Method for improving biomimetic mineralization capacity of surface of titanium alloy implant

A biomimetic mineralization, titanium alloy technology, applied in the direction of prosthesis, pharmaceutical formulation, drug delivery, etc., can solve the problem of not obtaining a nanometer surface layer, and achieve the effect of easily controlling repeatability, maintaining dimensional accuracy and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for improving the biomimetic mineralization ability of the titanium alloy implant surface, the specific steps are:

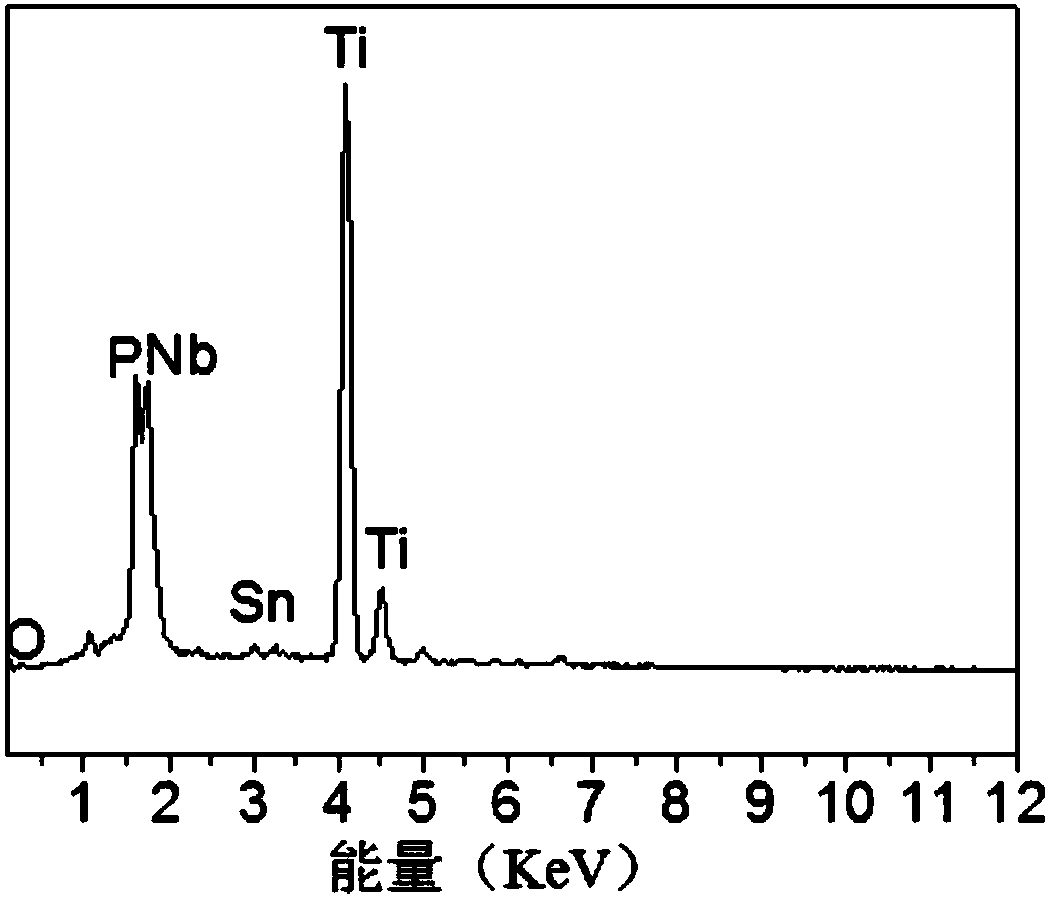

[0039] The sample is the TLM titanium alloy hot-rolled plate after vacuum smelting. The hot-rolled plate is cut into discs with a diameter of 100 mm and a thickness of 5 mm. #, 1200# water sandpaper grinding, surface polishing, ultrasonic cleaning with acetone and deionized water, drying, using the SNC-I type metal material surface nanometer test jointly manufactured by the Institute of Metal Research, Chinese Academy of Sciences and Chengdu New Crystal Technology Co., Ltd. The above-mentioned polished TLM wafers were SMAT treated by the machine. The treatment process was carried out under normal temperature and pressure. The impact balls used 50 GCr15 steel balls with a diameter of 5mm, the working frequency was 200Hz, and the vacuum was pumped to 3 As the ion source, the P ions used are selected by a symmetrical double-f...

Embodiment 2

[0052] This embodiment provides a method for improving the biomimetic mineralization ability of the titanium alloy implant surface, the specific steps are:

[0053] The sample is the TLM titanium alloy hot-rolled plate after vacuum smelting. The hot-rolled plate is cut into discs with a diameter of 100 mm and a thickness of 5 mm. #, 1200# water sandpaper grinding, surface polishing, ultrasonic cleaning with acetone and deionized water, drying, using the SNC-I type metal material surface nanometer test jointly manufactured by the Institute of Metal Research, Chinese Academy of Sciences and Chengdu New Crystal Technology Co., Ltd. The above-mentioned polished TLM wafers were SMAT treated by the machine. The treatment process was carried out under normal temperature and pressure. The impact balls used 50 GCr15 steel balls with a diameter of 2mm, the working frequency was 500Hz, and the vacuum was pumped to 3 As the ion source, the P ions used are selected by a symmetrical double-f...

Embodiment 3

[0055] This embodiment provides a method for improving the biomimetic mineralization ability of the titanium alloy implant surface, the specific steps are:

[0056] The sample is the TLM titanium alloy hot-rolled plate after vacuum smelting. The hot-rolled plate is cut into discs with a diameter of 100 mm and a thickness of 5 mm. #, 1200# water sandpaper grinding, surface polishing, ultrasonic cleaning with acetone and deionized water, drying, using the SNC-I type metal material surface nanometer test jointly manufactured by the Institute of Metal Research, Chinese Academy of Sciences and Chengdu New Crystal Technology Co., Ltd. The above-mentioned polished TLM wafers were SMAT treated by the machine. The treatment process was carried out under normal temperature and pressure. The impact balls used 50 GCr15 steel balls with a diameter of 8mm, the working frequency was 100Hz, and the vacuum was pumped to 17 ions / cm 2 , the injection beam density is 55μA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com