Patents

Literature

54 results about "Sieve analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil engineering) to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

Inorganic material in particles form

InactiveUS6165510ADoes not affect strengthPowder deliveryCosmetic preparationsInorganic materialsMaterials science

PCT No. PCT / EP97 / 00202 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 30126 PCT Pub. Date Aug. 21, 1997A cosmetic composition includes an inorganic material in granular form which, under condition of use of the cosmetic composition, breaks down to a particle size wherein less than 5% by weight, preferably less than 2% by weight, most preferably less than 1% by weight is above 45 microns, as measured by wet sieve analysis.

Owner:PQ SILICAS UK

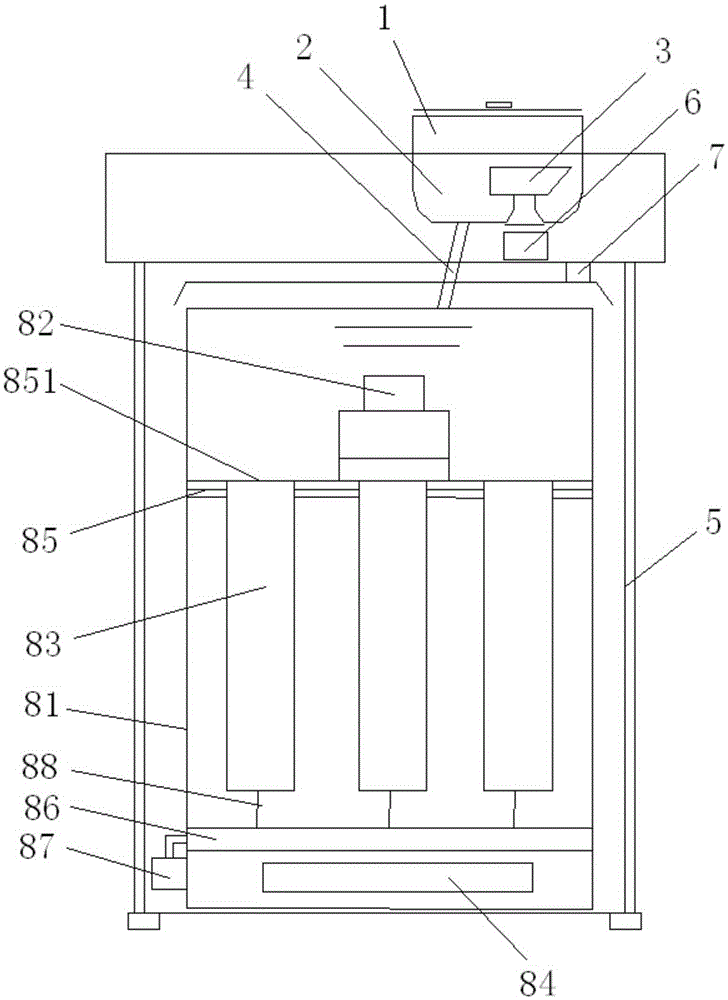

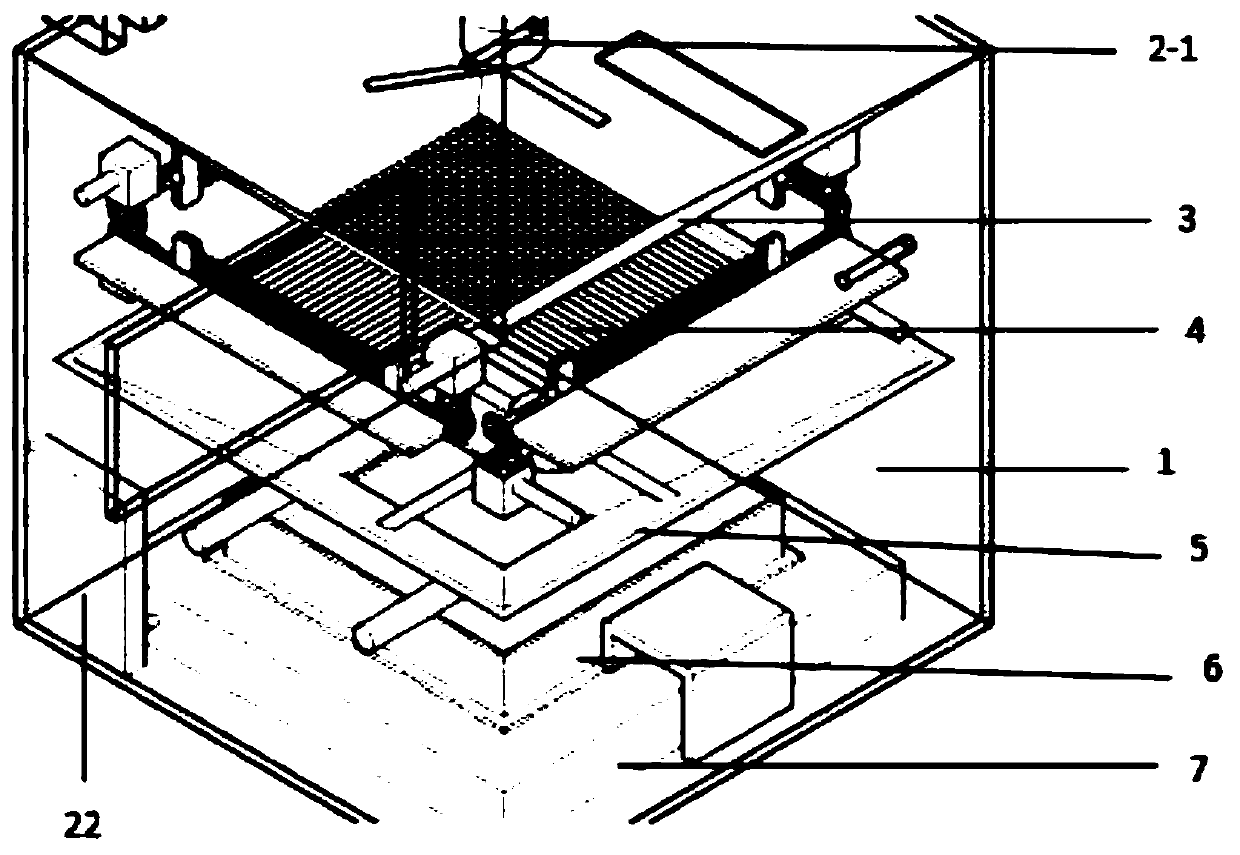

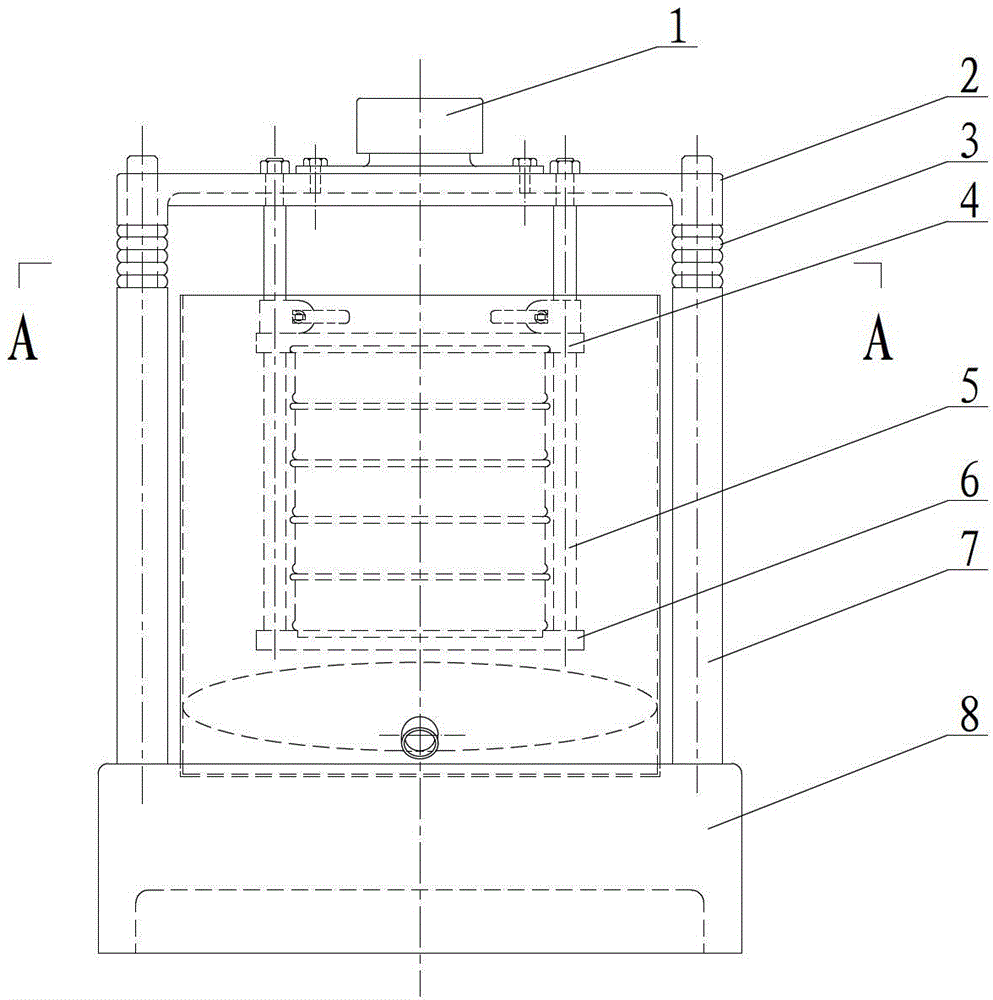

Particle material grading measurement instrument and measurement method thereof

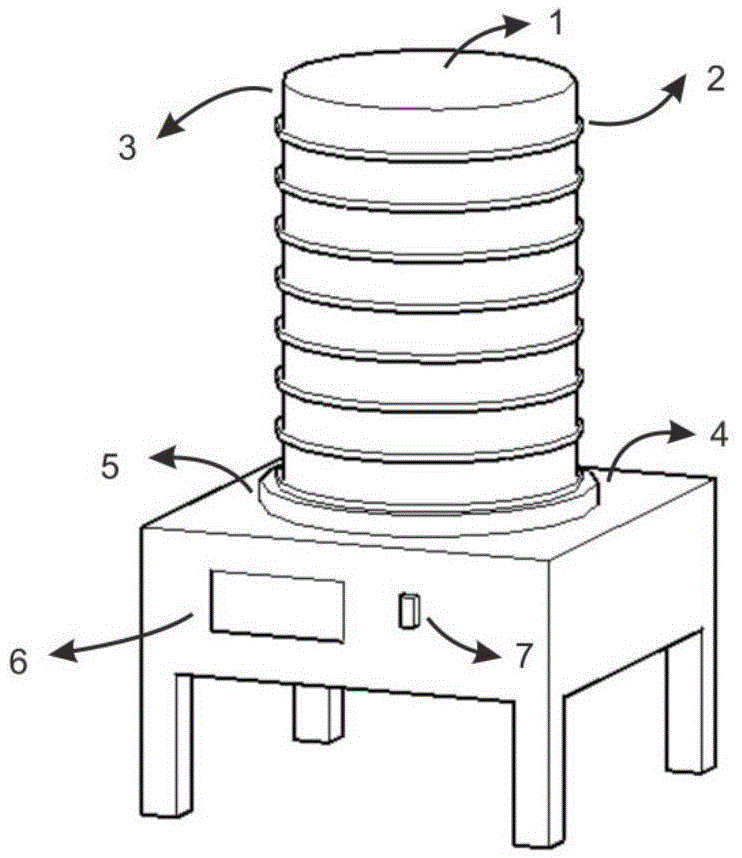

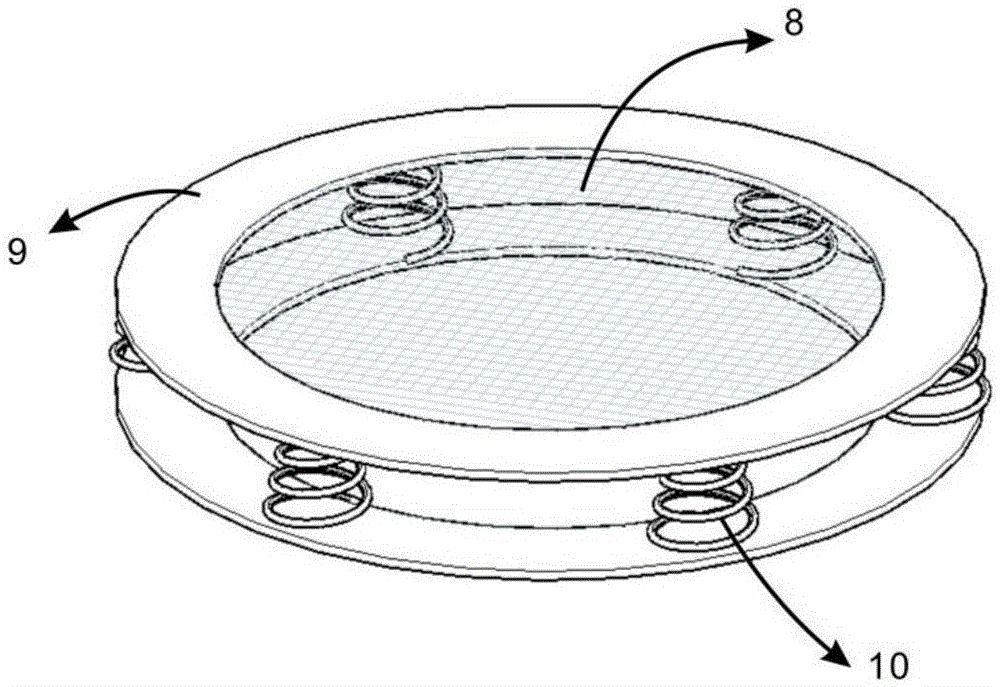

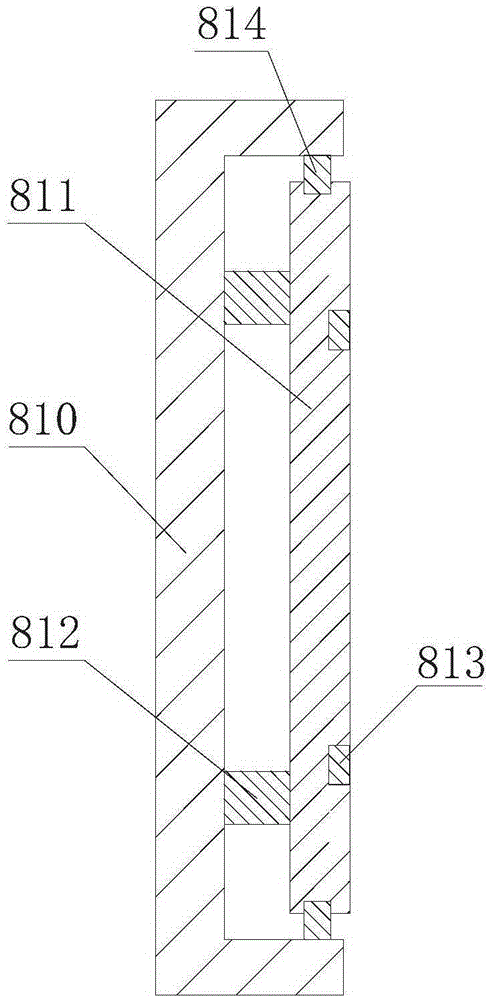

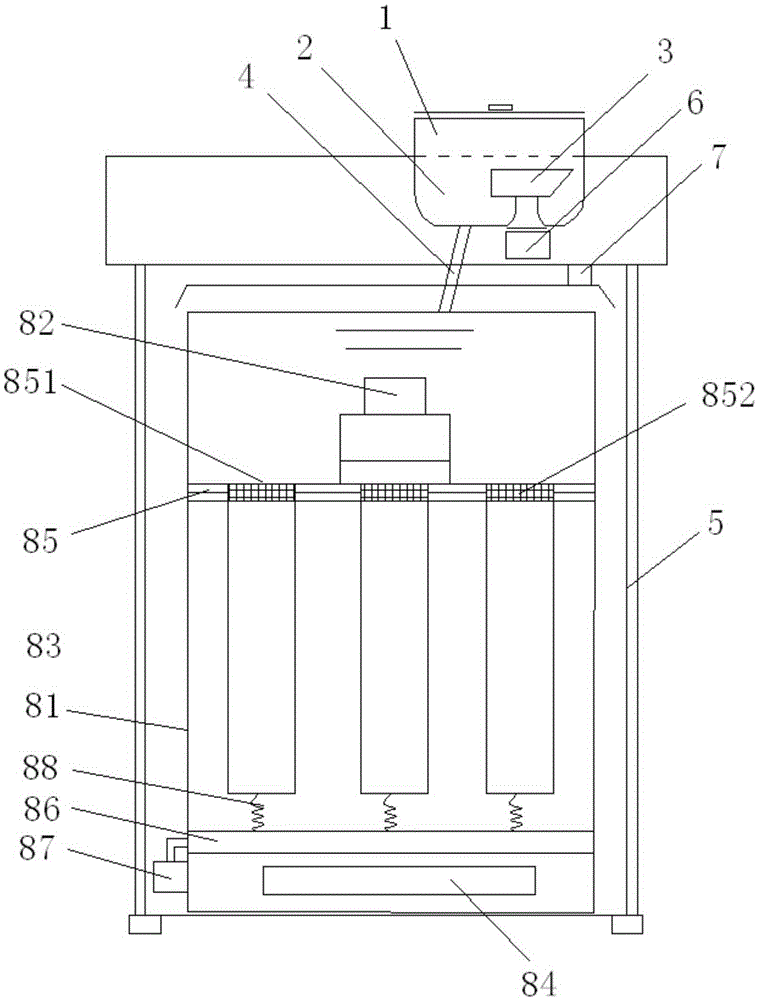

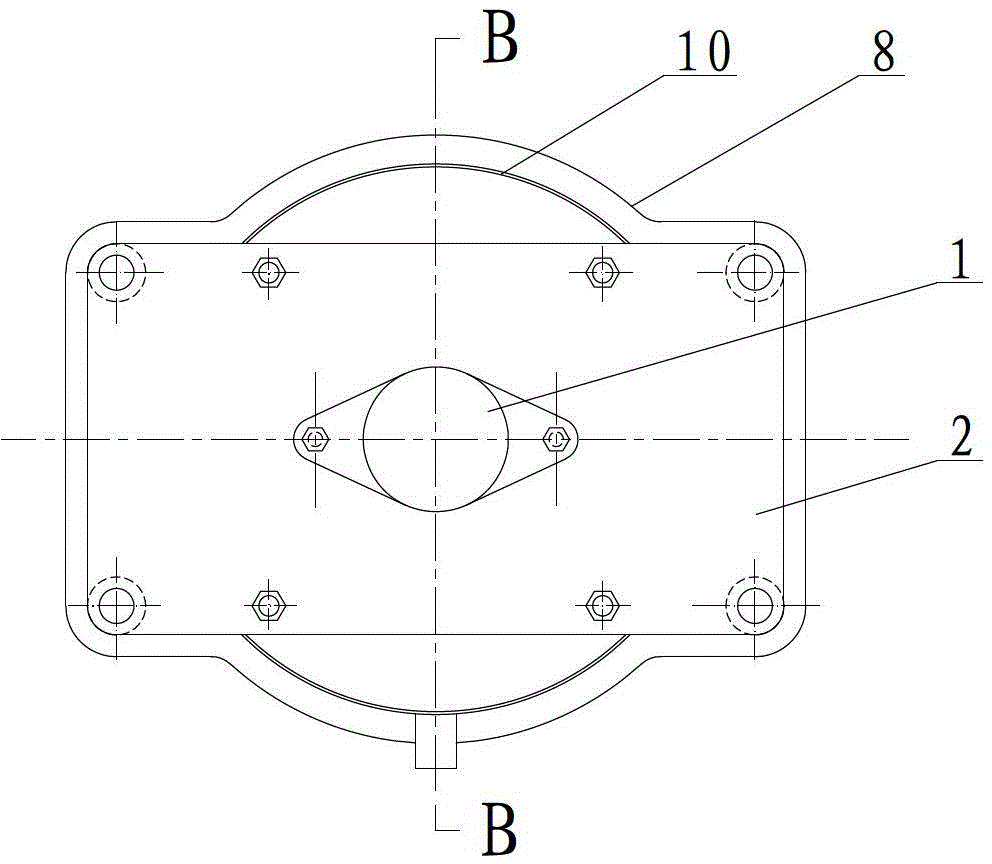

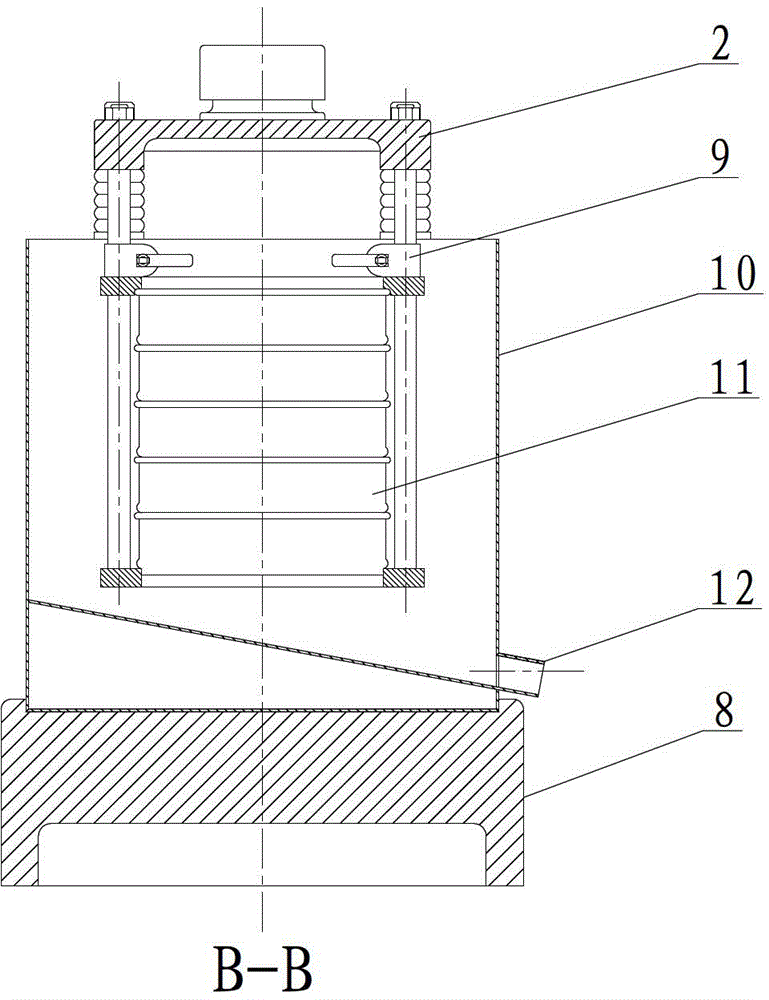

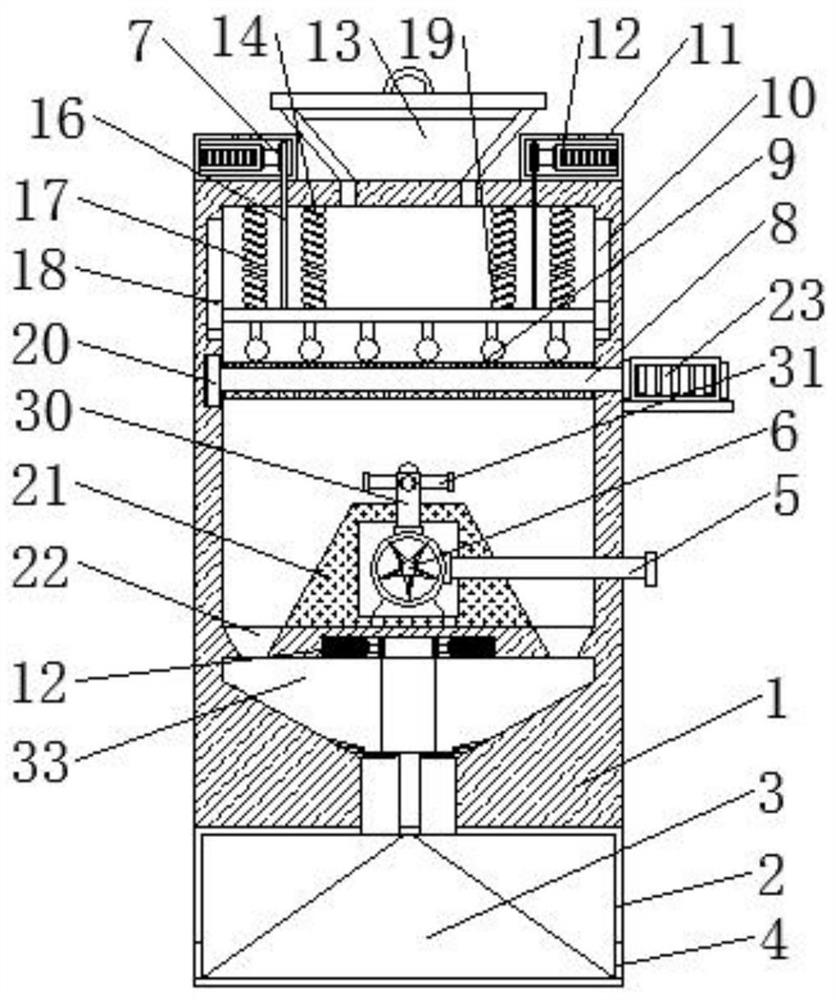

The invention discloses a particle material grading measurement instrument and a measurement method thereof. The particle material grading measurement instrument includes a base, a vibration table, sieve boxes, a sieve box cover, weight measurement units, a touch screen and a switch; the vibration table is arranged on the top of the base; the number of the sieve boxes is greater than 2, and the sieve boxes are stacked on the top of the vibration table from top to bottom; the sieve box cover is arranged on the top of the sieve box at the top; the weight measurement units are arranged in the sieve boxes; each weight measurement unit includes a sieve plate, a sensing ring, weight measurement springs, and strain gages, wherein the sensing ring includes an upper annular sheet and a lower annular sheet which are identical, the sieve plate is arranged on an inner ring of the upper annular sheet of the sensing ring; the diameters of sieve holes of the sieve plates of all the sieve boxes are decreasing gradually from top to bottom; the weight measurement springs are connected to the strain gages, the numbers of the weight measurement springs and the strain gages are 3-8, and the weight measurement springs and the strain gages are arranged between the upper annular sheets and the lower annular sheets; and the touch screen and the switch are arranged on a side wall of the base. After the particle material is sieved, the particle material grading measurement instrument can directly measure the mass of the particle material, can avoid errors, and can directly perform sieving analysis and export a grading graph and important data required by a test.

Owner:HOHAI UNIV

