Patents

Literature

294 results about "Laser methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

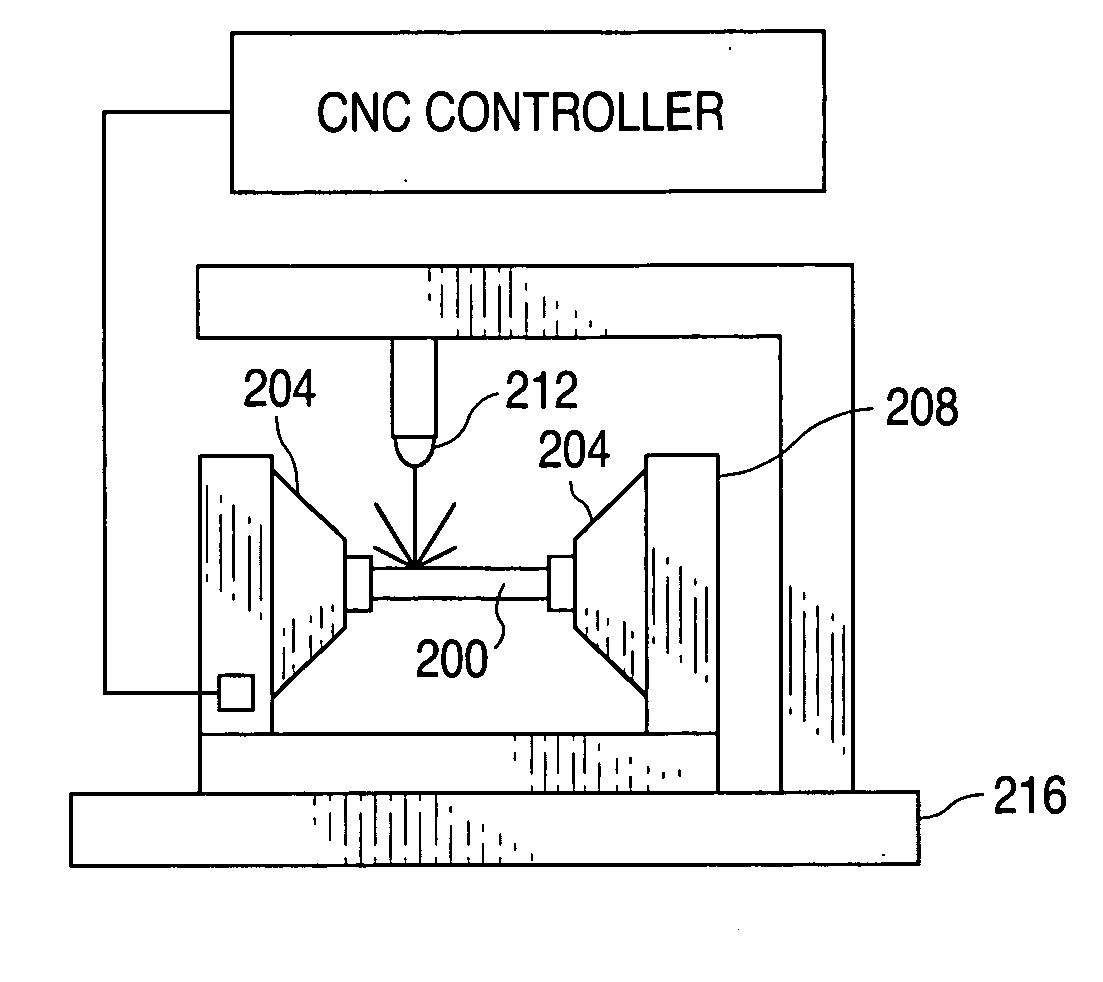

Fabricating medical devices with an ytterbium tungstate laser

Methods for fabricating a stent using a femtosecond laser with an Ytterbium Tungstate active medium are disclosed. In some embodiments, a method includes forming a pattern in the substrate with the laser, the pattern including a plurality of structural elements.

Owner:ABBOTT CARDIOVASCULAR

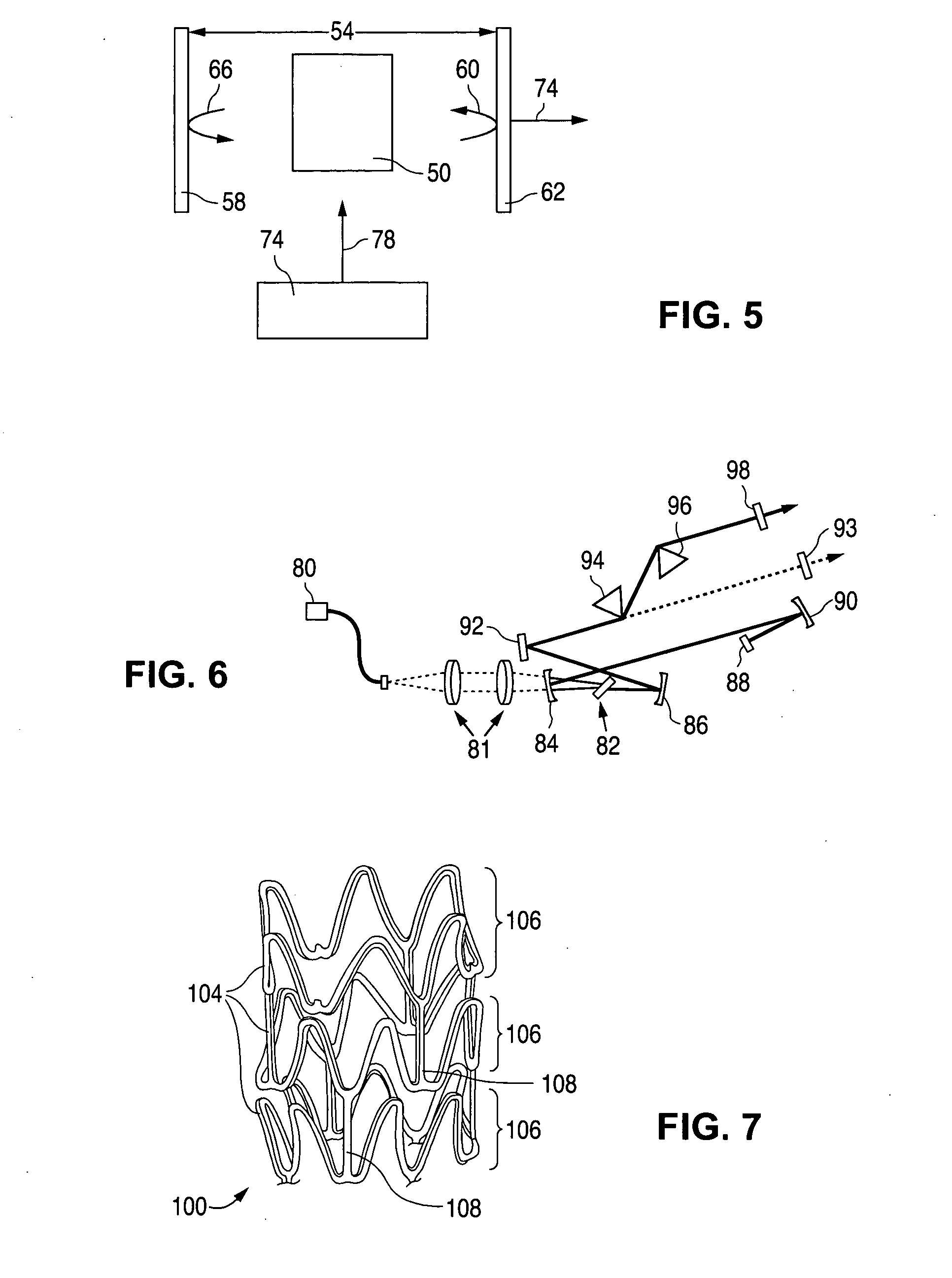

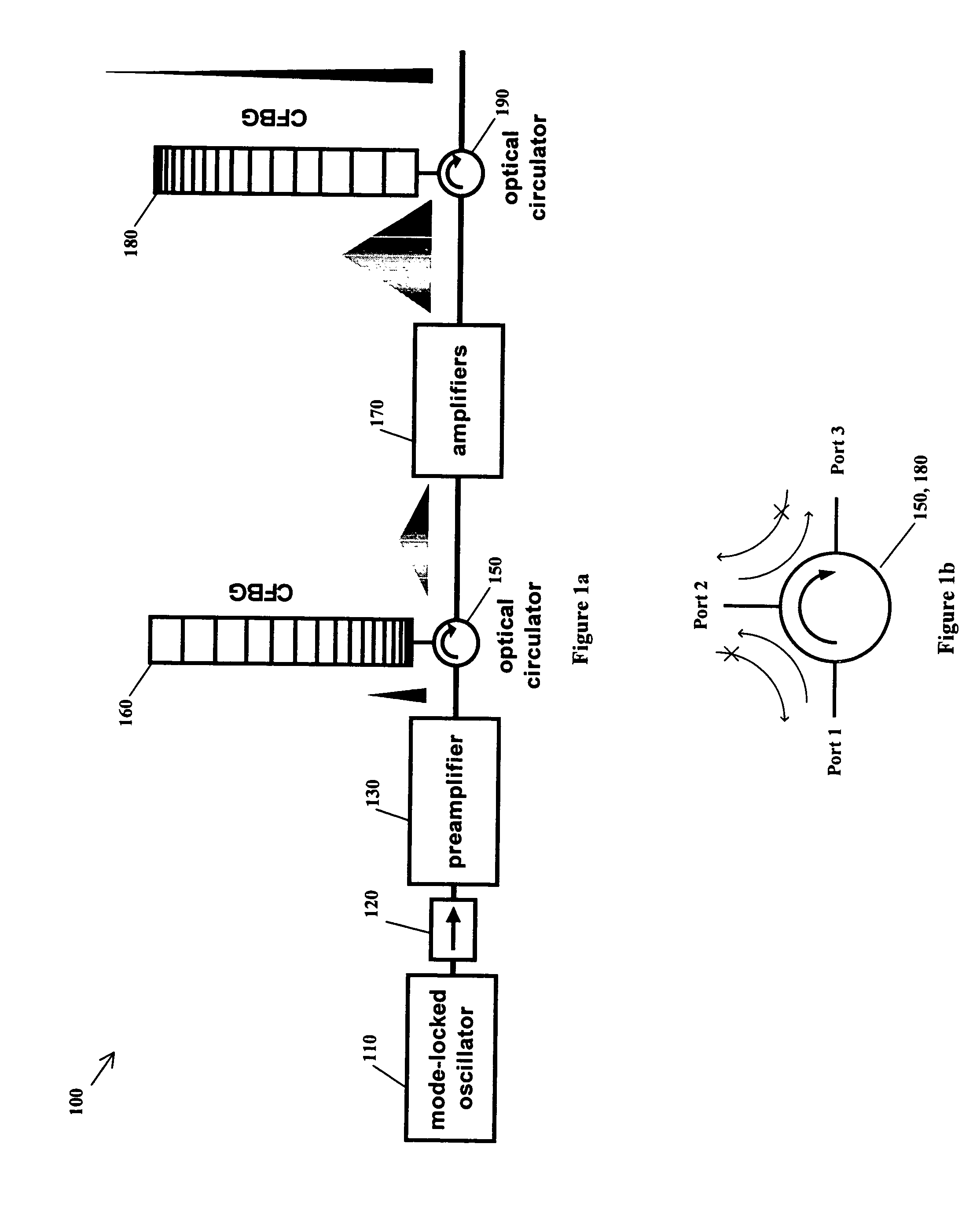

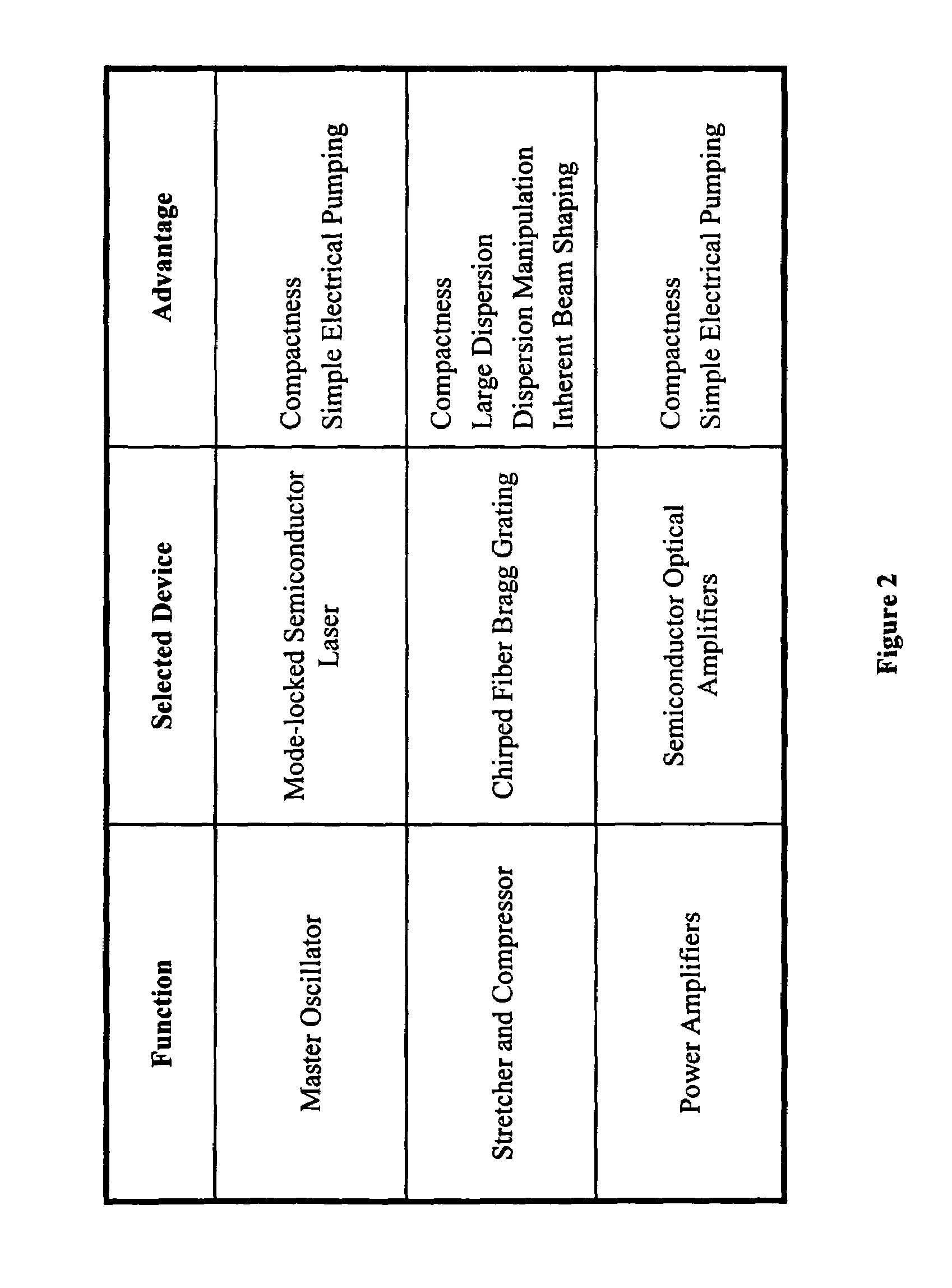

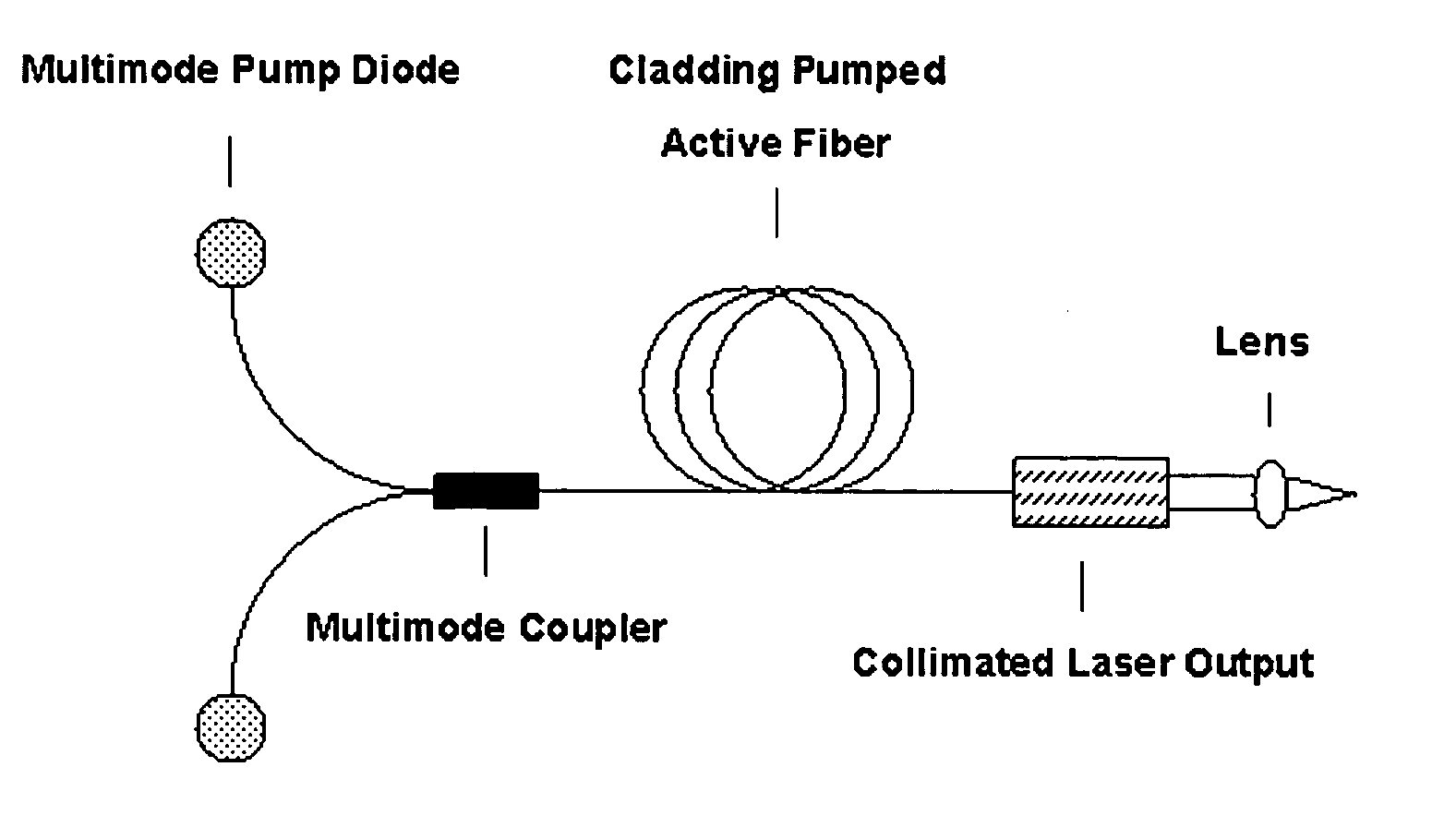

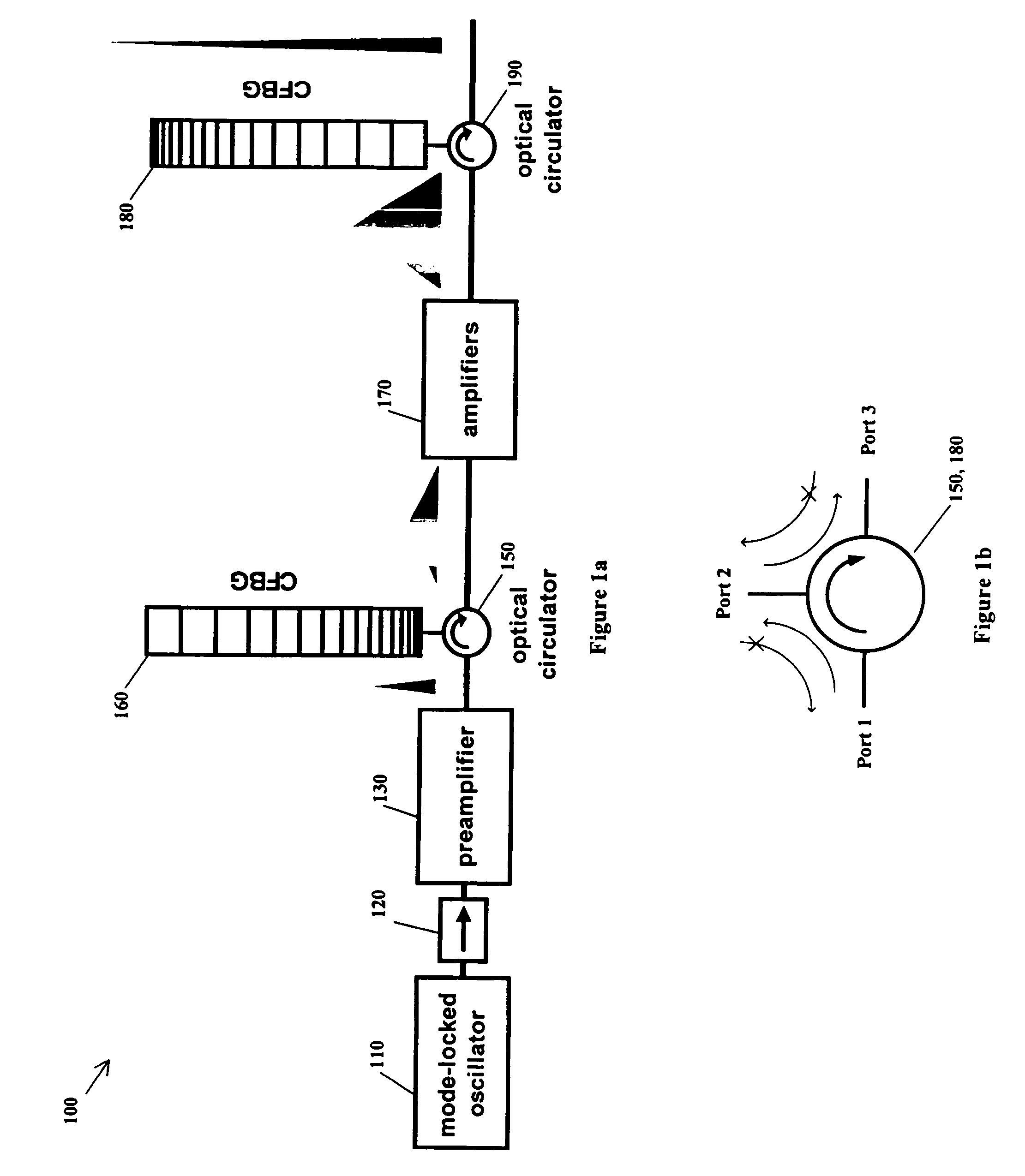

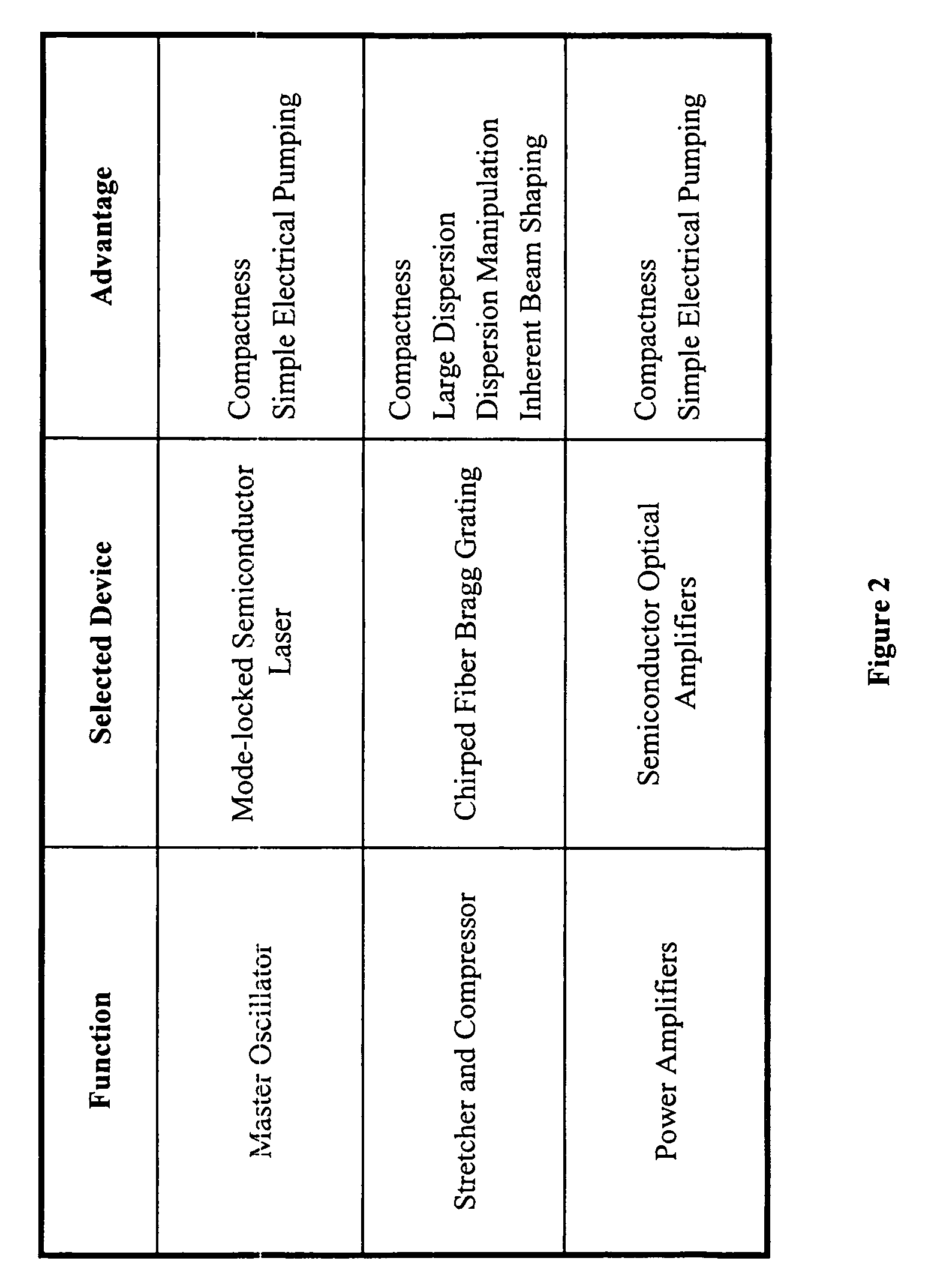

Extreme chirped/stretched pulsed amplification and laser

InactiveUS7095772B1Efficiently externally compressedIncrease powerExcitation process/apparatusSemiconductor amplifier structureChirped pulse amplificationFiber Bragg grating

Methods, devices and systems for generating ultrashort optical linear chirped pulses with very high power by amplifying the pulses so that their temporal duration is longer than the storage time of the amplifying medium. The additional gain factor is related to the ratio of the storage time to the stretched pulse. A preferred embodiment connects a mode locked laser source that generates optical pulses whose duration is stretched with a chirped fiber Bragg grating. Embodiments include methods, devices and systems causing an extreme chirped pulse amplifier (XCPA) effect in an oscillator.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

