Method for calibrating particle size analysis data by using laser method and sieve analysis method

A technology of particle size analysis and correction method, applied in particle size analysis, individual particle analysis, particle and sedimentation analysis, etc., can solve problems such as unavoidable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

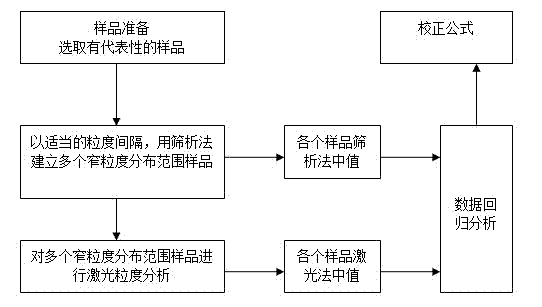

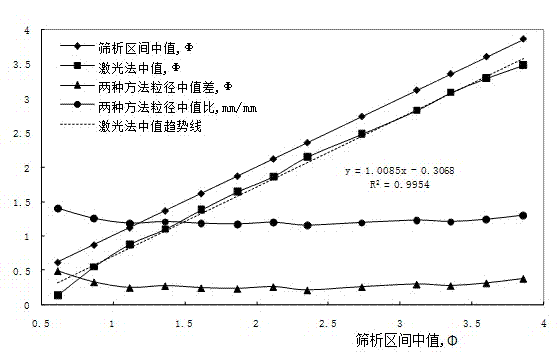

[0021] In this embodiment, we take the sieve analysis method as an example to describe the specific implementation process of the present invention in detail, as figure 2 As shown, the specific steps are as follows:

[0022] 1. Select a representative sample. Here we take a sample from a certain place as an example. The main components are quartz, feldspar, felsic debris, a small amount of opaque minerals, and a small amount of mica. The roundness of the particles is mostly sub-prismatic.

[0023] 2. The standard sieve is 2000-63um, the particle size interval is 0.25Φ, and the sieve analyzer is the sonic automatic sieve analyzer manufactured by the Nanjing Institute of Geography and Lake Sedimentation, Chinese Academy of Sciences. A representative sample of about 200g is selected using the sieve analyzer In the range of 710 ~ 63um, sieve according to the particle size interval of 0.25Φ. The vibrating sieve generally takes about 10 minutes. The quality of each particle size is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com