Patents

Literature

260results about How to "Easy fault detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fault tolerance software system with periodic external self-test failure detection

ActiveUS7096388B2Simple and rapid developmentImproved failure detectionSoftware testing/debuggingClient-sideMonitoring program

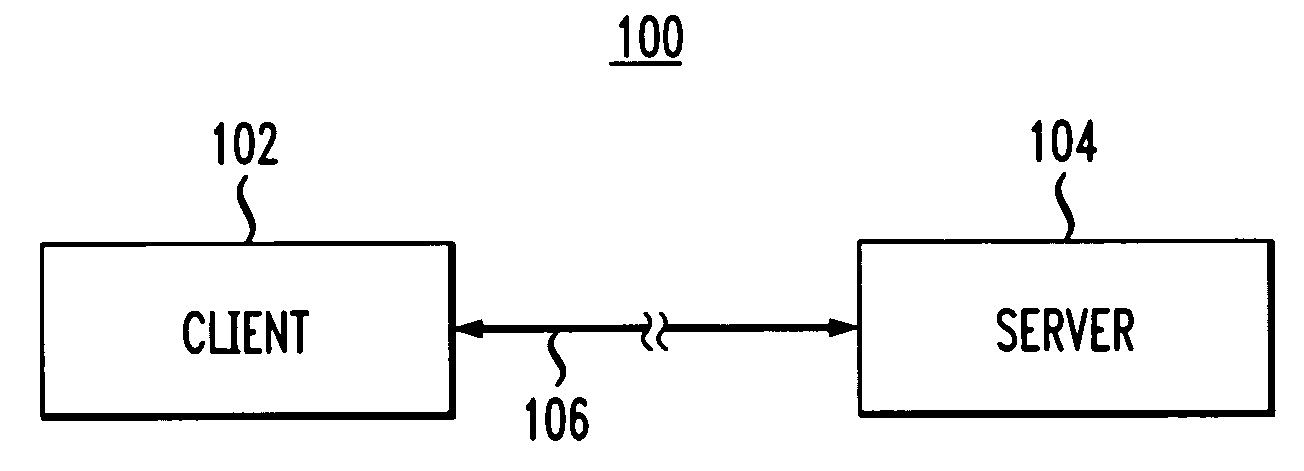

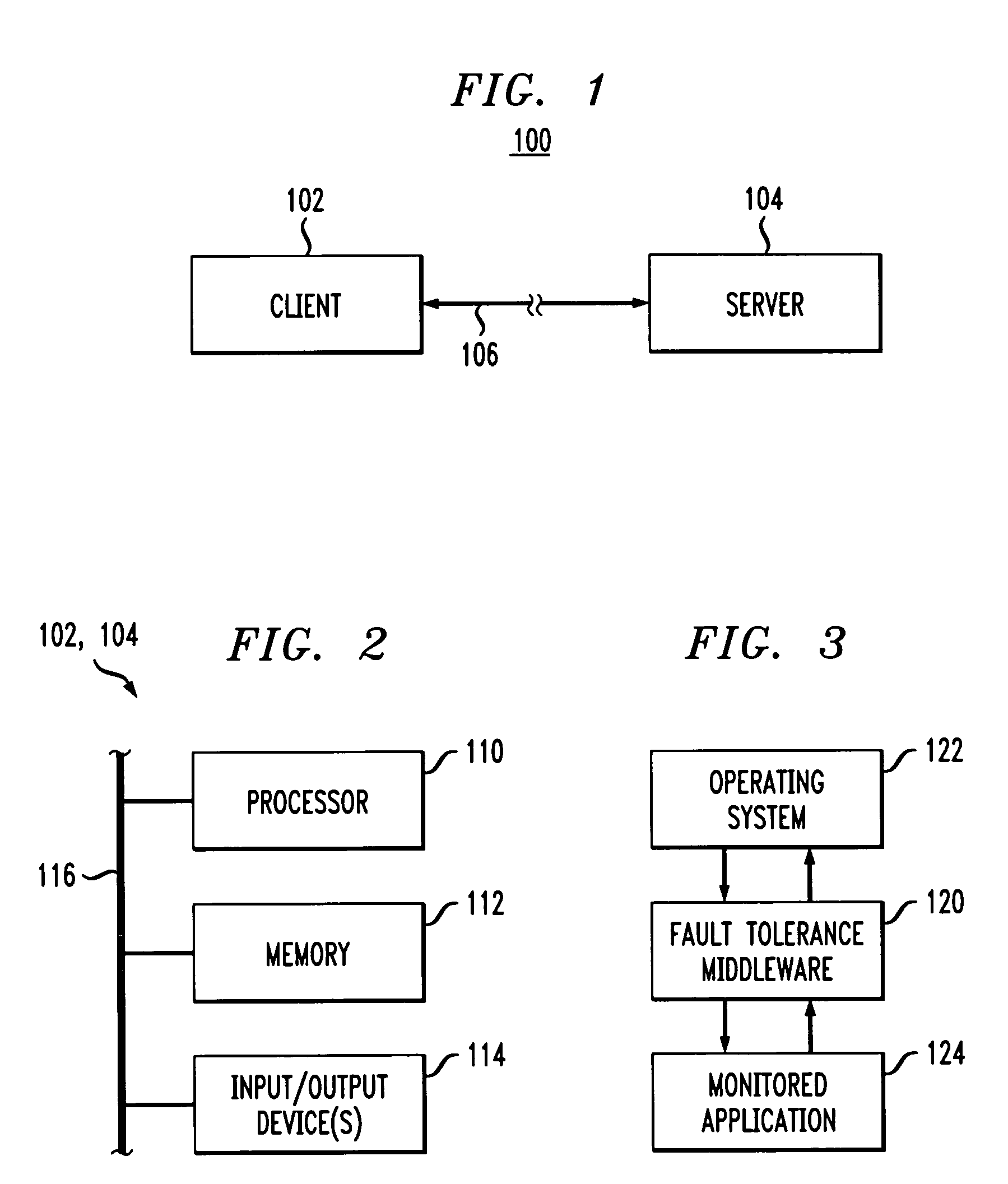

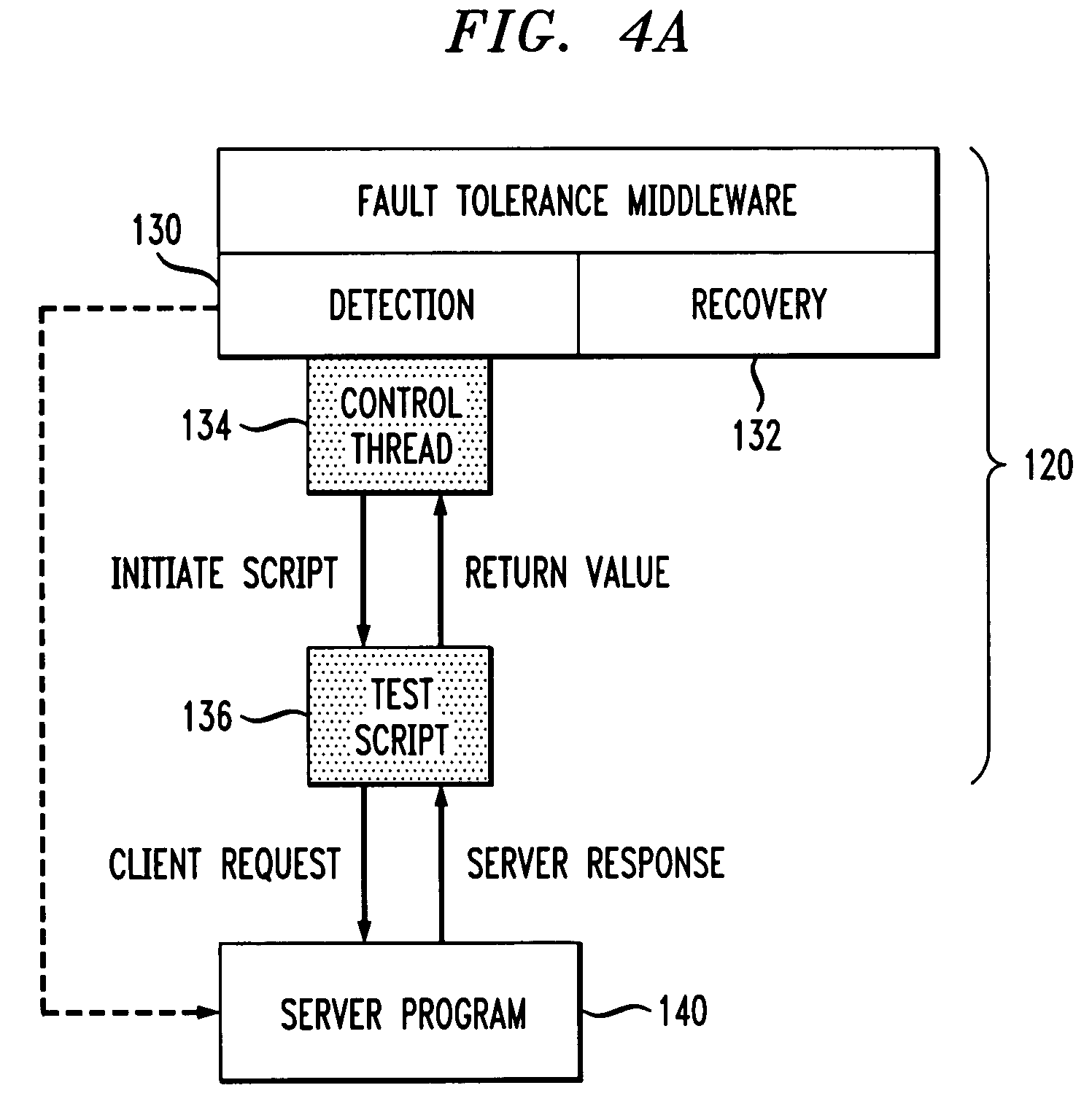

Fault tolerance is improved in a computing system which includes one or more computing machines by (i) executing a control thread or other control program in conjunction with a fault tolerance software system running on at least one of the machines, and (ii) initiating via the control program a test script program which sends one or more requests to a monitored program. The test script program also processes corresponding responses to the one or more requests, and generates a return value utilizable by the control program to indicate a failure condition in the monitored program. The computing system may be configured in accordance with a client-server architecture, with the fault tolerance software system and the monitored program both running on a server of the system. The test script program is preferably implemented in an object-oriented programming language such as Java, such that one or more components of the test script program comprise a base class from which one or more other components of the test script program are generatable for use with the monitored program.

Owner:AVAYA INC

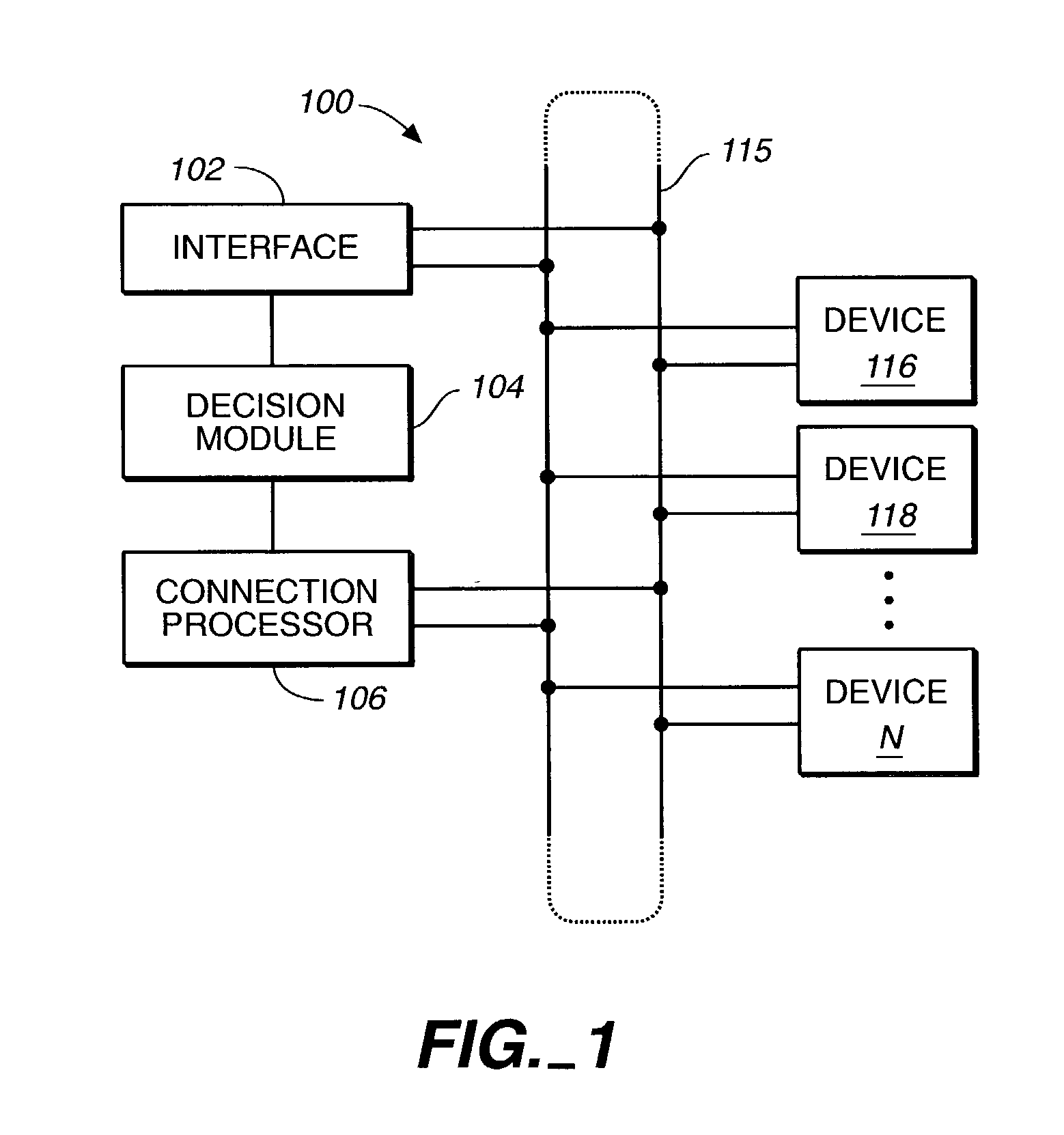

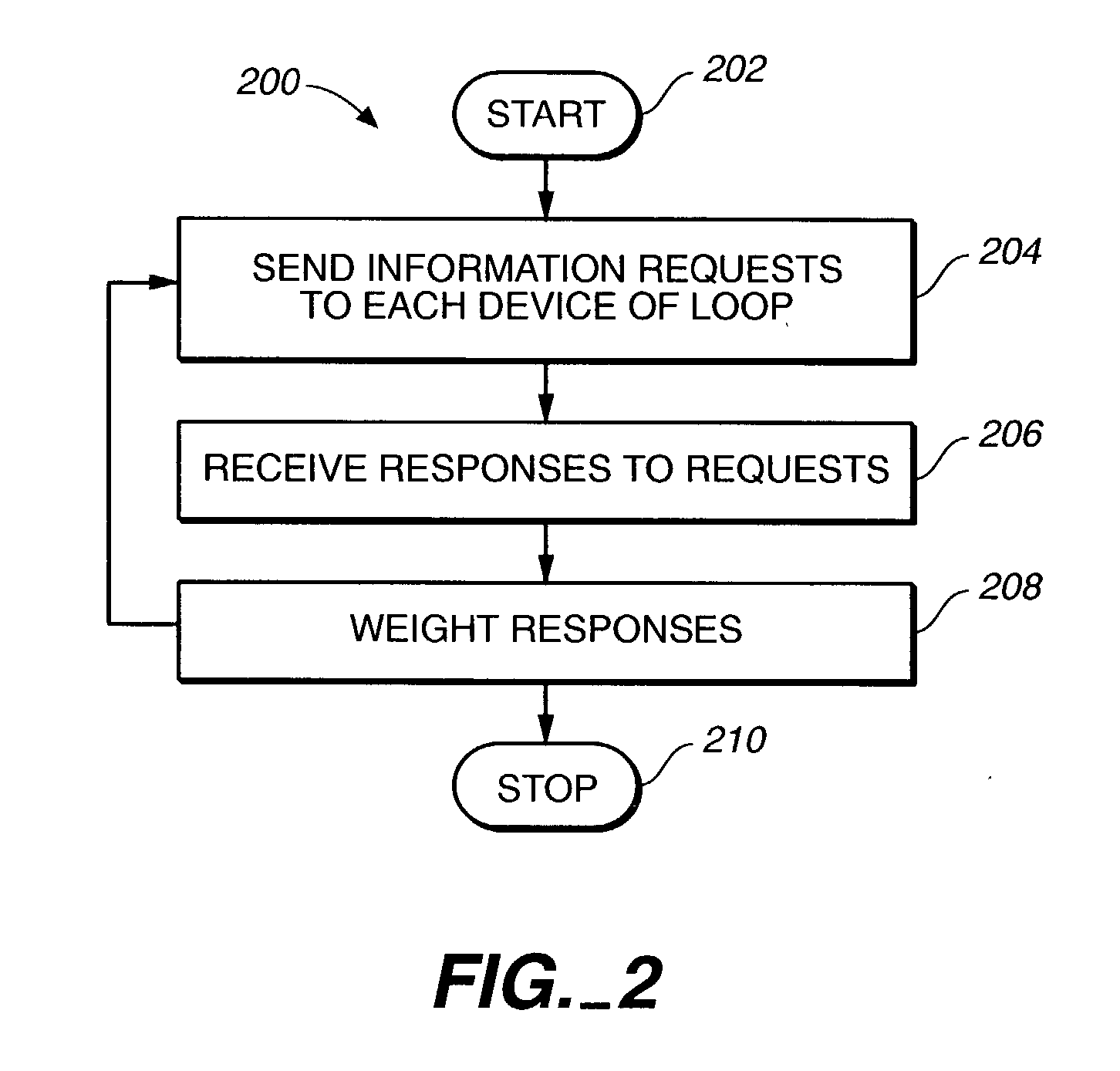

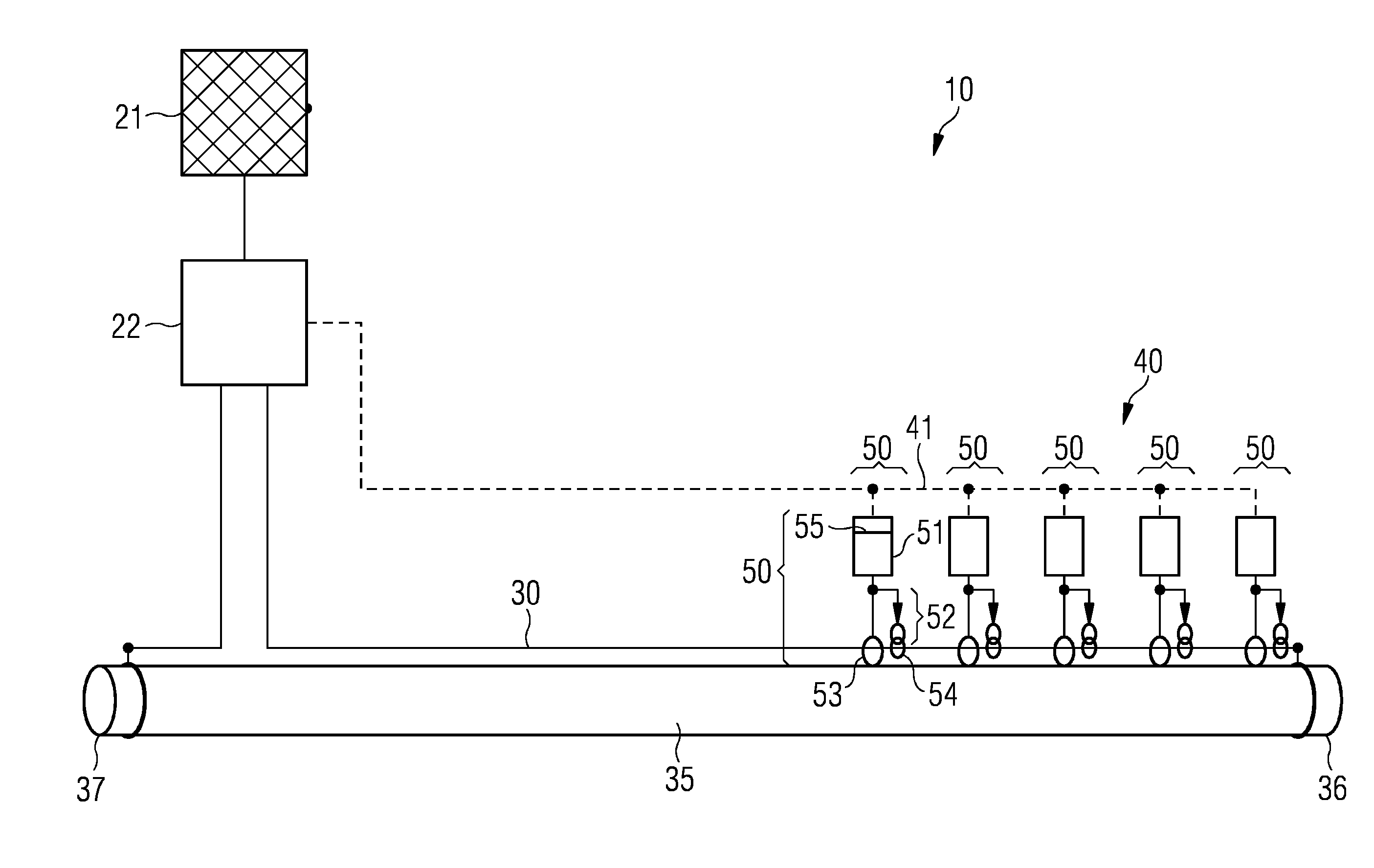

Method and apparatus for identifying one or more devices having faults in a communication loop

ActiveUS20040039981A1Easy fault detectionImprove replacement speedCorrect operation testingError detection/correctionOperabilitySystem identification

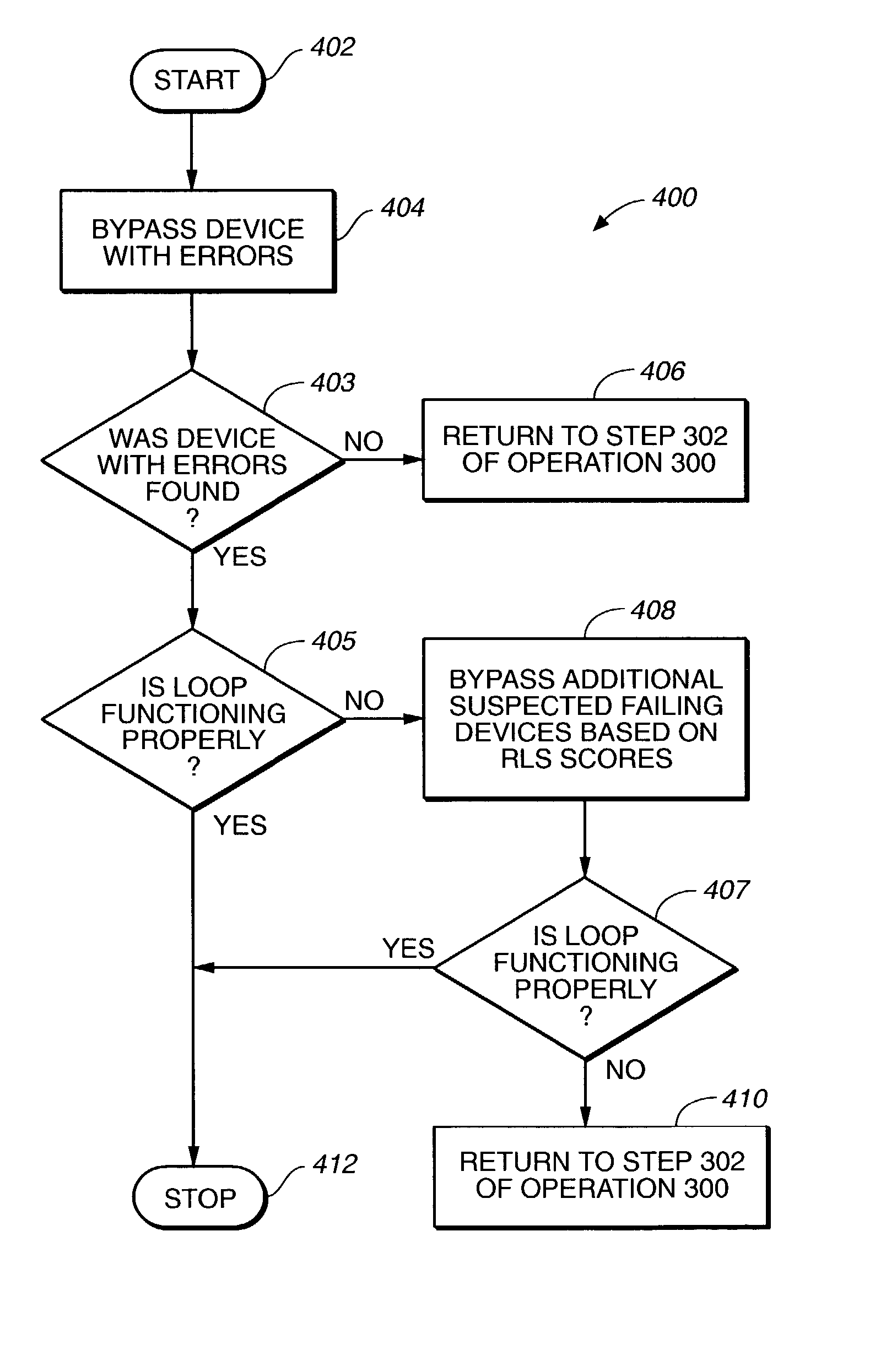

A system identifies one or more devices having faults in a communication loop. The system includes an interface, a decision module, and a connection processor. The interface is configured for sending requests for information to each device of the communication loop and for receiving responses to the requests. The devices may include computer disk drives for use in a storage system. The requests may include Read-Link Status (RLS) commands sent to the computer disk drives. The RLS commands may provide diagnostics of the disk drives connected to the loop. The decision module is communicatively connected to the interface for weighting the responses of each device to identify the devices having the faults. The responses may be weighted based on the relative potential for disrupting operability of the system. The communication loop may include an FC loop that allows communications between a host system and the computer disk drives.

Owner:NETWORK APPLIANCE INC

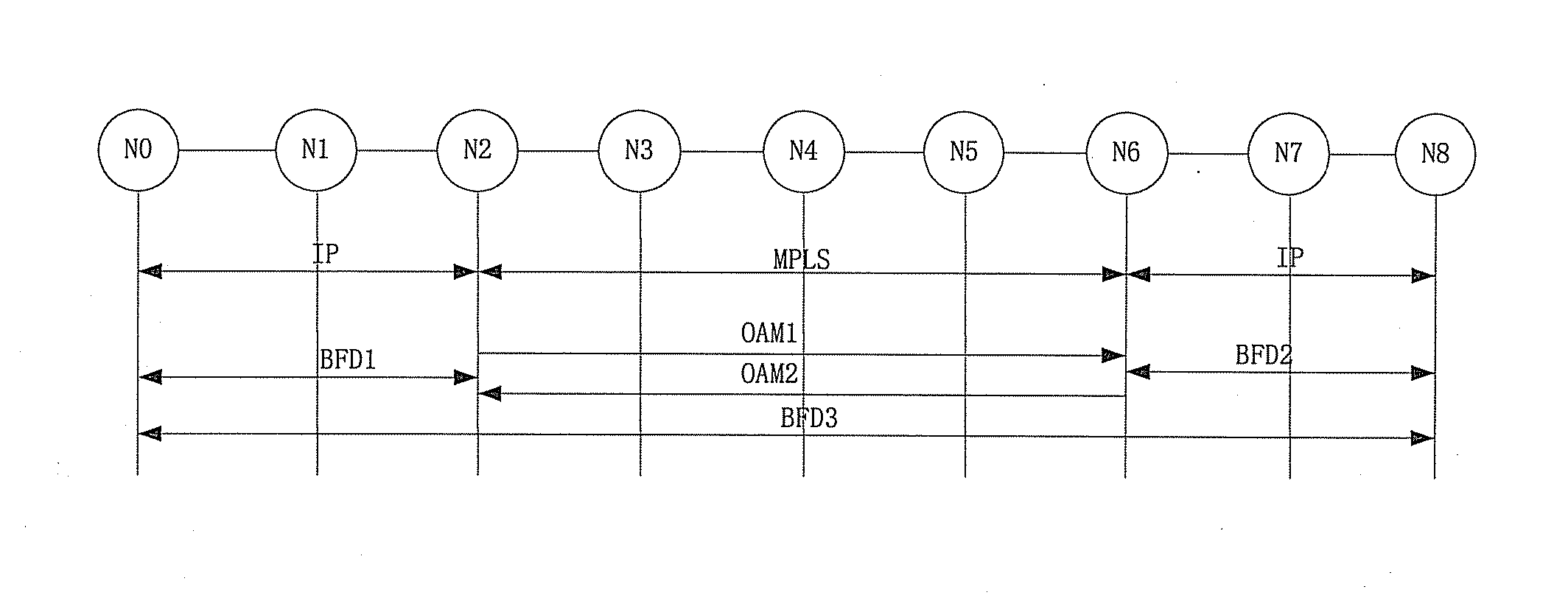

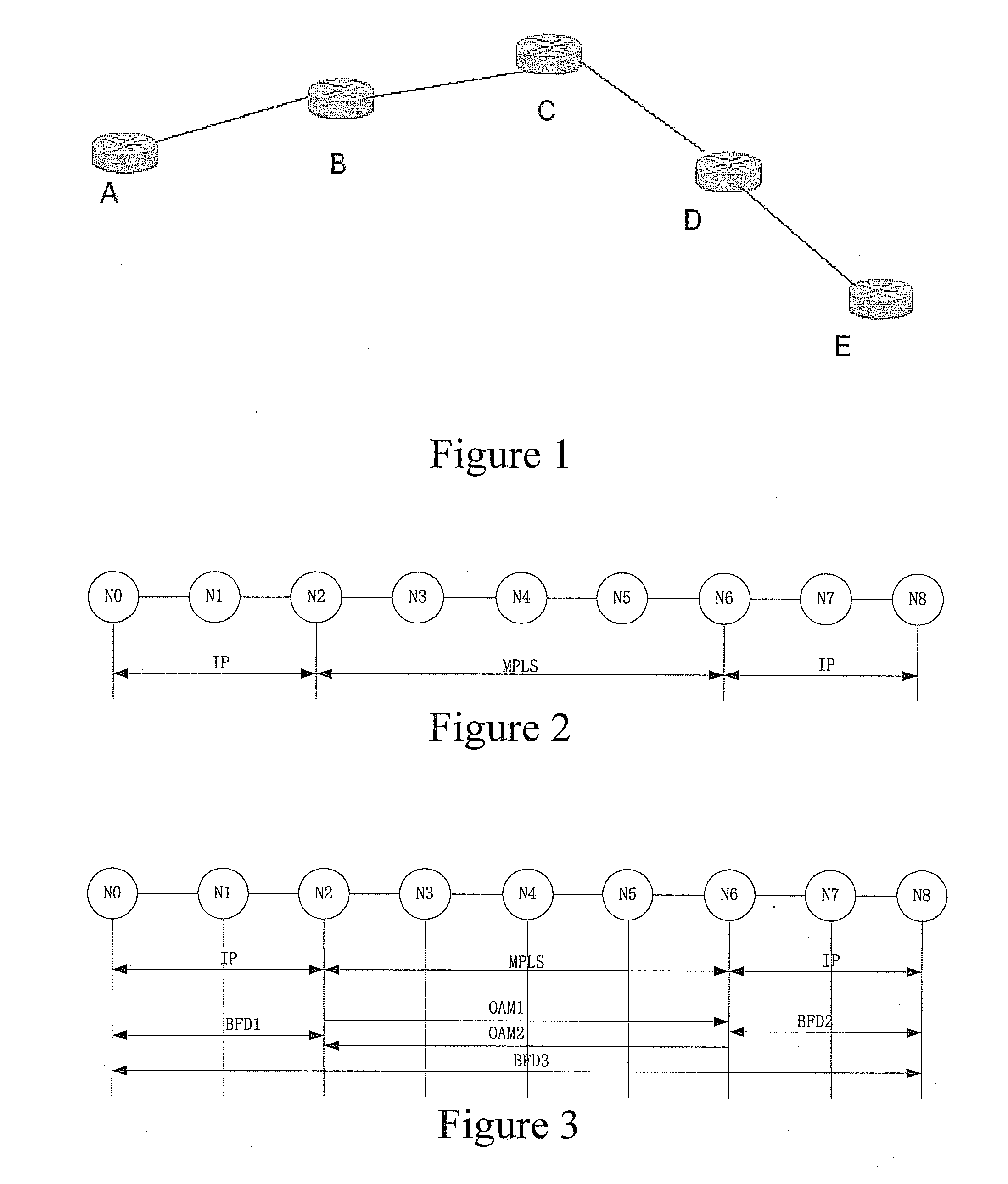

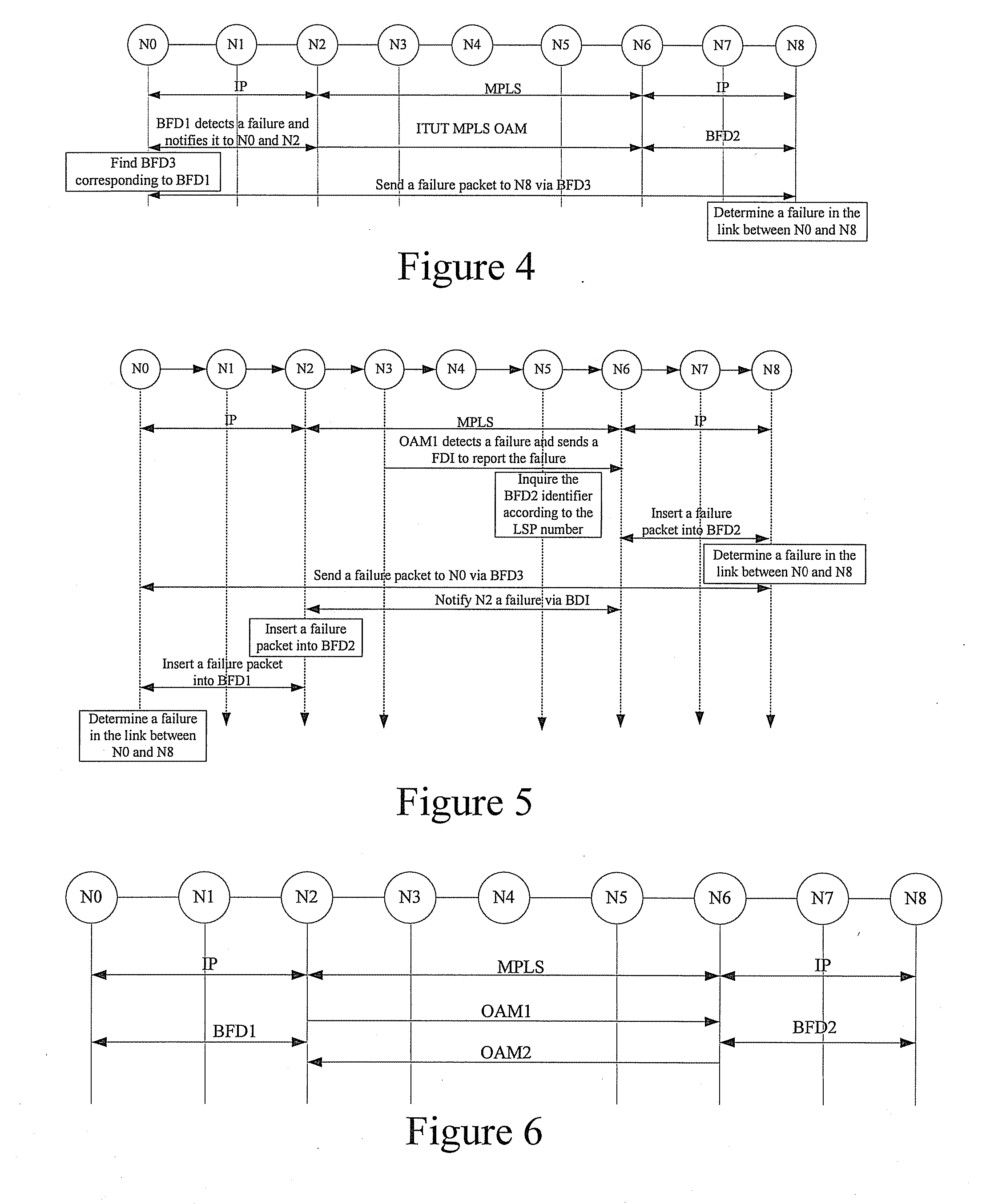

Method and system for detecting link failure between nodes in a hybrid network

ActiveUS20080037436A1Function increaseEasy fault detectionError preventionTransmission systemsDistributed computingNetwork segment

A method for detecting link failures between nodes in hybrid networks includes: establishing sub-BFD connections between nodes and edge nodes and establishing an end-to-end BFD connection. When a failure occurs in the sub-BFD connection of IP network segment, notify a peer node of the failure via the end-to-end BFD connection. When a failure occurs in the MPLS OAM mechanism of MPLS network segment, the edge node notifies the node of the failure via the sub-BFD connection. Another method includes: establishing sub-BFD connections between nodes and edge nodes. When one end of the sub-BFD connection failures, notify the IP network segment at the peer end of the failure via an extended MPLS OAM mechanism and notify the node of the failure via the sub-BFD connection of the IP network segment. An interworking between the BFD detecting mechanism and the MPLS OAM detecting mechanism in a hybrid network can be implemented.

