Battery pick-out equipment for hot-spot test of photovoltaic components

A photovoltaic module and battery technology, which is applied in photovoltaic power generation, photovoltaic modules, photovoltaic system monitoring, etc., can solve problems such as difficult detection, and achieve the effect of wide tolerance, simple method, and no obvious temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

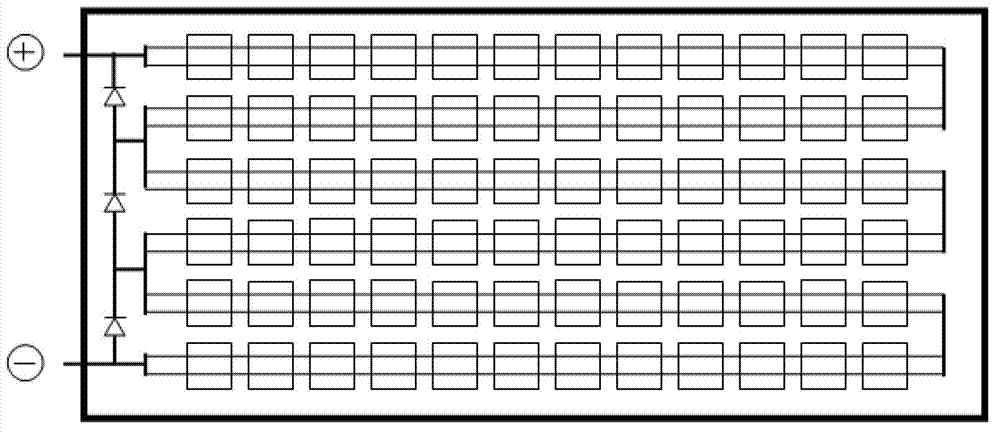

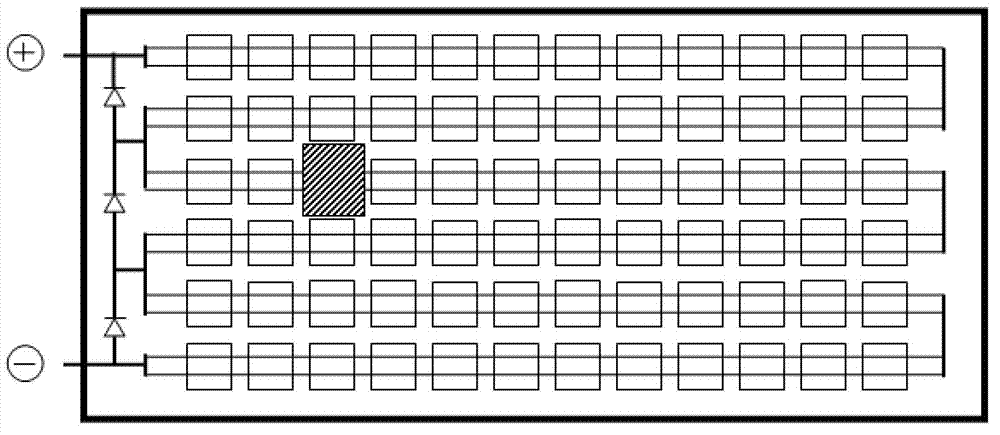

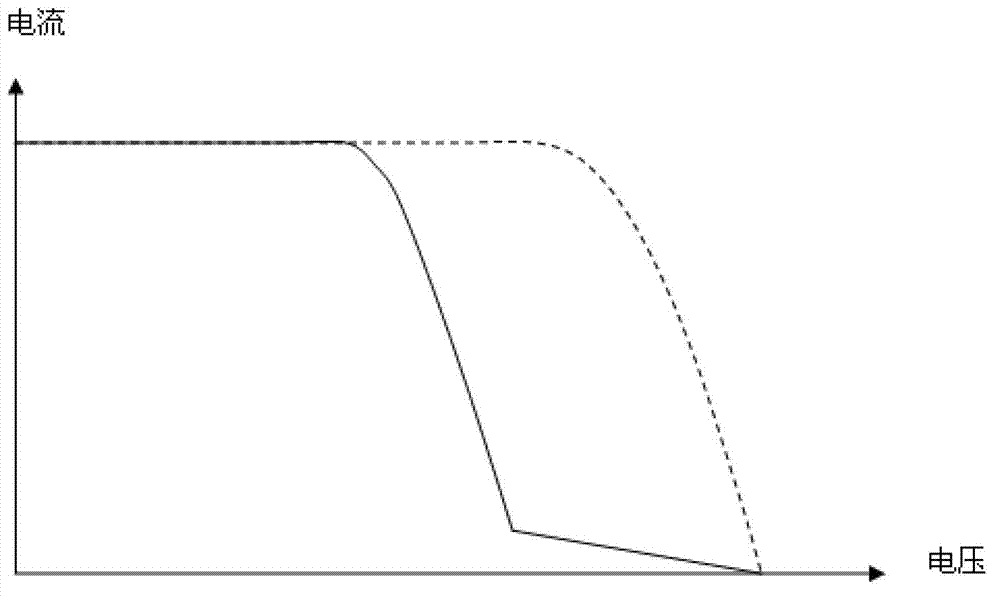

[0017] Such as Figure 4~Figure 9 As shown: the photovoltaic module hot spot test battery selection equipment includes rack 1, steady-state light source 2, photovoltaic module support frame 3, baffle 4, circuit connection line 5, data acquisition circuit 6, baffle rail 7, photovoltaic module Guide rail 8, baffle frame 9, photovoltaic module 10, etc.

[0018] Such as Figure 9 As shown, the present invention includes a frame 1, on which a baffle guide rail 7 and a photovoltaic module guide rail 8 are installed, and a photovoltaic module support frame 3 is installed on the photovoltaic module guide rail 8, and the photovoltaic module support frame 3 can be installed along the photovoltaic module The guide rail 8 moves; a steady-state light source 2 is installed on the frame 1 above the photovoltaic module support frame 3, and the steady-state light source 2 is a plurality of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com