Patents

Literature

67results about How to "Won't change shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

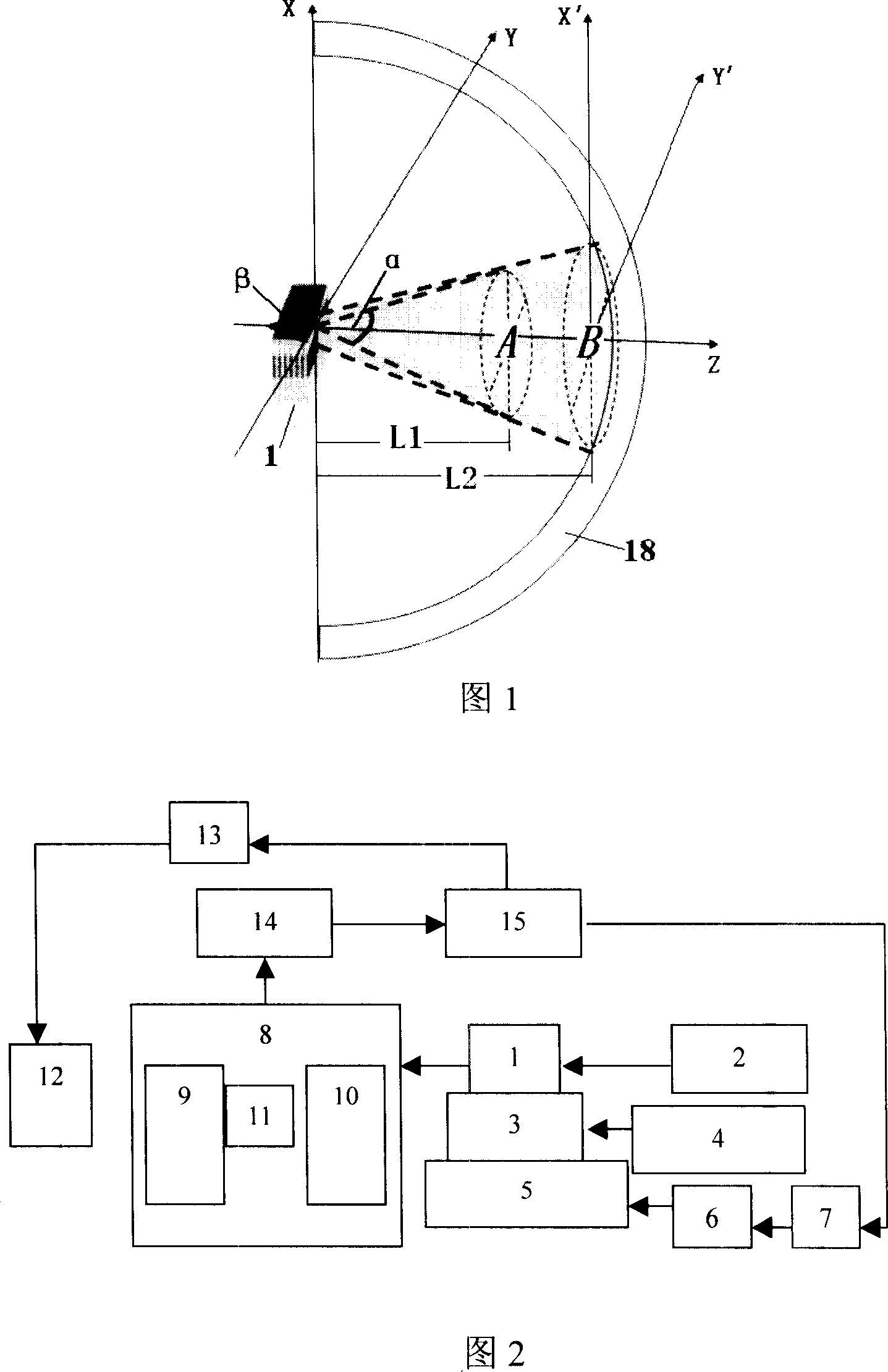

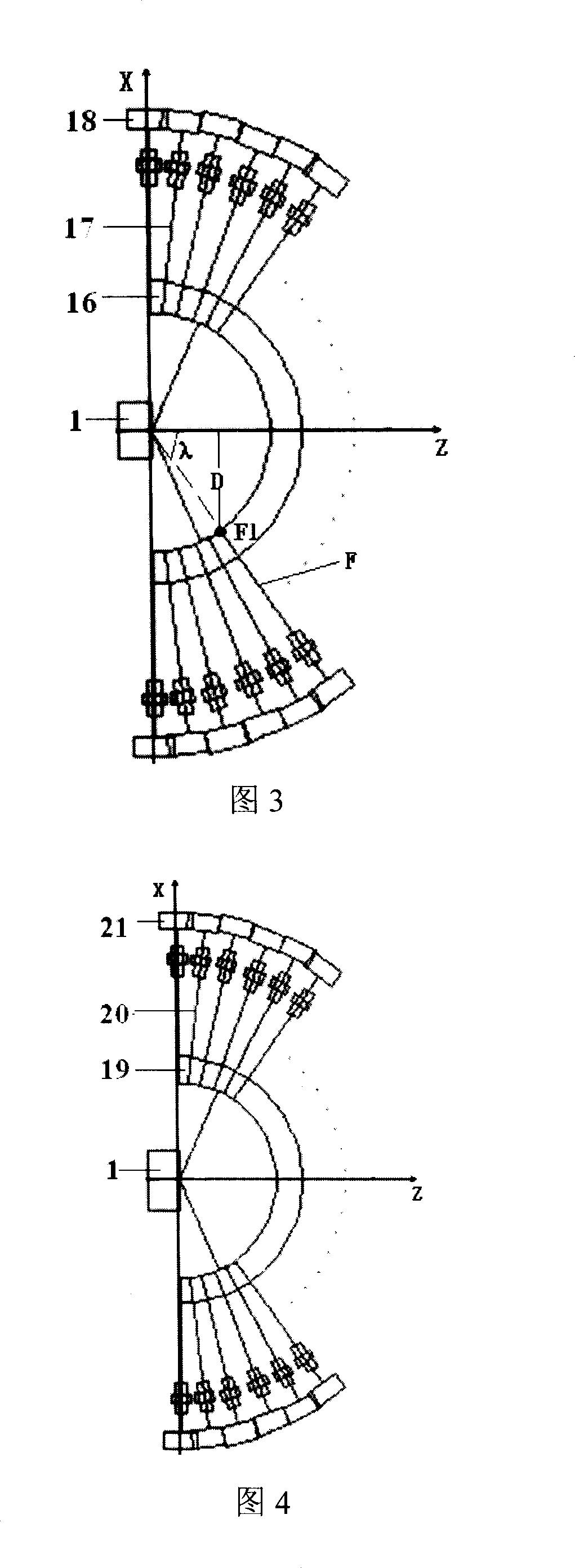

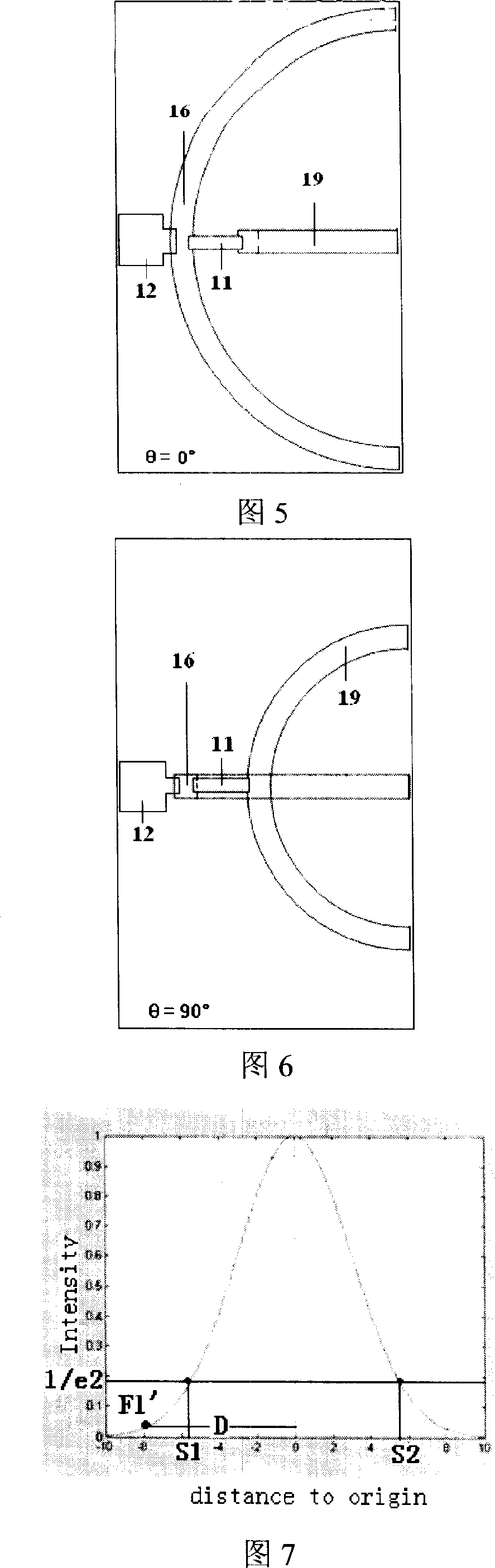

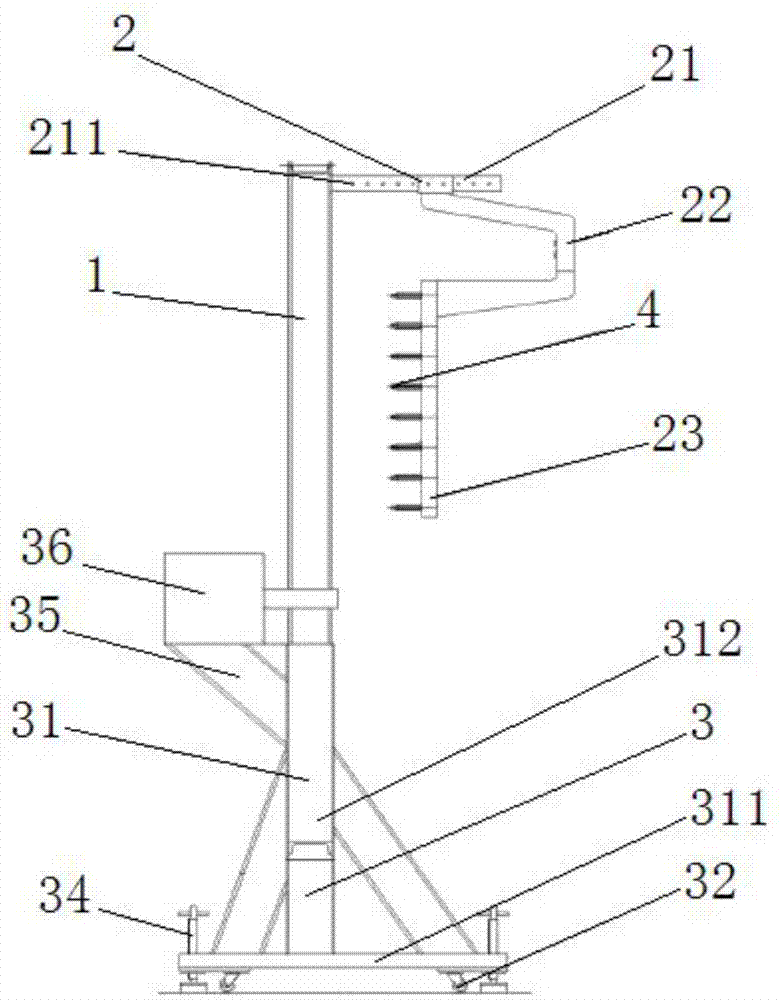

Method and its device for detecting high energy semiconductor laser divergence angle

InactiveCN101005191AAvoid test errorSolve the problem that the divergence angle of high-energy lasers cannot be testedLaser detailsSemiconductor lasersHigh energyLight spot

Using geometric characteristics of outer margin curves of two light spots at different distances along direction of beam transmission, the disclosed method obtains divergence angle of laser. Through rotational scanning detection, concentric placed two light detectors perpendicular to each other obtain outer margin curves. Multiple optical fibers are distributed on the said light detector evenly. The disclosed device is composed of drive power supply, cooling water platform, cooling water circulation system, 4D traveling platform, electrical motor set, drive, data acquisition module, and PC etc. The light-receiving module includes light detectors. The light-receiving module, data acquisition module, and PC are connected electrically. The invention solves issue of test error caused by regarding face radiation of area array laser as spot light source so as to avoid damaging and burning detector caused by too large power of laser. Advantages are: accurate and reliable.

