Patents

Literature

131results about How to "Strong craftsmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

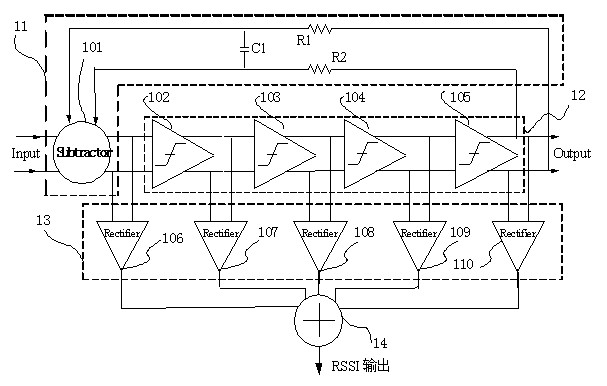

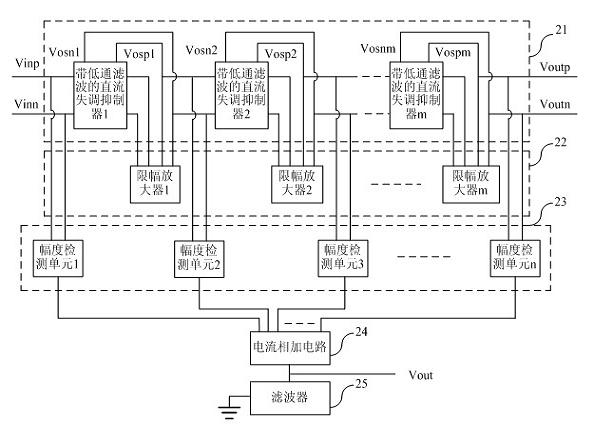

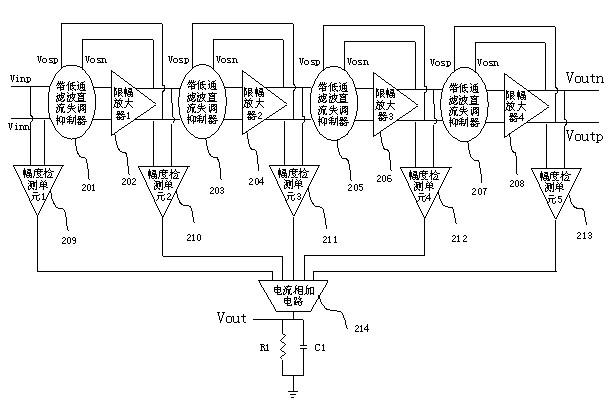

Amplitude detection circuit with direct current offset elimination function

ActiveCN102571227AOvercoming the inability to fully integrate on-chipGet over workReceivers monitoringIntermediate frequencySoftware engineering

The invention discloses an amplitude detection circuit with a direct current offset elimination function. The amplitude detection circuit has a differential structure, and consists of a direct current offset elimination circuit, an amplitude limiting amplification circuit, an amplitude detection circuit, a current addition circuit and a filtering circuit, wherein the direct current offset elimination circuit comprises a plurality of direct current offset suppressors with a low-pass filtering function; the amplitude limiting amplification circuit comprises a plurality of amplitude limiting amplifiers; and the amplitude detection circuit comprises a plurality of amplitude detection units. A differential radio frequency signal is amplified to be saturated by a plurality of stages of cascaded amplitude limiting amplifiers, the output of each stage of amplitude limiting amplifier is detected by the amplitude detection units, output detected amplitude values are transmitted to the current addition circuit for addition, and the sum is filtered by the low-pass filtering circuit to obtain output voltage related to the amplitude of the input signal. The circuit can be adapted to the requirements of high monolithic integration level of a radio frequency chip, and is applied to a high-integration level zero-intermediate frequency receiver with the requirement of signal amplitude detection.

Owner:杭州中科微电子有限公司

Method for producing low-carbon high-sulfur (sulfur-phosphorous) easy-to-cut structural steel continuous casting billet

A continuous casting billet of low-carbon and high-sulphur free-cutting constructional steel production method with the following properties: (1) primary smelting: tapping with degree of oxygen activity of 700ppm, adding right amount Al when tapping of 20% and refinery cinder when tapping of 90%; (2) molten steel refining in LF refined-smelting ladle furnace: (A) deoxidising on top of the slag: agitating and blowing argon from bottom with pressure of 0.5MPa and analyzing sample and adjusting components after energizing for 10 minutes; (B) slag refining: adding 58%CaO,11%Al2O3, 9%SiO2 and 8 %MgO to get degree of oxygen activity of 60ppm; (C) closing argon from bottom when temperature of molten steel is 90 Deg.C more than liquidus line temperature, and feeding sulfur core-spun yarn rapidly. (3) continuous casting: (A) casting rate rationally, such as square continuous casting billet with casting rate of 2m / min; (B) roller pressure of every sedan at the end of conticaster is different from that of 10Bar; (C) setting rational continuous casting technical parameter. Continuous casting billet, which is made by steel of many pattern numbers such as 1213 and 1215, possesses the properties of high stabilization of component, good continuous casting, low cost of manufacture, high quality of casting blank (which meets the rolling request of subsequent heat working) and profound economic benefit.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

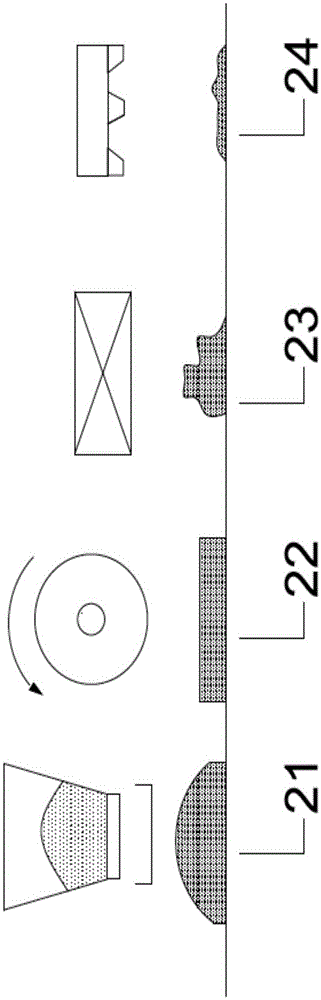

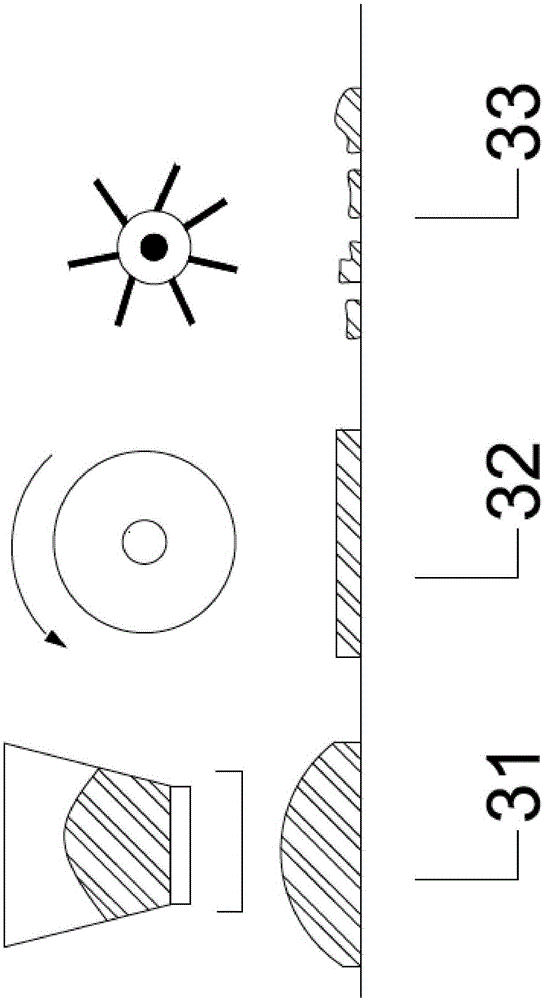

Ceramic polished brick and production method and production line of ceramic polished brick

ActiveCN105328782ASmooth transitionClear and smooth textureCovering/liningsCeramic shaping plantsYarnBrick

The invention discloses a ceramic polished brick and a production method and a production line of the ceramic polished brick. The production line comprises a range-shaped texture forming set, a material block forming set, an atomization spraying system, a third material distributing device, a first roll pressing device, a cutting device, a gorge-shaped texture forming set, a sixth material distributing device, a second roll pressing device, a seventh material distributing device and a press device, all of which are sequentially connected through a belt. According to a preparing method, color attaching pulp is attached to a micro powder stack jointly formed by material blocks formed by a range-shaped texture material belt subjected to the action of a texture manufacturing device and tooth roller crushing, the poking operation and super-through line material filling procedures are carried out on pressed powder through two sets of different mechanical arm combinations, wherein the pressed powder is formed through material supplementing, prepressing and cutting and edge removing. The polished brick obtains the polished brick decoration texture jointly composed of the range-shaped texture, the lava-shaped texture and the gorge-shaped texture. The range-shaped texture is smooth and natural, the edge of the lava-shaped texture has color lines fine like silk yarn, the texture is infinitely close to the difference texture of natural stone, and the stone imitating effect is extremely good.

Owner:GUANGDONG WINTO CERAMICS +3

Technology for producing high-purity high-carbon high-chromium bearing steel

InactiveCN1369568AStrong equipmentStrong craftsmanshipElectric furnaceProcess efficiency improvementThermal energySlag

A process for preparing super-purity high-C high-Cr bearing steel includes smelting in electric furnace, intermittently flowing out oxidative slags while adding lime, inputting oxygen in molten steel, tapping in ladle while adding special slags, alloy, carbonizer and deoxidizing agent, blowing argon gas from bottom of ladle, refining for 40-60 min, vacuum treating for 20-35 min, and casting ingots. Its advantages are ultrahigh purity and low contents of oxygen and Cr.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Method for improving central carbon segregation of tire cord steel

InactiveCN101775461AImprove segregationMeet the requirements of segregationMaterials scienceHot rolled

The invention discloses a method for improving the central carbon segregation in tire cord steel. The method produces 80 grade tire cord steel by adopting technical processes of electric furnace primary melting, refining, bloom concasting, billet rolling and rolled steel wire rolling by the billet, adopts control measures on each process, ensures strong stirring in argon blowing on the steel ladle bottom in a tapping process and a carbureting process after tapping; and the carburetion is controlled to be between 0.4 and 0.6 percent. Strong stirring is turned to be soft stirring after 10 minutes, until refining accepts the steel ladle. Alloying and carburetion are performed in sequence in LF refining, before aim carbon is adjusted, the temperature is ensured to be higher than 1,525 DEG C. In the method, the superheat degree of continuous casting is at 15 to 35 DEG C, full protection casting is adopted, a crystallizer is used for electromagnetic stirring, and the concasting bloom adopts soft press, so that the central carbon segregation of the tire cord steel is greatly improved, the hot-rolled rolled steel wire segregation of a tire cord steel finished product is not higher than 0.5 grade, and the control requirement of a tire cord steel user on the central carbon segregation can be met.

