Patents

Literature

320results about How to "Accuracy is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

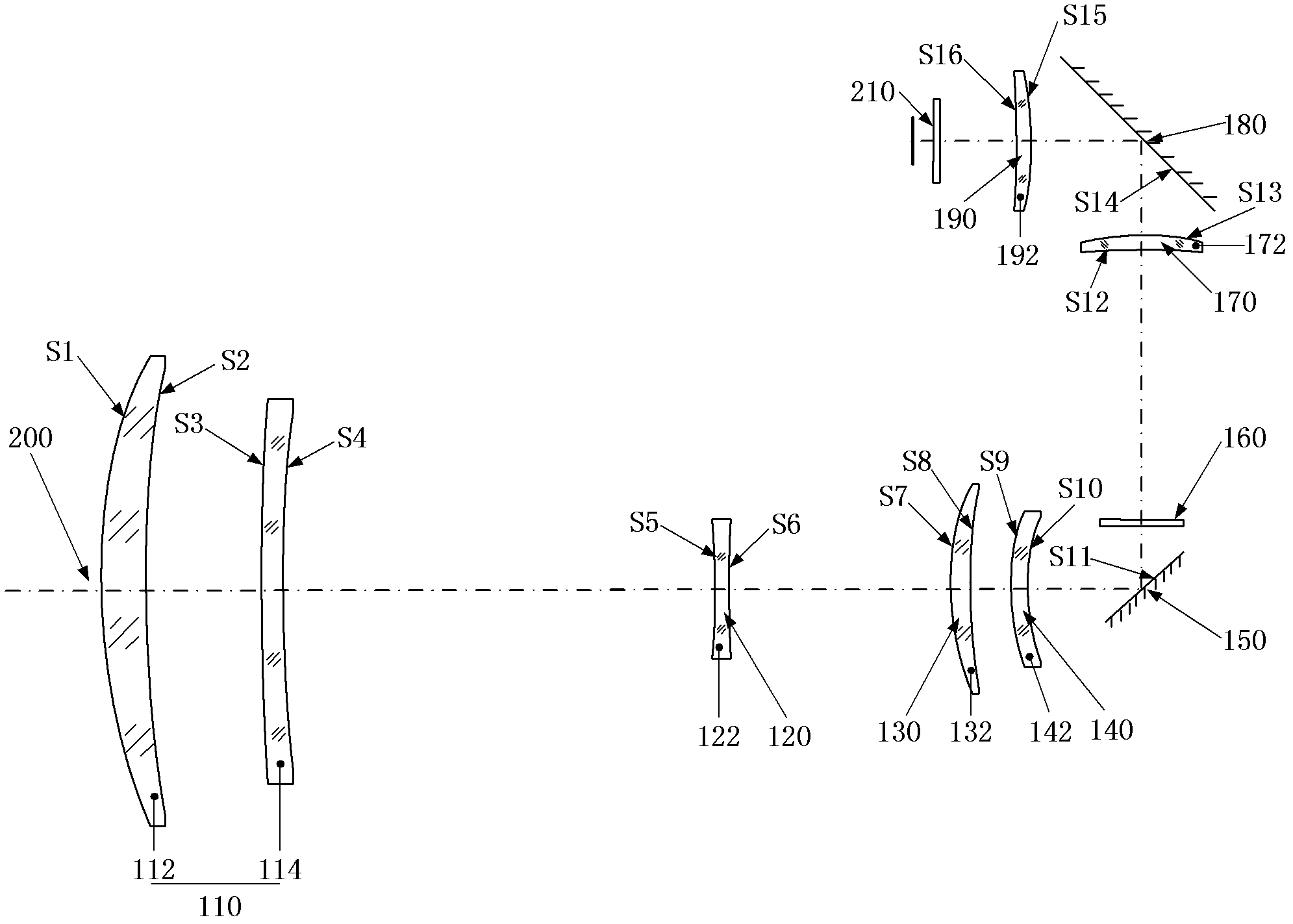

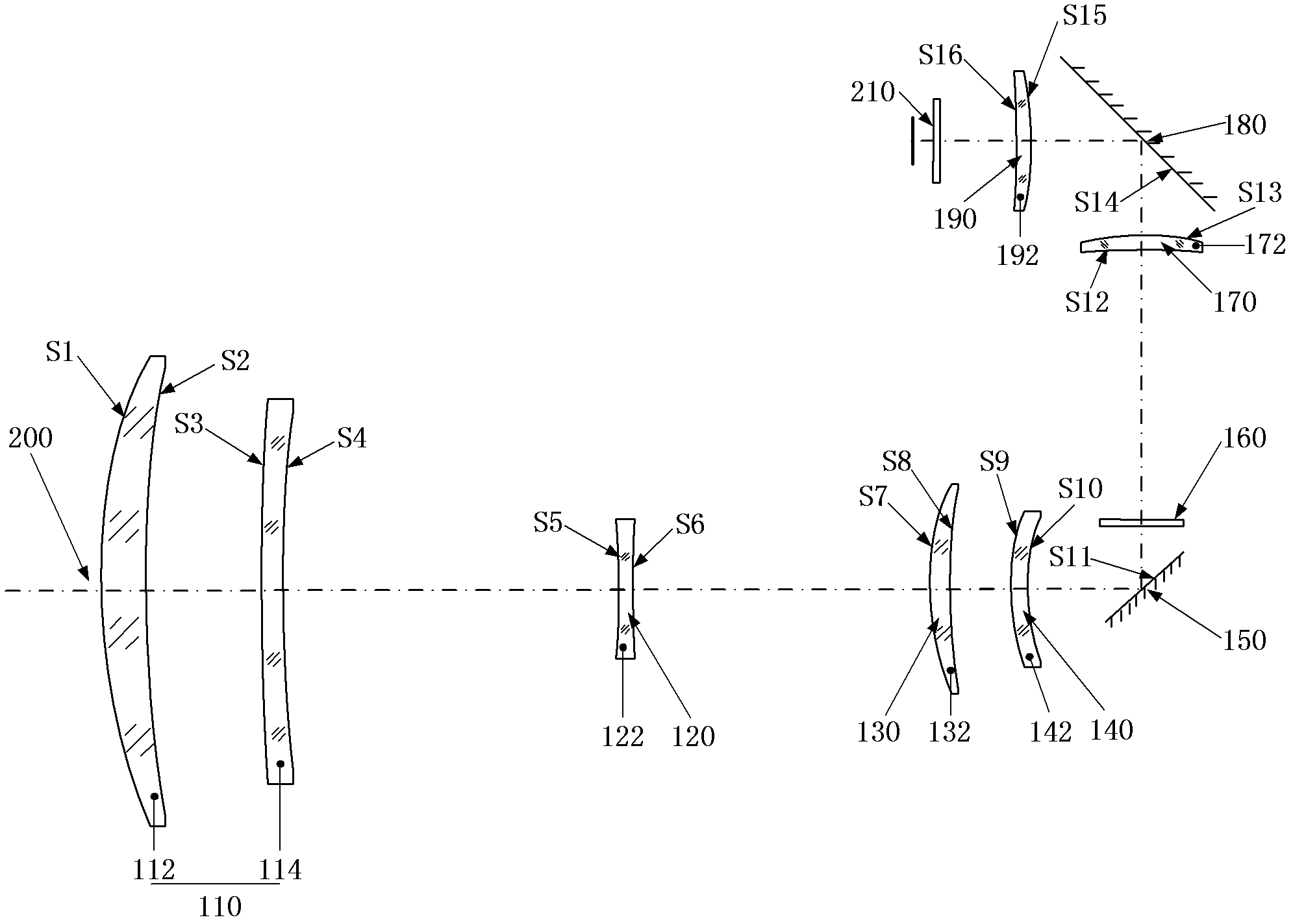

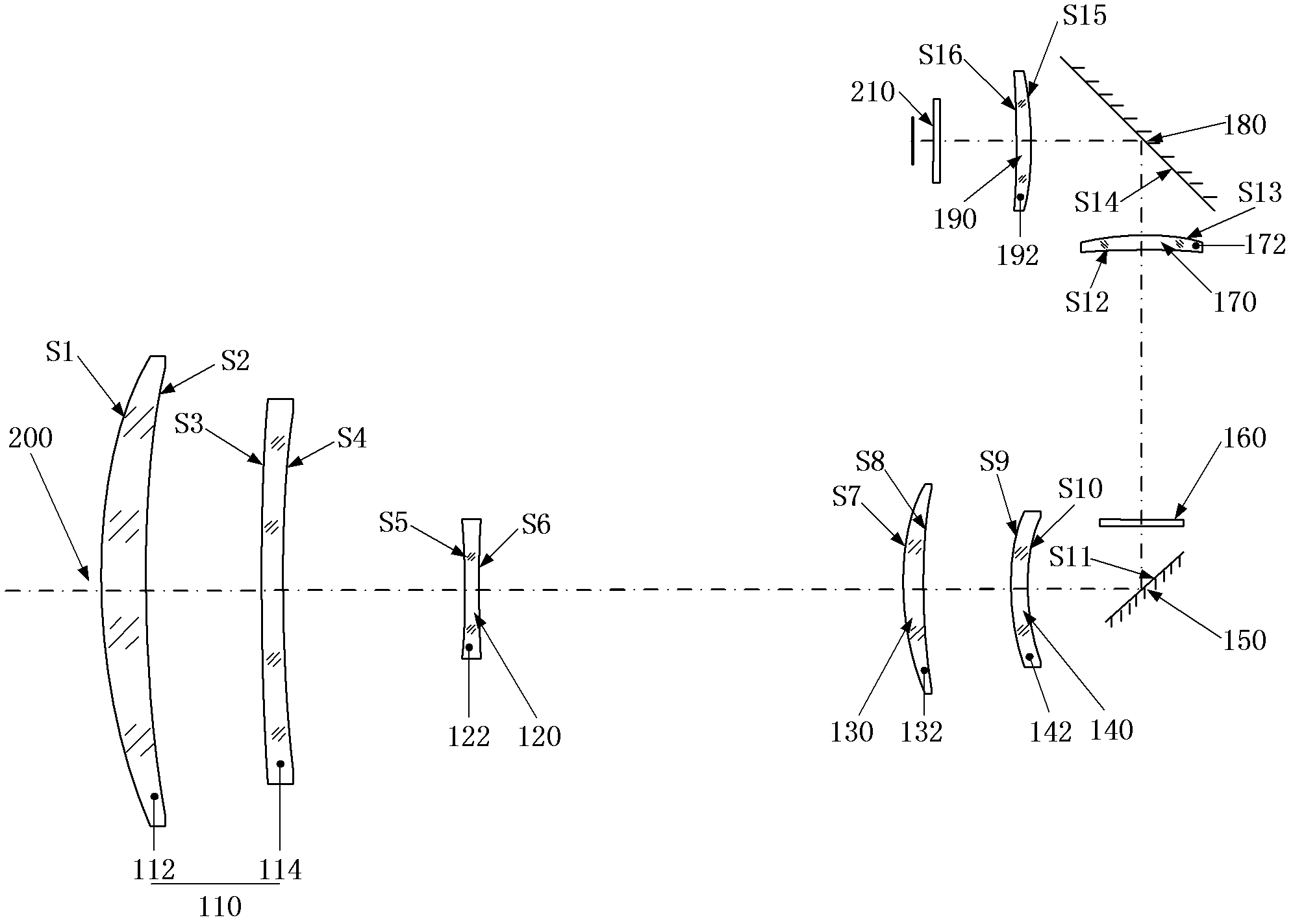

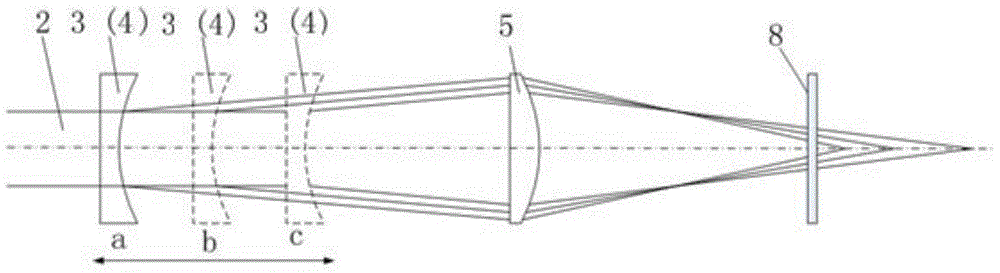

Medium wave infrared continuous zoom lens

The invention discloses a medium wave infrared continuous zoom lens. The medium wave infrared continuous zoom lens comprises a first lens group with positive diopter, a second lens group with negative diopter, a third lens group with positive diopter, a fourth lens group with negative diopter, a first reflector for turning back a light path, a flat plate reference source for correcting a background, a fifth lens group with positive diopter and a sixth lens group with positive diopter from an object space to an image space, wherein the first lens group serving as a front fixing group comprisesa crescent silicon positive lens of which the convex surface faces the object side and a crescent germanium negative lens of which the convex surface faces the object side; the second lens group is used as a zoom group; the third lens group is used as a compensation group; the fourth lens group is used as a rear fixing group; the fifth lens group is used as a relaying group; and the sixth lens group is used as a focusing group. The medium wave infrared continuous zoom lens can be applied to 640*512-element or even larger surface array refrigeration medium wave detectors; and the medium wave infrared continuous zoom lens has a simple structure and low motion charge; and only two lenses move during zooming.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

