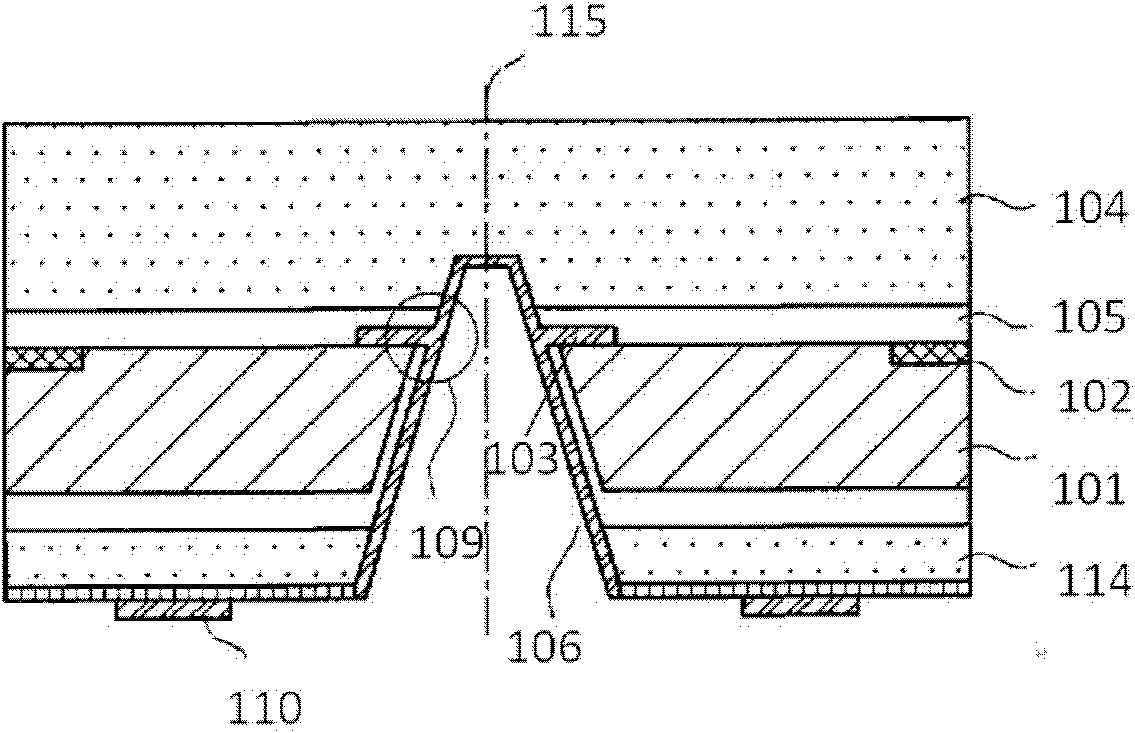

Method utilizing TSV (Through-Silicon-Via) to realize wafer level package of GaAs (gallium arsenide) image sensor

An image sensor and wafer-level packaging technology, applied in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of small signal delay, low capacitance value, high cost, etc., and achieve low cost, high interaction Continuous density, no radiation damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to fully demonstrate the advantages and positive effects of the present invention, the substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

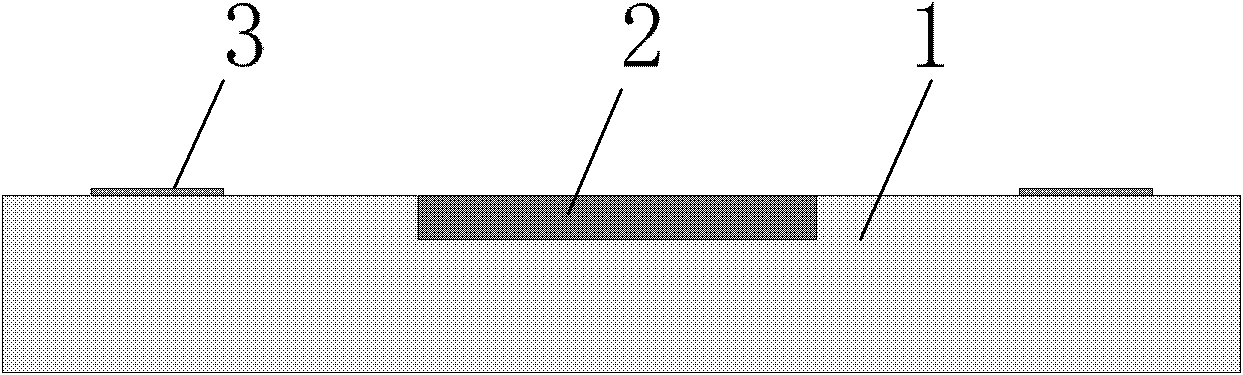

[0042] refer to figure 2 The GaAs image sensor wafer 1 includes several chips, and image sensing components are formed on the front of each chip through a preset manufacturing process, including the formation of image sensing units 2 and pad electrodes 3 . The pad electrode 3 is distributed in the non-functional area around the image sensing unit, and the material selected can be aluminum, gold or copper. The image sensor is used in the visible light range, and the wafer thickness is 350 μm.

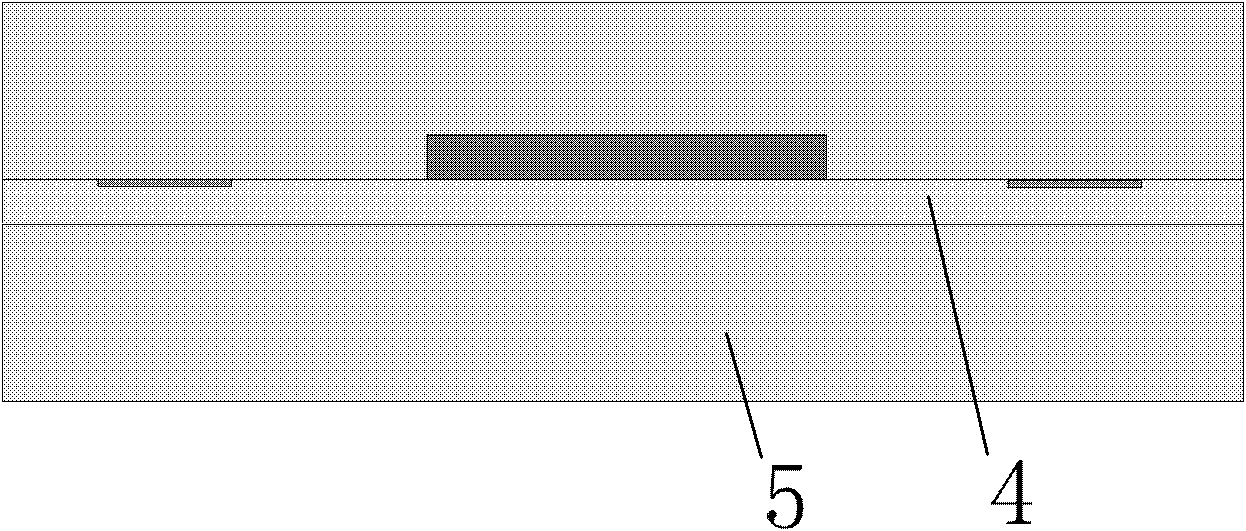

[0043] Thereafter, refer to image 3, bonding the wafer 1 to a transparent substrate 5 . The substrate plays the role of light transmission, protection from external pollution and mechanical damage, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com