Owner:HUAWEI TECH CO LTD

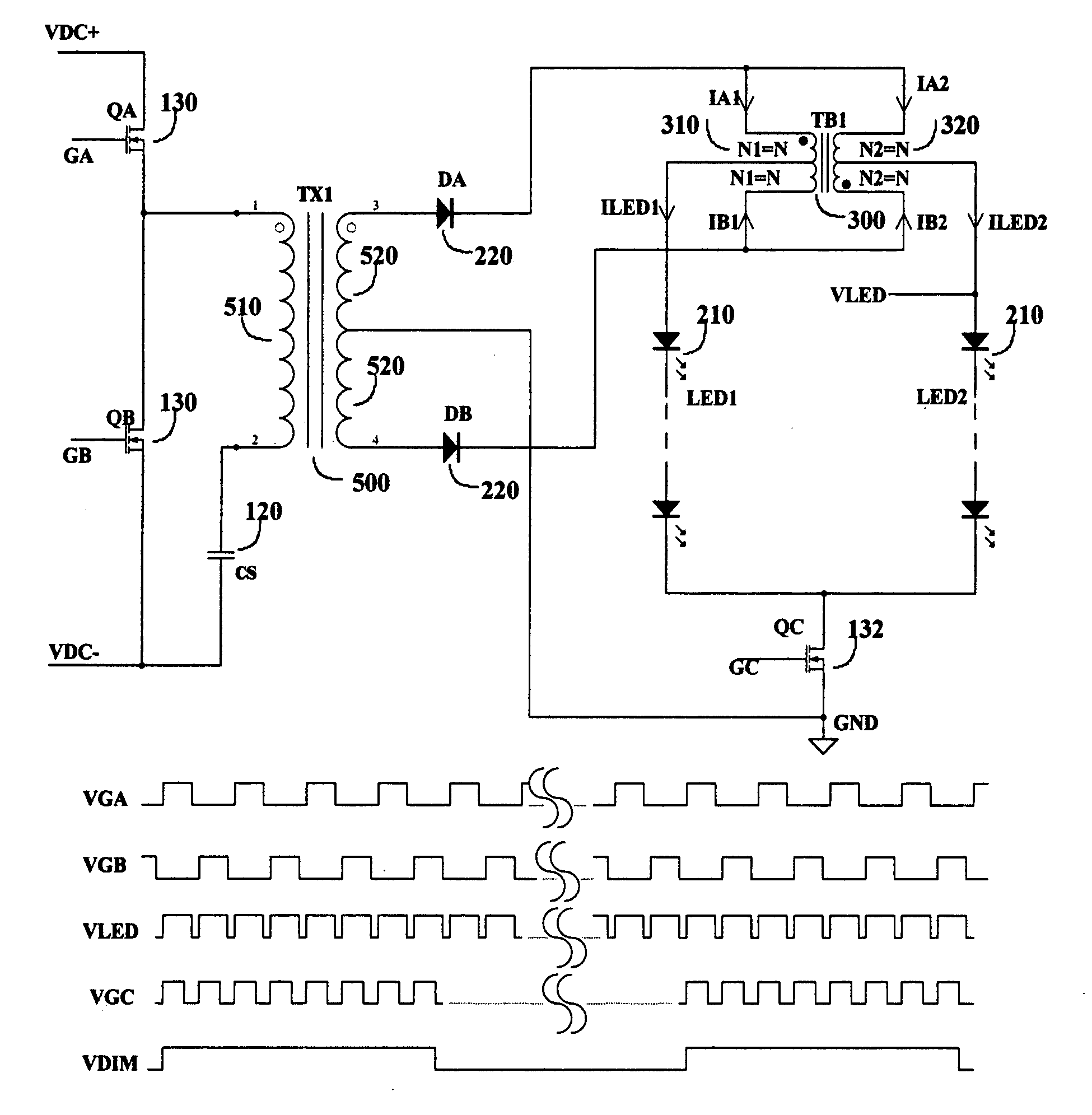

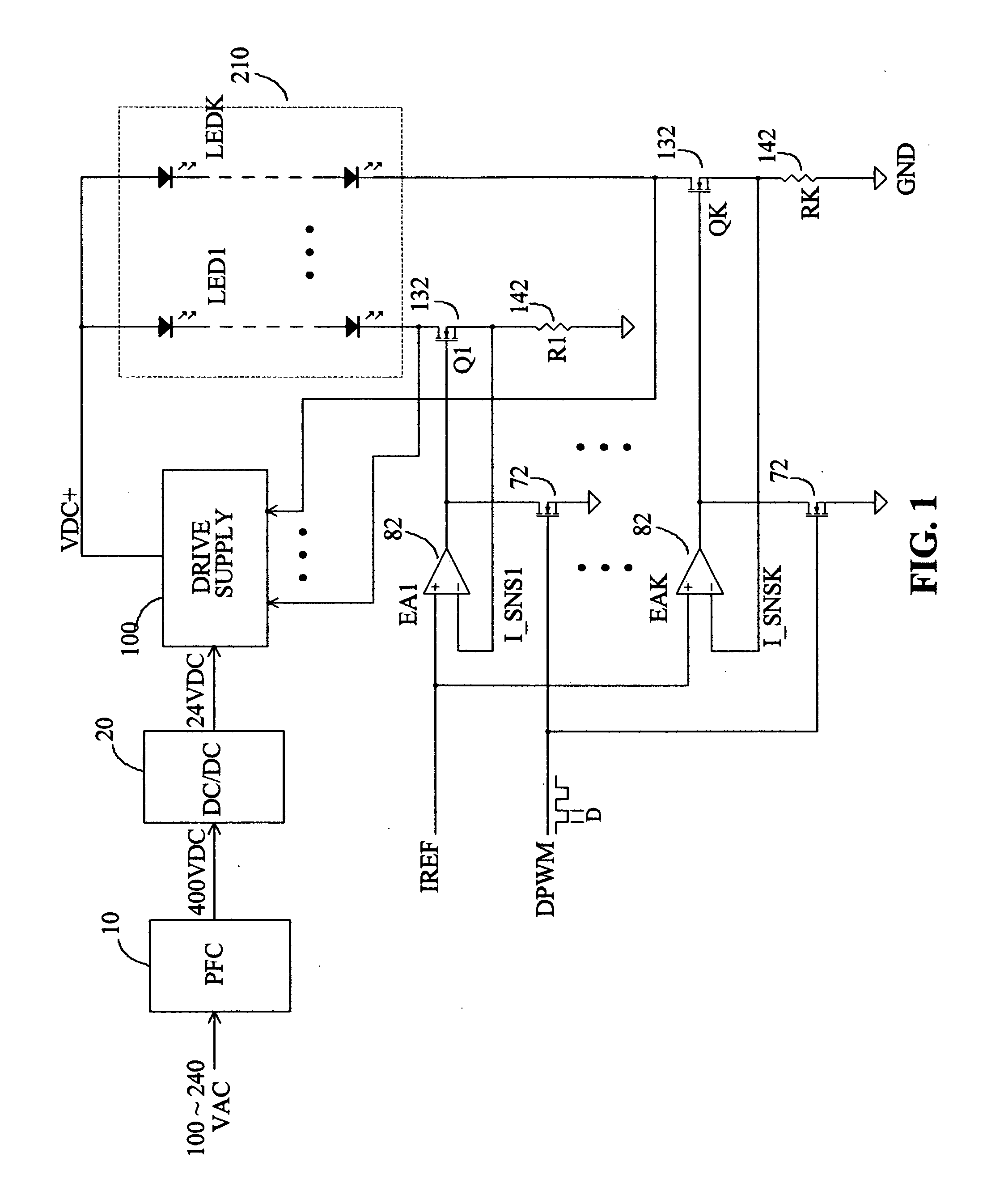

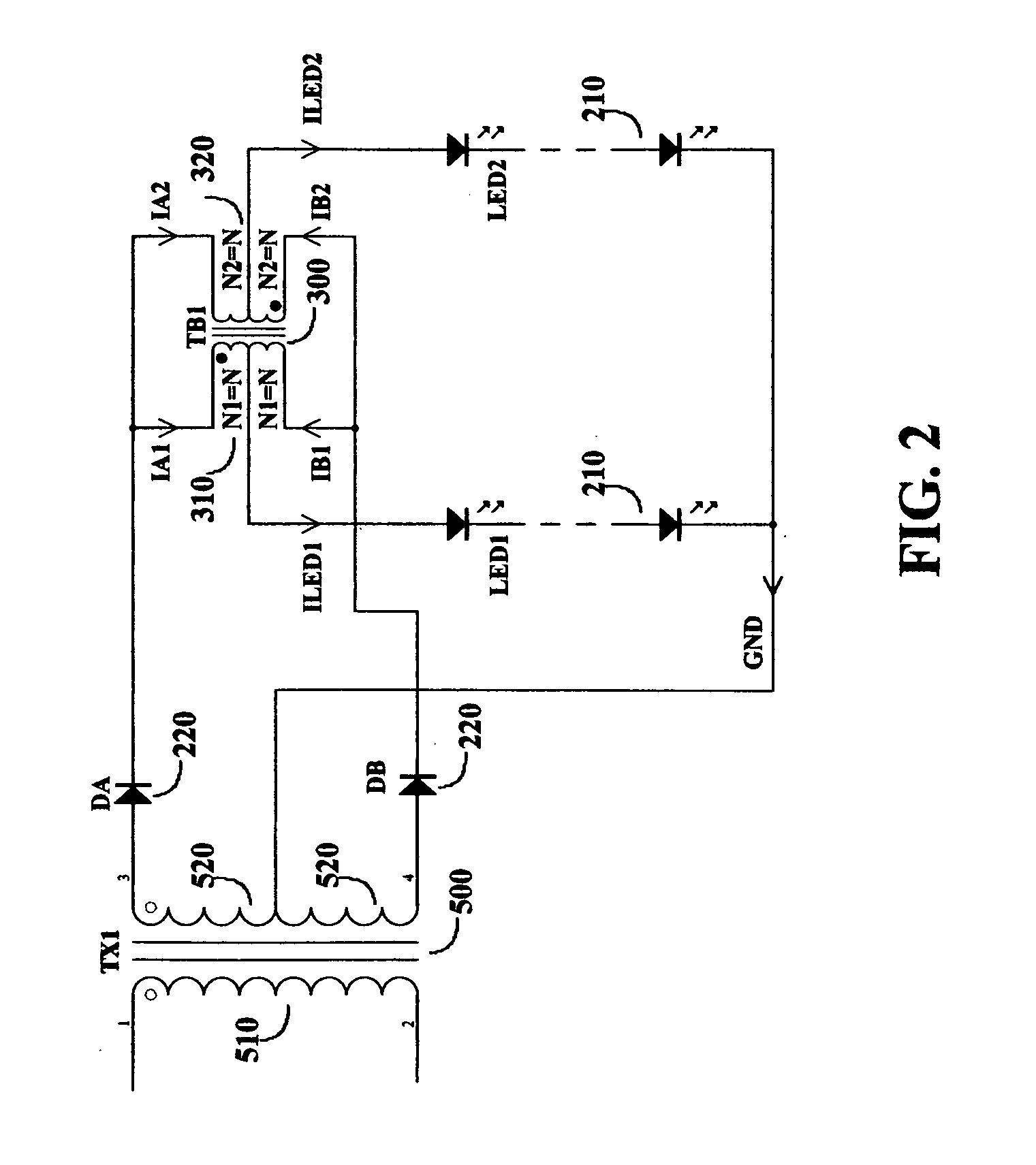

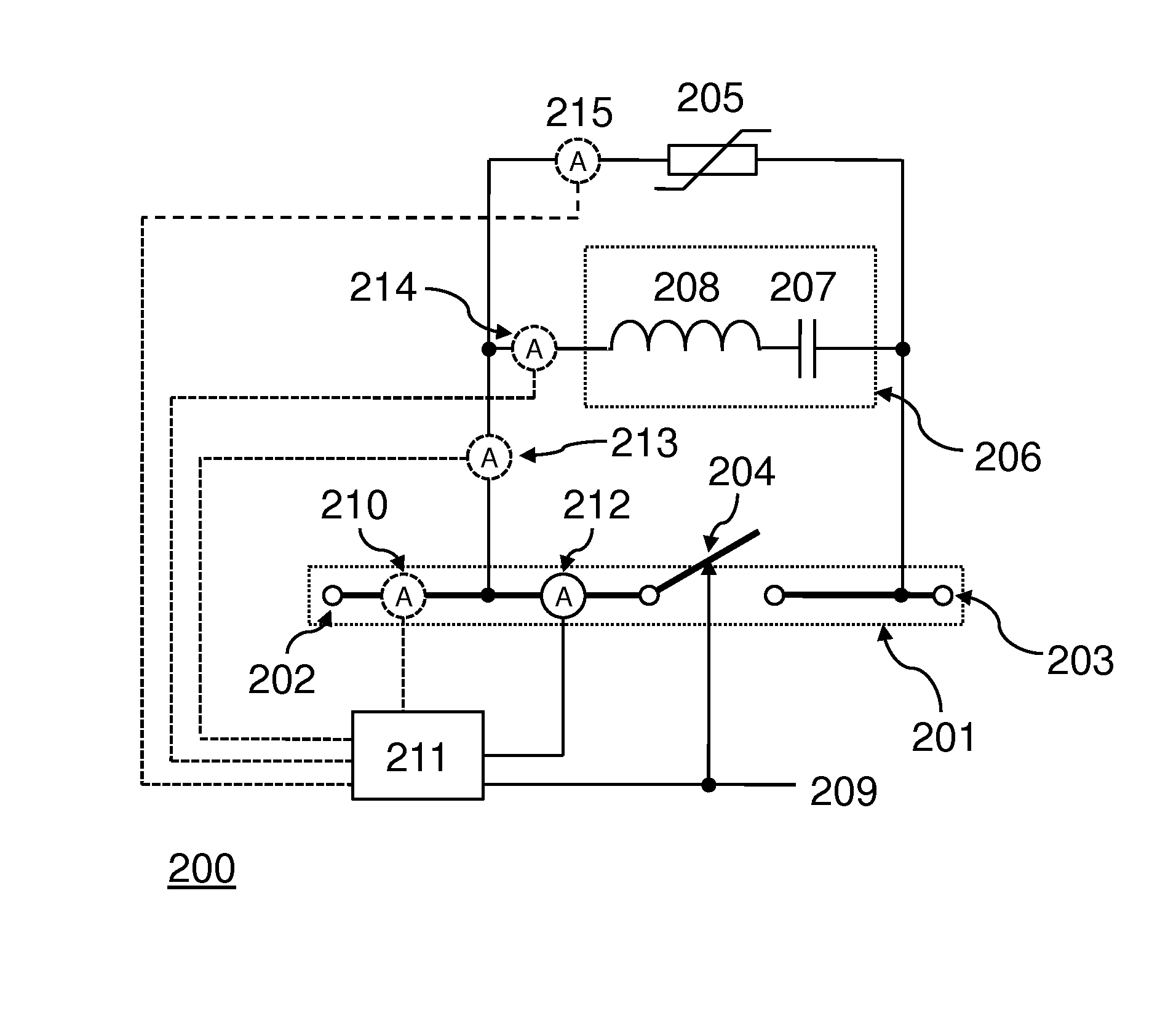

High efficiency drive method for driving LED devices

InactiveUS20120062147A1Improves current balancing accuracyHigh operating requirementsElectrical apparatusElectroluminescent light sourcesCapacitanceInductor

A set of unique concept of driving multiple LED strings with non-dissipative current balancing and non-dissipative synchronous current regulation is disclosed. Inductive components and capacitive components are utilized in the non-dissipative current balancing approach to drive the LED strings from AC supply source. The synchronous regulation method regulates the LED current with pulse width modulated switching action in synchronous with the AC supply source frequency. Both simultaneous and independent control of the LED string operation can be realized with synchronous regulation method when combined with suitable circuit configuration.

Owner:SUNTEC ENTERPRISES

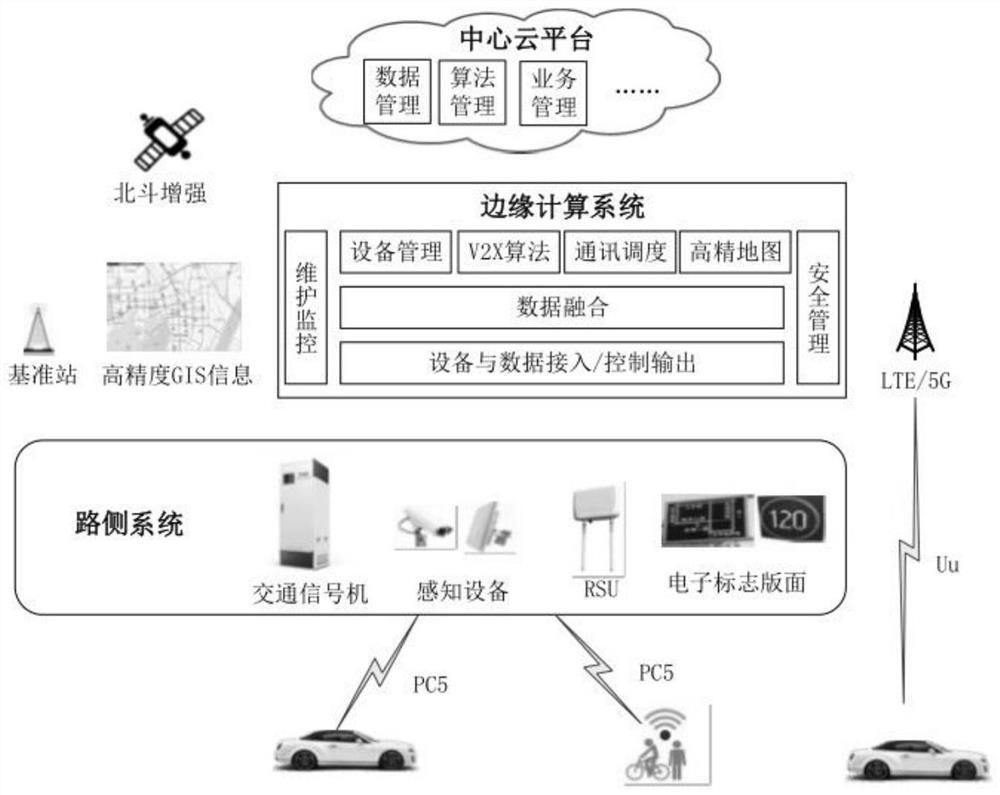

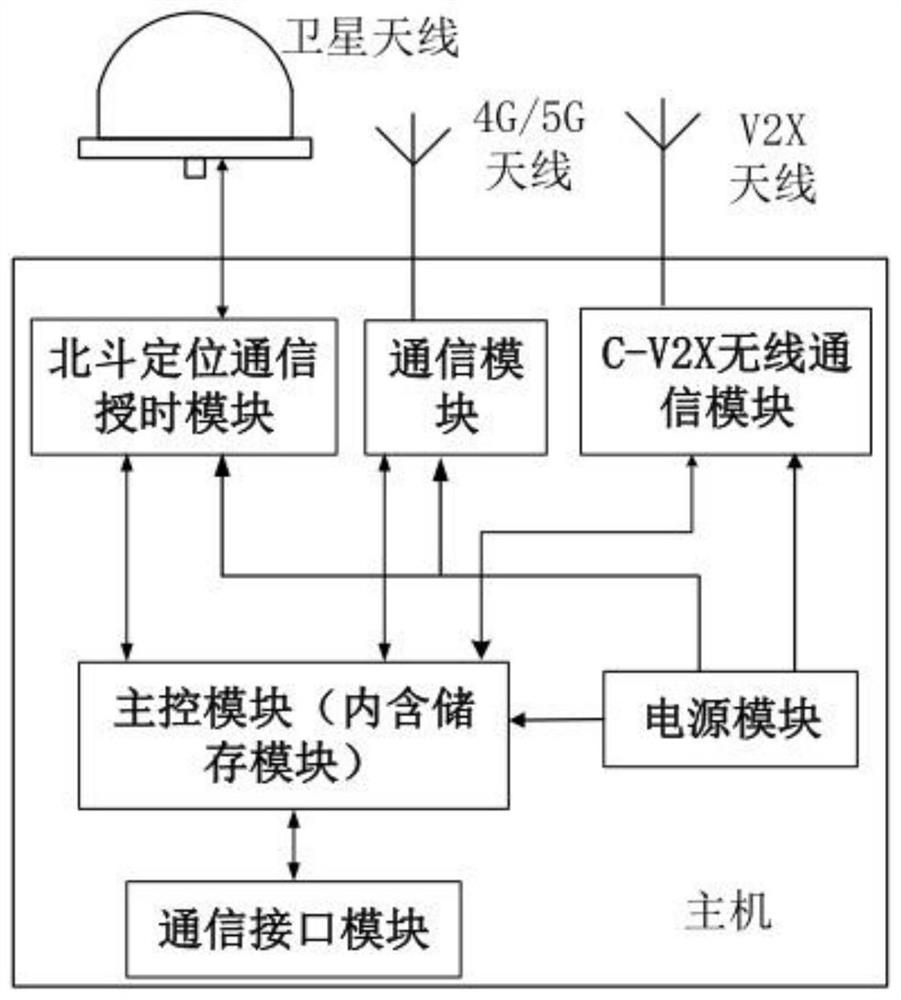

Vehicle-road cooperative road traffic system

PendingCN112289059AImprove computing powerEasy to manageControlling traffic signalsKey distribution for secure communicationEdge nodeRoad traffic

The invention discloses a vehicle-road cooperative road traffic system, which comprises a road side system, an edge computing system, vehicle-mounted terminal equipment, a central cloud platform and an intelligent traffic management and control system. The road side system is deployed on a traffic road and is used for acquiring vehicle information in real time and acquiring multi-dimensional traffic information; the edge computing system is deployed on the edge side, close to the traffic road and a traffic data source, of the front end of the vehicle-road cooperative road traffic system, cooperates with the central cloud platform, and receives and executes an adjustment vehicle-road cooperative optimization control strategy of the central cloud platform; the vehicle-mounted terminal equipment is arranged in a vehicle, is in communication connection with the road side system or / and the edge computing system and is used for acquiring vehicle information and multi-dimensional traffic information in real time, and the central cloud platform is in communication connection with the edge computing system and is used for receiving edge node information of the edge computing system; and theedge computing system manages and controls traffic facilities according to the adjustment vehicle-road collaborative optimization control strategy of the central cloud platform and a control scheme,thereby realizing management and control of vehicle-road collaborative road traffic.

Owner:CHINABATA NANJING TECH

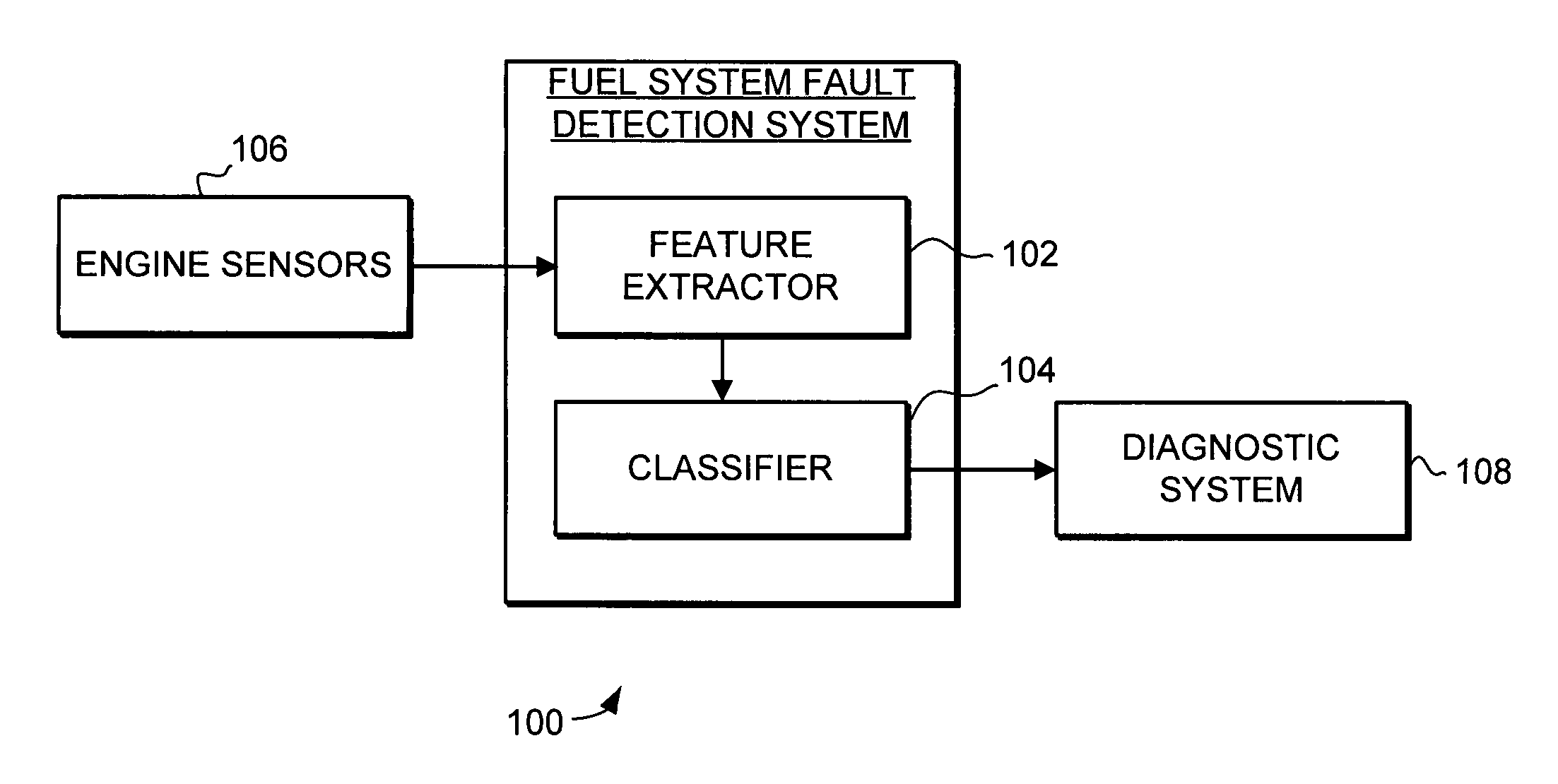

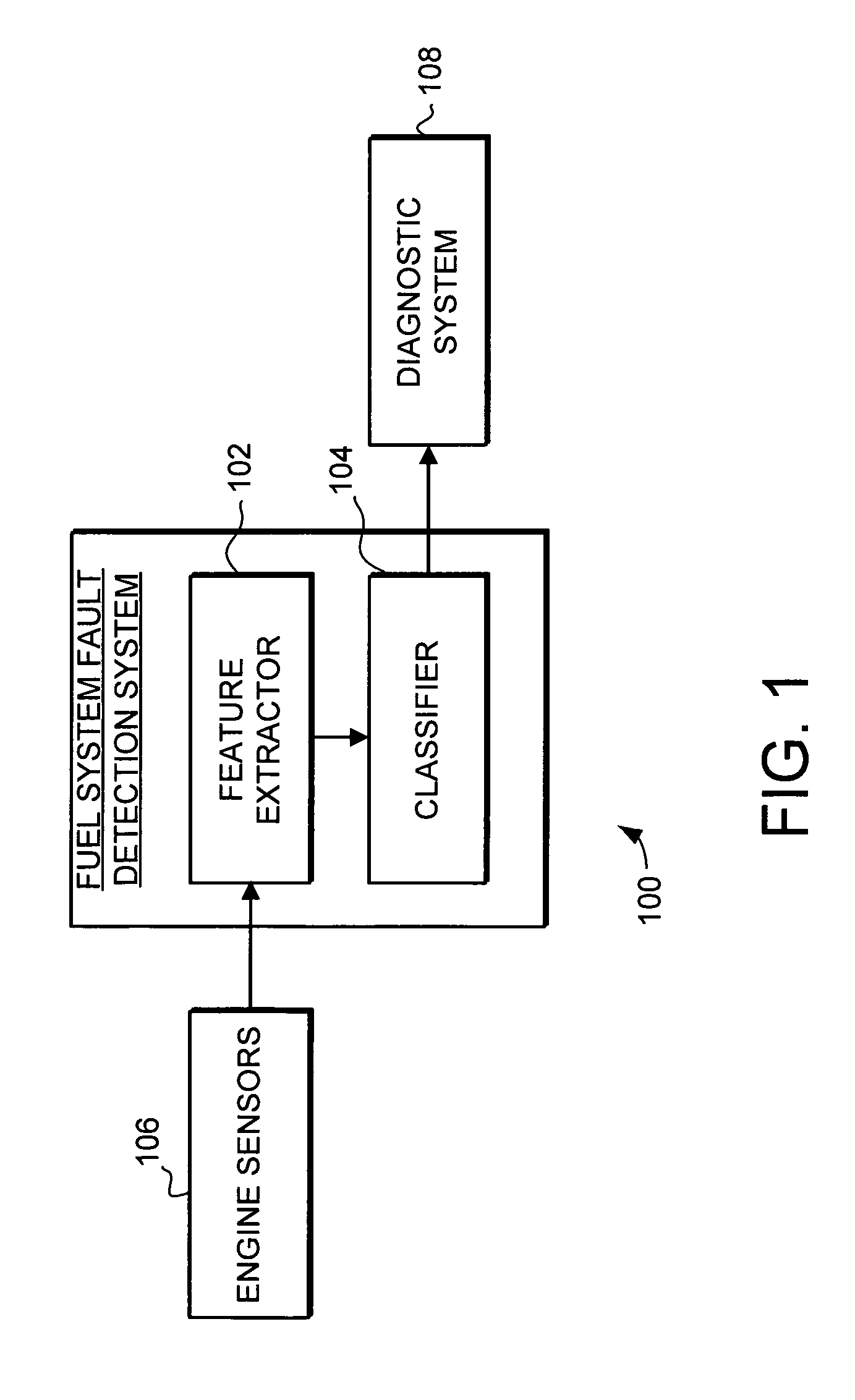

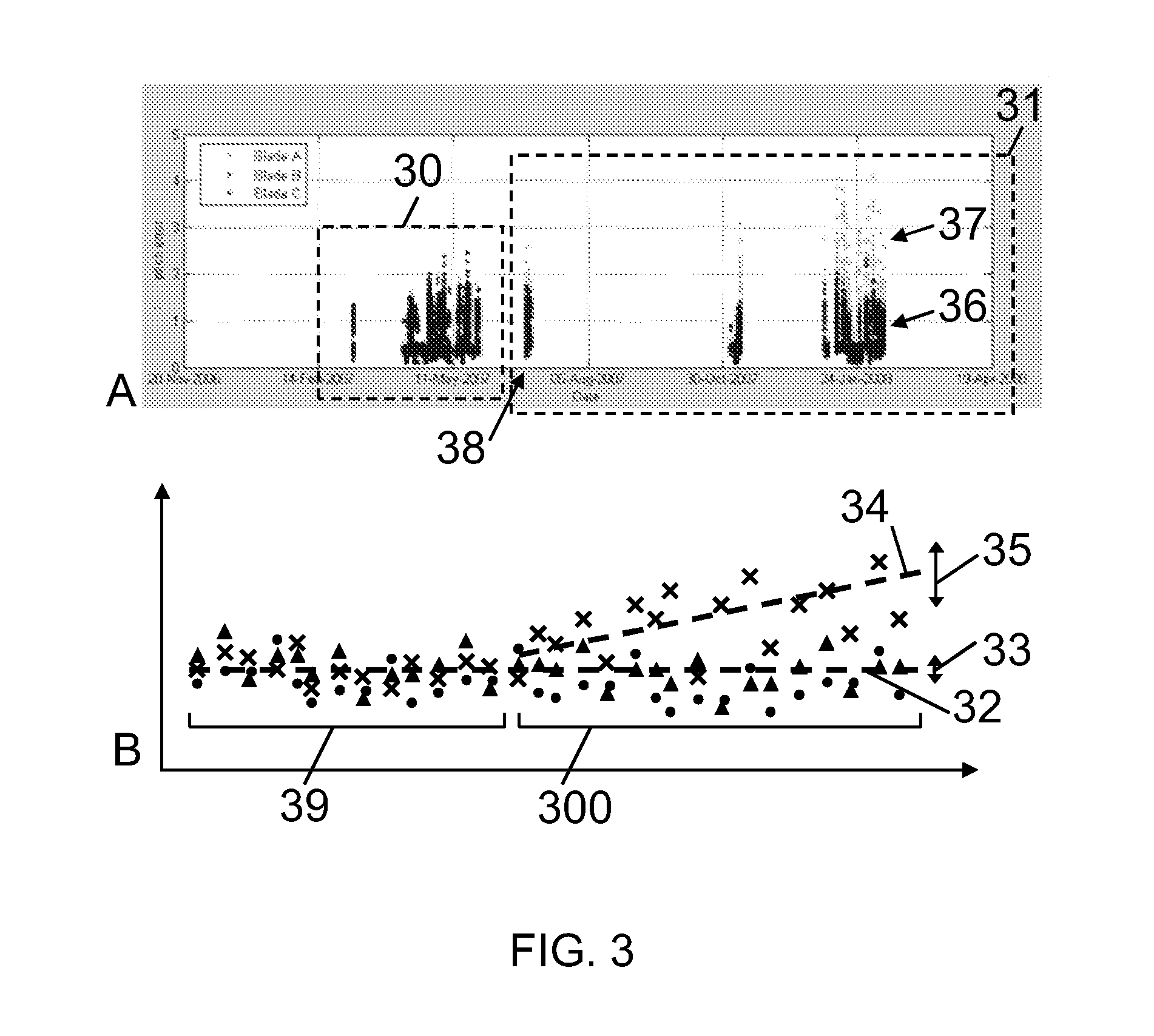

Fault detection system and method for turbine engine fuel systems

InactiveUS7693643B2Data efficientAccurate classificationVehicle testingAnalogue computers for vehiclesFeature extractionTurbine