Method for comprehensive recovery of valuable metals in brown iron type laterite-nickel ores

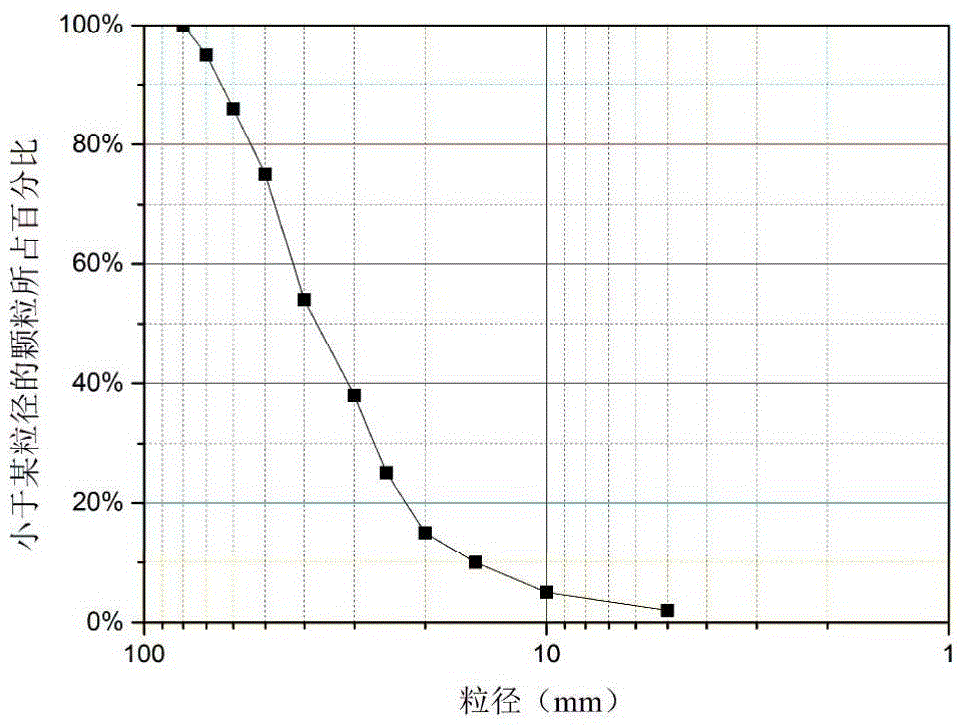

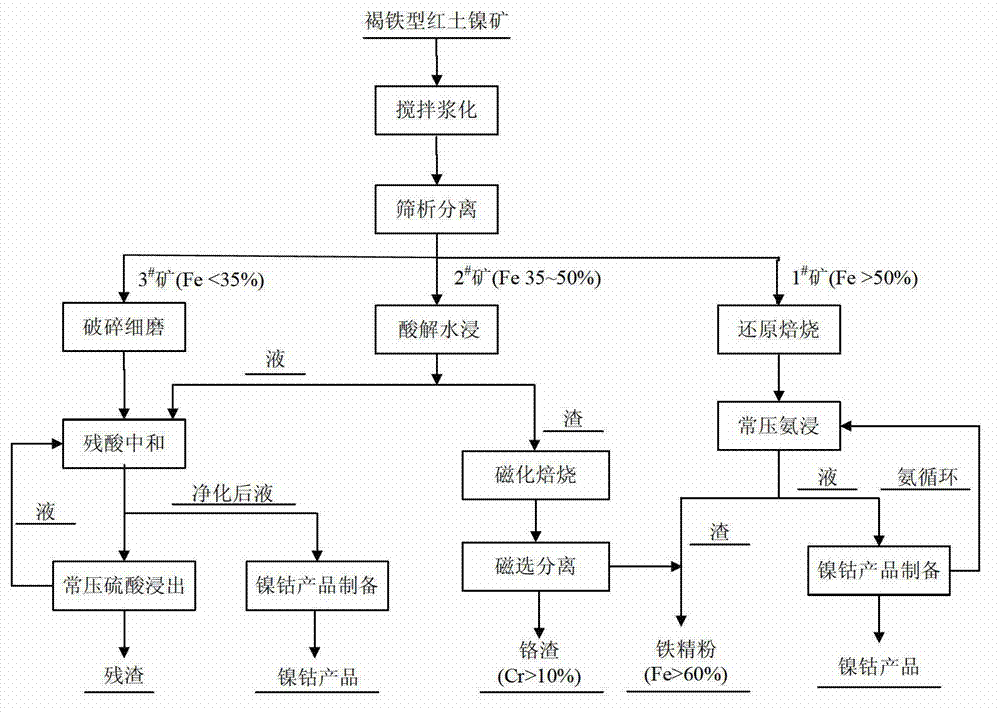

The invention discloses a method for comprehensive recovery of valuable metals in brown iron type laterite-nickel ores. The method comprises the following steps: preparing ore pulp from raw brown iron type laterite-nickel ores; then carrying out sieve analysis and separation by using a 30-mesh to 200-mesh screen mesh so as to obtain three nickel ores with different particle sizes; subjecting iron, silicon, magnesium, chromium, cobalt and nickel in the three different nickel ores to different degrees of separation and enrichment according to the physical characteristic of different sizes of mineral particles in the raw ores; and comprehensively recovering the valuable metals consisting of nickel, cobalt, iron and chromium in the ores by using three different but coupling processing processes selected according to different characteristics of the three nickel ores. The invention provides a novel technical idea for abundantly-reserved brown iron type laterite-nickel ores with an unrealized comprehensive economic value.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

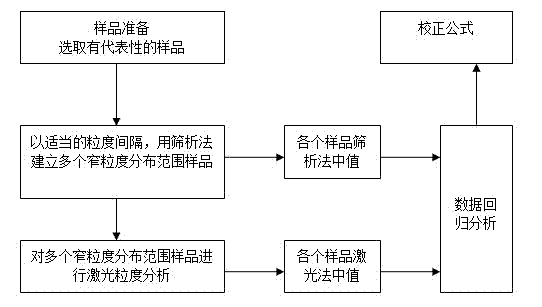

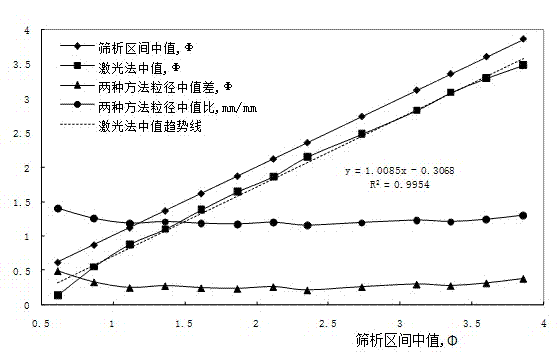

Method for calibrating particle size analysis data by using laser method and sieve analysis method

ActiveCN102890050ATroubleshoot calibration issuesParticle size analysisIndividual particle analysisParticle Size AnalyzerMaterials science

The invention relates to a method for calibrating particle size analysis data by using a laser method and a sieve analysis method, and belongs to the technical field of particle size analysis. The method comprises the following steps of: calculating sieve-analysis-method mid-values and laser-method mid-values of various narrow particle size distribution range samples which are selected from representative samples by using a sieve analysis method, and performing data regression analysis on the obtained sieve-analysis-method mid-values and the obtained laser-method mid-values so as to obtain a calibration formula; and finally, calibrating laser-method particle size analysis results of the samples into sieve-analysis-method particle size analysis results by using the calibrating formula, or calibrating the sieve-analysis-method particle size analysis results into the laser-method particle size analysis results by using the calibrating formula. According to obvious differences between data analyzed by the laser method and data analyzed by other methods, the calibrating formula is established on the basis of contrastive analysis of a large quantity of experimental data, and laser-method and sieve-analysis-method particle size analysis data are reasonably calibrated during data comparison and data docking in principle. The method can be used for calibrating data acquired by other particle size analysis methods.