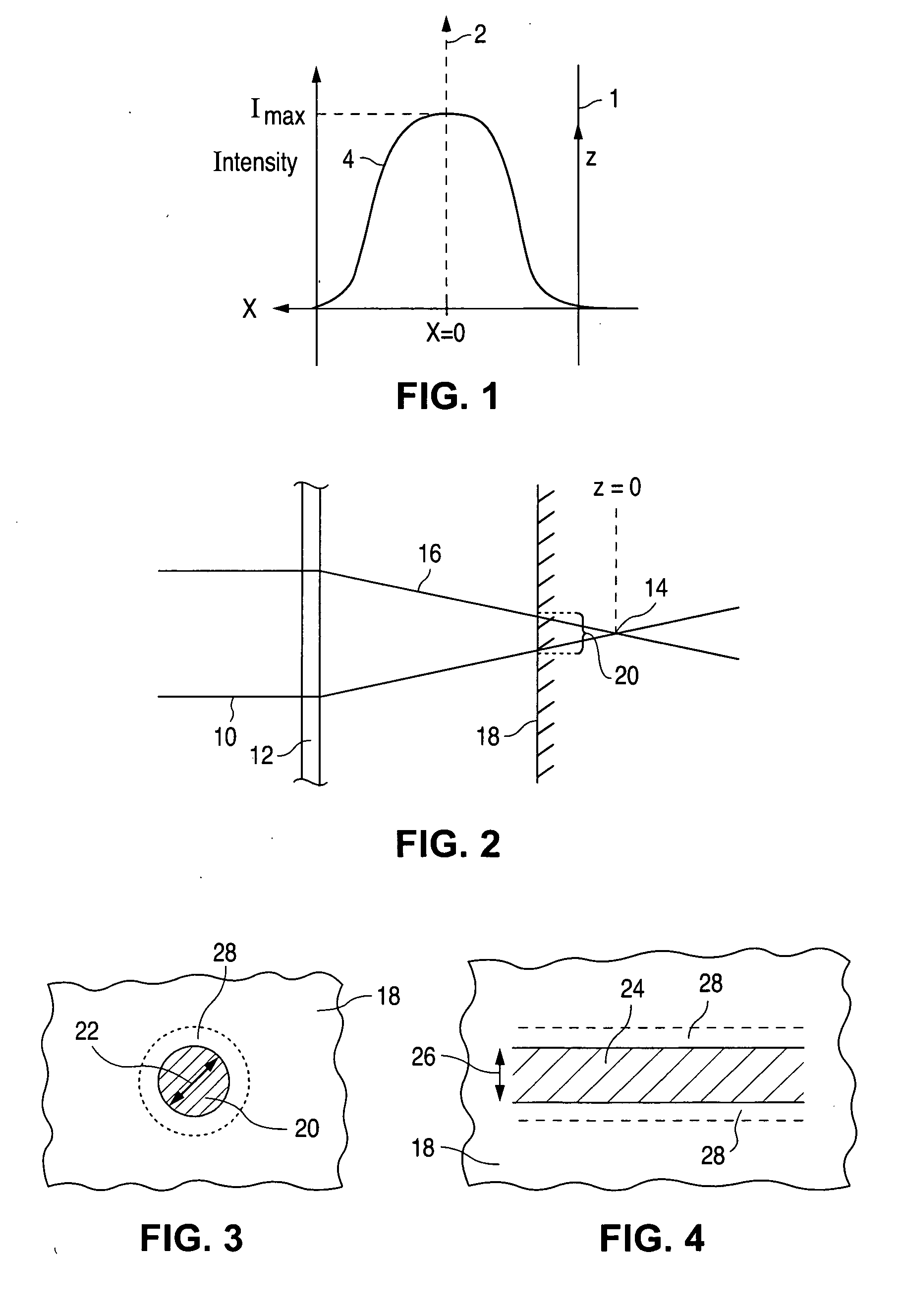

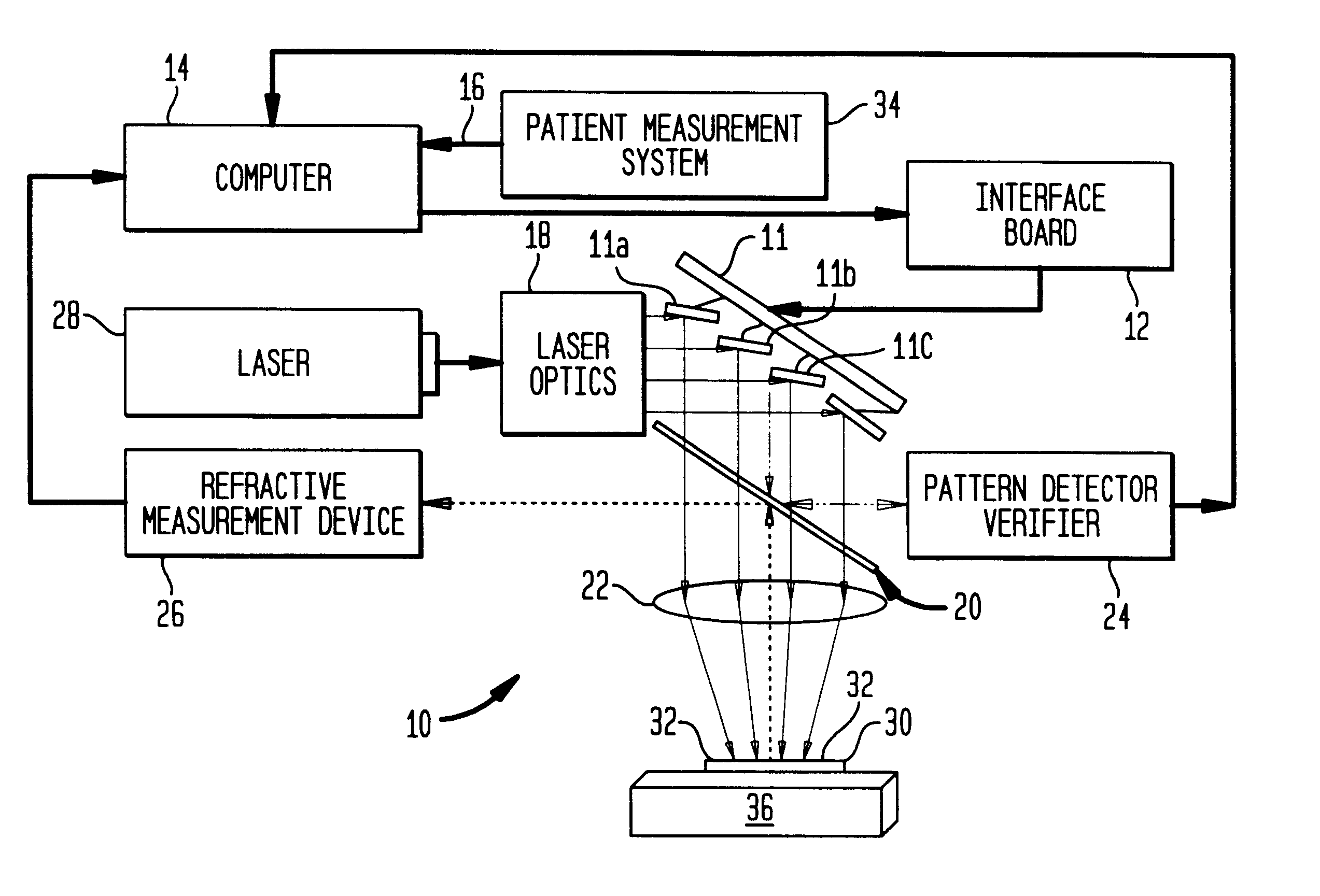

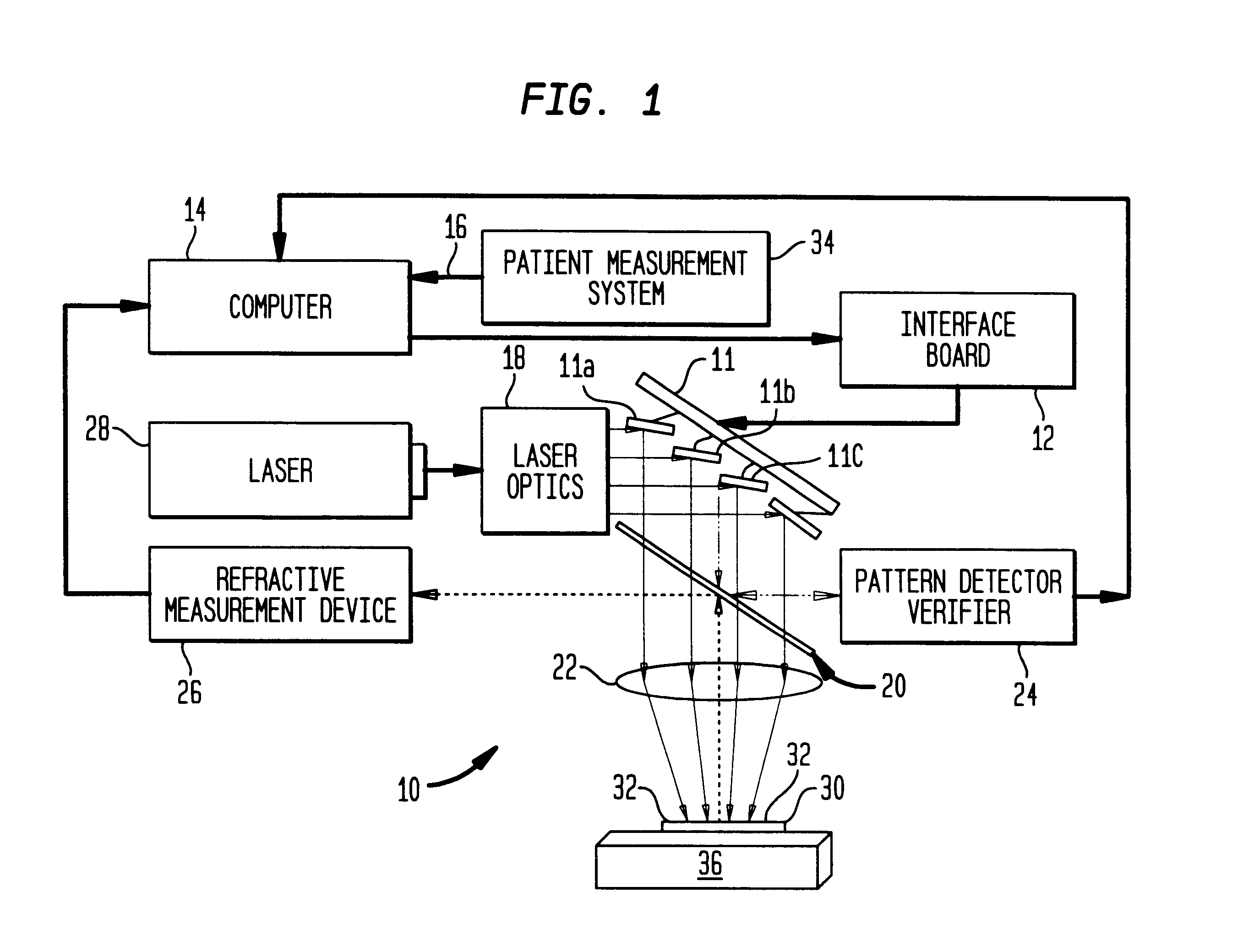

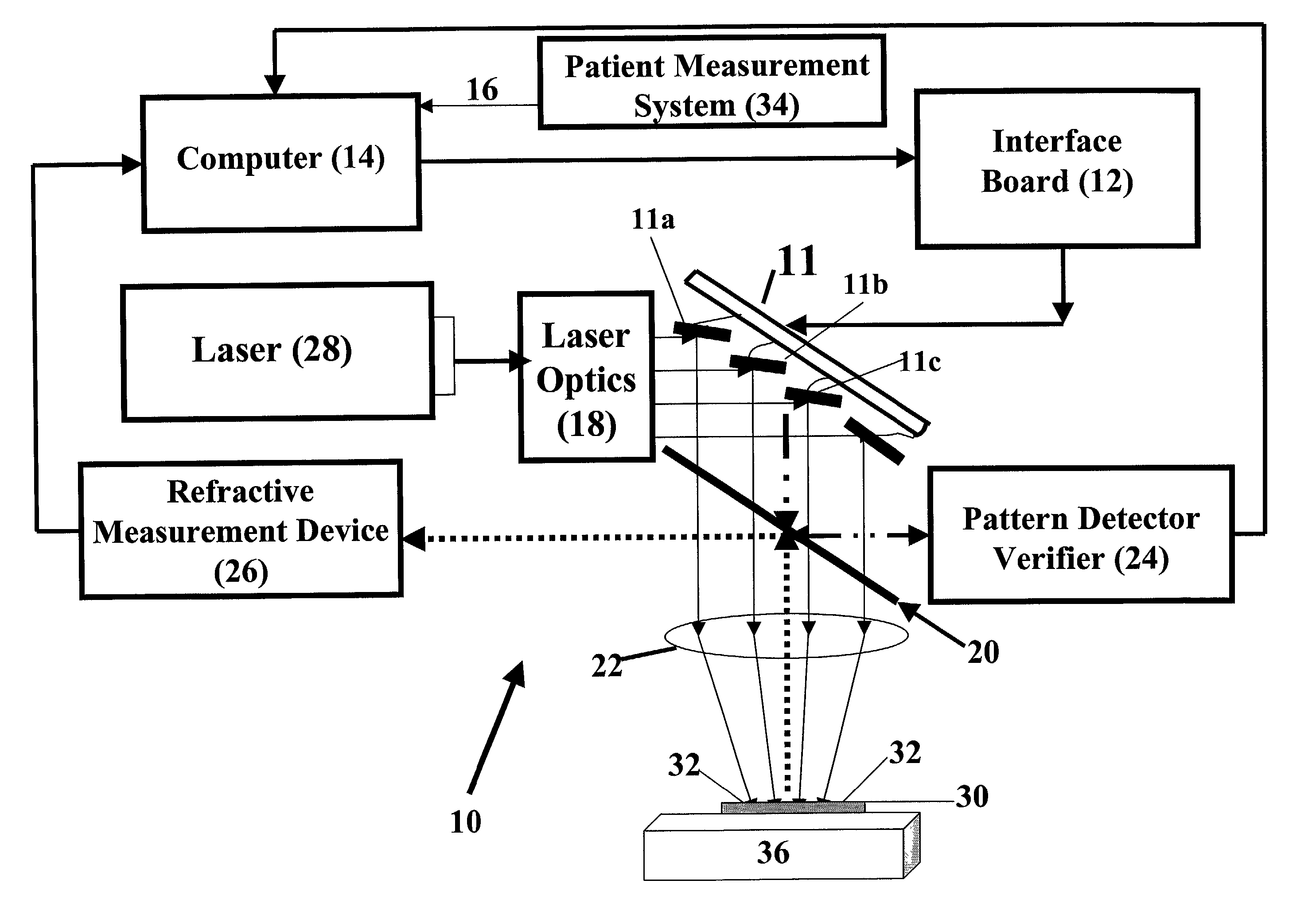

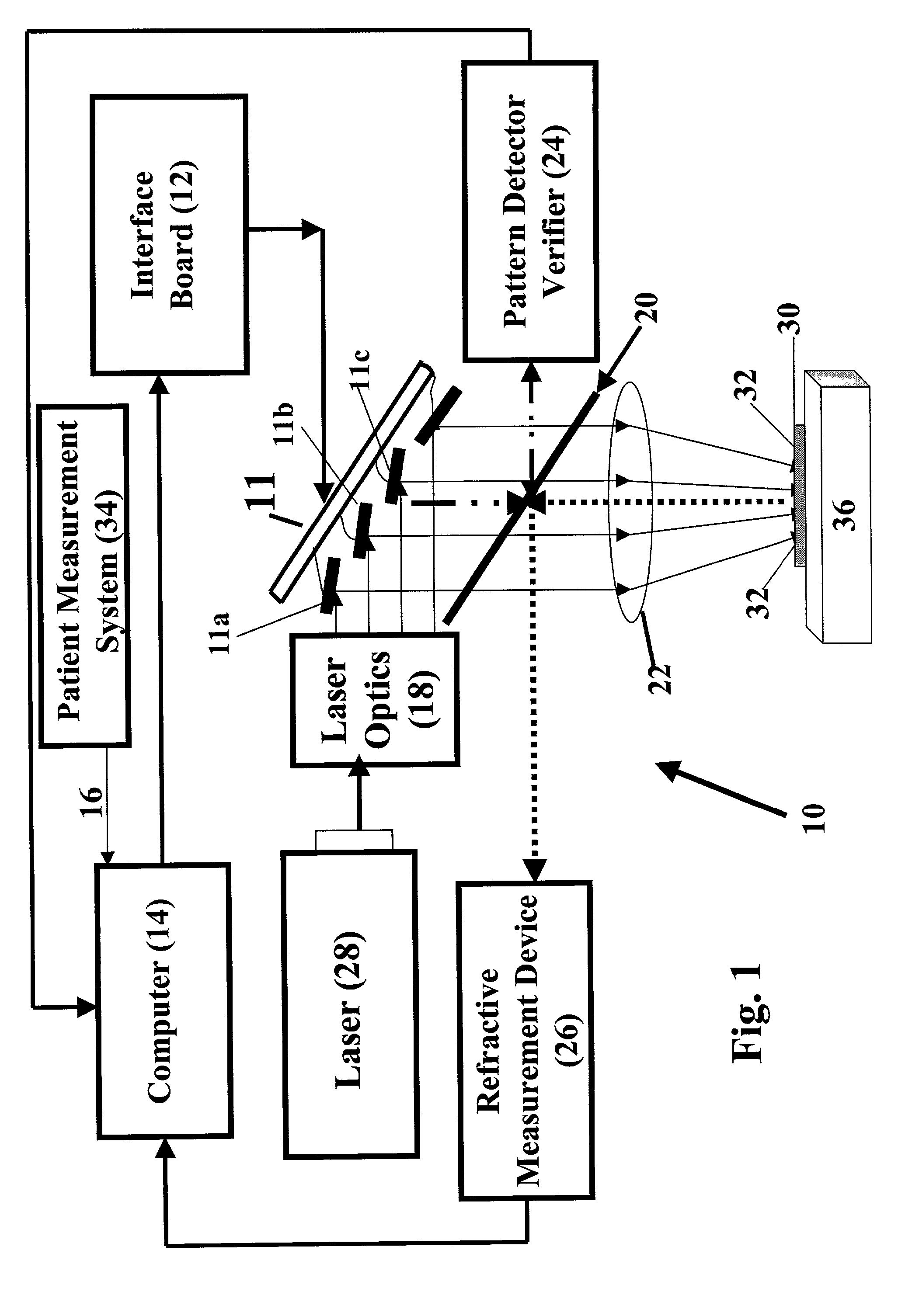

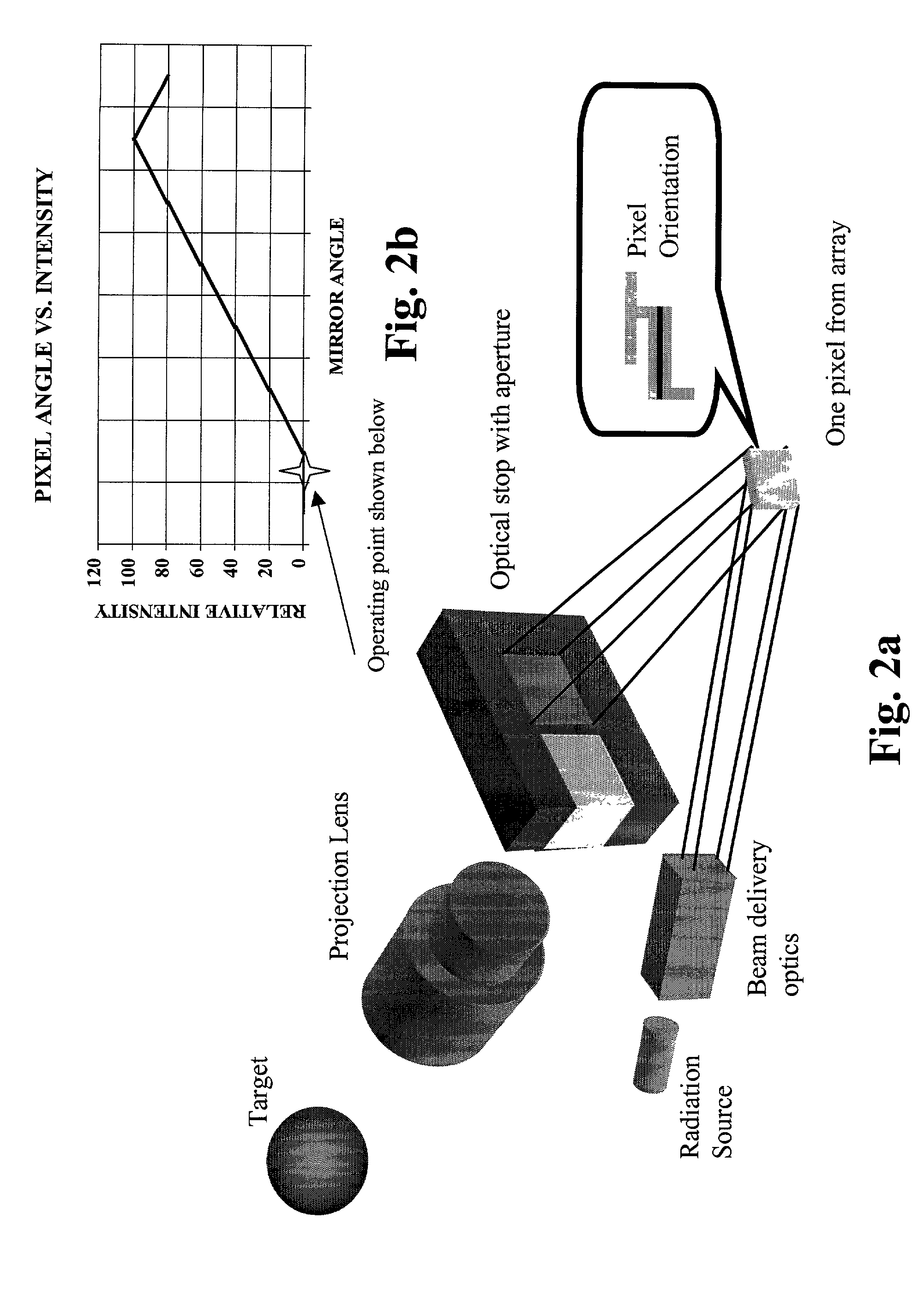

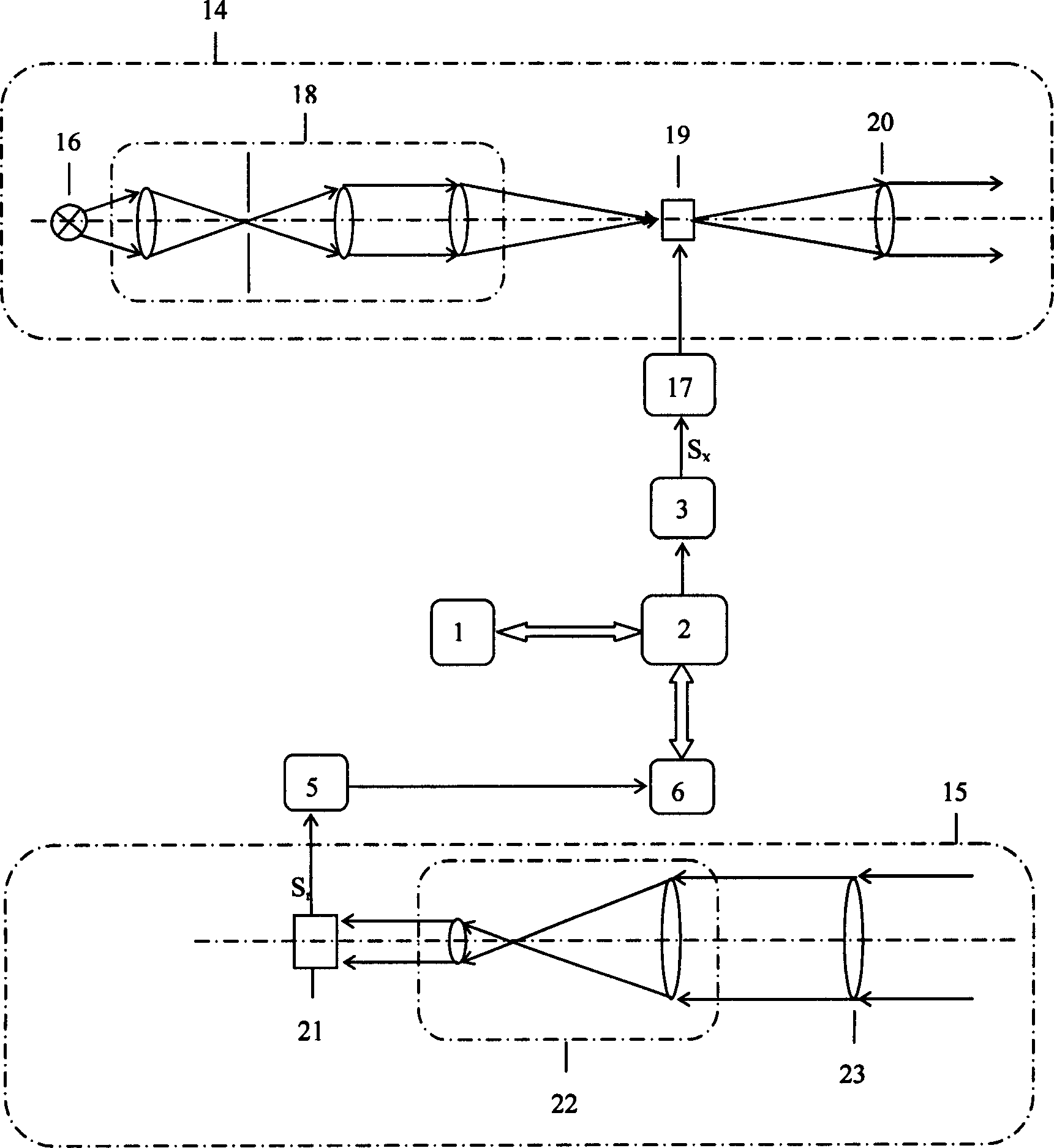

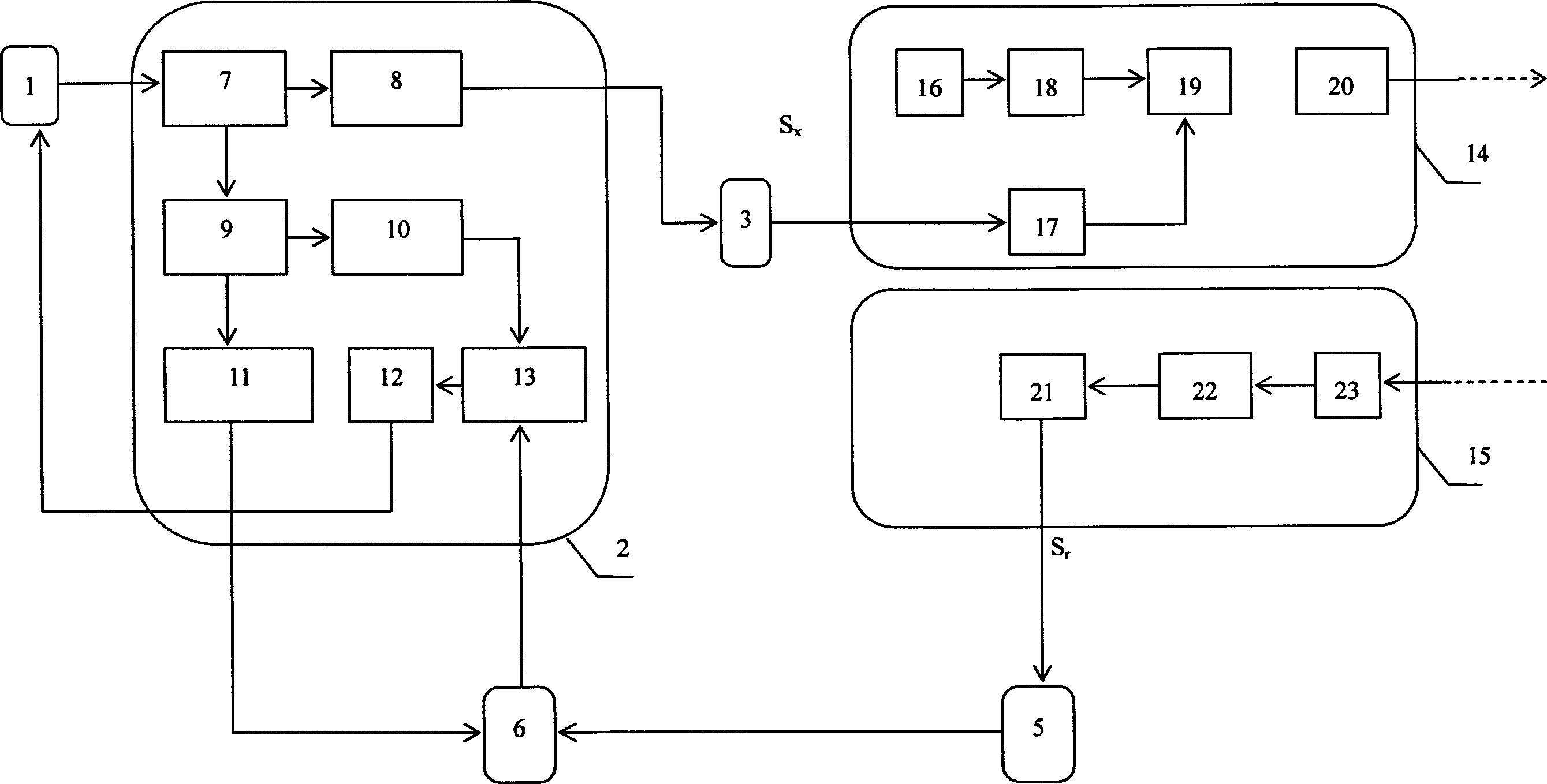

Laser method for shaping of optical lenses

A method for making accurate and precise customized corrections to the surface of an optical lens is described. An electronic correction contour is generated from a measured refractive correction for a patient, and transferred to the surface of the lens by ablation etching with one or more laser pulses. After each of the laser pulses, the refractive properties of the lens are measured and compared to the electronic contour correction derived from a patient's refractive correction. The ablation etching is terminated in localized areas where the refractive properties match the electronic correction contour. End point detection includes monitoring refractive qualities of the lens during the recontouring process, modifying the pattern through changes in the laser pulses.

Owner:WESTAR PHOTONICS

Portable laser

Methods and apparatus for modifying a material with a laser light beam, such as, for example, a laser light beam provided by portable laser, such as, for example, a portable optical fiber laser.

Owner:NUFERN

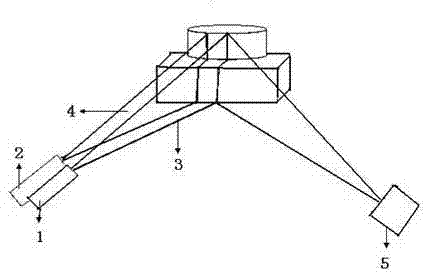

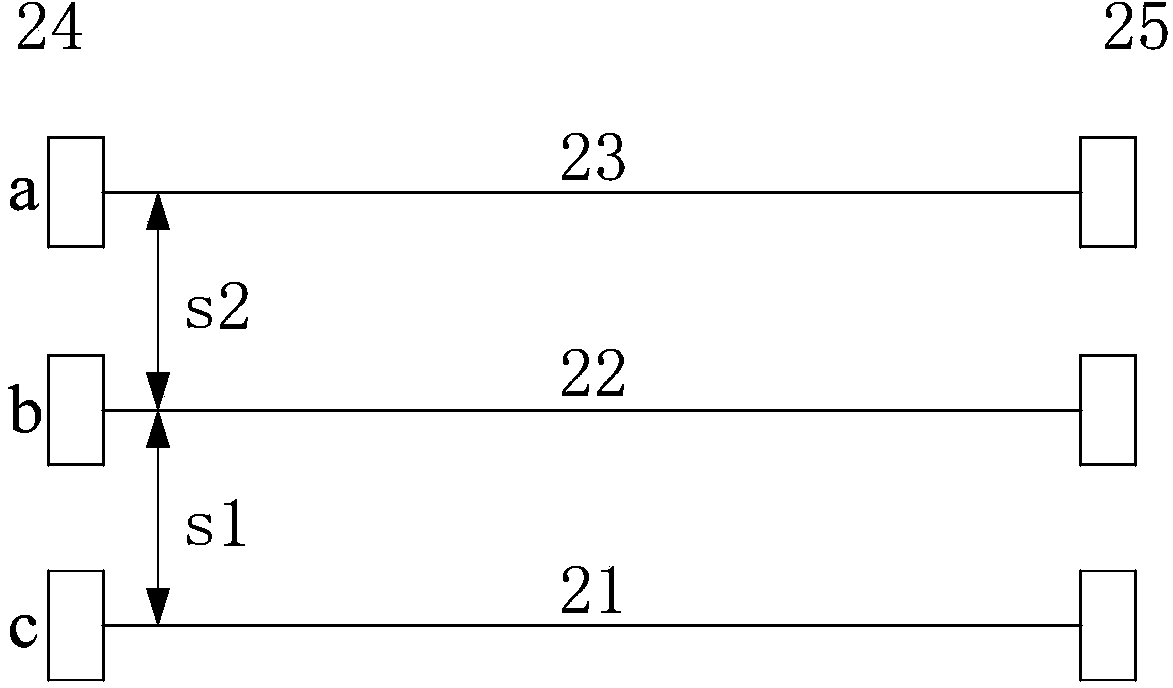

Three-dimensional information detection method based on two-line laser

InactiveCN102297658AImprove stabilityHigh precisionUsing optical meansThick lineThree dimensional measurement

The invention discloses a three-dimensional information detection method based on dual laser and belongs to the technical field of three-dimensional measurement. The method comprises the following steps of: adopting two lasers, and respectively solving laser plane equations of the first laser and the second laser; collecting an object image containing dual laser by utilizing a camera in the eventof detecting the three-dimensional information of an object, and solving a centre line of each laser thick line; and rebuilding three-dimensional data by utilizing inner parameters of the camera and the laser plane equations of both lasers. Compared with the single-laser measurement method, because of large information amount, the method disclosed by the invention specifically has higher stability, reliability and accuracy; and simultaneously, the operation requirements are simple, thus the method has the important application in detecting the surface three-dimensional information of objects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