Owner:HONEYWELL INT INC

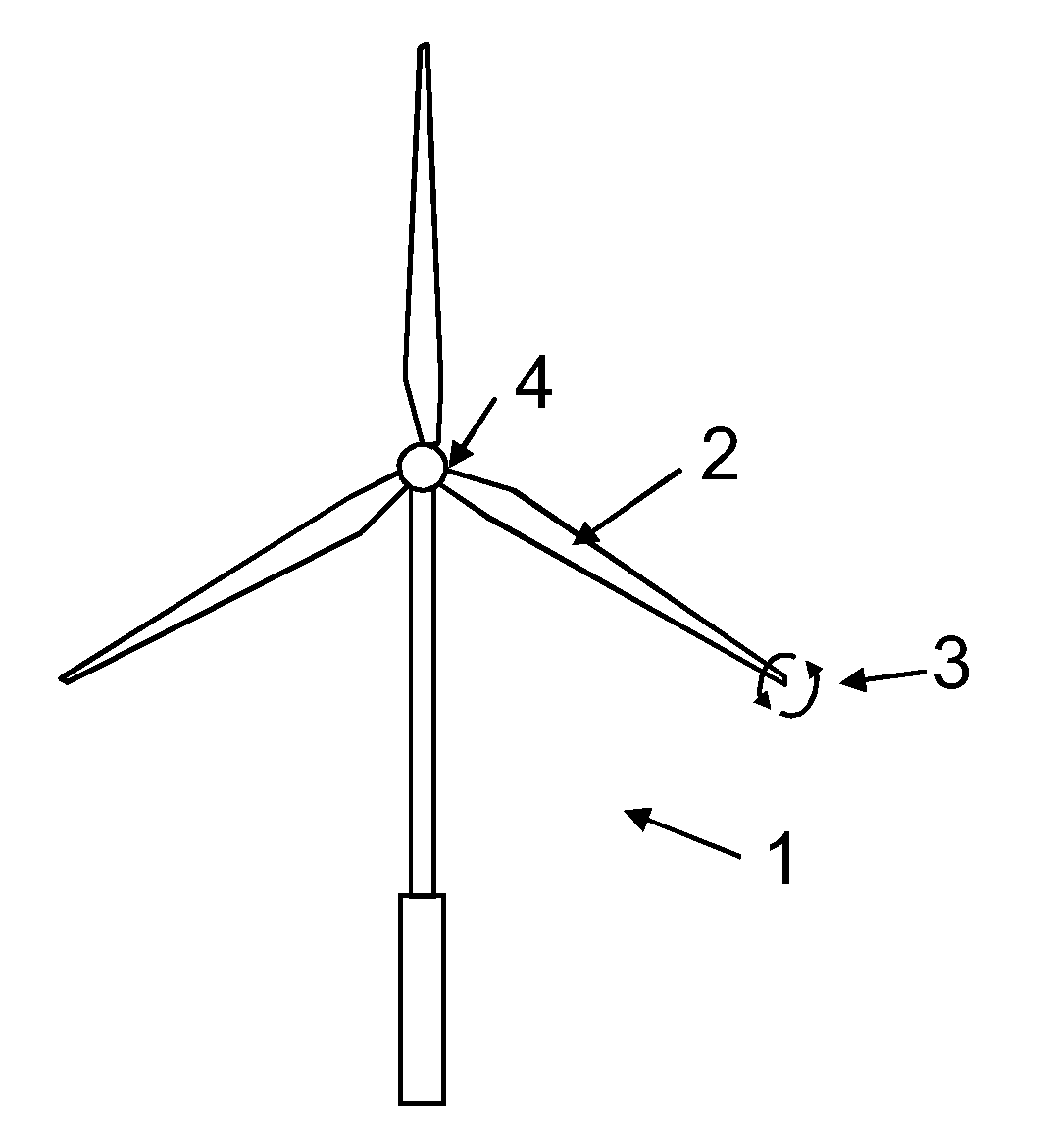

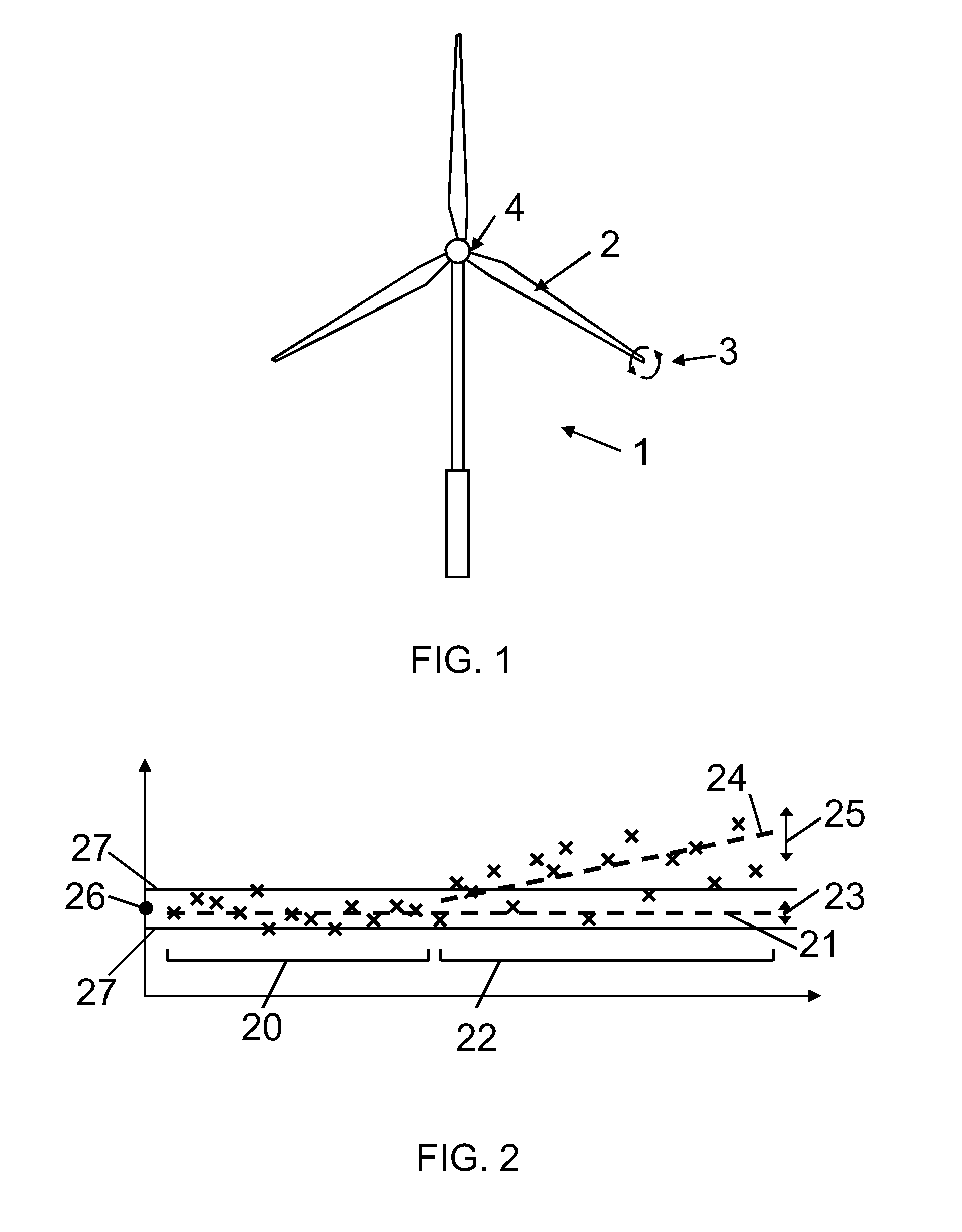

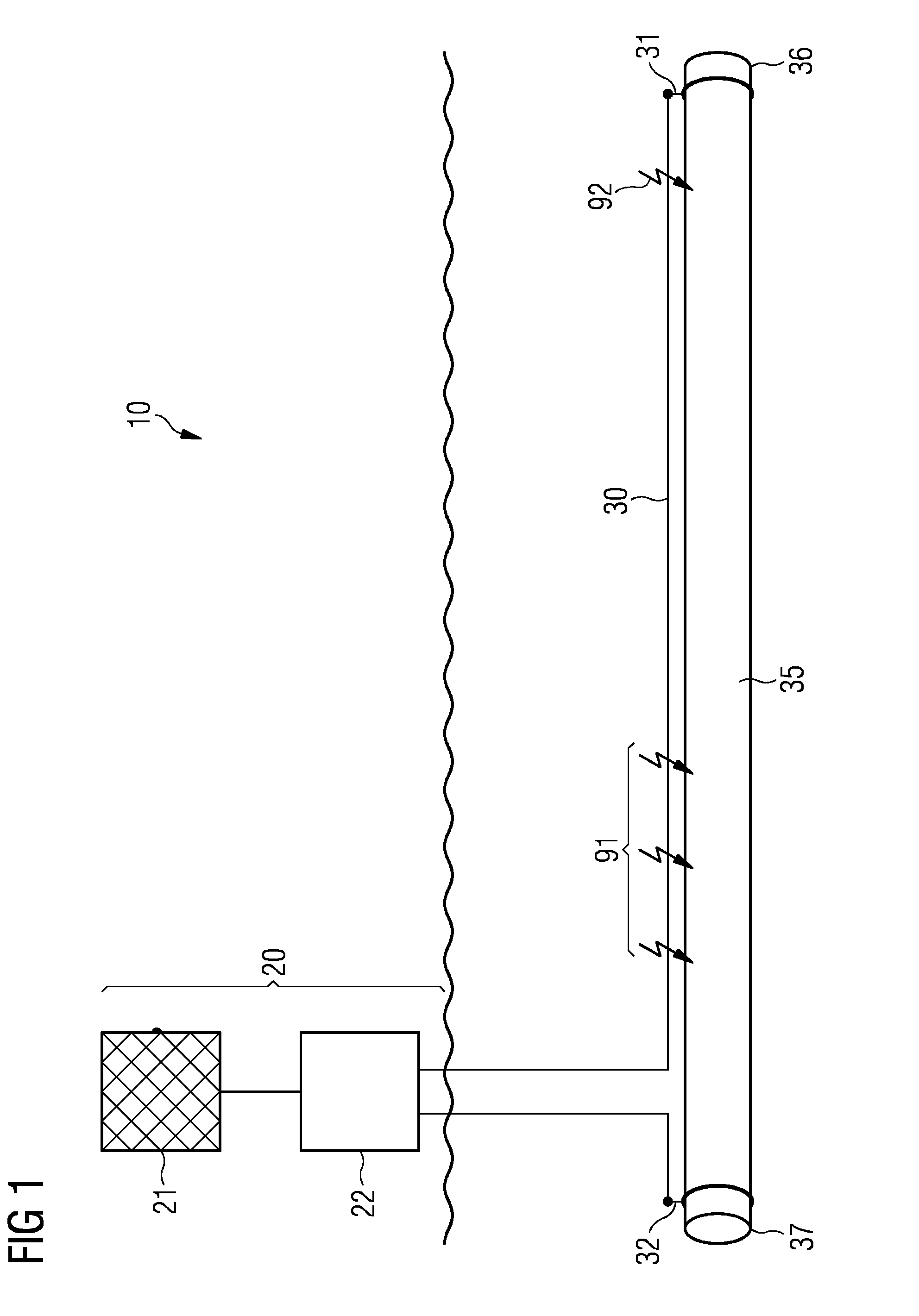

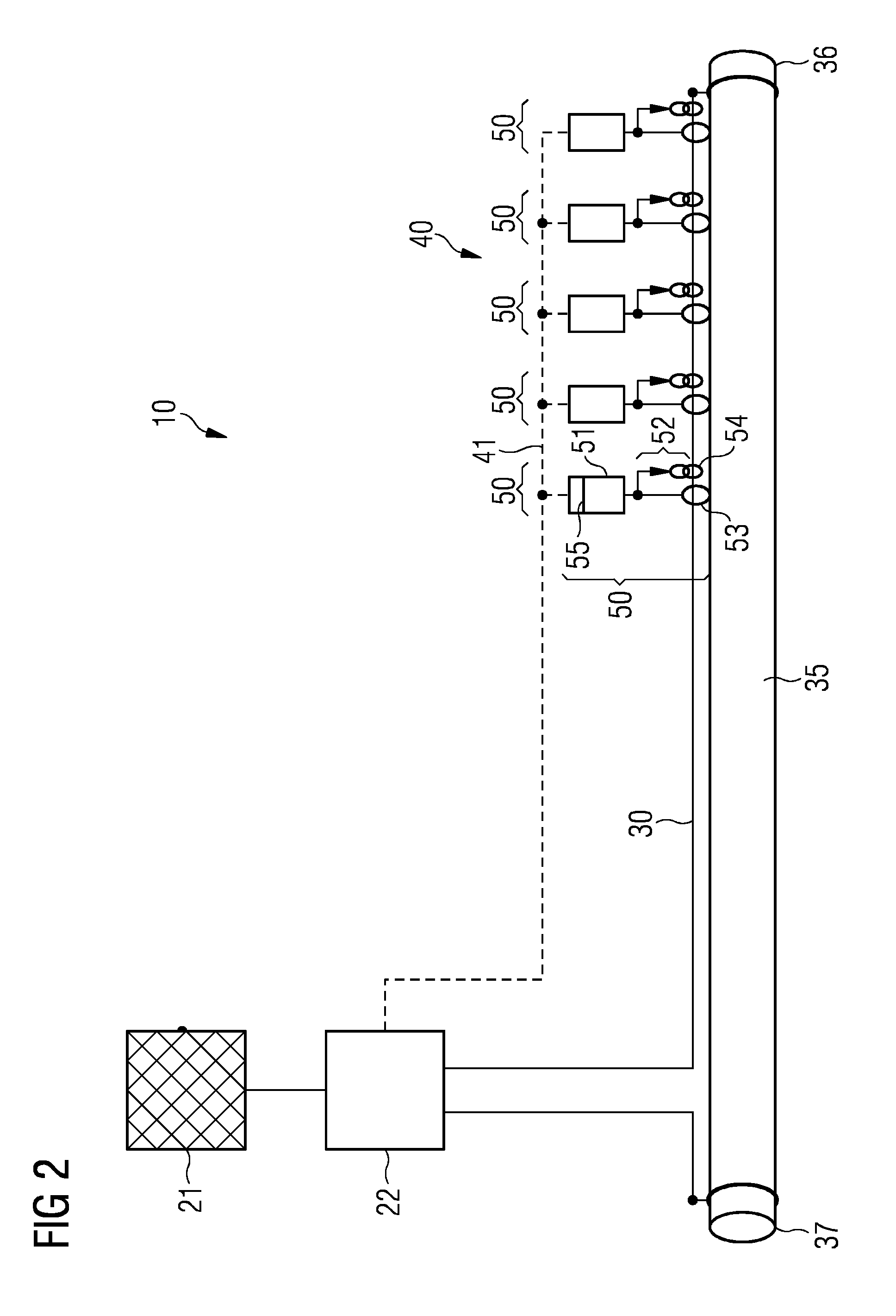

Pitch control system

InactiveUS20110158805A1Easy fault detectionAlleviates, mitigates or eliminates one or more problemsPropellersPump componentsPitch controlBlade pitch

The present invention relates to a pitch control system for operating the blade pitch of the rotor blades of a wind turbine generator. A method is disclosed wherein a command signal or pitch demand is applied to the blade pitch system of the rotor blades and the resulting response signal or pitch response is received. The received pitch response is compared to a reference and a signal indicative of a pitch system fault may be generated if a difference between the response signal and the reference is detected as being larger than a preset criterion. The deviating behaviour of a blade pitch system can thereby be detected which enables a testing or monitoring of the condition of the pitch system of the rotor blades of a wind turbine generator.

Owner:VESTAS WIND SYST AS

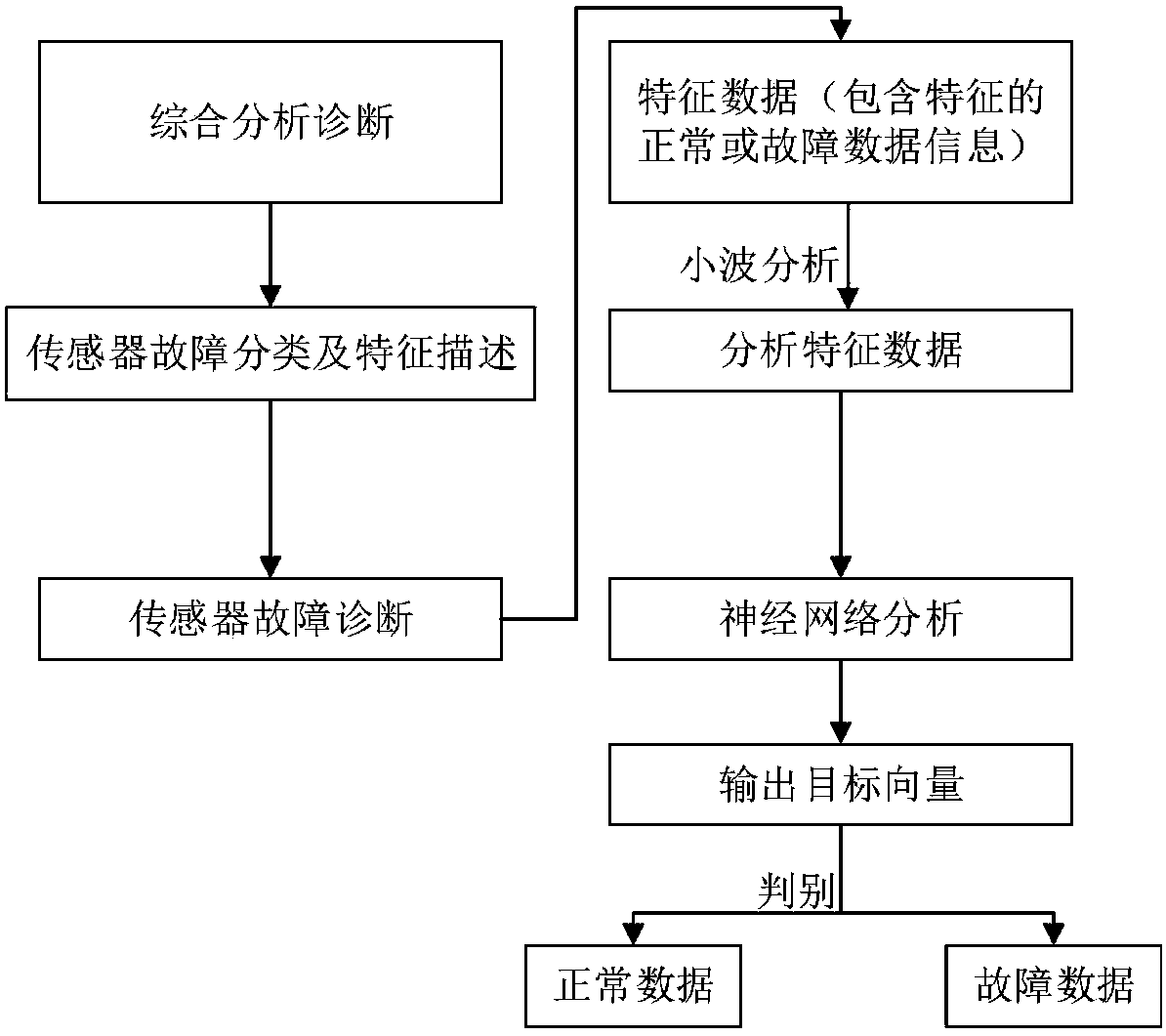

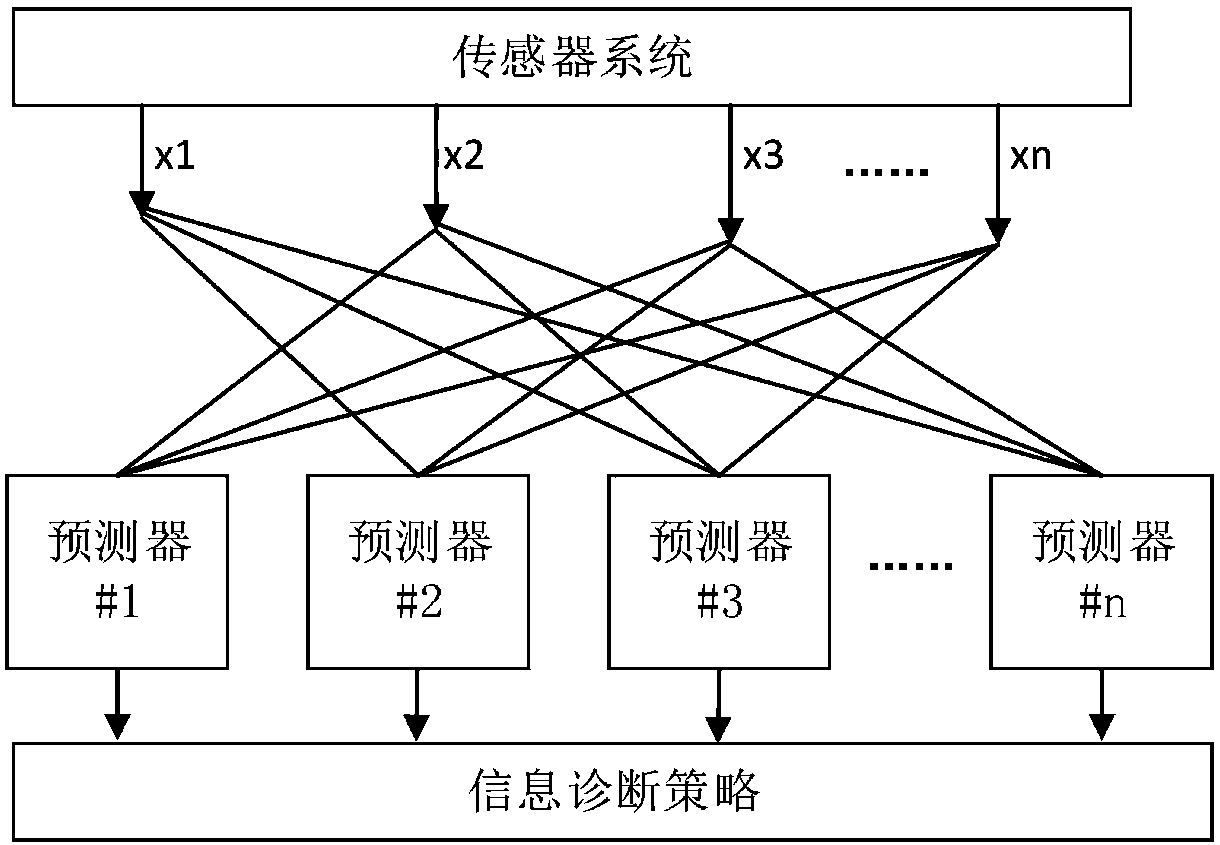

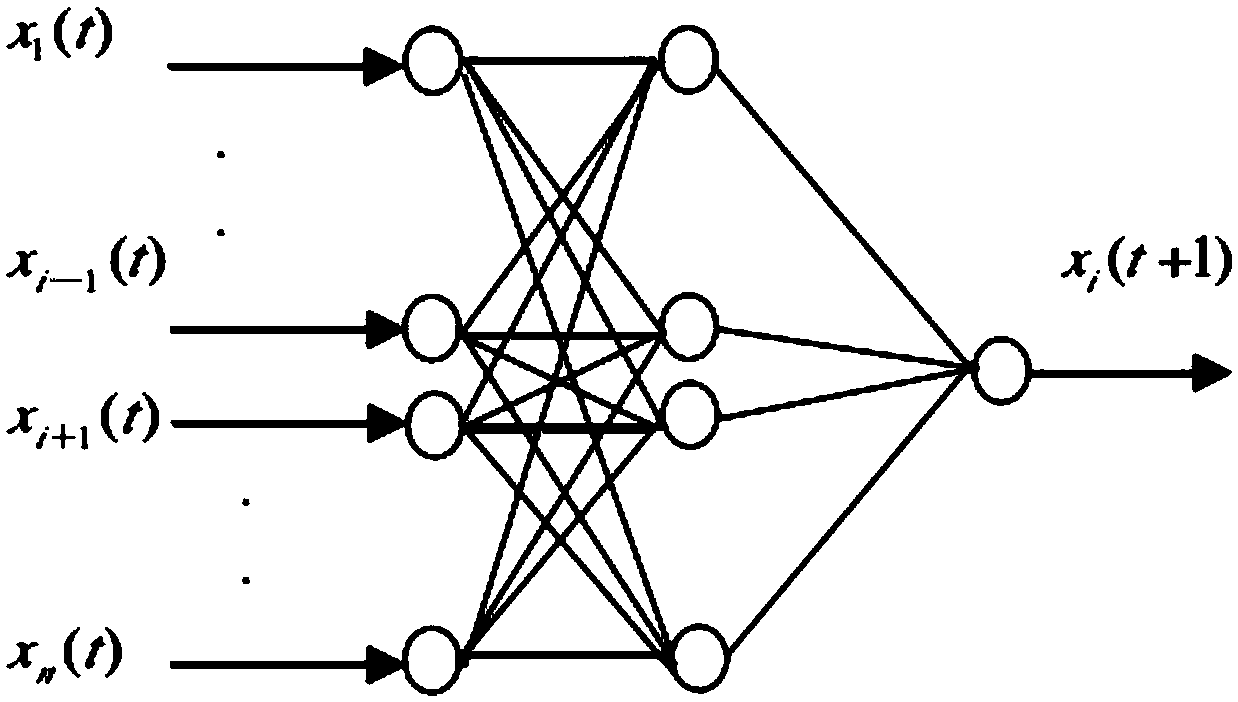

Air conditioning system sensor fault diagnosis method based on wavelet neural network

InactiveCN108507117AImprove learning abilityImprove approximation accuracyMechanical apparatusSpace heating and ventilation safety systemsDiagnosis methodsNetwork structure

The invention provides an air conditioning system sensor fault diagnosis method based on a wavelet neural network. The method is characterized by comprising the steps that comprehensive analysis and diagnosis are conducted for defining an air conditioner state control, a diagnosis condition set and a decision event set; sensor fault classification and characteristic description of an air conditioner system are used for classifying fault types; sensor fault diagnosis of the air conditioning system is used for generating a fault diagnosis flow; a network structure and a primary function are determined; selection and pretreatment of training samples are conducted; and an alarming threshold is set. The method has good diagnosis effect on abrupt changing faults such as bias faults and completefaults. Drift biases can be detected as long as the drift distance exceeds the alarming threshold. The method also has good fault detection effect on precision decrease faults of sensors.

Owner:上海智容睿盛智能科技有限公司

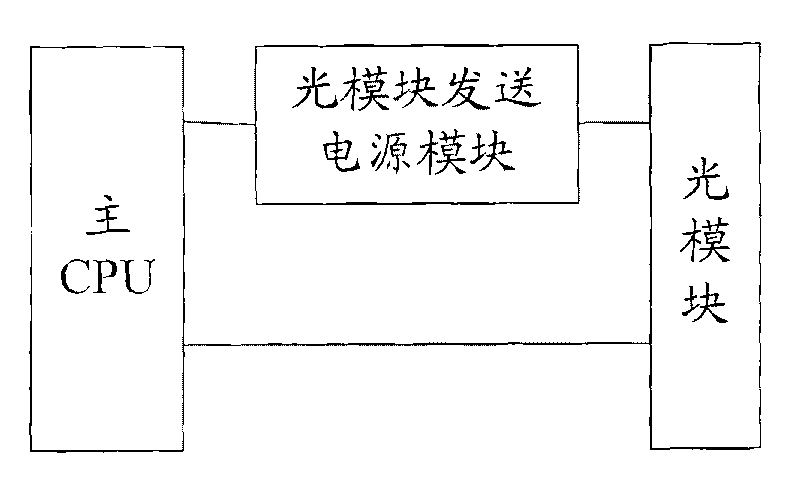

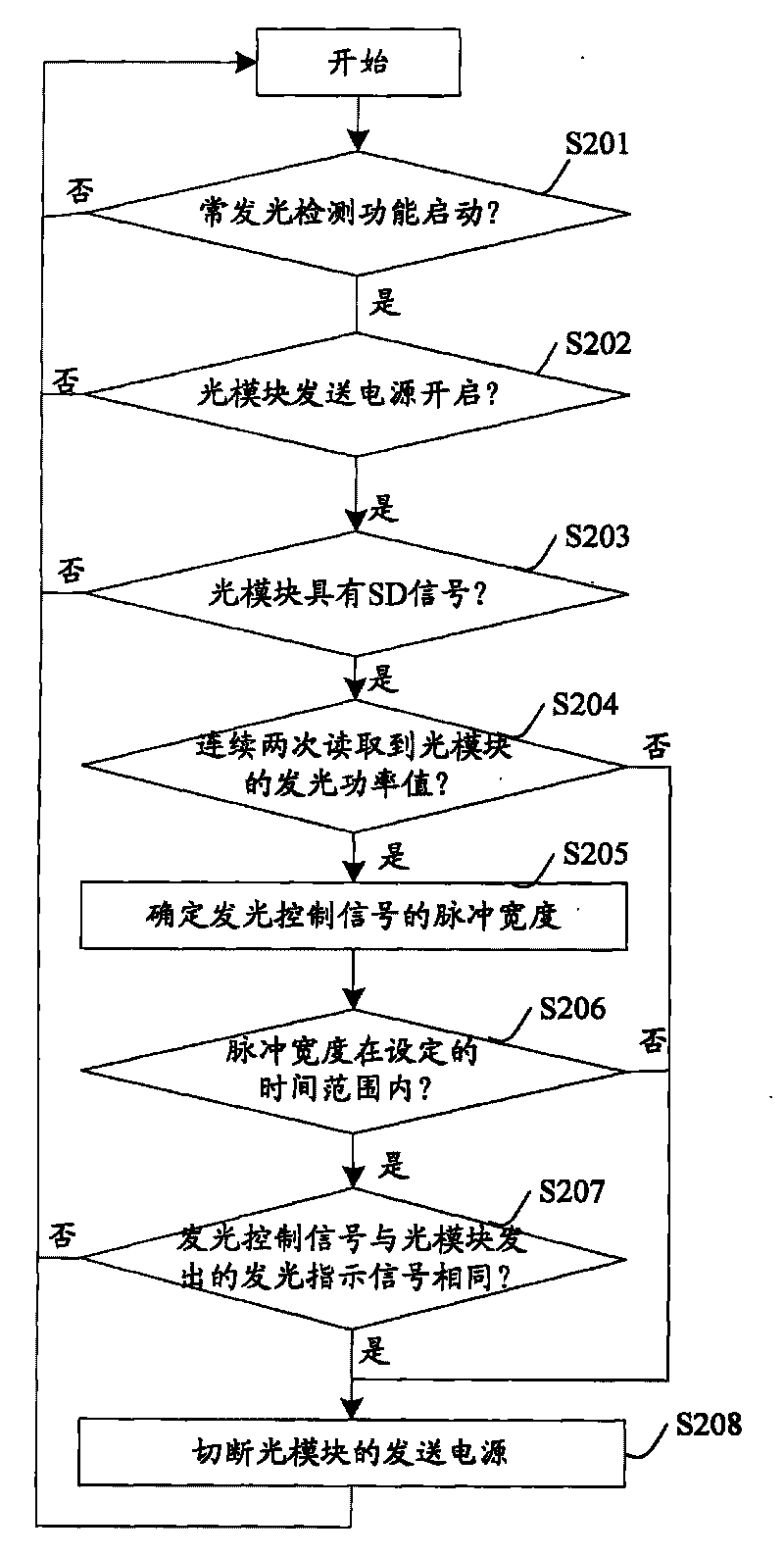

Failure detection and control method of optical network unit and optical network unit

The invention relates to a passive optical network, in particular to a failure detection and control method of an optical network unit and an optical network unit, enhancing the failure detection capability of the optical network unit. The detection method of the optical network unit comprises the steps of: when outputting an optical detection SD signal of an optical module, reading the transmission optical power of the optical module twice, wherein the time interval of reading the optical power twice is set time; when reading the valves of the optical power twice, determining that the optical network unit fails, wherein the valuing range of the set time is larger than one luminous time slot of the optical network unit and smaller than the time interval of continuous normal two-time illumination of the optical network unit. Further, the optical network unit is controlled by cutting off a transmission power supply of the optical module. By adopting the method, the failure detection capability of the optical network unit is enhanced and the optical network unit with failure is prevented from influencing other normal ONU equipment by cutting off the transmission power supply of the optical module.