Owner:NANJING IRON & STEEL CO LTD

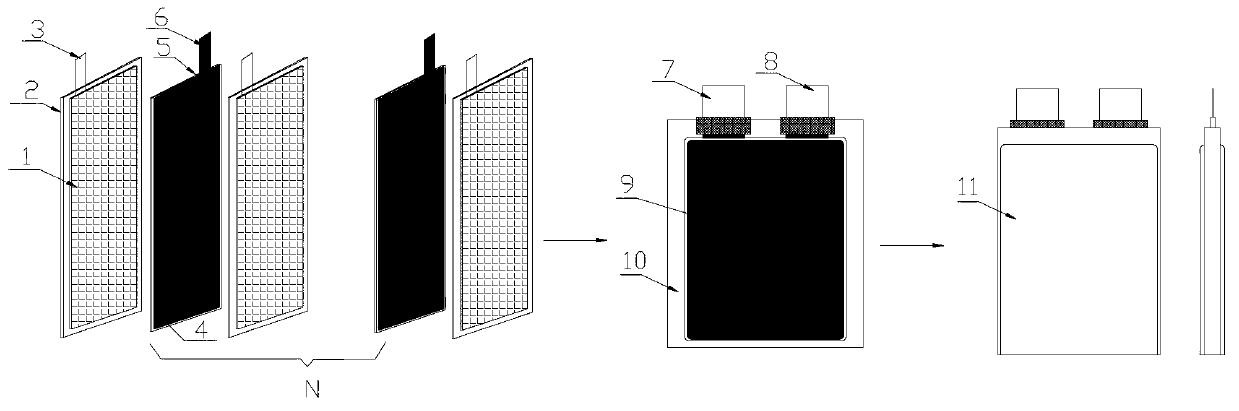

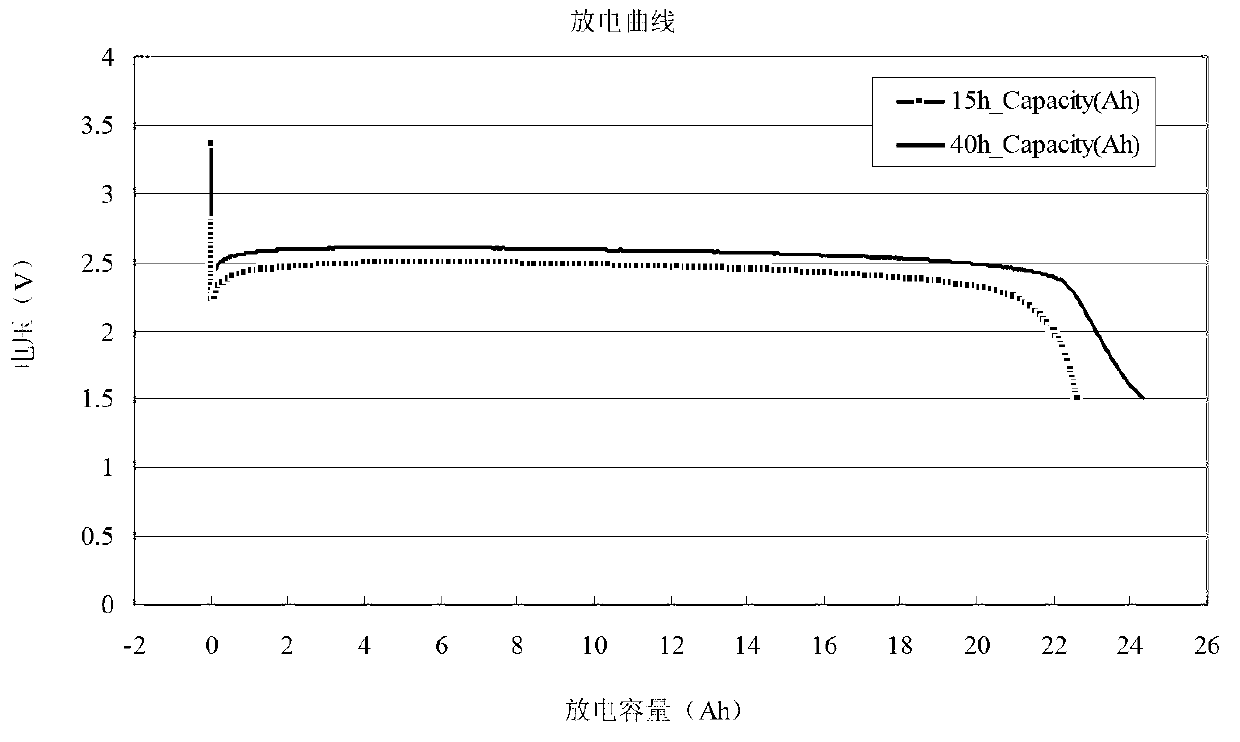

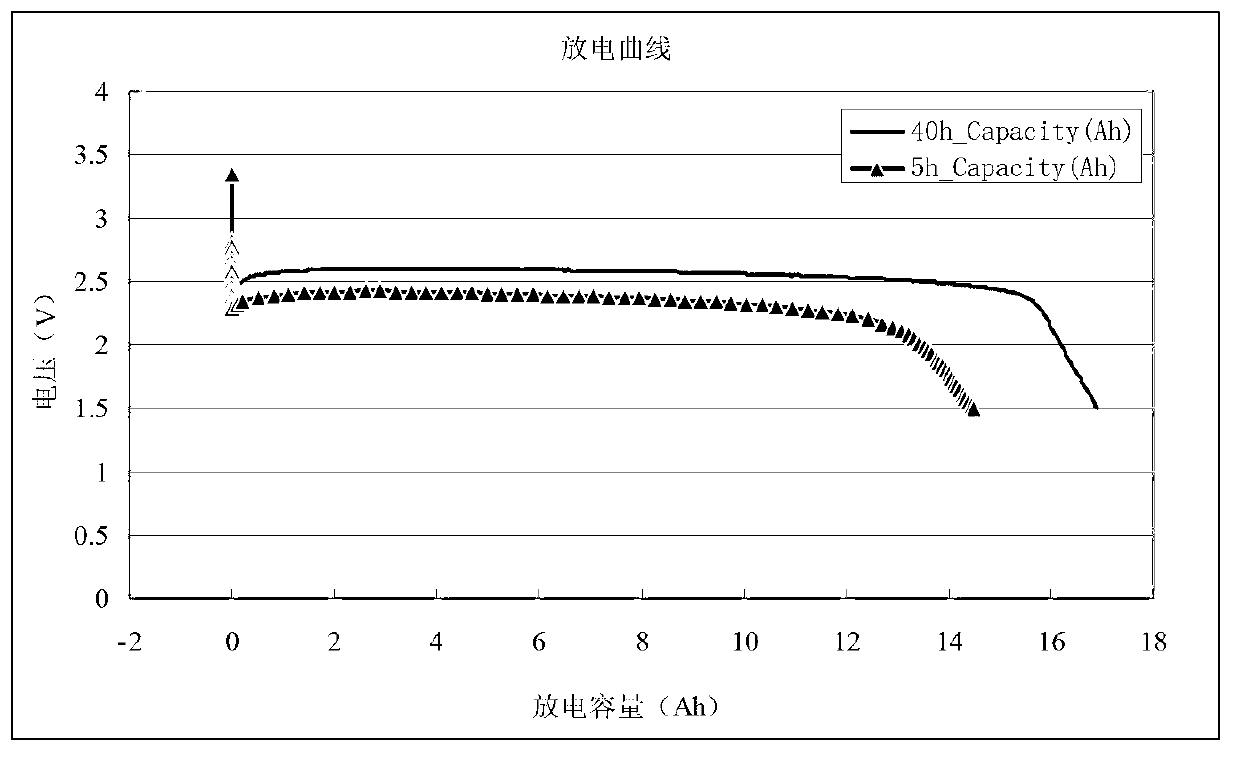

Primary fluorinated carbon lithium battery and preparation method thereof

InactiveCN103000915AImprove electrode conductivityLow viscosityNon-aqueous electrolyte cellsPrimary cell electrodesMetallic lithiumElectrolytic agent

The invention discloses a primary fluorinated carbon lithium battery and a preparation method thereof. The battery comprises a positive electrode, a negative electrode with metallic lithium as active materials, diaphragms, a non-aqueous electrolyte, pole lugs and a case, wherein the positive electrode comprises fluorinated carbon active materials and electric conduction additives, and the non-aqueous electrolyte comprises one component of lithium tetrafluoroborate (LIBF4), propylene carbonate(PC), 1,2dimethoxyethane (DME), gamma-butyrolactone (BL), dimethyl tetrahydrofuran (2Me-THF) and dioxolane (DOL). According to the primary fluorinated carbon lithium battery, the positive electrode is made of fluorinated carbon material with high fluoride content, various electric conduction additives are used for improving electric conductivity of the electrodes, and the electrolyte is low in viscosity, good in liquidity, and large in quantity of solid liquid interfaces, so that conductivity of the solid liquid interfaces and ions can be improved effectively, a liquid injection volume is reduced, electric discharge with different rates from 50h-rate to 5h-rate can be achieved, gravimetric specific energy of the battery achieves 400-610Wh / kg, and volumetric specific energy of the battery achieves 700-950Wh / L. Furthermore, the primary fluorinated carbon lithium battery is strong in processing property, and suitable for large-scale production and application.

Owner:天津蓝天特种电源科技股份公司

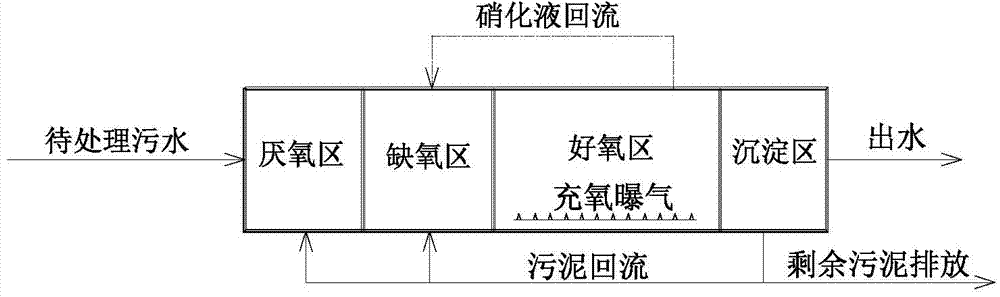

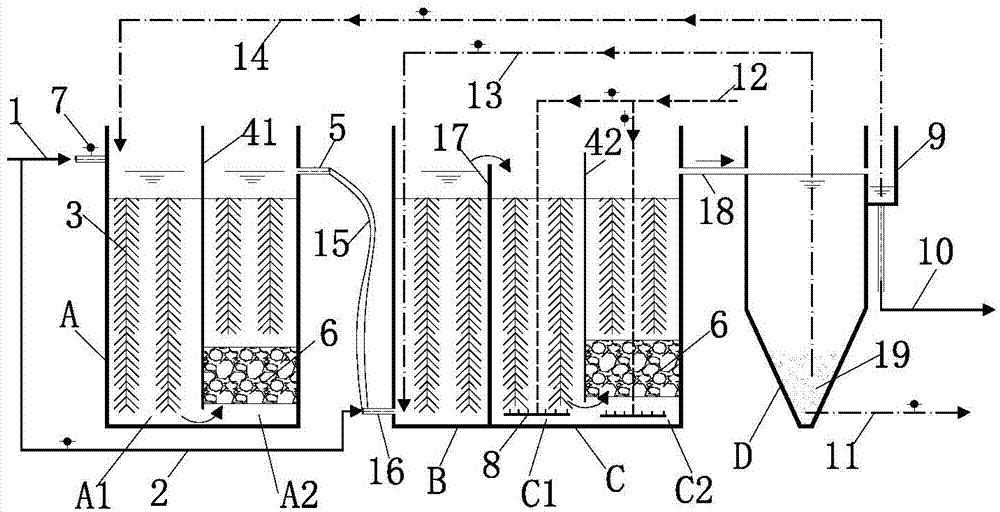

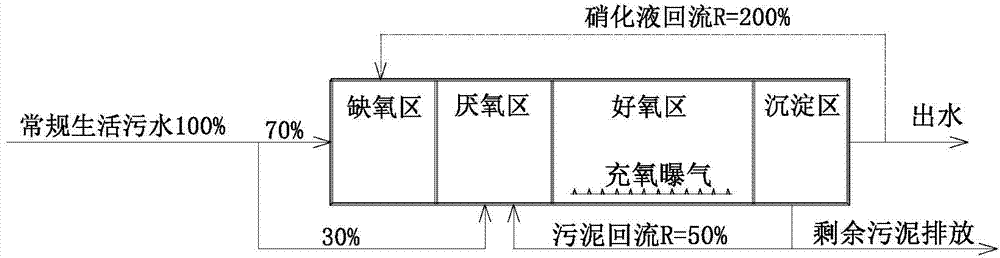

Improved A2/O biological membrane reactor capable of synchronously removing carbon, nitrogen and phosphorus, and operation method thereof

ActiveCN104710006AEfficient removalImprove the contradiction of sludge ageTreatment with aerobic and anaerobic processesWater dischargeSludge

The invention discloses an improved A2 / O biological membrane reactor capable of synchronously removing carbon, nitrogen and phosphorus and an operation method thereof. The reactor comprises an anoxic area, an anaerobic area, an aerobic area and a precipitation area which are communicated with one another in sequence, wherein the raw water is divided into two raw water paths I and II which enter the anoxic area and the anaerobic area respectively; part of water discharged from the upper part of the precipitation area returns to the anoxic area; the sludge at the bottom of the precipitation area returns to the bottom of the anaerobic area; the anoxic area is filled with film formation fillers and spherical suspension fillers; the anaerobic area is filled with the film formation fillers; the aerobic area is filled with the film formation fillers and the spherical suspension fillers; the clear water at the upper part of the precipitation area flows through the reactor and is finally discharged by a water outlet pipe; the sludge at the bottom of the precipitation area is discharged by a sludge discharging pipe. By virtue of the reactor and the operation method thereof, the problems of sludge age contradiction, competition of different strains on substrate carbon source, the mixture of the strains, suppression on the activity of the strains and the like in the conventional A2 / O process can be effectively solved; the organic matters and nitrogen and phosphorus in the sewage can be synchronously and efficiently removed.

