Patents

Literature

52results about How to "Maintain dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

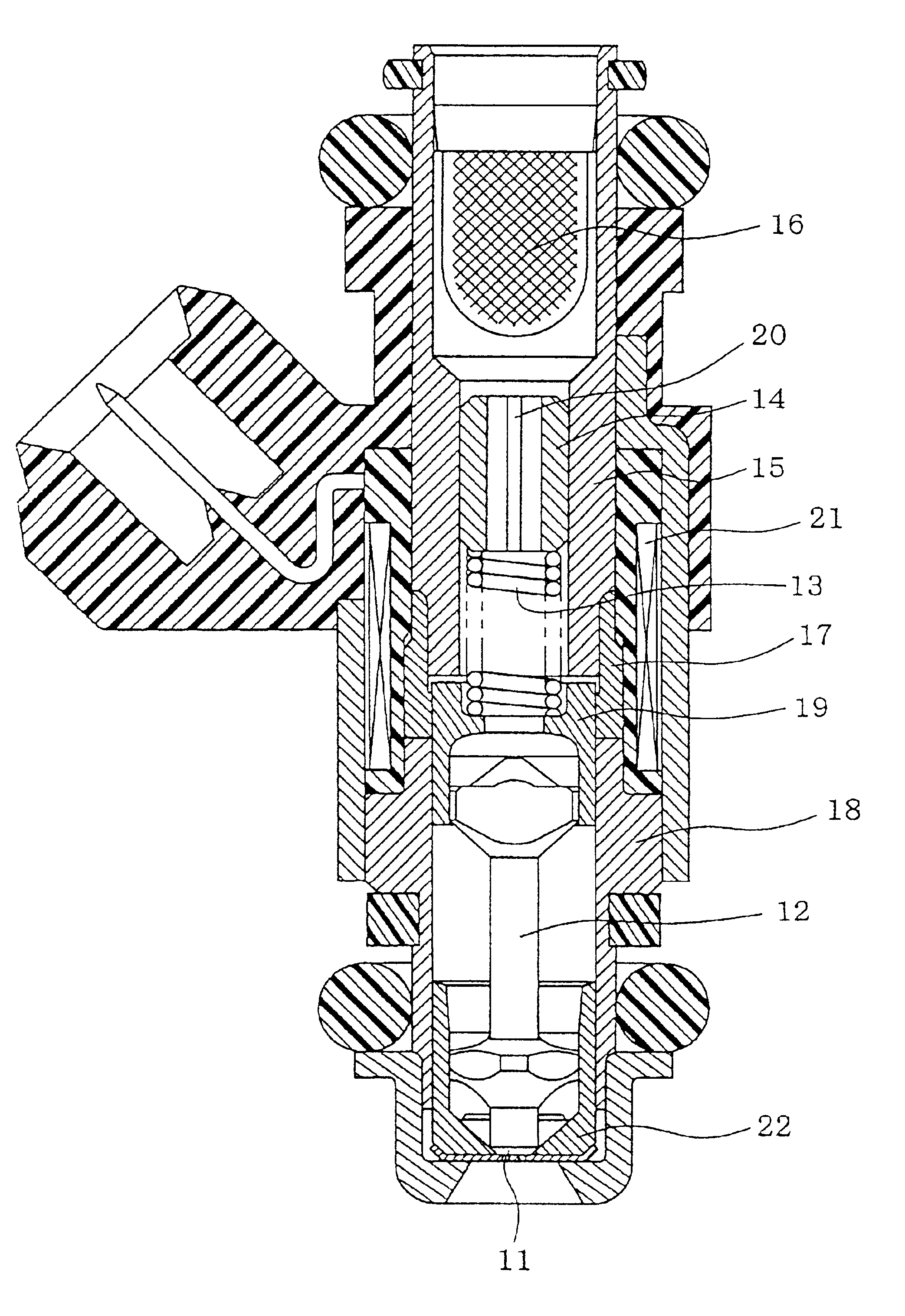

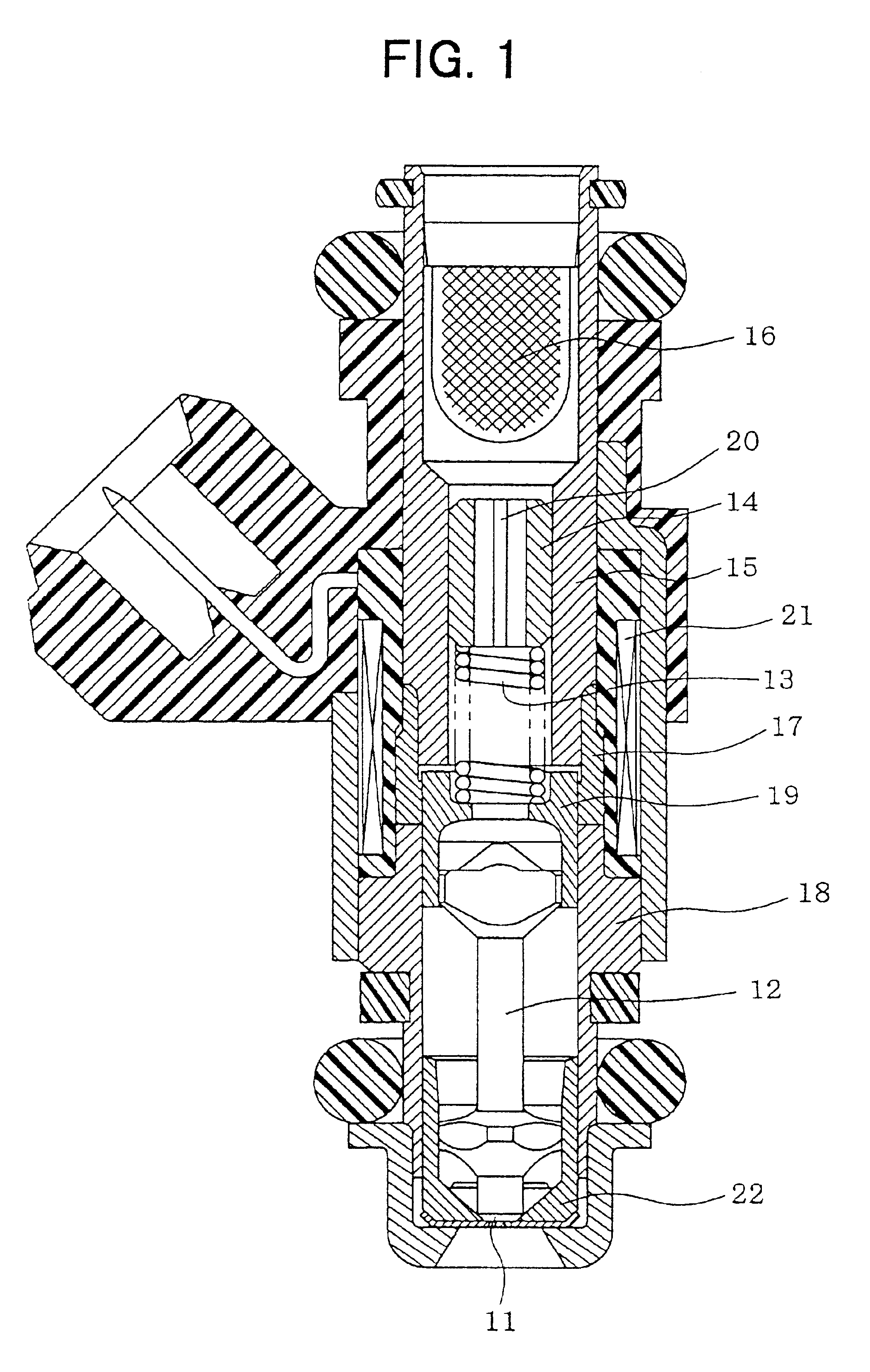

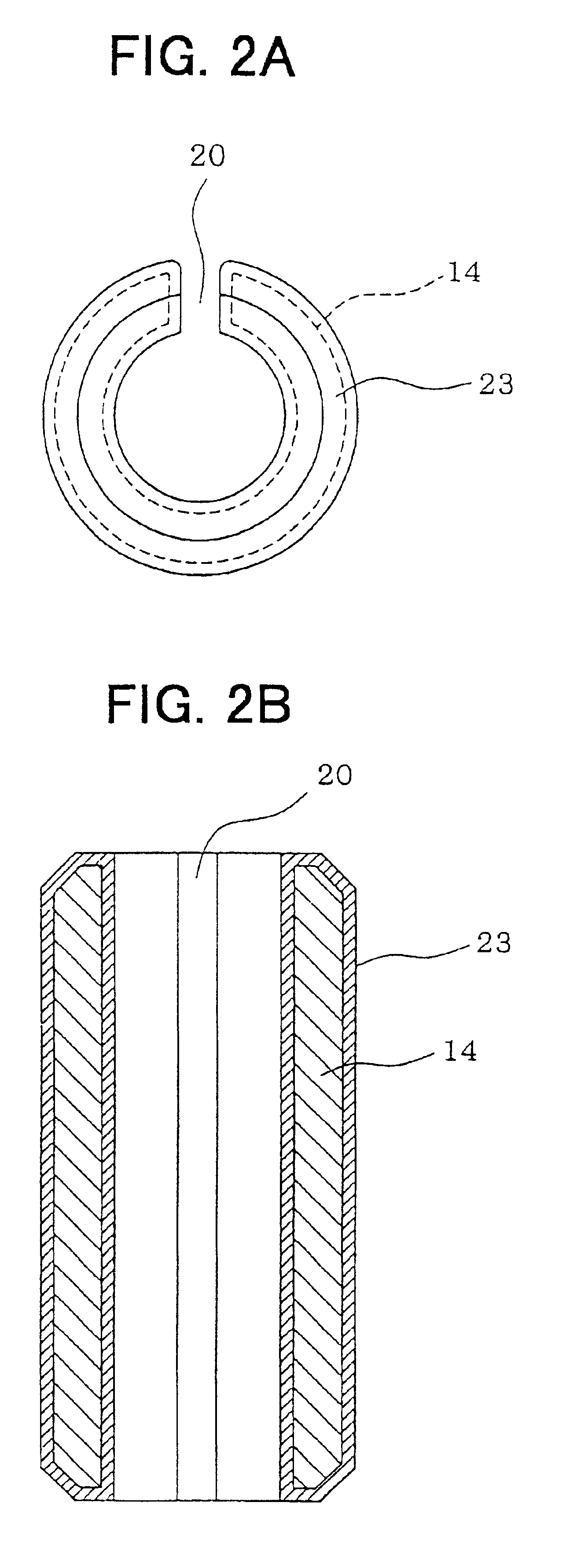

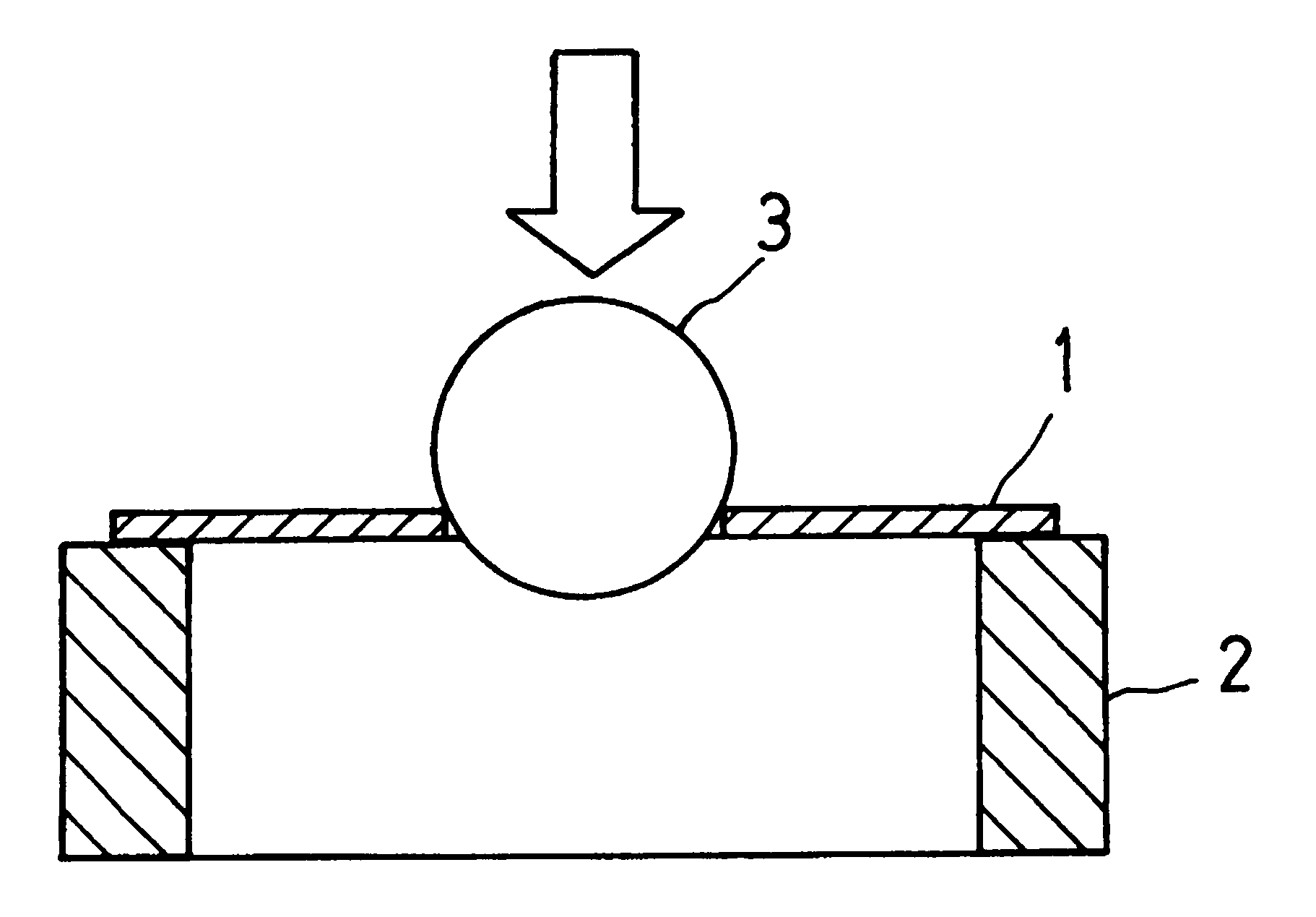

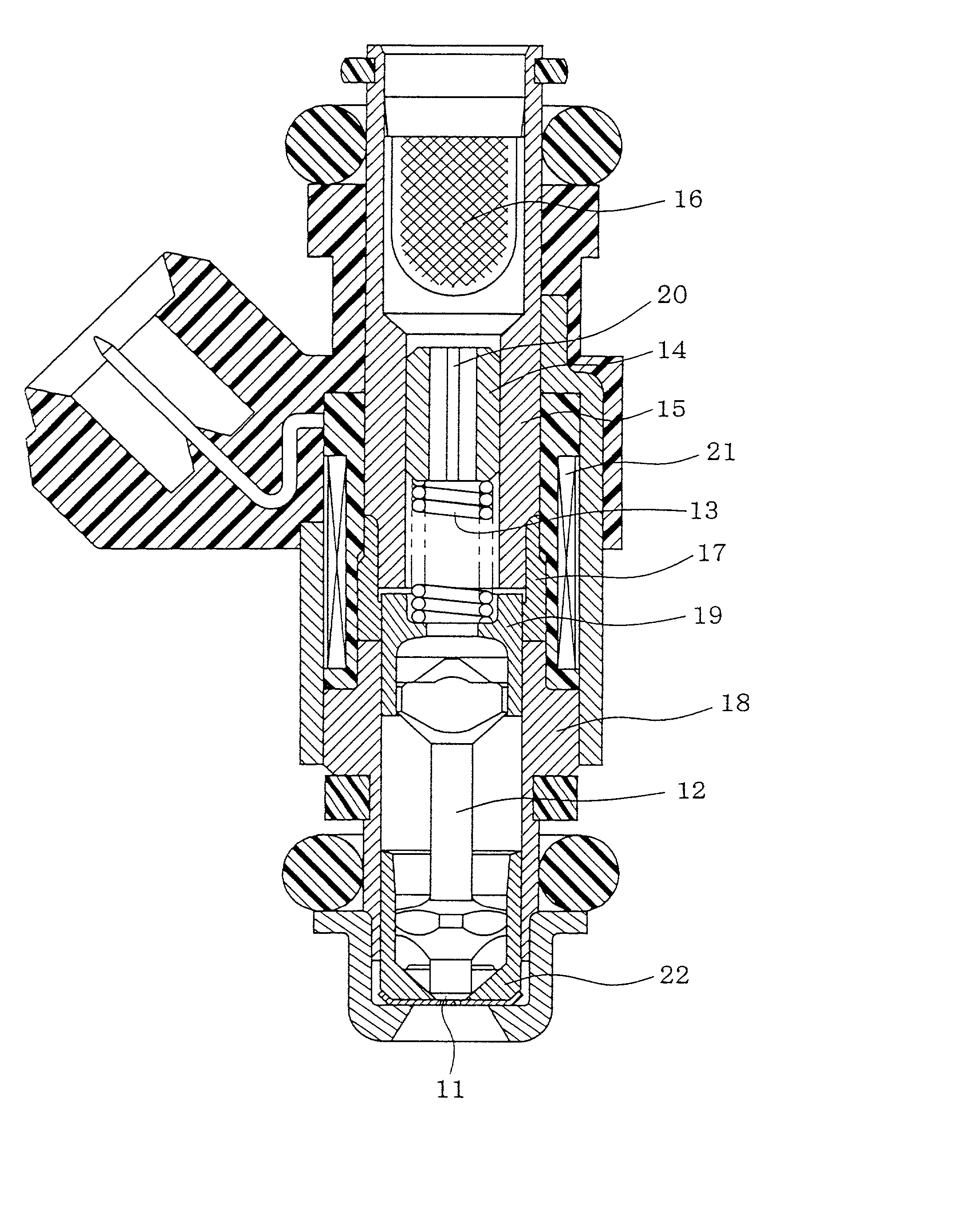

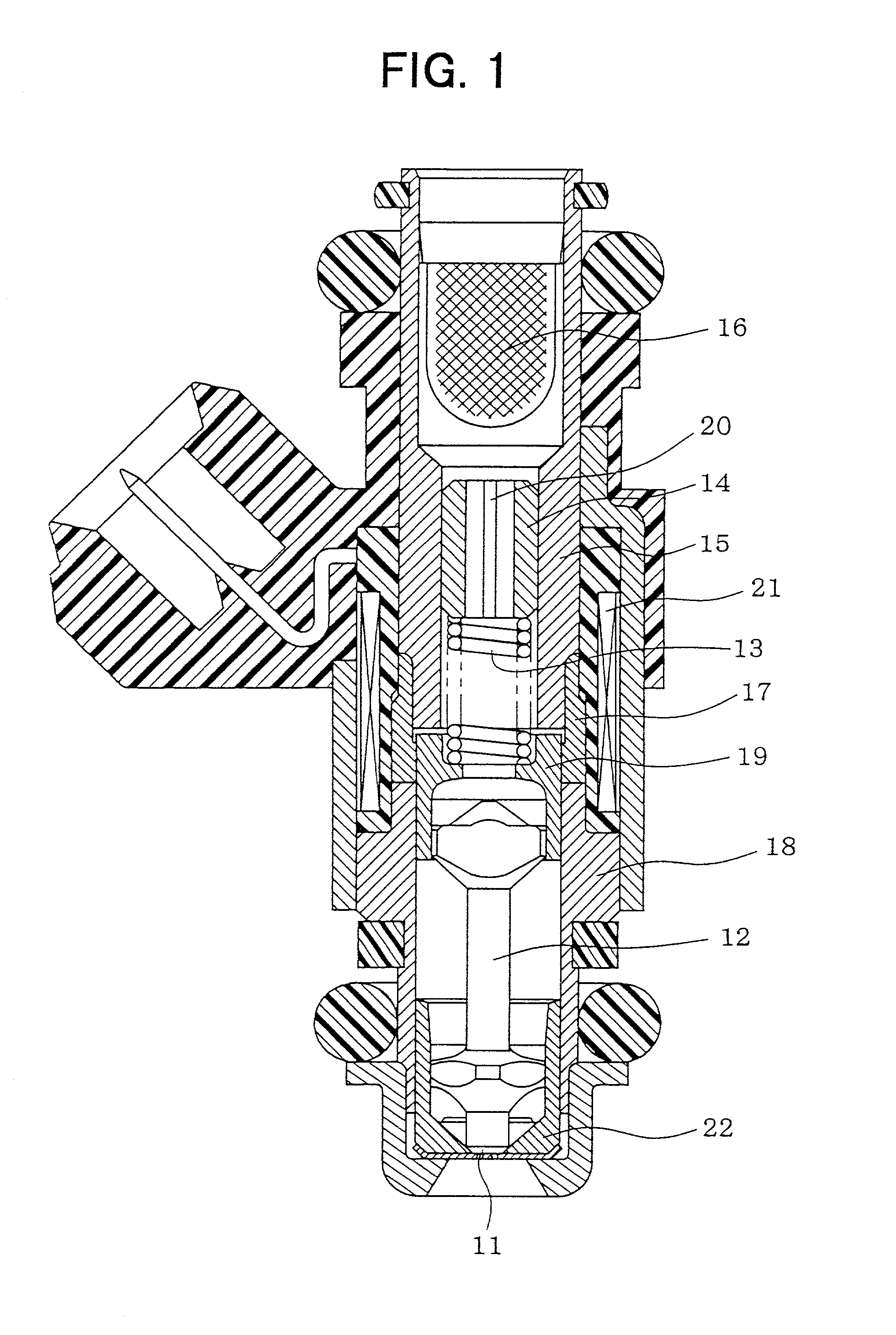

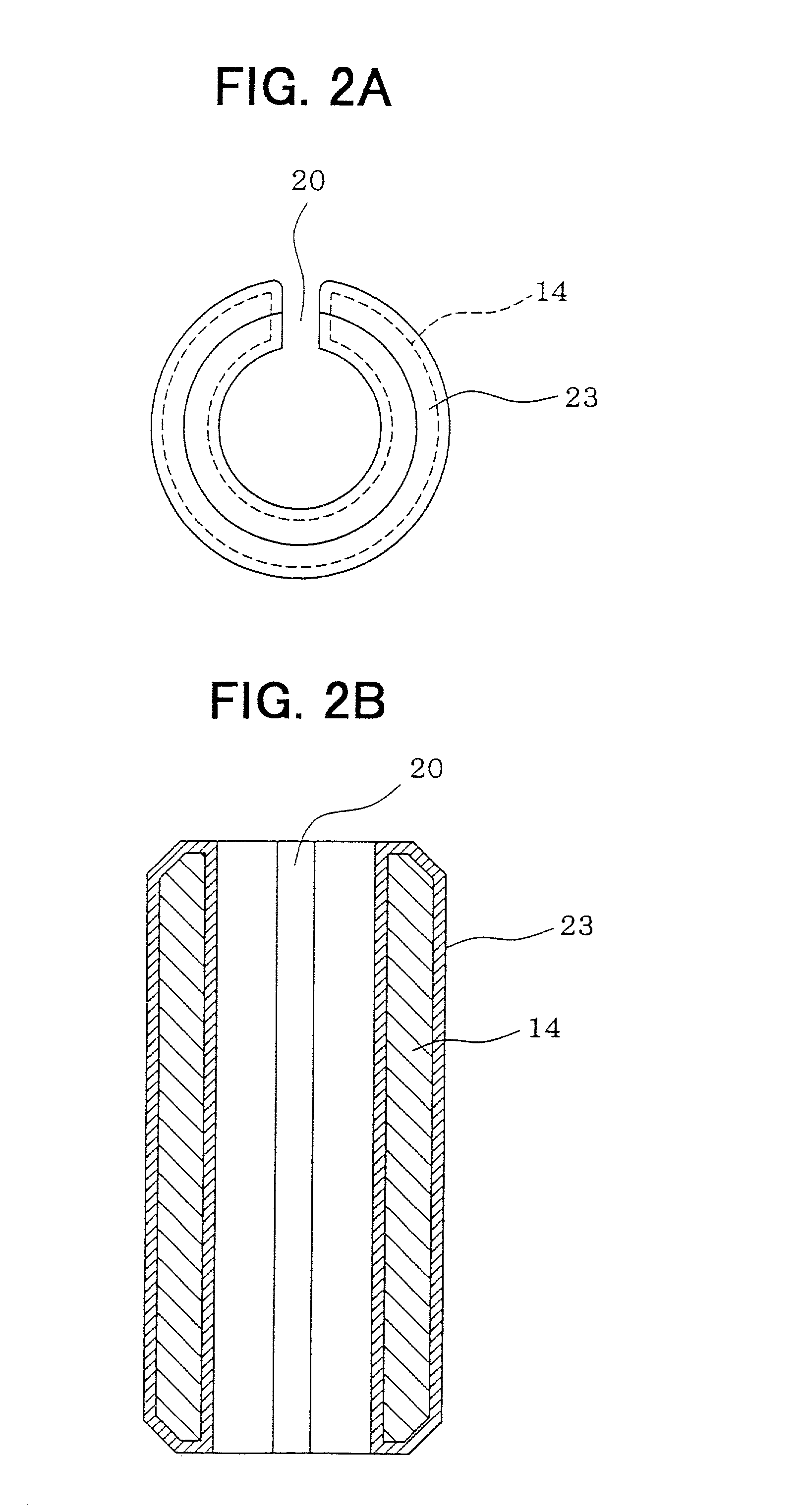

Adjustment pipe for fuel injection valve, and press-fitting structure and press-fitting method for the same

InactiveUS6834667B2Control deformationEasy to adjustVolume/mass flow measurementPipe elementsSpring forceEngineering

In a fuel injection valve, an adjustment pipe made of stainless steel and for adjusting a compression amount of a spring biasing a valve member is press-fitted into a cylindrical housing made of stainless steel, and a fuel injection amount is adjusted by adjusting a spring force of the spring in accordance with a press-fitted amount of the adjustment pipe. The adjustment pipe is immersed in an oxalic acid solution so that an oxalate film is formed thereon before being press-fitted into the cylindrical housing. Therefore, the oxalate film prevents a direct press-contact between an outer peripheral surface of the adjustment pipe and an inner peripheral surface of the cylindrical housing.

Owner:DENSO CORP

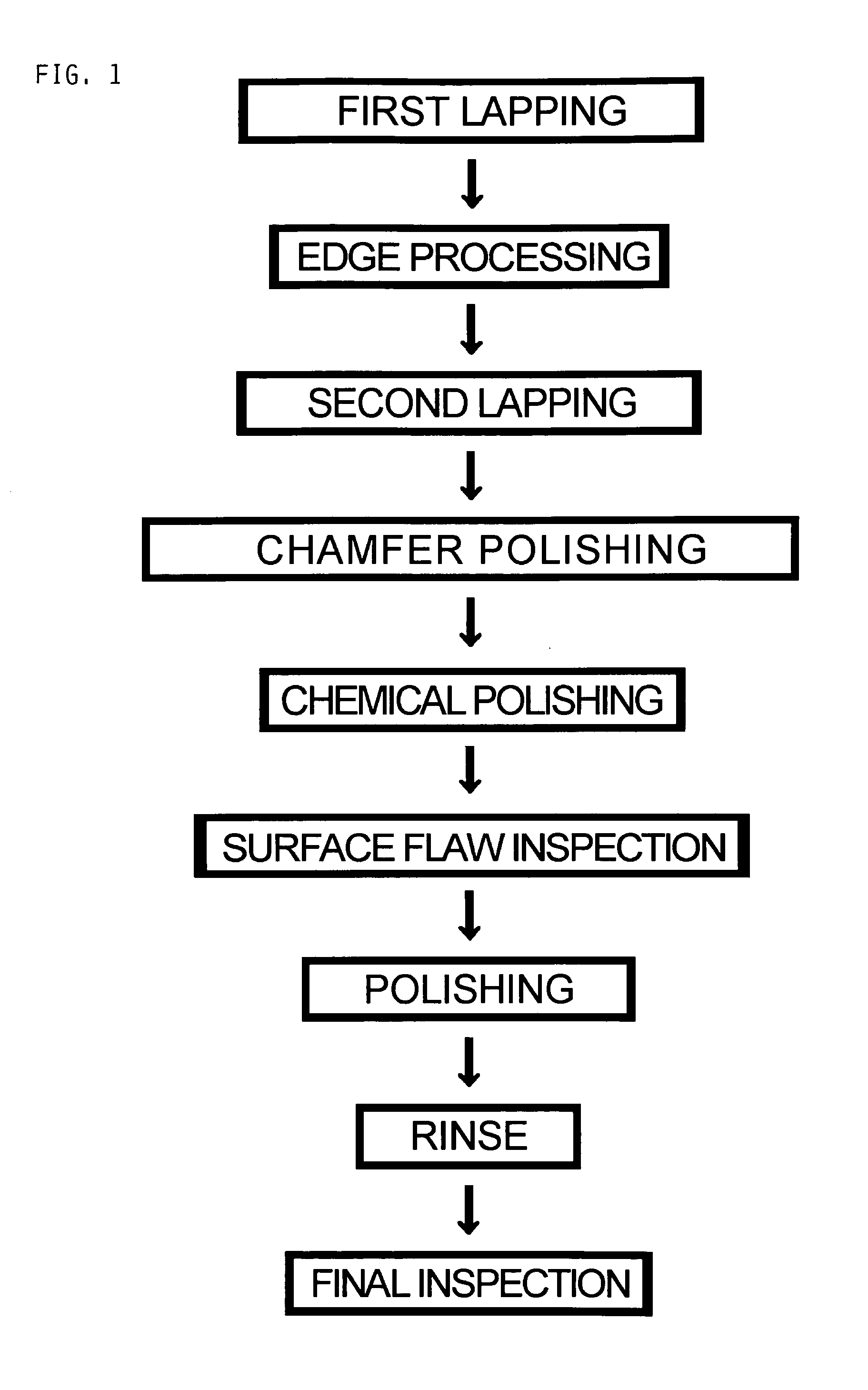

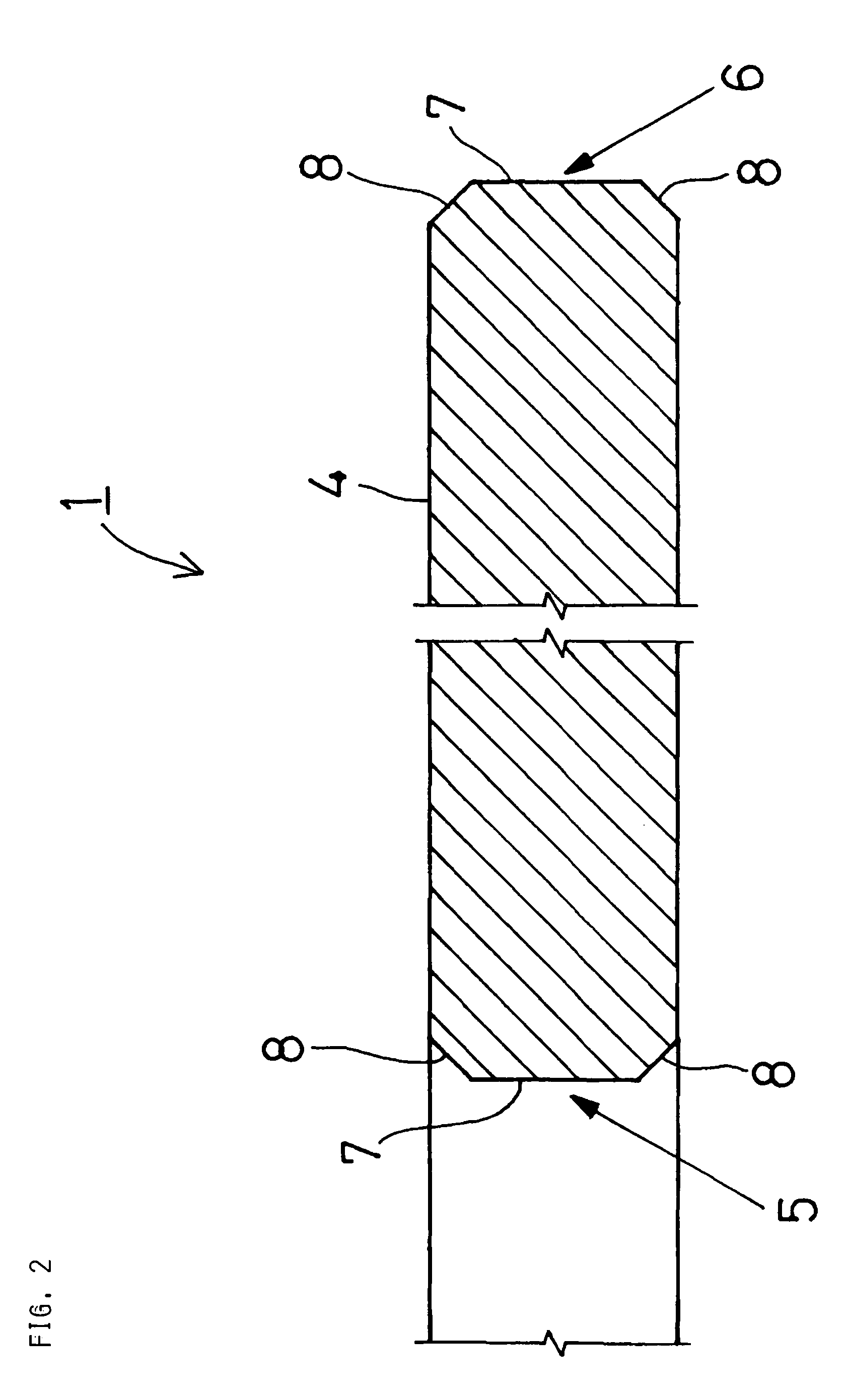

Method of surface-finishing glass substrate for magnetic disks and glass substrate for magnetic disks

InactiveUS20100266874A1Maintain dimensional accuracyMaintain roundnessEdge grinding machinesMagnetic materials for record carriersSurface finishSurface layer

An inner peripheral edge of a toroidal glass substrate for a magnetic disk is subjected to mechanical polishing in such a manner that the surface roughness is no greater than 9 nm in terms of Rmax. Then, the inner peripheral edge is subjected to chemical polishing to remove at least 2 μm of a surface layer. The inner peripheral edge has a non-conventional mirror-finished surface obtained by mechanical polishing. Thus, sufficient ring strength is obtained even when the chemical polishing depth is smaller than in the past. A polishing depth of less than 5 μm is sufficient.