Owner:ZTE CORP

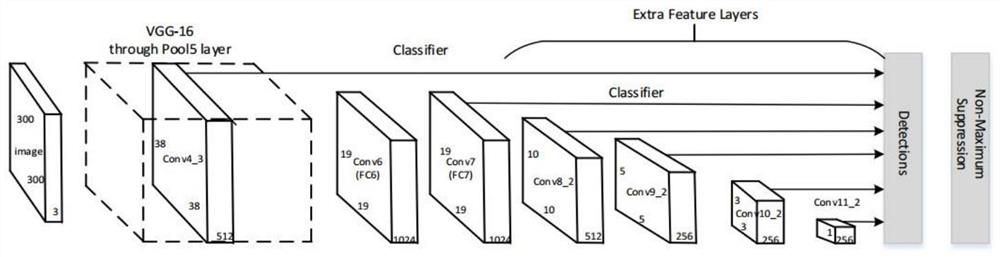

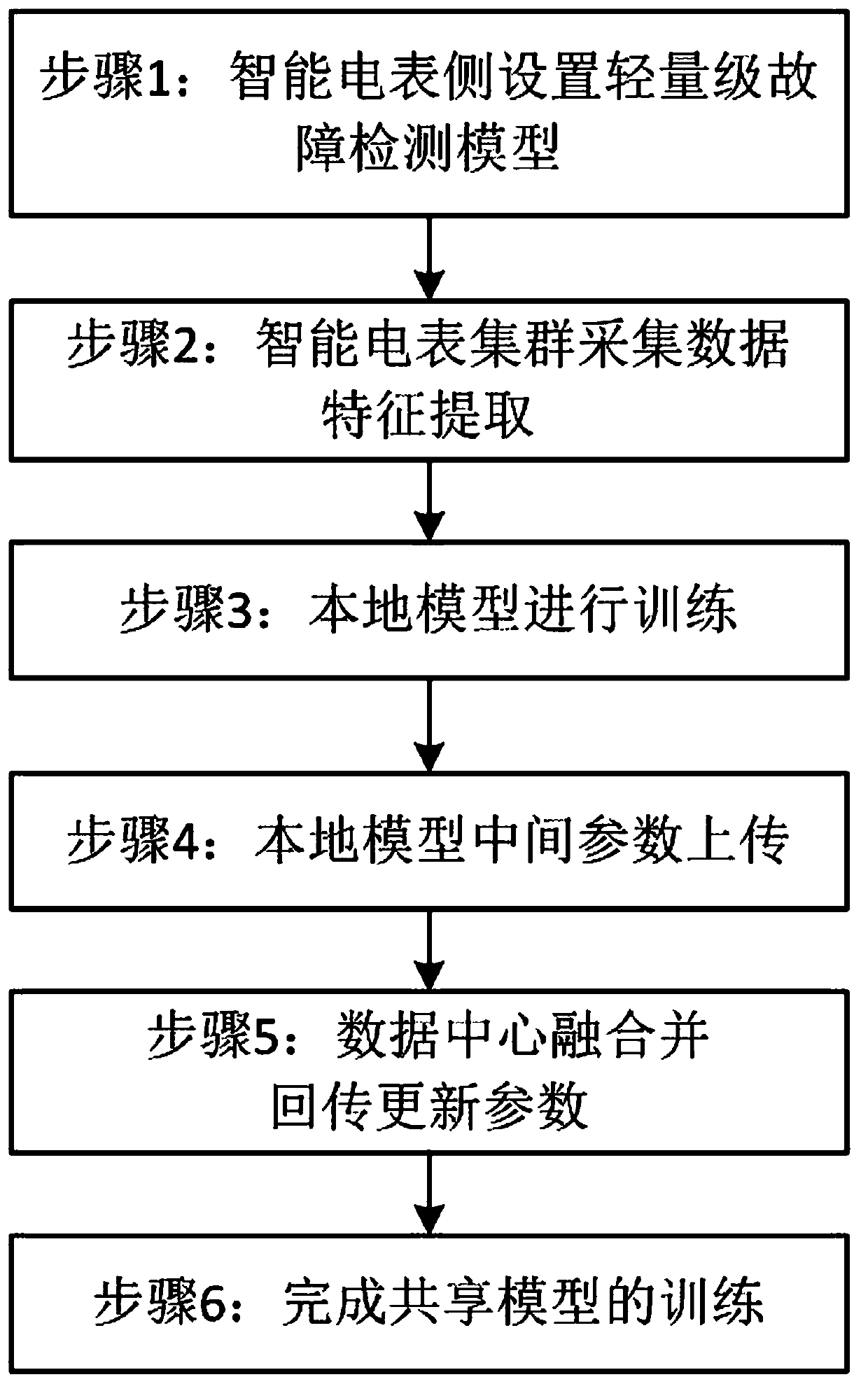

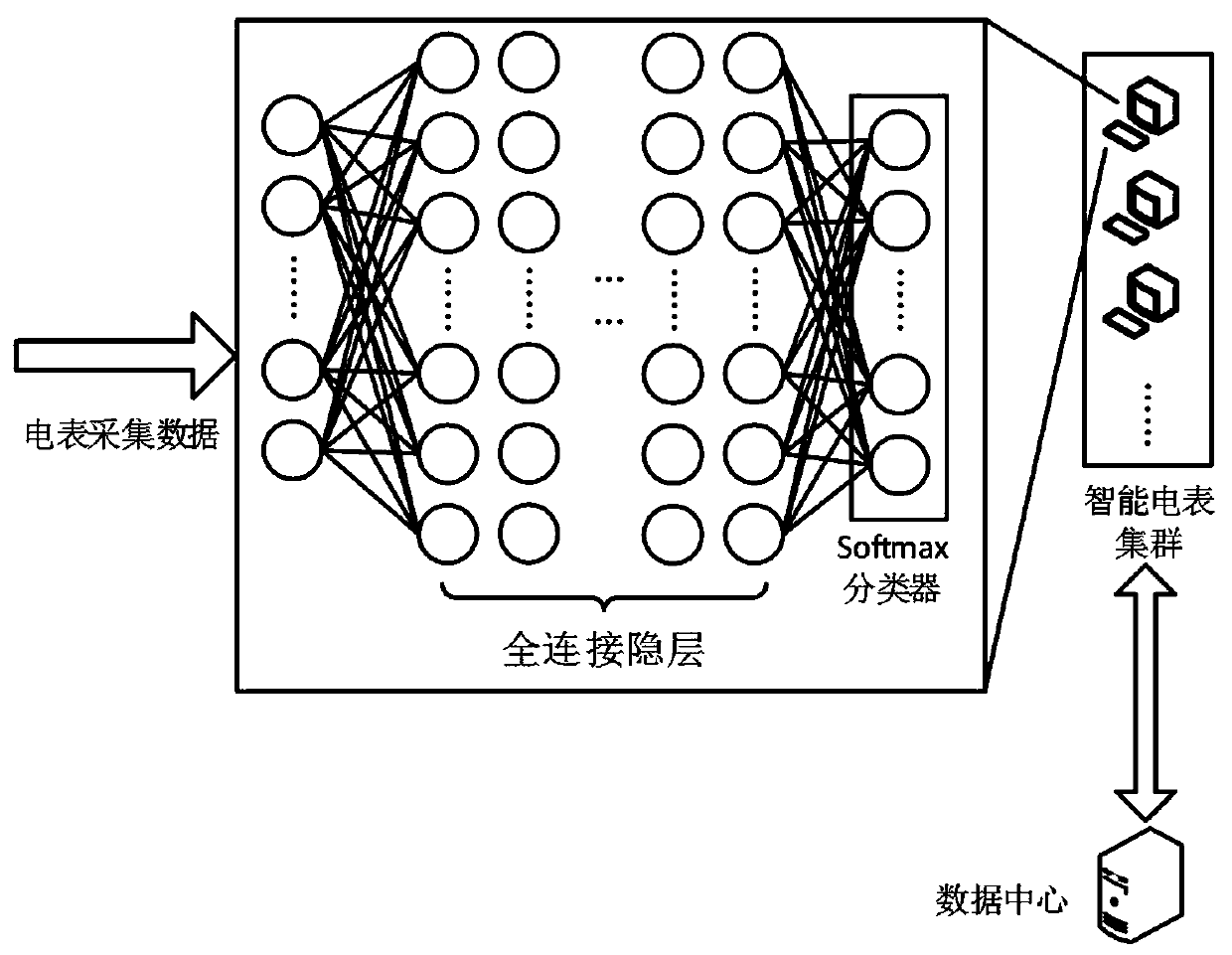

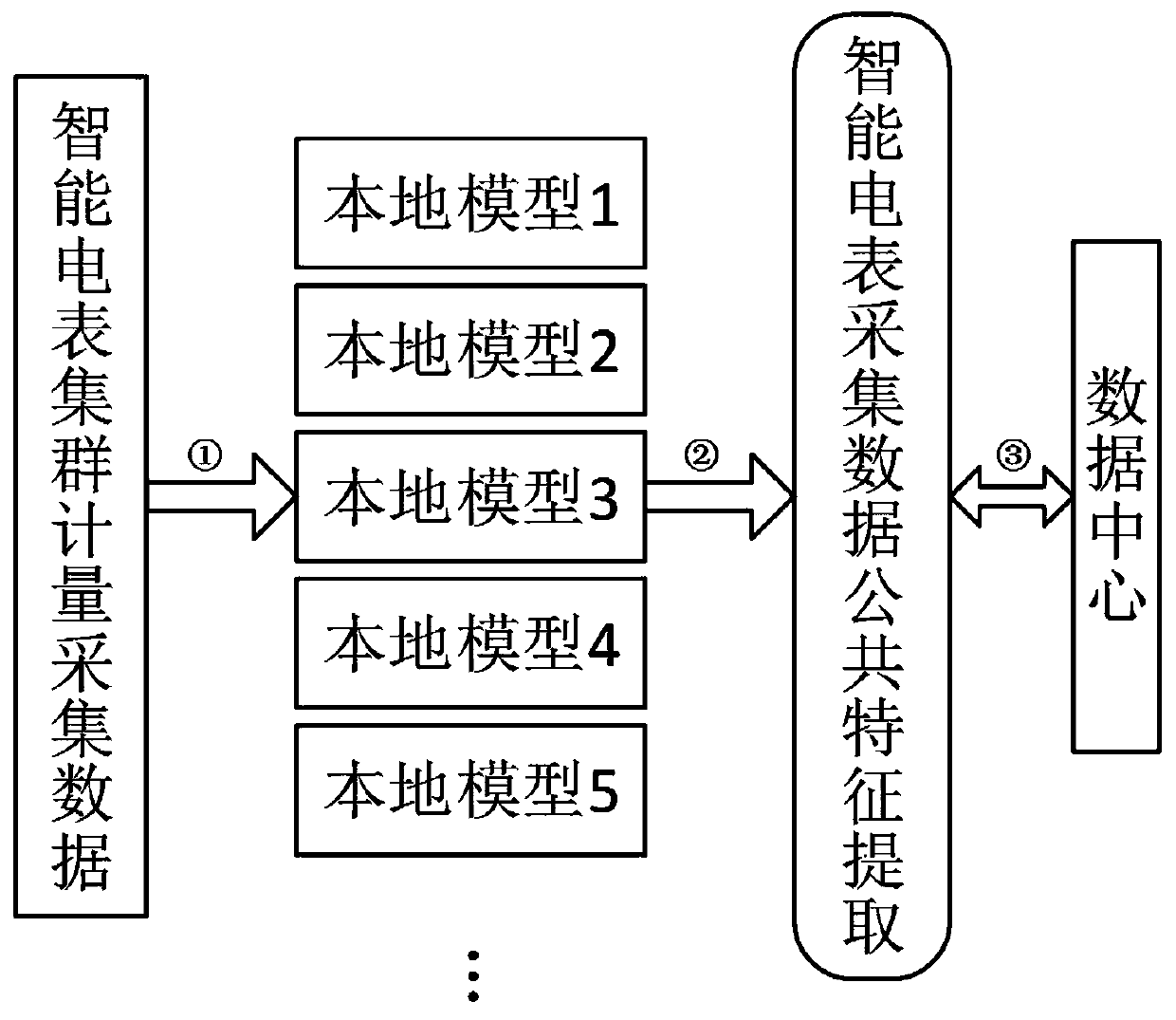

Intelligent electric meter fault diagnosis method and device based on federated learning

ActiveCN111537945AEasy fault detectionDatabase distribution/replicationElectrical measurementsClustered dataData ingestion

The invention discloses an intelligent electric meter fault diagnosis method and device based on federated learning. The diagnosis method comprises the steps that setting a lightweight fault detectionmodel capable of operating at an intelligent electric meter end; extracting intelligent electric meter cluster data features, namely extracting public overlapping features from intelligent electric meter acquisition data; training a fault detection model on each intelligent electric meter terminal; uploading the intermediate training parameters to a server of an electric power data center; enabling the server to perform parameter fusion calculation and return the parameters to each local model for updating; and completing training of shared models. By applying the technical scheme provided bythe invention, on the premise of protecting the user privacy data of the intelligent electric meter, huge cluster data can be fully utilized to improve the fault detection capability of the intelligent electric meter on the user side.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

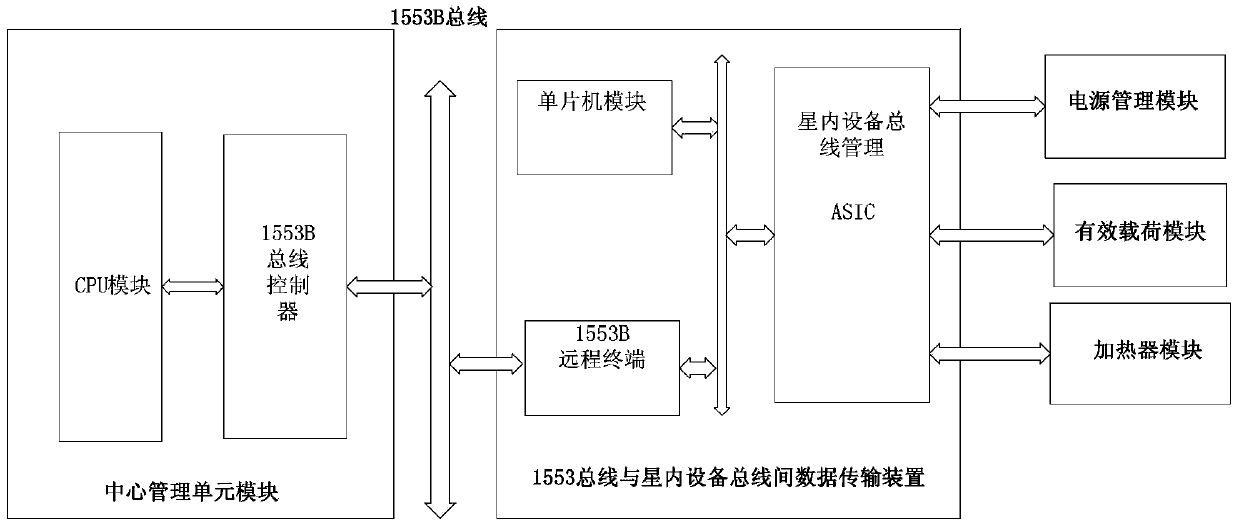

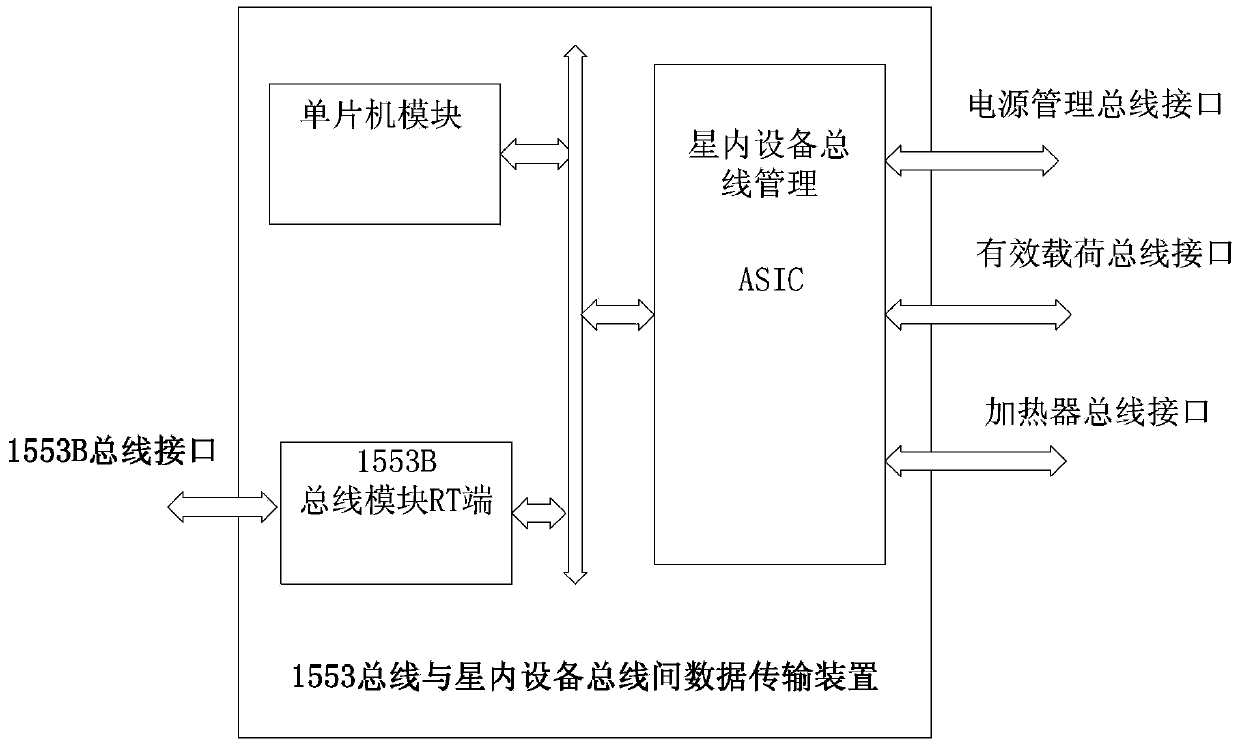

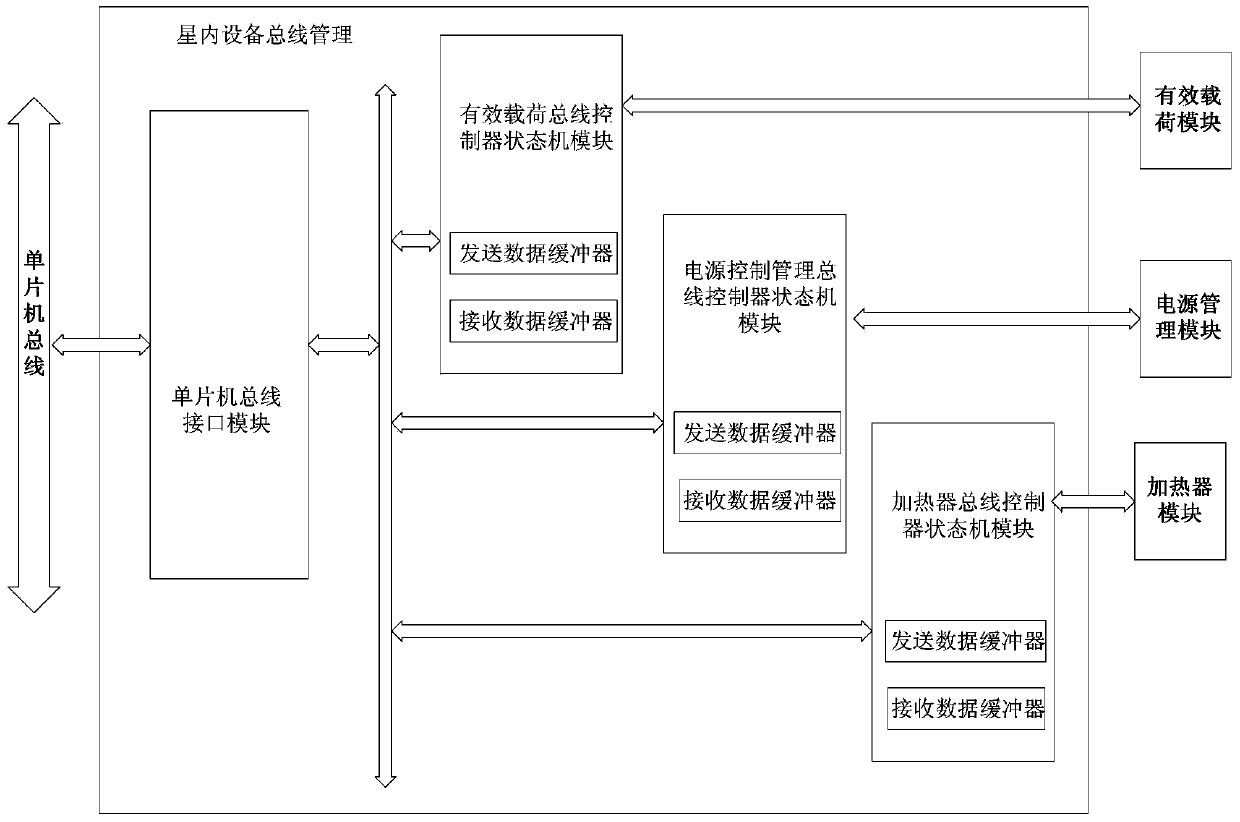

Device for transmitting telemetric and telecontrolled data between 1553B bus and satellite interior equipment bus

ActiveCN103473196ASimple designAchieve physical isolationElectric digital data processingMicrocontrollerComputer module

A device for transmitting telemetric and telecontrolled data between a 1553B bus and a satellite interior equipment bus comprises a 1553B bus module, a singlechip module and a satellite equipment bus management module. The satellite interior equipment bus management module is not used in the traditional design method, and telemetric and telecontrolled management of satellite interior equipment is realized by using a singlechip only; along with increasing of the number of satellite-borne equipment, the complexity of control logic of the singlechip is increased, and the reliability of a system is affected; and moreover, because the singlechip works in a serial mode, the singlechip only can acquire and process one telemetric parameter every time, the updating period of the telemetric parameters of the whole satellite is longer and longer, and detection and isolation of faults are affected. The device can overcome the shortcomings; the design of a singlechip system is simplified by the satellite interior equipment bus management module, and the control and management capability of the system on telemetry and telecontrol to the satellite equipment is improved.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

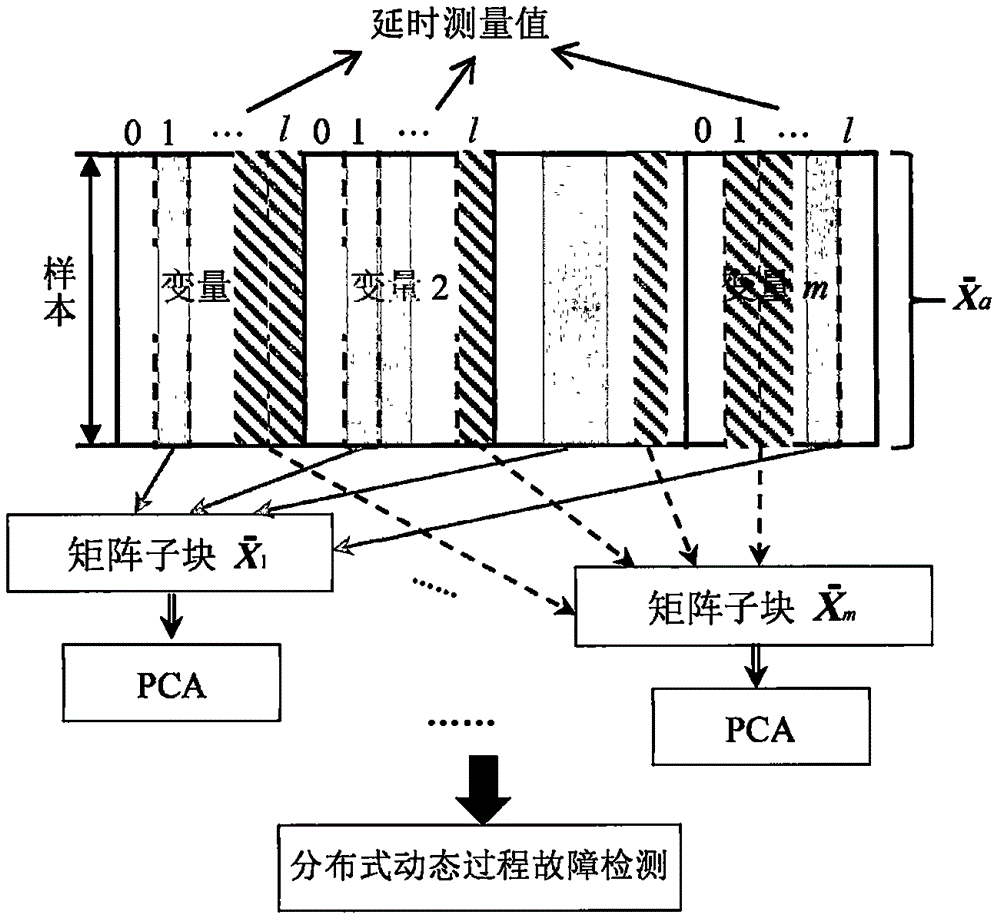

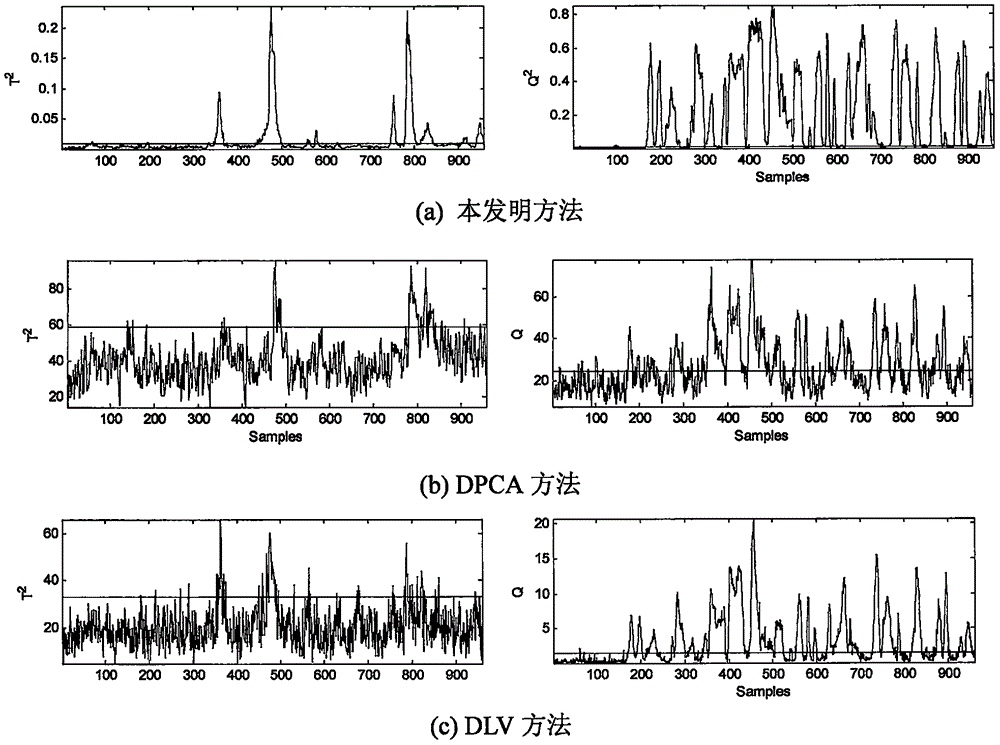

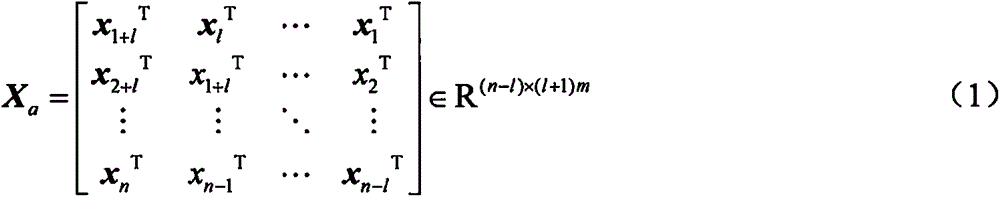

Distributed dynamic process fault detection method based on mutual information

ActiveCN105955219AImprove reliabilityReduce difficultyTotal factory controlProgramme total factory controlData setTime delays

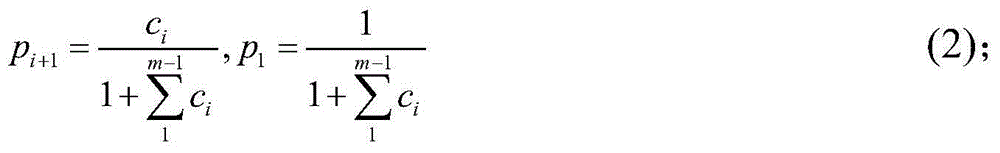

The invention relates to a distributed dynamic process fault detection method based on mutual information. The distributed dynamic process fault detection method based on mutual information comprises the steps: introducing a time-delay measured value for each measured variable of the process; by means of the correlation index defined by mutual information, distinguishing the auto-correlation and the cross-correlation displayed at different sampling time for each measured variable of the process; respectively establishing a corresponding principal component analysis fault detection model for a data set subblock corresponding to each variable; and at last, during the process of implementing on-line monitoring, utilizing Bayesian reasoning to integrate the results of different fault detection models into one probability type monitoring index so as to make a final fault decision conveniently. Compared with the prior method, the distributed dynamic process fault detection method based on mutual information fully considers the auto-correlation and the cross-correlation among different measured variables at different sampling time, and avoids losing the useful information which may be hidden in the complex dynamic characteristic of the process data.

Owner:北京安胜华信科技有限公司

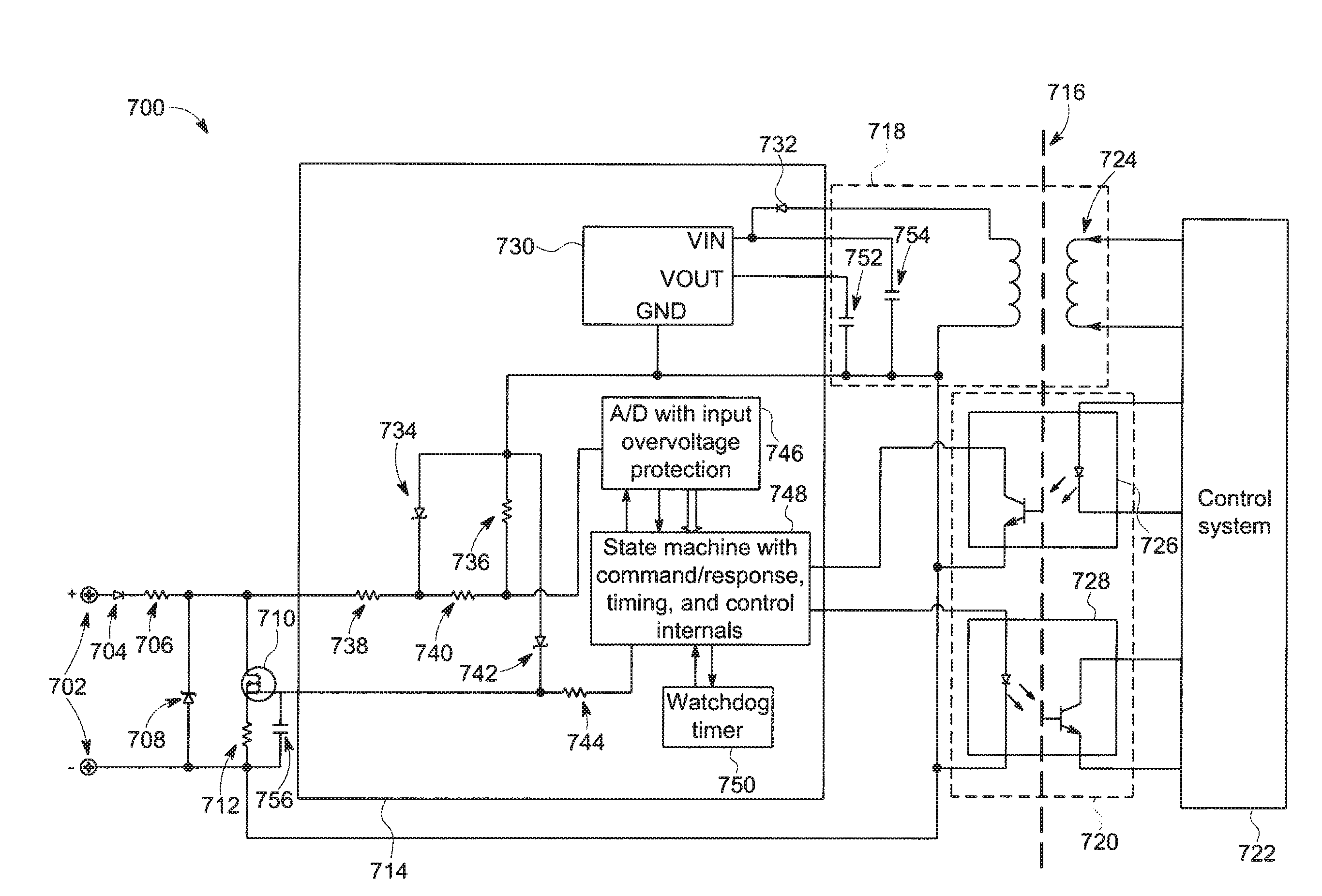

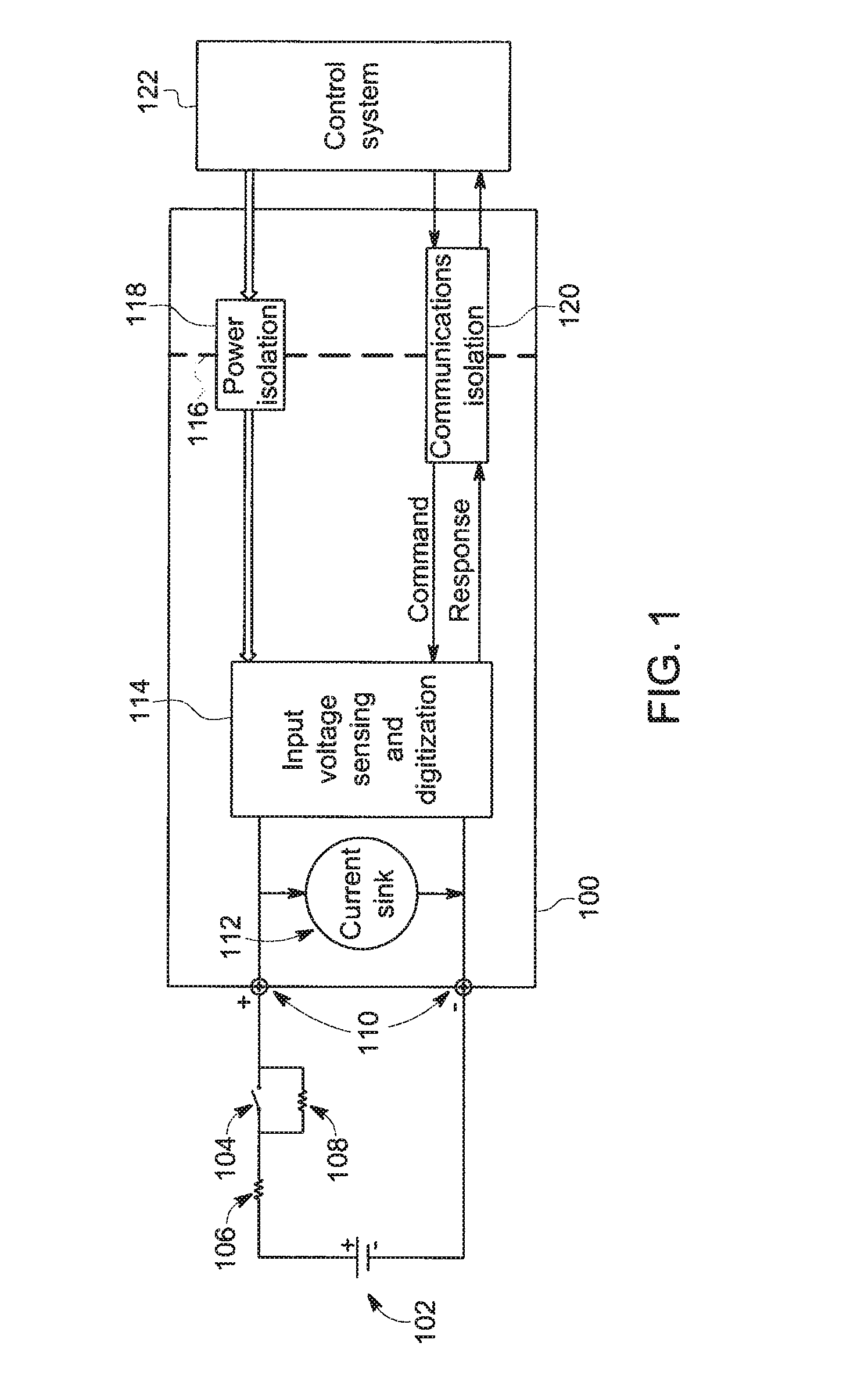

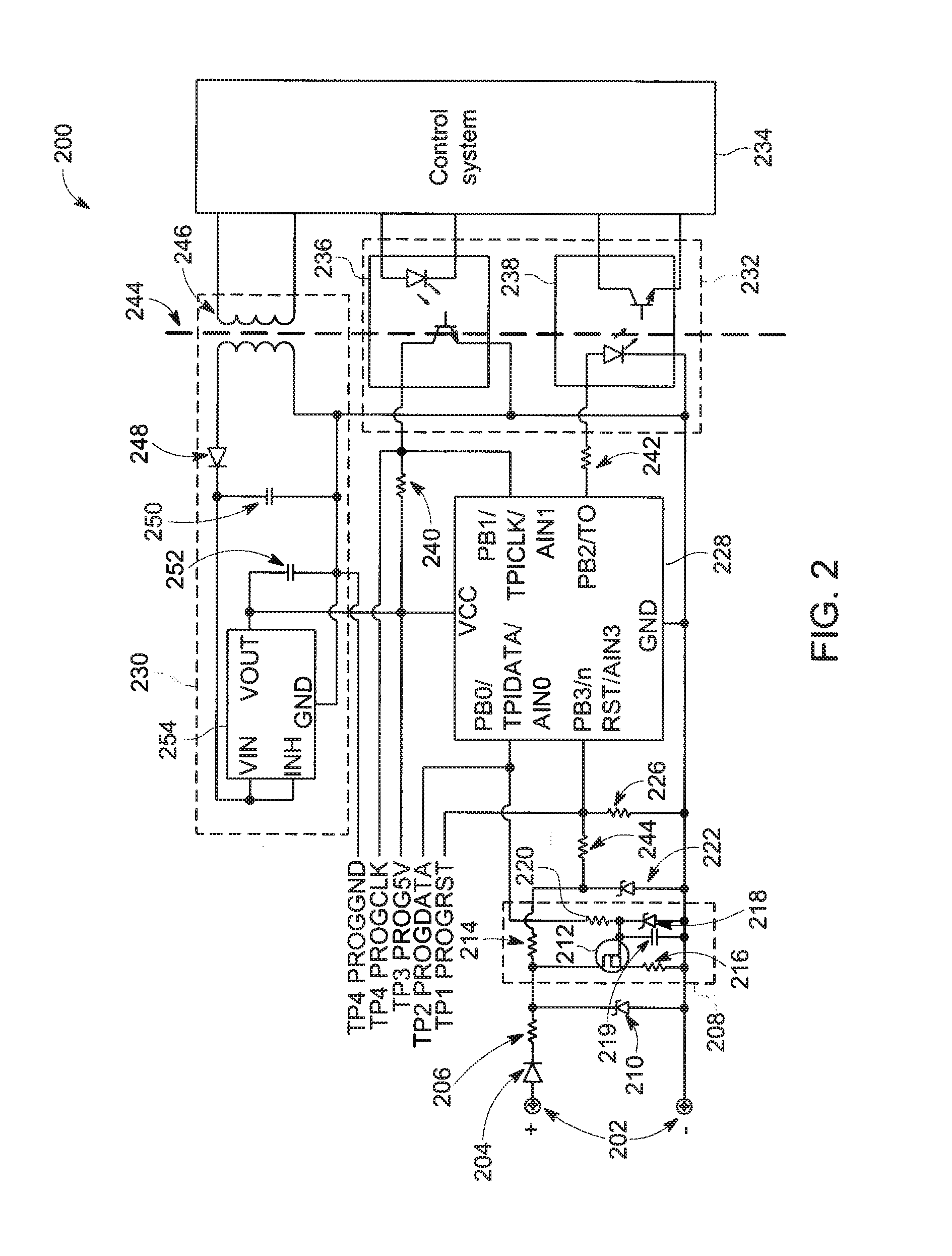

Programmable contact input apparatus and method of operating the same

InactiveUS20140312909A1Wide rangeEasy fault detectionProtective switch detailsContact testing/inspectionElectricityEngineering

At embedded control logic, electrical information with respect to a switching device is sensed. A decision is made as to an operation of the control logic based on the sensed information. The operation may be one or more of setting a wetting current or determining whether the electrical information is within an acceptable range.