Owner:CHINA PETROLEUM & CHEM CORP +1

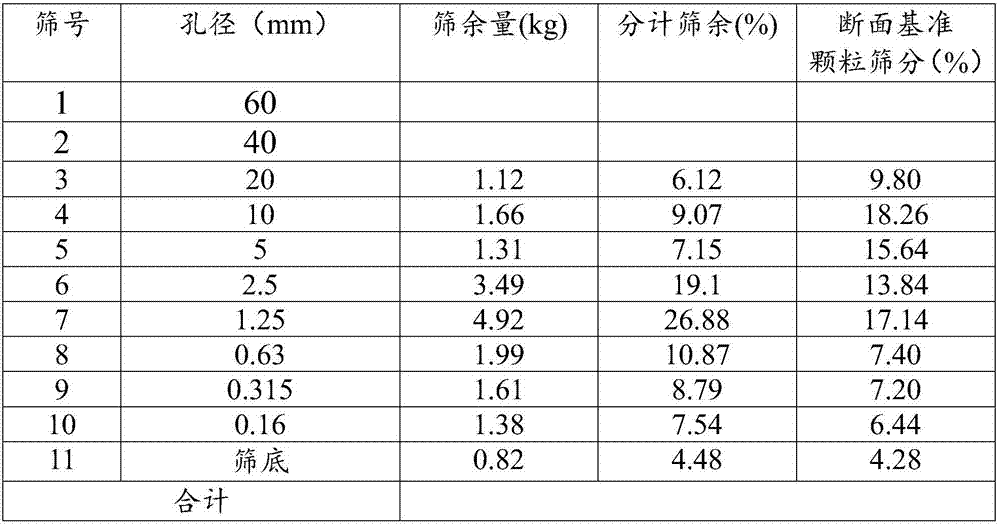

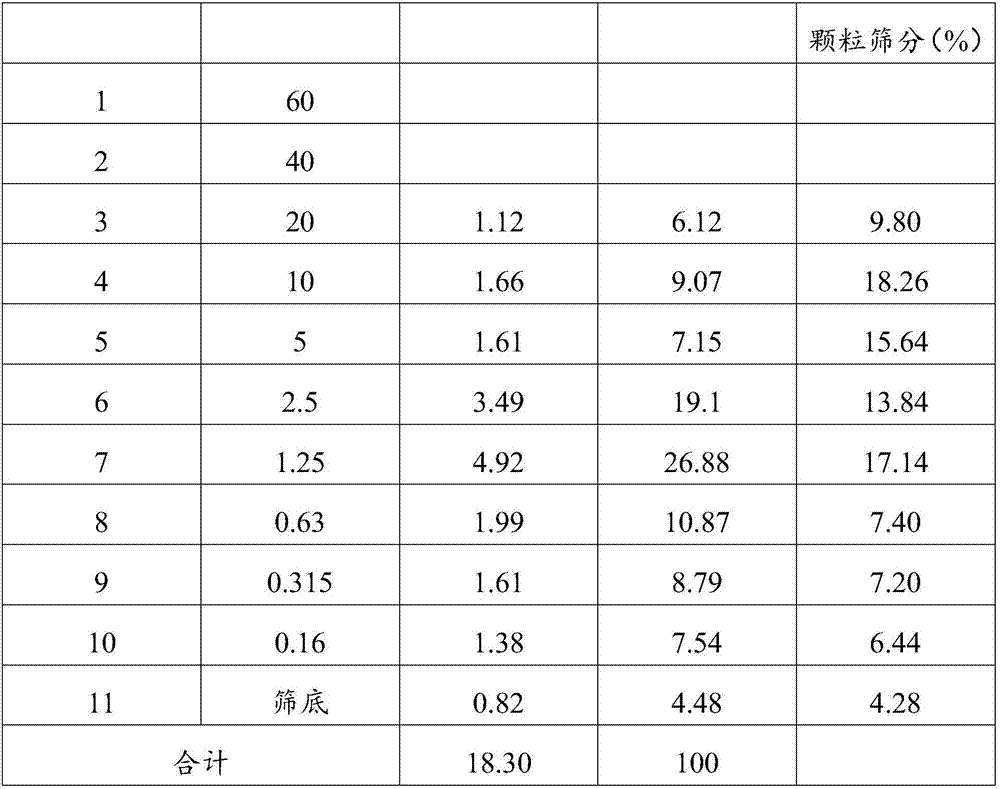

Grain graded screening method for roadbed fillers produced from construction waste

InactiveCN105776925AEfficient use ofLow costWeather/light/corrosion resistanceSolid waste managementProcess engineeringIndustrial engineering

The invention discloses a grain graded screening method for roadbed fillers produced from construction waste. Grain gradation adopts a screening test which comprises the following steps: (a) uniformly blending a sample, carrying out cutting-down by using a quartering method, and weighing a specified sample; and (b) sieving the sample by a sieve with the pore size of 2mm, weighing the mass of the sample on the sieve, and pouring the sample on the sieve into an upper sieve of multiple layers of sequentially-stacked coarse sieves for sieve analysis; and pouring the sample passing through the sieve with the pore size of 2mm into an upper sieve of multiple layers of sequentially-stacked fine sieves, and carrying out sieve analysis on a vibrating sieving machine. By the testing method used by the screening method, the aims of effectively utilizing the construction waste, reducing cost and protecting the environment are achieved; in addition, the fillers produced from the construction waste according to different mixing proportions can separately serve as an A-group filler, a B-group filler and a C-group filler of a railway bed and particularly are used as the A-group filler; and the applicable range is wide, the production process is simple and convenient, factory buildings are not required to be constructed, the cost is low, and the construction waste can be sufficiently utilized, so that the method is environment-friendly and practical.

Owner:刘庆国

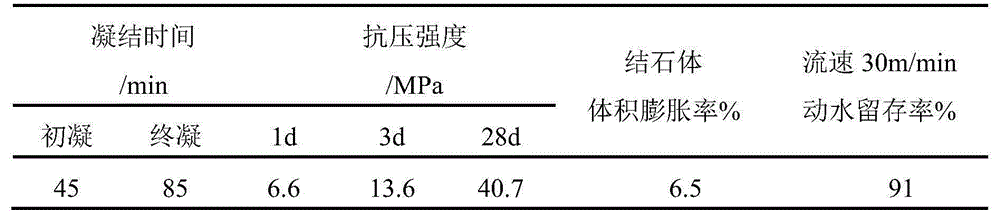

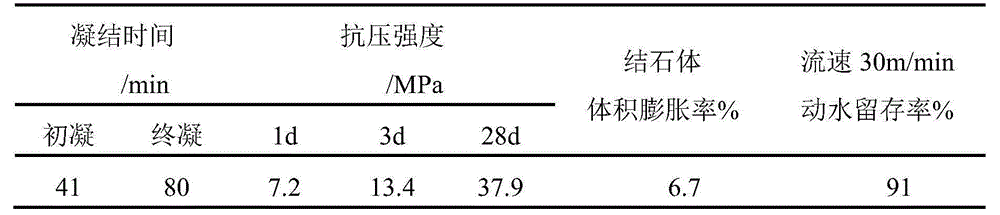

Cement-base composite material for grouting treatment of water-rich fractured rocks and preparation process of cement-base composite material

The invention relates to a cement-base composite material for grouting treatment of water-rich fractured rocks and a preparation process of the cement-base composite material. The cement-base composite material for grouting treatment of water-rich fractured rocks comprises, by mass, 69-77 parts of portland cement clinker, 23-31 parts of mineralizer and 0.34-1.55 parts of additive powder retarder. The mineralizer comprises, by mass, 75-79 parts of ground quartz, 6.8-7.6 parts of calcium chloride, 2.8-3.6 parts of lithium chloride, 1.9-2.4 parts of talcum powder, 2.0-2.5 parts of hydroxypropyl methyl cellulose, 2.1-2.6 parts of wollastonite powder, 0.6-0.9 part of titanium dioxide, 3.1-3.8 parts of sodium hexametaphosphate and 1.5-2.1 parts of super plasticizer. Since portland cement clinker and mineralizer are processed by the combined grinding technology, and specific surface area of the material is controlled to be larger than 500m2 / kg and residue on sieves of 80 micrometers in a vacuum sieving process is controlled to be less than 8% respectively by the Blaine method and the vacuum sieving analysis method, uniform performance of the material is achieved. Condensation time of the material is controllable, the strength of the material is high in early stage and later period, volume expansion of the material is slight, retention of the material is over 91% on a condition of 30m / min flowing water, and accordingly, the material can be applied to grouting reinforcement treatment engineering of water-rich fractured rocks widely.

Owner:SHANDONG UNIV

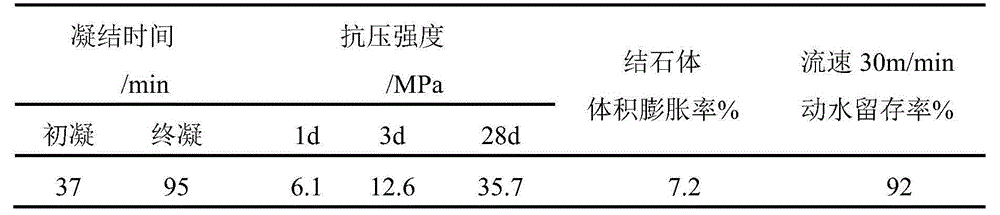

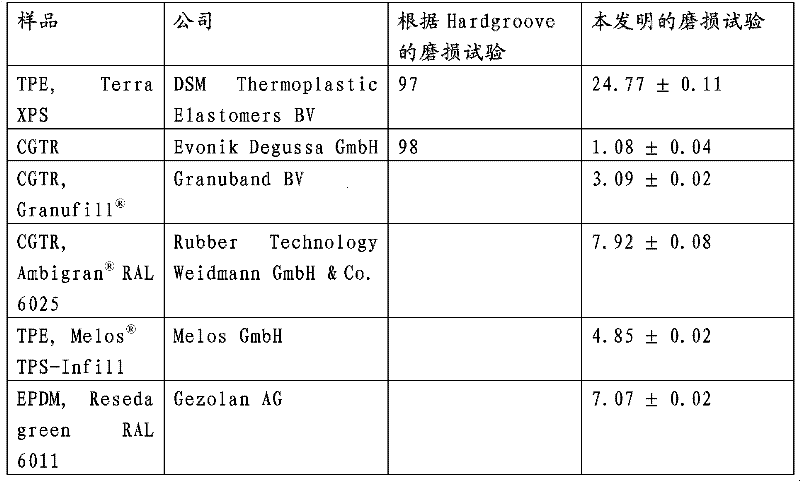

Rapid Wear Test of Granules

InactiveCN102272573AAccurate assessmentEasy to measureInvestigating abrasion/wear resistanceWear particleMaterials science

The present invention discloses a rapid test for determining particle attrition in which i) a particle is ground, ii) a sieve analysis is performed on the ground product, and iii) the result of the sieve analysis is compared to at least one reference value A comparison was made to classify the particle attrition where the particle was ground in a cutting mill.

Owner:EVONIK DEGUSSA GMBH

Silica-loaded granular rubber and process for producing the same

InactiveUS7625971B2Less powderyEasy to handleSynthetic resin layered productsCellulosic plastic layered productsSilica particlePolymer science

Owner:TOKUYAMA CORP +1

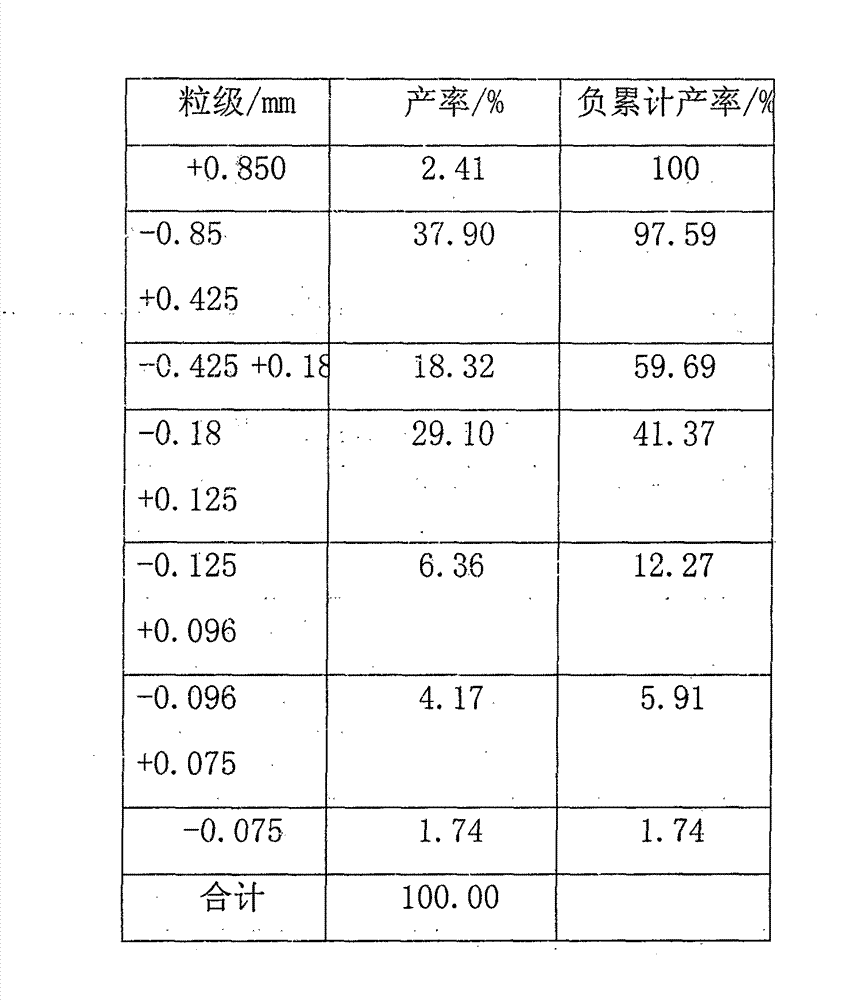

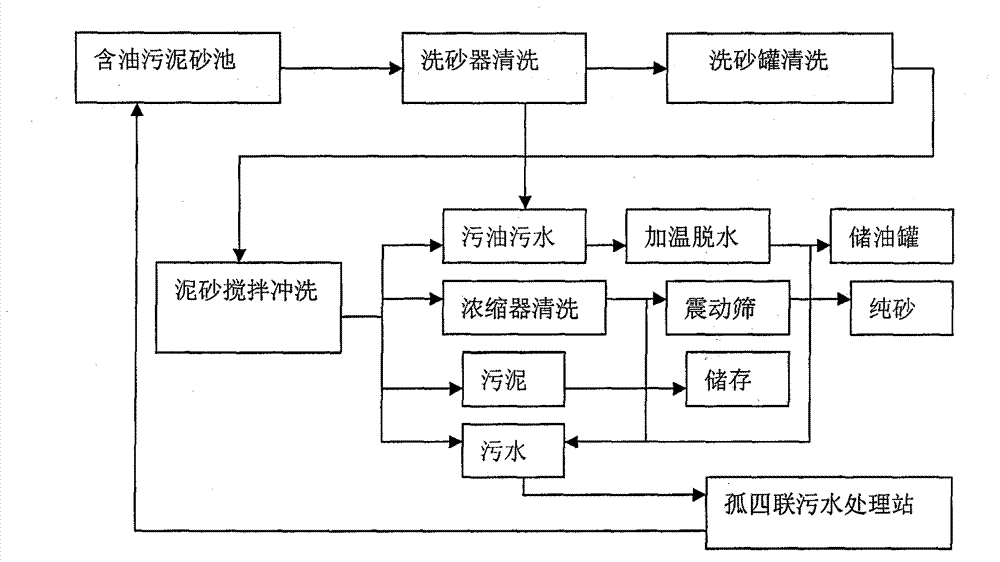

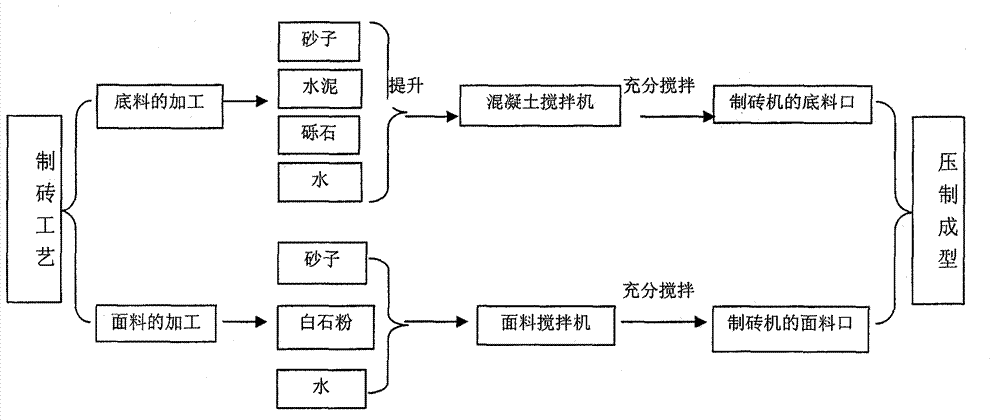

Method for recycling oil-containing sludge sand

The invention provides a method for recycling waste oil-containing sludge sand. The technical scheme is as follows: the method comprises the following steps: carrying out oil-water-sludge-sand separation, and researching the particle size composition of the oil-containing sludge sand by a sieve analysis process, wherein the particle size distribution of the oil-containing sludge sand is mainly concentrated at 0.1-0.85mm, the yield is 90%, the average particle size is 0.23mm, the sludge content is 1.74%, and the oil-containing sludge sand is suitable for making baking-free bricks; and adding 15-50% of cement, 10-30% of gravel, 1-10% of curing agent and 20-50% of clear water into the separated sand, stirring in a stirrer to make mortar, transmitting into a molding press by a transmission band, and carrying out molding pressing to obtain the mechanically pressed baking-free bricks. The invention effectively solves the problem that the sludge sand pollutes the soil and environment, saves the precious energy sources and abundant funds, can generate huge social benefit and economic benefit, and is suitable for wide popularization and use.