Owner:TOYO KOHAN CO LTD

Nanopore array film on stainless steel surface and preparation method thereof

InactiveCN102268713ALess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

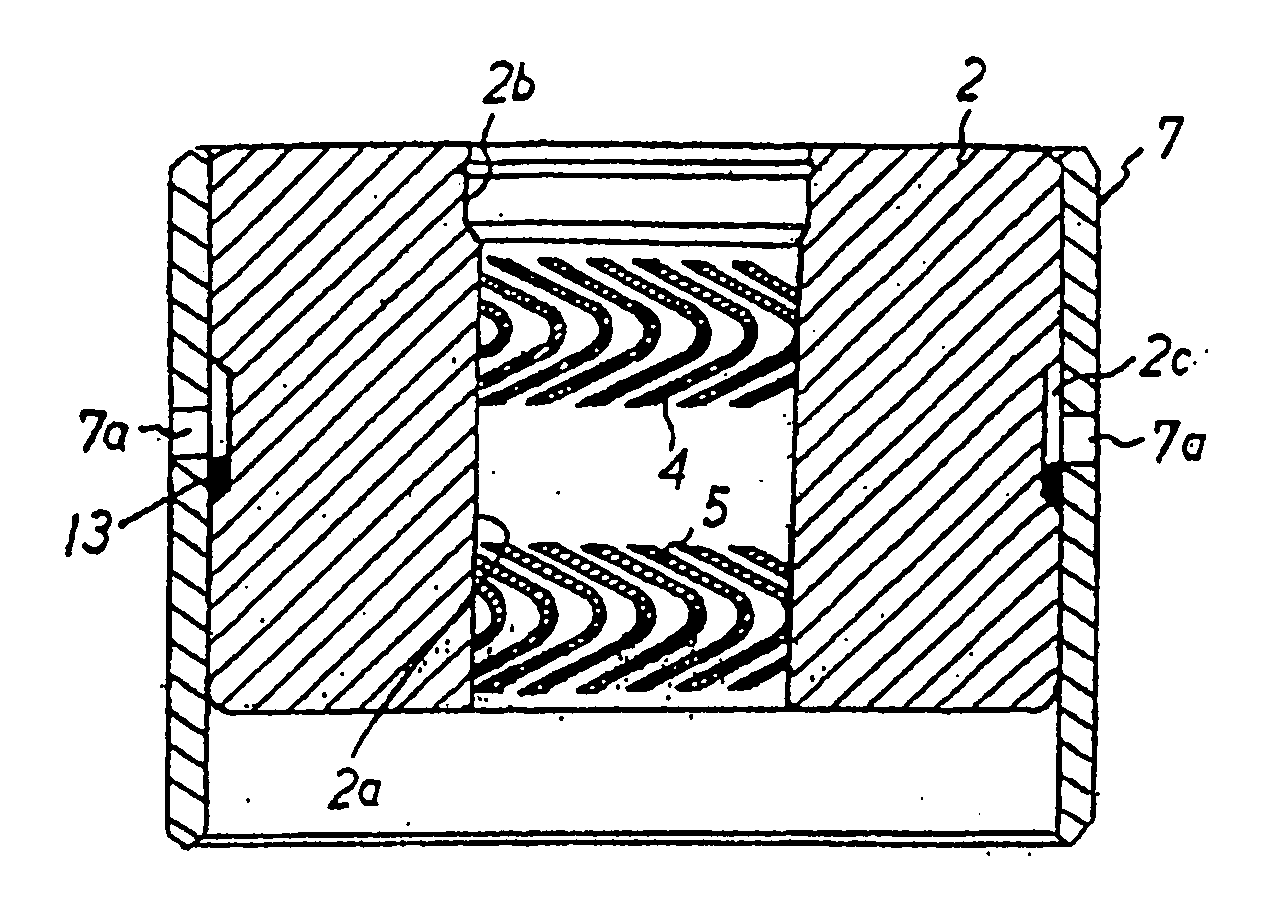

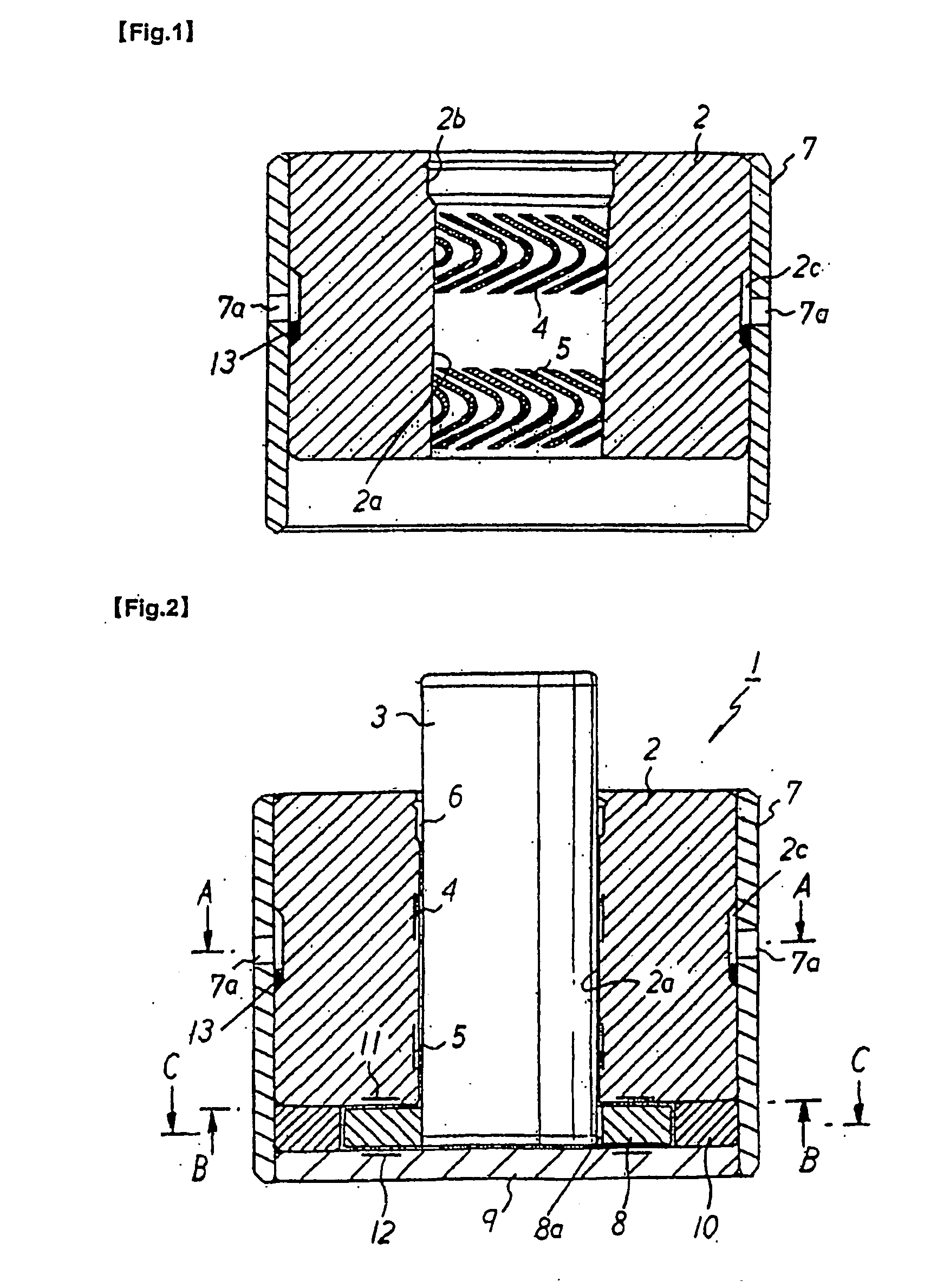

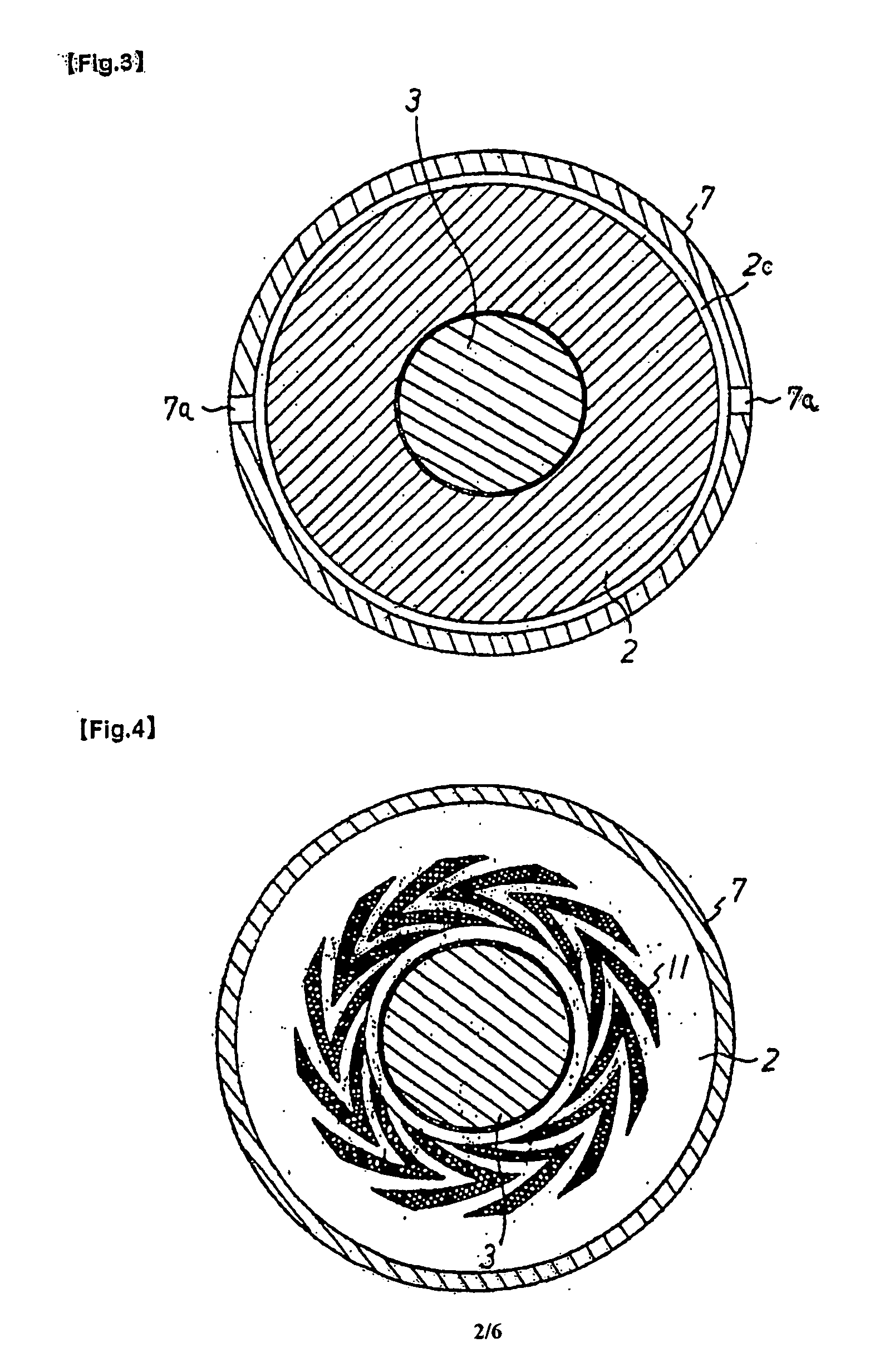

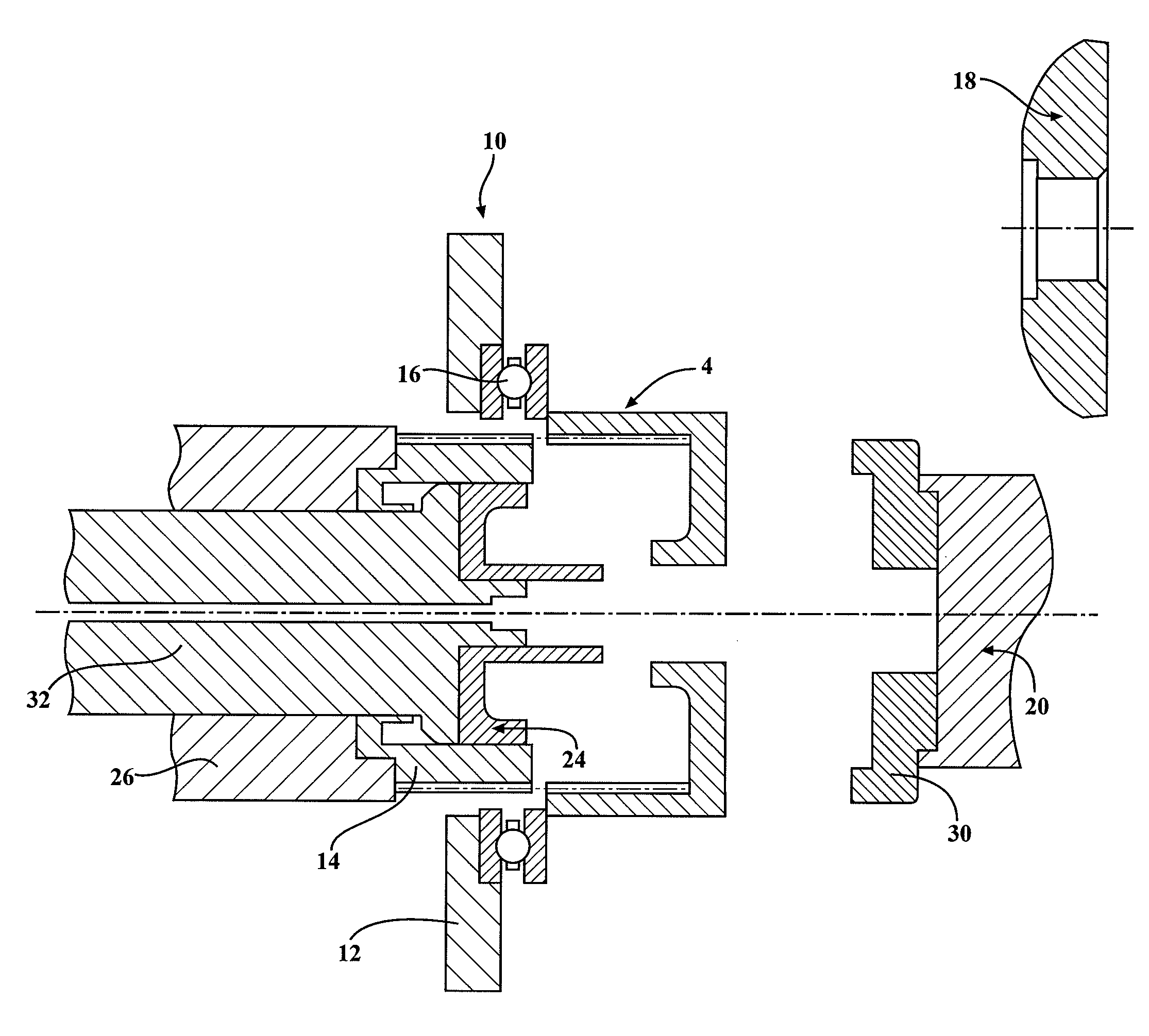

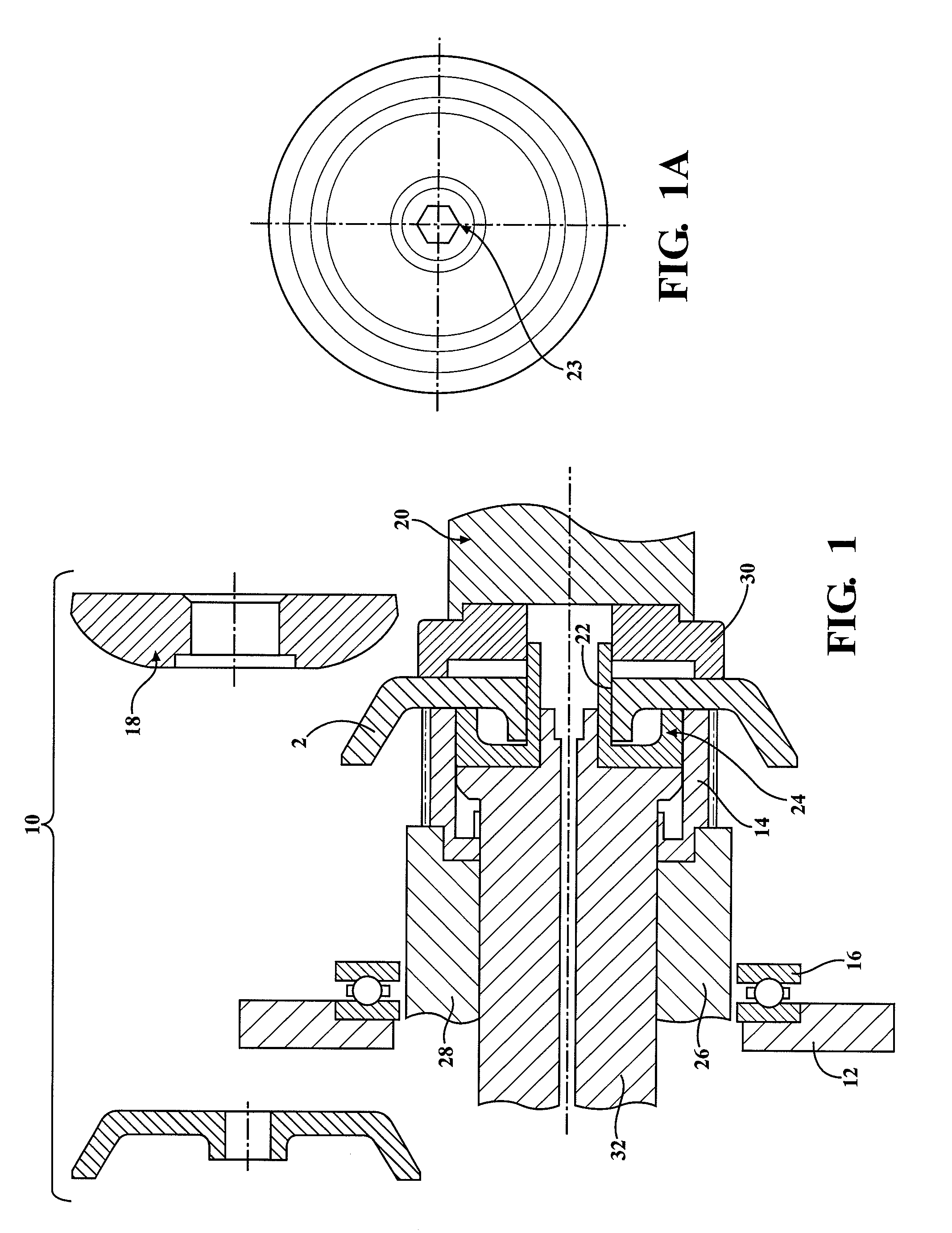

Fluid Dynamic Pressure Bearing

InactiveUS20090160277A1Maintain dimensional accuracyMaintain geometric accuracyShaftsBearing componentsAdhesiveEngineering

A fluid dynamic bearing (1) with a rotating shaft (3) inserted into a sleeve (2) fitted into a case (7) is disclosed. Tree rotating shaft (3) rotates freely without contact with the sleeve (2) by means of dynamic pressure force generated by the lubricant fluid that fills the gap formed around the rotating shaft (3). An adhesive groove (2c) is formed around the entire outer circumferential surface of the sleeve (2). At least one hole (7a) facing the adhesive groove (2c) is formed in case (7), and case (7) and sleeve (2) are; adhered by the injection of an adhesive (13) into adhesive groove (2c) from the hole (7a). The fluid dynamic pressure bearing, manufactured in this manner provides a high-quality bearing that is easy to construct, that can be adapted to low-cost manufacturing, and that can maintain dimensional and structural accuracy and in which the case (7) and sleeve (2) can be reliably adhered together with the adhesive (13). Such bearing will maintain long-term airtightness of the joint between the sleeve (2) and the case (7) and prevent leakage of lubricant fluid during manufacture. The bearing can be used for a spindle and other compact motors for driving memory devices for magnetic discs and optical discs (such as a CD or a DVD), motors for polygon mirrors used for scanning processes of laser beam printers, and for small motors for use such as in axial flow fans.

