Patents

Literature

136results about How to "The test process is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

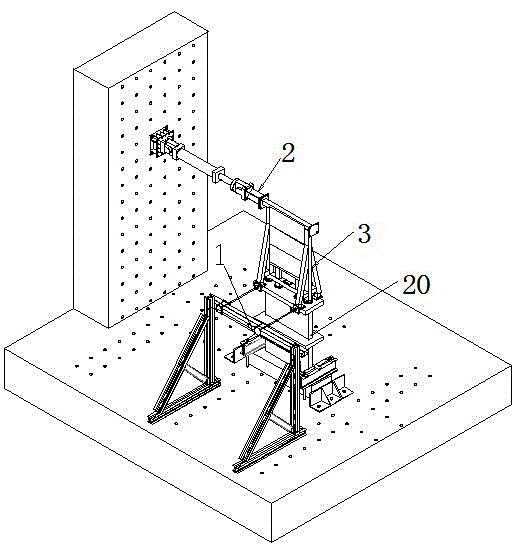

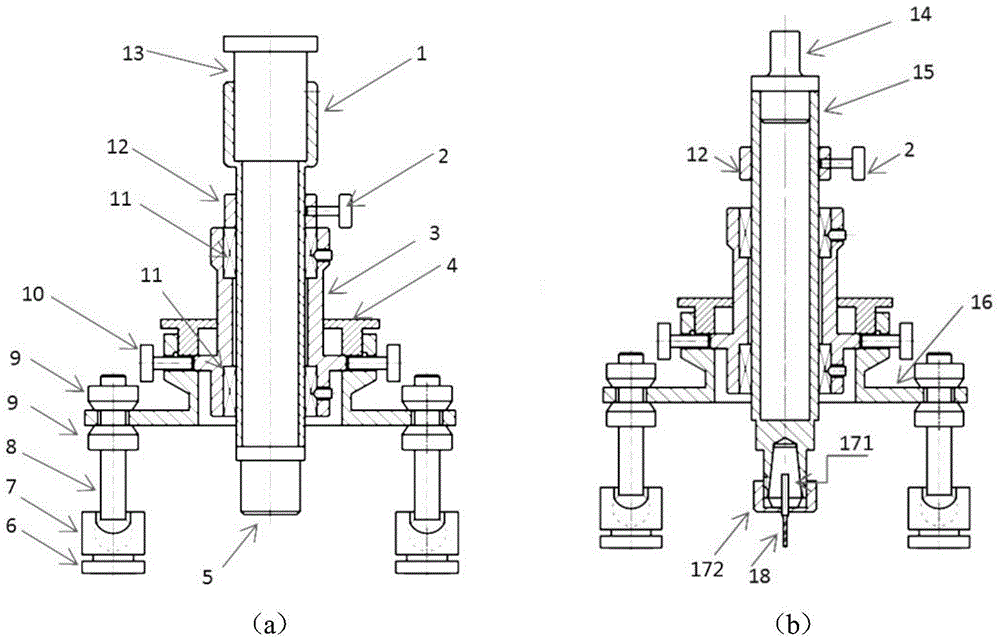

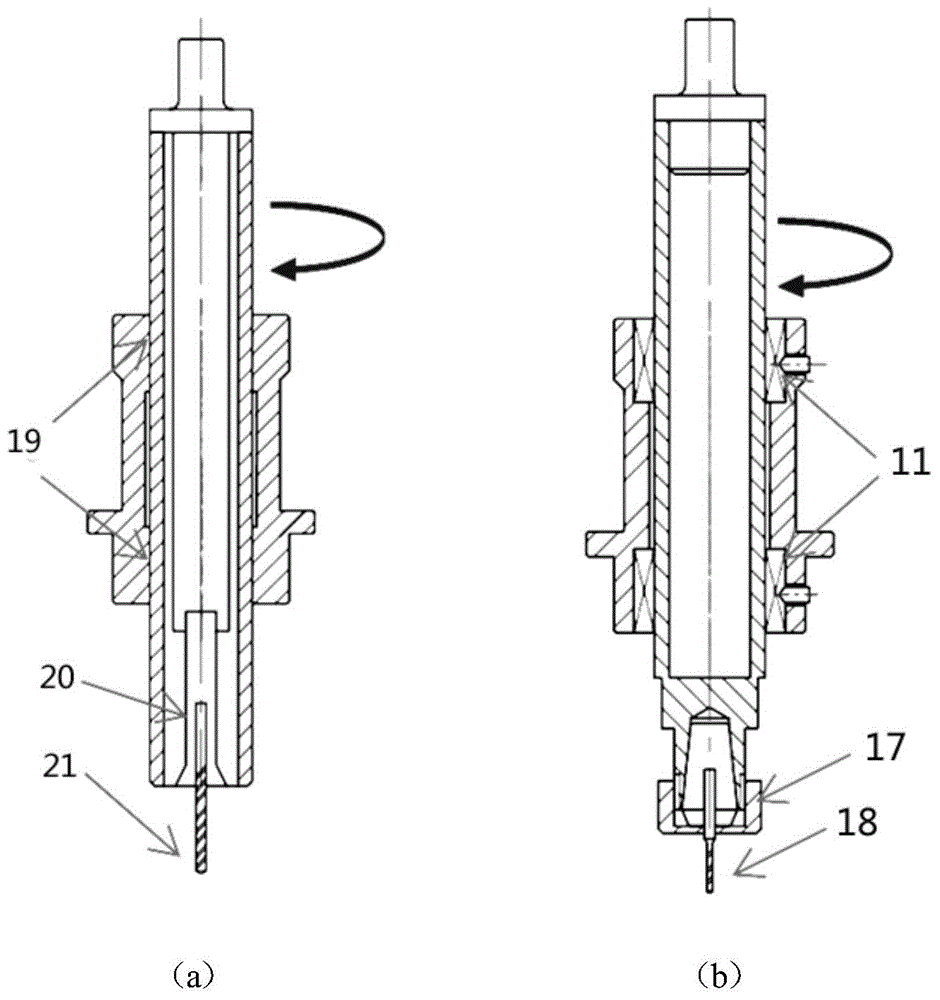

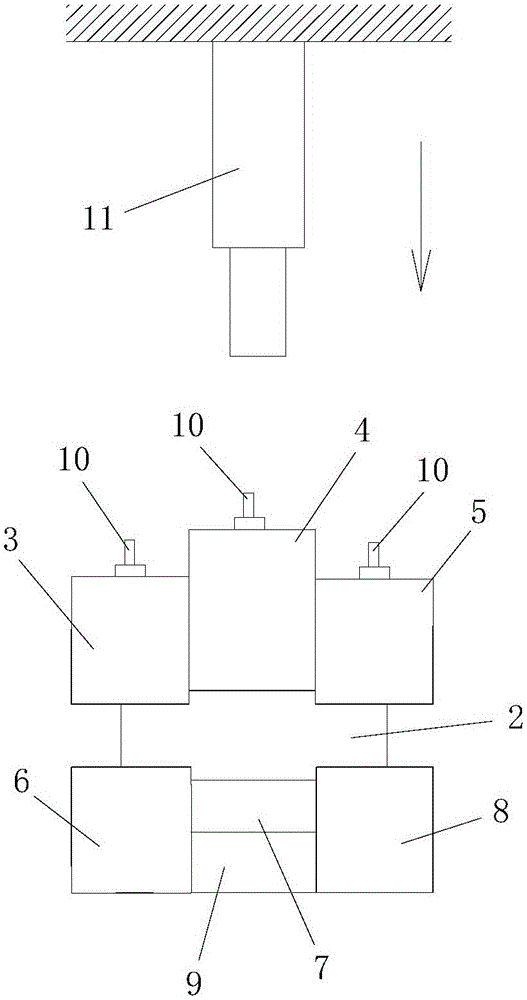

Device and method for measuring mechanical properties of rocks

InactiveCN102221501AThe test process is fastEasy to operateMaterial strength using tensile/compressive forcesEngineeringBottom pressure