Owner:GE INTELLIGENT PLATFORMS LTD

Fault Detection in Subsea Power Cables

InactiveUS20140361785A1Easy fault detectionDrawback can be obviatedEmergency protective circuit arrangementsVoltage-current phase angleOcean bottomMeasurement point

A method of detecting a fault in a subsea power cable or in a direct electric heating system including a subsea power cable is provided. Measuring points are distributed along the subsea power cable. The method includes measuring at each measuring point a current in the subsea power cable and comparing the currents measured at the different measuring points.

Owner:SIEMENS AG

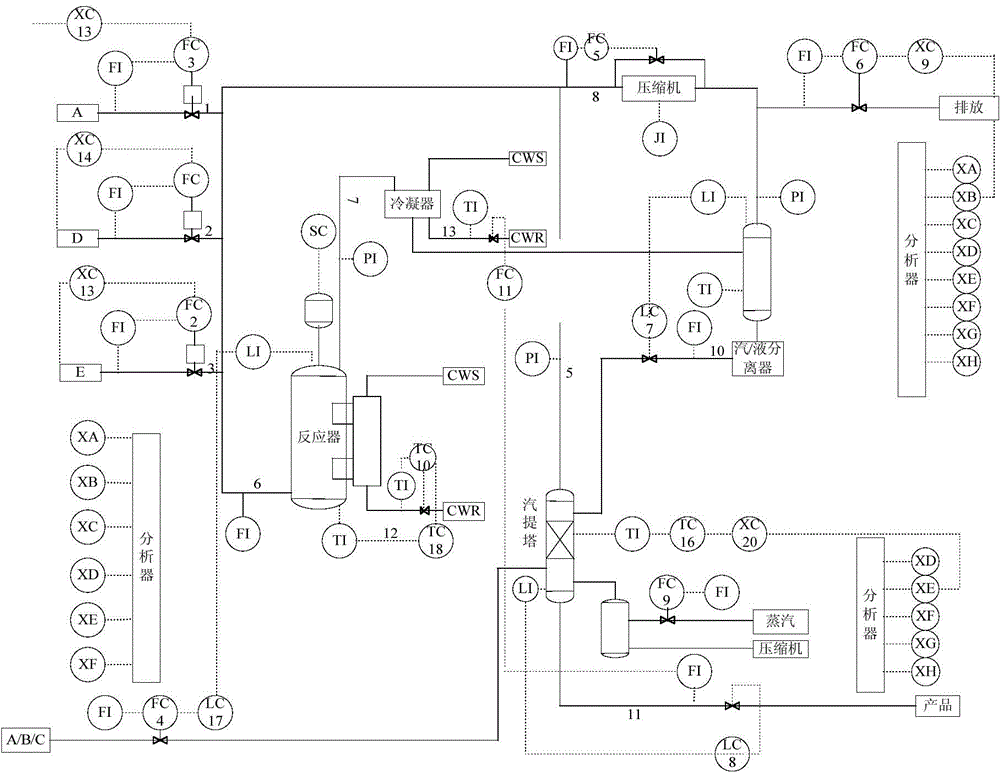

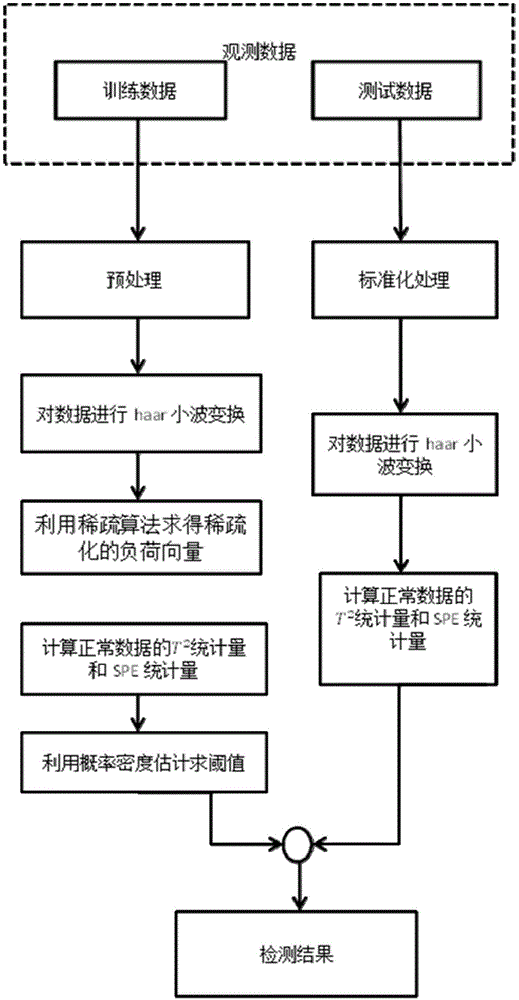

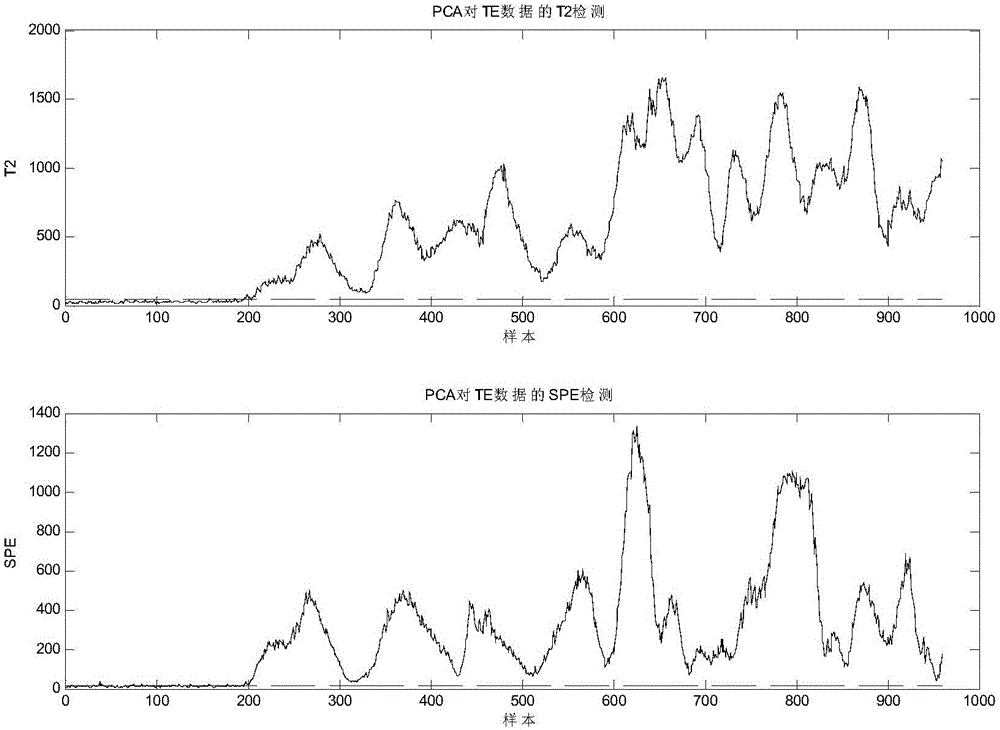

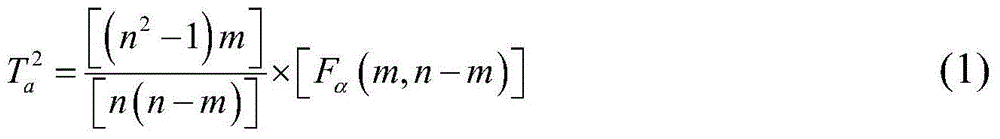

Continuous chemical process fault detection method

InactiveCN104062968AEasy fault detectionImprove accuracyElectric testing/monitoringData compressionLinear regression

The invention relates to a continuous chemical process fault detection method. The continuous chemical process fault detection method comprises the following steps that (1) a linear regression model of a vector Xj and a vector Y is built, and a regression constraint function is introduced; (2) data compression is carried out through haar wavelet transformation to improve computational efficiency; (3) a regression constraint construction sparse pivot element model with the addition of 1-norm and 2-norm is built, and an optimal solution of a sparse pivot element is worked out through derivation of the SPCA algorithm; (4) the optimal threshold value of the T2 statistic and the optimal threshold value of the SPE statistic are estimated through the kernel density estimation (kde) method; (5) calculation of the T2 statistic and the SPE statistic is conducted on fault data, and the value of the T2 statistic and the value of the SPE statistic of the fault data are obtained in sequence; (6) whether a fault exists in the data is detected. According to the continuous chemical process fault detection method, the data size related to a pivot element after sparsity is reduced, so that the calculated quantity is reduced, the computation time is shortened, real-time performance of monitoring is improved, and accuracy and efficiency of fault detection can be improved.

Owner:EAST CHINA UNIV OF SCI & TECH

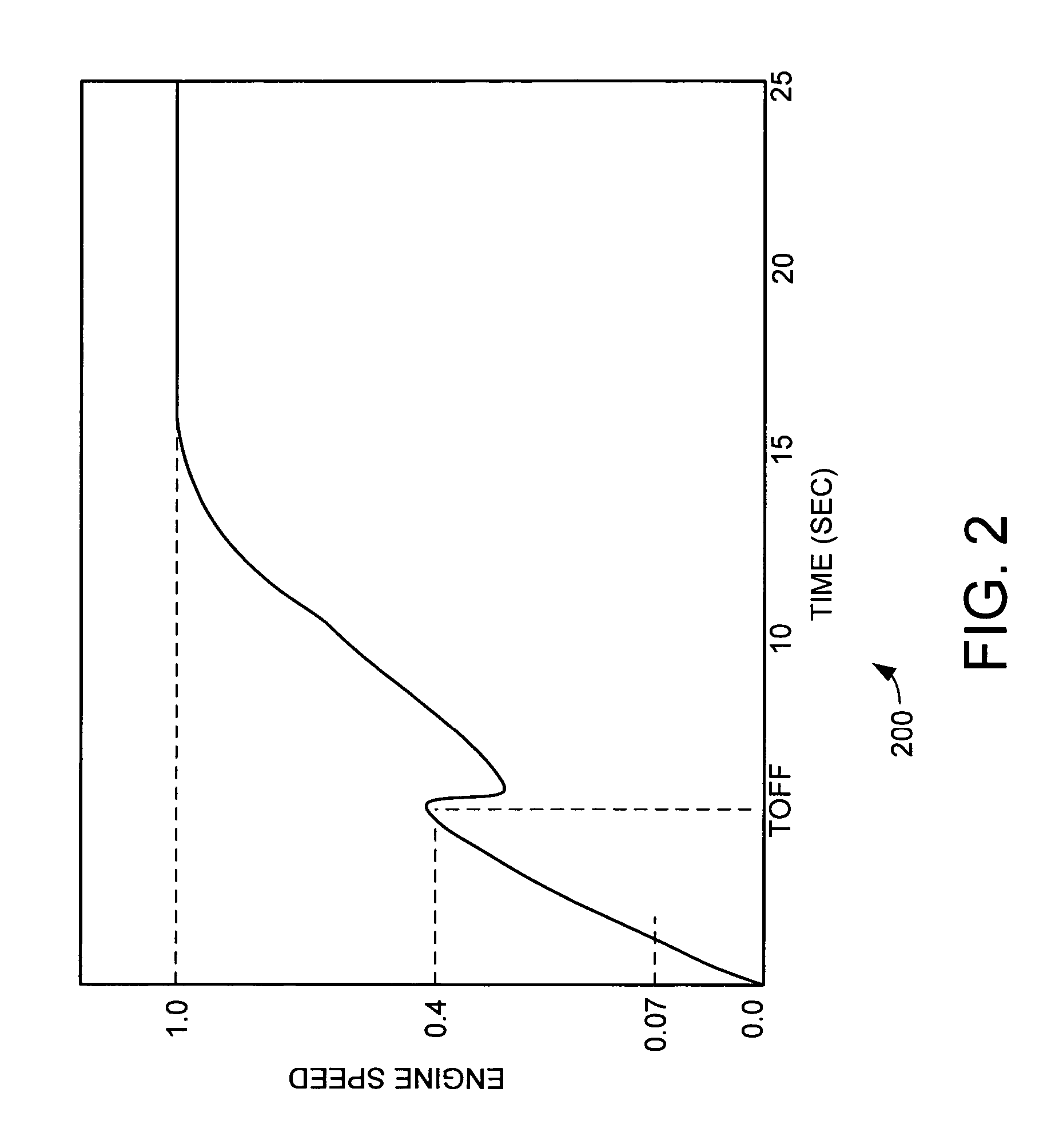

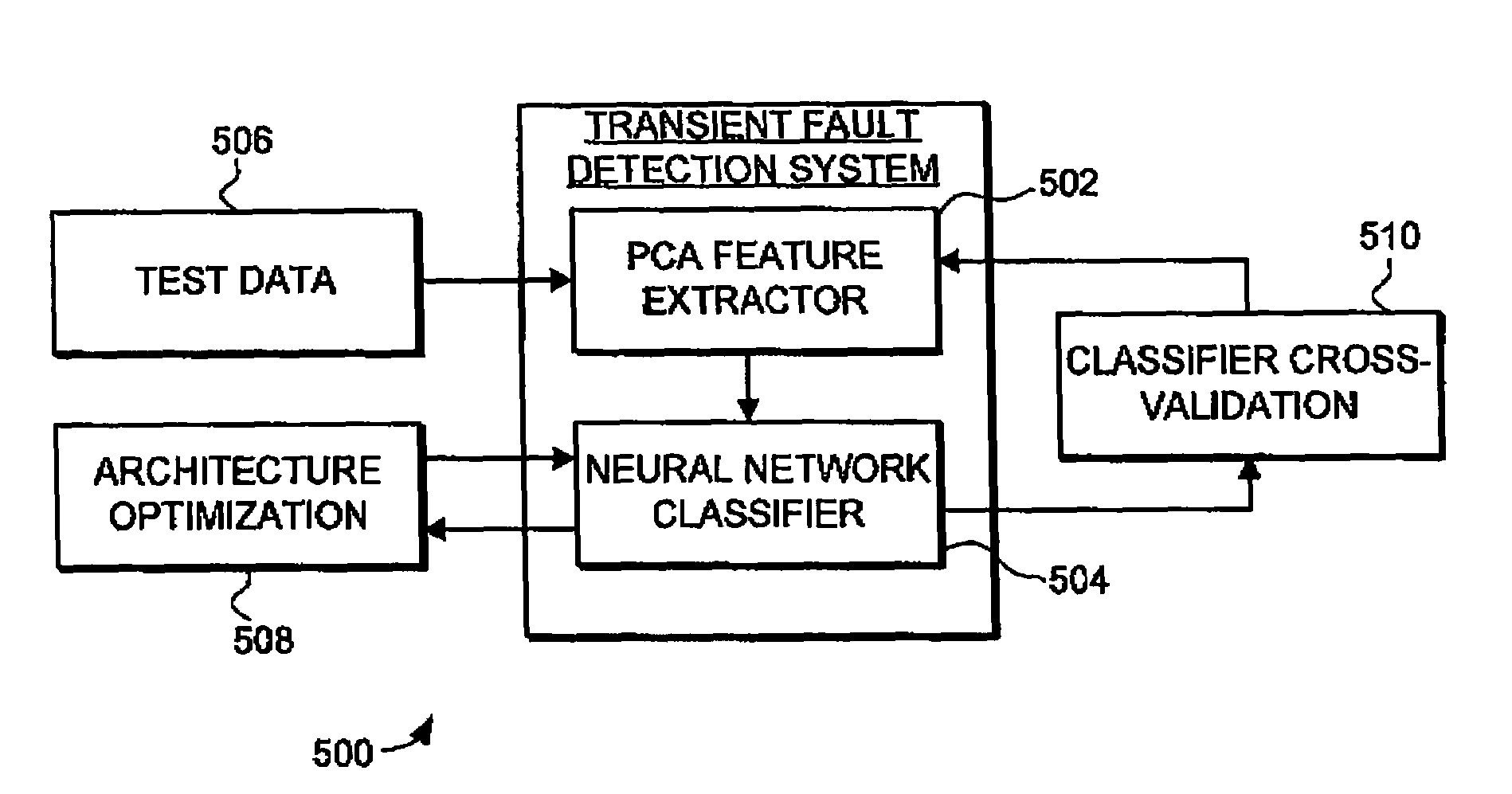

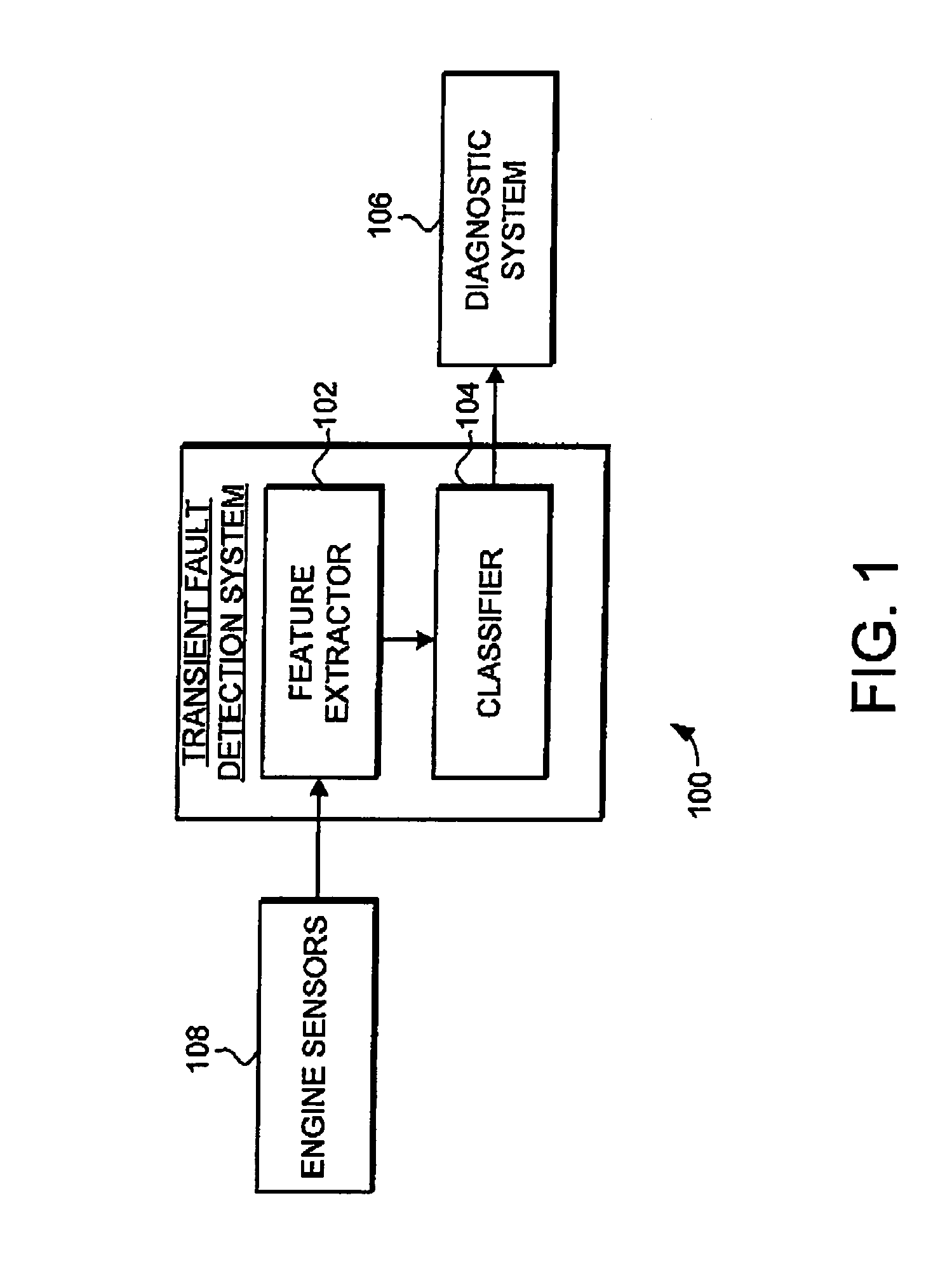

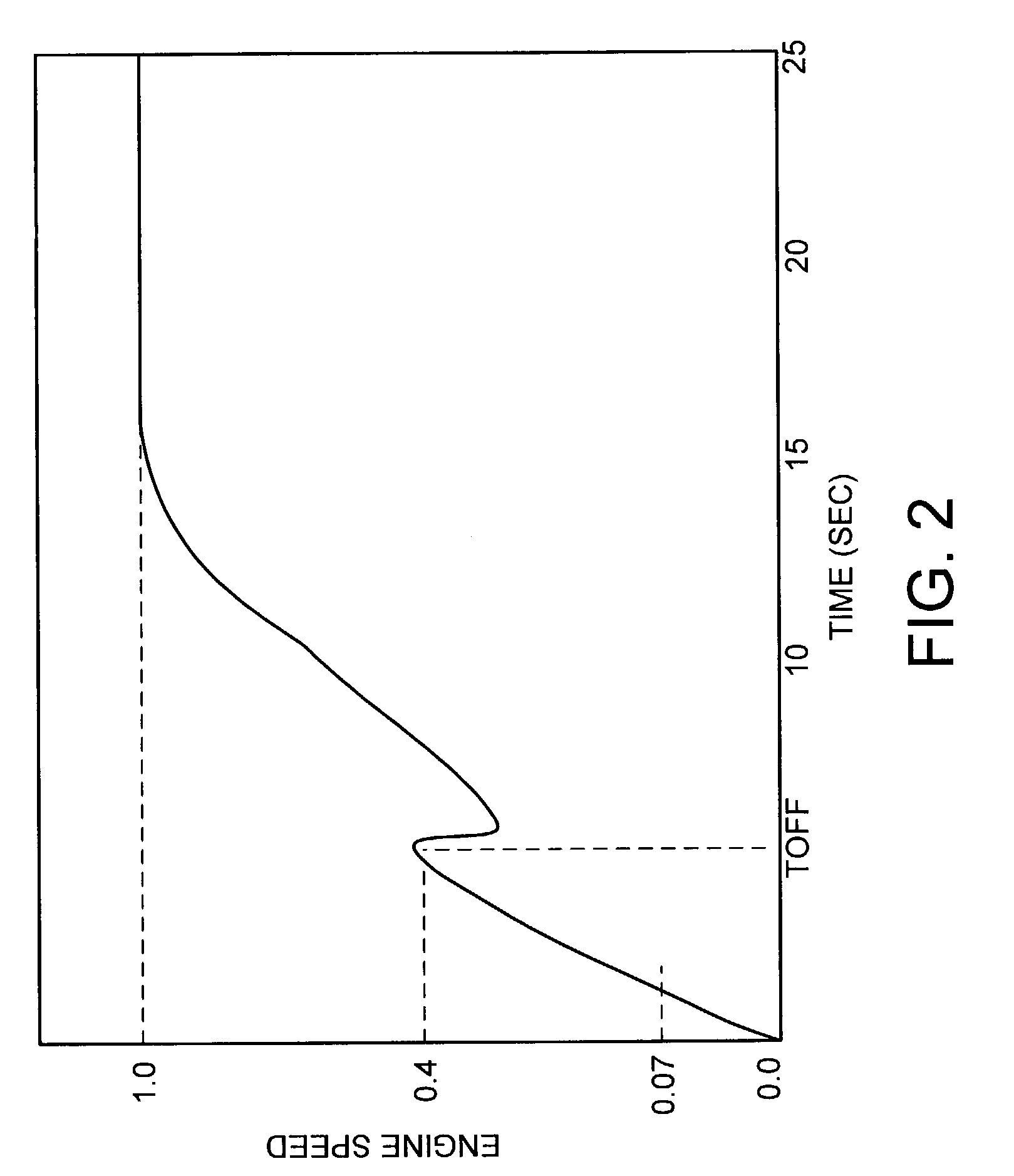

Transient fault detection system and method

InactiveUS7043348B2Improve performanceData efficientVehicle testingAnalogue computers for vehiclesDetection performanceDiagnostic system

A transient fault detection system and method is provided that facilitates improved fault detection performance in transient conditions. The transient fault detection system provides the ability to detect symptoms of fault in engine that occur in transient conditions. The transient fault detection system includes a feature extractor that measures sensor data during transient conditions and extracts salient features from the measured sensor data. The extracted salient features are passed to a classifier that analyzes the extracted salient features to determine if a fault has occurred during the transient conditions. Detected faults can then be passed to a diagnostic system where they can be passed as appropriate to maintenance personnel.

Owner:HONEYWELL INT INC

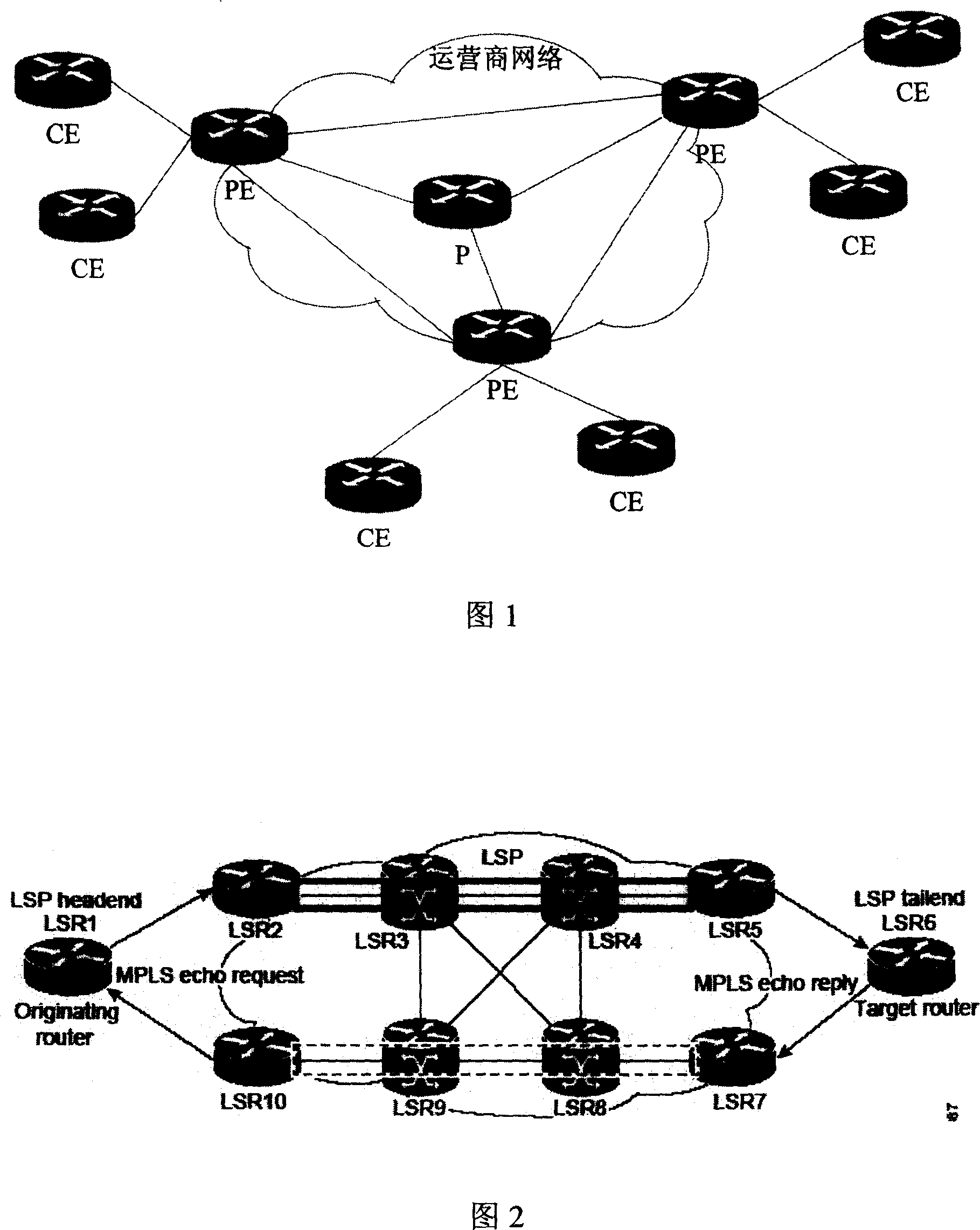

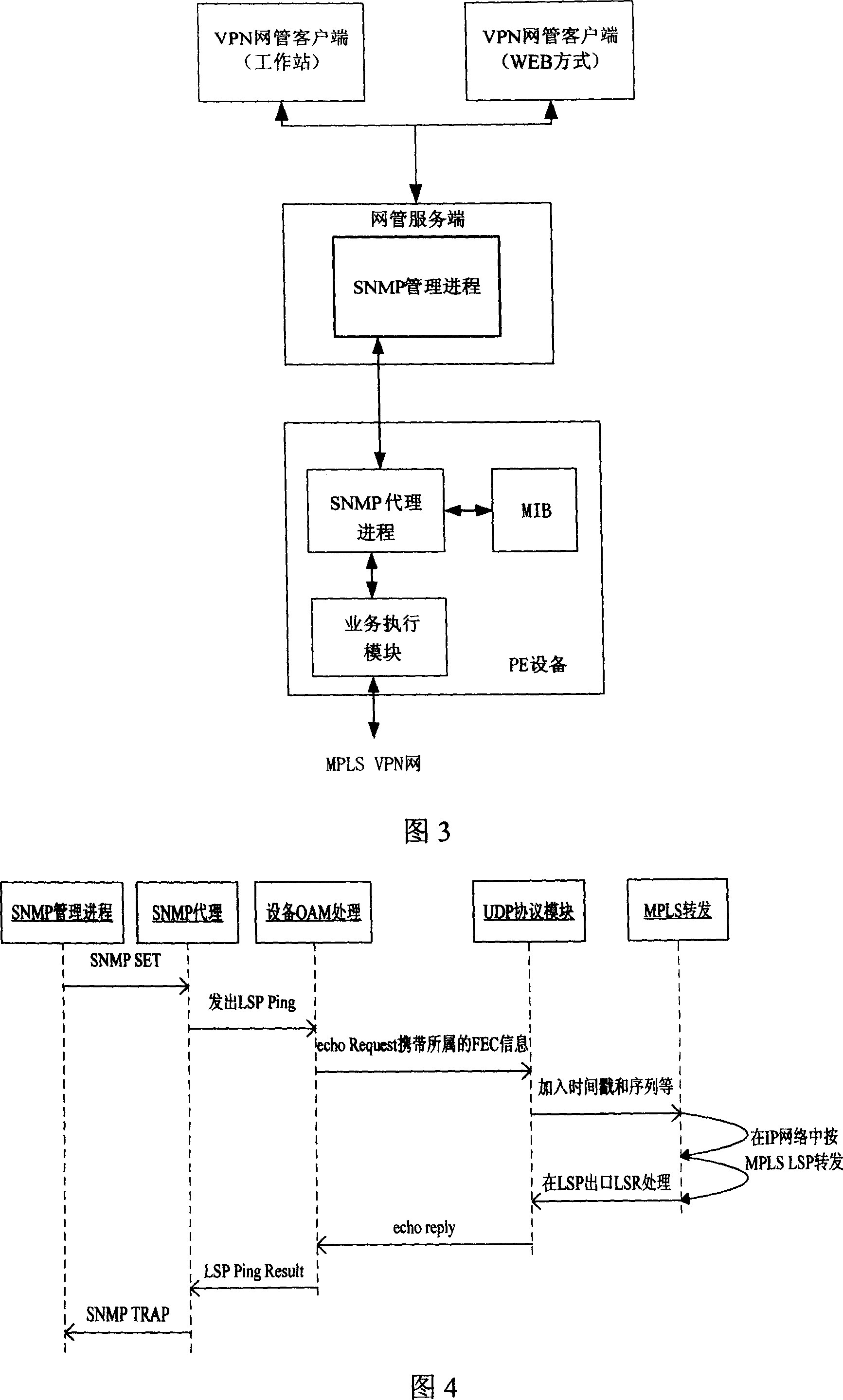

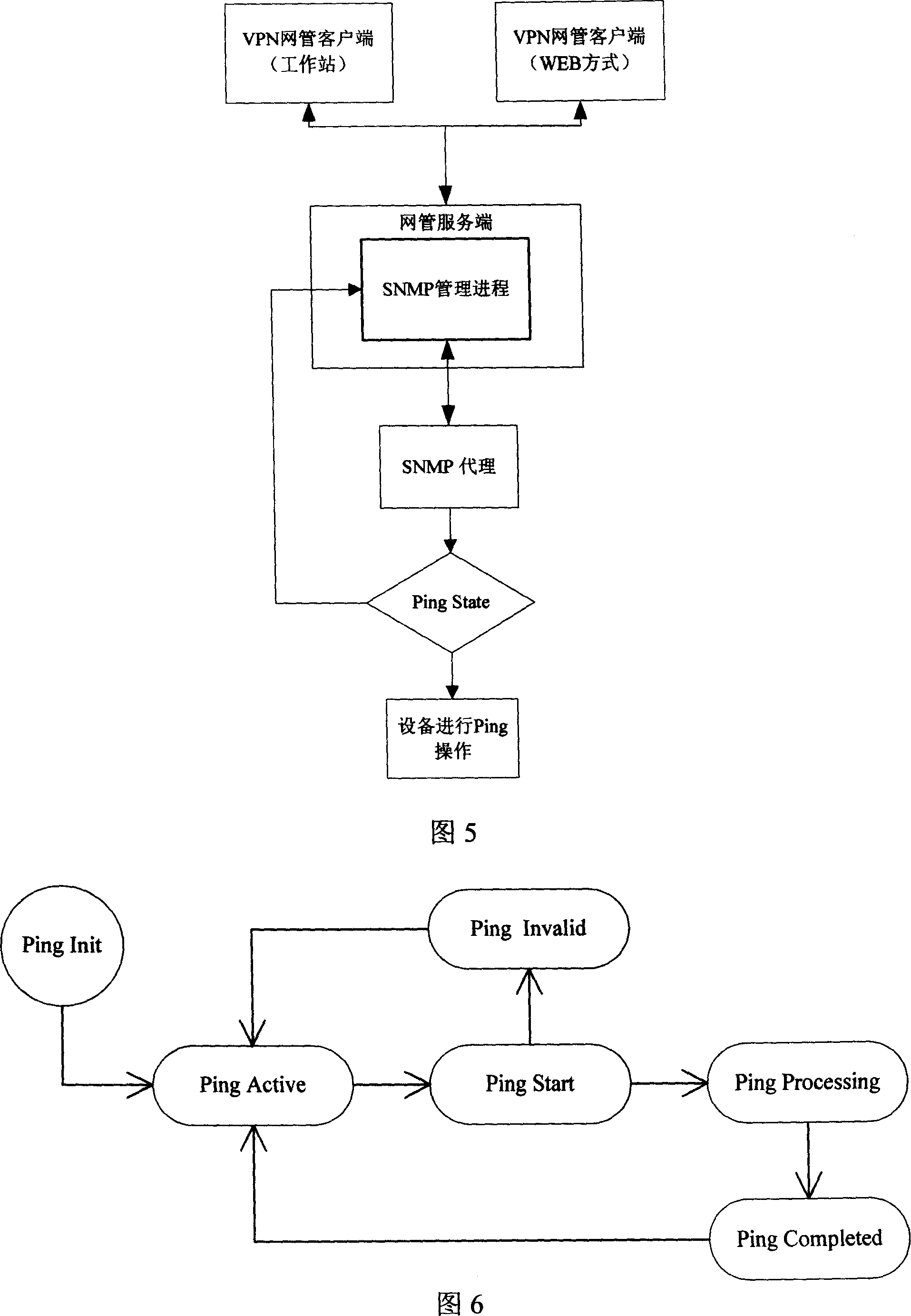

Method for detecting connectivity of multi-protocol label switching virtual private network

ActiveCN101114994AEasy fault detectionConvenient connectivity testingNetworks interconnectionPrivate networkManagement process

The invention discloses a connectivity detection method of MPLS VPN. Based on the SNMP agreement, a private MIB library is loaded in a PE device, and the SNMP agent process in the PE device conducts operation on the private MIB library, and the steps comprise that : (a) the user set a Ping parameter at the network management client terminal, and the SNMP agent process in the PE device sets the network element MIB library and transmits the Ping parameter to a business execution module; (b) the business execution module starts up the Ping operation according to the Ping parameter and returns the Ping result to the SNMP agent process to store the result in the MIB library; (c) the SNMP management process of the network management terminal returns the Ping result which is taken from the private MIB library to the network client terminal. The method of the invention can enable the user more conveniently to conduct the VPN business connectivity detection in the VPN business management system.

