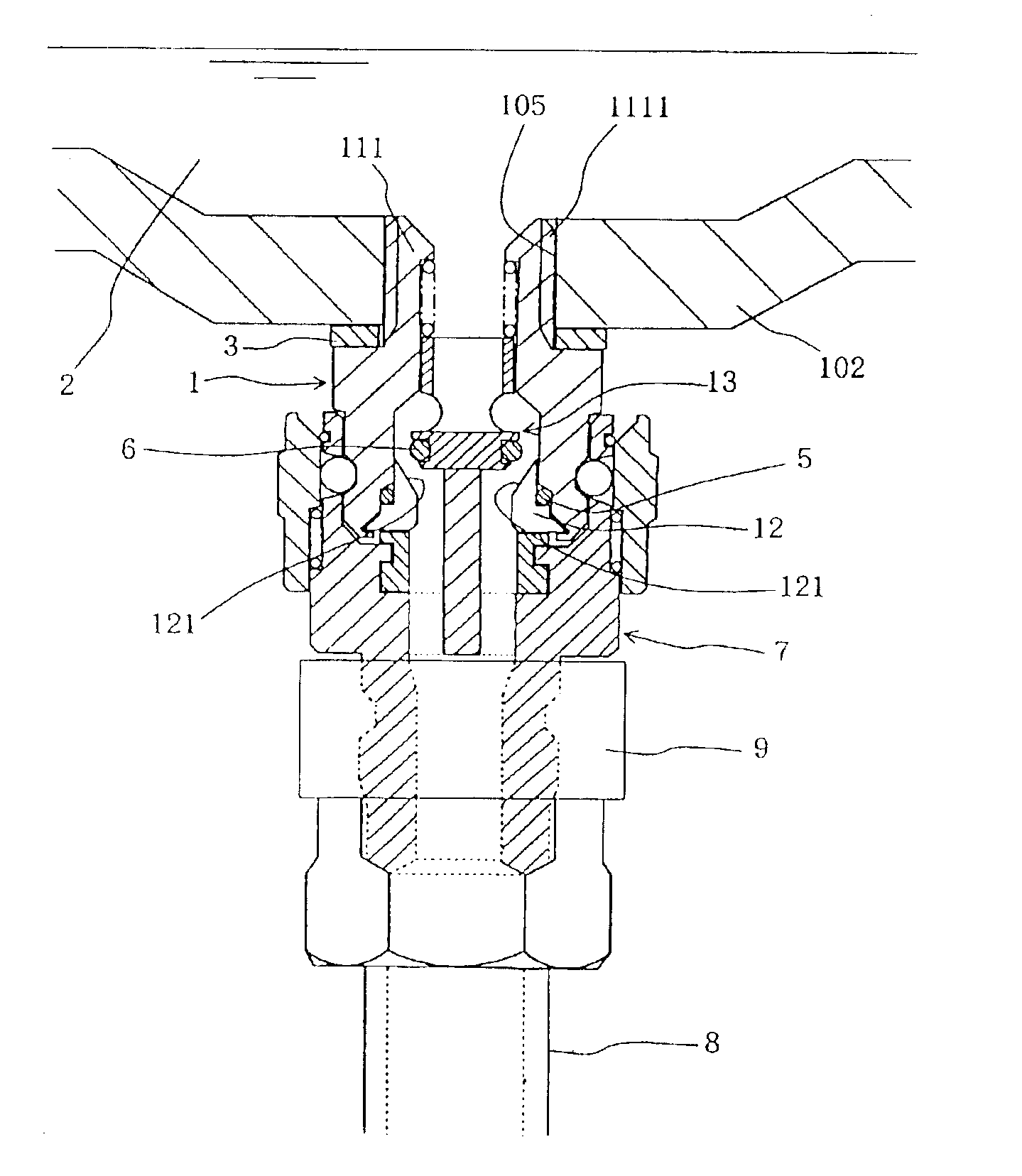

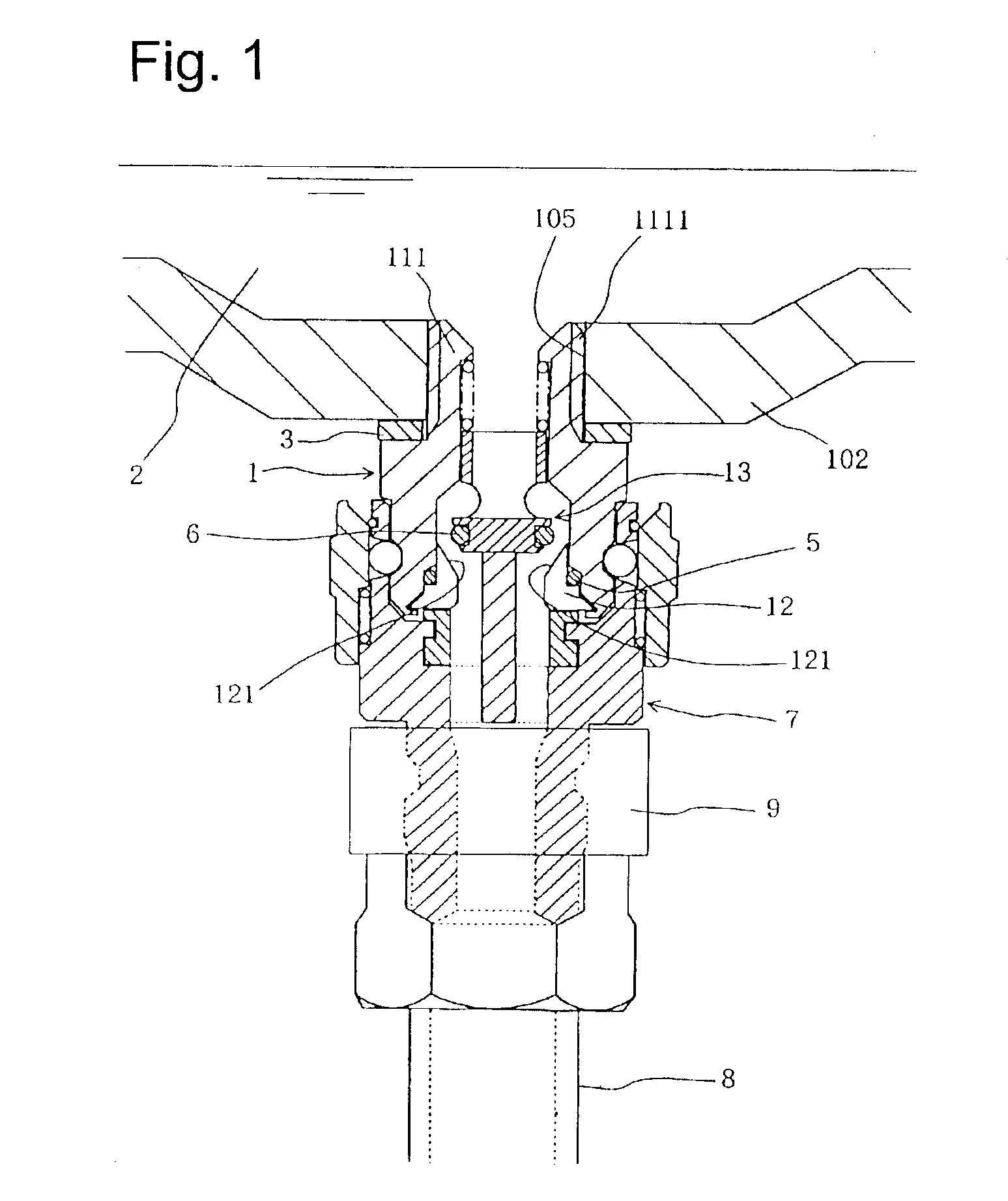

Compact mechanical seal

A mechanical seal having a compact structure is disclosed. The mechanical seal includes a stationary seal part fitted around a rotary shaft such that the stationary seal part is maintained in a stationary state when the rotary shaft rotates, and a rotary seal part sealably fitted around the rotary shaft such that the rotary seal part is rotated together with the rotary shaft when the rotary shaft rotates. The rotary seal part has an annular rotary seal face being in close contact with a stationary seal face of the stationary seal part in a state of being elastically pressed against each other during the rotation of the rotary shaft. The rotary seal part does not frictionally contact with the rotary shaft, so that it is not worn. Accordingly, the mechanical seal can be reliably used for a prolonged period of time.

Owner:KIM HAN SIK

Axial lash control for a vane-type cam phaser

InactiveUS20080254900A1Prevent leakagePrevent oil leakageValve arrangementsYielding couplingEngineeringInternal combustion engine

A camshaft phaser for varying the timing of valves in an internal combustion engine. A rotor includes a plurality of vanes disposed in a stator having a plurality of lobes, forming a plurality of alternating timing advance and timing retard chambers. Pressurized oil is supplied selectively to the chambers to change the phase angle of the camshaft with respect to the crankshaft. The rotor is captured between a stator plate and a rotor cover plate. Axial surfaces of the rotor form wiping surfaces with their respective plates. The rotor is divided equatorially into two interlocking sections, the lower section riding on the stator plate and the upper section riding on the cover plate. An axially slidable labyrintian seal formed at the juncture of the upper and lower sections prevents oil leakage. A lash spring between the upper and lower sections urges the sections into zero-lash with their respective plates.

