Conductive slip ring fault test device and test method

A conductive slip ring and testing device technology, which is applied in measuring devices, grounding resistance measurement, and electrical measurement, can solve the problems of conductive slip ring fault detection difficulties, achieve the effects of solving fault detection difficulties, improving efficiency, and facilitating fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

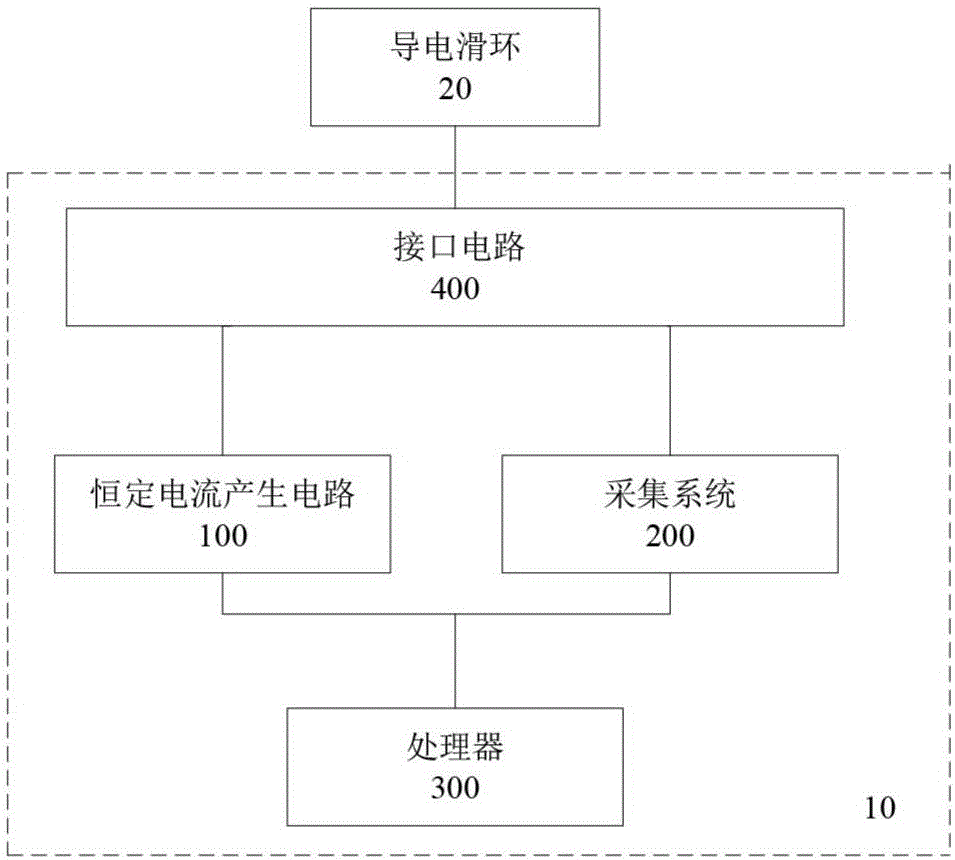

[0032] figure 1 A block diagram showing a conductive slip ring fault testing device according to an exemplary embodiment of the present invention.

[0033] Such as figure 1 As shown, the conductive slip ring fault testing device 10 according to the exemplary embodiment of the present invention includes: a constant current generating circuit 100 , an acquisition system 200 and a processor 300 .

[0034] As an example, the test device 10 may be a hand-held device including the above-mentioned components, and may be powered by a lithium battery. In addition, an interface circuit 400 is provided on it, and the interface circuit 400 can be electrically connected to the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com