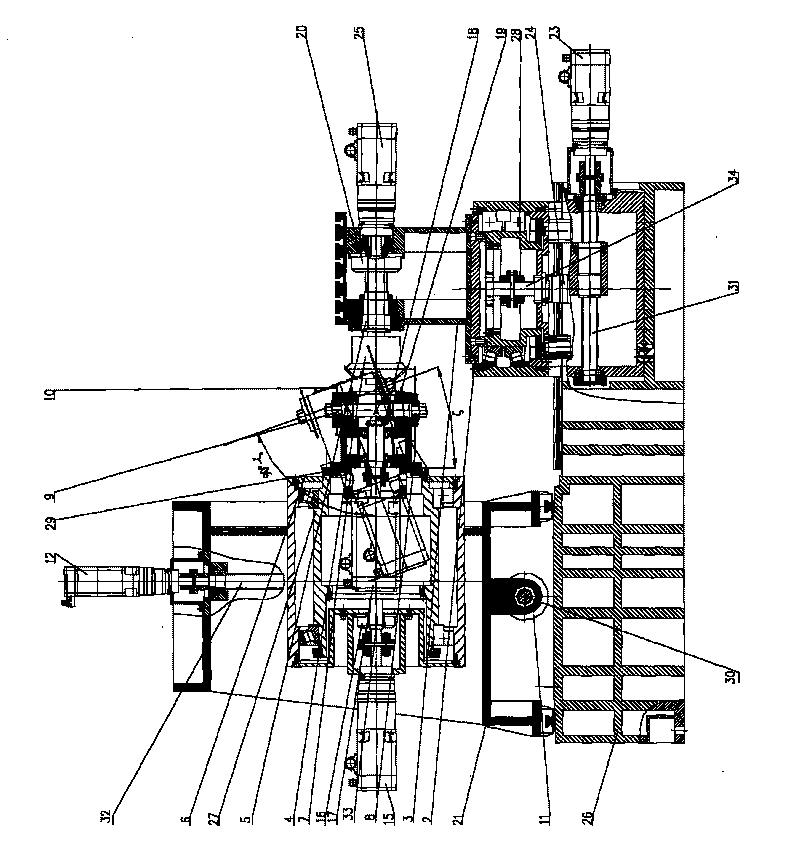

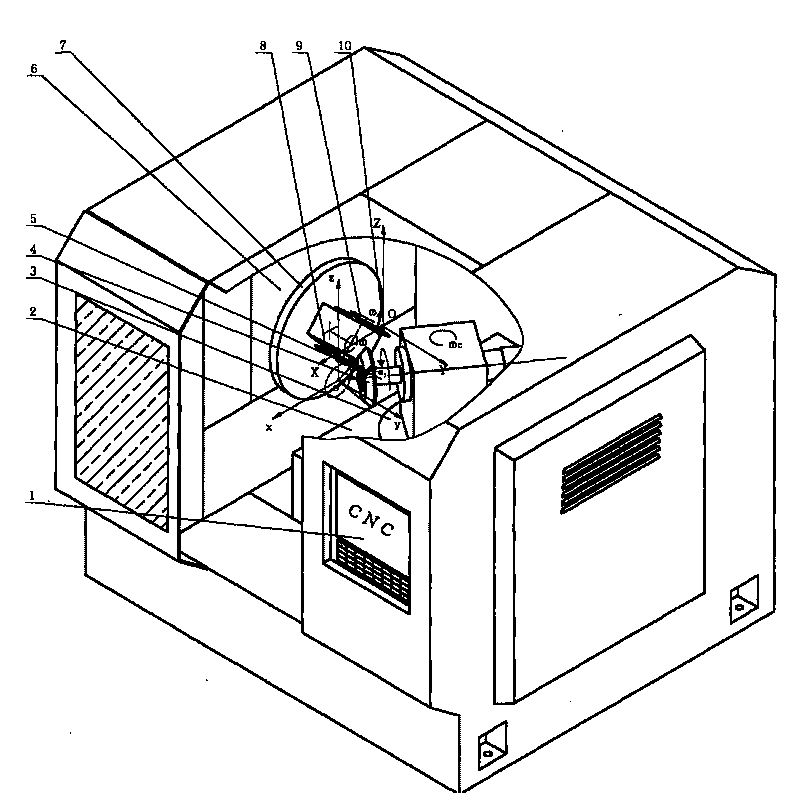

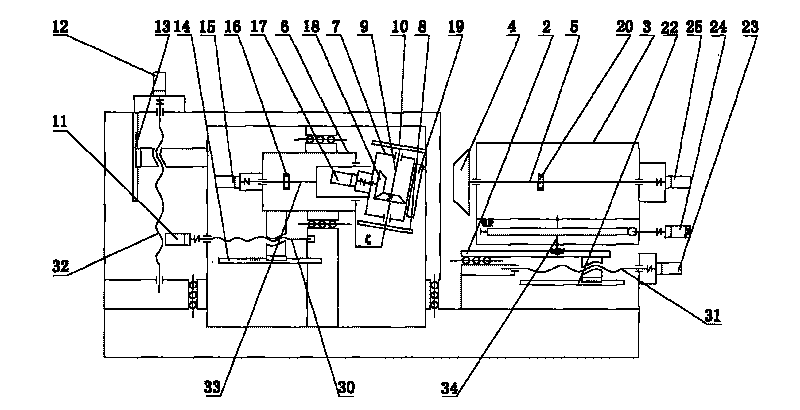

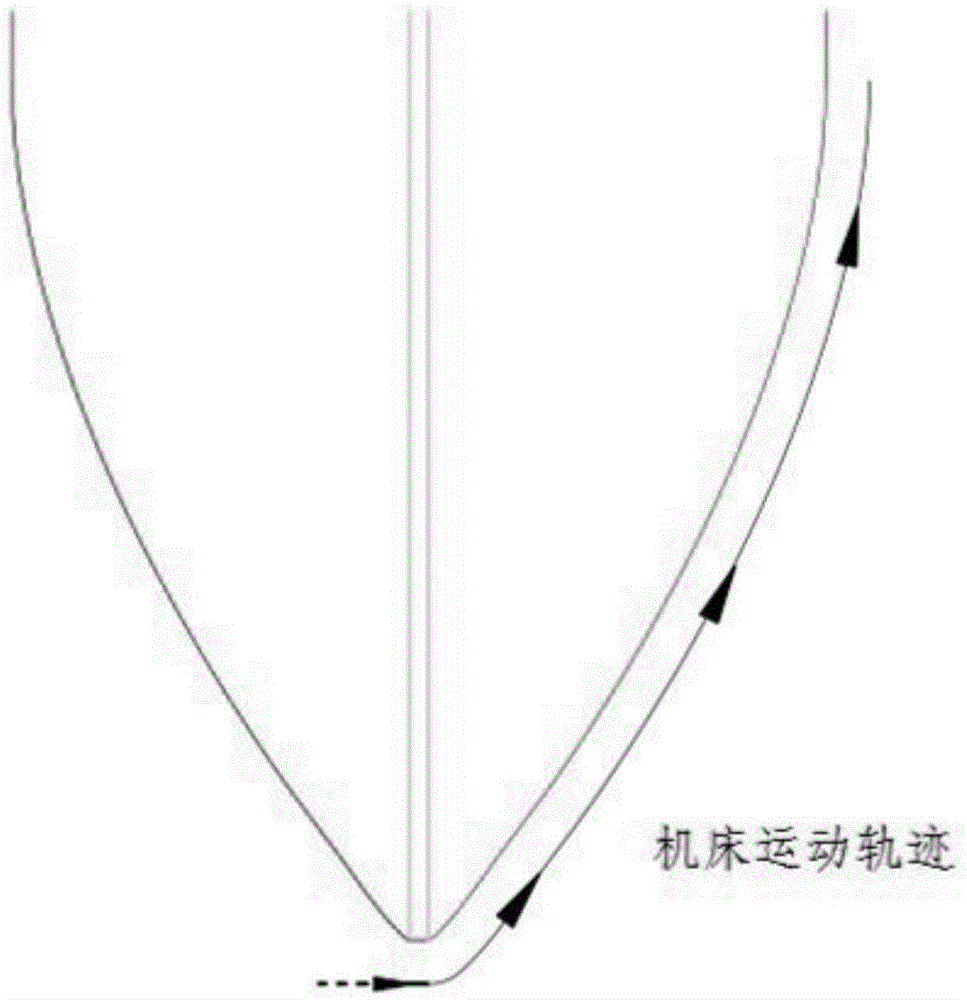

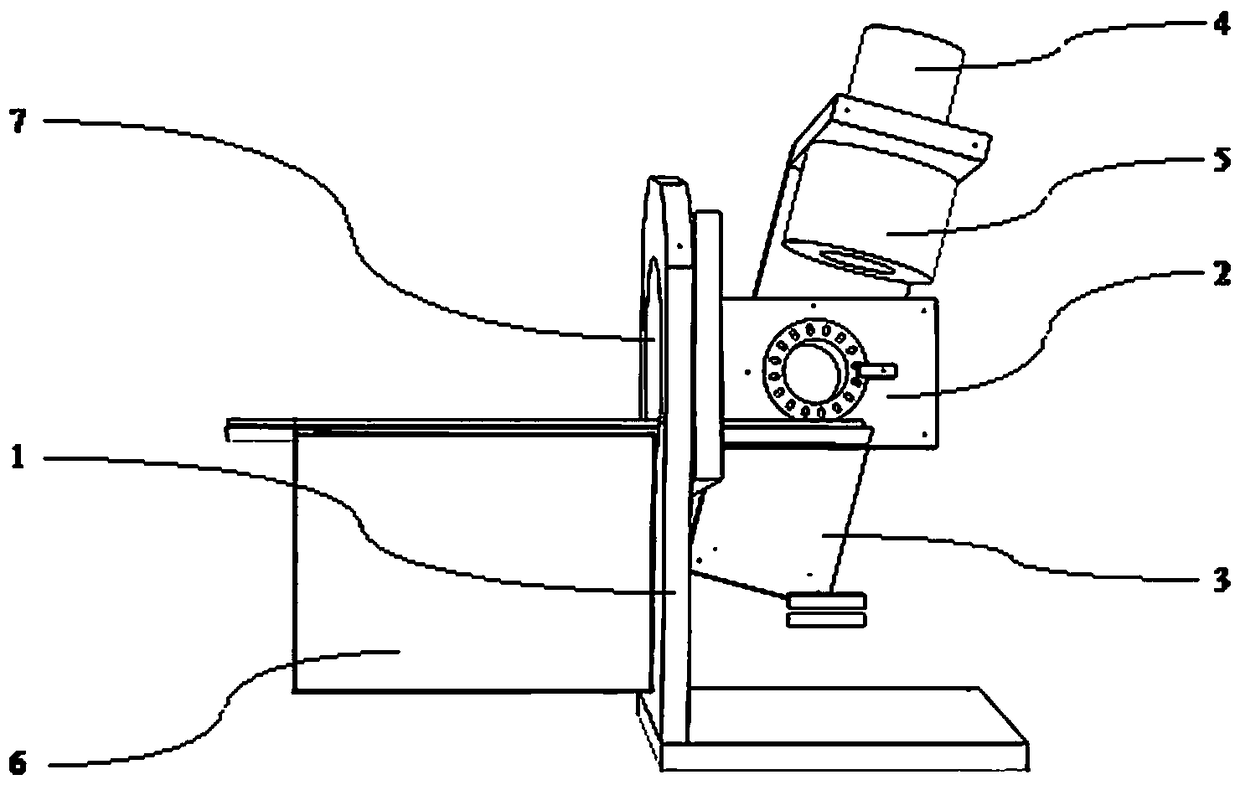

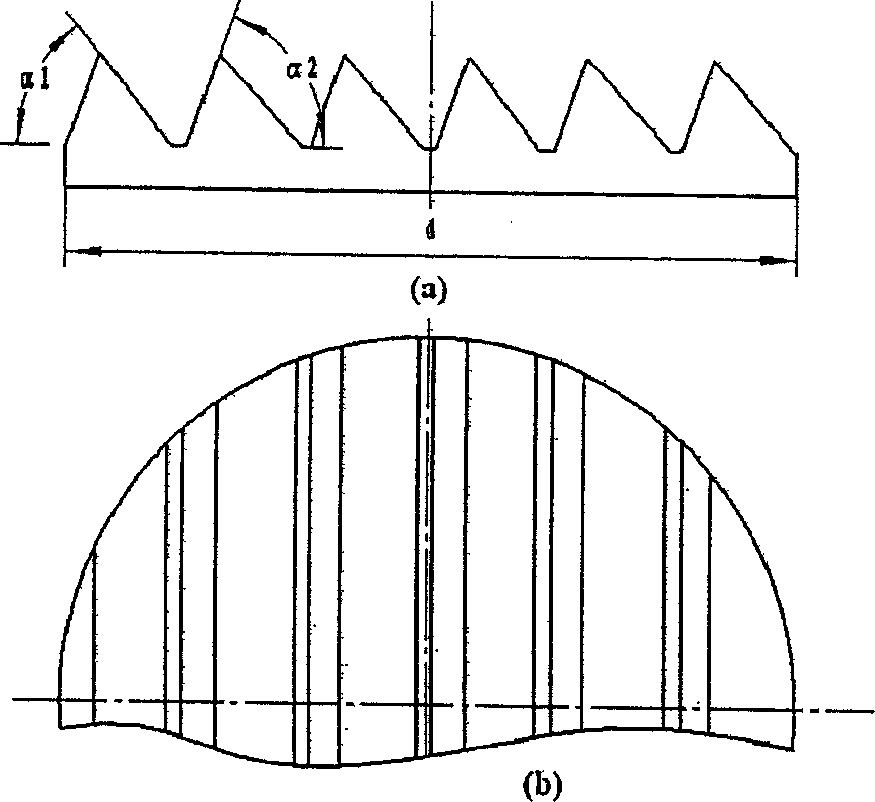

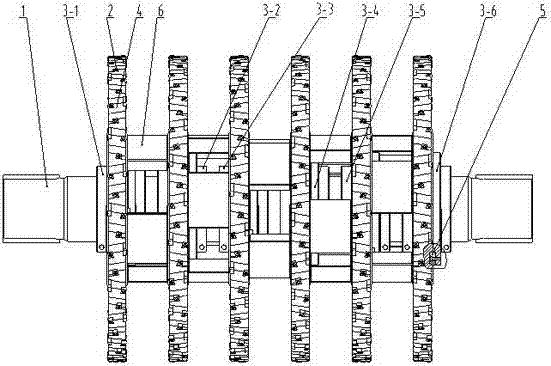

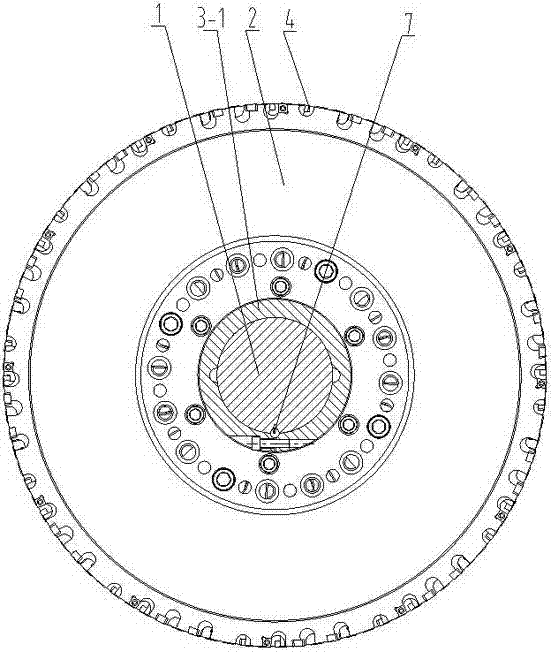

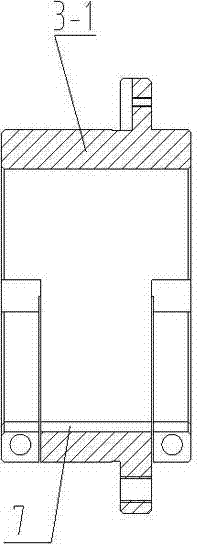

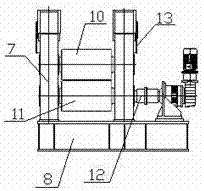

Spiral bevel gear cutting machine tool and gear cutting method

The invention discloses a spiral bevel gear cutting machine tool and a gear cutting method. The gear cutting machine tool comprises a cutting tool system, a workpiece system, a machine tool body and a numerical control system, wherein the cutting tool system comprises an XZ working table, an X-axis lead screw, a Z-axis lead screw, a short shaft, a tool base revolving drum, a tool base, No.1 milling cutters, a milling cutter shaft, No.2 milling cutters, a gear shaft and a correcting wedge. The rotating centre line of the tool base revolving drum and the rotating centre line of the short shaft are collinear; the right end surface of the tool base revolving drum is fixedly connected with an annular flange plate at the left end of the tool base by the correcting wedge; the right end of the tool base is provided with the milling cutter shaft; the rotating centre line of the milling cutter shaft and the rotating centre line of the short shaft are intersectant; and both ends of the milling cutter shaft are provided with the No.1 milling cutters, the No.2 milling cutters or grinding wheels. The left end surface of the tool base is provided with a drive motor; the drive motor is meshed with a bevel gear on the milling cutter shaft by the gear shaft; and the rotating centre line of the output shaft of the drive motor and the rotating centre line of the milling cutter shaft are vertically intersectant. The invention also provides a method for processing helical bevel gears by utilizing the machine tool.

Owner:JILIN UNIV

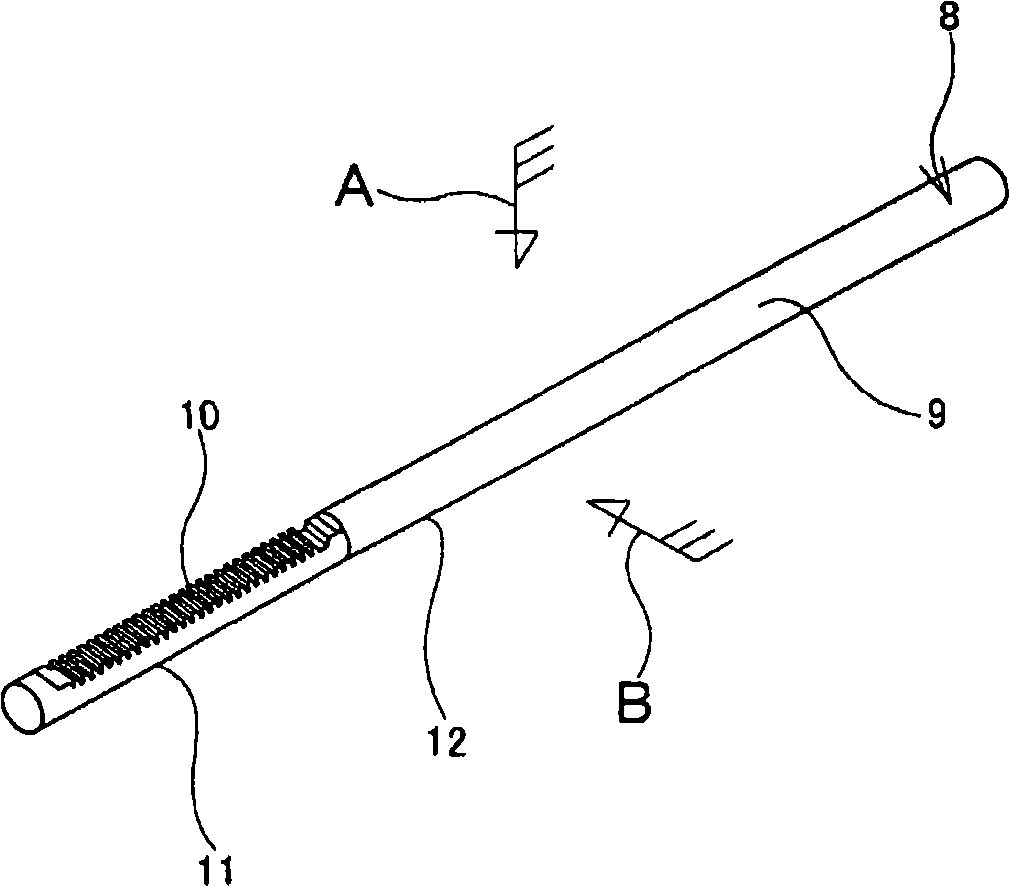

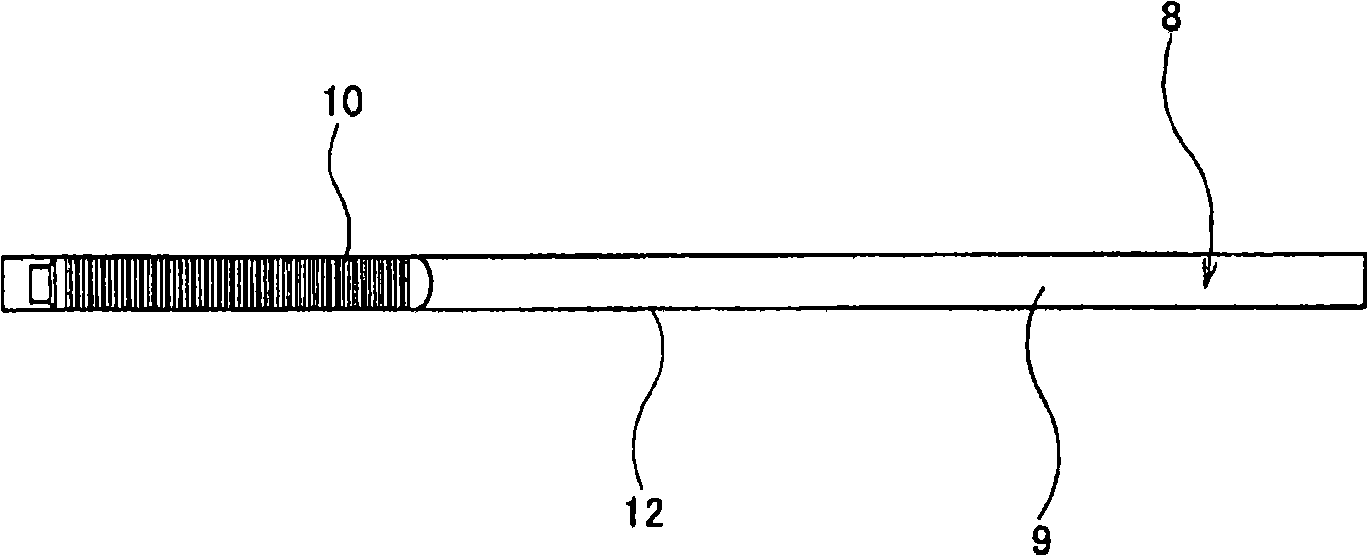

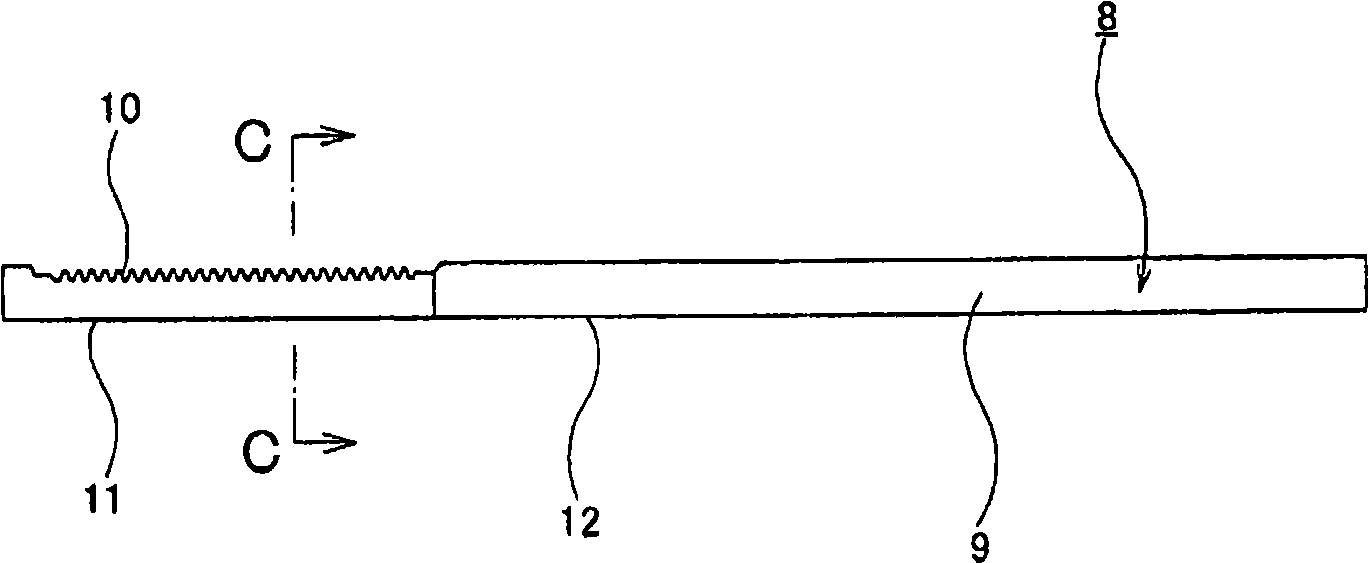

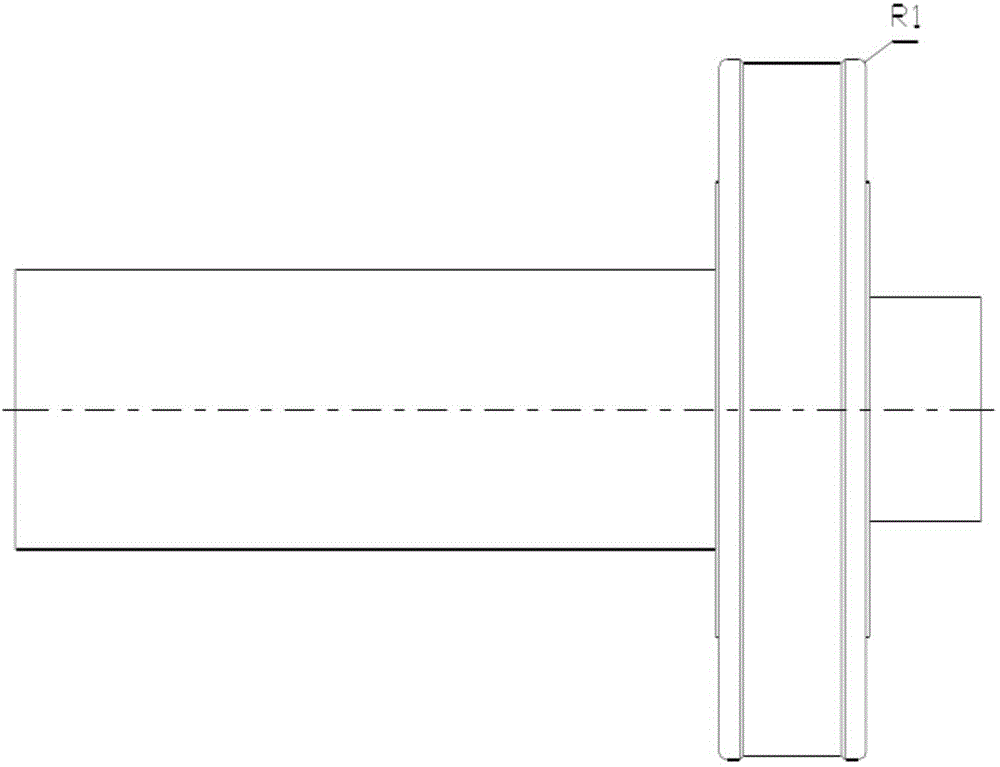

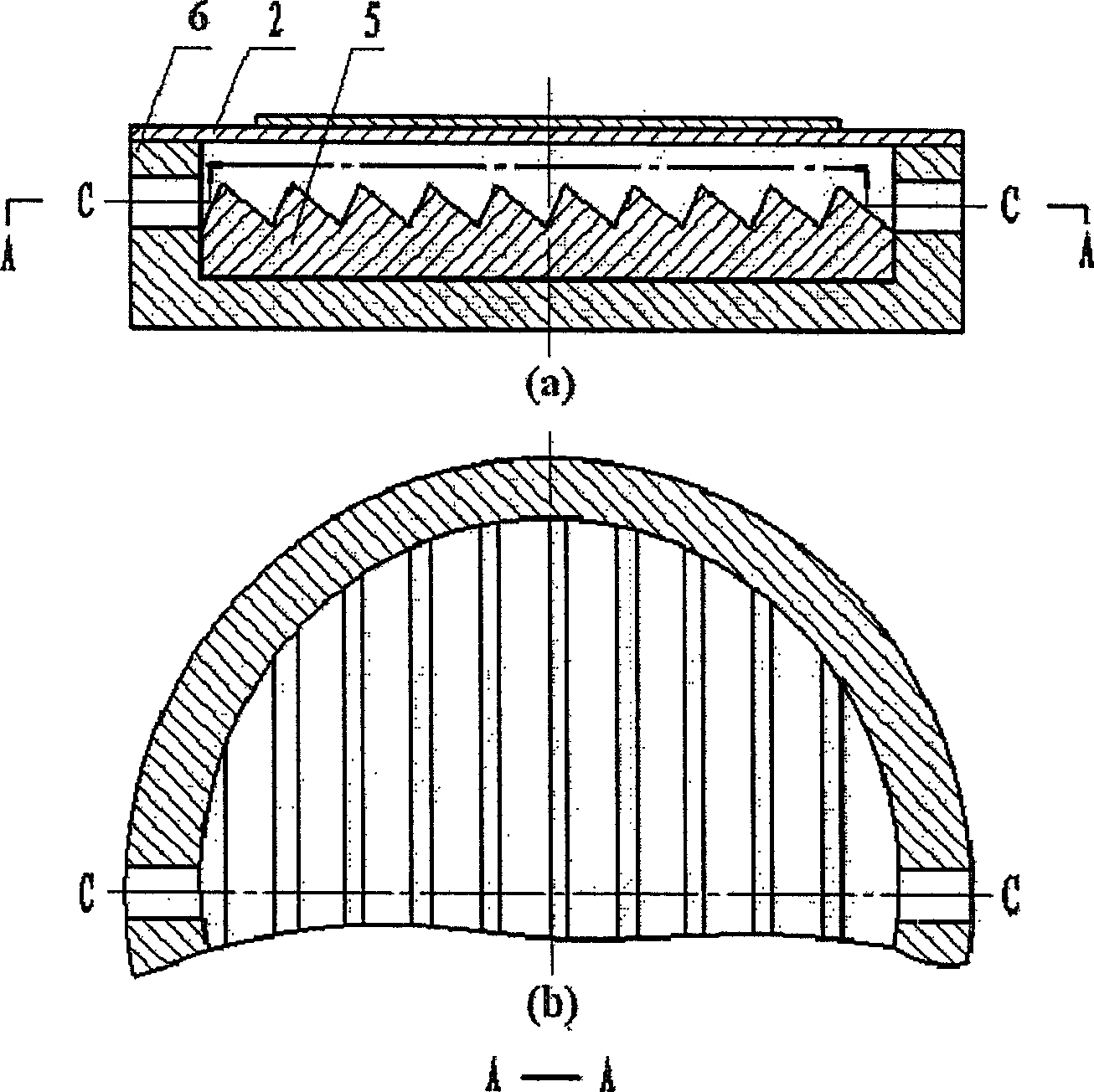

Rack and production method thereof

ActiveCN101547759AAvoid volumePrevent protrudingMetal-working apparatusPortable liftingEngineeringMechanical engineering

A light-weight structure capable of sufficiently ensuring any of the width size, strength and rigidity of a rack tooth (10), and a production method thereof. A rack tooth (10) is formed by plastic working on one side surface in the radial direction of a part in the axial direction of a sectionally circular rod unit (9). The radius of curvature of the section shape of a portion deviated in the circumferential direction from a rack-tooth (10) forming portion is set to be larger than the radius of curvature of the section shape of an outer circumferential surface of the remaining part in the axial direction of the rod unit (9). For this purpose, as shown by (A)->(B), the part in the axial direction and the remaining part in the circumferential direction are formed into a partially cylindrical surface portion (17) having a radius of curvature larger than that of the outer circumferential surface of a material (13) while a portion in the axial direction of the material (13) and a portion in the circumferential direction are being crushed, thereby defining an intermediate material (20).Then, as shown by (C)->(D), the above rack tooth (10) is formed at a portion in the axial direction ofthe intermediate material (20) and a portion in the circumferential direction. Finally, as shown by (E)->(F), it is subjected to sizing to complete a rack (8).