Owner:张俊峰

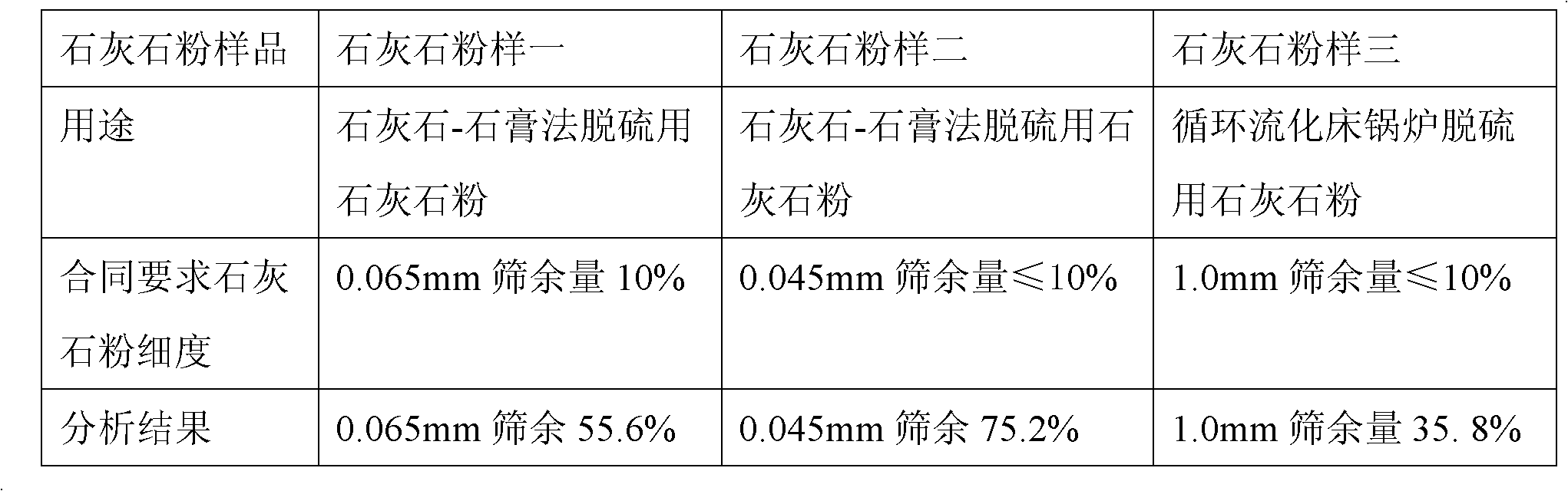

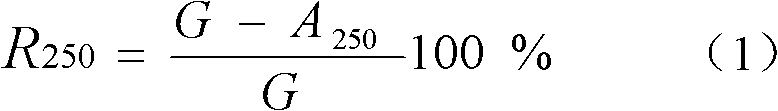

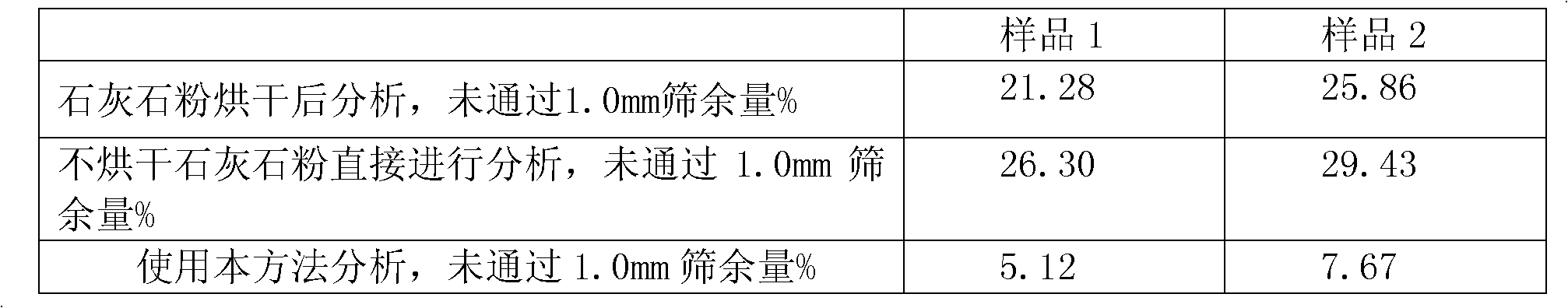

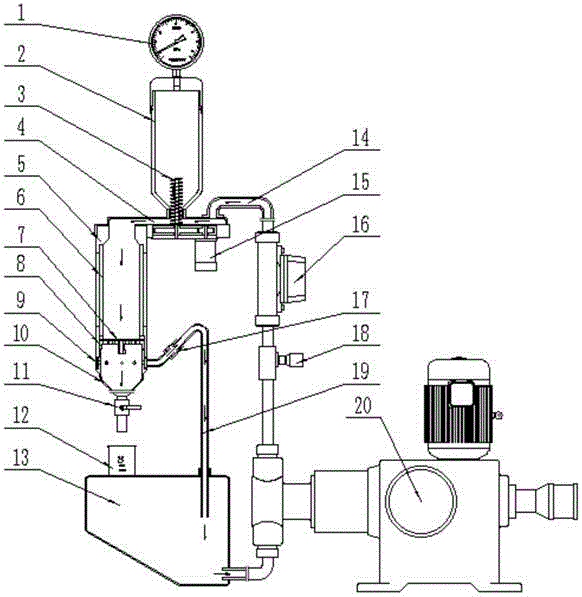

Water flushing analysis method for limestone fineness for desulfurization of thermal plant

InactiveCN102628787AAnalysis method is simpleSatisfy the analytical requirements of limestone powder fineness for desulfurizationWeighing by removing componentPreparing sample for investigationRelative standard deviationRepeatability

The invention discloses a water flushing sieving analysis method for limestone fineness for desulfurization of a thermal plant. The analysis method comprises the following steps of: selecting sieves different diameters according to the requirements of the thermal plant and a limestone powder supplier on the fineness; pouring a weighted limestone powder sample into the sieves; sieving in a water flushing way; filtering the sieved limestone powder together with water; drying at the temperature of 100 DEG C; and weighting to analyze the fineness of the limestone powder. The method has the advantages that: a standard for the limestone powder fineness analysis method for desulfurization of the thermal plant is not provided at present; the analysis method is simple and has high accuracy; relative standard deviations in repeated tests and analysis tests in experimental rooms are below the generally-allowed standard of 5 percent; and the analysis requirement of the thermal plant on the analysis of limestone powder during desulfurization can be met.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

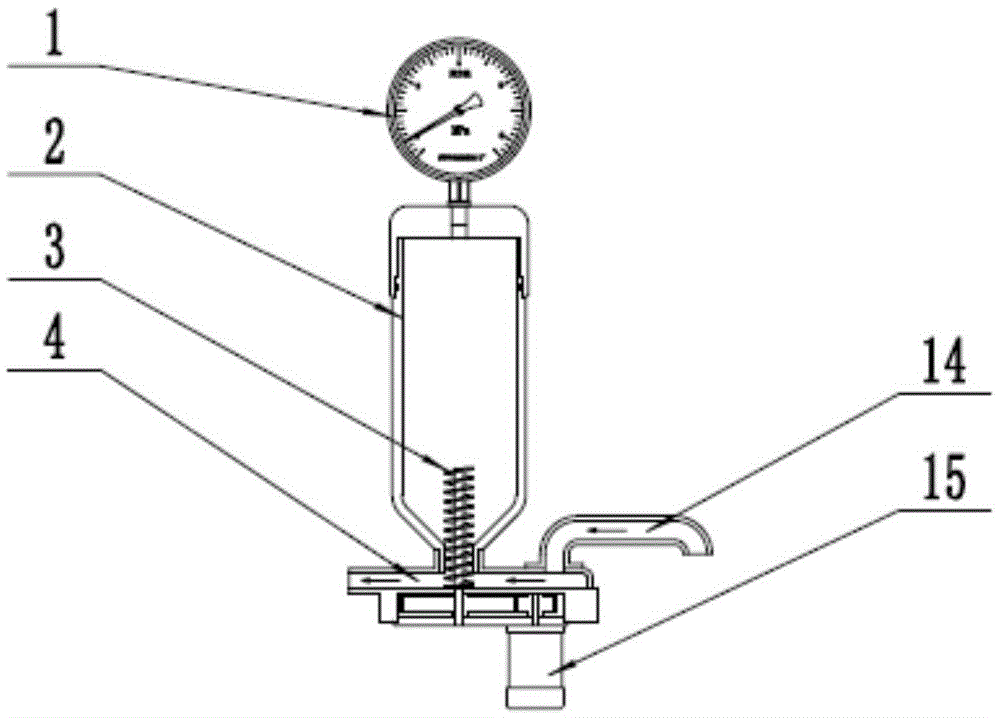

Detection system for sand blocking precision of sand prevention medium of sand prevention sieve tube for oil field

InactiveCN105651675AAccurate control of sanding speedPermeability/surface area analysisSpeed control systemControl system

Owner:CHINA NAT OFFSHORE OIL CORP +2

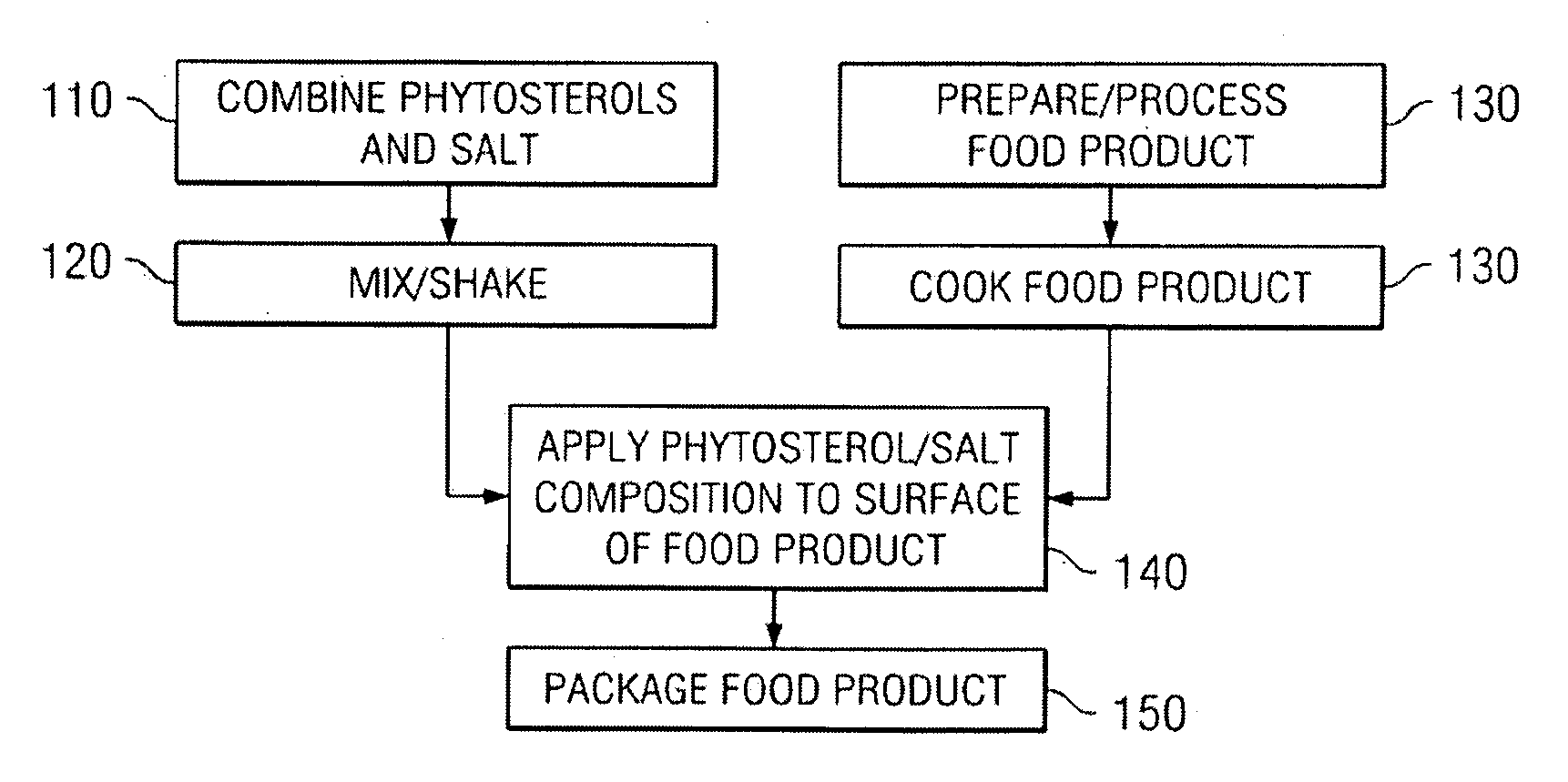

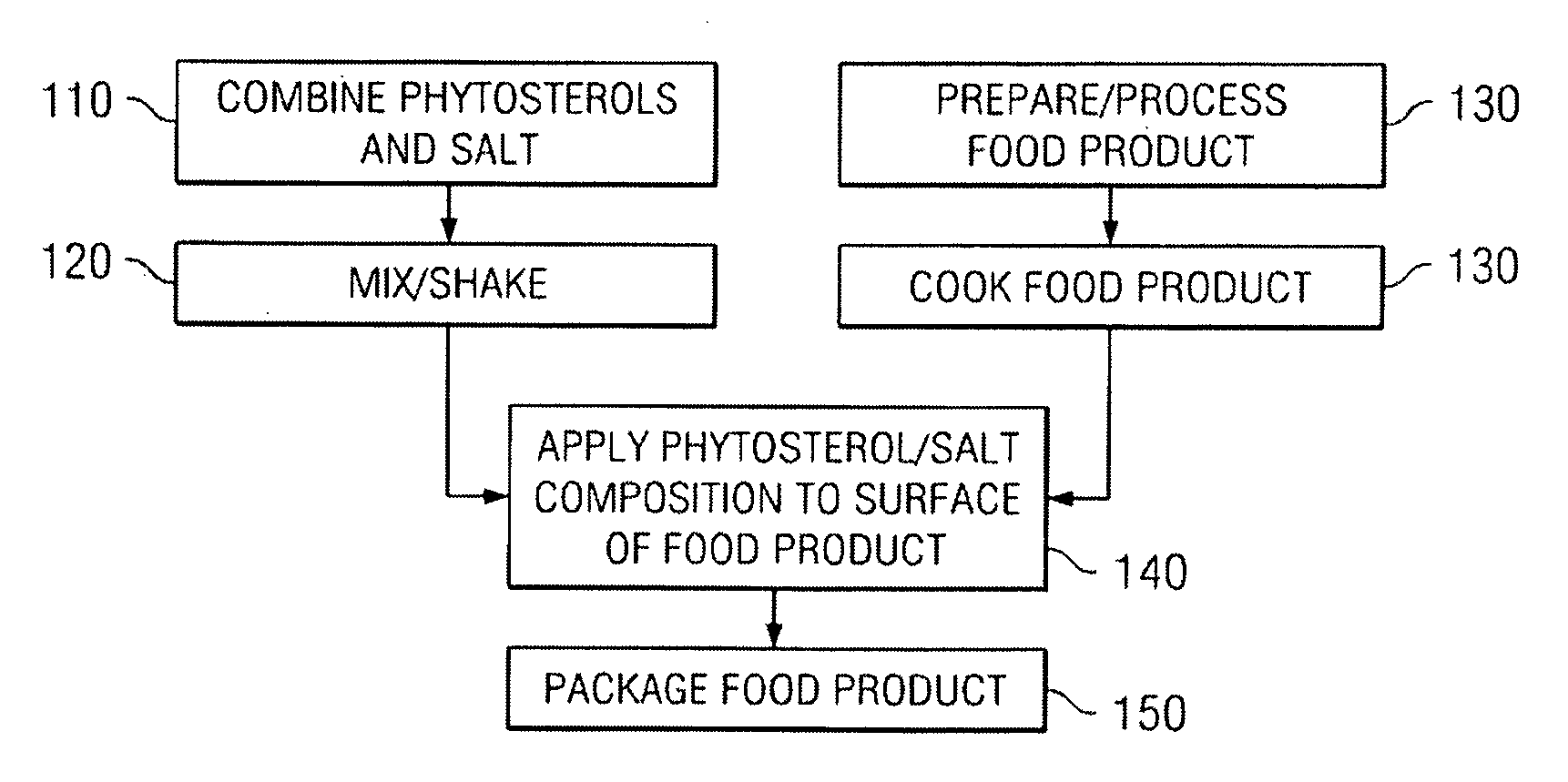

Phytosterol/Salt Composition for Topical Application to Food Products

A phytosterol / salt mixture for even topical application to snack products. At least one free phytosterol in dry form is combined with at least one salt of a similar particle size to form a homogenous blend and applied to the surface of a hot snack food product. The at least one free phytosterol can also be part of a phytosterol blend comprised of at least 95% free phytosterols. To ensure that neither the phytosterol nor salt component settles out and to provide for uniformity of the homogenous blend, the phytosterol blend is of a similar size distribution to the at least one salt. In test runs, a phytosterol blend and at least one salt were combined in a ratio of approximately 53:47, with size ranges determined by sieve analysis to generally fell within the range of 149 to 400 microns.

