Rapid Wear Test of Granules

A rapid test, particle technology, applied in the field of particles, to achieve the effect of simple operation

Inactive Publication Date: 2011-12-07

EVONIK DEGUSSA GMBH

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The test is also free for finely divided particles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

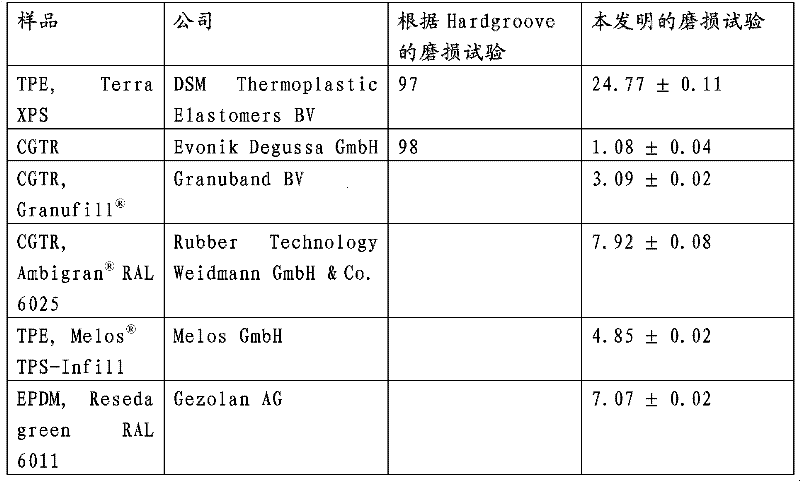

[0110] Multiple samples were tested in the same manner.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

The present invention discloses a rapid test for determining particle attrition in which i) a particle is ground, ii) a sieve analysis is performed on the ground product, and iii) the result of the sieve analysis is compared to at least one reference value A comparison was made to classify the particle attrition where the particle was ground in a cutting mill.

Description

technical field [0001] The present invention relates to rapid wear tests of granules, preferably inorganic or organic granules, particularly preferably plastic granules, especially those used as filling materials for artificial turf. Furthermore, the rapid test of the invention enables the determination of the strength and adhesion of layers of material on surfaces or in interlayers of multi-layered particles. Background technique [0002] Plastic pellets are the typical form of supply of thermoplastics from raw material manufacturers to the plastics processing industry. Due to their free-flowing capabilities, they are bulk materials, like sand or gravel, and are therefore relatively easy to transport and further process. [0003] The use of plastic pellets as artificial turf infill material has been discussed in depth recently. For example, European patent application EP 1 416 009 A1 discloses the use of coated rubber particles as a dusting material or loose elastic layer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/56

CPCG01N3/565G01N3/56G01N2203/0284

Inventor M·克鲁兹R·弗茨F·D·库恩

Owner EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com