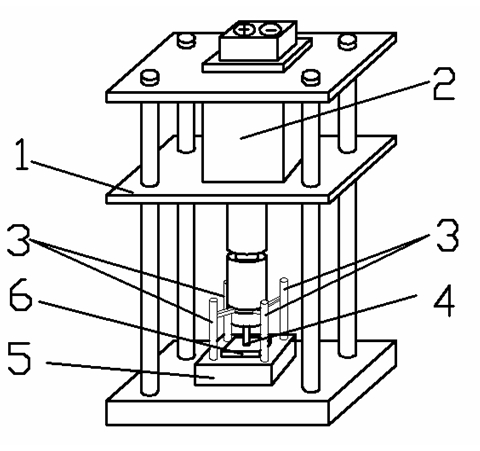

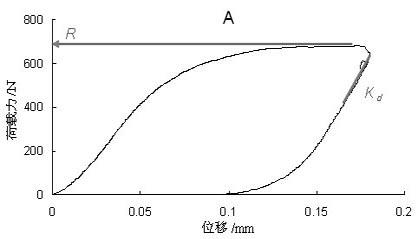

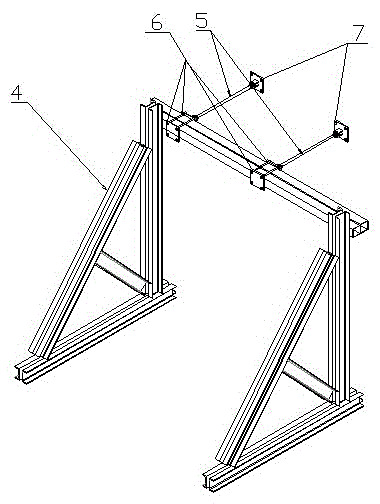

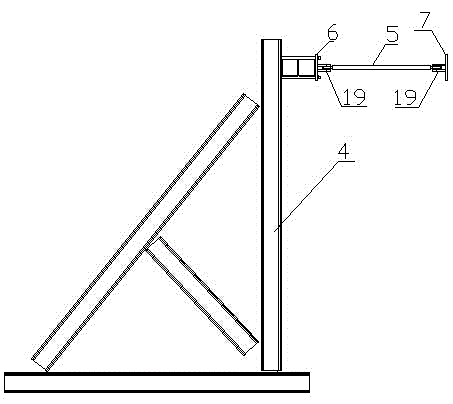

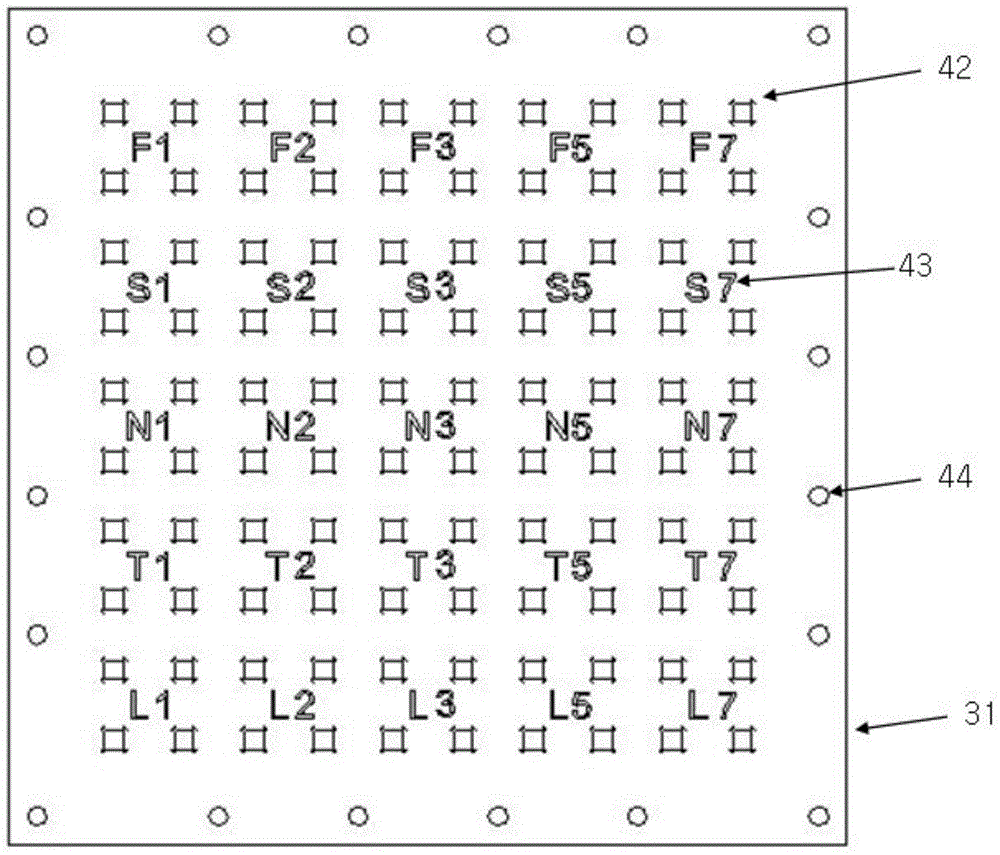

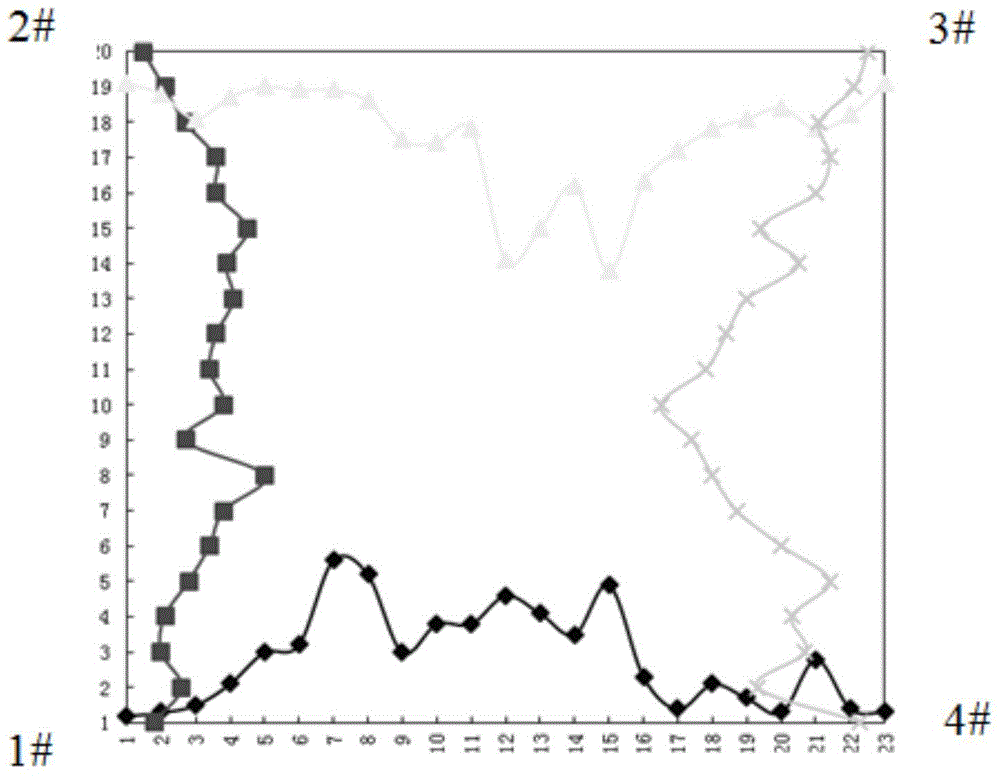

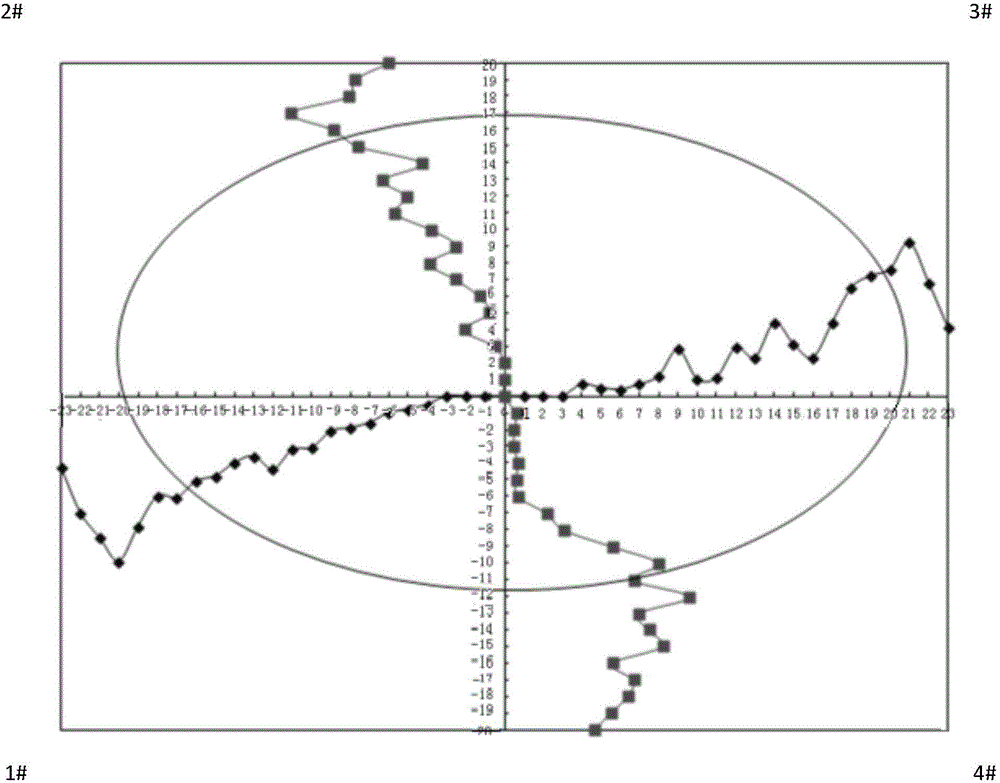

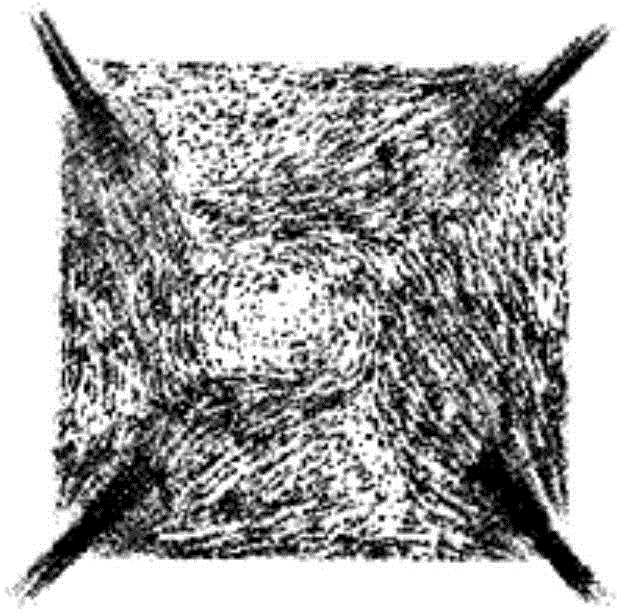

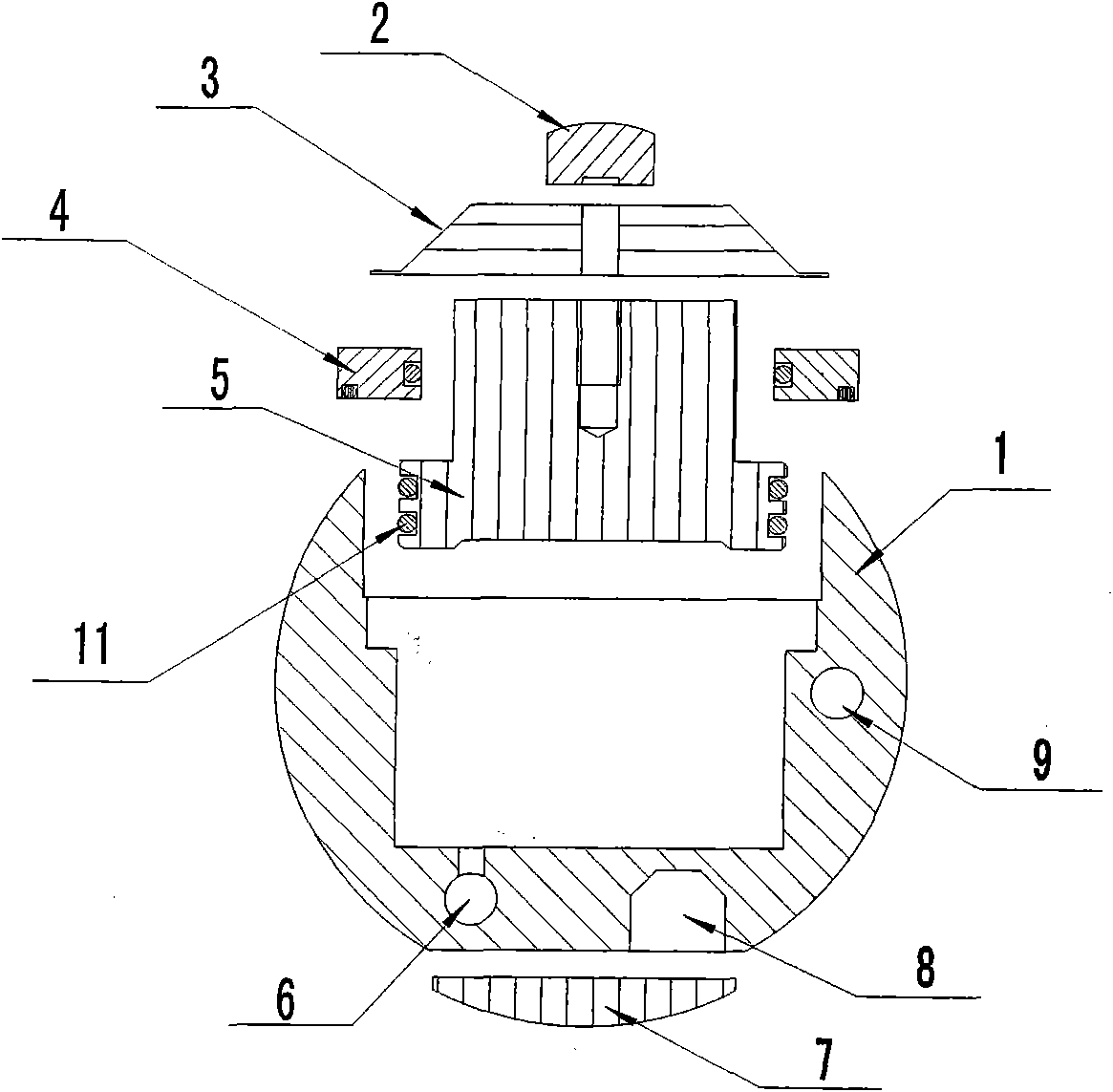

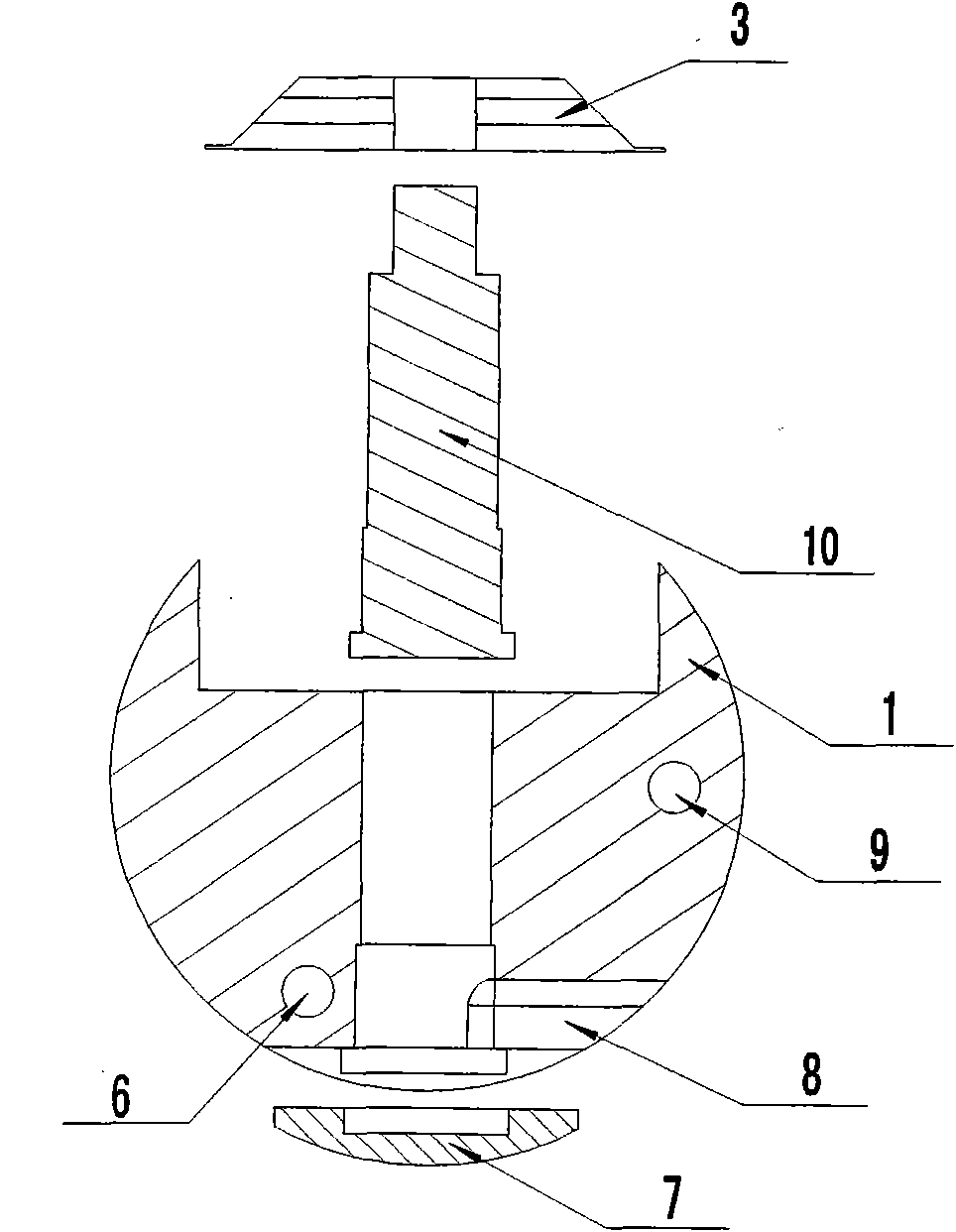

The invention relates to a device and a method for measurement, in particular to the method for calculating the mechanical properties of a series of rock sample materials by recording relationships between testing forces / loads and indentation depths / displacements at different moments. The device comprises a rack, a DC motor, displacement measurers, a rigid flat-bottom pressure head and a sample fixing station, wherein the rack is divided into two layers; the upper layer of the rack is provided with the DC motor of which one end is connected with the rigid flat-bottom pressure head; the displacement measurers are distributed about the rigid flat-bottom pressure head; and the sample fixing station is fixed on a base of the lower layer of the rack. The reliability and effectiveness of the method can be evaluated by comparing basic rock mechanical property measurement results with those obtained by other conventional testing means. In addition, compared with conventional mechanical test methods such as single-pressing tests, single-pulling tests, triaxial compression tests and the like in laboratories, the method has the advantages of short test process, simplicity and convenience of operation, low requirements on samples, economy and the like.

Owner:HOHAI UNIV

Resource configuration method and system

InactiveCN110147915AImprove the collaboration systemReduce difficultyResourcesTransmissionData matchingProcess configuration

The invention relates to a resource configuration method and system, being characterized by: carrying out the systematic sorting of complex resource configuration related elements through employing various technologies, carrying out the analysis of different dimensions, and setting a resource configuration system architecture model which can be referenced by an application-level service; assistingorganizations or individuals through innovation and reform; establishing a resource configuration system on the basis of an existing resource exchange system or no resource exchange system, so as topromote organizations and individuals, and individuals and individuals to establish a new cooperation mode under the condition of ensuring the legitimate identity and the data validity of networking,and ensuring the authenticity, the consistency and the non-tampering property of the data in different system transmission processes, thus realizing efficient utilization of data; and the data serviceand the intelligent service are combined with economy, resources and users to better research and distribute through communication with the server; and values are mined from big data such as geographic space, time, resources, users, reputations and demands, and data matching of resource demands and supply is established, and the association relationship between a regular mode and geographic lawsis acquired, and a sustainable and long-term-development complete business mode is created.

Owner:陕西爱尚物联科技有限公司

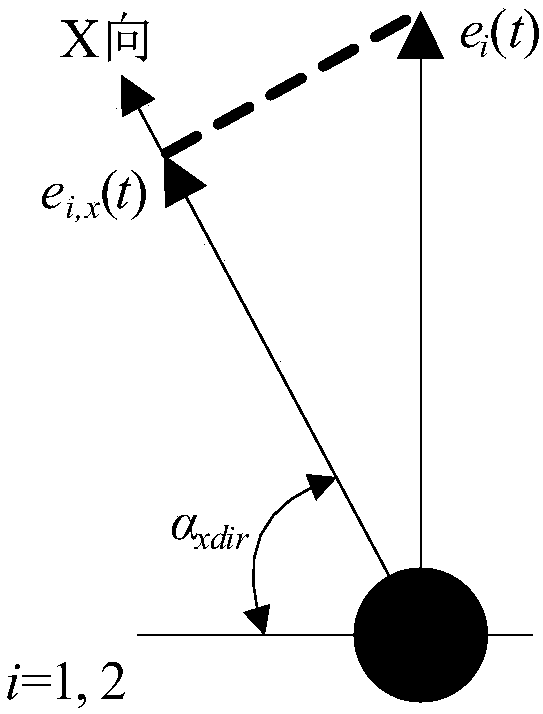

Modeling and compensation method of radial thermal drift error of spindle of horizontal numerically-controlled machine tool

ActiveCN107942934ASolve the problem of radial thermal error compensationImproved accuracy and stabilityProgramme controlComputer controlNumerical controlThermal deformation

The invention, which belongs to the field of error compensation of a numerically-controlled machine tool, provides a modeling and compensation method of a radial thermal drift error of a spindle of ahorizontal numerically-controlled machine tool. Two thermal drift errors along the radial direction of a spindle of a umerically-controlled machine tool and corresponding key point temperatures are tested; on the basis of a thermal tilt deformation mechanism of the spindle, a thermal inclination angle of the spindle is obtained and the correlation between the thermal inclination angle and the temperature difference between the left side and the right side of a spindle box is analyzed; according to the positive or negative situation of the thermal drift errors of the tested two points and stretching or contraction situations of the left side and right side of the spindle box, a thermal deformation situation of the spindle is classified and thermal drift error models under various thermal deformation attitudes are established; the influence on the model prediction result by the structural dimension of the machine tool is analyzed; and during real-time compensation, the thermal deformation attitude of the spindle is automatically determined based on the temperatures of the key points and the spindle is compensated by selecting a corresponding thermal drift error model automatically. Therefore, the determination of the thermal deformation attitude of the spindle of the numerically-controlled machine tool is realized during the processing process; and on the basis of the thermal deformation mechanism, the radial thermal drift error of the spindle is predicted.

Owner:DALIAN UNIV OF TECH

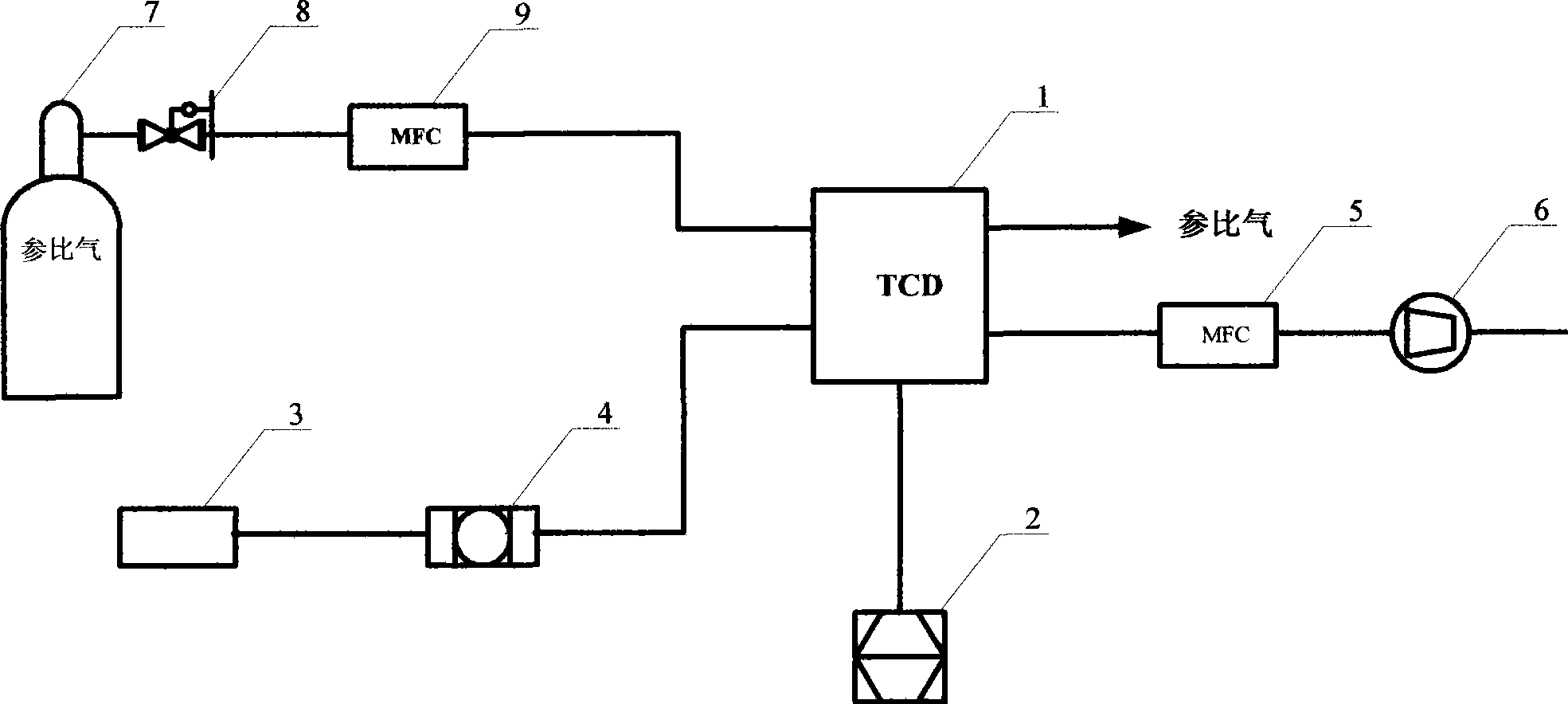

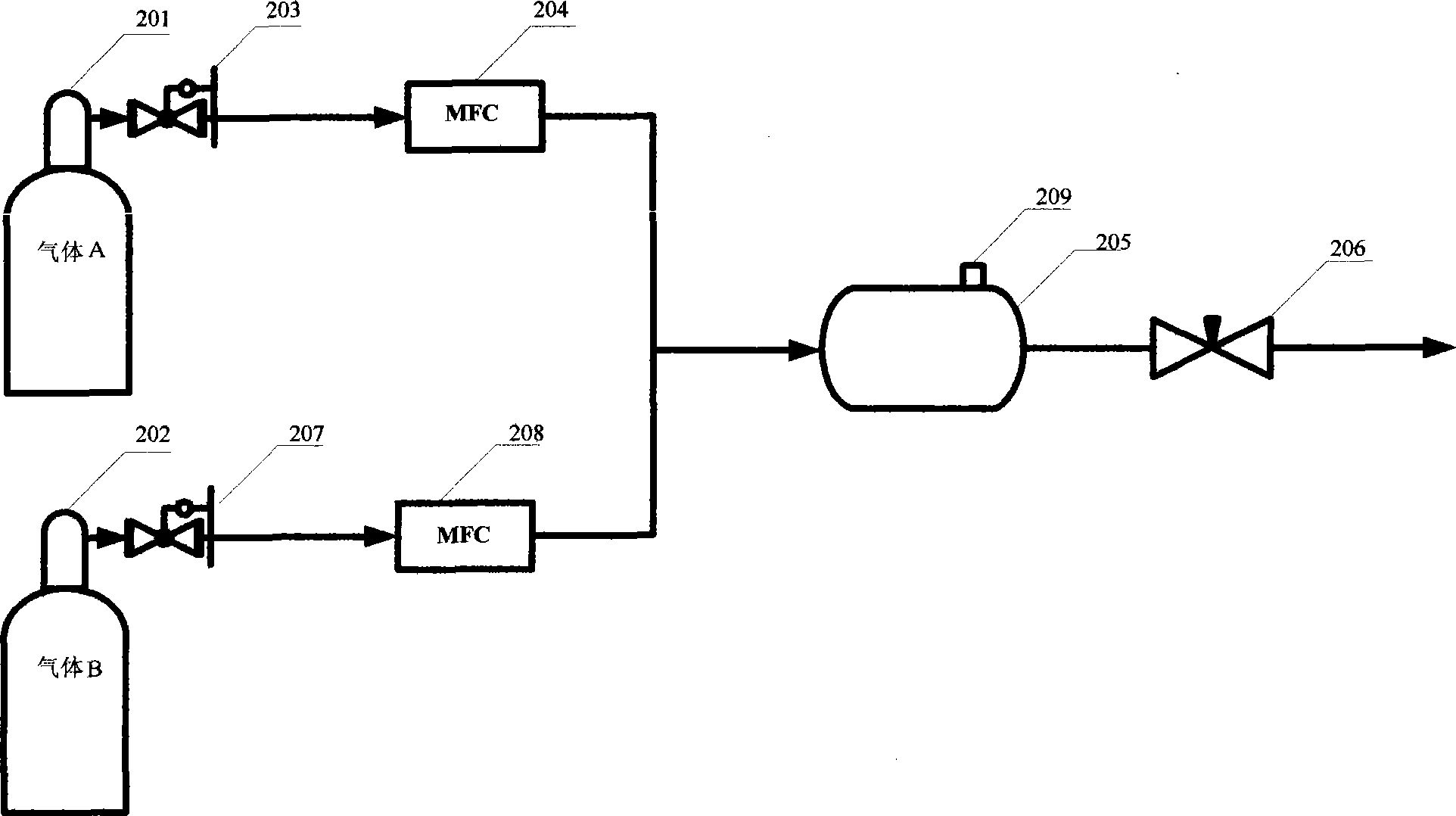

Method and apparatus for real-time detecting mixing gas component content by thermal conductivity detector

InactiveCN101377469AFast testing processImprove general performanceMaterial thermal conductivityGas cylinderData acquisition

The invention discloses a method for real-time detecting component content of mixed gas with thermal conductivity detector, and a device thereof. The computer data acquisition system of the device is connected with the signal output end of the thermal conductivity detector; one of the gas cylinders, one of the pressure regulating valves, and one of the mass flow controllers are orderly connected with the thermal conductivity detector; and a sampling probe is connected with the to-be-detected gas inlet of the thermal conductivity detector through a pipeline. The method comprises the following steps: firstly, scaling the gas content and voltage output value of the TCD detecting system before detection; secondly, introducing the to-be-detected gas into the sampling system through the sampling probe during detection; thirdly obtaining the content of a certain component of the to-be-detected mixed gas by referring to the concentration relation between the voltage and the concentration of the certain component in the mixed gas generated during the scaling step. The invention is an effective method for detecting the concentration variation of a certain component within the mixed gas with fast detection, simple and convenient operation, accurate analysis result, wide application range and good stability.

Owner:SOUTH CHINA UNIV OF TECH

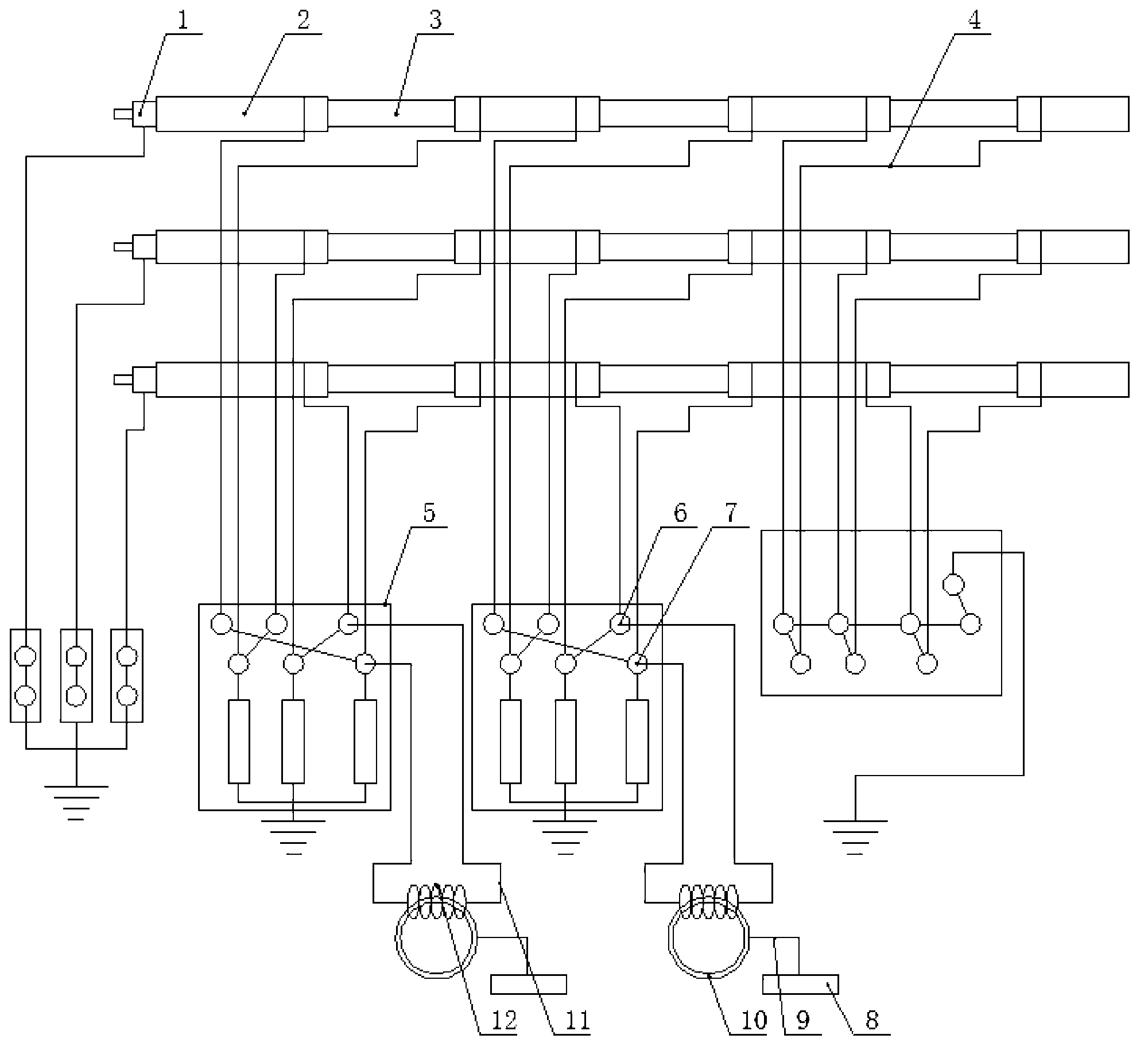

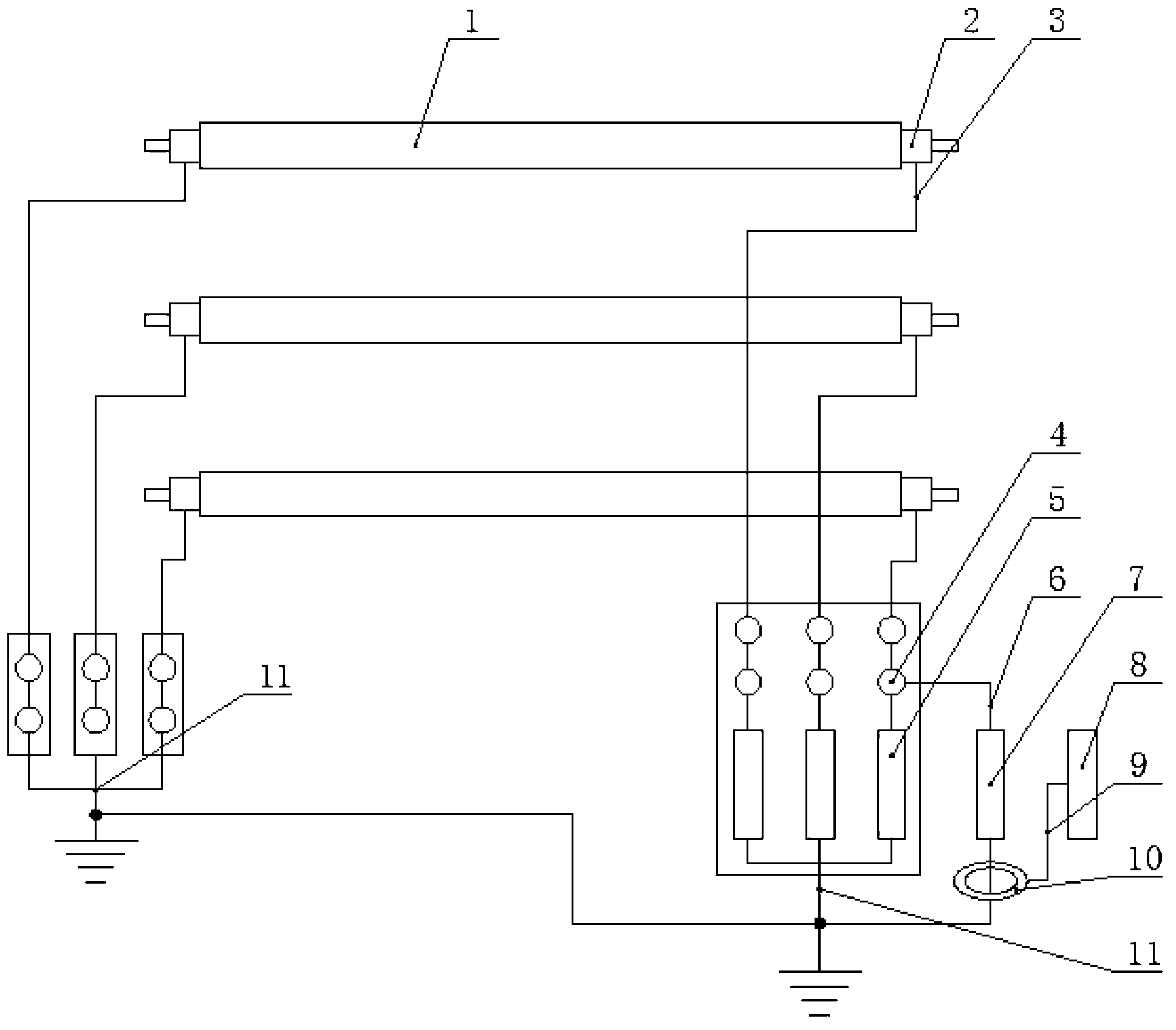

Partial discharge test device for high-voltage cable insulation middle joint and use method

ActiveCN103308832AAvoid cross-connection boxes and connecting pieces with different size standardsThe test process is fastTesting dielectric strengthMeasurement deviceEngineering

The invention relates to a partial discharge test device for a high-voltage cable insulation middle joint and a use method. The partial discharge test device is characterized in that each cross bonding link box and two connecting points connected with the same insulation middle joint are respectively connected with one end of a cable, and the middle of the cable is wound into a plurality of turns of coils; and a high frequency current sensor is reeved through the coils, and the output end of the high frequency current sensor is connected with a partial discharge measurement device. According to the partial discharge test device provided by the invention, the two connecting points connected with the insulation middle joint are connected by the cable, and the partial discharge live detection of the insulation middle joint is realized through the output of the high frequency current sensor, so that the defect that the high frequency current sensor can not be placed because the size standard of the cross bonding link boxes and connection sheets is different is overcome, and the test process is quick and very convenient.

