Continuous chemical process fault detection method

A fault detection, chemical process technology, applied in the field of continuous chemical process fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

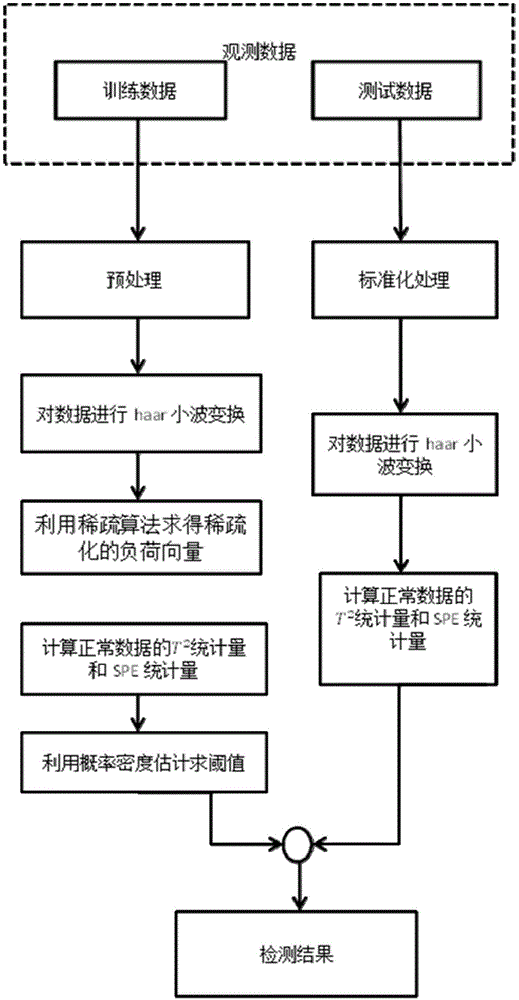

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

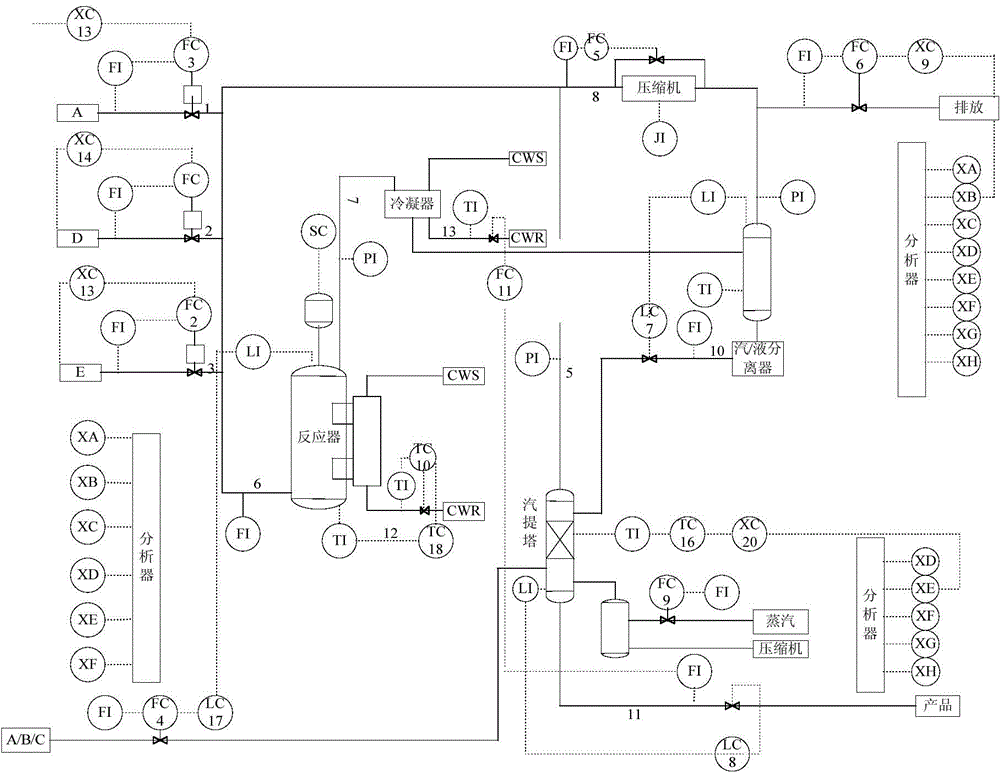

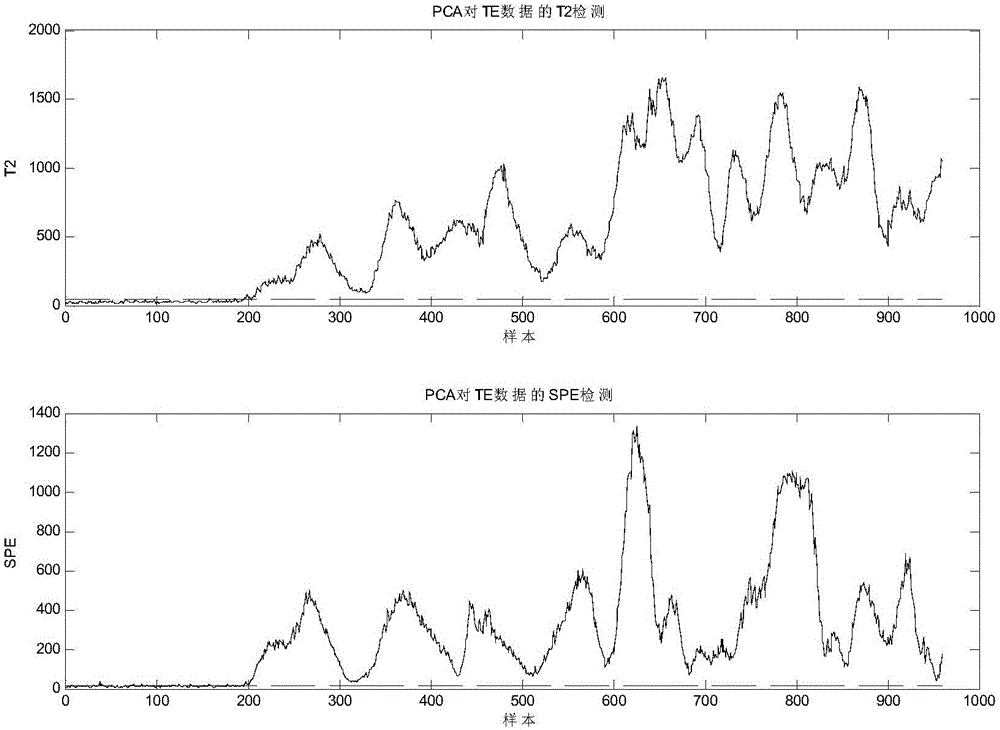

[0060] In the process of fault detection, the data utilized is the data collected in the Tennessee-Eastman (TEP) process model. The TEP process model was created by Eastman Chemical Company to provide a realistic industrial process for evaluating process control and monitoring methods. The test process is based on a real continuous chemical industrial process, in which the composition, kinetics, operating conditions, etc. have been modified due to patent issues. The process consists of five main units: reactor, condenser, compressor, separator, and stripper; and contains eight compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com