Sewing machine

A sewing machine and machine frame technology, applied to sewing machine components, sewing machine needle holders, sewing equipment, etc., can solve the problems of rapid wear of inclined grooves and guide pins, lack of durability, and chaotic meeting time of sewing needles 7, etc., and achieve improvement The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

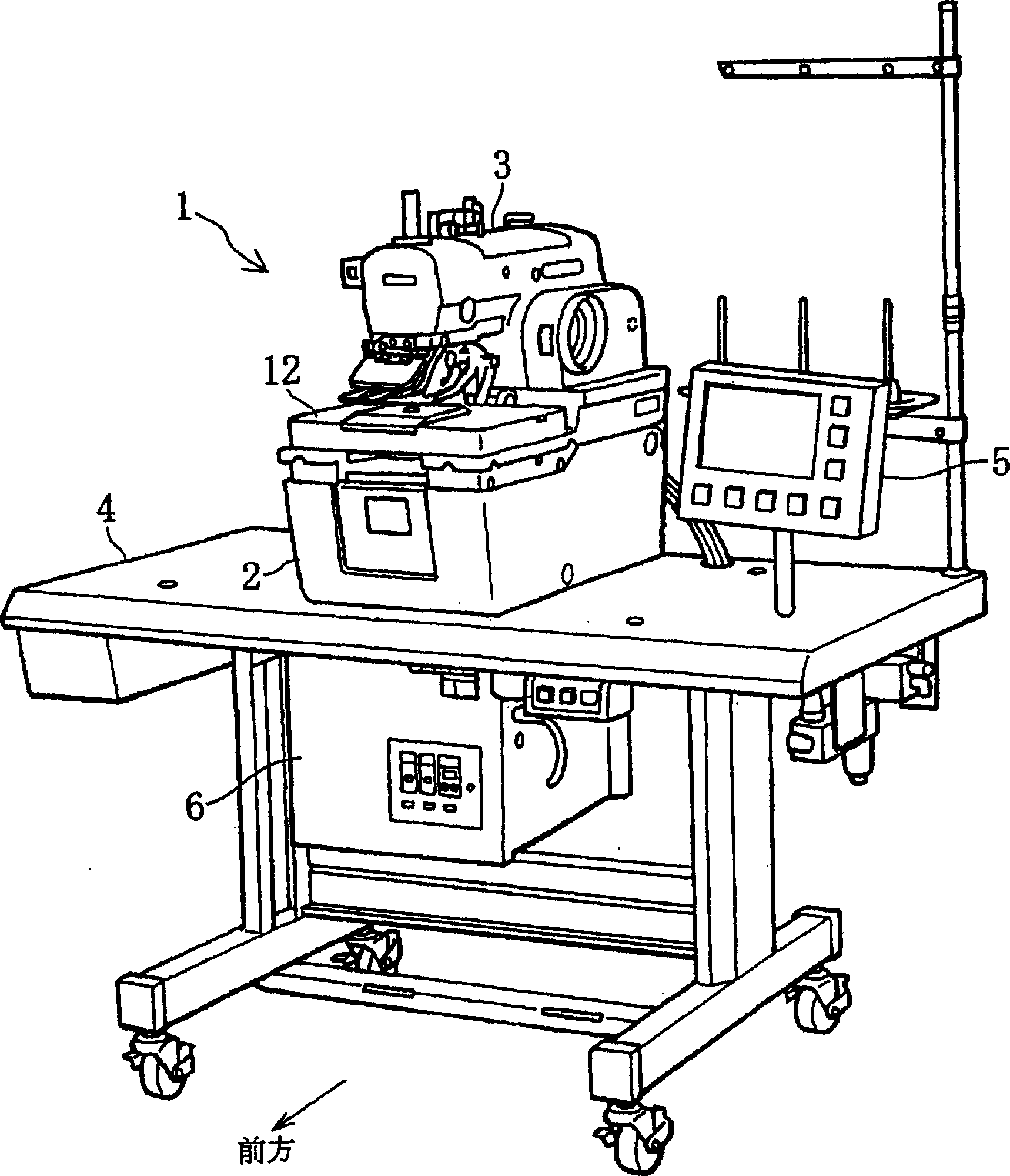

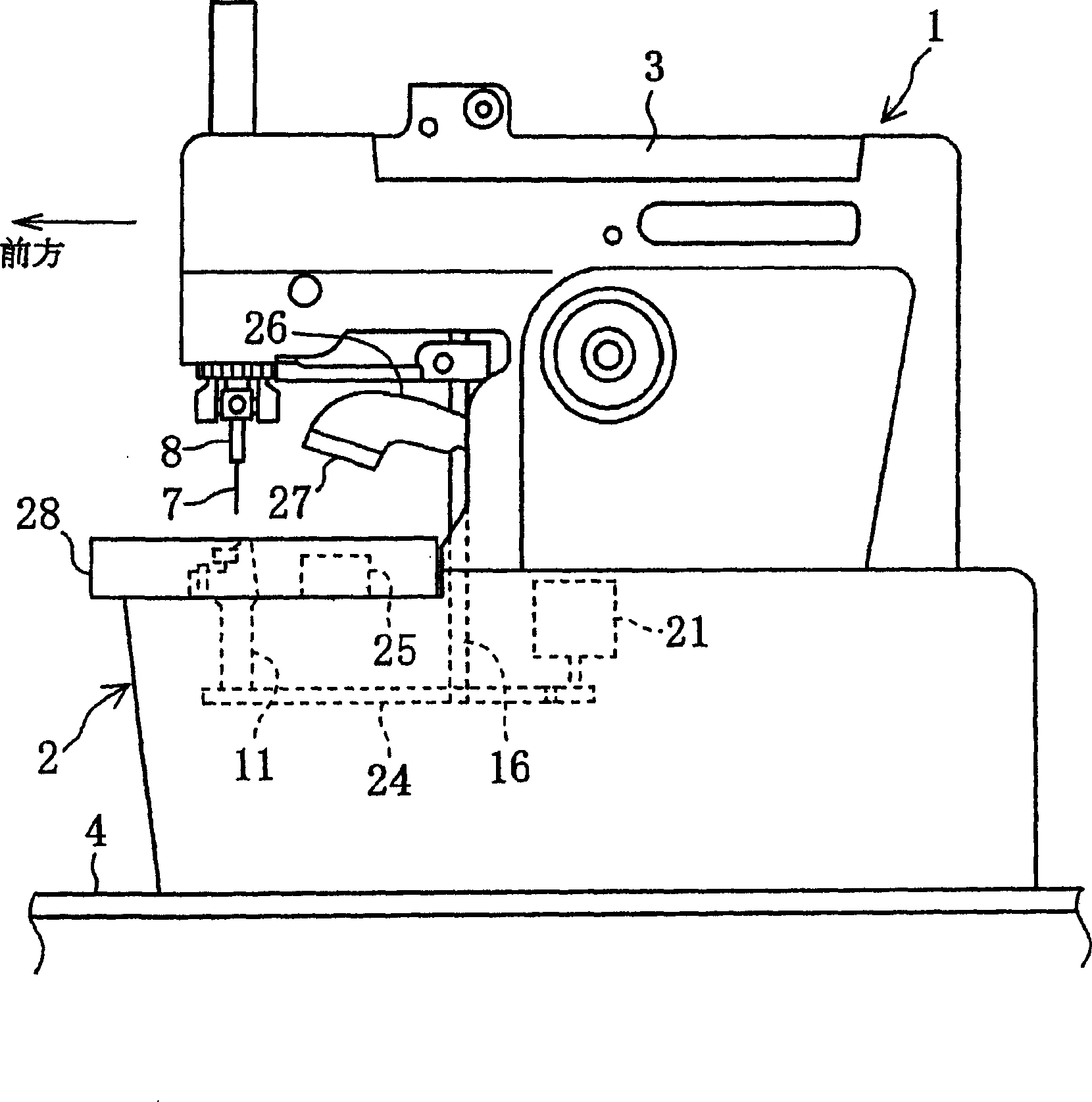

[0033] like figure 1 , figure 2 As shown, the electronic buttonhole sewing machine 1 is configured to integrally have an arm portion 3 extending continuously forward from the upper rear portion of the base portion 2 on a base portion 2 having a substantially rectangular box shape, and the electronic The buttonhole sewing machine 1 is placed on the table 4 . An operation panel 5 is provided on the upper side of the platen 4 for instructing various operations such as selecting one of a variety of round buttonhole stitches. On the lower side of the platen 4, a control device 6 composed of a microcomputer for controlling the operation of each mechanism is provided.