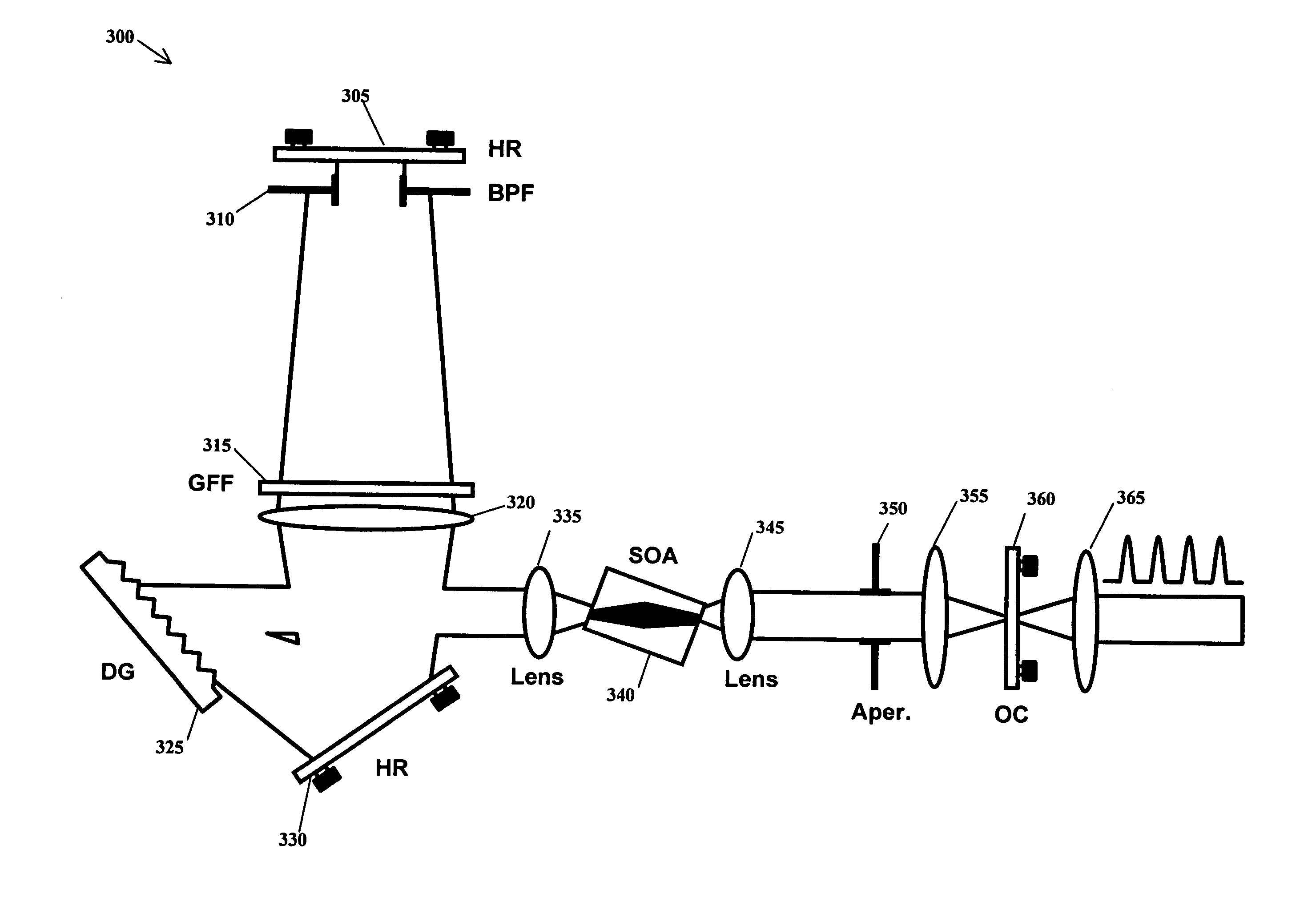

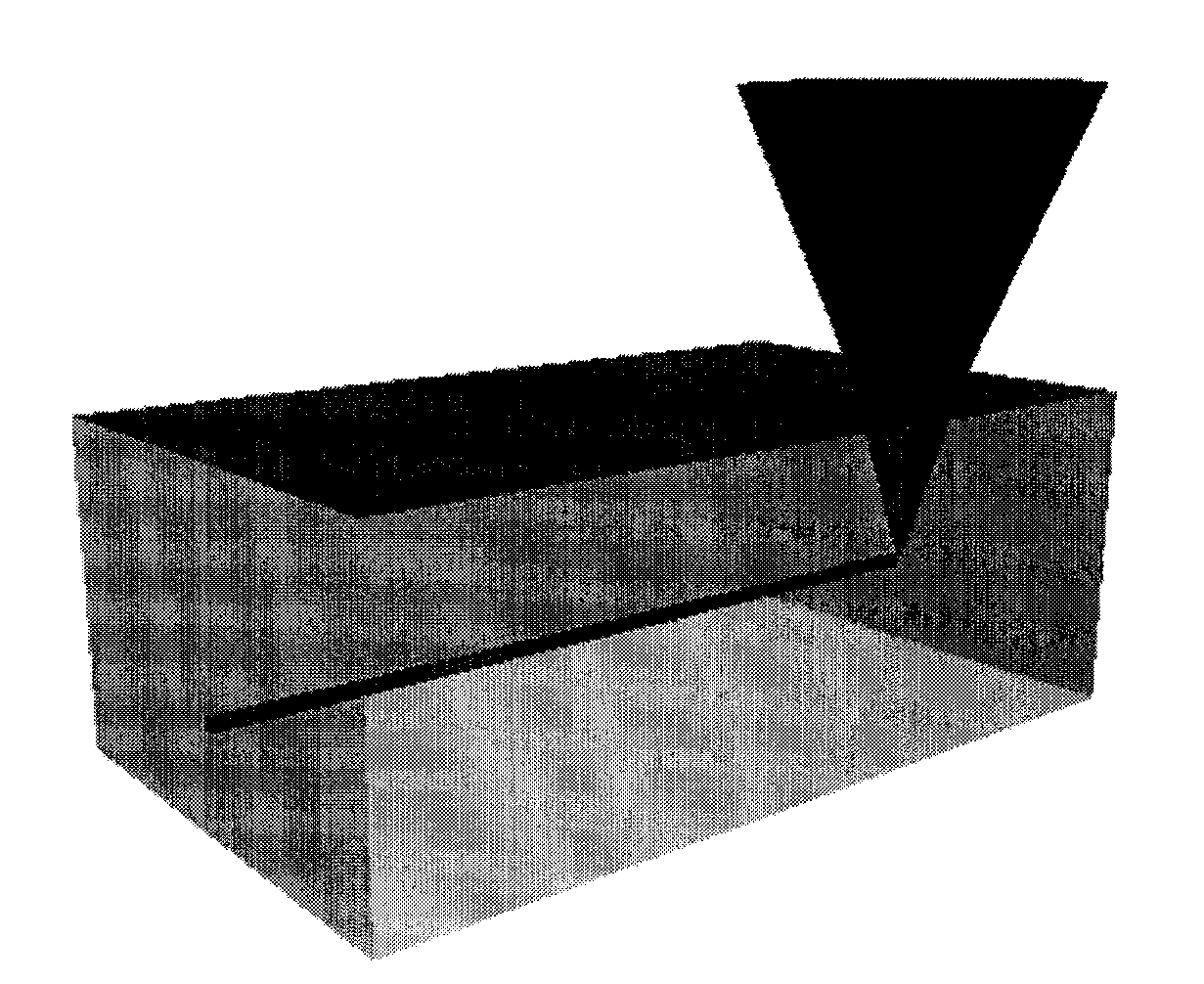

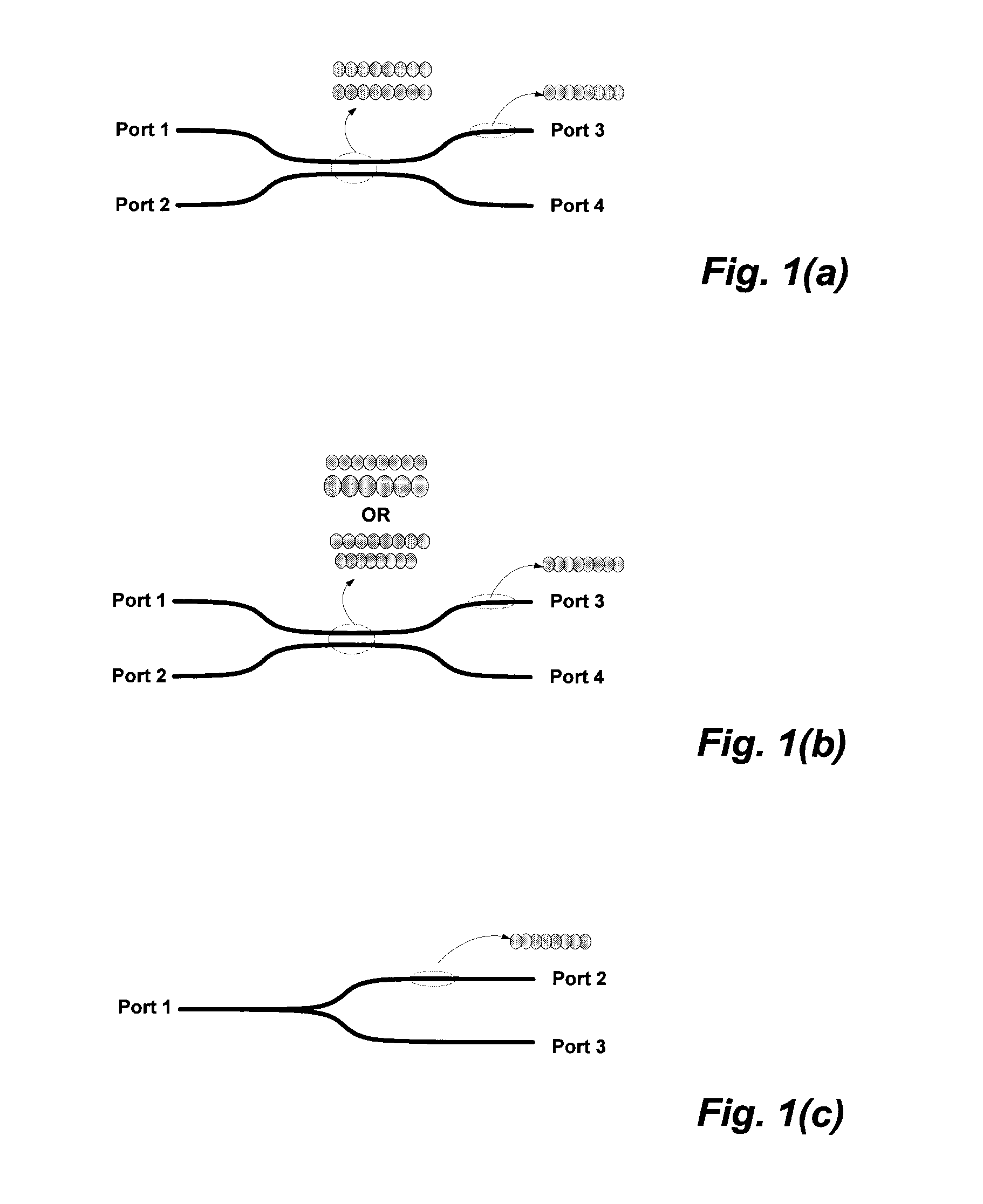

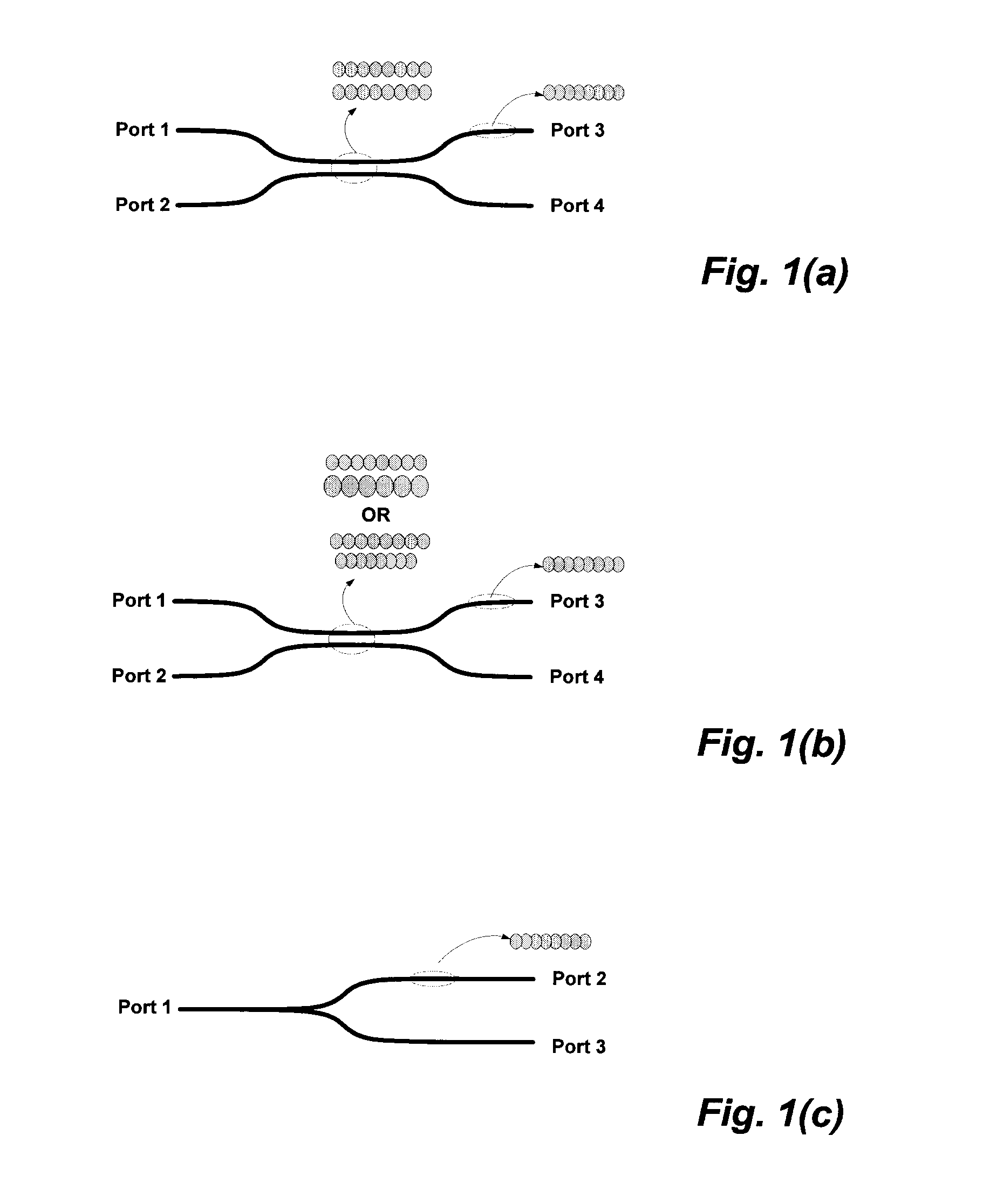

Optical devices and digital laser method for writing waveguides, gratings, and integrated optical circuits

ActiveUS20090304331A1Short timeChange the refractive indexGlass making apparatusOptical articlesGrating couplingLaser fabrication

The invention relates to devices having periodic refractive index modulation structures and fabrication methods for the devices using a laser means. By focusing a pulsed laser beam into a transparent material substrate, a path of laser modified volumes can be formed with modified refractive index compared with the unprocessed material. By selecting appropriate laser parameters and relative scan speed, the laser modified path defines an optical waveguide. Separation distance of the individual modified volumes define a periodic modification pattern along the waveguide path, so that the waveguide structures also exhibit grating responses, for example, as spectral filters, Bragg reflectors, grating couplers, grating sensors, or other devices. This method of direct laser fabrication enables one-step fabrication and integration of periodic or aperiodic refractive-index modulation devices together with optical waveguiding properties to enable low-cost, multifunctional I D, 2D or 3D optical circuit fabrication for simple and complex applications.

Owner:HERMAN +1

Metal foil laminated polyimide resin substrate

ActiveUS20110005812A1Improve adhesionGood adhesivenessDuplicating/marking methodsPrinted circuit aspectsPolymer scienceMetal foil

The present invention relates to a metal foil laminated polyimide resin substrate whereina metal foil is directly laminated on one side or both sides of a polyimide resin substrate; andthe surface of the metal foil to be bonded to the polyimide resin substrate has a surface roughness (Rzjis) of 3.0 μm or less; a surface area ratio (B) of 1.25 to 2.50, in which the surface area ratio (B) is calculated as a ratio [A / 6550] of a surface area of a two-dimensional region with a surface area of 6550 μm2 which is determined by a laser method (three-dimensional area: A μm2) to the area of the two-dimensional region; and a chromium content per unit area of the two-dimensional region of 2.0 mg / m2 or more.

Owner:UBE IND LTD

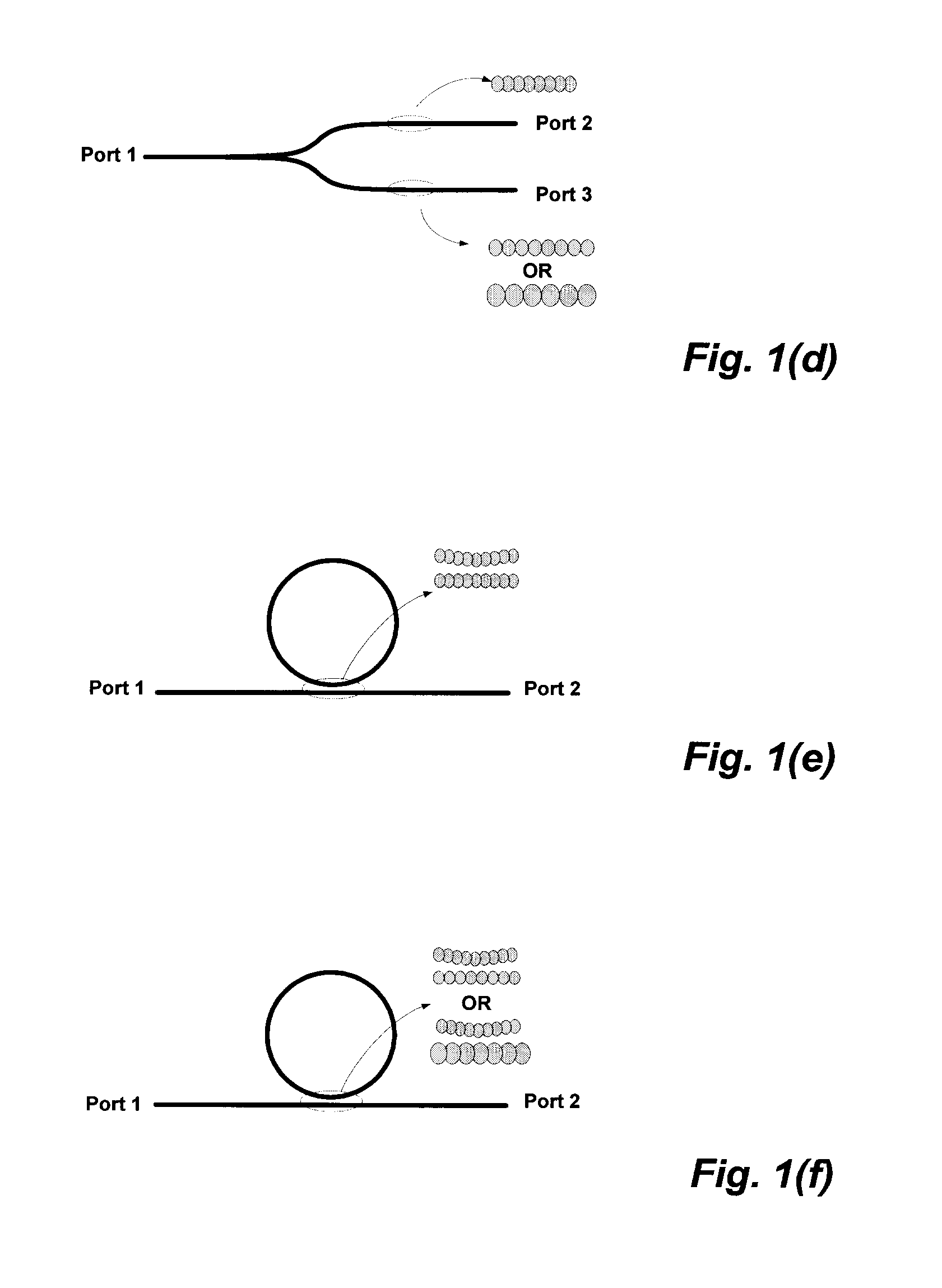

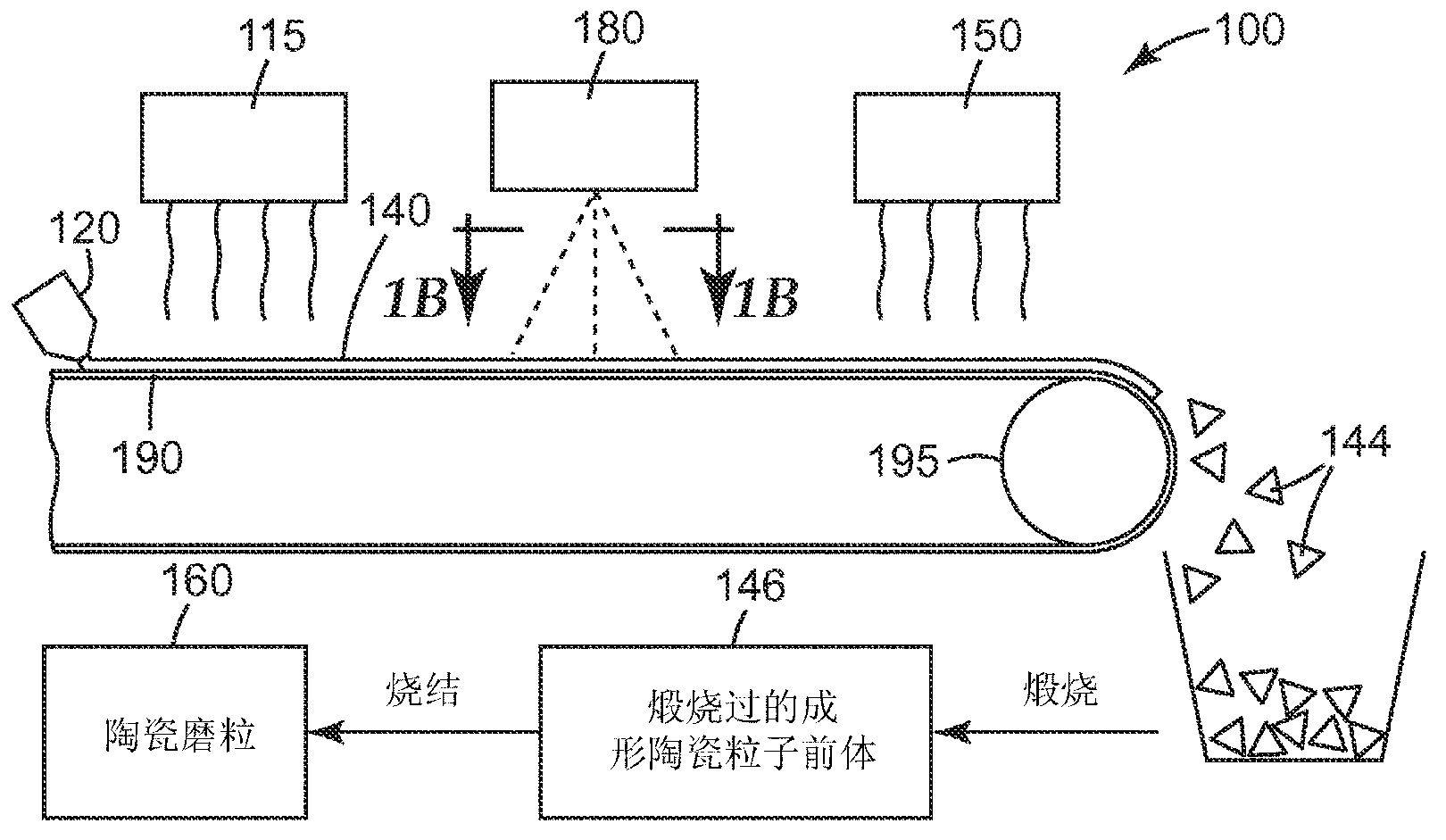

Laser method for making shaped ceramic abrasive particles, shaped ceramic abrasive particles, and abrasive articles

InactiveCN103189164ALow costImprove adhesionOther chemical processesAbrasion apparatusThermal treatmentLaser beams

A method of making shaped ceramic abrasive particles includes cutting a layer of ceramic precursor material using a laser beam and forming shaped ceramic precursor particles. Further thermal processing provides shaped ceramic abrasive particles. Shaped ceramic abrasive particles producible by the methods and abrasive articles containing them are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

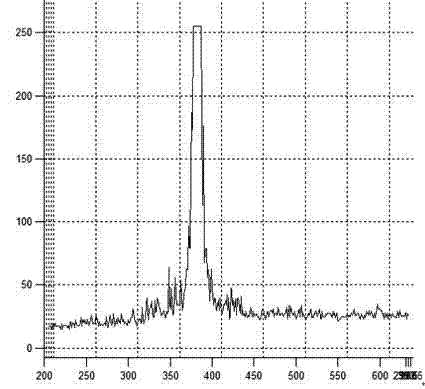

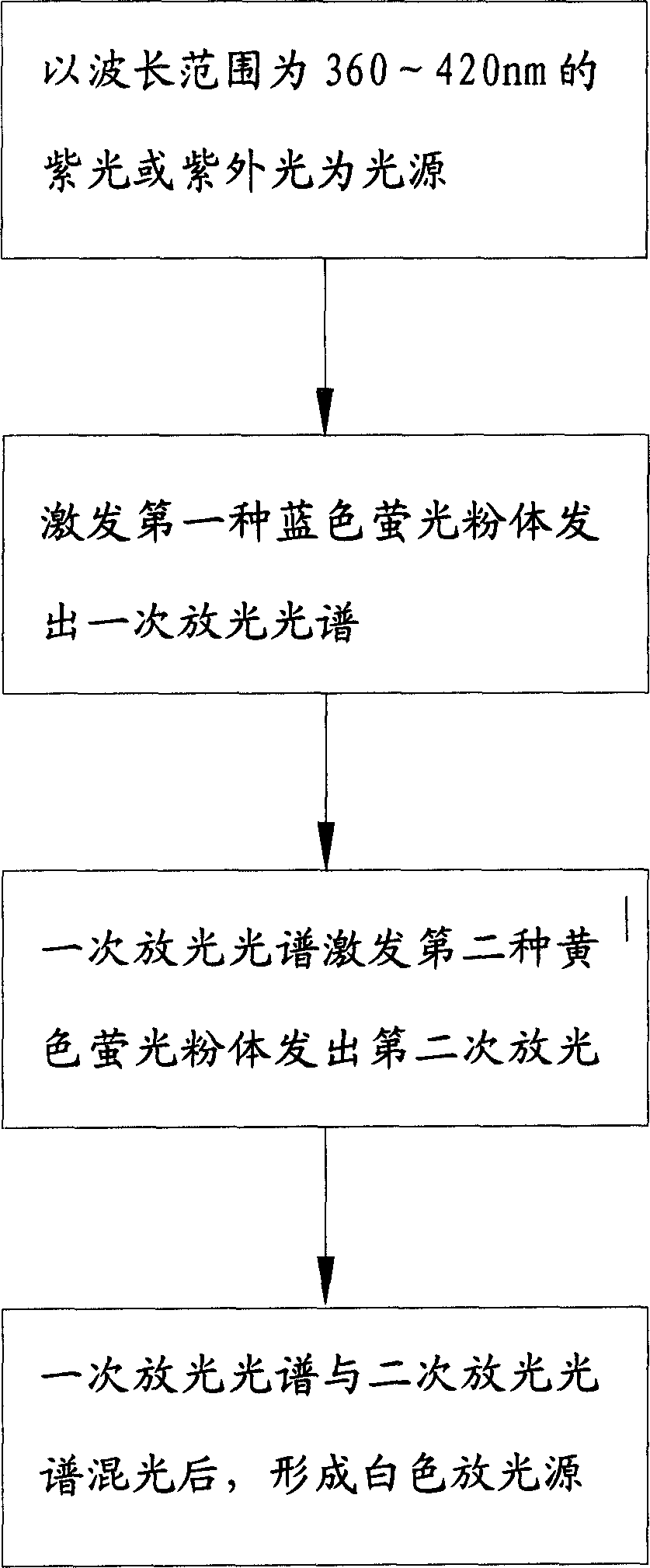

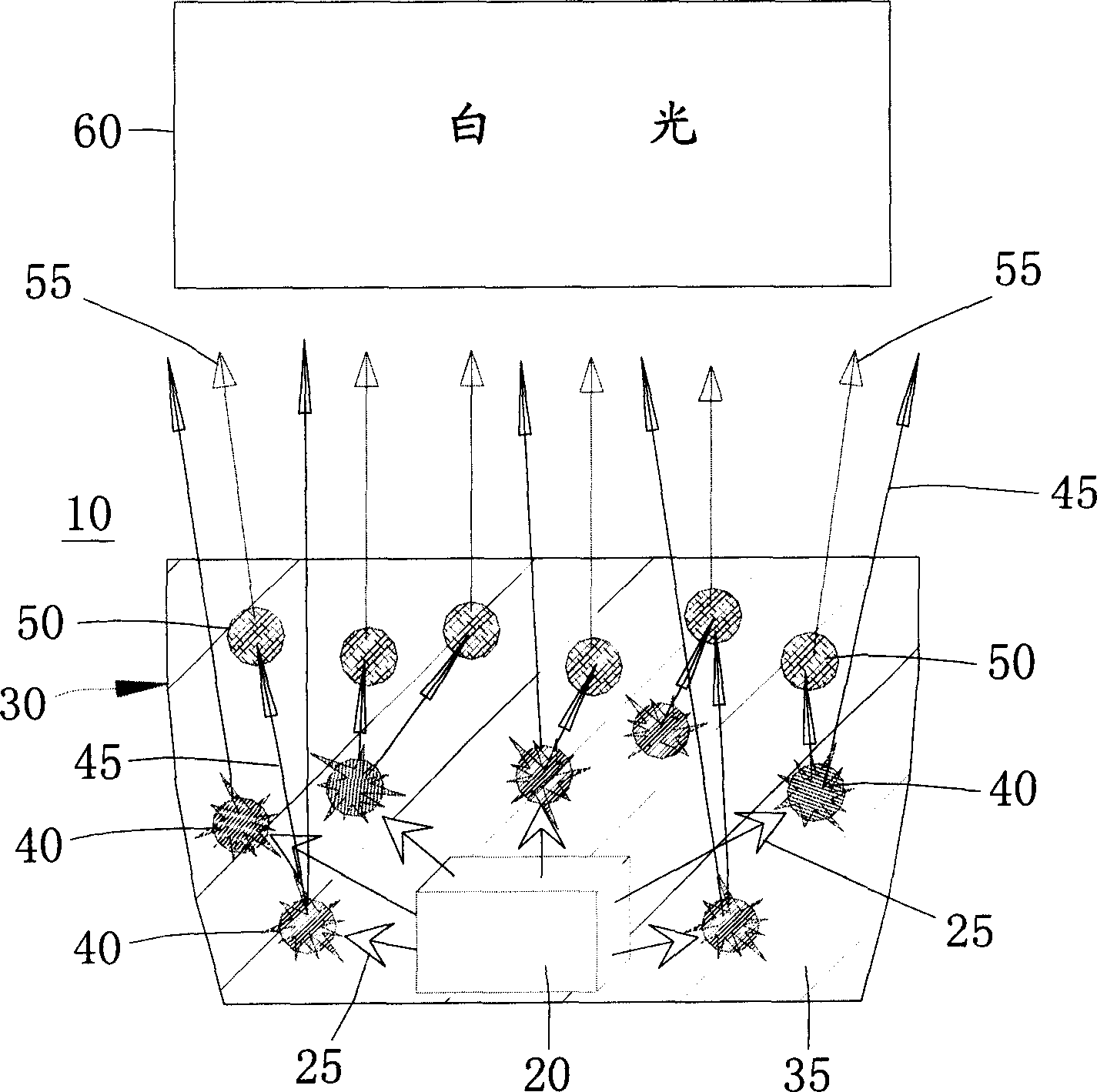

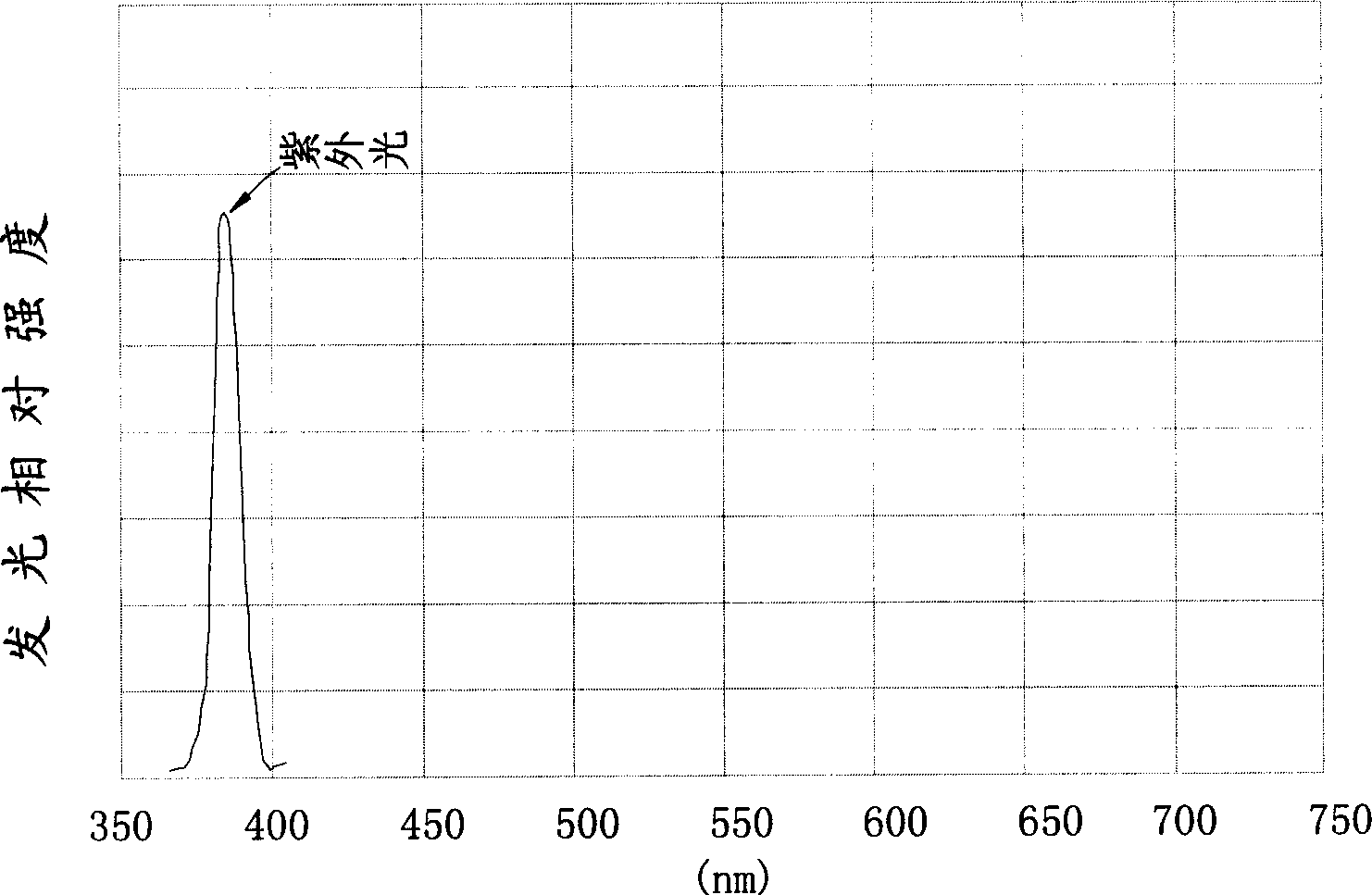

Method for generating source of white light in secondary laser mode and white light luminescence component

The invention is a method for using the secondary laser method to generate the white light source, it uses light source which can emit out ultraviolet and purple light (wavelength is 360-420nm), such as the illuminant diode (LED) and radium (LD), excites the blue fluorescence powder to emit out the primary excited light spectrum of the wideband whose main peak is blue light, then, the primary excited light spectrum excites the yellow fluorescence powder whose stage energy is lower, the secondary excited light spectrum can be emitted out whose main peak is yellow, through adjusting the proportion of the two kinds of fluorescence powder, the primary excited light spectrum and the secondary excited light spectrum can generate the complementary effect, and generate the whole spectrum white light; additional, there also can add in the red fluorescence powder and the green fluorescence powder excited by the ultraviolet light or the purple light, in order to adjust the color and the color temperature of the white light, and it can adjust the light source of other different color.