Owner:STATE GRID CORP OF CHINA +1

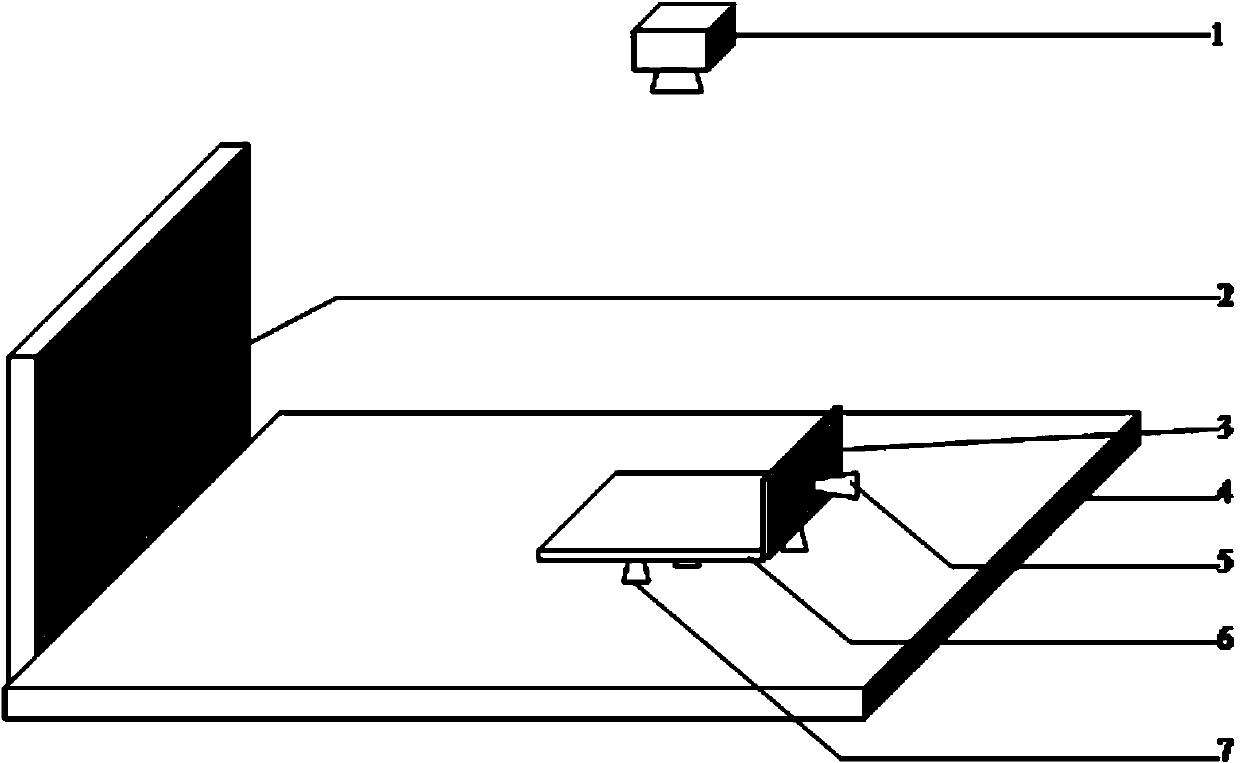

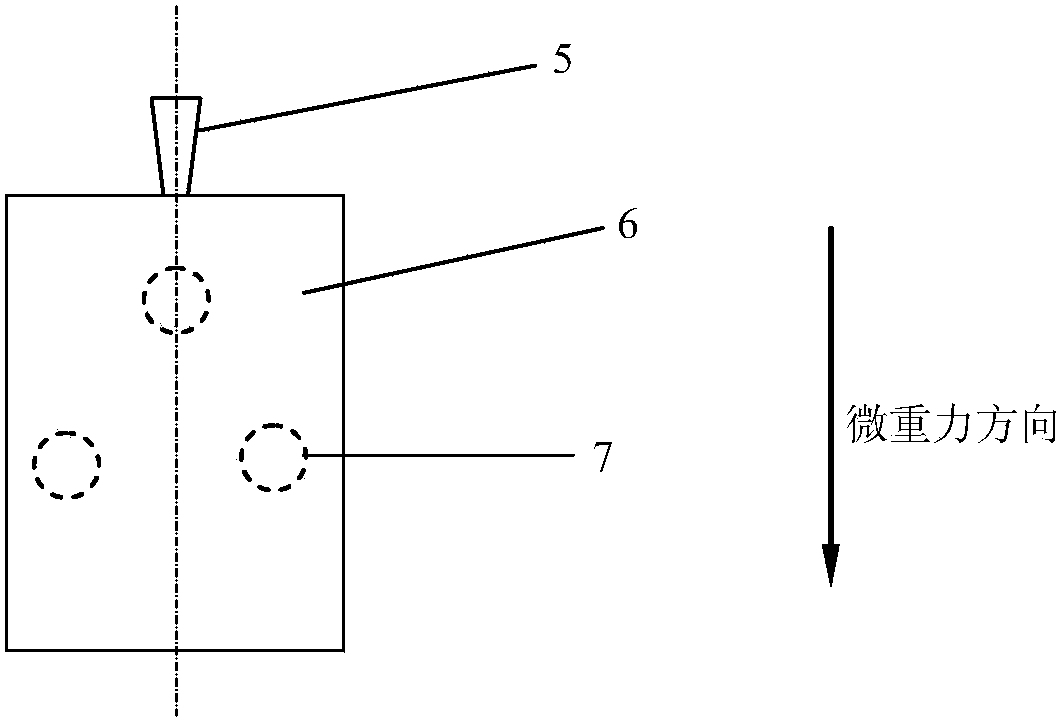

Autonomous landing navigation control ground test verification system under microgravity environment

InactiveCN103419947AEasy to testThe test process is fastCosmonautic condition simulationsCelestial bodyEngineering

The invention relates to an autonomous landing navigation control ground test verification system under a small celestial body (asteroid and comet) microgravity environment and belongs to the technical field of ground semi-physical simulation. The autonomous landing navigation control ground test verification system under the microgravity environment specifically comprises a small celestial body surface topography simulation part, a base part, a lander mounting platform and an external measurement part, wherein the lander mounting platform comprises a mounting platform body, multiple flotation air legs, one small-thrust nozzle, wherein the multiple flotation air legs are fixed at the bottom of the mounting platform body in a regular polygon shape, so as to realize a high-pressure air cushion, so that frictionless motion is realized; the small-thrust nozzle is arranged in the inverse direction of to-be-simulated microgravity and used for generating a thrust so as to serve as the microgravity borne by a lander; the external measurement part is used for measuring space states such as the position and posture of the lander mounting platform relative to the small celestial body surface topography simulation part. The system can simulate different microgravities by virtue of changing the thrust of the nozzle and has the advantages of simplicity in test, rapidness, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-voltage short-cable insulation terminal partial discharge testing device and using method

ActiveCN103323751ARealize live detectionThe test process is fastTesting dielectric strengthMeasuring equipmentPartial discharge

The invention relates to a high-voltage short-cable insulation terminal partial discharge testing device. One end of each cable is connected to the upper end of each protective layer protector. A power resistor is connected to the middle portion of each cable in series. The other end of each cable is connected with a grounding end of each protective layer protector and a direct grounding point of one end of each electric cable. A high-frequency current sensor is sleeved at intervals on the cable between the grounding end of each protective layer protector and each power resistor. An output end of the high-frequency current sensor is connected with partial discharge measuring equipment. The upper ends of the protective layer protectors of an insulation terminal and the grounding points are connected through the cables, output of the high-frequency current sensor is collected to complete partial discharge live detection of the insulation terminal, under the premise that normal operation of a circuit is guaranteed, live detection in which the protective layer protector is connected to the ground to detect electric cable terminal partial discharge is achieved, a testing process is quick, and convenience is achieved.

Owner:STATE GRID CORP OF CHINA +1

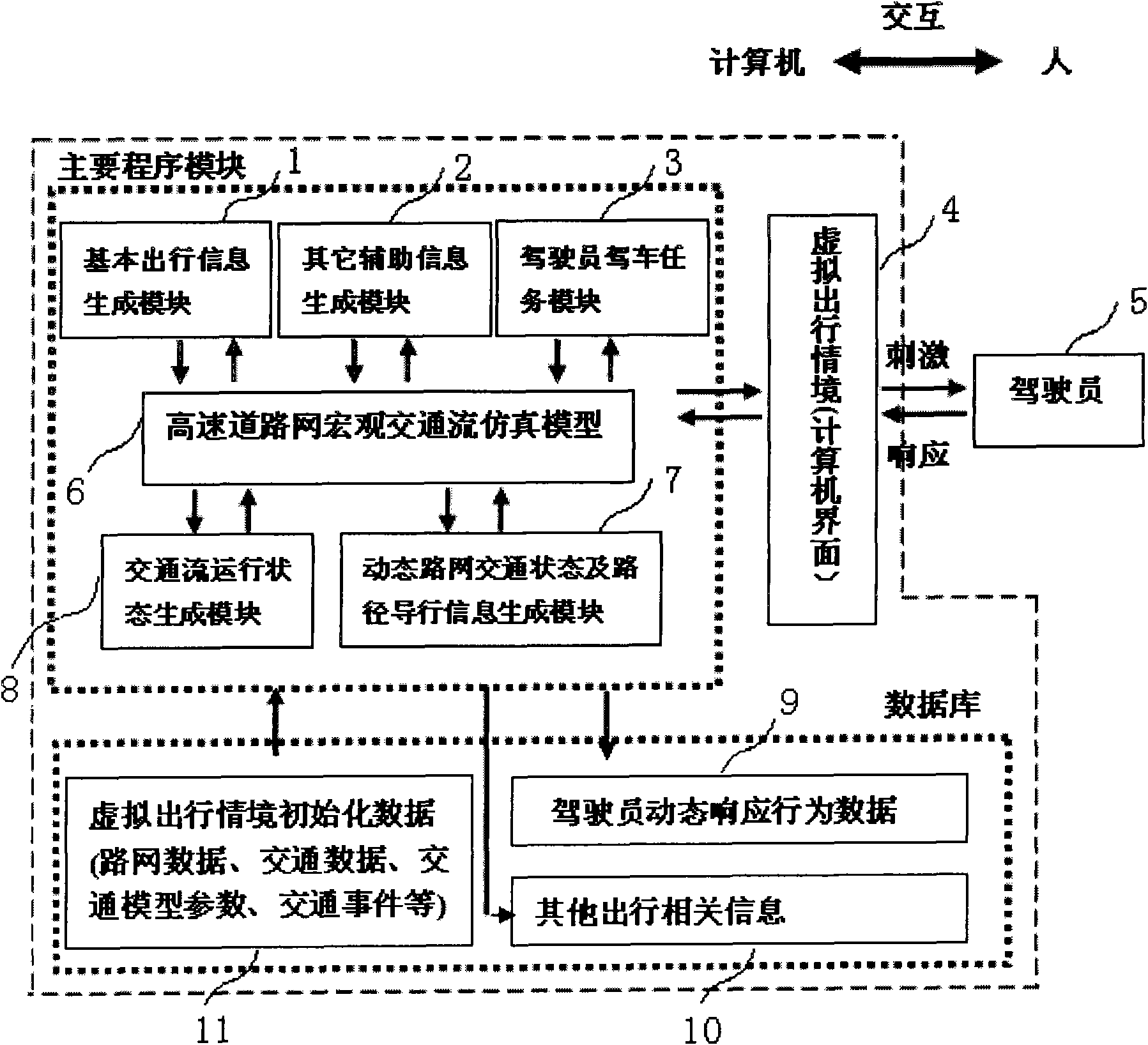

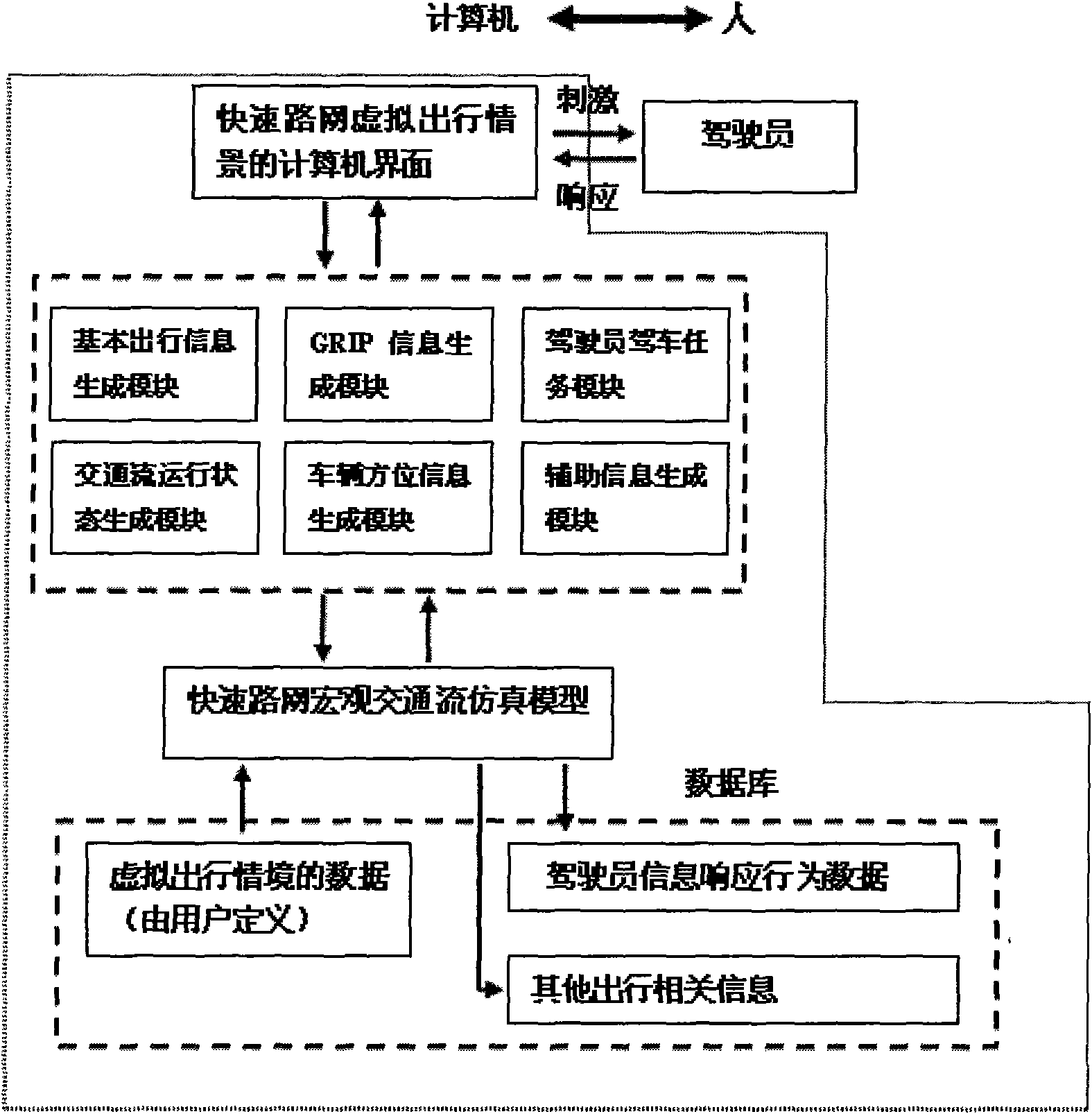

Vehicle-borne dynamic traffic information induction system analog design method facing behavior research

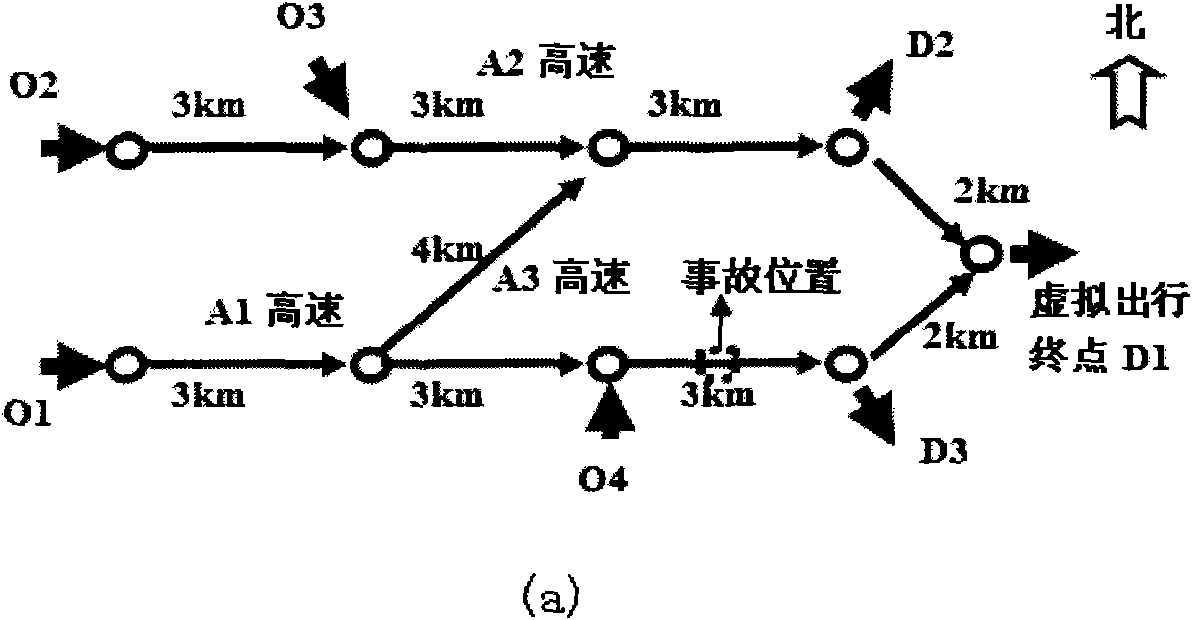

InactiveCN101639871AThe test process is fastEfficient human-machine interface designSpecial data processing applicationsDriver/operatorSimulation

The invention relates to a vehicle-borne dynamic traffic information induction system analog design method facing behavior research. The method comprises: building program modules, such as a highway network macroscopic traffic flow simulation model, a traffic flow running state generating module, a driver driving task module, a dynamic road network traffic state and guiding information generatingmodule, a basic travel information generating module, other assistant information generating modules and the like; and driving virtual travel situation taking a computer interface as a carrier. The invention has the characteristics that a driver can go through vivid traffic flow state so as to ensure that the driver behavior data is more reliable, the development cost of a vehicle-borne information system analog program is low, analog tests are simple and easy to operate, test fields are free from limitation, test process is quick, test cost is lower and the like. The invention can provide basic data for driver behavior analysis, vehicle-borne dynamic traffic information system optimization design, operation, evaluation and the like under the environment of traffic information.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