Owner:DELPHI TECH INC

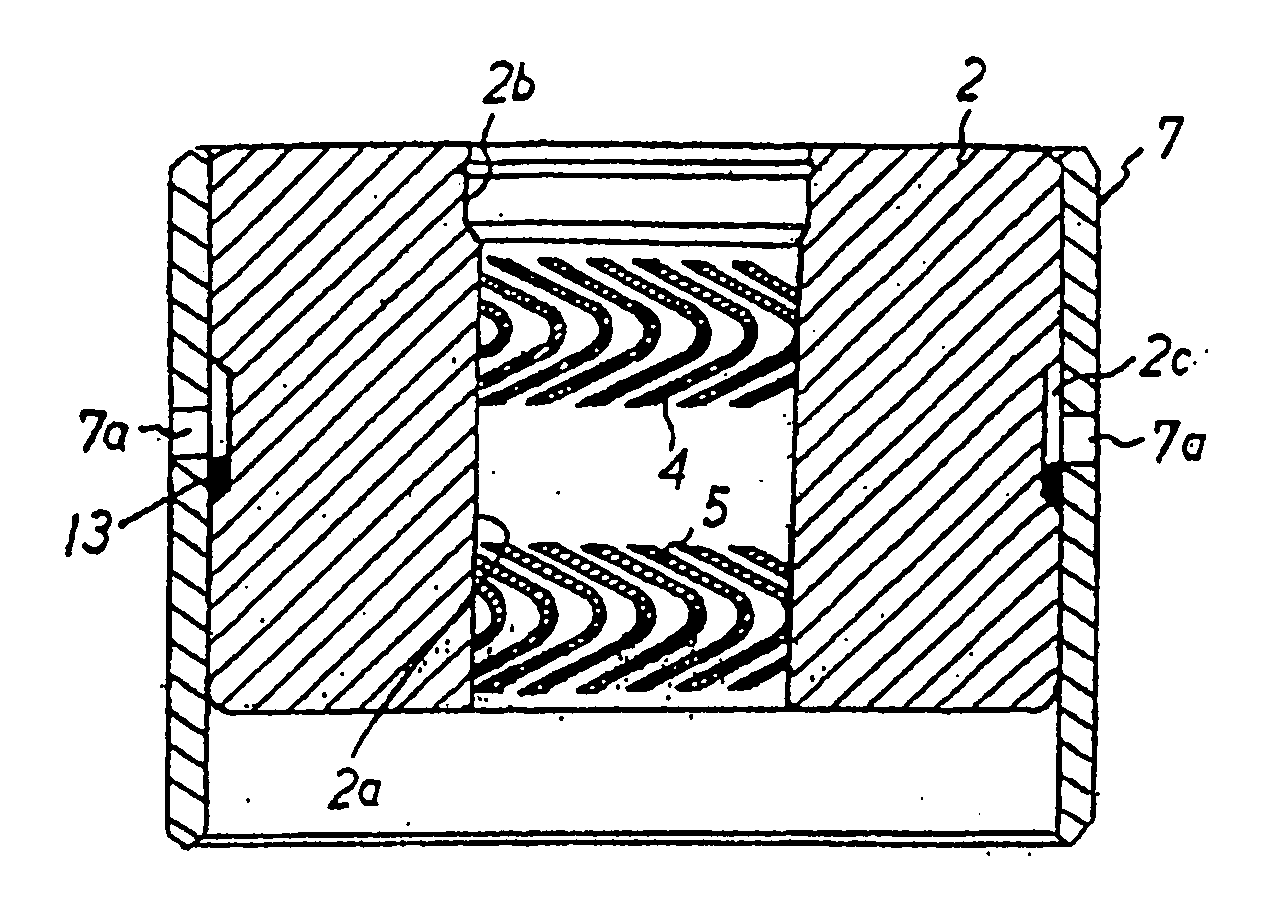

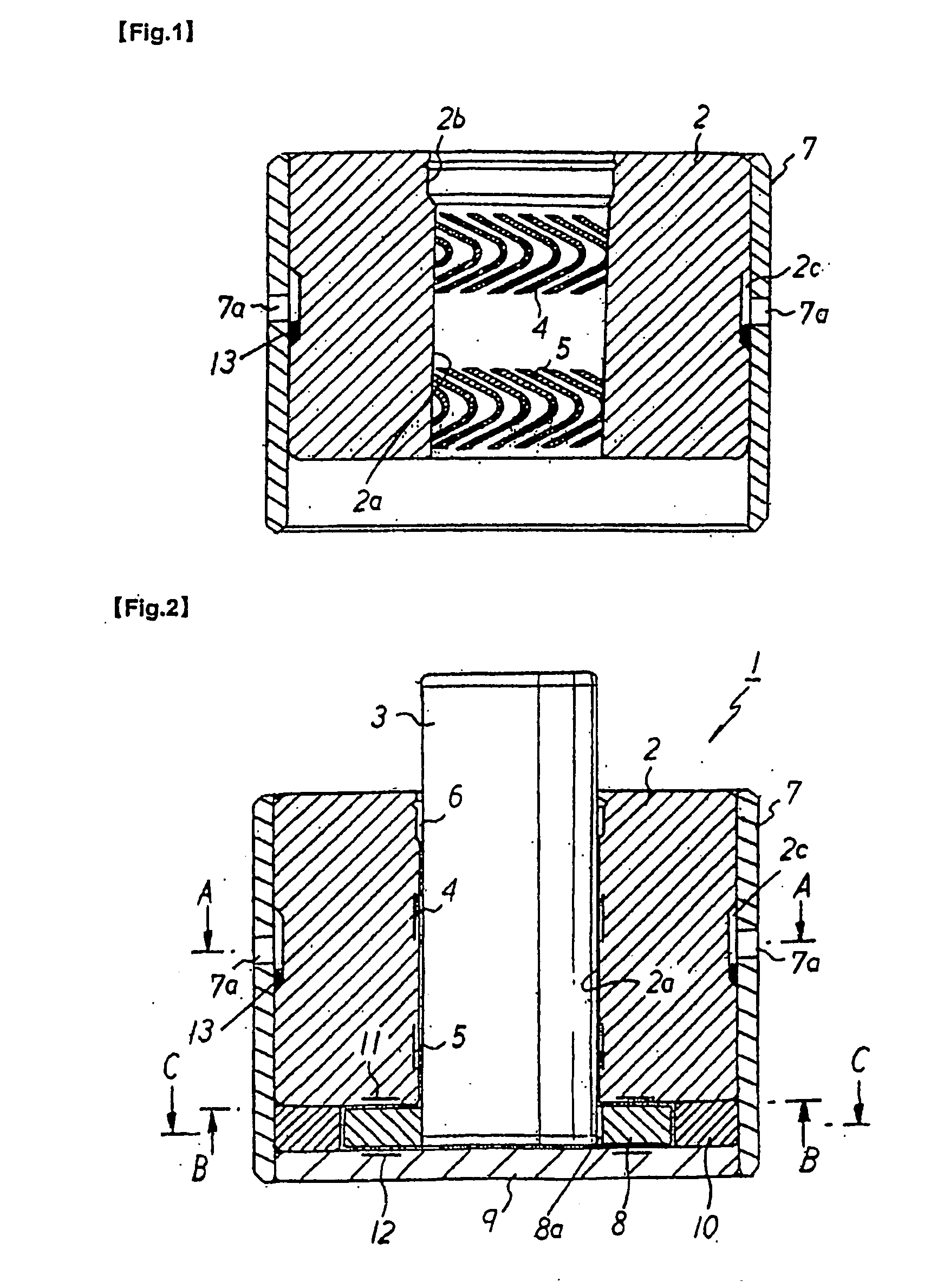

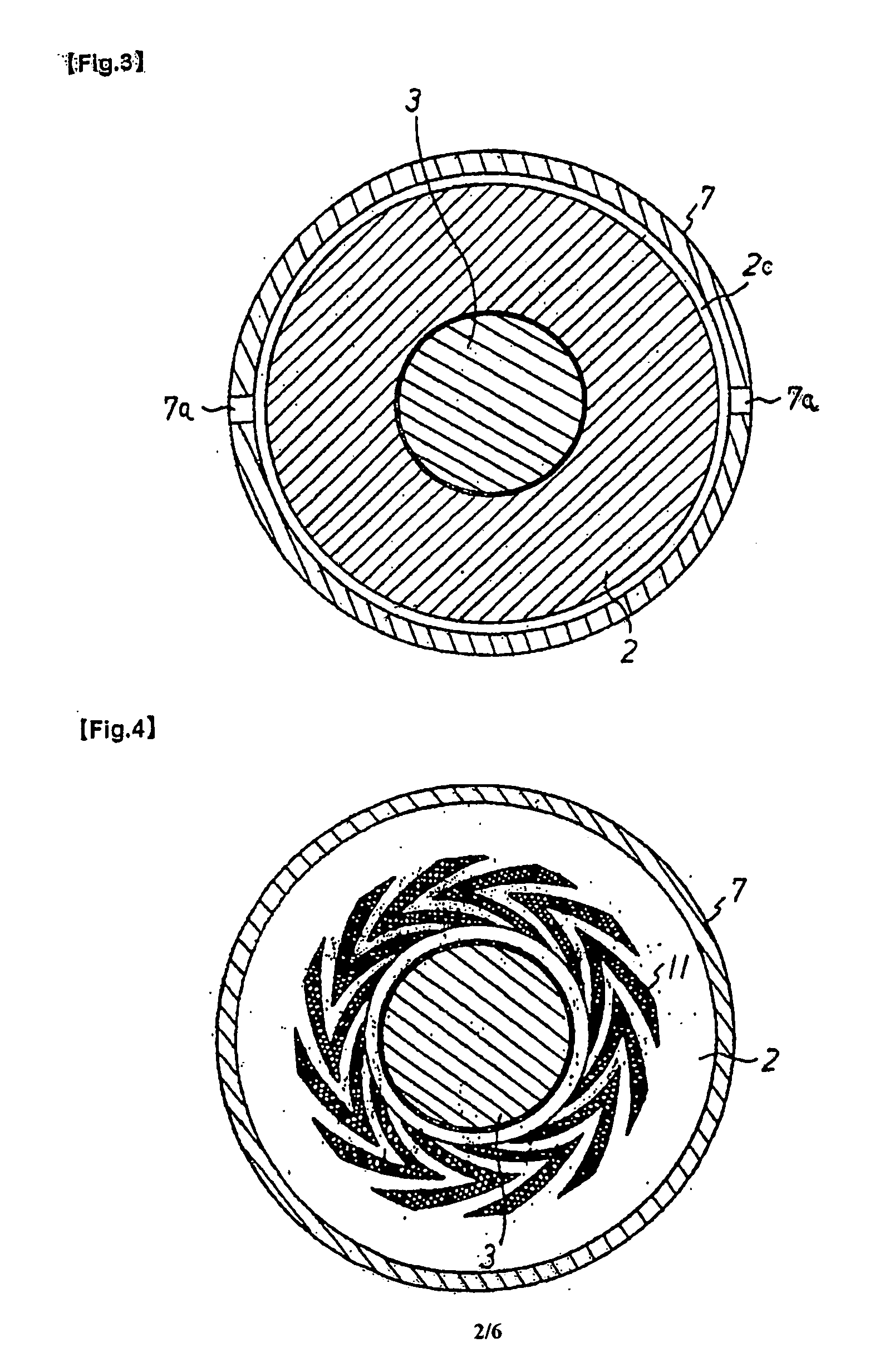

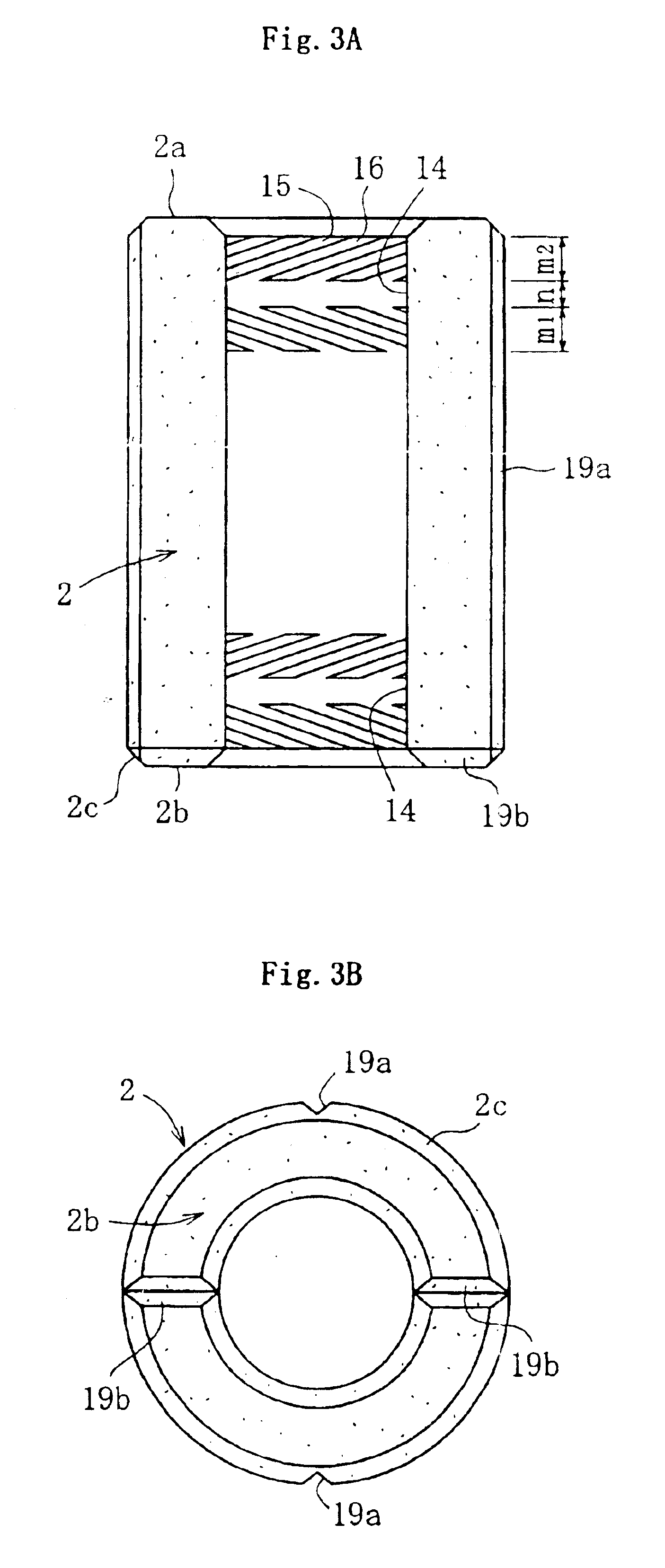

Fluid Dynamic Pressure Bearing

InactiveUS20090160277A1Maintain dimensional accuracyMaintain geometric accuracyShaftsBearing componentsAdhesiveEngineering

A fluid dynamic bearing (1) with a rotating shaft (3) inserted into a sleeve (2) fitted into a case (7) is disclosed. Tree rotating shaft (3) rotates freely without contact with the sleeve (2) by means of dynamic pressure force generated by the lubricant fluid that fills the gap formed around the rotating shaft (3). An adhesive groove (2c) is formed around the entire