Method for generating source of white light in secondary laser mode and white light luminescence component

A technology of white light source and light-emitting components, which can be applied to laser components, lasers, luminescent materials, etc., and can solve the problems of poor laser efficiency of red phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

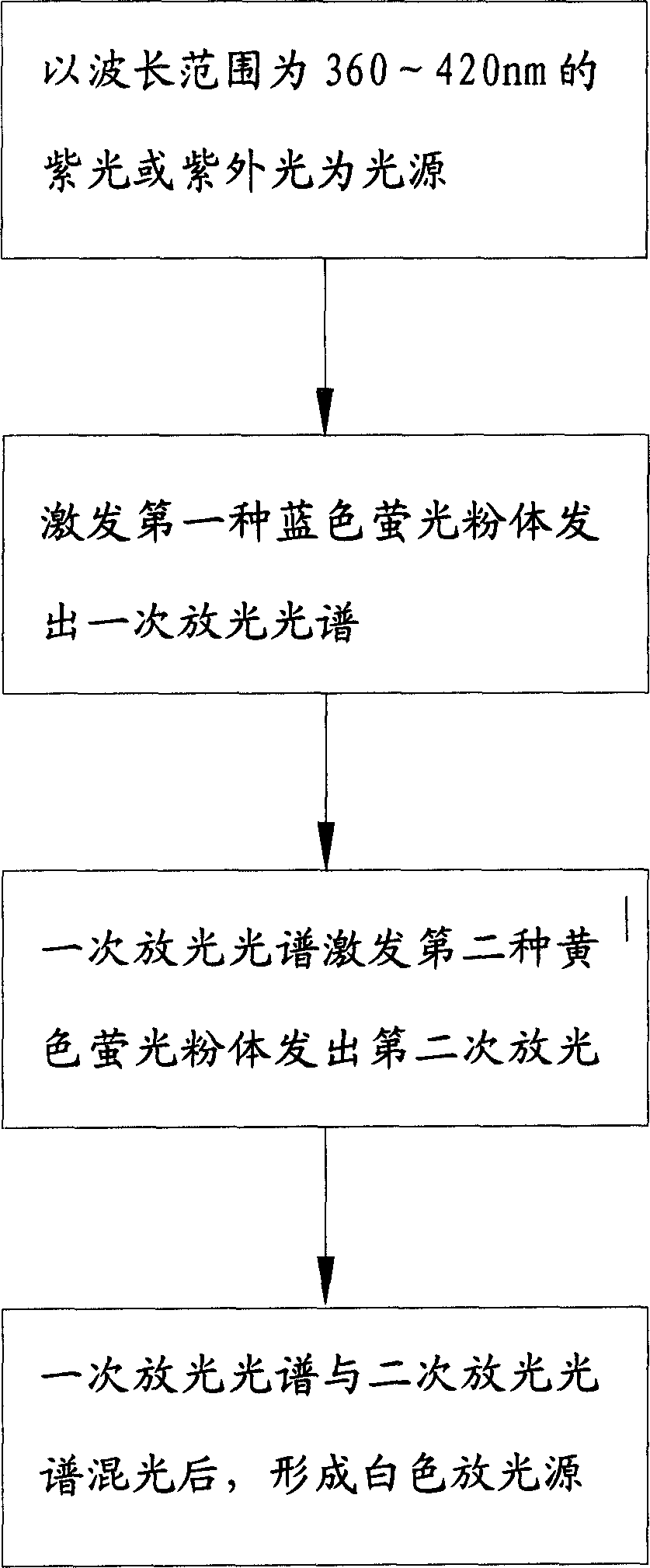