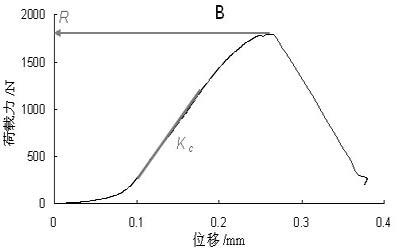

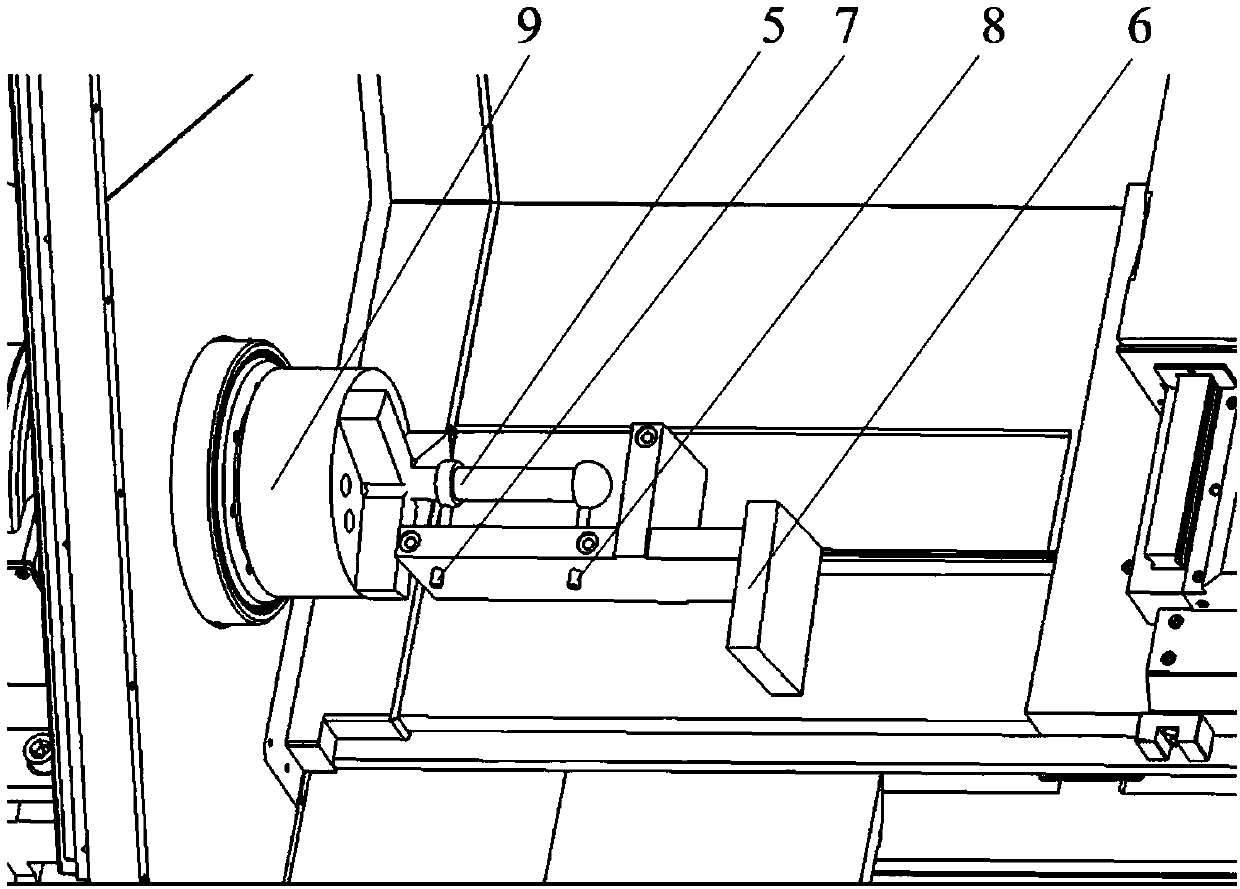

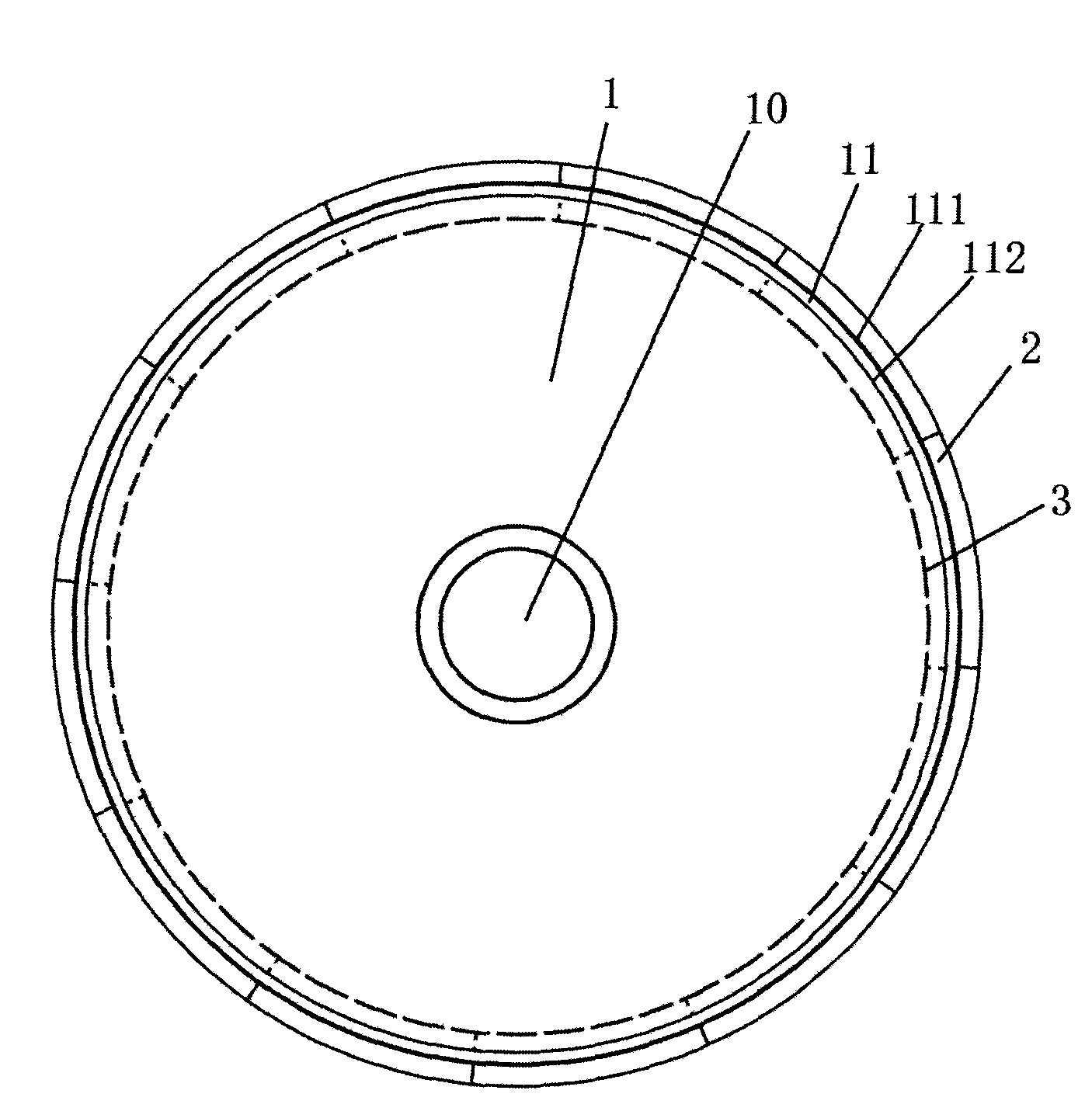

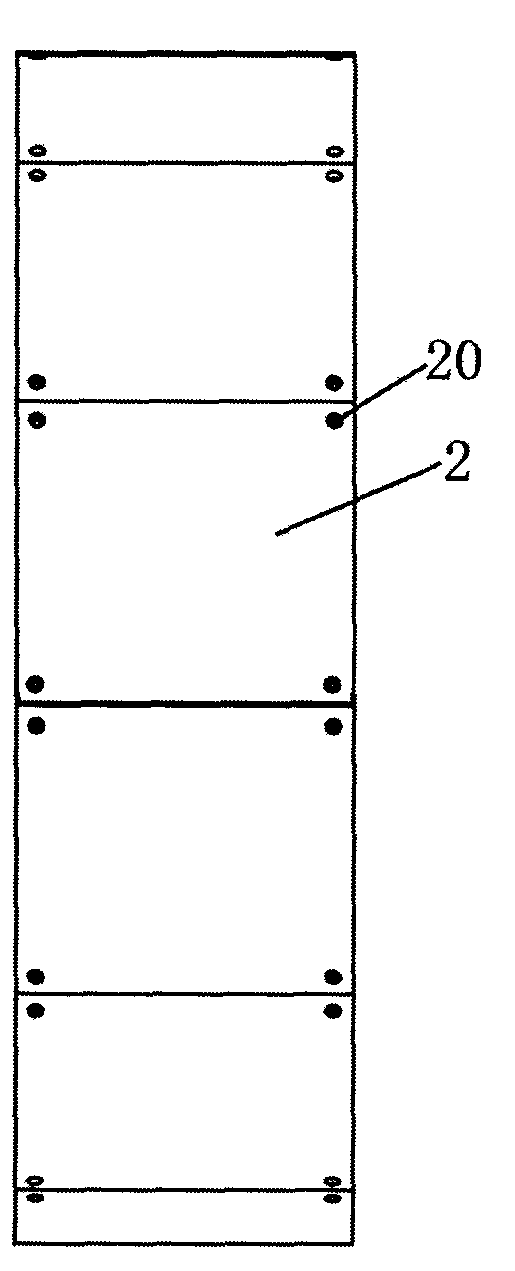

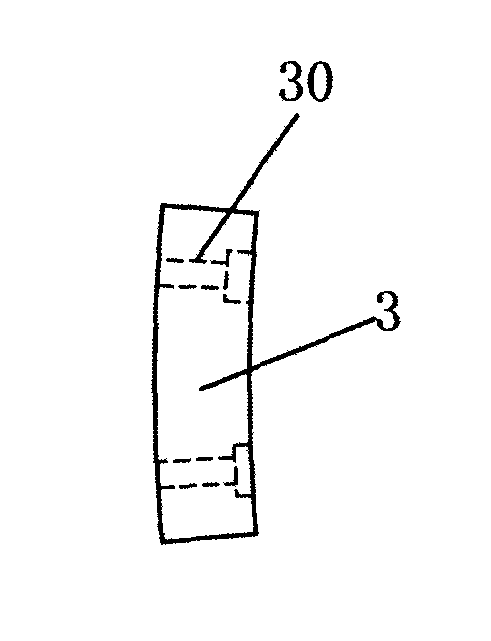

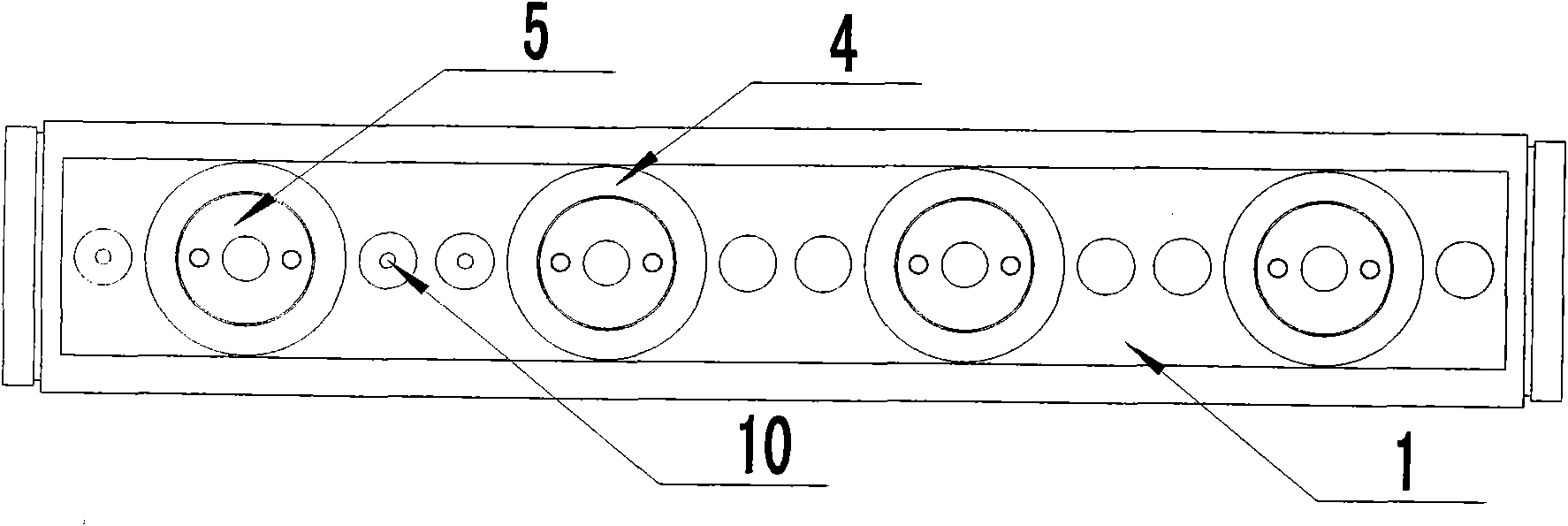

Drum device of indoor tyre testing machine

The invention discloses a drum device of an indoor type testing machine. The drum device is characterized by comprising a smooth steel base drum, a plurality of modularized road simulation units and a plurality of dynamic balance compensation units, wherein a spindle mounting hole is arranged in the centre of the smooth steel base drum axially; the modularized road simulation units are respectively detachably arranged on outer surface of the circumferential surface of the smooth steel base drum, and the modularized road simulation units are arranged in an end-to-end connecting manner; and the dynamic balance compensation units are respectively detachably arranged on the inner surface of the circumferential surface of the smooth steel base drum, and the dynamic balance compensation units are in dynamic balance compensation matching with the modularized road simulating units. Therefore, the drum device integrates road spectrum and road simulation in a proving ground of the modularized road simulation units and dynamic balance compensation of the dynamic balance compensation units, thereby simulating a tyre test in the proving ground.

Owner:汕头市浩大轮胎测试装备有限公司

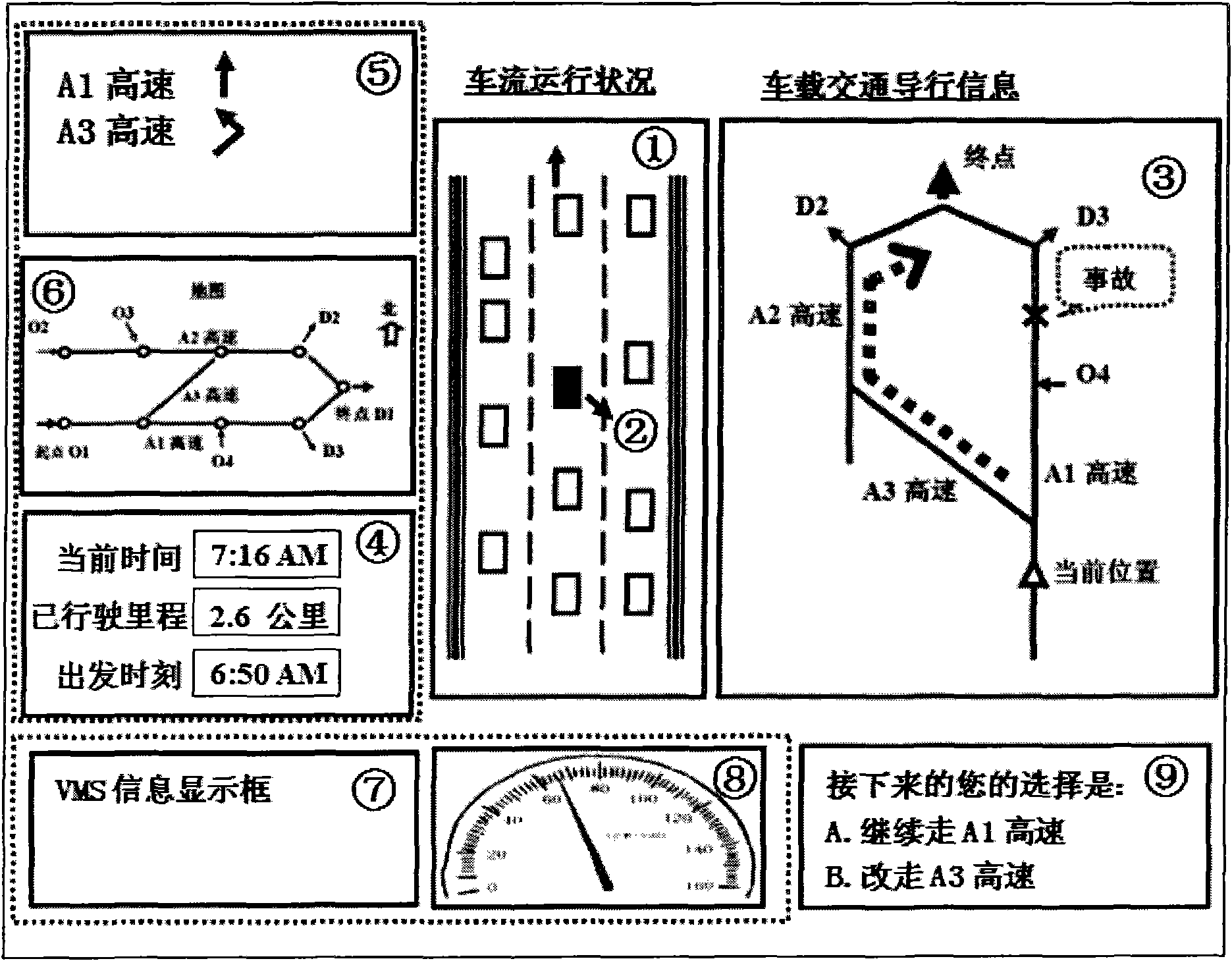

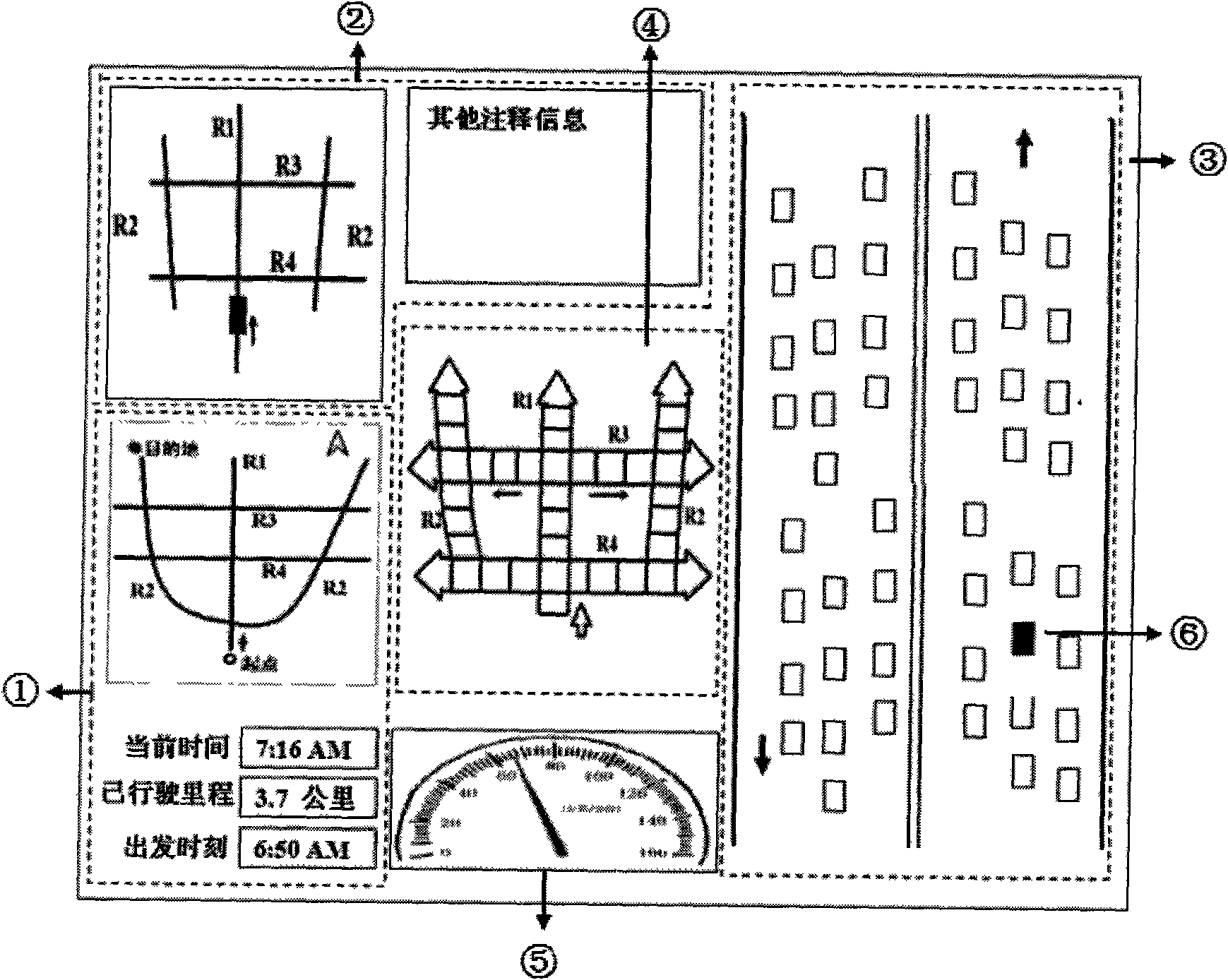

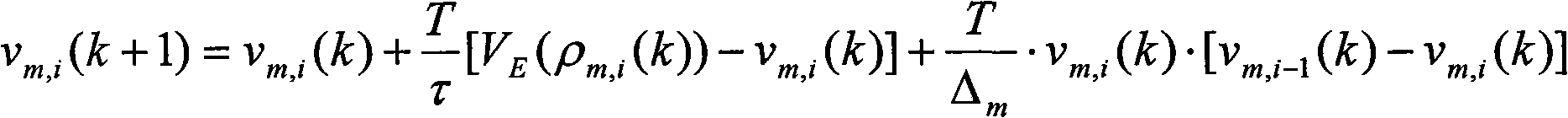

Computer dynamic simulation method of driver dynamic response behavior about graphic path information board

InactiveCN101556625AEasy to collect dataThe test process is fastDetection of traffic movementSpecial data processing applicationsDriver/operatorSide information

The invention relates to a computer dynamic simulation method of driver dynamic response behavior about graphic path information board. A simulation system provides more vivid fast road trip condition and a human-computer interaction interface which meets the human engineering principle for driver; the information of the trip condition comprises basic trip information, traffic flow operating state, GRIP information, vehicle azimuth information and other auxiliary information. The traffic condition and the GRIP information passed by the driver in the trip process are obtained by simulation of simulation mathematic model of macroscopic traffic flow of fast road network so as to lead the traffic condition passed by the driver in the trip process to be more real and increase the reliability of colllected response behavior data of the driver. The driver inputs the path selected by the mouse and the keyboard to the computer in the simulation trip process. The simulation method has the characteristics of low development cost, simple and convenient simulation test, easy operation, no limitation to test fields, fast test process and lower test cost and the like and can provide basic data for analysis and modeling of dynamic path selection behavior of the driver.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

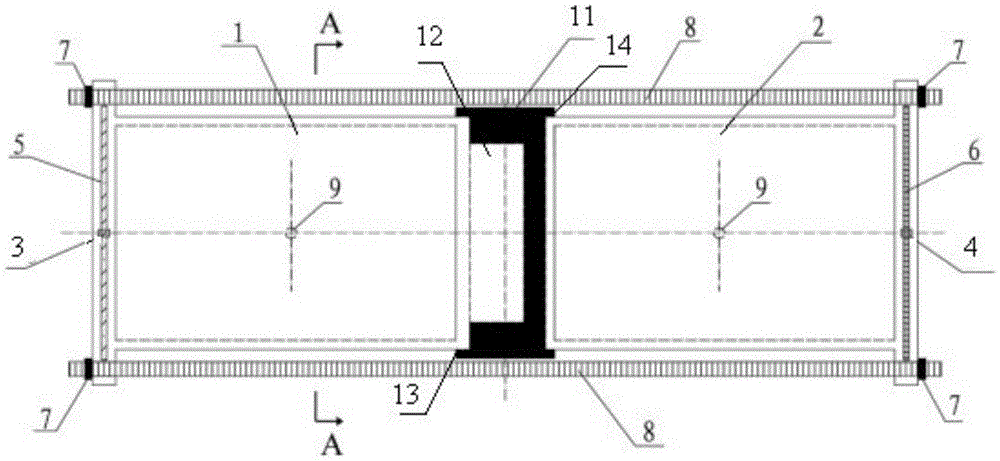

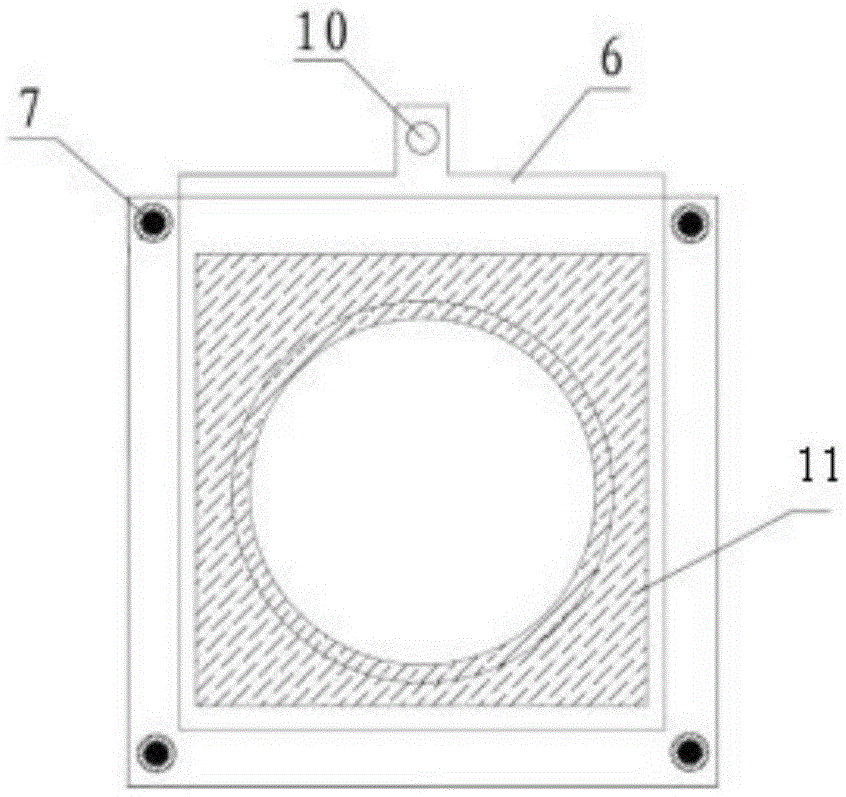

Detachable and reusable shear wall earthquake-proof performance test loading rack and test method