Owner:DALIAN MARITIME UNIVERSITY

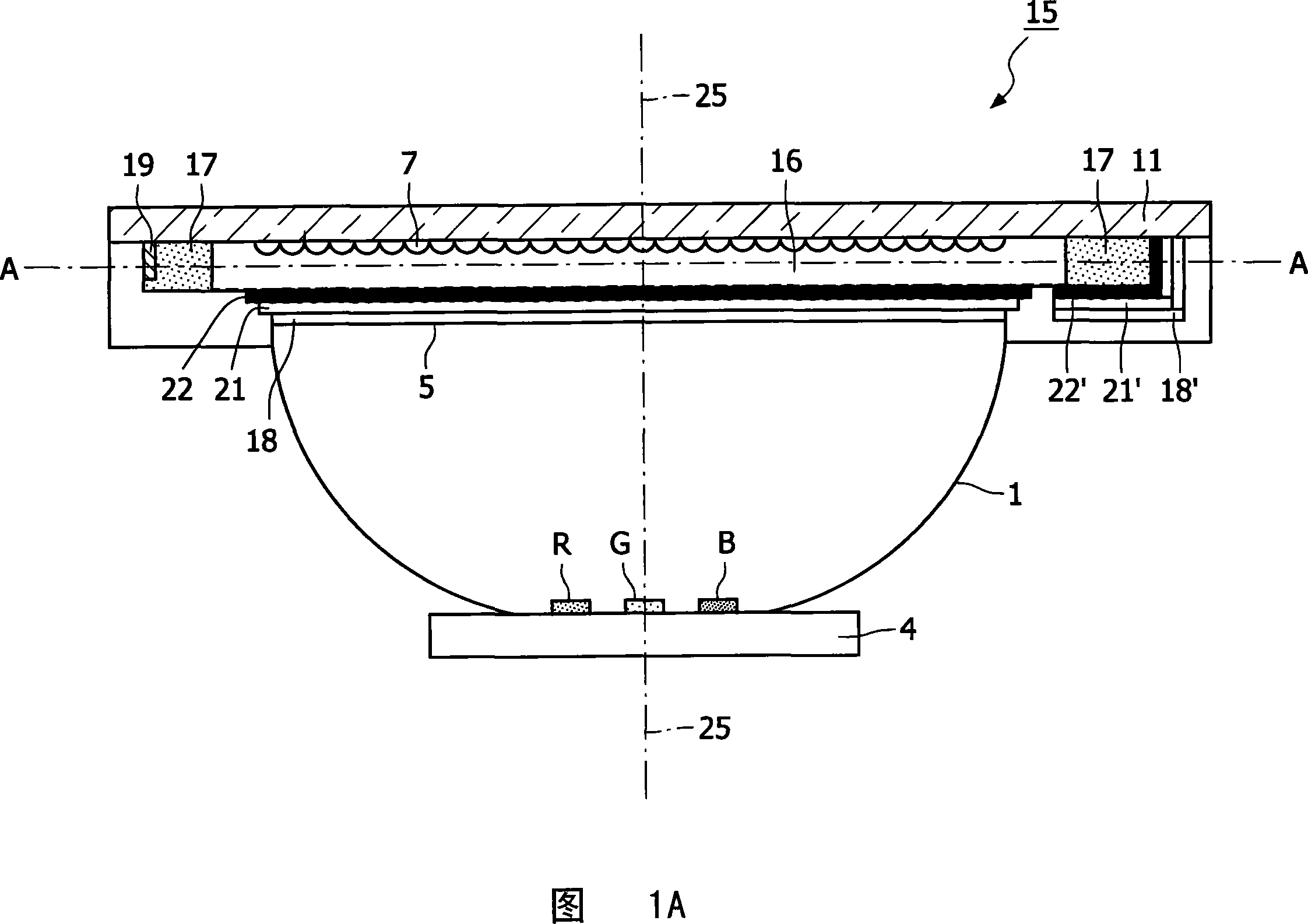

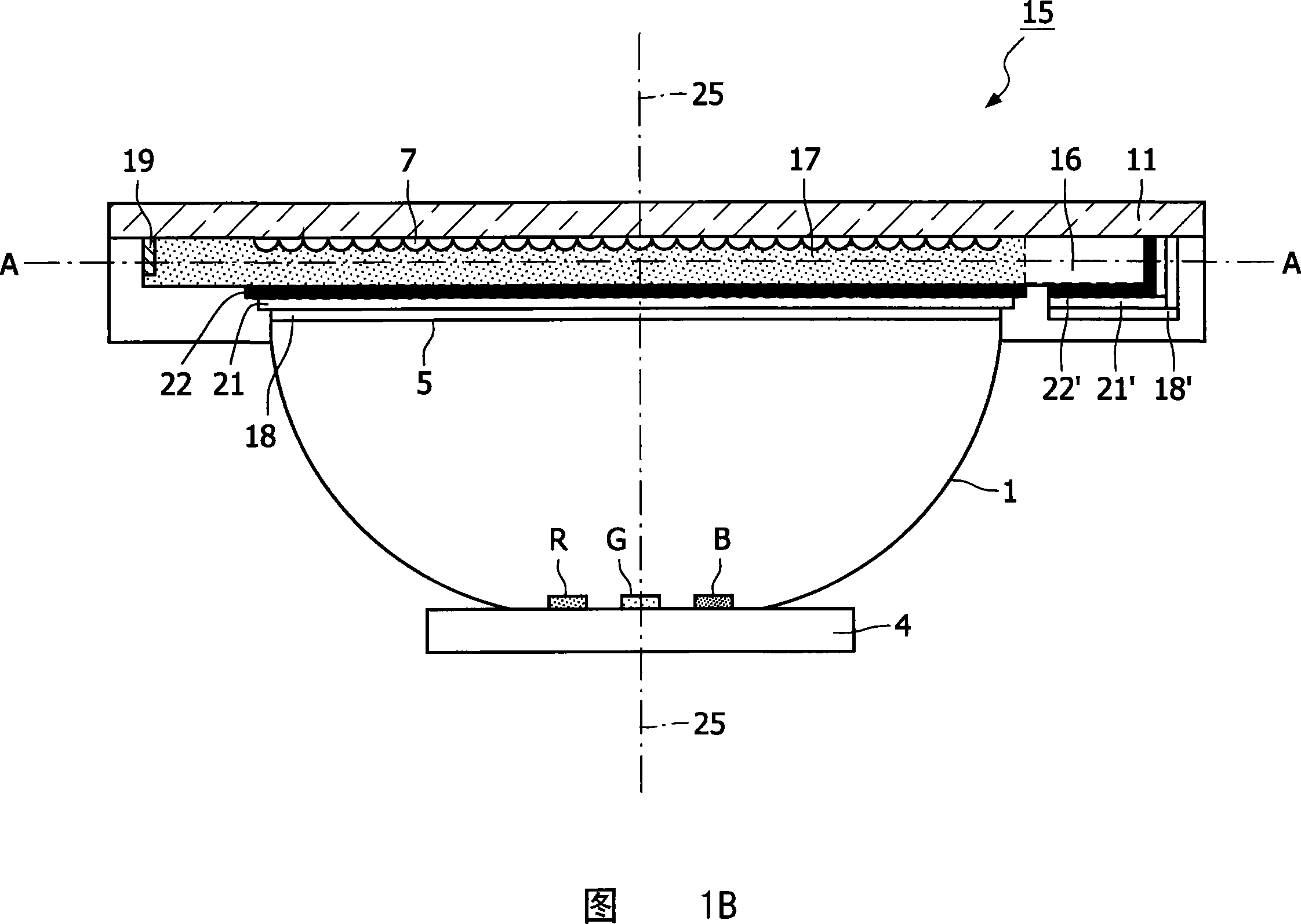

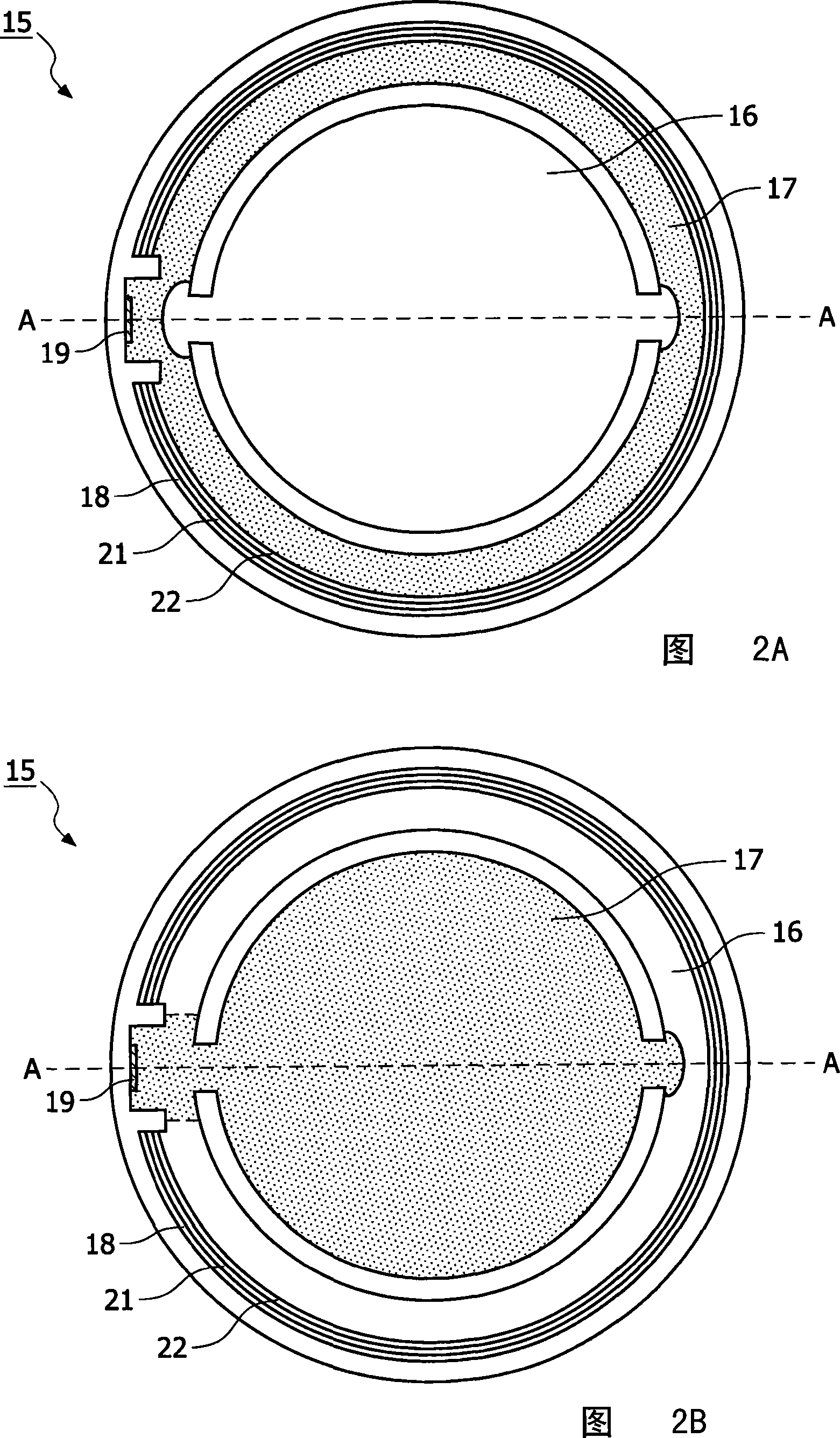

Illumination system

InactiveCN101073028ADynamic AdjustmentQuick sequence operationPoint-like light sourceDiffusing elementsElectricityLighting system

An illumination system has a plurality of light emitters (R, G, B) and a light- collimator (1) for collimating light emitted by the light emitters. The light-collimator is arranged around a longitudinal axis (25) of the illumination system. A light-exit window (5) of the light-collimator at a side facing away from the light-emitters is provided with a translucent cover plate (11) provided with a switchable optical element (15) based on electrowetting. The light-exit window of the light-collimator or the translucent cover plate is provided with a light-dispersing structure (7) for broadening an angular distribution of the light emitted by the illumination system. The optical element (15) being switchable in a mode of operation reducing the effect of the light-dispersing structure (7). Preferably, the effect of the light-dispersing structure is substantially counteracted when the switchable optical element operates in the mode of operation reducing the effect of the light-dispersing structure.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

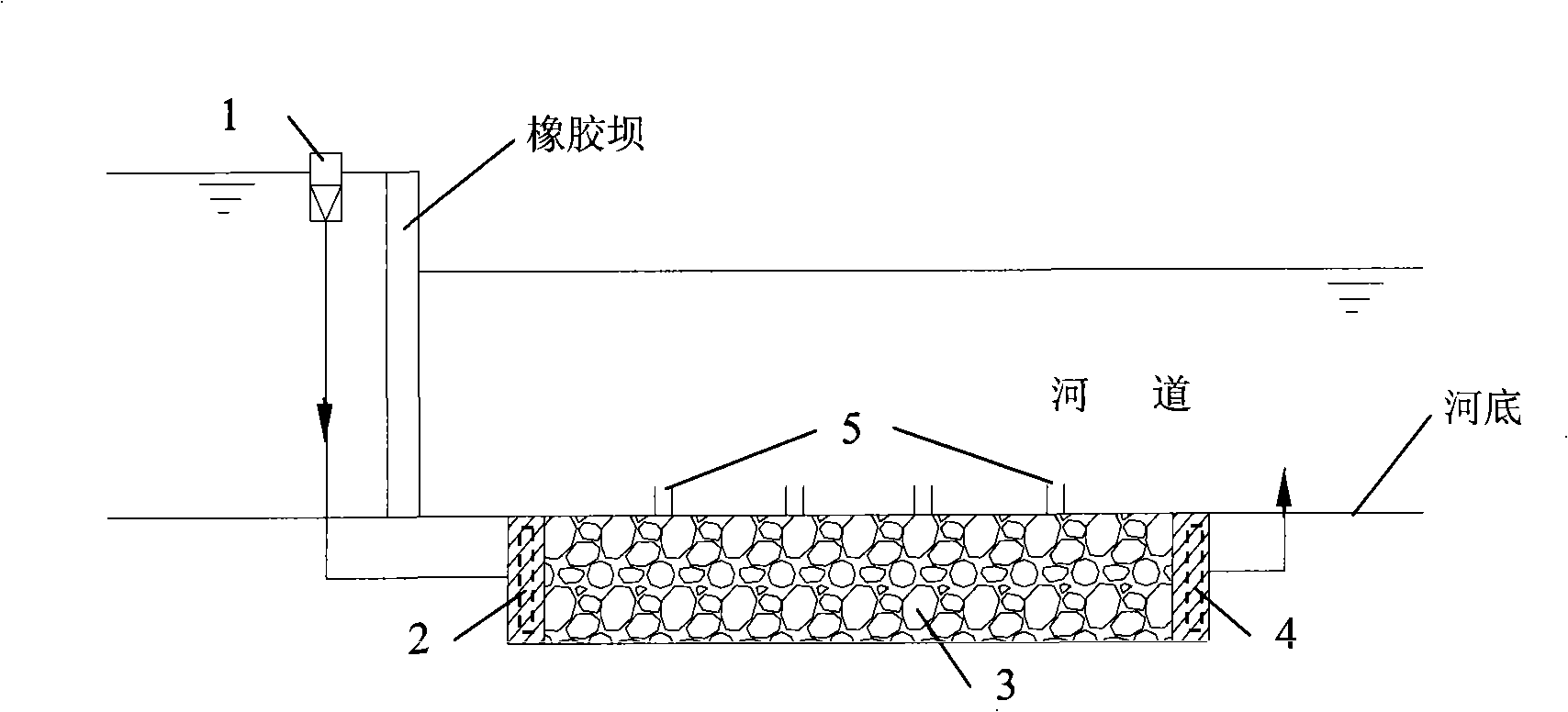

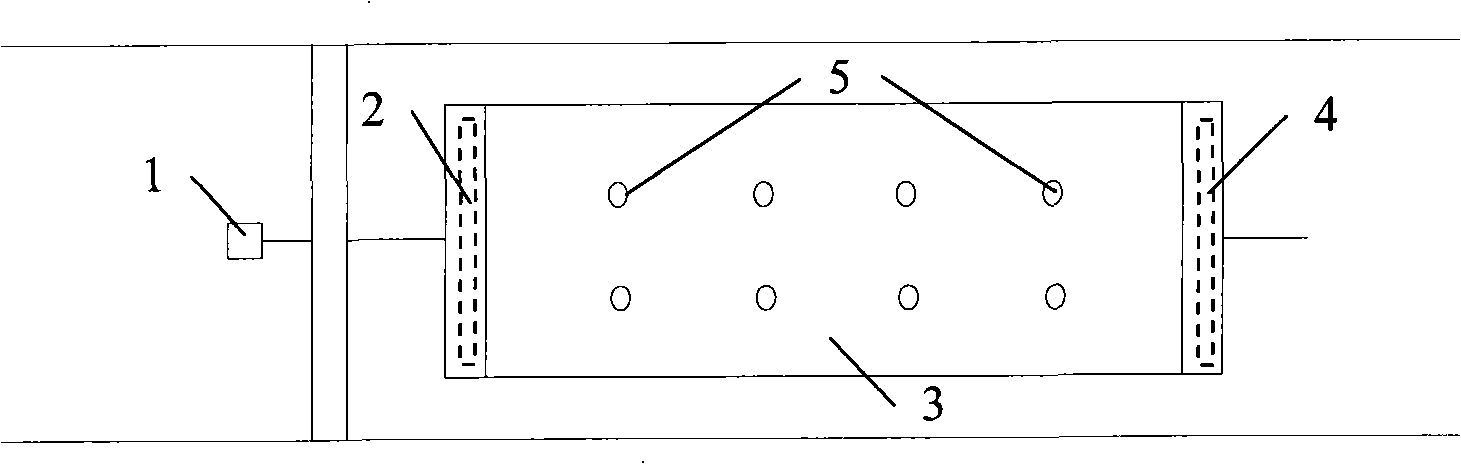

Riverbed type percolation filtration water quality purification technique for renovation of municipal pollution river water

InactiveCN101293699AWon't change shapeEfficient removalTreatment using aerobic processesSustainable biological treatmentLand resourcesFiltration

The invention discloses a river bed infiltration water purification technology used for repairing the water body of polluted city rivers, which follows that below the river beds of city rivers, the purification structure of a filler infiltration bed (3) is built, by utilizing water head (the height of water formed by artificial construction rubber dam or the natural height of water of river channels), polluted river water is transported to a water distribution system (2) by adopting a floating type water getting device (1), the river water to be treated is evenly distributed to the whole purification unit of the filler infiltration bed (3) by the water distribution system (2), and the river water after a purification treatment is discharged into the lower reaches of river channels by a water collecting system (4). The purification technology of the invention realizes an effective purification treatment on the river water simultaneously without occupying limited land resources at the two sides of the river channels, thus not changing the shape of the river channels, not influencing the flow of the river water, nor having any negative impact on the landscape effect of the two banks of the river channels.

Owner:申欢 +1

Highly heat-conducting phase change heat storage material and preparation method therefor

InactiveCN105154021AHigh thermal conductivityFast heat absorption and releaseHeat-exchange elementsPorosityVoid ratio

The invention discloses a highly heat-conducting phase change heat storage material and a preparation method therefor. The heat storage material is prepared by compounding 67.5% by mass of paraffin, 7.5% by mass of expanded graphite and 25% by mass of through-hole foamed aluminum. The melting point of selected paraffin in the materials is 40-60 DEG C, and the porosity of the selected through-hole foamed aluminum in the materials is over 90%. The material has the advantages that the material is fast in heat absorption and heat release speed and great in heat storage, and is not varied in shape after phase change.

Owner:JIANGSU QIZHENG NEW ENERGY

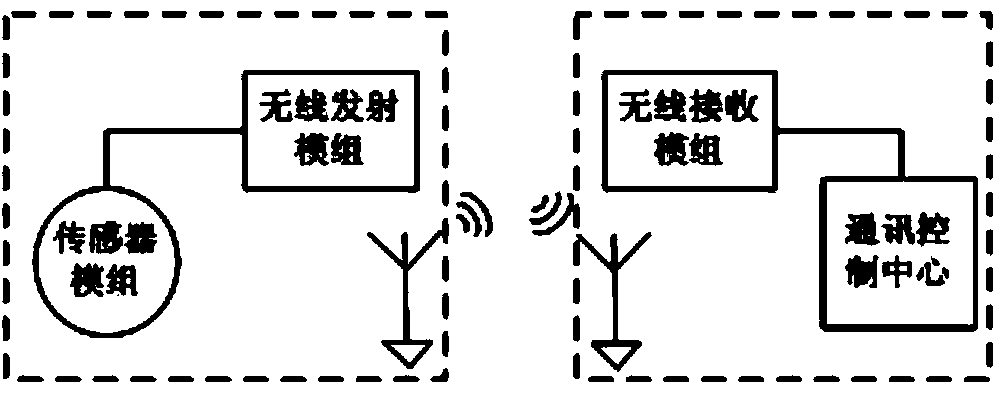

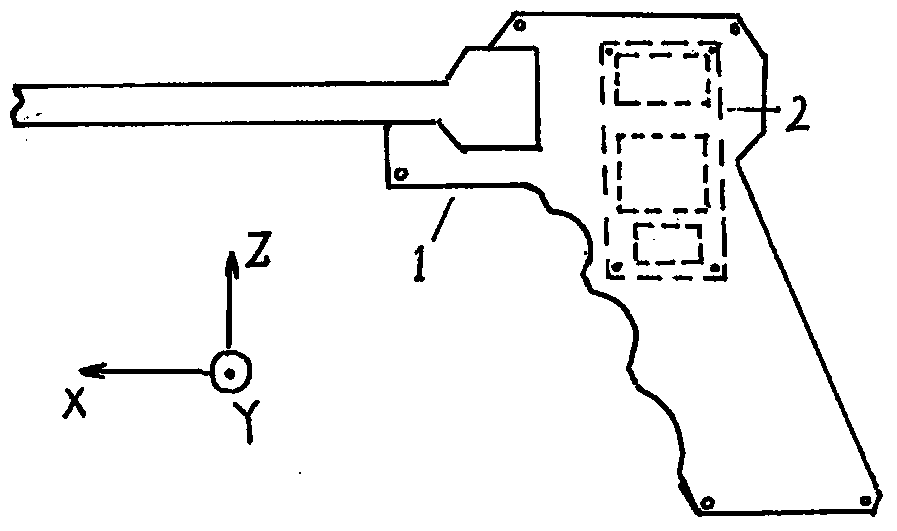

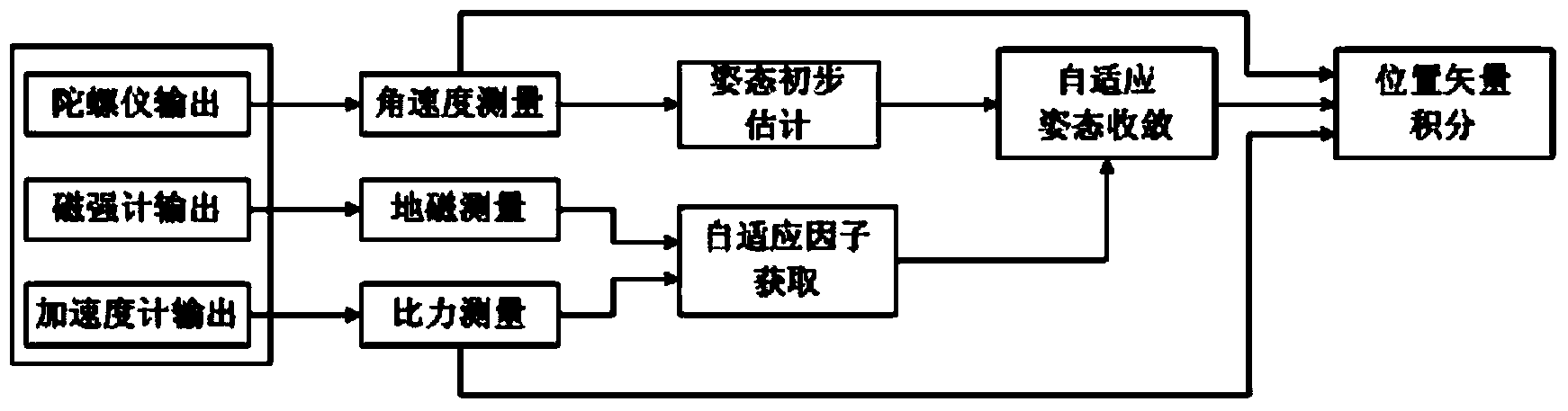

Endoscope system with anti-interference capacity and surgical navigation function

ActiveCN104224089AAvoid influenceReduce space pressureDiagnosticsSurgeryTriaxial accelerometerGyroscope

The invention provides an endoscope system with an anti-interference capacity and a surgical navigation function. A surgical navigation subsystem is realized by an inertial navigation module, and the inertial navigation module comprises three sensors, i.e., a triaxial accelerometer, a triaxial gyroscope and a triaxial magnetometer. Depending on a micro-electro-mechanical system technique, the navigation subsystem can be integrated in a handle of an endoscope, so that the endoscope has a positioning function. In a positioning algorithm, through proper anti-interference treatment, positioning errors caused by external magnetic fields and movement of the endoscope are reduced, and the positioning stability and accuracy are improved.