Owner:苏州科建环保科技有限公司

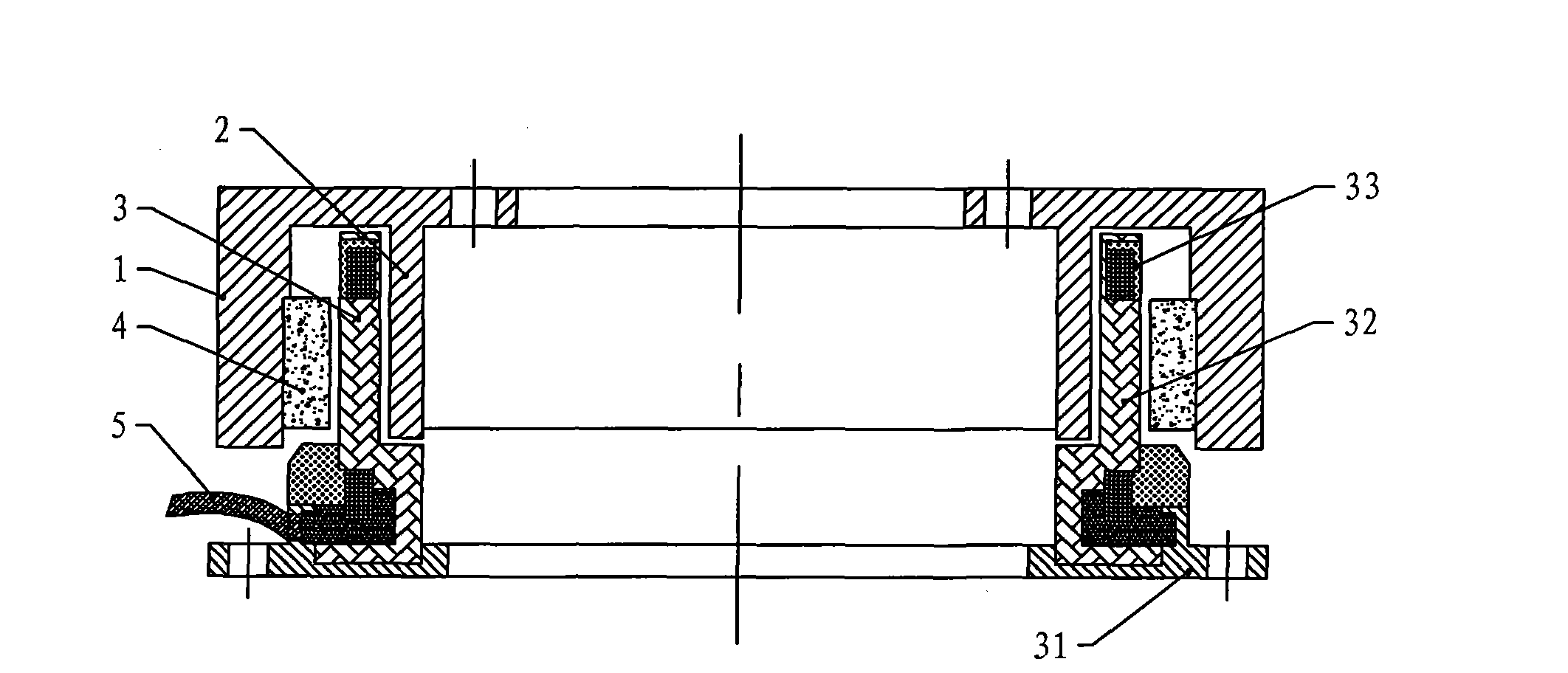

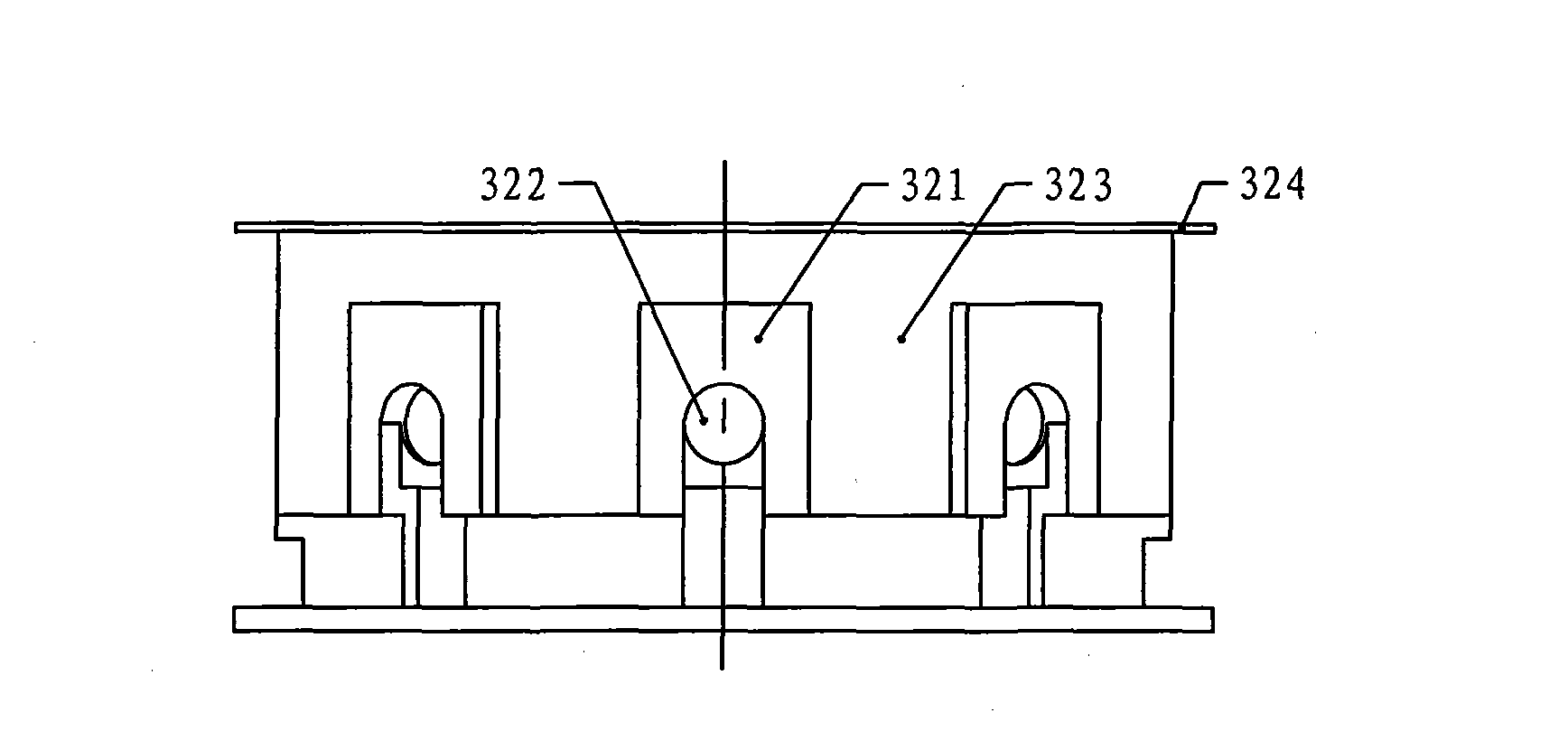

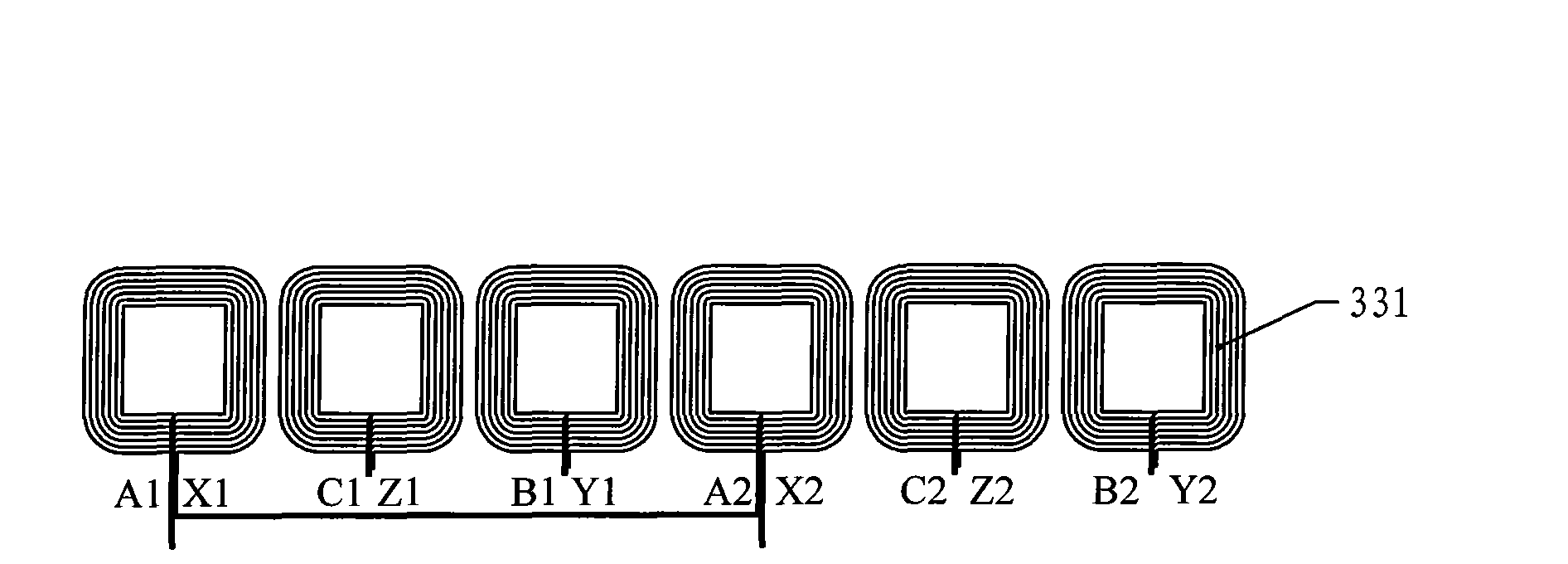

Flywheel motor adopting no-cross one-range winding

InactiveCN101640465AEasy to placeIncrease magnetic inductionMagnetic circuit rotating partsWindings conductor shape/form/constructionEngineeringFlywheel

The invention discloses a flywheel motor adopting a no-cross one-range winding, relating to the technical field of the motor and solving the problems that the existing flywheel motor has complex structure, large power consumption and poor moment stability. A rotor in the invention is a wheel body of a flywheel; an outer rotor iron core and an inner rotor iron core of the rotor are fixedly connected on a torque output shaft; a no-iron core frame type stator is fixed between the inner rotor iron core and the outer rotor iron core; permanent magnets are fixed on the inner rotor iron core or the outer rotor iron core and the side wall corresponding to the no-iron core frame type stator; a winding of the no-iron core frame type stator consists of a plurality of groups of planar coils which areevenly distributed and fixed on the side wall of the frame; two adjacent groups of planar coils have an electric angle of 240 degrees, and have no cross; three position sensors are respectively fixedon the frames at the central positions of three adjacent groups of planar coils; and the ratio of the number Z of the planar coils and the number 2p of poles of the permanent magnets is 3 / 4. The flywheel motor is applicable to the technical fields of posture control of the satellites and control moment gyros and the like.

