Method for preparing super-hydrophobic surface material with adjustable contact angle by one-step laser method

A technology of superhydrophobic surface and contact angle, which is applied in the field of preparing superhydrophobic surface materials with adjustable contact angle by one-step laser method, can solve the problems of expensive materials, destroying the contact angle of materials, and time-consuming, and achieves simple, easy-to-operate, Process fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Base PTFE sheet pretreatment

[0031] Cut the polytetrafluoroethylene sheet with a thickness of 2mm into circular pieces with a diameter of 2cm, and process 4 samples at the same time, then put them in acetone, absolute ethanol and deionized water in sequence, and use an ultrasonic cleaner to ultrasonically clean them for 5 minutes , to remove impurities such as organic matter and inorganic matter on the surface of the substrate, and then put it in an oven and dry it at 60°C to prepare for laser processing;

[0032] (2) Set CO 2 Process parameters of laser engraving machine

[0033] Use a carbon dioxide gas laser with a wavelength of 10.6μm, turn on the laser engraving machine, set the spot diameter to 0.1mm, the engraving speed to 20mm / s, the frequency to 80KHZ, the spot engraving time to 1ms, the power to 20%, and the number of engravings to 5 times; The rated output power of the laser is 10W;

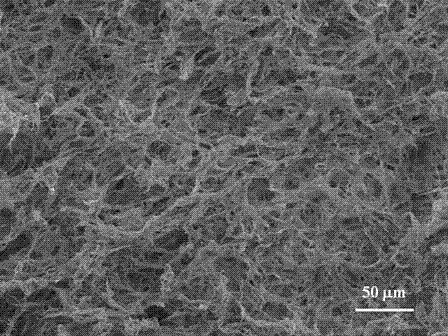

[0034] (3) Use laser operating software for engraving

[0035]Tak...

Embodiment 2

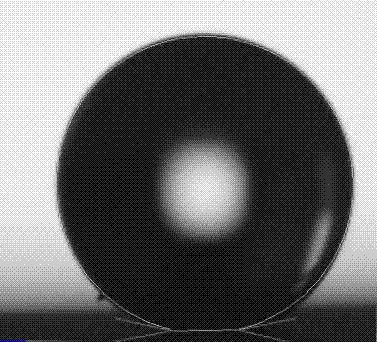

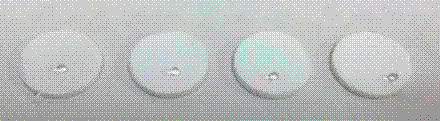

[0038] Get the remaining 3 cut and cleaned polytetrafluoroethylene substrate sheets in Example 1 and place them on the sample table of the laser engraving machine. Other parameters are set with the same as in Example 1. times, 50 times, the prepared superhydrophobic surface samples such as Figure 5 As shown, from left to right are samples engraved 5, 10, 20, and 50 times. The water droplets are basically spherical on the surface, and the above samples are all super-hydrophobic. The surface tumbles off.

[0039] After inspection, the contact angles of the superhydrophobic surfaces with engraving times of 5, 10, 20 and 50 times were 167°, 165°, 165°, and 163° in turn, all of which were superhydrophobic surfaces. After half a year of long-term storage in laboratory conditions or outdoor environments, the contact angle of the material remains basically unchanged, and it still maintains good super-hydrophobic properties and good stability. It also shows that when other parameters...

Embodiment 3

[0041] (1) Base PTFE sheet pretreatment

[0042] Cut the polytetrafluoroethylene plate with a thickness of 2mm into a square of 1cm×1cm, and process 6 samples at the same time, and then put them in acetone, absolute ethanol and deionized water in sequence, and use an ultrasonic cleaner to ultrasonically clean them for 5 minutes to remove Impurities such as organic matter and inorganic matter on the surface of the substrate are then placed in an 80°C oven for drying, ready for laser processing;

[0043] (2) Set CO 2 Process parameters of laser engraving machine

[0044] Use a carbon dioxide gas laser with a wavelength of 10.6μm, turn on the laser engraving machine, set the spot diameter to 0.1mm, the engraving speed to 20mm / s, the frequency to 80KHZ, the spot engraving time to 0.1ms, the power to 30%, and the number of engravings to 5 times; The rated output power of the laser is 10W;

[0045] (3) Use laser operating software for engraving

[0046] Place the polytetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com