Method for detecting air conditioner refrigerant leakage and air conditioner

A technology for refrigerant leakage and detection methods, which is applied in heating methods, space heating and ventilation, lighting and heating equipment, etc., can solve the problems affecting refrigerant accuracy, low detection accuracy, and high misjudgment rate. The effect of high precision and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

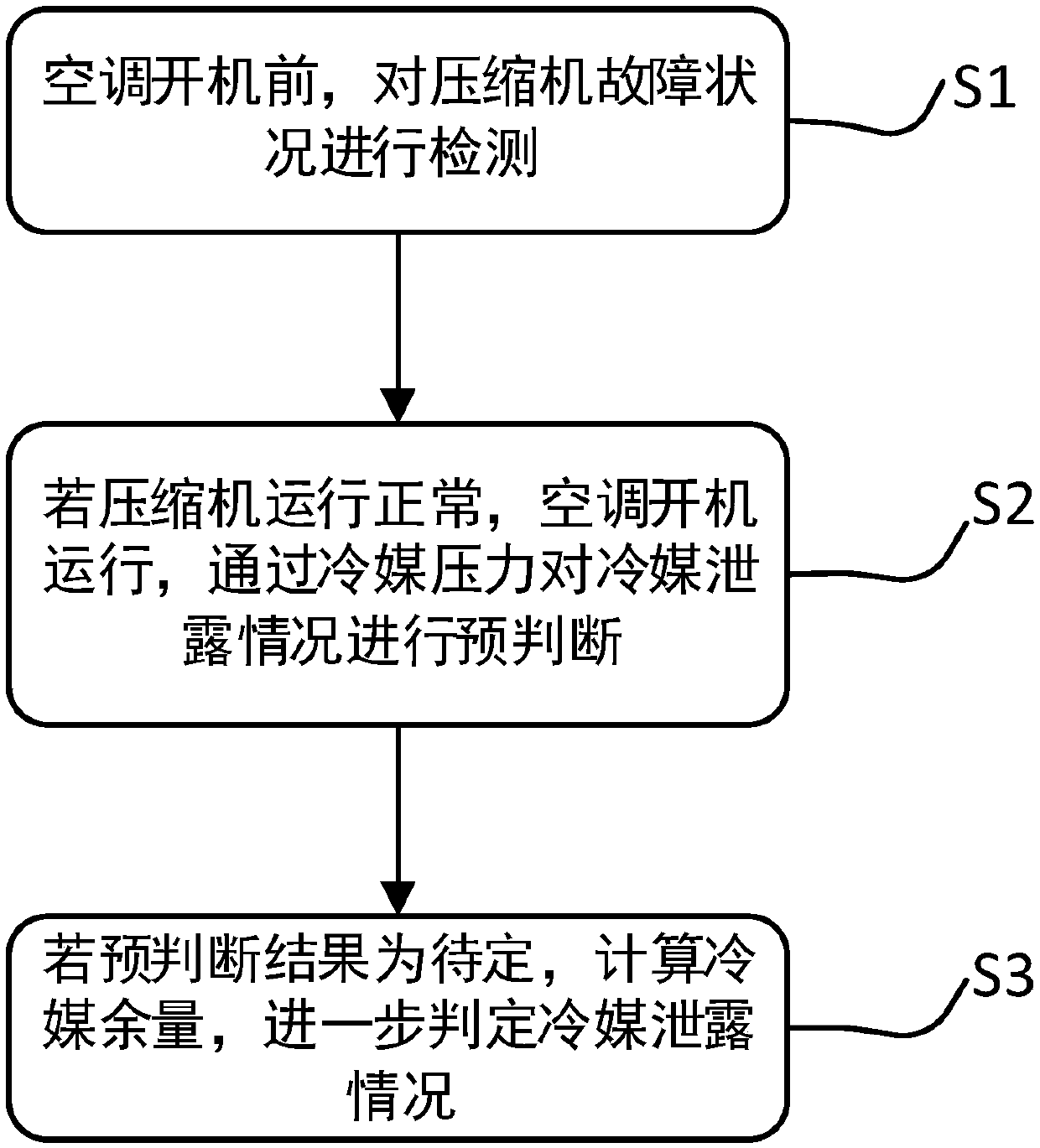

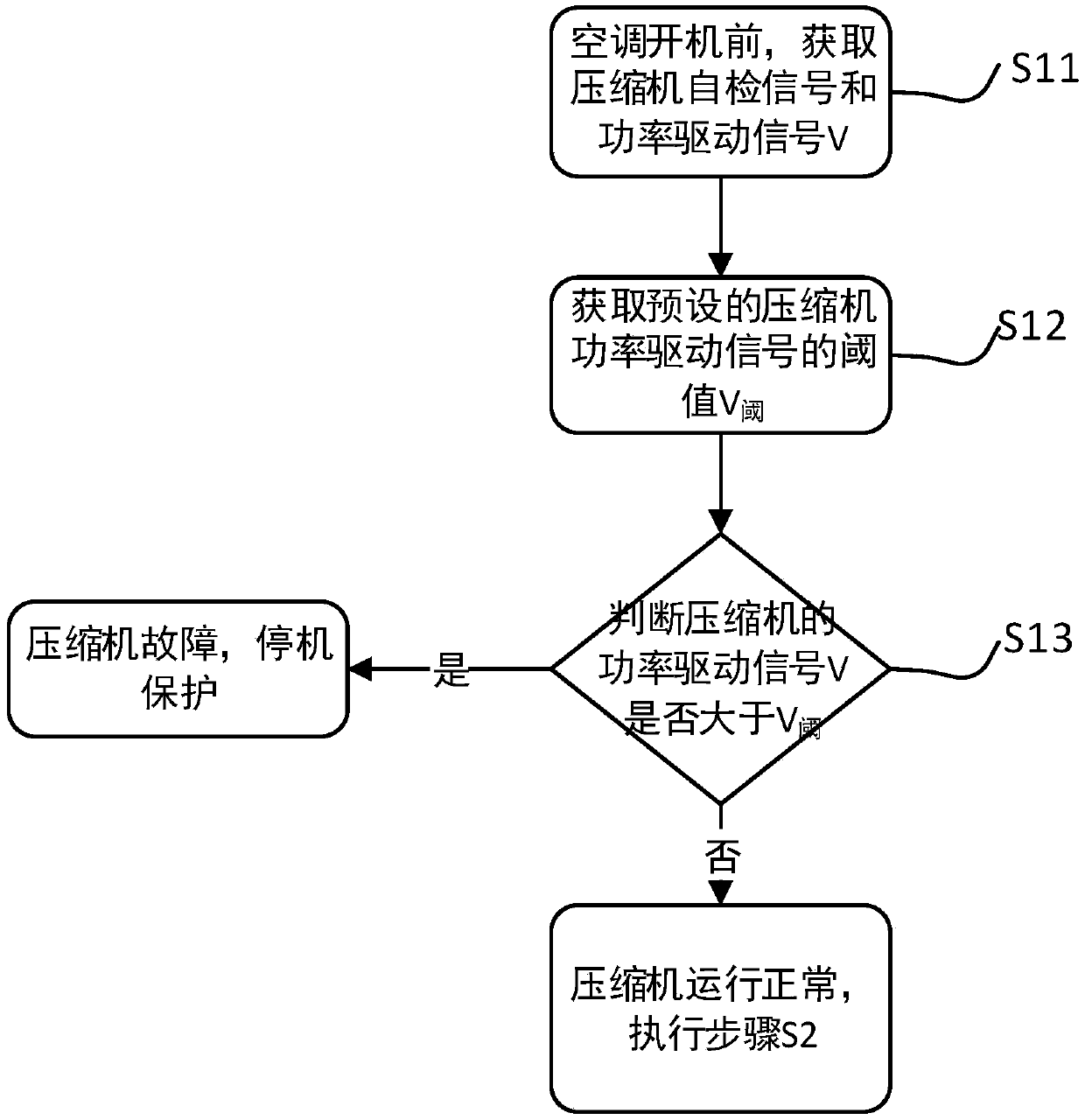

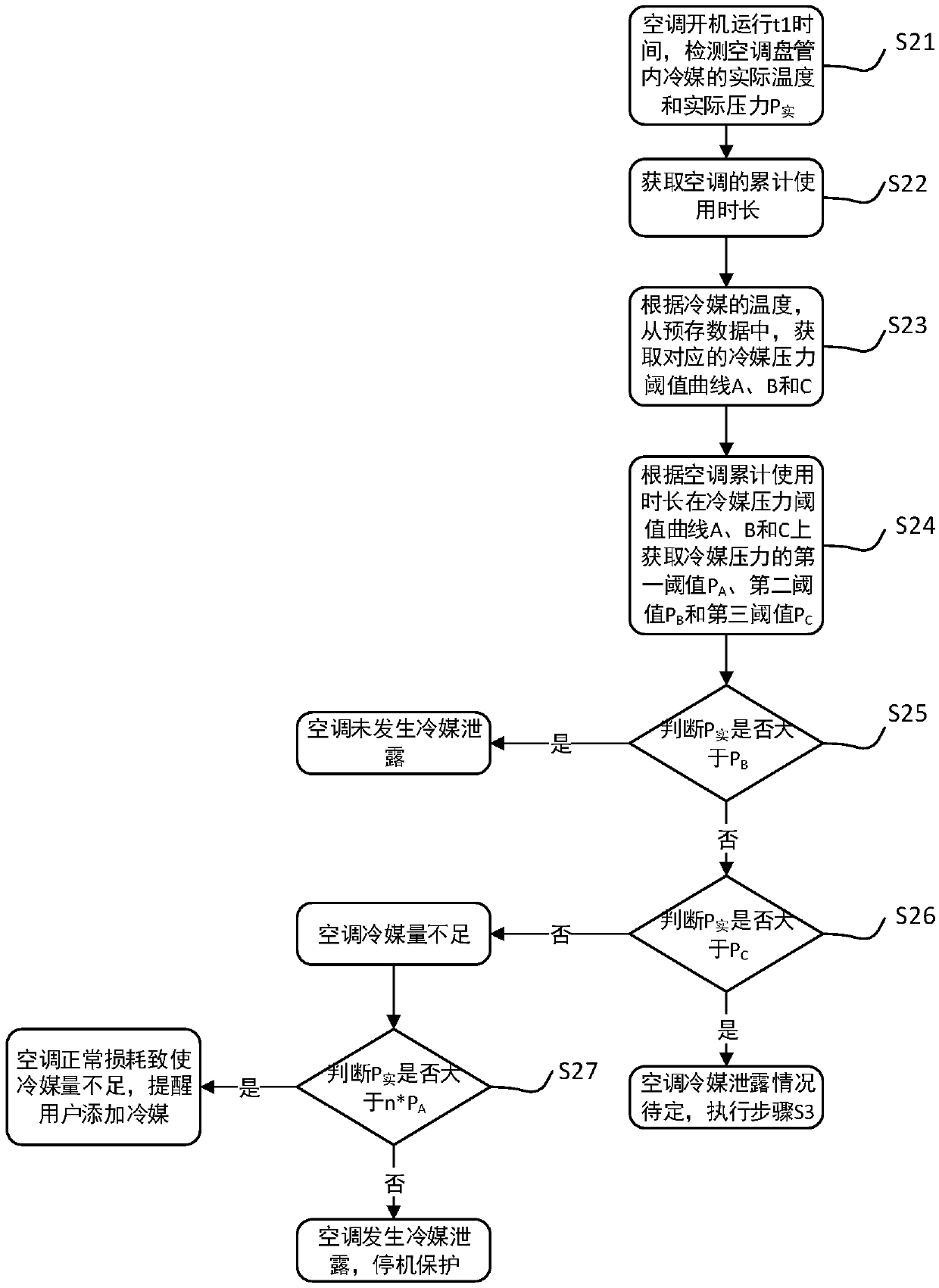

[0036] Such as figure 1 As shown, a method for detecting refrigerant leakage of an air conditioner includes step S1: before starting the air conditioner, detect the failure status of the compressor; if the compressor is running normally, perform step S2; The situation is pre-judged; if the pre-judgment result is pending, step S3 is executed; S3: calculate the remaining amount of refrigerant, and further determine the leakage of refrigerant.

[0037] Specifically, the detection principle of the air-conditioning refrigerant leakage detection method is as follows: firstly, before starting the machine, the failure status of the compressor is detected through the step S1 to determine whether the air-conditioning compressor is faulty. The reason is that if the air-conditioning compressor Faults will affect the accuracy of air-conditioning refrigerant leakage judgments. Second, if the air-conditioning compressor fails and is turned on rashly, it may cause the compressor to burn out, ...

Embodiment 2

[0071] An air conditioner, the air conditioner adopts the above method for detecting refrigerant leakage of an air conditioner to detect refrigerant leakage.

[0072] In summary, it is not difficult to conclude that the air conditioner refrigerant leakage detection method and the air conditioner of the present invention have the advantages of high detection accuracy and low misjudgment rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com