Owner:FRITO LAY NORTH AMERICA INC

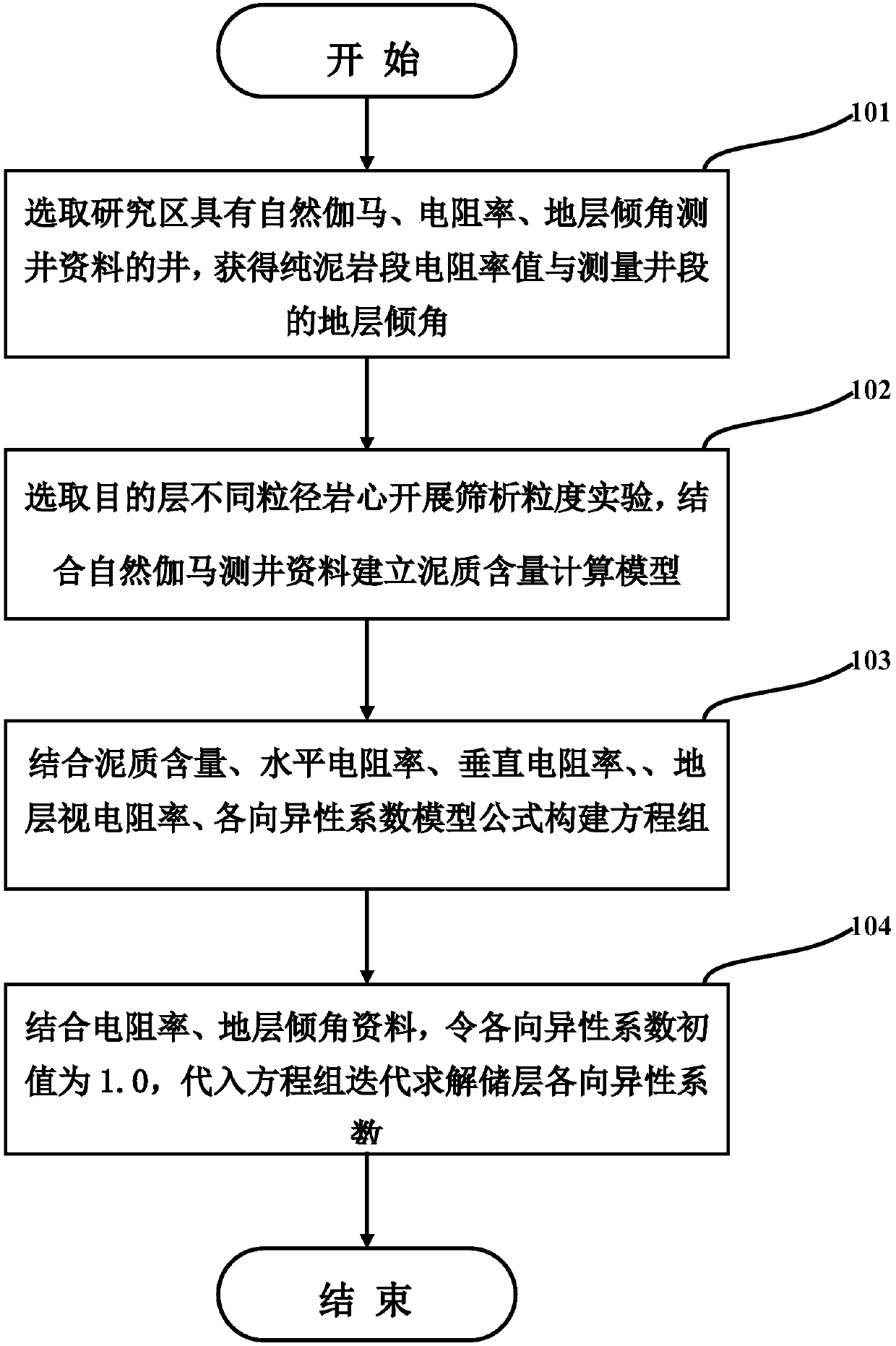

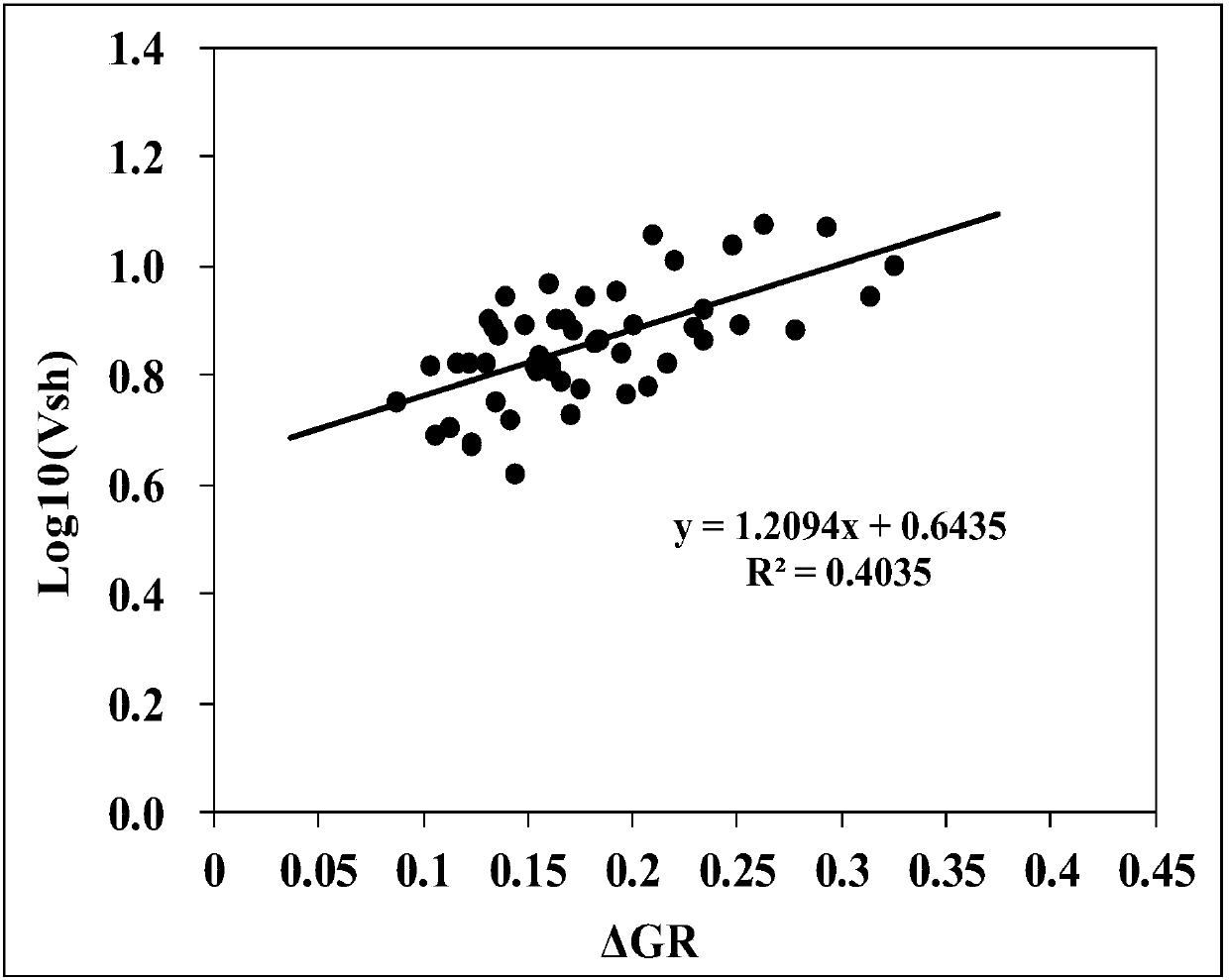

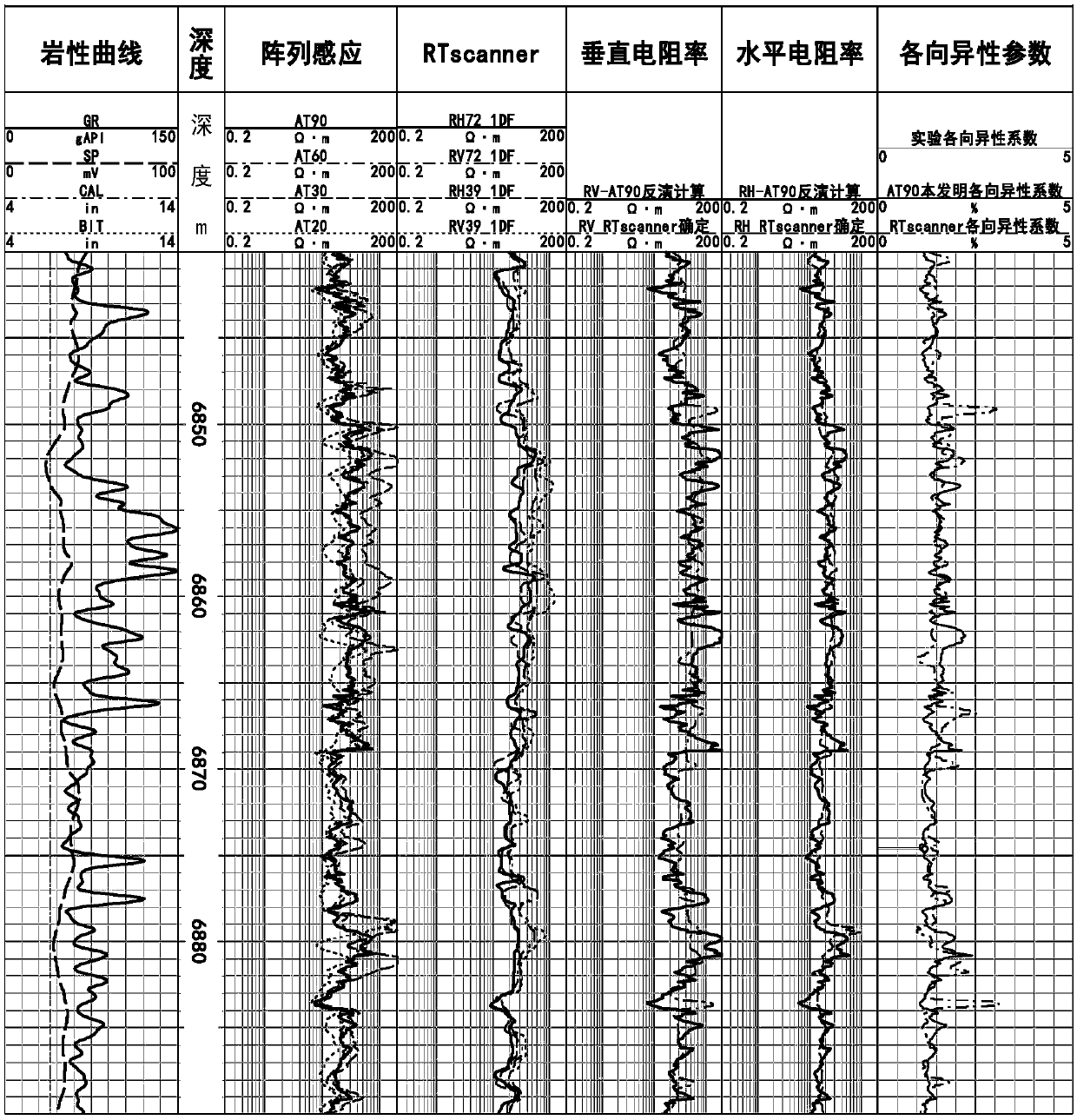

Method for determining anisotropy coefficient of resistivity of reservoir

ActiveCN107784159AAccurately determineDesign optimisation/simulationBorehole/well accessoriesRock coreGranularity

The invention discloses a method for determining the anisotropy coefficient of the resistivity of a reservoir. The method includes the following steps that a well with natural gamma, resistivity, anddip logging data in a study area is selected firstly, the resistivity value of a pure shale section and the stratum dip angle of a measured well section are obtained; rock cores, different in particlesize, of a target layer are selected for carrying out the granularity sieve-analysis experiment, and through the combination with the natural gamma well-log information, a mud content calculation mode is built; through the combination of the mud content, the horizontal resistivity, the vertical resistivity, the anisotropy coefficient and the apparent formation resistivity model formula, an equation set is formed; through the combination of the resistivity and the stratum dip angle, the initial value of the anisotropy coefficient is made to be 1.0 and is substituted into the equation set for obtaining the anisotropy coefficient of the reservoir through iterative solution. When the method is actual use, without the rock-core resistivity anisotropy coefficient experiment, by using the well-logging data and a theoretical model, the anisotropy coefficient of the resistivity of the reservoir is obtained through iterative solution, and a basic parameter is provided for accurate correction ofthe resistivity of the reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for selecting and breeding new high-lipid-content Botryococcus strain

InactiveCN103146678AEnable high-throughput screeningMutant preparationMicroorganism based processesIce waterFluorescence

The invention relates to development and utilization of Botryococcus, and aims to provide a method for selecting and breeding a new high-lipid-content Botryococcus strain. The method comprises the following steps: adding particle Xanthan gum into a Botryococcus solution, putting in an ice water bath, and applying ultrasonic to prepare the Botryococcus colony into unicells; after carrying out ultraviolet radiation mutagenesis and low-melting-point agarose immobilization culture, carrying out NR fluorescence microscopy in-vivo sieving analysis to obtain high-lipid-content Botryococcus candidate mutants; and carrying out amplification culture and lipid content determination to select and breed the new high-lipid-content Botryococcus strain. Compared with the traditional selecting and breeding method, the method provided by the invention is more simple and convenient, has the advantages of higher efficiency and the like, can implement high-flux sieving analysis, and can provide a necessary technique for breeding Botryococcus.

Owner:ZHEJIANG UNIV

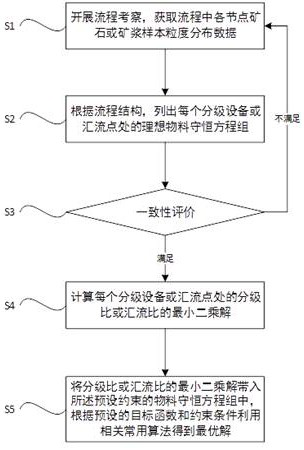

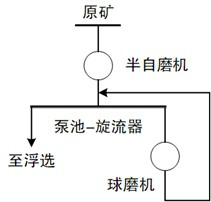

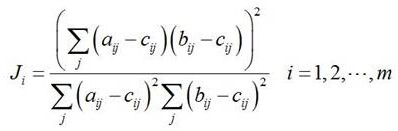

Calculation method for inspecting particle size distribution data consistency correction in ore crushing or grinding process

ActiveCN111932391AAchieve estimatesImplement fixesData processing applicationsDesign optimisation/simulationProcess engineeringMechanical engineering

The invention provides a calculation method for inspecting particle size distribution data consistency correction in an ore crushing or grinding process, and relates to the technical field of technological process data collaborative calculation. The method comprises the following steps: obtaining particle size distribution sieve analysis data of ore or ore pulp samples of each node of a process; and based on the material conservation principle of each grading device or confluence point in the process, as a preset constraint condition, taking the minimization of the sum of squares of deviationsbetween the to-be-corrected data of the content of each particle size of each node and the measured data as an objective function, and calculating to obtain an optimal solution, namely the correctedparticle size distribution of each node ore or ore pulp sample. Through the algorithm, particle size distribution data of all points meeting the material conservation principle at a sampling moment are obtained, and errors introduced in a sampling process, a screening process and the like are reduced to a certain extent; the obtained result is helpful for on-site technicians to judge the working condition of the process and give a next operation strategy. Calculation steps are clear and concise, additional correction steps are not needed, and programming implementation is facilitated.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

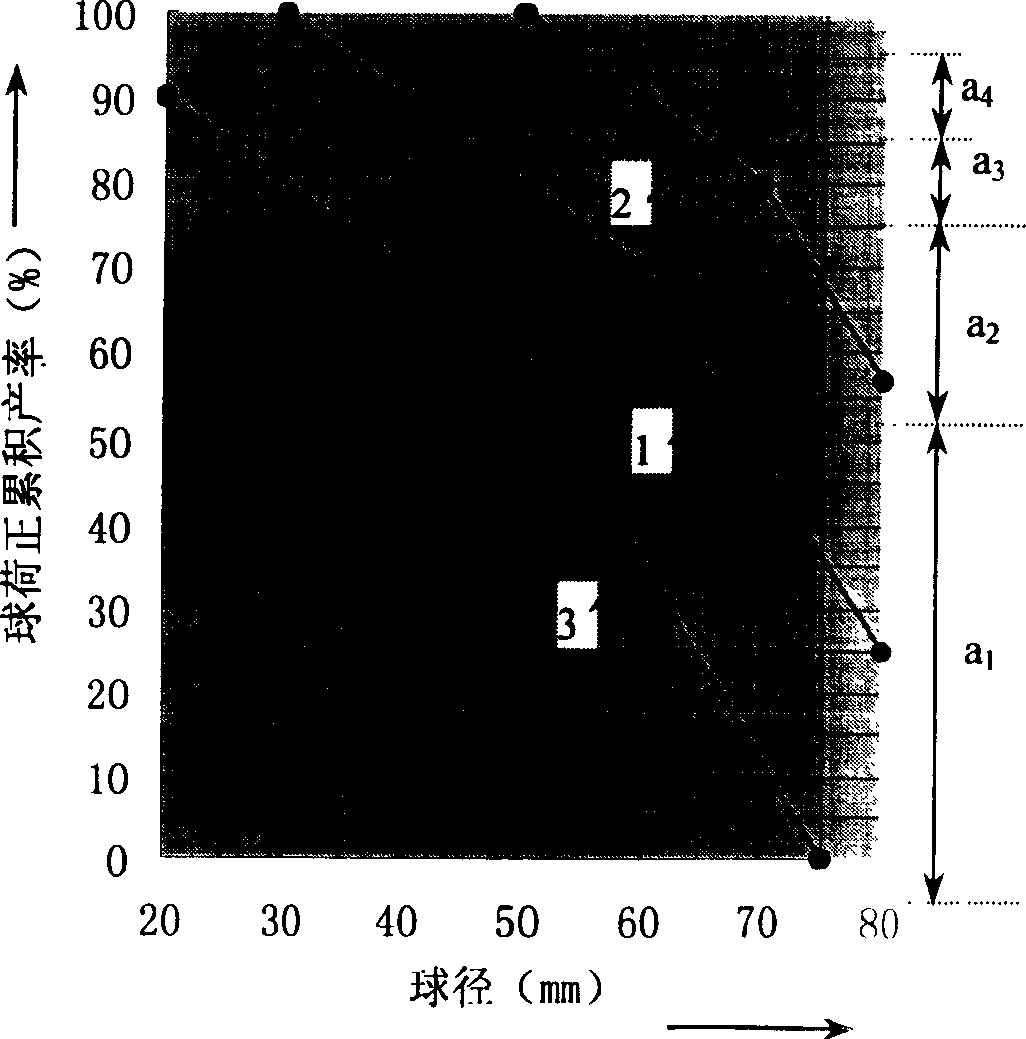

Method for determining size and proportion of ore grinding medium of first-stage ball mill

ActiveCN111241691AImprove adaptabilityQuick size determinatioCement productionDesign optimisation/simulationHardnessSteel ball

The invention relates to a method for rapidly determining the size and proportion of an ore grinding medium of a first-stage ball mill. The method comprises the following steps: dividing a material into materials of a plurality of grades according to the particle size composition of an ore grinding material; determining and measuring the Mohs hardness of ore to be ground and the particle size composition of a material of each particle grade, calculating the ball diameter of the material of each particle grade by using a Bundy simple empirical formula and the Mohs hardness of the ore to be ground, and calculating the optimal proportion of grinding medium according to the content of each particle grade in the ore to be ground. The method disclosed by the invention has the advantages that (1)the method disclosed by the invention has good adaptability to materials with the maximum particle size of 5-25mm; (2) according to the method disclosed by the invention, the proper size and proportion of a steel ball medium for ore grinding can be quickly determined by using simple ore hardness test, size fraction sieve analysis experiment and theoretical calculation, the steps are simple, the period is short, and the production time can be saved, and (3) the proper size and proportion of steel balls are determined according to the ores with different types and different particle sizes suchthat the production time is saved, and the ore grinding efficiency is improved.

