Principal component tracking based industrial fault monitoring method and application thereof

A principal component tracking, fault detection technology, applied in general control systems, electrical testing/monitoring, testing/monitoring control systems, etc., can solve problems such as high false alarm rate, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

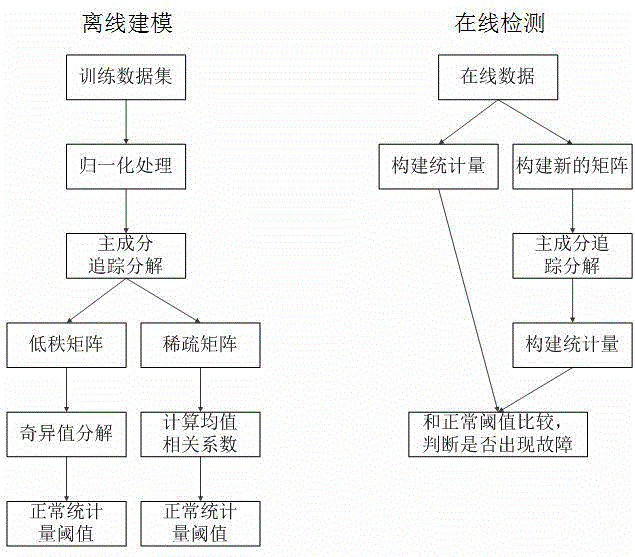

Method used

Image

Examples

Embodiment

[0071] As one of the most important basic industries in the national economy, iron and steel smelting is an important indicator to measure a country's economic level and comprehensive national strength. Blast furnace ironmaking is the most important link in the production process of the iron and steel industry, so it is of great significance to study the abnormal working condition diagnosis and safe operation methods of large blast furnaces.

[0072] The blast furnace is a huge airtight reaction vessel, and its internal smelting process is a typical "black box" operation through a series of complex physical, chemical and heat transfer reactions under high temperature and high pressure conditions. It is precisely because of the complexity inside the blast furnace that the data collected are diverse, linear, nonlinear, non-Gaussian and dynamic. Therefore, our proposed method is effective for the diagnosis of blast furnace faults. The effectiveness of the method of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com