InactiveCN105067211AReduce design heightLight in massVibration testingAxial pressureAxial compression

The invention relates to a detachable and reusable shear wall earthquake-proof performance test loading rack and a test method. The test loading rack comprises a wall steel frame apparatus, a loading connecting apparatus, and an anti-sidesway module, wherein the wall steel frame apparatus comprises a loading beam, a steel frame wall, and steel frame wall fulcrum bars; two sides of the steel frame wall are provided with inclined strut type wall fulcrum bars; the wall fulcrum bars are in fixed connection with the bottom of the steel frame wall and a shear wall test piece floor; a jack is arranged on the square steel tube frame of a hollow part on the steel frame wall; the loading beam is fixed on the upper part of the steel frame wall, and is in connection with the loading connecting apparatus through loading terminals at ends of the loading beam; the anti-sidesway module comprises fixed steel frames and anti-sidesway pull rods; two ends of the anti-sidesway pull rods are respectively hinged to the fixed steel frames and the steel frame wall fulcrum bars in the wall steel frame apparatus. The loading rack can increase the shear span ratio of a shear wall test piece, meet the requirement that the shear span ratio is greater than 3 in an earthquake-proof performance test, apply axial pressure to the shear wall test piece, and meet requirements for different axial compression ratios required by a shear wall test.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

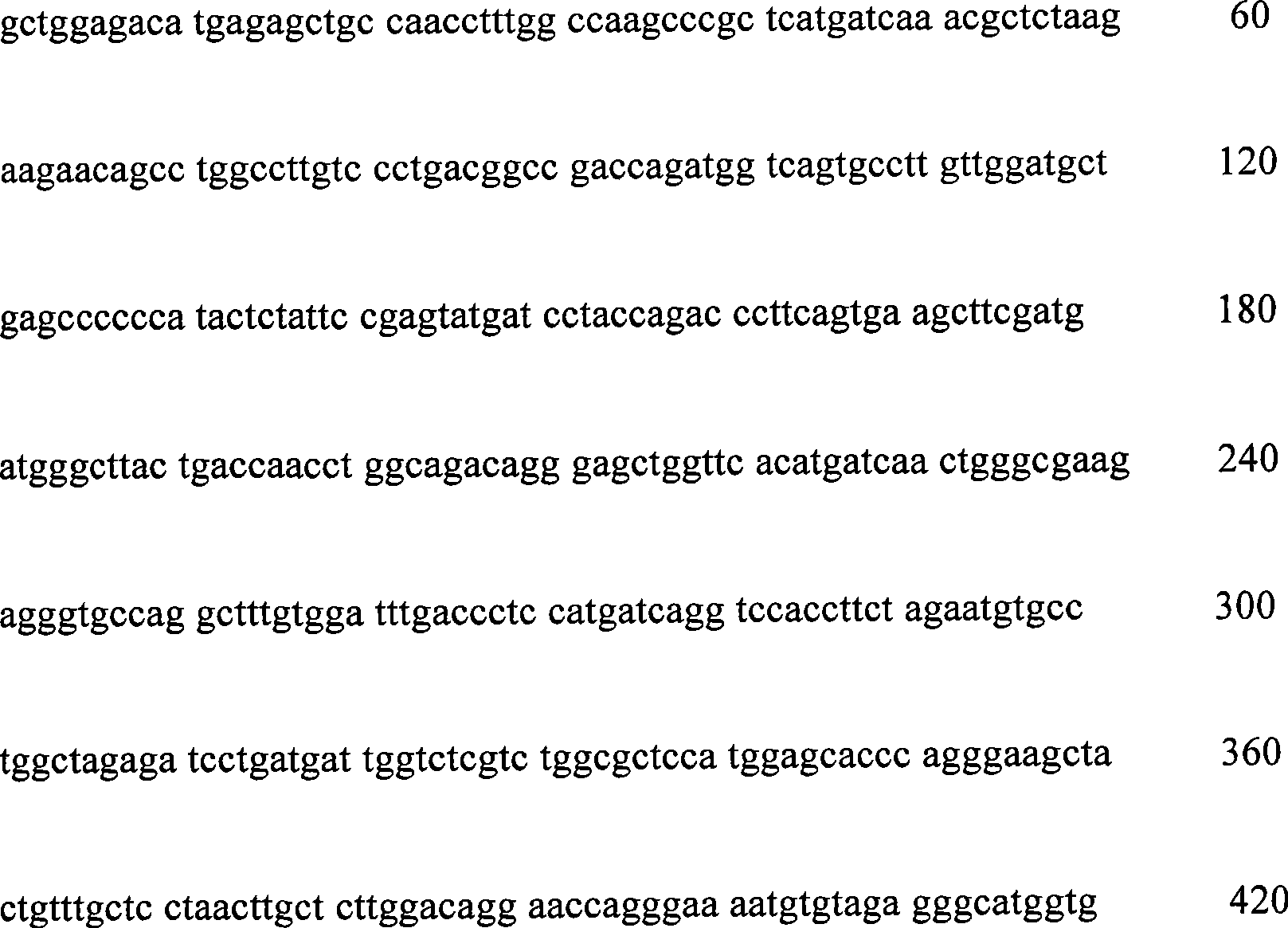

Two-hybrid yeast for detecting estrogen-like compound in environment and biological test method

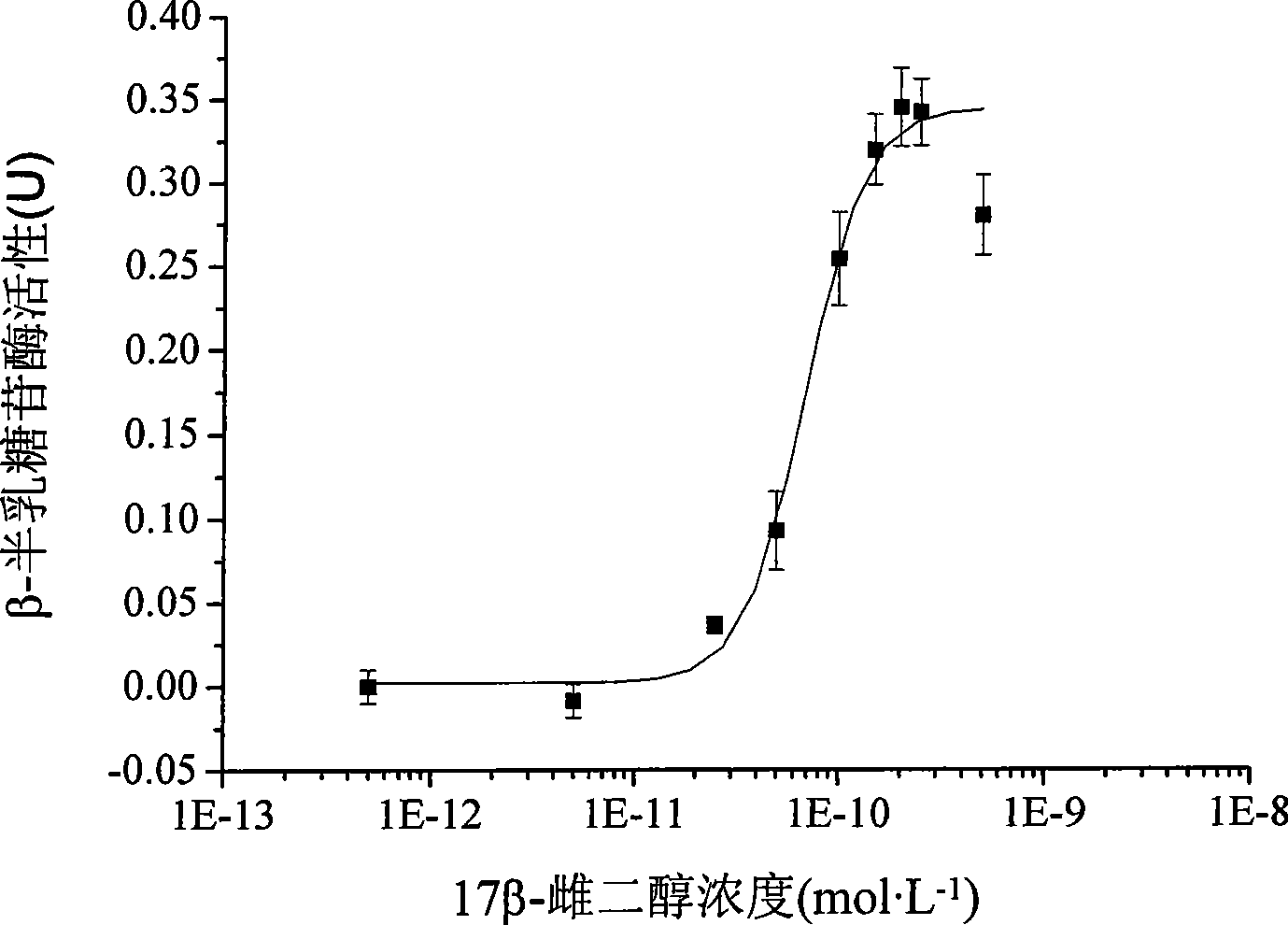

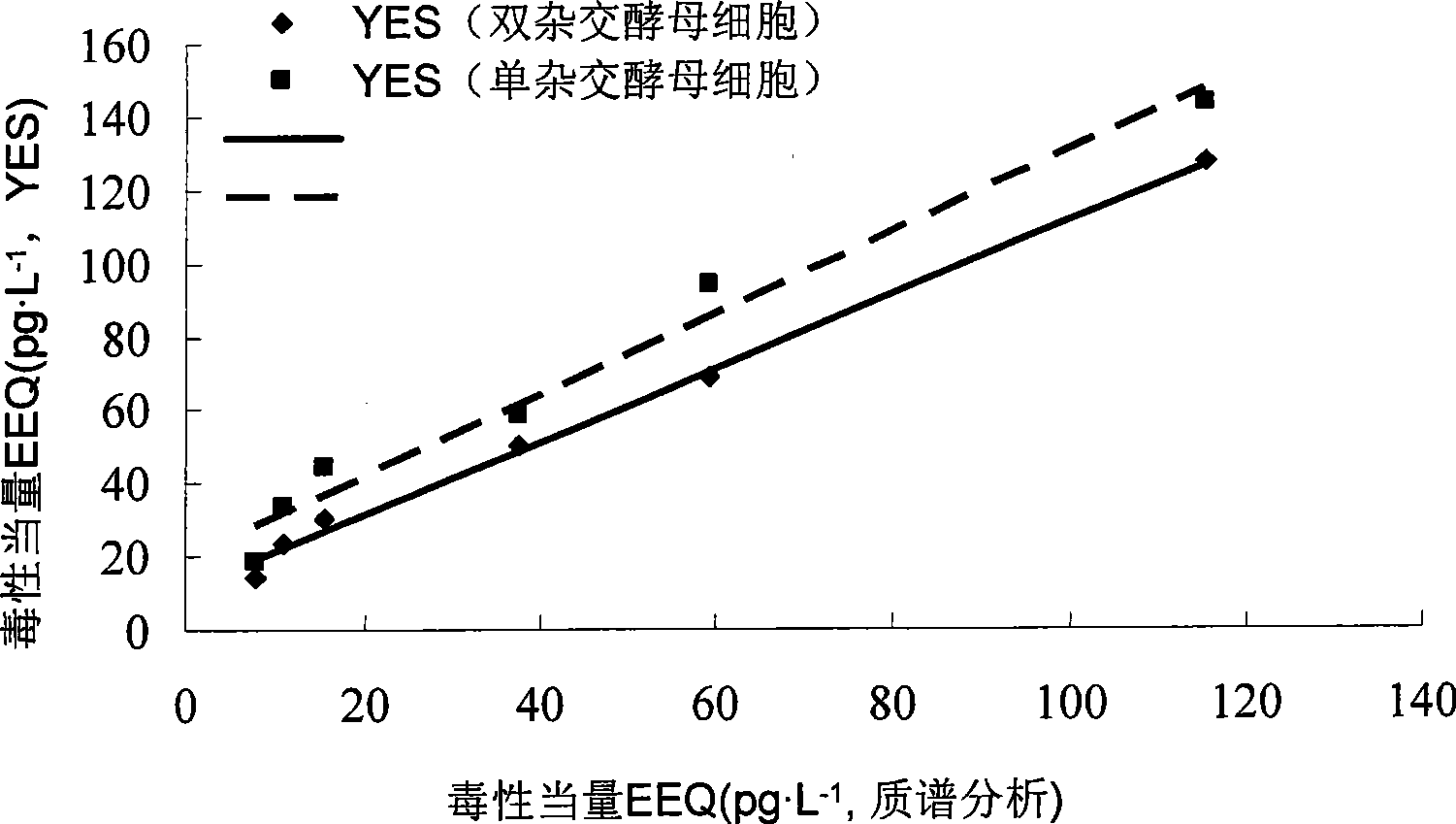

ActiveCN101469315AThe test process is fastTest stableFungiMicrobiological testing/measurementBiotechnologyMammal

The invention provides a two-hybrid yeast for detecting estrogen-like compounds in environmental samples and a preparation method thereof, wherein the yeast contains pGBKT7-ER yeast expression plasmids and pGAD424-GRIP1 yeast expression plasmids, wherein the pGBKT7-ER yeast expression plasmids contain estrogen receptor genes, and the pGAD424-GRIP1 yeast expression plasmids contain estrogen receptor coactivated factor genetic fragments with the sequence of SEQ ID No.2. The invention also provides a bioassay method for detecting the estrogen-like compounds in the environment, which comprises: co-culturing two-hybrid yeast cells and a sample to be detected, adding a reaction liquid of o-nitrobenzene-beta-D-galactopyranoside for reaction, and calculating the concentration of the estrogen-like compounds according to the detected absorbance value of supernatant at 420 nanometers after the reaction stops. The invention adopts the two-hybrid yeast of recombinant estrogen receptor genes for test, and is more close to the actual action conditions of an endocrine system of a mammal; constructed yeast cell genes have stable character and are easy to culture and screen; the screening process of the whole estrogen-like effect is simple to operate; and the required quantity of the sample is small, and the cost is low.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

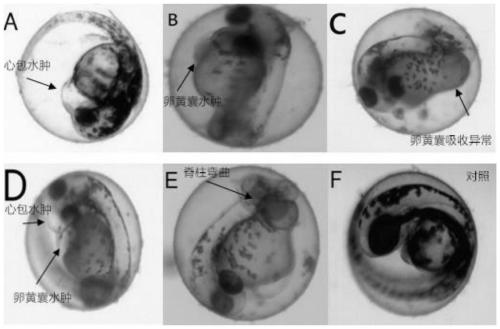

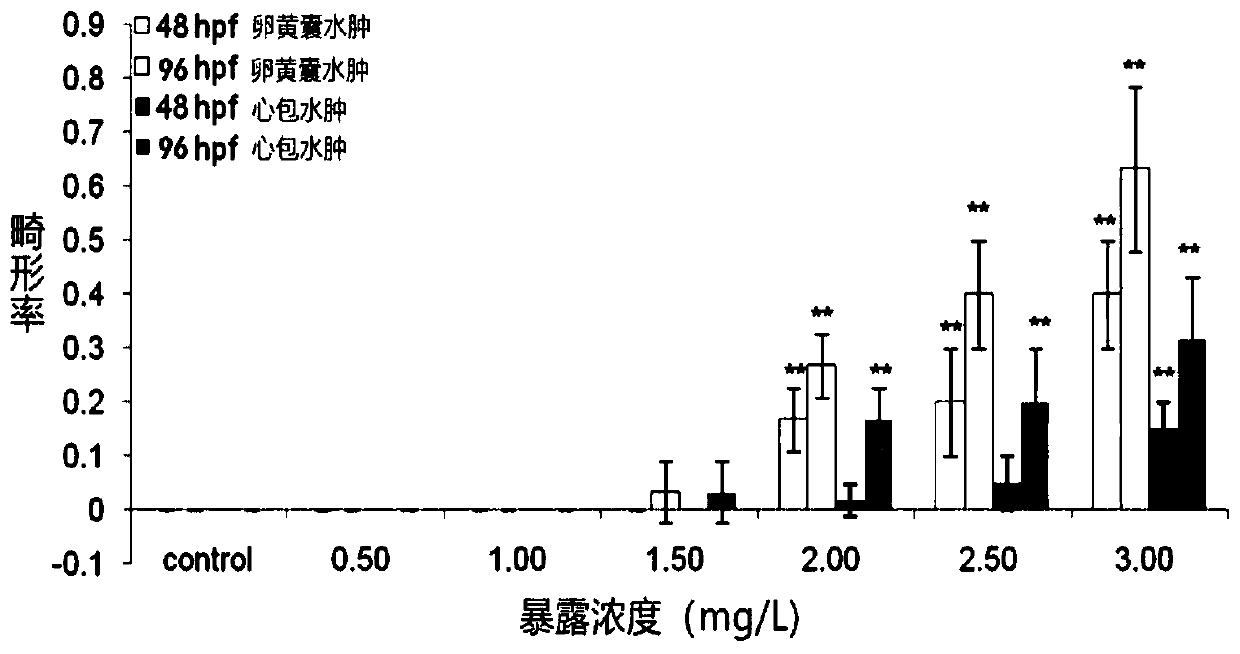

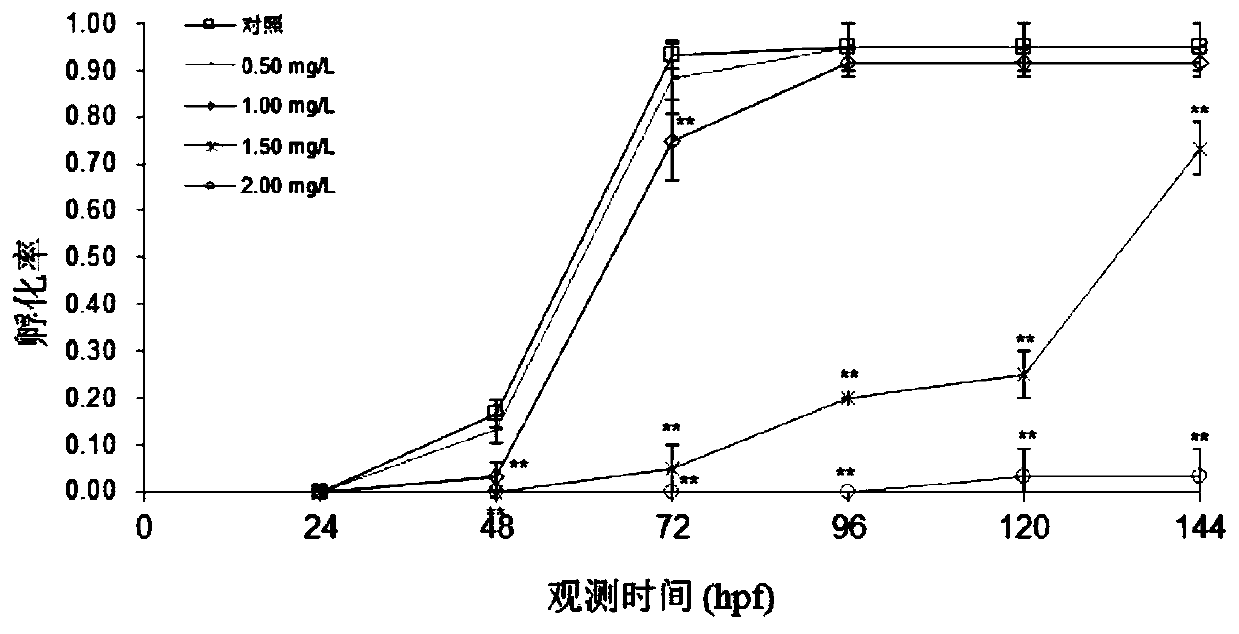

Method for evaluating influence of pollutants on zebra fish biotoxicity

The invention provides a method for evaluating the influence of pollutants on zebra fish biotoxicity. The method comprises the following steps of: respectively carrying out toxicity tests on zebra fish embryos, larva zebra fish and adult zebra fish to respectively obtain LC50 values and / or sub-lethal doses of zebra fish in different growth stages; selecting the zebra fish at a growth stage with the lowest LC50 value and / or sub-lethal dose as the most sensitive stage zebra fish; evaluating the toxicity strength of pollutants by adopting the LC50 value and / or the sub-lethal dose of the most sensitive stage zebra fish; according to the evaluation method, toxicity tests are carried out on zebra fish at different growth stages respectively, the most sensitive stage zebra fish can be determinedaccording to the biotoxicity difference of pollutants to zebra fish at different stages, and important guiding significance is achieved on zebra fish protection work by determining the most sensitivestage of zebra fish; in addition, the toxicity strength of pollutants is evaluated by the biotoxicity of zebra fish at the most sensitive stage, and the accuracy of pollutant toxicity evaluation is improved.