Owner:TIANJIN UNIV

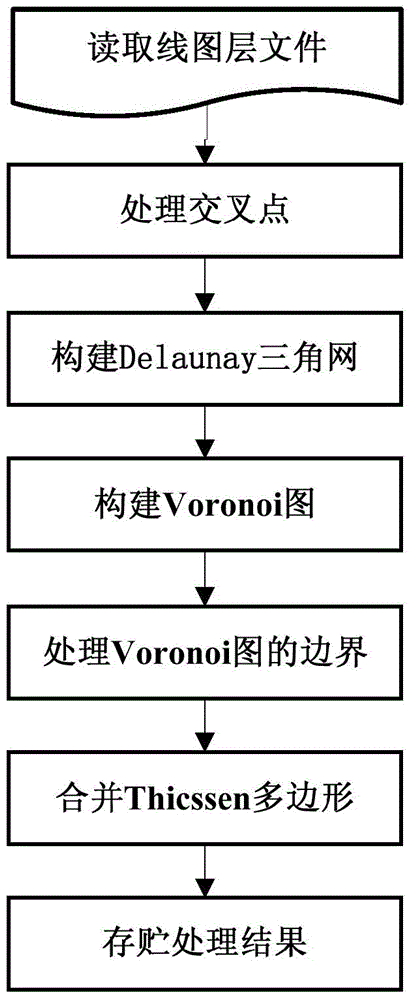

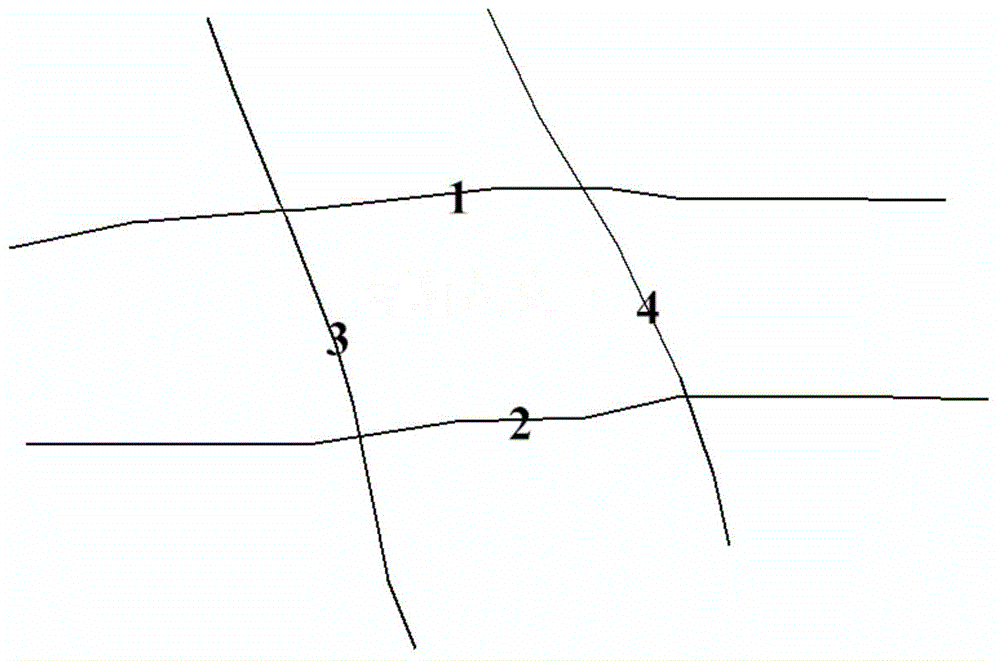

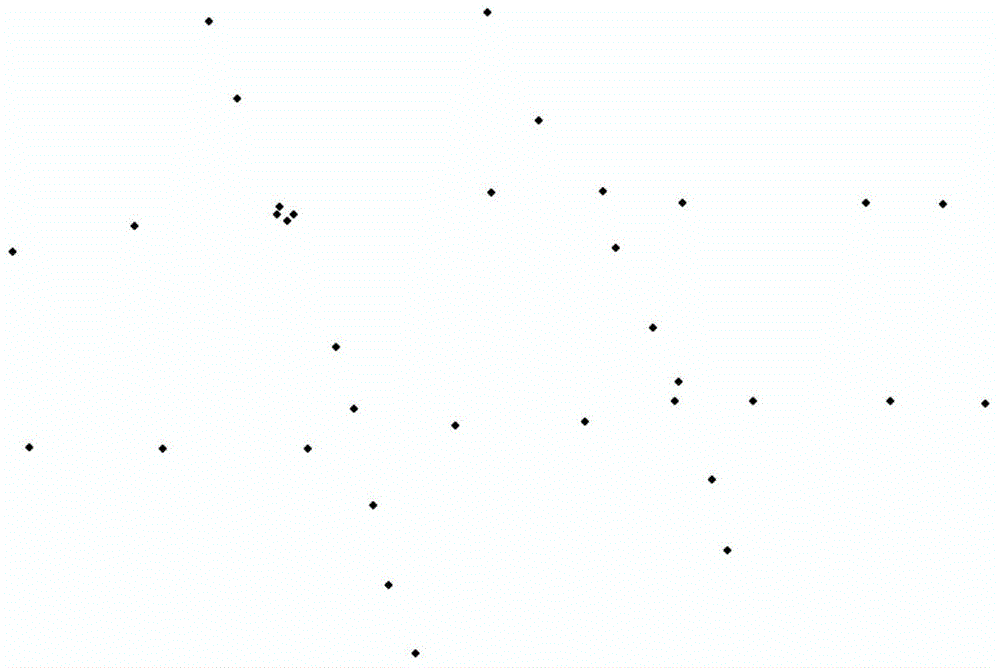

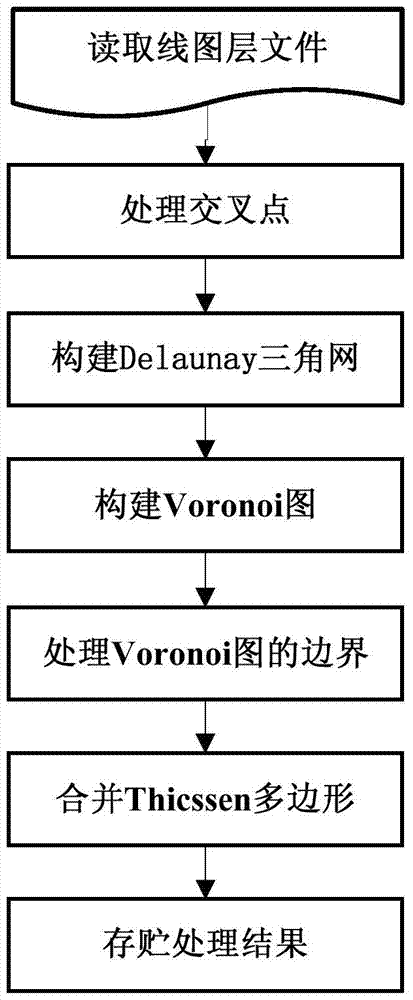

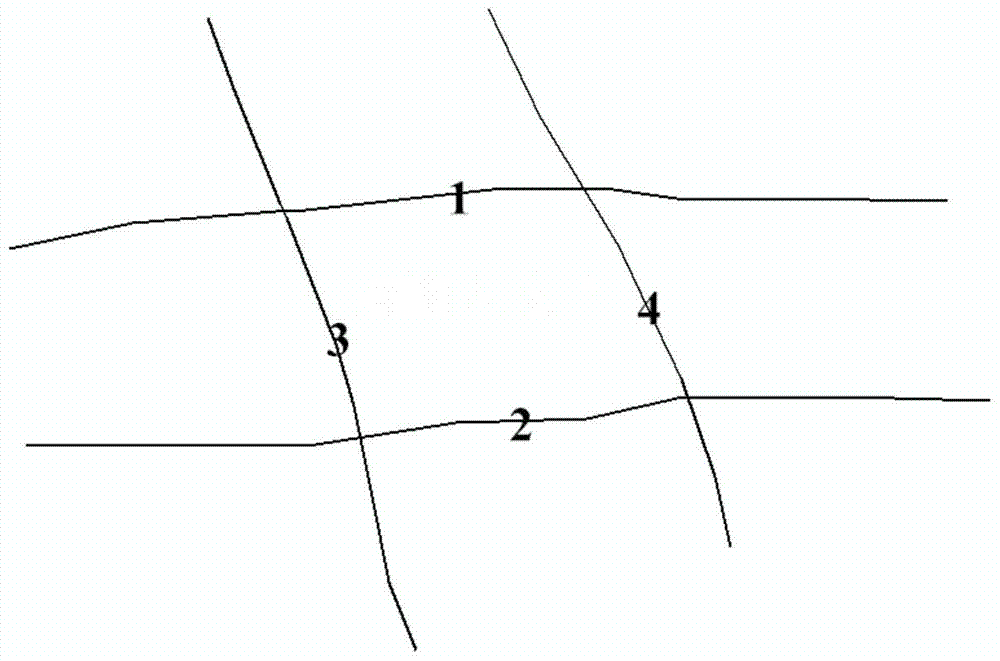

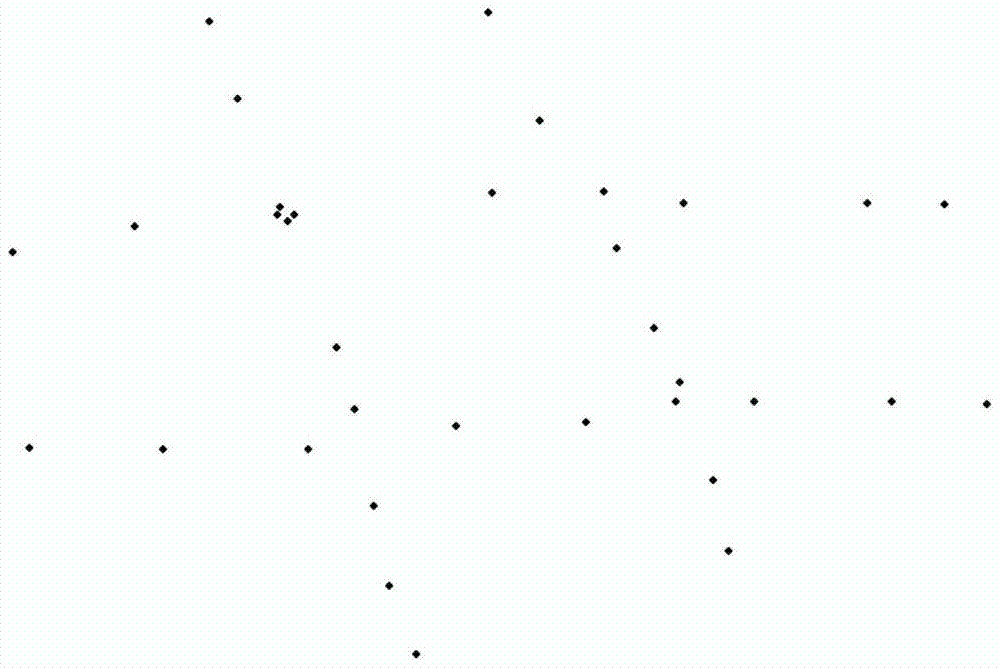

Spatial subdivision method for intersecting linear geographic elements

InactiveCN104915991AWon't change shapeAvoid situations where Voronoi diagrams cannot be generated3D modellingLinear elementSubdivision method

The invention discloses a spatial subdivision method for intersecting linear geographic elements. The method includes the following steps that: intersecting linear elements are dispersed so as to form point sets based on the principle of a Voronoi distribution model; point addition processing is performed on intersecting positions of every two intersecting linear elements; Delaunay triangulation and Voronoi diagram generation are performed based on the point sets; and a generated Voronoi diagram is clipped, and sub regions generated by point sets which belong to the same linear element are merged, so that sub regions of different linear elements can be obtained, and therefore, spatial subdivision of the intersecting linear geographic elements can be realized.

Owner:NANJING NORMAL UNIVERSITY

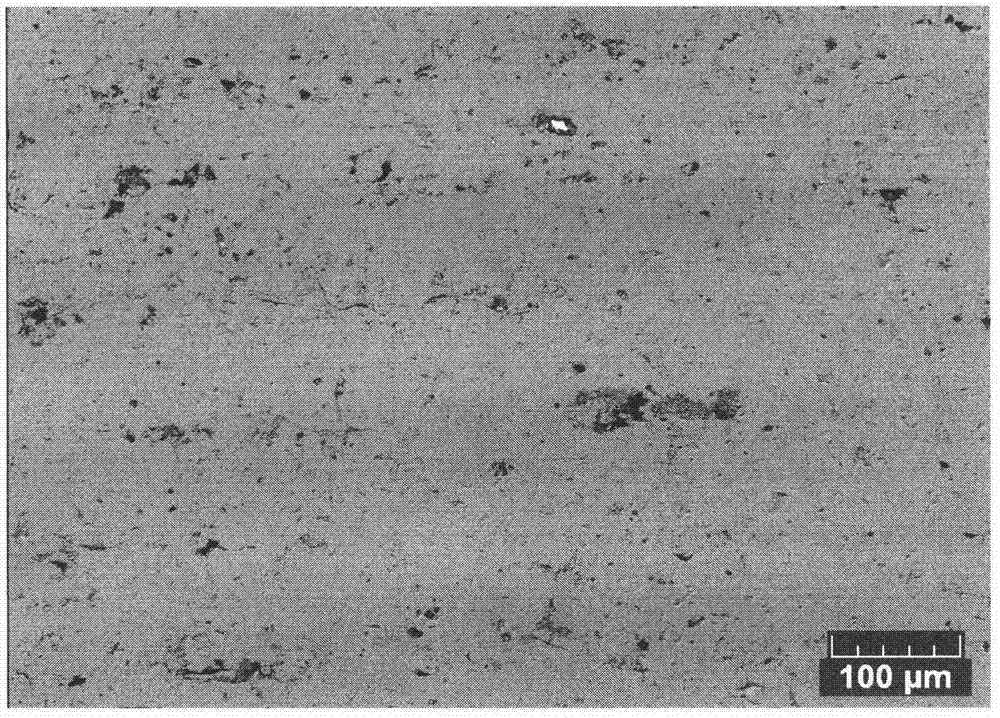

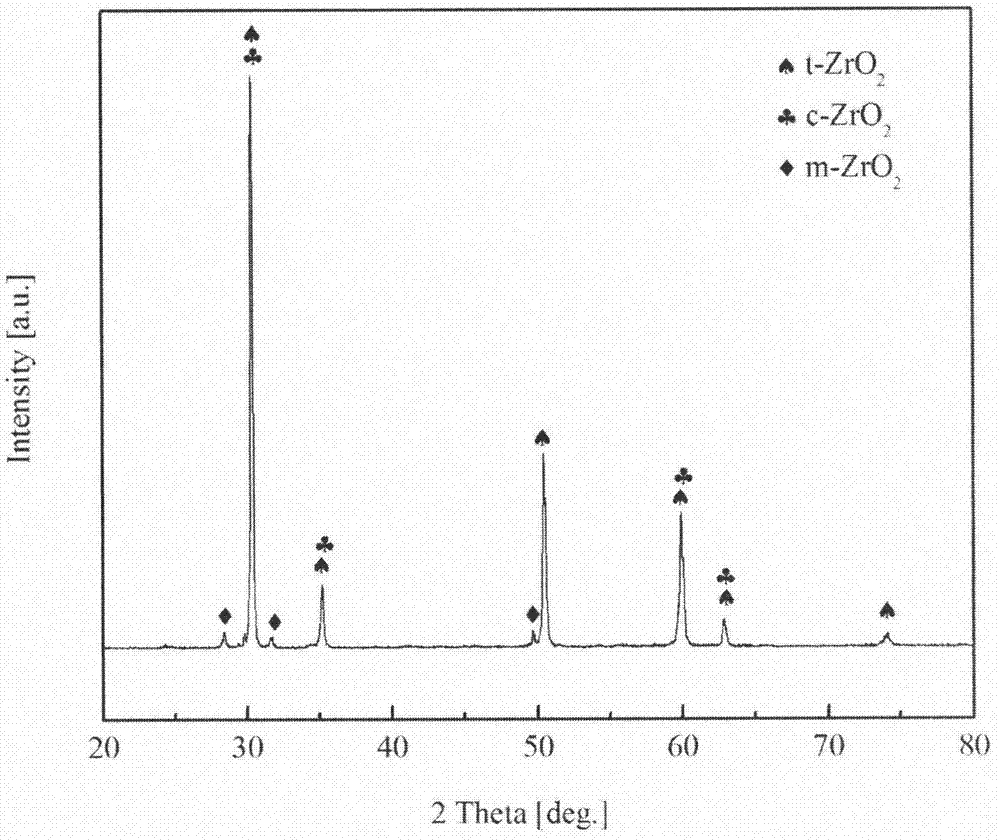

Preparation method of plasma-sprayed ceramic coating for strengthening surface of water pump impeller

InactiveCN107299310AExtend the life cycleHigh temperature resistantMolten spray coatingThermal sprayingChemical plating

The invention relates to a preparation method of a plasma-sprayed ceramic coating for strengthening surface of a water pump impeller. The preparation method comprises the following steps: ultrasonically washing the surface of the water pump impeller with acetone, and drying; processing the surface of the water pump impeller through sand-blasting roughening by brown aluminum oxide; preheating the surface of a base body; and spraying ceramic powder onto the surface of the base body of the water pump impeller to obtain a durable and corrosion-resistant ceramic coating, wherein the ceramic coating on the surface of the impeller is obtained by being spraying for a plurality of times. The preparation method overcomes shortages of laser surface modification, thermal spraying, chemical plating and electroplating. The preparation method has the advantages that the use cycle of a water pump is obviously prolonged; requirements of the water pump impeller surface on corrosion resistance and cavitation resistance are met; workpieces are recycled repeatedly; processes are simple and feasible; the production efficiency is high; the automation degree is high; the sustainable development strategy is met; and the method has market economic benefits.