Owner:ZTE CORP

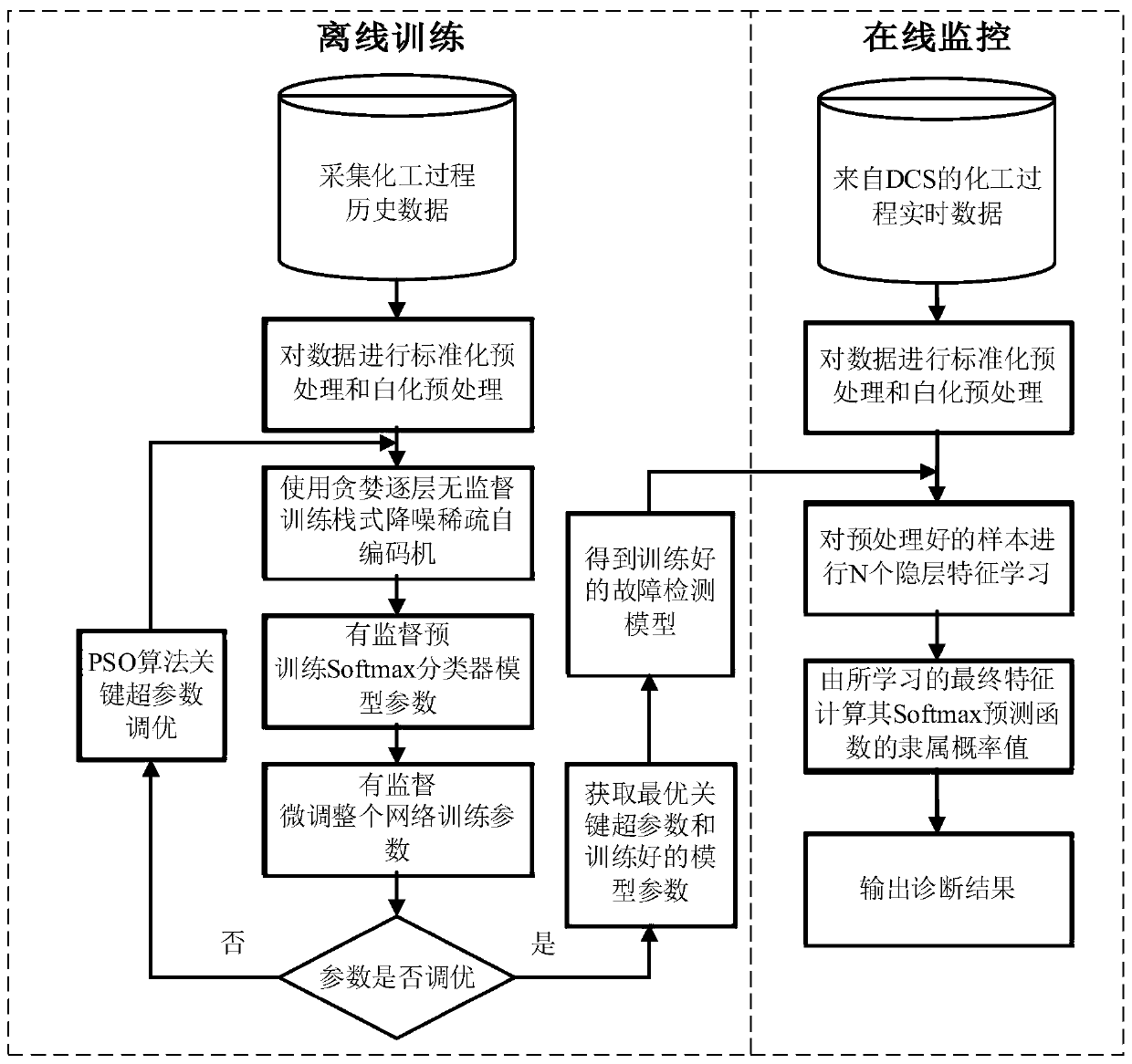

Chemical fault detection method based on particle swarm optimization and a noise reduction sparse coding machine

PendingCN109800875AGood clustering performanceSave energyCharacter and pattern recognitionNeural learning methodsChemical processSelf adaptive

The invention discloses a chemical fault detection method based on particle swarm optimization and a noise reduction sparse coding machine. The method comprises the following steps of carrying out unsupervised feature learning on standardized and whitened training data by using a plurality of stacked noise reduction sparse autocoders; carrying out Softmax classifier model training in a supervisedmanner; and finally, finely adjusting the weight parameters of the whole network through supervision, and introducing a particle swarm optimization algorithm into the key adjustable hyper-parameters for automatic optimization to obtain a trained chemical process fault detection intelligent model for fault detection of process real-time data. According to the invention, the greedy layer-by-layer training method of the deep neural network is adopted to adaptively and intelligently learn knowledge implied by original data in the chemical process; Compared with a traditional method, the method hasthe advantages that the method is more intelligent, the fault detection performance can be improved, and due to the fact that an automatic optimization algorithm is added, much time is saved comparedwith manual parameter tuning.

Owner:SOUTH CHINA UNIV OF TECH

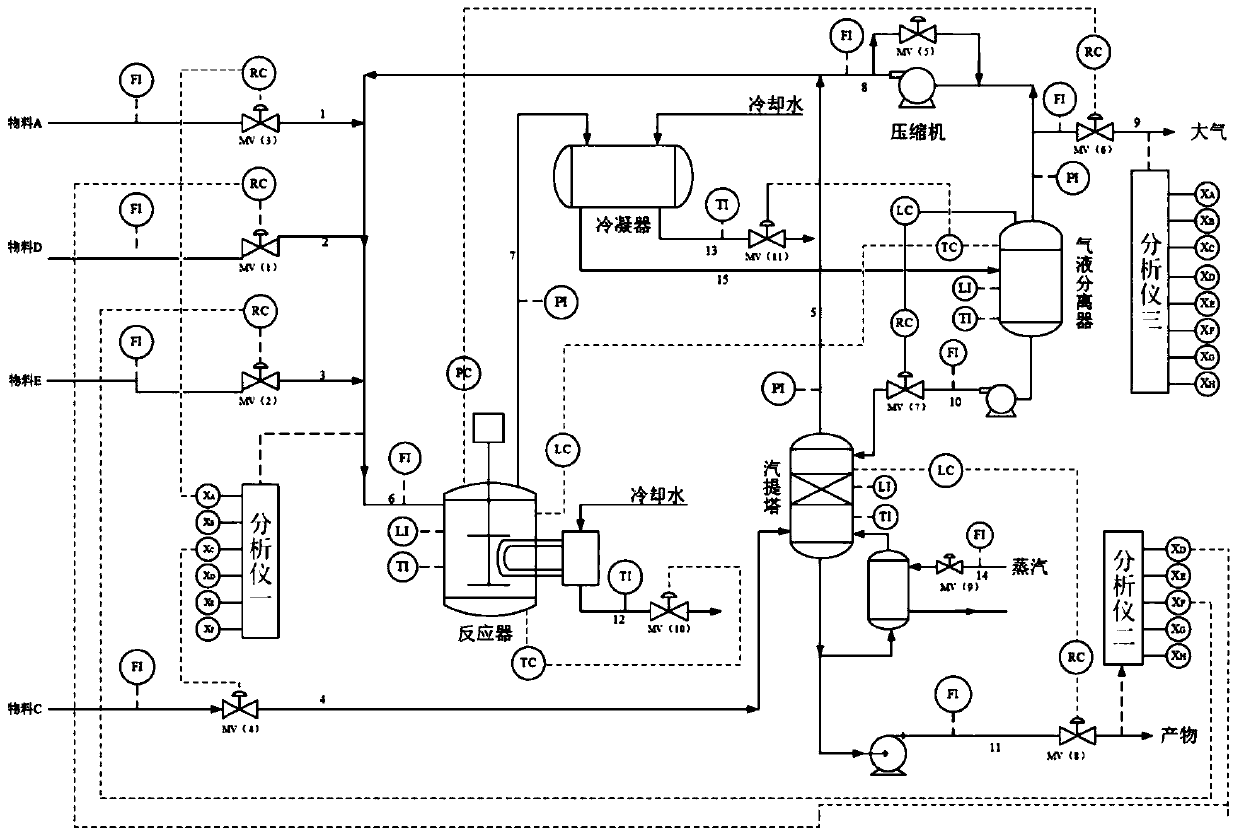

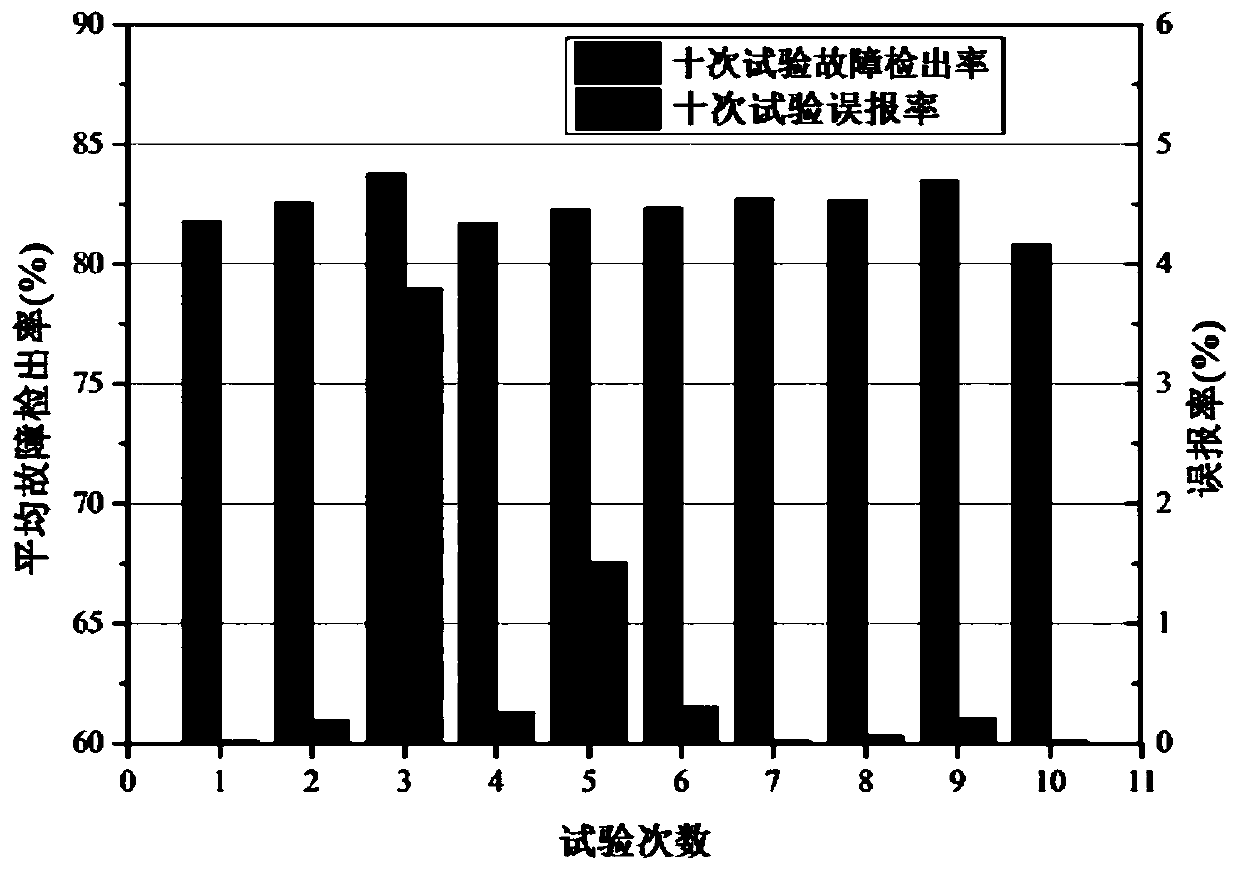

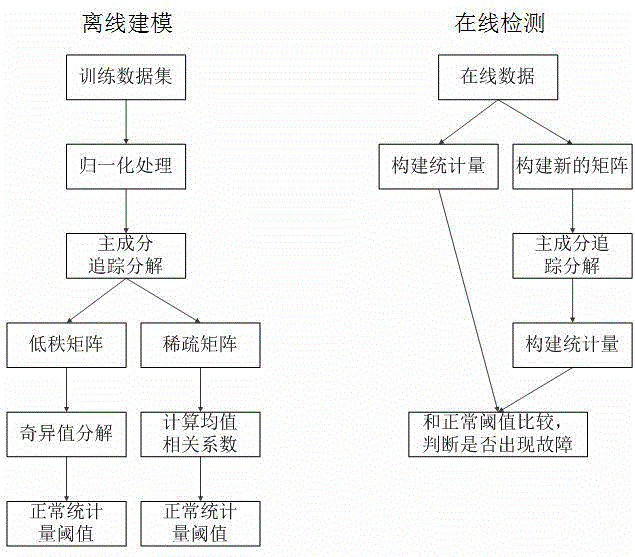

Principal component tracking based industrial fault monitoring method and application thereof

ActiveCN104793604AImplement fault detectionEasy fault detectionElectric testing/monitoringCorrelation coefficientMatrix decomposition

The invention discloses a principal component tracking based industrial fault monitoring method and application thereof, and belongs the technical field of industrial process monitoring and diagnosing. The method includes decomposing industrial collected data into a low rank matrix including complete process operation information and a sparse matrix including sensor noise and process faults according to a principal component tracking method; performing fault detection in the low rank matrix by the aid of a statistical magnitude T2, and performing fault detection in the sparse matrix by the aid of a statistical magnitude of a mean value correlation coefficient. Compared with the prior art, the principal component tracking based industrial fault monitoring method has the advantages that according to the characteristic that the matrixes are decomposed by the principal component tracking method, different statistical magnitudes are adopted for the matrixes with different characteristics, effective information included in the data are fully utilized, and accordingly, high accuracy in industrial fault detection is achieved.

Owner:ZHEJIANG UNIV

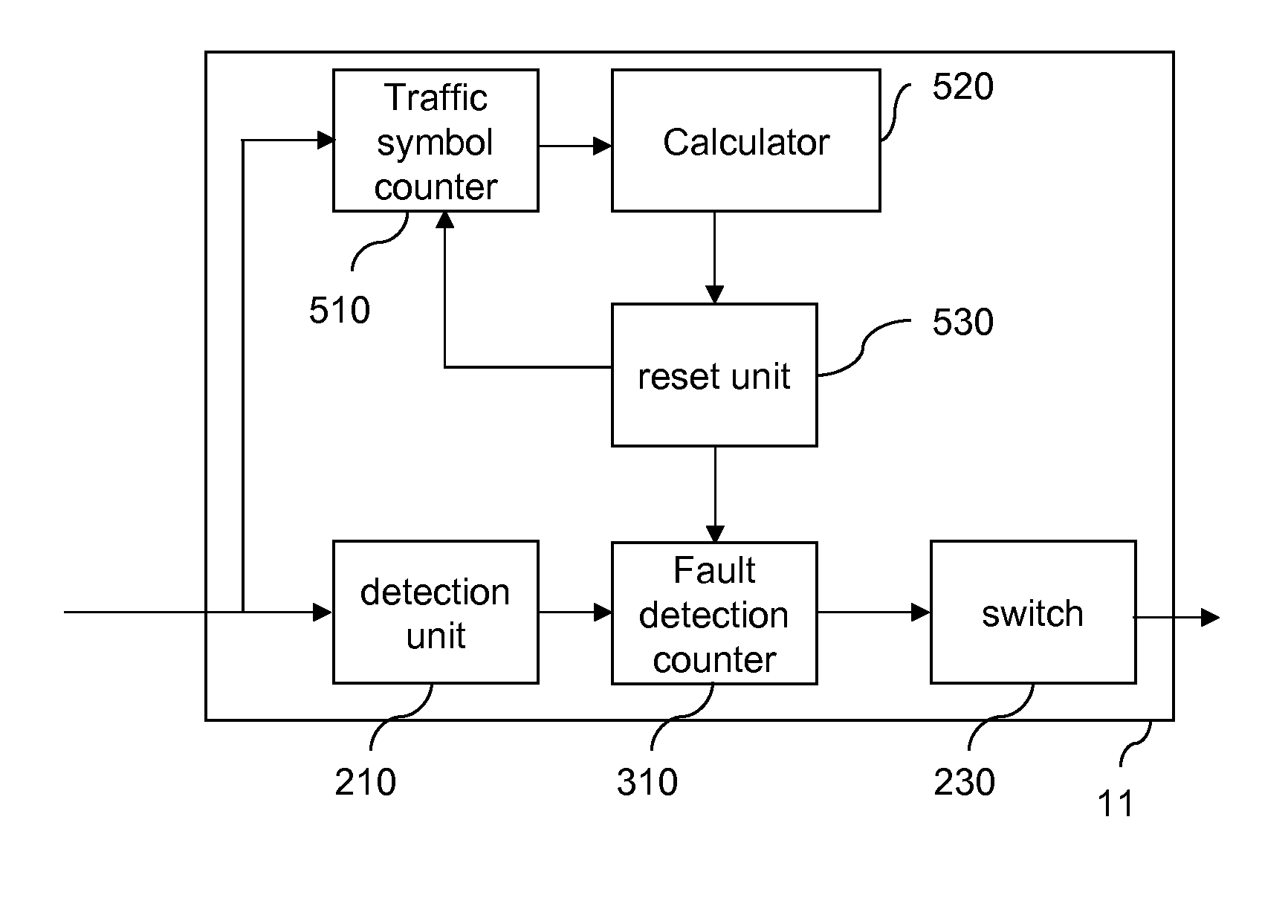

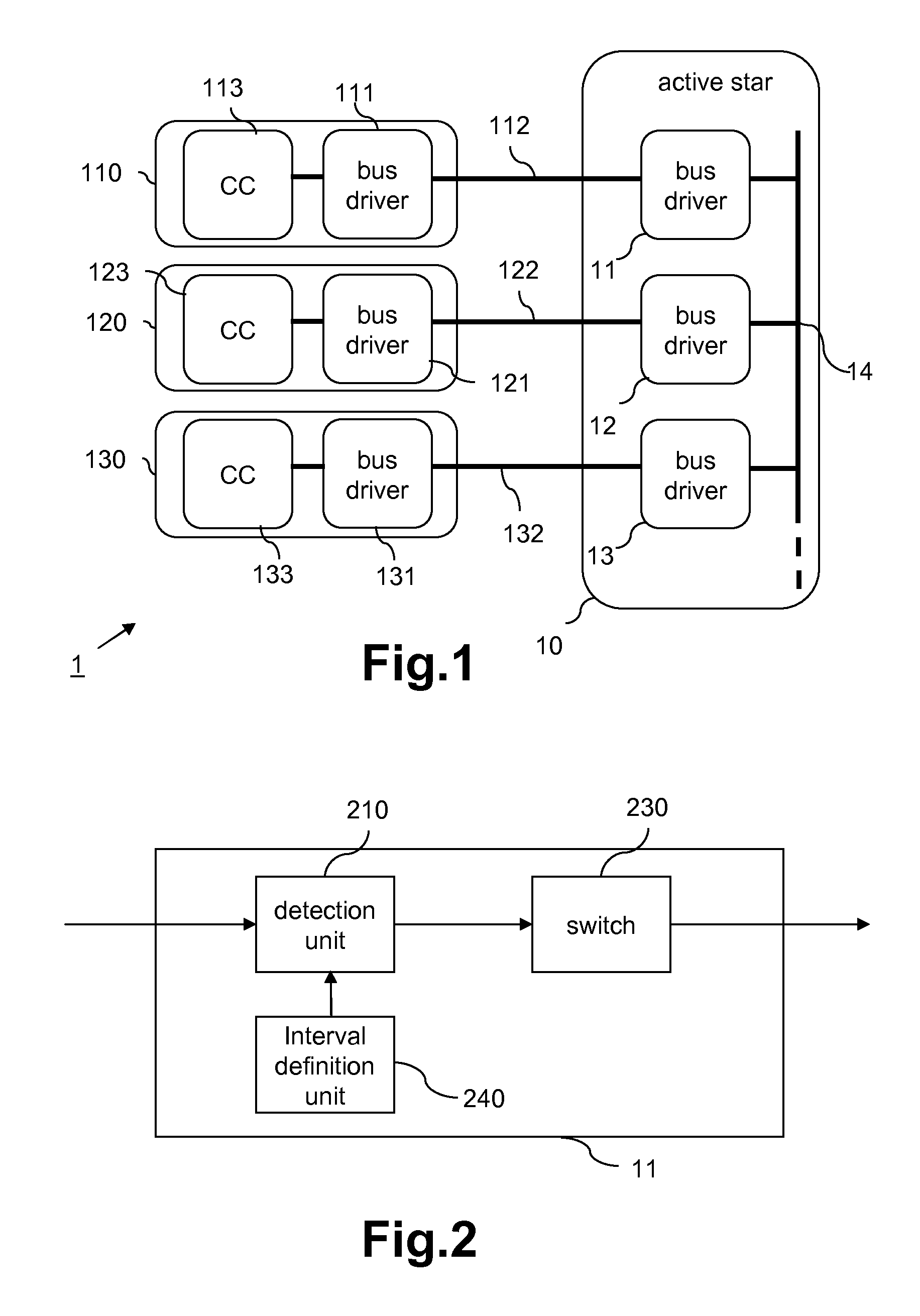

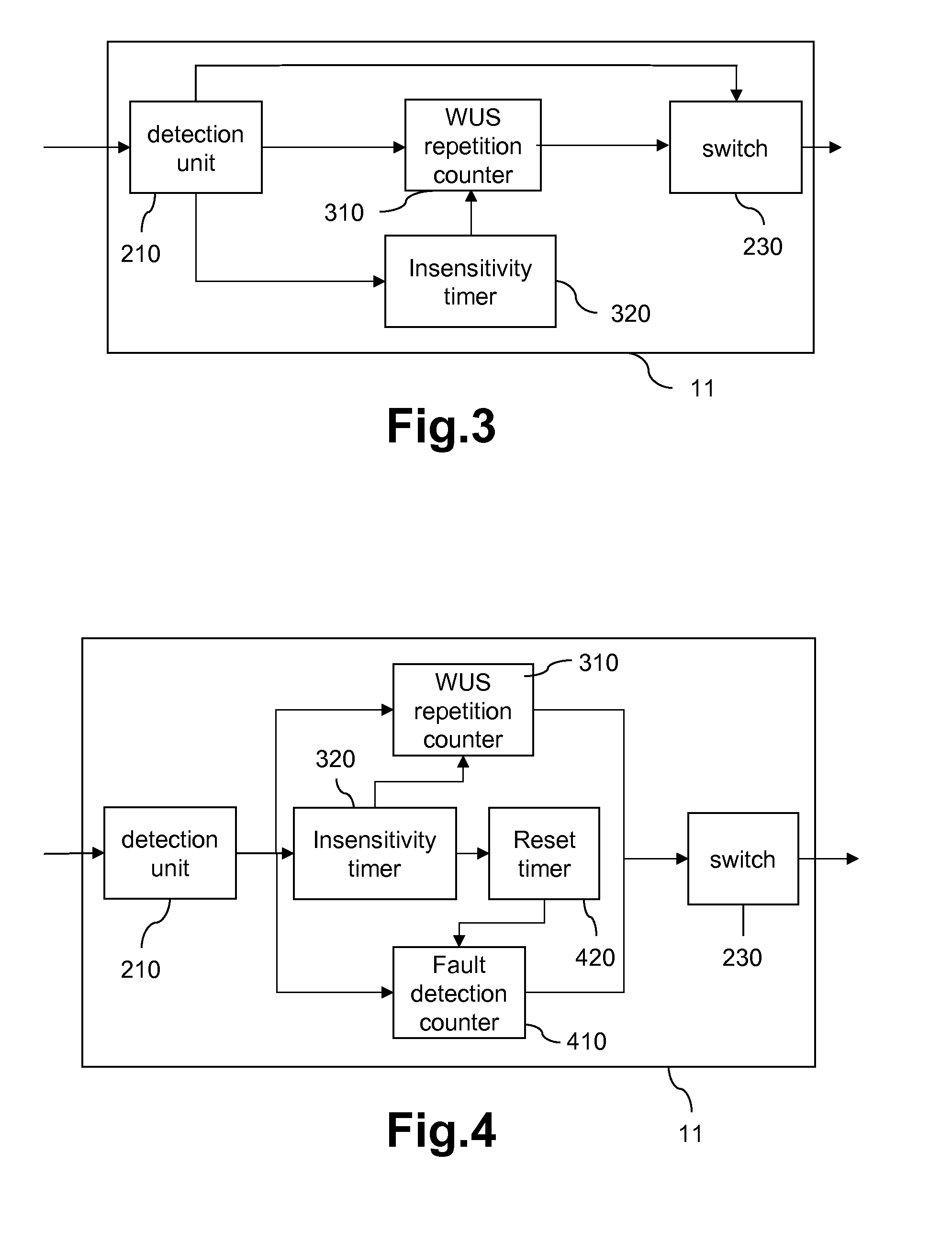

Star network and method for preventing a repeatedly transmission of a control symbol in such a star network

ActiveUS20100262689A1Avoid spreadingEasy fault detectionMultiple digital computer combinationsStar/tree networksComputer networkProtection mechanism

A star network (1) having a star coupler (14) and at least a first and second network branch (112, 122), wherein each network branch (112, 122) comprises at least one network node (110, 120) and a bus driver (11, 12) connected between the star coupler (14) and the at least one network node (110, 120). A first bus driver (11) of the first network branch (112) is adapted to detect a symbol pattern comprising at least two predetermined equal control symbols, which are transmitted from the first network node (110) to the second network node (120), wherein a control symbol is part of a control pattern. The control pattern is used to force at least the second network node (120) to switch into a predetermined state. The first bus driver (11) is disabling the first network branch (112) from the star network (1) based on whether the transmitted symbol pattern is detected. By using the protection mechanism a reliable detection of babbling idiots is provided. Moreover, in case of detecting such babbling idiots the remaining network nodes are separated and the network can operate without being influenced by the faulty network node.

Owner:NXP BV

Method and apparatus for the detection of faults in data computations

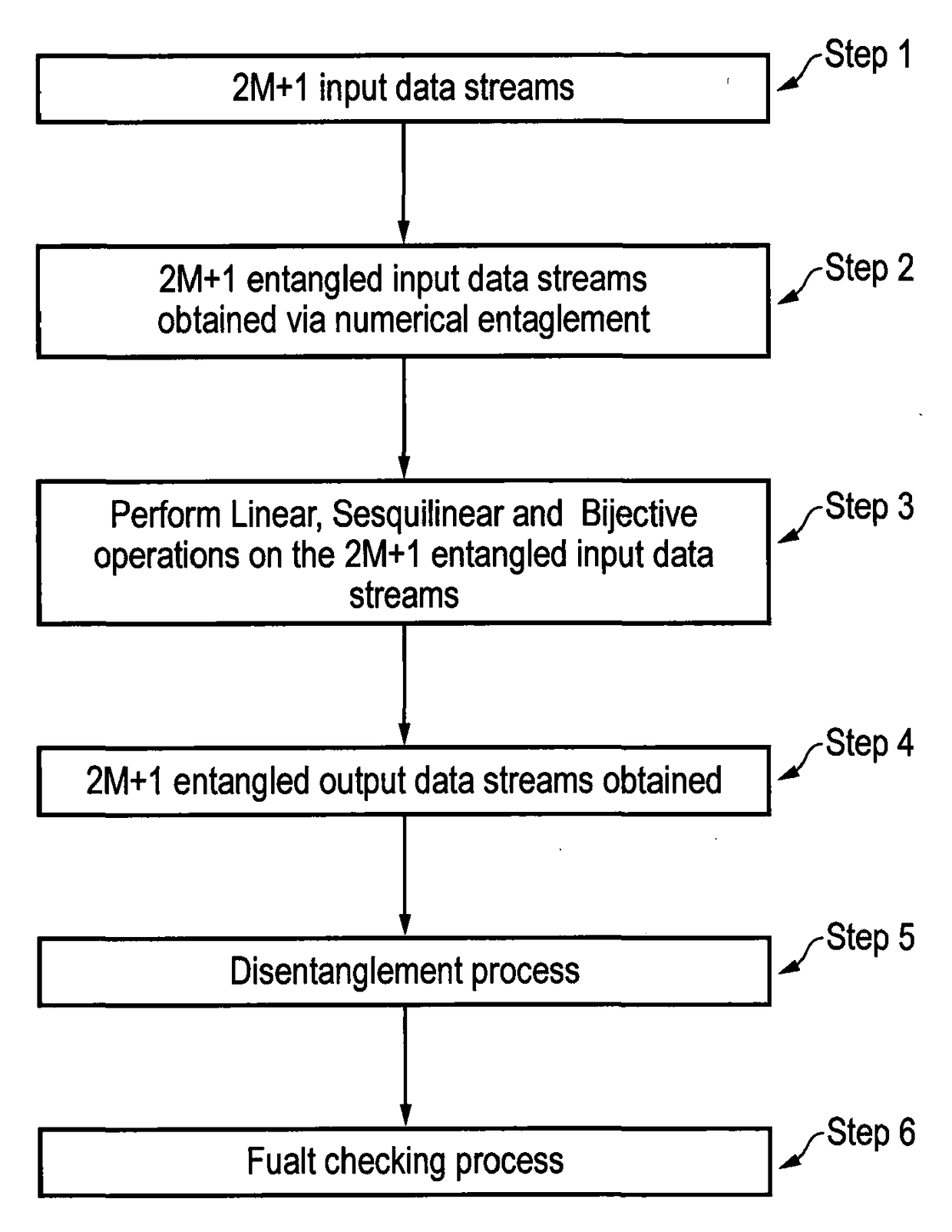

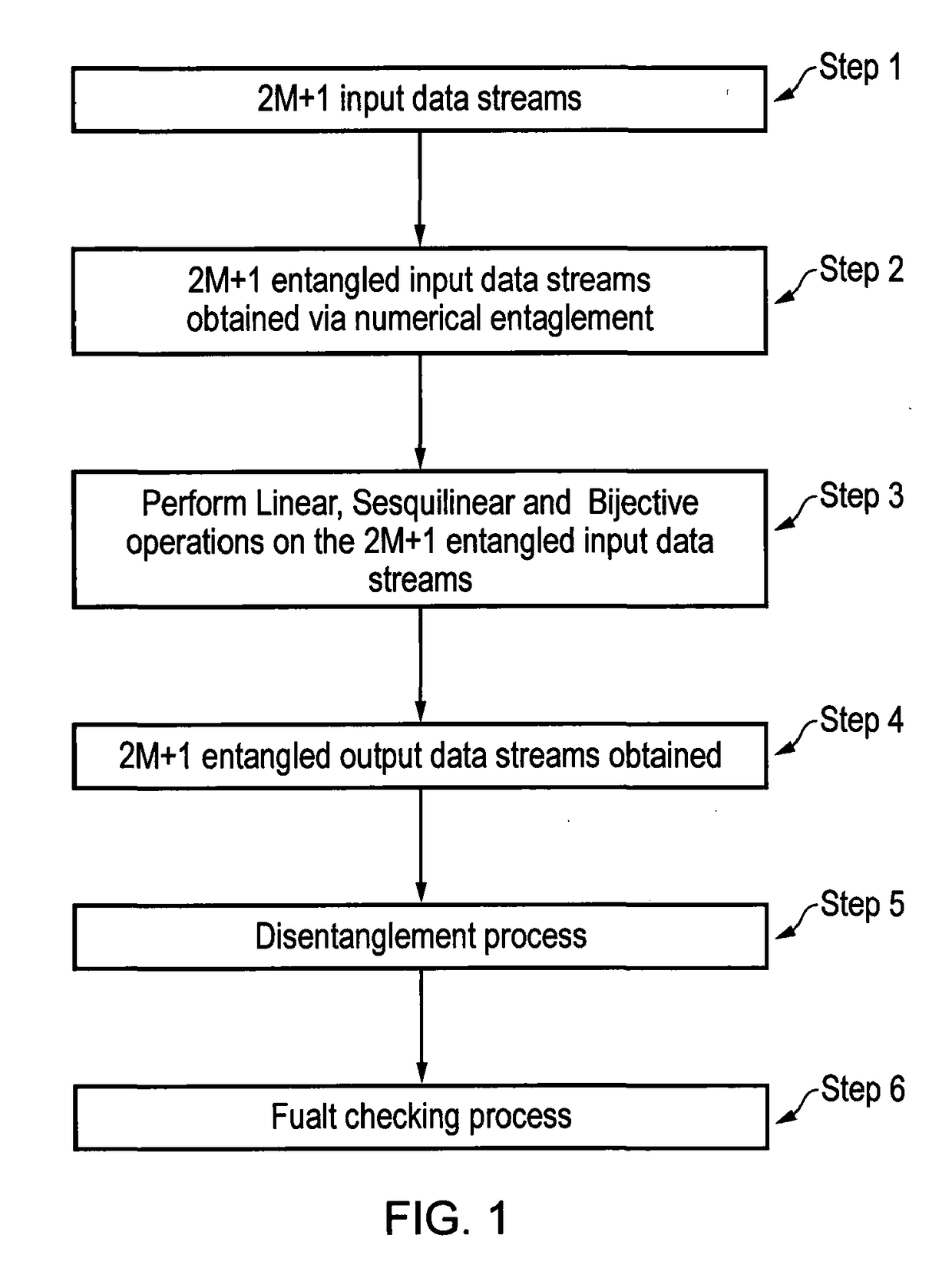

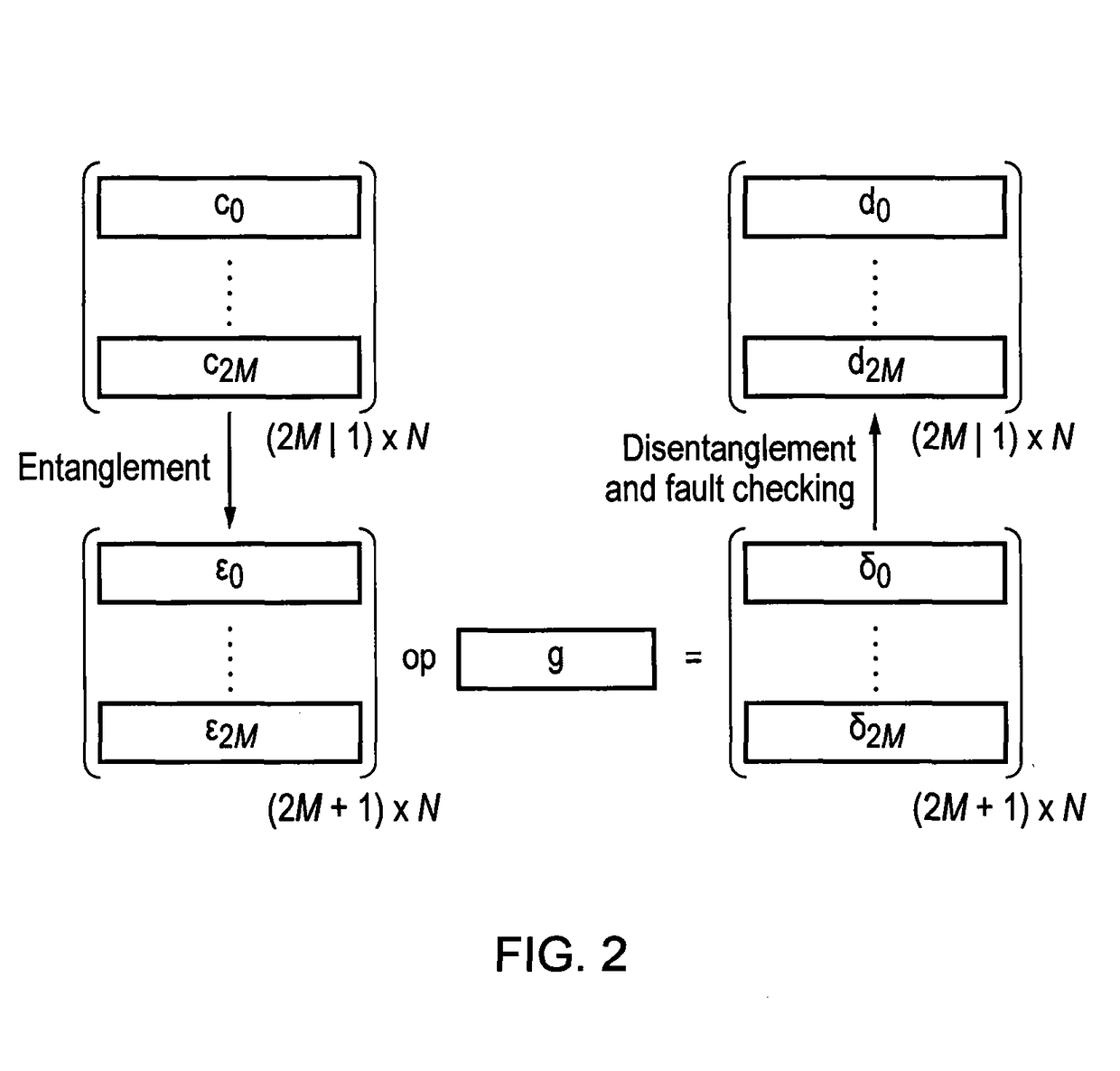

InactiveUS20170300372A1Improve offsetEasy fault detectionComputation using non-contact making devicesPlatform integrity maintainanceData streamLinearity

A method and apparatus for detecting and mitigating faults in numerical computations of M input data streams is claimed (embodiments of FIG. 1 and FIG. 14). Such faults may occur due to circuit or processor malfunctions stemming from (but not limited to): supply voltage or current fluctuation, timing signal errors, hardware device noise, or other signalling, hardware, or software non-idealities. The invented method and apparatus for numerical entanglement linearly superimposes M input data streams to form M numerically-entangled data streams that can optionally be stored in-place of the original inputs (as in the example embodiments of: Step 2 of FIG. 1 and item 1054 of FIG. 14). A series of operations, such as (but not limited to): scaling, additions / subtractions, inner or outer vector or matrix products and permutations, can then be performed directly using these entangled data streams (as in the example embodiment of Step 3 of FIG. 1, operator g of FIG. 2, FIGS. 6-11, item 1053 of FIG. 14). The output results are disentangled from the M entangled output streams by additions and arithmetic shifts (example embodiments of Steps 4 and 5 of FIG. 1, “disentanglement and fault checking” of FIG. 2, item 1056 of FIG. 14). A post-computation reliability check detects processing errors affecting disentangled outputs (example embodiments of item 1056 of FIG. 14, FIGS. 15a, 15b, 16a, 16b, 17a, 17b).