Owner:NANYA PLASTICS CORP

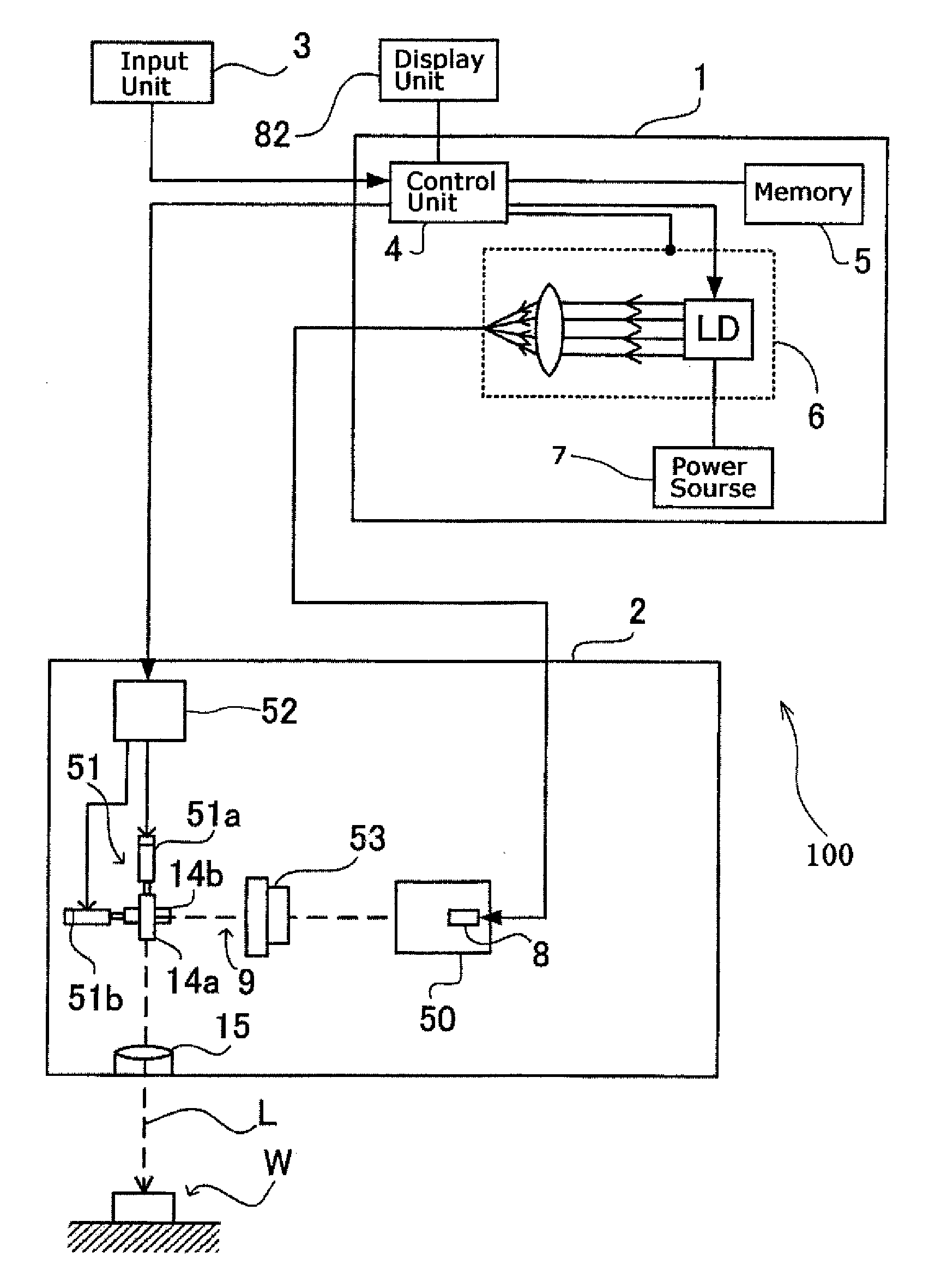

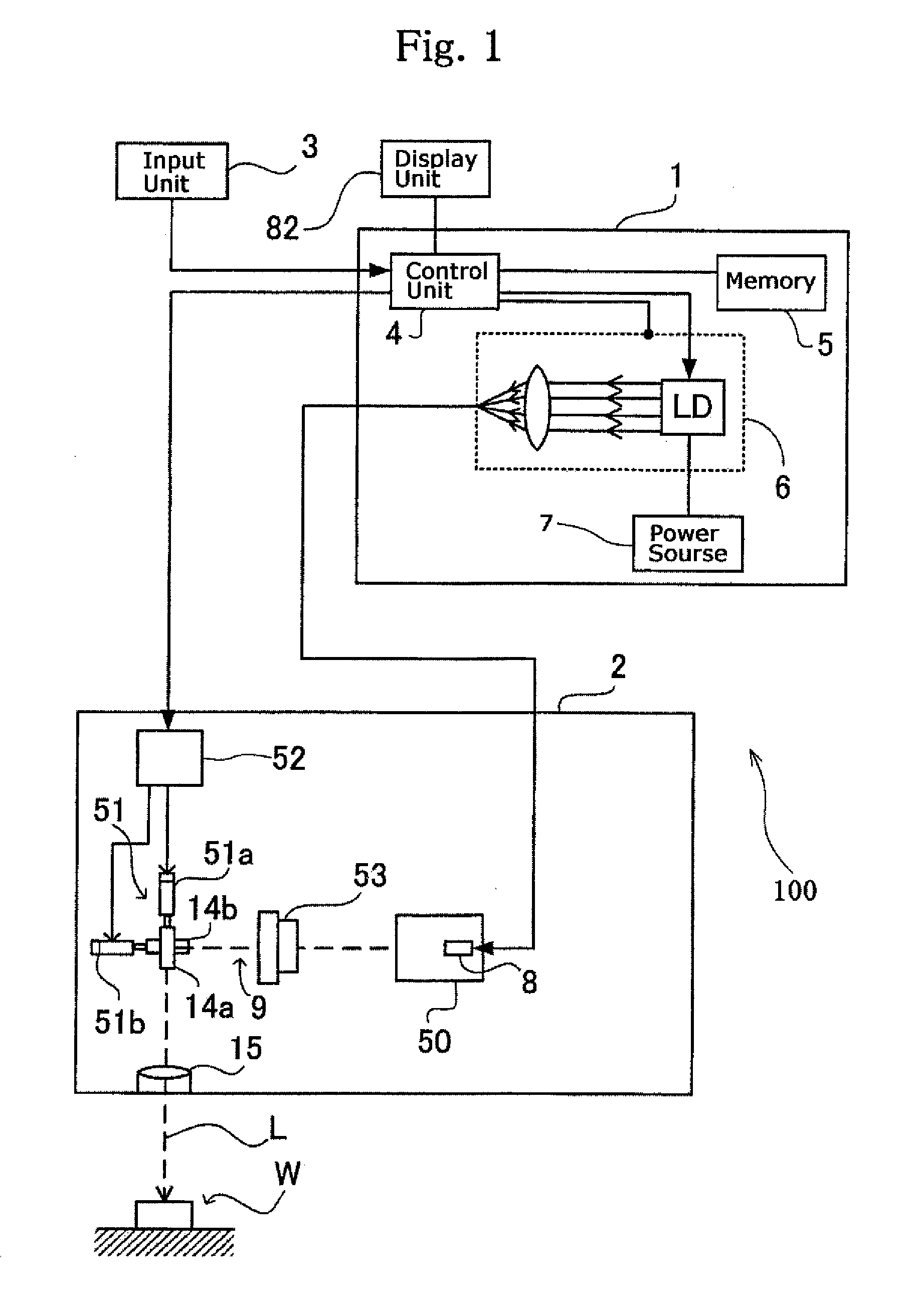

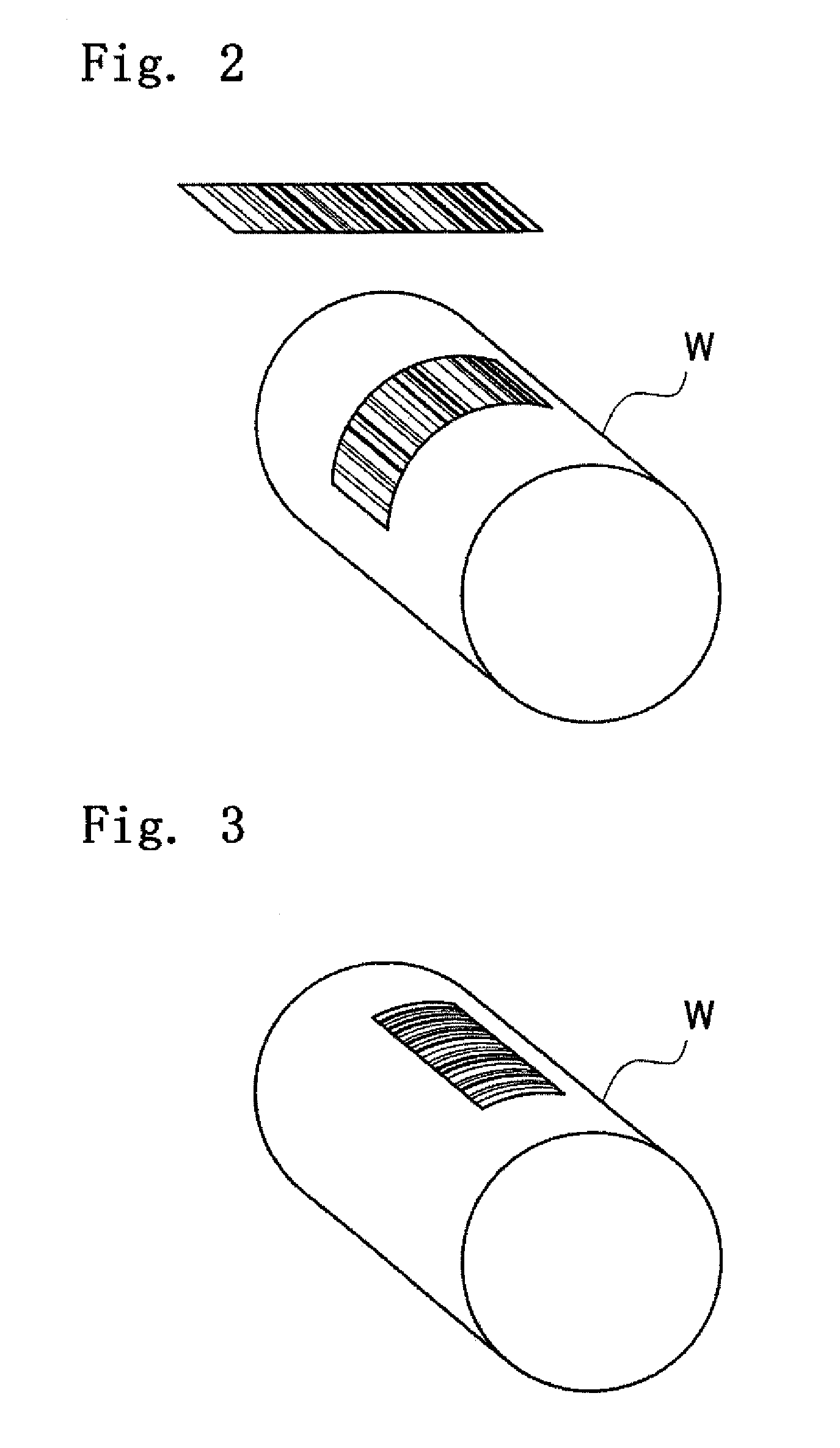

Method Of and System For Setting Laser Processing Conditions, Laser Processing System, Computer Program For Setting Laser Processing Conditions, Computer Readable Medium and Recording Device On Which Laser Processing Conditions Are Recorded

ActiveUS20080011854A1Improve read rateReduce readabilityDigital data processing detailsCharacter and pattern recognitionLaser processingArtificial intelligence

A laser method of printing a pattern on works which is read at a high read rate by optical readers and a system for implementing the laser processing method are described. print pattern data is generated based on printing conditions including at least an original print pattern such as a character string that are specified by users and then converted into data representing an actual print pattern to be actually printed on works according to a three dimensional profile of the works so that an orthogonal projection of that actual print pattern is identical with the original print pattern.

Owner:KEYENCE

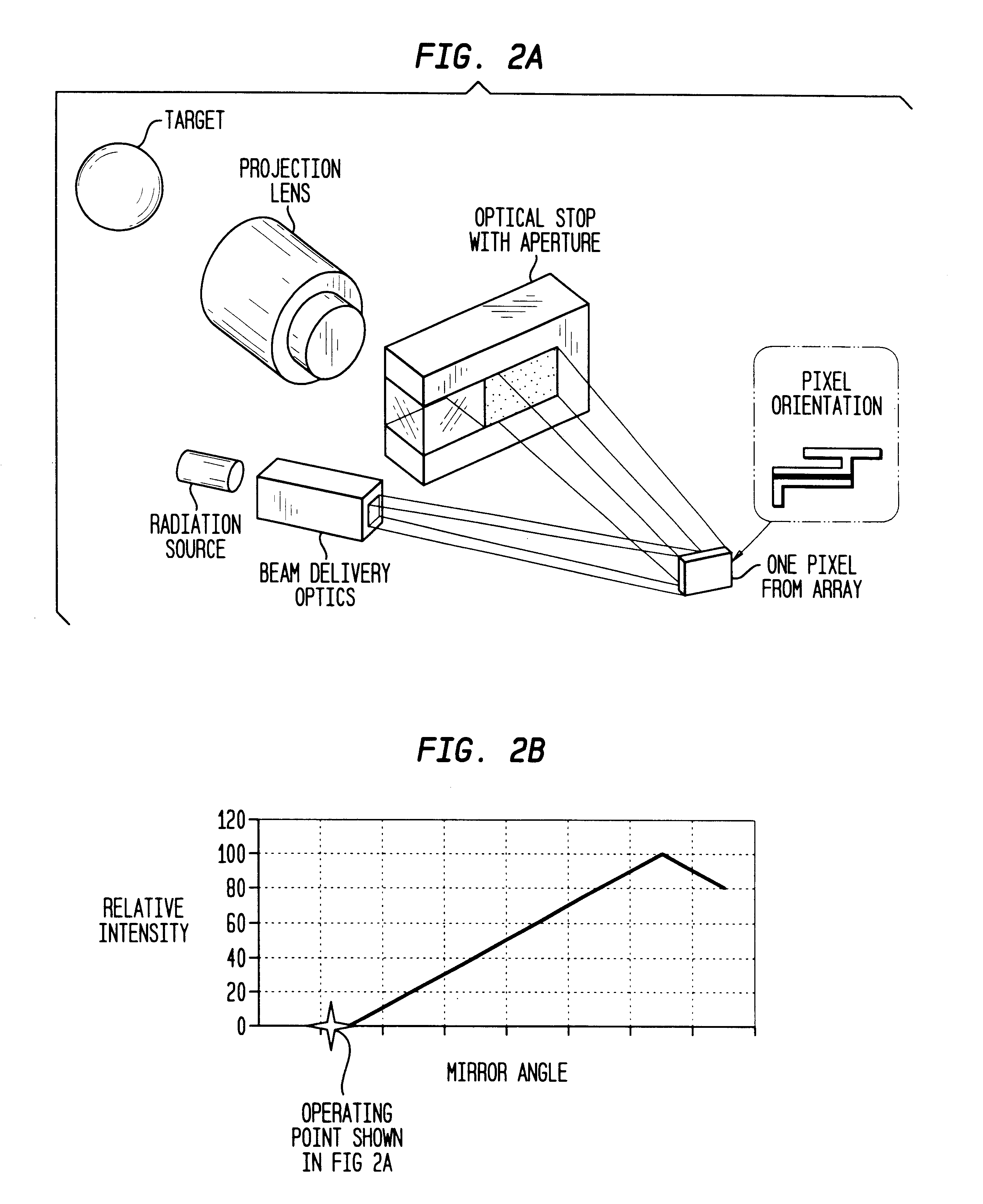

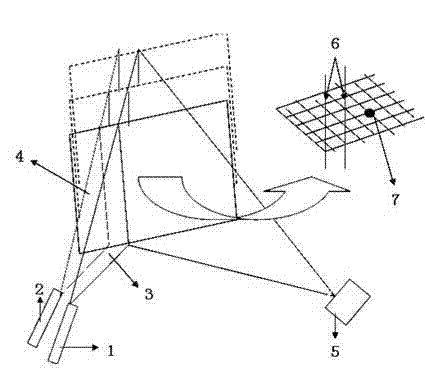

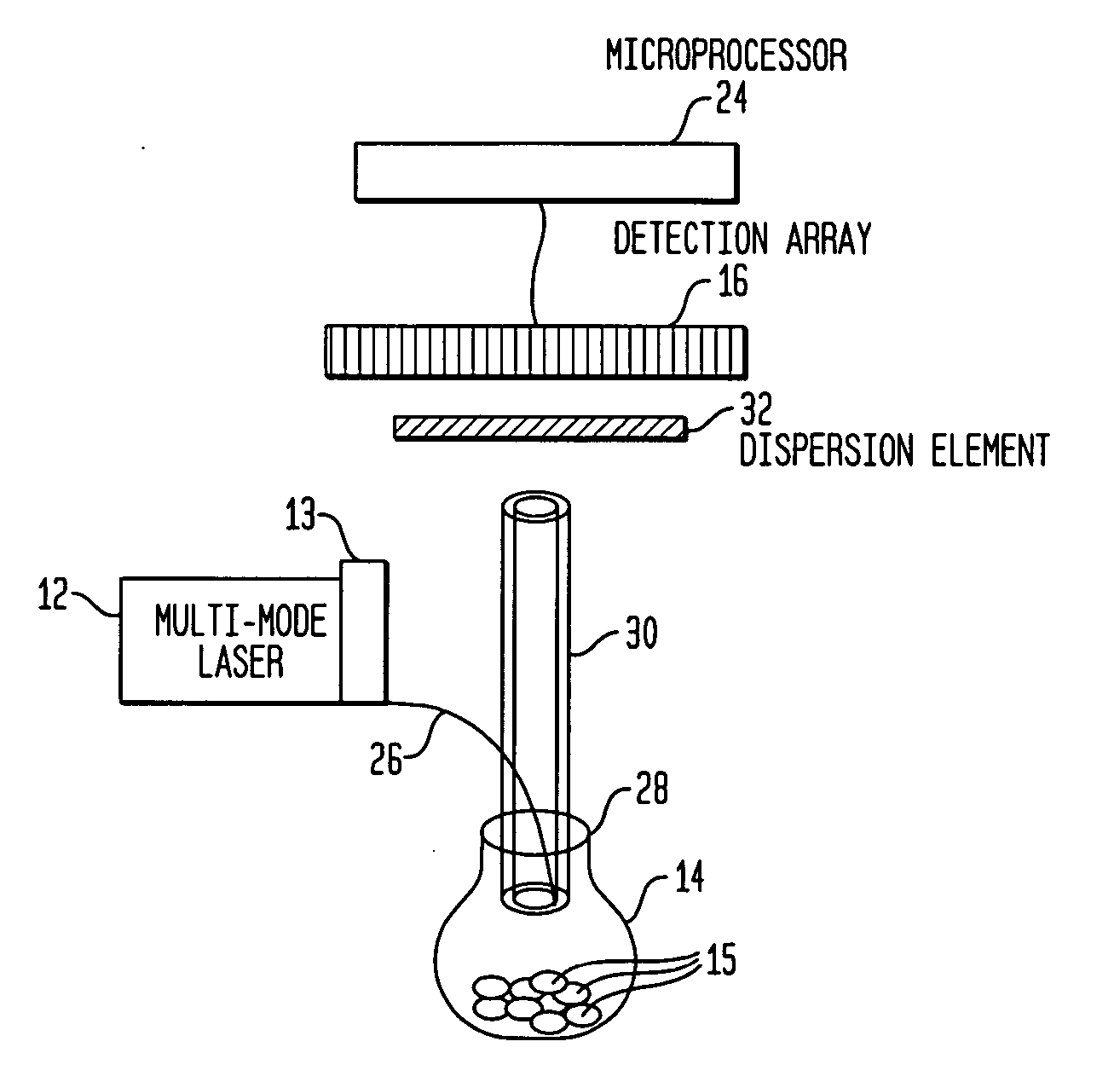

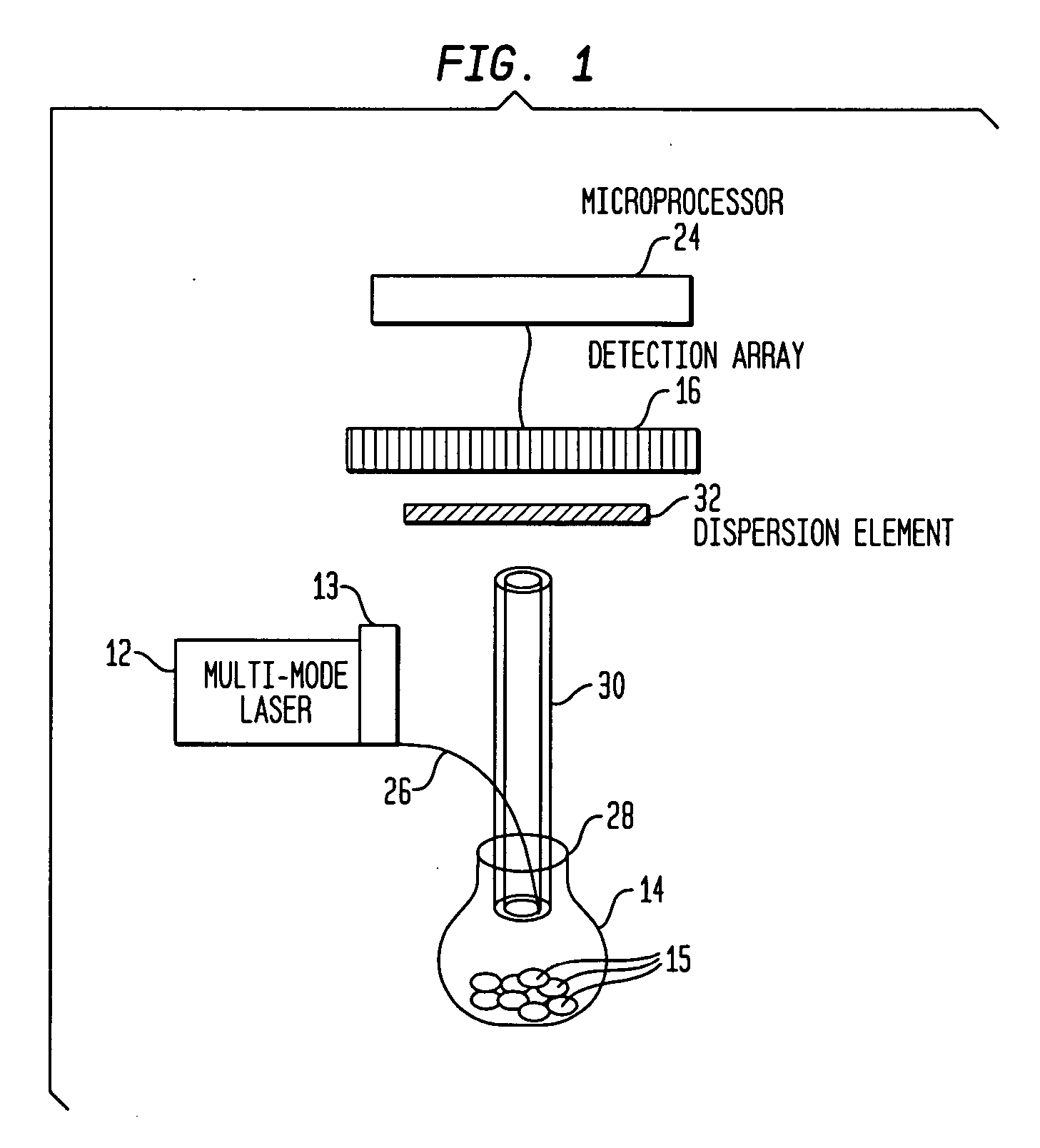

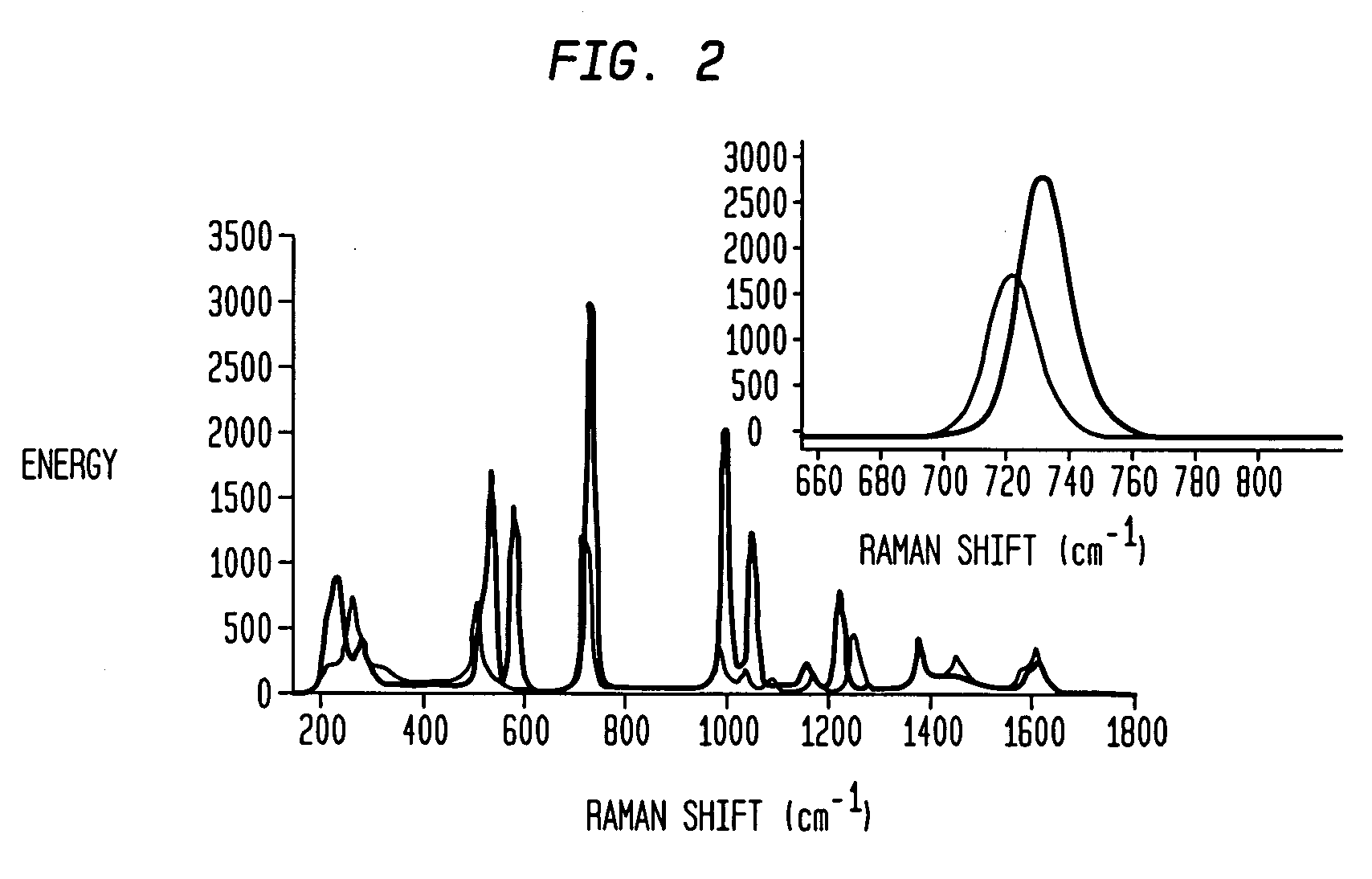

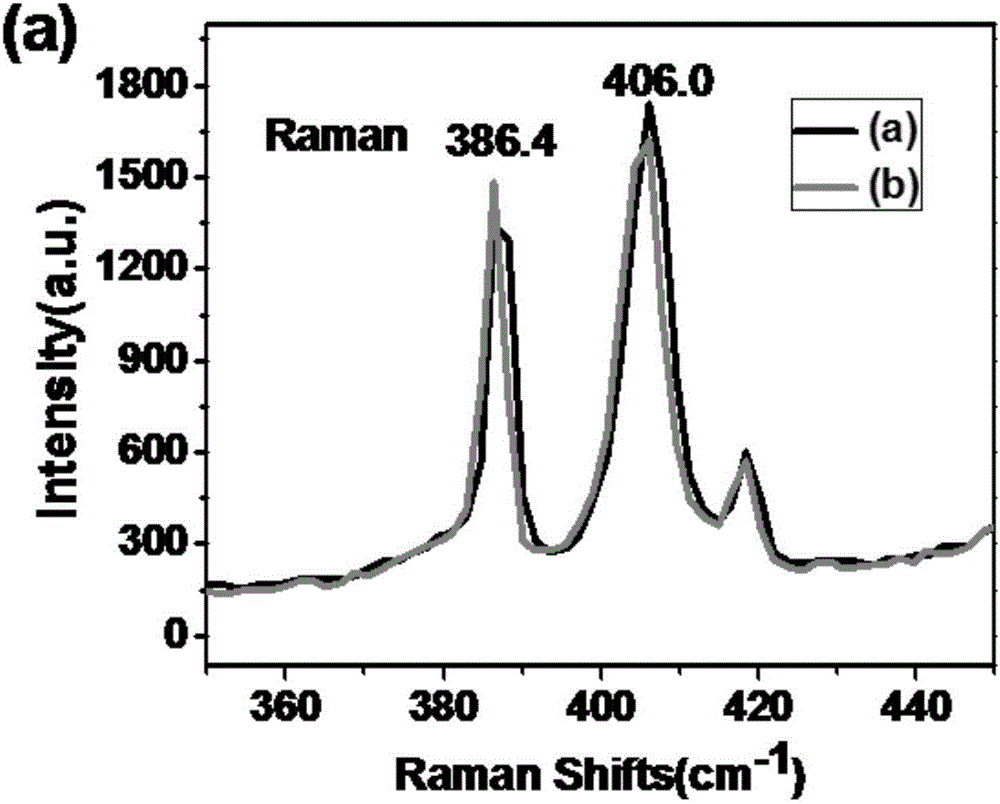

Raman spectroscopy with stabilized multi-mode lasers

InactiveUS20060176478A1Inexpensively determineReduces mode hoppingRadiation pyrometryRaman scatteringImage resolutionSpectral filtering

Methods and apparatus for analysis of a sample using Raman spectroscopy, which employs a multi-mode radiation source and a spectral filter, are disclosed. The source radiation produces a Raman spectrum consisting of scattered electromagnetic radiation that is separated into different wavelength components by a dispersion element. A detection array detects a least some of the wavelength components of the scattered light and provides data to a processor for processing the data. The resulting spectroscopic data has higher resolution and stability than conventional low-resolution Raman systems.