Owner:ANSTEEL GRP MINING CO LTD

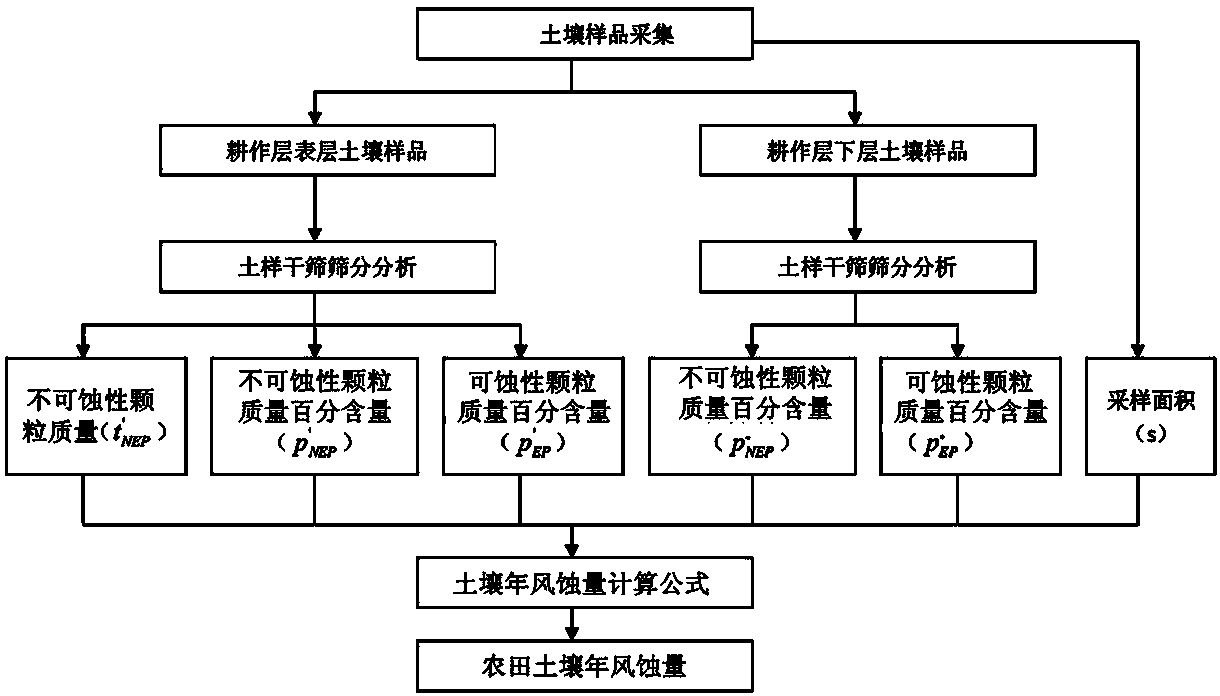

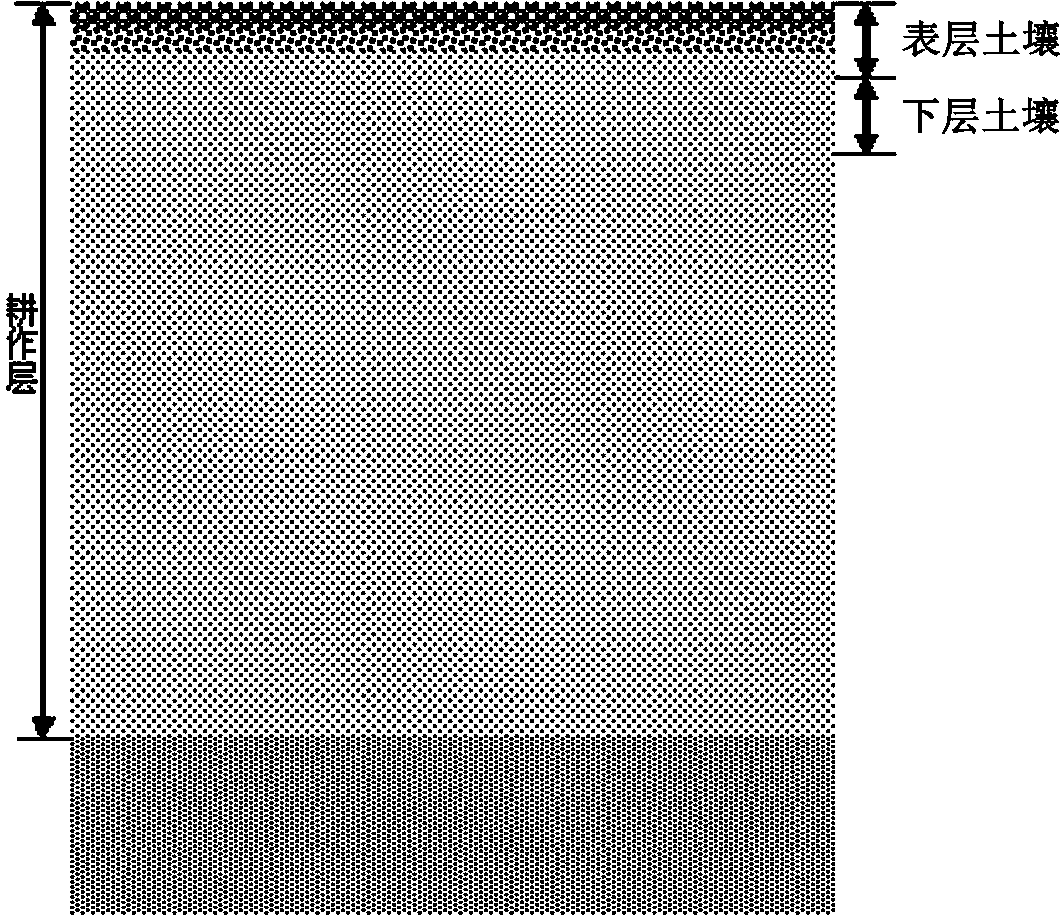

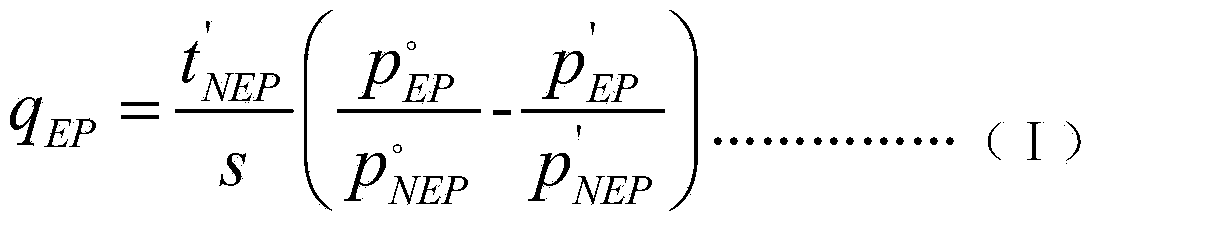

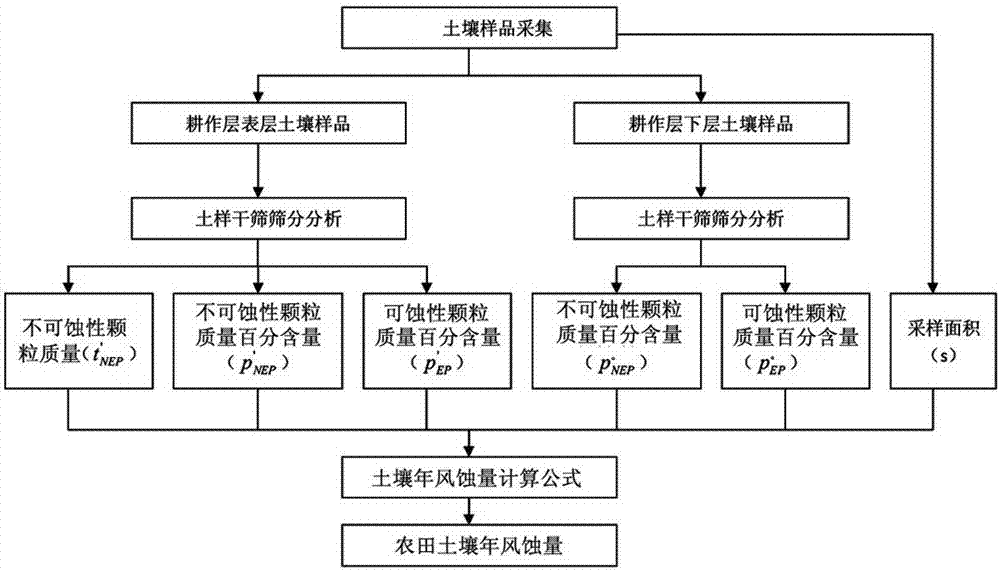

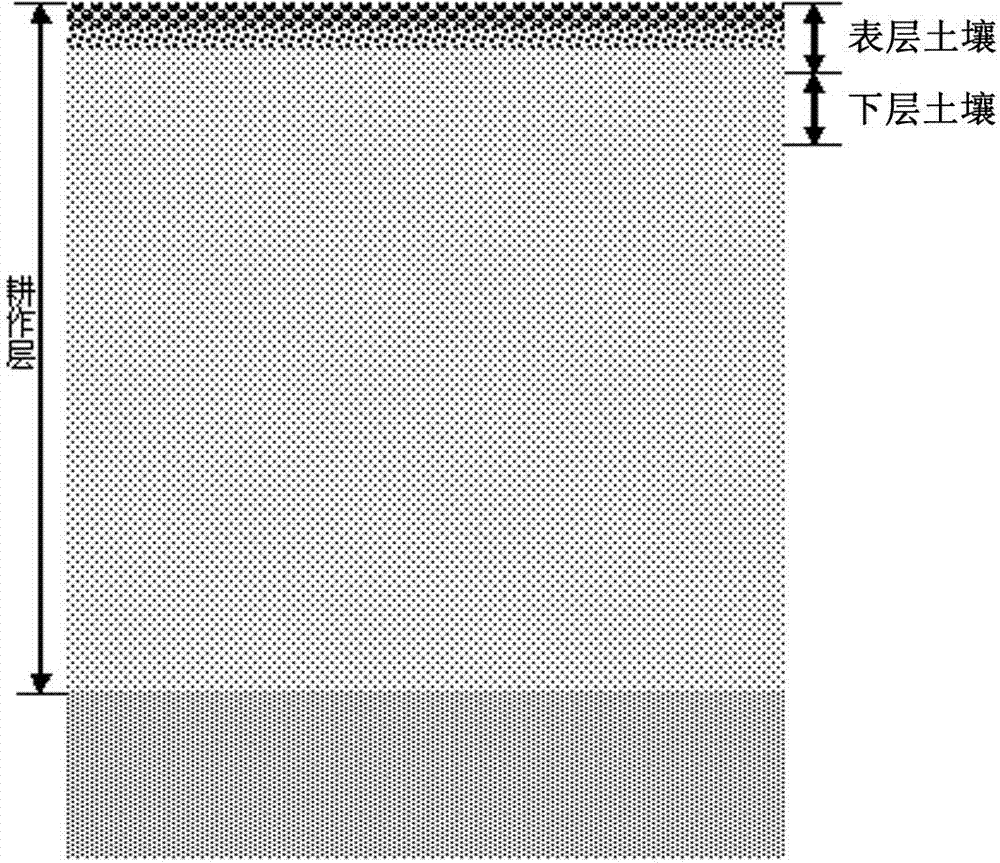

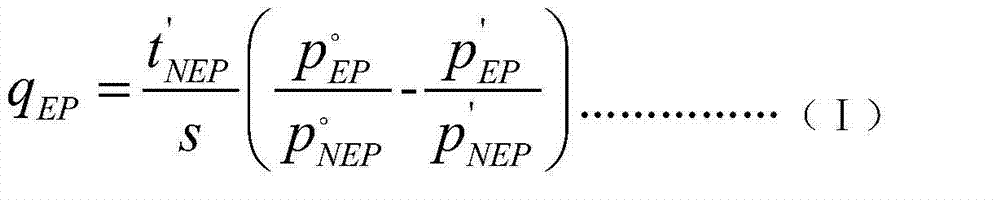

Farmland soil year wind erosion amount estimation method

ActiveCN103454063ASolving this pressing problem in wind erosion researchEasy to operateAerodynamic testingSurface layerSoil science

The invention discloses a farmland soil year wind erosion amount estimation method. The method comprises the following steps that plough layer surface layer soil and plough layer lower layer soil are respectively collected, dry sieving analysis is carried out to detect the content of erosive particles and non-erosive particles in the surface layer soil and the lower layer soil, and the content is substituted to a formula for calculation to obtain soil year wind erosion amount. According to the method, the difference of the content of erosive particles between the surface layer soil and the lower layer soil is used for estimating the current soil year wind erosion amount, and the problem which demands prompt solution in the soil wind erosion research is solved. The method is simple, practical, and quick in operation and convenient to operate, samples of the plough layer surface layer soil and the lower layer soil only need to be collected for analysis and calculation after the wind erosion season in spring is over, and the year wind erosion amount of farmland can be obtained. The method is wide in application range and can be applied to estimation of year wind erosion amount of almost all wind erosion farmlands.

Owner:河北省科学院地理科学研究所

Method for monitoring amount of water and soil loss

InactiveCN107037196AReliable dataEarth material testingParticle size analysisSoil scienceReduced size

The invention relates to a method for monitoring the amount of water and soil loss. The method includes the steps of 1, determining standard granule sieving results; 2, arranging a runoff cylinder, sieving substances in the runoff cylinder, and conducting reduction calculation. The step 1 includes the steps that 1.1, three sections are arranged in 6 cm diameter downstream a soil loss monitoring point to take samples; 1.2, content percentages of granules of various sizes are determined; 1.3, samples are taken from air dried and loose soil samples according to quartering and are sieved, and standard granule sieving results are calculated. The step 2 includes the steps that 2.1, the content percentages of the granules of various sizes are calculated; 2.2, sieving results of the substances in the runoff cylinder are compared with the determining standard granule sieving results, and the actual content of granules with reduced sizes in the runoff cylinder is calculated; 2.3, according to the actual content of the granules with the reduced sizes, the actual soil loss amount of the monitoring point is obtained. The method for monitoring the amount of the water and soil loss has the advantages that relatively reliable data is provided for water erosion monitoring results of mountainous areas and hilly areas where water erosion conditions are severe.

Owner:哈密新智源水利水电工程建设监理有限公司

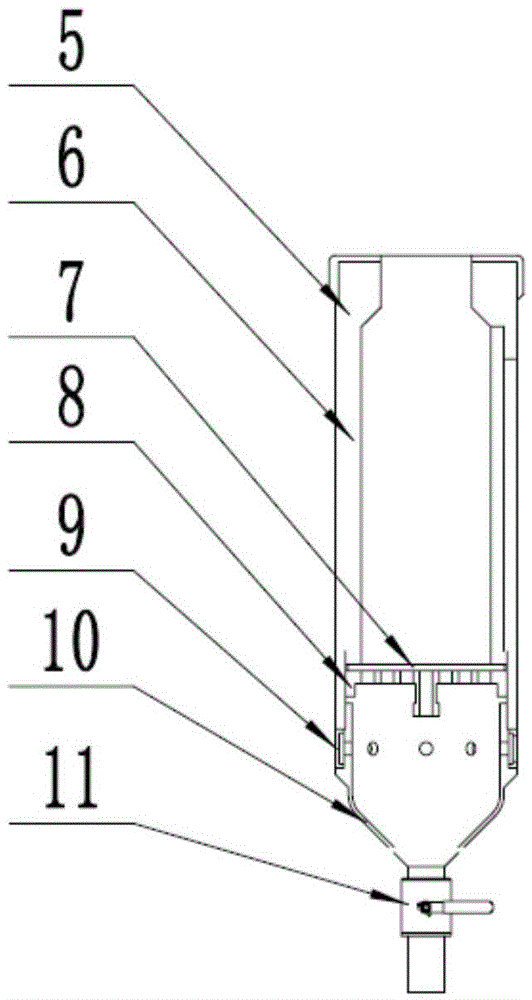

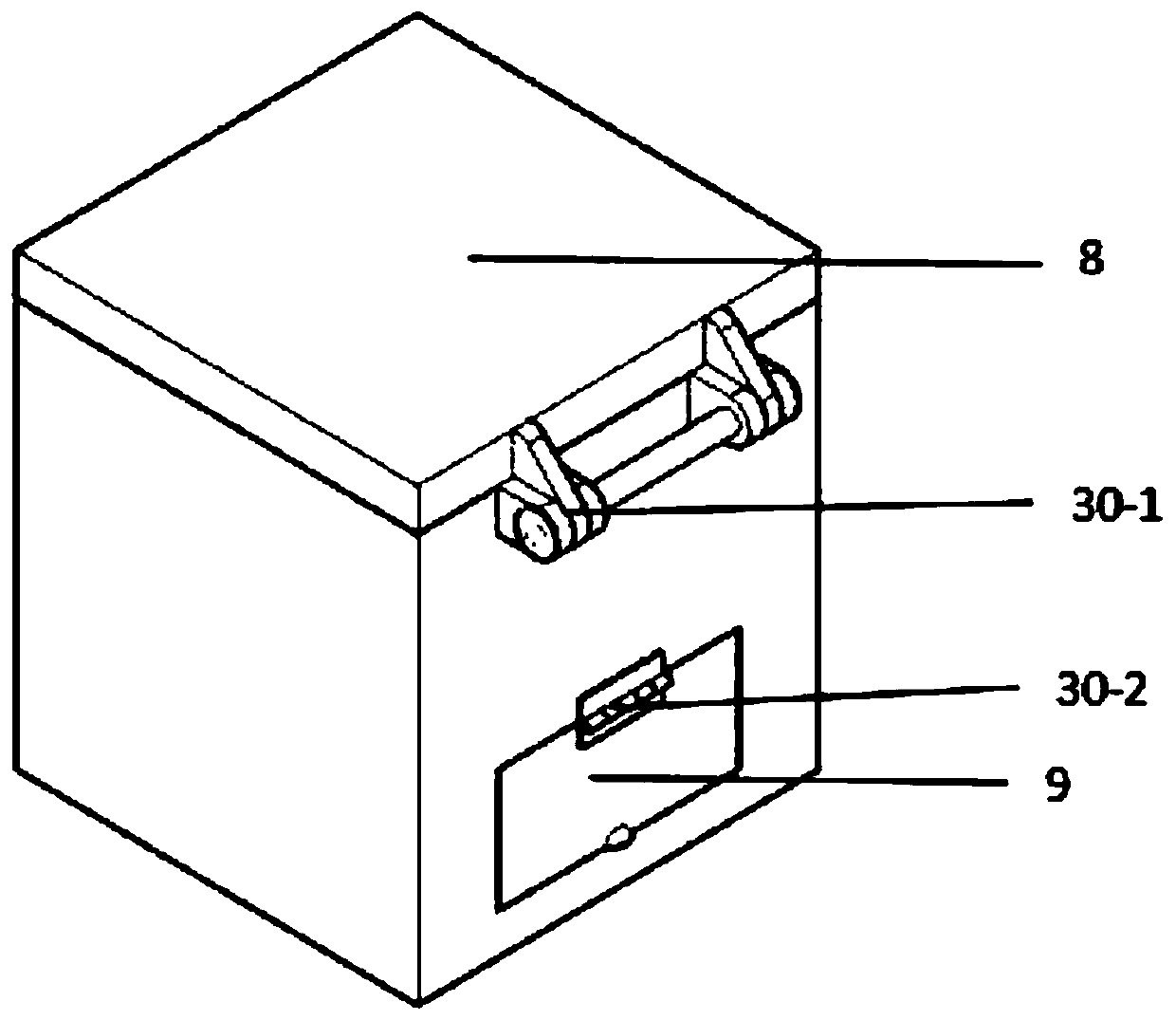

Cement fineness negative pressure sieve analysis apparatus

InactiveCN105300858APlay a restrictive roleGuarantee job securityParticle size analysisEngineeringMicro motor