Owner:NSK LTD

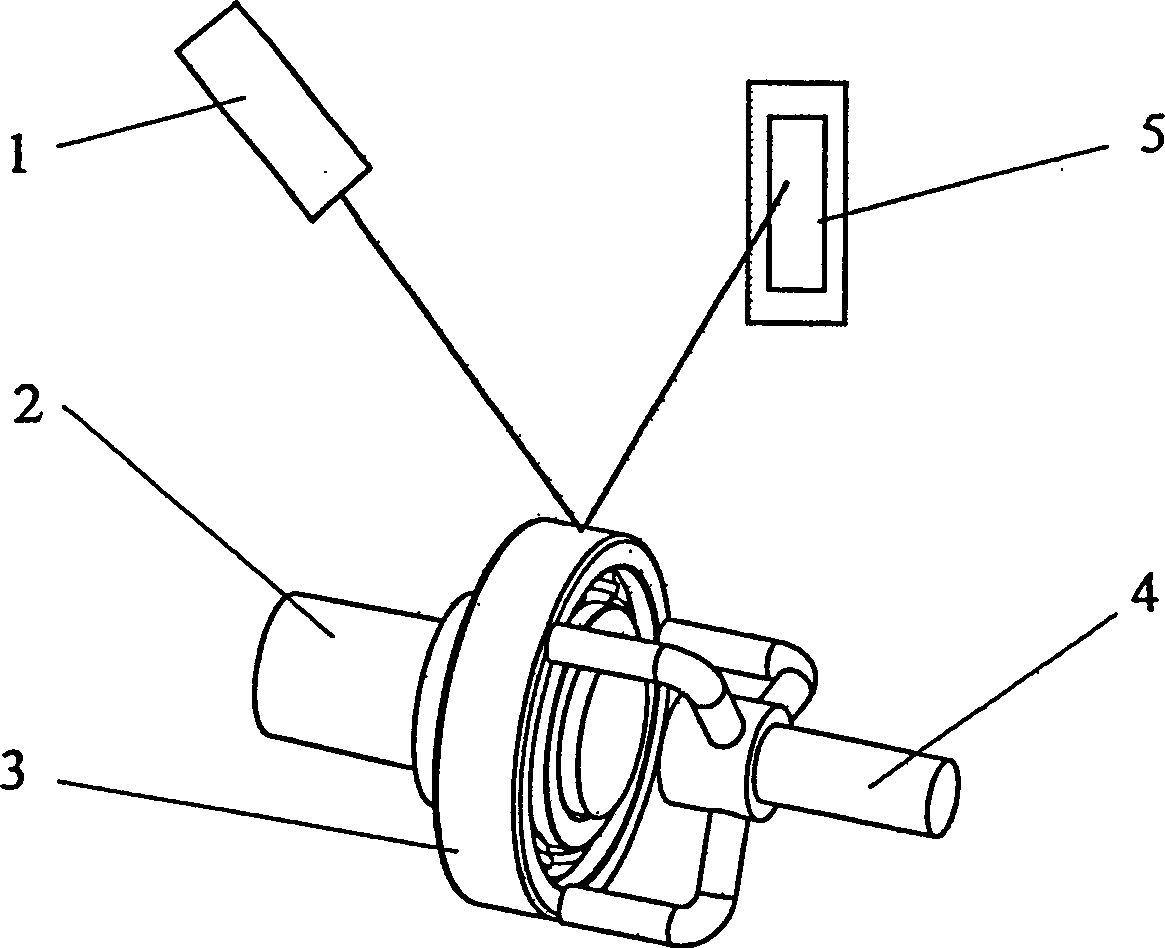

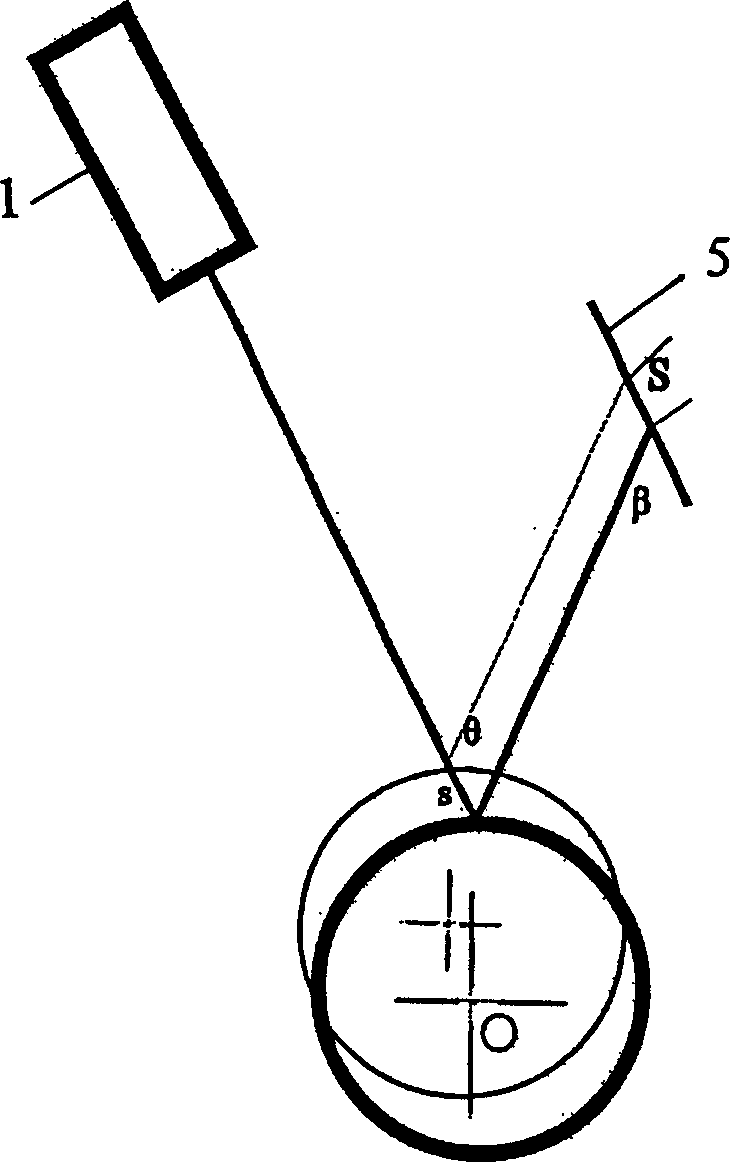

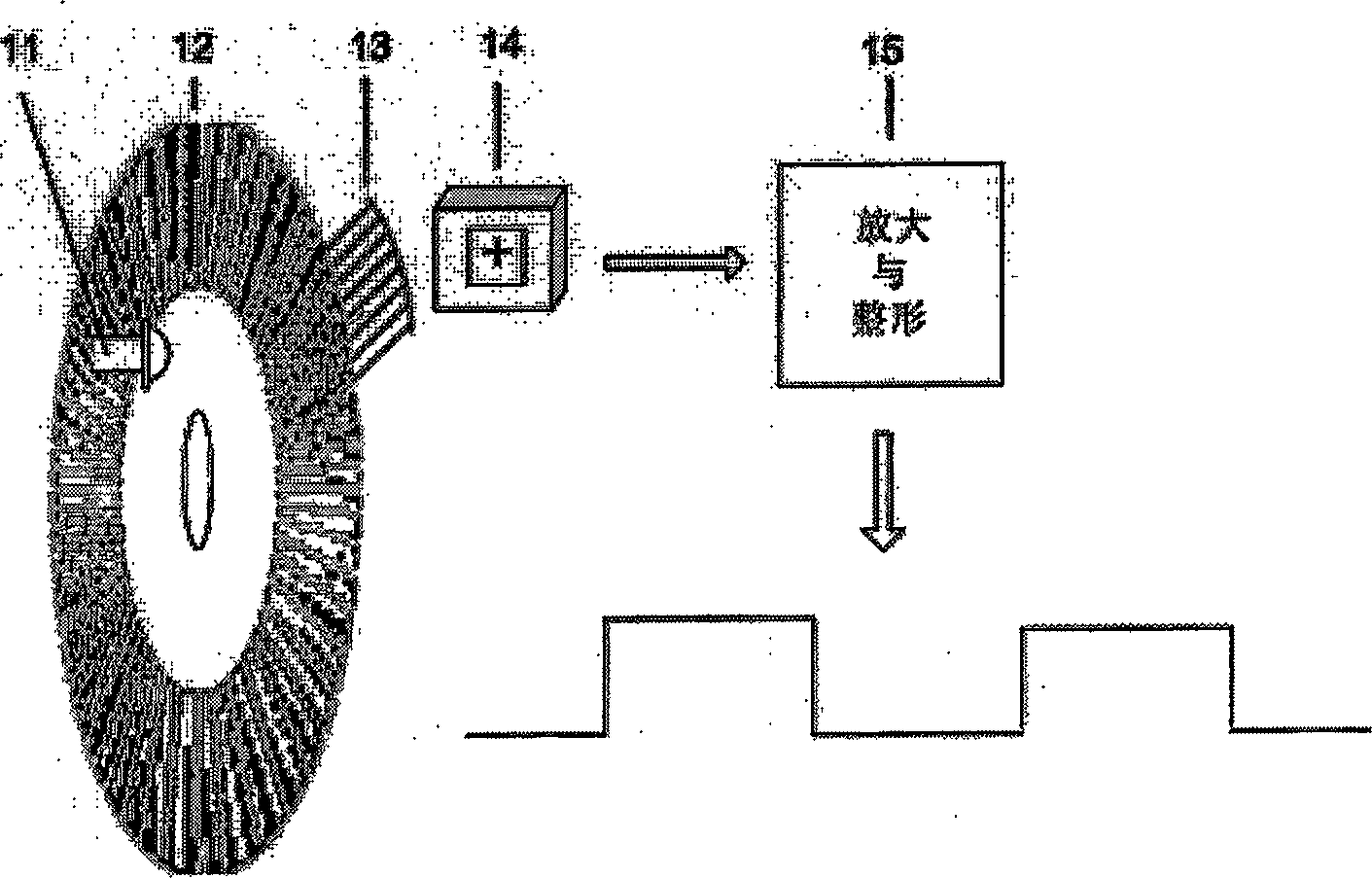

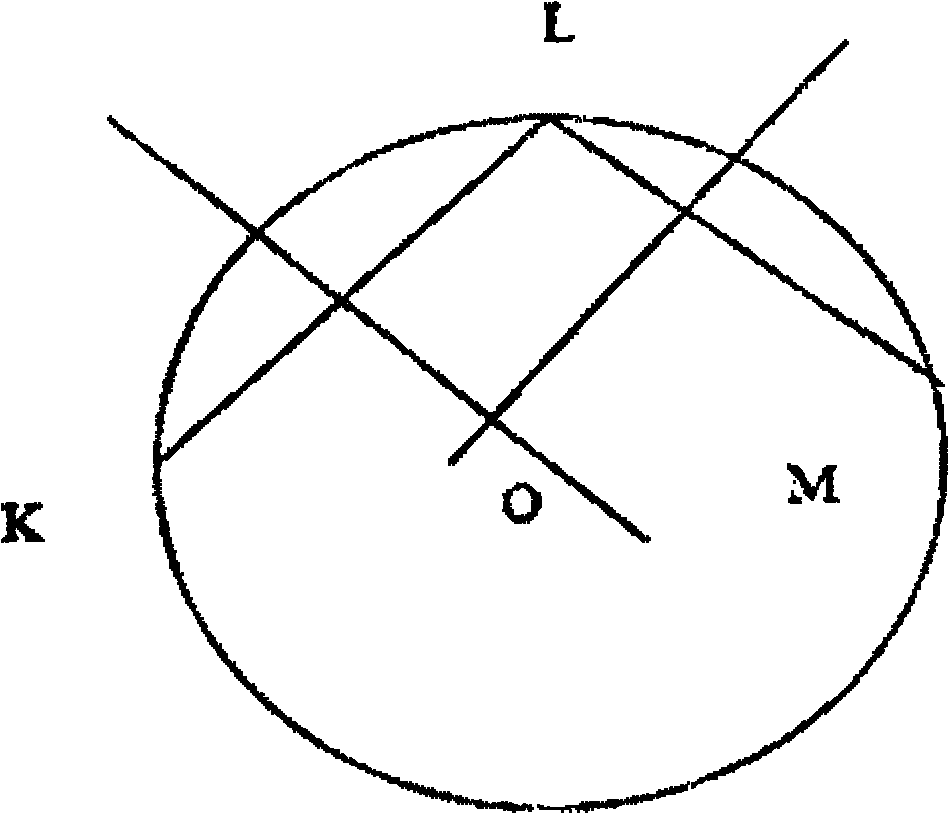

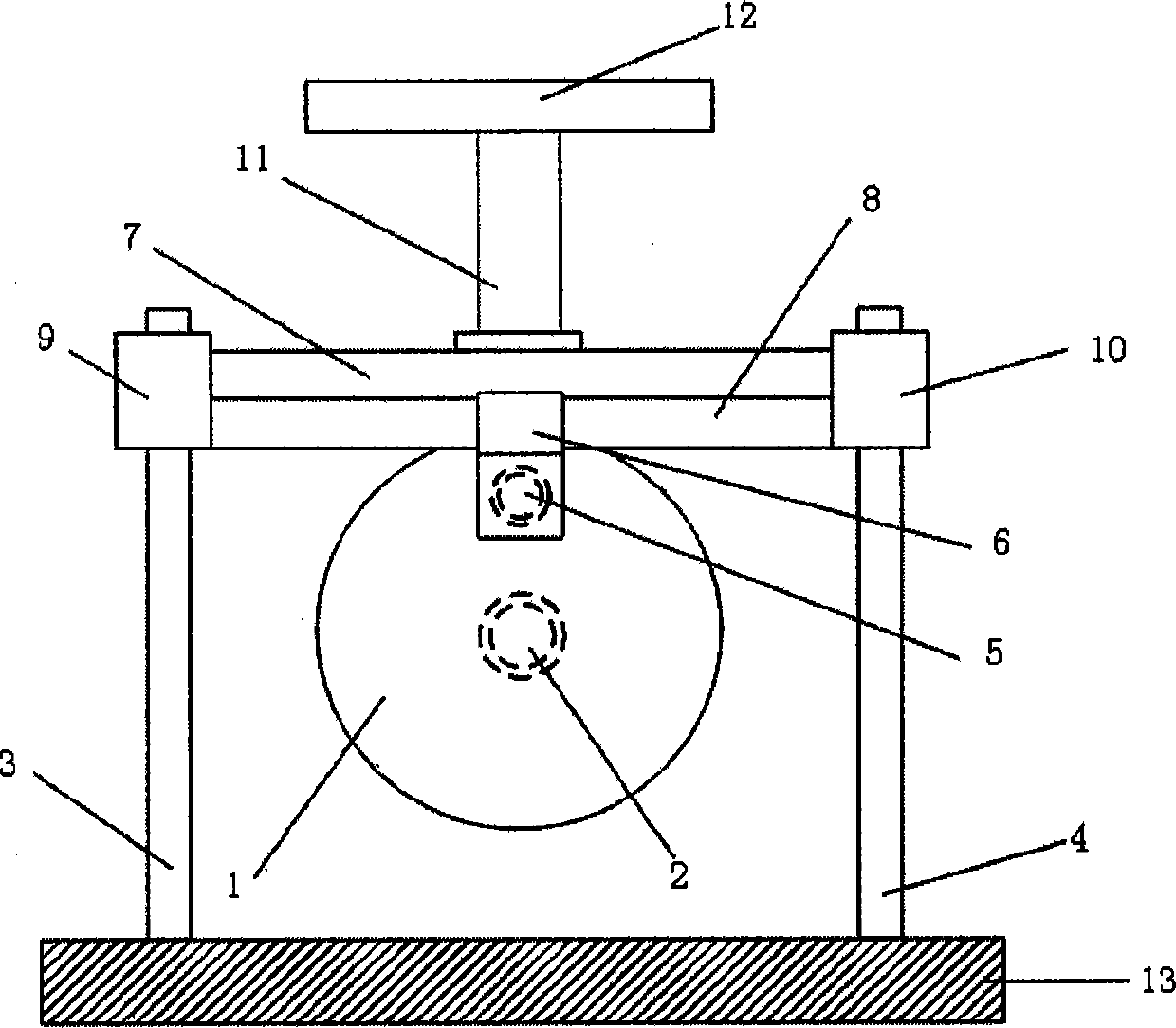

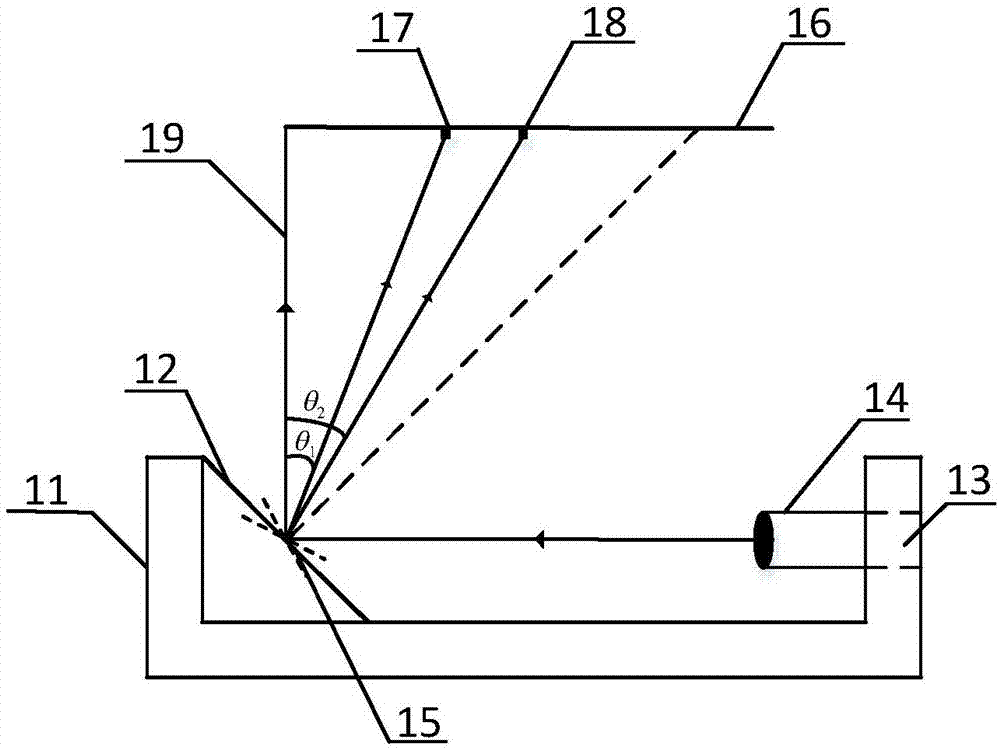

Laser method for measuring vibration displacement of rolling bearing

InactiveCN1687720AAvoid instabilityEasy to installSubsonic/sonic/ultrasonic wave measurementMachine bearings testingRolling-element bearingEngineering

The invention discloses the laser testing method of the roller bearing vibration displacement. Equip the bearing on the spin axis of the test bed; makes use of the reflection of the laser through the bearing surface to arrive the PSD sensor surface; the PSD position sensor gives the facula position. The internal loop and the main axis of the bearing can be viewed as the rigid body because the radial force carried by the external loop of the bearing. When the spin axis spins, the inner and the external loops and the roller bring about the vibration and reflect the displacement s of certain point of the bearing surface by the PSD sensor. The invention has simple structure, clear principle and high precision.

Owner:ZHEJIANG UNIV

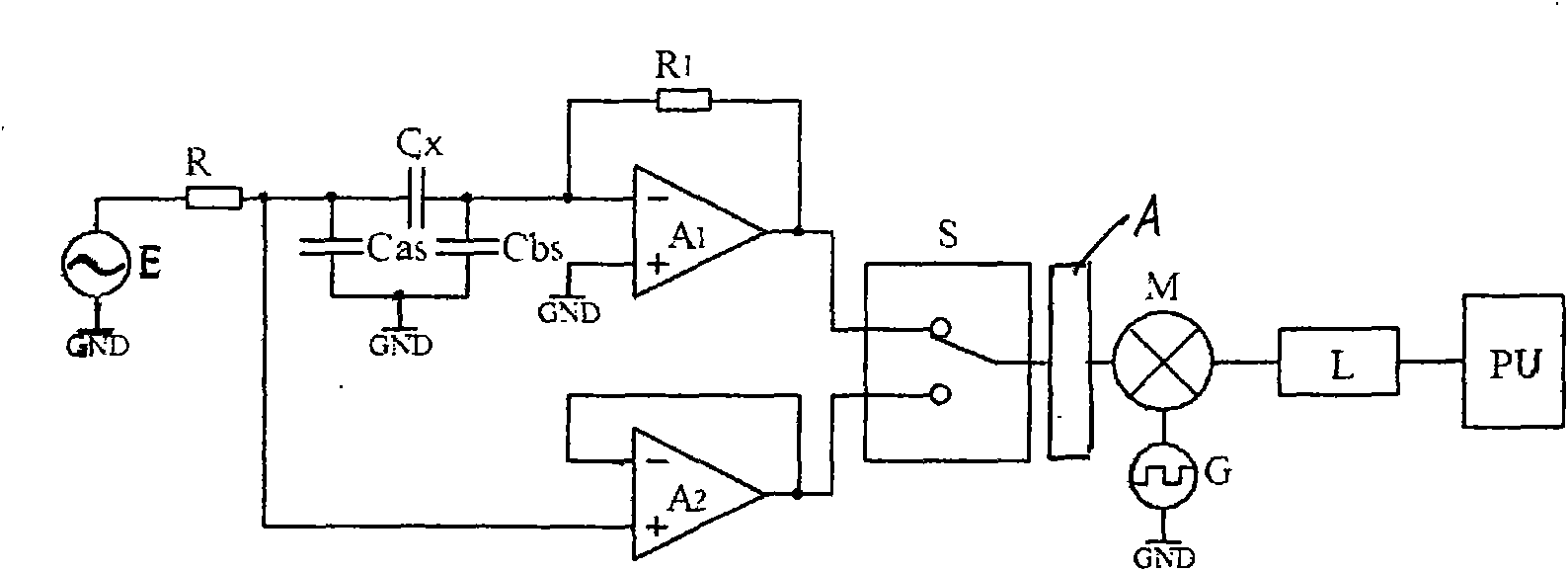

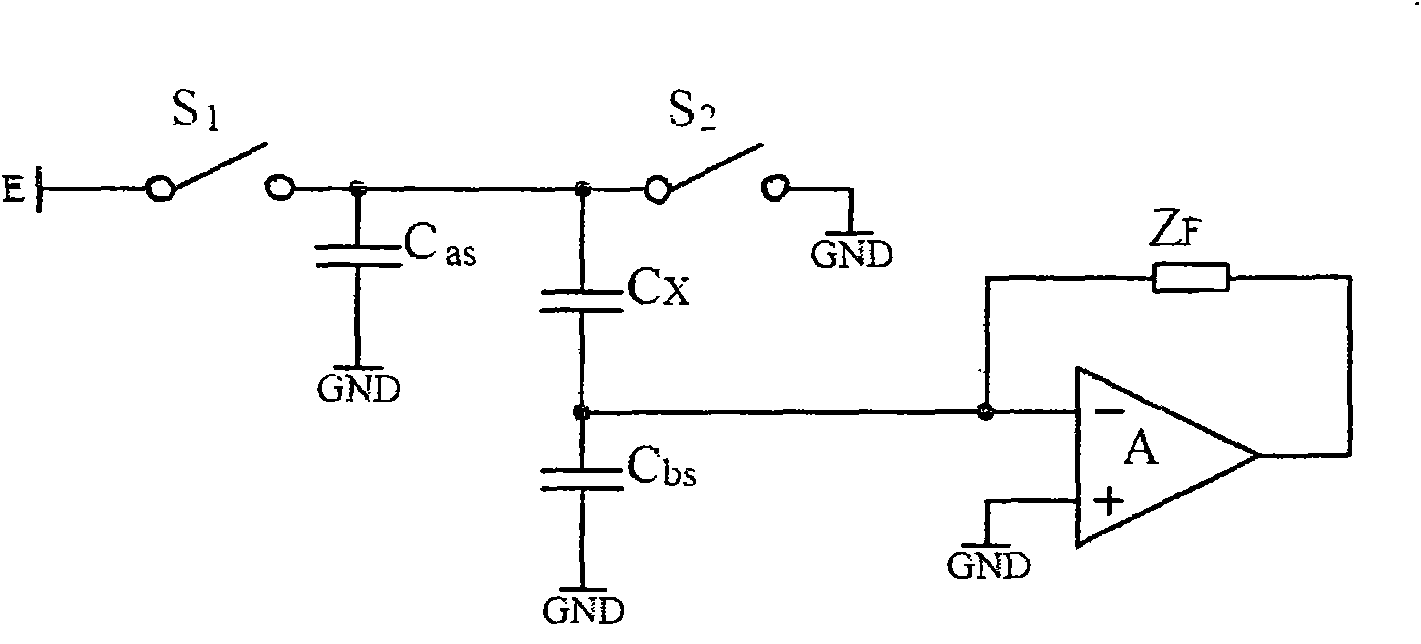

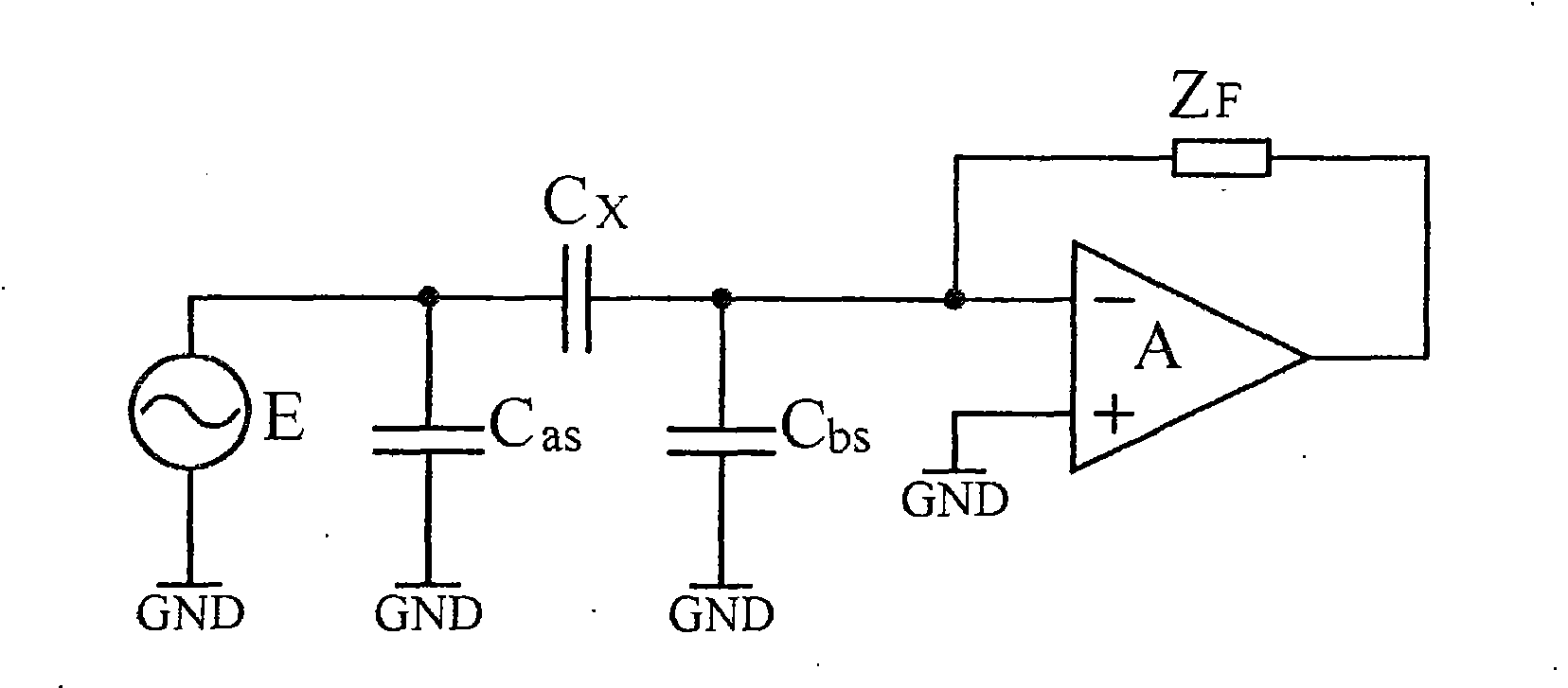

Micro capacitance measurement method and special device

InactiveCN102012464AAvoid influenceEliminate the effects ofResistance/reactance/impedenceCapacitanceCurrent limiting

The invention discloses a micro capacitance measurement method and a special device. The device is provided with a sine wave voltage driving source, a current-limiting resistor, a preposed operational amplifier, a feedback resistor, a voltage follower, an amplifying unit, a reference signal generator, a multiplying unit, a low-pass filter, a selective switch and a detection processing unit. The precision and the resolution of the method are high to the micro capacitance measurement.

Owner:彭建学 +1

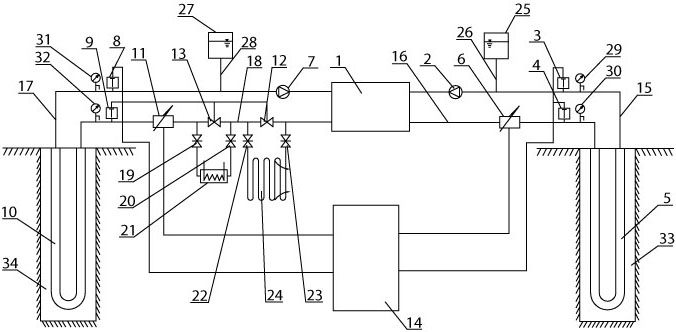

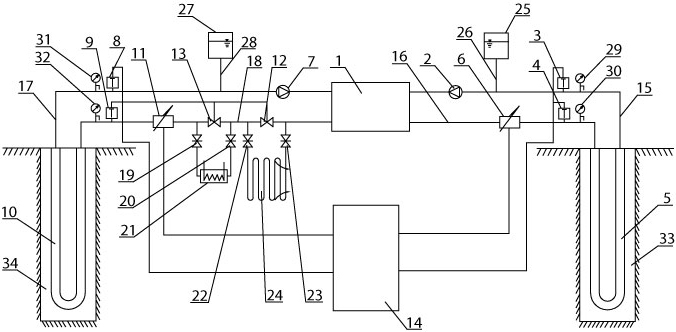

Synchronous cold/thermal response ground thermal property tester

A synchronous cold / thermal response ground thermal property tester relates to a ground thermal property tester. The invention solves the problem that when an air source heat pump type tester is used to test summer heat removal operating condition and winter heat absorption operating condition during the measurement of the ground thermal property, only one operating condition can be tested once and the test result is not accurate. In the tester of the invention, on the cold response side of a water-water heat pump unit, a cold response side water supply pipe, a cold response side flowmeter, a cold response side supply water temperature sensor, a cold response side U tube, a cold response side return water pipe, a cold response side return water temperature sensor and a cold response side circulating pump constitute a loop; and on the thermal response side of the water-water heat pump unit, a thermal response side water supply pipe, a radiator valve, a fin radiator, a heater valve, an electric heater, a thermal response side flowmeter, a thermal response side supply water temperature sensor, a thermal response side U tube, a thermal response side return water pipe, a thermal response side return water temperature sensor and a thermal response side circulating pump constitute the other loop. The synchronous cold / thermal response ground thermal property tester is used in the measurement of the ground thermal property.