Owner:RAMAN SYST

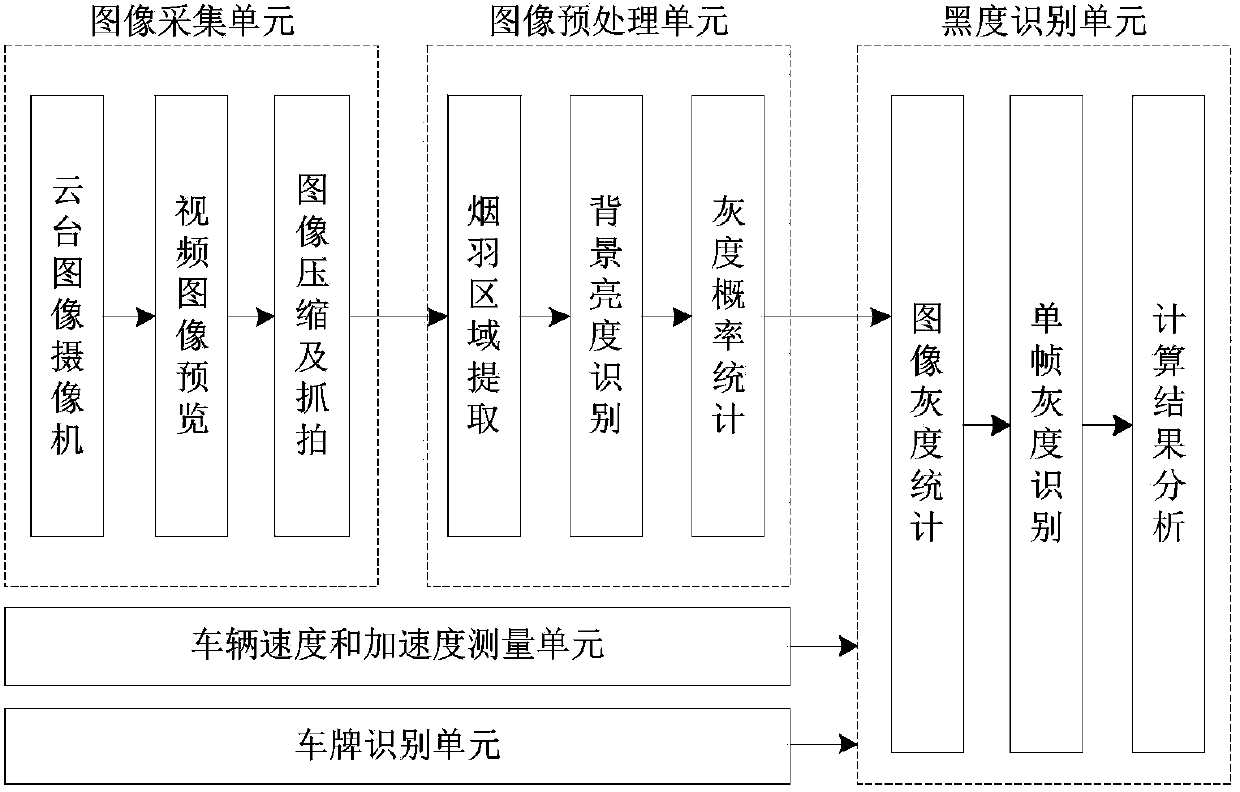

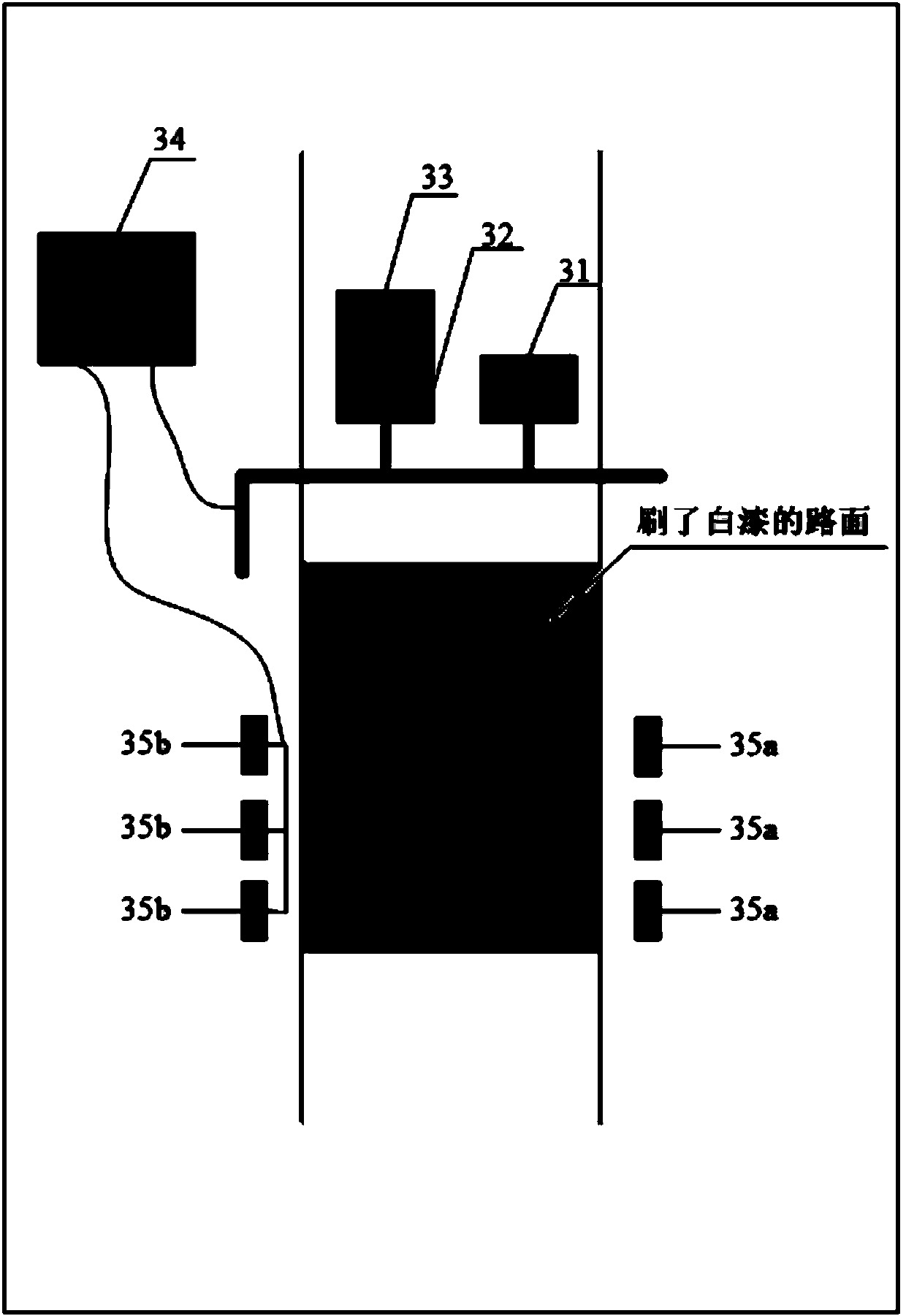

Exhaust gas blackness automatic detection device for diesel vehicles

InactiveCN103808723AColor measuring devicesInvestigating moving fluids/granular solidsLicenseImage pre processing

The invention discloses an exhaust gas blackness automatic detection device for diesel vehicles. The exhaust gas blackness automatic detection device comprises an image collecting unit, an image preprocessing unit, a vehicle speed and acceleration measuring unit, a license plate identifying unit and a blackness identifying unit. Through the exhaust gas blackness automatic detection device, the speed and acceleration data of diesel vehicles are obtained through a laser method to assist in blackness identification; license plate images and exhaust gas images of diesel vehicles are obtained on the testing section coated with white paint through a vertical shooting method; license plate information and ringelmann blackness level of the diesel vehicles are obtained by preprocessing image and identifying blackness.

Owner:UNIV OF SCI & TECH OF CHINA

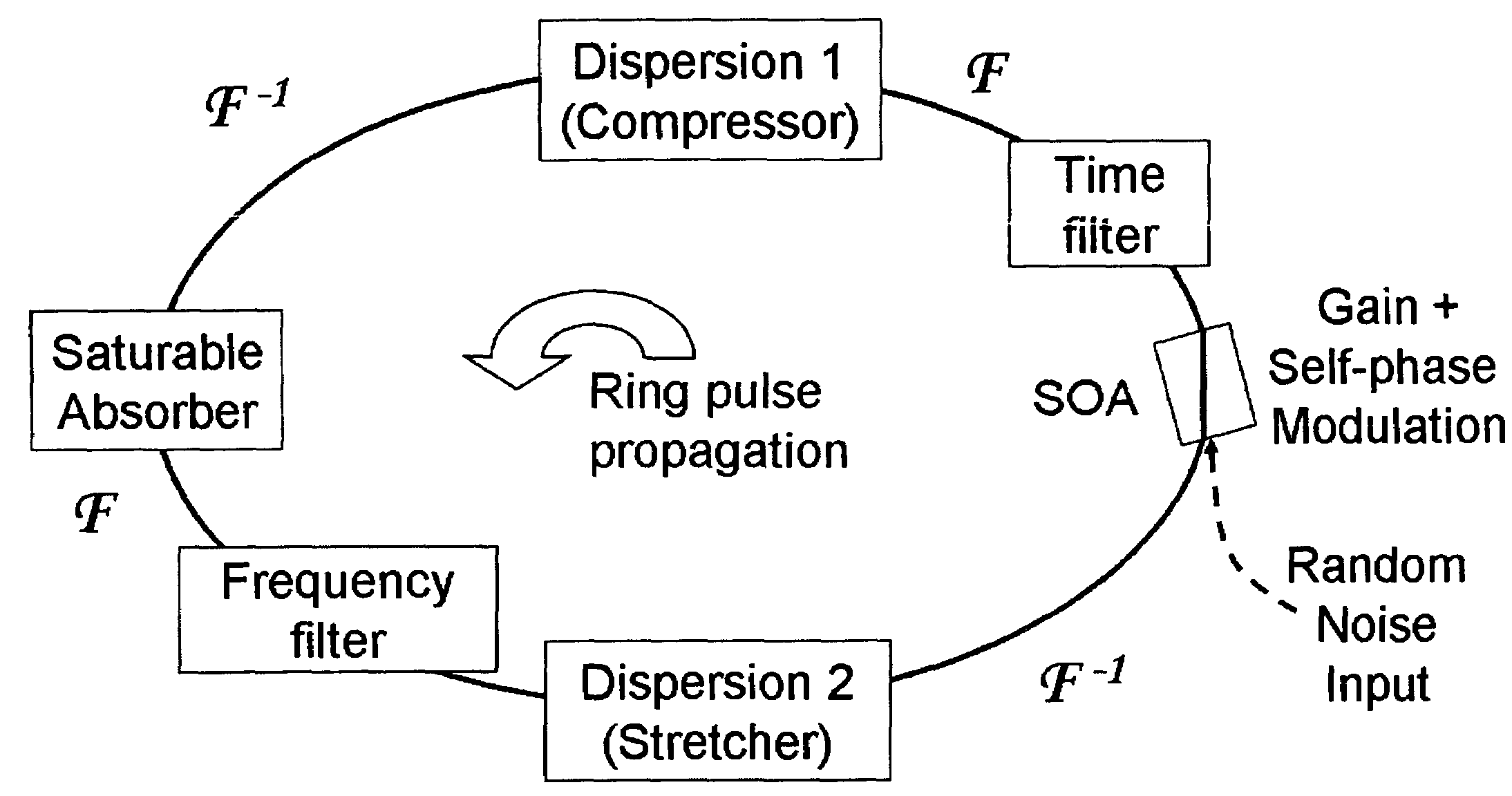

Extreme chirped/stretched pulsed amplification and laser

InactiveUS7561605B1Efficiently externally compressedIncrease powerLaser using scattering effectsOptical resonator shape and constructionGratingChirped pulse amplification

Methods, devices and systems for generating ultrashort optical linear chirped pulses with very high power by amplifying the pulses so that their temporal duration is longer than the storage time of the amplifying medium. The additional gain factor is related to the ratio of the storage time to the stretched pulse. A preferred embodiment connects a mode locked laser source that generates optical pulses whose duration is stretched with a chirped fiber Bragg grating. Embodiments include methods, devices and systems causing an extreme chirped pulse amplifier (XCPA) effect in an oscillator.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

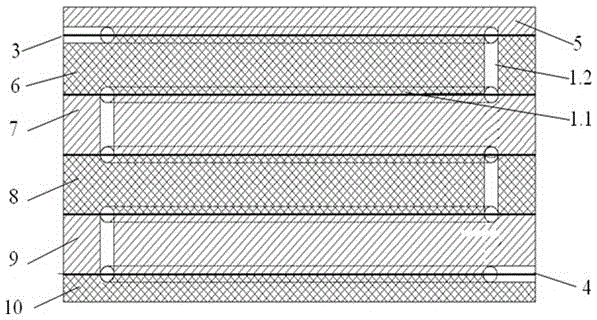

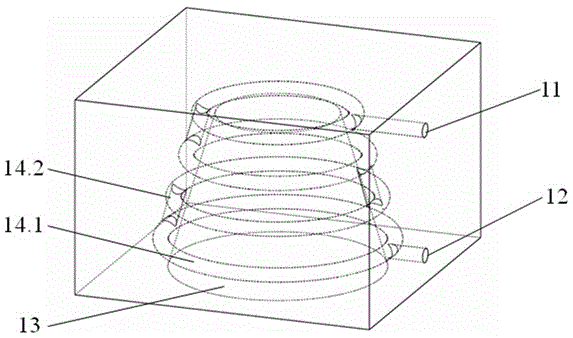

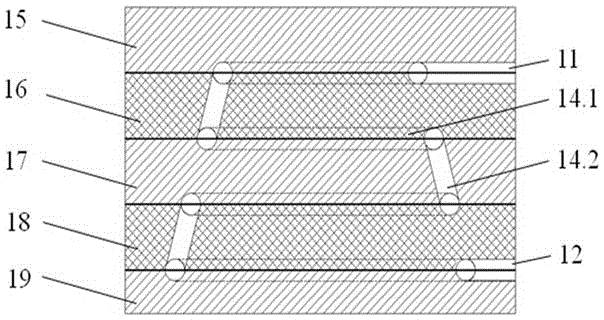

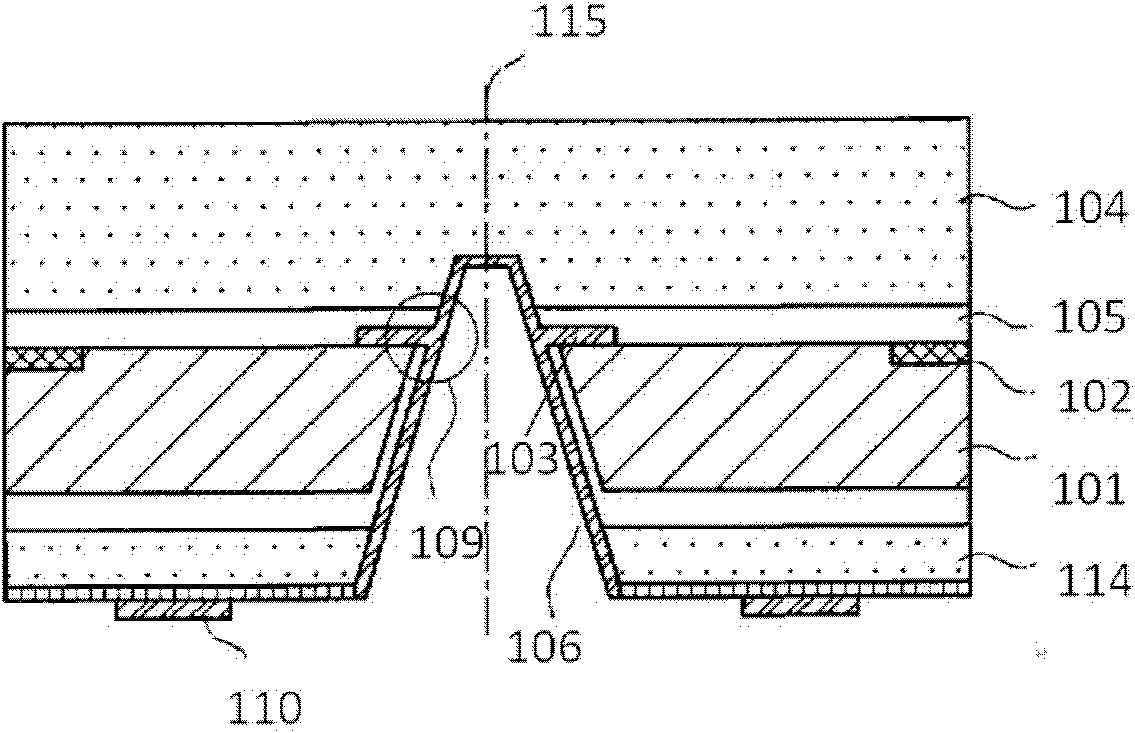

3D precision shaping method of conformal cooling structure of injection mold

InactiveCN105128227AImprove temperature uniformityImprove cooling efficiencyAdditive manufacturing apparatusEngineeringDesign space

Provided is a 3D precision shaping method of a conformal cooling structure of an injection mold. Based on heat transfer calculation, an efficient heat exchange conformal cooling flow channel three-dimensional model is established for the cavity face contour of the injection mold, layered structural division is performed on the conformal cooling flow channel three-dimensional model, corresponding structures in different layers are machined through a machining method, a laser method or a chemical etching method, and the structures in different layers are stacked and positioned according to corresponding sequence. The layered structures are welded through a diffusion welding method achieved by adding an intermediate layer, and 3D precision shaping of a conformal cooling flow channel is achieved; finally, a mold cavity is machined in a diffusion welding solid surface through a machining method, and 3D precision shaping of the conformal cooling structure of the injection mold is completed. By means of the method, the design space can be greatly expanded, and conformal cooling structures in any complicated shape can be manufactured. High strength and high precision of the conformal cooling structure is guaranteed, production cost is low, production efficiency is high, and the requirement for batch industrial production can be met.

Owner:XIAN ZHITUO PRECISION WELDING

Optical devices and digital laser method for writing waveguides, gratings, and integrated optical circuits

ActiveUS8270788B2Short timeChange the refractive indexGlass making apparatusOptical articlesSpectral filteringLaser fabrication

The invention relates to devices having periodic refractive index modulation structures and fabrication methods for the devices using a laser means. By focusing a pulsed laser beam into a transparent material substrate, a path of laser modified volumes can be formed with modified refractive index compared with the unprocessed material. By selecting appropriate laser parameters and relative scan speed, the laser modified path defines an optical waveguide. Separation distance of the individual modified volumes define a periodic modification pattern along the waveguide path, so that the waveguide structures also exhibit grating responses, for example, as spectral filters, Bragg reflectors, grating couplers, grating sensors, or other devices. This method of direct laser fabrication enables one-step fabrication and integration of periodic or aperiodic refractive-index modulation devices together with optical waveguiding properties to enable low-cost, multifunctional 1D, 2D or 3D optical circuit fabrication for simple and complex applications.

