Sieve analysis experimental machine

An experimental machine and sieve analysis technology, which is applied in the direction of measuring devices, particle size analysis, and analytical materials, can solve the problems of ineffective control of time, difficulty in calculation, and prolongation of experiment time, so as to improve economic benefits and work efficiency, and reduce human work. The effect of burden and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

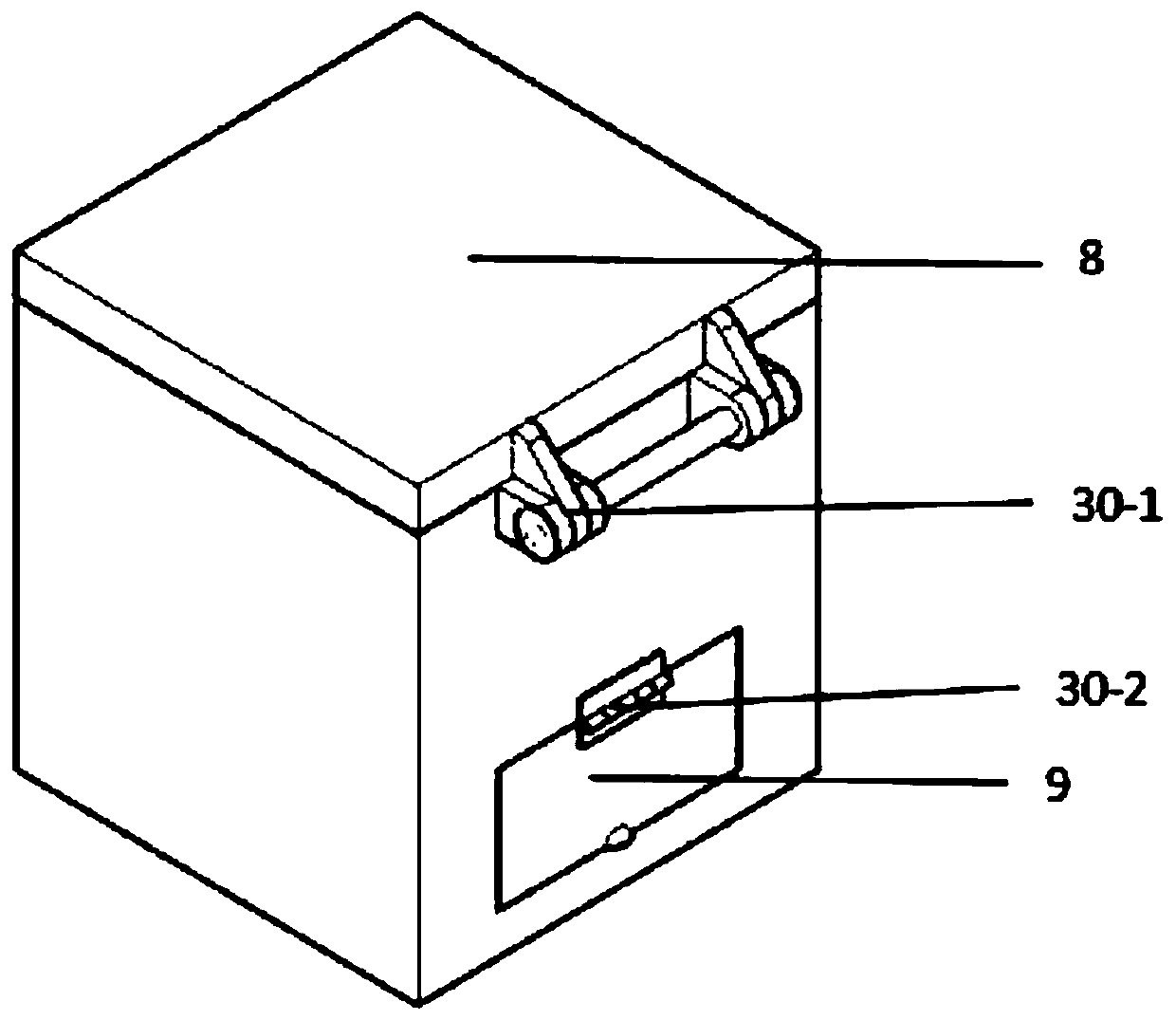

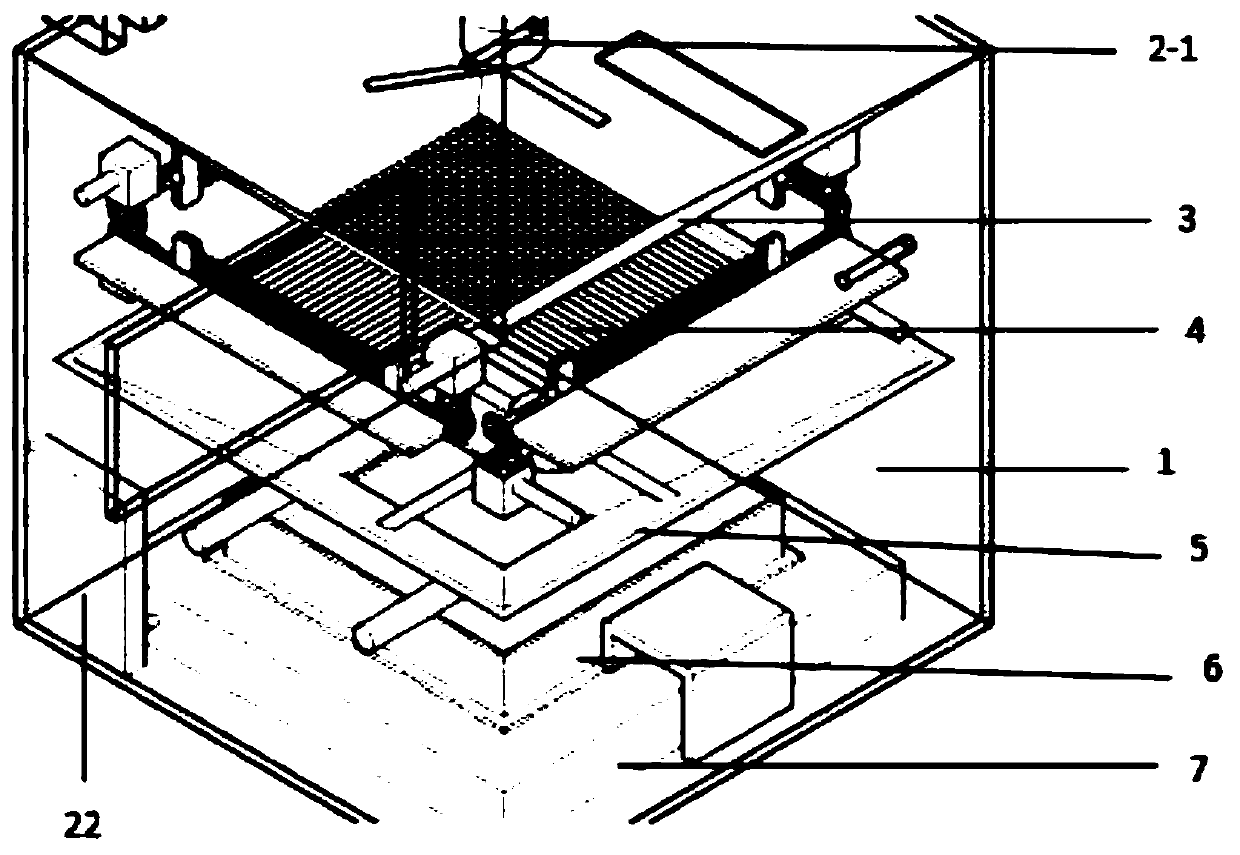

[0028] see Figure 1-2 , a sieve analysis test machine device, comprising a test machine shell 1, a hair dryer, a guide device 3, a net device 4, a funnel device 5, a collection box 6, a weighing device 7, and a processor 22; the test machine The casing 1 is located at the periphery of the sieve analysis test machine device, and is included in all devices; the first electric blower device 2-1 is located at the top of the sieve analysis test machine device, so that the sand particles can fully fall, and it is connected with the top of the sieve analysis test machine device. The upper cover 8 is welded through the connecting rod 14; the guide device 3 is located at the bottom of the first hair dryer 2-1, and the bottom is a buckle 12, which is nested in the square line 16 of the net device 4 below; the net The device 4 is located at the lower part of the guide device 3, and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com