Method and its device for detecting high energy semiconductor laser divergence angle

A test method and laser technology, which is applied in the direction of semiconductor laser, single semiconductor device test, optical instrument test, etc., can solve the problems of CCD and detector saturation, affect the measurement accuracy, change the shape of the light spot, etc., and achieve easy production and assembly, structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

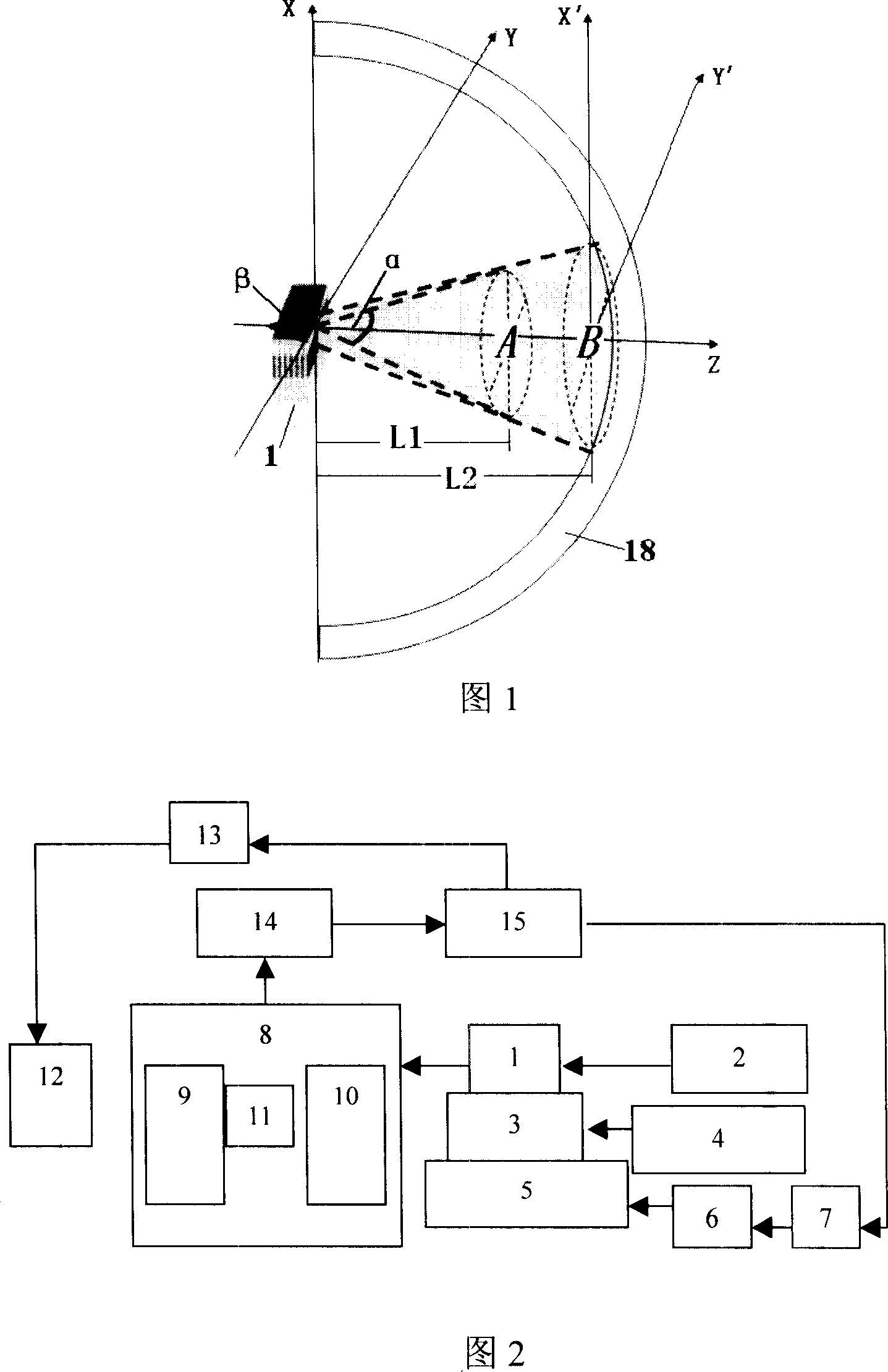

[0050] Figure 1 shows the basic testing principle of the present invention. In the previous divergence angle testing methods, the laser is usually equivalent to a point light source. Therefore, only one spot at a certain distance from the laser, such as the spot A at the distance L1 in Figure 1, can be used to calculate the laser's Divergence angle, the divergence angle obtained in this way is α in Figure 1. The invention calculates the divergence angle of the laser on the basis of the geometrical characteristics of the outer edge curves of two light spots where the laser beam is transmitted to different distances. As shown in Figure 1, the divergence angle is calculated based on the spot A and spot B at two distances from the lasers L1 and L2, and the angle can be expressed as β in the figure. Obviously, compared with α, β takes into account the influence of the size of the light-emitting surface of the laser itself on the divergence angle, and can more accurately represent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com