Owner:UCL BUSINESS PLC

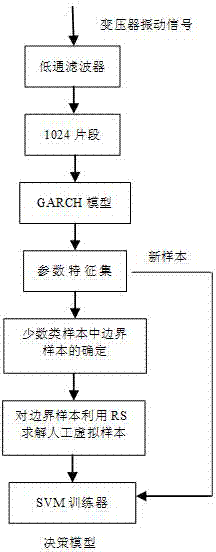

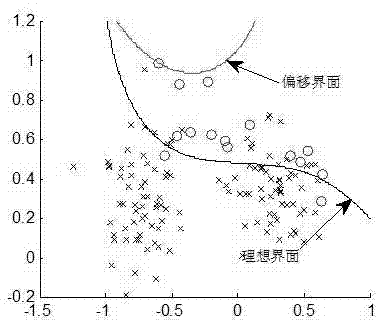

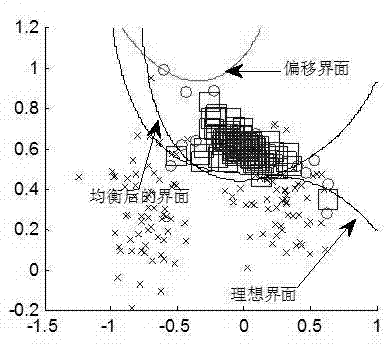

Transformer fault detecting method based on simplified set unbalanced SVM (support vector machine)

ActiveCN103941131AAddressing slow performanceImprove performanceElectrical testingDecision modelAlgorithm

Disclosed is a transformer fault detecting method based on a simplified set unbalanced SVM. The method comprises (1) obtaining a characteristic vector set through a fault characteristic extracting method based on GARCH models; (2) performing determination of boundary samples on minority-class samples to obtain a minority-class boundary sample set S, wherein the minority-class samples are fault samples; randomly selecting N[x]={2, , ISI}, wherein ISI is the cardinal number of S, a[i]=1, and i=1, N[x], and setting N[z] to be 1, utilizing a simplified set solution algorithm to obtain Z[1] and repeating the operation for N[L]-N[M] times, wherein N[L] is the number of majority samples, N[M] is the number of minority samples, and accordingly, N[L]-N[M] is the number of artificial minority samples, and guaranteeing N[z]=ISI for at least one once; (3) combining the artificial minority samples obtained in the step (2) with original minority samples to serve as the training samples of an SVM classifier and lastly to obtain an SVM decision model; (4) inputting newly-obtained transformer characteristic vectors into the decision model for judgment. The transformer fault detecting method based on the simplified set unbalanced SVM is applied to transformer fault detection.

Owner:STATE GRID CORP OF CHINA +2

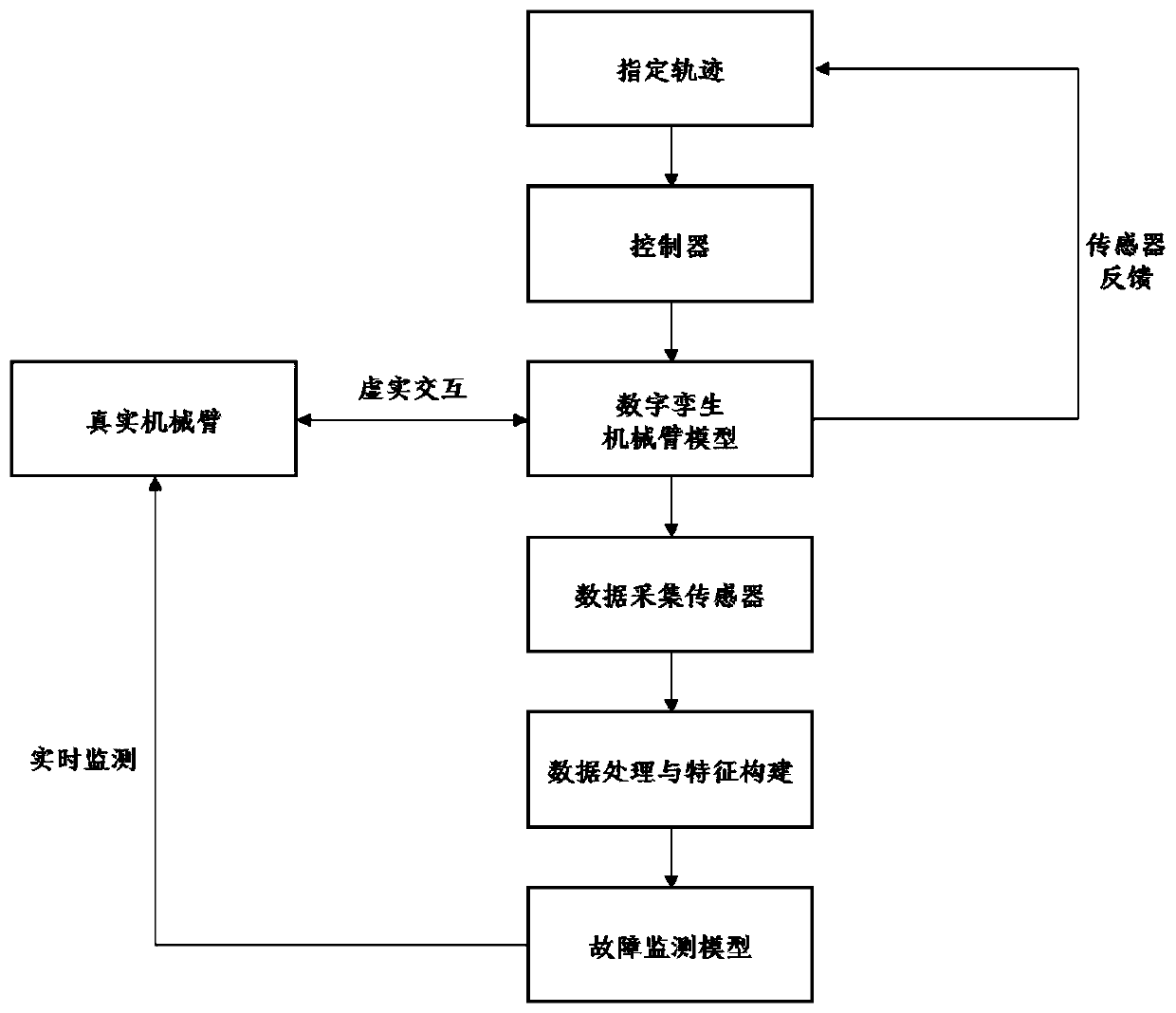

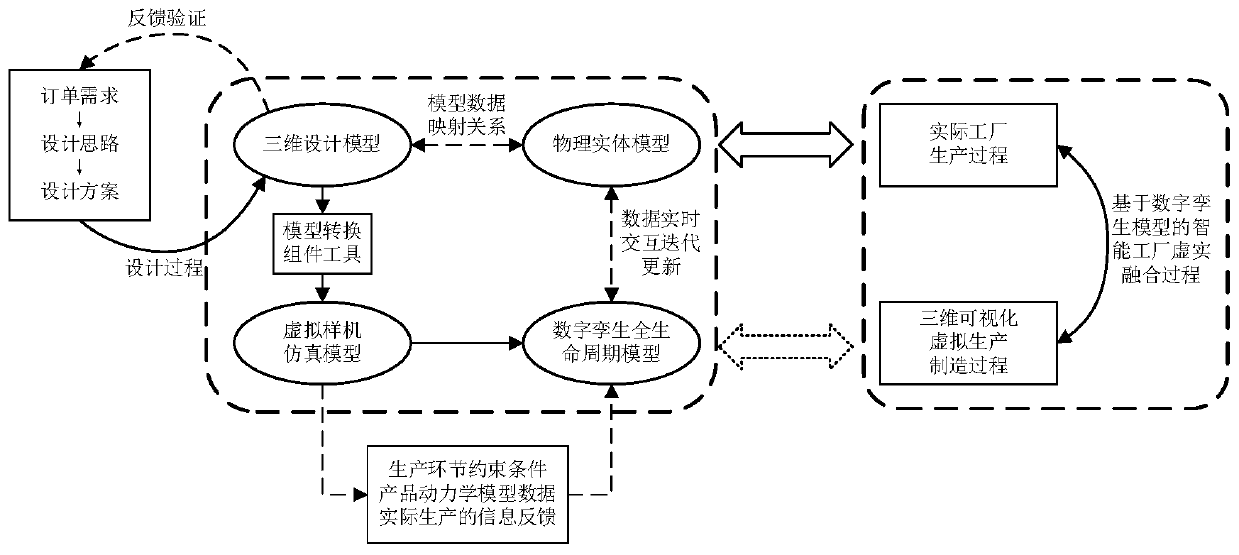

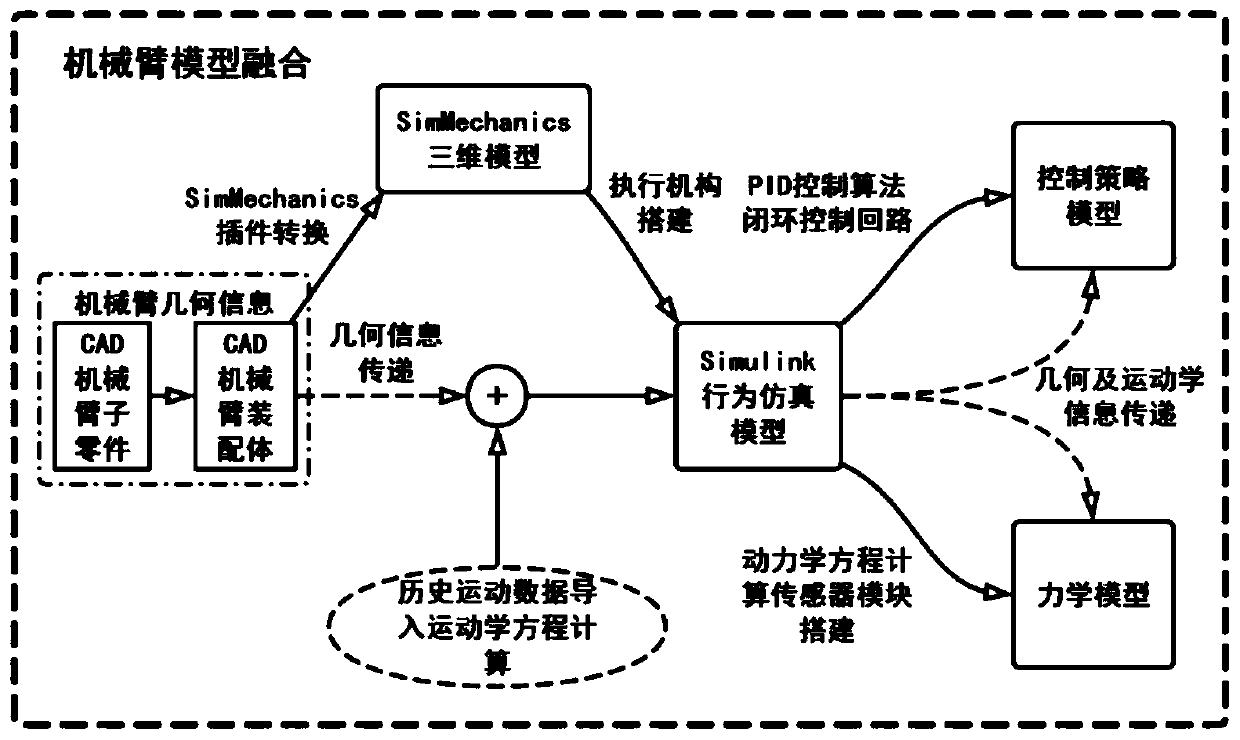

Digital twin-driven mechanical arm modeling, control and monitoring integrated system

ActiveCN111496781ARealize expected trajectory tracking controlAchieving System Uncertainty and External DisturbancesProgramme-controlled manipulatorIntegrated systemsModel building

The invention discloses a digital twin-driven mechanical arm modeling, control and monitoring integrated system. The system comprises a digital twin simulation model building module used for buildinga mechanical arm digital twin integrated simulation model based on a mechanical arm CAD assembly model; a mechanical arm control module used for realizing the closed-loop feedback control of the mechanical arm digital twin integrated simulation model; a data acquisition, preprocessing and feature building module used for acquiring mechanical arm operation data and preprocessing the operation data,and building mechanism characteristics for mechanical arm fault monitoring according to mechanical arm kinematics and kinetic characteristics; and a fault monitoring module used for monitoring a mechanical arm operation state of the closed-loop operation process of the mechanical arm digital twin integrated simulation model in real time by utilizing the preprocessed mechanical arm operation dataand the built mechanism characteristics. The digital twin-driven mechanical arm modeling, control and monitoring integrated system provided by the invention can effectively realize the real-time faultmonitoring of the expected trajectory tracking control of an intelligent assembly mechanical arm and the running process of a digital twin closed-loop system.

Owner:ZHEJIANG UNIV

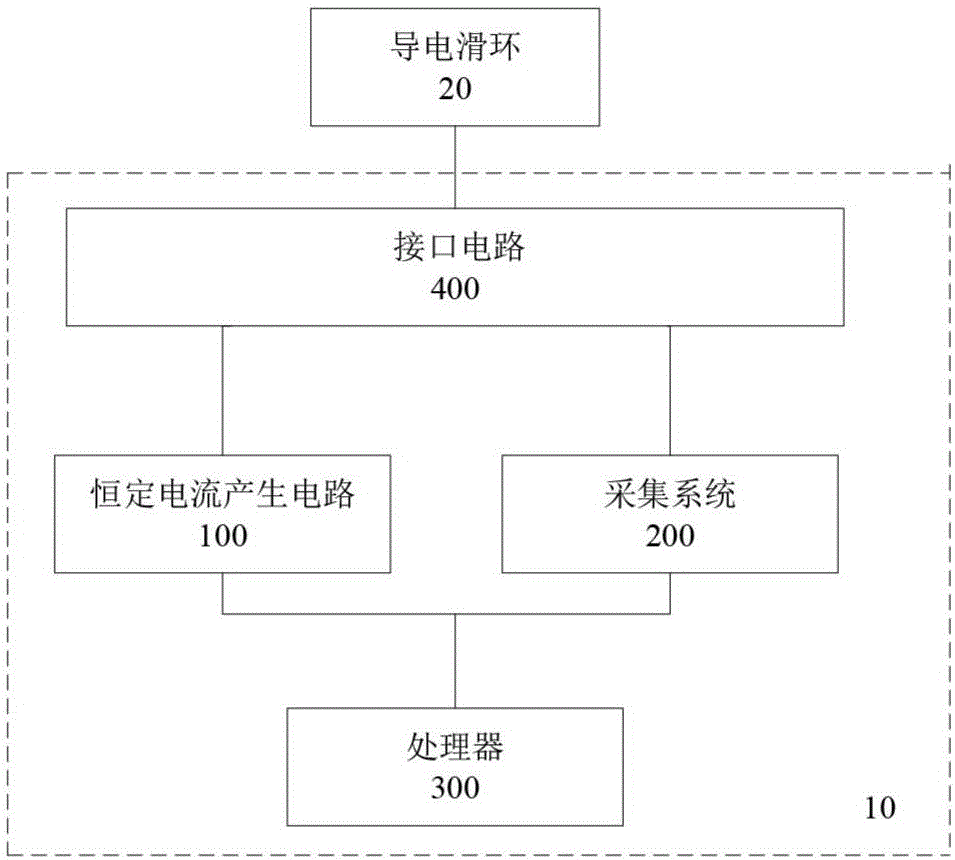

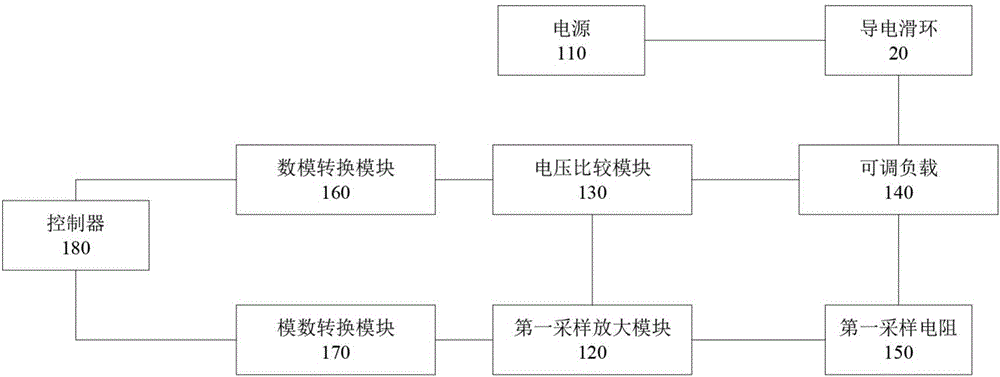

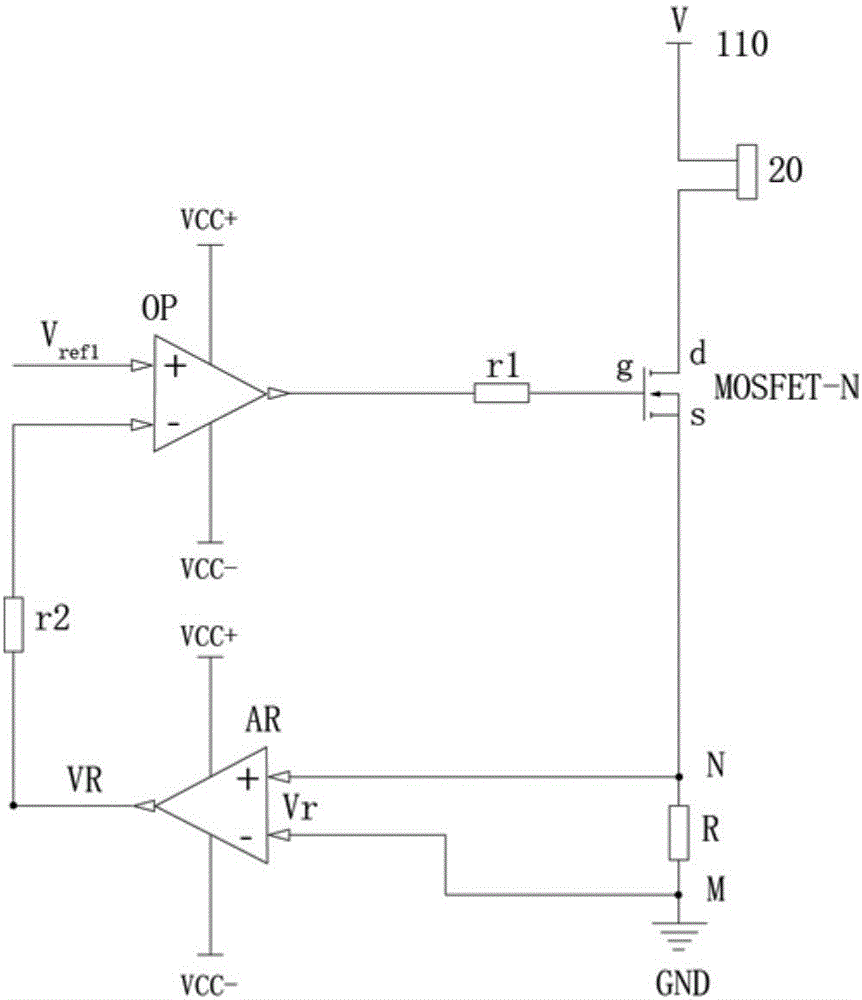

Conductive slip ring fault test device and test method

ActiveCN106680630AConvenient fault locationEasy fault detectionEarth resistance measurementsElectrical testingElectrical resistance and conductanceEngineering

Provided are a conductive slip ring fault test device and a test method. The test device is electrically connected with the conductive slip ring to form a test loop, wherein the test device comprises a constant current generating circuit which provides a first constant current for the test loop when the test device is in a contact resistance test pattern, an acquisition system determining voltage values of two ends of the conductive slip ring when the first constant current flows through the conductive slip ring, a processor determining a contact resistance value of the slip ring in the first constant current based on the voltage values and comparing the contact resistance with the first resistance threshold value, wherein when the contact resistance value is no less than the first resistance threshold value, the result information indicating that the conductive slip ring is already faulty is sent and when the contact resistance value is smaller than the first resistance threshold value, the result information indicating that the conductive slip ring works normally is sent. According to the test device and method, the conductive slip ring fault is capable of being found timely and therefore the problem of being difficult in conductive slip ring fault detection on the spot is solved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

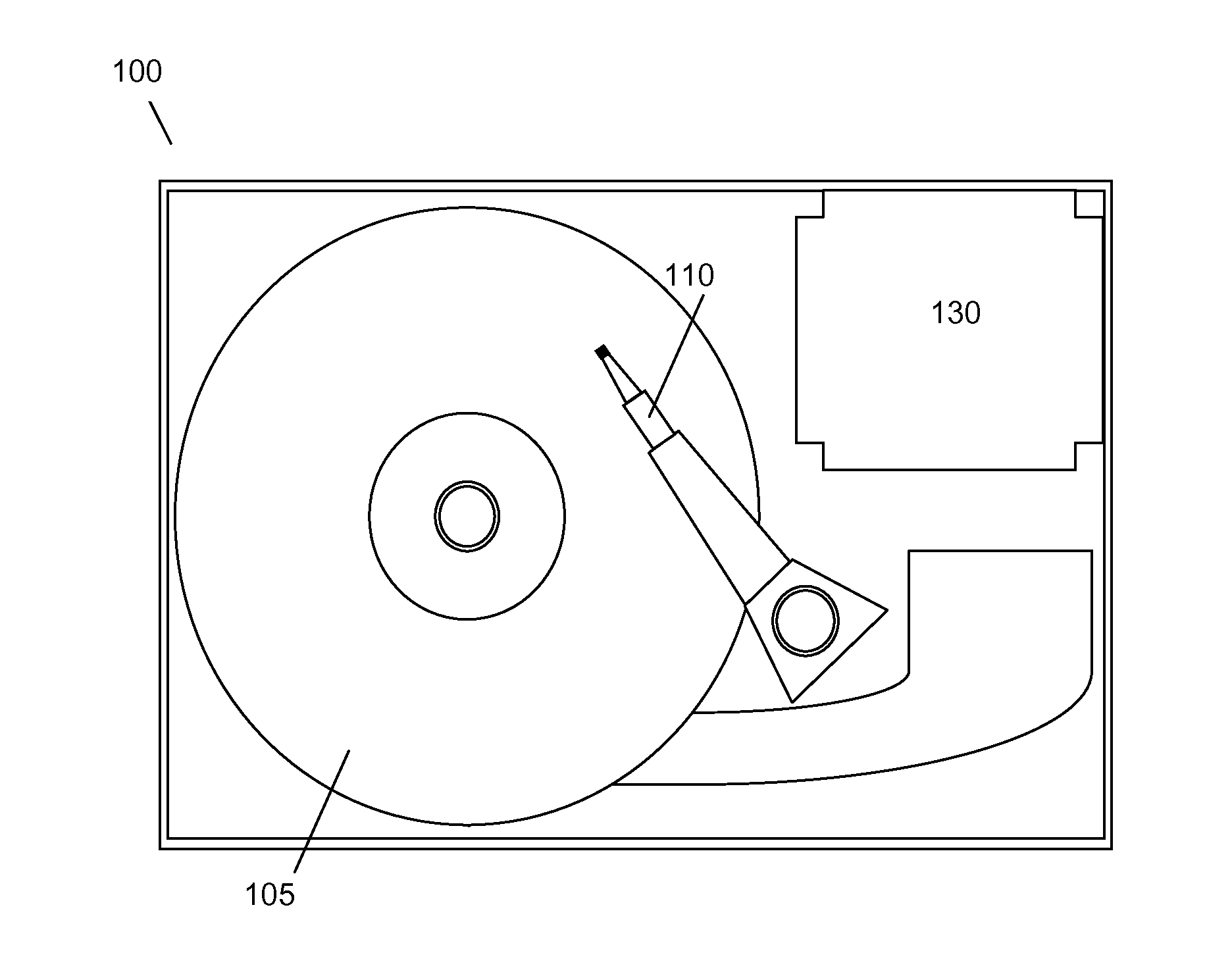

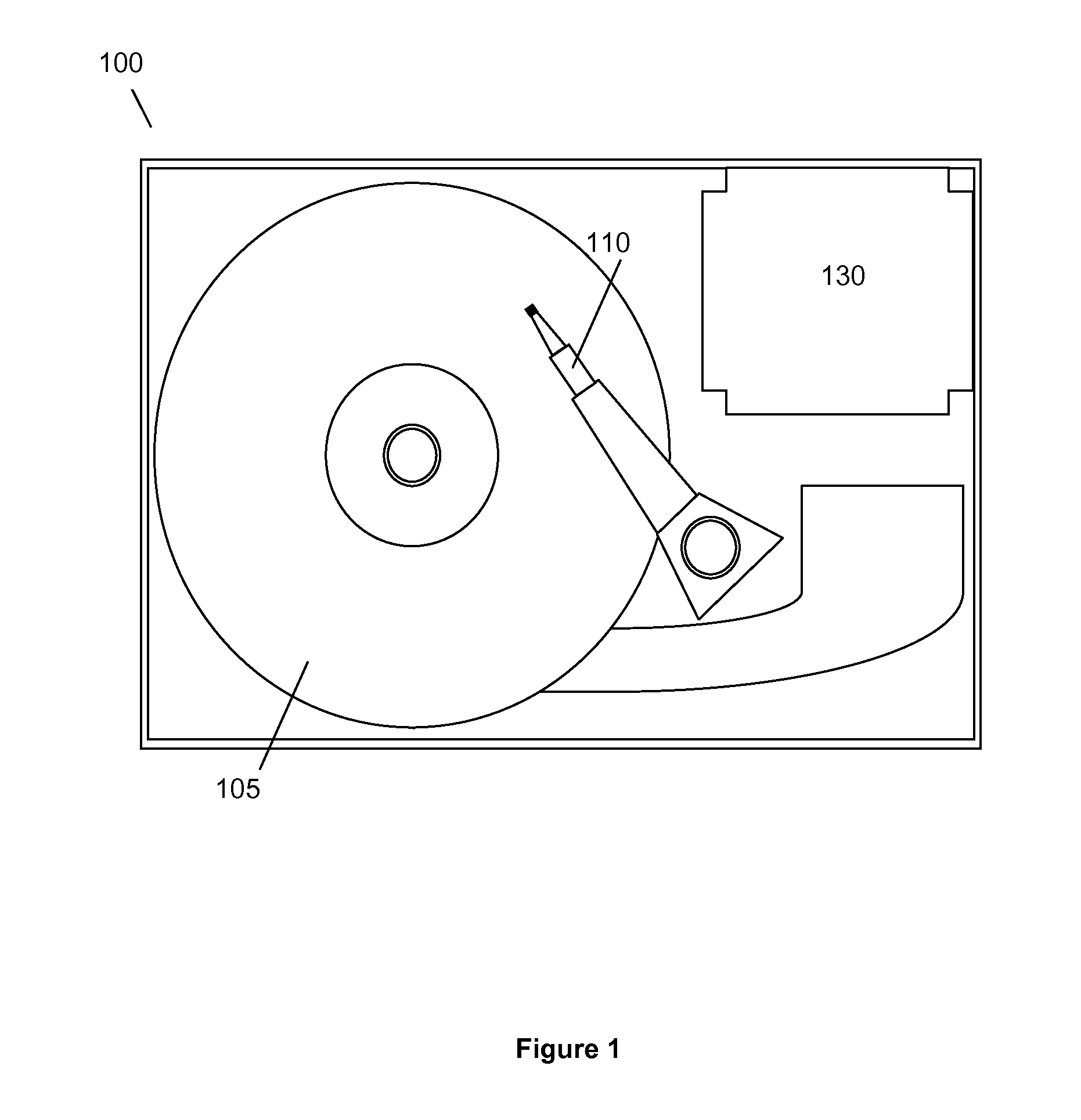

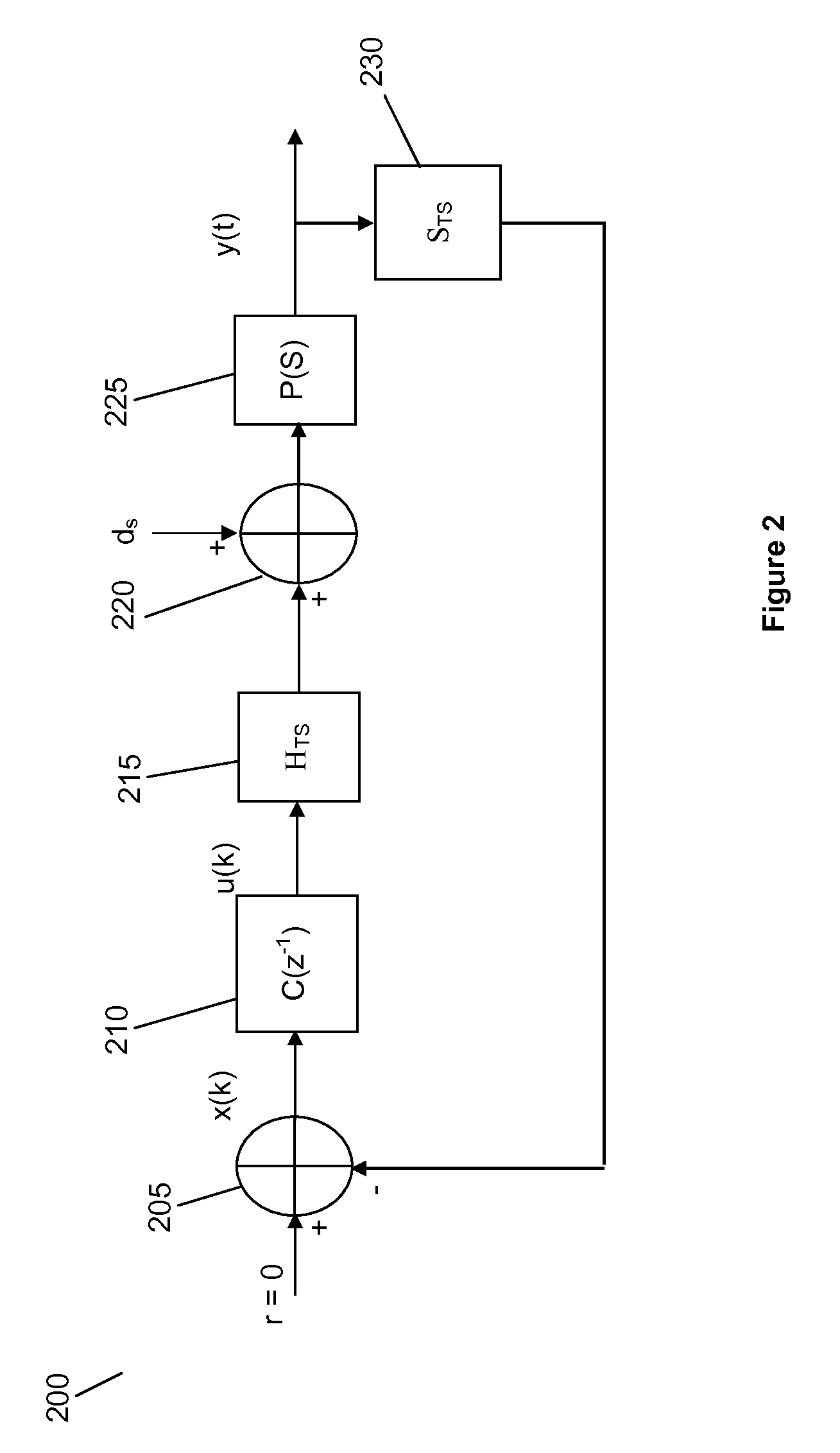

System for write fault protection in a hard disk drive

InactiveUS20120038997A1Improve write protection performanceImprove throughput performanceModification of read/write signalsRecord information storageHard disc driveControl signal

This invention relates to a system and method performed by a controller in a hard disc drive to generate a write fault signal. The system performs in the following manner. The system begins by receiving a sample of a position error signal. The system then generates a control signal from the position error signal. A sample of the control signal is then captured by the system. The system then determines a parameter to test from the captured sample of the control signal. The absolute value of the parameter is then calculated and compared to a threshold value. The system then generates a write fault error signal in response to a determination that the absolute value of the parameter is greater than or equal to the threshold value.