Owner:CHINESE ACAD OF FISHERY SCI

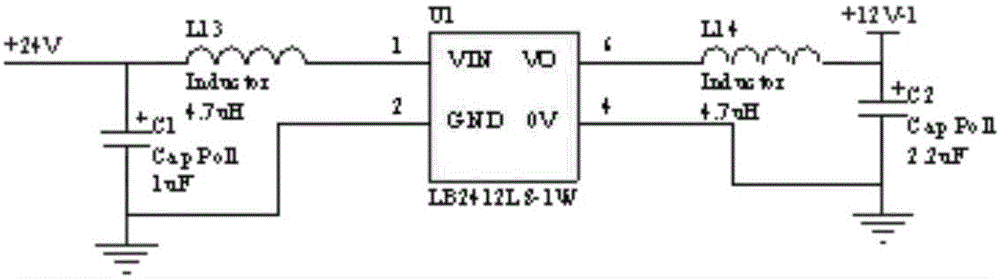

Function checking device of electric car battery management system

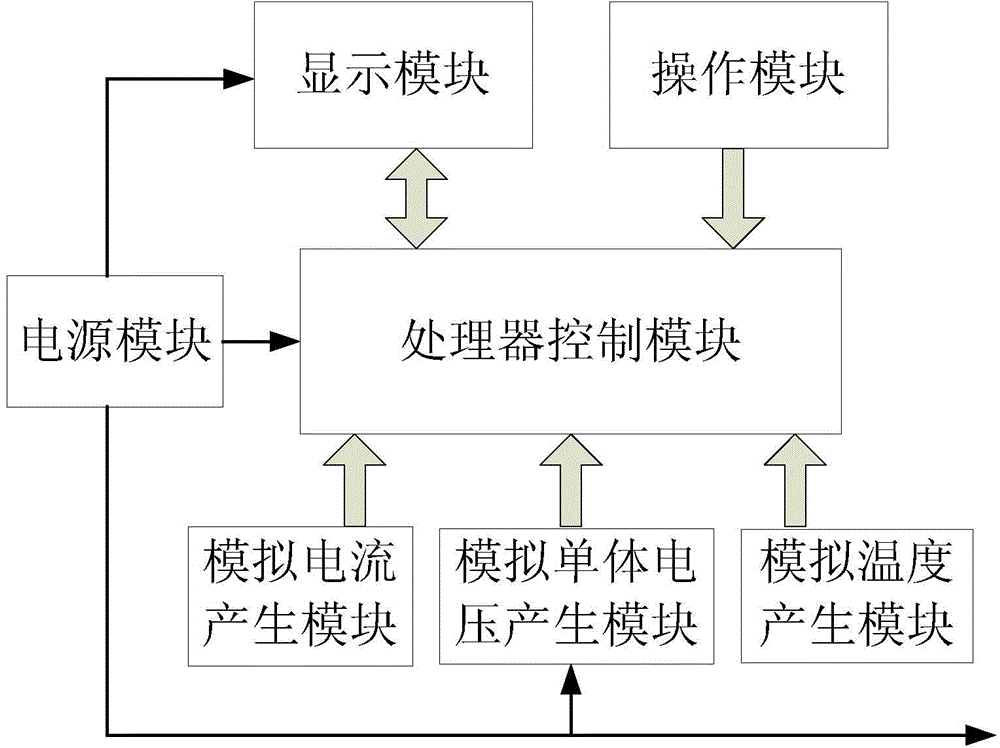

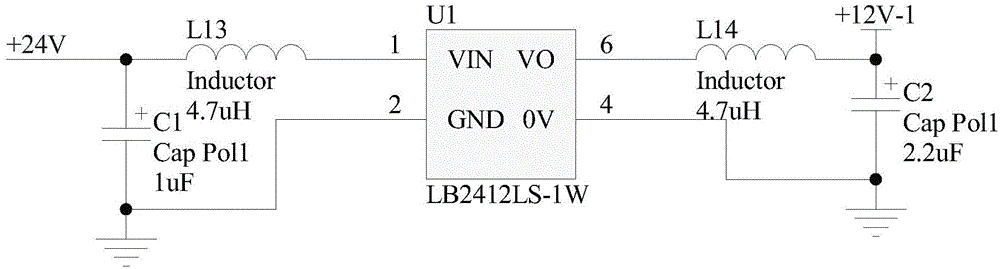

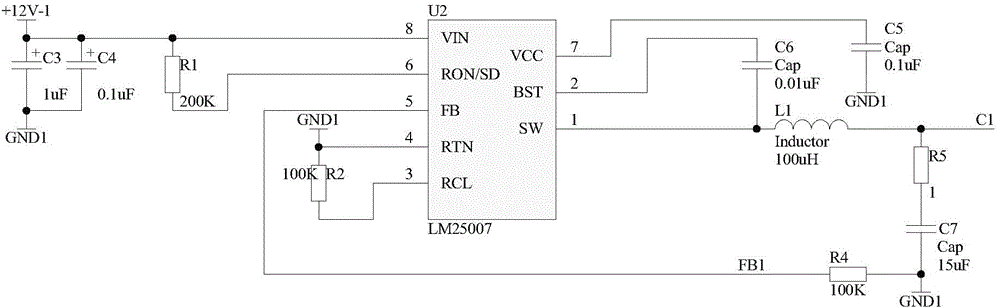

InactiveCN104535867AEasy to identifyAvoid electrical interferenceElectrical testingAutomotive batteryElectric cars

The invention discloses a function checking device of an electric car battery management system. The function checking device mainly comprises a power source module, a simulation monomer voltage generation module, a simulation temperature generation module, a simulation current generation module, a processor control module, an operation module and a display module, wherein the power source module, the simulation monomer voltage generation module, the simulation temperature generation module, the operation module and the display module are connected with the processor control module. The function checking device can conveniently, easily and rapidly detect the electric car battery management system, high quality and high efficiency of production of the battery management system are ensured, and meanwhile a channel is provided for software and hardware debugging of research and development products of the battery management system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

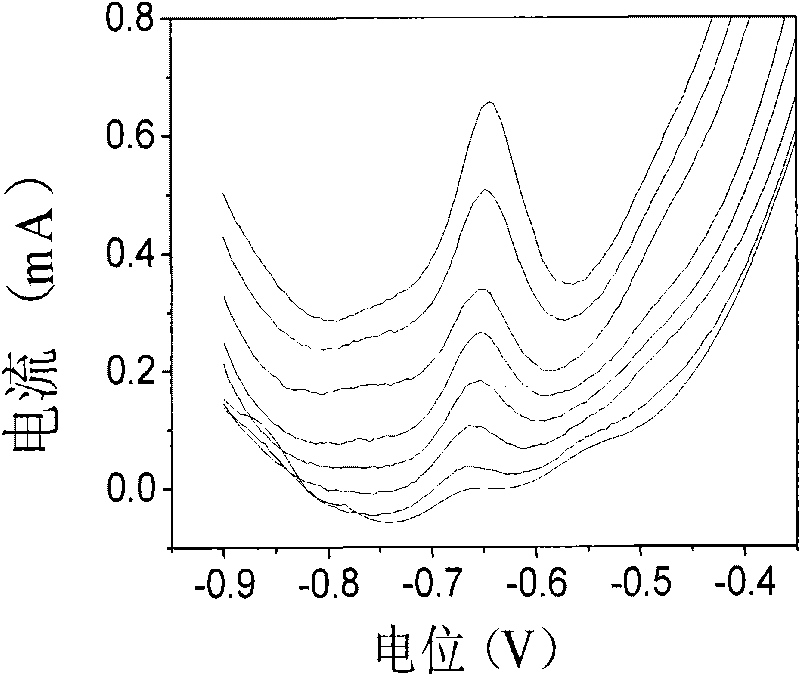

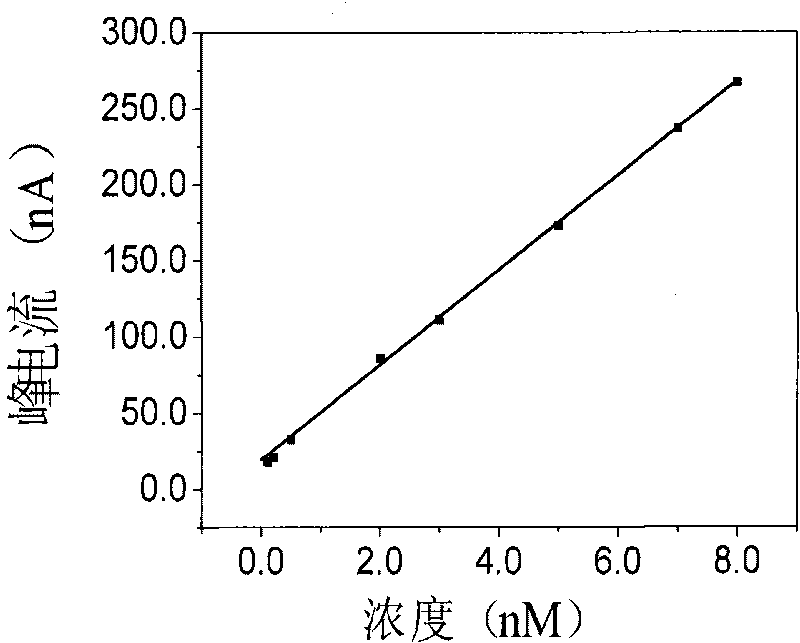

Preparation of bismuth membrane electrode

InactiveCN101706468AEasy to makeHigh sensitivityMaterial electrochemical variablesSodium acetateUrine sample

The invention relates to an electrode, in particular to a chemically modified bismuth membrane electrode. The bismuth membrane electrode is prepared by the following steps: mixing Nafion and ionophore according to the volume fraction of 1:1-1:1.5, and conducting ultrasound on the mixture for 20-40min to be uniform, then dripping the mixture to the surface of glassy carbon electrode polished cleanly, drying the mixture at room temperature, subsequently hardening the mixture by blowing hot air to the mixture, after the mixture cools to room temperature, putting the glassy carbon electrode to acetic acid-sodium acetate buffer solution which contains 100-1, 500mug / L Bi(III) and has the pH being 4.5, and applying -1.2V electric potential under stirring situation for 180s of deposition and enrichment. The electrode is simple in making, small, exquisite and nimble, wherein the sensitivity is up to 31.38nA / Nm, the detection limit can be up to 4.4 multiplied by 10-11M. The electrode can be used in the application fields such as environmental monitoring, food security and clinical detection and the like with simple operation and short test process, and can also be used for detecting the content of heavy metal in seawater, fresh water, blood, urine samples and vegetables.

Owner:烟台海岸带可持续发展研究所

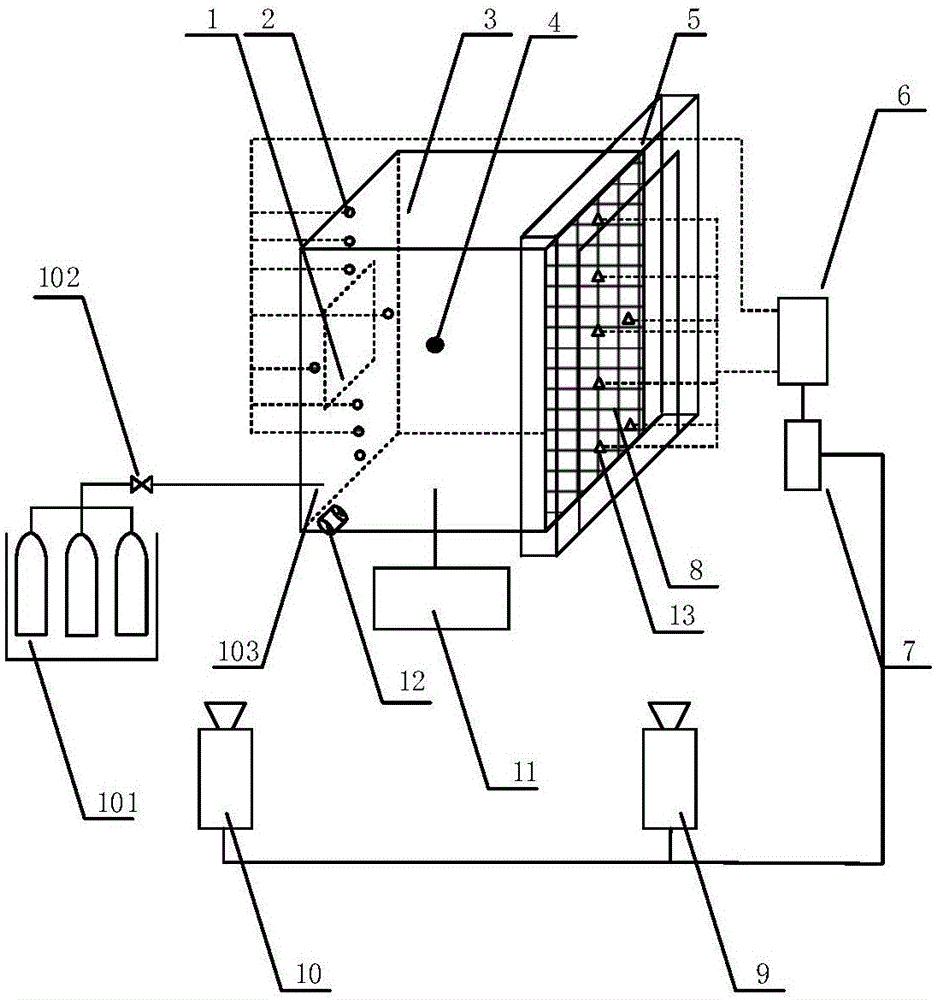

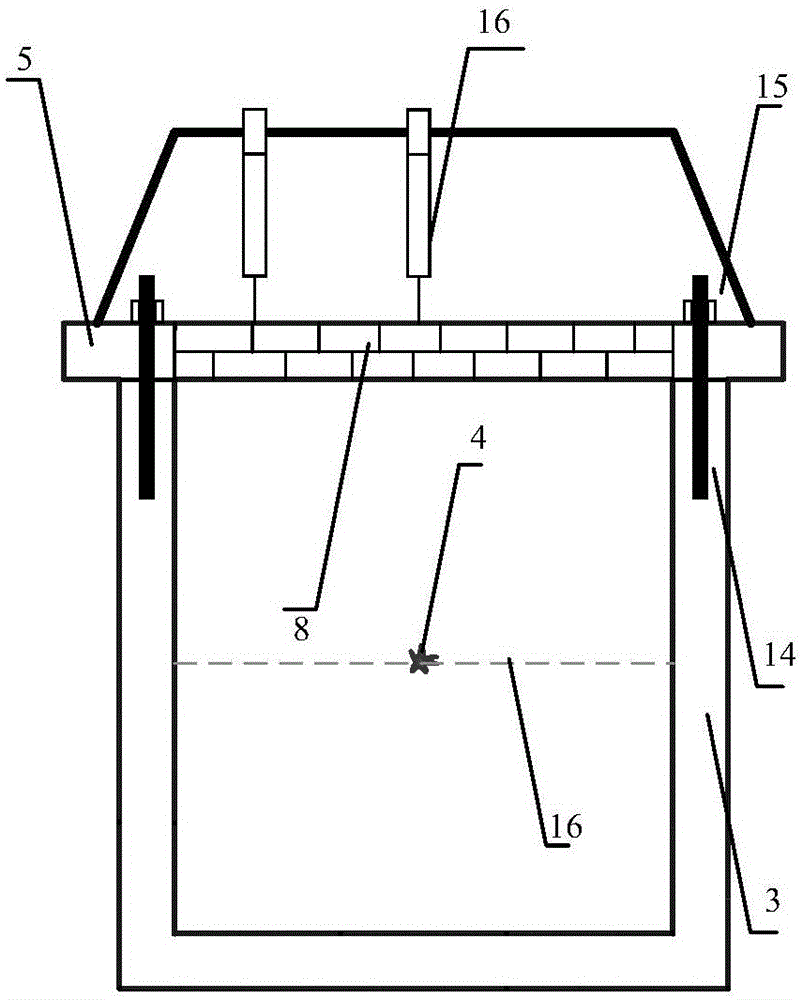

Testing apparatus of dynamic response of filler wall under combustible gas explosion

Disclosed in the invention is a testing apparatus of a dynamic response of a filler wall under combustible gas explosion. The testing apparatus comprises a reinforced concrete room (3) without rear side wall and a reinforced concrete frame (5) fixedly connected to the rear side wall of the room (3). A testing brick wall (8) is prefabricated on the frame (5). An explosion venting hole (1) is formed in a front side wall of the room (3) and is filled with an explosion venting material. A plurality of pressure sensors (2) are arranged at the inner side of the front side wall of the room (3). Besides, a displacement meter (16) is arranged at the outer side of the testing brick wall (8); and the pressure sensors (2) and the displacement meter (16) are in signal connection with a data acquisition unit (6). An igniting head (4) is arranged inside the room (3); and a combustible gas source connected with the room (3) is also arranged outside the room (3). According to the testing apparatus, a real combustible gas explosion load can be used for loading the filler wall.

Owner:PLA UNIV OF SCI & TECH

Residual stress measurement system through hole-drilling method

The invention discloses a residual stress measurement system through a hole-drilling method, and belongs to the technical field of material processing and experimental stress analysis. The system comprises two parts: a drilling device and stress calculation software. The drilling device is formed by a speed-adjustable electric hand drill, a tool microscope, a drill rod, a guide cylinder and a magnetic support base and the like; and the calculation software is programmed through C language, and can give residual stress in an assigned direction, or principal stress and included angle in real time. Since a drilling guide device adopts an embedded ball bearing mode, an rotary friction effect of the drill rod is totally prevented; since the support adopts permanent magnetic bases and lock nuts each having a breach, site positioning and fillet weld stress measurement are realized greatly; and since the calculation program takes features of change of hole edge plastic deformation and processing strain with the stress value into consideration, a stress calculation formula of any two vertical directions is given to enable welding residual stress measurement to become much easier and accurate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

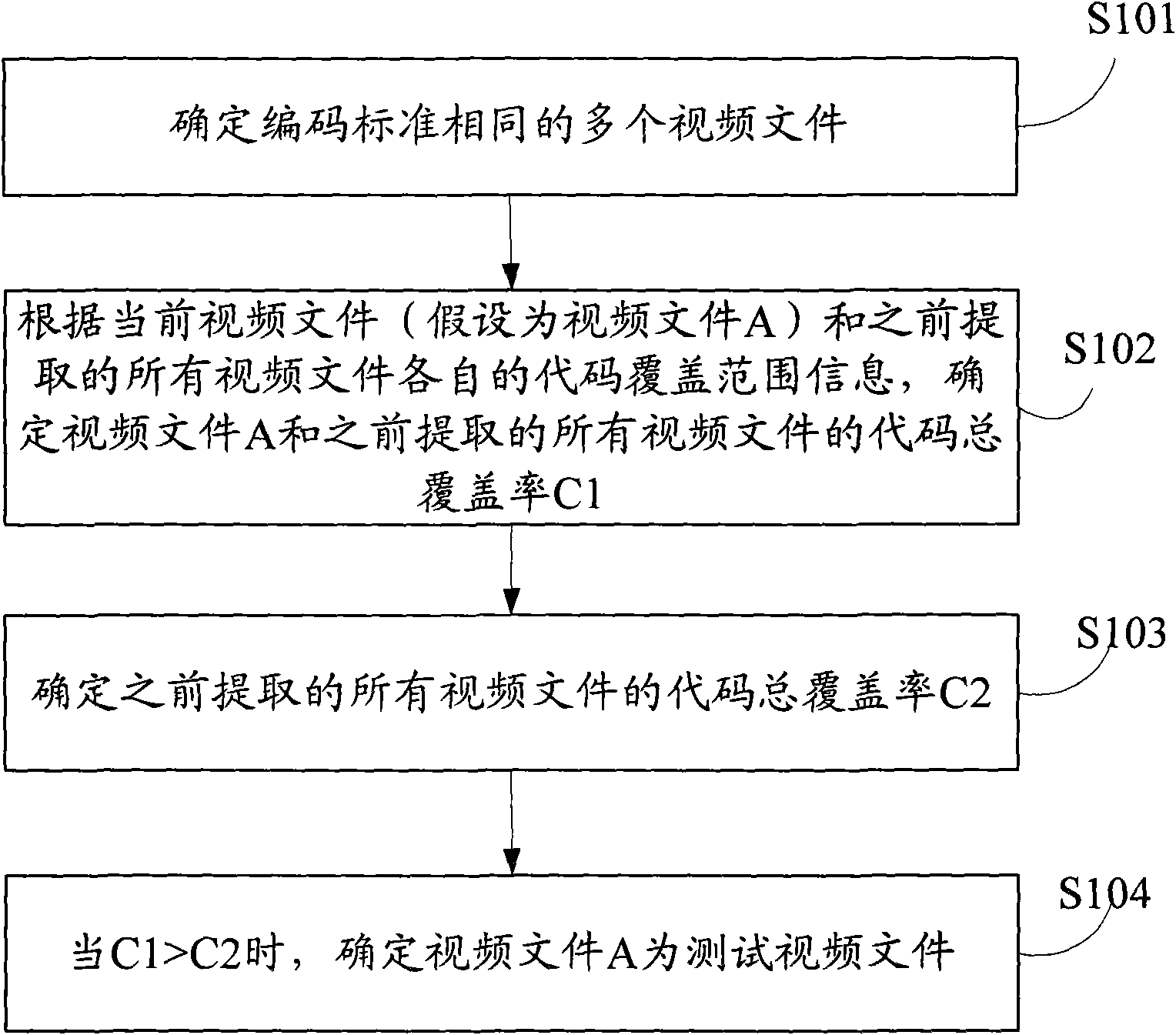

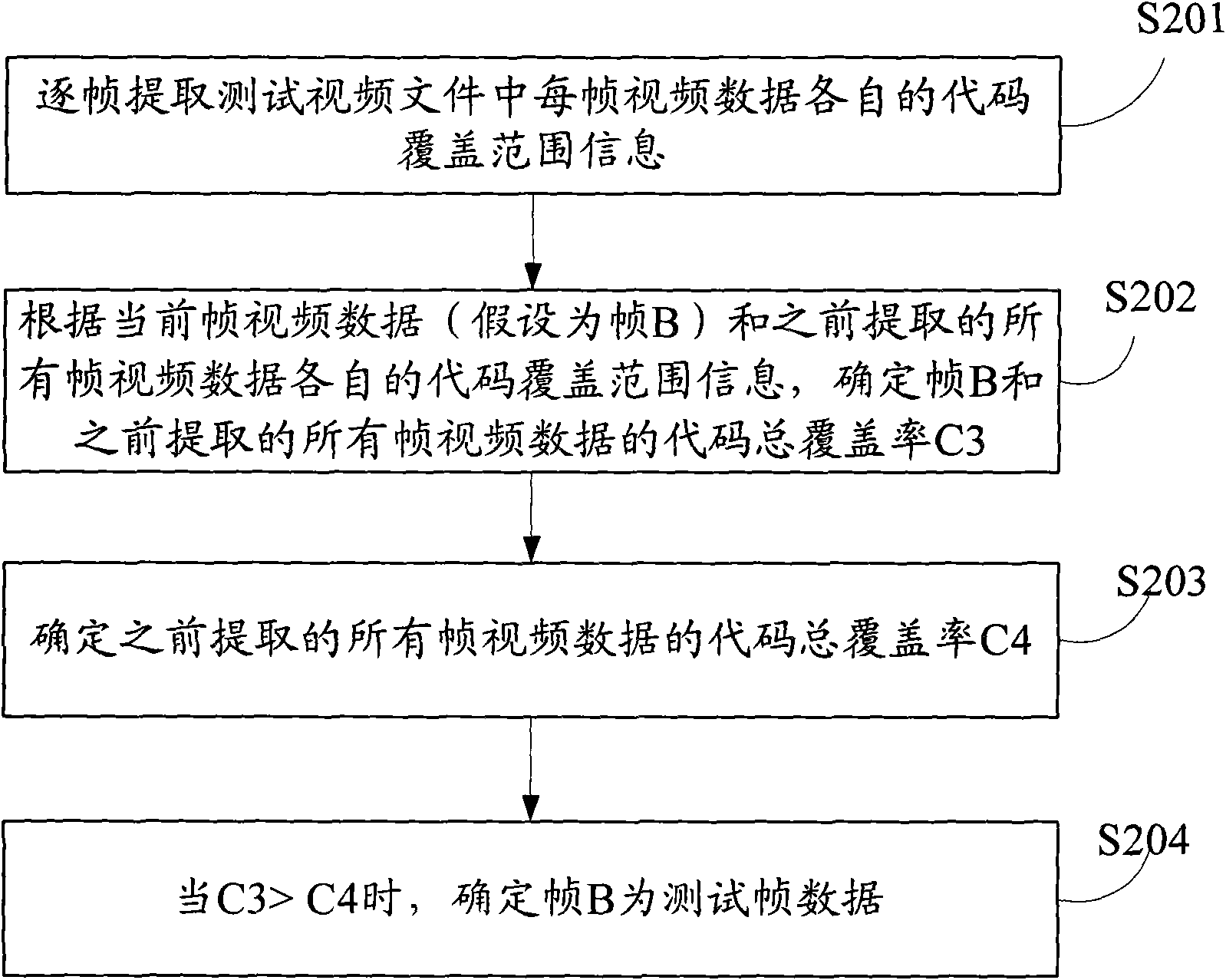

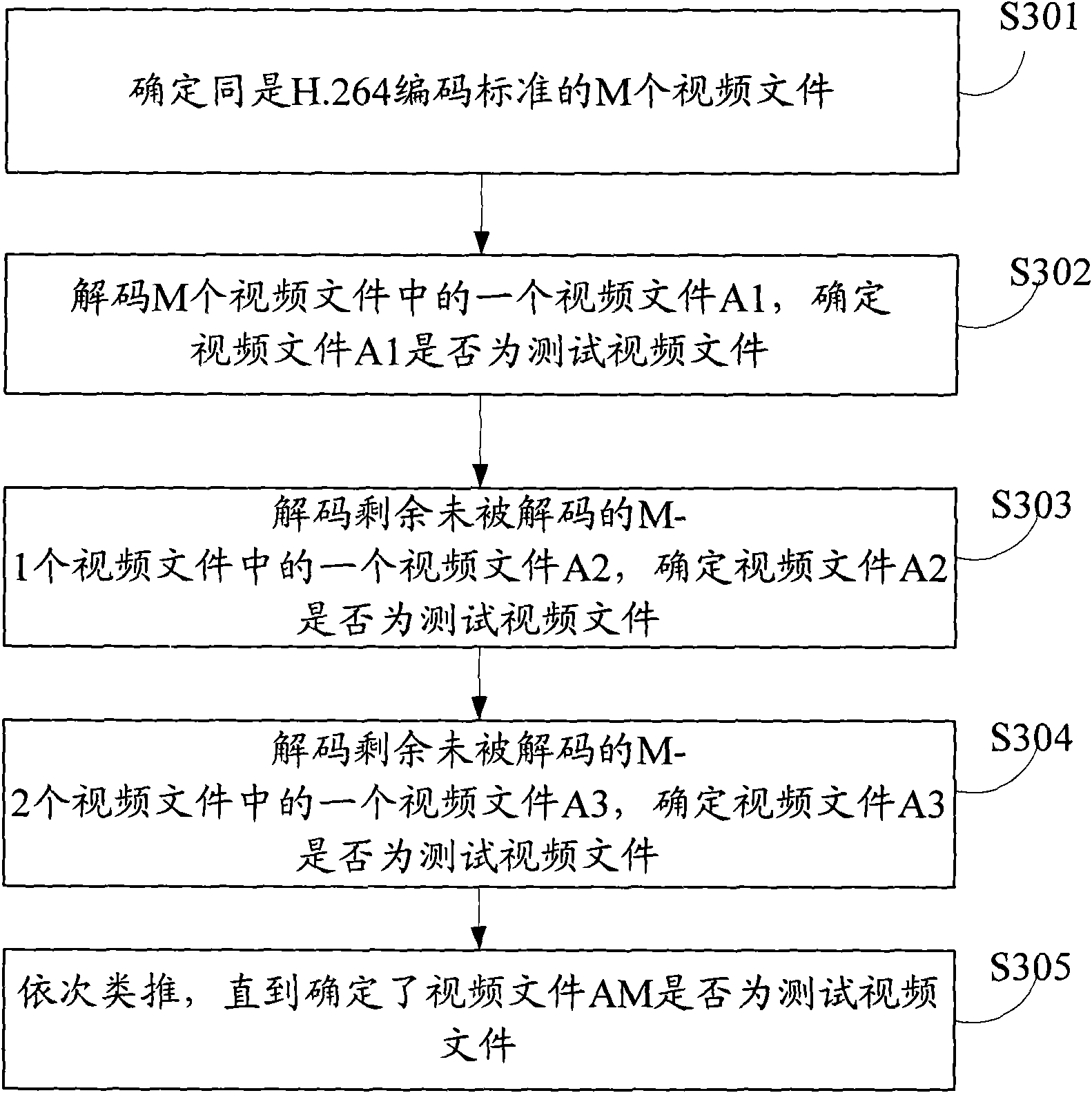

Screening method of video test stream and system thereof

ActiveCN101600125AMeet the decoding performance test requirementsDecoding performance test requirements meetTelevision systemsComputer architectureScreening method