Owner:MINEBEA CO LTD

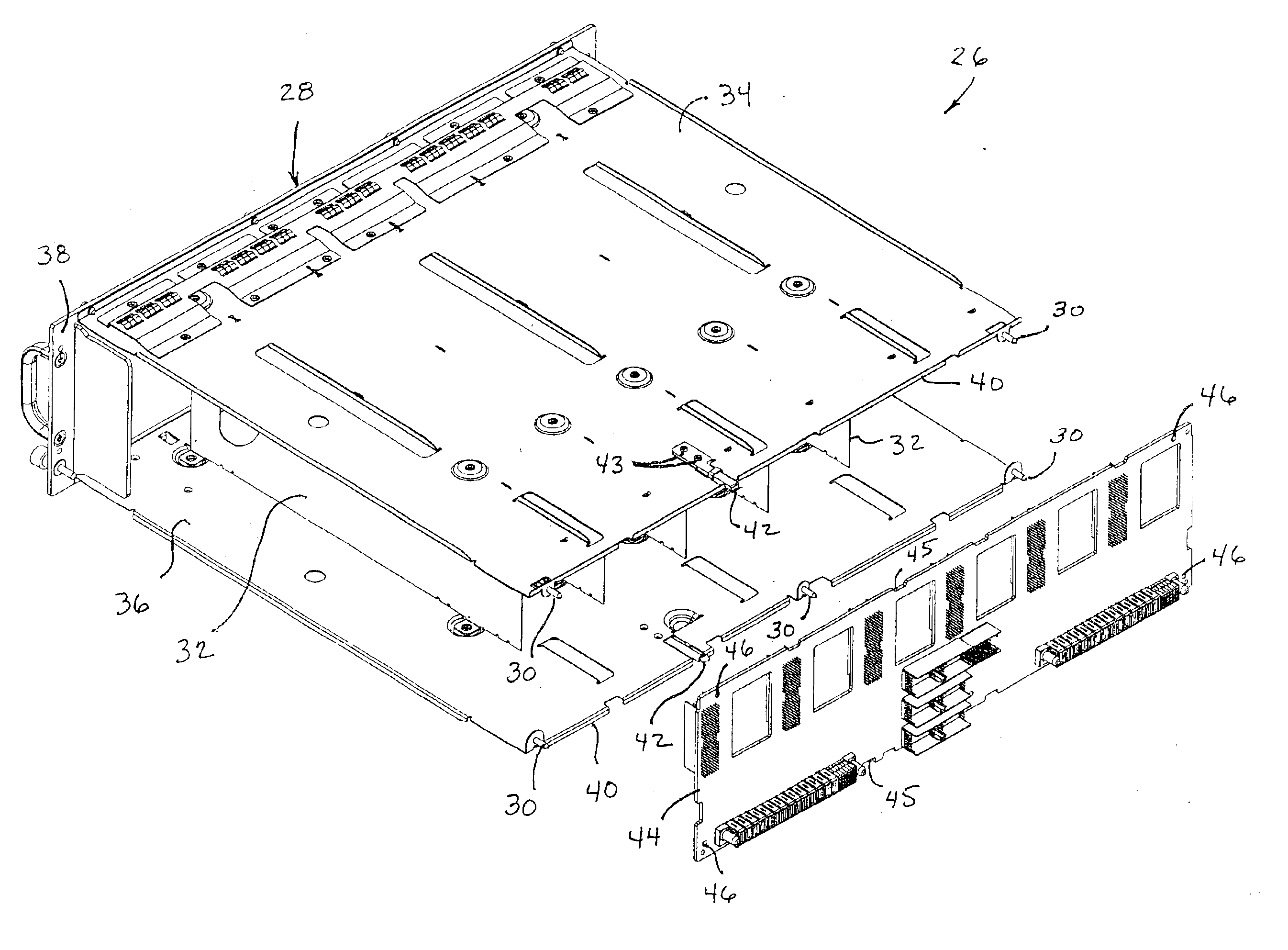

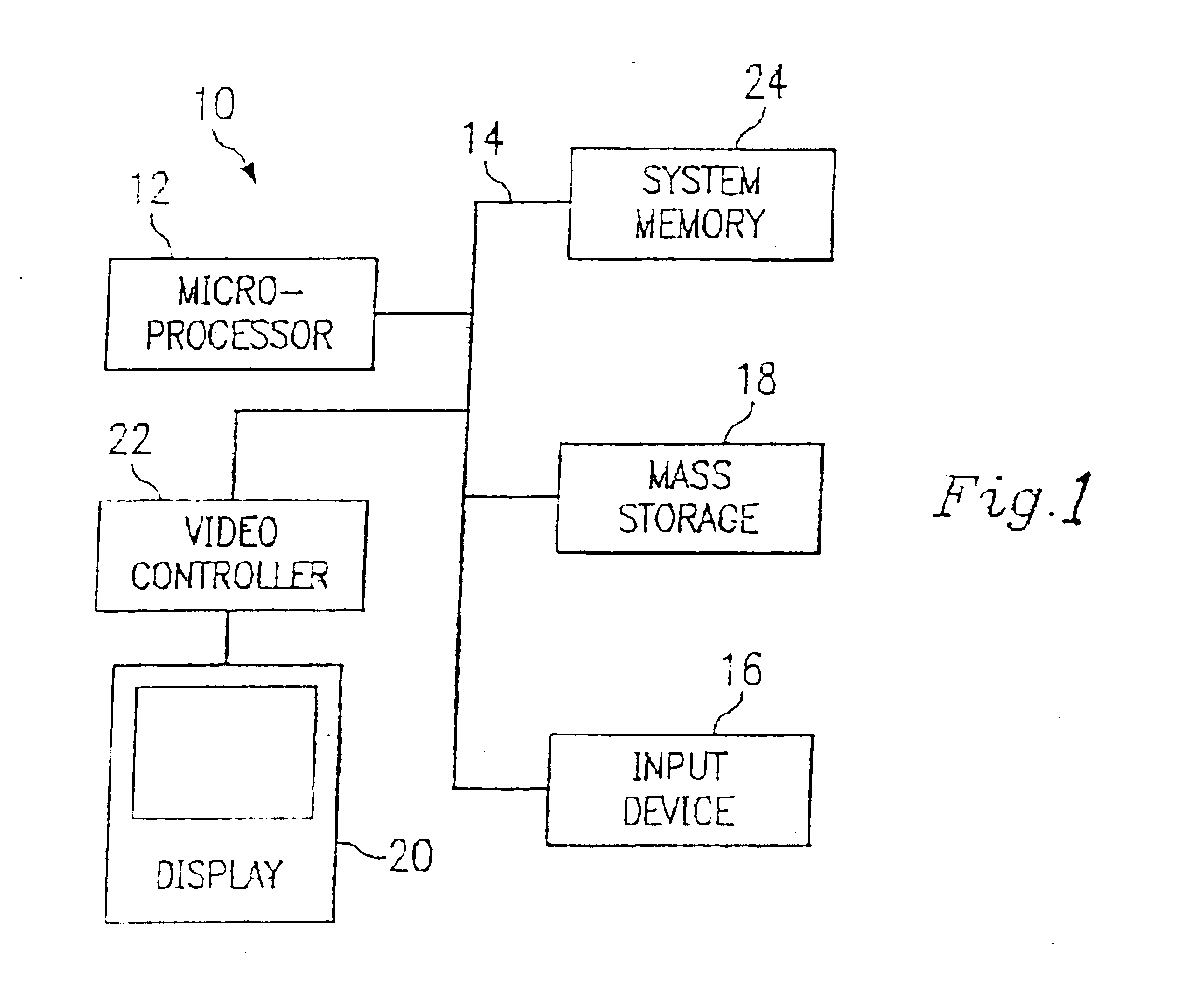

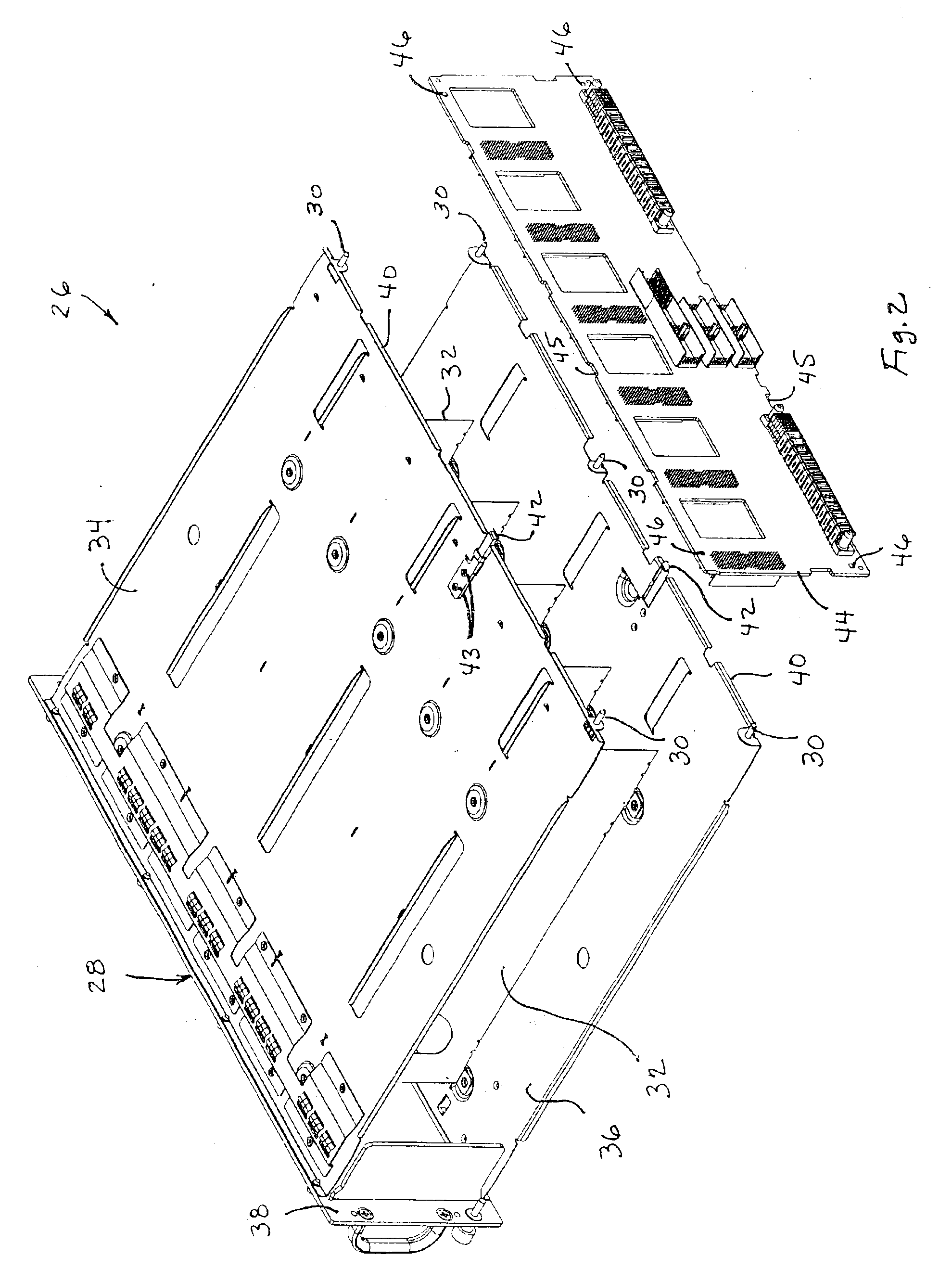

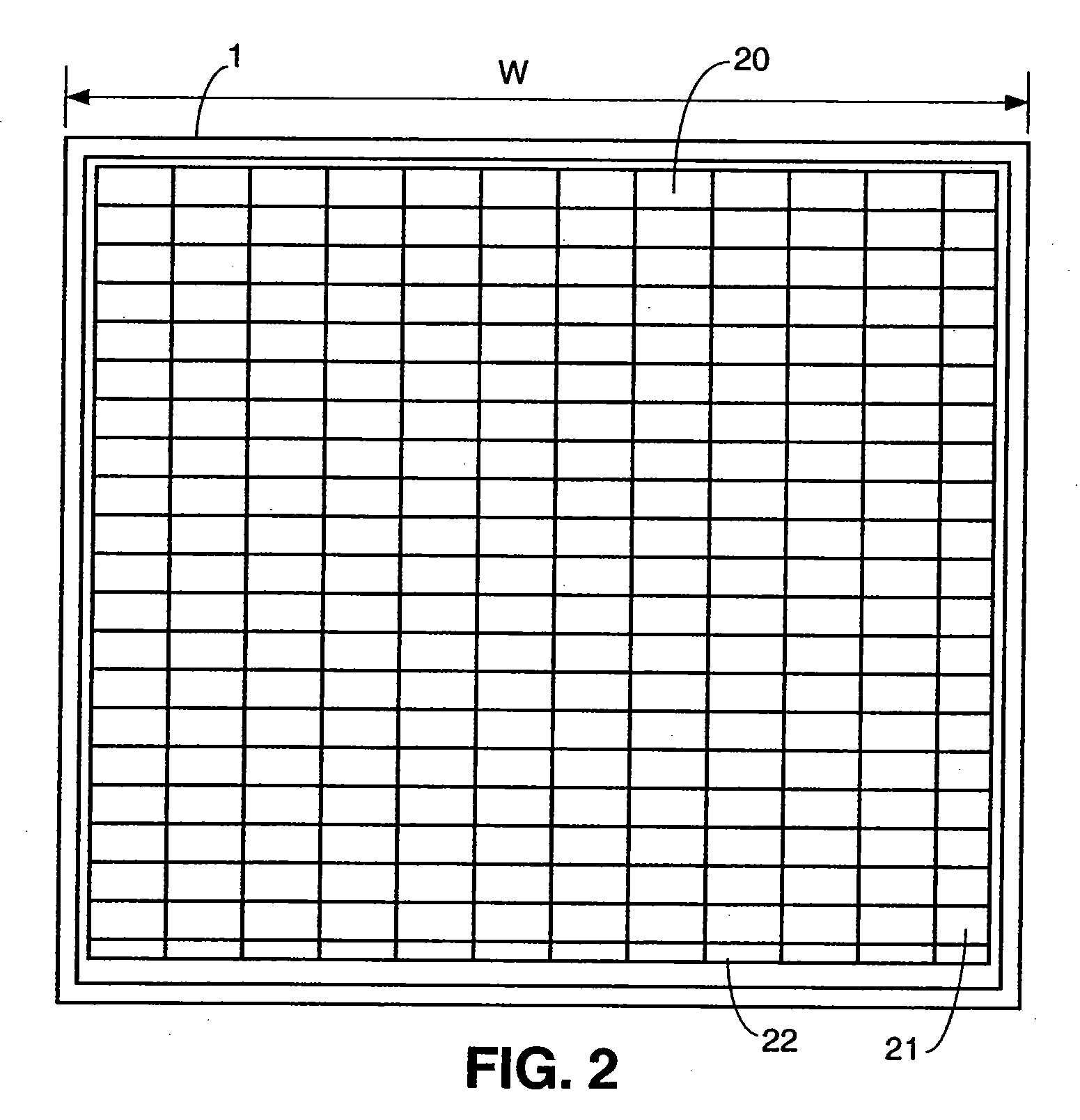

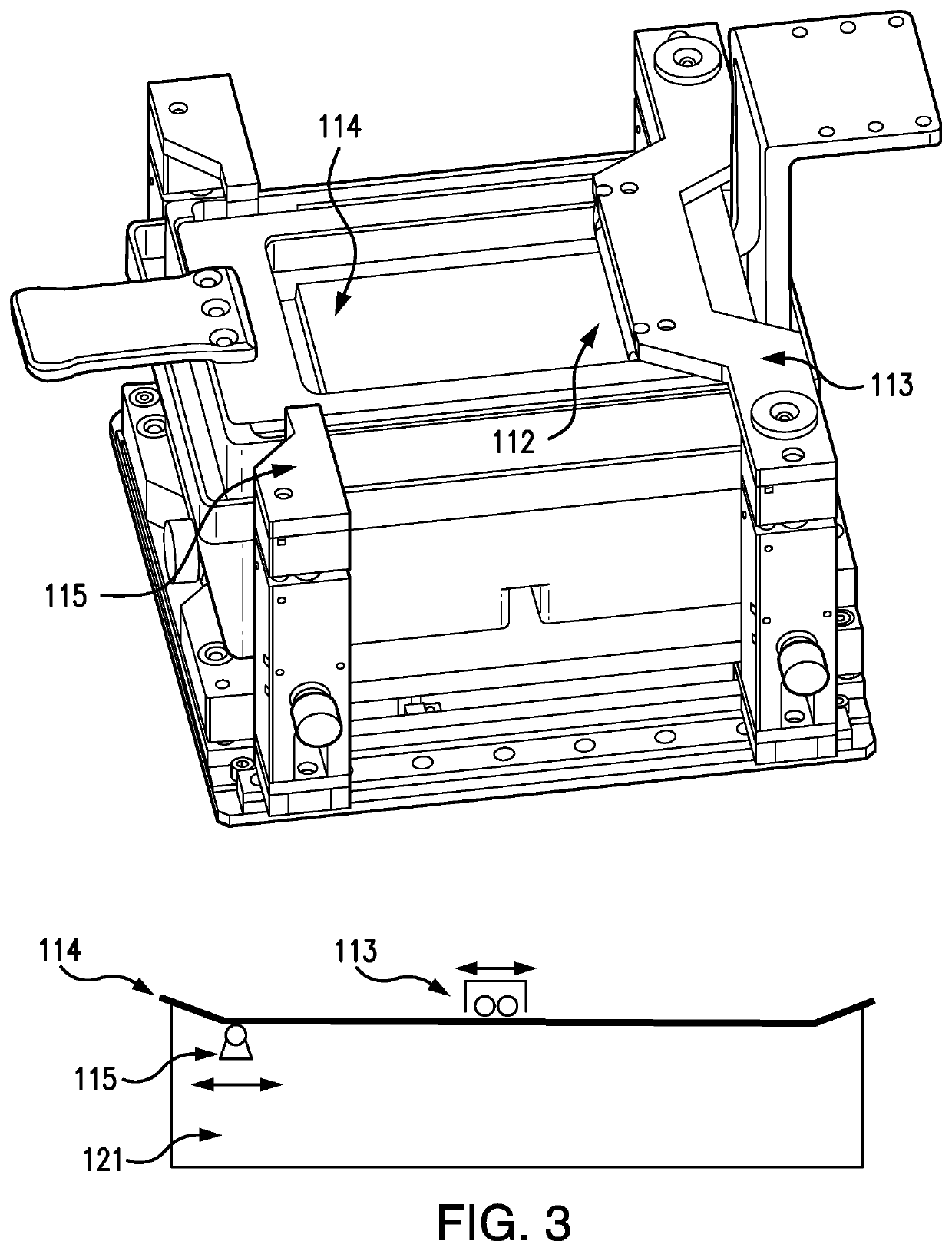

PCB as a structural component and internal chassis alignment

InactiveUS6847521B2Maintain dimensional accuracyPrecise positioningSubstation/switching arrangement detailsMagnetic/electric field screeningEngineeringHandling system

An information handling system includes a first module including first alignment members and a second module including second alignment members for engagement with the first alignment members. A PCB is retained on the first module to provide a structural member for the first module, to maintain dimensional accuracy of the first module, and to accurately position the first alignment members for alignment with the second alignment members.

Owner:DELL PROD LP

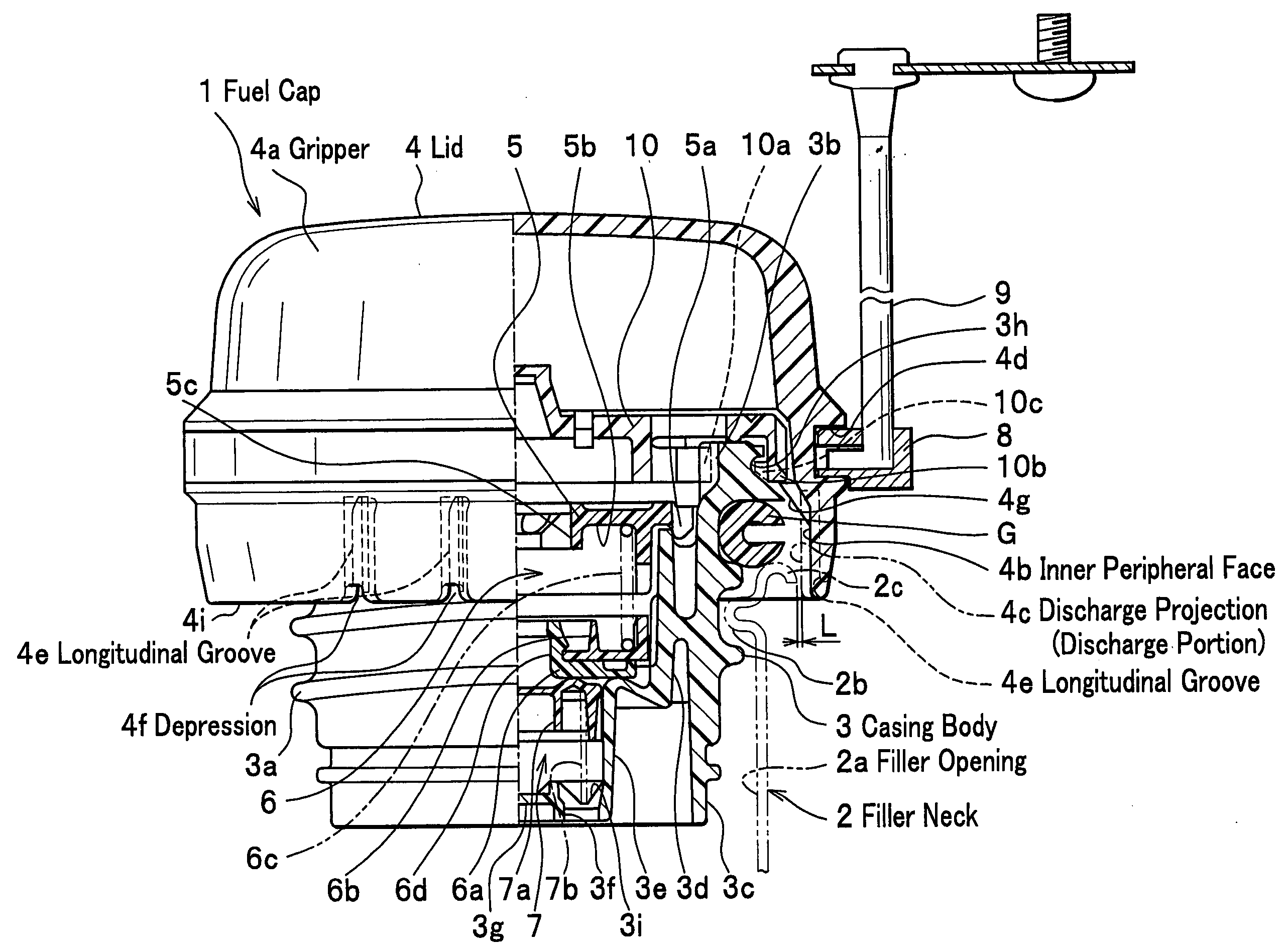

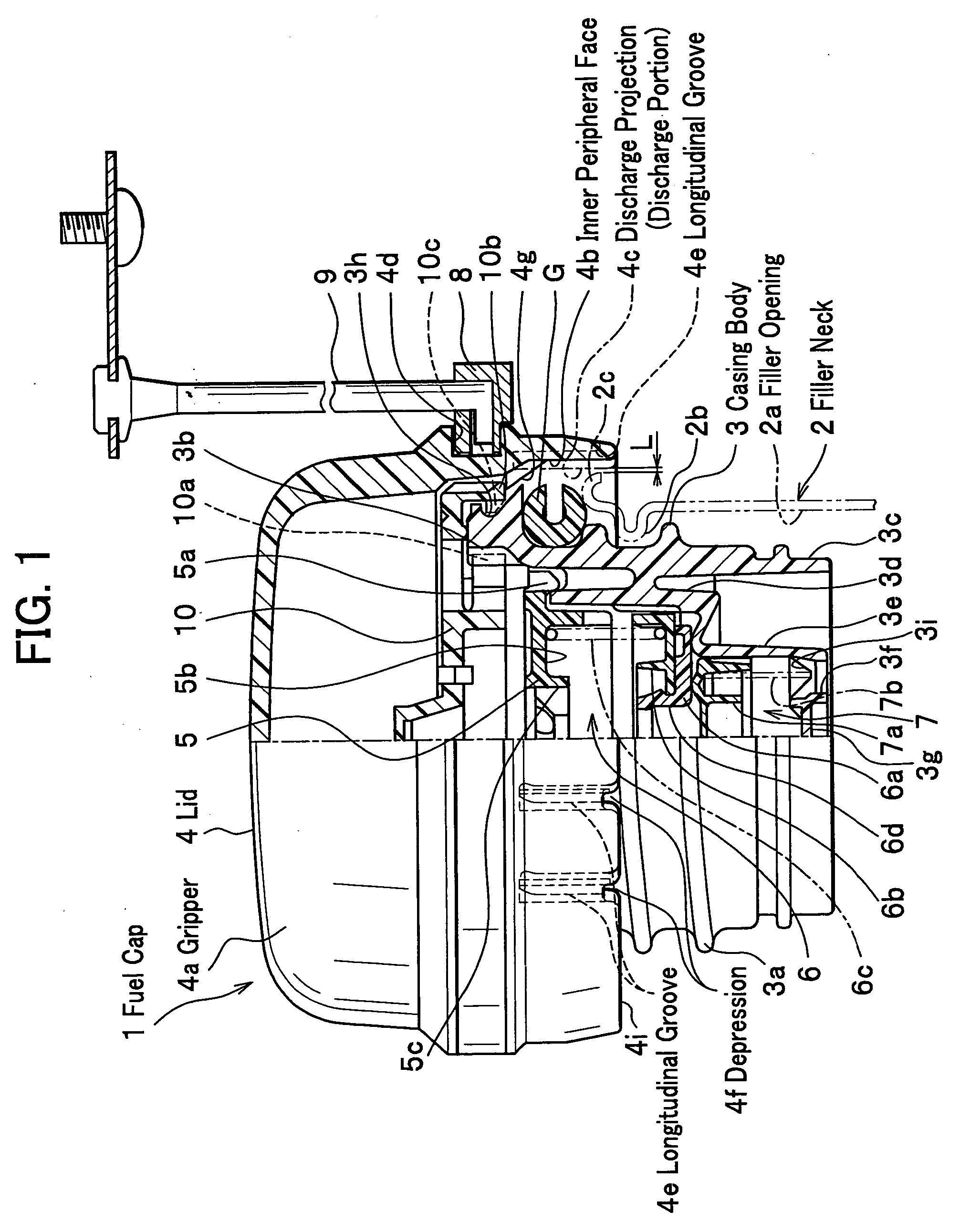

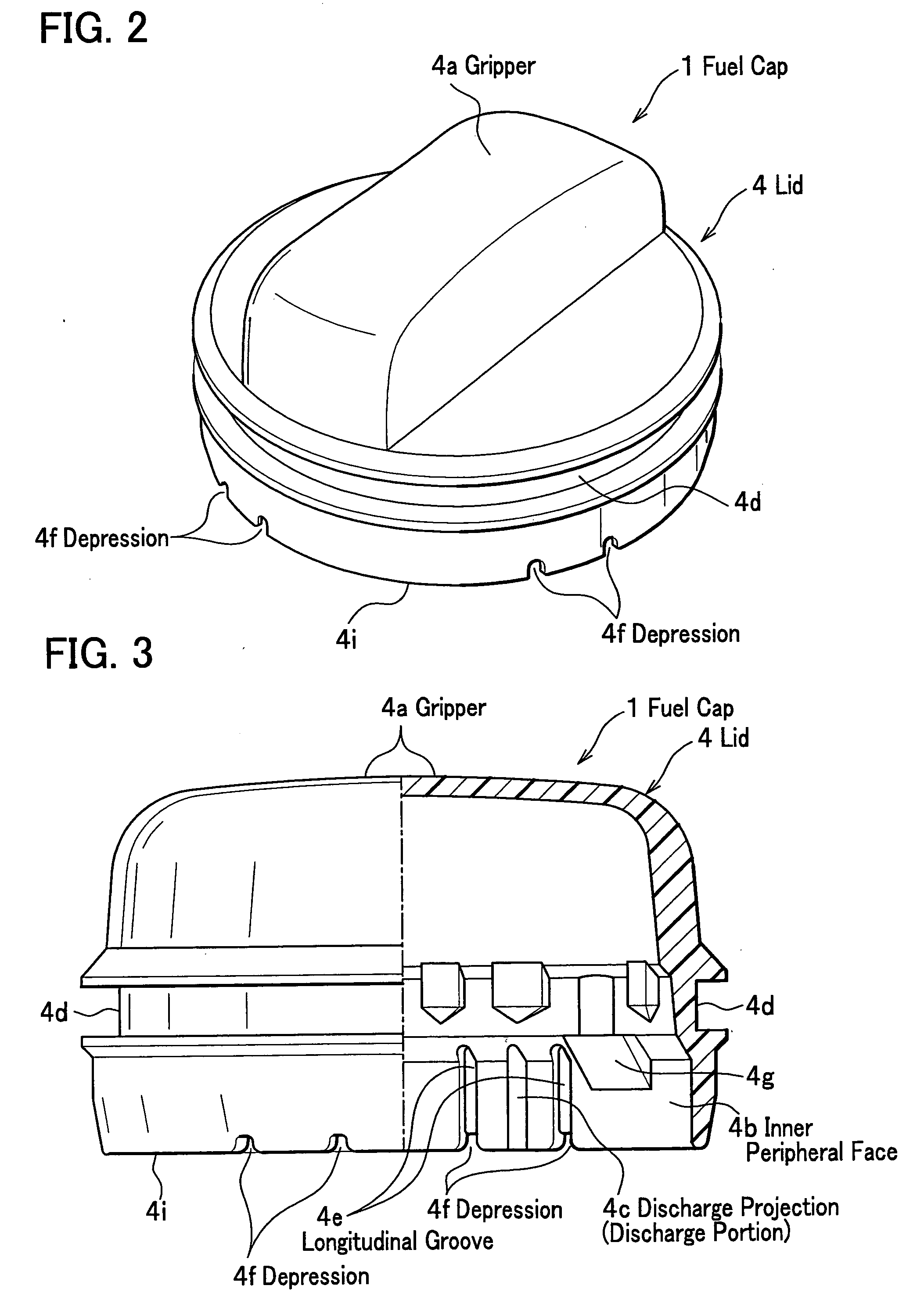

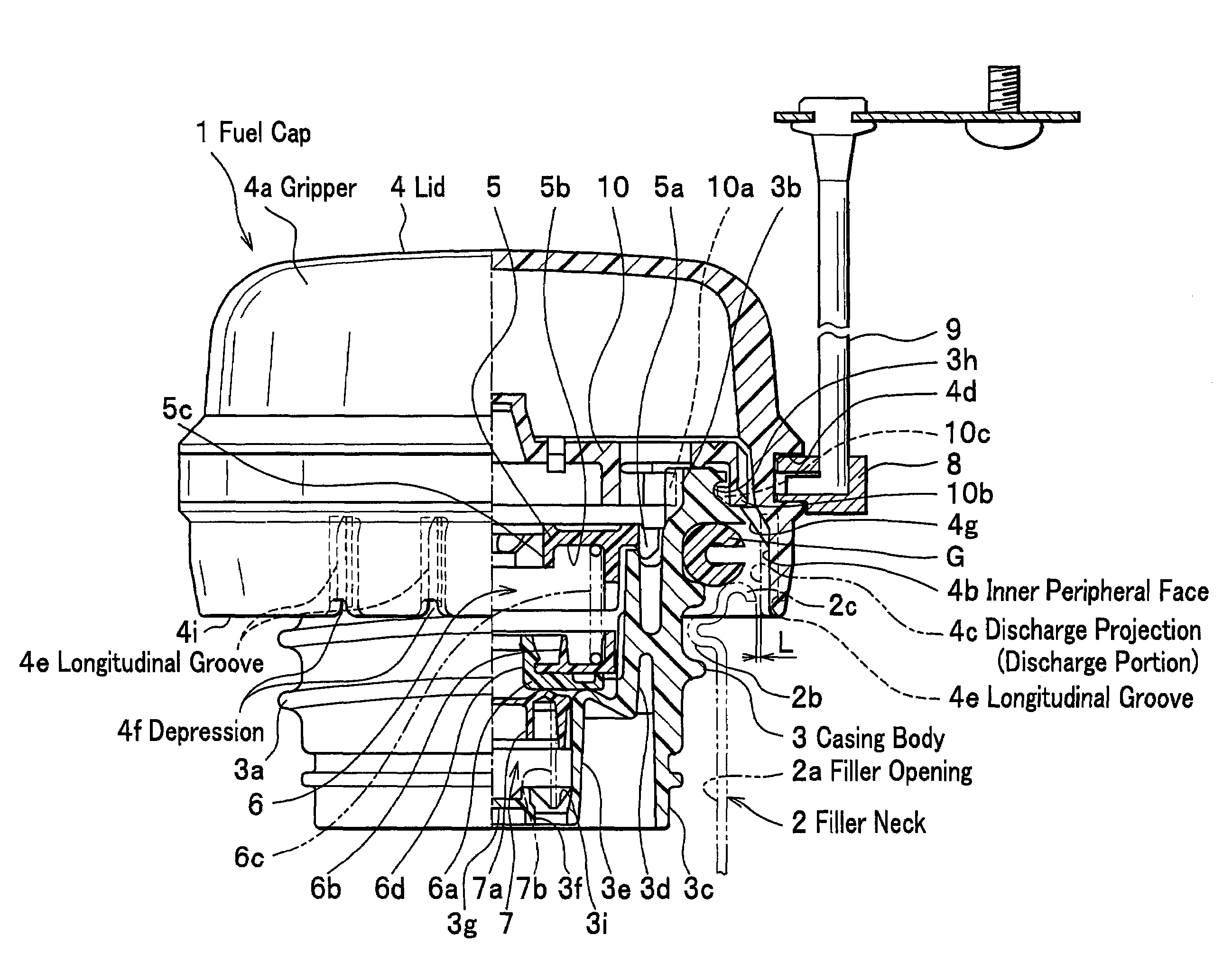

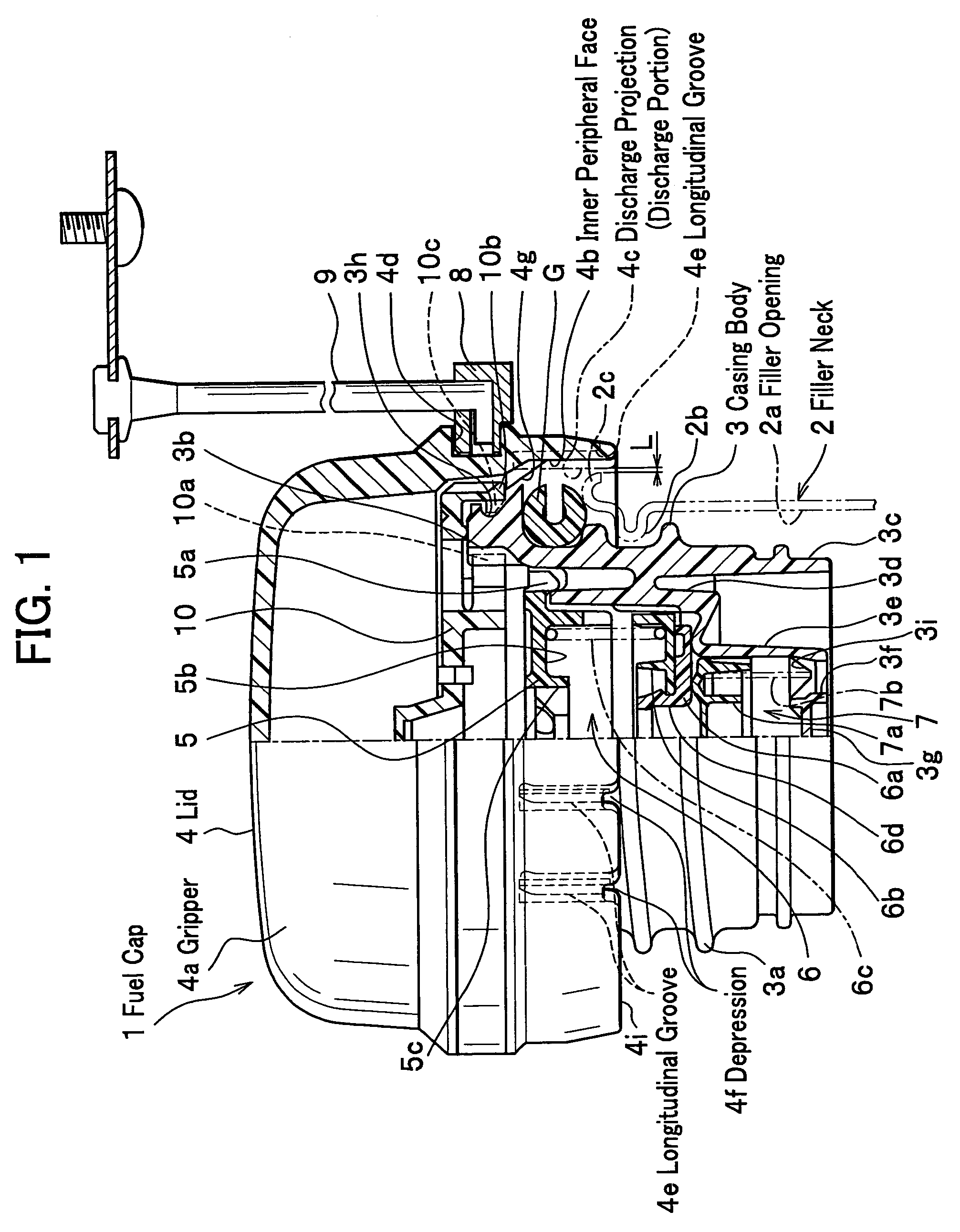

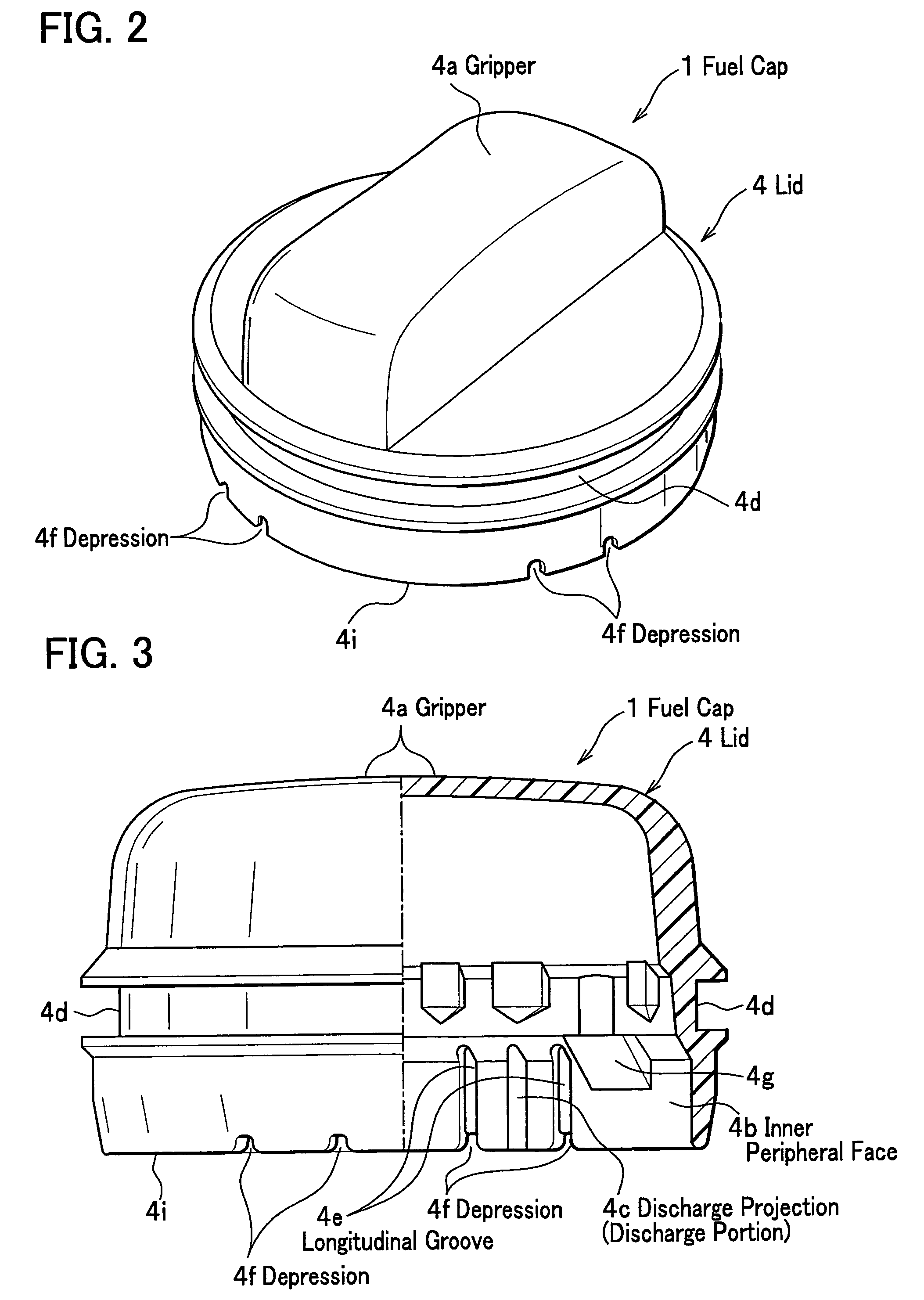

Vehicle fuel cap

ActiveUS20060037959A1Small outer diameterPrevent intrusionTyre partsRefuse receptaclesFuel tankConductive materials

A vehicle fuel cap of the present invention comprises a casing body for opening / closing a filler opening of a filler neck communicating with a fuel tank; and a lid that is equipped at an upper portion of the casing body and is formed of a conductive material, and the vehicle fuel cap forms a discharge portion in the lid for discharging static charged in the lid to the filler neck, wherein the discharge portion comprises a projection form provided on an inner peripheral face of the lid opposite to an outer peripheral edge of the filler opening, and on the inner peripheral face a longitudinal groove is formed at both sides of the discharge portion and along an axial direction of the casing body.

Owner:HONDA MOTOR CO LTD +1

Adjustment pipe for fuel injection valve, and press-fitting structure and press-fitting method for the same

InactiveUS20020062866A1Control deformationEasy to adjustVolume/mass flow measurementPipe elementsSpring forceEngineering

In a fuel injection valve, an adjustment pipe made of stainless steel and for adjusting a compression amount of a spring biasing a valve member is press-fitted into a cylindrical housing made of stainless steel, and a fuel injection amount is adjusted by adjusting a spring force of the spring in accordance with a press-fitted amount of the adjustment pipe. The adjustment pipe is immersed in an oxalic acid solution so that an oxalate film is formed thereon before being press-fitted into the cylindrical housing. Therefore, the oxalate film prevents a direct press-contact between an outer peripheral surface of the adjustment pipe and an inner peripheral surface of the cylindrical housing.