Owner:HERMAN +1

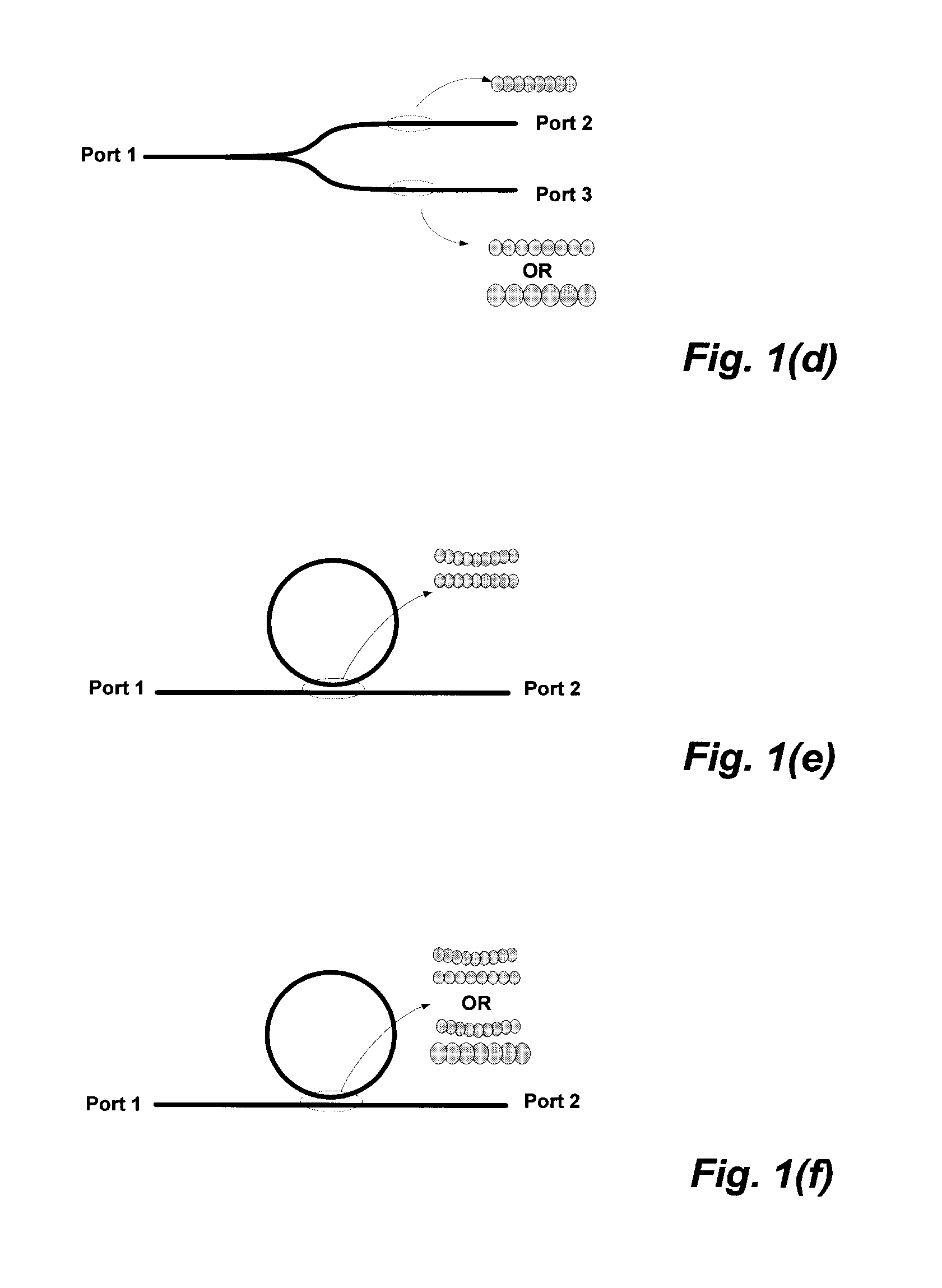

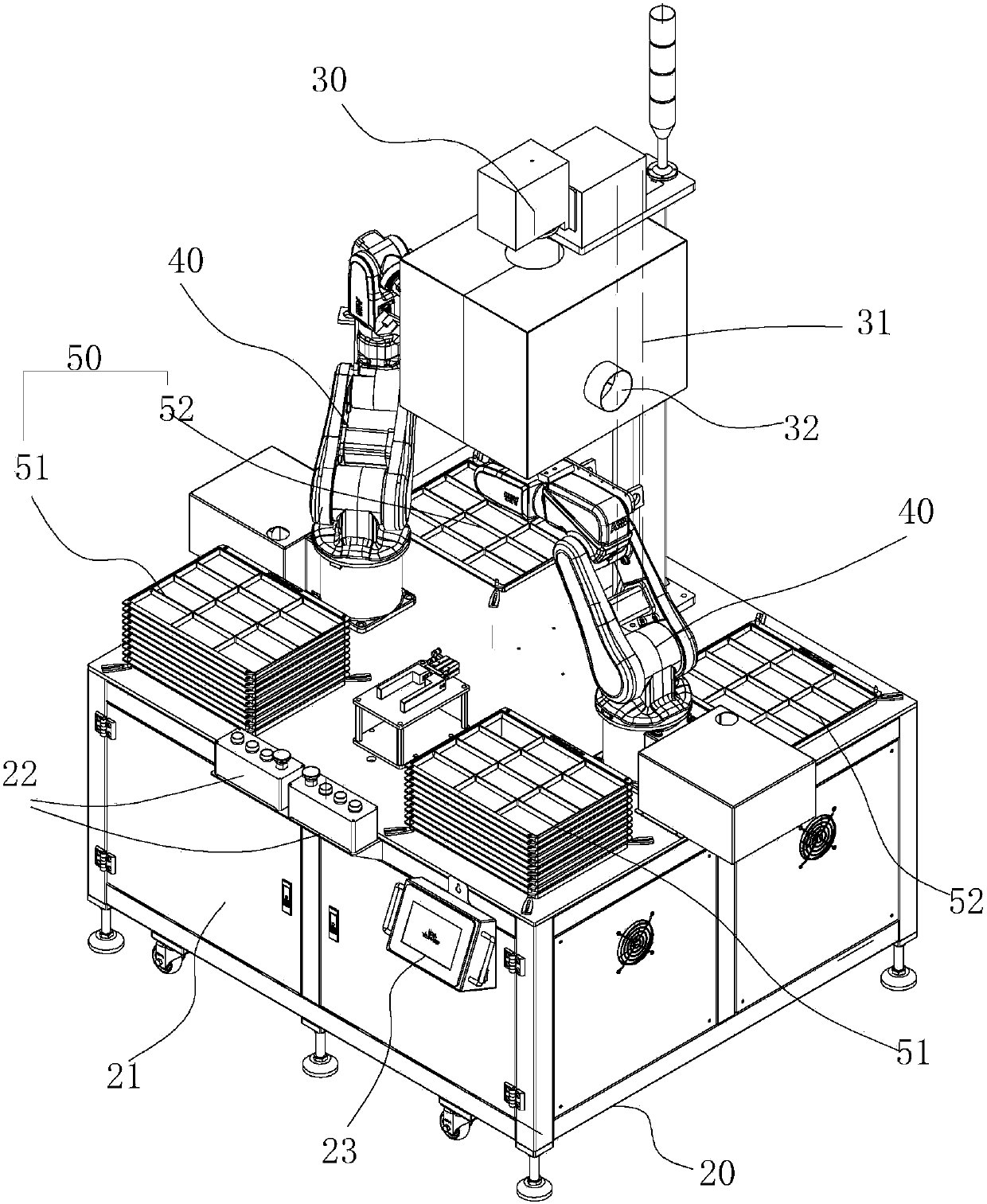

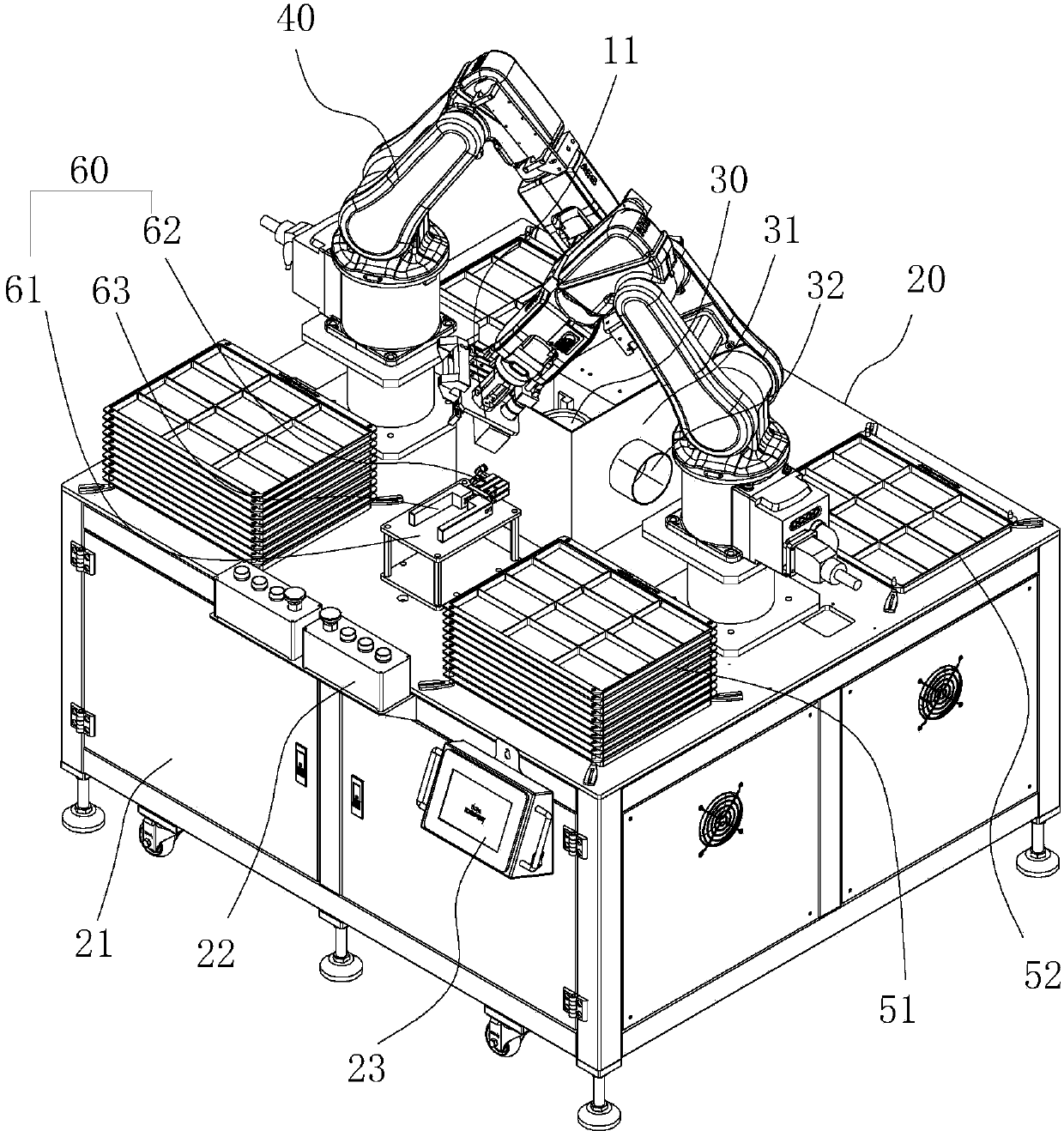

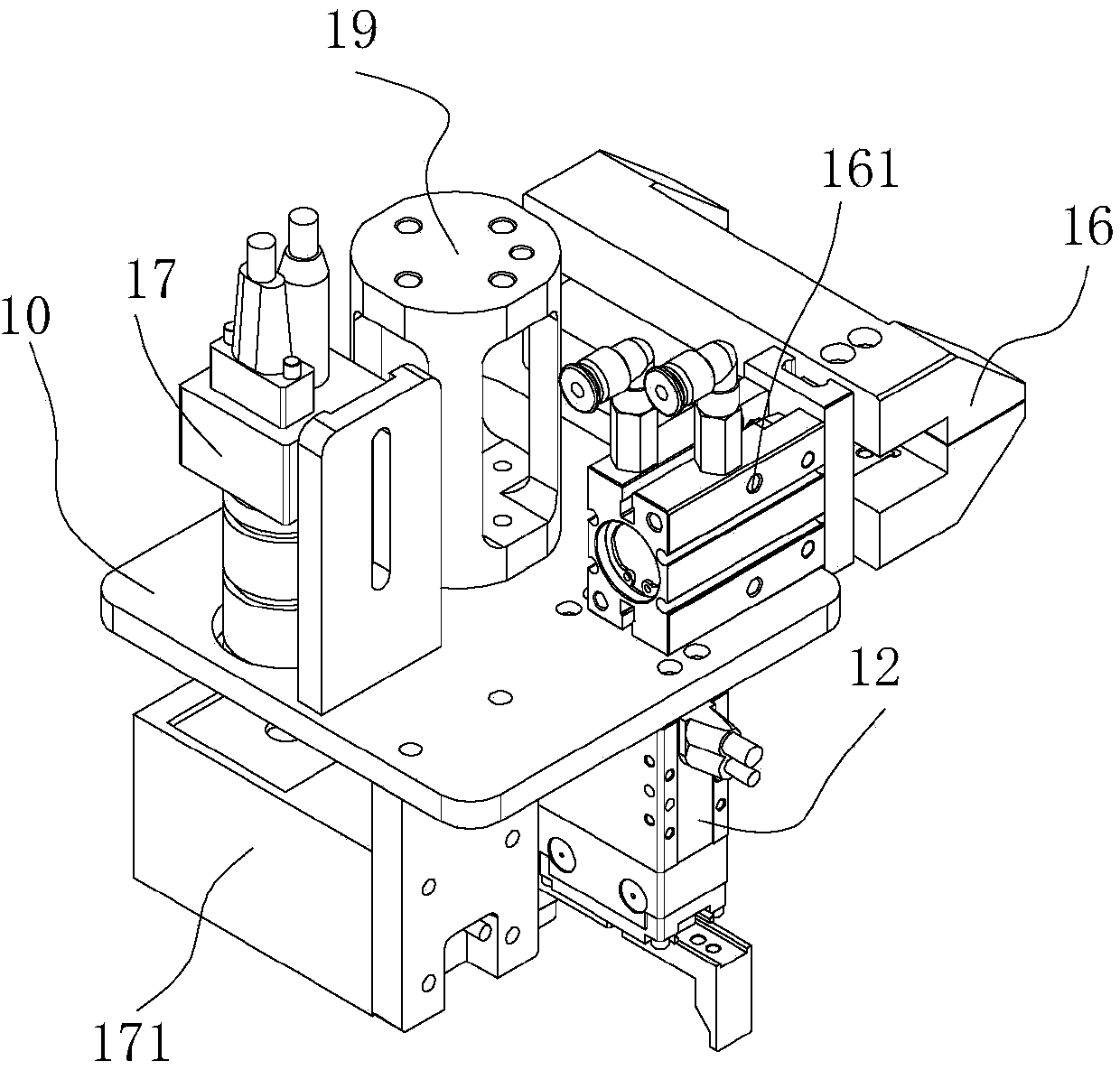

Laser method and laser equipment adopting robot

InactiveCN104175008ARealize fully automated operationPrecise positioningProgramme-controlled manipulatorGripping headsEngineeringProduct defect

The invention discloses a laser method and laser equipment adopting a robot. The laser equipment comprises a base and a laser machine arranged on the base, and the robot and a material area used for storing workpieces are further arranged on the base; a free end of the robot is provided with a clamp structure used for clamping the workpieces to move between the material area and a laser area; the clamp structure is provided with a clamping portion used for clamping the workpieces; the laser equipment further comprises a positioning mechanism used for positioning the workpieces. The robot is adopted for moving materials from a feeding area to the laser area of the laser machine and further moving the materials to a discharging area after laser operation is finished, full-automatic operations of the workpieces in the laser process are realized, and accordingly production efficiency is improved, and product defects resulted from manual operations are reduced; by the aid of the positioning mechanism, precision in workpiece positioning during clamping is realized to further realize precision laser of the workpieces.

Owner:SHENZHEN RAPOO TECH

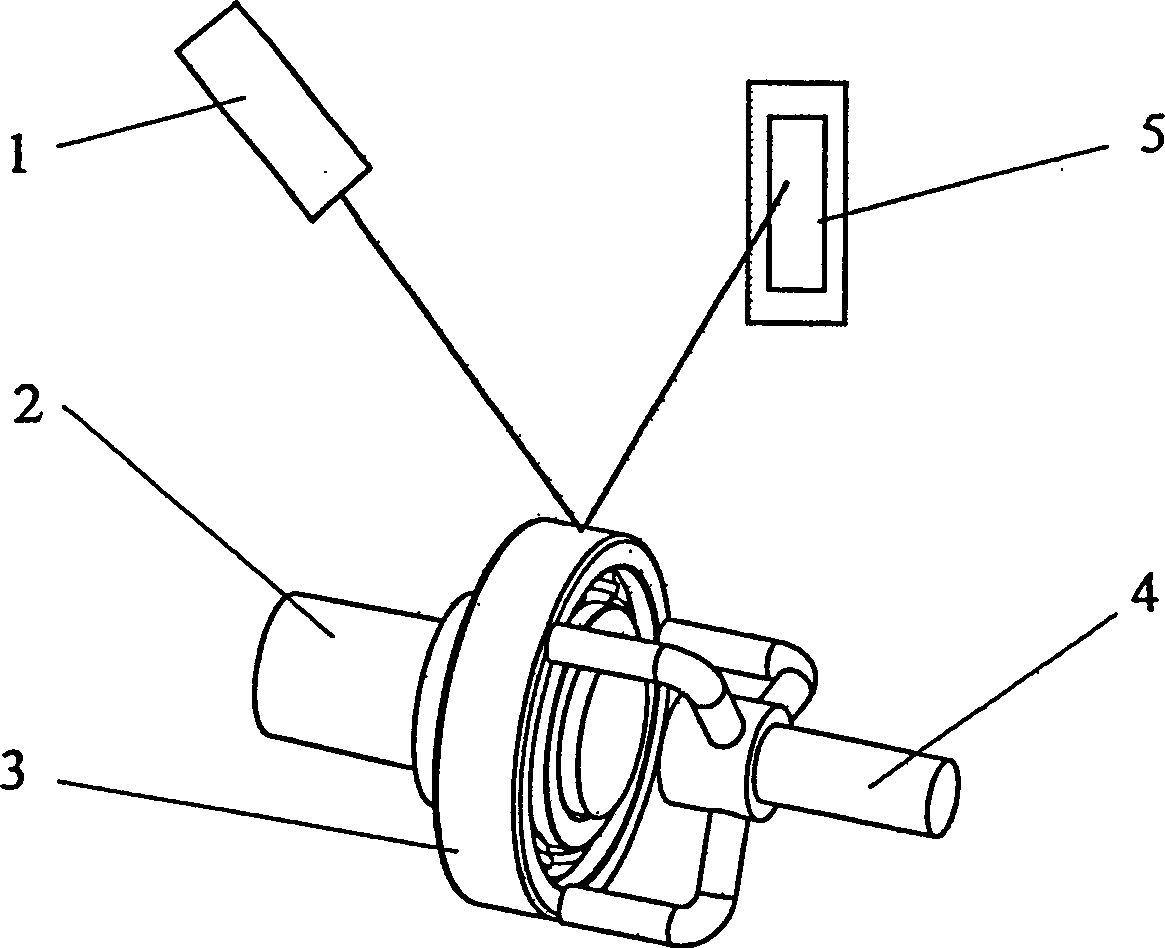

Laser method for measuring vibration displacement of rolling bearing

InactiveCN1687720AAvoid instabilityEasy to installSubsonic/sonic/ultrasonic wave measurementMachine bearings testingRolling-element bearingEngineering

The invention discloses the laser testing method of the roller bearing vibration displacement. Equip the bearing on the spin axis of the test bed; makes use of the reflection of the laser through the bearing surface to arrive the PSD sensor surface; the PSD position sensor gives the facula position. The internal loop and the main axis of the bearing can be viewed as the rigid body because the radial force carried by the external loop of the bearing. When the spin axis spins, the inner and the external loops and the roller bring about the vibration and reflect the displacement s of certain point of the bearing surface by the PSD sensor. The invention has simple structure, clear principle and high precision.

Owner:ZHEJIANG UNIV

Method utilizing TSV (Through-Silicon-Via) to realize wafer level package of GaAs (gallium arsenide) image sensor

InactiveCN102544040AReduce volumeImprove package reliabilitySemiconductor/solid-state device manufacturingRadiation controlled devicesEtchingInterconnection density

The invention relates to a method utilizing TSV (Through-Silicon-Via) to realize wafer level package of a GaAs (gallium arsenide) image sensor. The method comprises the following steps: combining wet etching with mechanical machining to machine a groove; manufacturing a resin insulating layer in the groove; then manufacturing a through hole in resin by using a laser method; electroplating the inner part of the groove and the inner part of the through hole to realize the back extraction of the electrode of a front wafer surface; and making a passivating layer and solder bumps. The whole process is completed at a wafer level, and the interconnection density is high while the package cost is reduced. Meanwhile, a manufactured interconnection structure has high reliability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

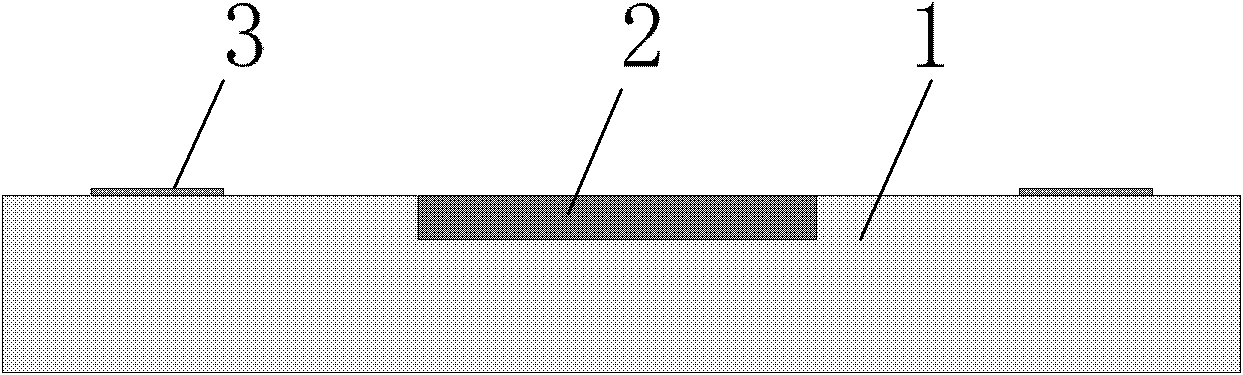

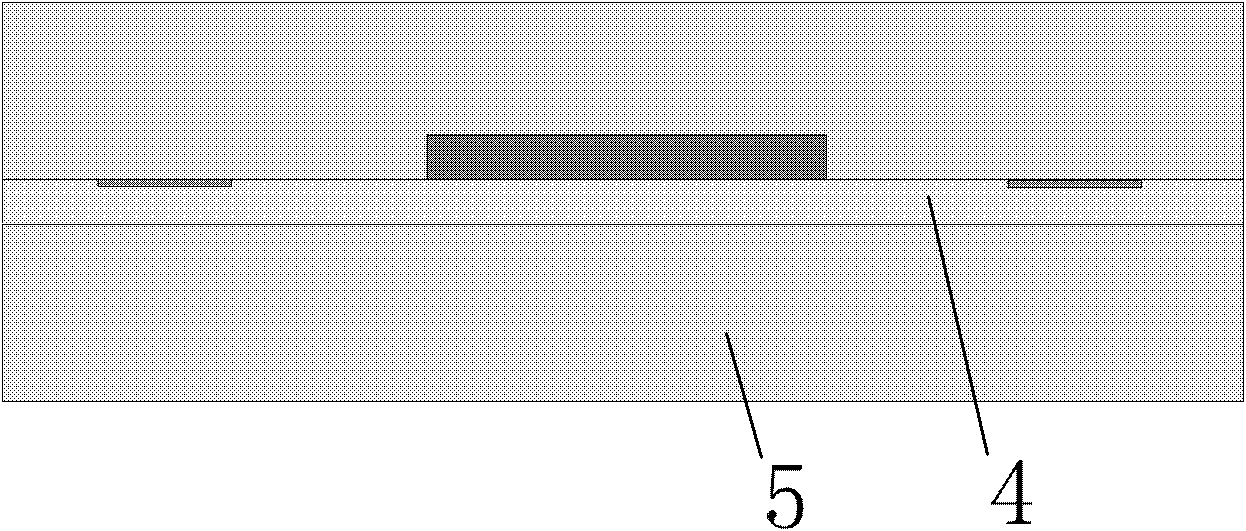

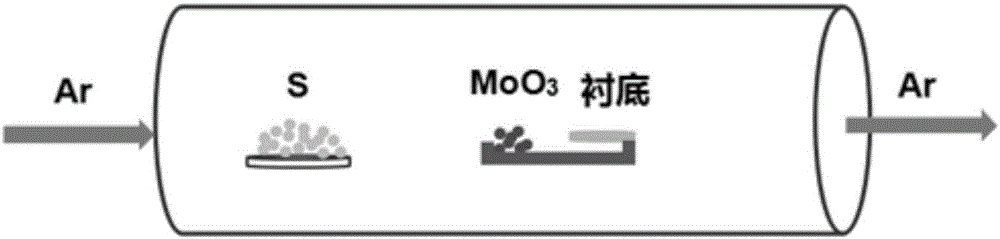

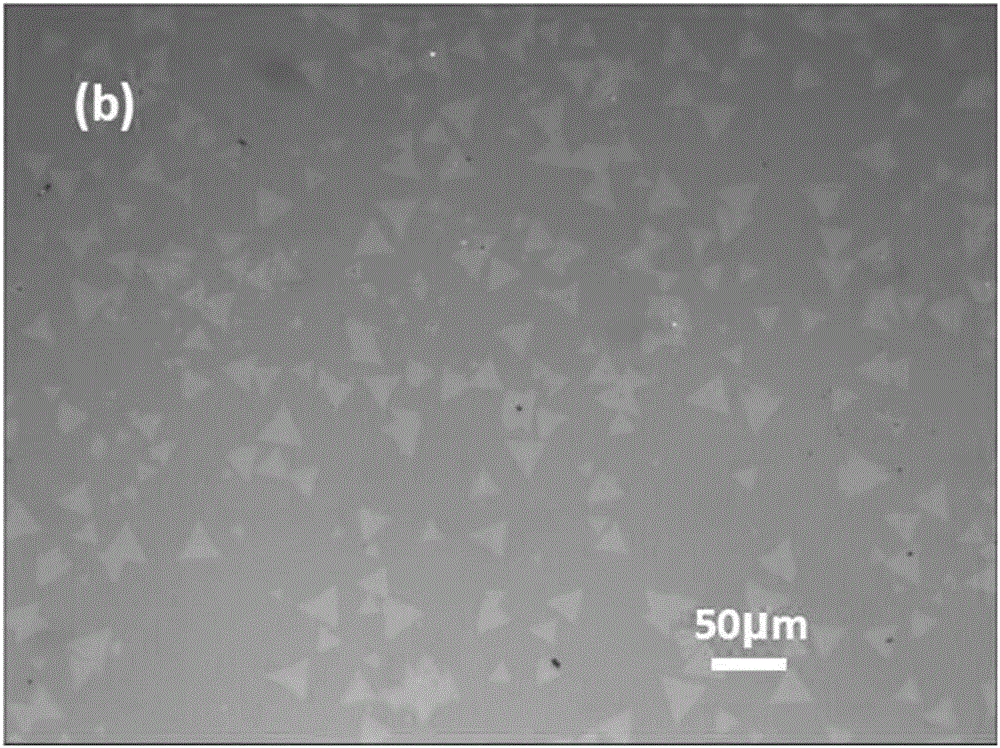

Method for preparing monolayer molybdenum disulfide

InactiveCN106835073AReduce stepsAvoid potential dangerChemical vapor deposition coatingHigh probabilityPiranha solution

The current methods for preparing single-layer molybdenum disulfide include micromechanical exfoliation, liquid-phase ultrasonic exfoliation, lithium ion intercalation, laser method, annealing layer-by-layer thinning method, and chemical vapor deposition method. Molybdenum disulfide prepared by chemical vapor deposition method has large size, uniform surface and controllable layer number. When molybdenum disulfide is prepared by chemical vapor deposition, molybdenum disulfide is easy to nucleate and grow on defects such as impurities or scratches on the substrate. If the substrate is not cleaned cleanly, molybdenum disulfide will easily grow into multi-layer or solid materials. To clean the substrate thoroughly, toxic and dangerous drugs such as acetone and piranha solution will be used. These drugs are toxic to the human body, so the operation process is potentially dangerous. Based on the above problems, the object of the present invention is to provide a simplified chemical vapor deposition method for the preparation of single-layer molybdenum disulfide, which can produce high-quality single-layer molybdenum disulfide without using toxic hazards such as acetone and piranha solution. Drugs are used to clean the substrate, avoiding potential danger.

Owner:BEIJING JIAOTONG UNIV

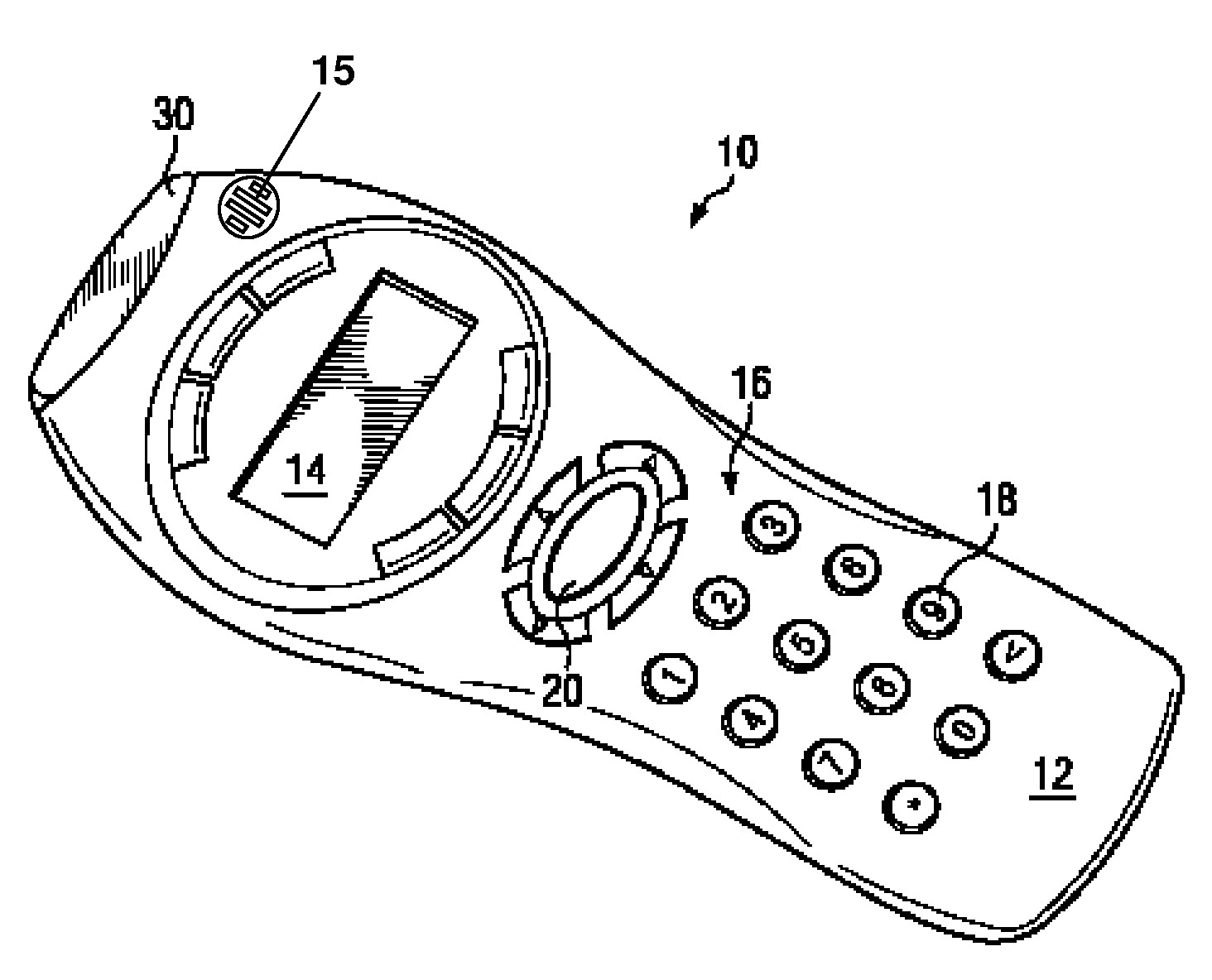

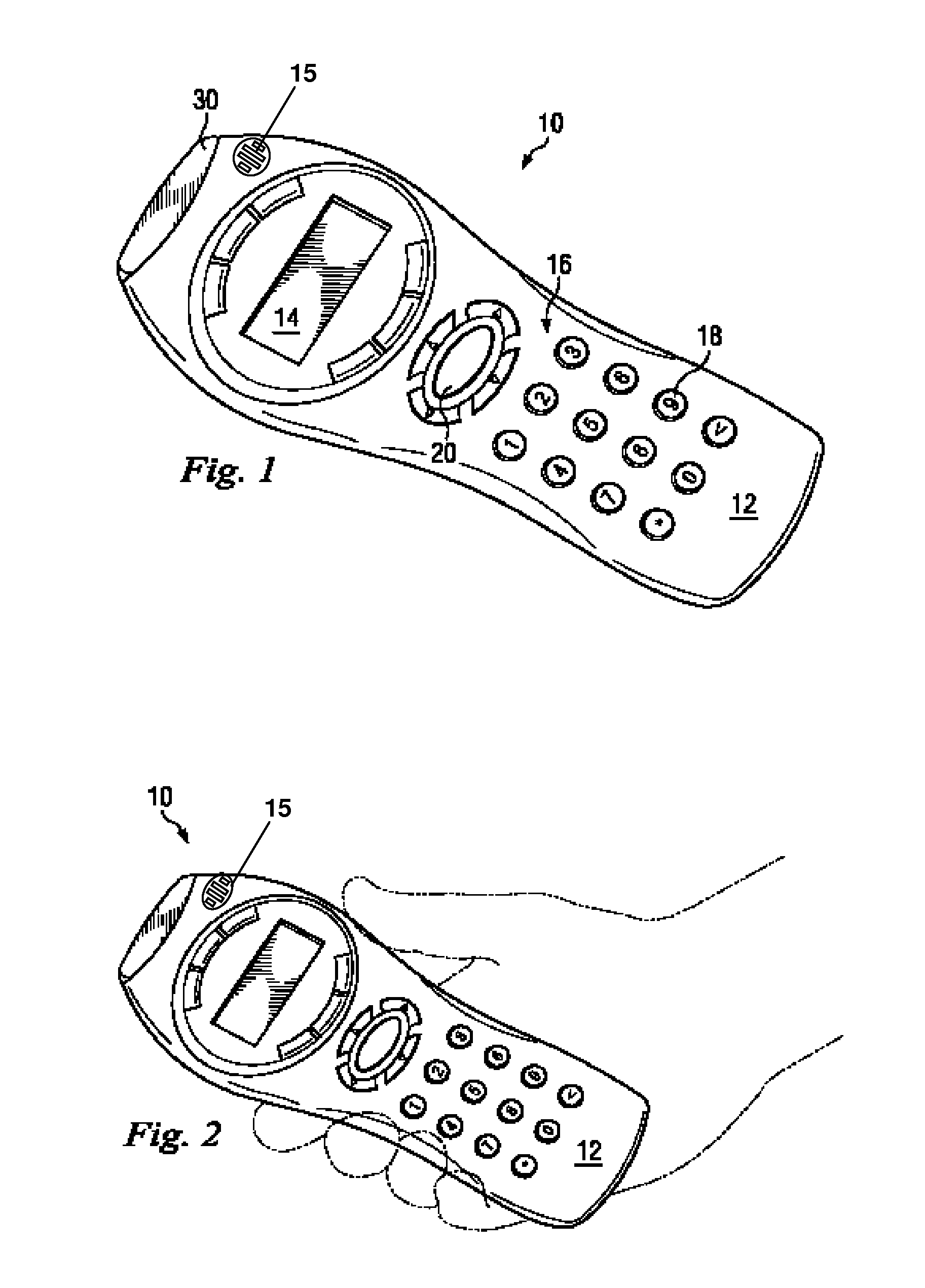

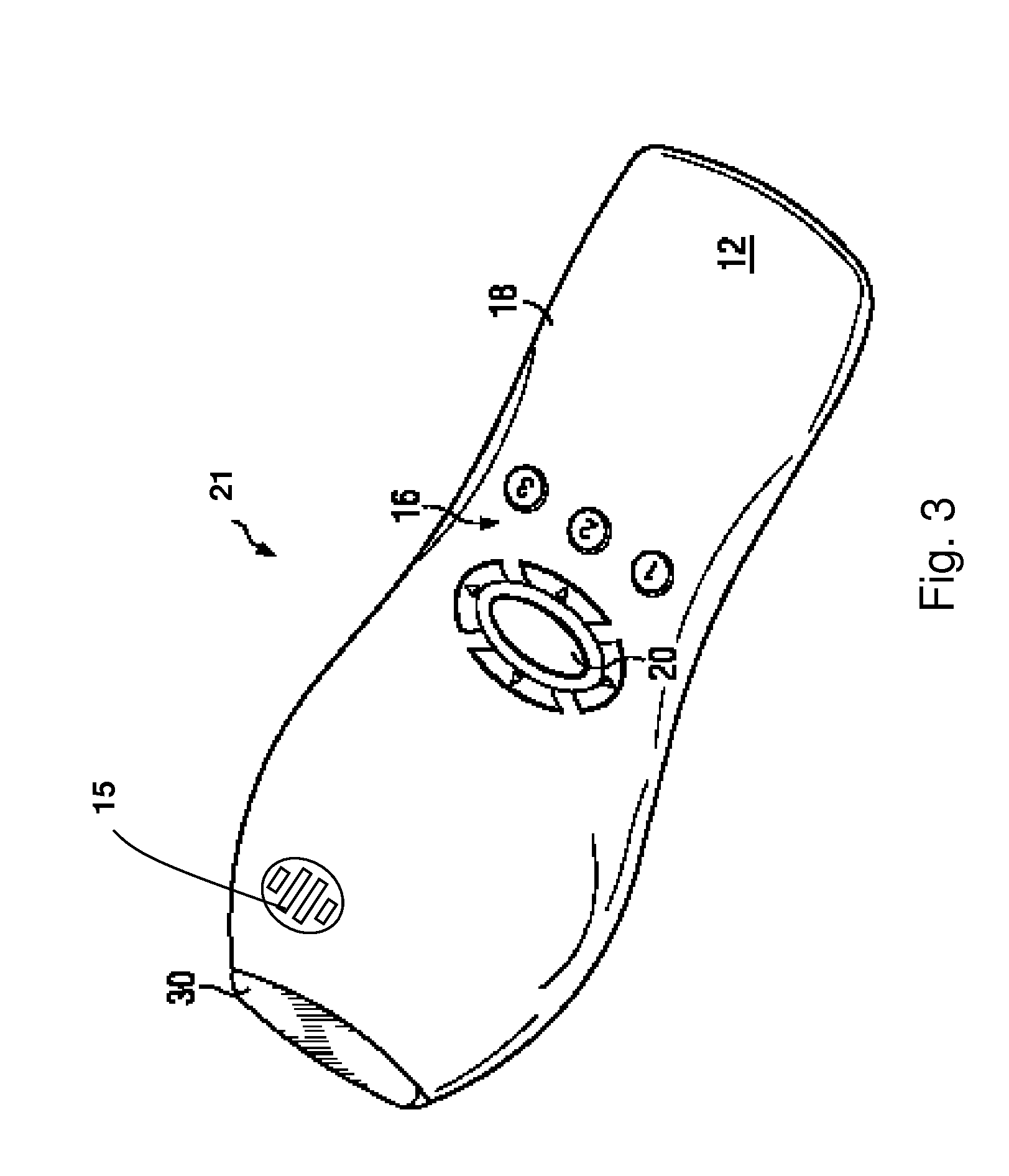

Therapeutic pulse laser methods and apparatus

InactiveUS20090088822A1Improve efficiencyControl functionality is limitedLight therapyHand heldEngineering

A method and apparatus for providing therapeutic pulse laser treatment. The treatment method includes delivering more than one therapeutic laser light protocol from a hand held therapeutic laser device according to a preprogrammed schedule. At one or more select times during the preprogrammed schedule, the hand held therapeutic laser device will produce audio output. The audio output provides information to the user and directs him or her to execute a step in the overall treatment plan. For example, the audio output may signal to the user that it is necessary to make a change in or between treatment protocols, move the laser device, pause treatment, or otherwise control the delivery of therapeutic laser light. The ability of a relatively untrained user to implement the method may be enhanced if the audio output is delivered as synthetic speech output.