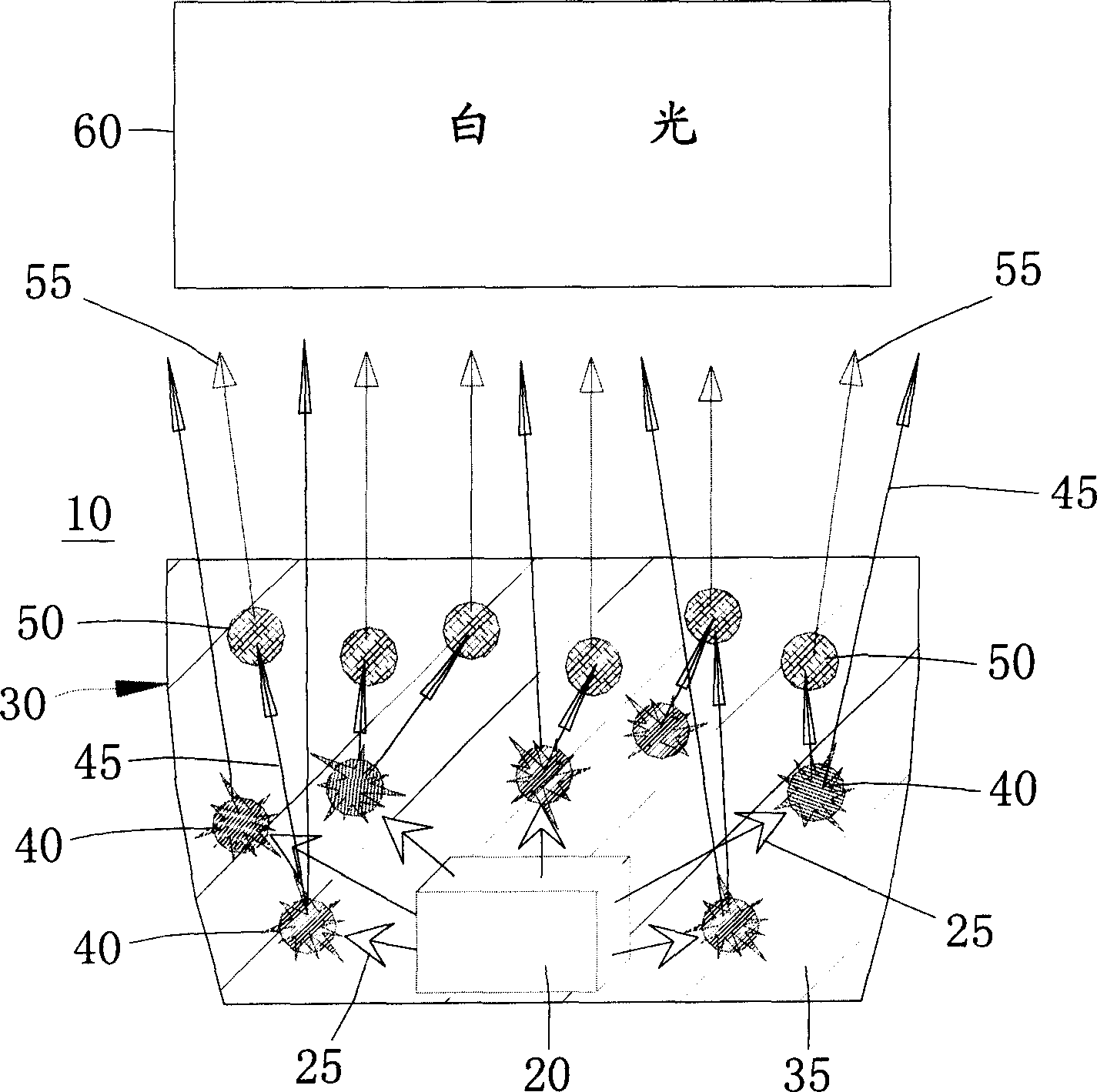

[0043] Please refer to figure 2 , the present invention produces the method for white light source with secondary laser mode, can be actually applied to white light emitting assembly 10, and produces the white light source of high purity, so, can be applied to provide indoor lighting, special lighting, LCD backlight source, scanner , fax machines, mobile phones and military lighting and other purposes.