Owner:HARBIN INST OF TECH

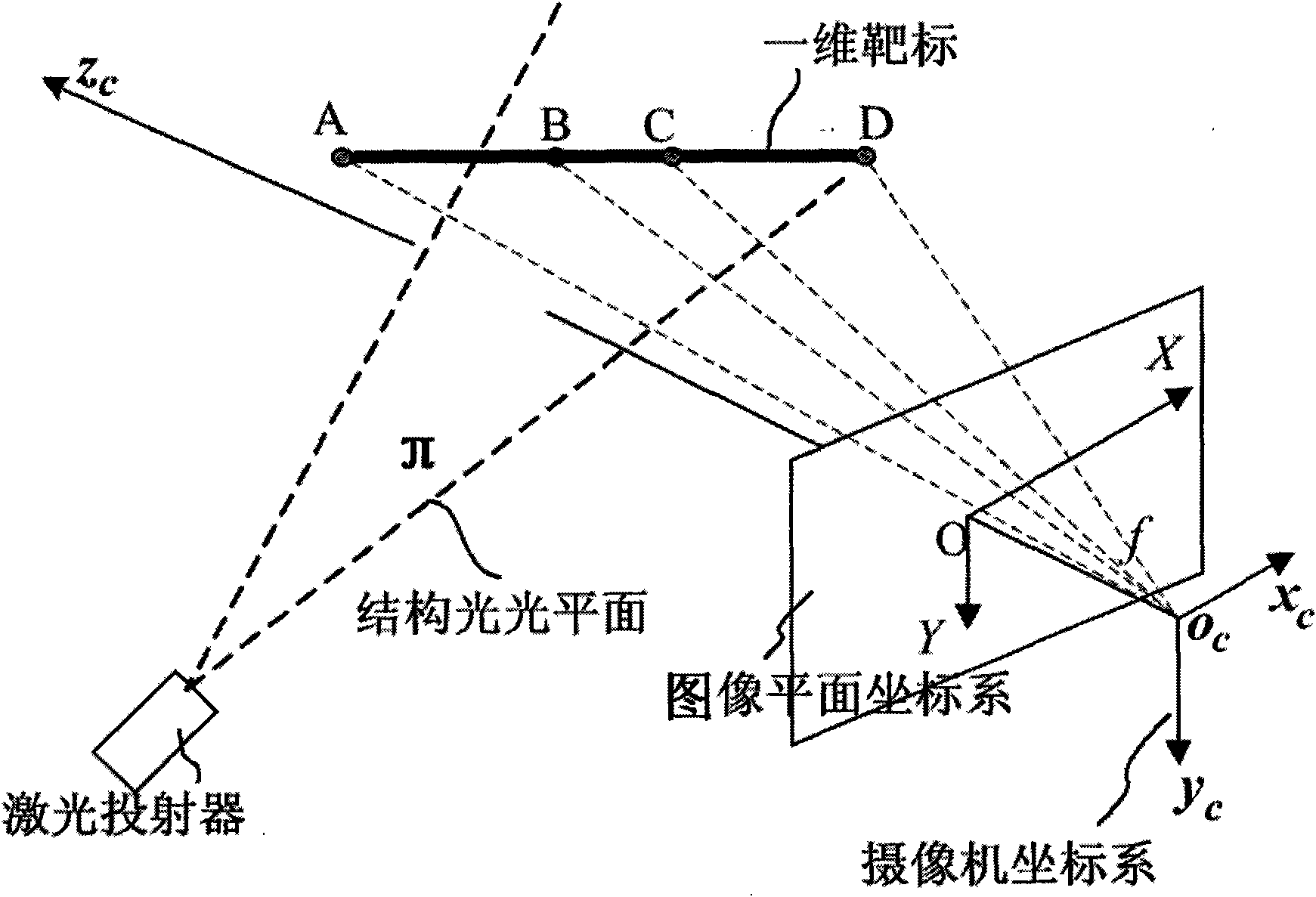

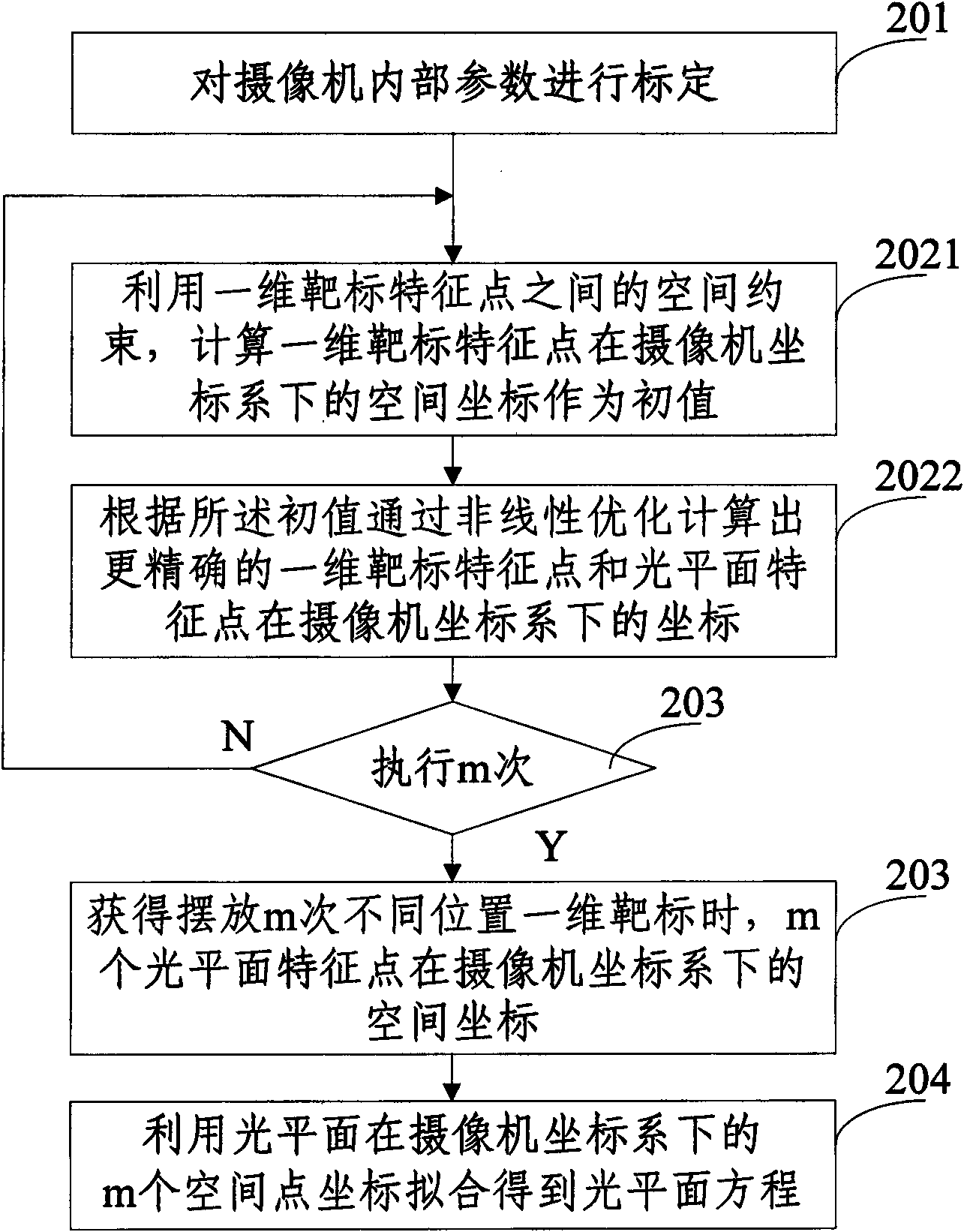

Method for calibrating structure light vision transducer based on one-dimensional target drone

InactiveCN101586943AEasy to processAccuracy is easy to guaranteeUsing optical meansTransducerPlane equation

The invention provides a method for calibrating structure light vision transducer based on one-dimensional target drone, the method comprises: calibrating video camera interior parameters; arranging the one-dimensional target drone on different positions to calculate space coordinates of different crosses of one-dimensional target drones on different positions and the light plane as space coordinates of light plane different characteristic points; fitting the light plane equations by the obtained space coordinates of light plane different characteristic points. According to the invention, the structure light vision transducer can be calibrated by arranging the one-dimensional target drone arbitrarily on the position intersected with the light plane, the calibration is flexible, without auxiliary apparatuses.

Owner:BEIHANG UNIV

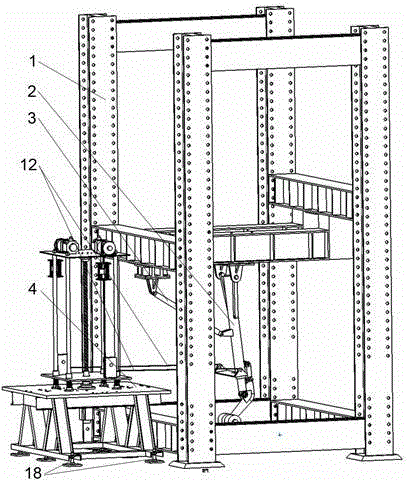

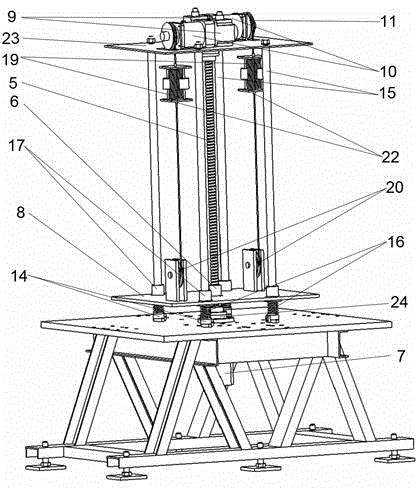

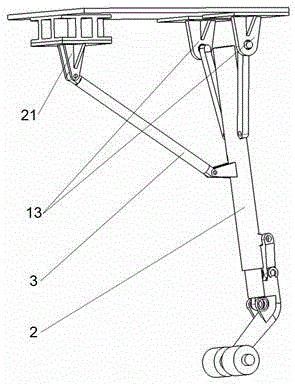

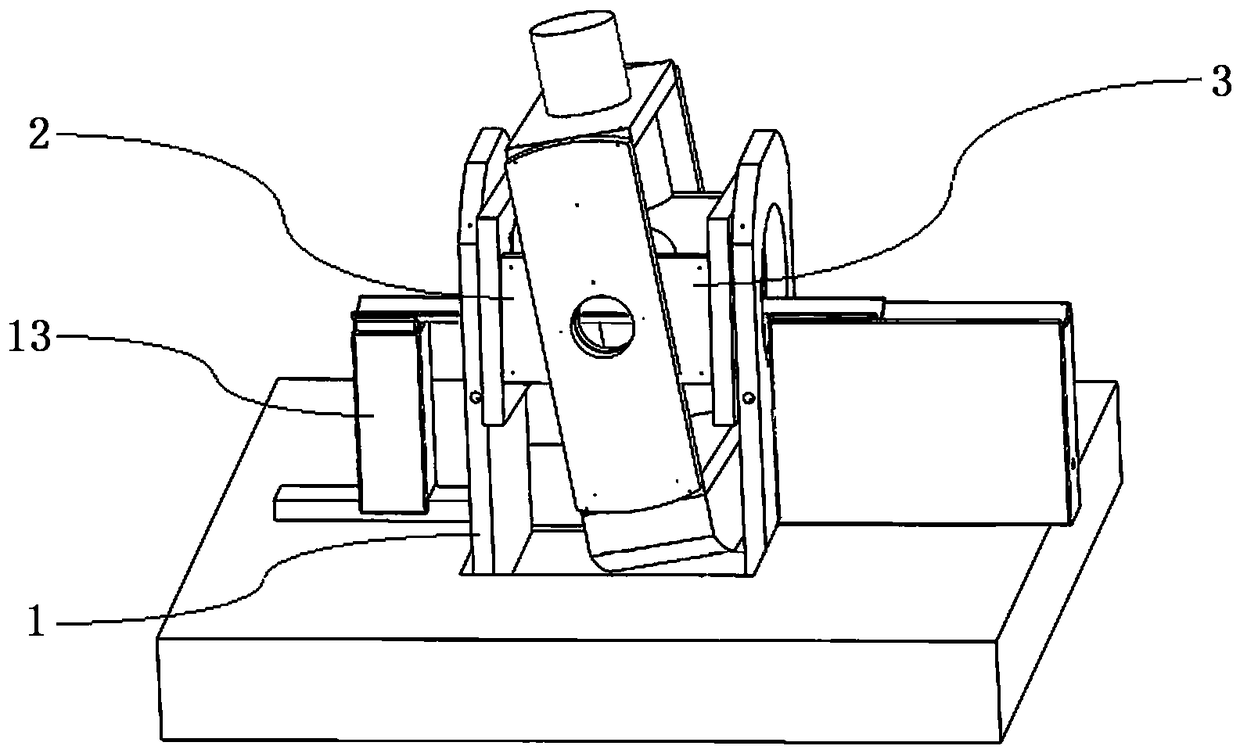

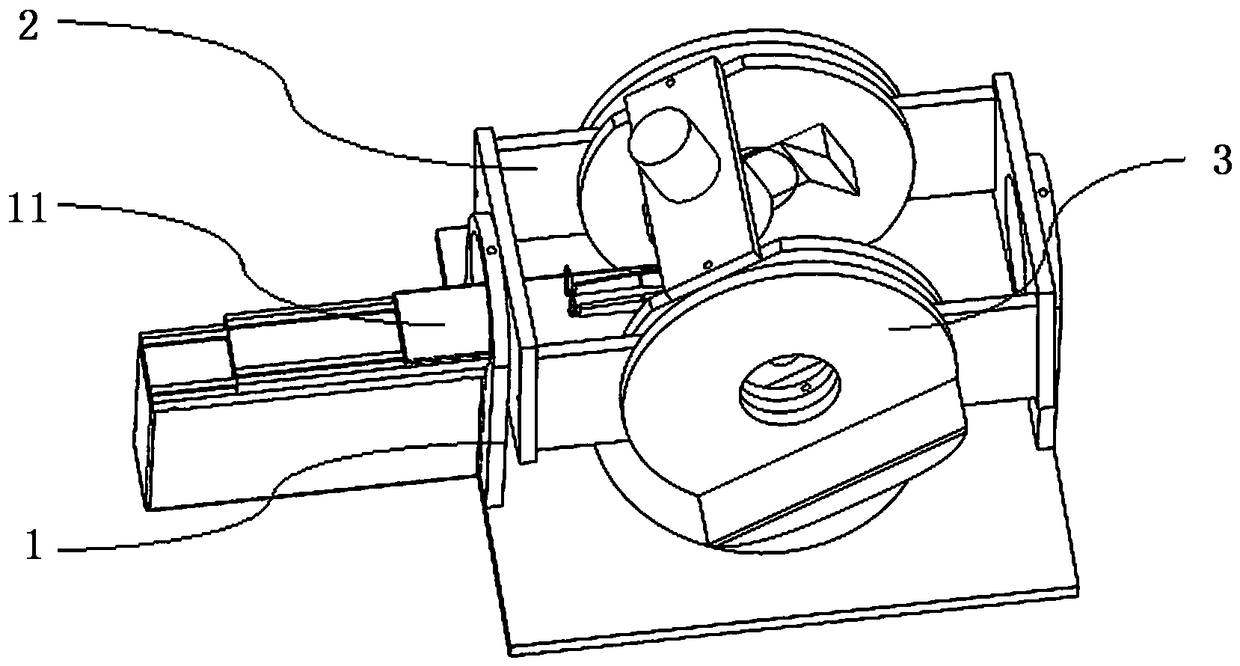

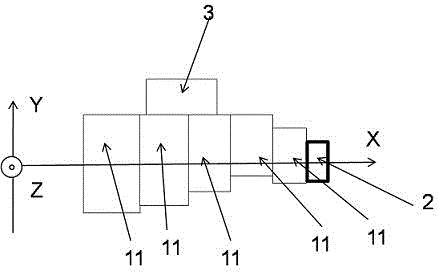

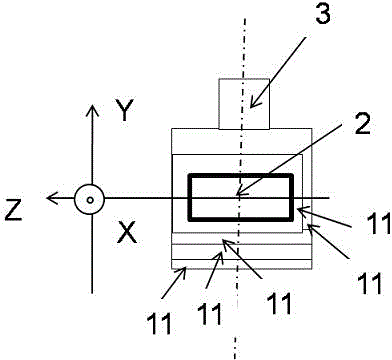

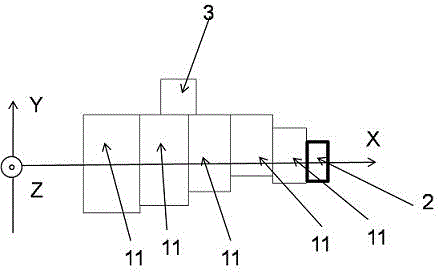

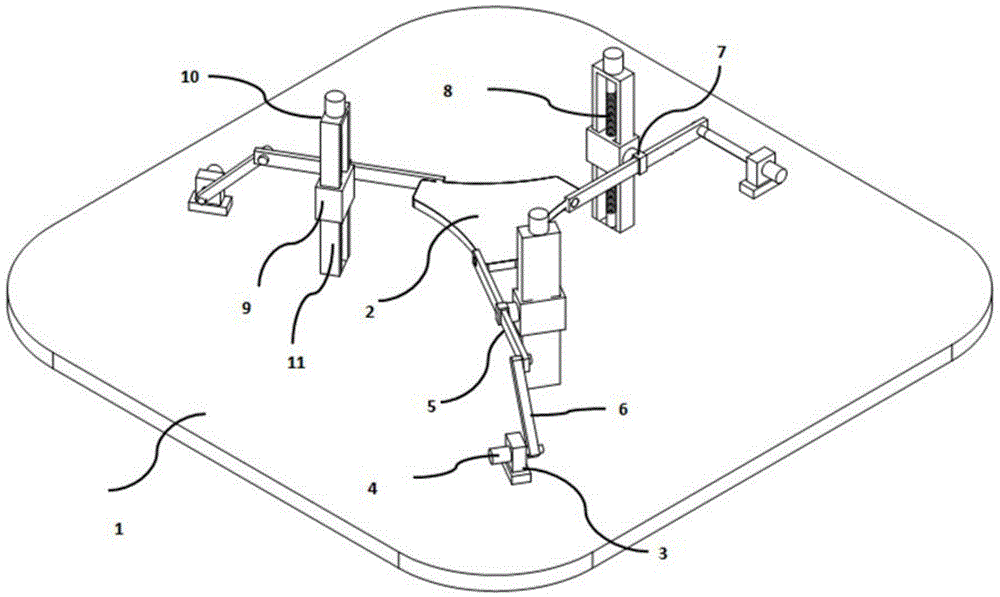

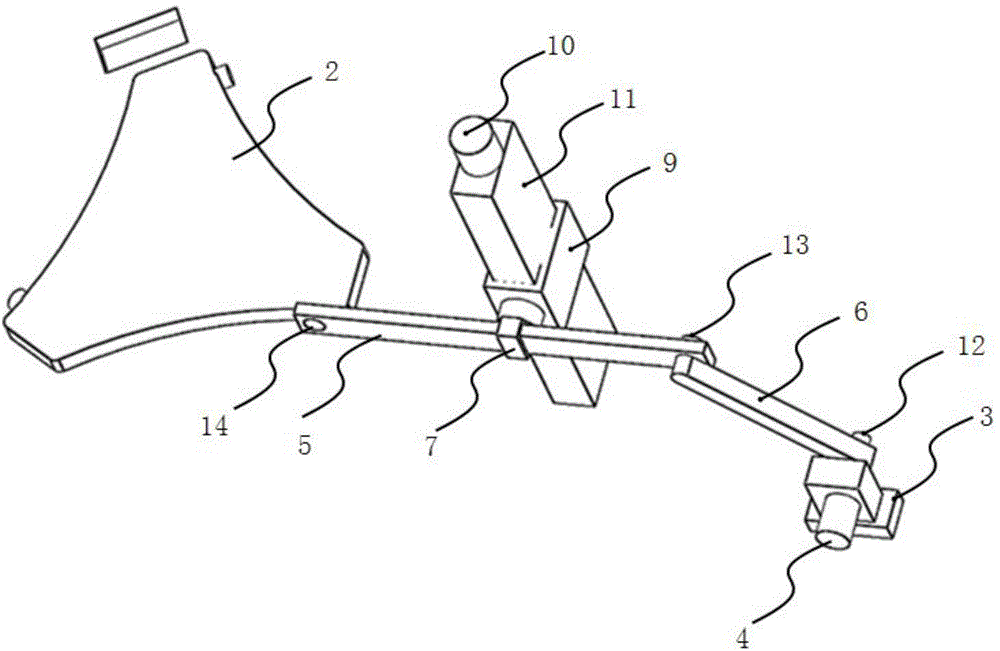

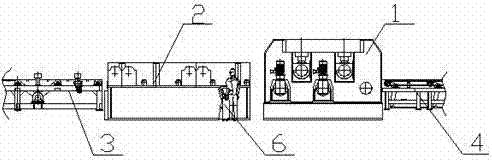

Aerodynamic loading system and loading method for undercarriage self-control spring-damping system

ActiveCN102717897AGood load simulation continuitySmall footprintAircraft components testingAerodynamic loadActuator

The invention discloses an aerodynamic loading system and a loading method for aero-undercarriage self-control spring-damping system and belongs to aero-undercarriage control test systems. The aerodynamic loading system comprises a test rack (1), an aero-undercarriage (2), a strutting actuator (3) and a support frame (4), wherein the strutting actuator (3) and the support frame (4) are connected on the aero-undercarriage (2), an aerodynamic loading direction control mechanism controls the direction of aerodynamic load during undercarriage control, and an aerodynamic loading size simulation mechanism controls the size of the aerodynamic load during the undercarriage control. The aerodynamic loading system and the loading method for the self-control spring-damping system is high in loading accuracy, good in loading simulation continuity, concise in structure and applicable to tests of undercarriage control of various planes and can provide corresponding accurate parameters for design and development of aero-undercarriages.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