Owner:YANGZHOU UNIV

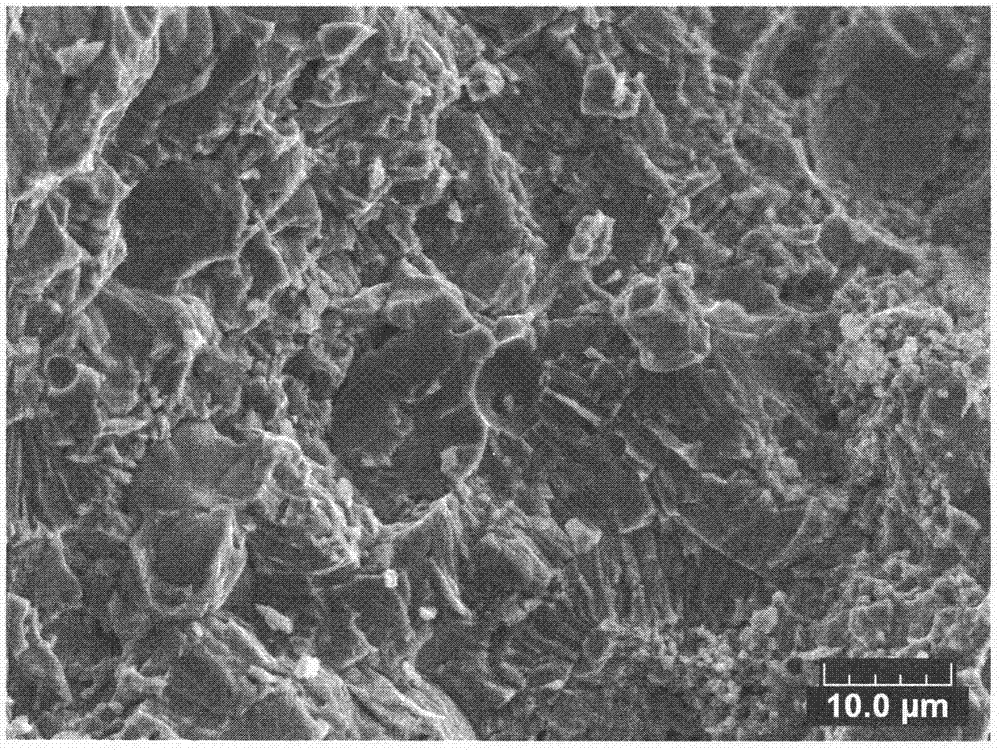

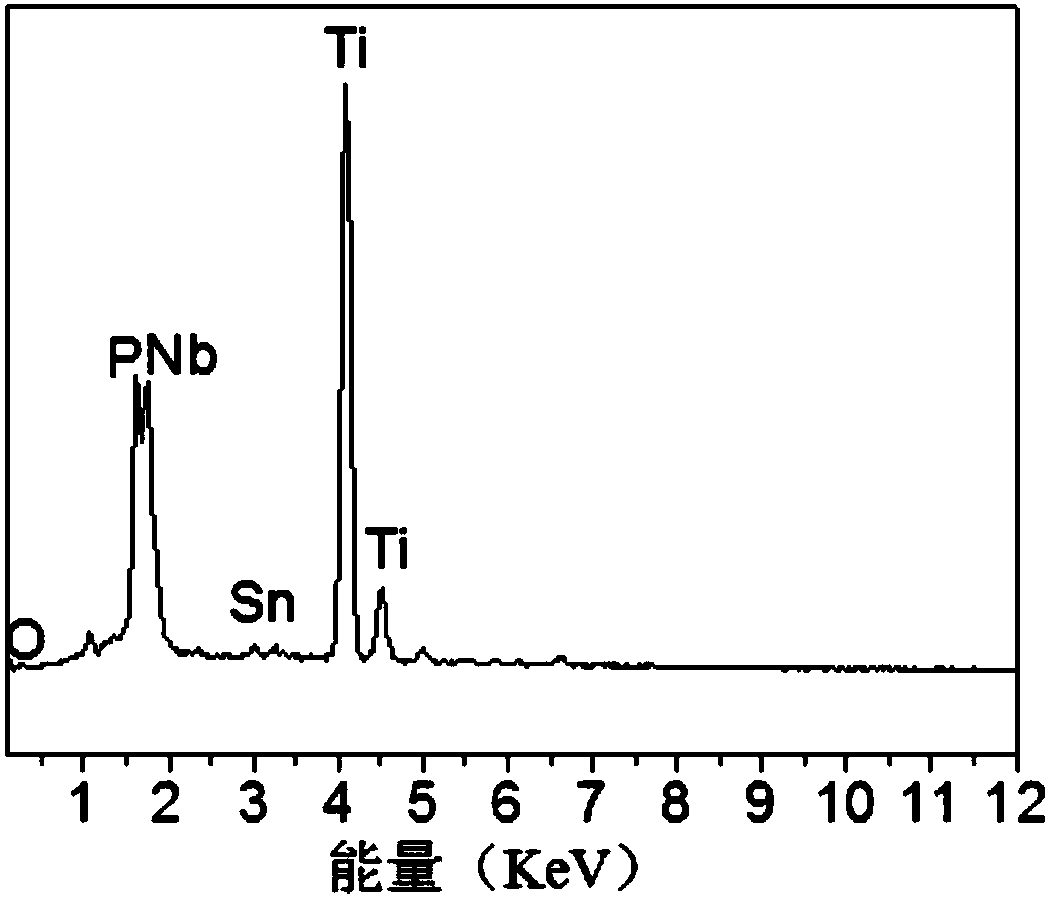

Method for improving biomimetic mineralization capacity of surface of titanium alloy implant

ActiveCN108042847AImprove biological activityQuick responseVacuum evaporation coatingSputtering coatingSurface layerSimulated body fluid

The invention discloses a method for improving biomimetic mineralization capacity of the surface of a titanium alloy implant. According to the method, after the surface of the titanium alloy implant is subjected to mechanical grinding treatment, a nanocrystallized surface layer is produced, P ions are injected into the nanocrystallized surface layer with an ion injection technology, the injectioneffect is enhanced due to presence of more dislocation and other defects on the nanocrystallized implant surface, and injected ion concentration is increased three times or more than that of an implant without surface nanocrystallization; globular apatite is fully distributed on the surface of the implant after 28 days of soaking with simulated body fluid, and accordingly, biological activity of the titanium alloy implant is obviously improved.

Owner:ANHUI UNIV OF SCI & TECH

Novel metal base material shaping heat accumulating material and preparation method thereof

InactiveCN105295847AHigh thermal conductivityFast heat absorption and releaseHeat-exchange elementsParaffin waxVoid ratio

The invention discloses a novel metal base material shaping heat accumulating material and a preparation method thereof. The heat accumulating material is prepared by compounding paraffin and porous foamy copper, wherein the mass fraction of paraffin is 83.2%, the mass fraction of porous foamy copper is 16.8%, the melting point of the selected paraffin in the material is 40-60 DEG C, and the voidage of the selected porous foamy copper is 98% or above. The material has the advantages that the heat absorption and discharge speed is quick, and the appearance after phase change is unchanged.

Owner:JIANGSU QIZHENG NEW ENERGY

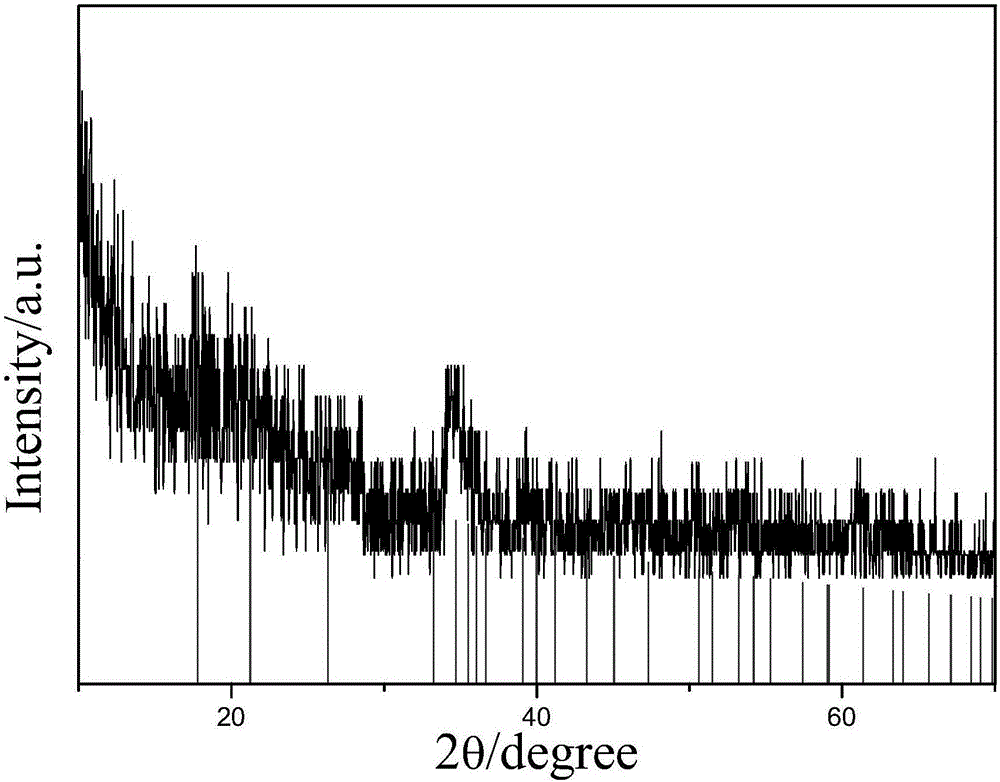

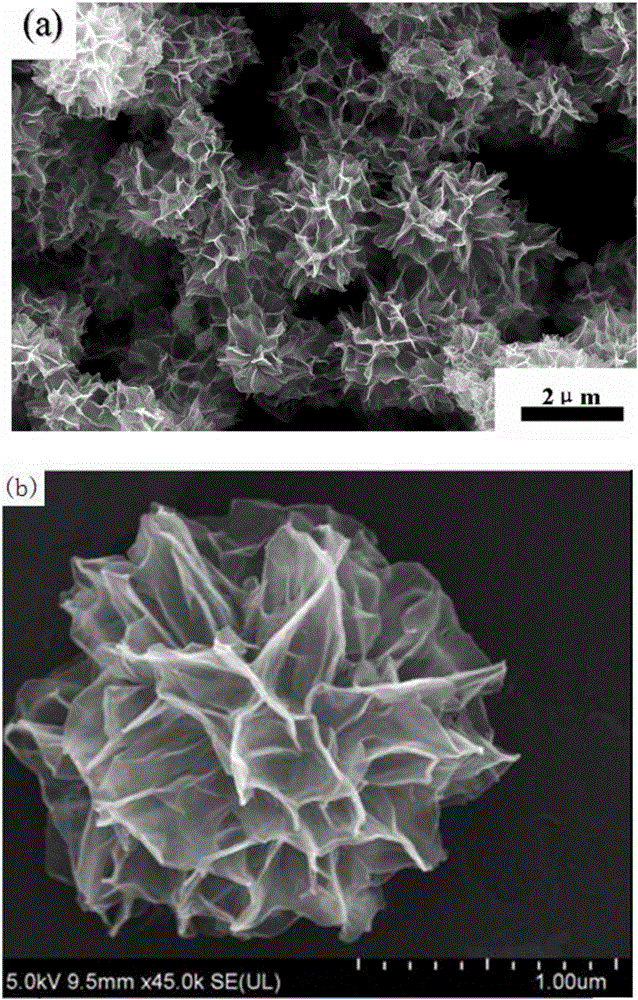

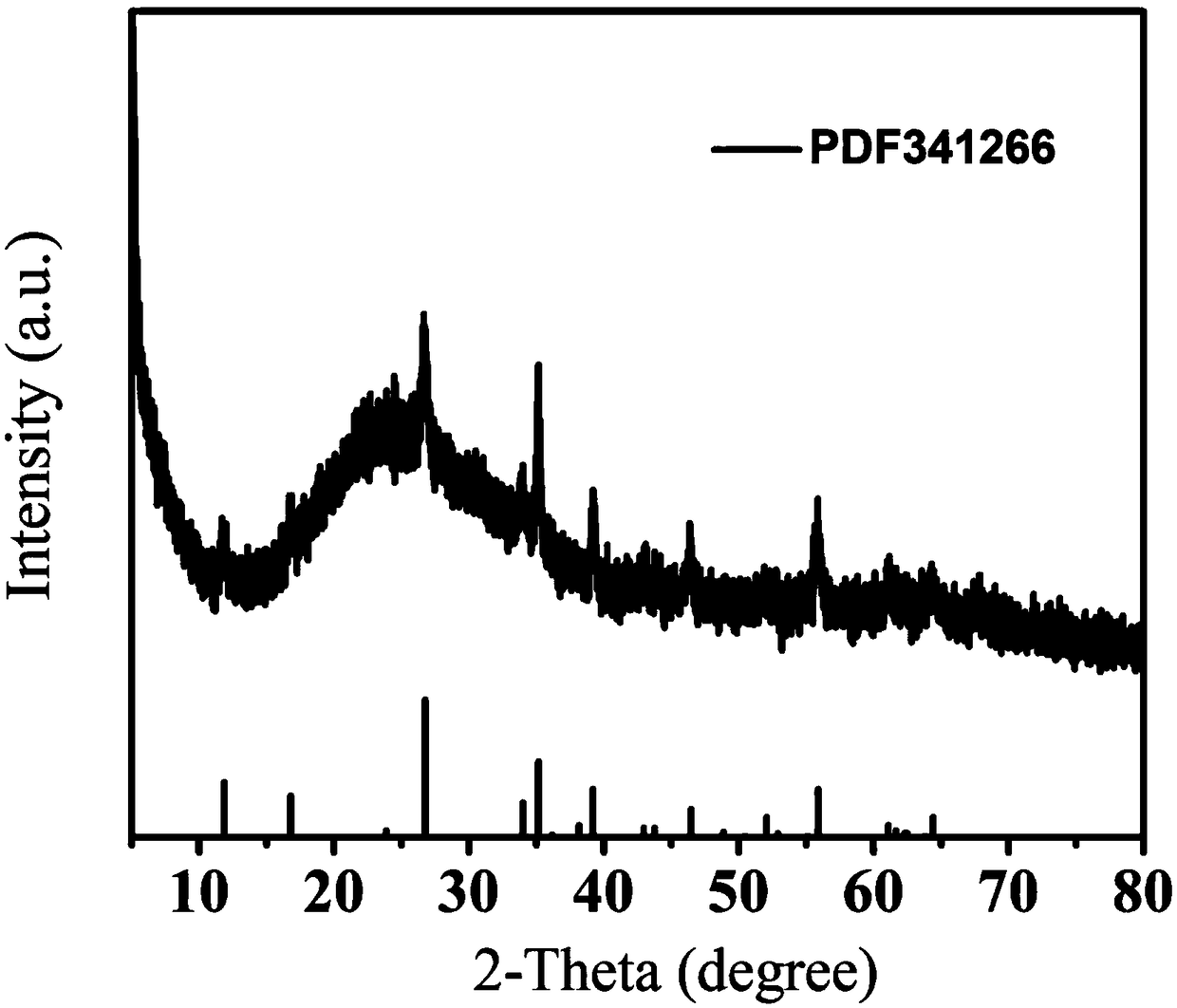

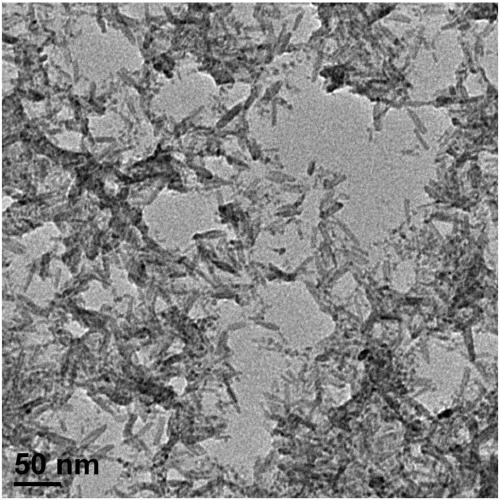

Flowerlike alpha-FeOOH porous micro-nanospheres and preparation method thereof

ActiveCN106430324ANarrow particle size distributionHigh specific surface areaIron oxides/hydroxidesNanotechnologyCrystal morphologyIon

The invention provides flowerlike alpha-FeOOH porous micro-nanospheres and a preparation method thereof, and relates to the technical field of nano materials. The preparation method comprises the following steps: firstly, dissolving Fe2SO4.7H2O in a mixed system of water and N,N-dimethylfomamide (DMF), and then performing heat treatment and a hydrolytic reaction to obtain the flowerlike alpha-FeOOH porous micro-nanospheres. The flowerlike alpha-FeOOH porous micro-nanospheres are formed by assembling mono-crystalline flowerlike spheres of which the spherical diameter is 2[mu]m, and the specific surface area of the porous micro-nanospheres is 258m<2> / g. The flowerlike alpha-FeOOH porous micro-nanospheres provided by the invention are obtained by virtue of a hydrolysis precipitation method, and are specifically obtained by preparing deionized water and DMF into a solution, then adding Fe2SO4.7H2O to perform a hydrolytic reaction, and raising the reaction temperature to about 40 DEG C to promote the reaction, so that the yield of the product is increased and the crystal morphology cannot be changed; and by virtue of ultrasonic washing, the flowerlike alpha-FeOOH porous micro-nanospheres with uniform particle size distribution, high surface activity and good adsorptivity are obtained.