The present invention discloses a cement fineness negative pressure sieve analysis apparatus comprising a test sieve, a sieve seat, a jet nozzle, a straw, a support, a micro-motor, a cyclone and a filter, the filter comprises a housing, a motor, a filter bag and a dust hopper, the motor, the filter bag and the dust hopper are arranged in the housing, a connection plate is arranged between the motor and the filter bag, the connection plate is provided with one or more connecting holes, and the filter bag is located below the connecting holes; a vibration rack is arranged between the dust hopper and the filter bag, and the vibration rack is driven by a vibrating driving device, and is in transmission connection with the filter bag; a sealing door includes a door frame body, a sealing door plate arranged on the inner side of the door frame body, an elastic member arranged between the door frame body and the sealing door plate, and a seal ring connected with the inner wall of the housing. The cement fineness negative pressure sieve analysis apparatus is reasonable in structure, safe and reliable to use, easy to deash, low in noise, and good in sealing effect.

Owner:KUNSHAN TRANSPORTATION ENG TEST CENT CO LTD

Preparation method for water-based mica iron oxide and paint prepared from water-based mica iron oxide

ActiveCN104046057AGood dispersionIncrease dosageAnti-corrosive paintsPigment treatment with organosilicon compoundsWater basedRust

The invention discloses a preparation method for water-based mica iron oxide. The preparation method is as follows: adding the prepared mica iron oxide into a water-based amino silane compound and then uniformly mixing; and dehydrating, drying, proportioning and dosing, and carrying out sieve analysis after heating the mixed substances to obtain the water-based mica iron oxide. The invention further discloses water-based anticorrosive paint which comprises water-based mica iron oxide, acrylic emulsion, a flash-rust preventing agent, talcum powder, modified zinc phosphate, aluminum triphosphate, precipitated barium sulfate, zinc oxide, texanol ester alcohol, triethanolamine, a preservative and deionized water. According to the preparation method disclosed by the invention, mica iron oxide is obtained according to the conventional method for producing mica iron oxide, and the water-based mica iron oxide is obtained by further processing, so that the defect of the existing mica iron oxide hard precipitate is solved, and therefore, the water-based mica iron oxide is good in dispersion, and production cost of paint is lowered. When the prepared water-based mica iron oxide is used for preparing paint, anticorrosive effect of the prepared paint is improved.

Owner:TONGLING ZHIRUN MICA PIGMENT

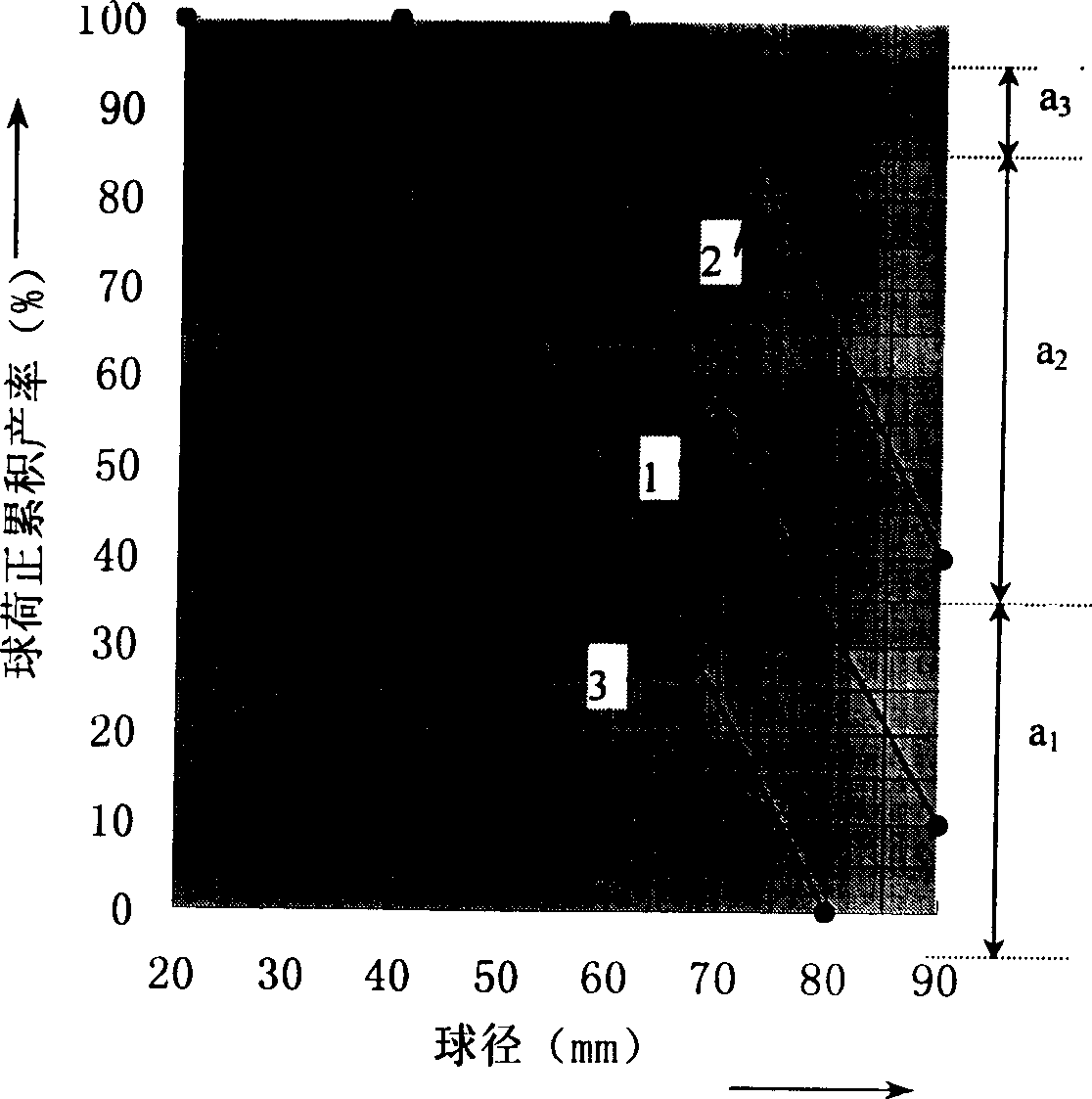

Ball grinder accurate ball loading method

InactiveCN1278775CAccurate ball diameterChoose accuratelyGrain treatmentsBall bearingMineral particles

The invention relates to a method for accurately loading and replenishing balls in a ball mill, which belongs to the technical field of ore crushing and fine grinding. According to the purpose of ore grinding, this accurate and convenient method of filling balls is proposed, including: measuring the mechanical parameters of the ore to be ground; screening and analyzing the new feed ore and sand return of the mill, and calculating the full feed The ore particle size is composed and grouped; the ball diameter value required by each group of ore particles is calculated using the ball diameter semi-theoretical formula; the ball ratio of the balls initially loaded in the mill is determined according to the ore particles of each group and the required ball diameter to be ground; Draw the positive cumulative characteristic curve of the particle size of the ball charge, and then obtain the ball diameter and the proportion of the ball to be added accurately from the graph. Applying this method to replenish balls, due to the precise ball diameter, reasonable proportion and simple method, increases the output per hour of the mill, improves the quality of the grinding product, reduces the power consumption of the ball, and increases the dissociation degree of the grinding product monomer. The beneficiation recovery rate and concentrate grade have also been improved.

Owner:KUNMING UNIV OF SCI & TECH +2

Method for producing eucommia ulmoides gum

The invention provides a method for producing eucommia ulmoides gum. The method comprises cleaning, fermentation, washing, stewing, smashing, sieving, rinsing and briquetting. The method comprises the following steps of 1, putting leaves of eucommia ulmoides into a tank and carrying out cleaning, 2, feeding the cleaned leaves of eucommia ulmoides into a fermentation tank, carrying out fermentation, feeding the fermentation products into a water extractor and carrying out washing and drying, 3, putting the dried fermentation products into a stewing device and carrying out stewing, 4, feeding the stewing products into a waterpower smasher and carrying out smashing under the conditions of a waterpower smashing concentration of 2-20%, humidity less than 50%, a waterpower smashing rate of 20-80m / s and the optimal waterpower smashing rate of 30-50m / s, 5, sieving the smashed gum by a sieving device, 6, rinsing the gum silk obtained by the sieve analysis device in a rinsing device, and 7, feeding the eucommia ulmoides gum into a briquetting device and carrying out briquetting molding. The method reduces a material consumption amount, reduces pollution, improves a yield, reduces a production cost, and improves elasticity, toughness and tensile strength of the eucommia ulmoides gum.

Owner:TIANJIN PACIFIC PHARMA

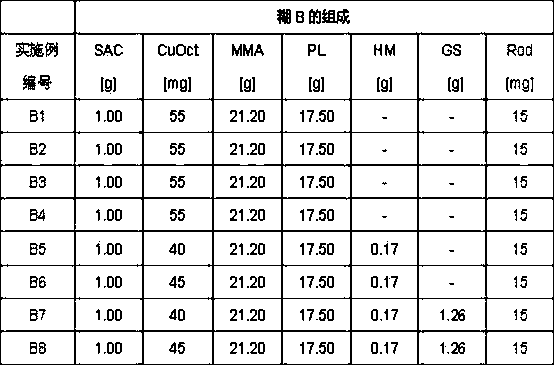

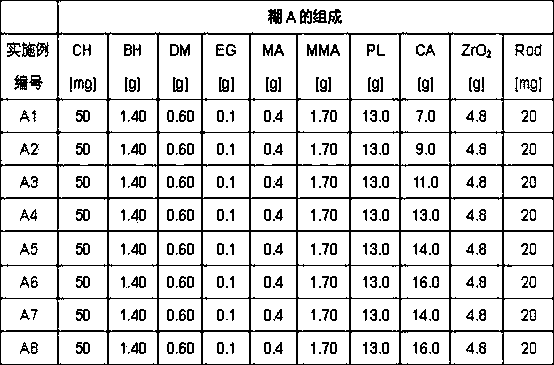

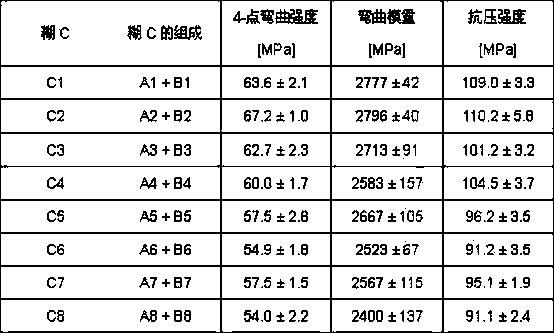

Paste-like bone cement

A paste contains at least one monomer for radical polymerisation, at least one polymer that is soluble in said at least one monomer for radical polymerisation, and at least one filling agent that is poorly soluble or insoluble in said at least one monomer for radical polymerisation. The filling agent is a particulate inorganic calcium salt comprising the following properties: at least 90% by weight of the particulate inorganic calcium salt have a particle size of less than 63 mum, as determined by means of sieve analysis; and the solubility in water of the particulate inorganic calcium salt at 20° C. is less than 8.5 g per litre. A kit and the paste is usable for mechanical fixation of articular endoprostheses, for covering skull defects, for filling bone cavities, for femuroplasty, for vertebroplasty, for kyphoplasty, for the manufacture of spacers or for the production of carrier materials for local antibiotics therapy, as well as a form body.

Owner:HERAEUS MEDICAL

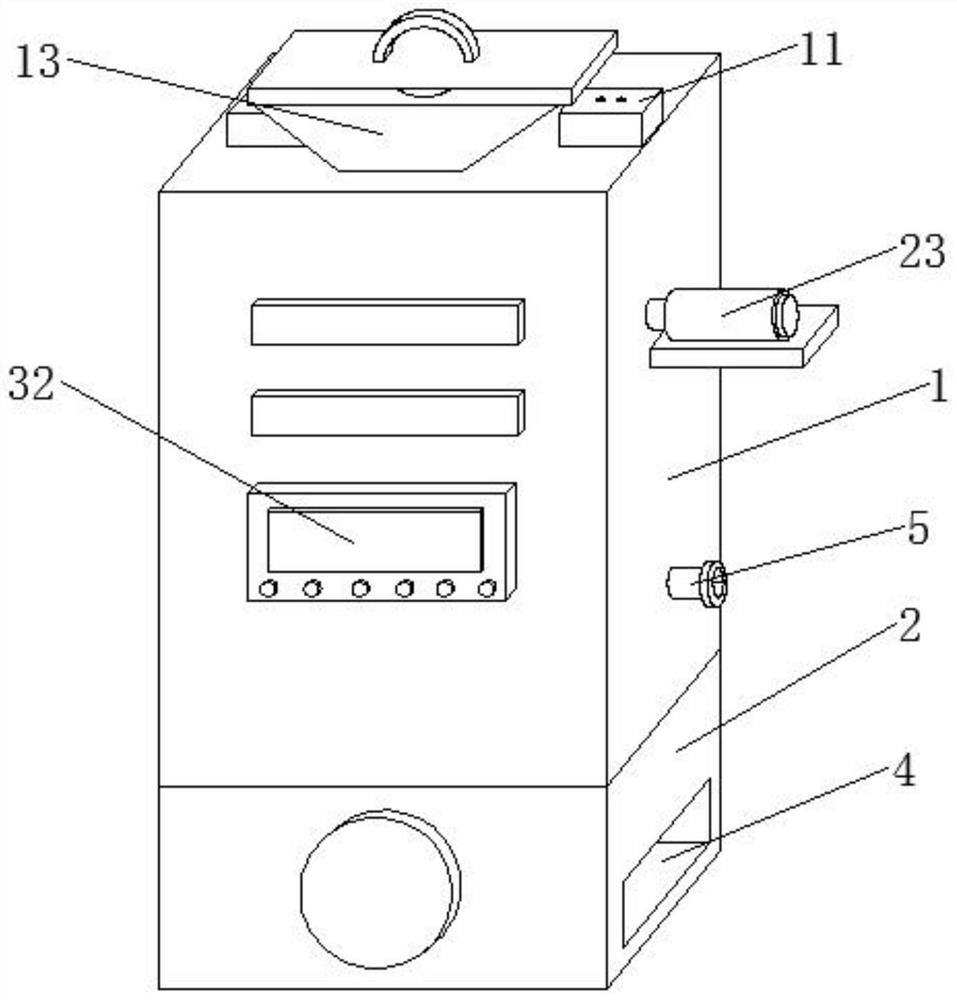

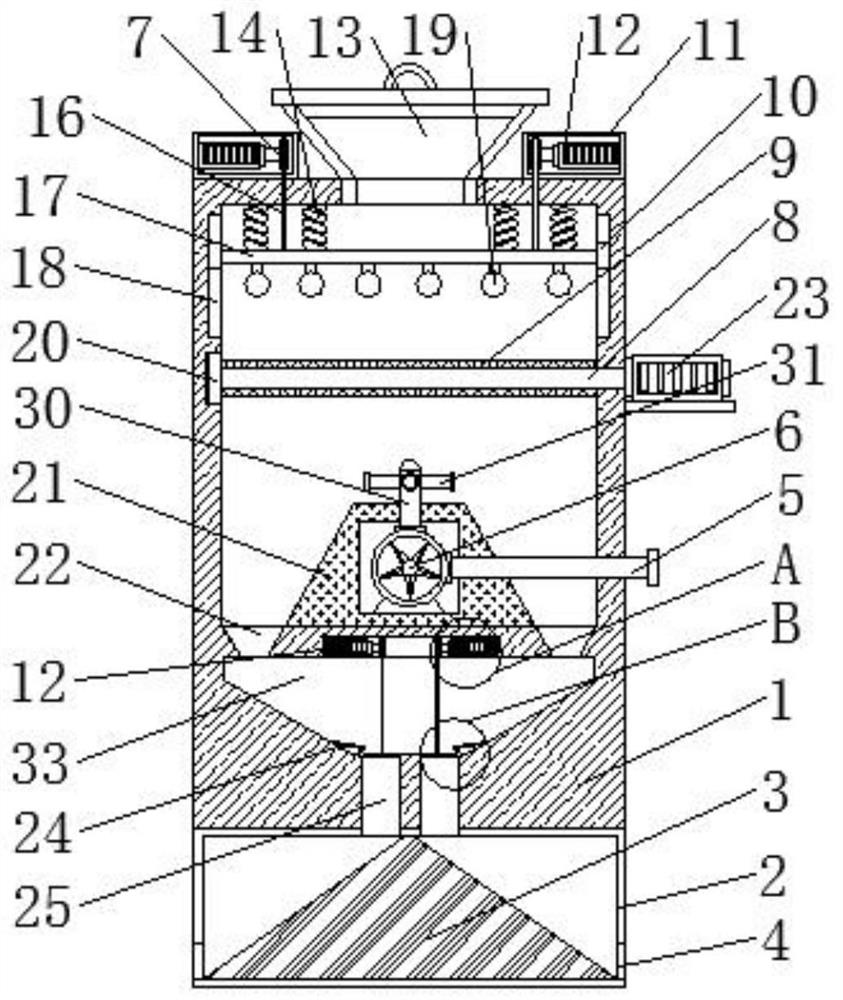

Sieve analysis experimental machine

InactiveCN109799158ASieve analysis works wellGuarantee the efficiency of sieve analysis experimentsParticle size analysisMaterial weighingElectricityFineness modulus

The invention relates to a sieve analysis experimental machine, which comprises an experimental machine shell, an electric blowing device, a guide device, a net device, a funnel device, a collection box, a weighing device and a processor. The experimental machine shell is positioned on the outer periphery of the sieve analysis experimental machine; the electric blowing device is positioned on theupper portion of the sieve analysis experimental machine; the guide device is positioned below the electric blowing device; the net device is positioned below the guide device; the funnel device is positioned below the net device; the collection box is positioned below the funnel device; the weighing device is positioned below the collection box; the processor is positioned on an inner side of thesieve analysis experimental machine. By control of the net device, sieve analysis operation can be well carried out; by connection with a computer, sand diameters can be judged, a fineness modulus diagram is drawn, and sieve analysis experimental efficiency is guaranteed. In addition, by the sieve analysis experimental machine manual workload can be relieved, manpower resources are saved, and economic benefits and operating efficiency are improved.