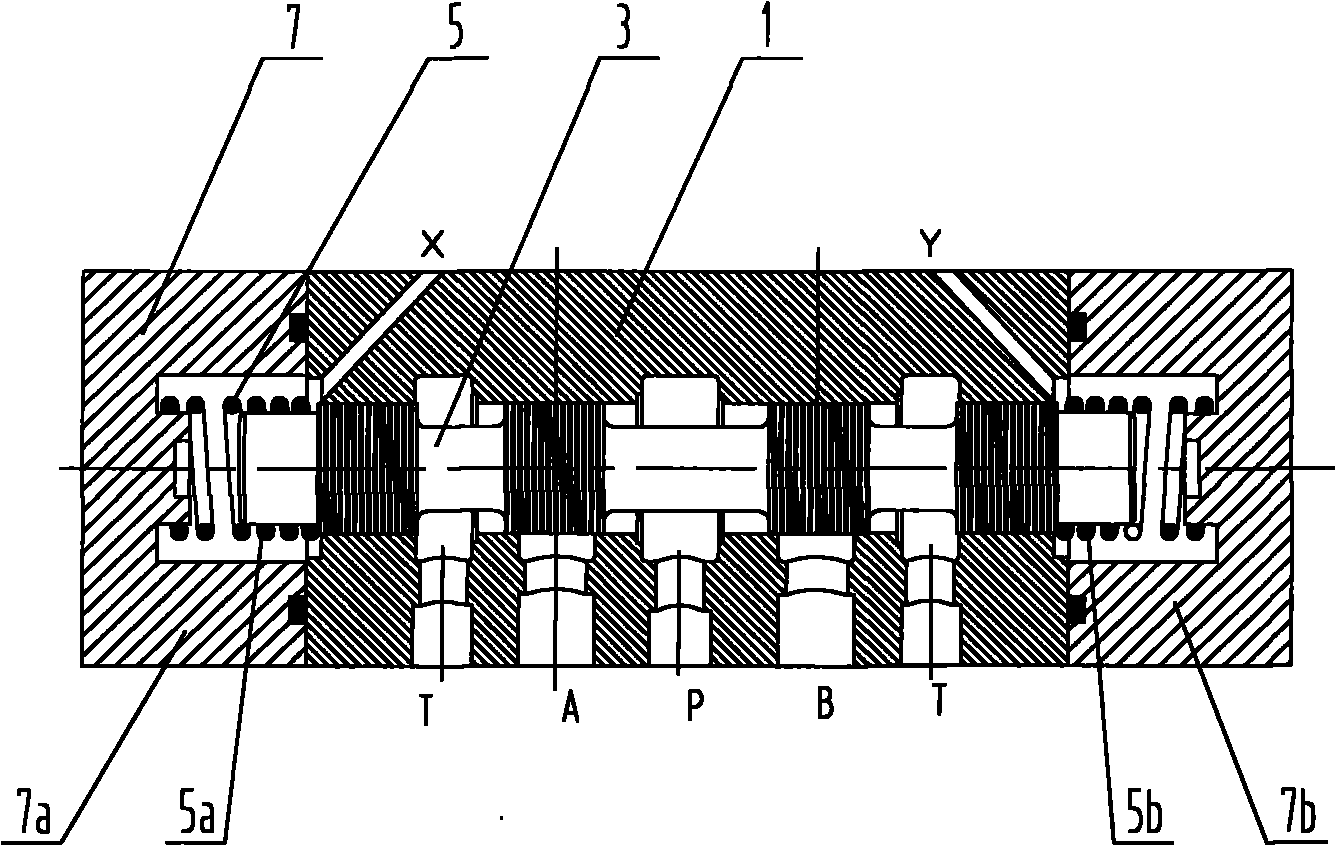

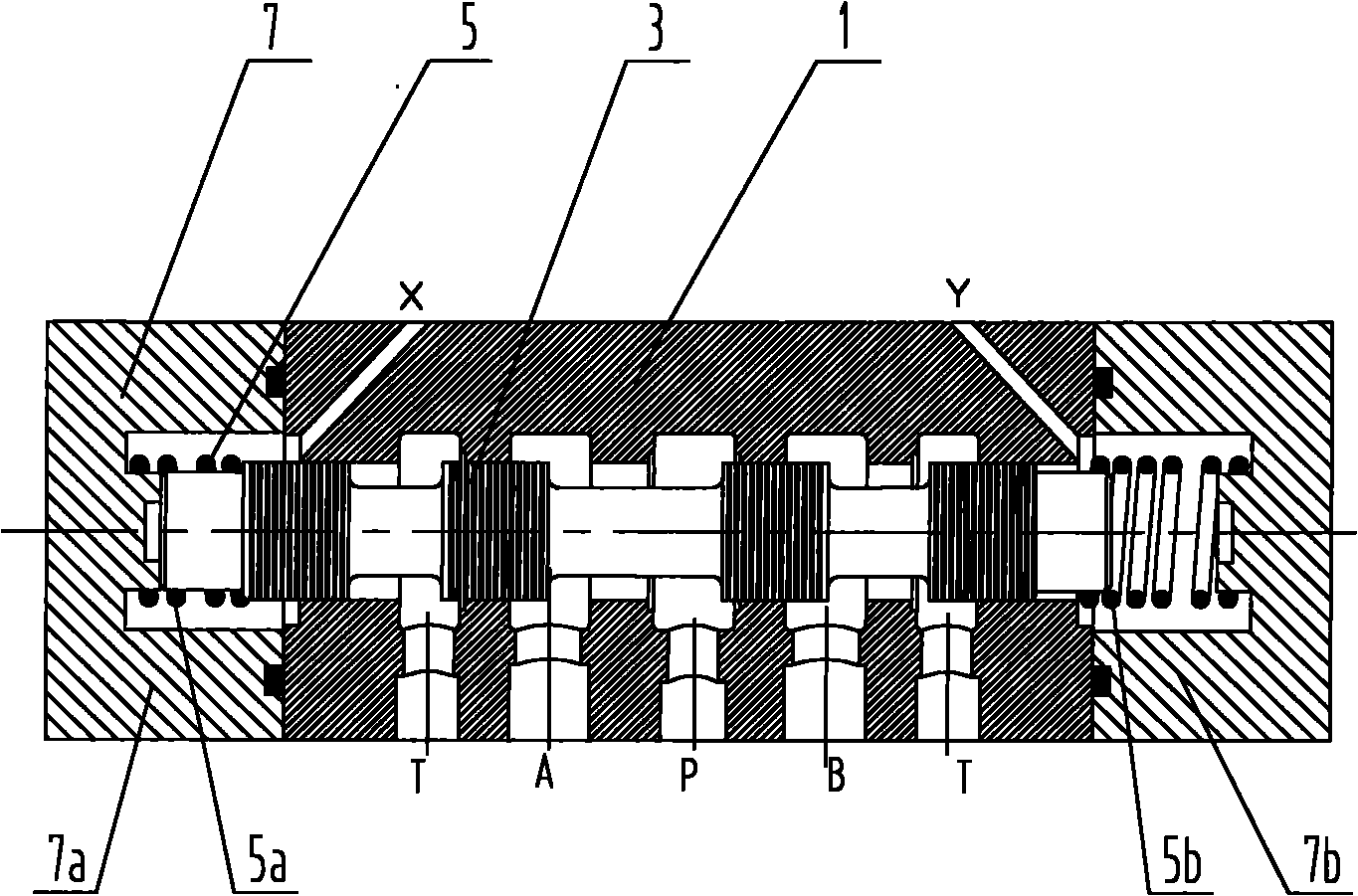

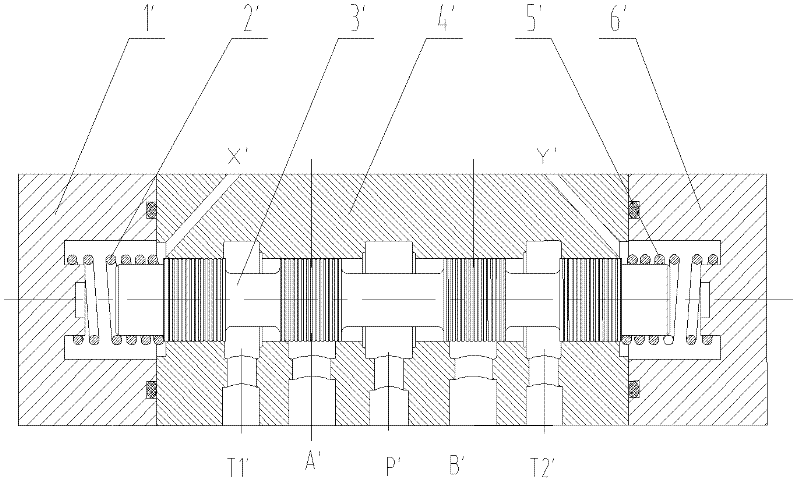

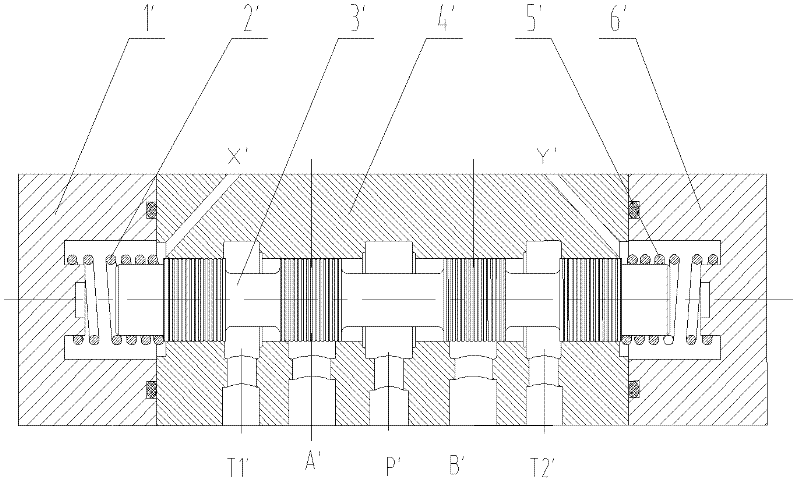

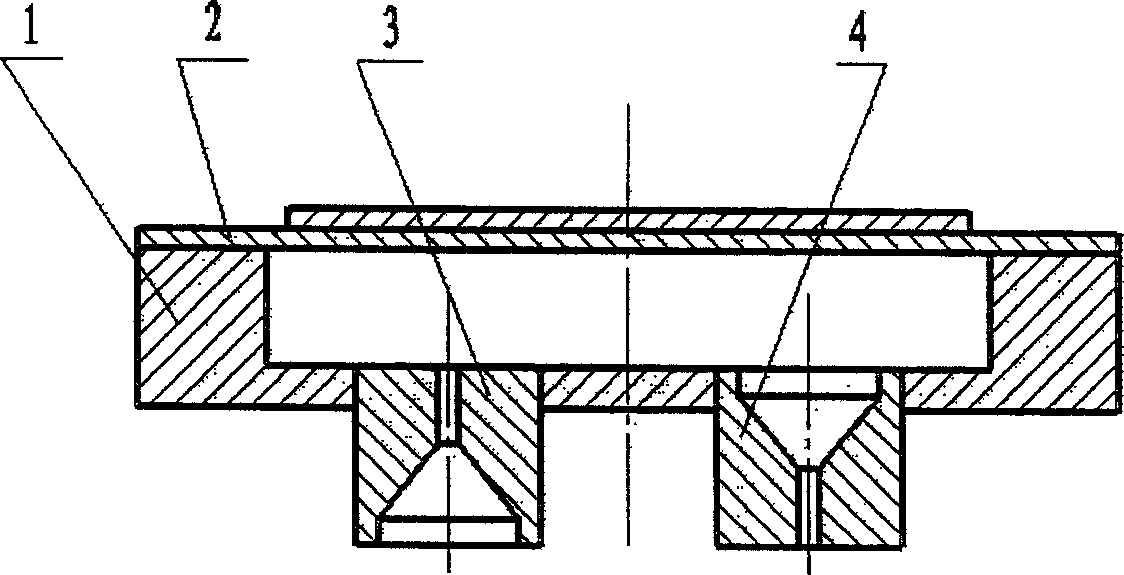

Hydraulic valve, hydraulic valve bank and control method thereof

InactiveCN101893011AEasy to processAccuracy is easy to guaranteeServomotor componentsMultiple way valvesEngineeringHydraulic brake

The invention relates to a hydraulic valve, a hydraulic valve bank and a control method thereof. The hydraulic valve comprises a valve body and a valve core, wherein the valve core is arranged in the cavity of the valve body, the valve core is in a split type structure and comprises a first valve core and a second valve core, and a valve pocket can be arranged between the valve body and the valve core. The hydraulic valve bank provided by the invention also comprises a first valve core and a second valve core which form a split type structure, and the valve cores are integrated into a valve block. In the control method of the hydraulic valve and the hydraulic valve bank provided by the invention, oil drain ports R on the valve body or the valve block are simultaneously used as control ports K so as to realize a four-position function. By using the split type valve core structure, the hydraulic valve solves the problems of long matching surface between the valve core and the valve body in the hydraulic valve, difficult accuracy guarantee and inconvenient processing and assembly. Besides, the valve core can not be clamped easily and has high contamination resistance. Additionally, because of the use of the valve pocket, the hydraulic valve has the advantages of good part interchangeability, convenient maintenance and replacement and greatly prolonged overall service life.

Owner:SANY HEAVY IND CO LTD (CN)

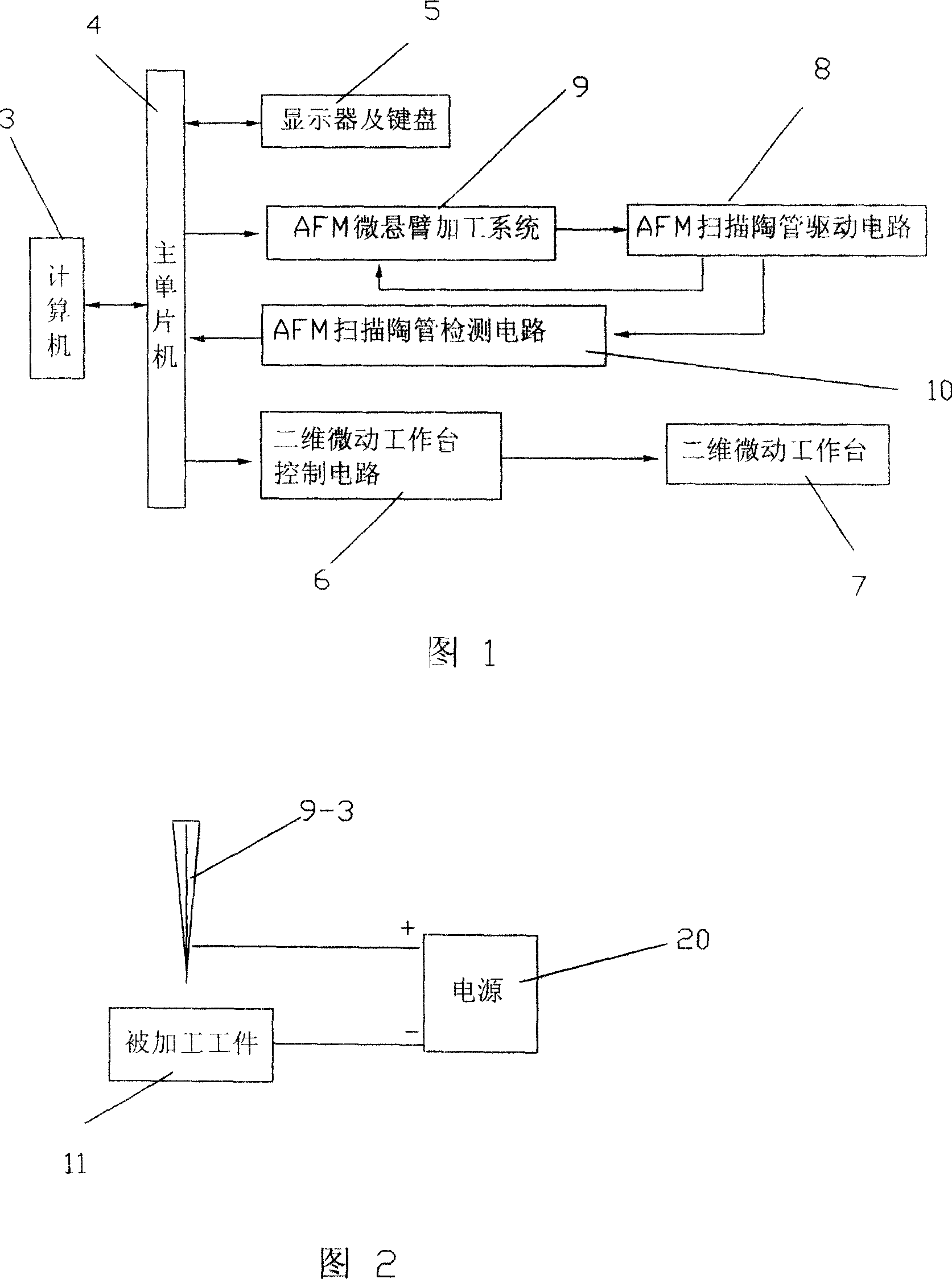

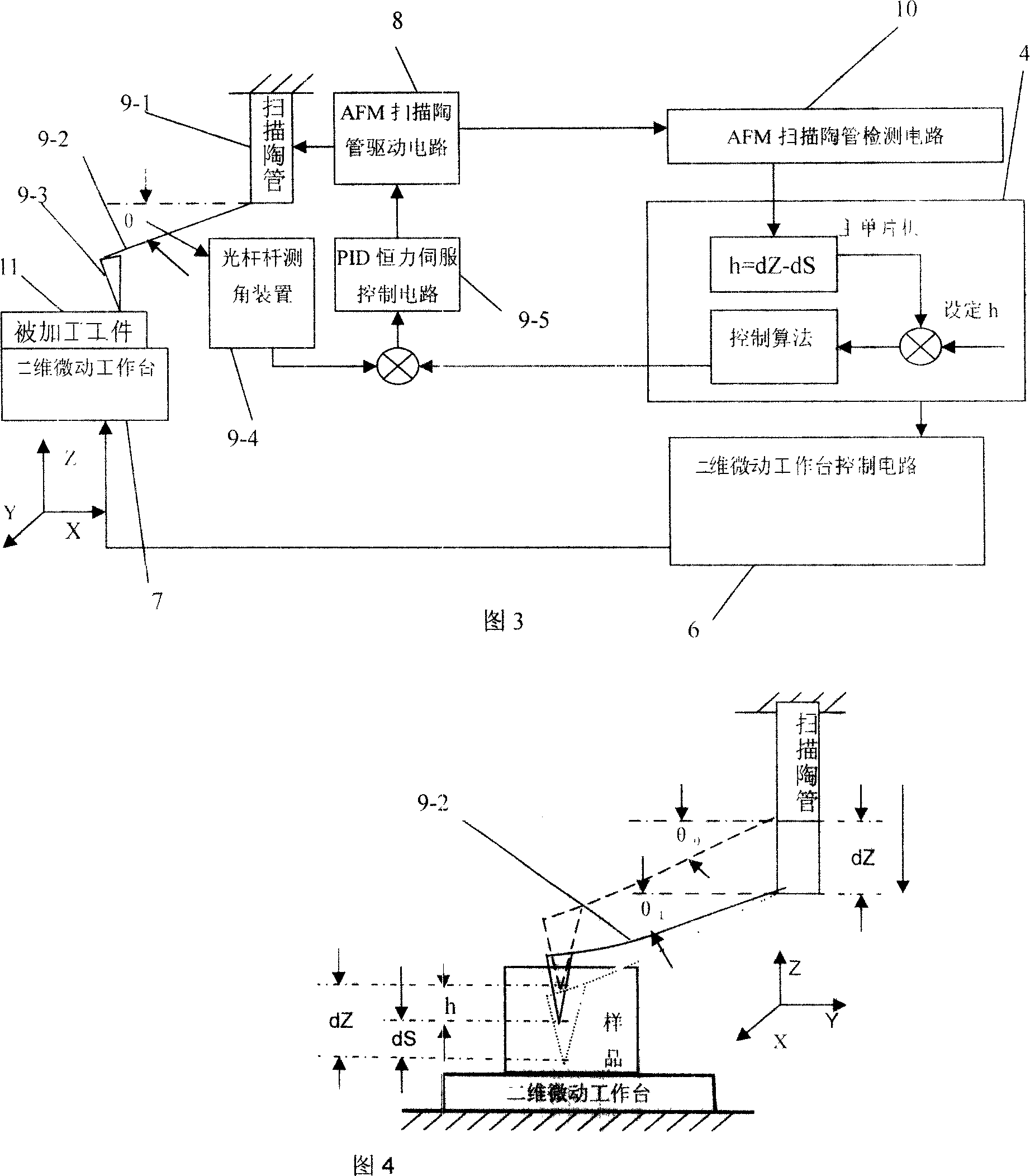

Method for making Nano microstructure based on constant force mode of atomic force microscope

InactiveCN101003357AAccuracy is easy to guaranteeHigh repeatability positioning accuracyNanostructure manufactureMagnetic force microscopeAtomic force microscopy

A process based on the constant-force mode of atomic force microscope for preparing nano-class microstructure with controllable depth and large range of precise sizes features that 2D micro-motion bench and its control circuit is additionally used. The extension of scanning ceramic tube is driven by AFM driver circuit to make the probe tip to prick into the surface of a workpiece to be processed. The variation amount of scanning ceramic tube is detected by the real-time detection circuit and transmitted to single-chip computer. Said scanning ceramic tube is extended continuously in the relative direction until the processed depth setting is equal to the difference between the motion amount of said scanning ceramic tube in height direction and said deformation amount of cantilever.

Owner:HARBIN INST OF TECH

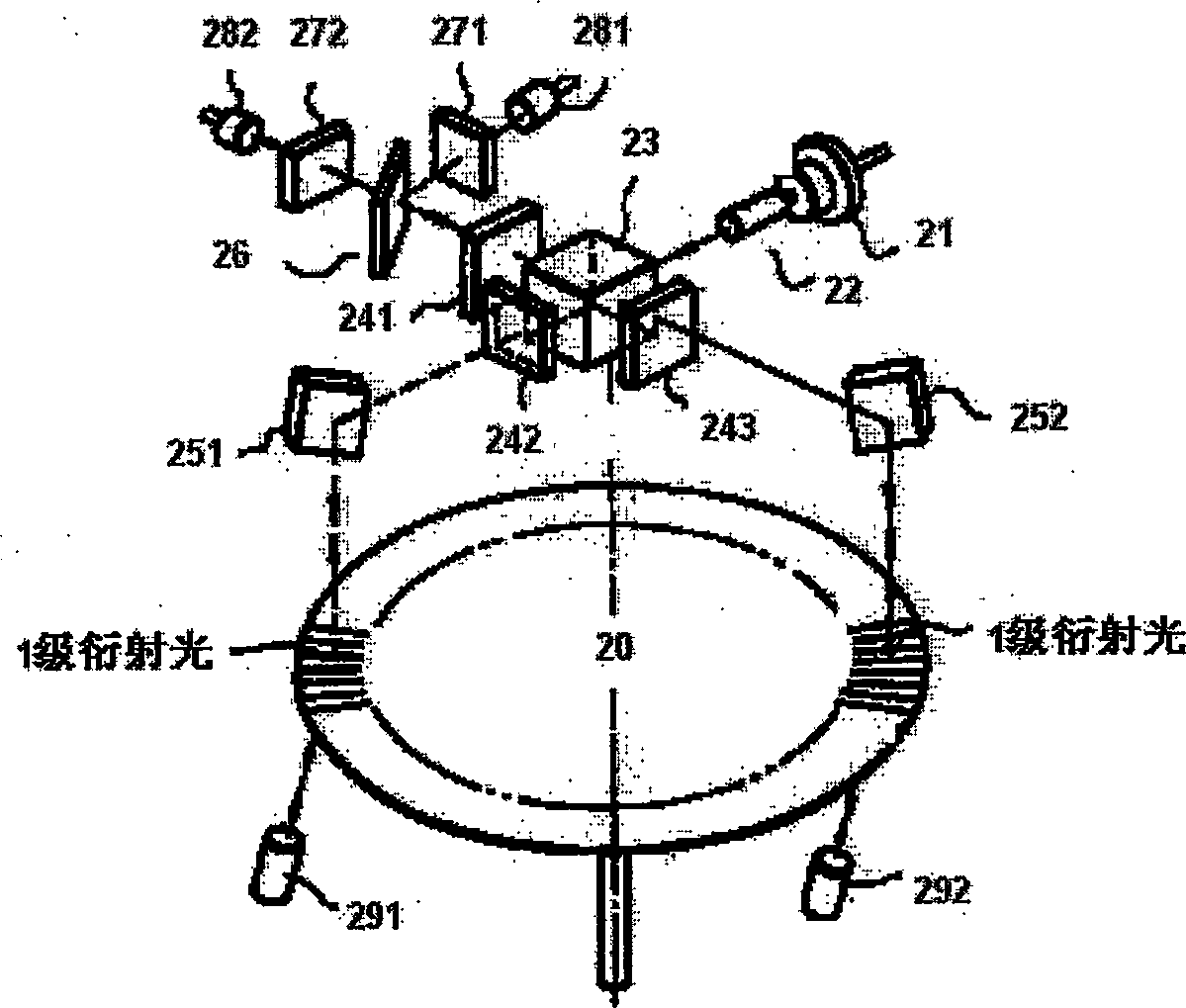

Laser encoder, displacement measurement method of using the laser encoder, and fabricating method of numerically controlled machine

ActiveCN1873377ALower manufacturing requirementsReduce manufacturing costConverting sensor output opticallyNumerical controlBand shape

The invention discloses a laser coder. It includes one laser source, diffraction grating, polarization beam splitter prism, collimating lens, 1 / 4 wave plate, objective lens, coding disc, concave lens, cylindrical lens, and photo electricity receiver. The coding disc can rotate around center fixed rotating shaft. And its surface is the laser reflecting surface, and set three sets of information rail which is made up of banded unit. The invention also discloses the laser coder displacement measuring method and digital controlled machine tool processing method.

Owner:SIEMENS NUMERICAL CONTROL

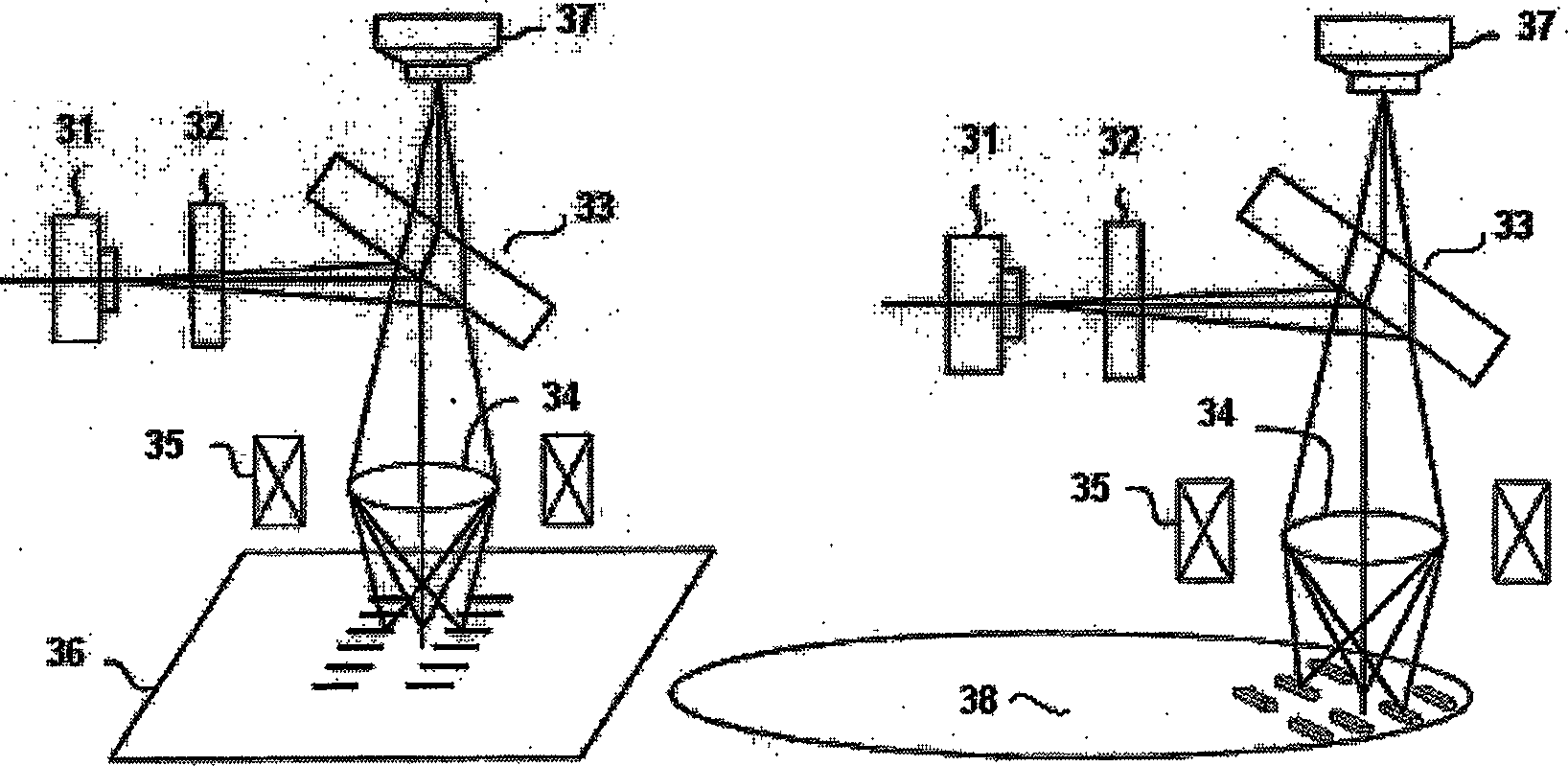

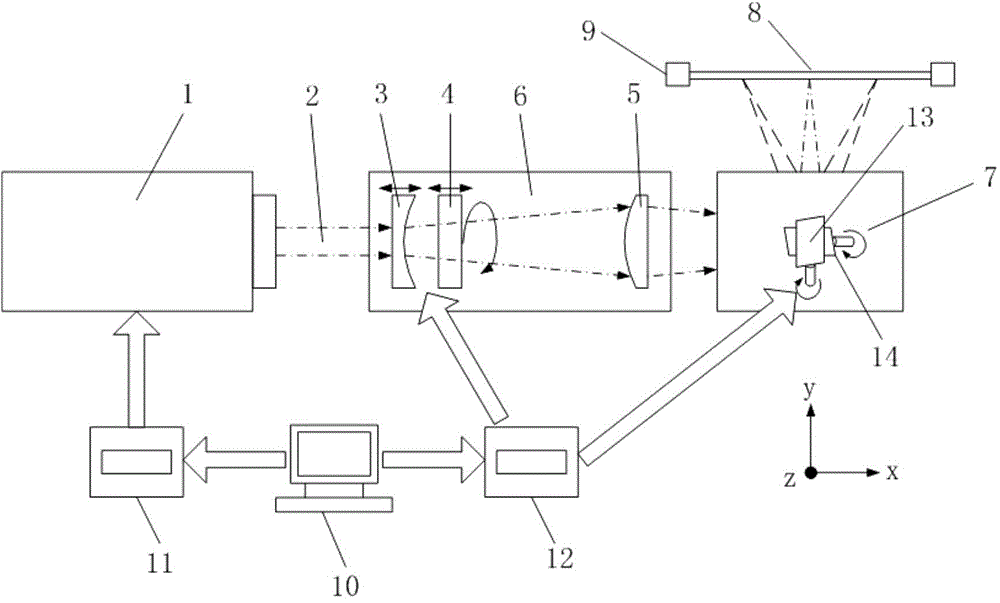

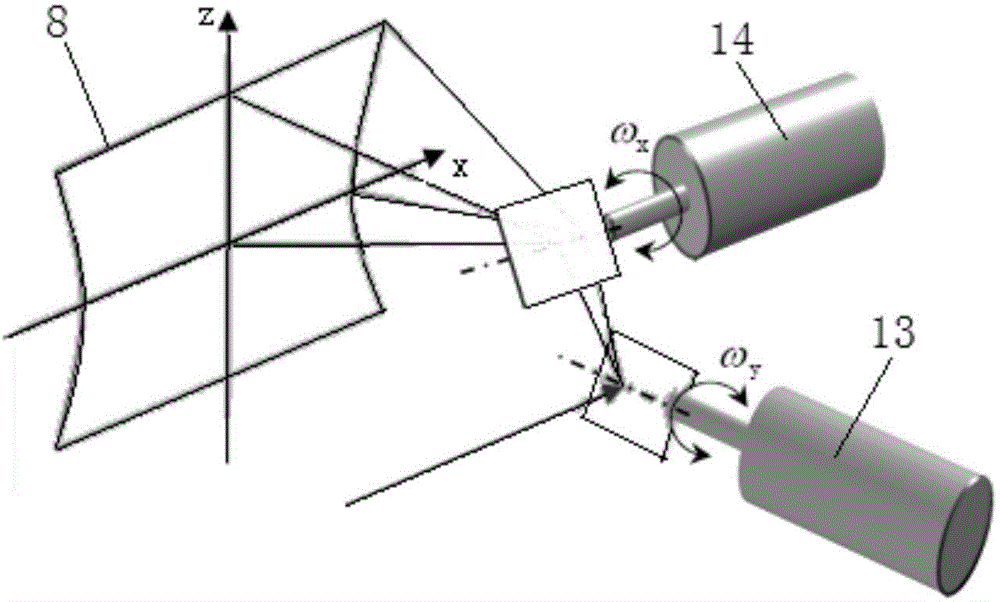

Light path device and method for laser peening forming of large workpiece

The invention discloses a light path device and method for laser peening forming of a large workpiece. The light path device comprises a laser device, a dynamic focusing and shape righting system, a scanning galvanometer system, the formed workpiece, a computer, a laser control card and a movement control card. The laser control card is connected with the laser device and is used for controlling starting of the laser device and various parameters of laser. The movement control card is connected with the dynamic focusing and shape righting system and the scanning galvanometer system. Both the laser control card and the movement control card are controlled by the computer. The dynamic focusing and shape righting system and the scanning galvanometer system are controlled by the computer to make corresponding movement after a specific shot blasting path is given, the shape of the section and the focusing position of a high-energy pulse laser beam are changed after the high-energy pulse laser beam emitted by the laser device passes through the dynamic focusing and shape righting system, and then the high-energy pulse laser beam points to a specific emergent direction after passing through the scanning galvanometer system, so that scanning and shot blasting on the large workpiece by laser are achieved through continuous movement of the dynamic focusing and shape righting system and the scanning galvanometer system.