Owner:HARBIN INST OF TECH

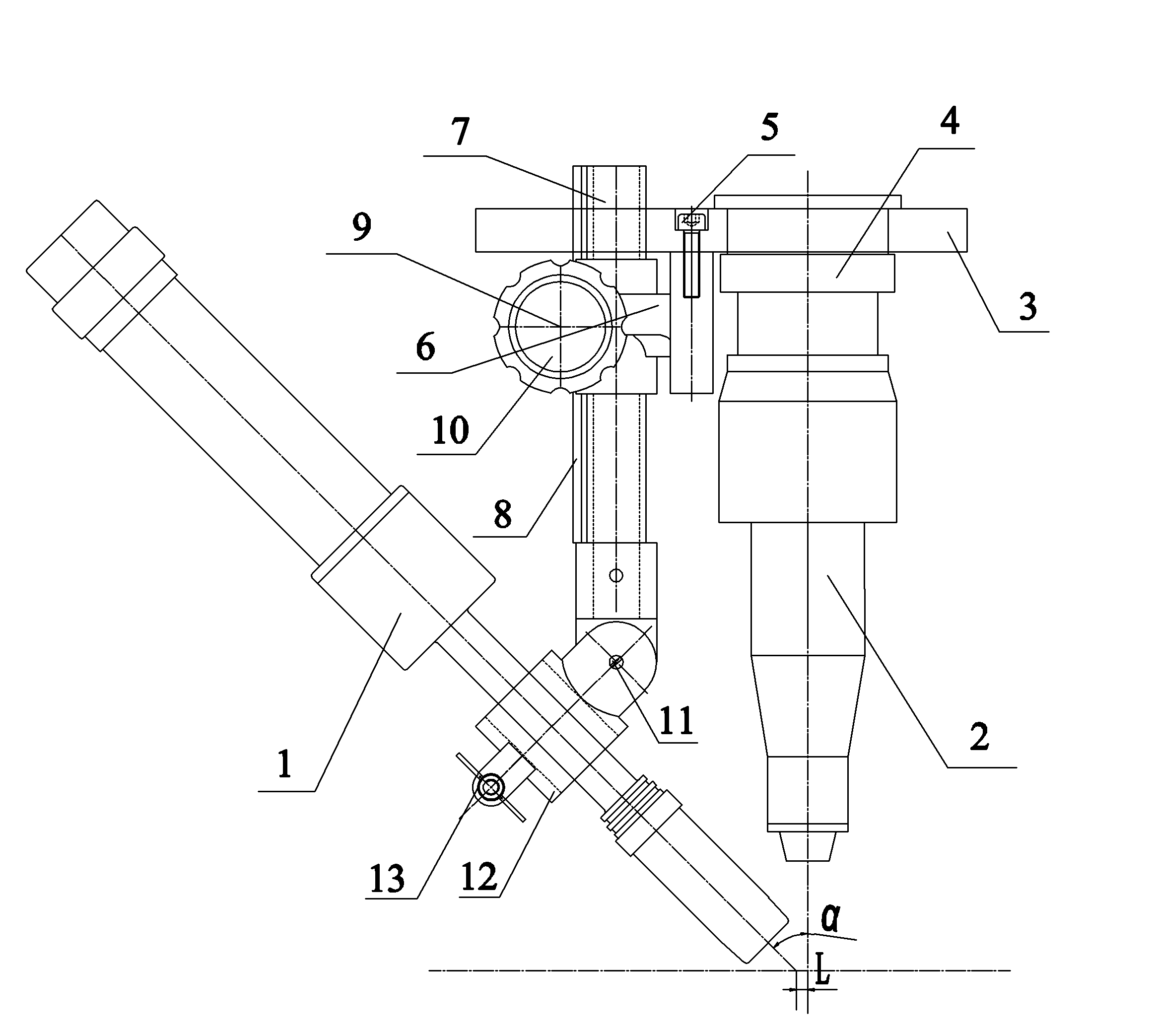

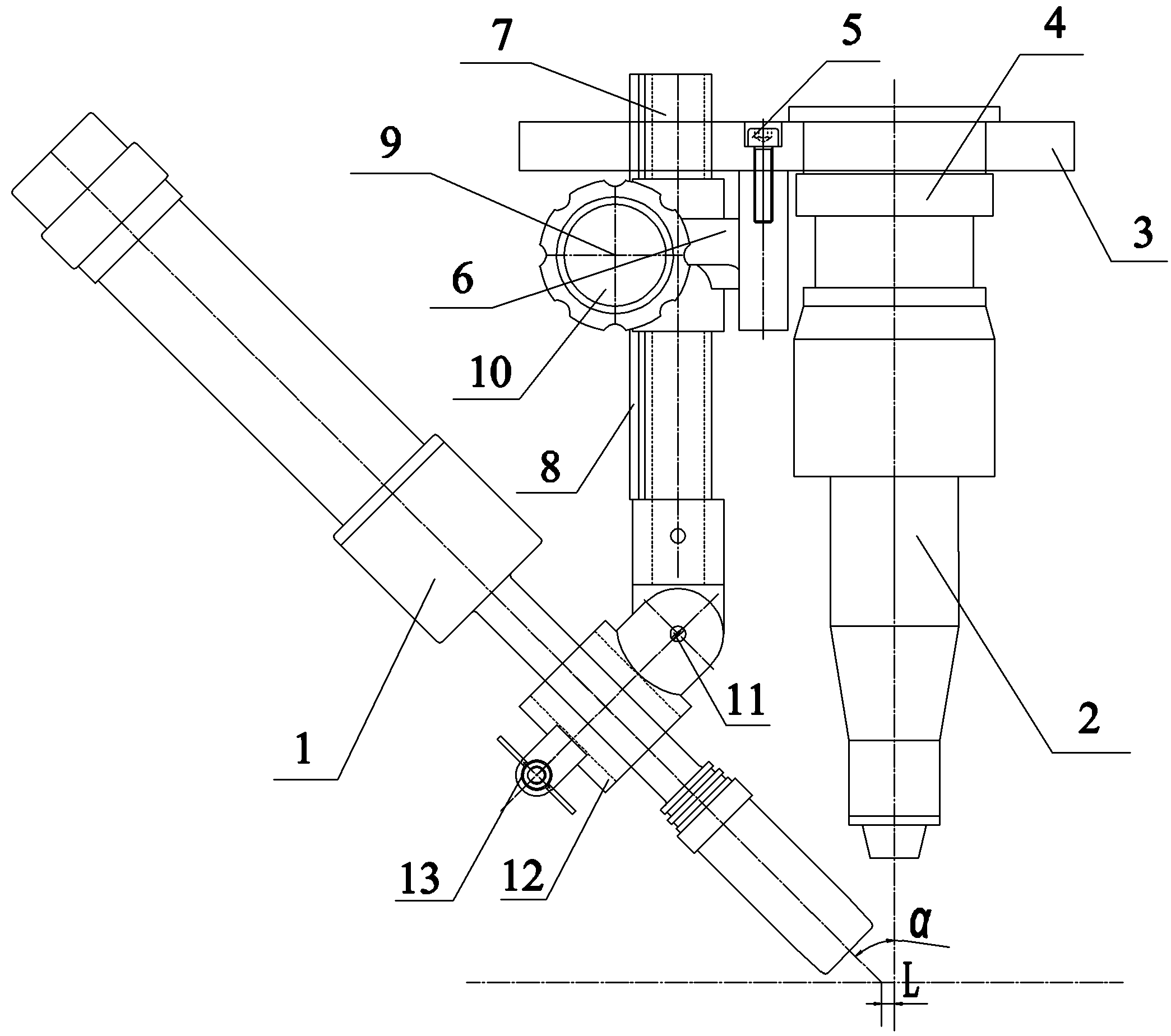

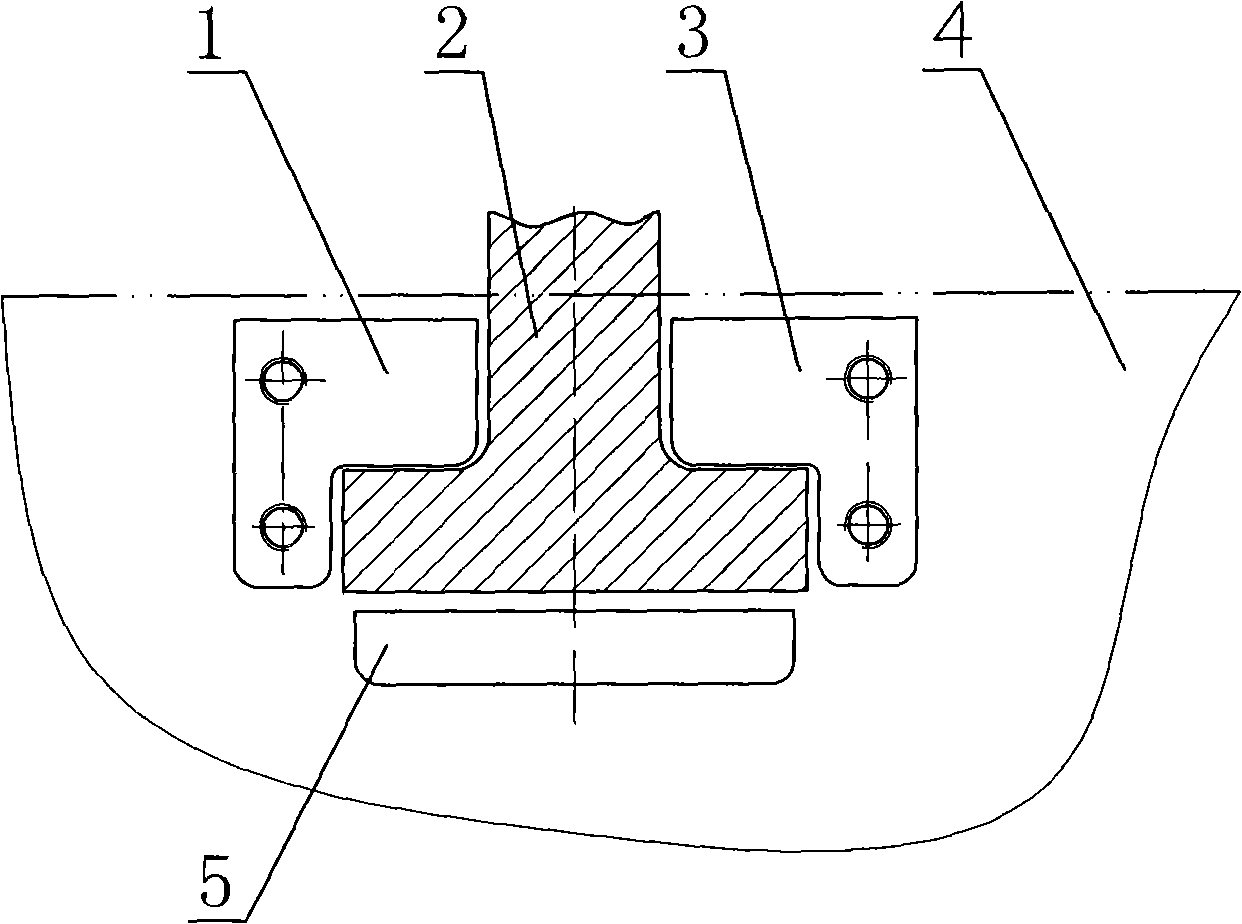

Laser combined welding head regulating mechanism

InactiveCN102380730AReasonable structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesYttriumPlasma arc welding

The invention relates to a laser combined welding head regulating mechanism, which comprises a welding gun, a laser head, an aluminum alloy plate, a spiral sleeve, a sleeve holder, a guide post, a rack, a gear, a knob and a clamping sleeve, wherein the spiral sleeve is sleeved in a hole in the aluminum alloy plate; the laser head is arranged on the spiral sleeve; the sleeve holder is fixed on the aluminum alloy plate through a screw; the guide post and the rack are arranged in a sleeve on the sleeve holder; the gear is embedded on the knob; the clamping sleeve is connected with the guide post through a first butterfly nut; and the welding gun is arranged on the clamping sleeve and is fixed by a second butterfly nut. In the invention, the structure of the mechanism is reasonable, the manufacturing of the mechanism is convenient and the manufacturability of the mechanism is high; the position relationship of the laser head and the welding gun can be regulated flexibly according to different requirements of a welding process, so as to regulate a light-thread distance and the angle of the welding gun; and the welding gun may be a tungsten electrode argon arc welding gun, a consumable arc welding gun or a plasma arc welding gun; the laser head may be a yttrium aluminum garnet (YAG) laser or an optical fiber laser welding head; and the application range of the combined welding head regulating mechanism can be enlarged.

Owner:WUXI HANSHEN ELECTRIC

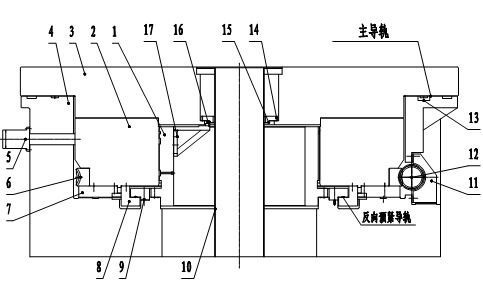

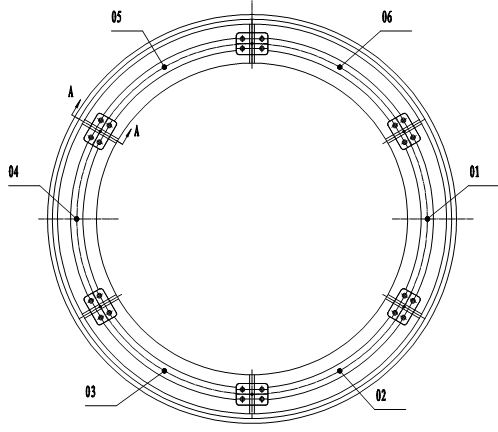

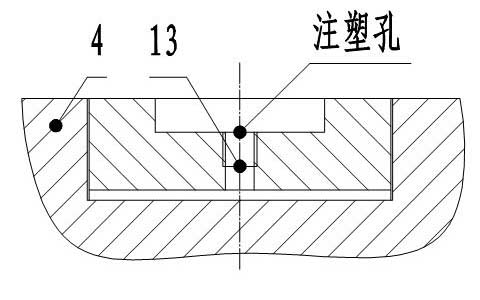

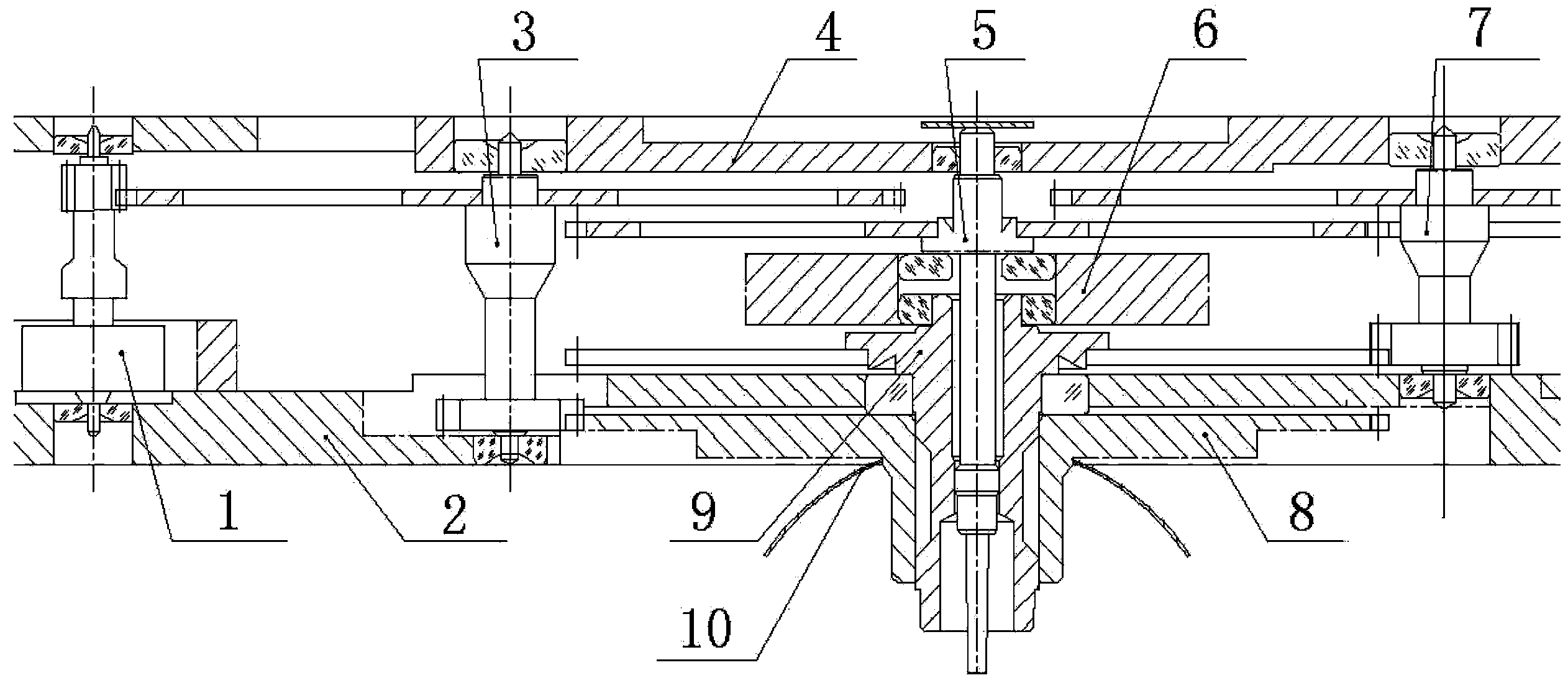

Large and heavy numerical control static-pressure revolving platform

ActiveCN102059558AAccuracy is easy to guaranteeStrong craftsmanshipLarge fixed membersManufacturing cost reductionNumerical control

The invention discloses a large and heavy numerical control static-pressure revolving platform. In the invention, a constant-current static-pressure closed guide rail is used for axial unloading and positioning; a constant-current opposed oil cavity is used for radial positioning; a radial damping oil cylinder is used for locking and applying Coulomb frictional damping; a double-lead worm gear isused for precision scale division; a closed loop control system consists of round gratings; and the revolving platform has high scale division accuracy, repeated location accuracy, heavy load and high rigidity and can realize accurate location at any angles and bear heavy cutting load. The large and heavy numerical control static-pressure revolving platform disclosed in the invention mainly comprises six parts of a supporting part, a scale division rotating part, a closed guide rail part, a worm part, a round grating full closed loop part and a radial locking part. The processing and assembling process of the large and heavy numerical control static-pressure revolving platform can improve the accuracy and the production efficiency of the static-pressure revolving platform, reduce the manufacturing cost and meet the requirement of the industrialization of large high-grate numerical control machine tools in China for large and heavy numerical control static-pressure revolving platforms.