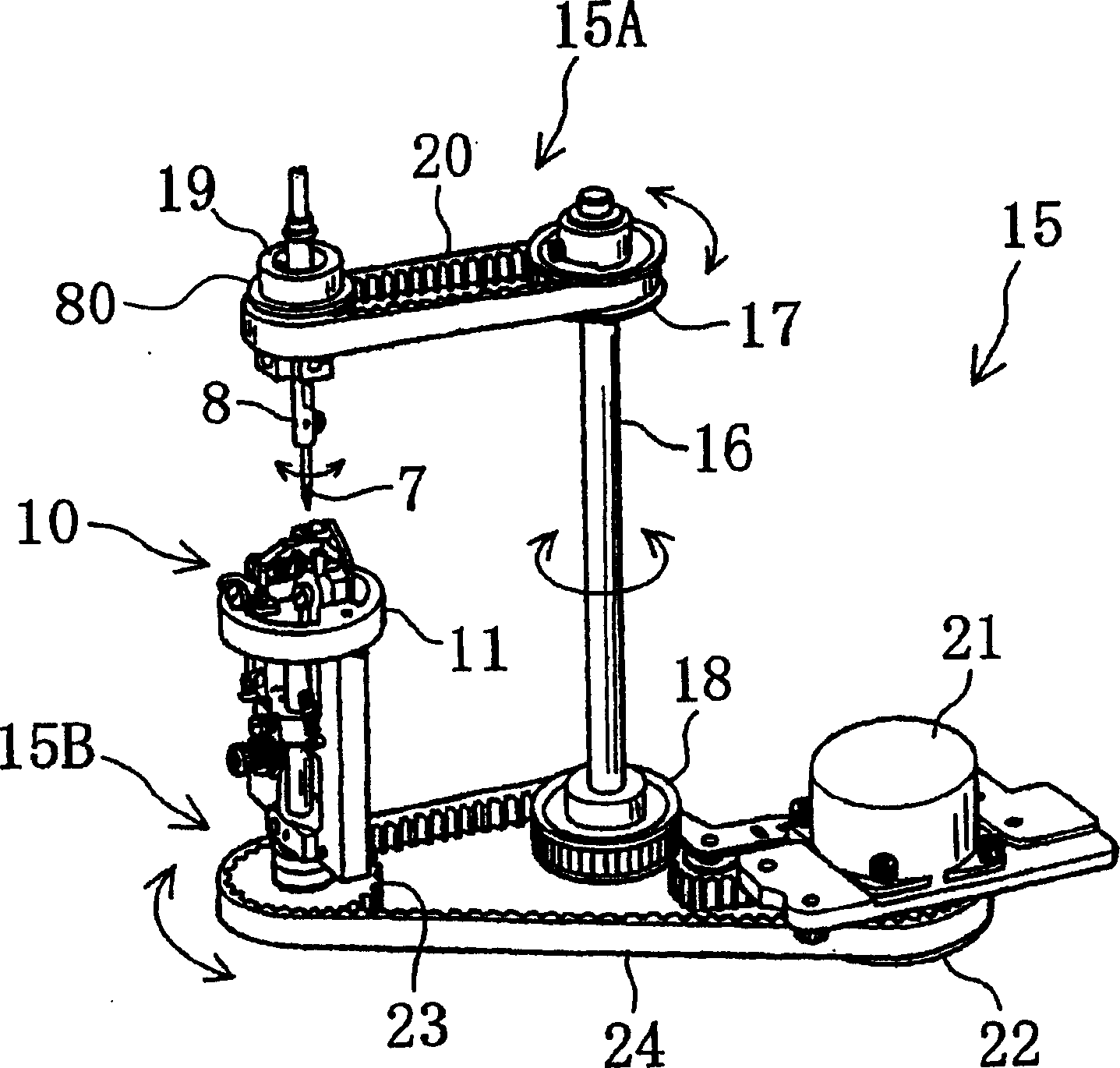

[0034] A hollow (tubular) needle bar 8 is provided at the front end of the arm portion 3. The needle bar 8 can be moved up and down by a needle bar vertical movement mechanism 30 to be described later. A sewing needle 7 is attached to the lower end of the needle bar 8. The needle bar 8 can be swung left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com