Owner:DENSO CORP

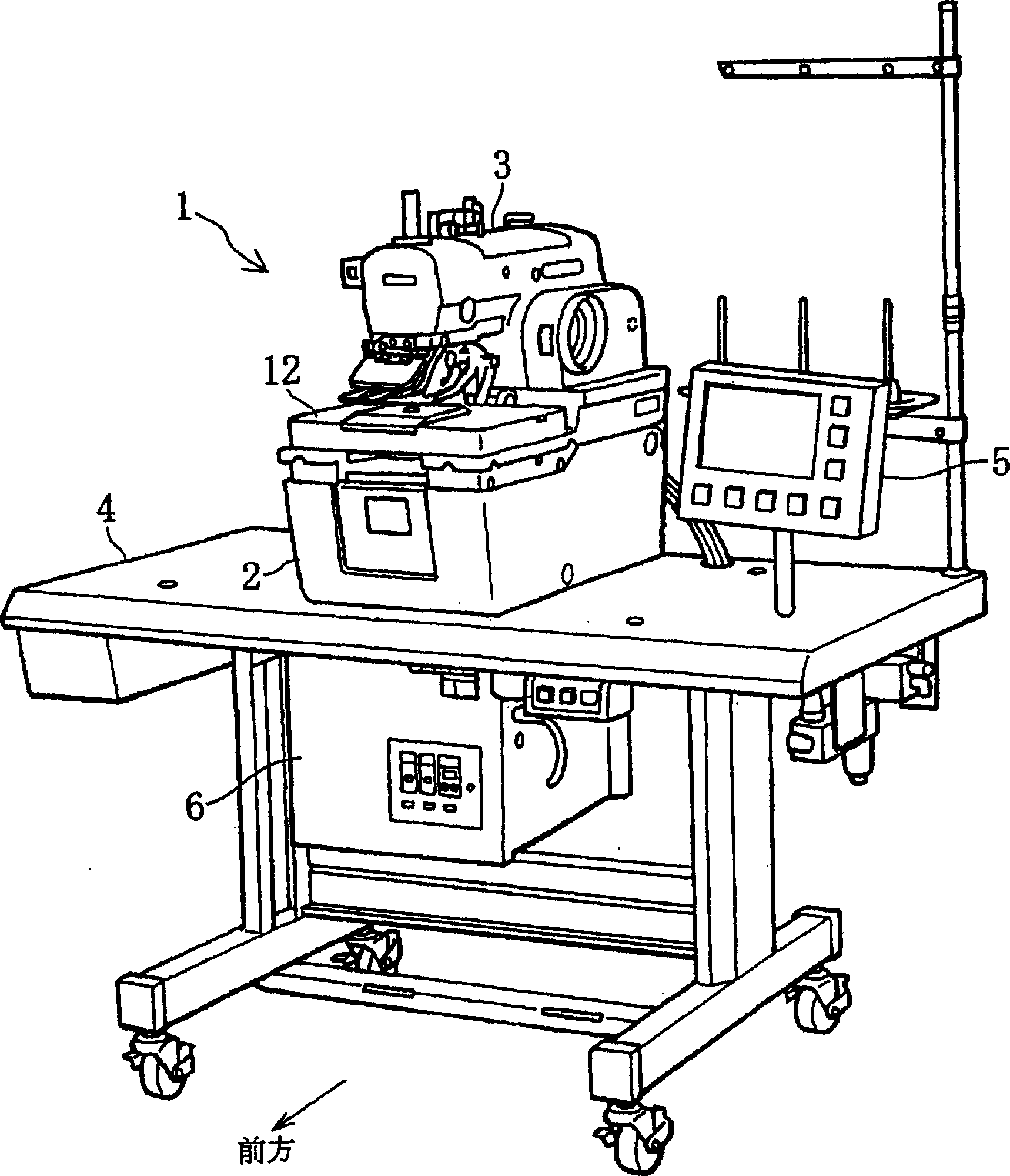

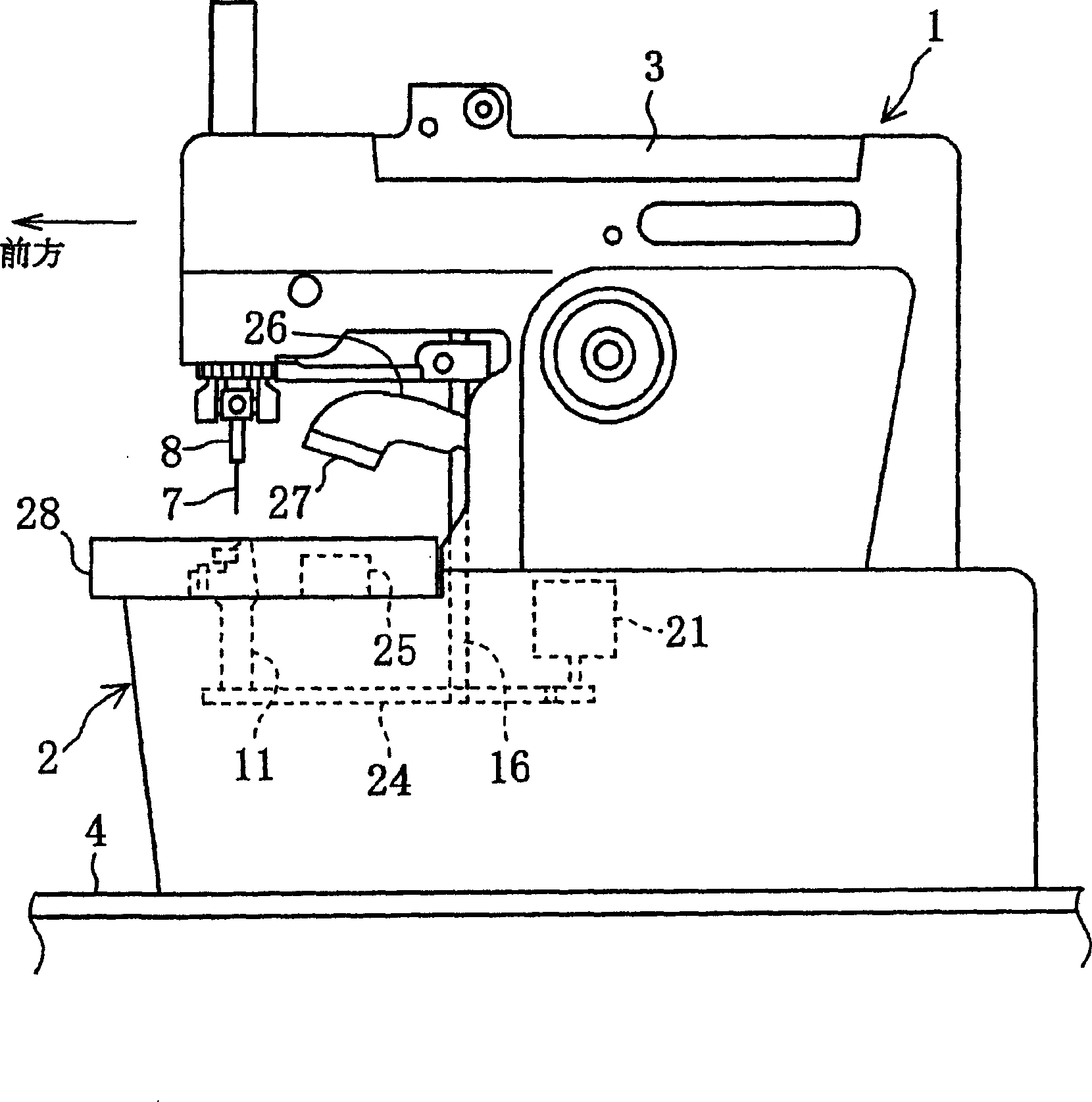

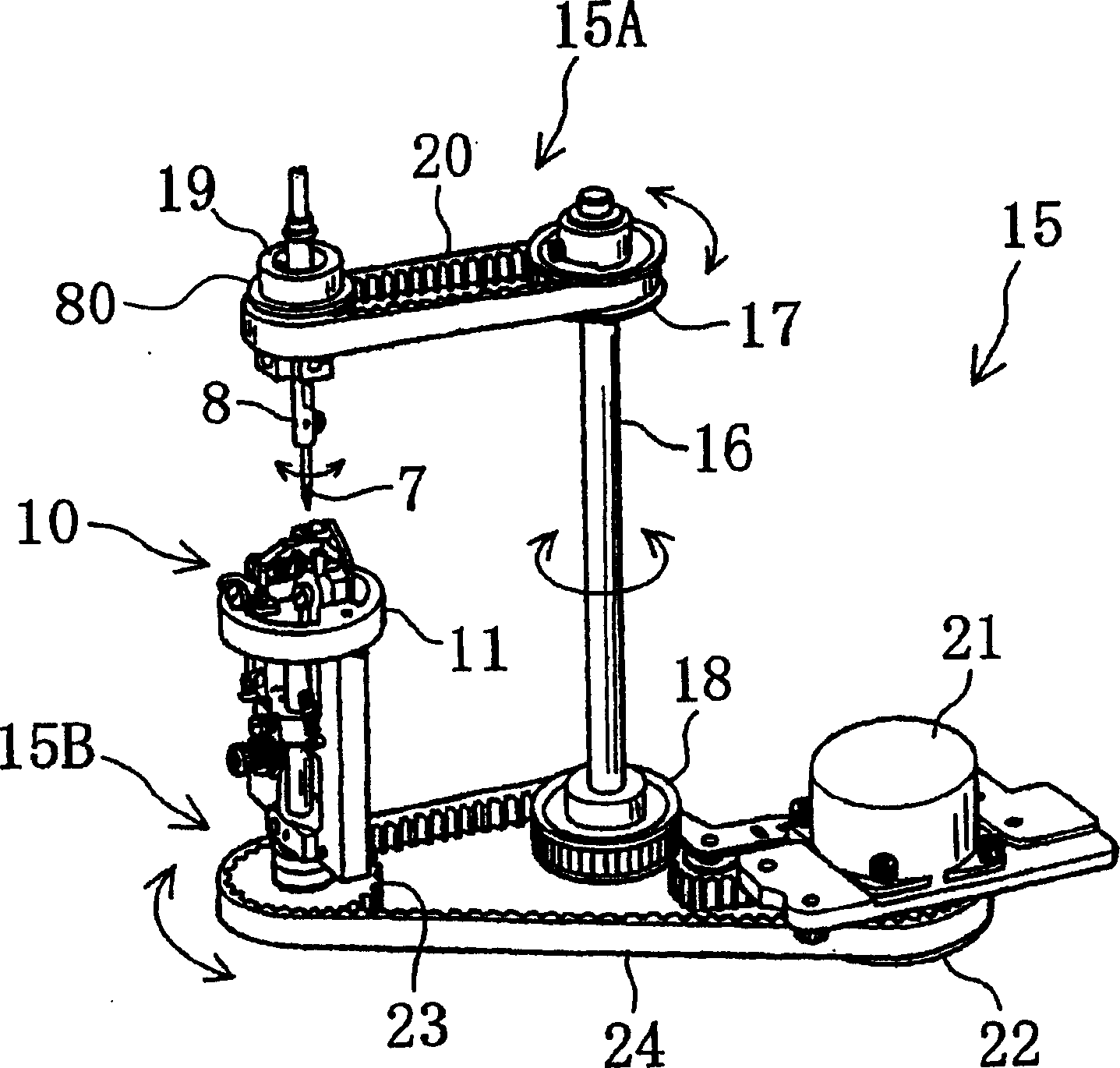

Sewing machine

ActiveCN1824872AAvoid unreasonable forceIncreased durabilityNeedle barsLoop takersEngineeringVertical motion

The sewing machine of the present invention has a needle bar crank linked to a main shaft, a vertical movement transmission mechanism linked to the needle bar crank, and a needle swing mechanism for swinging the needle bar. The up and down movement transmission mechanism includes: a ring-shaped member having a space defined by a ring-shaped inner peripheral surface, through which the needle bar passes; and a pair of upper and lower needle bar frame members, which are fixed on the outside of the needle bar, and Arranged on the upper and lower sides of the ring member. The ring member is journally connected to the needle bar crank. A clearance for swinging is ensured between the annular inner peripheral surface of the space of the annular member and the outer periphery of the needle bar. The needle bar can swing without being in contact with the annular inner peripheral surface within the swing gap.

Owner:BROTHER KOGYO KK

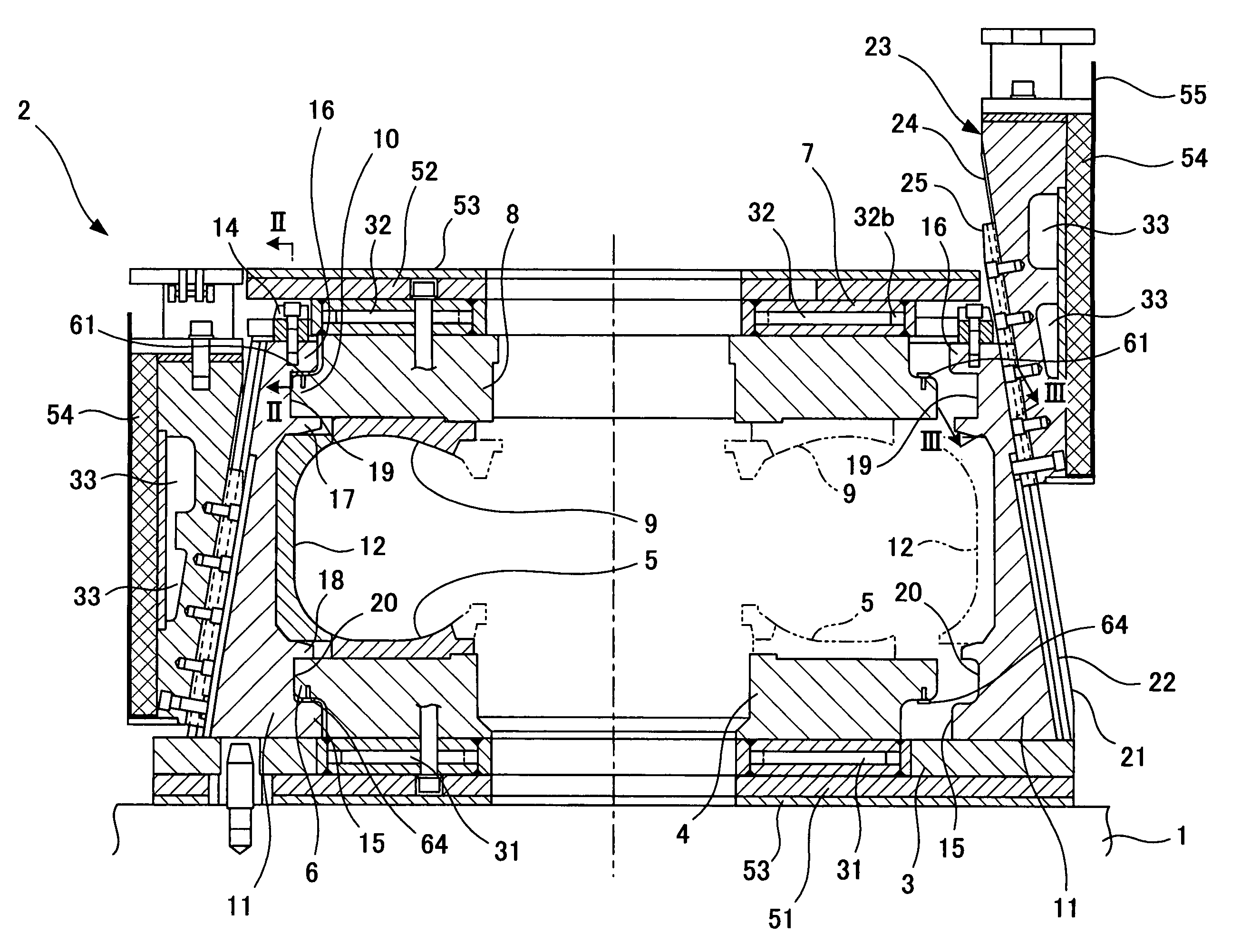

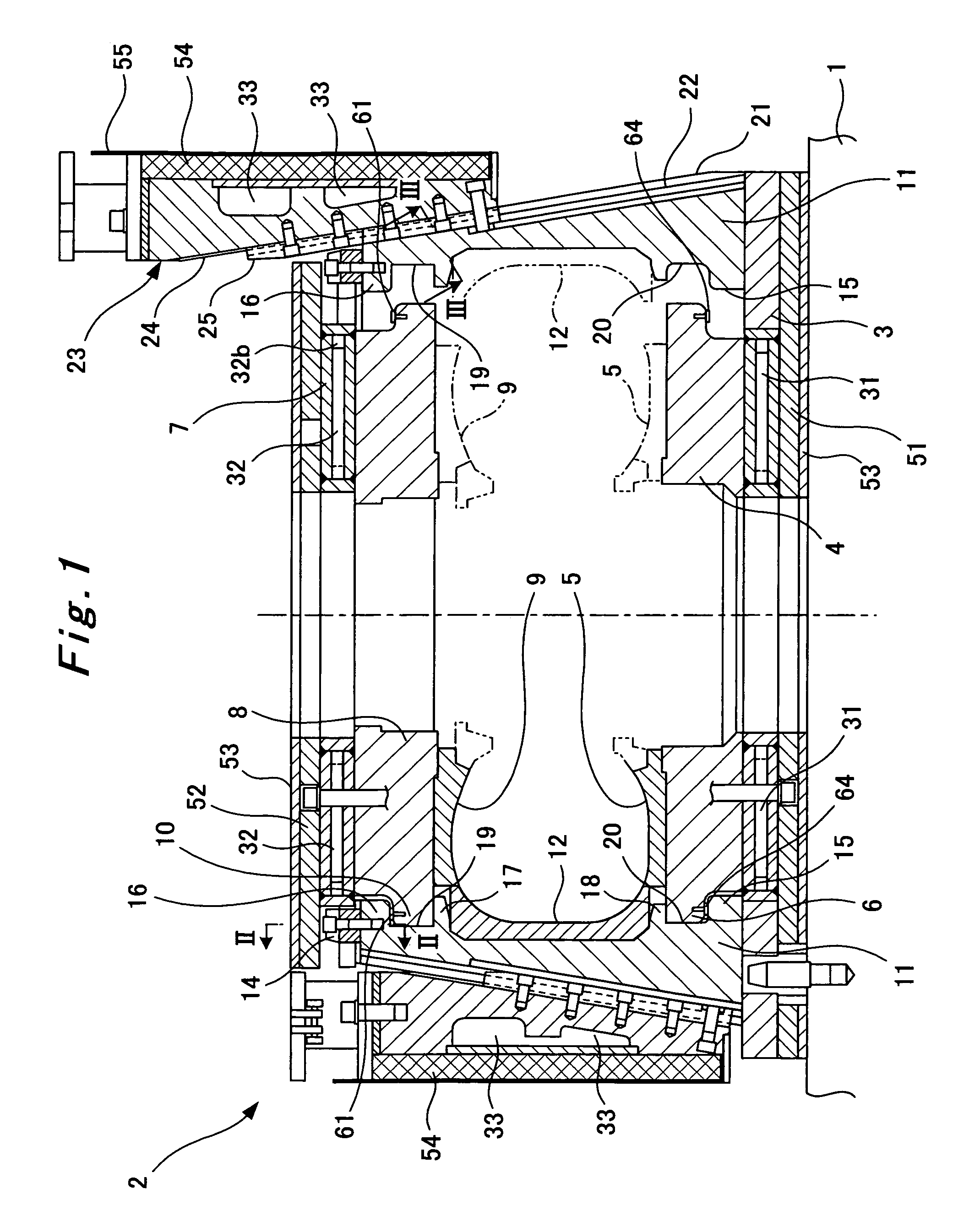

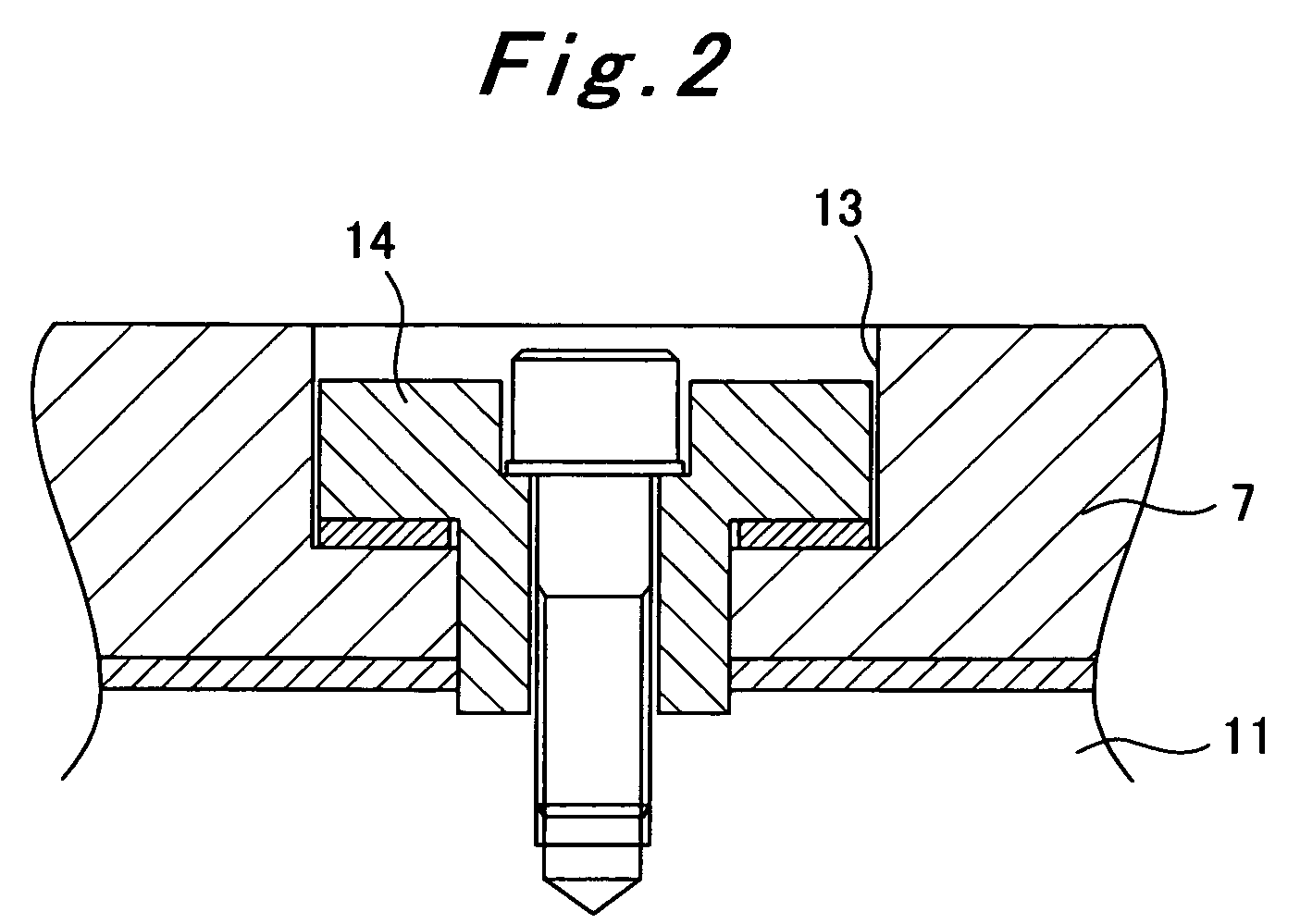

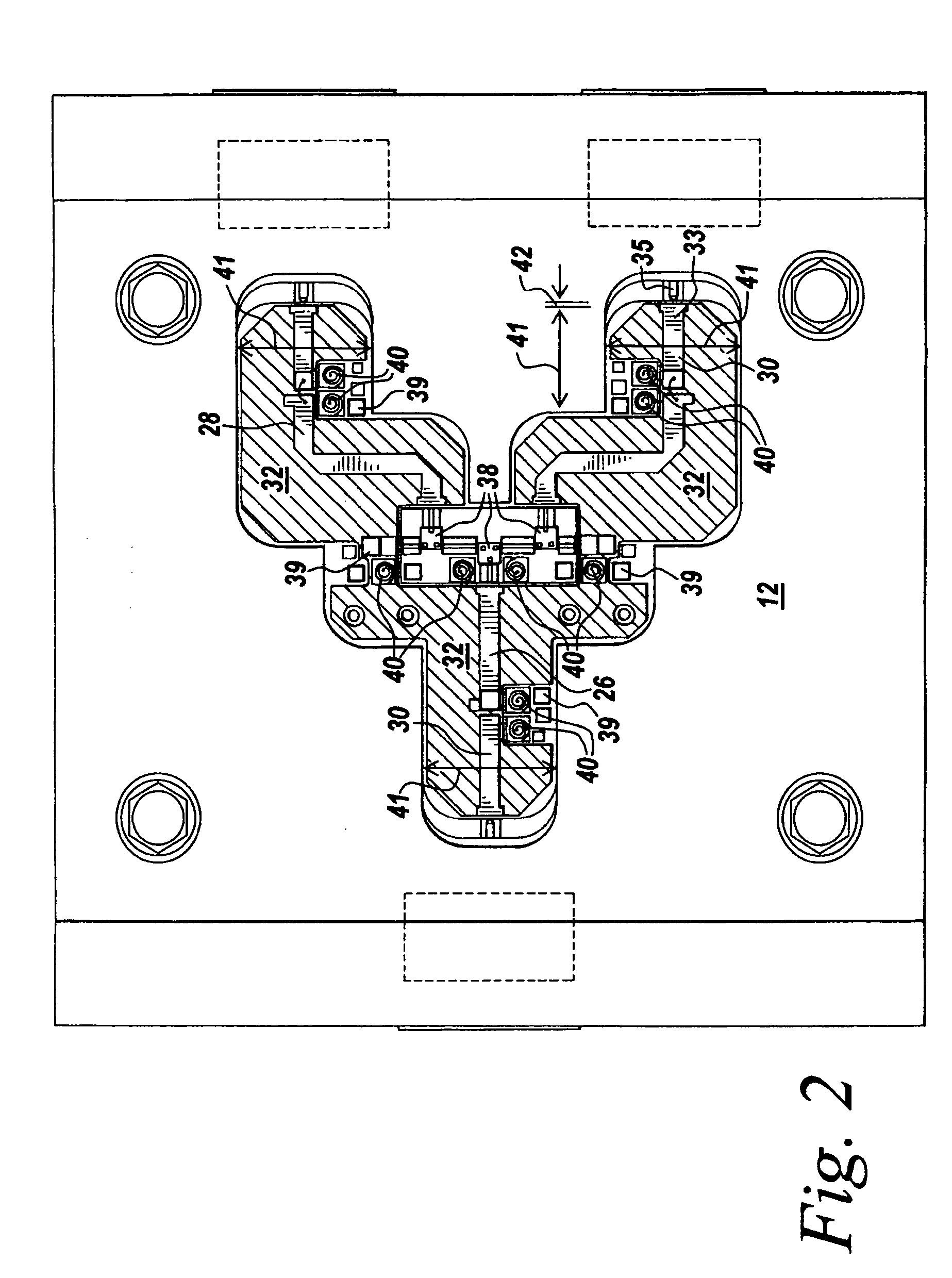

Tire vulcanizing apparatus

Disclosed is a tire vulcanizing apparatus including: upper and lower circular plates, to which sidewall dies for forming side portions of a tire are attached; respectively; and plural segments, to which tread dies separated as plural pieces for forming a tread portion of the tire are attached; respectively, in which apparatus, the upper and lower circular plates are held by engagement of lug portions, formed respectively on upper and lower portions of the segments, with protrusions on outer circumferential portions of the upper and lower circular plates so as to prevent the upper and lower circular plates from moving away from each other, the apparatus being constituted by providing adjustment plates, used for maintaining a measurement between the upper and lower circular plates, to an interface between the protrusion of each of the upper and lower circular plates and a corresponding one of the lug portions of each segment.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

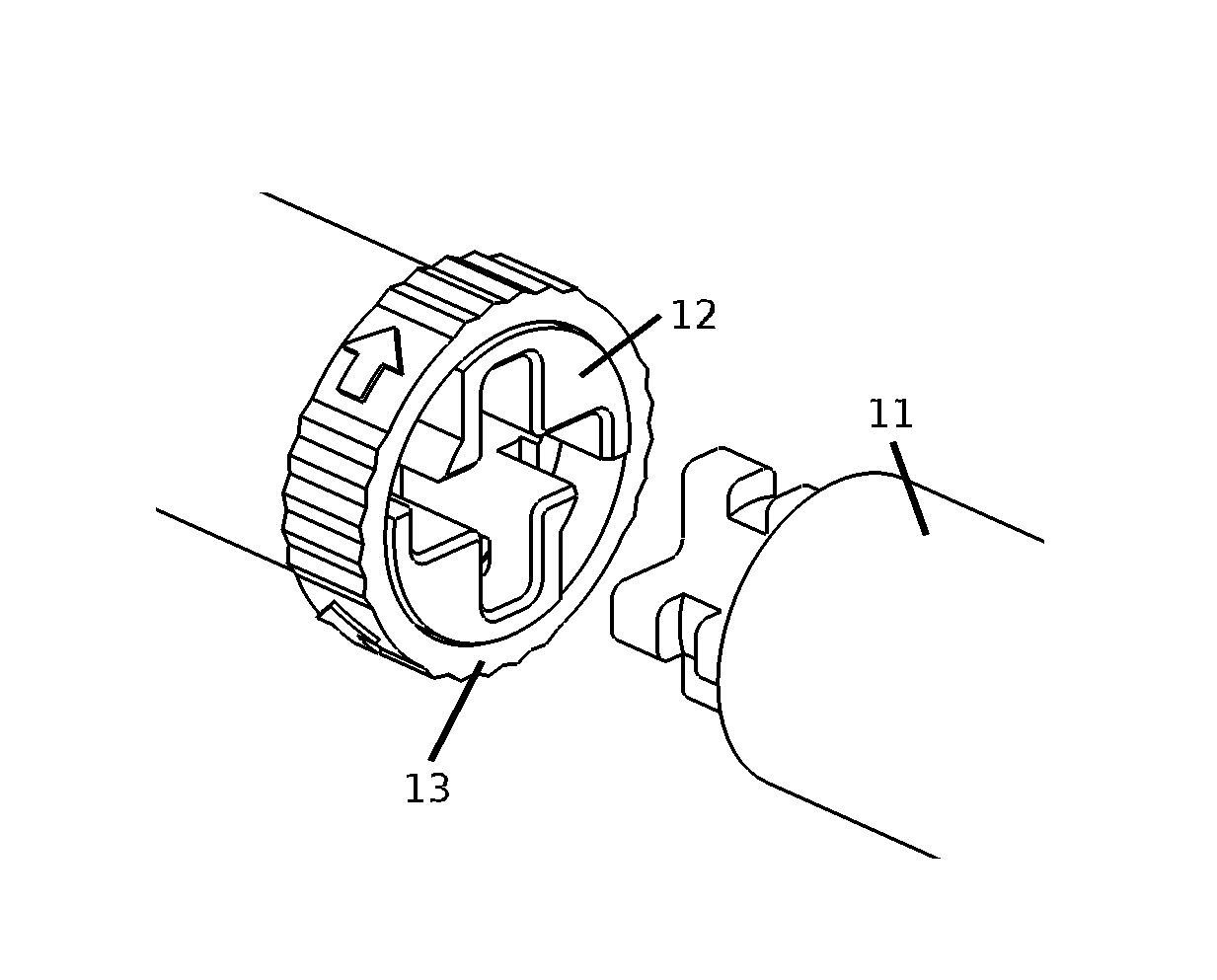

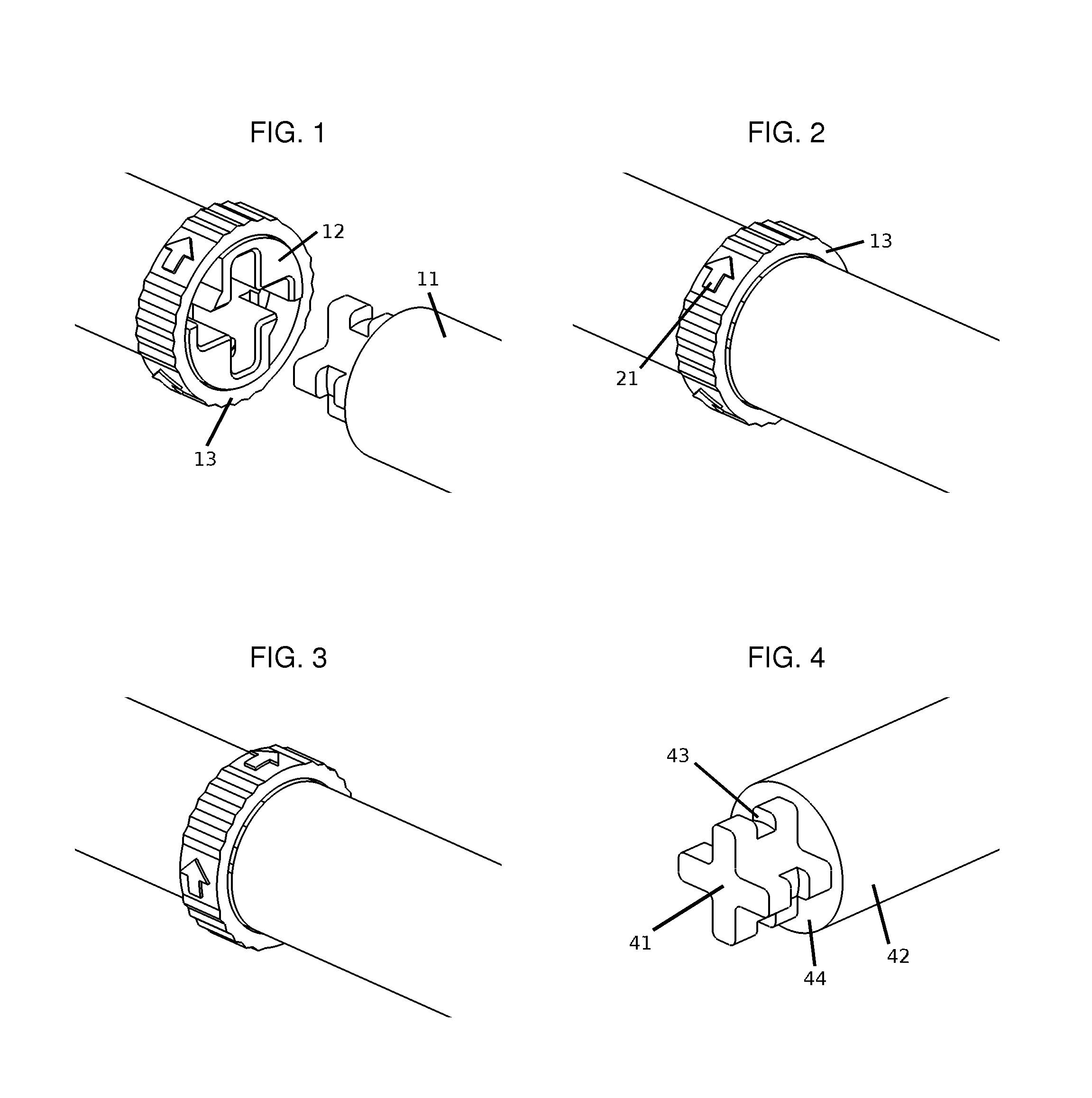

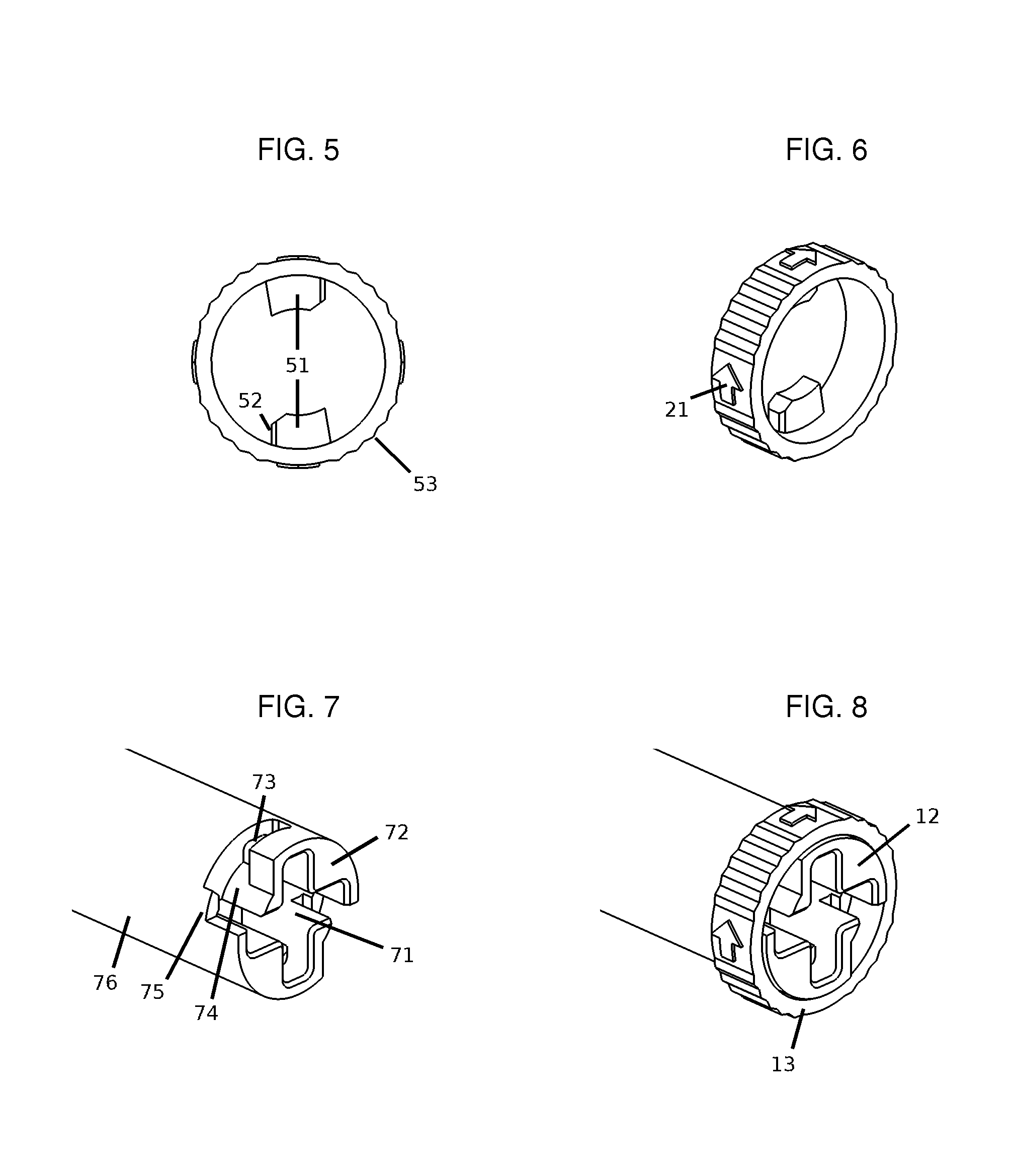

Multi-force resistant mechanical joint

InactiveUS9086087B1Firmly connectedSimple to separateToysRod connectionsSacroiliac jointBiomedical engineering

A mechanical joint that resists any direction of imposed force and can be connected in set rotational increments is comprised of three elements: a plug attached to the male-side of the joint, and a receptacle and a tabbed ring attached to the female-side side of the joint. The male-side and female-side are connected by sliding the plug into the receptacle and rotating the tabbed ring a partial turn. Reversing the connecting steps separates the joint.