Owner:SHANGHAI JIAO TONG UNIV

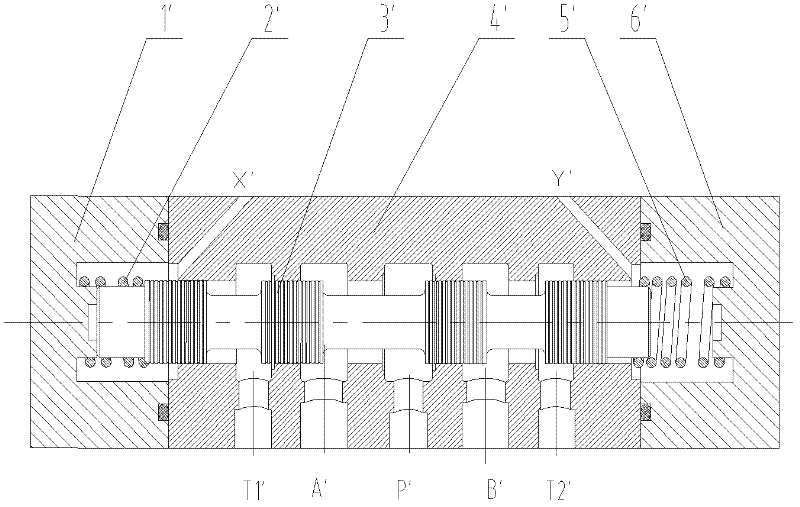

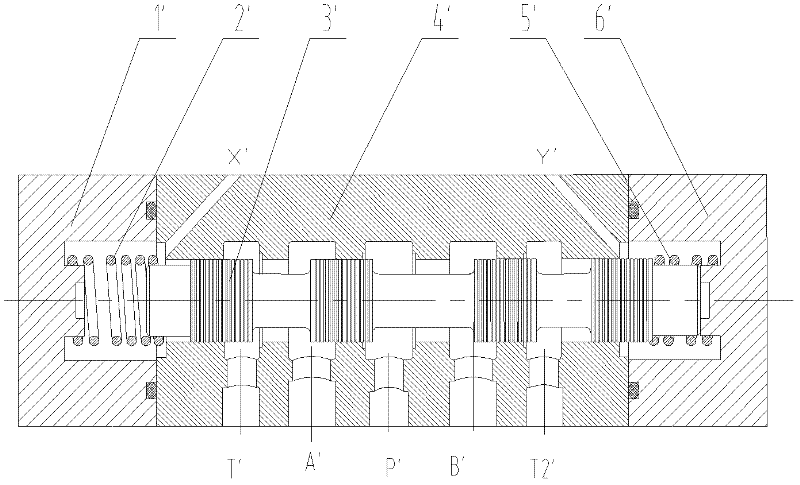

Hydraulic valve, hydraulic valve group and hydraulic valve control method

ActiveCN102297171ALow machining accuracy requirementsEasy to processServomotor componentsMultiple way valvesHigh resistanceEngineering

A hydraulic directional control valve and the control method thereof, a hydraulic control valve set, and a hydraulic control system and engineering machinery comprising the said valve or the valve set. The said hydraulic control valve comprises: a valve body (10); a valve pocket sleeve provided in the cavity of the valve body (10); a valve plug provided in the valve pocketsleeve. The valve pocket sleeve is a split type valve pocketsleeve, comprising at least a first valve pocket sleeve (21) and a second valve pocket sleeve (22). The valve plug is a split type valve plug, comprising at least a first valve plug (31) and a second valve plug (32). The said first valve plug (31) and the second valve plug (32) are in a synchronous working conditionstate. The hydraulic directional control valve is provided with at least three fluid ports, and at least two working positions may be realized. The split type valve pocket sleeve and valve plug impart offer the following benefits to the valve plug: simple valve plug assembly, less likelihood to of valve plug getting stuck, strong high resistance to contamination, good interchangeability of parts, and much longer overall service life.

Owner:SANY AUTOMOBILE MFG CO LTD

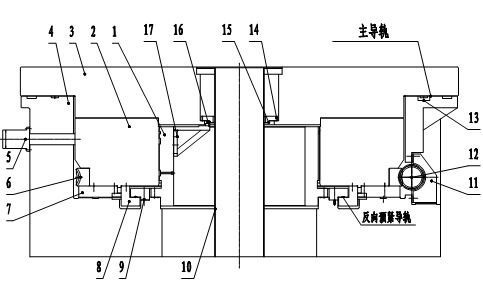

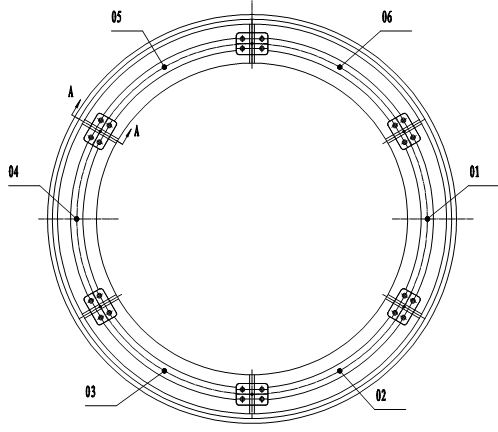

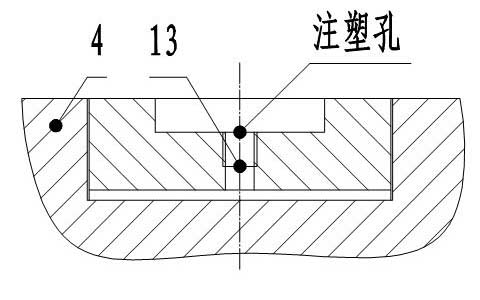

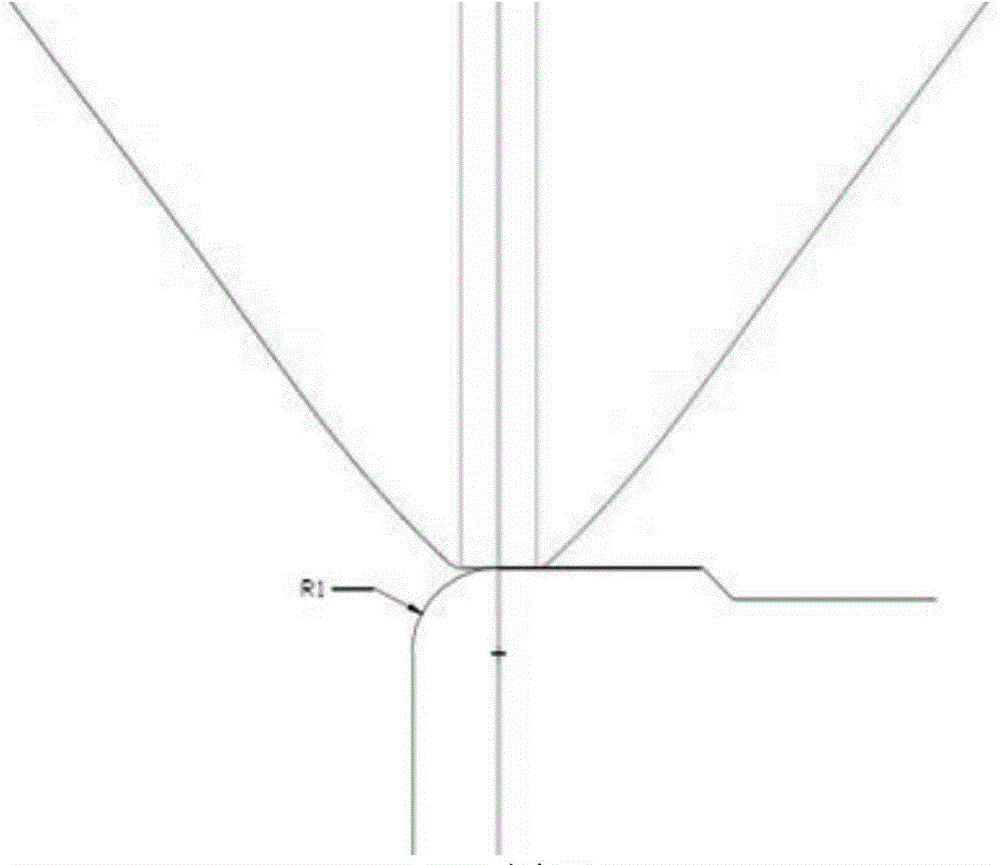

Large and heavy numerical control static-pressure revolving platform

ActiveCN102059558AAccuracy is easy to guaranteeStrong craftsmanshipLarge fixed membersManufacturing cost reductionNumerical control

The invention discloses a large and heavy numerical control static-pressure revolving platform. In the invention, a constant-current static-pressure closed guide rail is used for axial unloading and positioning; a constant-current opposed oil cavity is used for radial positioning; a radial damping oil cylinder is used for locking and applying Coulomb frictional damping; a double-lead worm gear isused for precision scale division; a closed loop control system consists of round gratings; and the revolving platform has high scale division accuracy, repeated location accuracy, heavy load and high rigidity and can realize accurate location at any angles and bear heavy cutting load. The large and heavy numerical control static-pressure revolving platform disclosed in the invention mainly comprises six parts of a supporting part, a scale division rotating part, a closed guide rail part, a worm part, a round grating full closed loop part and a radial locking part. The processing and assembling process of the large and heavy numerical control static-pressure revolving platform can improve the accuracy and the production efficiency of the static-pressure revolving platform, reduce the manufacturing cost and meet the requirement of the industrialization of large high-grate numerical control machine tools in China for large and heavy numerical control static-pressure revolving platforms.

Owner:NANJING GONGDA CNC TECH

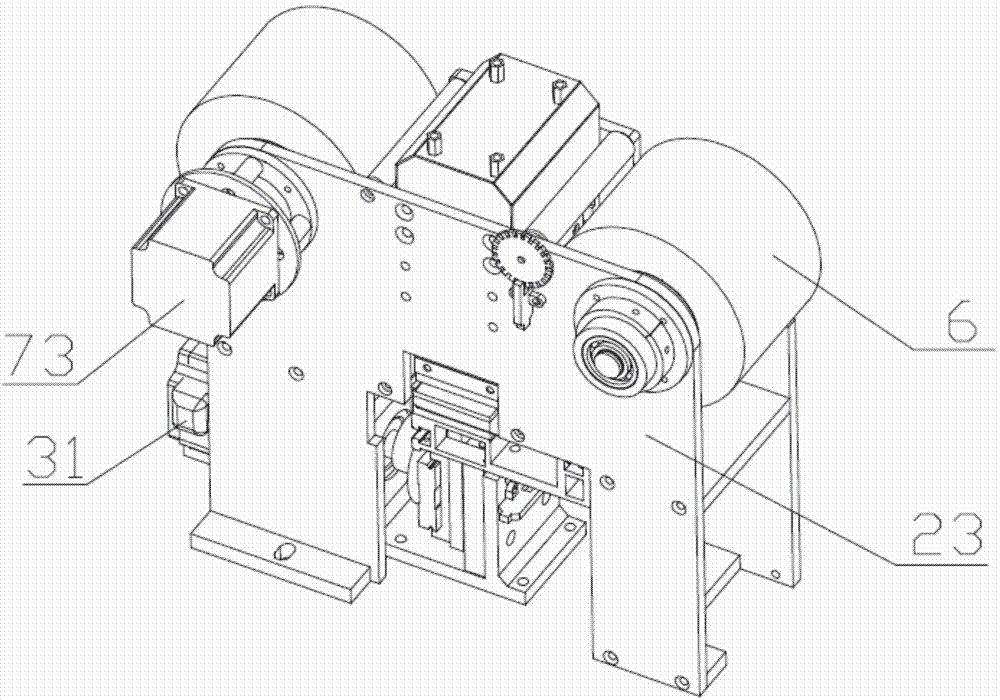

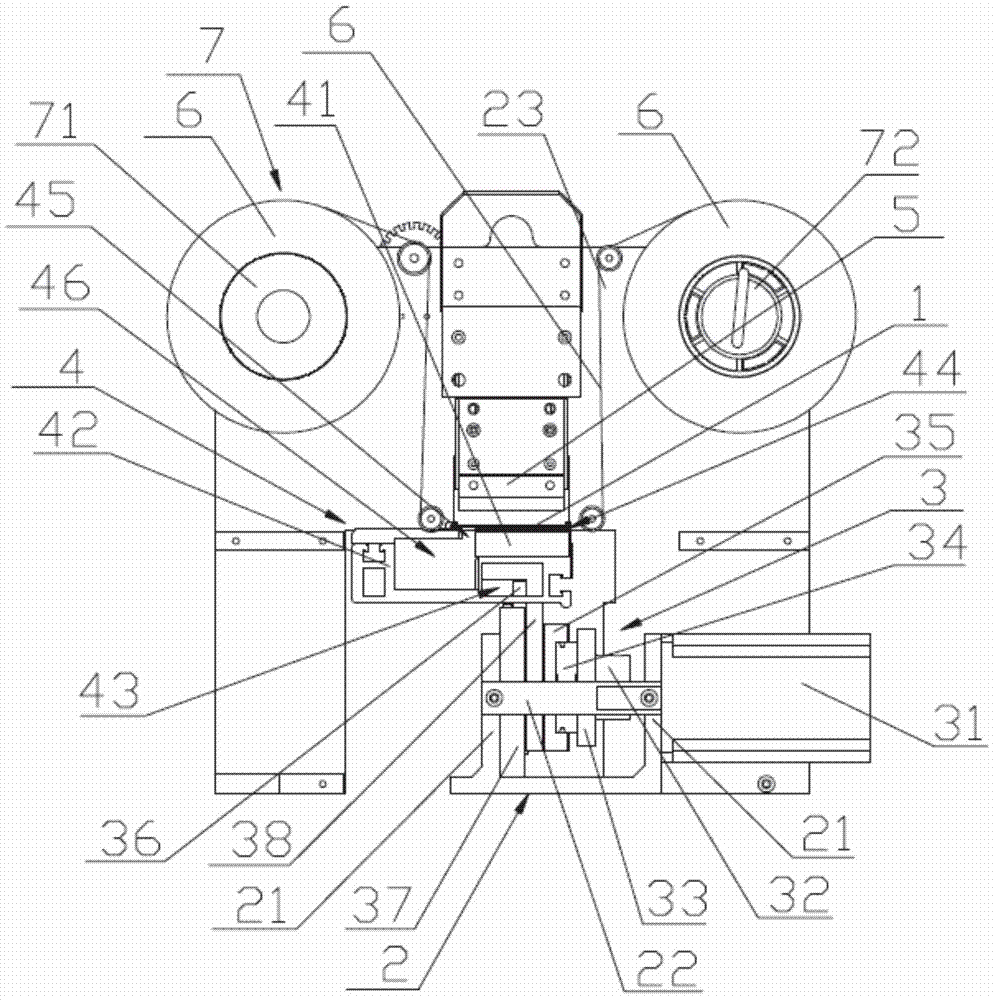

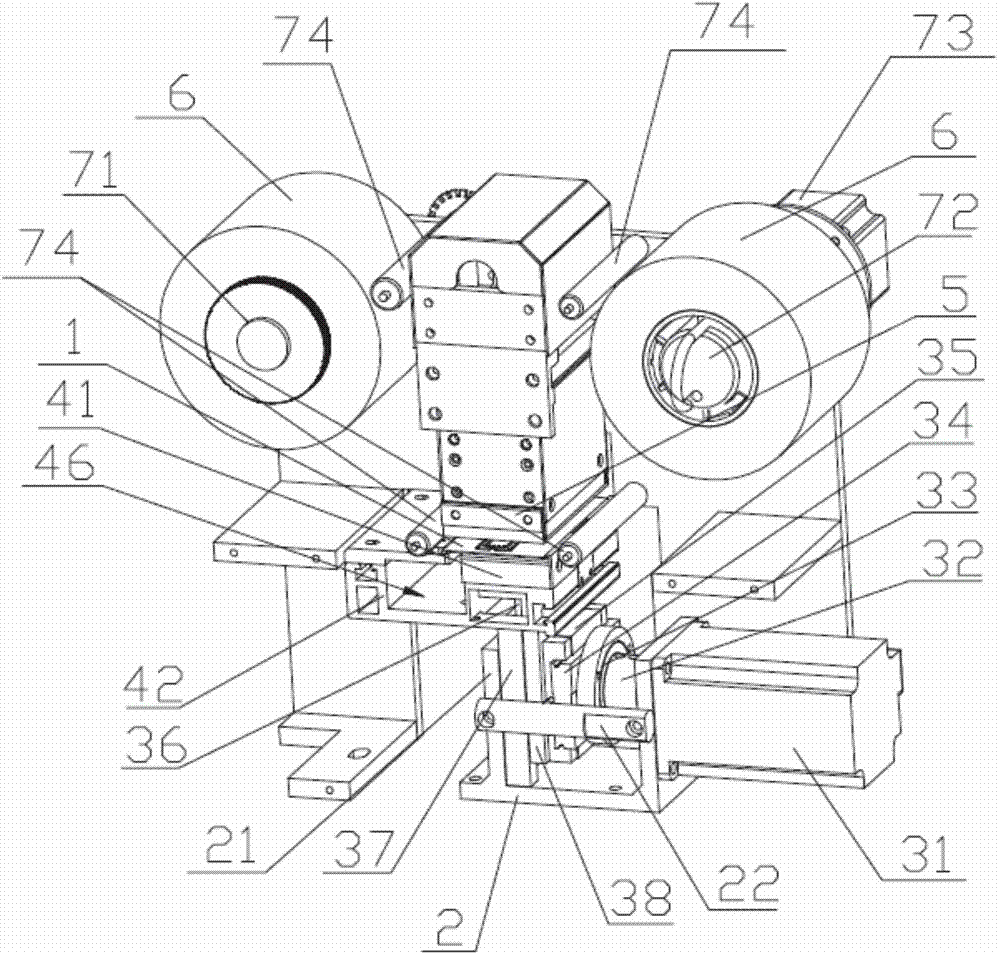

Grinding wheel numerically-controlled finishing control device and control method special for face gear grinding

InactiveCN104057396ARealize real-time data communicationFirmly connectedAbrasive surface conditioning devicesNumerical controlGear grindingGear wheel

The invention discloses a grinding wheel numerically-controlled finishing control device and a control method special for face gear grinding. The device comprises a grinding wheel main shaft unit (1), a grinding wheel finishing device (2), a control device (3) and a transmission mechanism (4), wherein the control device comprises an IPC (Industrial Personal Computer), an SERCOS card, a control panel, an SERCOS optical fiber, a KE rectification power supply module, a KW main shaft control module, a KW feed control module and a PLC-IO module; the SERCOS card is mounted on the IPC through an ISA socket; the control panel is connected with the SERCOS card through a control line for sending out a control command; the SERCOS card is connected with the KE rectification power supply module, the KW main shaft control module and the KW feed control module through the SERCOS optical fiber; the KW main shaft control module is connected with a finisher main shaft motor and a grinding wheel main shaft motor; the KW feed control module is connected with each feed motor through a control line. According to the device and the method provided by the invention, the control of the numerically-controlled rectification process of the grinding wheel special for the face gear grinding is realized.