Owner:NANJING GONGDA CNC TECH

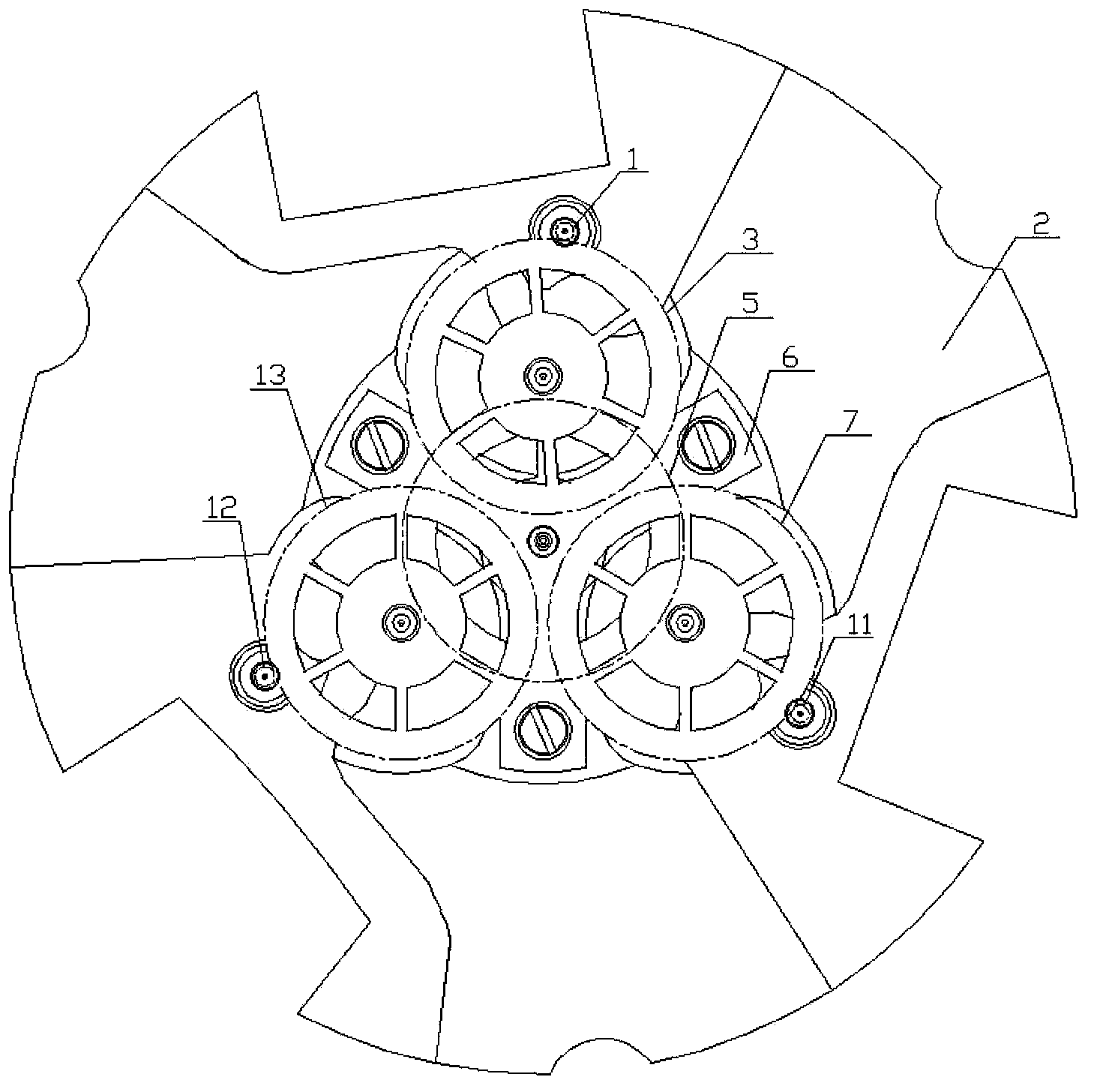

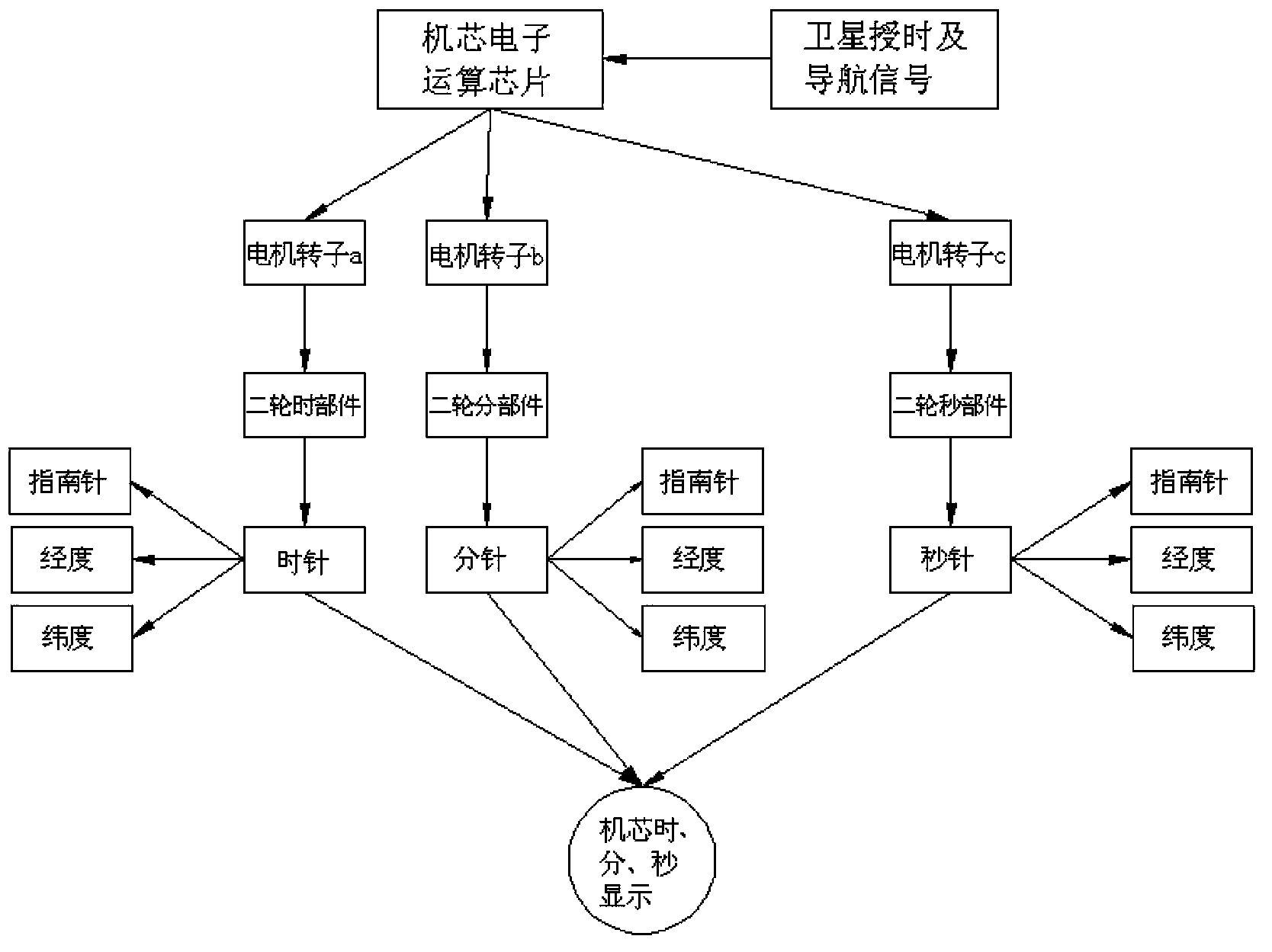

Watch indicating mechanism driven by motors

InactiveCN104142617AReduce thicknessSchool time is fastVisual indicationRadio-controlled time-piecesSatelliteEngineering

The invention discloses a watch indicating mechanism driven by motors. The watch indicating mechanism comprises a minute gear component, a second gear component, a two-gear hour component, a two-gear minute component, a two-gear second component, an hour gear motor rotor, a minute motor rotor and a second gear motor rotor, wherein the minute gear component is installed on a jewel bearing in a center hole of a main clamp plate component, the second gear component penetrates through a center hole of a middle clamp plate component and a center hole of the minute gear component and is arranged on a jewel bearing on the middle clamp plate component, and the two-gear hour component, the two-gear minute component, the two-gear second component, the hour gear motor rotor, the minute motor rotor and the second gear motor rotor are installed on the main clamp plate component through jewel bearings. An hour gear is installed in the minute gear component, and an hour gear spring abuts against the hour wheel. The watch indicating mechanism has the advantages that an hour hand, a minute hand and a second hand are driven by the respective independent motors, all the components are independent of one another and do not interfere with one another, and therefore the timing speed is high; the motors are evenly distributed in a movement and therefore more stable in the process of transmitting moment out; in addition, a central gear component and the minute gear component are integrated, a gear spanning component is omitted, the thickness of the movement is reduced, the structure is simple, and the manufacturability is high; particularly, an electronic calculation chip is additionally installed in a watch, and therefore satellite time service and navigation signals can be received at any time.

Owner:TIANJIN SEAGULL WATCH CO LTD

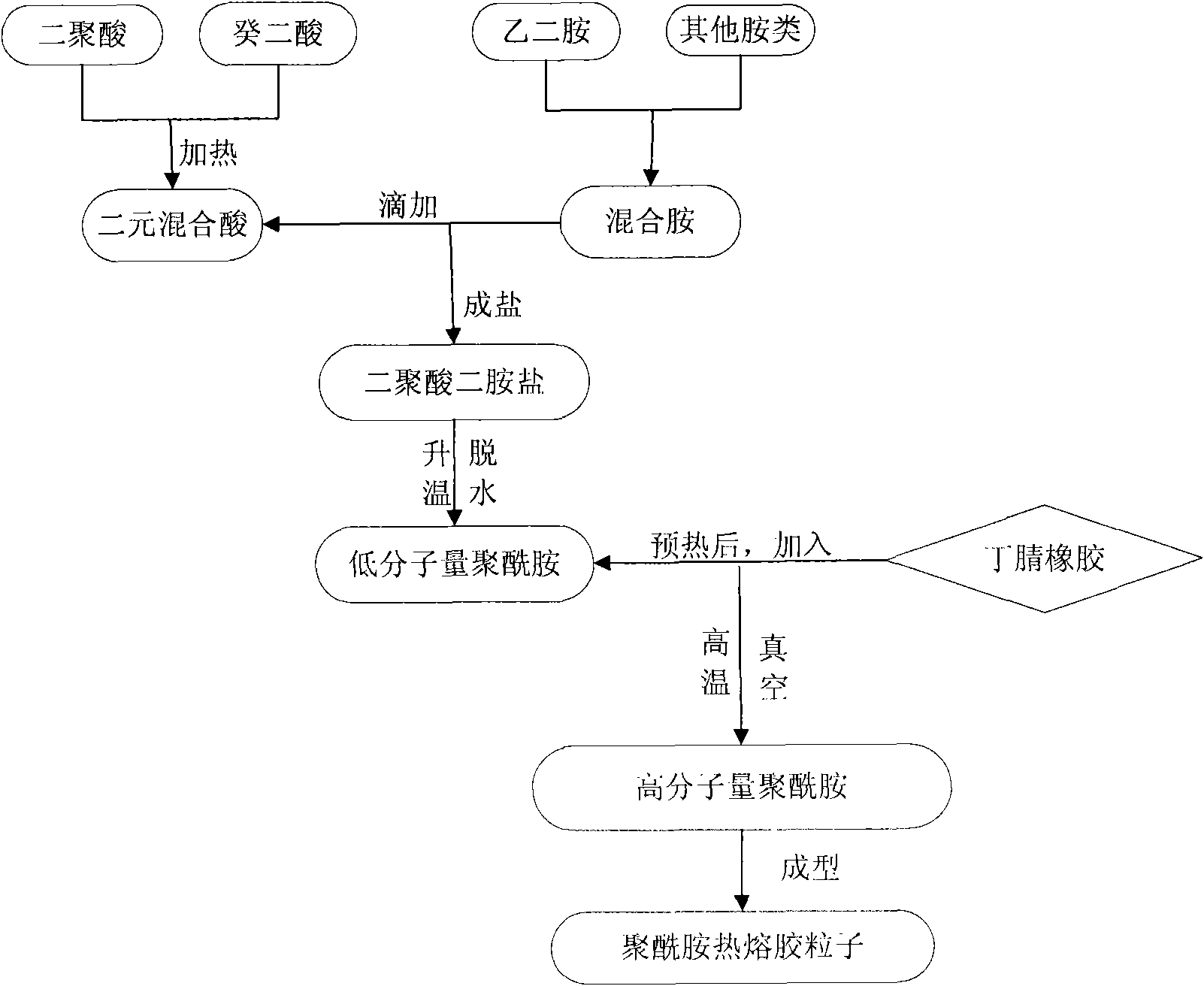

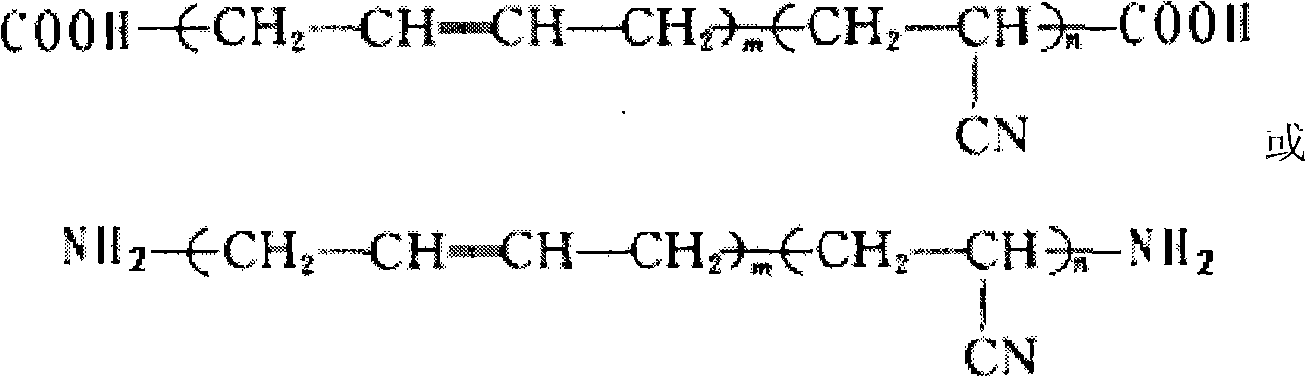

Low temperature resistant daiamid hot melt adhesive with high air tightness and application thereof

