Laser method for measuring vibration displacement of rolling bearing

A vibration displacement, laser measurement technology, used in vibration testing, mechanical bearing testing, measuring devices, etc., can solve the problems of unstable measurement system, low frequency response, difficult application, etc., to avoid instability and easy to ensure accuracy. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

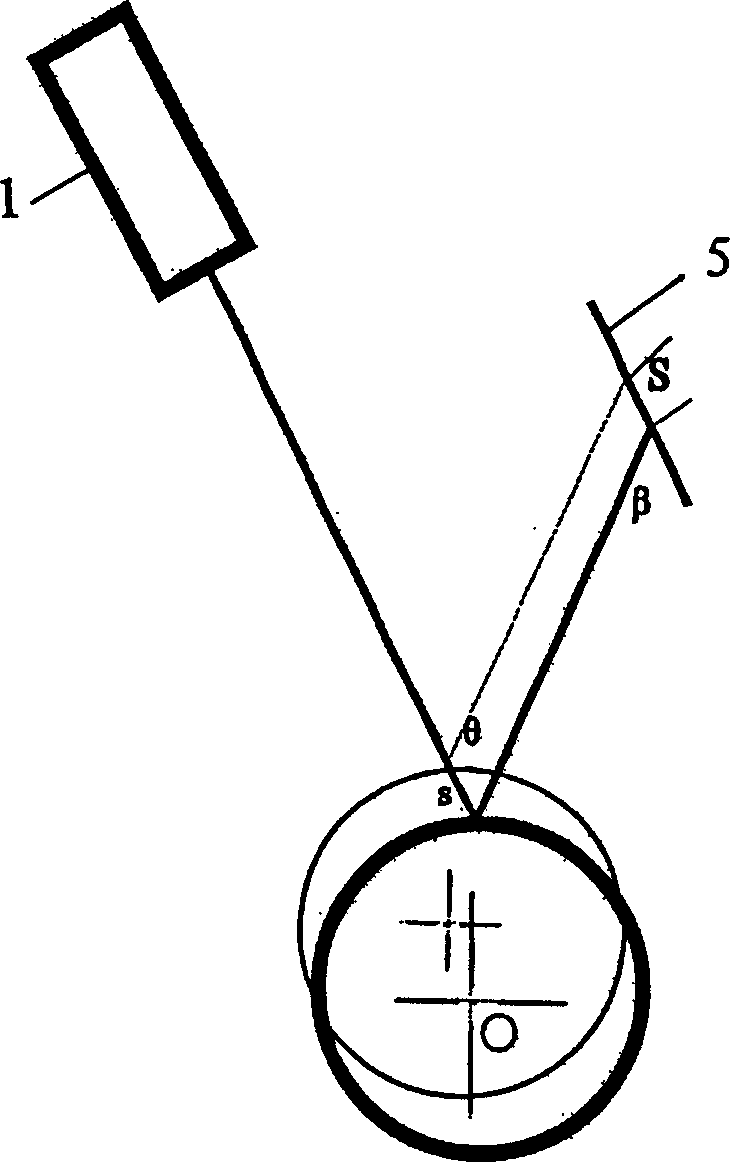

[0018] Taking advantage of the small divergence angle of the reflected laser, a PSD position sensor is placed at the end of the reflected laser to measure the tiny displacement during the vibration process. Since the measurement sampling frequency is much higher than the maximum vibration frequency of the bearing measurement, the maximum vibration frequency is given by the measurement standard, so the measurement results can reflect the amplitude and frequency of the bearing vibration.

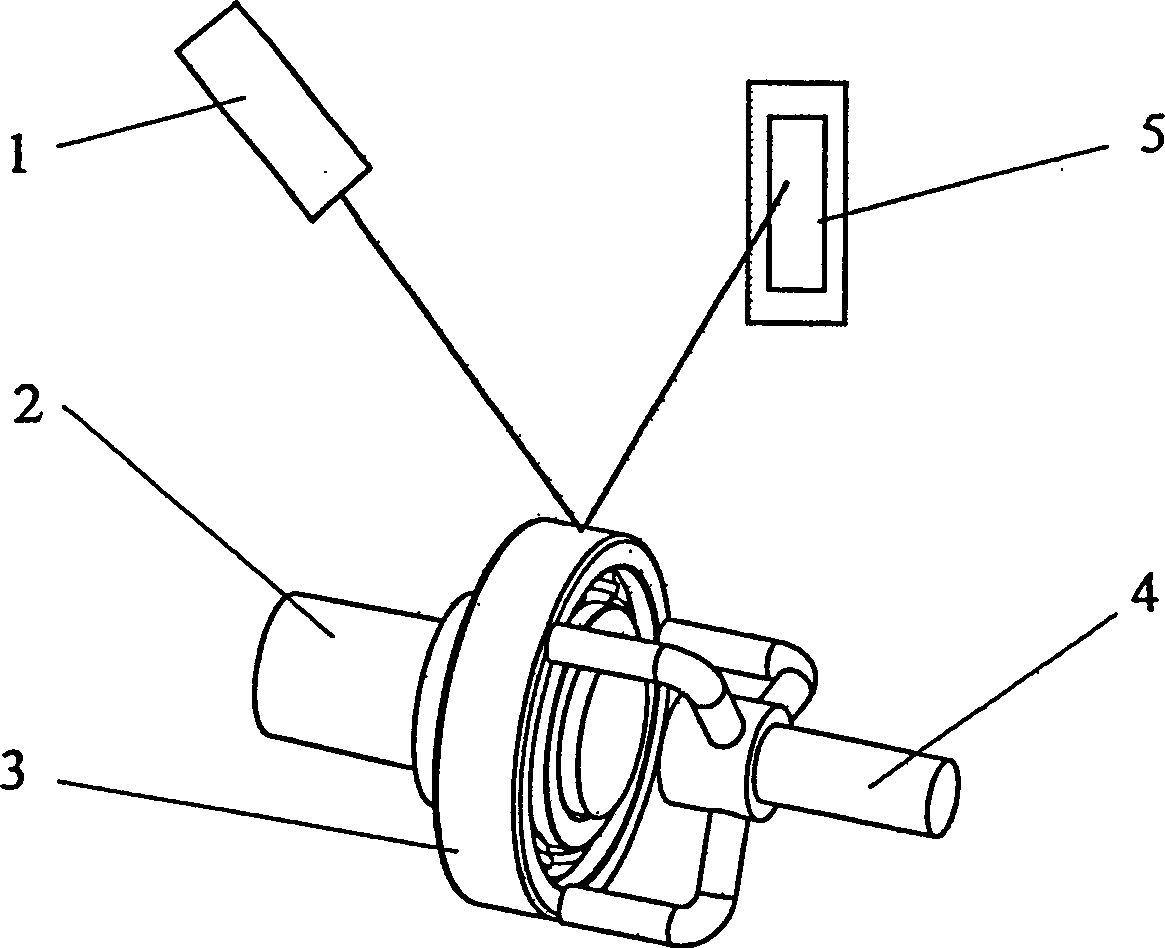

[0019] Such as figure 1 , figure 2 As shown, in the present invention, the tested bearing 3 is installed on the rotating shaft 2 of the test bench (such as the s0910 type bearing vibration measurement test bench), and the thrust device 4 is loaded from the end face of the tested bearing 3, so that the outer surface of the tested radial bearing 3 There is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com