Owner:LED HEALING LIGHT

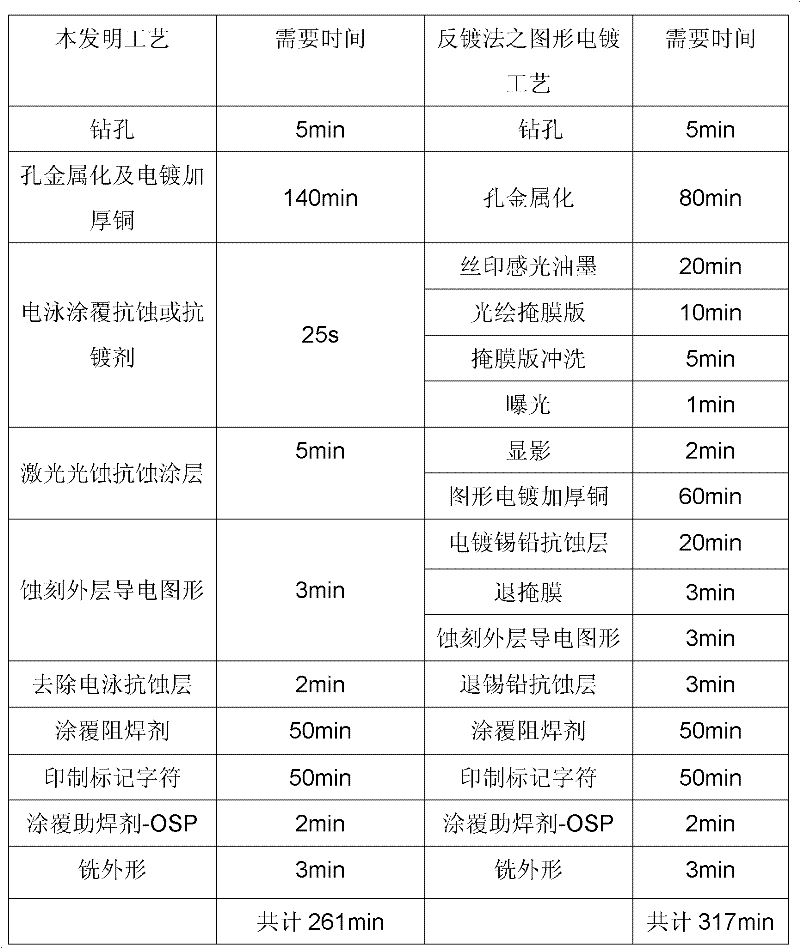

Method for producing anti-corrosion pattern in production of printed circuit board

ActiveCN102510671ASave processSave light paintingConductive material chemical/electrolytical removalResistEtching

The invention relates to a method for producing an anti-corrosion pattern in production of a printed circuit board, and the method comprises the steps of: drilling a hole, metalizing the hole, performing electrophoretic coating of a resist, producing the anti-corrosion pattern by laser, performing chemical etching and the like. The method with the electrophoretic coating of a resist and the production of the anti-corrosion pattern by the laser is adopted for replacing an existing tenting method process with the steps of hot-press lamination of an anti-corrosion photoinduced masking dry film, exposure, developing and the like or replacing the steps of pattern electroplating of an anti-corrosion metal layer and the like. According to the method disclosed by the invention, a process route for producing the anti-corrosion pattern is shortened, the operation steps are simplified, the operability is improved, the anti-corrosion coating is applied by electrophoresis, materials are easy to obtain, the operation is simple and easy, and the formed anti-corrosion coating is thin in thickness, uniform and reliable; and the anti-corrosion pattern formed by direct photoetching through the laser method is high in precision, good in an environment and great in production flexibility. The method disclosed by the invention is suitable for sample, small-batch, multi-variety and higher-precision production of the circuit boards, and is also suitable for production of ordinary circuit boards.

Owner:德中(天津)技术发展股份有限公司

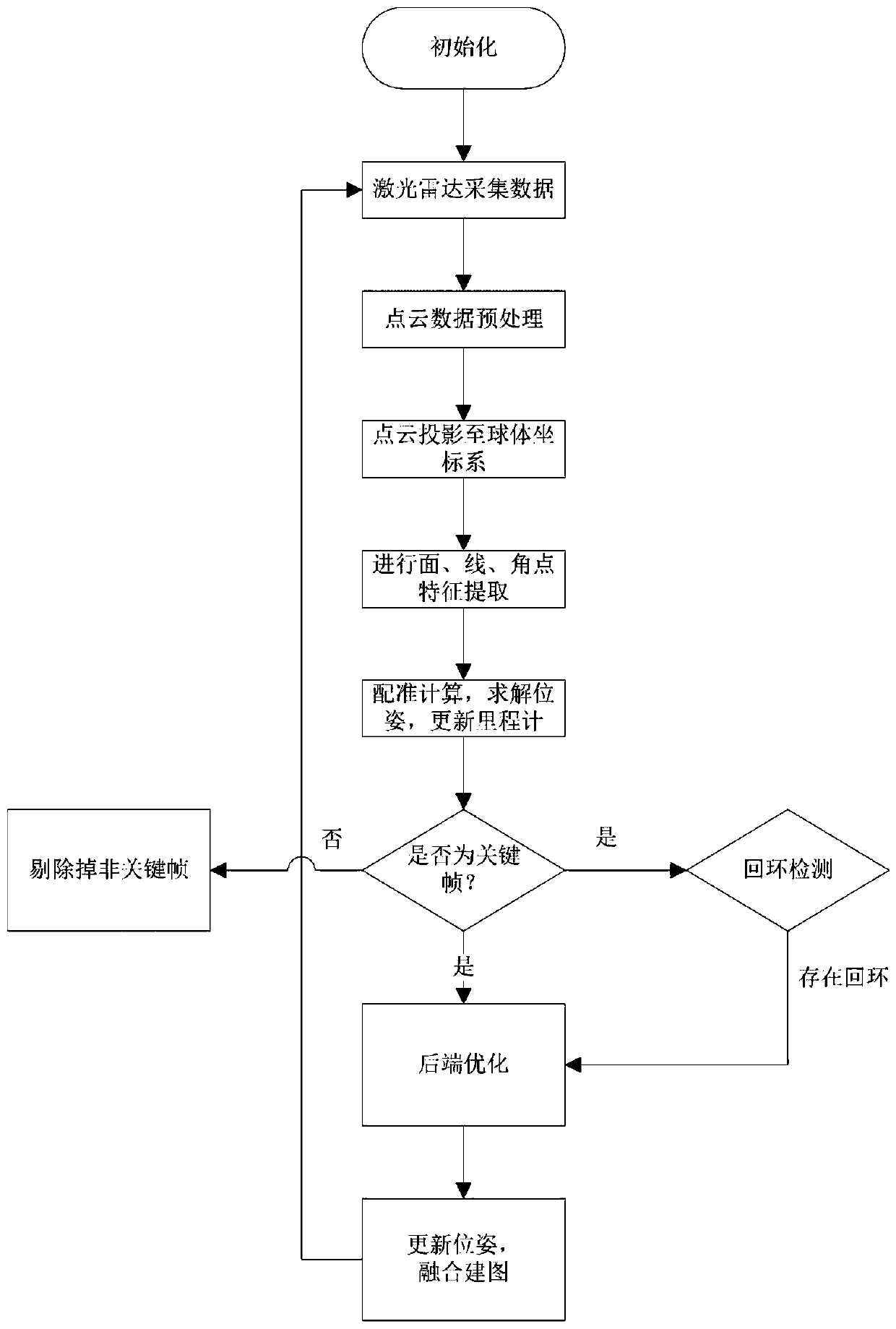

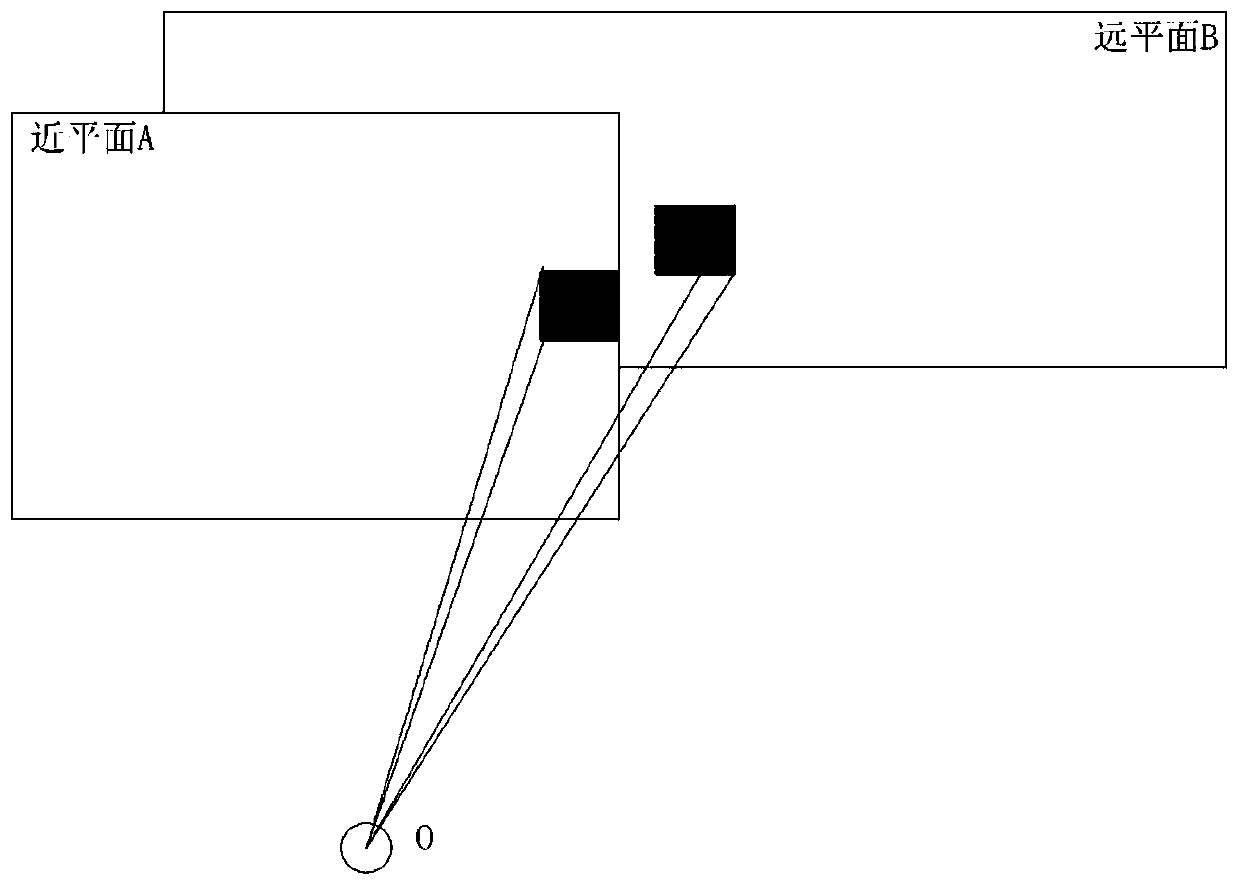

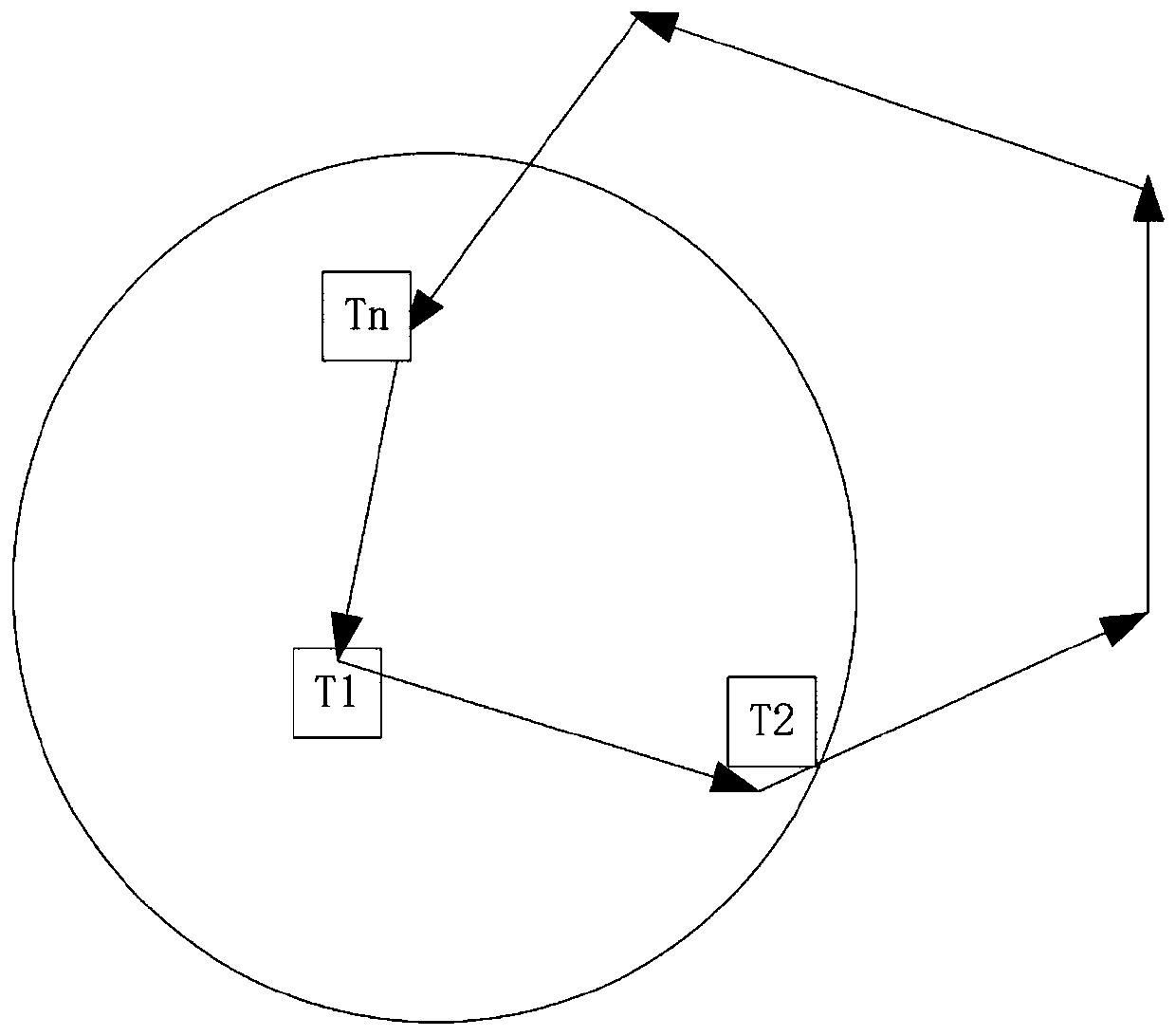

Laser SLAM method based on surface line corner feature extraction

ActiveCN111583369AReliable mapping effectIncrease the error of pose estimationImage enhancementImage analysisPoint cloudFeature extraction

The invention discloses a laser SLAM method based on facial line corner feature extraction, which comprises the following steps: (1) initializing a map and various parameters, and allocating memory; (2) collecting point cloud collected by the 3D laser radar; (3) carrying out data preprocessing on the collected point cloud; (4) carrying out projection; (5) removing blocking points; (6) extracting surface, line and corner features; (7) carrying out surface normal vector estimation on the surface and line features; (8) performing front-end registration calculation on the angular point feature information; (9) removing redundant parts in the point cloud, and storing key frame information, pose information and carrier track information; (10) performing loopback detection on the key frame information and the motion trail information; (11) performing back-end optimization; (12) updating the pose, performing fusing and mapping, and publishing map information and track information; and (13) skipping to the step (2), and continuing to run until the mapping is completed or the process is closed.

Owner:TIANJIN UNIV

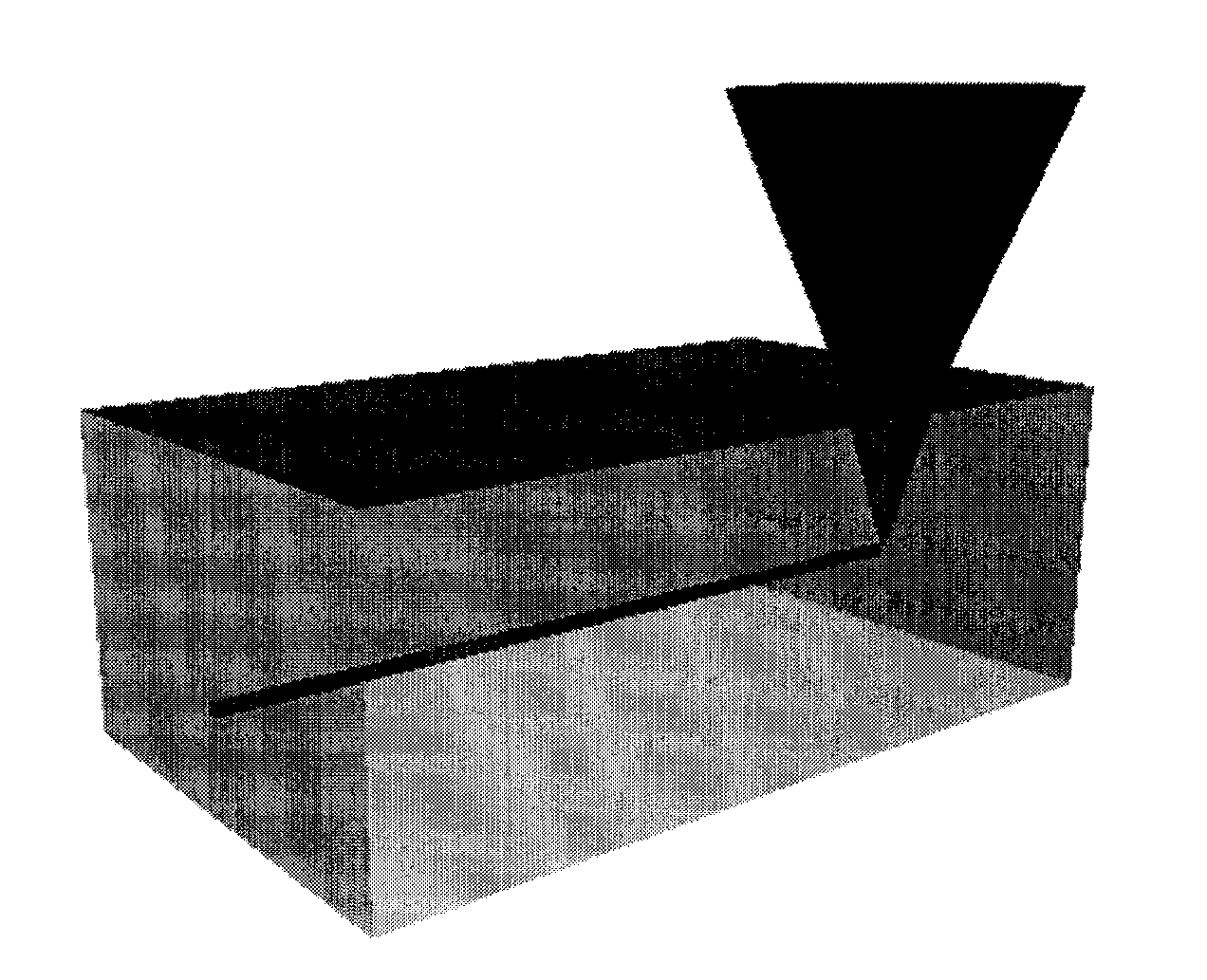

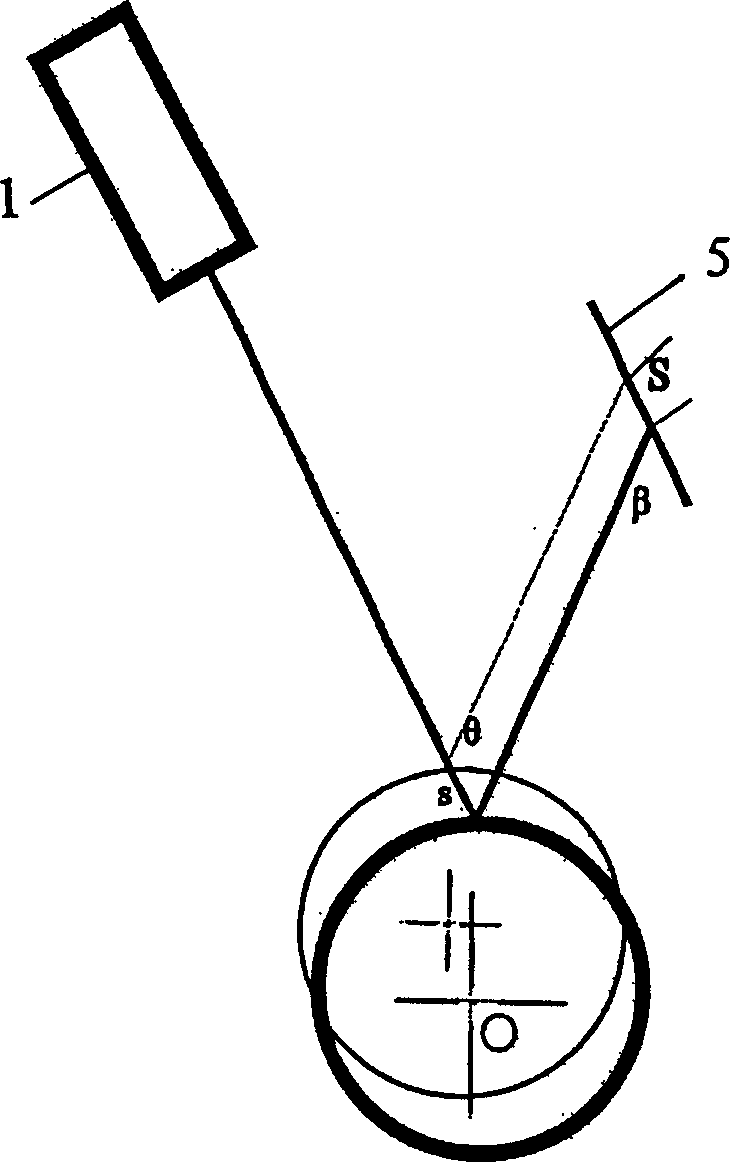

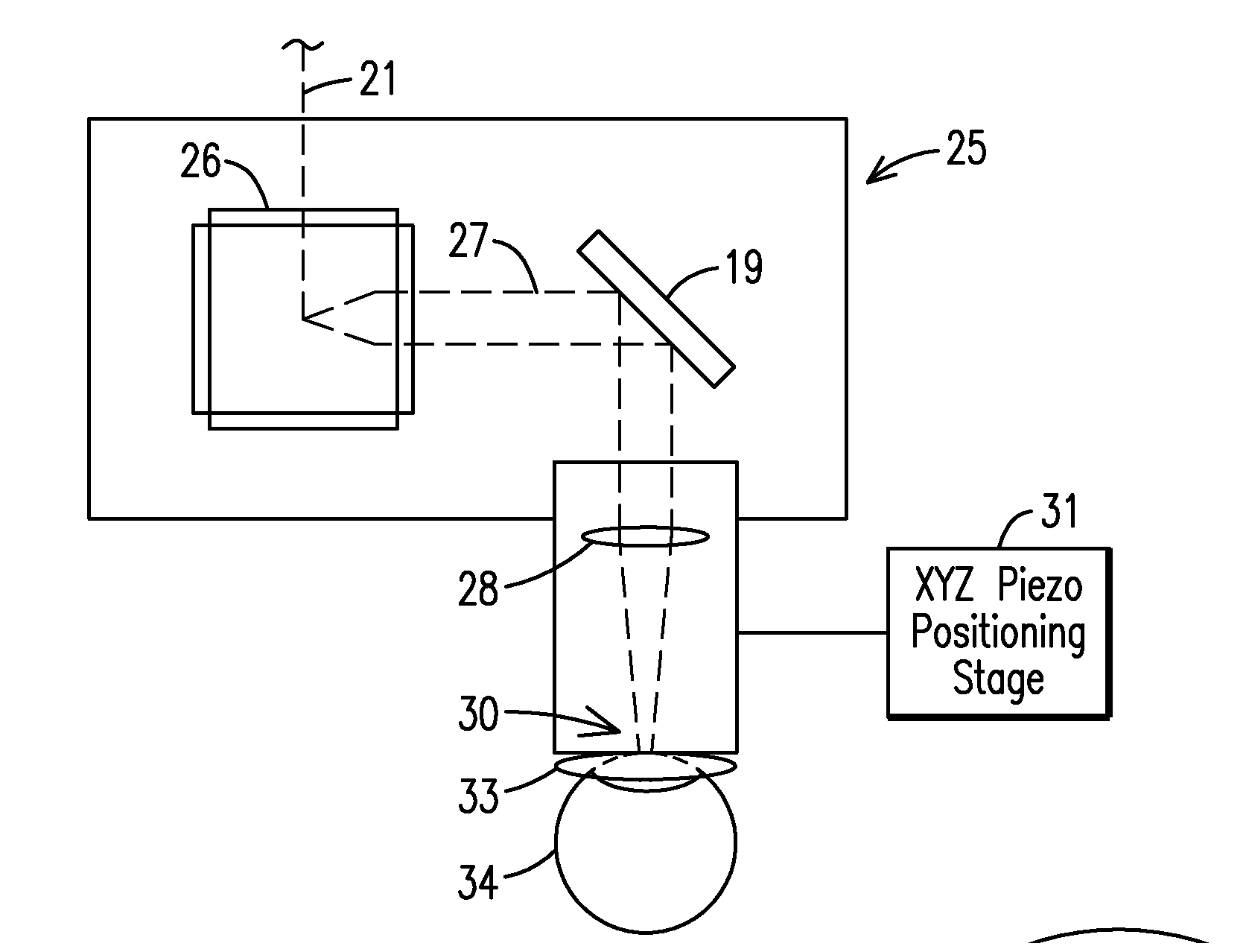

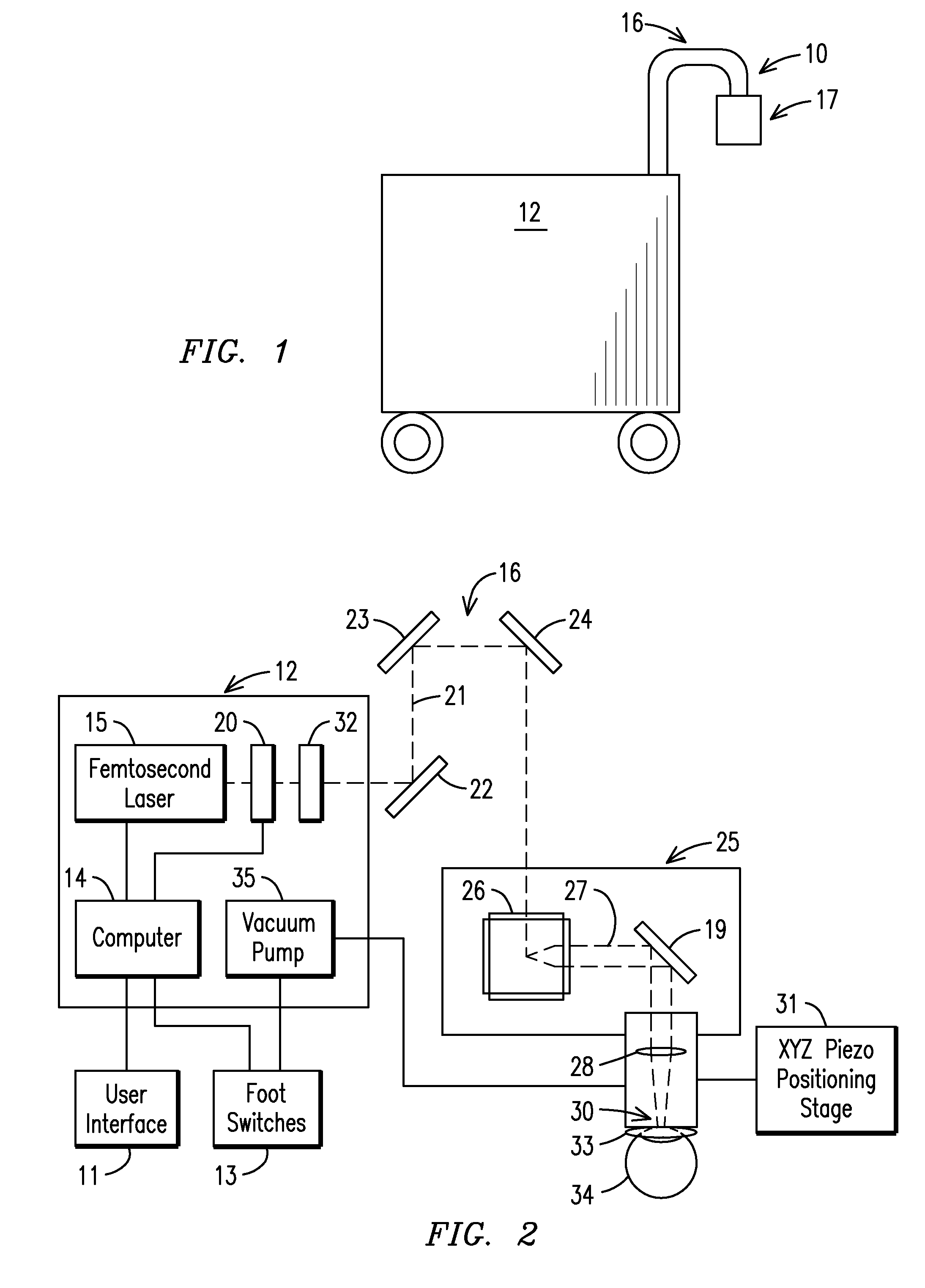

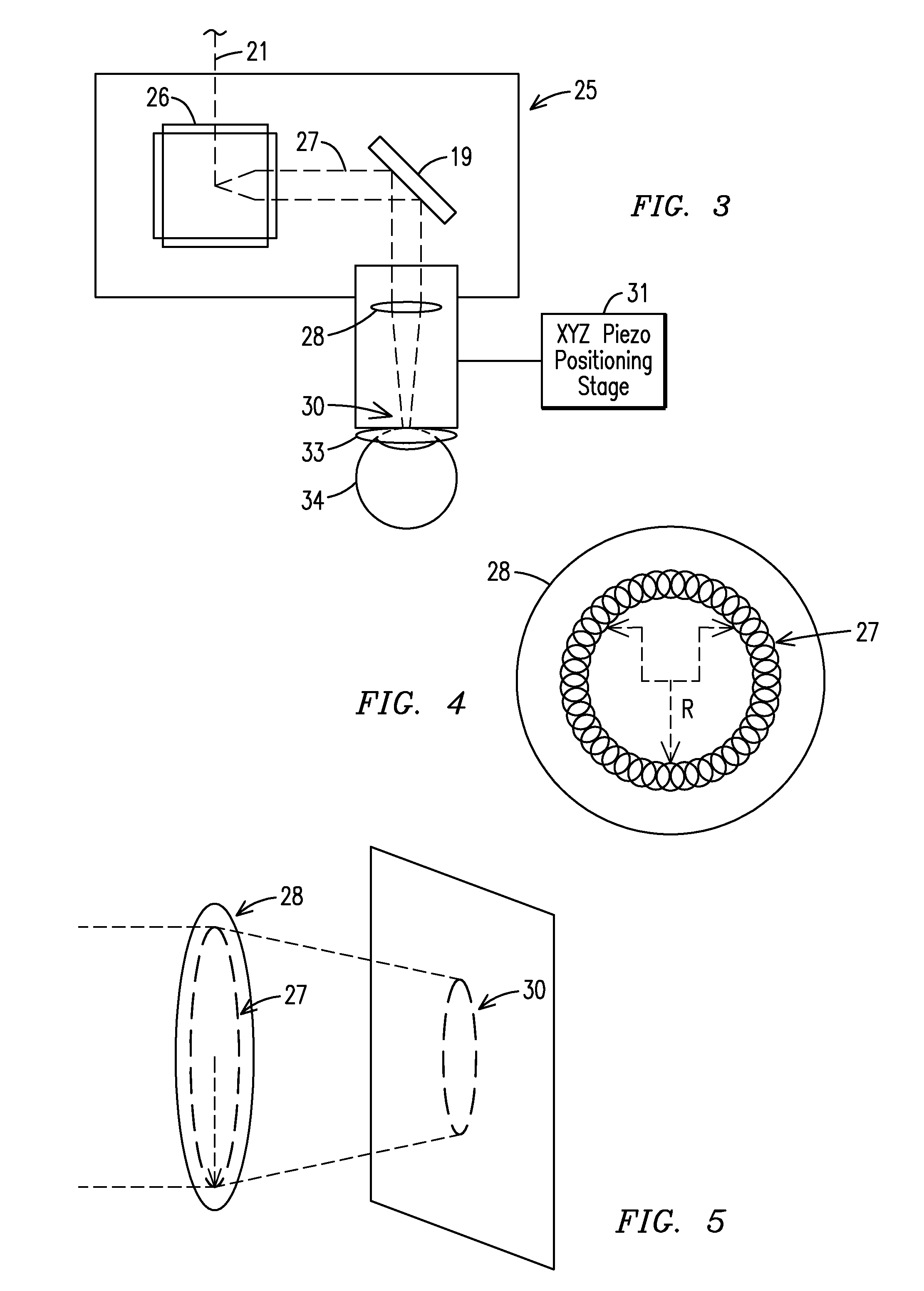

Ophthalmological laser method and apparatus

The present invention relates to a femtosecond laser ophthalmological apparatus and method that creates a flap on the cornea for LASIK refractive surgery or for other applications that require removal of corneal and lens tissue at specific locations such as in corneal transplants, stromal tunnels, corneal lenticular extraction and cataract surgery. The femtosecond laser is transferred to a hand piece module via a rotating mirror arm module. In the hand piece, the femtosecond laser beam is scanned into overlapping circles of laser pulses which are then moved in an overlapping trajectory on a patient's eye to ablate the eye tissue in a predetermined pattern.