Owner:SHARMAN CHARLES SCOTT

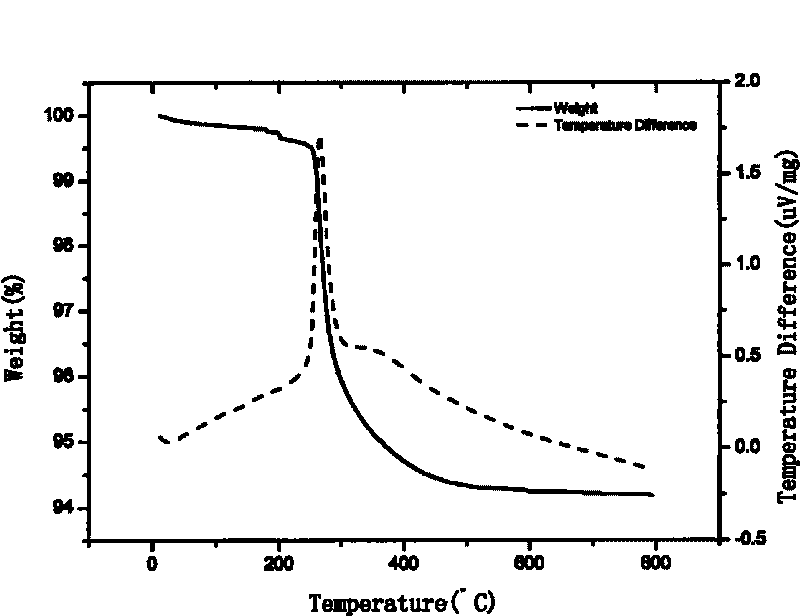

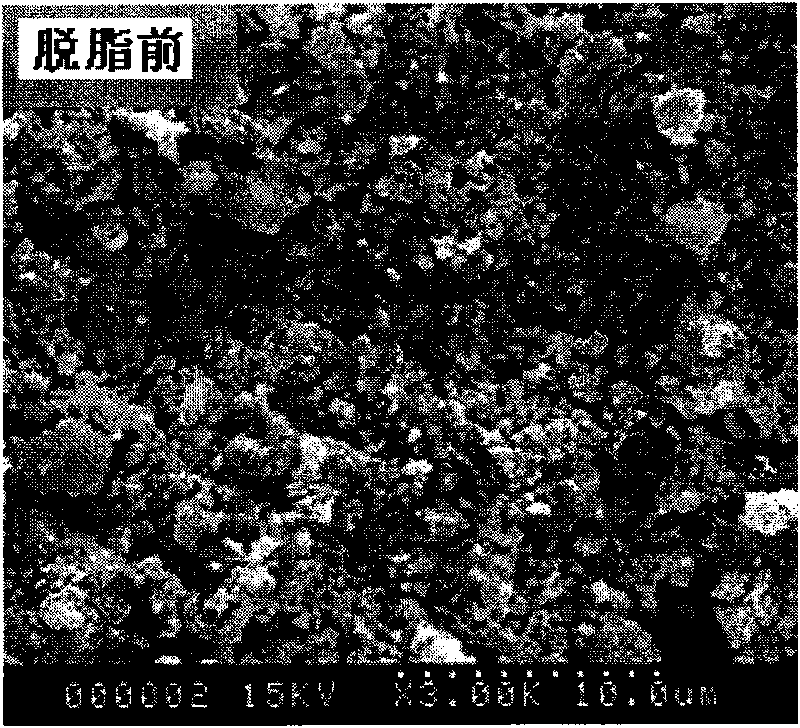

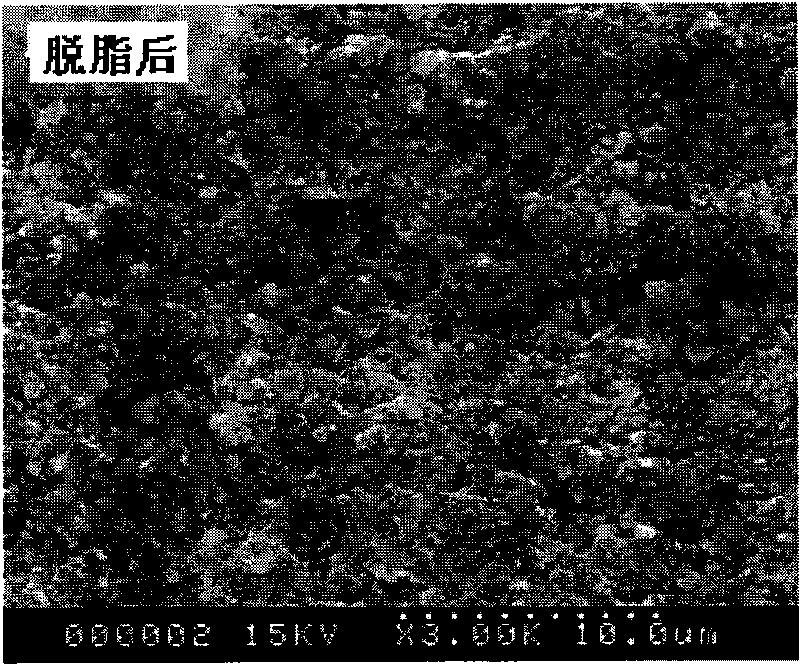

Degreasing method used for transparent alumina ceramic injection molding product

The invention relates to the field of the injection molding of transparent ceramics and ceramic powder, which discloses a degreasing method used for a transparent alumina ceramic injection molding product. The method comprises the following steps: firstly, injecting and molding a ceramic crude blank, wherein the assistant materials of the ceramic crude blank are alumina and an adhesive, and the adhesive comprises the following components by weight percent: 18-20% of polypropylene, 70-80% of paraffin and 1-12% of stearic acid; secondly, immersing the ceramic crude blank in an extraction solvent and extracting for 3-4h at the temperature of 45-60 DEG C, wherein the extraction solvent is prepared by mixing 20-30% of alcohol by volume and 70-80% of normal heptane by volume; then, discharging the extraction solvent and drying the ceramic crude blank in the air at room temperature; and finally, burying the ceramic crude blank in alumina powder and carrying out thermal degreasing for 56-60h hot.

Owner:XI AN JIAOTONG UNIV

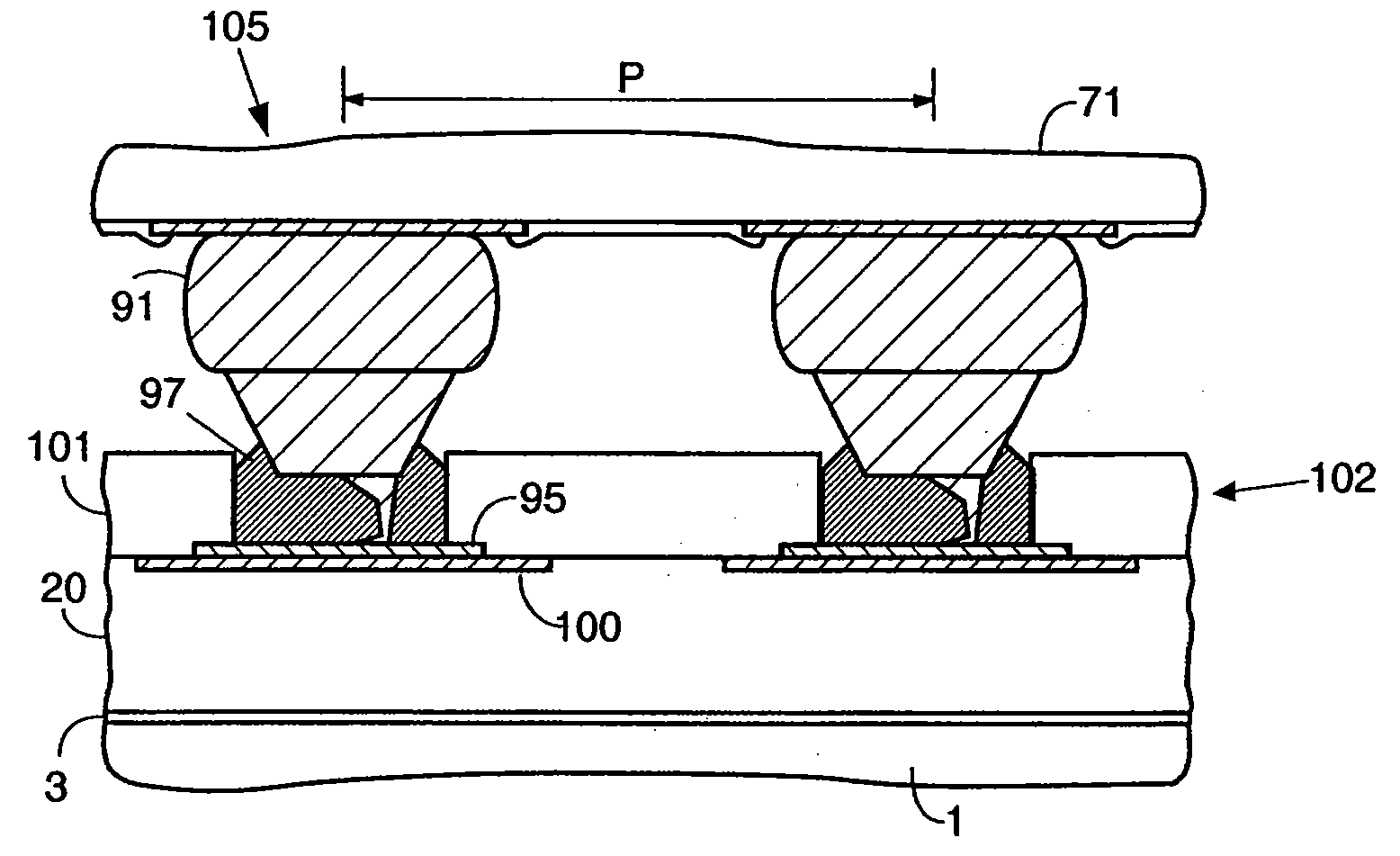

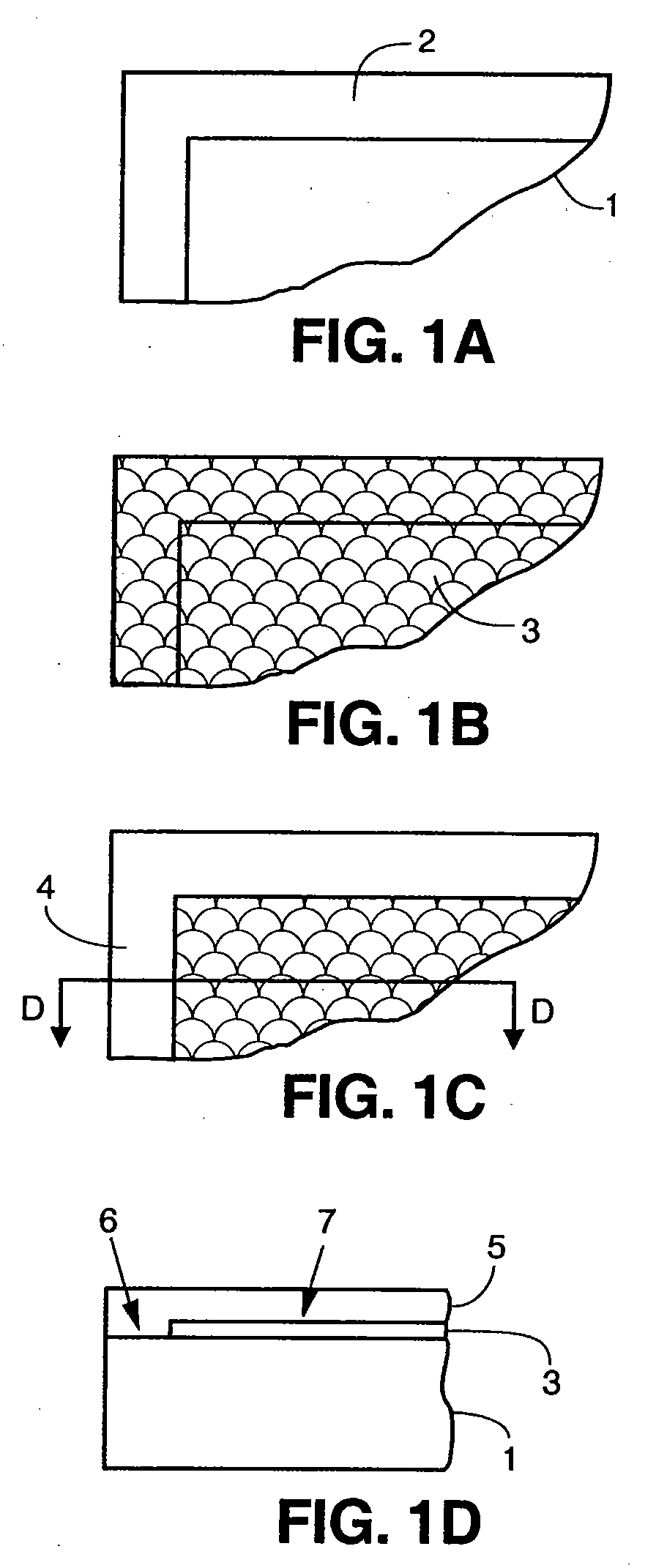

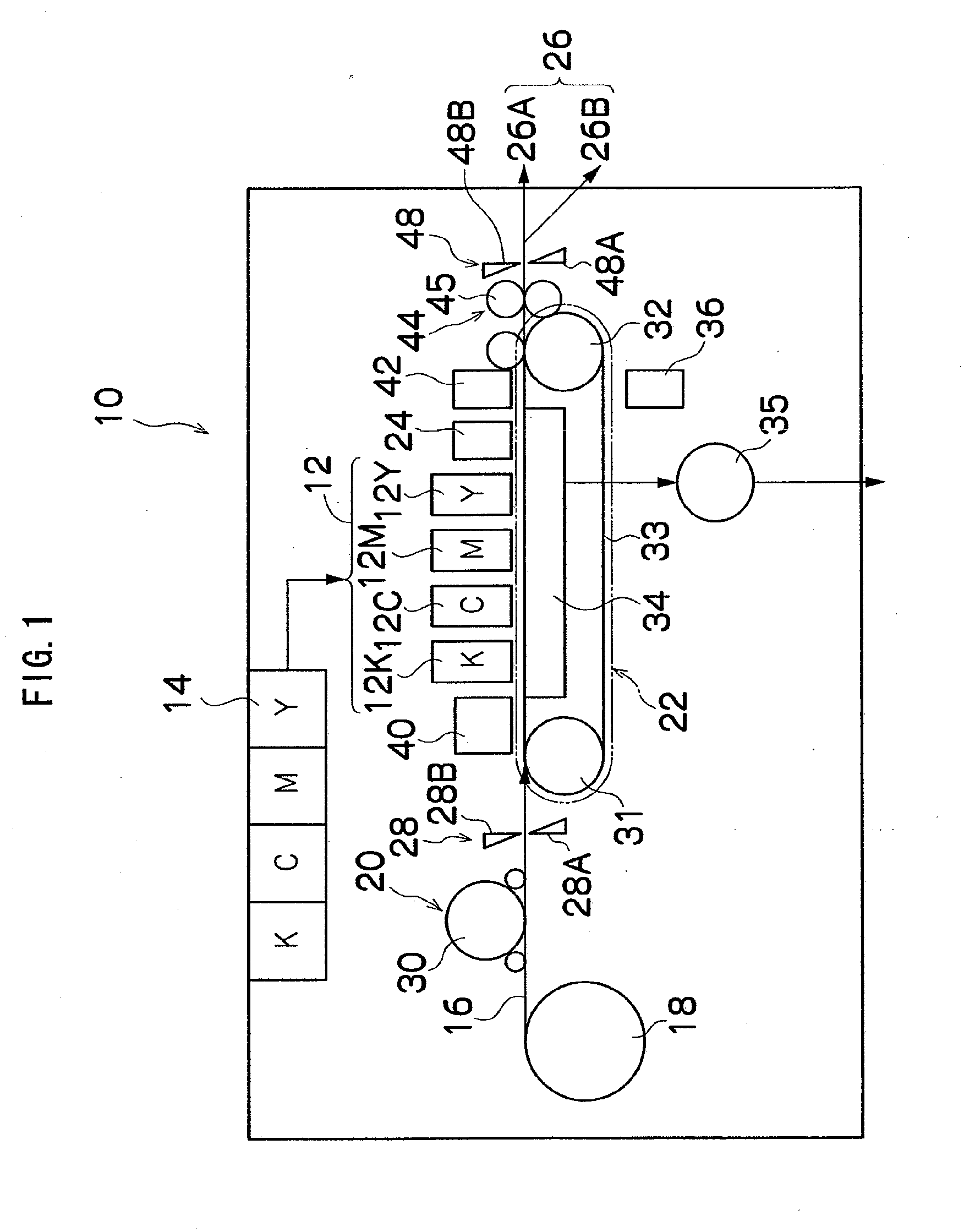

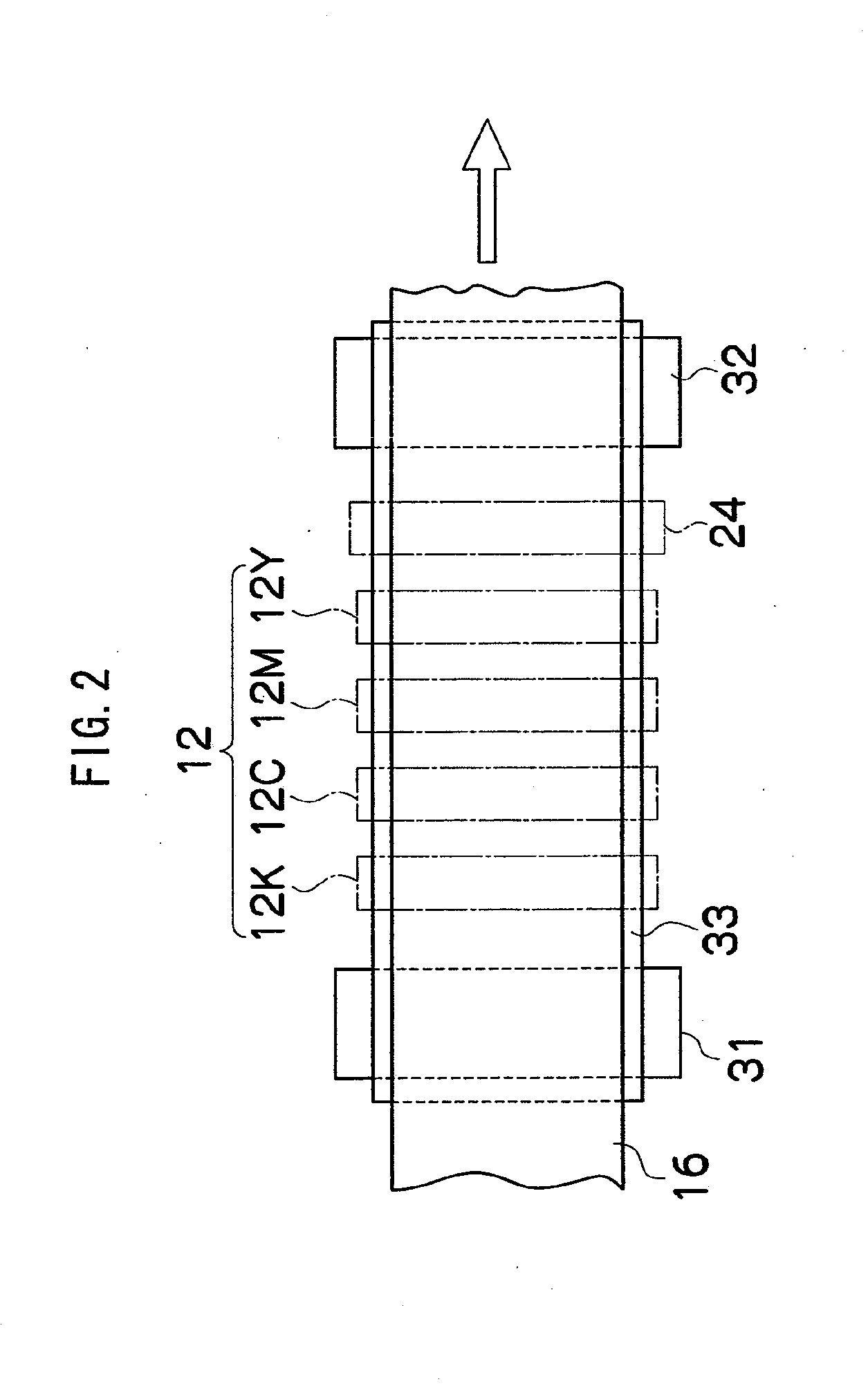

Fabrication Method For Electronic System Modules

InactiveUS20070245554A1Conveniently formMaintain dimensional accuracyPrinted circuit assemblingFinal product manufactureSurface plateElectromagnetic shielding

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths as narrow as 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is preferably used to fabricate the interconnection circuits. A multi-layer interconnection circuit is fabricated on the glass panel using a release layer. A special assembly layer is formed over the interconnection circuit comprising a thick dielectric layer with openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings using a squeegee to form wells filled with solder. IC chips are provided with gold stud bumps at I / O pad locations, and these bumps are inserted in the wells to form flip chip connections. The IC chips are tested and reworked. The same bump / well connections can be used to attach fine-pitch cables. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server or supercomputer embodiment is also described.

Owner:SK HYNIX INC

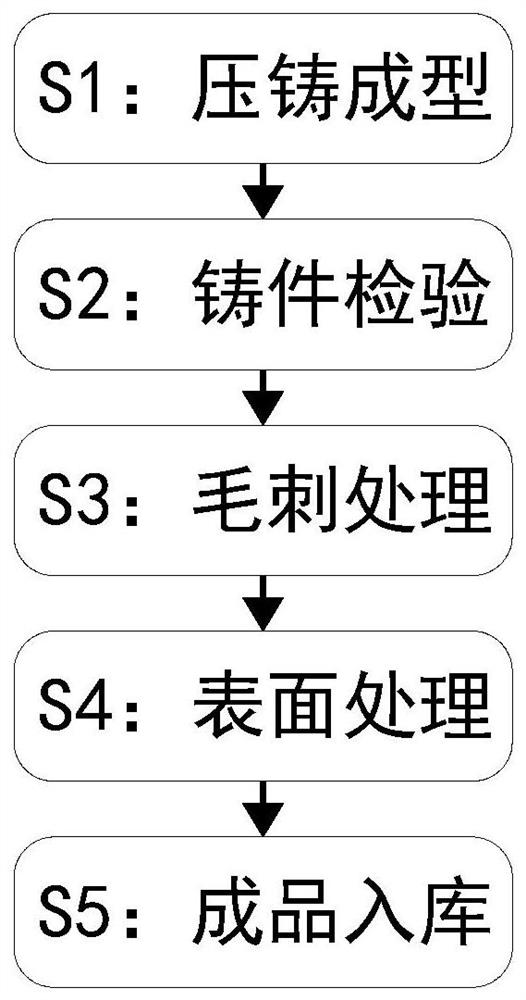

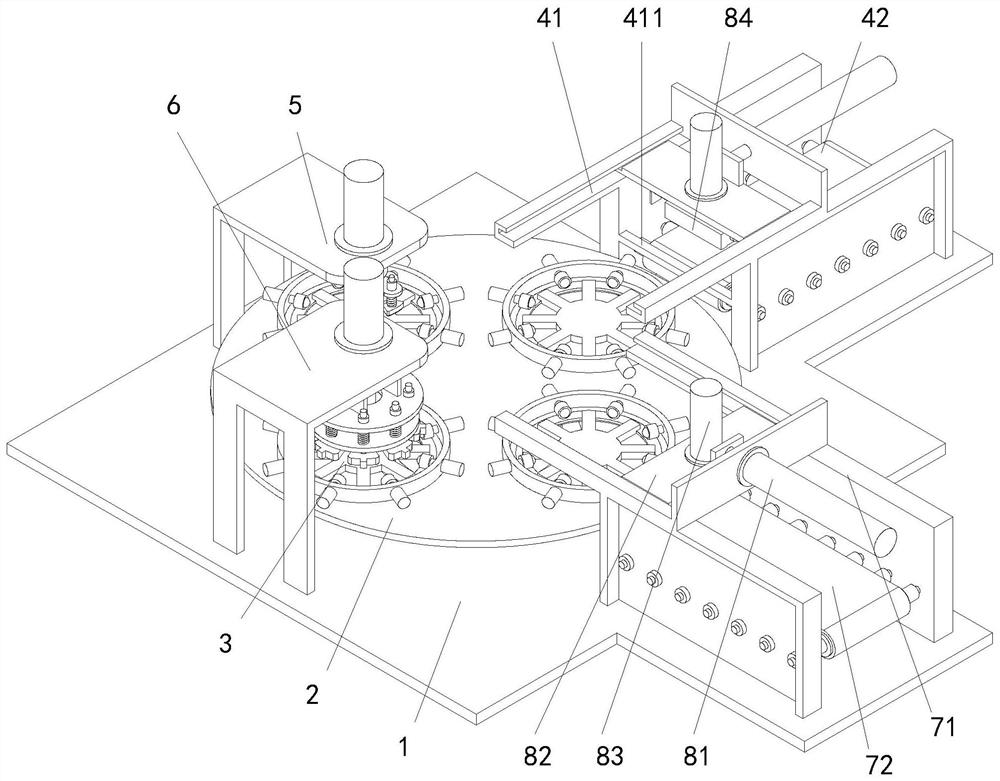

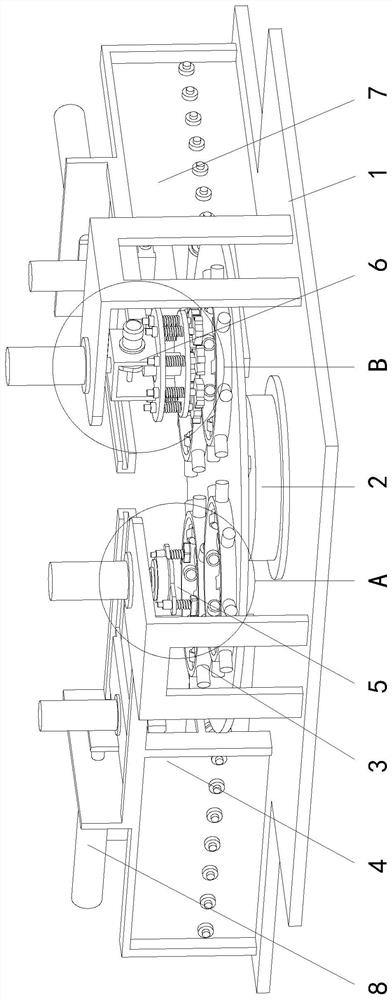

Motor rotor die-casting manufacturing process

ActiveCN111872345AAvoid damageMaintain dimensional accuracyGrinding machinesManufacturing stator/rotor bodiesManufacturing technologyElectric machine

The invention relates to a motor rotor die-casting manufacturing process, in particular to a motor rotor casting groove wall cleaning device. The motor rotor die-casting manufacturing process comprises a base, an intermittent transposition mechanism, a clamping and positioning mechanism, a feeding mechanism, a shifting and positioning mechanism, a groove wall cleaning mechanism, a discharging mechanism and a grabbing and feeding mechanism. The device provided by the motor rotor die-casting manufacturing process is suitable for carrying out streamlined processing treatment on motor rotor laminations, the efficiency is greatly improved, the grinding quality uniformity is high, damage to the motor rotor laminations due to improper grinding can be avoided, the grinding quality is ensured, andthe size precision and the appearance attractiveness of the motor rotor laminations are maintained.

Owner:威海立安精密铸造有限公司

Antibacterial stainless steel and preparing method thereof

The invention particularly relates to antibacterial stainless steel and a preparing method thereof. According to the technical scheme of the antibacterial stainless steel and the preparing method thereof, stainless steel obtained after surface pretreatment is put into a dopamine buffer solution to be deposited for 0.1 h to 72 h under the condition with the temperature ranging from -5 DEG C to 40 DEG C; then the obtained stainless steel is put into a solution containing titanium ions to be deposited for 0.1 h to 6 h; and finally the obtained stainless steel is put into a solution containing silver ions to be deposited for 0.1 h to 6 h, and therefore the antibacterial stainless steel is obtained. The concentration of the dopamine buffer solution ranges from 0.01 mol / L to 1 mol / L, the concentration of the solution containing the titanium ions ranges from 0.001 mol / L to 1 mol / L, and the concentration of the solution containing the silver ions ranges from 0.001 mol / L to 1 mol / L. By means of the antibacterial stainless steel and the preparing method thereof, the technology is simple, environment friendliness is achieved, and the cost is low; the surface antibacterial nanometer film layer structure of the antibacterial stainless steel prepared through the method is well-defined and orderly, is firmly combined with a base material, is high in corrosion resistance and hardness and has good antibacterial performance both under the illumination condition and the non-illumination condition.