ActiveCN101633829AImprove sealingImprove low temperature resistanceAdhesivesPolymer sciencePolyamide

The invention relates to low temperature resistant daiamid hot melt adhesive with high air tightness and application thereof. The daiamid hot melt adhesive comprises a dimer unsaturated fatty acid polymerization unit, a C2-C12 aliphatic diamine polymerization unit, and 1 to 30 molar percent of chemigum polymerization unit by taking total molar number of the dimer unsaturated fatty acid polymerization unit or the aliphatic diamine polymerization unit as reference. Compared with the conventional daiamid hot melt adhesive, the air tightness of the daiamid hot melt adhesive is obviously improved.

Owner:SHANGHAI LIGHT IND RES INST +1

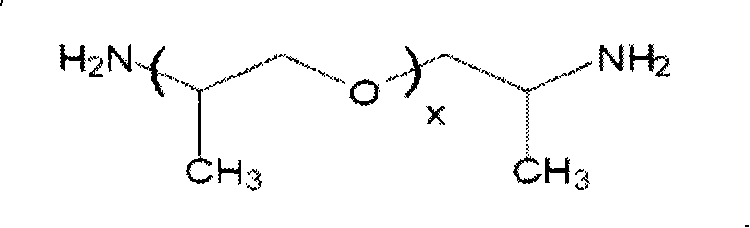

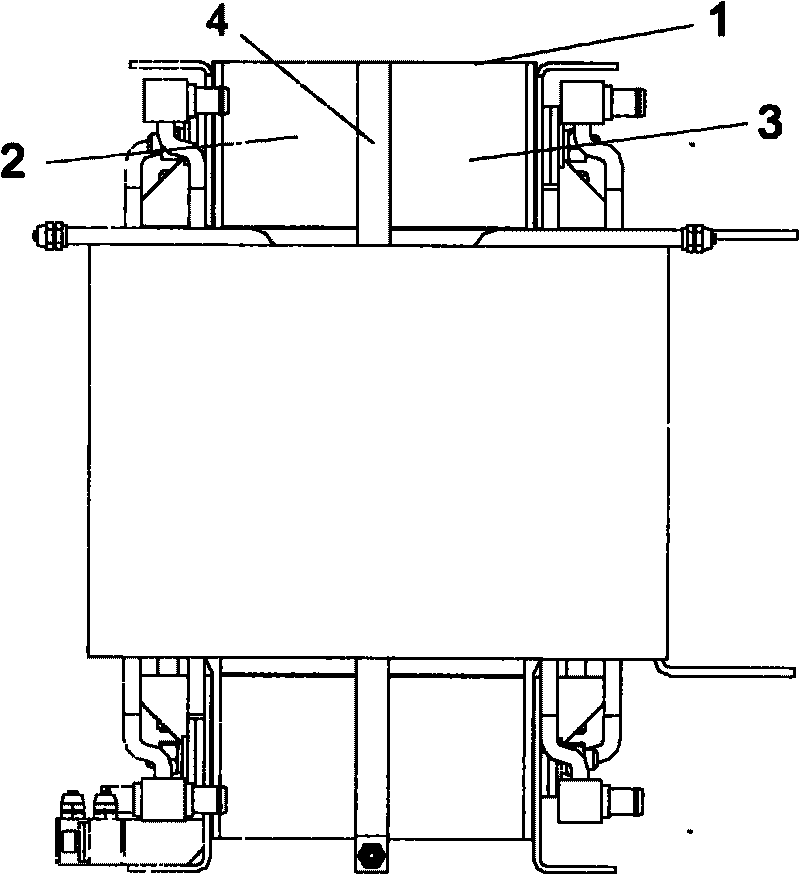

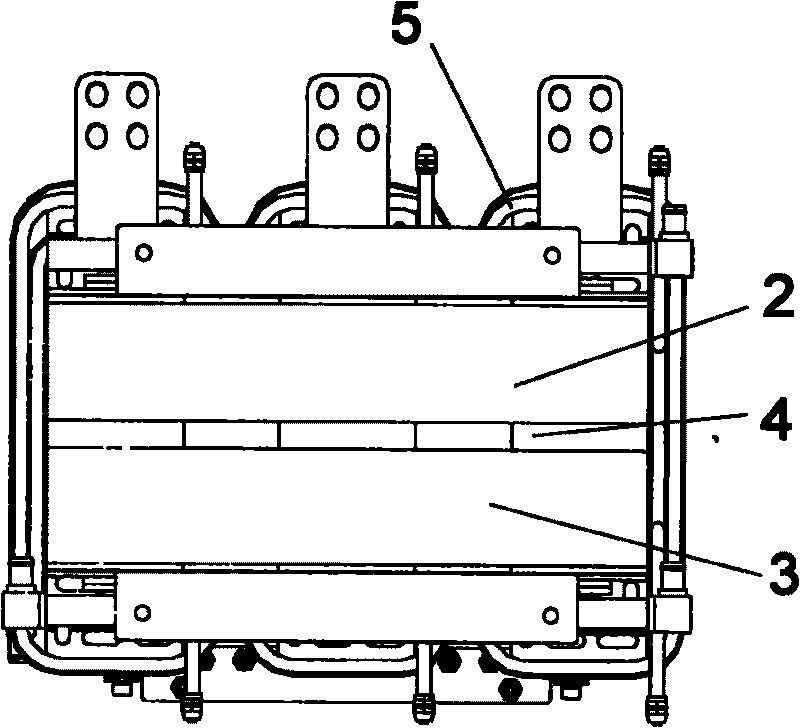

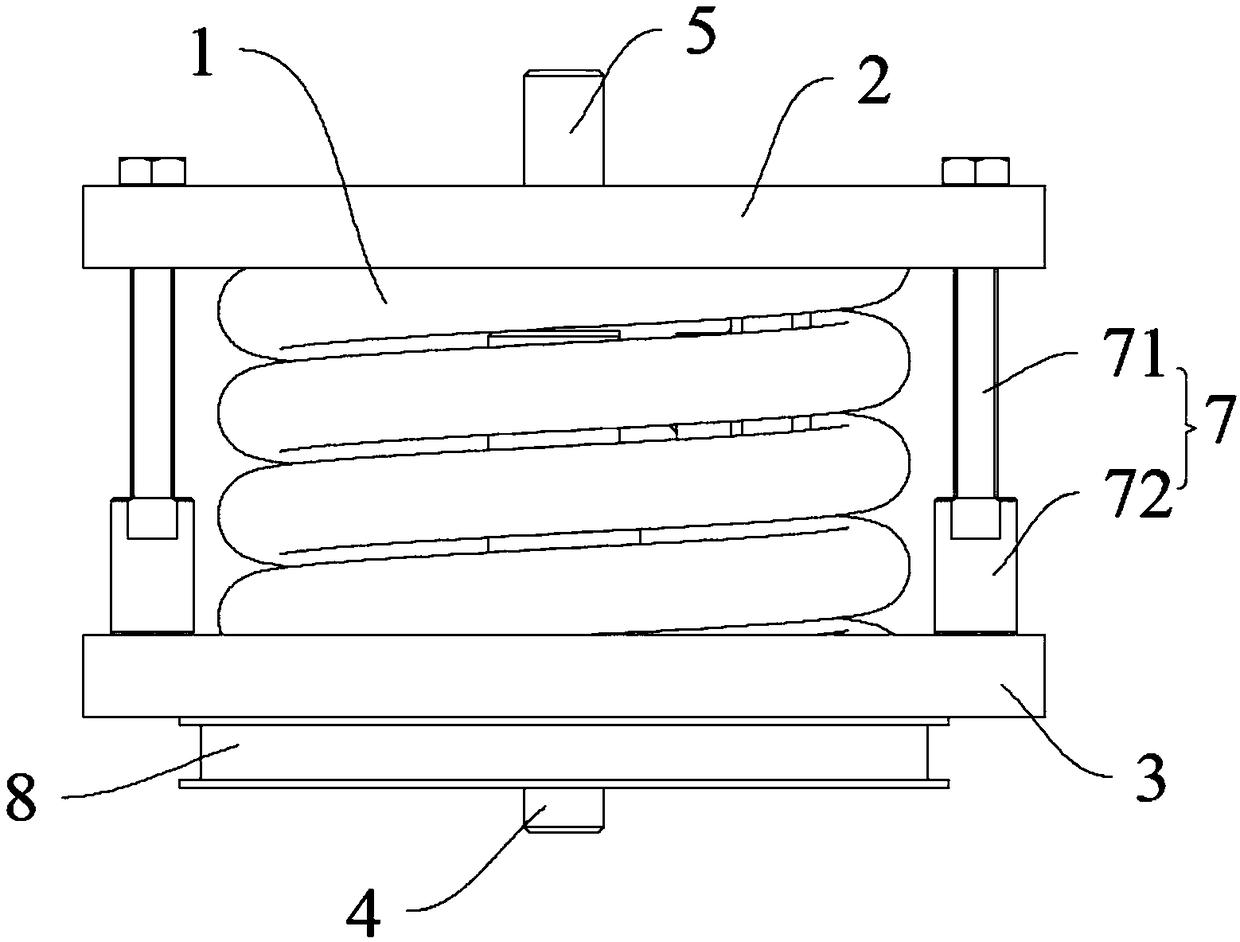

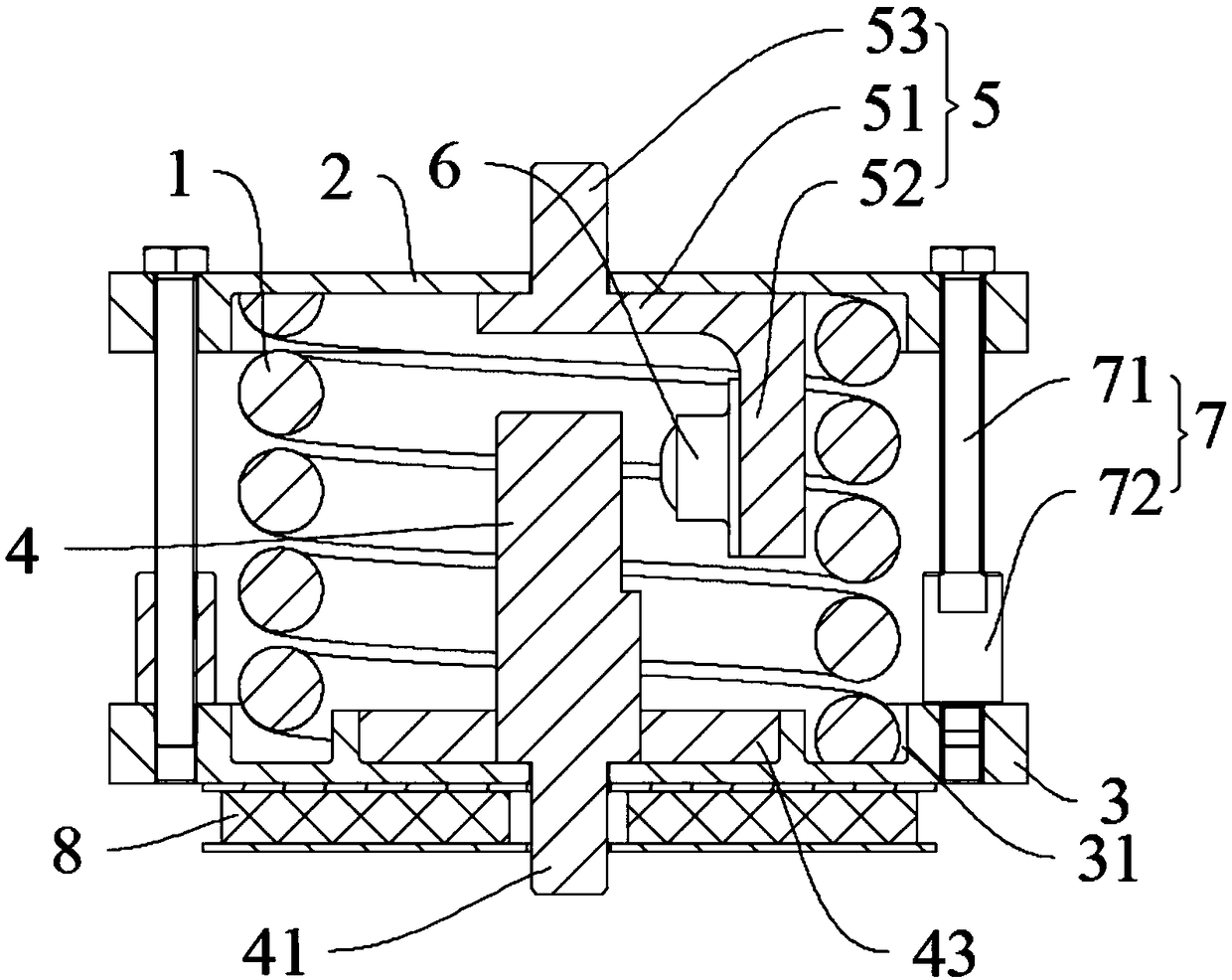

Strong cooling heat dissipation method and device of high-power iron core reactor

ActiveCN101692378AImprove cooling effectTemperature controlTransformers/inductances coolingTransformers/inductances magnetic coresEngineeringHeat pipe

The invention discloses a strong cooling heat dissipation method and device of a high-power iron core type reactor. The iron core of the reactor is divided into two parts between which a radiator is arranged, and the two divided irons cores are clung to two sides of the radiator, and the heat of the iron cores are taken out by the radiator arranged between the divided iron cores of the reactor so as to cool the iron cores. The radiator can be a plate-type water-cooling radiator or a pipe-type water-cooling radiator or a heat pipe radiator. The plate-type or pipe-type water-cooling radiator can be of a coiled pipe type radiator structure or of a groove-shaped cycling plate type radiator structure. In the invention, the iron core of the reactor is divided into two parts, and a heat dissipation device is arranged between the two parts, thereby effectively controlling the temperature of the iron core and playing a good role of heat dissipation for the reactor. Some special reactors have considerable heat value due to factors such as large current and environment factor when in work, and better heat dissipation effect can be achieved by adding various styles of reactors in the iron core or the side faces of the iron core and coils.