Owner:BEIHANG UNIV

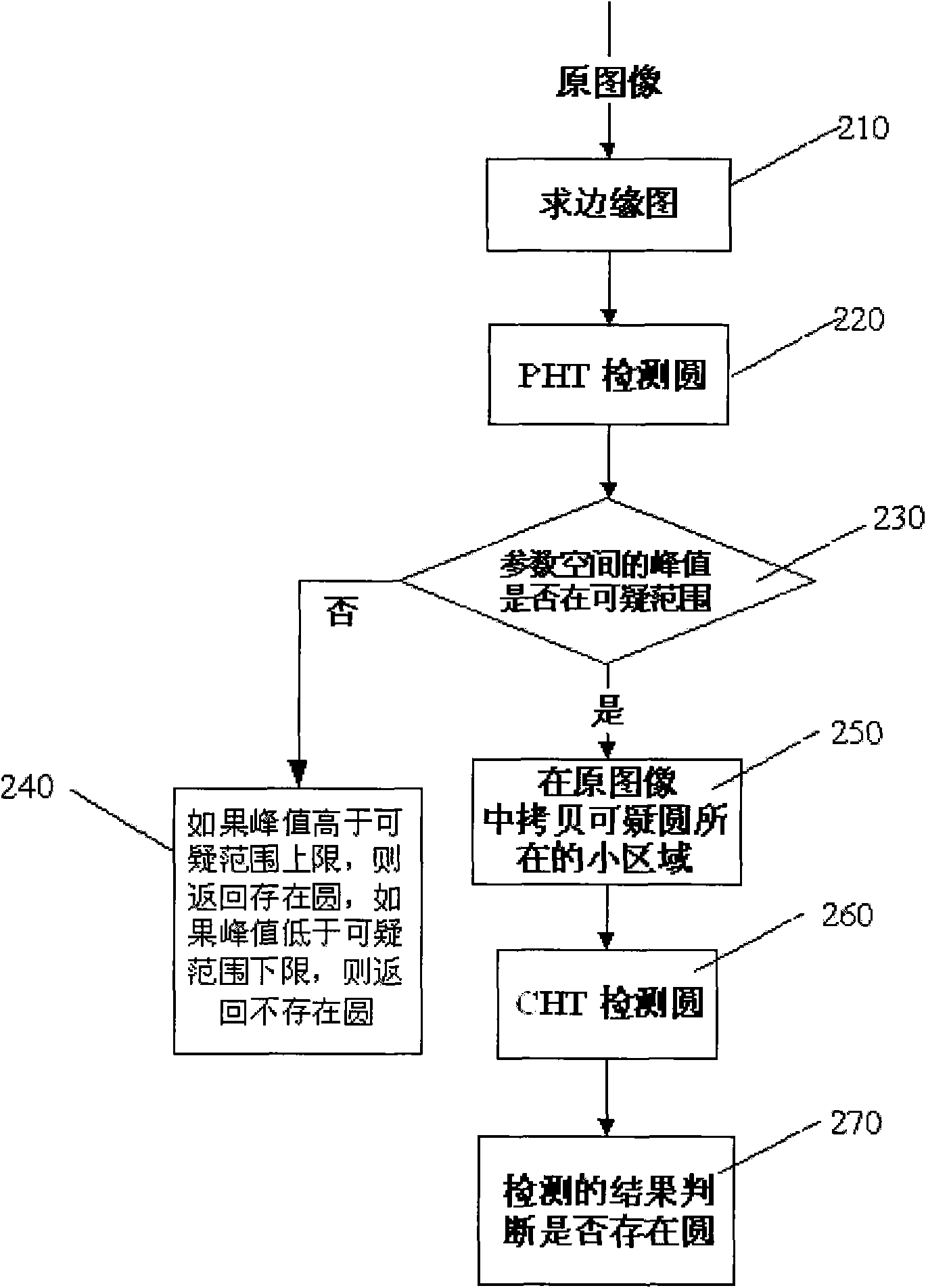

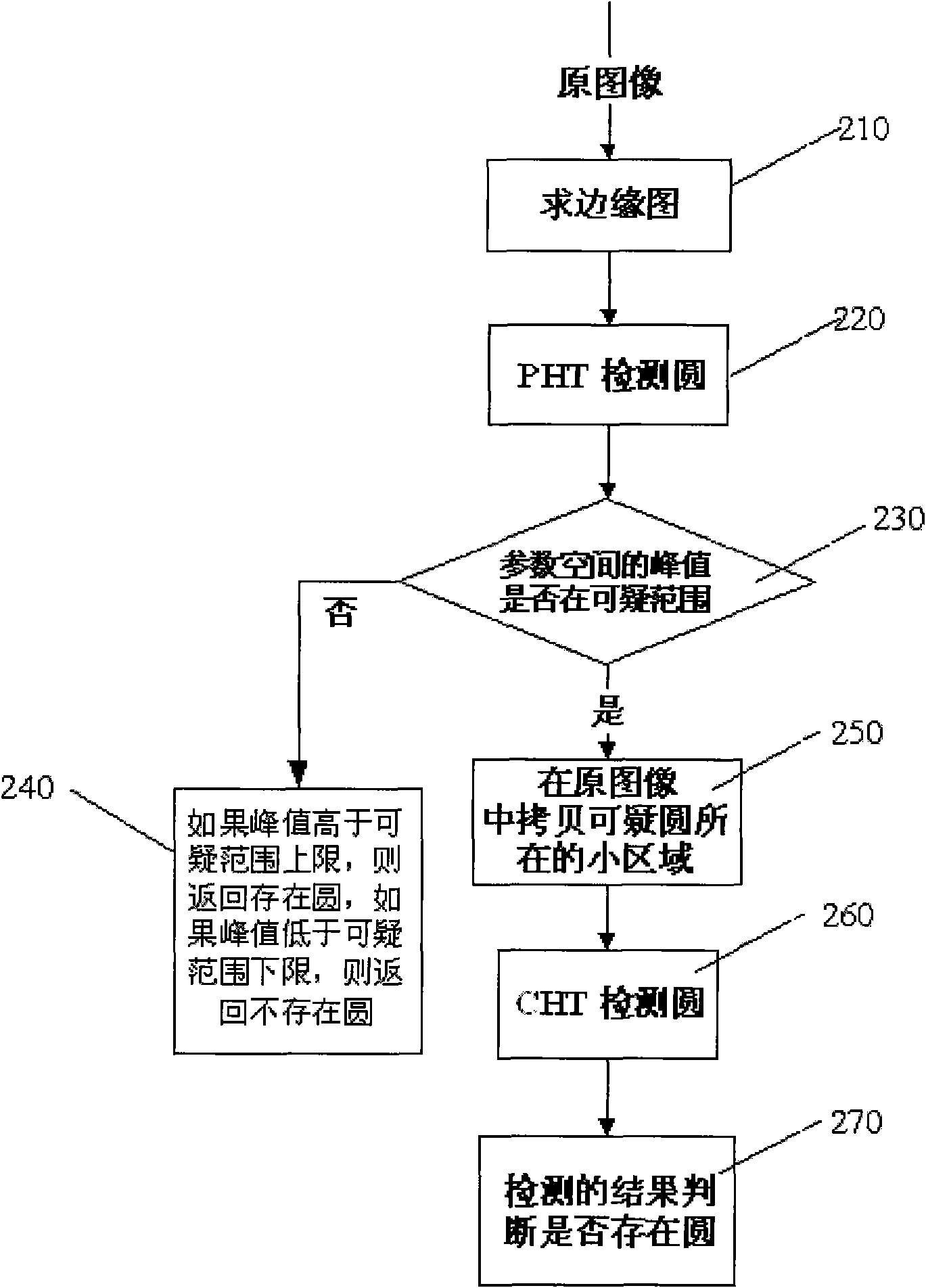

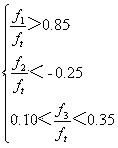

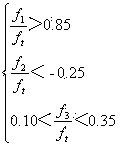

Circle detection method

The invention provides a circle detection method which comprises the following steps that: an edge map of an input image is obtained; a PHT method is used to detect a circle on the edge map; whether the peak in a parameter space obtained by the PHT is within a suspicious area is judged; if the peak is not within the suspicious area and is higher than the upper limit of the area, back to 'circle exists'; if the peak is lower than the lower limit of the suspicious area, back to 'circle does not exist'; if the peak is within the suspicious area, a small area image in which a suspicious circle corresponding to the current peak is in is copied from the original image; in the small area image in which the suspicious circle is located, the CHT method is used to detect the circle; and whether the circle exists if judged according to the detection results. The circle detection method has well guaranteed speed and precision, and is applicable to actual projects.

Owner:HANVON CORP

Small size uncooled dual-field-of-view infrared optical system

ActiveCN104267484ARealize switchingFocusingRadiation pyrometryOptical elementsWide fieldOptical axis

The invention provides a small size uncooled dual-field-of-view infrared optical system which comprises a first positive meniscus lens and a detector. A biconcave lens, a second positive meniscus lens, a negative meniscus lens and a third positive meniscus lens are sequentially arranged from the first positive meniscus lens to the detector along the optical axis; the first positive meniscus lens, the second positive meniscus lens and the third positive meniscus lens each have positive diopter, and the biconcave lens and the negative meniscus lens each have negative diopter. Both the curved surface S3 of the biconcave lens and the curved surface S7 of the negative meniscus lens are aspheric surfaces, and the aspheric surface S7 is further provided with a binary diffraction surface. The lenses of different types are reasonably arranged and the positive diopter and the negative diopter of the lenses are selected, so that the whole dual-field-of-view infrared optical system has a smaller size and a larger zooming ratio, has a larger zooming range under the switching conditions of a narrow field of view and a wide field of view, and is suitable for occasions with small size requirements for infrared optical systems.

Owner:山东神戎电子股份有限公司

Medical linear accelerator and control method thereof

ActiveCN108310681AReduce penumbraAvoid shakingX-ray/gamma-ray/particle-irradiation therapyRotation flapFixed frame

The invention relates to a medical linear accelerator. The medical linear accelerator comprises a fixed frame, a treatment bed and a rotation device, an entrance / exit hole corresponding to the position of the treatment bed is arranged in the fixed frame, the rotation device is composed of first and second rotation frames, the end portion of the first rotation frame is provided with a central holein consistent with the entrance / exit hole, and the axis of the entrance / exit hole and the axis of an assembling bearing of the first rotation frame are coaxial with the rotation axis of the first rotation frame; the second rotation frame is connected with the first connection frame, the rotation axis of the first rotation frame is vertically intersected with the rotation axis of the second rotation frame; and the second rotation frame is provided with a beam generation device and a beam limiting device. According to the medical linear accelerator, the treatment bed does not move during work, abeam can be input to the human body at any angle in the 3D space, and the accelerator has an automatic isocenter verification function and an automatic beam verification function.

Owner:沈阳世联科技有限公司

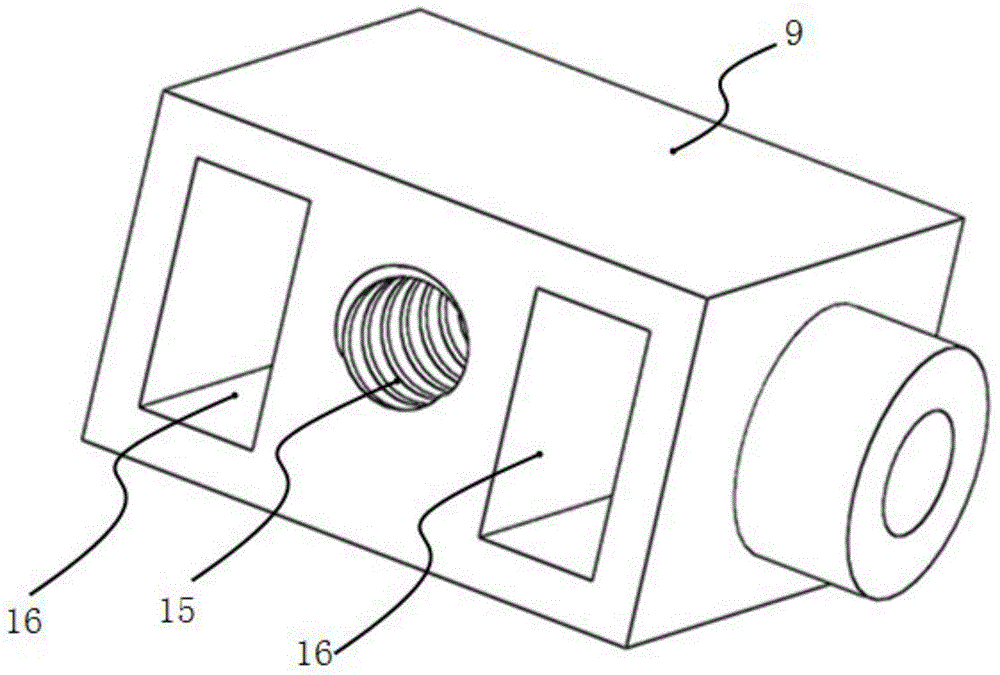

Orthogonal mode adaptor

ActiveCN104617359AAccuracy is easy to guaranteeReduce processing costsWaveguide type devicesCommunications systemMicrowave

The invention discloses an orthogonal mode adaptor. The orthogonal mode adaptor comprises a coupled cavity and a transverse output end. The coupled cavity comprises at least two coupling sections which are communicated from left to right. The coupled cavity is communicated with the transverse output end in the back direction. In all the coupling sections from left to right, the first coupling section is a rectangular body with the axis in the direction from left to right, wherein the difference between the width and the height of the left end face of the first coupling section is smaller than 20%. The upper surfaces of all the coupling sections are flush. Meanwhile, a rectangular longitudinal output end is an external port, and the normal at the center of the external port coincides with the direction of the normal at the center of the cross section of the first coupling section from left to right. The orthogonal mode adaptor has the advantages that the orthogonal mode adaptor can be easily obtained by conducting milling and cutting through a machining center, and the influence of the assembly error of a cover plate and a base on the device performance is small, and the orthogonal mode adaptor can be widely applied to microwaves especially satellite communication systems of millimeter waves and terahertz frequency bands and other communication systems.

Owner:成都赛纳赛德科技有限公司

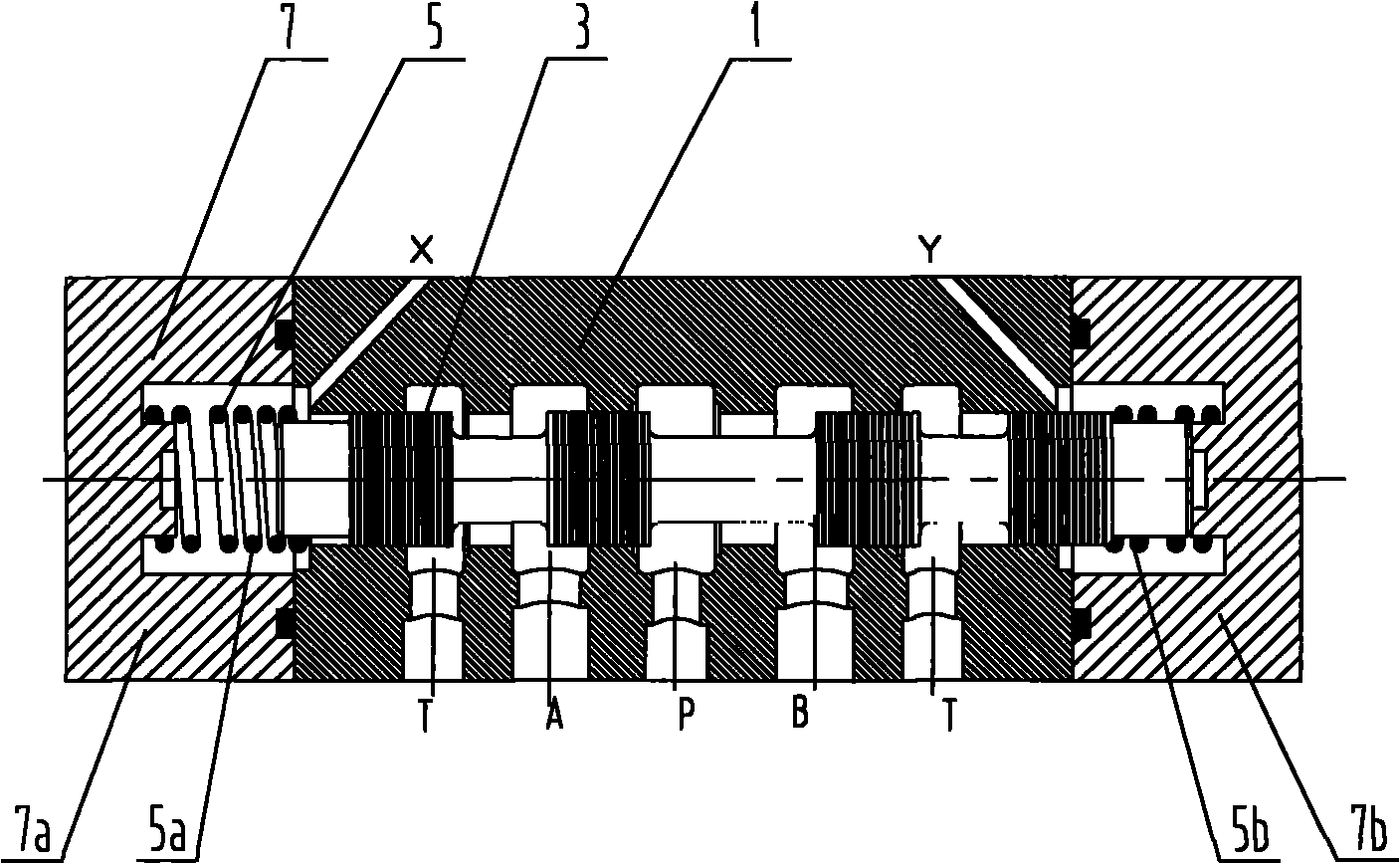

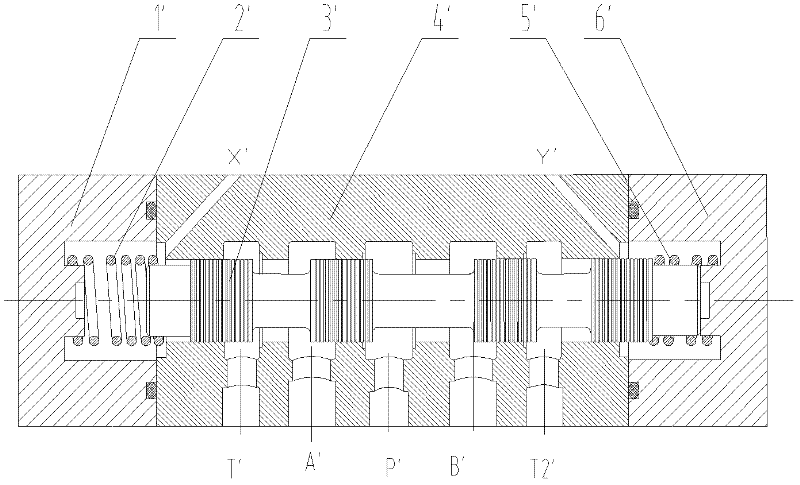

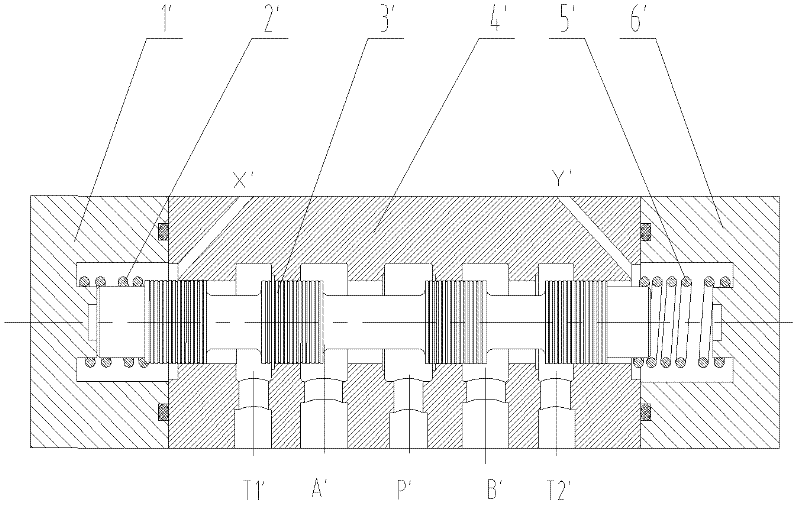

Hydraulic directional valve, hydraulic directional valve group and hydraulic directional valve control method

ActiveCN102297172ALow machining accuracy requirementsEasy to processServomotor componentsMultiple way valvesHigh resistanceEngineering

A hydraulic directional control valve and the control method thereof, a hydraulic control valve set, and a hydraulic control system and engineering machinery comprising the said valve or the valve set. The said hydraulic control valve comprises: a valve body (10); a valve pocket sleeve provided in the cavity of the valve body (10); a valve plug provided in the valve pocketsleeve. The valve pocket sleeve is a split type valve pocketsleeve, comprising at least a first valve pocket sleeve (21) and a second valve pocket sleeve (22). The valve plug is a split type valve plug, comprising at least a first valve plug (31) and a second valve plug (32). The said first valve plug (31) and the second valve plug (32) are in a synchronous working conditionstate. The hydraulic directional control valve is provided with at least three fluid ports, and at least two working positions may be realized. The split type valve pocket sleeve and valve plug impart offer the following benefits to the valve plug: simple valve plug assembly, less likelihood to of valve plug getting stuck, strong high resistance to contamination, good interchangeability of parts, and much longer overall service life.

Owner:SANY AUTOMOBILE MFG CO LTD

Intelligent card hot stamping device

The invention discloses an intelligent card hot stamping device. The intelligent card hot stamping device comprises a frame, as well as a hot stamping strip conveying mechanism, a hot stamping head, a card positioning seat and a hot stamping feeding mechanism which are arranged on the frame, wherein the hot stamping head is arranged below the card positioning seat, and a hot stamping strip in the hot stamping strip conveying mechanism passes through a position between the hot stamping head and the card positioning seat; the hot stamping feeding mechanism is connected to the card positioning seat and positioned below the card positioning seat, the hot stamping feeding mechanism comprises a card positioning seat driving mechanism for driving the card positioning seat to move up and down in a reciprocating manner, and the card positioning seat driving mechanism comprises a motor and a transmission mechanism for connecting the motor and the card positioning seat; the hot stamping strip conveying mechanism comprises a hot stamping strip, a wheel for winding the non-used hot stamping strip, the wheel for winding the used hot stamping strip and the motor, and the motor is connected to the wheel for winding the used hot stamping strip. The hot stamping device disclosed by the invention has the advantages of compact structure, simple transmission structure, high hot stamping precision, good stability in working and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

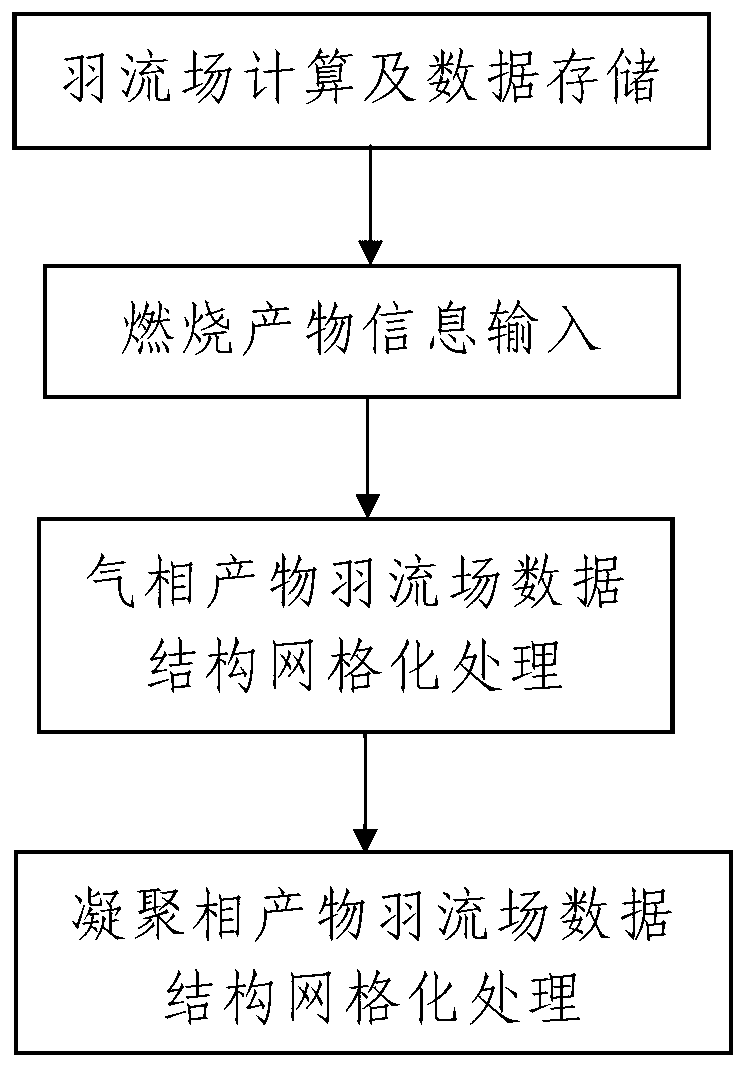

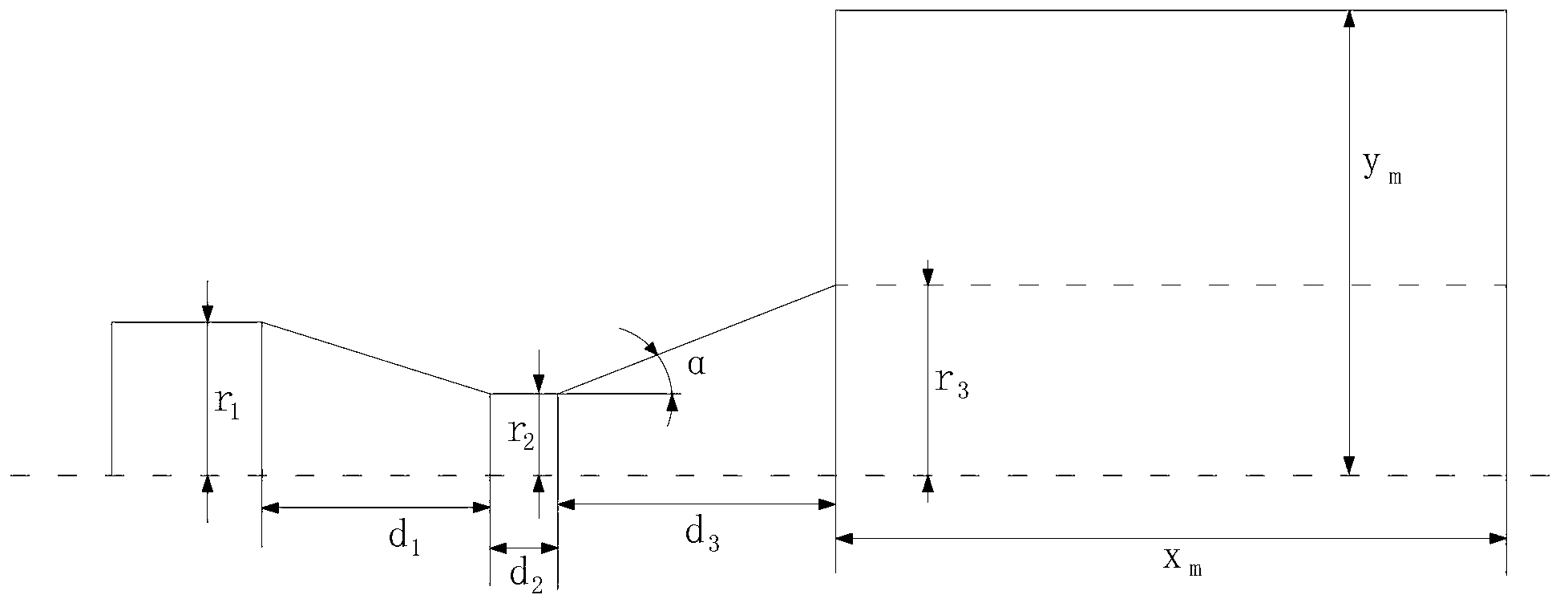

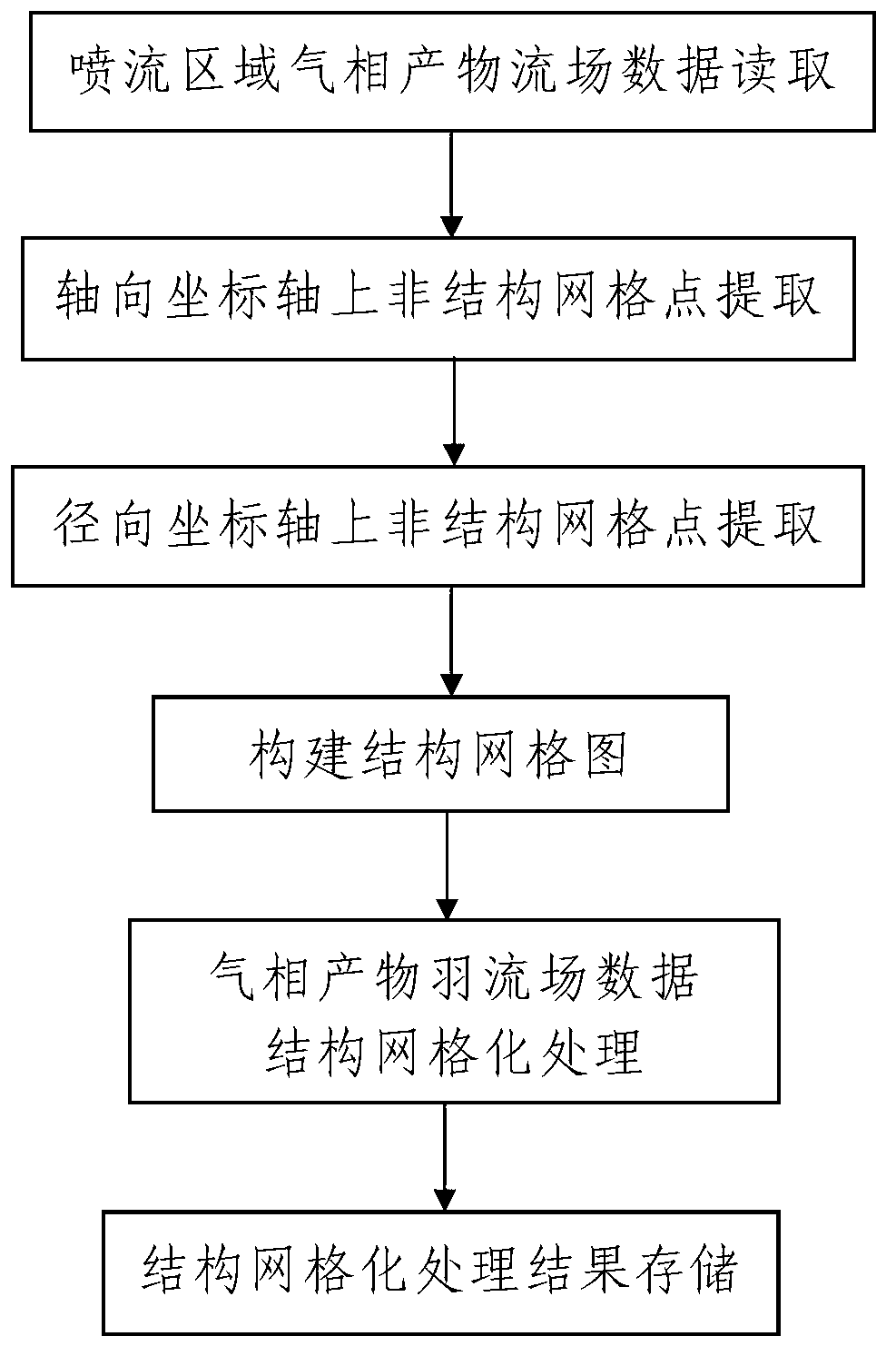

Structure gridding processing method of plume field data for formula design of solid propellant

ActiveCN103218504AThe method steps are simpleReasonable designSpecial data processing applicationsJet flowGas phase

The invention discloses a structure gridding processing method of plume field data for a formula design of solid propellant. The method comprises the steps of: 1, plume field calculation and data storage; 2, combustion product information input; 3, structure gridding processing of gaseous product plume field data, wherein the processing process comprises the following steps of: reading gaseous product plume field data in a jet flow area, building a structure grid chart, and carrying out structure gridding processing of the gaseous product plume field data; and 4, structure gridding processing of condensed product plume field data, wherein the processing process comprises the following steps of: setting initial parameters, reading particle trajectory data, obtaining the quantity of rectangular grids at nozzle inlets of a motor, confirming upper and lower boundaries of the rectangular grids of each nozzle inlet, and carrying out the structure gridding processing of the condensed product plume field data. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization, good using effect and capability of simply, conveniently and rapidly converting an unstructured grid based flow field data into a structured grid based corresponding data for subsequent calculation use.