Owner:HITACHI ASIA

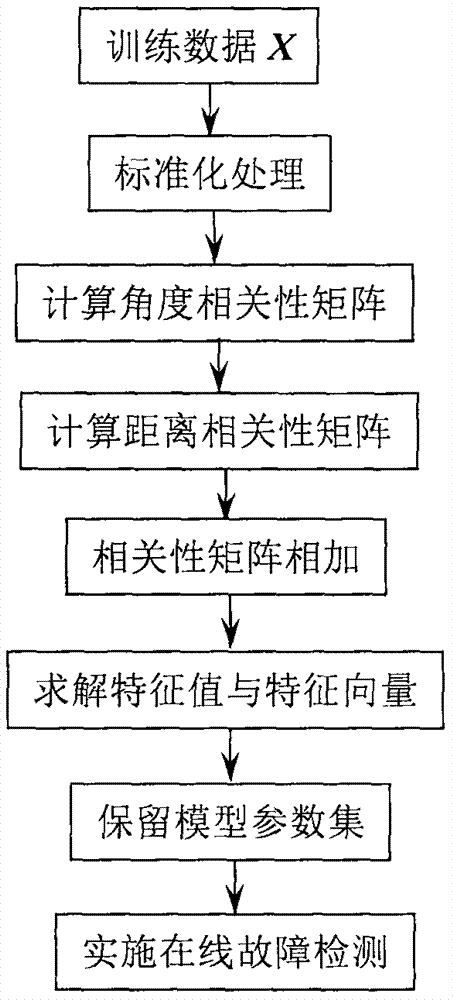

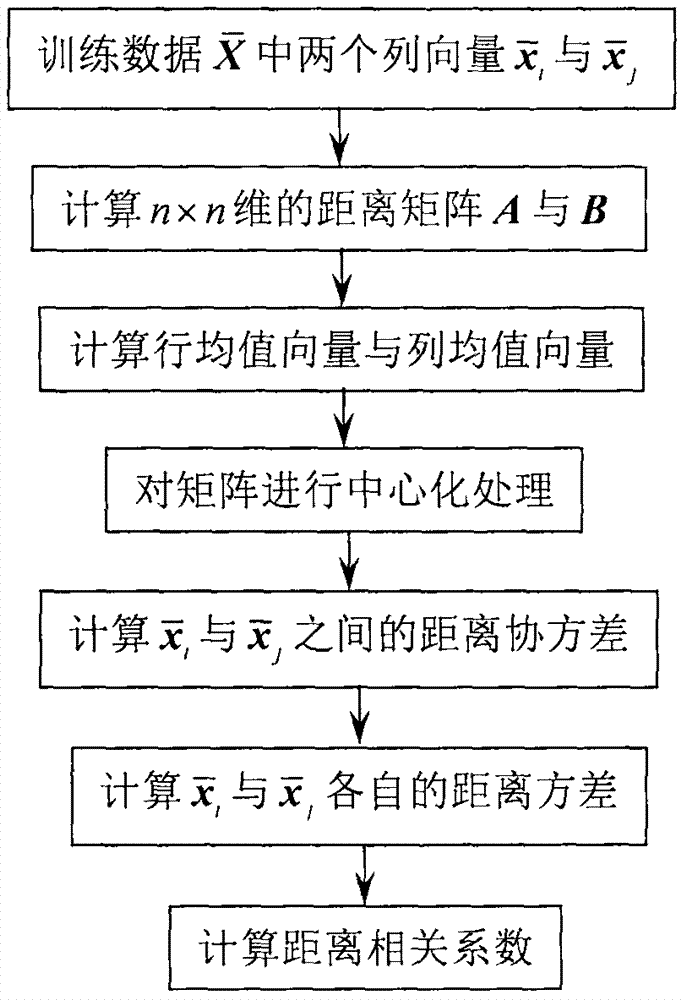

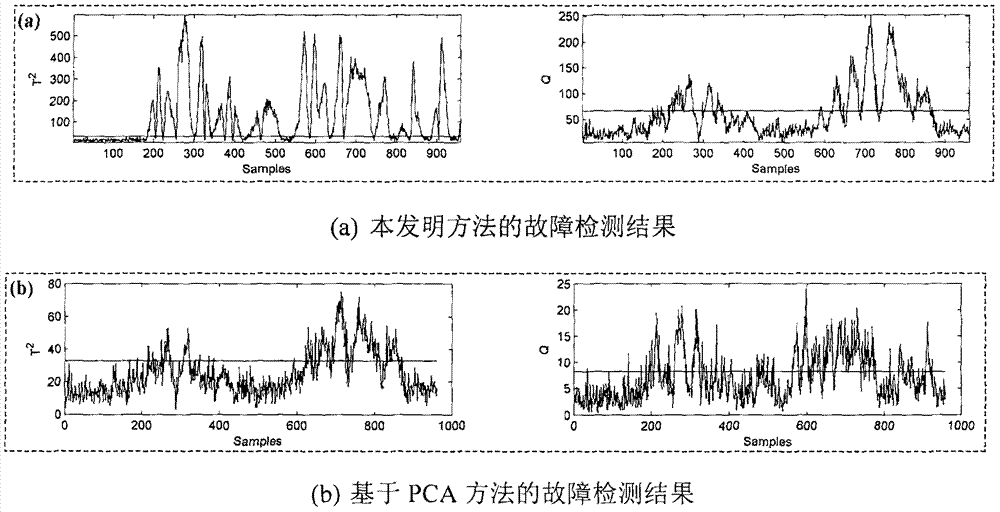

Improved type principal component analysis model-based fault detection method

InactiveCN106940808AEasy fault detectionCharacter and pattern recognitionFeature vectorKernel principal component analysis

The invention discloses an improved type principal component analysis model-based fault detection method which is aimed at improving effects exerted by a conventional PCA algorithm on fault detection via further discovery of characteristics of distance correlation between training data. The method comprises the following steps: an angle correlation matrix and a distance correlation matrix of the training data are calculated, a new correlation matrix is obtained after the angle correlation matrix and the distance correlation matrix are added up, and corresponding characteristic values and vectors are calculated. An improved PCA model is built via use of the characteristic vectors, and the PCA model is applied to on-line fault detection. Compared with a conventional method, the fault detection method disclosed in the invention is advantageous in that angle correlation and distance correlation of the training data are taken into account at an off line modeling phase, data correlation characteristics are fully discovered, the improved type PCA model built via the fault detection method can be used for comprehensively describing potential characteristics of normal data, and good fault detection effects should be exerted.

Owner:NINGBO UNIV

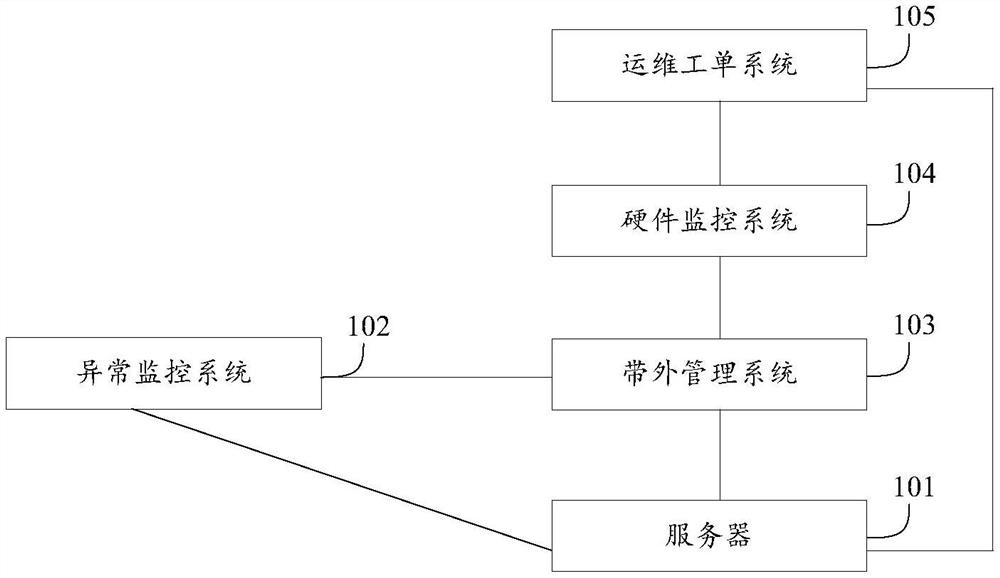

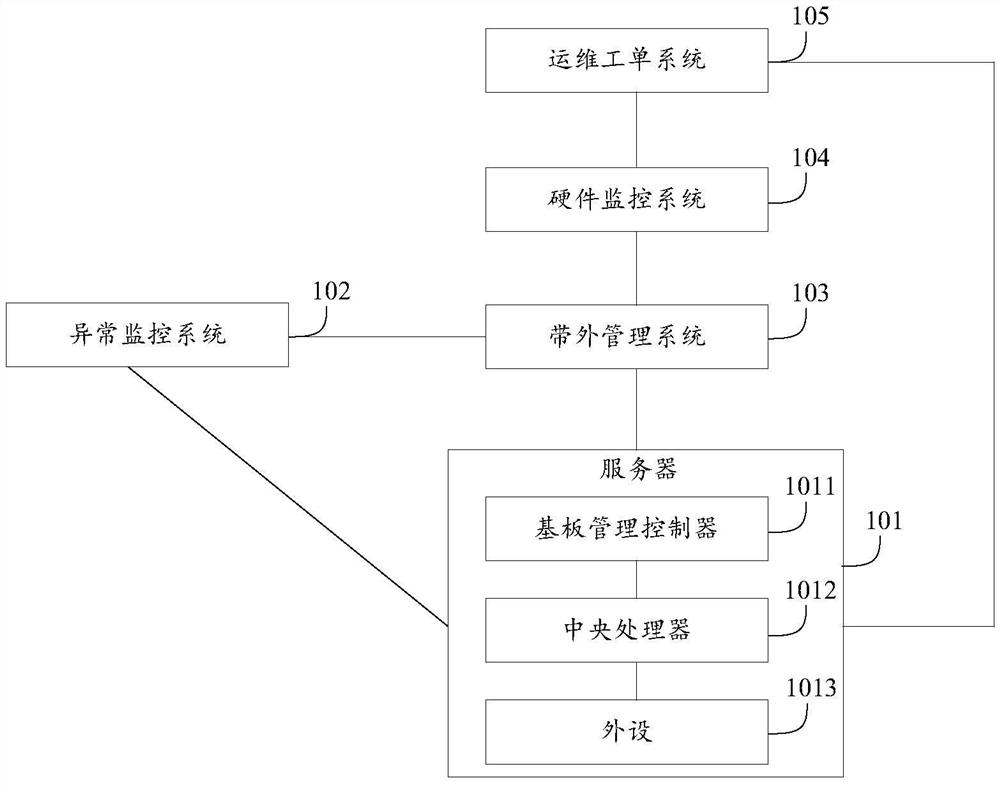

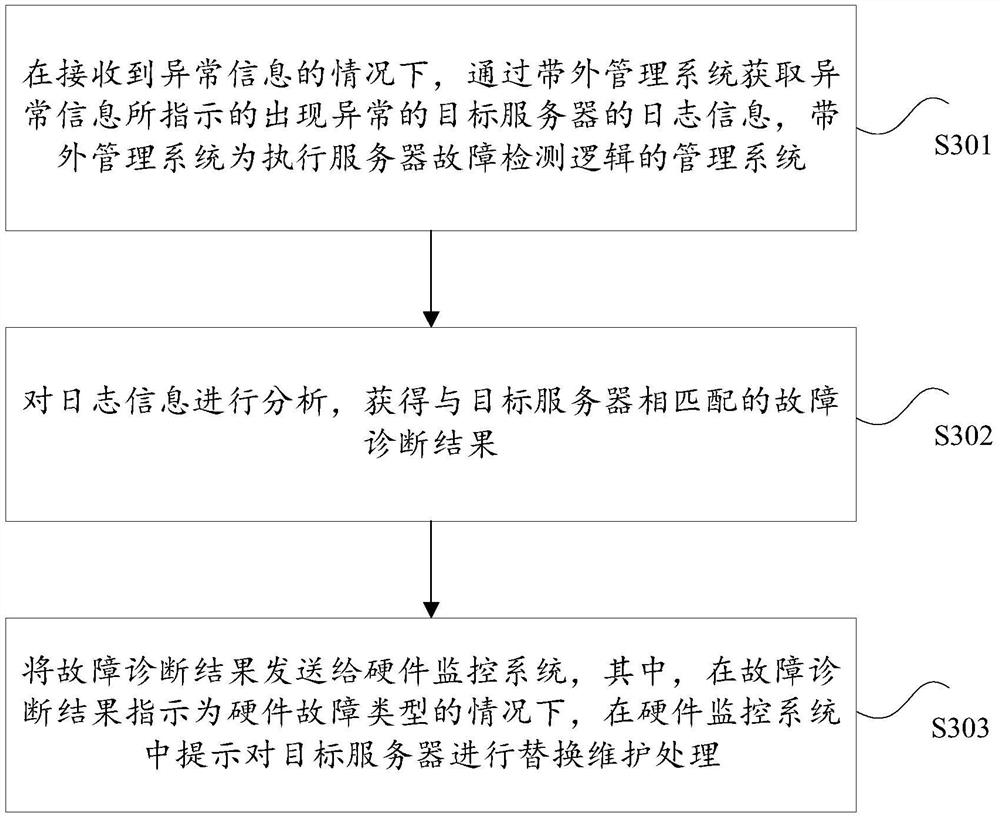

Server fault processing method and device, storage medium and electronic equipment

The invention discloses a server fault processing method and device, a storage medium and electronic equipment. The method comprises the steps of: under the condition that abnormal information is received, obtaining log information, indicated by the abnormal information, of an abnormal target server through an out-of-band management system, wherein the out-of-band management system is a managementsystem executing server fault detection logic; analyzing the log information to obtain a fault diagnosis result matched with the target server; and sending the fault diagnosis result to a hardware monitoring system, and prompting to perform replacement maintenance processing on the target server in the hardware monitoring system under the condition that the fault diagnosis result indicates a hardware fault type. According to the invention, the fault processing effect can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

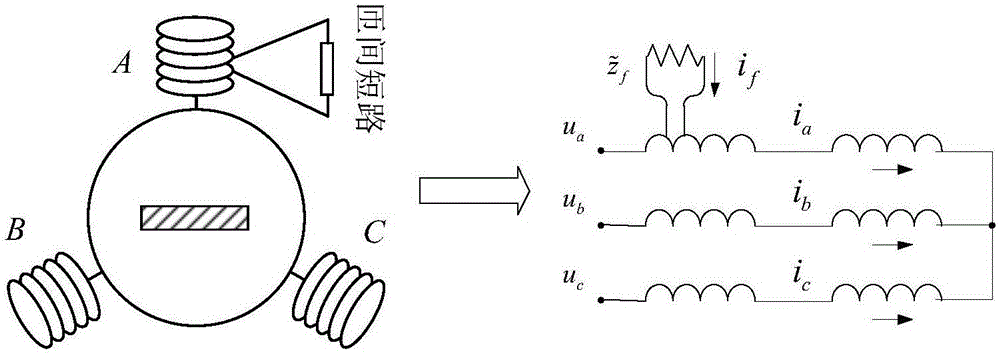

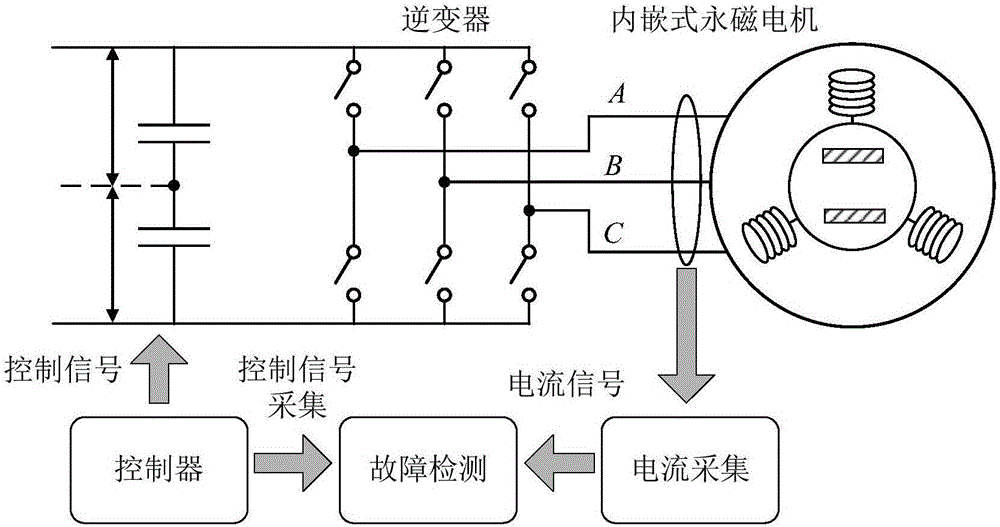

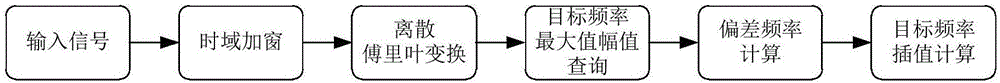

Frequency converter driving embedded permanent magnet synchronous motor stator inter-turn short-circuit fault diagnosis method

InactiveCN106841901AEffective decoupling of salient polarity interference factorsAvoid influenceDynamo-electric machine testingFrequency changerFrequency spectrum

The invention discloses a frequency converter driving embedded permanent magnet motor stator inter-turn short-circuit fault diagnosis method. According to the method, a current signal of an operating motor and an inside signal of a controller are used for realizing inter-turn short-circuit fault detection and degree judgment. The method comprises the flowing steps of firstly, a proper inverter switch signal is selected to be used as a detecting excitation source; the injection of an additional high-frequency signal is not needed; the additional loss caused by a high-frequency injection detecting method is avoided; meanwhile, the early fault detection reliability is enhanced; secondly, three-phase current is subjected to rotational coordinate conversion; the switching current harmonic in a three-phase coordinate system is converted under a rotary coordinate system; the saliency interference factor of the motor is effectively decoupled; finally, a frequency domain multipoint interpolation extraction algorithm is used, and multi-fault feature information is comprehensively used, so that the influence of noise interference and frequency spectrum leakage on the detection result is effectively avoided. The method has the advantages that the application range is wide; the fault detection effect is good; the recognition precision is high; the stator inter-turn short-circuit fault can be diagnosed in real time, and the fault degree index is given.

Owner:ZHEJIANG UNIV

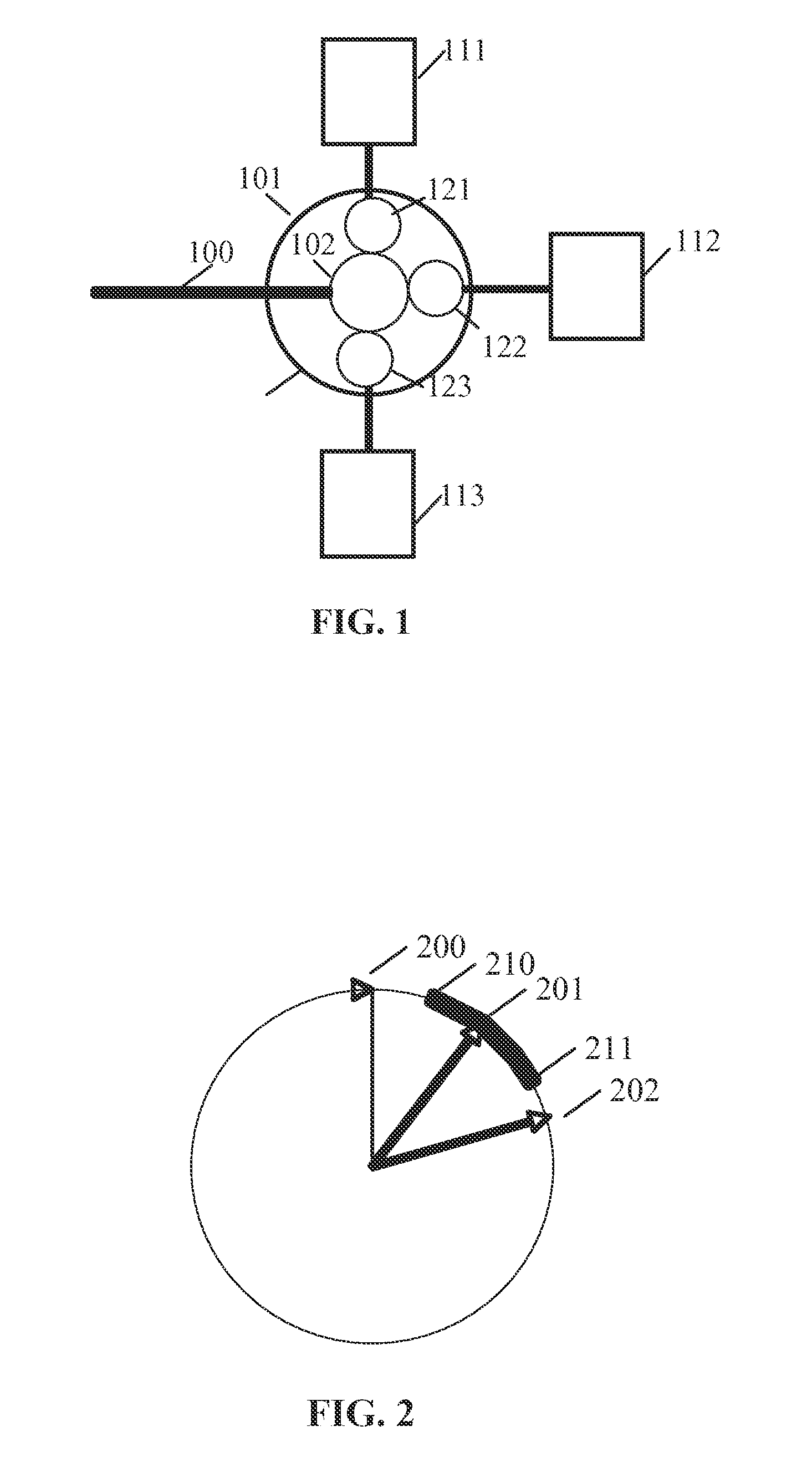

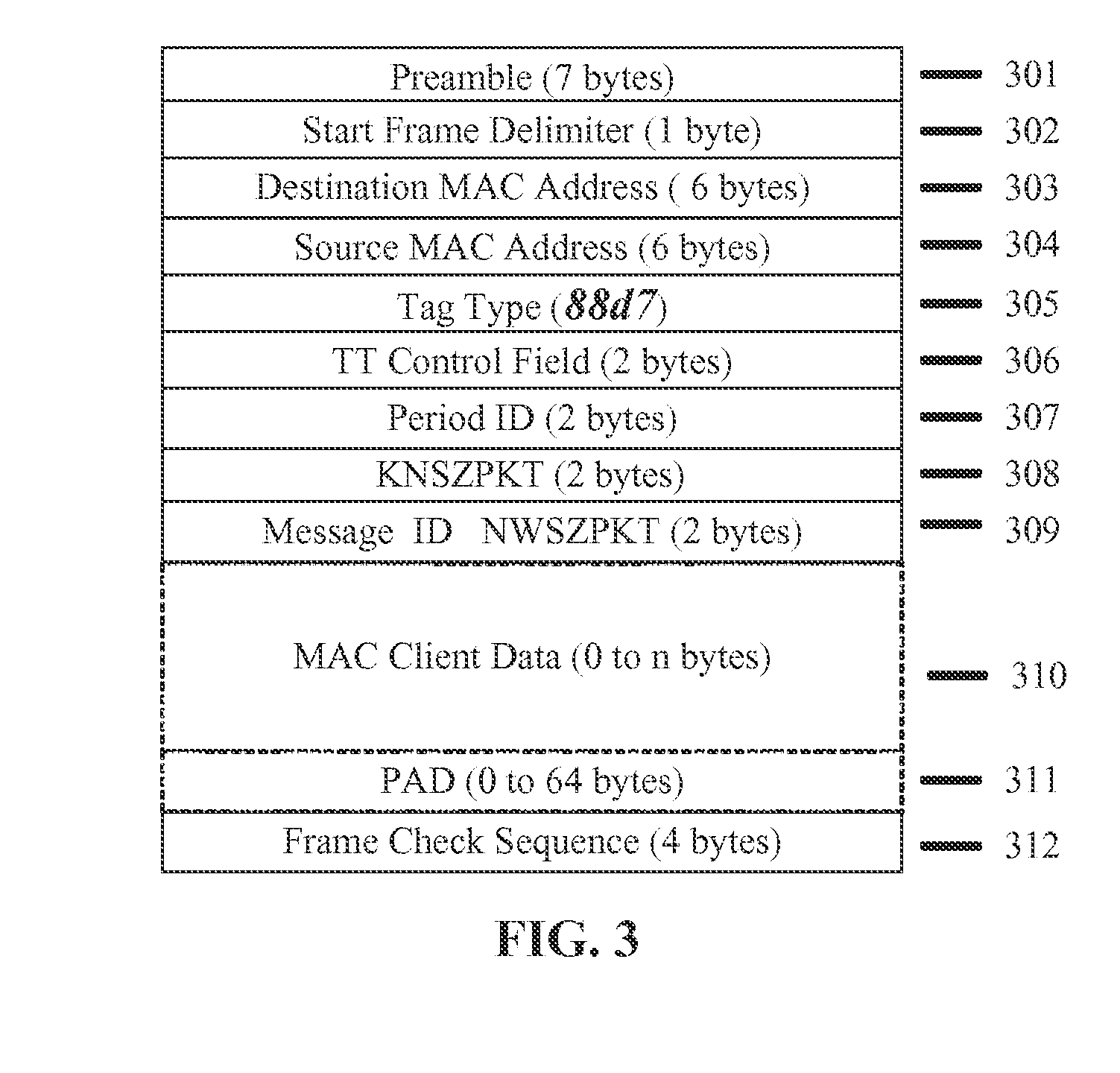

Communication method and apparatus for the efficient and reliable transmission of tt ethernet messages

ActiveUS20100281130A1Easy fault detectionLow failure rateUser identity/authority verificationTime-division multiplexReliable transmissionComputerized system

The goal of the present invention is to improve the useful data efficiency and reliability in the use of commercially available ETHERNET controllers, in a distributed real time computer system, by a number of node computers communicating via one or more communication channels by means of TT ETHERNET messages. To achieve this goal, a distinction is made between the node computer send time (KNSZPKT) and the network send time (NWSZPKT) of a message. The KNSZPKT must wait for the NWSZPKT, so that under all circumstances, the start of the message has arrived in the TT star coupler at the NWSZPKT, interpreted by the clock in the TT star coupler. The TT star coupler is modified, so that a message arriving from a node computer is delayed in an intelligent port of the TT star coupler until the NWSZPKT can send it precisely at the NWSZPKT into the TT network.

Owner:HONEYWELL INT INC +1

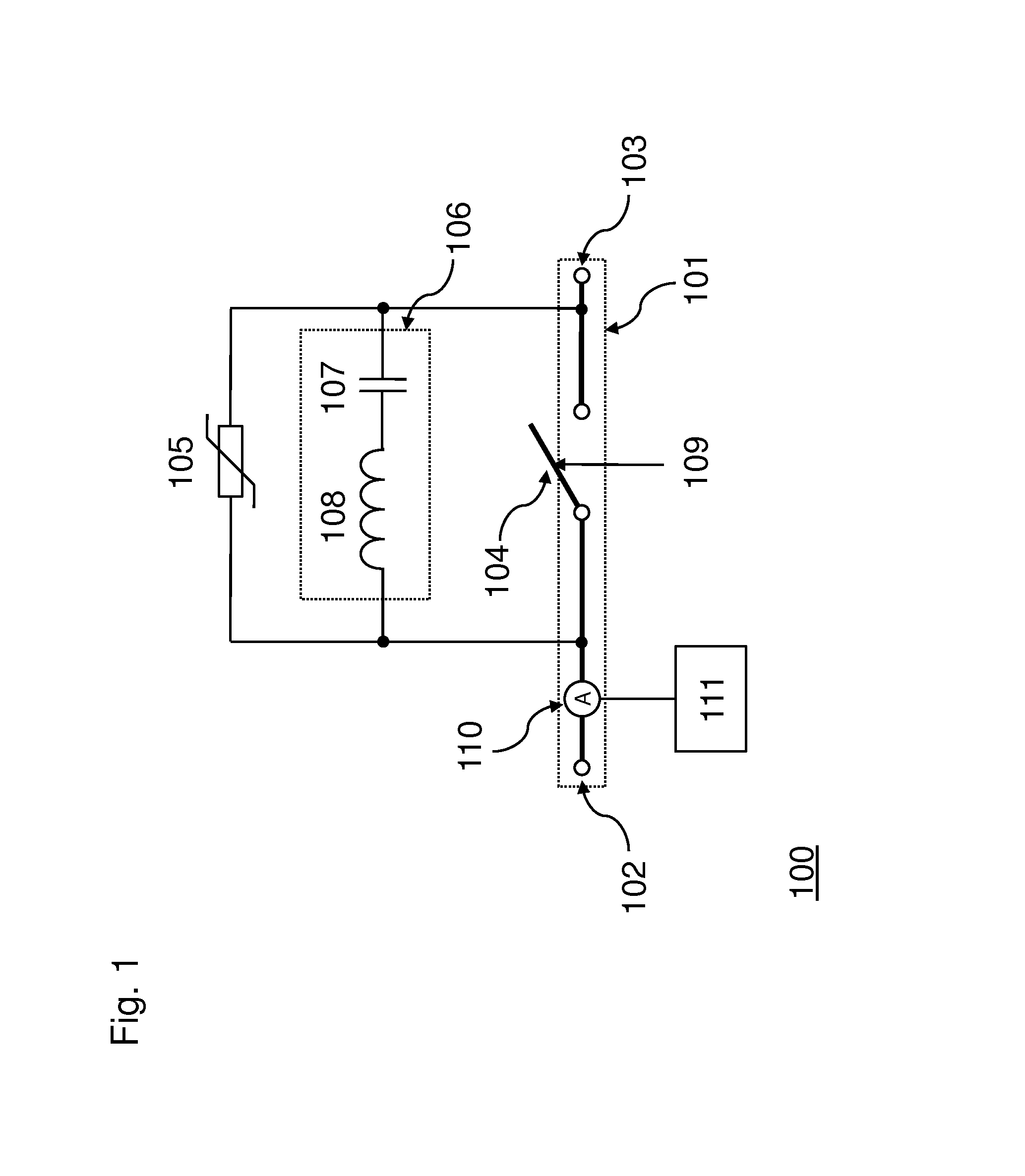

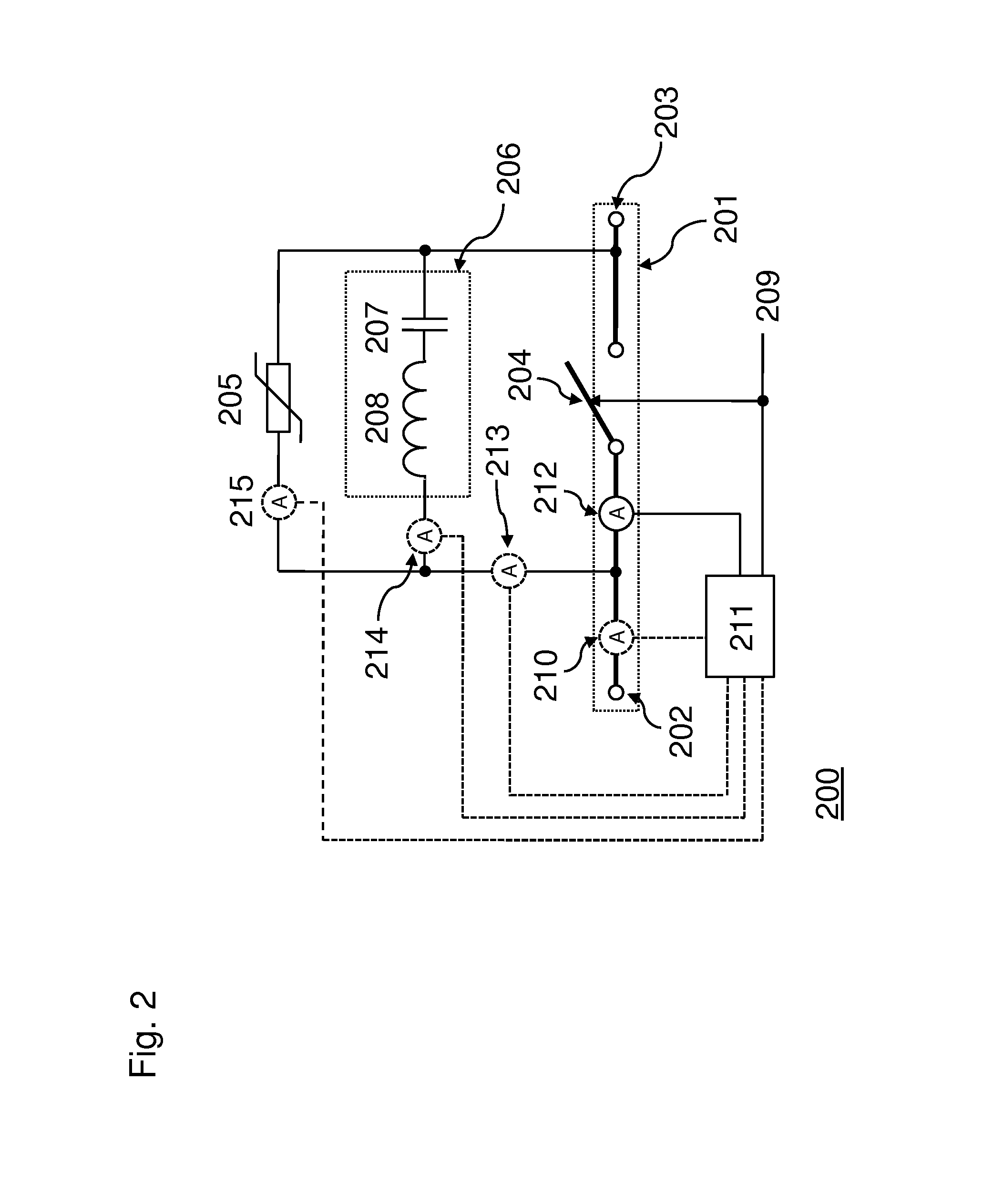

Fast breaker failure detection for HVDC circuit breakers

ActiveUS20140055903A1Reduce riskAvoid arcingProtective switch detailsCircuit-breaking switches for excess currentsNonlinear resistorPower flow

Owner:HITACHI ENERGY SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com