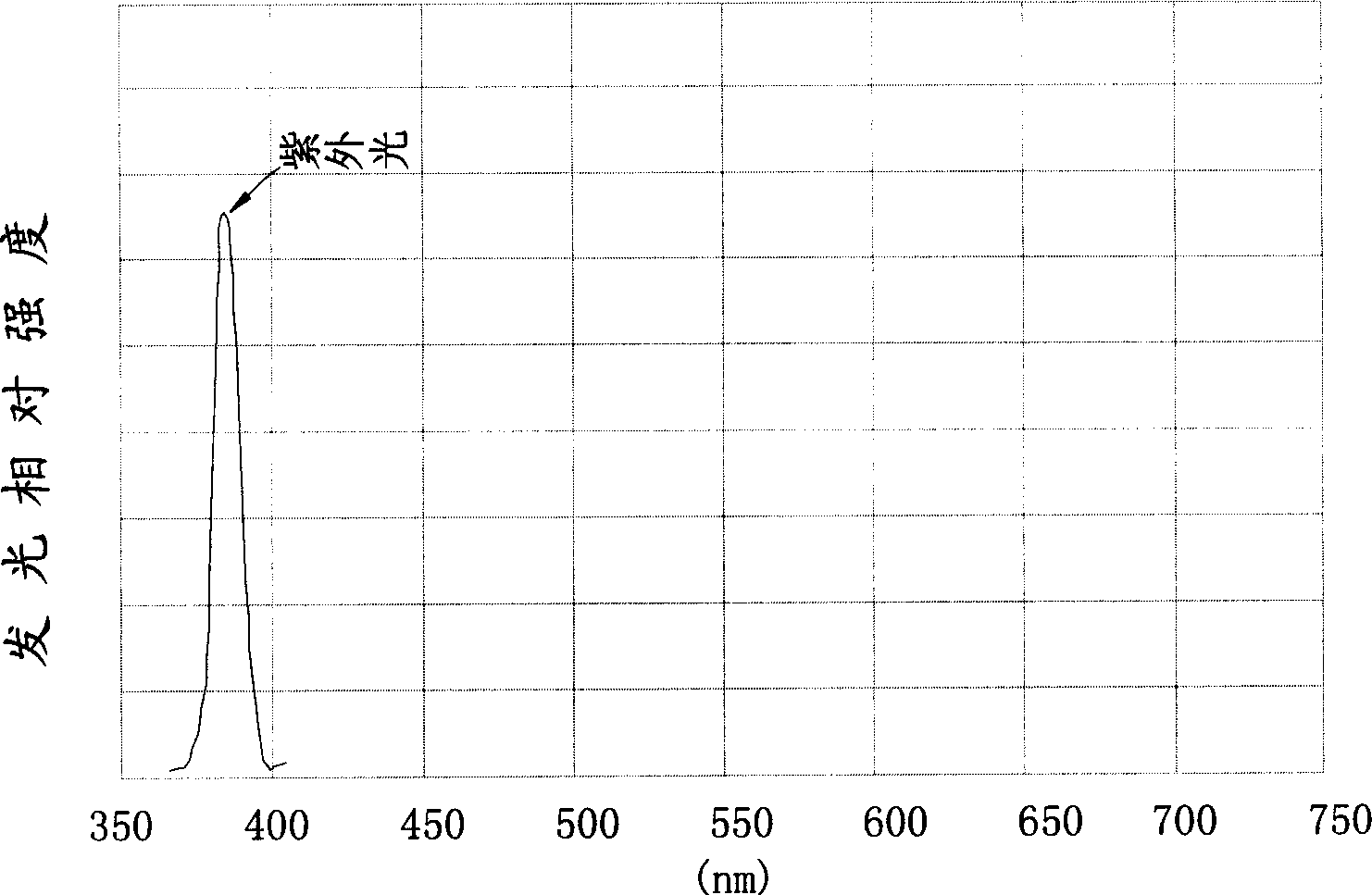

[0044] The white light emitting component 10 of the present invention is composed of an ultraviolet light or ultraviolet light chip 20 that can emit purple light or ultraviolet light with a wavelength of 360-420nm, and a resin encapsulation layer 30 coated on the ultraviolet light or ultraviolet light chip 20, wherein the The resin encapsulation layer 30 is formed by mixing the blue phosphor powder 40 and the yellow phosphor powder 50 with the encapsulation material 35, or further mixing red phosphor powder and green phosphor powder, and then heat curing or light hardening. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com