Method and apparatus for mechanical transmyocardial revascularization of the heart

a technology heart muscle, which is applied in the field of mechanical transmyocardial revascularization of the heart, can solve the problems of large and expensive laser equipment for performing such procedures, inaccessibility to many patients, and difficulty in obtaining the techniqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

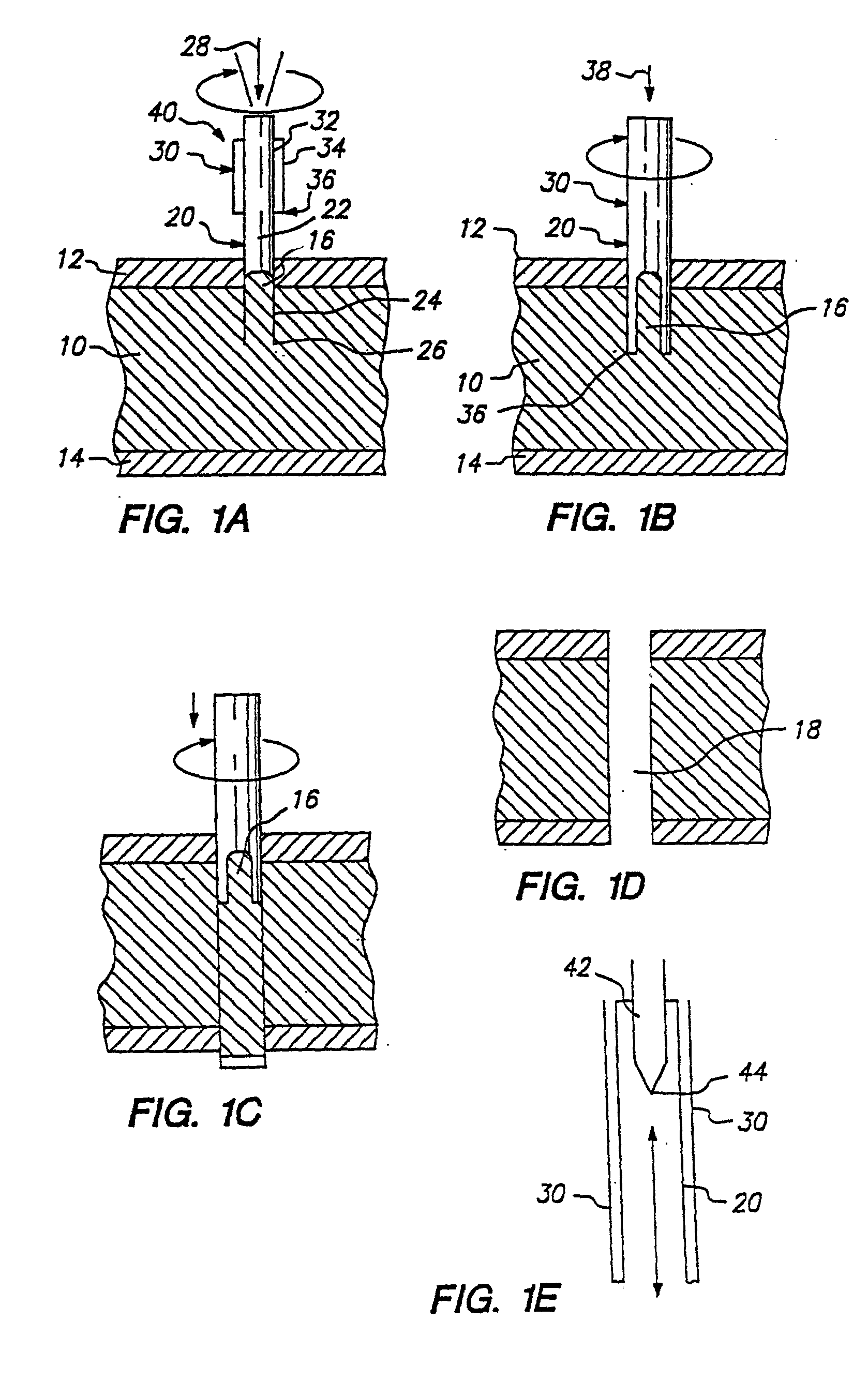

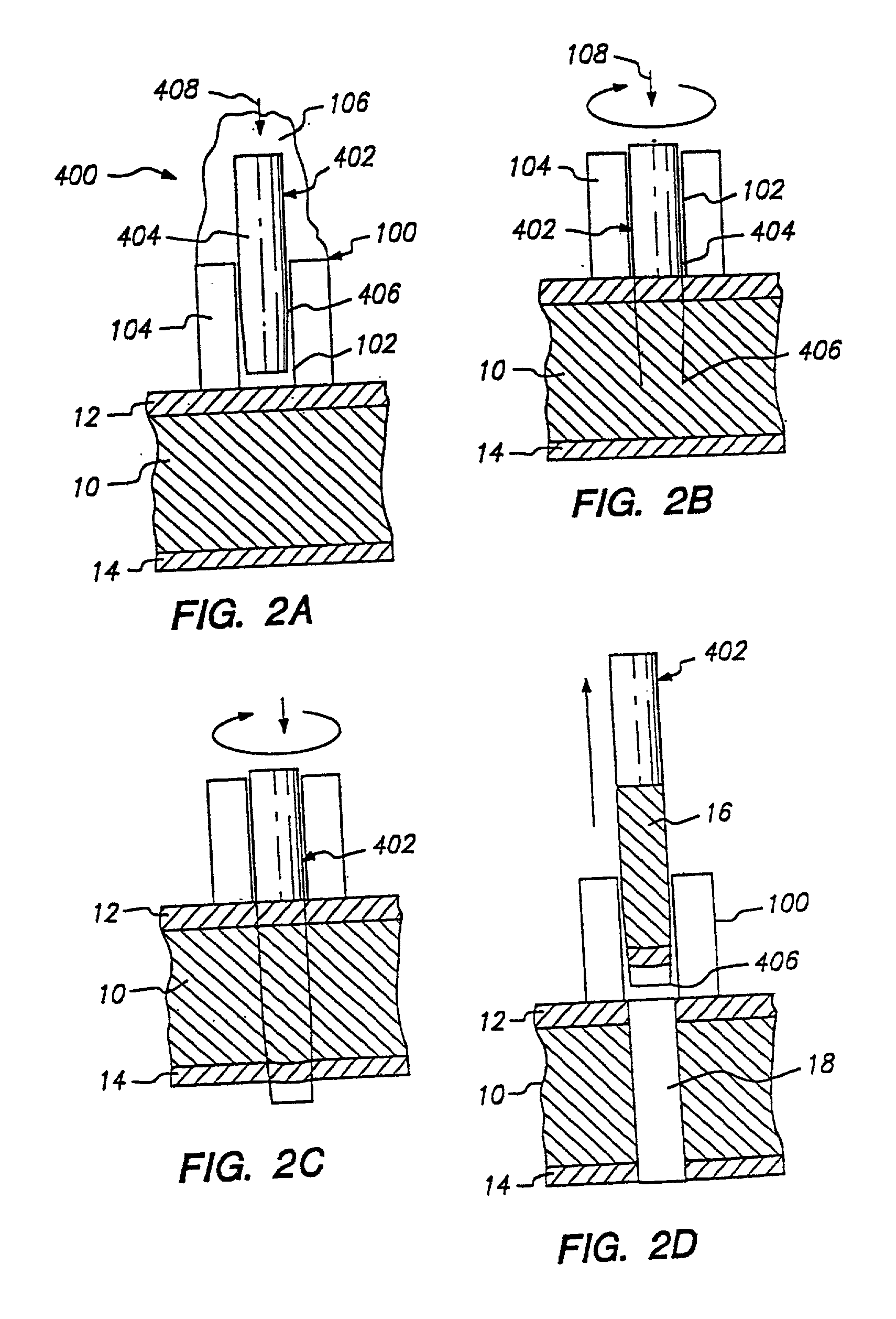

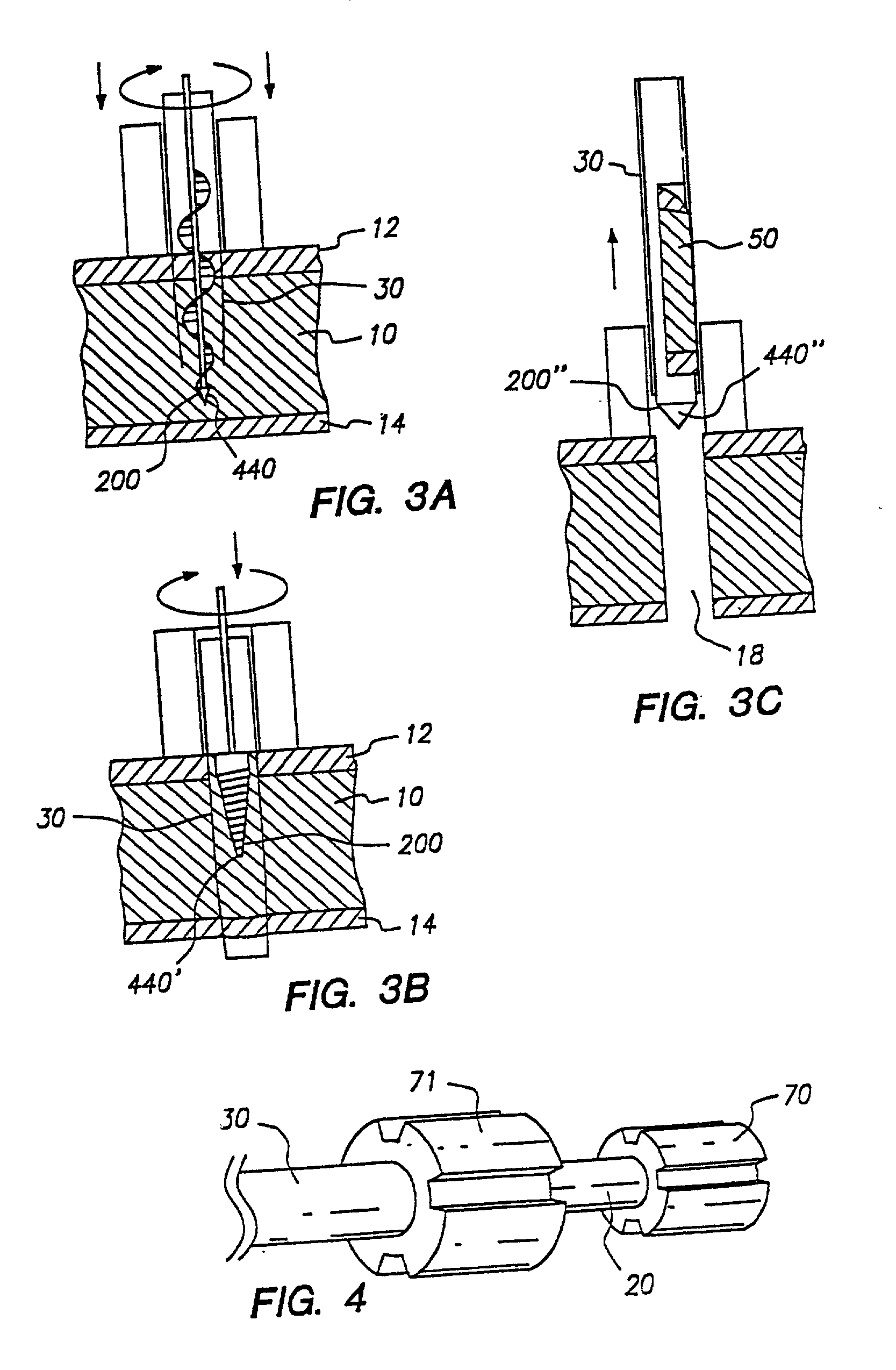

24. While a variety of embodiments of the present invention are disclosed herein, one exemplary presently preferred embodiment is illustrated in FIGS. 1A through 1D. FIGS. 1A through 1D each represent a different stage in the process of creating a channel 18 in the myocardium 10, which has an outer wall (epicardium) 12 and an inner wall (endocardium) 14.

25. FIG. 1A illustrates that the apparatus of this embodiment of the present invention has a cutting tip assembly 40 with an inner cylindrical needle 20, which has a tubular hollow internal bore 22 within its body 24. Because inner needle 20 is cylindrical, it has a lateral axis 28. Inner needle 20 has a sharpened edge 26, which may be made sharp through use of a variety of geometries (e.g., beveled inward, beveled outward). A presently preferred cutting edge defines an angle less than 45 degrees, and preferably less than 30 degrees, from the lateral axis 28. The cutting edge is sharpened using conventional techniques used in, for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com