Owner:WUHAN UNIV OF SCI & TECH

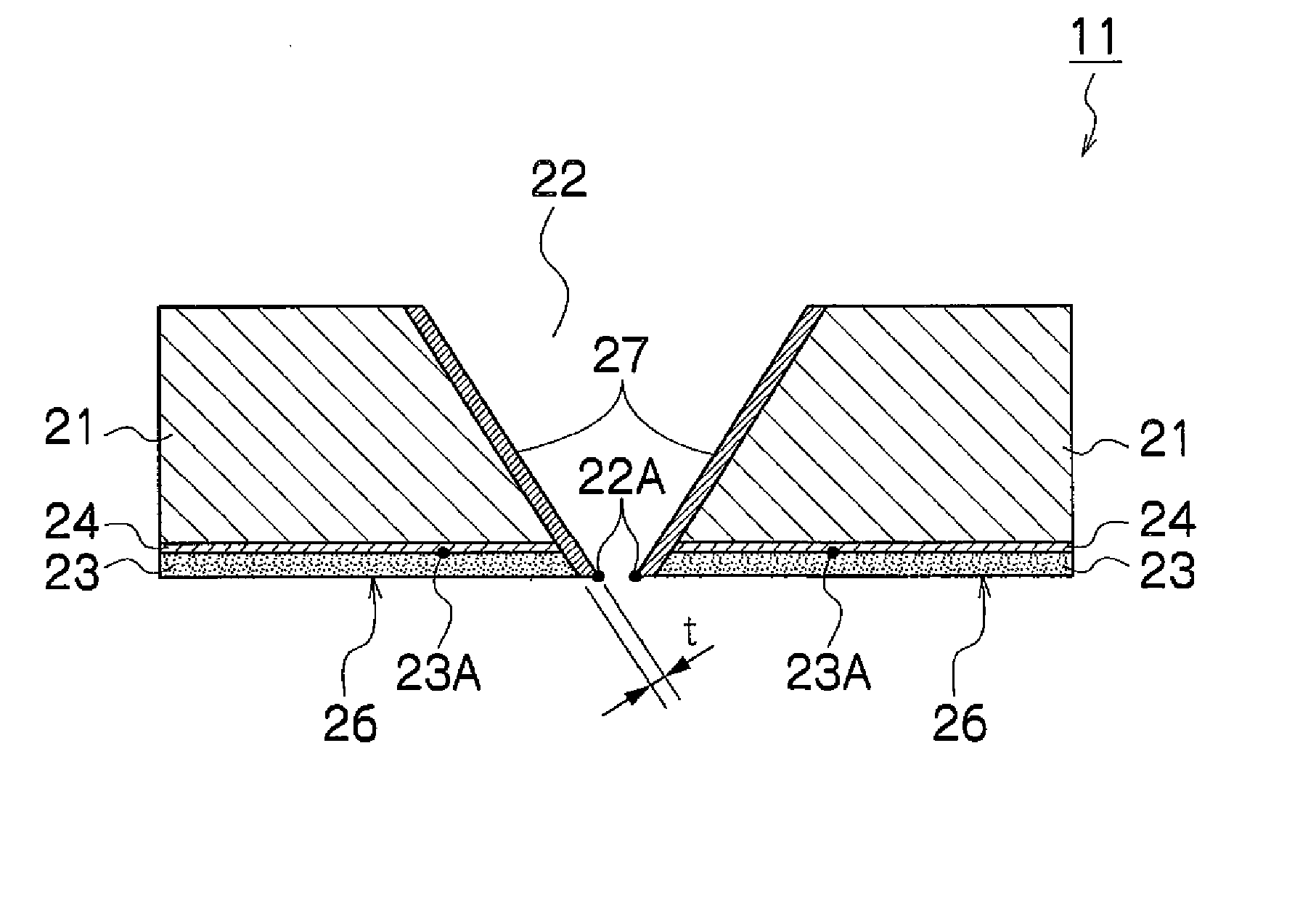

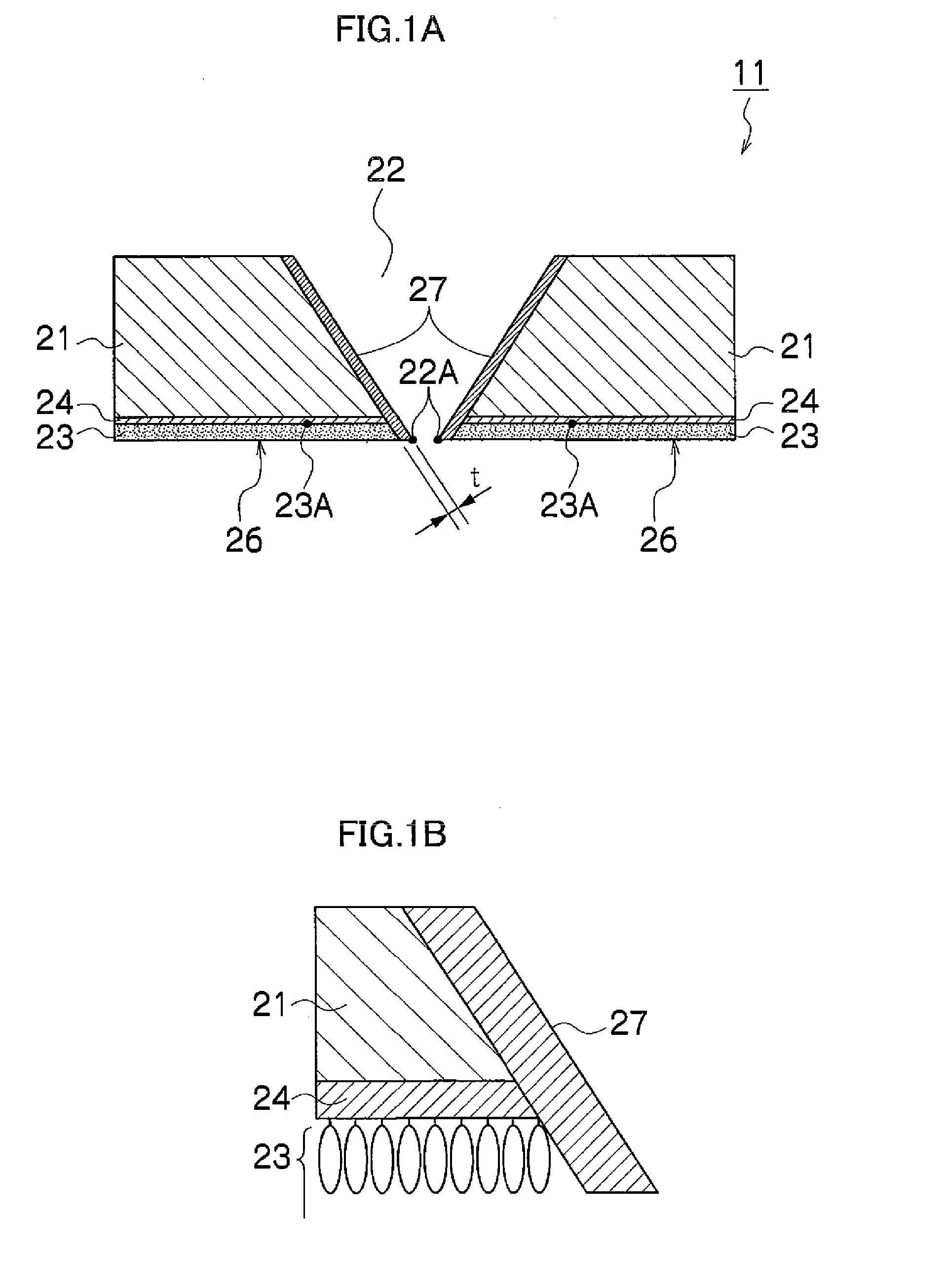

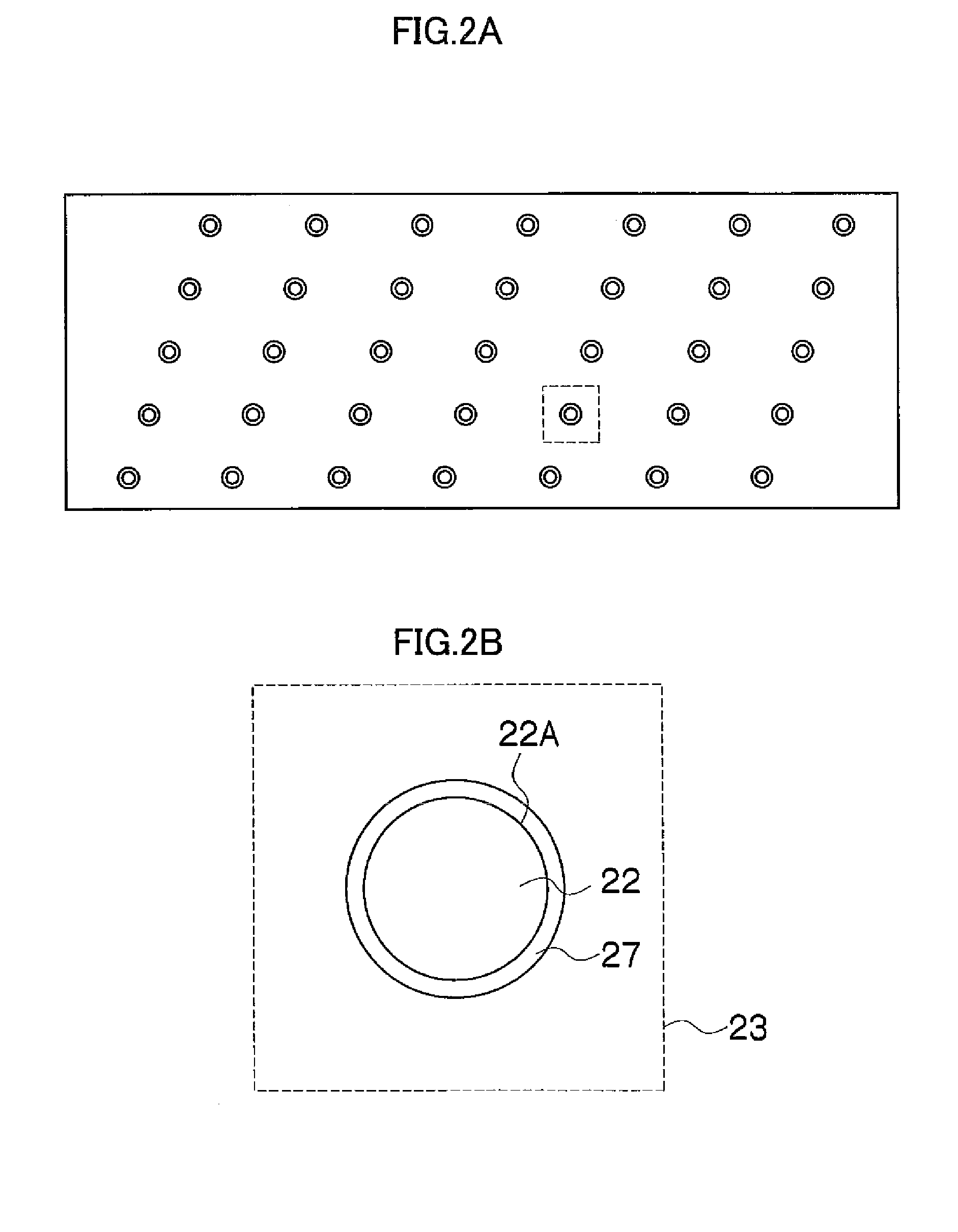

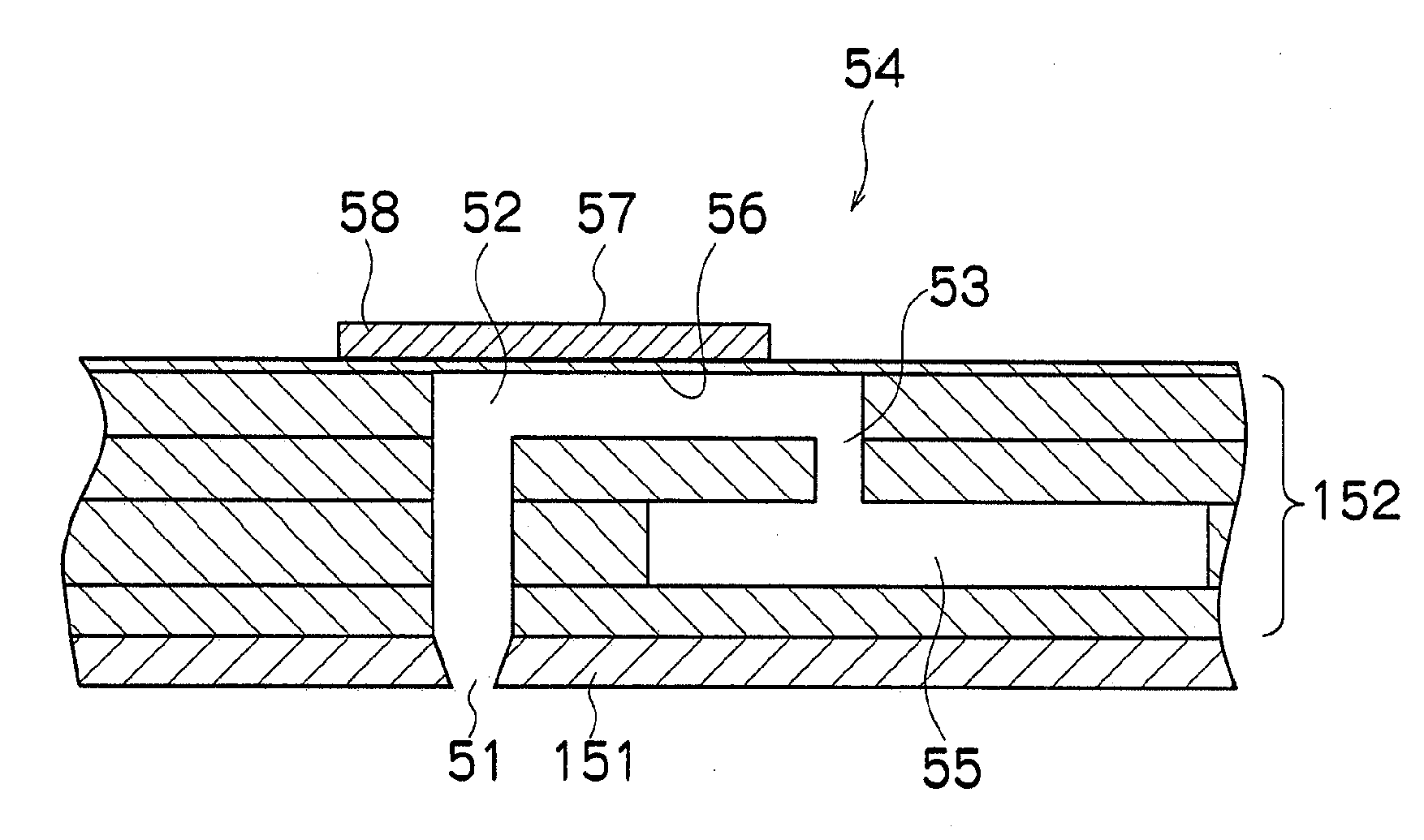

Nozzle plate, ink ejection head, and image forming apparatus

InactiveUS20080239000A1Shape and dimensional accuracy be maintainMaintain accuracyPrintingNozzleEngineering

A nozzle plate includes: a plate substrate in which a nozzle is formed, ink being ejected through an ejection port of the nozzle in the plate substrate; and a p-type doped layer which forms a whole perimeter of an edge portion defining an inner perimeter of the ejection port of the nozzle in the plate substrate.

Owner:FUJIFILM CORP

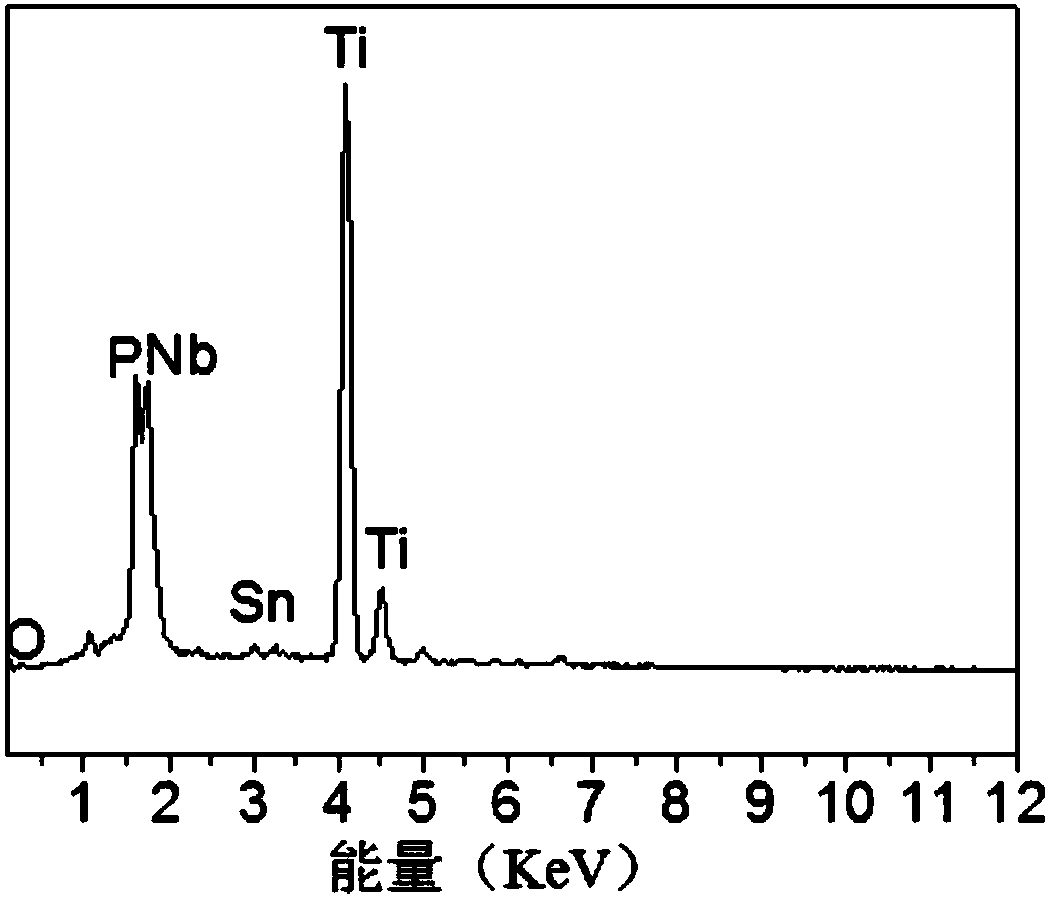

Method for improving biomimetic mineralization capacity of surface of titanium alloy implant

ActiveCN108042847AImprove biological activityQuick responseVacuum evaporation coatingSputtering coatingSurface layerSimulated body fluid

The invention discloses a method for improving biomimetic mineralization capacity of the surface of a titanium alloy implant. According to the method, after the surface of the titanium alloy implant is subjected to mechanical grinding treatment, a nanocrystallized surface layer is produced, P ions are injected into the nanocrystallized surface layer with an ion injection technology, the injectioneffect is enhanced due to presence of more dislocation and other defects on the nanocrystallized implant surface, and injected ion concentration is increased three times or more than that of an implant without surface nanocrystallization; globular apatite is fully distributed on the surface of the implant after 28 days of soaking with simulated body fluid, and accordingly, biological activity of the titanium alloy implant is obviously improved.

Owner:ANHUI UNIV OF SCI & TECH

Vehicle fuel cap with axial longitudinal grooves in casing body

ActiveUS7543715B2Small outer diameterPrevent intrusionTyre partsRefuse receptaclesFuel tankConductive materials

A vehicle fuel cap comprises a casing body for opening / closing a filler opening of a filler neck communicating with a fuel tank; and a lid that is equipped at an upper portion of the casing body and is formed of a conductive material, and the vehicle fuel cap forms a discharge portion in the lid for discharging static charge in the lid to the filler neck, wherein the discharge portion comprises a projection form provided on an inner peripheral face of the lid opposite to an outer peripheral edge of the filler opening, and on the inner peripheral face a longitudinal groove is formed at both sides of the discharge portion and along an axial direction of the casing body.

Owner:HONDA MOTOR CO LTD +1

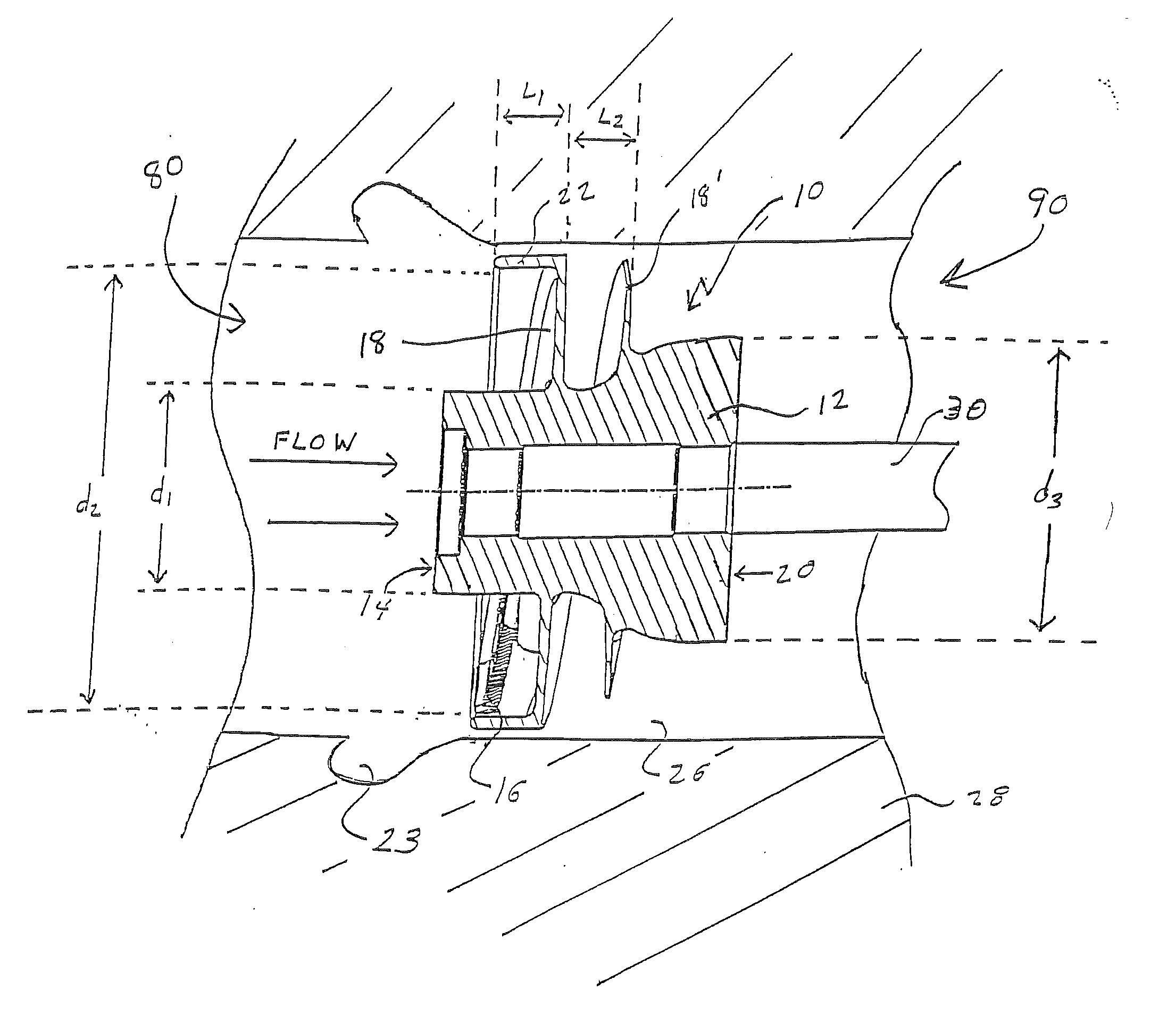

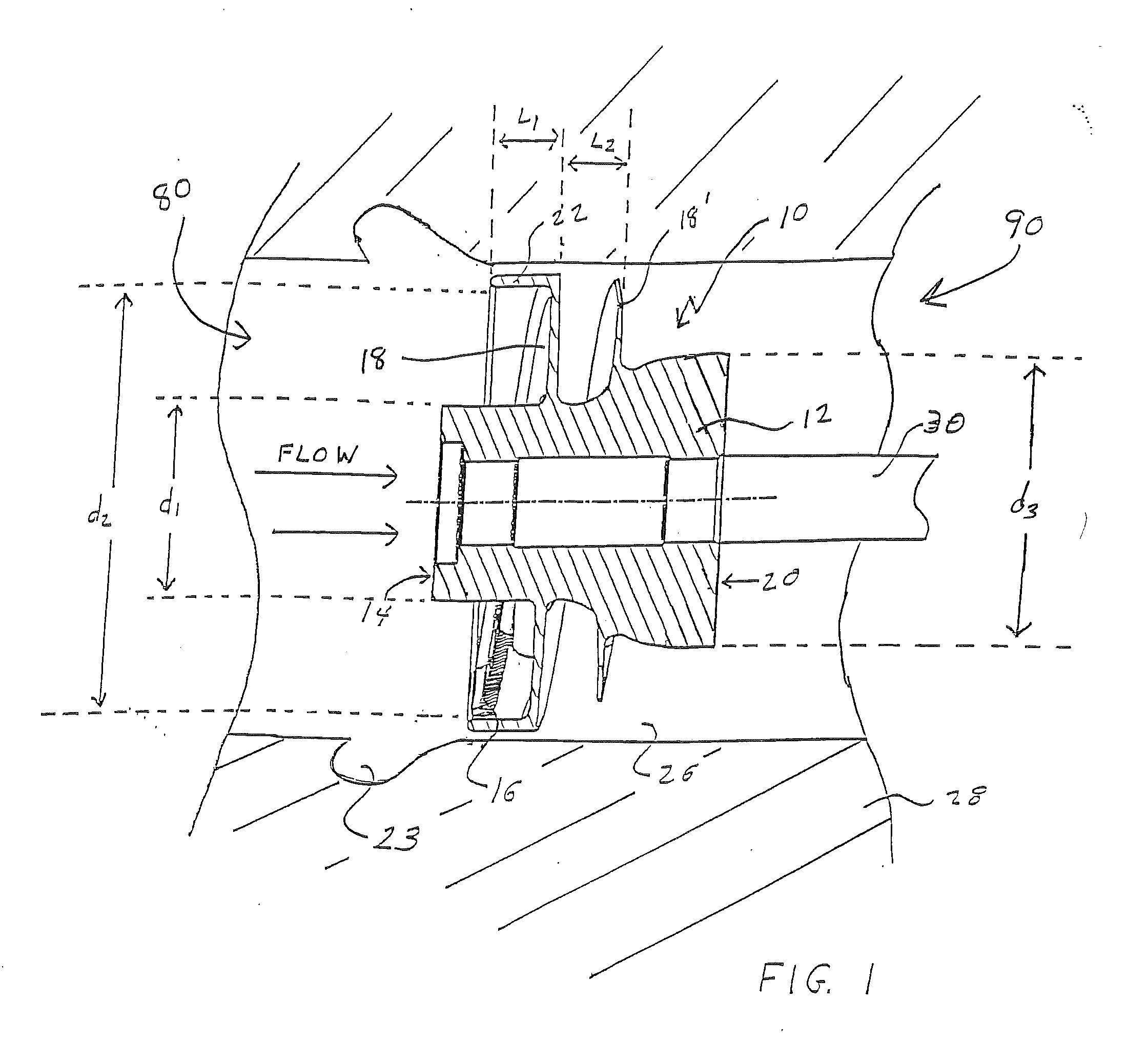

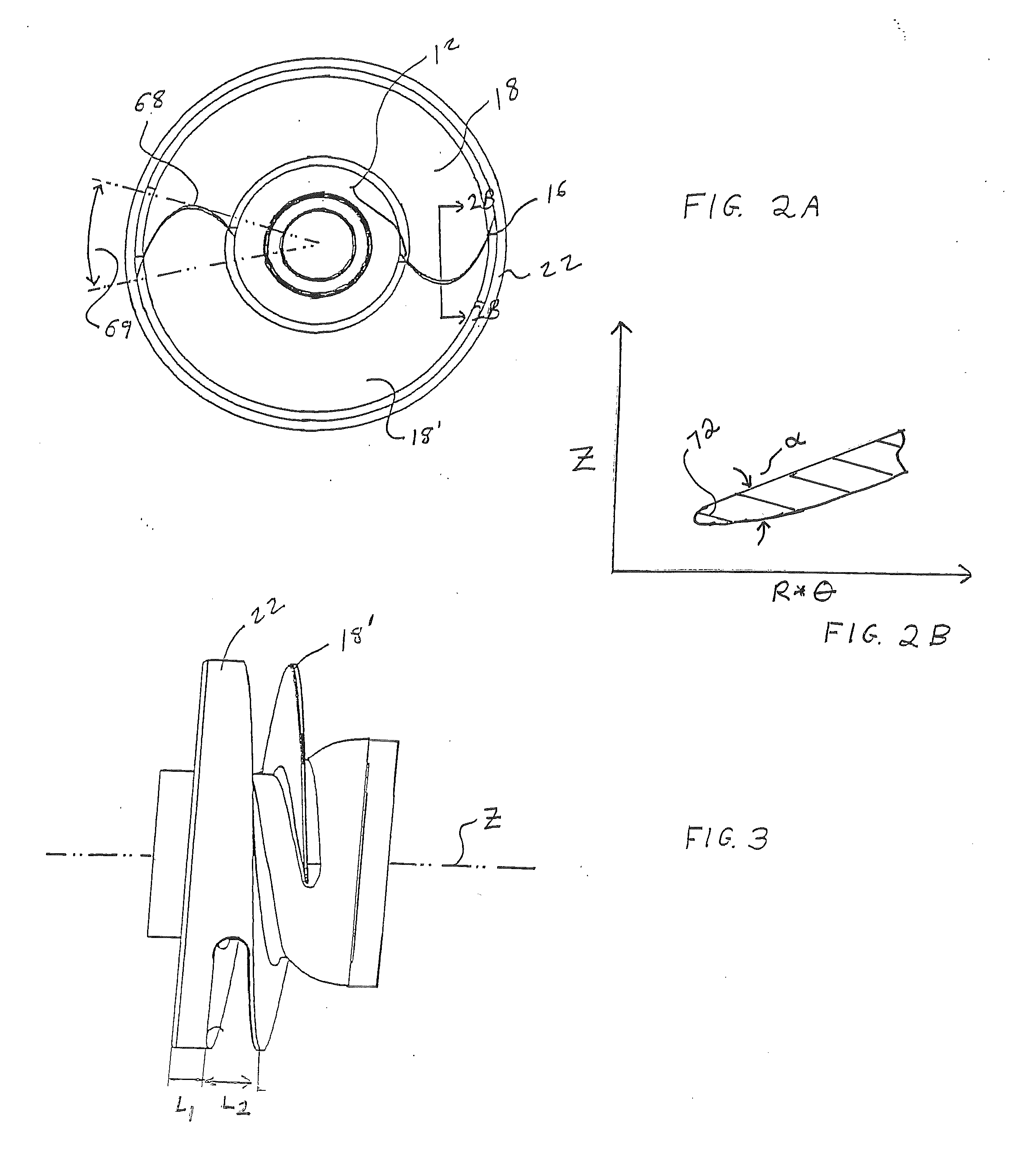

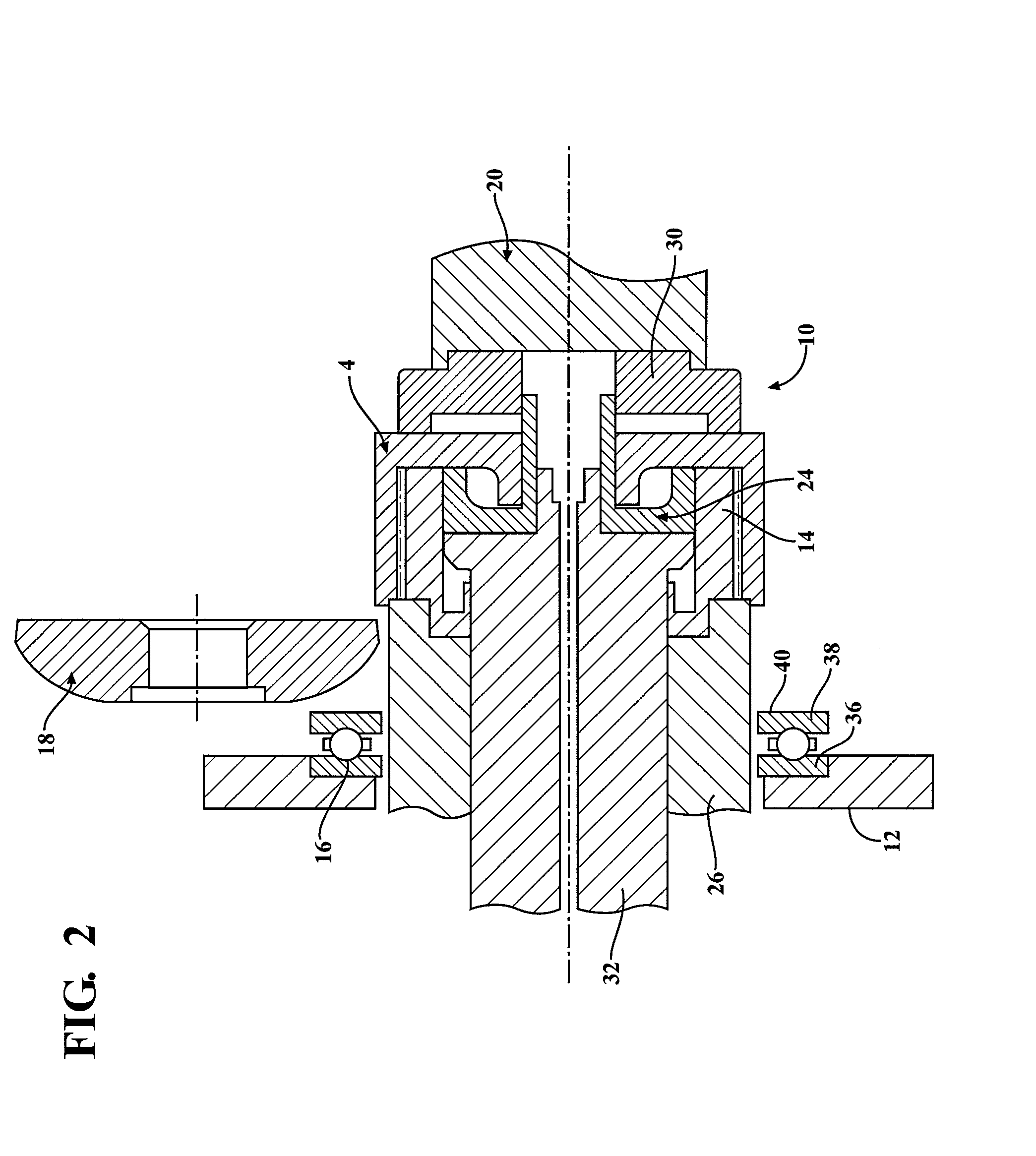

Inducer with Cavitation Instability Controls to Reduce Vibrations and Radial Loads

ActiveUS20130330185A1Reduce manufacturing costMaintain dimensional accuracyPump componentsStatorsCavitationInstability

An inducer includes a hub having an inlet end and an outlet end. At least one full size blade has an inner edge is affixed to the hub and an outer edge. This full size blade extends rearwardly from the inlet end in a helical configuration. A partial shroud encloses a first length of the full size blade outer edge adjacent the inlet end. A second length of the full size blade outer edge that is adjacent to the outlet end is free of the partial shroud. It is within the scope of the disclosure to include short blades symmetrically offset from the two full size blades. These short blades have a short blade inner end affixed to the partial shroud and a short blade outer end extending from the partial shroud towards the hub, but terminating prior to reaching the hub.