outer circumferential surface of the sleeve (2). At least one hole (7a) facing the adhesive groove (2c) is formed in case (7), and case (7) and sleeve (2) are; adhered by the injection of an adhesive (13) into adhesive groove (2c) from the hole (7a). The fluid dynamic pressure bearing, manufactured in this manner provides a high-quality bearing that is easy to construct, that can be adapted to low-cost manufacturing, and that can maintain dimensional and structural accuracy and in which the case (7) and sleeve (2) can be reliably adhered together with the adhesive (13). Such bearing will maintain long-term airtightness of the joint between the sleeve (2) and the case (7) and prevent leakage of lubricant fluid during manufacture. The bearing can be used for a spindle and other compact motors for driving memory devices for magnetic discs and optical discs (such as a CD or a DVD), motors for polygon mirrors used for scanning processes of laser beam printers, and for small motors for use such as in axial flow fans.

Owner:MINEBEA CO LTD

Hydrodynamic bearing unit

InactiveUS6843602B2Prevent leakagePrevent oil leakageShaftsRecord information storageOil pressureEngineering

A hydrodynamic bearing unit is provided, by which the touch between oil and a sealing member in a housing is prevented to prevent oil leakage. A bearing member made of a sintered lubricant-containing metal is disposed along the inner periphery of the housing and a spindle is supported in a non-contact manner by the hydrodynamic oil pressure that is generated in a bearing gap by the rotation of the spindle. The opening of the housing is sealed by the sealing member. A ventilation path is formed so as to communicate a sealed space enclosed by the distal end of the spindle at the bottom of the housing, the bearing member and the housing with open air. An oil reservoir is formed between the inner periphery of the housing and the outer periphery of the bearing member at the end portion of the opening side of the housing. The oil reservoir is made so as to communicate with the ventilation path.

Owner:NTN CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com