Owner:SHIDAI ELECTRIC FACTORY ZHUZHOU ELECTRIC LOCOMOTIVES INST MIN OF RAILWAYS

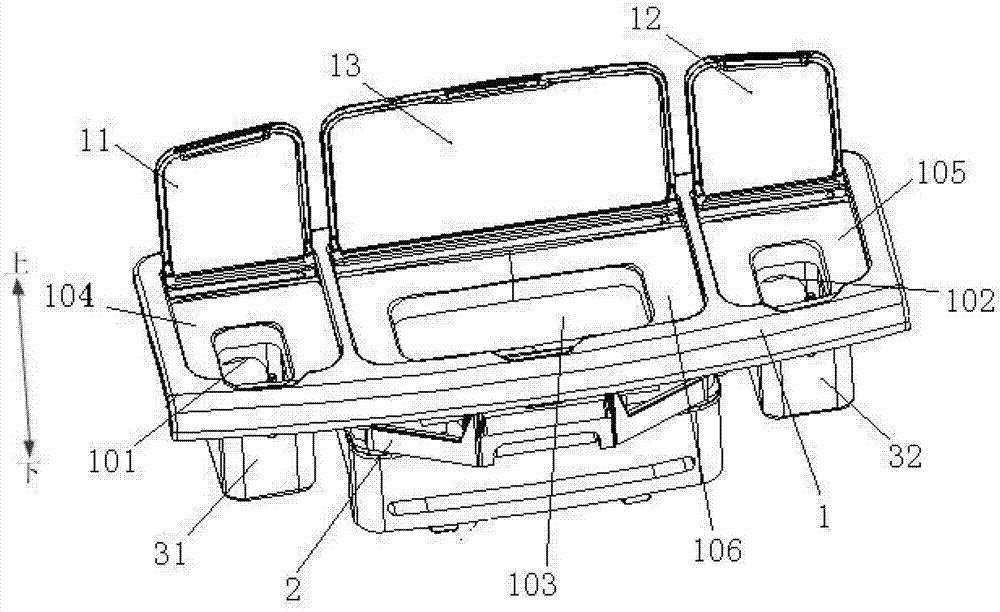

Washing machine and spray nozzle body assembly thereof

ActiveCN103485134AEasy to openEasy to closeOther washing machinesTextiles and paperSpray nozzleEngineering

The invention discloses a washing machine and a spray nozzle body assembly thereof. The spray nozzle body assembly comprises an outer cover, a spray nozzle main body, a first storage box and a second storage box. Particularly, the outer cover is provided with a first opening, a second opening and a third opening; the spray nozzle main body is arranged on the outer cover and is communicated with the third opening; the first storage box and the second storage box are respectively arranged on the outer cover; the first storage box is communicated with the first opening; and the second storage box is communicated with the second opening. According to the spray nozzle body assembly of the washing machine, which is disclosed by the embodiment of the invention, a detergent and a softener can be added into the storage boxes through the first opening and the second opening so as to implement one-step addition and repeated putting; and one or more of washing powder, the detergent and the softener also can be directly put in through the third opening in the middle of the outer cover so as to implement one-step putting and one-step washing.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Wet fully-winding and curing process for preparing hydrogen cylinder with carbon fiber lining

The invention relates to a wet fully-winding and curing process for preparing a hydrogen cylinder with a carbon fiber lining, which comprises the following steps of: (1) weighing 100 weight parts of epoxy resin, 30 to 60 parts of curing agent and 10 to 20 parts of additive and adding the epoxy resin, the additive and the curing agent into an glue mixing tank in turn; (2) stirring with a stirrer for 8 to 10 minutes continuously, directionally and uniformly to obtain mixed glue; (3) slowly pouring the mixed glue into an impregnation tank; (4) allowing fibers to pass through the impregnation tank under the action of a tensioner to combine the fibers and the glue together, and performing wet winding which is to spirally and circularly wind the mixture on the surface of the aluminum lining so as to completely cover the surface of the aluminum lining; and (5) placing the winded hydrogen cylinder into a curing furnace for curing, and obtaining the product. Compared with the prior art, the process has the advantages that: the cured products have no air bubbles, are susceptible to infiltration, do not turn yellow and the like.