The invention provides a screening method of video test stream and a system thereof, which is used for solving the problems that the existing test methods have lower efficiency and can not ensure to achieve the decoding performance test requirements of video decoder chips. The method comprises the following steps: determining a plurality of video files with the same coding standard; extracting code coverage range information of a plurality of video files one by one, and determining a first code overall coverage rate of a current video file and all previously extracted video files according tothe code coverage range information of the current video file and all previously extracted video files after extracting the code coverage range information of one video file; determining a second code overall coverage rate of all previously extracted video files; determining the current video file to be the test video file when the first code overall coverage rate is greater than the second code overall coverage rate. The technical proposal of the invention reduces the video test stream, accelerates the test process, and ensures to achieve the decoding performance test requirements of video decoder chips.

Owner:南通市崇川科技园投资发展有限公司

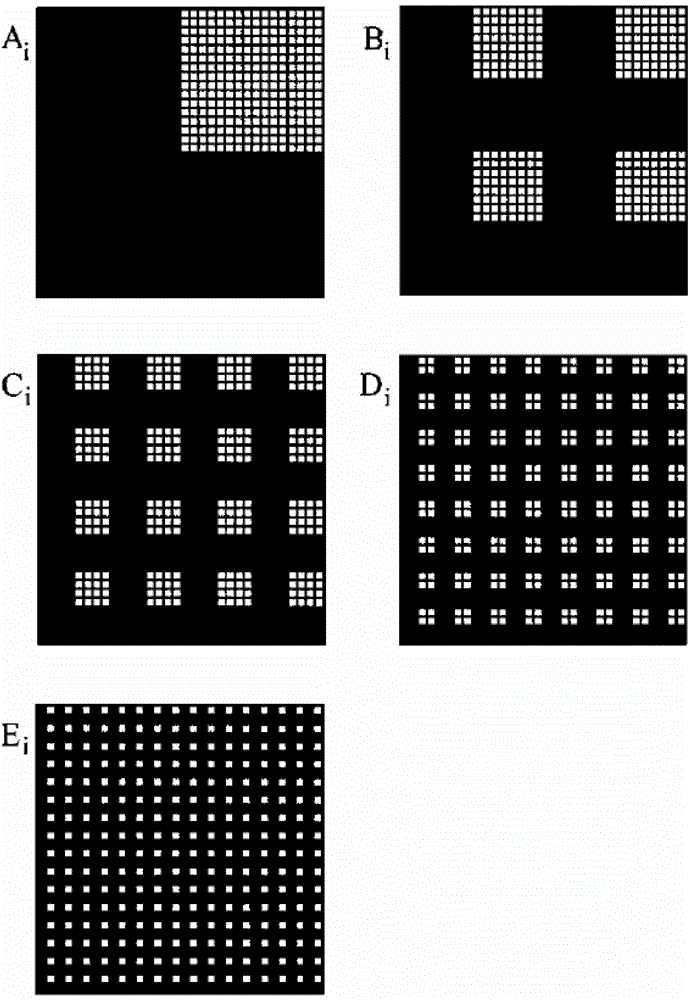

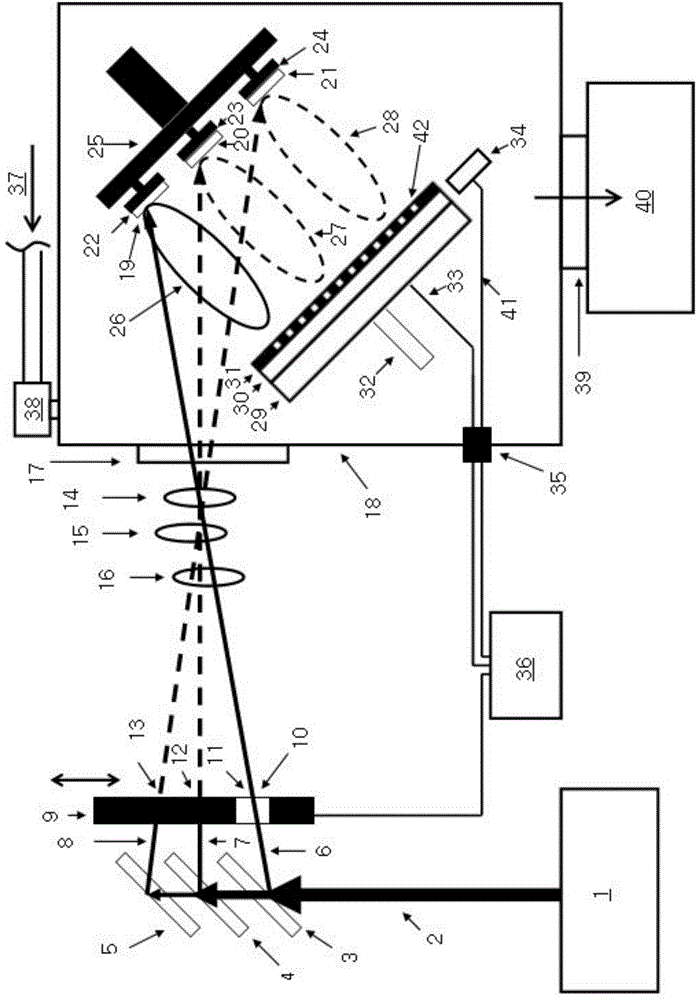

System and method of multi-element pulsed laser deposition for synthesizing composite material in batches

InactiveCN104593732AImprove production efficiencyThe test process is fastVacuum evaporation coatingSputtering coatingSource materialMaterial synthesis

The invention discloses a system and method of multi-element pulsed laser deposition for synthesizing a composite material in batches in the field of materials science. The method comprises the following steps of: using several beams of high energy laser, focusing the high energy laser beams and evaporating different source material targets by the focused high energy laser to generate different laser plasma beams, and finally depositing the source material unevenly on a substrate. The system and the method provided by the invention are simple and easy to use and have the characteristics of low cost, high efficiency, strong coordination and so on. The system and the method can be used for large-batch material synthesis in novel material research.

Owner:SHENZHEN ARRAYED MATERIALS TECH CO LTD

Fipronil immune detecting method

The method includes the following procedures: incubating the diluent of the peridium antigen. Adding a confining liquid and incubating. Mixing the processed specimen with the enzyme-marked antibody and incubating. Taking out the enzyme-marked board, adding the substrate fluid and incubating. Adding sulphuric acid solution to end the reaction. 450mm wavelength, determining the OD value and detecting the fipronil content in the specimen. The invention provides the features of easy of operation, the short detecting procedure. The invention can be utilized in the application and research area such as the environment control, the food industry and pesticide. It is particularly suitable for the grass root and the markets monitors section.

Owner:江苏省农业科学院植物保护研究所

System and method applicable to measuring power conditions in intelligent cold furnace of large-sized boiler

ActiveCN104808013AAccurate measurementAvoid intensityFluid speed measurementMeasurement deviceData acquisition

The invention discloses a system and a method applicable to measuring power conditions in an intelligent cold furnace of a large-sized boiler. The system comprises a burning tangential circle measurement device, a near-wall wind measurement device, an image acquisition system, a data acquisition and processing system and a mobile platform system, wherein the data acquisition and processing system receives all analog signals and digital signals which are acquired by the burning near-wall wind measurement device and the burning tangential circle measurement device, then the signals are sent to a data acquisition instrument, the data acquisition instrument processes signals transmitted by a data acquisition board and then sends the signals to a computer to carry out data processing, and the data acquisition instrument further gives out an instruction to control the mobile platform system to operate. The system disclosed by the invention can show air power conditions in the furnace qualitatively and quantitatively in real time, the whole measurement process does not need any participation of testers after installation and debugging operations are completed, thereby avoiding measurement operations of the testers in a severe environment, reducing the work intensity, and improving the measurement accuracy.

Owner:STATE GRID CORP OF CHINA +1

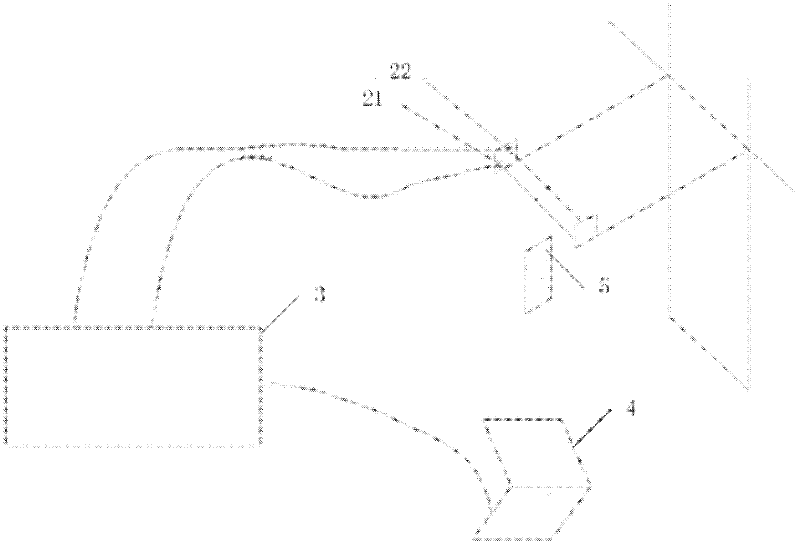

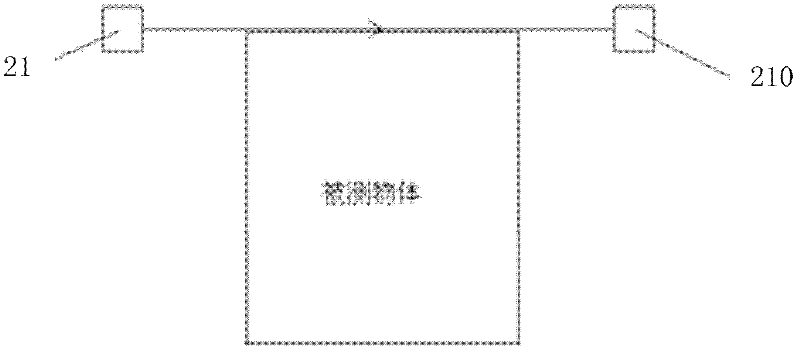

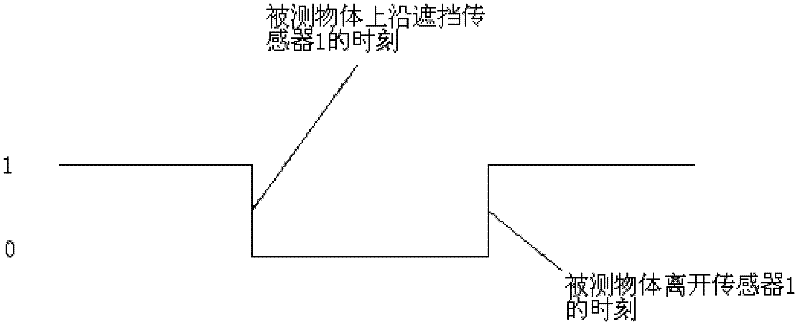

Simple speed measuring device

InactiveCN102539820AReduce testing costsThe test process is fastDevices using time traversedElectromagnetic wave reradiationLight beamEngineering

The invention provides a simple speed measuring device which comprises a first photoelectric sensor, a second photoelectric sensor, a control console and a computer, wherein the computer is connected to the control console; the control console is connected with the first photoelectric sensor and the second photoelectric sensor; light beams of the first photoelectric sensor are parallel to light beams of the second photoelectric sensor; and the light beams of the first photoelectric sensor are vertical to the movement direction of a tested object. The simple speed measuring device has the advantages of reducing the testing cost, accelerating and simplifying testing procedures and can be applied to severe environments.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

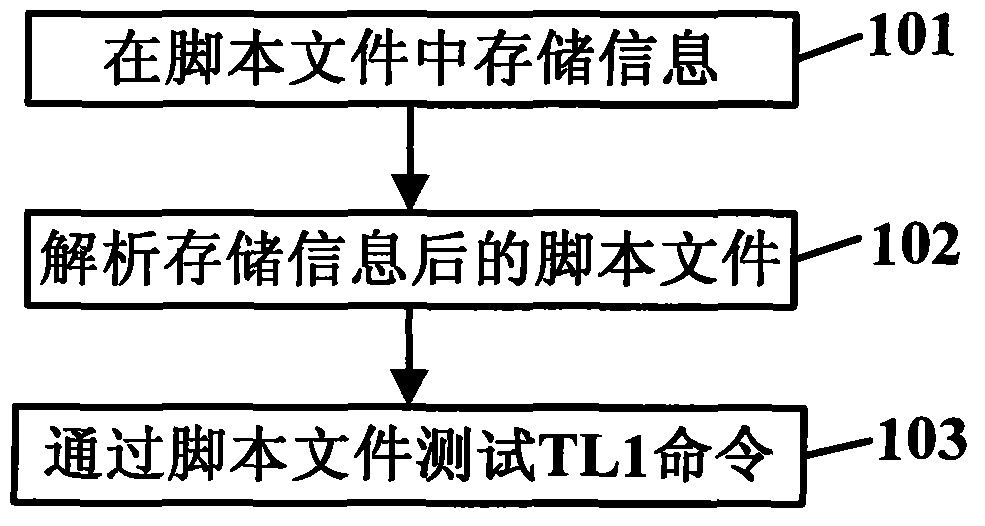

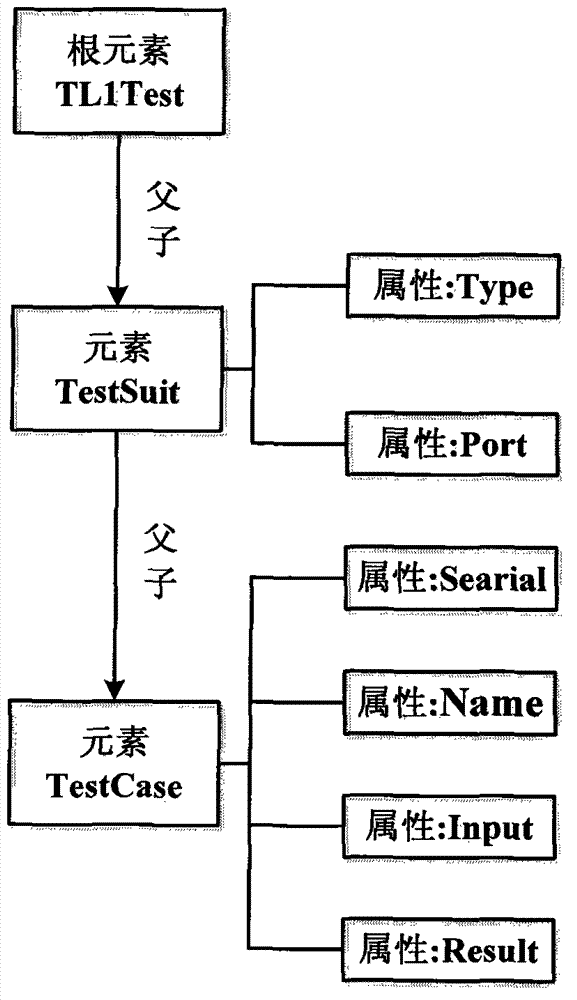

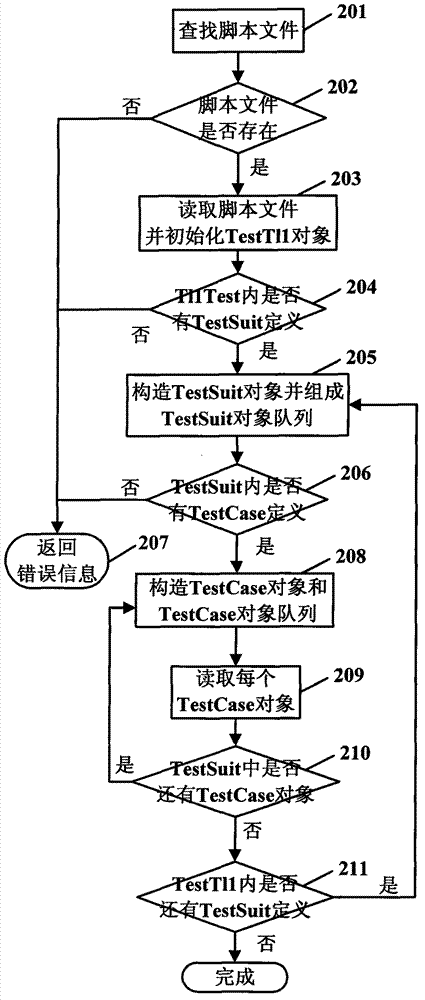

Transaction language-1(TL1) command automatically testing method based on extensible markup language (XML) script

ActiveCN102882737AShorten development timeImprove accuracyHardware monitoringData switching networksTest scriptSoftware engineering

The invention discloses a transaction language-1 (TL1) command automatically testing method based on an extensible markup language (XML) script, and relates to the field of TL1 command testing. The method comprises the following steps of: (A), storing test script entity information, test module information and test item information in an XML-format script file; (B), resolving the stored script file; and (C), testing a TL1 command by using the resolved script file, and judging whether the TL1 command is successfully transmitted. By the method, whether the TL1 command is successfully transmitted can be automatically tested by using the XML-format script file, the testing time is reduced, the work efficiency is improved and the research and development time of communication equipment is reduced.

Owner:WUHAN FIBERHOME TECHNICAL SERVICES CO LTD

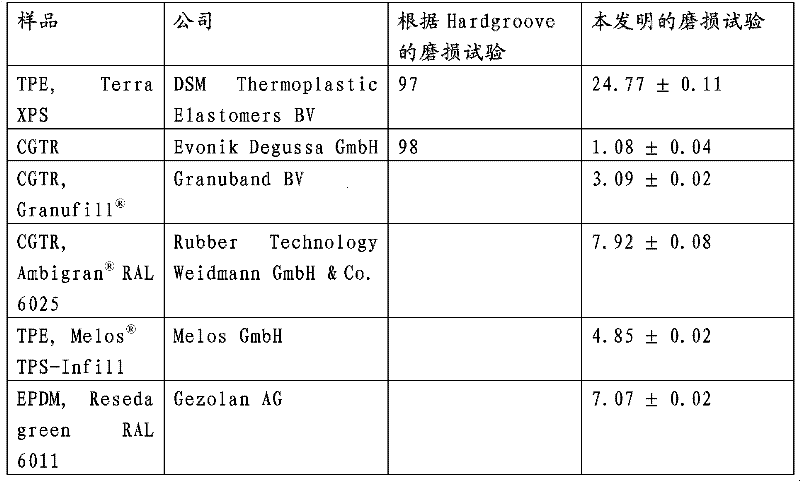

Rapid Wear Test of Granules

InactiveCN102272573AAccurate assessmentEasy to measureInvestigating abrasion/wear resistanceWear particleMaterials science

The present invention discloses a rapid test for determining particle attrition in which i) a particle is ground, ii) a sieve analysis is performed on the ground product, and iii) the result of the sieve analysis is compared to at least one reference value A comparison was made to classify the particle attrition where the particle was ground in a cutting mill.