Owner:HEFEI UNIV

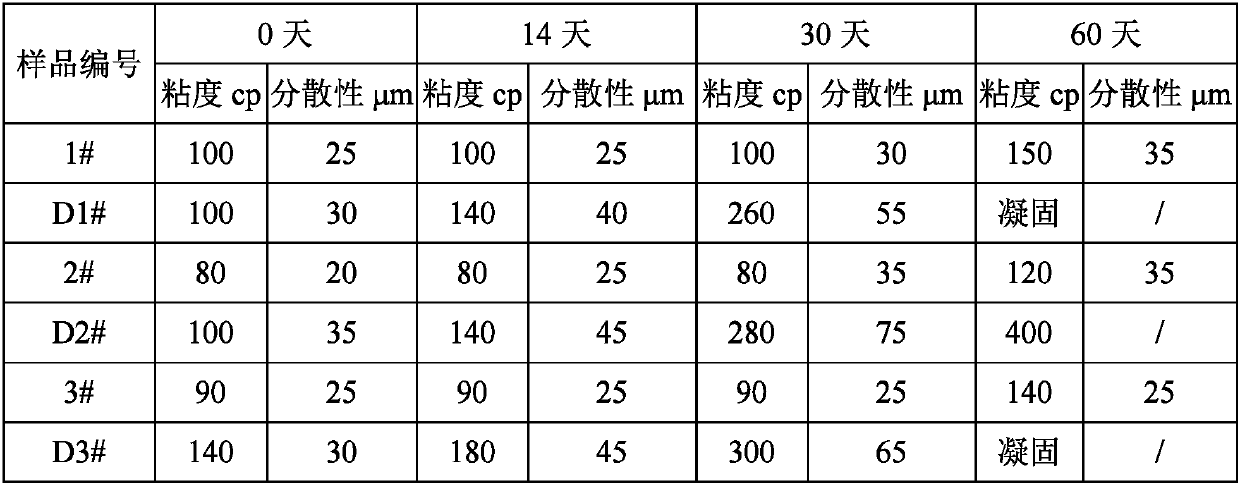

Method for preparing slurry titanium dioxide by hydrothermal method

InactiveCN111019401AReduce hydroxylDense and uniform shapeTitanium dioxidePigment physical treatmentPhysical chemistrySlurry

The invention belongs to the technical field of slurry titanium dioxide preparation, and discloses a method for preparing slurry titanium dioxide by a hydrothermal method, which comprises the following steps: preparing a titanium dioxide base material into 300-450g / L slurry, and regulating the temperature of the slurry to 70-90 DEG C and the pH value to 9-10.5; adding a silicate solution into theslurry, and adjusting the pH value of the slurry to 5-8; performing a hydrothermal reaction on the slurry at 150-180 DEG C at the reaction time for 2-6 h; cooling the reacted slurry to 60-70 DEG C, adding an aluminum salt solution and an inorganic acid or inorganic alkali solution into the slurry at the same time, keeping the pH of the slurry constant at 6-9, and homogenizing for 30 minutes; adjusting the pH value of the slurry to 6-8, and carrying out a hydrothermal reaction at 150-200 DEG C for 4-6 h; sieving and washing the slurry to obtain a filter cake; pulping and dispersing, and sandingand sieving the slurry to obtain slurry titanium dioxide. The slurry titanium dioxide has high weather resistance and high dispersion stability and is environmentally friendly, and the method is freeof dust.

Owner:LOMON BILLIONS GRP CO LTD

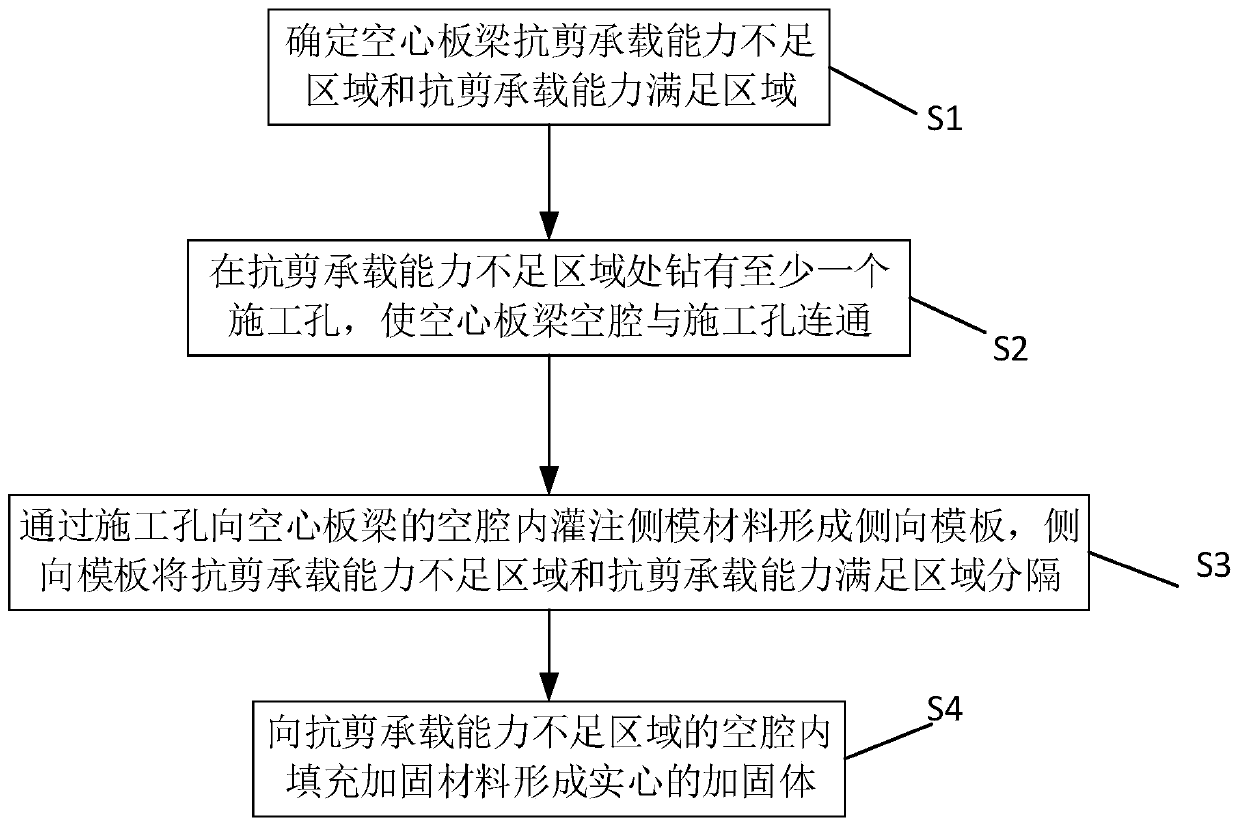

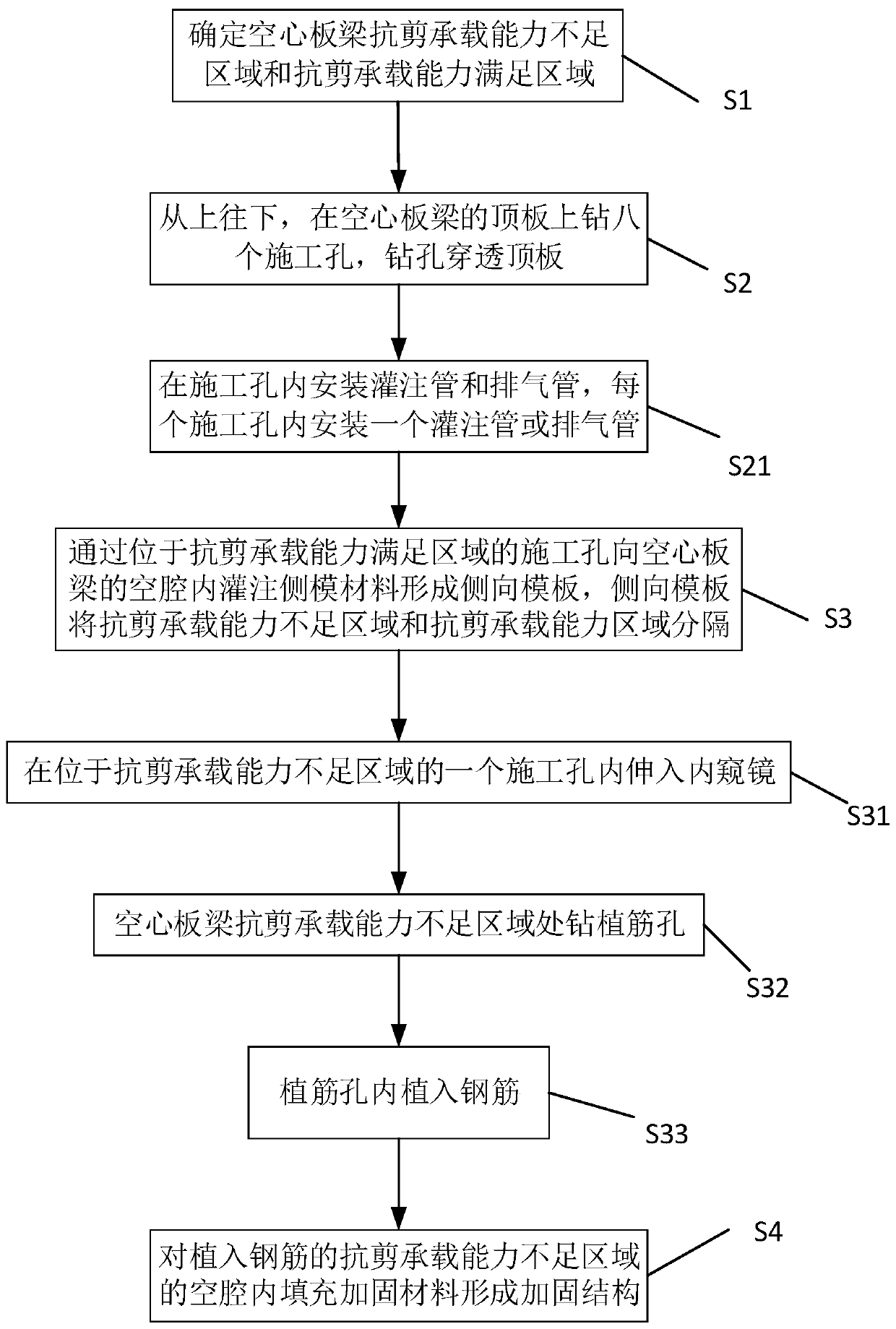

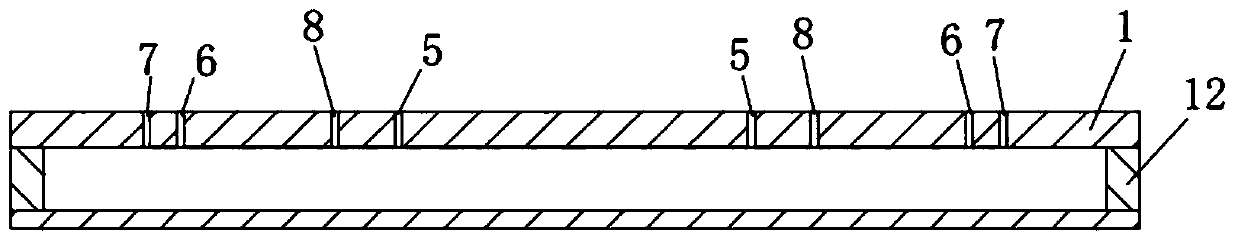

Hollow slab beam reinforcing method and hollow slab beam

PendingCN110093868AFilled tightlyEasy accessBridge erection/assemblyBridge strengtheningEngineeringBearing capacity

The invention relates to the technical field of bridge reinforcement, in particular to a hollow slab beam reinforcement method. The method comprises the following steps of S1, determining a shear bearing capacity insufficient area and a shear bearing capacity satisfaction area of the hollow slab beam; S2, drilling at least one construction hole in the shear bearing capacity insufficient area so that the cavity of the hollow slab girder is communicated with the construction holes; S3, pouring lateral framework materials into the cavity of the hollow slab beam through the construction holes to form a lateral formwork, wherein the lateral formwork separates the shear bearing capacity insufficient region from the shear bearing capacity satisfaction region; and S4, filling the cavity of the shear bearing capacity insufficient region with reinforcing materials to form a solid reinforcing body. Through the construction holes, it can be ensured that reinforcing materials enter the cavity, andthe lateral formworks can prevent the reinforcing materials from flowing from the shear bearing capacity insufficient area to the shear bearing capacity satisfaction area, so the using amount of the reinforcing materials is reduced, the maintenance and reinforcement cost is reduced, and the situation that the bearing capacity of the lower structure of the bridge is affected due to excessive increase of the dead weight of the hollow slab beam is avoided.

Owner:南京博瑞吉工程技术有限公司

Heat storage material and preparation method thereof

InactiveCN104164218AImprove thermal conductivityFast heat absorption and releaseHeat-exchange elementsParaffin waxActive carbon

Owner:ZHENJIANG XINMENGXI ENERGY TECH

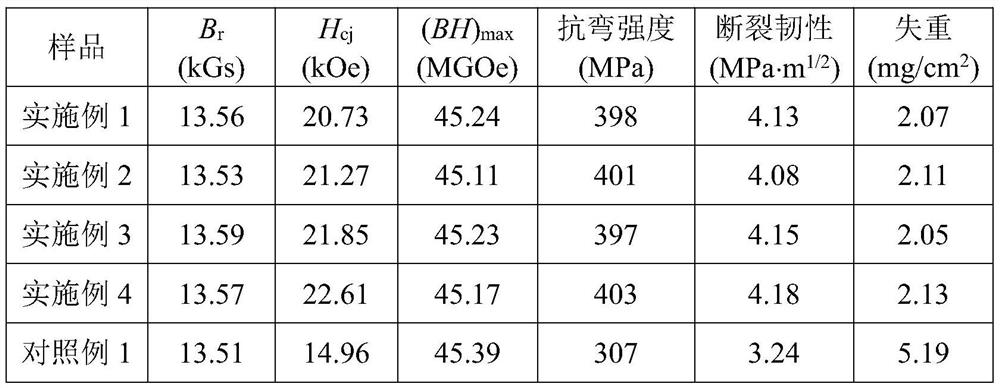

High-performance sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN112017834AImprove corrosion resistanceImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsAlloyUltimate tensile strength

The invention discloses a preparation method of a high-performance sintered neodymium-iron-boron magnet. The method comprises the following steps: respectively smelting a main phase alloy and a grainboundary phase alloy, respectively pulverizing, mixing, molding, carrying out grain boundary diffusion, sintering, and carrying out tempering heat treatment to finally obtain the sintered neodymium-iron-boron magnet. Heavy rare earth Dy or Tb, corrosion-resistant metals Co, Cu, Al and Zn and carbon nanotubes with excellent strength and flexibility are added during grain boundary phase alloy smelting, the added heavy rare earth Dy or Tb can improve the coercive force of the magnet, the added corrosion-resistant metals Co, Cu, Al and Zn can improve the potential of a grain boundary phase and reduce the chemical activity of the grain boundary phase, and the added high-melting-point carbon nanotubes do not change the nano form when the grain boundary phase is smelted, so that the mechanical property of the magnet is improved. Therefore, according to the sintered neodymium-iron-boron magnet prepared by the method, the corrosion resistance and the toughness of the magnet are remarkably improved on the basis of ensuring relatively high magnetic performance.

Owner:HEFEI UNIV OF TECH +1

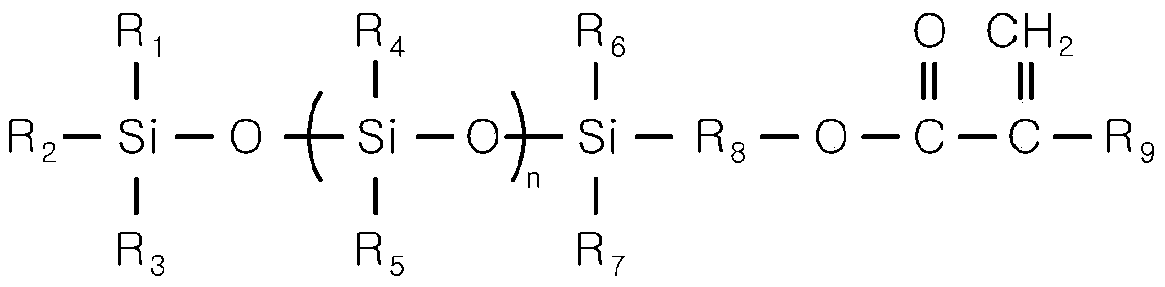

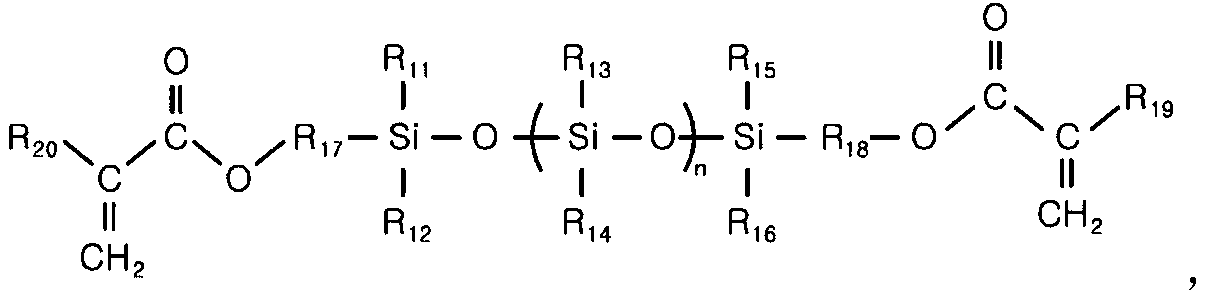

Adhesive film and optical member comprising same

PendingCN111094483AAvoid damagePrevent shape changeNon-macromolecular adhesive additivesOptical filtersPolymer scienceMeth-

Provided are an adhesive film and an optical member comprising same, the adhesive film comprising at least two types of (meth)acrylic monomers for a (meth)acrylic prepolymer, and (meth)acrylate containing silicon, wherein the release force of the adhesive film with respect to a polyimide film is approximately 0.5 gf / in to 5 gf / in.