Owner:NANJING INST OF TECH

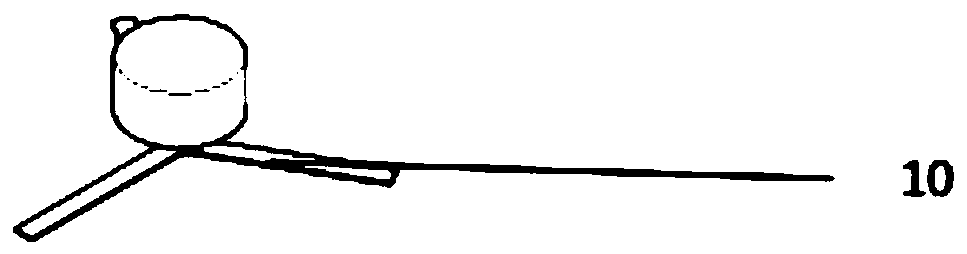

A kind of wet particle size analysis vibrating sleeve sieve and its application

InactiveCN103252318BEasy to operateImprove classification accuracySievingScreeningWater dischargeComputer science

The invention discloses a wet-type grading analysis vibrating sieve set and application of the wet-type grading analysis vibrating sieve set. The wet-type grading analysis vibrating sieve set can efficiently and accurately conduct screen analysis of materials. According to the structure, the vibrating sieve set comprises an electromagnetic vibrator, a vibrating disk, rubber springs, a standard sieve set upper pressing disk, a standard sieve set hanging frame, a standard sieve set hanging chassis, vibrating disk supporting rods, a base, a standard sieve set upper pressing disk fixing clamp, a water trough, standard sieve set bodies and a water discharging opening. An application method of the vibrating sieve set comprises a first step of lifting the vibrating disk and taking down the vibrating disk and the sieve set handing frame together from the vibrating disk supporting rods, a second step of selecting needed standard sieve set bodies, a third step of placing standard sieves which are sleeved in the hanging frame, a fourth step of stably placing the vibrating disk on rubber springs arranged on the supporting rods, a fifth step of plugging the water discharging opening of the water trough with a rubber plug and pouring water into the water trough, a sixth step of starting the vibrator and discharging materials below the finest-mesh sieve, and a seventh step of respectively filtering, drying, weighing and sampling different particles, and conducting analysis and test. The wet-type grading analysis vibrating sieve set is wide in application range, high in grading precision, less in dust in operation environment, and capable of being widely applied to scientific researches and production.

Owner:UNIV OF SCI & TECH LIAONING

Cement negative pressure sieve analysis instrument capable of achieving heat dissipation conveniently

ActiveCN112474347AQuick clean upImprove cleaning efficiencySievingGas current separationRotational axisDrive shaft

The invention discloses a cement negative pressure sieve analysis instrument capable of achieving heat dissipation conveniently, and relates to the field of cement processing. The cement negative pressure sieve analysis instrument comprises an instrument body, a storage box is installed at the bottom of the instrument body, a guide block is installed in the storage box, discharge ports are formedin the two sides of the storage box, a material falling port, a cavity and a guide port are formed in the lower portion in the instrument body, and baffles are fixed to the two sides in the cavity. Through arrangement of a third motor, a driving shaft, the material falling port, the cavity, the baffles, second motors, second reels, second pull ropes, the discharge ports, a rotating shaft and a partition plate, when shaking balls move to the uppermost part of the instrument body, a worker starts the third motor through an operation table, the third motor works to drive the driving shaft to rotate, the driving shaft rotates so as to drive a filter screen to rotate, after the filter screen rotates by 90 degrees, cement with large granularity on the filter screen falls into the material falling port and falls into the cavity through the material falling port, and therefore the cement on the filter screen is convenient to clean away.

Owner:富强科技股份有限公司

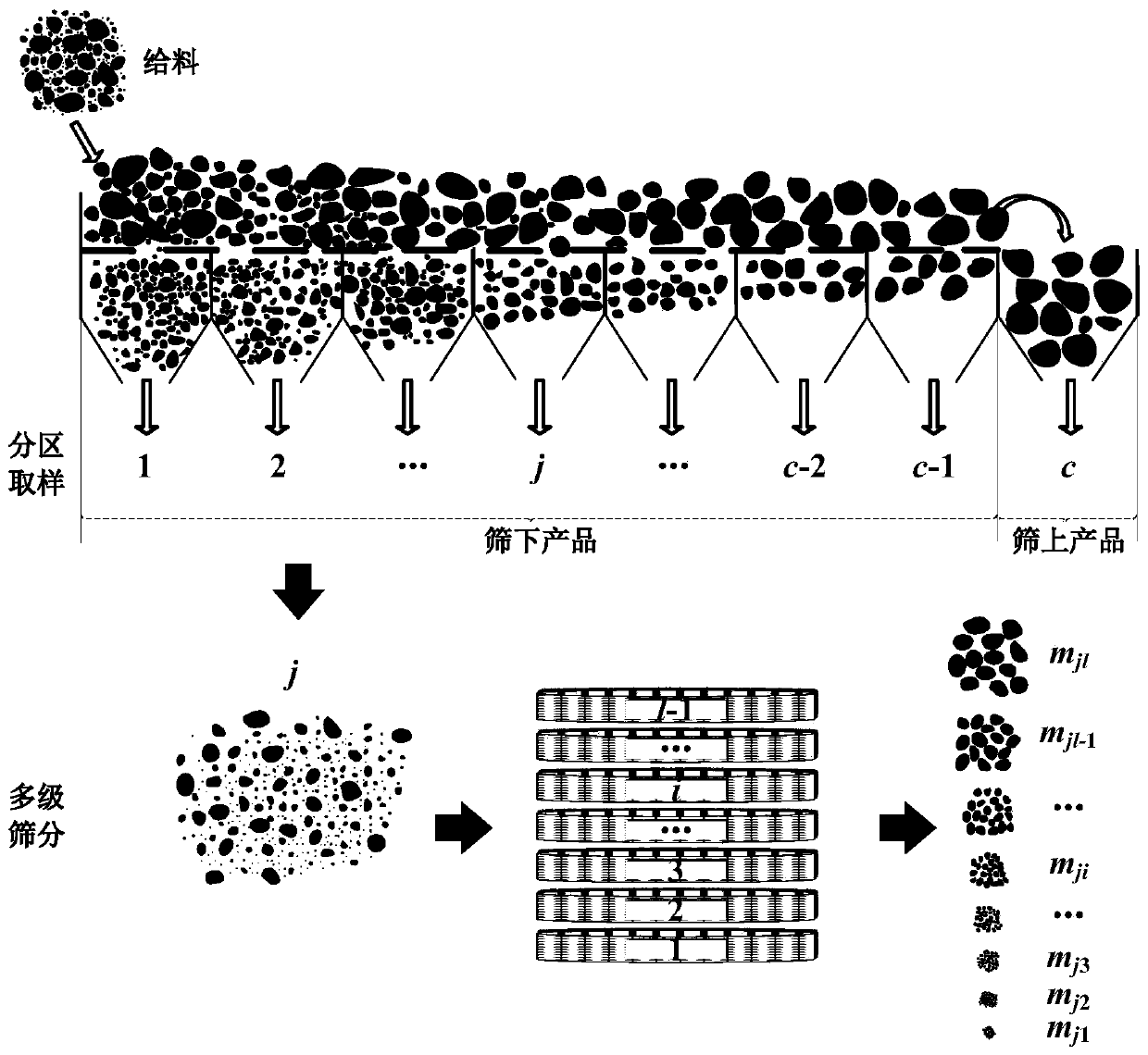

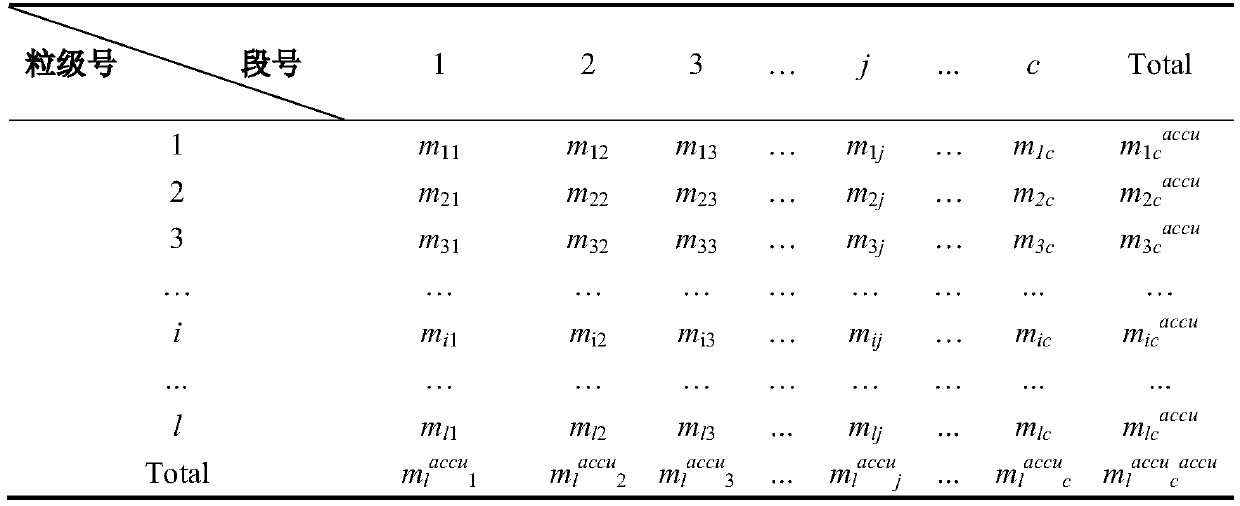

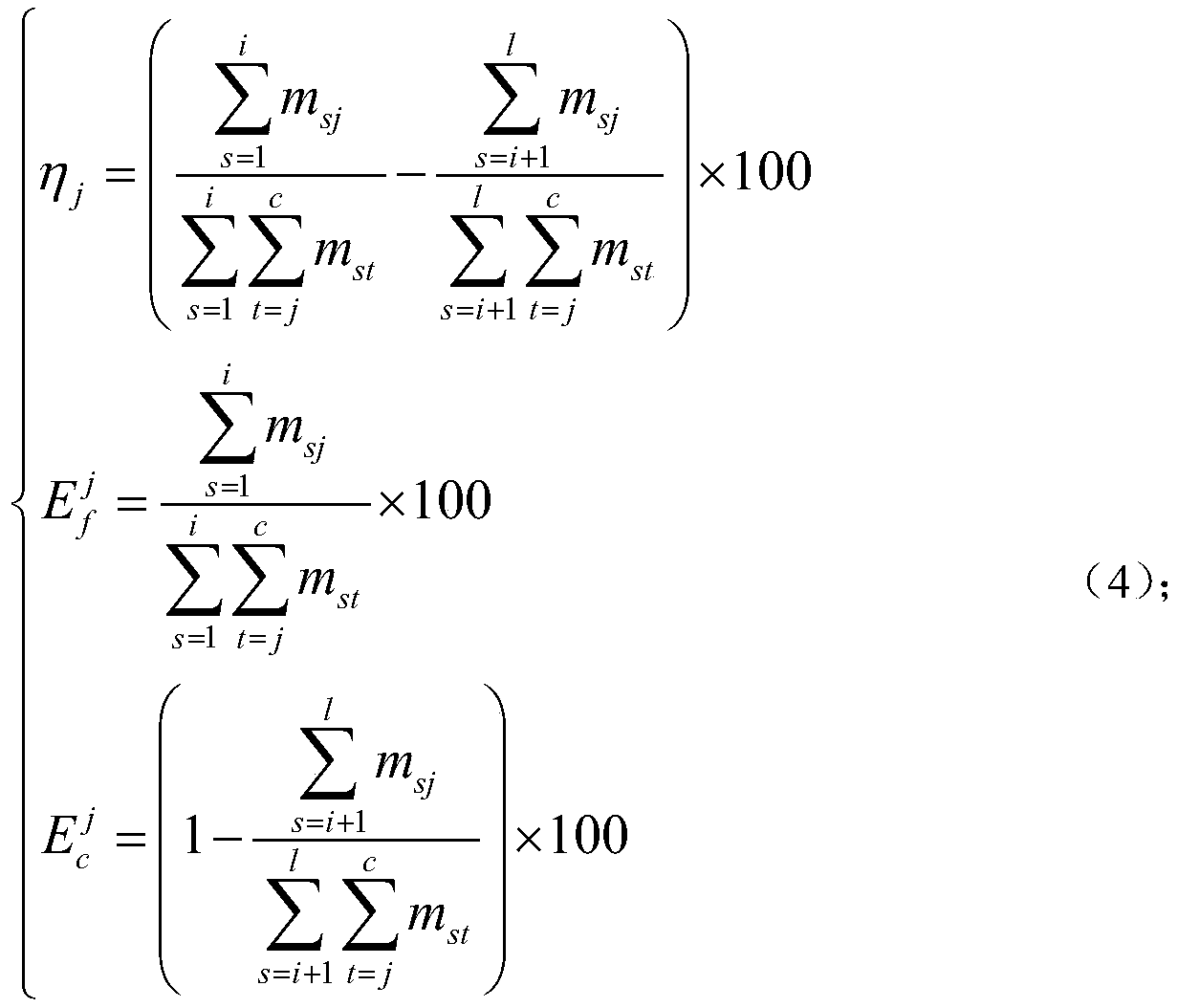

Partitioned multi-stage screening analysis and effect evaluation method

InactiveCN110851764AAccurately determineEasy to determineComplex mathematical operationsProcess engineeringIndustrial engineering

The invention discloses a partitioned multi-stage screening analysis and effect evaluation method which comprises the following steps: uniformly dividing an undersize product into c-1 regions according to the screen length in the material flow migration direction, and taking an oversize product as a cth region; screening the materials in each area for 1-1 time, dividing the materials into 1 size fractions which are sequentially 1, 2, 3... 1 from small to large, and respectively weighing the materials with different size fractions in each area to obtain the mass of the materials; and further obtaining the sieve penetration distribution rule of the materials of each size fraction in different areas, and obtaining the sieve surface of each area, the lengths of different sieve surfaces, the overall sieving efficiency and the total mismatch content. The method can accurately, conveniently and reliably determine the screening distribution rule of the materials of each size fraction in the screening process, evaluate the screening effect of the screen surfaces in different areas, and provide reference for optimization of key process parameters in the screening process and structural design of the high-performance vibrating screen.

Owner:CHINA UNIV OF MINING & TECH +1

Fast abrasion test for granules

InactiveUS20110247392A1Accurate classificationEasy to useUsing mechanical meansInvestigating abrasion/wear resistanceFasting testsSieve analysis

Fast test for determining the abrasion of granules, in the case of whichi.) granules are milled,ii.) the milled product is subjected to a sieve analysis, andiii.)the results of the sieve analysis are compared with at least one reference value in order to classify the abrasion of the granules,the granules being milled in a cutting mill.

Owner:EVONIK DEGUSSA GMBH

Phytosterol/salt composition for topical application to food products

A phytosterol / salt mixture for even topical application to snack products. At least one free phytosterol in dry form is combined with at least one salt of a similar particle size to form a homogenous blend and applied to the surface of a hot snack food product. The at least one free phytosterol can also be part of a phytosterol blend comprised of at least 95% free phytosterols. To ensure that neither the phytosterol nor salt component settles out and to provide for uniformity of the homogenous blend, the phytosterol blend is of a similar size distribution to the at least one salt. In test runs, a phytosterol blend and at least one salt were combined in a ratio of approximately 53:47, with size ranges determined by sieve analysis to generally fell within the range of 149 to 400 microns.

Owner:FRITO LAY NORTH AMERICA INC

Estimation Method of Annual Wind Erosion of Farmland Soil

ActiveCN103454063BSolving this pressing problem in wind erosion researchEasy to operateAerodynamic testingSoil scienceSurface layer

Owner:河北省科学院地理科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com