Owner:EVONIK DEGUSSA GMBH

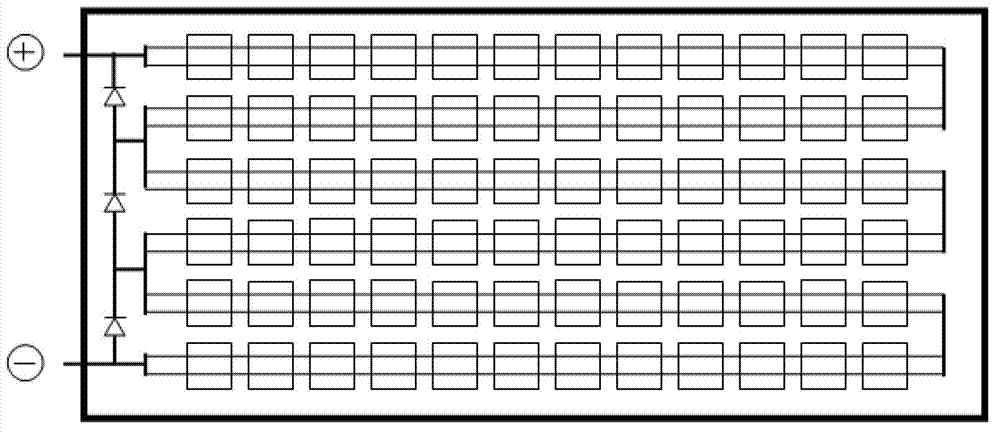

Battery pick-out equipment for hot-spot test of photovoltaic components

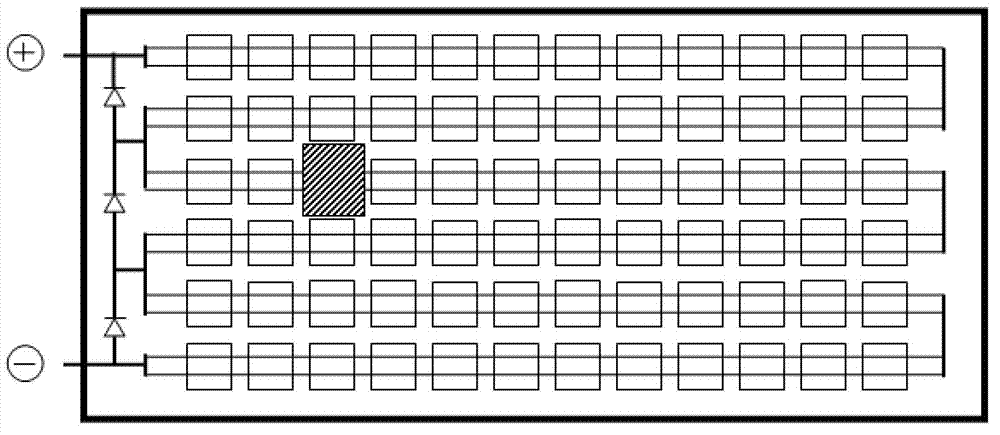

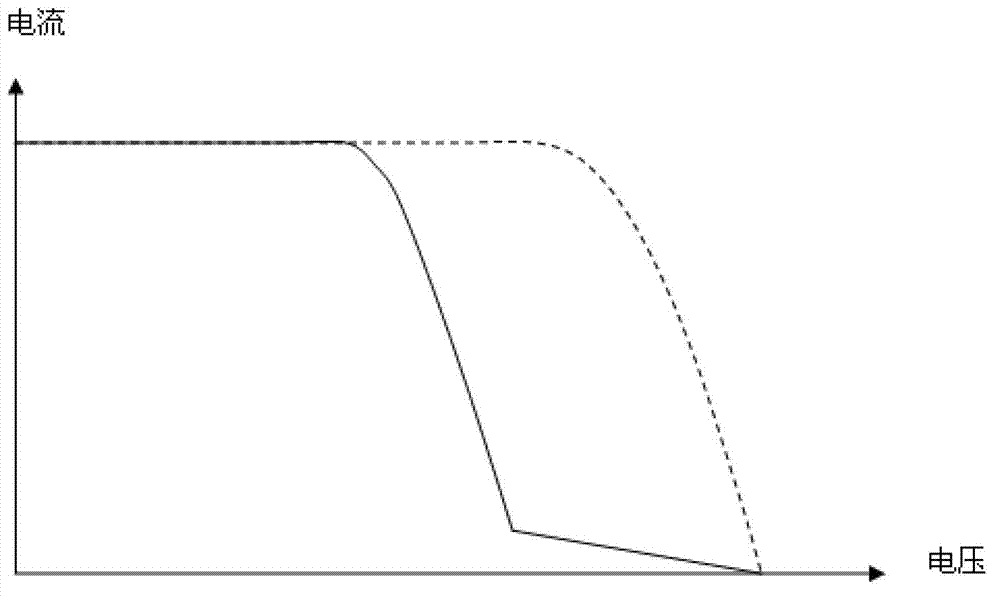

ActiveCN102928762ARealize full inspectionImprove tolerancePhotovoltaic monitoringPhotovoltaic energy generationData acquisitionEngineering

The invention relates to battery pick-out equipment for a hot-spot test of photovoltaic components. The battery pick-out equipment comprises a machine frame and is characterized in that baffle guide rails and photovoltaic component guide rails are mounted on a machine frame, a photovoltaic component support frame is mounted on the photovoltaic component guide rails and can move along the photovoltaic component guide rails; steady-state light sources and a plurality of light sources in array distribution are mounted on the machine frame above the photovoltaic component support frame; one or more group of baffle components are mounted between the steady-state light sources and the photovoltaic component support frame; the baffle components comprise baffle supports of which the two ends are arranged on the baffle guide rails, and the baffle supports can move along the baffle guide rails; a plurality of baffles capable of shielding the steady-state light sources are arranged on the baffle supports; a space for placing photovoltaic components is formed between the baffles and the photovoltaic component support frame; and a data acquisition circuit is mounted at one end of the machine frame. The battery pick-out equipment only requires measurement of the reverse dark-state leakage current of batteries, and can achieve multi-way monitoring at the same time, thereby greatly speeding up the test.

Owner:WUXI INSPECTION TESTING & CERTIFICATION INST

Drilling hole transverse perforation device of rock destruction characteristic and ground stress parameter measurement

InactiveCN101864944ASimple and fast operationShort timeSurveyStrength propertiesEngineeringScrew thread

The invention discloses a drilling hole transverse perforation device of rock destruction characteristics and ground stress parameter measurement. A cavity is a hollow opening cylinder body, a pressurizing hole, a return pressure hole and a wiring groove are arranged in the cavity, a movable lug is fixed in the cavity through a return pressure pad, a digital displacement sensor is also fixed in the cavity, a pad plate is fixed on the upper parts of the movable lug and the digital displacement sensor through screw threads, a plurality of cone heads with different curvatures are fixed on the pad plate through screws, and a pressure bearing plate is fixed on the cavity through screws. Firstly, an oil pressure pump is used for pressurization through the pressurizing hole, the pressure is relieved through the return pressure hole after the experiment is completed, and the digital displacement sensor transmits the displacement data of the movable lug into a receiver through a data line arranged in the wiring groove. The device has the advantages of convenient use, low cost, precision and high speed. The invention uses ordinary engineering drilling holes, and breaks through the stress area limitation of the Good man jack, so the tested rock is destructed, and the intensity, the deformation destruction parameters and the ground stress parameters of the rock with different depth in weathering zones can be measured.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

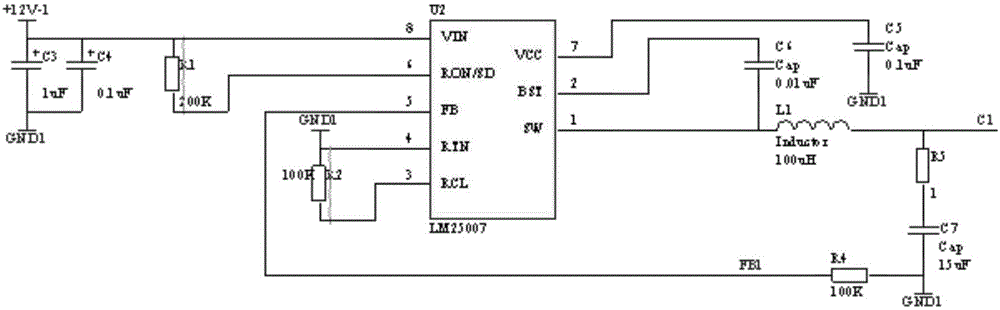

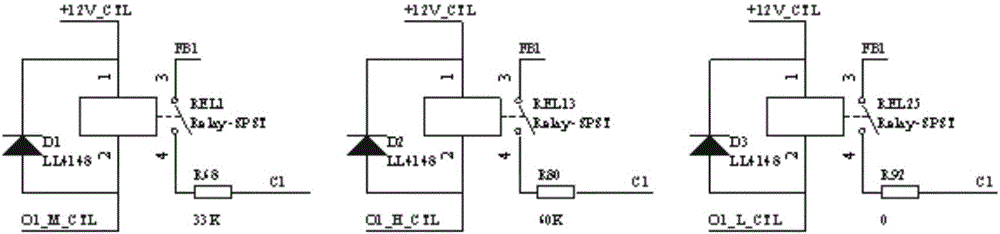

Function verifying device of electric vehicle cell management system

InactiveCN106199436AEasy to identifyAvoid electrical interferenceElectrical testingAutomotive batteryElectric vehicle

The invention discloses a function verifying device of an electric vehicle cell management system. The device mainly comprises a power supply module, a simulation single body voltage generation module, a simulation temperature generation module, a simulation current generation module, a processor control module, an operation module and a display module. The power supply module, a simulation cell voltage generation module, the simulation temperature generation module, the operation module and the display module are connected to the processor control module. The device can conveniently, simply and rapidly detect the electric vehicle cell management system, the high quality and high efficiency of BMS cell management system production is ensured, and at the same time, a channel is provided for the software and hardware debugging of a BMS research and development product.

Owner:ANHUI CHANGCHENG TRANSPORTATION MACHINERY MFG

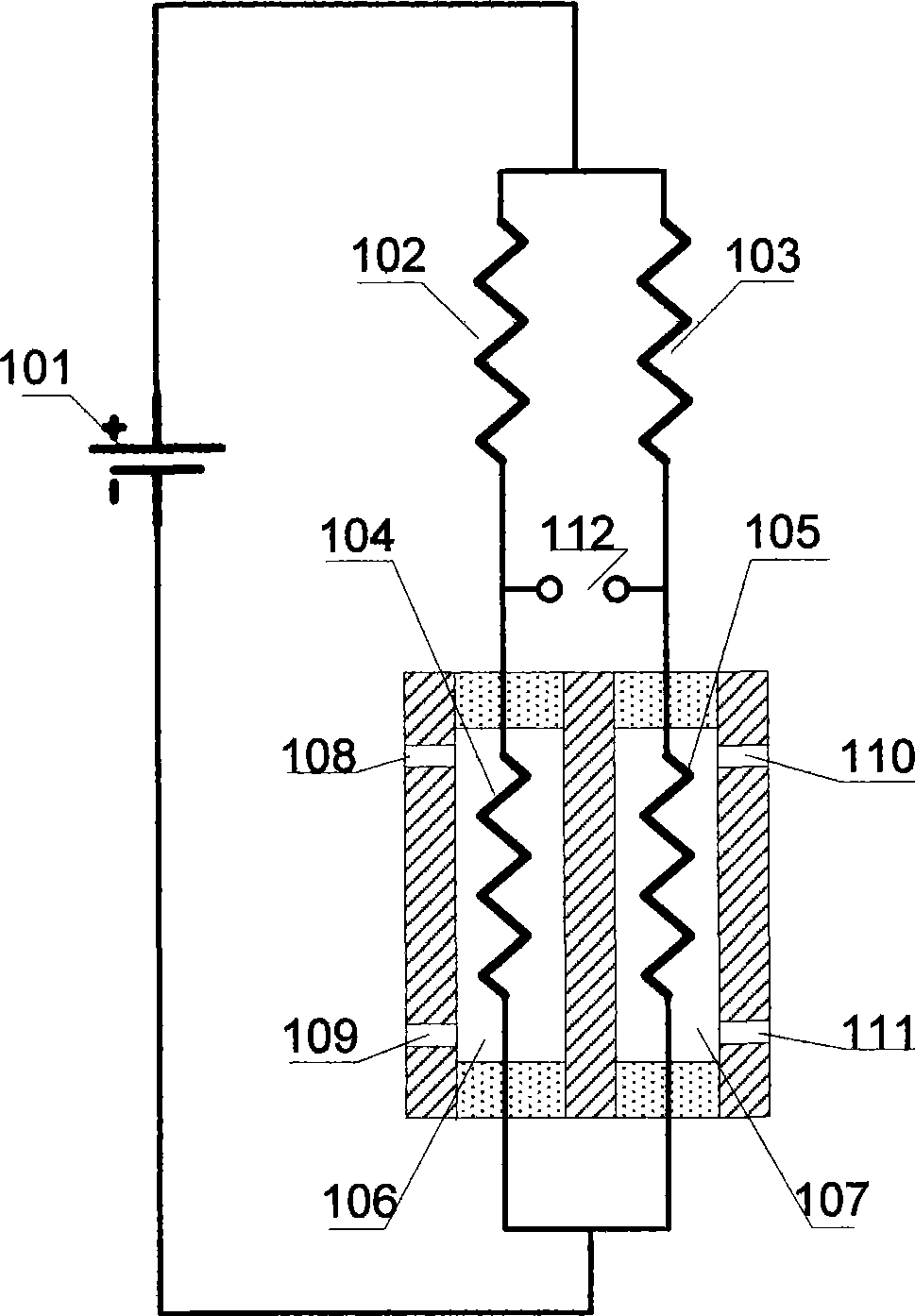

Electrochemical accelerated concrete hydration product corrosion measurement device

InactiveCN105548319AEasy to measure performance impactImprove sealingMaterial analysis by electric/magnetic meansMeasurement deviceDissolution

The invention relates to an electrochemical accelerated concrete hydration product corrosion measurement device, and mainly solves the problems of slow experiment process and restricted adaptability of existing technologies in measurement of concrete hydration product dissolution. The device comprises a cathode cylindrical test area, an anode cylindrical test area, a cathode end square base, an anode end square base, a cathode plate, an anode plate, nuts, screw rods, a test piece fixed area, wiring terminals and circular vent holes. The device provided by the invention has the advantages of simple structure, reasonable design, wide measurement range, wide application range, good adaptability and good durability. At the same time, test pieces of different shapes can be obtained by changing the shape of a test piece groove, thus being convenient for measuring the coupling effect of other factors and dissolution on concrete performance. The device provided by the invention can be applied to the concrete hydration product corrosion measurement field.

Owner:HARBIN INST OF TECH

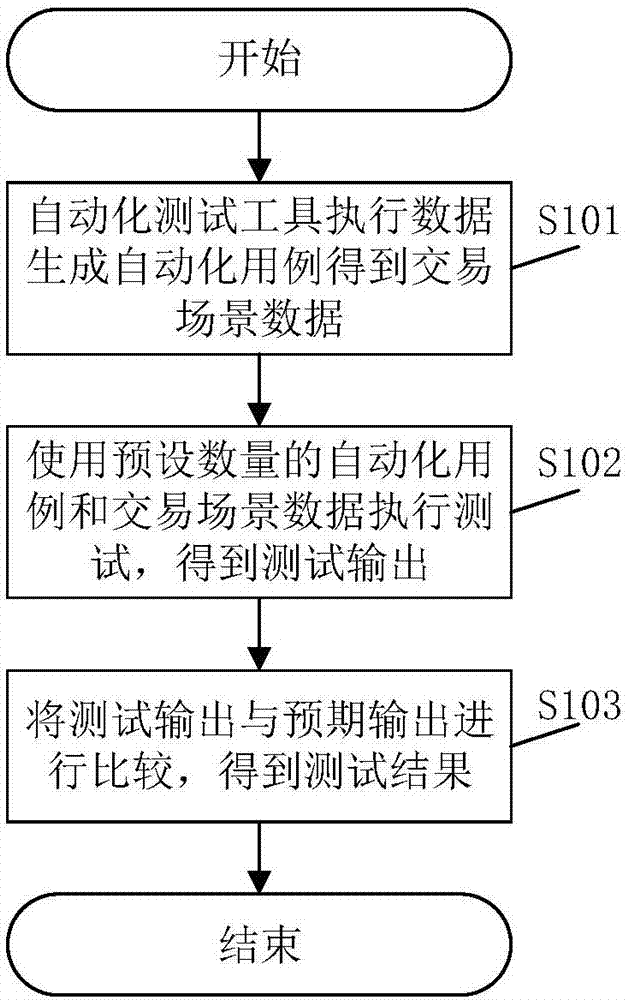

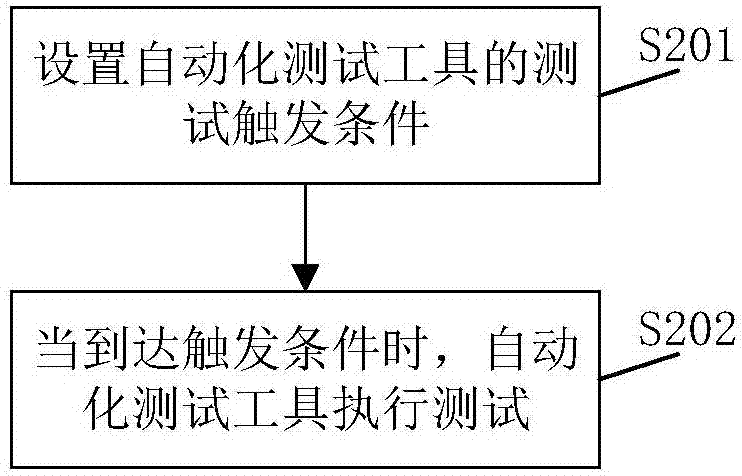

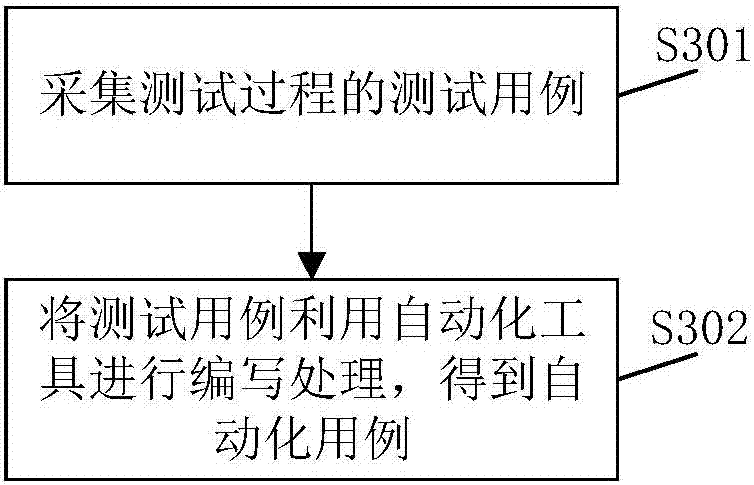

Software testing method and software testing system

InactiveCN107368428AThe test process is fastImprove test efficiencySoftware testing/debuggingData preparationSoftware testing

The application discloses a software testing method. The software testing method comprises the following steps that an automation testing tool executes data-generation automation cases to obtain transaction scene data, wherein the data-generation automation cases are written and obtained by the automation tool according the transaction scene data; the automation cases with a preset quantity and the transaction scene data are used for executing test to obtain testing output, wherein the testing process is written by the automation tool to obtain the automation cases; and the testing output is compared with preset output to obtain a testing result. The software testing method disclosed by the invention has the advantages that in testing, multiple groups of scene data are firstly generated by data preparation cases, and the automation cases in a testing scene are tested by corresponding to multiple scene data to achieve the scene-reusing effect and accelerate the testing process, so that the testing efficiency is greatly improved, and the function iteration of fast changes can be better handled. The application also discloses a software testing system with the beneficial effects.

Owner:MASHANG CONSUMER FINANCE CO LTD

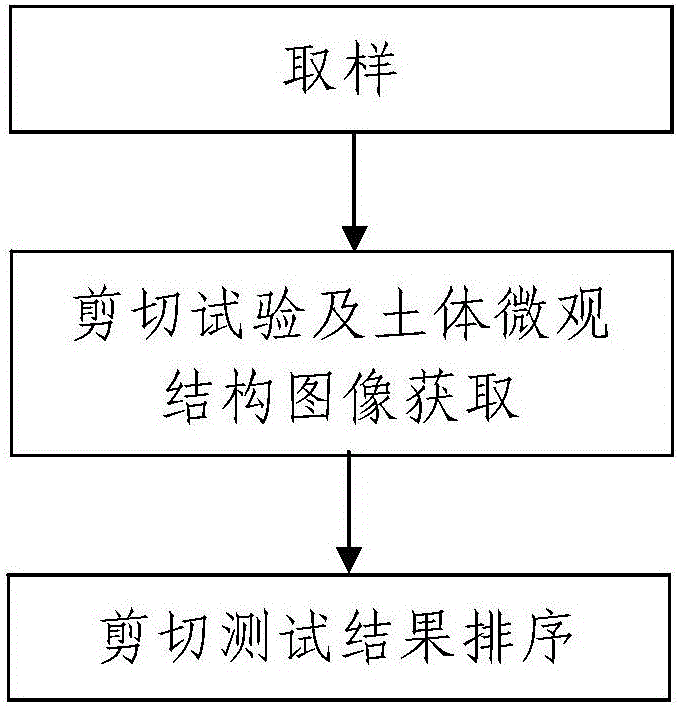

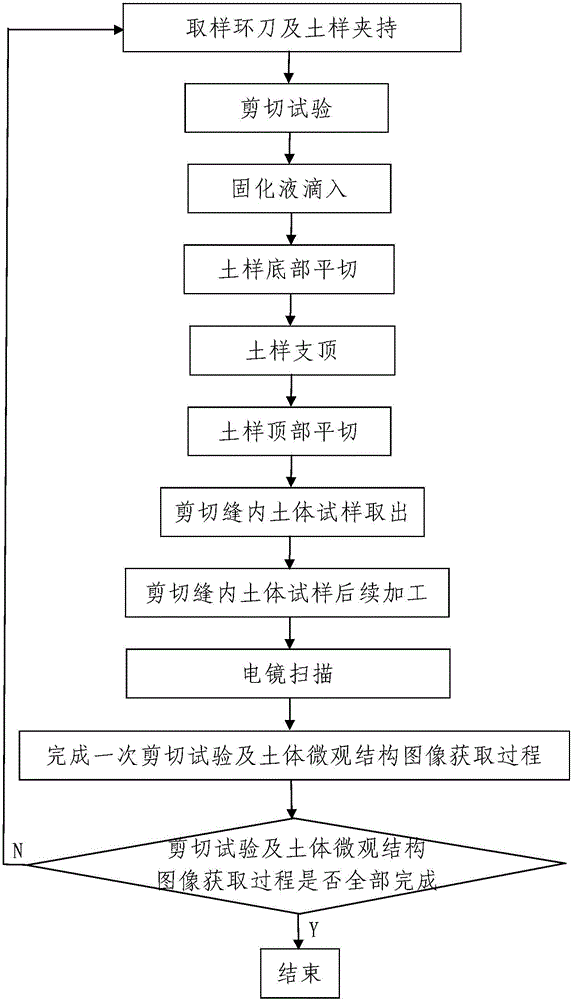

Observation method of soil body shear zone expansive process

ActiveCN106198256AThe method steps are simpleIngenious and reasonable designMaterial strength using steady shearing forcesSoil scienceStructure of the Earth

The invention discloses an observation method of a soil body shear zone expansive process. The observation method includes the steps of: 1) sampling: cutting to-be-tested soil samples from a to-be-tested soil body shear zone at different depths by means of a sampling cutting ring; 2) performing shear test and obtaining soil body micro-structural images, wherein a shear test result of the to-be-tested soil samples from the to-be-tested soil body shear zone at different depths is obtained, and the step 2) includes the processes of: clamping the sampling cutting ring and the soil sample, performing the shear test, dropwise adding a curing liquid, level-cutting the bottom of the soil sample, supporting the soil sample, level-cutting the top of the soil sample, taking the soil sample out from a shear seam, subsequently processing the soil sample in the shear seam, and performing electron microscope scanning; 3) sequencing the shear test result. The method has reasonable design and simple operations, is good in use effects, can easily obtain the shear strength of different depths and the micro-structure of the shear positions of the soil body shear zone so as to perform simple and direct observation of the soil body shear zone expansive process.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com