Owner:SAMSUNG SDI CO LTD

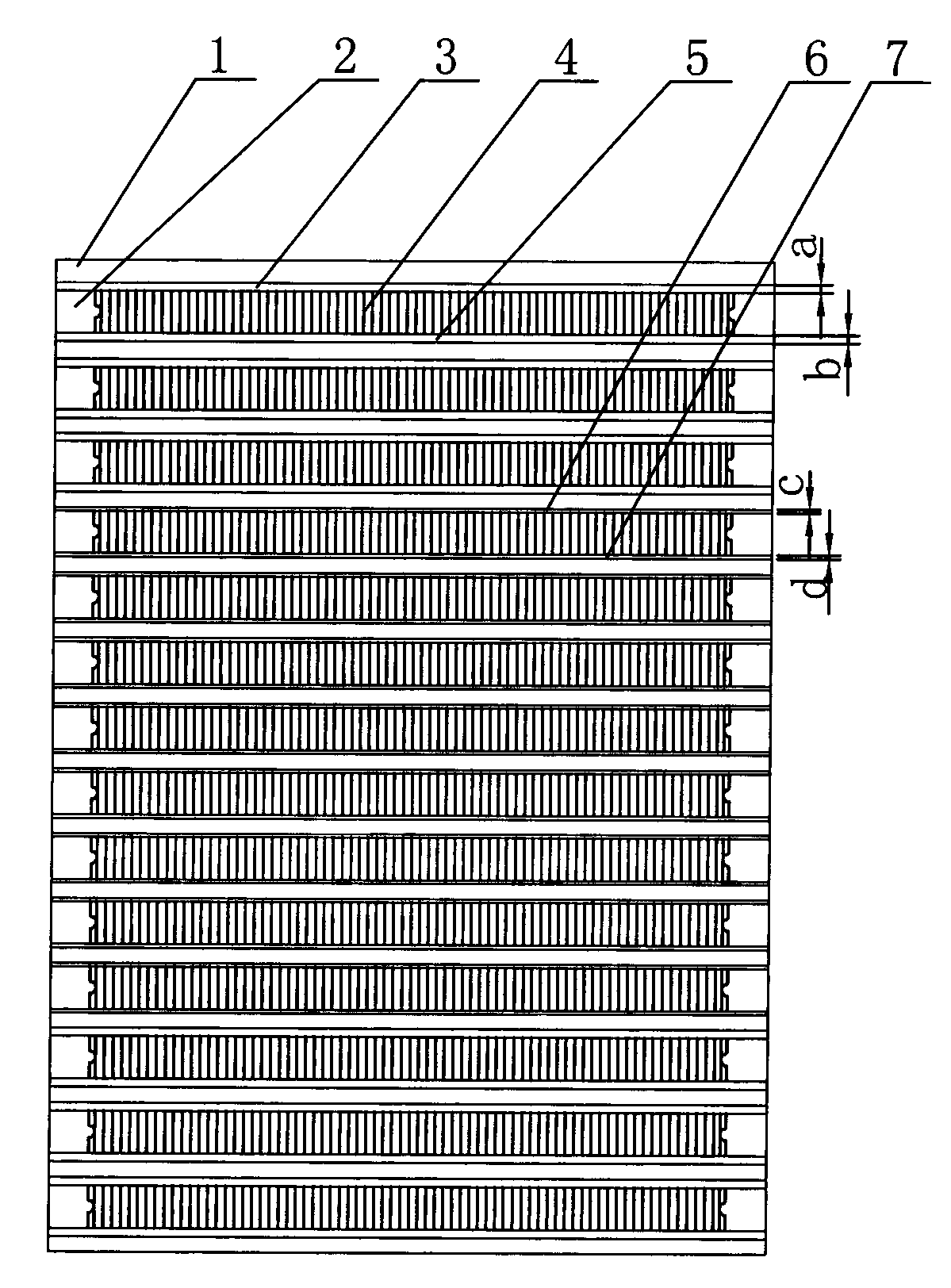

High-strength aluminum-plate fin-type heat exchanger

InactiveCN103376005AReduce leakageWon't change shapeHeat exchanger casingsLaminated elementsEngineeringHigh intensity

The invention relates to a high-strength aluminum-plate fin-type heat exchanger comprising covering plates mounted symmetrically up and down. A plurality of heat exchanging channels are mounted between the covering plates. The heat exchanging channels structurally comprises a first partitioning plate and a second partitioning plate, fins distributed evenly are mounted between the first partitioning plate and the second partitioning plate, and seal strips are mounted the ends of the fins. The high-strength aluminum-plate fin-type heat exchanger is reasonable in structure and convenient to produce; the inner structure of the heat exchanger is reshaped, different thicknesses of the partitioning plates and fins in the channels, so that the purpose of reducing leakage of the heat exchanger can be achieved. Other additional equipment are omitted, shape of the heat exchanger is unchanged, limit of space is free, using reliability is good, and application range is wide.

Owner:WUXI FANGSHENG HEAT EXCHANGER MFG

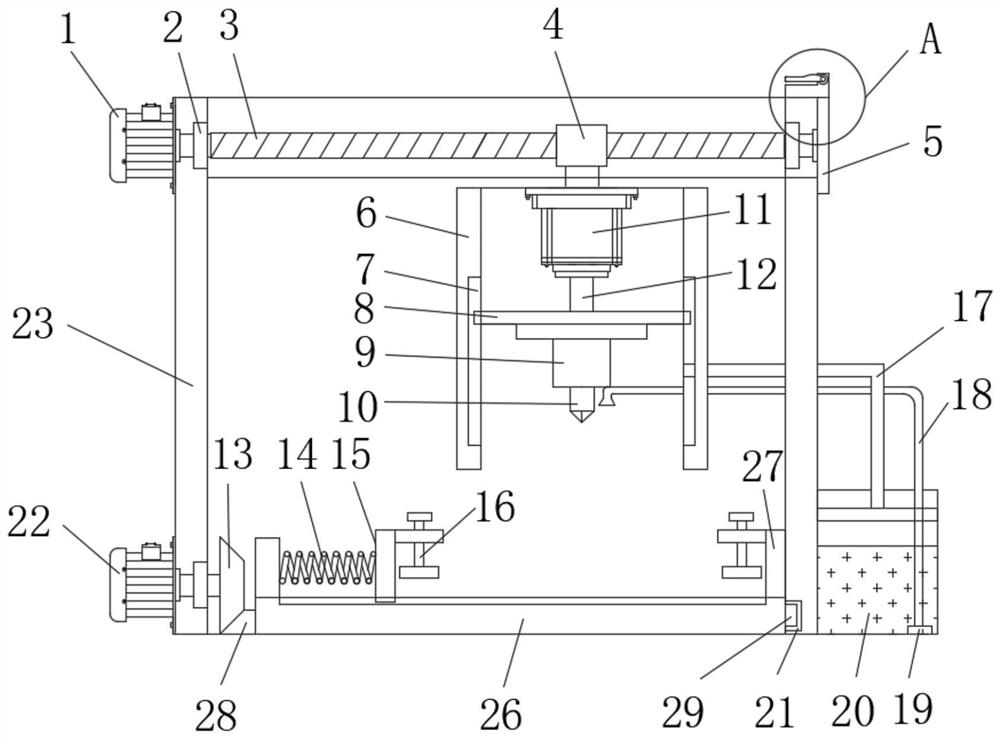

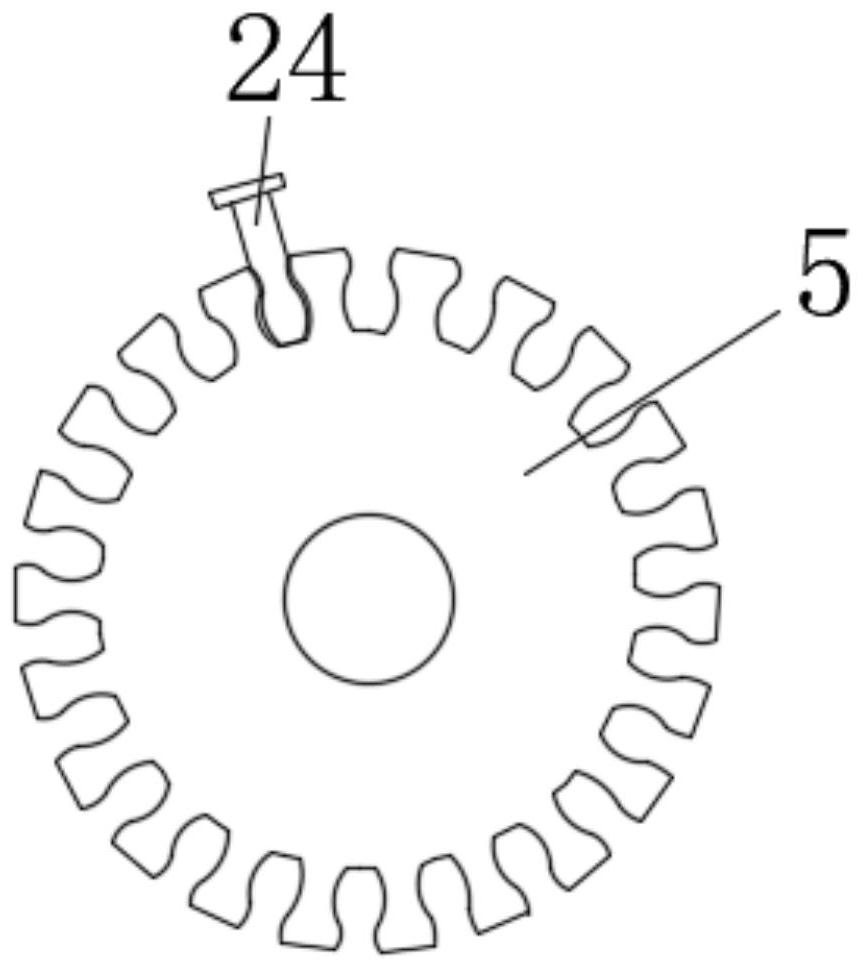

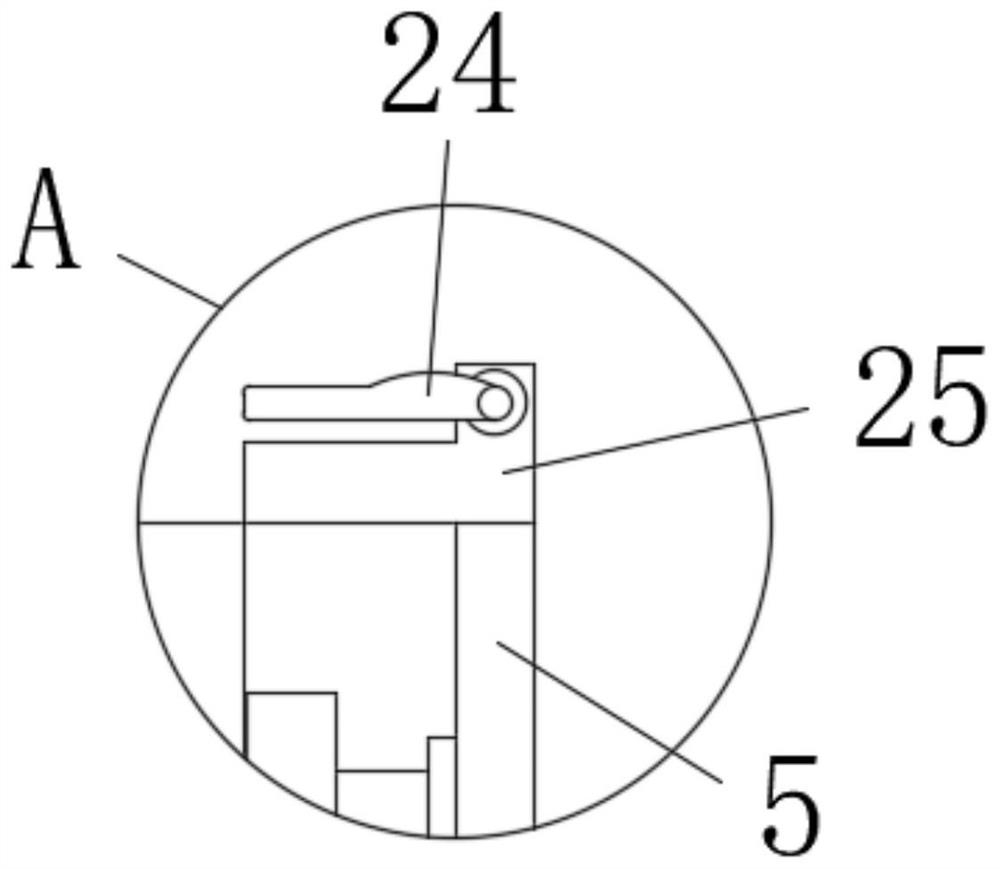

Drilling machine capable of conducting quick positioning and used for machine manufacturing

PendingCN112122641AImprove work efficiencyEnsure offsetFeeding apparatusPositioning apparatusElectric machineryManufacturing engineering

The invention belongs to the technical field of machine manufacturing, and discloses a drilling machine capable of conducting quick positioning and used for machine manufacturing. The machine comprises a supporting frame, a first motor is fixed on one side of the supporting frame, a threaded rod is fixed at the output end of the first motor, bearings are fixed on two sides of the threaded rod, a gear is arranged on the side, away from the first motor, of the threaded rod, the threaded rod is sleeved with a sliding base, a hydraulic cylinder is fixed to the lower portion of the sliding base, vertical rods are arranged on the two sides of the hydraulic cylinder, a fixing frame is arranged on one side of the transverse straight portion of the supporting frame, and a limiting pin is arranged above the fixing frame. According to the machine, the gear and the limiting pin are arranged, the gear is connected with the threaded rod capable of driving the whole punching device, and after the position of the punching device is determined, the gear is fixed through the limiting pin so that it can be guaranteed that when the punching device works, the punching position cannot shift due to vibration.

Owner:YANGZHOU POLYTECHNIC INST

Novel phase-change heat-storage material and preparation method thereof

InactiveCN104164221ANo change in chemical propertiesWon't change shapeHeat-exchange elementsParaffin waxParaffin oils

The invention discloses a novel phase-change heat-storage material and a preparation method thereof, the phase-change heat-storage material is composed of paraffin, expandable graphite, active carbon and copper powder by mixing, wherein paraffin mass fraction accounts for 60%, the paraffin melting point is selected between 50-70 DEG C, expandable graphite mass fraction accounts for 20%, and sum of mass fraction of active carbon and copper powder accounts for 20%. The material has the advantages of fast heat absorption and heat release speed, no corrosivity to metal containers and no changed profile after phase change.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

Highly-heat-conductive shaped phase-change heat-storage material and preparation method thereof

InactiveCN105154017AImprove thermal conductivityFast heat absorption and releaseHeat-exchange elementsParaffin oilsGraphite

The invention discloses a highly-heat-conductive shaped phase-change heat-storage material and a preparation method thereof. The heat-storage material is prepared from compounding paraffin, expanded graphite and porous foamed copper, wherein the mass percentage of the paraffin accounts for 74.88%; the mass percentage of the expanded graphite accounts for 8.32%; the mass percentage of the porous foamed copper accounts for 16.8%; the melting point of the paraffin selected in the above-mentioned materials is in the range of 40 DEG C to 60 DEG C; and the voidage of the porous foamed copper selected in the above-mentioned materials is more than 98%. The material has the advantages of rapid heat-absorption and heat-release efficiencies, large heat storage capacity, and invariant shape after phase change.

Owner:JIANGSU QIZHENG NEW ENERGY

Method for marking on growing trees

ActiveCN103798071ADoes not affect growthDoes not affect deliveryHorticulture methodsDistilled waterMarking out

The invention relates to a method for marking on growing trees. The method comprises the following steps: polishing parts of the trees which require to be marked by abrasive cloth until the parts are smooth and clean; cleaning the parts which are polished by the abrasive cloth with distilled water; then inputting contents which require to be marked into a computer, enabling a laser machine to be aligned with the parts of the trees which are air-dried in the step (2), and starting the laser machine to mark corresponding contents on the parts; finally coating a liquid medicine on the parts. With the adoption of the method disclosed by the invention, the trees are marked and the growth of the trees is not affected.

Owner:姜军

Novel inorganic composite high-thermal-conductivity phase-change heat storage material and preparation method thereof

InactiveCN106701027AMaintain physical and chemical propertiesHigh phase change enthalpyHeat-exchange elementsPorositySuper absorbent

The invention discloses a novel inorganic composite high-thermal-conductivity phase-change heat storage material and a preparation method thereof. The heat storage material is prepared from, in percentage by mass, 83.2% of crystal salt hydrate, 0.8% of an SAP (super absorbent polymer) and 16% of porous aluminum through composition, and the porosity of selected porous aluminum in the materials is 90% or higher. The material has the advantages that the heat absorption and release speeds are high, the heat storage capacity is high, and the appearance is unchanged after phase change.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