Owner:AEROJET ROCKETDYNE INC

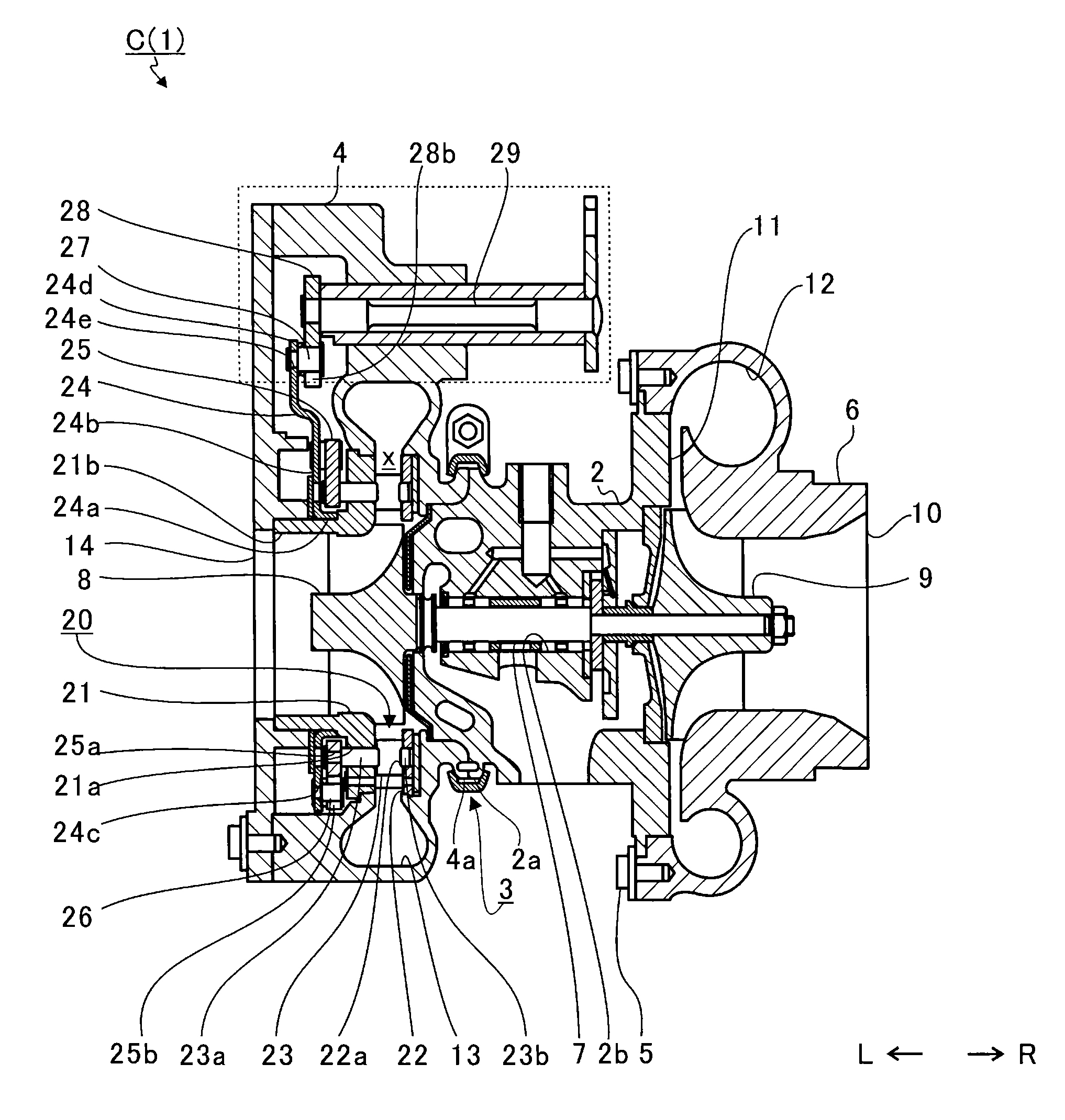

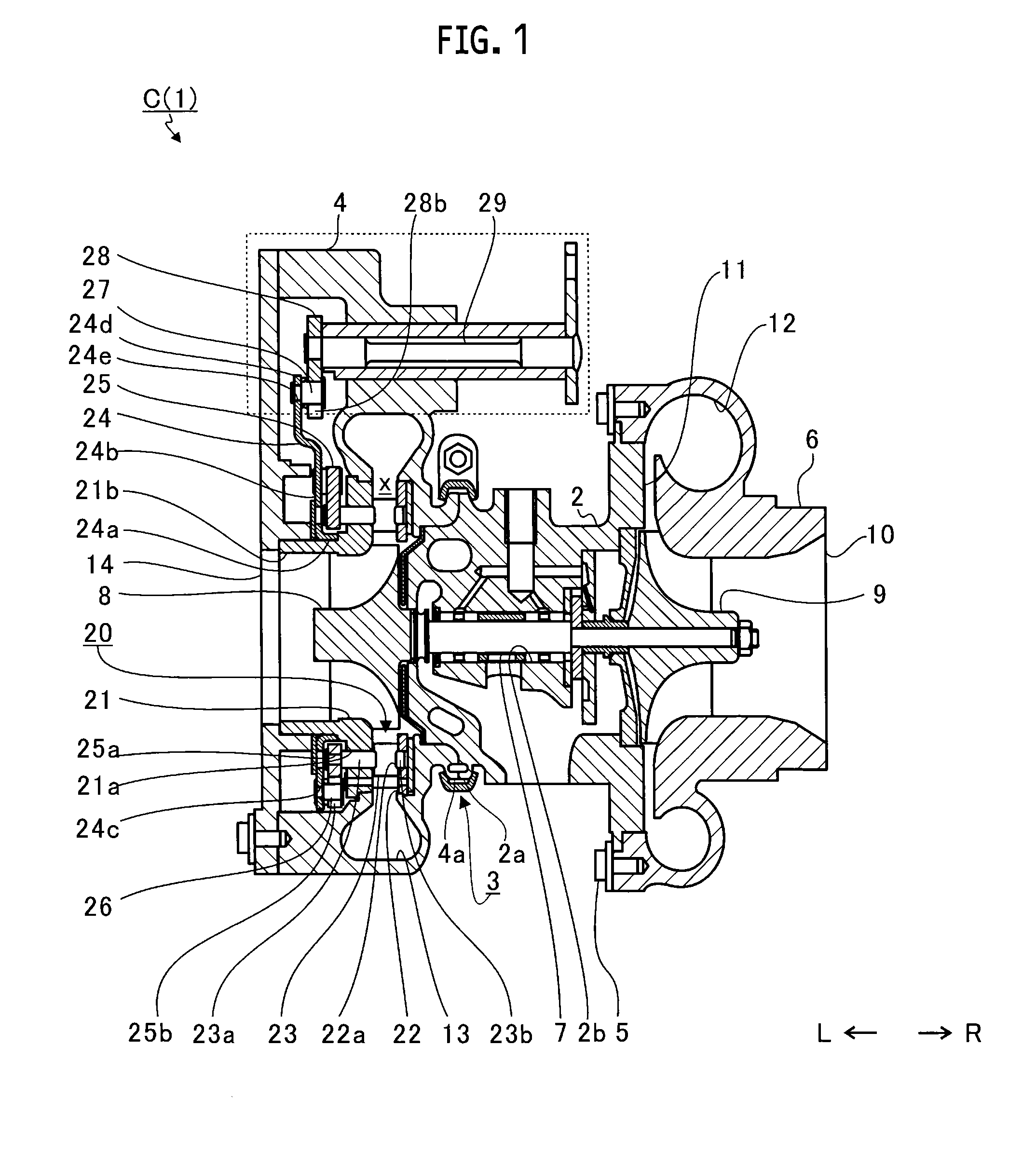

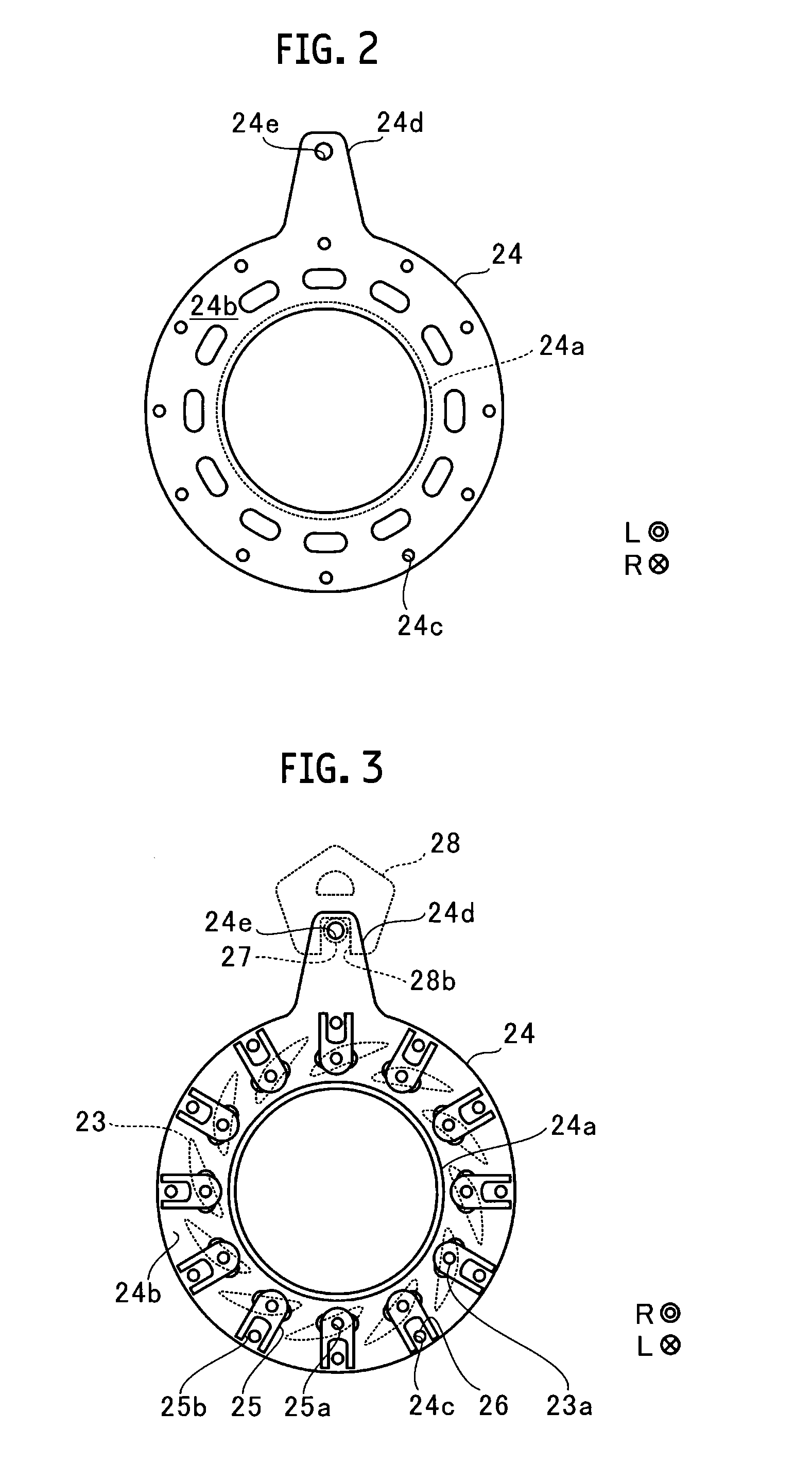

Bearing structure and turbocharger

ActiveUS20150184541A1Inhibiting bearing surface of bearingPrecise maintenancePump componentsShaftsTurbochargerBearing surface

A shaft includes: two large-diameter portions; and a small-diameter portion formed between the two large-diameter portions. A bearing includes: an annular body in which to insert the shaft; two bearing surfaces being opposite the large-diameter portions; and an intervening surface located between the two bearing surfaces on an inner circumferential surface of the body, and being opposite the small-diameter portion with a clearance formed between the intervening surface and the small-diameter portion. No anti-corrosion treatment is applied to the large-diameter portions. An anti-corrosion treatment is applied to at least any one of: an exposed portion of an outer peripheral surface of the body of the bearing, which is exposed to the outside of the housing; the intervening surface of the bearing; an opposite end surface of the bearing; and the small-diameter portion of the shaft.

Owner:IHI CORP

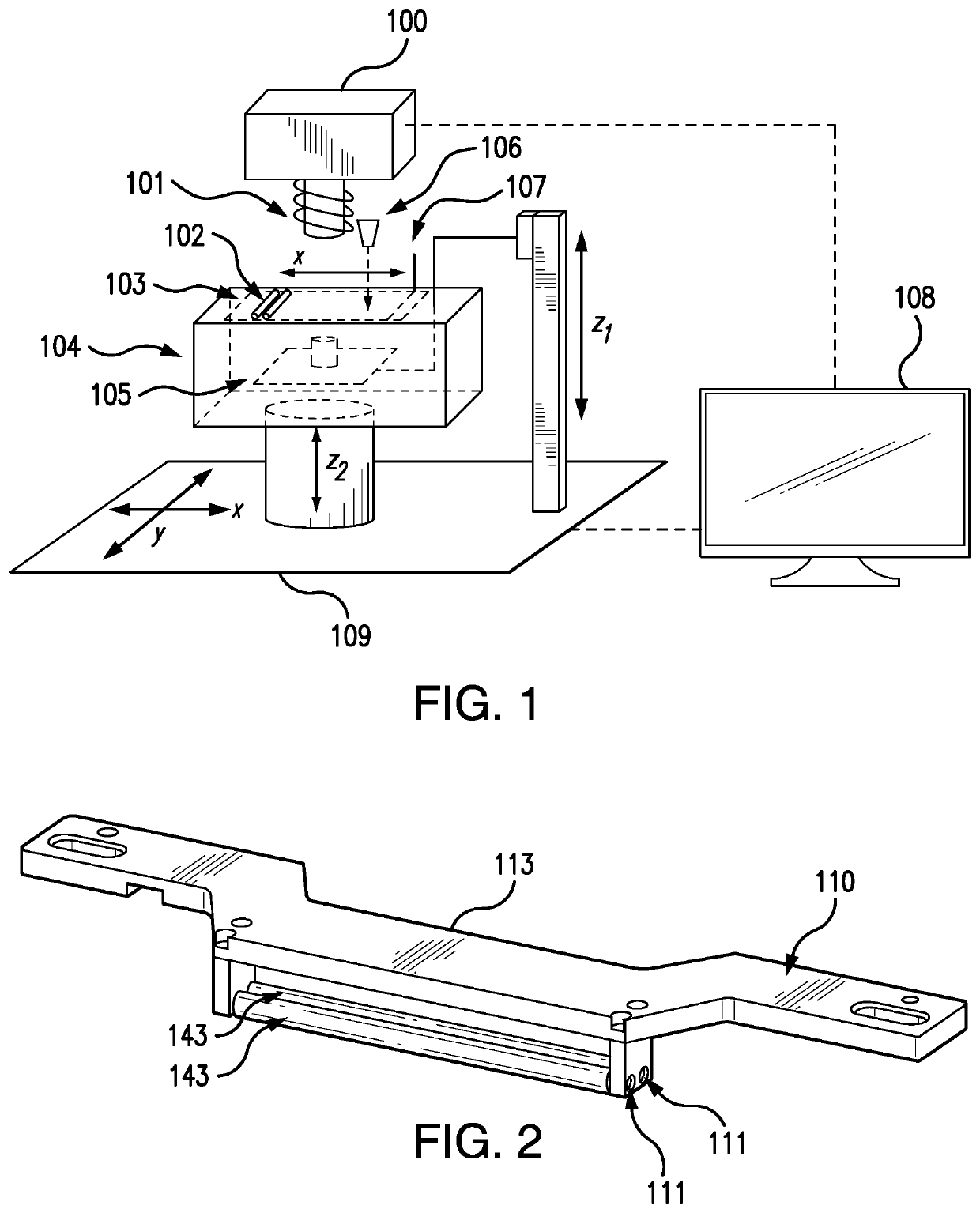

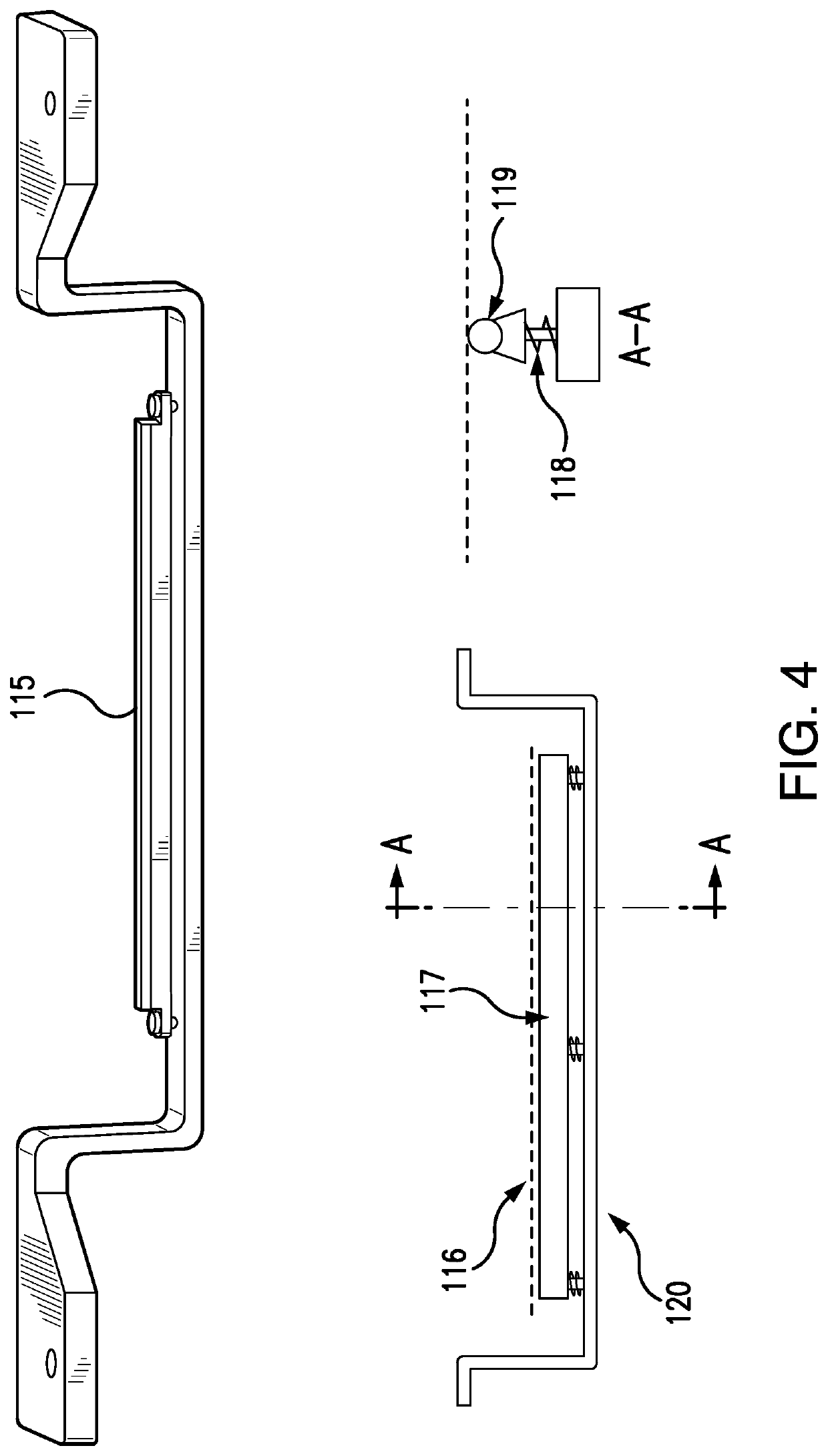

Roller-membrane layering micro stereolithography

PendingUS20210299952A1Improve accuracyIncrease speedManufacturing platforms/substrates3D object support structuresStereolithographiesEngineering

The speed and control over layer thickness in multi-layer 3-D printing is enhanced when producing a sample layer by projecting an image of the layer from light engine onto an optically clear membrane in contact with a printing material to prepare a sample layer in contact with the membrane, followed by moving the sample away from the membrane to separate the two, then moving the sample back toward the membrane to a point where the distance between the membrane and sample, as measured by a laser displacement sensor, is equal to the thickness of the next layer. While the sample moves back toward the membrane a dual-roller spreader or rotary roller spreader oscillates on the membrane to simultaneously to drive away printing material and flatten the membrane. A bubble scrapper is employed to remove bubbles from the printing material as they form.

Owner:BMF NANO MATERIAL TECH CO LTD

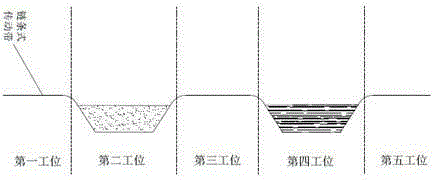

Heat treatment method of special-shaped forging

InactiveCN105177267AEvenly heatedMaintain dimensional accuracyFurnace typesHeat treatment bathsFree coolingHeat treated

The invention relates to a heat treatment method of special-shaped forgings, which comprises the following steps: S1: after discharging the special-shaped forgings, putting the special-shaped forgings on a conveyer at equal intervals, conveying the special-shaped forgings to a first station by the conveyer, and heating; S2: after heating the special-shaped forgings, conveying to a second station by the conveyer, and quenching in a cold bath salt for 2-5 minutes; S3: conveying the special-shaped forgings to a third station by the conveyer, and naturally cooling in the third station; S4: conveying the special-shaped forgings to a fourth station by the conveyer, cleaning and airing; and S5: conveying the special-shaped forgings to a fifth station by the conveyer, and carrying out tempering. All the stations are connected together by the conveyer, so that the special-shaped forgings can be conveyed to the corresponding positions at one time, thereby avoiding scalds and other hurts caused by manual operation.

Owner:JIANGSU LEAP MACHINE

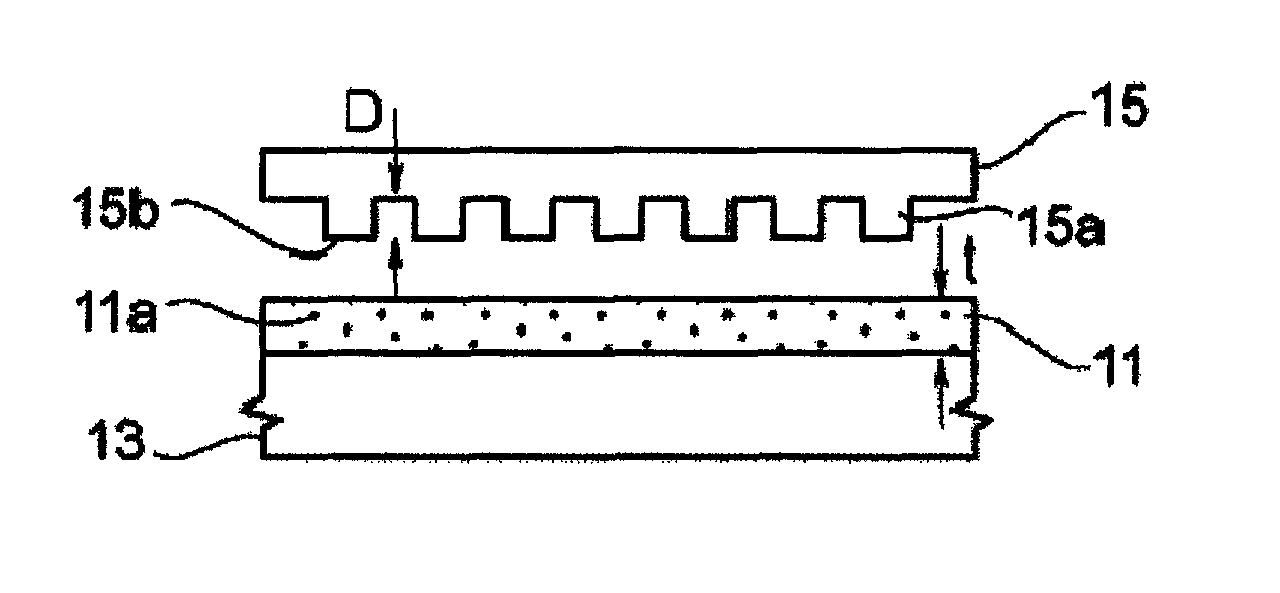

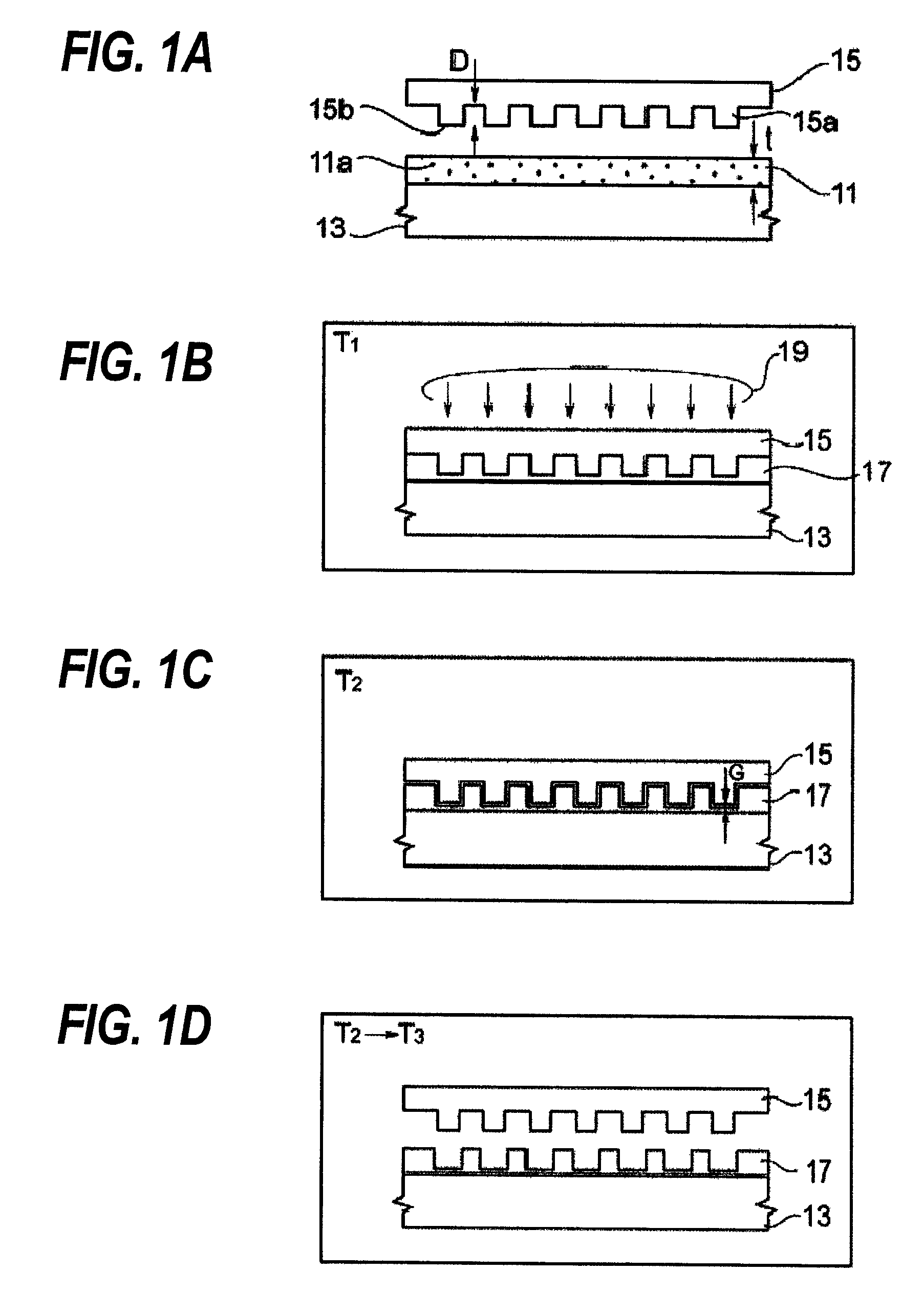

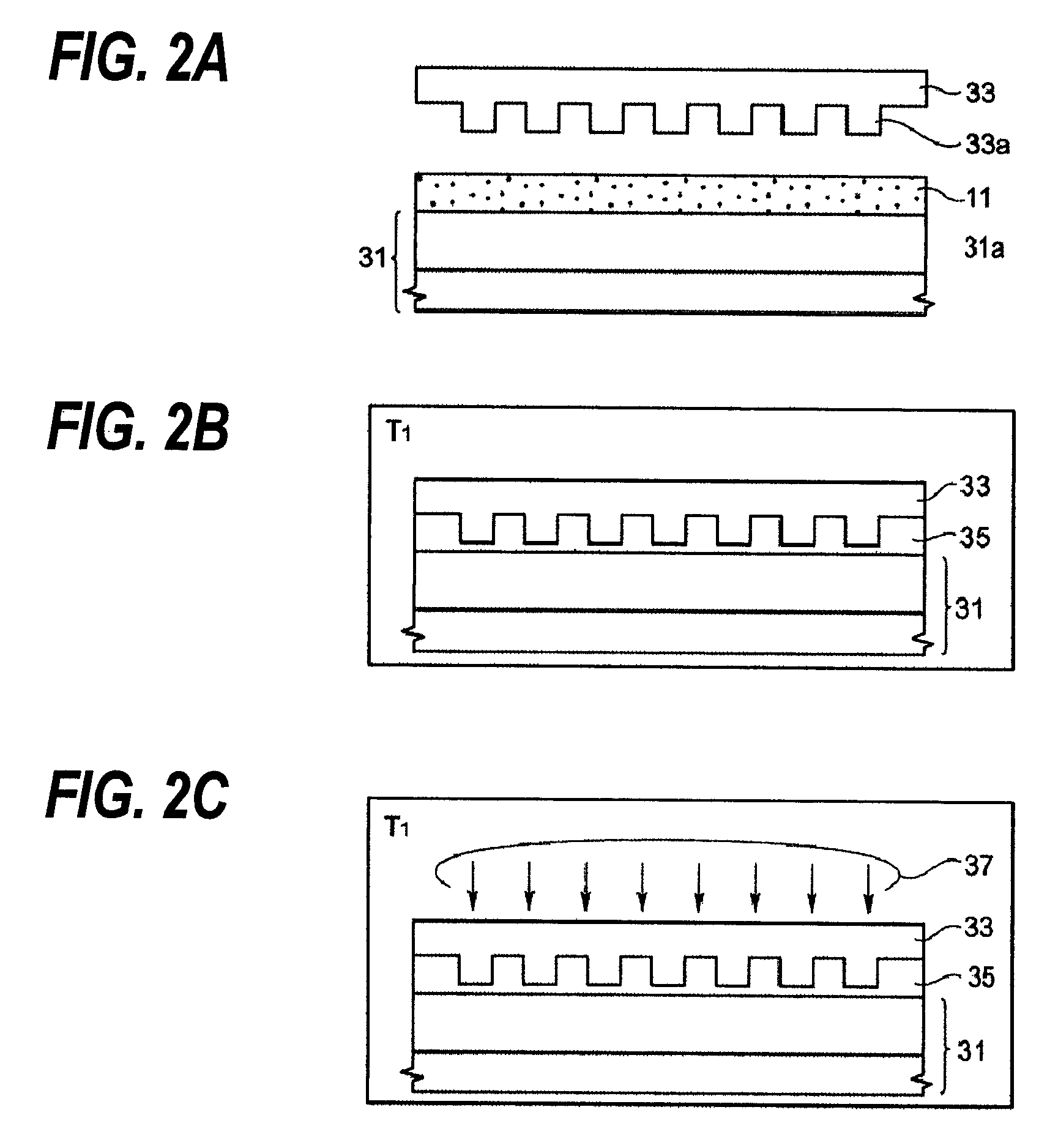

Method for transcribing patterns on resin body, method for manufacturing planar waveguide, and method for manufacturing micro-lens

ActiveUS8241535B2Improve the immunityDimensional accuracy of the pattern may be maintainedMaterial nanotechnologyNanoinformaticsUV curingUltraviolet

The present invention is to provide a method for manufacturing a planar optical waveguide and a micro-lens using a transcribed resin formed by the optical nano-imprint technique. The method includes a step for forming a resin contained with ultraviolet curable materials on the substrate. The mold is pressed against the resin. This step forms a patterned resin that reflects the pattern formed in the mold. After hardening the resin by irradiating the ultraviolet rays, the resin is cooled down as the mold is pressed against the resin from the temperature T1, where the mold is pressed, to T2 below T1. After cooling down the temperature of the resin, the mold is detached to complete the resin with the pattern transcribed from the mold.