Owner:XIAN MODERN CHEM RES INST

Three-branched-chain six-freedom-degree robot drive mechanism

InactiveCN104149084ASimple form of exerciseIncrease flexibilityProgramme-controlled manipulatorMachine toolSix degrees of freedom

The invention relates to a three-branched-chain six-freedom-degree robot drive mechanism which is mainly and technically characterized in that three branched chains identical in structure are arranged between a movable platform and a fixed platform, a fixed platform motor is arranged on a fixed platform motor support, and the fixed platform motor, second connection rods, first connection rods and the movable platform are sequentially connected; sliding guide rails are evenly distributed on the fixed platform in the circumferential direction, a guide rail top motor is arranged at the top end of each sliding guide rail, a screw rod is arranged in each sliding guide rail through a bearing, sliding blocks are arranged on the sliding guide rails in a sliding mode, and the middle portions of the sliding blocks are meshed with the screw rods in a spiral mode; connection sleeves are arranged on the outer sides of the sliding blocks and connected with the first connection rods in a sliding mode. The three-branched-chain six-freedom-degree robot drive mechanism is reasonable in design, has the advantages of being simple and reliable in structure, stable in movement of the movable platform, and the like, has good drive performance, robustness and bearing capacity, and can be applied to the fields of detection of machine tools and robots according to different needs.

Owner:HEBEI UNIV OF TECH

Valveless piezoelectric pump

InactiveCN1710282ASmall structure sizeLow costFlexible member pumpsPositive-displacement liquid enginesEngineeringPiezoelectric pump

Owner:BEIJING UNIV OF TECH

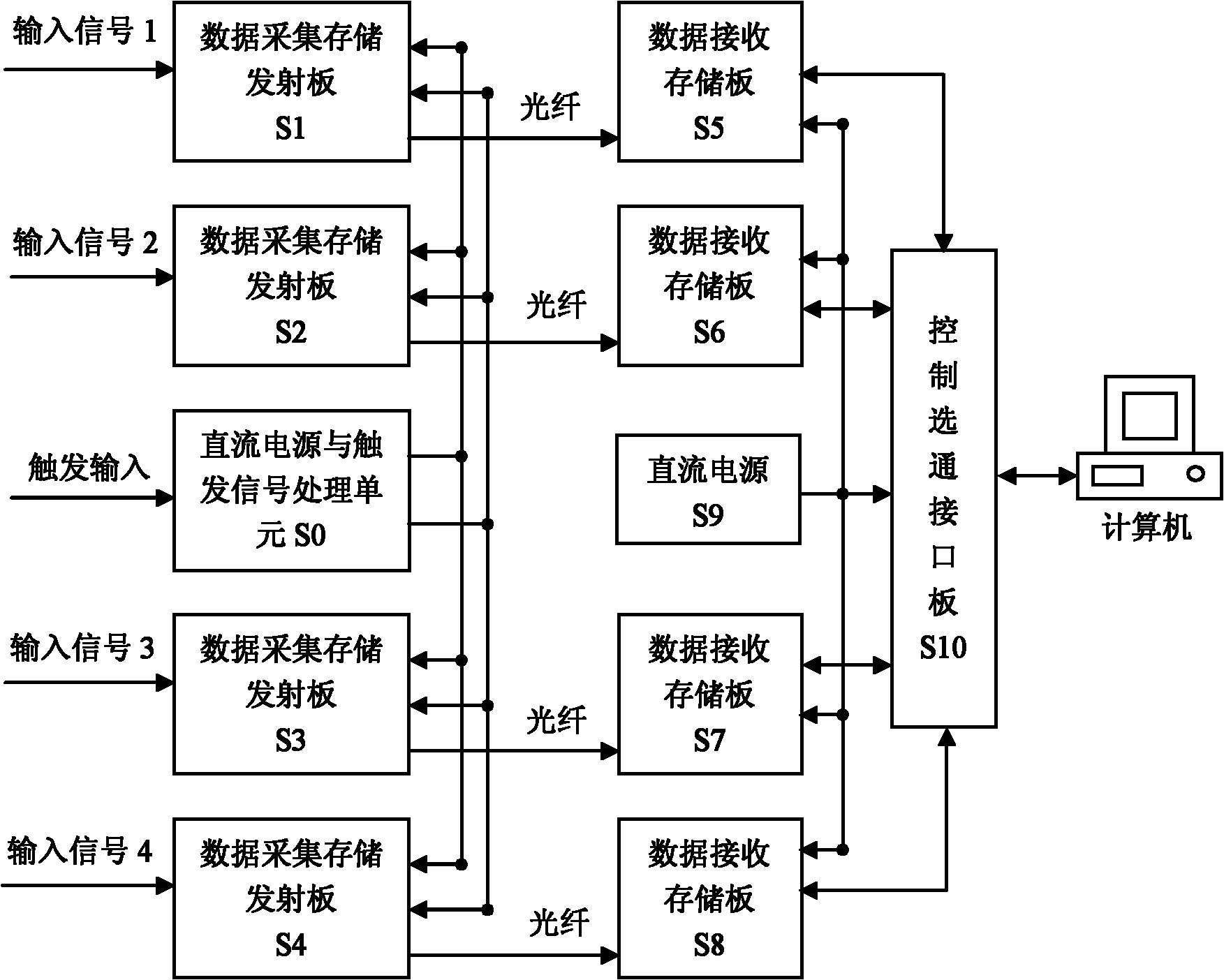

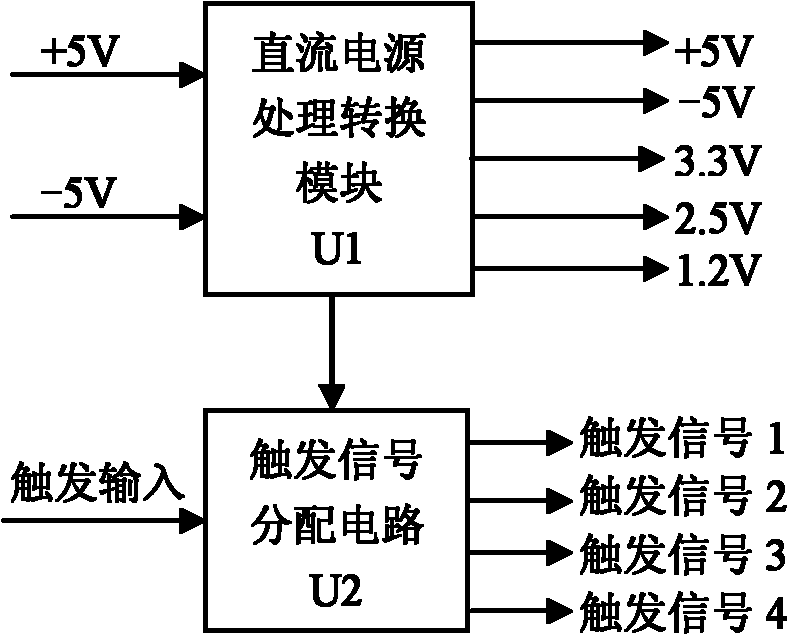

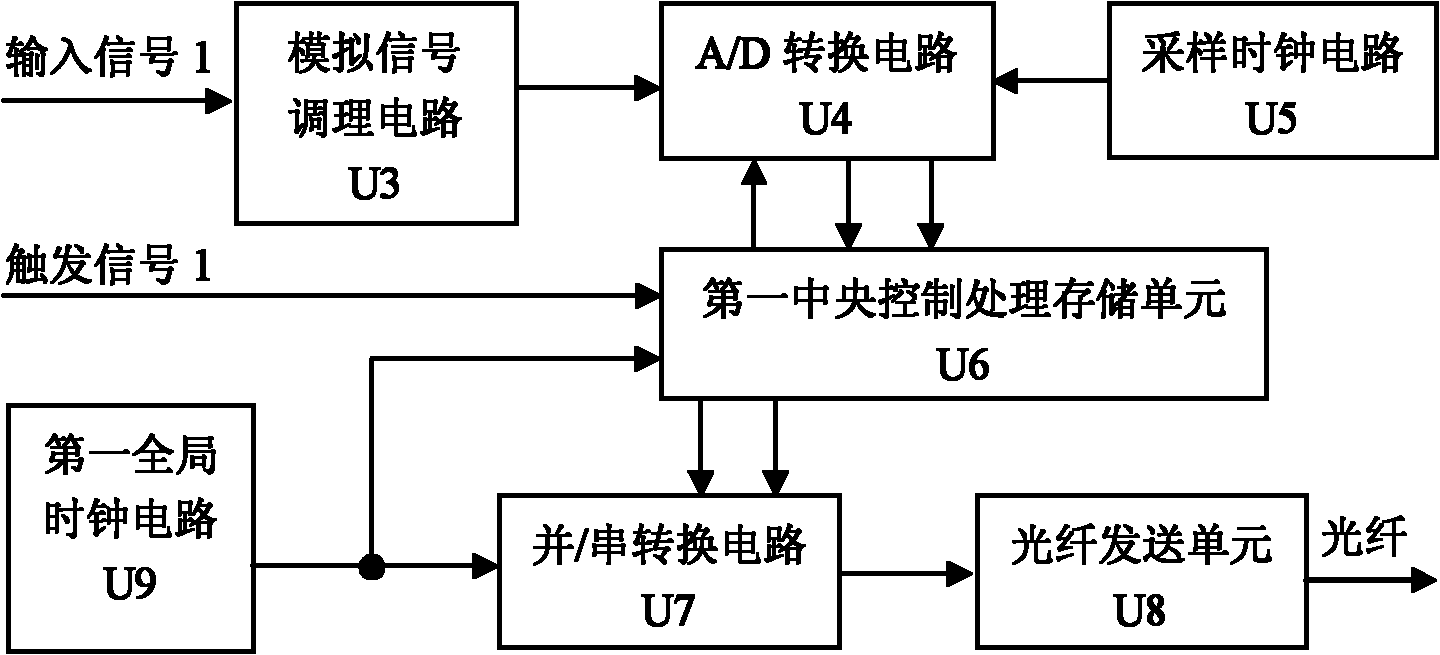

Multipath pulse signal acquisition device for use in radiation detection

ActiveCN102096088AGuaranteed accuracyEnsure reliabilityX/gamma/cosmic radiation measurmentTest inputDistributed circuit

The invention relates to a multipath pulse signal acquisition device for use in radiation detection. A data acquisition, storage and transmission unit comprises a plurality of data acquisition, storage and transmission plates, a plurality of synchronous output signals converted by a trigger signal distributing circuit are used as the trigger input signals of the data acquisition, storage and transmission plates, and the data acquisition, storage and transmission plates are driven by the trigger input signals to process and store each collected and tested input signal and transmit each collected and tested input signal to a data receiving and storing unit; each data receiving and storing plate is used for receiving and storing the tested input signal transmitted by each data acquisition, storage and transmission plate and storing and transmitting the tested input signal to a control gate interface board; and a direct-current power supply supplies power to the data acquisition storage unit and the control gate interface board. The device solves the technical problems of limited application space and insufficient transmission bandwidth of the current quick pulse signal measuring equipment. The device can measure and display multiple signals in real time and guarantee the accuracy and reliability of the data.

Owner:NORTHWEST INST OF NUCLEAR TECH

Optimal initial pressure global optimization method for steam turbine set based on multi-factor

The invention relates to an optimal initial pressure global optimization method for the steam turbine set based on multi-factor, and belongs to the technical field of steam turbine set operation technologies. The method comprises building a quantitative calculation model for steam turbine variable pressure operation consumption differences, obtaining an economic characteristic variation trend in a feasible sliding pressure interval of the steam turbine set under different pitch peak working conditions according to a global variable pressure optimization test, and blending the economic characteristic variation trend with other target parameters of primary frequency modulation characteristics, backpressure characteristics and the like of the set to obtain optimal operation initial pressure of the steam turbine set based on multi-factor to be adapted to power station site actual operation demands and achieve both the power station economy and the power grid safety. The optimal initial pressure global optimization method is applicable to optimal initial pressure global optimization of the steam turbine set.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

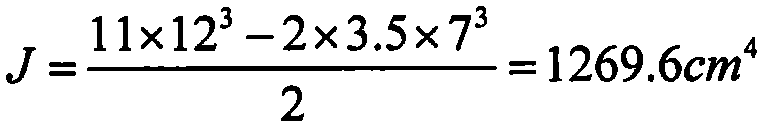

Multi-cutter head for milling main journal of crankshaft and manufacturing process of multi-cutter head

The invention relates to the field of machining and manufacturing of crankshafts and in particular relates to a multi-cutter head for milling a main journal of a crankshaft and a manufacturing process of the multi-cutter head. The multi-cutter head comprises a spindle, cutter head bodies and cutter head seats, wherein multiple identical cutter head bodies provided with multiple blades are fixed on multiple cutter head seats through which cutter teeth of the cutter head bodies are staggered through straight end-face keys and the multiple cutter head seats have certain angle; the multiple cutter head seats are and connected and locked onto the spindle through round keys; a detachable adjusting cushion block is arranged between every two cutter head bodies. According to the multi-cutter head, the cutter head bodies are connected with the cutter head seats, cutter teeth of each cutter head body are staggered, the distance between every two cutter head bodies can be adjusted by the rapidly detached adjusting cushion block arranged between the cutter head bodies, thus the multi-cutter head is convenient and ingenious, rigidity of serially cutter groups and the cutter head bodies are guaranteed from the structure, each cutter head is uniform in stress and small in vibration during milling, interrupted cut is met, the production efficiency is high, the machining efficiency is high, the precision is easily guaranteed, and the multi-cutter head is long in service life.

Owner:XIAOGAN EZHIJIUZHOU MACHINE TOOL

Profile straightening machine

ActiveCN107088594AStable correction processImprove stabilityMetal working apparatusControl systemPosition sensor

The invention discloses a profile straightening machine which comprises a hydraulic system, a control system, a feeding roller way, a pressure straightening mechanism, a rolling straightening mechanism and a discharge roller way; the feeding roller way, the pressure straightening mechanism, the rolling straightening mechanism and the discharge roller way are sequentially arranged back and forth; the rolling straightening mechanism is composed of a rack I, a lathe bed I, a straightening roller, an oil cylinder pressing mechanism, a main transmission mechanism and a displacement measurement mechanism; the oil cylinder pressing mechanism provides a pressing force; an upper roller can carry out up and down displacement along the guide rail surface of the rack I; the opening quantities of the upper roller and a lower roller are regulated to carry out straightening movement on a workpiece in an up and down direction; the pressure straightening mechanism is composed of a lathe bed II, a horizontal oil cylinder, a movable pressure block, a fixed stop dog and a position sensor to carry out bending on the workpiece in a horizontal direction; and the discharge roller way is a liftable roller way. Compared with the traditional workpiece straightening machine, the profile straightening machine is reasonable in structure design, convenient to operate and high in shaping efficiency and shaping accuracy.

Owner:TAIAN HUALU METALFORMING MACHINE TOOL

High-precision high-acceleration low-frequency sinusoidal vibration system

InactiveCN104180820AAvoid many problems with experimentationEasy to testMeasurement devicesVibration amplitudeHigh acceleration

The invention relates to a high-precision high-acceleration low-frequency sinusoidal vibration system which comprises a rotating motor, a crank disc, a crankshaft, a horizontal rolling guide rail, a vertical rolling linear bearing, an upright post, a worktable, a balance weight and a position sensor, wherein a left guide post and a right guide post are arranged on a base; a left linear bearing and a right linear bearing are respectively arranged on the left guide post and the right guide post and can move up and down on the guide posts; two ends of a transverse beam are respectively connected with the left linear bearing and the right linear bearing; the horizontal rolling guide rail is fixedly connected to the transverse beam; a horizontal guide rail slide block can move from left to right on the horizontal rolling guide rail; and the upright post and the worktable are arranged on the transverse beam. According to the mechanical system, high-precision and high-acceleration low-frequency sinusoidal vibration can be realized, the defects of a centrifuge test are overcome, the flexibility of research trial is improved, the problems that a low-frequency section of the conventional vibration table is low in vibration amplitude and vibration frequency precision, the testing requirements of a high-precision inertia type instrument cannot be met and the like are solved, and a high-order error item coefficient of the inertia type instrument is tested.

Owner:HARBIN INST OF TECH

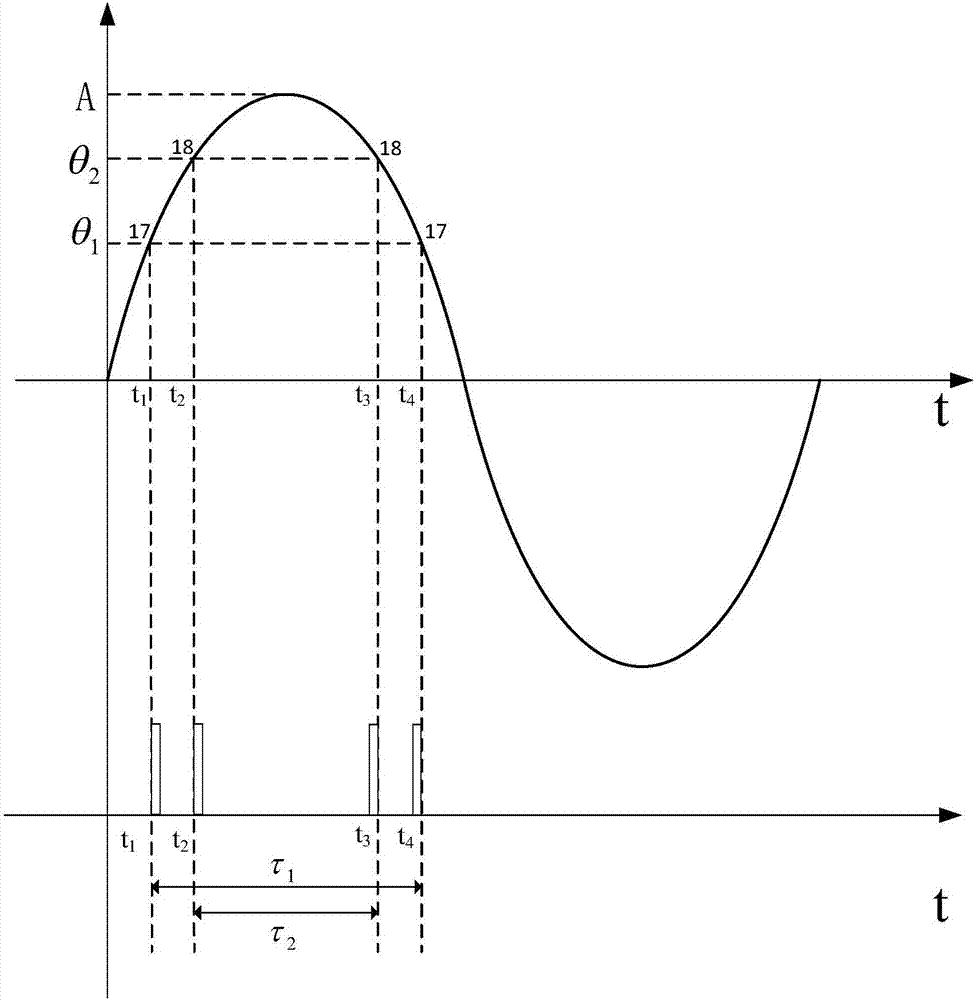

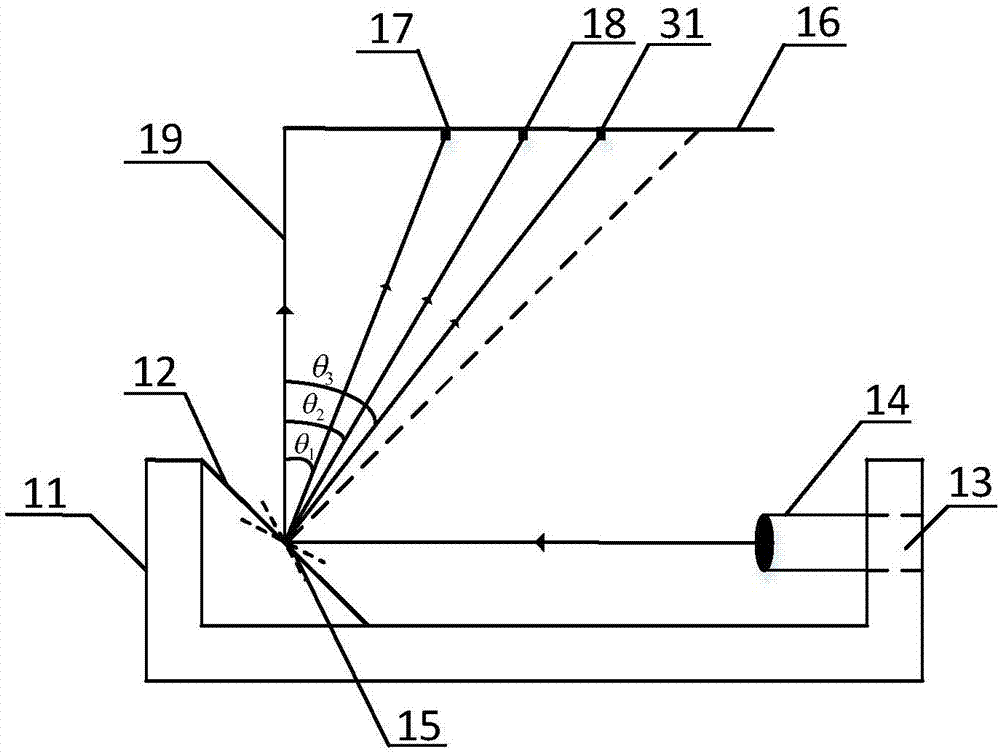

Measurement system ad method of amplitude of resonant type scanning mirror

ActiveCN107402061AHigh measurement accuracyReduce measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration amplitudePhotovoltaic detectors

The invention belongs to the field of micro-opto-electro-mechanical systems and particularly relates to a measurement system ad method of the amplitude of a resonant type scanning mirror. The system comprises a laser, a tool clamp used for fixing the laser and a to-be-measured scanning mirror, a photosensitive fixed scale and at least two photoelectric detectors arranged on the photosensitive fixed scale. Laser rays irradiate into the center of the to-be-measured scanning mirror. Incidence light is reflected by the to-be-measured scanning mirror so that scanning paths are formed. The photoelectric detectors capture electrical signals of respective position of reflection light generation marks. According to the electrical signals obtained in the step 3 and the position relation of the photoelectric detectors, the vibration amplitude of the to-be-measured scanning mirror is obtained. By use of the photoelectric detectors for detection, the measurement quantity of the system is reduced and a problem of low measurement precision when the photoelectric detectors are used for measuring and calculating the amplitude of the to-be-measured scanning mirror is solved.

Owner:XI AN ZHISENSOR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com