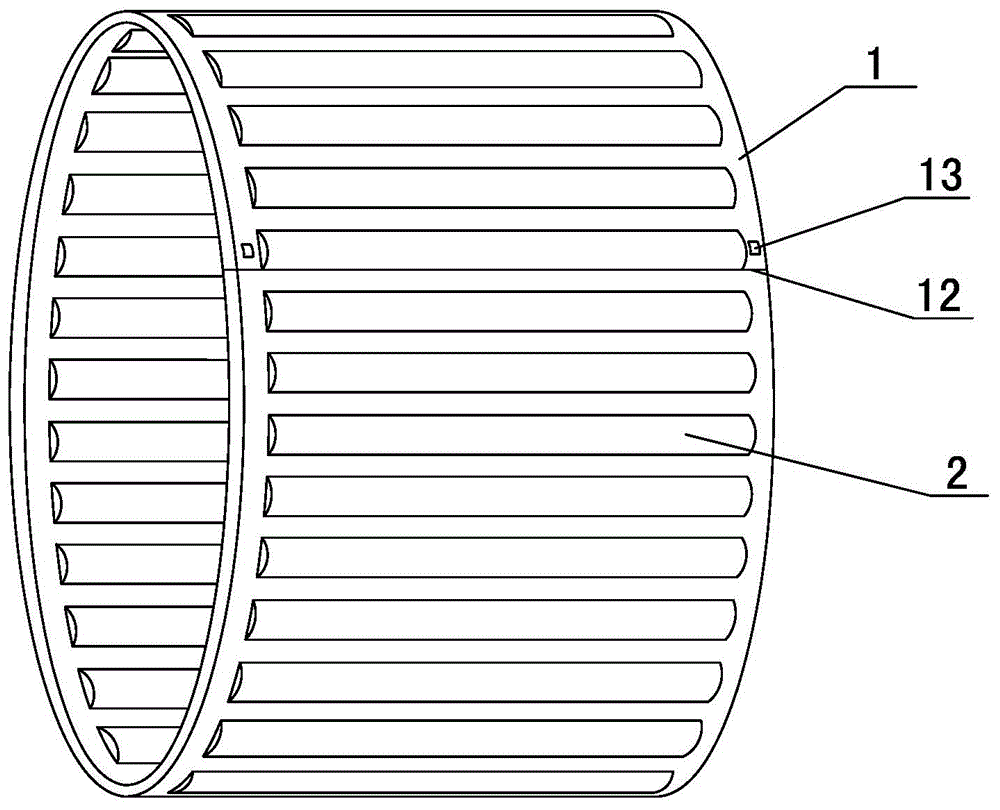

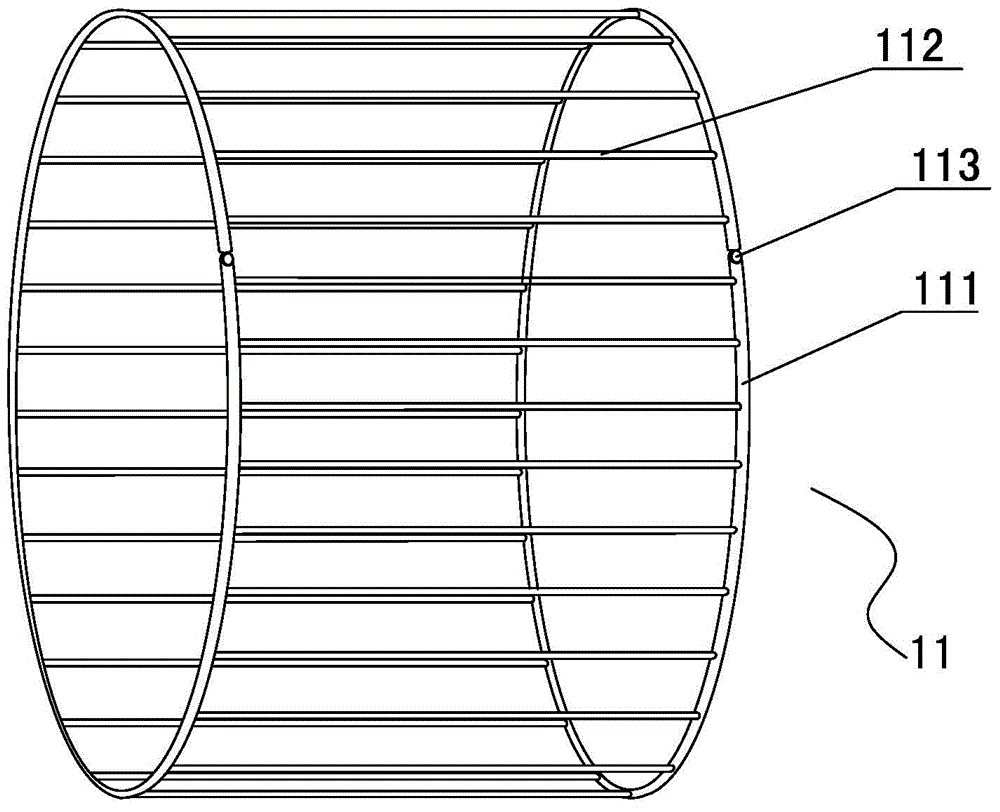

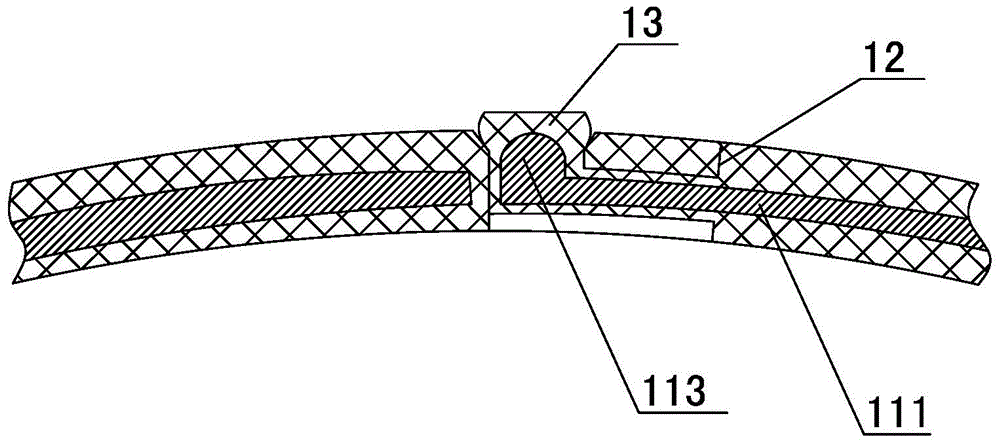

Bearing rolling needle holder

The invention discloses a bearing rolling needle cage. A cage body consists of multiple separation strips for separating adjacent rolling needles and two connecting rings for respectively connecting the end parts of the two ends of each separation strip; a disconnecting place for opening the cage body is axially arranged on the cage body; one edge of the disconnecting place is provided with a buckle connected with a bayonet on the other edge; and the diameter of the head part of the buckle is larger than the diameter of the bayonet. The bearing rolling needle cage has the following advantages that as the disconnecting place is arranged on the cage body, after the rolling needles are quickly assembled, the cage body can coat an inner ring after being opened from the disconnecting place and the projection on one edge of the crack is connected with the other edge, so that the assembly is convenient and consumes little time; and preferably, the cage body consists of an openable metal framework and a shape layer wrapping the metal framework, and as the shape layer is preferably manufactured from PEEK which is better in deformation and recovery performance, the cage body can be opened conveniently and the recovered shape cannot be changed.

Owner:NINGBO ZHONGHE AUTO PATS

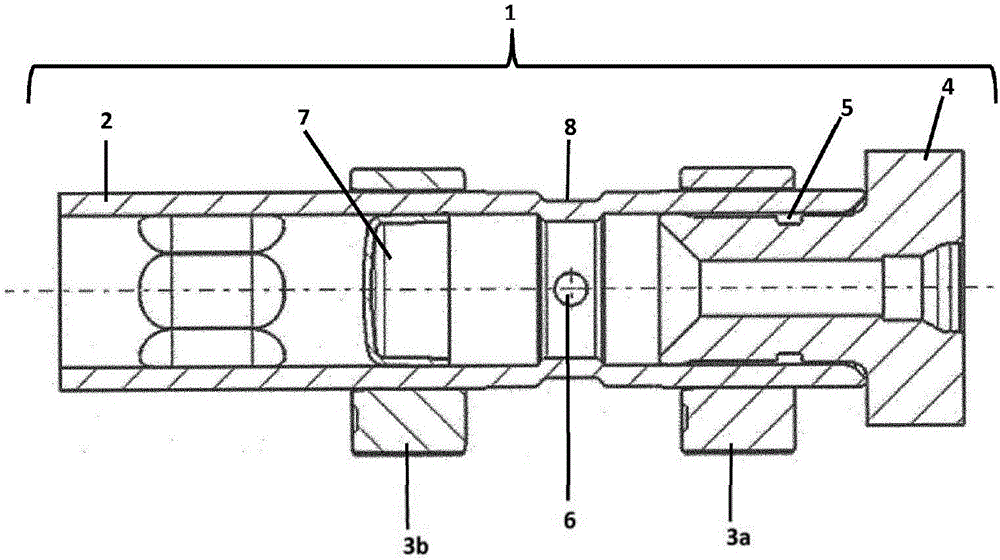

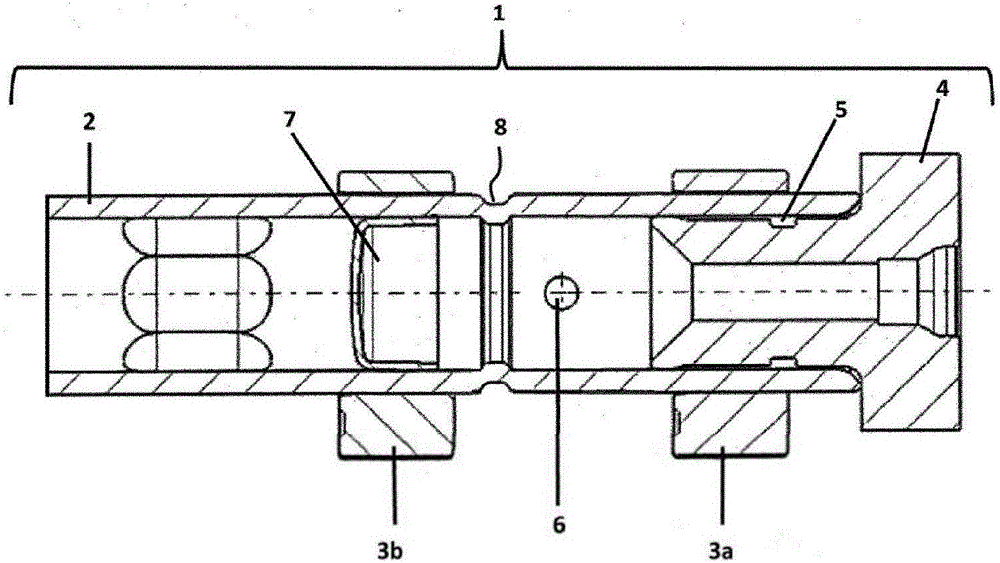

Camshaft having a closing cover

ActiveCN106414916AAvoid affecting oil pressurePrevent impact sizeCamsValve arrangementsCamshaftEngineering

The invention relates to a hollow cylindrical camshaft (1), which is equipped with a closing cover (7) and supply openings (6), wherein sliding of the closing cover (7) is prevented by means of one or more recesses (8) introduced into the camshaft (1). The recesses (8) are rolled-in points, indentations, notches, plastic deformation introduced from outside by means of a punch, or introduced retaining means (9) that protrude into the interior of the camshaft (1). The one or more recesses (8) are arranged in one or more planes orthogonal to the axial direction of the camshaft (1), wherein the one or more recesses (8) can be arranged rotationally symmetrically or symmetrically or asymmetrically in said one or more planes.

Owner:THYSSENKRUPP PRESTA TECCENTER AG

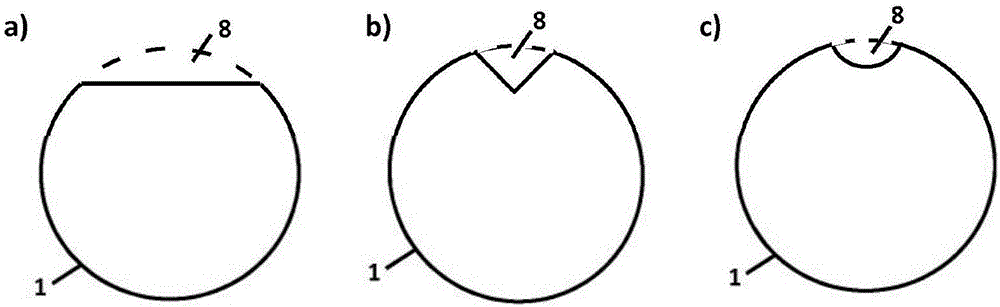

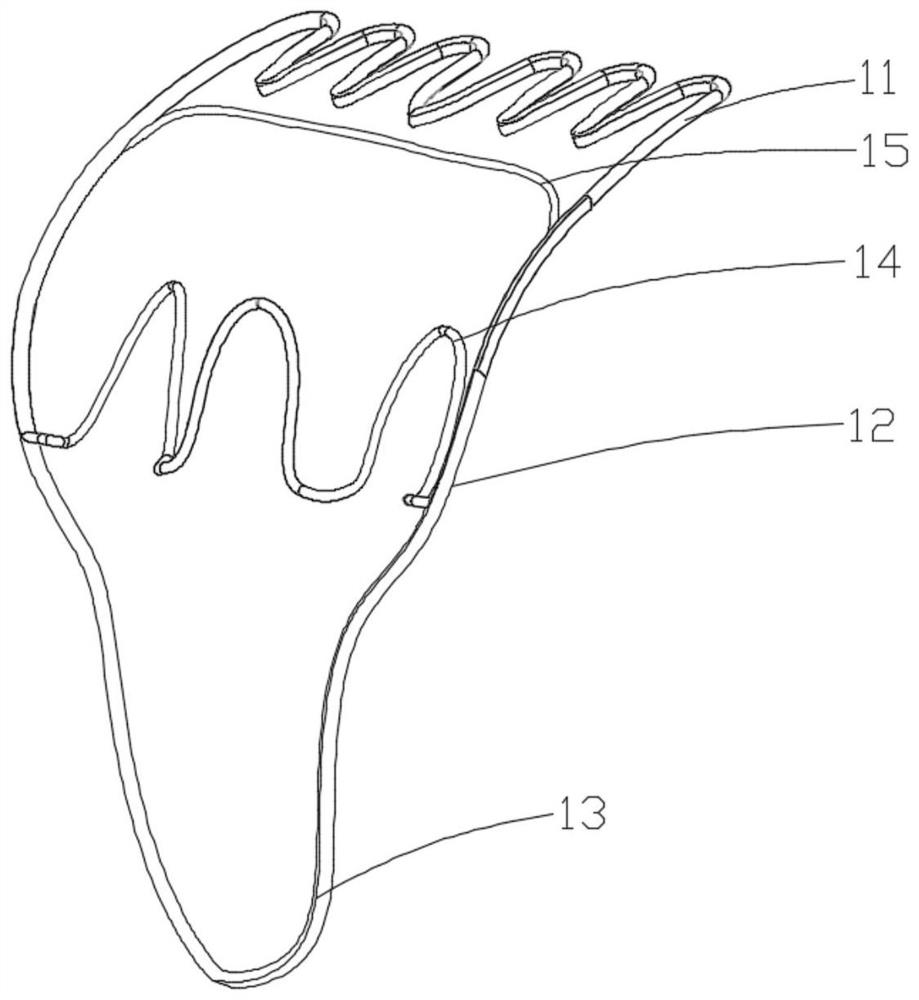

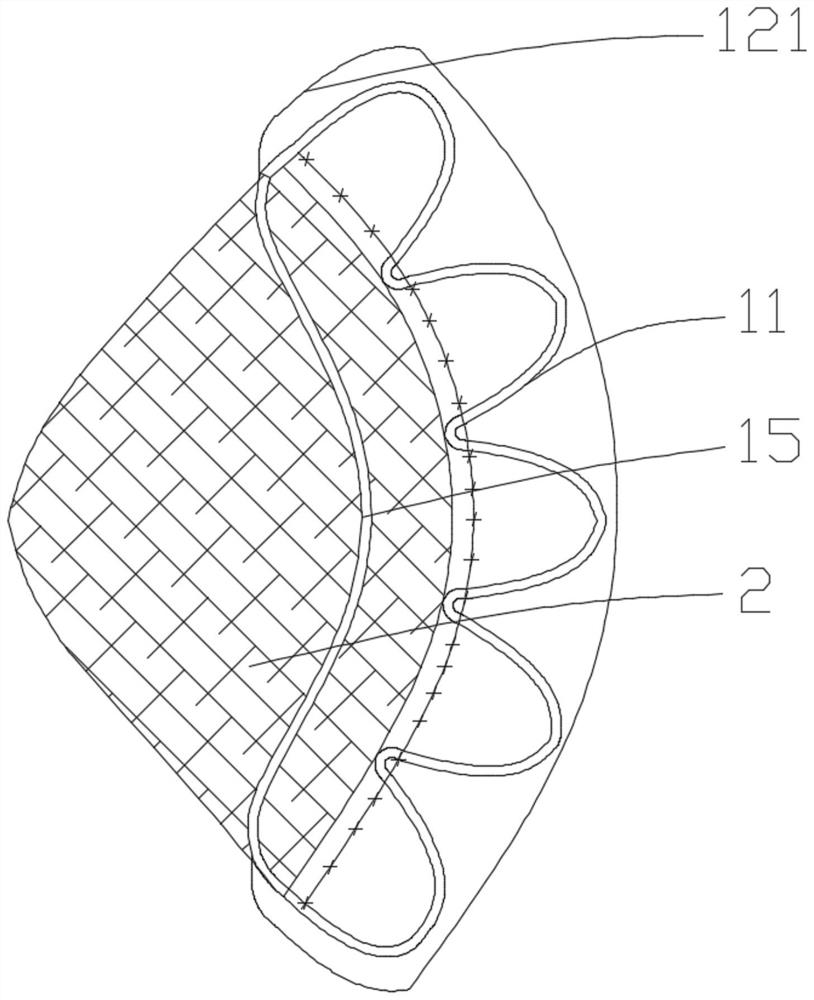

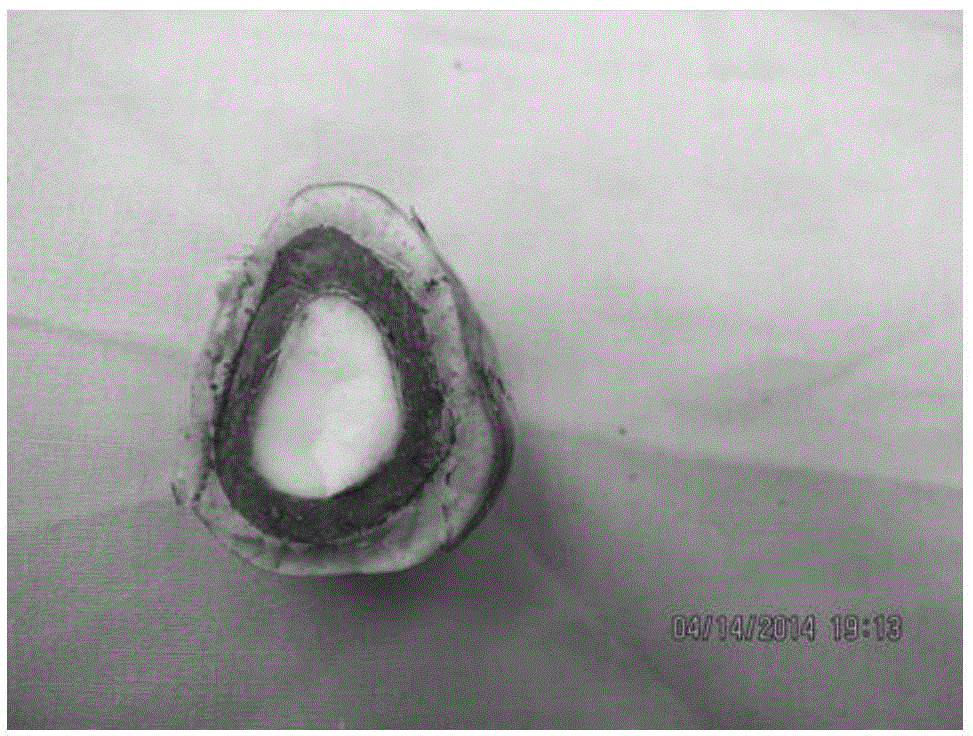

Repair device for preventing valve regurgitation

InactiveCN113712707AWon't change shapeAvoid damageAnnuloplasty ringsValvular regurgitationEngineering