Owner:SUMITOMO ELECTRIC IND LTD

Helical spline forming

ActiveUS20140007638A1Minimize stress concentrationAvoid damageGear wheelsMetal rolling arrangementsThrust bearingEngineering

A flow-forming machine and method for forming a final part having helical splines. The flow forming machine is provided with a stripper plate for removing the final part having the helical splines therein from the mandrel and a thrust bearing is located between the stripper plate and the final part during stripping of the final part from the mandrel to allow relative motion between the stripper plate and the final part to successfully strip the final part from the mandrel without damaging and while maintaining the integrity of the helical splines of the final part. The ejector driver and mandrel may be rotated in either direction to help in successfully stripping the final part from the mandrel.

Owner:MAGNA POWERTRIAN INC (US)

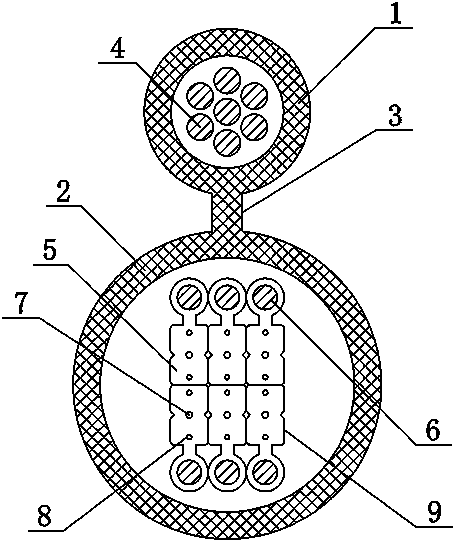

Self-supporting easy-branched butterfly-shape optical cable

InactiveCN103353651AStrong self-supporting strengthImprove laying effectFibre mechanical structuresUltimate tensile strengthMechanical property

The invention relates to a self-supporting easy-branched butterfly-shape optical cable. The optical cable comprises an outer sheath (2), a suspension wire sheath (1), a suspension wire (4) and self-supporting butterfly-shape optical cable units (9). The outer sheath (2) and the suspension wire sheath (1) are a circular structure. The outer sheath (2) and the suspension wire sheath (1) are connected through a connection portion (3). The suspension wire (4) is arranged in the suspension wire sheath (1). The plurality of self-supporting butterfly-shape optical cable units (9) are arranged in the outer sheath (2). Each self-supporting butterfly-shape optical cable unit (9) comprises a butterfly sheath (5), a self-supporting suspension wire (6) and an optical fiber (7). The self-supporting suspension wire (6) wraps a head of the butterfly sheath (5). The optical fiber (7) is arranged on a middle portion of the butterfly sheath (5). The optical cable of the invention has the advantages that the outer sheath and the butterfly sheath are provided with the suspension wire so that self-supporting intensity is high; overhead laying cost is low, operation is convenient and labor intensity is low; branch usage is convenient; the cable after laying is under uniform stress so that optical cable machinery performance can be improved.

Owner:成都亨通光通信有限公司

Colored stainless steel based on ion implantation and preparation method thereof

InactiveCN102021525BThe process steps are simpleProcess environment is cleanVacuum evaporation coatingSputtering coatingRoom temperatureHardness

The invention relates to a colored stainless steel based on ion implantation and a preparation method thereof. The technical scheme is as follows: placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel to obtain the colored stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 1*10<17>-1*10<19> ions / cm<2>; or placing a stainless steel to be colored in a vacuum chamber of an ion implantation apparatus, vacuumizing to 0.1-1*10<-5>Pa, and implanting ions on the surface of the stainless steel, wherein the accelerating voltage for ion implantation is 10-100kV, and the ion implantation amount is 5*10<15>-5*10<19> ions / cm<2>; and taking out, carrying out heat treatment, and cooling to room temperature in the furnace to obtain the colored stainless steel. The invention has the advantages of simple process and clean environment, and the obtained colored stainless steel has the characteristics of multiple color varieties, high reproducibility, uniform color, beautiful appearance, high durability and no separation. Compared with the stainless steel prior to preparation, the surface hardness and the corrosion resistance are obviously improved.

Owner:WUHAN UNIV OF SCI & TECH

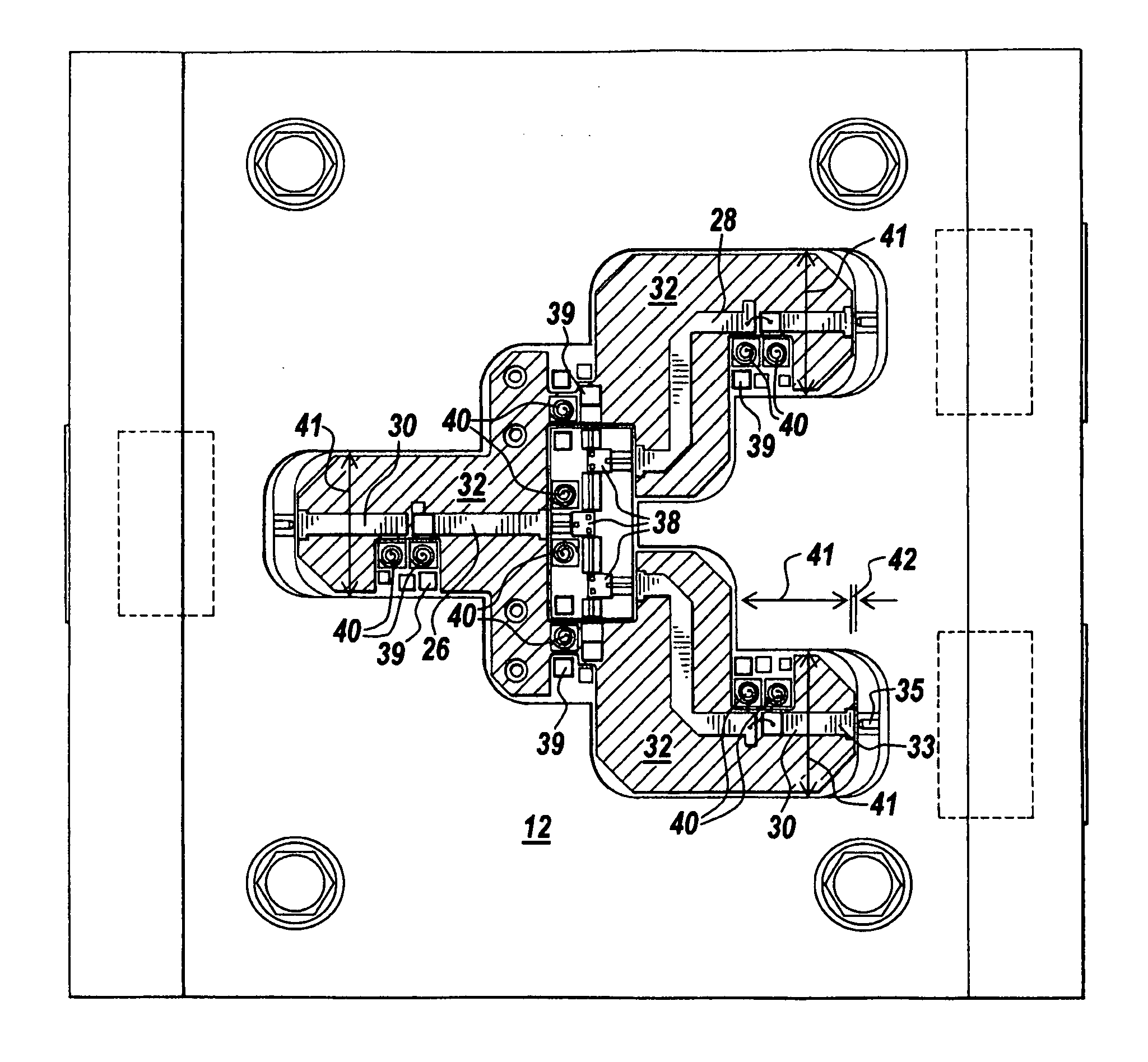

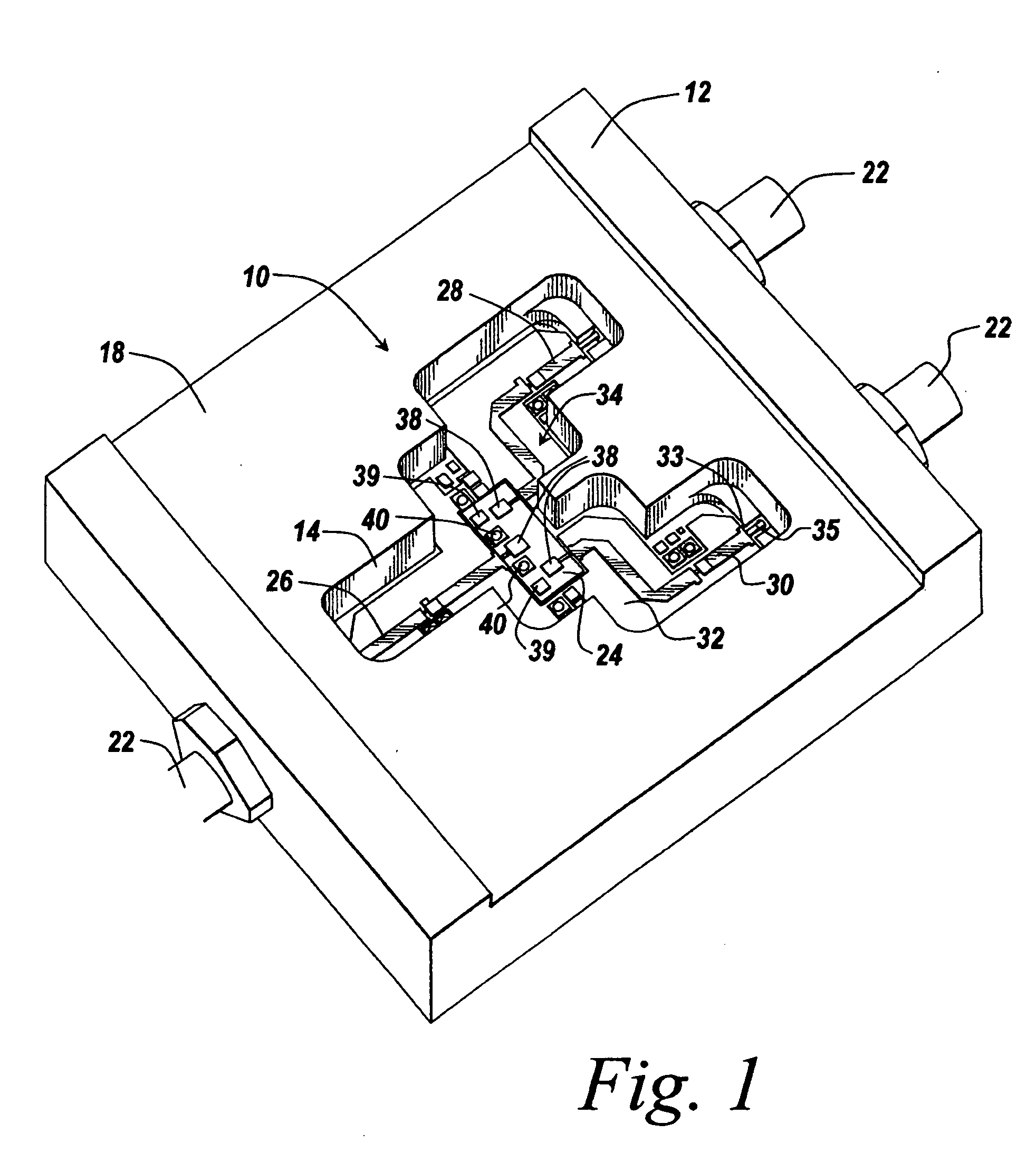

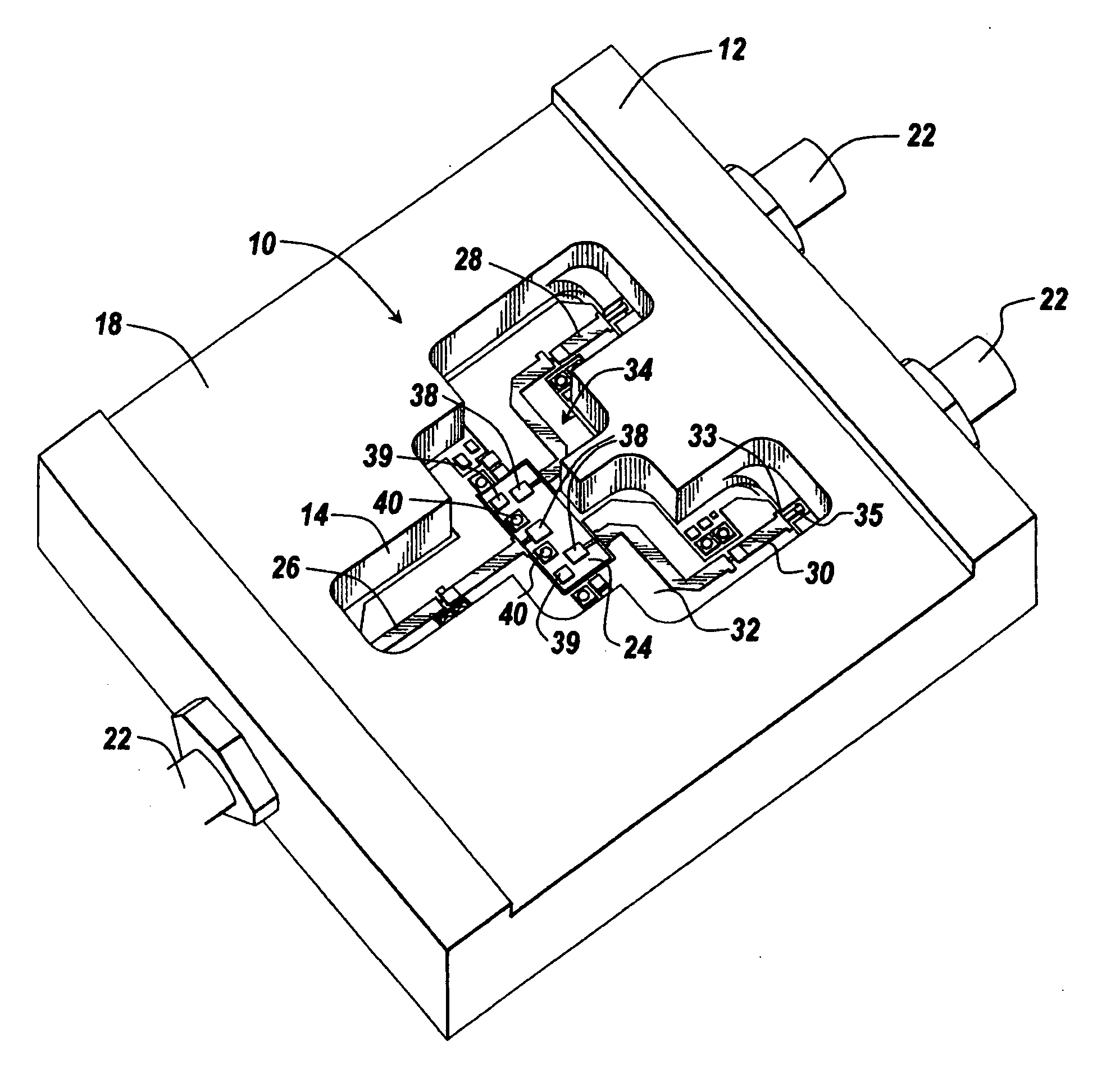

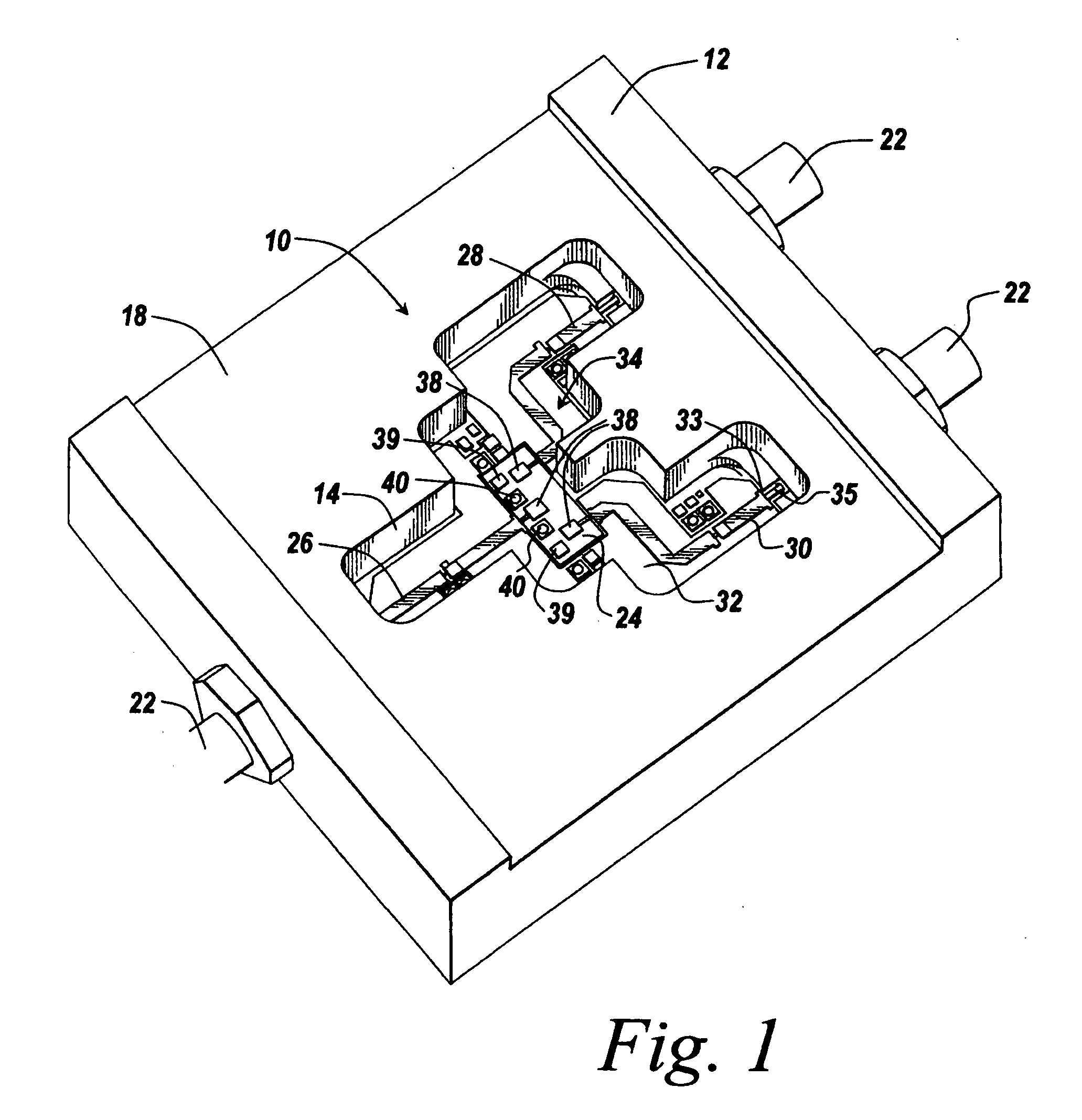

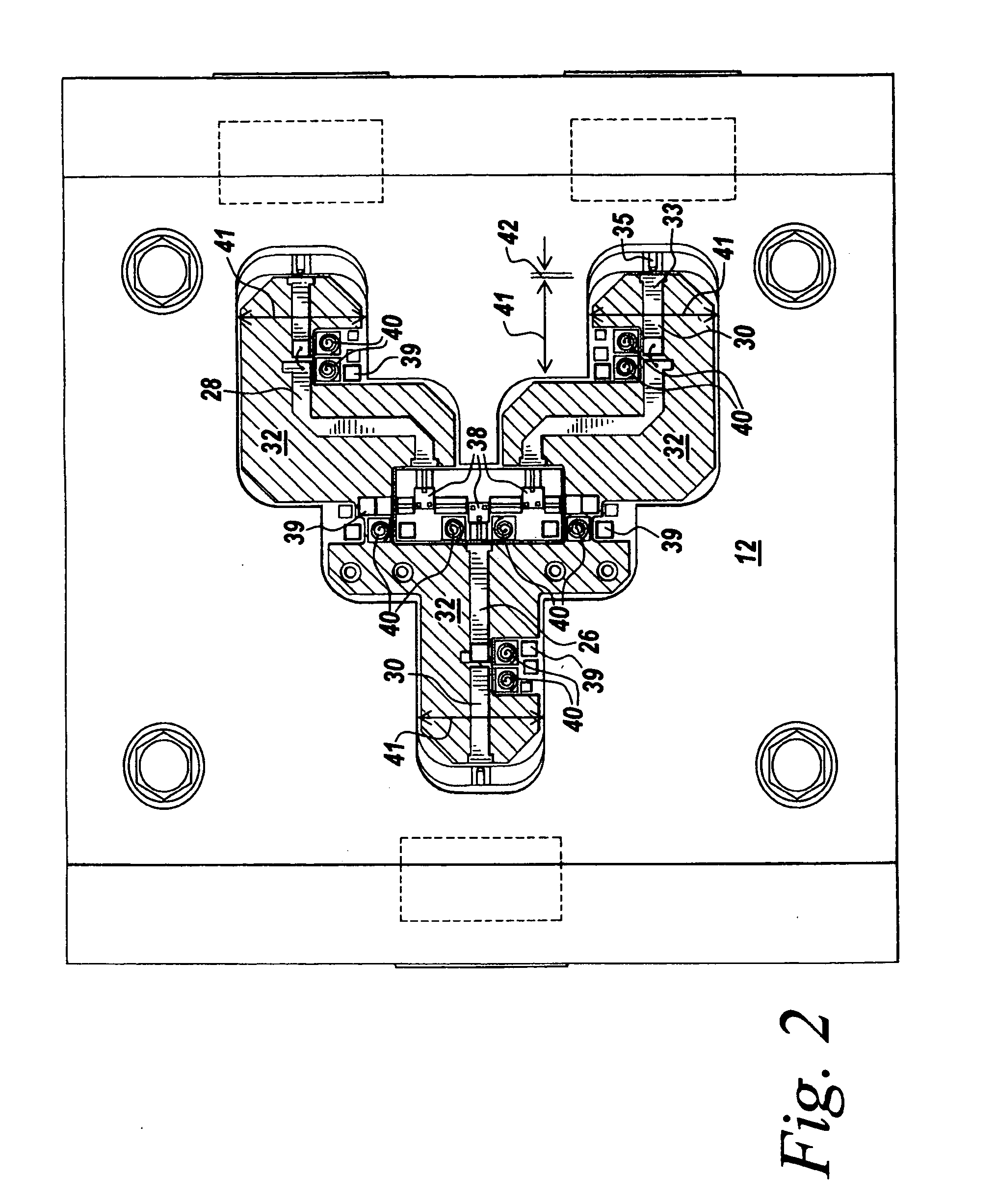

Method and apparatus for rapid prototyping of monolithic microwave integrated circuits

InactiveUS20050190009A1Circuit losses are minimizedMaintain dimensional accuracyAdditive manufacturing apparatusAmplifiers wit coupling networksAdhesiveRapid prototyping

A system is provided for rapidly prototyping monolithic microwave integrated circuit modules to provide an experimental structure that can be physically made to operate by stereolithographically rendering an SLA part directly from the designer's drawings and by coating the part with a conductive layer, with the smoothness being better than 0.001 inch and with the dimensional accuracy being better than 3 mils for some applications. In one embodiment, the coating for the SLA model is made from either rhodium or gold having a thickness of less than 1 / 10,000th of an inch, with a nickel barrier being first deposited followed by the gold. The particular SLA plastic is a high temperature plastic to prevent bubbling during the metal deposition step which in one embodiment involves sputtering. The coated model has a microfinish of Ra<0.001 inch, with active devices being electrically attached to the coating through the use of conductive adhesives or eutectic solder. This provides a device in which active devices are attached to the layer without soldering and without introduction of heat which might destroy the metallized layer and alter and the critical dimensions.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Heat treatment method of special-shaped forgings

InactiveCN109182709AGuaranteed mechanical propertiesImprove surface qualityFurnace typesQuenching agentsMechanical componentsRoom temperature

The invention discloses a heat treatment method of special-shaped forgings. The heat treatment method of the special-shaped forgings comprises the following specific steps: (1) the special-shaped forgings are discharged from a furnace for air cooling to reach the room temperature, and then, are placed on a transfer device; (2) the special-shaped forgings are conveyed to a first station by the transfer device for primary heating; (3) the special-shaped forgings obtained in the step (2) are secondarily heated continuously; (4) the special-shaped forgings obtained in the step (3) are conveyed toa second station for quenching by the transfer device; and after quenching, the special-shaped forgings are taken out for air cooling; (5) the special-shaped forgings are conveyed to a third station for tempering by the transfer device; (6) the special-shaped forgings obtained in the step (5) are conveyed to a fourth station for water cooling by the transfer device; and (7) the cooled special-shaped forgings are conveyed to a fifth station by the transfer device for blow cooling and air cooling to reach the room temperature. The method can improve the rigidity, the hardness, the wear resistance, the fatigue strength and the toughness of steel to the greatest extent to meet different use requirements of various mechanical parts and tools.

Owner:JIANGSU LEAP MACHINE

Method of manufacturing flow channel substrate for liquid ejection head

InactiveUS20100101087A1Good air bubble removal propertyMaintain dimensional accuracyWriting implementsMetal-working apparatusLiquid jetEngineering

Owner:FUJIFILM CORP

Method and apparatus for rapid prototyping of monolithic microwave integrated circuits

InactiveUS20050253666A1Circuit losses are minimizedMaintain dimensional accuracyAdditive manufacturing apparatusCoupling devicesAdhesiveRapid prototyping

A system is provided for rapidly prototyping monolithic microwave integrated circuit modules to provide an experimental structure that can be physically made to operate by stereolithographically rendering an SLA part directly from the designer's drawings and by coating the part with a conductive layer, with the smoothness being better than 0.001 inch and with the dimensional accuracy being better than 3 mils for some applications. In one embodiment, the coating for the SLA model is made from either rhodium or gold having a thickness of less than 1 / 10,000th of an inch, with a nickel barrier being first deposited followed by the gold. The particular SLA plastic is a high temperature plastic to prevent bubbling during the metal deposition step which in one embodiment involves sputtering. The coated model has a microfinish of Ra<0.001 inch, with active devices being electrically attached to the coating through the use of conductive adhesives or eutectic solder. This provides a device in which active devices are attached to the layer without soldering and without introduction of heat which might destroy the metallized layer and alter and the critical dimensions.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

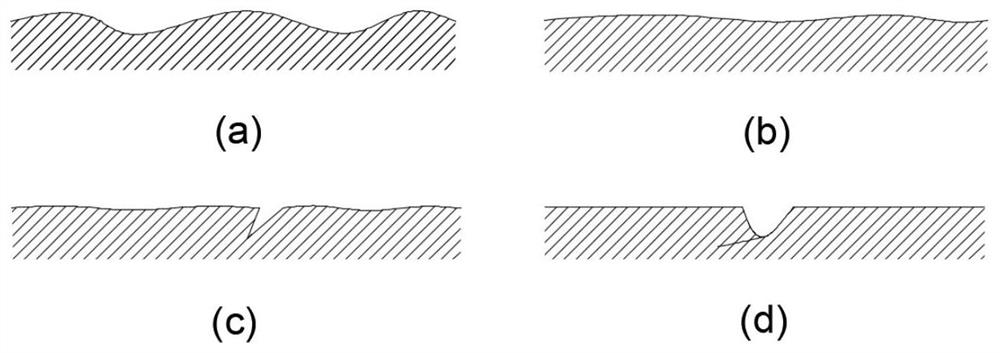

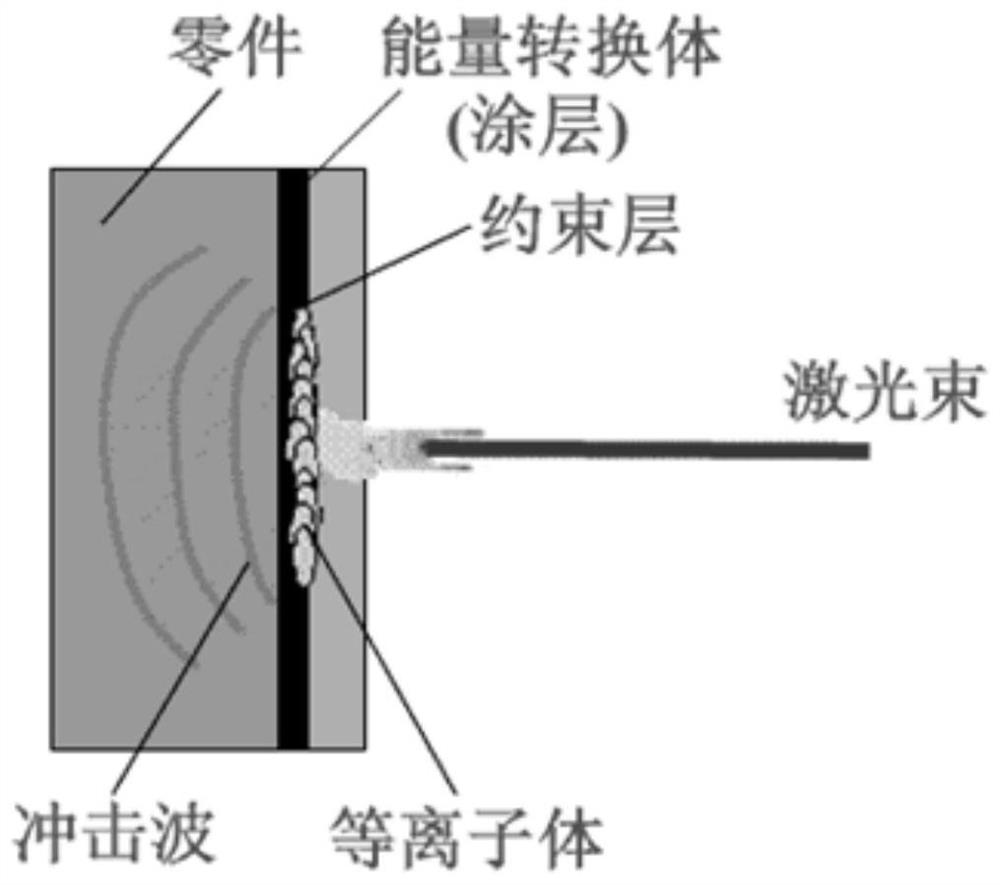

Method for repairing micro-contact fatigue damage of tooth surface and repairing device

ActiveCN113523708AImprove mechanical propertiesAddress process complexityProcess efficiency improvementLaser beam welding apparatusControl systemMonitoring system

The invention discloses a method for repairing micro-contact fatigue damage of a tooth surface and a repairing device. The method comprises the following steps that a to-be-repaired gear is fixed on a motion platform through a clamp; geometrical morphology characteristics of a to-be-repaired area are measured by using a three-dimensional morphology instrument, collected information is input to a comprehensive control and monitoring system, and material and mechanical characteristics of the to-be-repaired gear are compared through a database to determine optimal laser shock repair process parameters; the optimal process parameters are imported into a pulse laser generator, the laser generator emits laser according to the optimal process parameter scheme, and laser beams are exported through a light path regulation and control system and a light path system; meanwhile, a water restraint layer system controls a water nozzle to form a water restraint layer on the tooth surface; and the laser acts on the to-be-repaired area on the tooth surface, so that the gear generates the required reinforced repair effect, and the purpose of repairing the tooth surface damage is achieved. The problems that in a traditional repairing mode, the process is complex, roughness is high, abrasion resistance is poor, and the gear can be repaired only after obvious defects or faults occur to the gear are solved.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com