Owner:HUANG CHENG HAO

Method for preparing super-hydrophobic surface material with adjustable contact angle by one-step laser method

The invention relates to a method for preparing a super-hydrophobic surface material with an adjustable contact angle by a one-step laser method. The method comprises the following steps: (1) cutting a polytetrafluoroethylene base material and then sequentially placing the polytetrafluoroethylene base material in acetone, absolute ethyl alcohol and deionized water, ultrasonically cleaning for 3-10min respectively and then drying at 50-100 DEG C; (2) setting the spot diameter of a CO2 laser engraving machine to 0.1-0.5mm, setting an engraving speed to 20-40mm / s, setting frequency to 20-80KHZ, setting spot engraving time to 0.1-1ms, setting power to 20-40%, and setting engraving times to 1-5; (3) placing the treated polytetrafluoroethylene base material on the sample platform of the laser engraving machine, controlling a laser device to process a dot matrix or line matrix pattern on the polytetrafluoroethylene base material by laser operation software, and then obtaining the super-hydrophobic surface material provided with a surface with different contact angles. The preparation method disclosed by the invention is simple and rapid, low in cost and environmentally friendly; the prepared super-hydrophobic surface material is stable in structural performance, the contact angle can be manually adjusted with the changes of process parameters, and the method is suitable for industrialized production applications.

Owner:HUBEI POLYTECHNIC UNIV

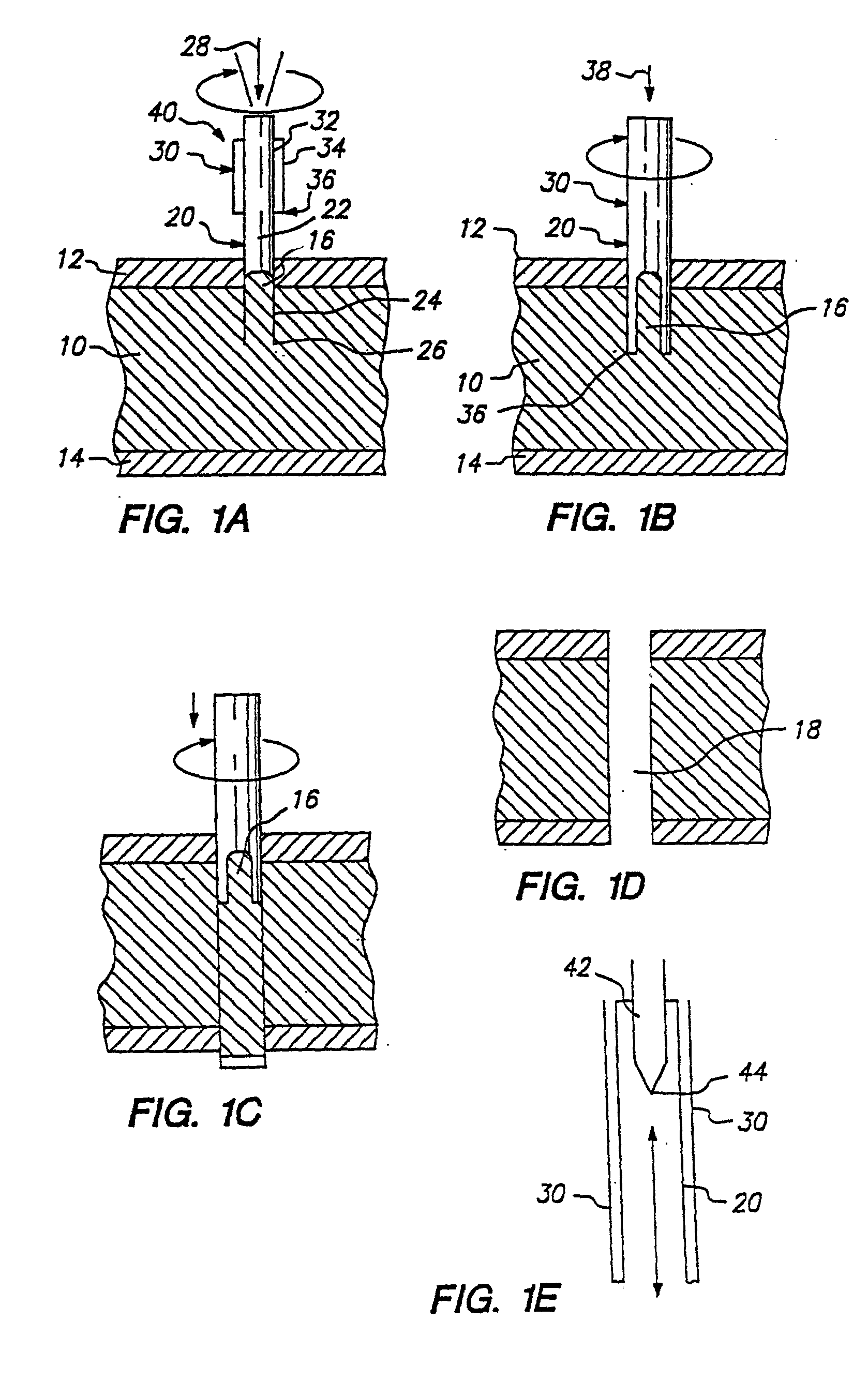

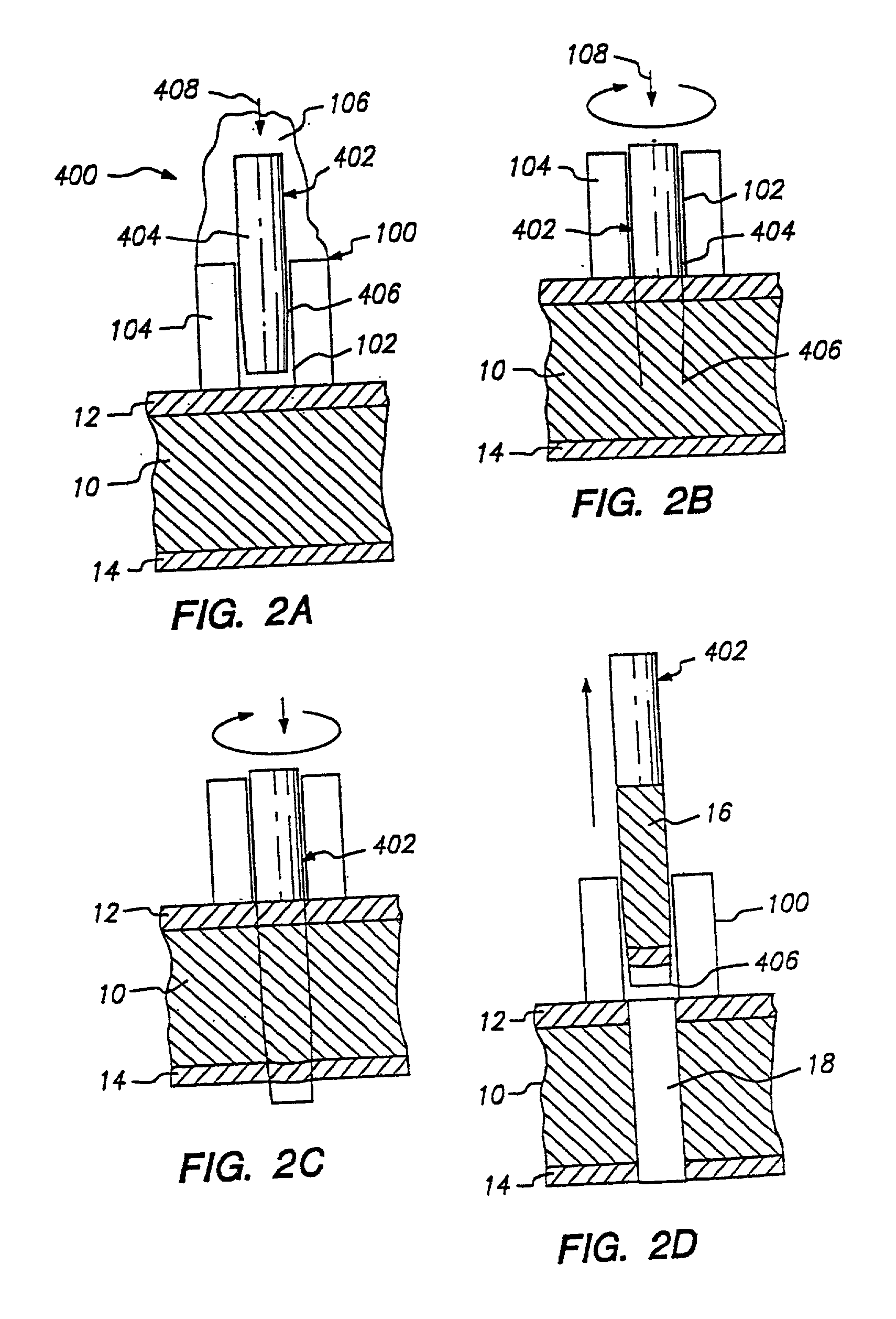

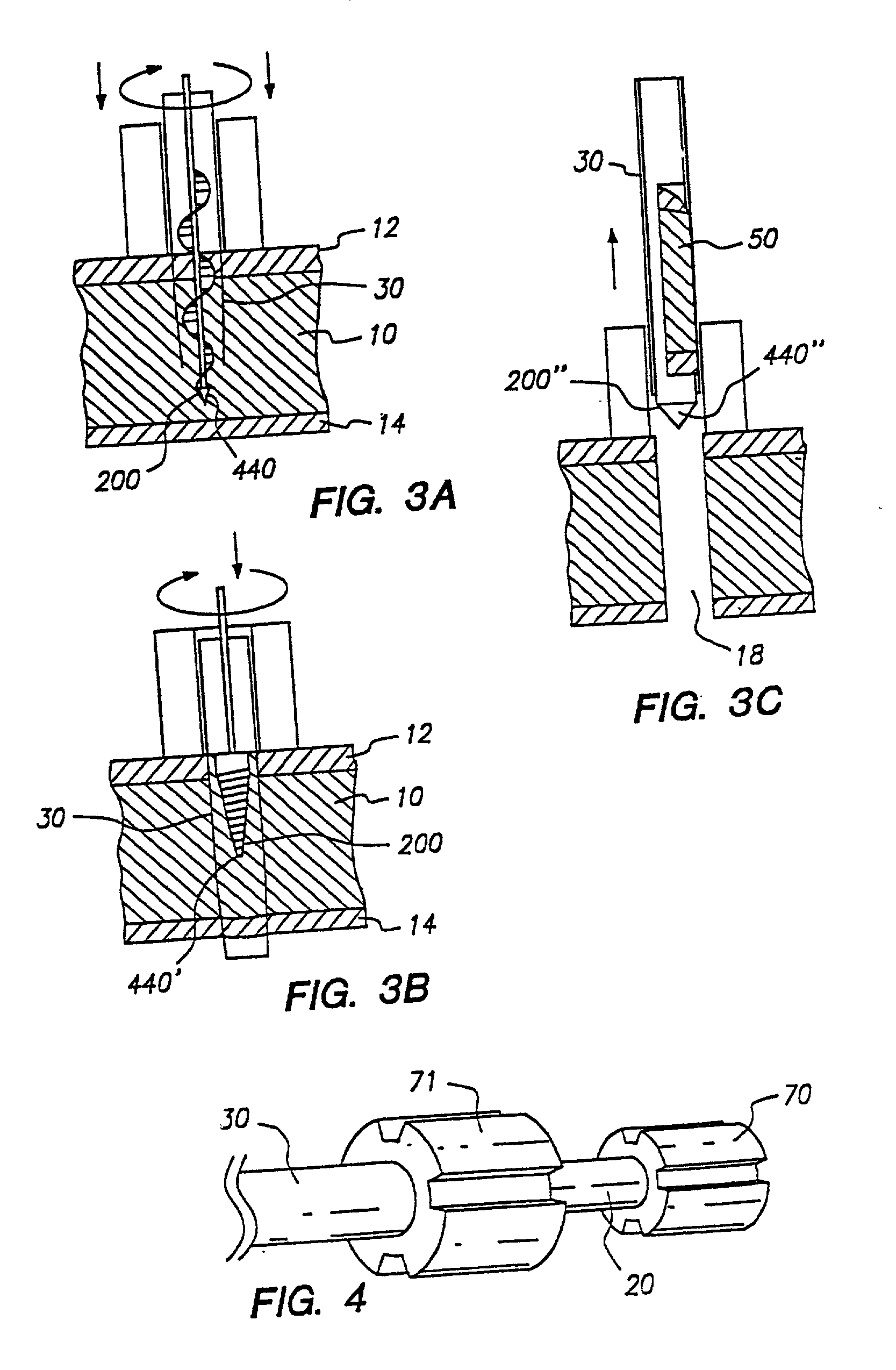

Method and apparatus for mechanical transmyocardial revascularization of the heart

InactiveUS20010001124A1Without excessive tearingEasy to cutSurgical needlesVaccination/ovulation diagnosticsCardiac muscleEngineering

An apparatus for creating revascularization channels in tissue, such as the myocardium of the heart, mechanically cuts the channels using a hand piece with easily removable cutting tip assemblies having angled, sharpened edges to allow rapid tip replacement. The cutting tip assembly has an inner needle within an outer hollow needle with each needle attached to the hand piece for independent rotation and axial movement. The inner needle may be hollow, or formed with a pointed tip, and may rotate counter to the outer needle to enhance gripping and storage of the tissue excised by the outer needle. The hand piece may attach a cylindrical magazine of cutting tip assemblies or one cutting tip assembly. The cutting tip assembly may be heated to provide thermal damage to the heart muscle during the creation of the channel, providing some of the advantages of the laser method of TMR.

Owner:MUELLER RICHARD L

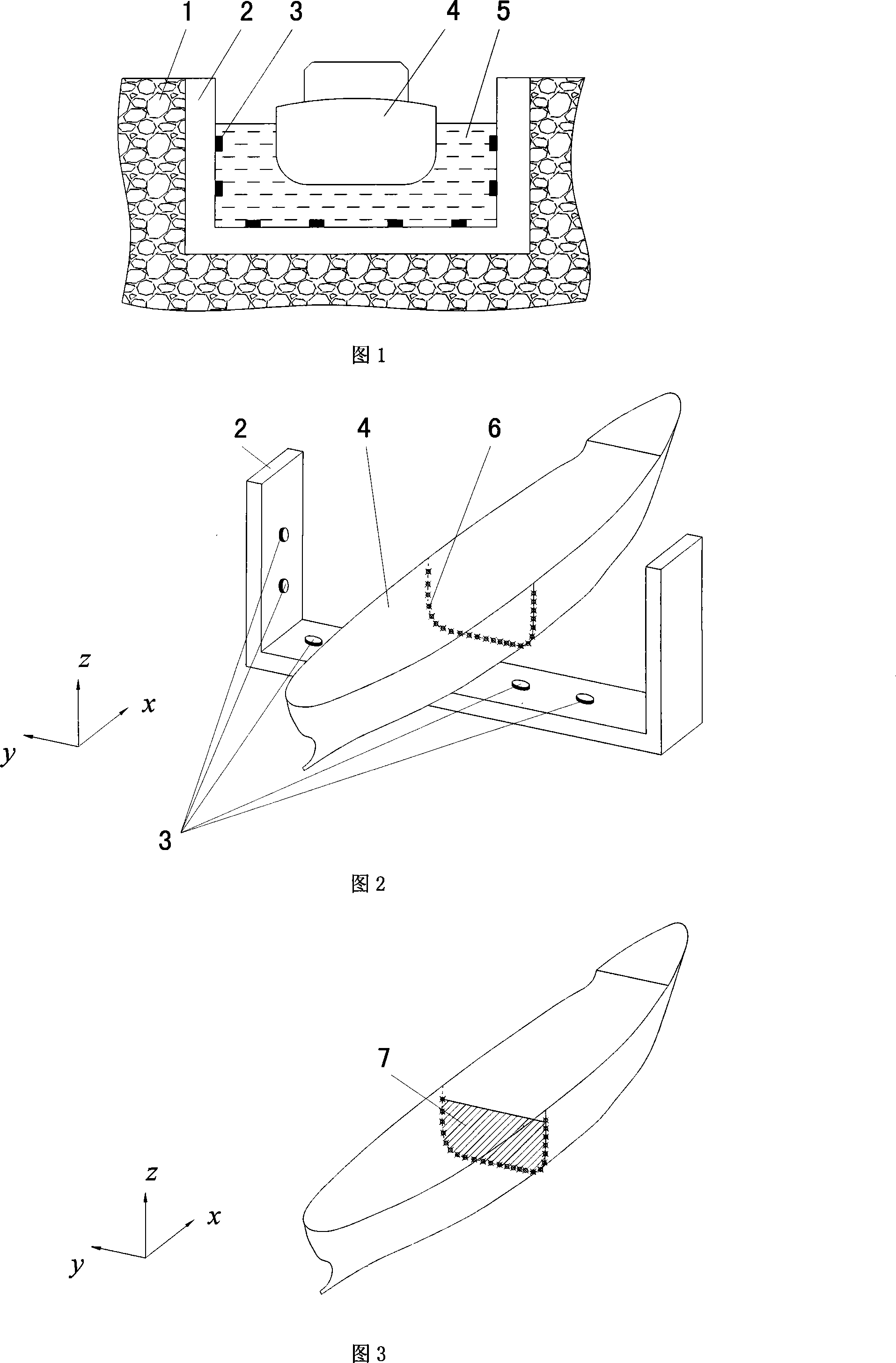

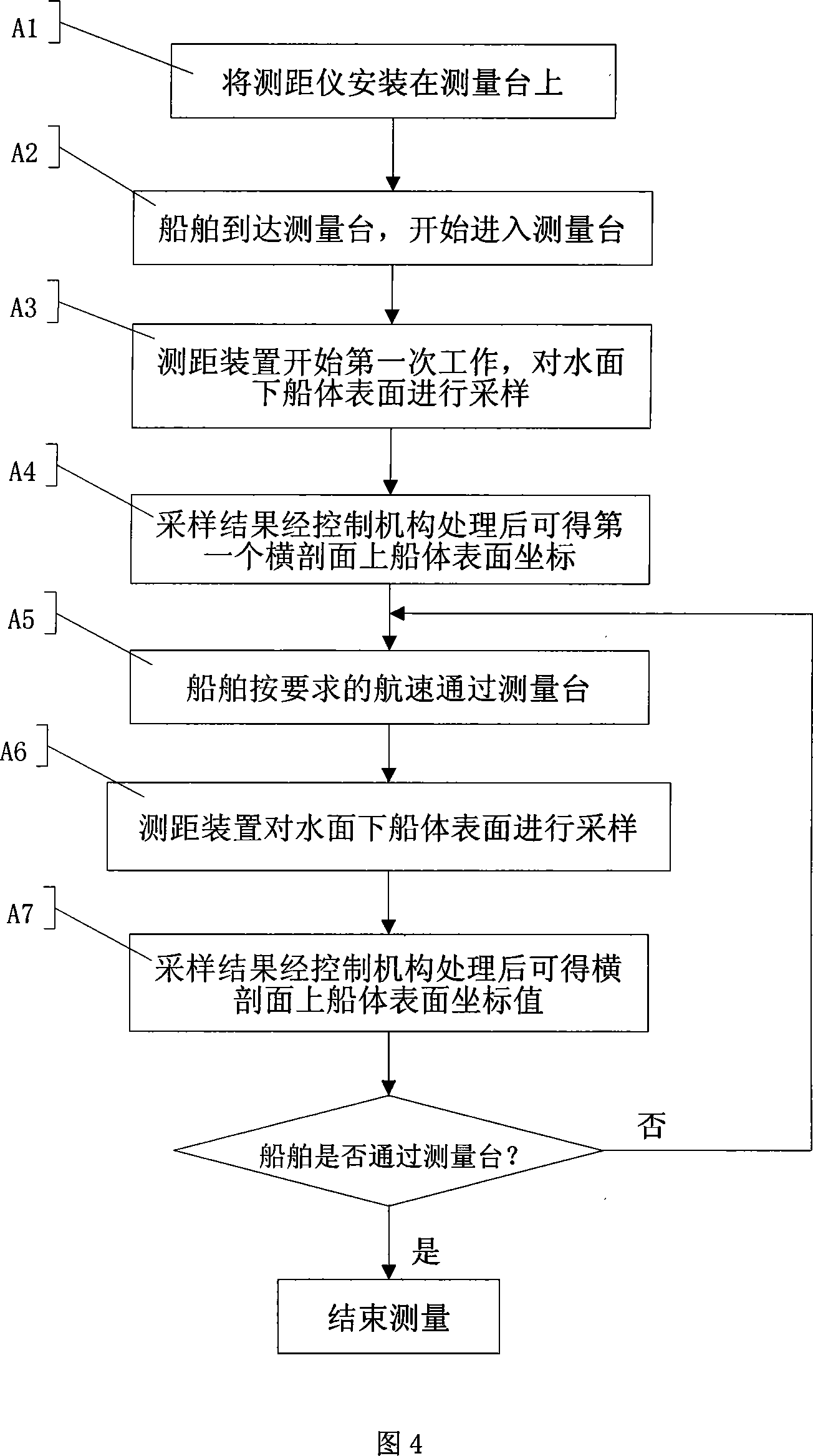

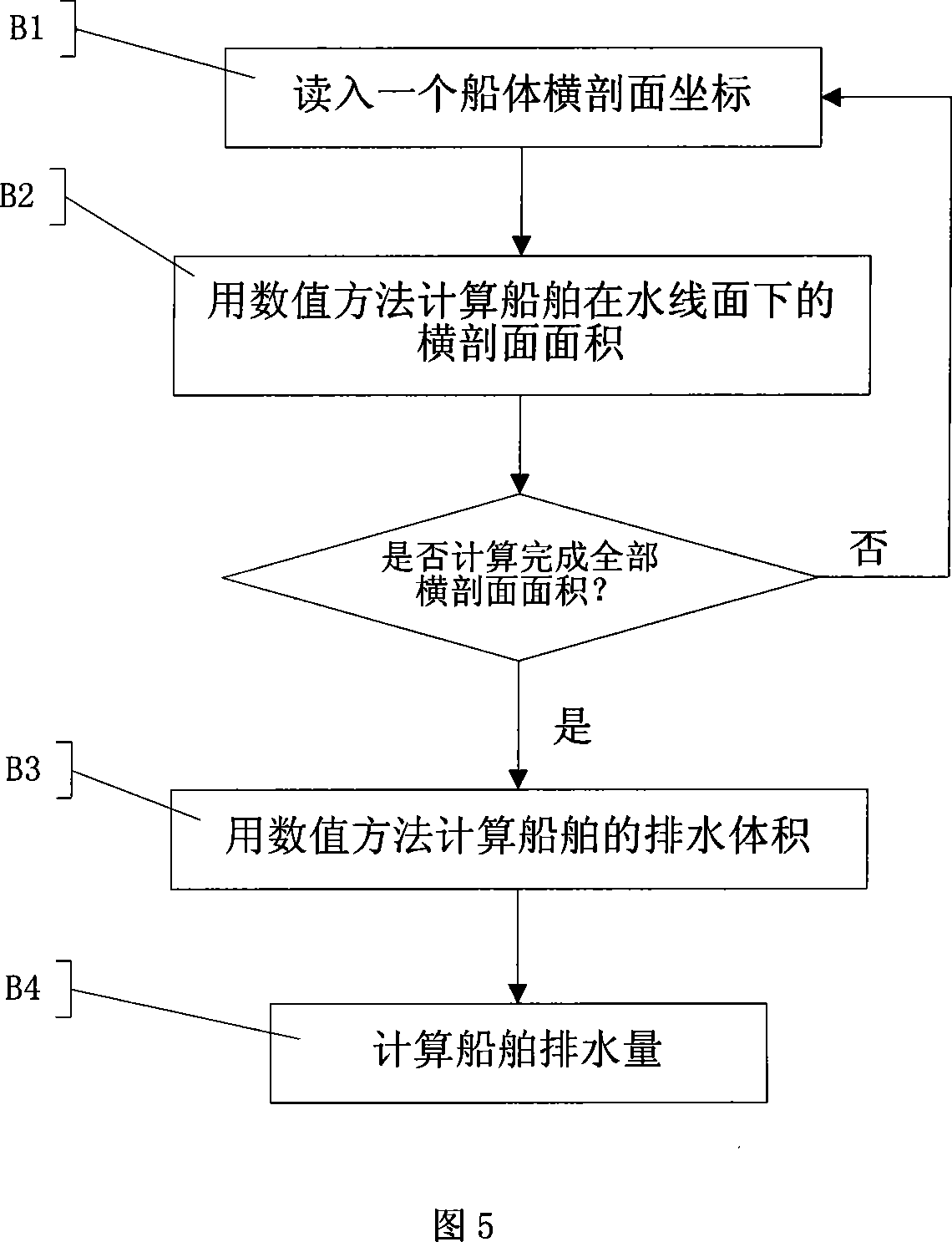

Ship displacement measuring apparatus and its measurement method

InactiveCN101216338AWarranty recordReal-time measurementVolume measurement apparatus/methodsElectromagnetic wave reradiationMeasurement deviceMarine navigation

The invention relates to a device for measuring water displacement of ships and a measurement method thereof. The device comprises a measurement table and a device for measuring surface coordinates of an underwater ship body. The device for measuring surface coordinates of underwater ship body adopts non-contact distance measurement with an ultrasonic or laser method, and is composed of distance meters and a control mechanism that are disposed on the measurement table. The distance meters are installed on the bottom surface and two side surfaces of the measurement table, and the number of the distance meters is determined according to the size of the measurement table. The method for measuring water displacement of ships comprises the methods of measuring surface coordinates of ship body and of calculating water displacement. The invention has the advantages of simple operation and good reliability, can real-time measure the water displacement of ships, the measurement accuracy can satisfy the cargo weight measurement standards of China, and the invention can adapt the unfavorable measurement conditions, such as waves with certain amplitude and vertically and horizontally swinging of the ship body, so as to ensure to record the draft and water displacement on the premise of not affecting normal navigation of ships. The invention is suitable for measuring the water displacement during normal navigation of ships.

Owner:WUHAN UNIV OF TECH

Low temperature production method of transparent conductive oxide film

InactiveCN101429643AExcellent transparent conductivityGood visible light transmittanceVacuum evaporation coatingSputtering coatingNiobiumRoom temperature

The invention provides a low temperature preparation method for a transparent conductive oxide film. After a seed crystal layer is prepared through a pulsed laser method, niobium doped titanium oxide transparent conductive film material is prepared in succession respectively through the pulsed laser method or a magnetron sputtering method. The seed crystal layer can be anatase crystal type titanium oxide single-crystal. The thickness of the seed crystal layer is controlled at the length of c shafts of 0.5 to a plurality of unit cells. The titanium oxide base film material is continuously bred and prepared on the substrate material with the seed crystal layer through the pulsed laser method or the magnetron sputtering method. The preparation process has less dependency on the preparation technology and growing conditions. The preparation technology is flexible and is full of selectivity. The visible light transmission rate of the obtained titanium oxide base transparent conductive film is higher than 90 percent; and the resistivity at a room temperature is lower than 8x10<-4>ohm.cm. The method realizes the growth and preparation of the transparent conductive oxide film capable of replacing ITO.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Laser method for shaping of optical lenses

A method for making accurate and precise customized corrections to the surface of an optical lens is described. An electronic correction contour is generated from a measured refractive correction for a patient, and transferred to the surface of the lens by ablation etching with one or more laser pulses. After each of the laser pulses, the refractive properties of the lens are measured and compared to the electronic contour correction derived from a patient's refractive correction. The ablation etching is terminated in localized areas where the refractive properties match the electronic correction contour. End point detection includes monitoring refractive qualities of the lens during the recontouring process, modifying the pattern through changes in the laser pulses.

Owner:WESTAR PHOTONICS

Laser method for measuring water quality and measurer therefor

InactiveCN1844890AImprove the efficiency of water quality analysisReduce analysis costsMaterial analysis by optical meansInformation processingTurbidity

The invention relates to a laser water quality detecting method and relative detector, which can via the on-line detection on each layer of water to attain the water quality in one dimension and different layers as the backward disperse water intrinsic curve; and via extracting information from said curve, attain the adsorb parameter, disperse parameter, and turbidity of water. Wherein, said intrinsic curve can be used in underwater depth measure and the detection and prediction of red tide. The invention comprises a control unit, a false random signal generate synchronous processing unit, a D / AC unit, a signal modulate unit, an A / DC unit, an optical emitter and an optical receiver. The invention has large information processing amount, high detecting efficiency, while it can reduce detecting time and cost when detecting large-scale water.

Owner:HARBIN ENG UNIV

Method for making local laser metal color on surface of printing material

InactiveCN101905581ASolve the prominent visual effectEnhance local visual effectsVacuum evaporation coatingSputtering coatingUV curingUltraviolet

The invention discloses a method for making local laser metal color on the surface of a printing material, and aims to overcome the defects that the conventional whole laser embossing layer influences the local protruding visual effect of a printed matter, and the local laser method has deficient technical means, poor laser effect and low production efficiency. The technical scheme has the key points that: the method comprises the following steps of: coating a release agent on a specific film; printing image-text on a release layer; making the laser embossing layer on the image-text; plating aluminium on the laser embossing layer; gluing the aluminium plating layer; compounding the film and the printing material; peeling the film; and remaining the image-text, the laser embossing layer and the aluminium plating layer on the printing material; and the method is characterized in that: the step of making the laser embossing layer on the image-text comprises the substeps of: intagliating an area range needing the laser embossing layer on a gravure printing device on a cylinder; locally printing UV-cured gloss oil on the image-text; embossing laser grains on a UV-cured gloss oil area by using an embossing device; and curing the UV-cured gloss oil area by using a UV curing device to obtain the local laser embossing layer.

Owner:SHANTOU KINGSPACK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com