The invention relates to the field of medical instruments, in particular to a repair device for preventing valve regurgitation. The device comprises: a mounting bracket; and a single anti-regurgitation leaflet prosthesis for replacing the function of a single autologous leaflet, wherein one end of the single anti-regurgitation leaflet prosthesis is fixed on the mounting bracket. The repair device only replaces a single valve leaflet with a problem, the original functions of the remaining part of the autologous valve leaflet are reserved, meanwhile, the shape of an autologous valve ring is not changed, damage to intracardiac tissue is small, meanwhile, the implantation amount of an implant is small, and irritation is small.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

Treatment method of oil palm seed core-shell material for manufacturing handicraft articles

InactiveCN104589890AIncrease profitAchieve diversificationSpecial ornamental structuresResource utilizationProduct processing

The invention belongs to the field of agro-product processing, and relates to a treatment method of an oil palm seed core-shell material for manufacturing handicraft articles. The method comprises the following steps: firstly selecting a thick-shell type oil palm seed, carbonizing and dehydrating, drying, filling a germination aperture, and polishing the thick-shell type oil palm seed to obtain the oil palm seed core-shell material. The treatment method disclosed by the invention is simple and safe in operation and low in cost, the chemical method is used for treating the surface of the nuclear-shell material so as to obtain the oil palm seed core-shell material with smooth surface through polishing and different colors on the premise of not changing the appearance shape and size, the individual needs of the handicraft article material can be satisfied, the maximization of resource utilization and the diversification of the core-shell material are realized, the comprehensive utilization level of the oil palm is improved; the treatment method has important significance to promote the oil palm industry development of China and enrich the tourist market products of China.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

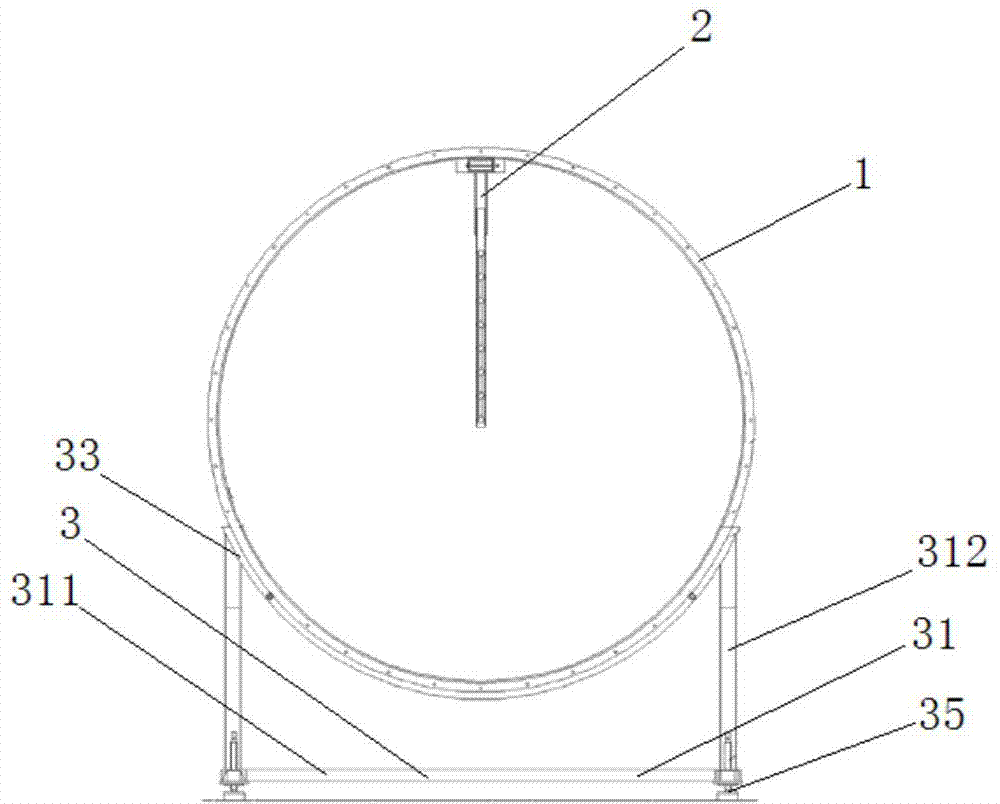

Device for measuring sound mode of engine pipeline

InactiveCN104776910AReduce in quantityImprove versatilitySubsonic/sonic/ultrasonic wave measurementMeasurement deviceMicrophone

The invention discloses a device for measuring a sound mode of an engine pipeline. The device comprises an annular body, a bracket and microphones, wherein the annular body is in butt joint with the opening of the engine pipeline; the bracket is arranged on the annular body, extends toward the centering direction of the annular body and can rotate relative to the opening of the engine pipeline; the microphones are sequentially arranged on the bracket along the extension direction of the bracket at intervals and are used for detecting the intensity magnitude of sound wave from the engine pipeline. In the device for measuring the sound mode of the engine pipeline, the microphones are arranged on the bracket at intervals, and the bracket can rotate relative to the opening of the engine pipeline, the intensity magnitude of sound wave of the whole engine pipeline can be detected in all directions; compared with the prior art, the device has a smaller number of microphones, and can adapt to various engine pipelines of different cross sections in a rotating way, thereby increasing the universality.

Owner:CHINA AIRPLANT STRENGTH RES INST

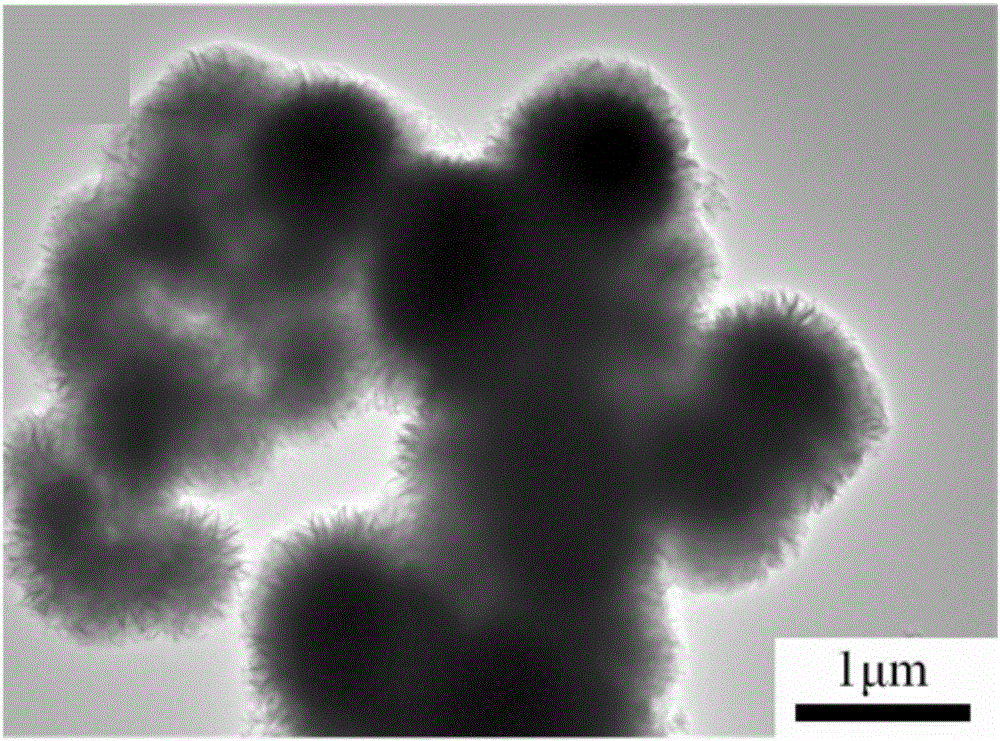

Preparation of small-sized hydroxyl iron oxide nanorod

InactiveCN109052483AUniform particle size distributionImprove surface activityIron oxides/hydroxidesNanotechnologyIron(III) chlorideHydrolysis

The invention discloses a preparation method of a hydroxyl iron oxide nanorod, relating to the technical field of nano materials. The preparation method of the hydroxyl iron oxide nanorod comprises the steps of dissolving FeCl3.6H2O in water, then adding potassium permanganate, performing thermal treatment while stirring, and reacting to obtain the hydroxyl iron oxide nanorod that has a diameter of 35 nm and is 5 nm wide. The small-sized rod-like nano iron oxide is acquired in one step through hydrolysis of ferric chloride and strong oxidation of potassium permanganate. Specifically, the method comprises steps of adding FeCl3.6H2O and deionized water in deionized water, ultrasonic dissolving and then adding potassium permanganate, reacting during stirring for a while, and ultrasonic washing to obtain small-sized beta-FeOOH nanorods with particles distributed uniformly.

Owner:NORTHEAST NORMAL UNIVERSITY

High temperature phase change composite heat storage material and preparation method thereof

InactiveCN108003843ALarge latent heat of phase changeHigh temperature stabilityHeat-exchange elementsHeat conductingEnergy conversion efficiency

The invention belongs to the technical field of heat storage materials, and particularly discloses a high temperature phase change composite heat storage material and a preparation method thereof. Thehigh temperature phase change composite heat storage material is prepared from, by weight, 60-80 parts of inorganic salt, 24-30 parts of expanded graphite, 8-15 parts of copper powder and 3-8 parts of graphene. The prepared composite phase change heat storage material is higher in heat conducting performance and higher in heat absorption and release speed; the maximum enthalpy value reaches up to228.7 mA cm<-2>, the thermal conductivity is 4.2 mW / mg, the material has the advantages of being large in phase change latent heat, high in high temperature stability, small in toxicity and corrosivity and the like, and the phase change heat storage material is adopted, so that the energy conversion efficiency is improved.

Owner:TIANJIN QIZHEN ENERGY SAVING TECH CO LTD

A Spatial Division Method for Intersecting Linear Geographical Elements

InactiveCN104915991BWon't change shapeAvoid situations where Voronoi diagrams cannot be generated3D modellingGeographic featureLinear element

The invention discloses a spatial subdivision method for intersecting linear geographic elements. The method includes the following steps that: intersecting linear elements are dispersed so as to form point sets based on the principle of a Voronoi distribution model; point addition processing is performed on intersecting positions of every two intersecting linear elements; Delaunay triangulation and Voronoi diagram generation are performed based on the point sets; and a generated Voronoi diagram is clipped, and sub regions generated by point sets which belong to the same linear element are merged, so that sub regions of different linear elements can be obtained, and therefore, spatial subdivision of the intersecting linear geographic elements can be realized.

Owner:NANJING NORMAL UNIVERSITY

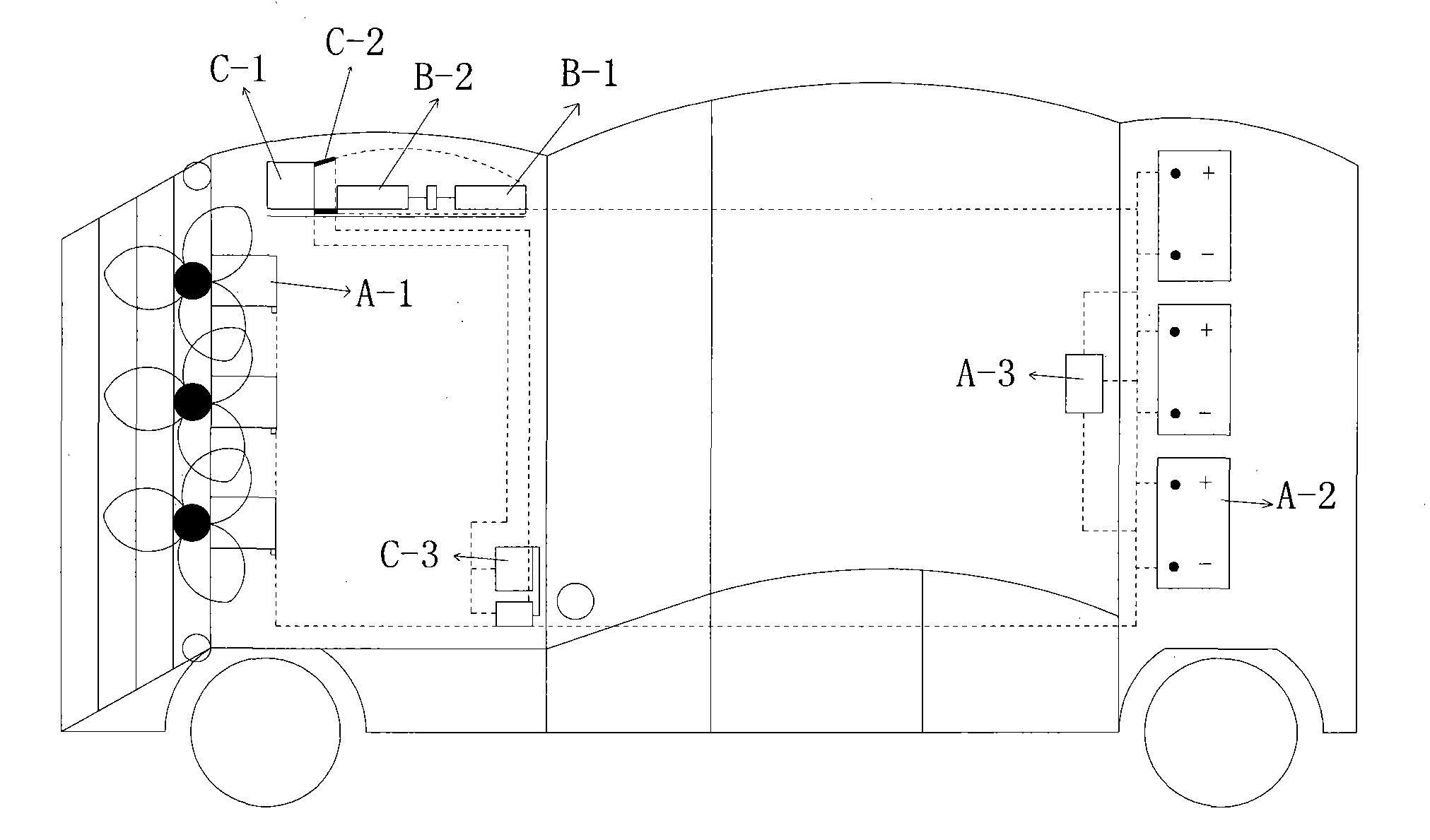

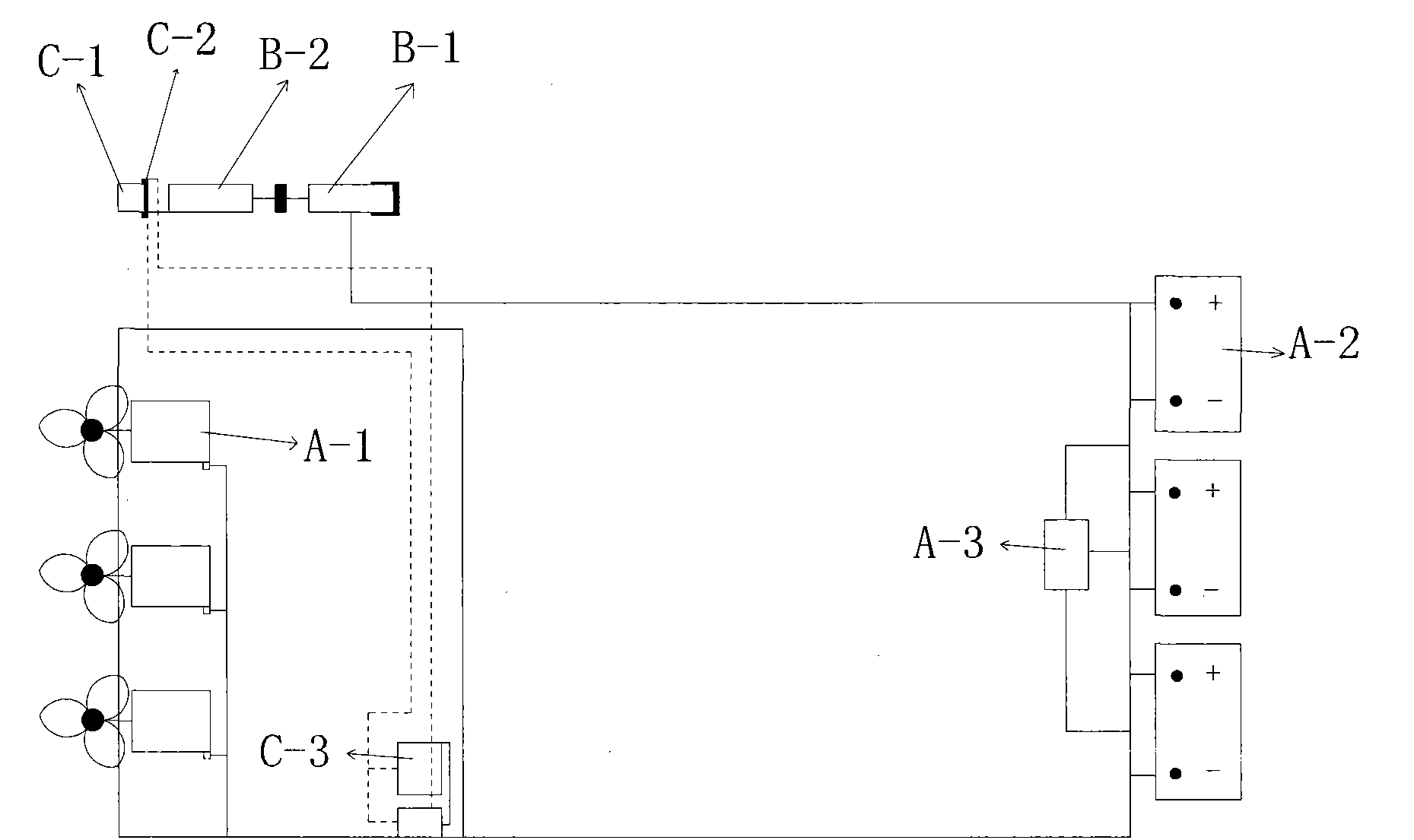

Electric car adopting wind energy

InactiveCN103754121AWon't change shapeDoes not increase dragVehicular energy storageElectric propulsionAerodynamic dragConservation energy

The invention provides an electric car adopting wind energy. The electric car comprises a car body, a wind power generation unit, a storage battery and a main electric motor. The wind power generation unit is connected with the storage battery and used for converting the wind energy into electric energy and then storing the electric energy into the storage battery. The main electric motor is connected with the storage battery and used for converting the electric energy into kinetic energy driving the car to drive. The electric car is characterized in that the wind power generation unit is arranged at the front end of the car body. The electric car aims to save the energy, the air resistance in the driving process of the car is converted into the electric energy, the electric energy is stored into the storage battery and supplements power for driving of the car, tail gas exhaust can be effectively reduced, and pollution can be reduced.

Owner:黄师荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com