Owner:上海康巴赛特科技发展有限公司

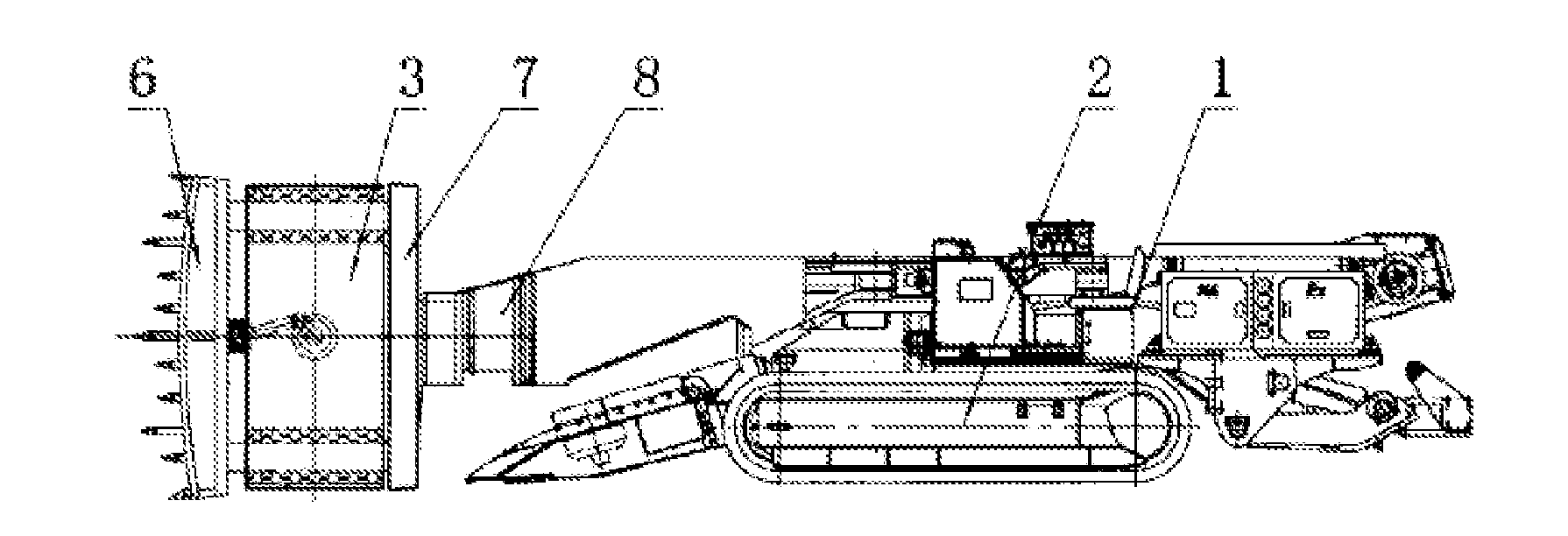

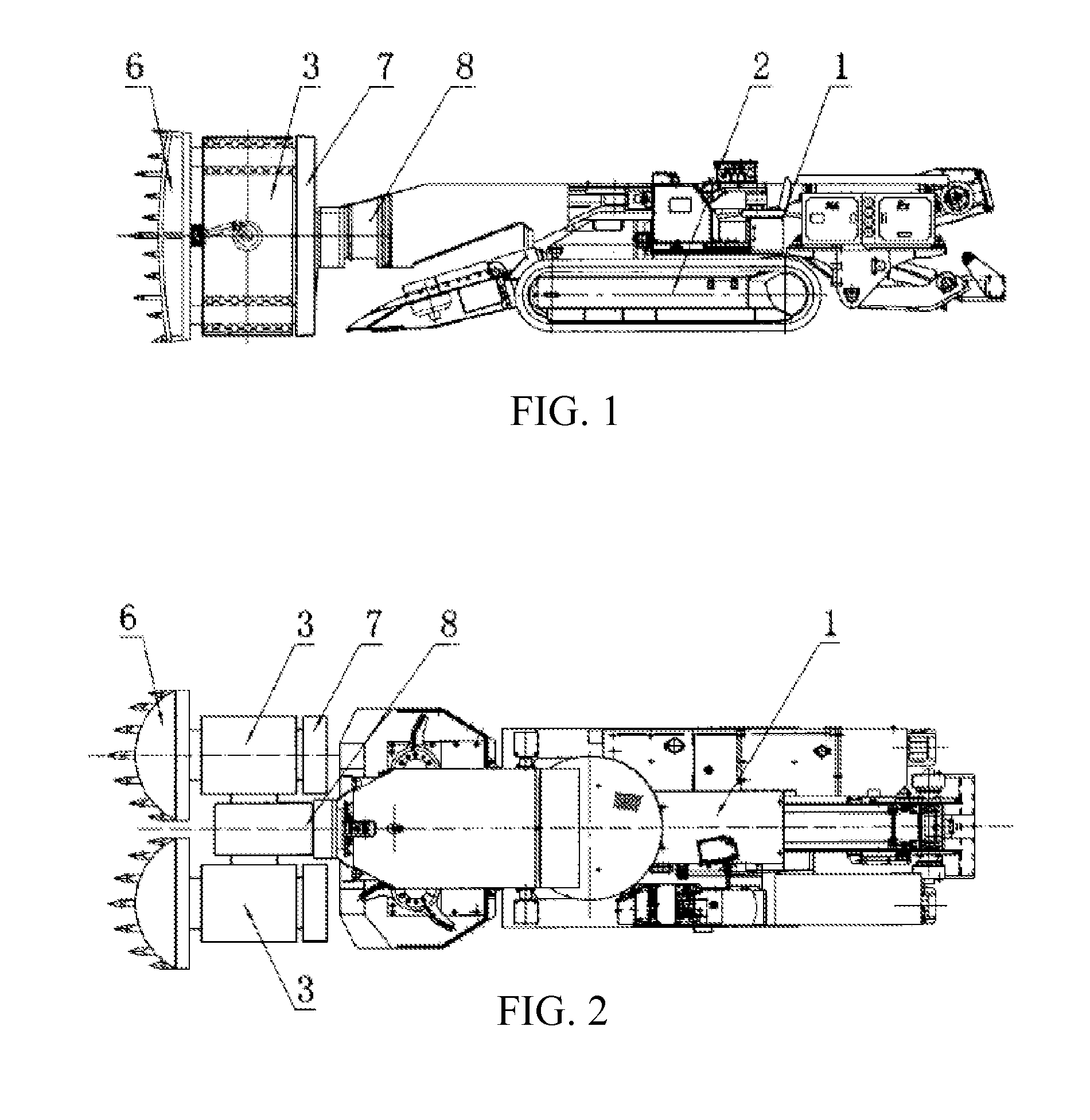

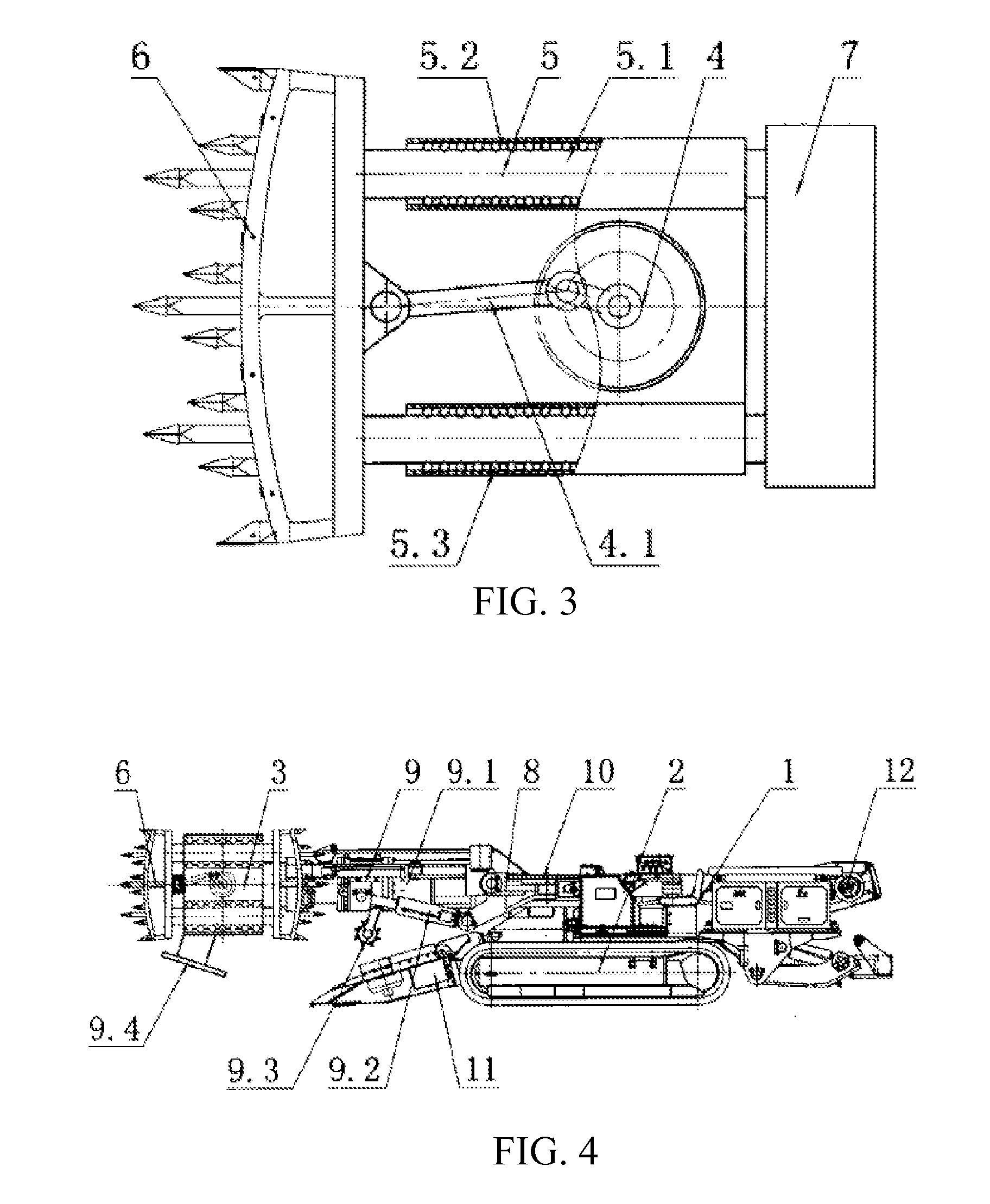

Rolling friction or suspension friction impact mining method and wear-resistant impact mining machine using said method

InactiveUS20150130256A1Increase widthExtended service lifeConstructionsReciprocating drilling machinesWear resistantEngineering

A rolling friction or suspension friction impact mining method and a wear-resistant impact mining machine using said method. The mining machine comprises a reciprocating impact part (3). The reciprocating impact part comprises an impact drive device (4), a rolling reciprocating device, and an impact head (6). The rolling reciprocating device comprises a rubbing body (38), a rubbing body support (39), an impact guiding element (5.1), and a position-limiting mechanism. The rubbing body (5.3) are disposed between the robbing body support (39) and the impact guiding element (5.1), and inside of the position-limiting mechanism to form rolling guiding. The impact drive device is disposed with a damage-prevention mechanism, a rotary power buffer device, and a structural buffer device, such that the impact head reciprocatingly move and have rolling or suspending friction under the support of the impact guiding element, thereby preventing the damage-prevention force to damage a power drive device and a rolling channel guiding device, and preventing the impact vibration caused by the reciprocating impact part to affect the machine body and other parts. The overall stability is therefore enhanced, and the service life is extended.

Owner:LIU SUHUA

Overall manufacturing process for pure electric vehicle

The invention relates to an overall manufacturing process for a pure electric vehicle. The overall manufacturing process comprises: a) skeleton feeding; b) assembly of a front circumference assembly and a rear circumference assembly; c) door prefabrication; d) installing and welding of skeleton components; e) general assembly and welding; f) door assembly; g) electrical assembly; h) assembly of a chassis assembly and layout of chassis harnesses; i) interior and exterior decoration; j) maintenance, assembly and commissioning; k) coating; and l) inspection and warehousing and other procedures. The overall manufacturing process has the beneficial effects that the overall manufacturing efficiency is improved due to the reasonable process, and the reasonableness, technology, reliability, operability and maintainability of the overall structure are enhanced.

Owner:JINGGONG ZHENJIANG AUTOMOBILE MFG

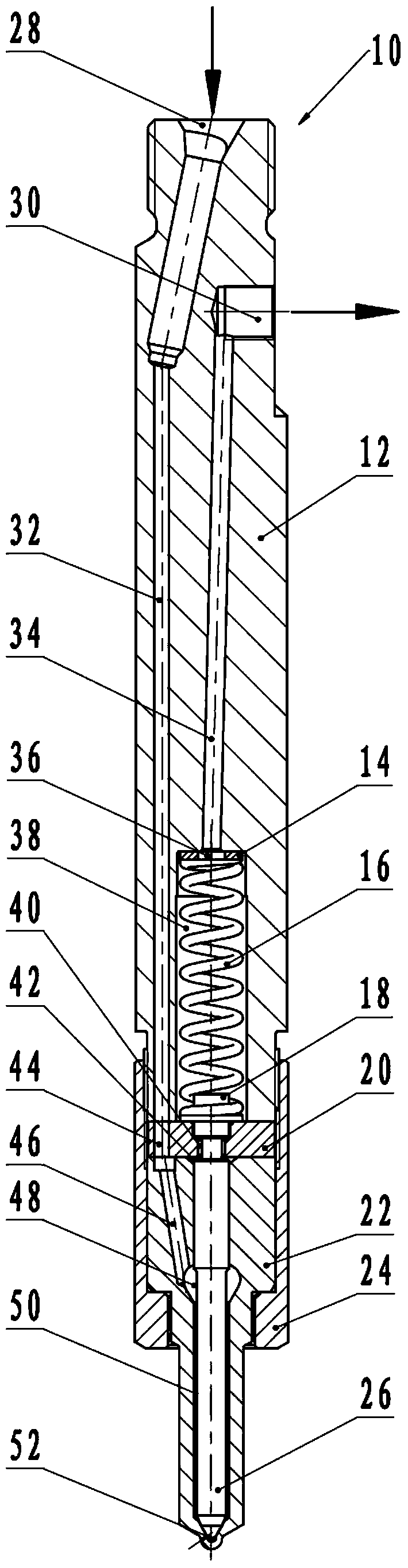

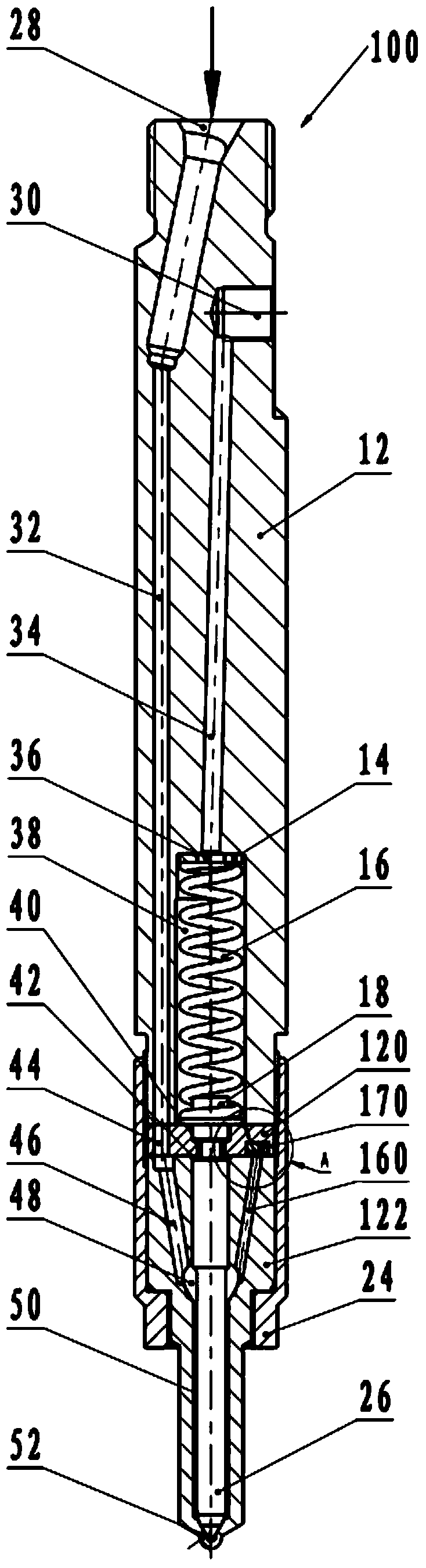

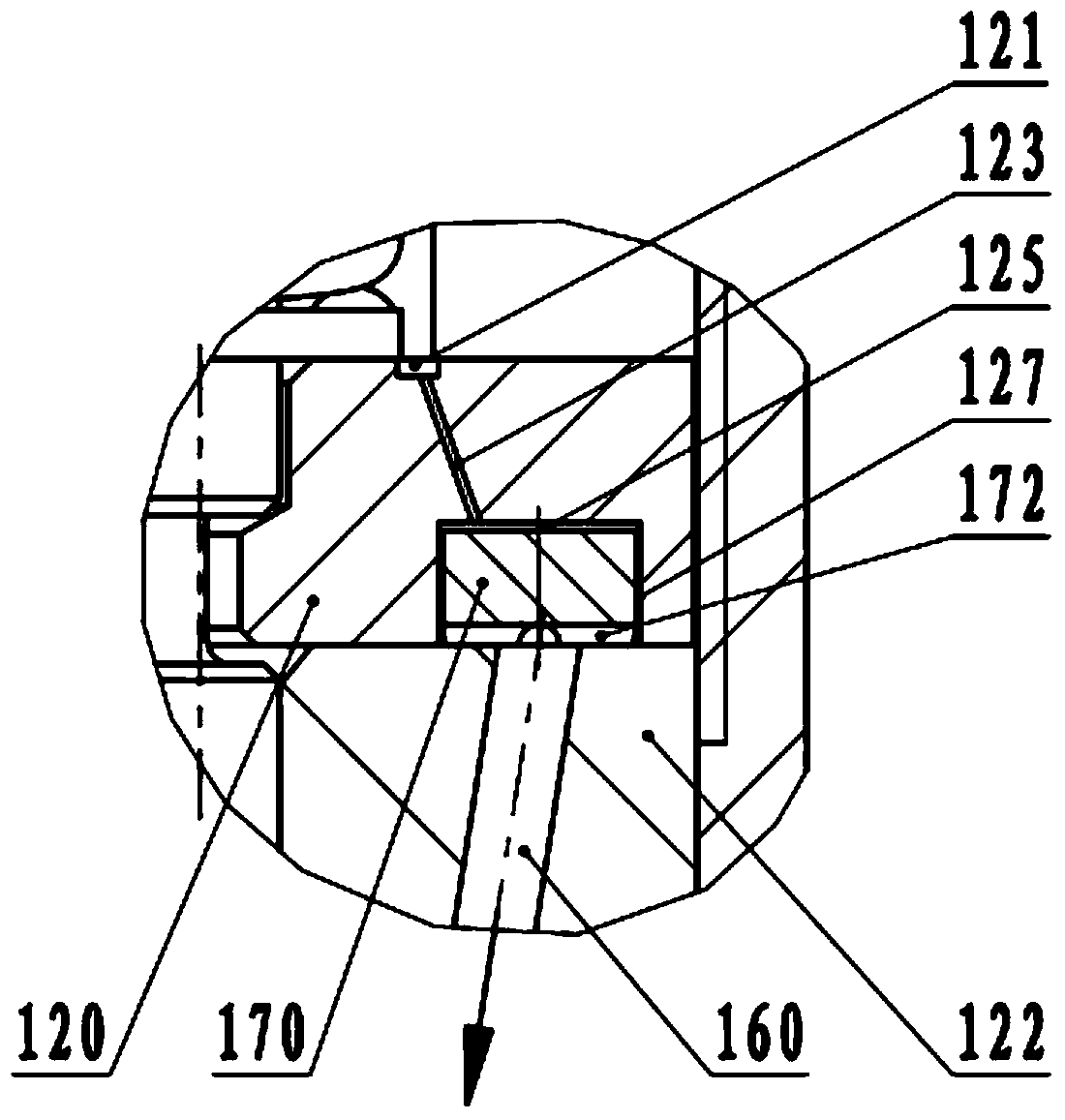

Self-relieving non-return-oil oil atomizer and refitting method of same

ActiveCN103644061AThe modification method is simpleStrong craftsmanshipFuel injection apparatusMachines/enginesFuel oilCheck valve

The invention discloses a self-relieving non-return-oil oil atomizer which is formed by refitting a traditional mechanical oil atomizer. The self-relieving non-return-oil oil atomizer is characterized in that a tiny metering hole is arranged in the traditional mechanical oil atomizer, the tiny metering hole is communicated with a low-pressure oil return side spring cavity and a high-pressure working side oil containing groove; a valve is arranged and is a check valve, two sides of the check valve are provided with a low-pressure oil return side and a high-pressure working side respectively, and the tiny metering hole enables fuel oil to flow in the direction from the low-pressure oil return side to the high-pressure working side; a blocking plug is utilized to block an oil return opening matched with the valve to enable the tiny metering hole and the valve to have the one-direction flowing function. Or the self-relieving non-return-oil oil atomizer is directly formed according to the technical scheme, the mechanical oil atomizer has a non-return-oil function and can relieve pressure automatically, an oil return pipeline device is achieved, and the oil atomizer can stably and reliably operate.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

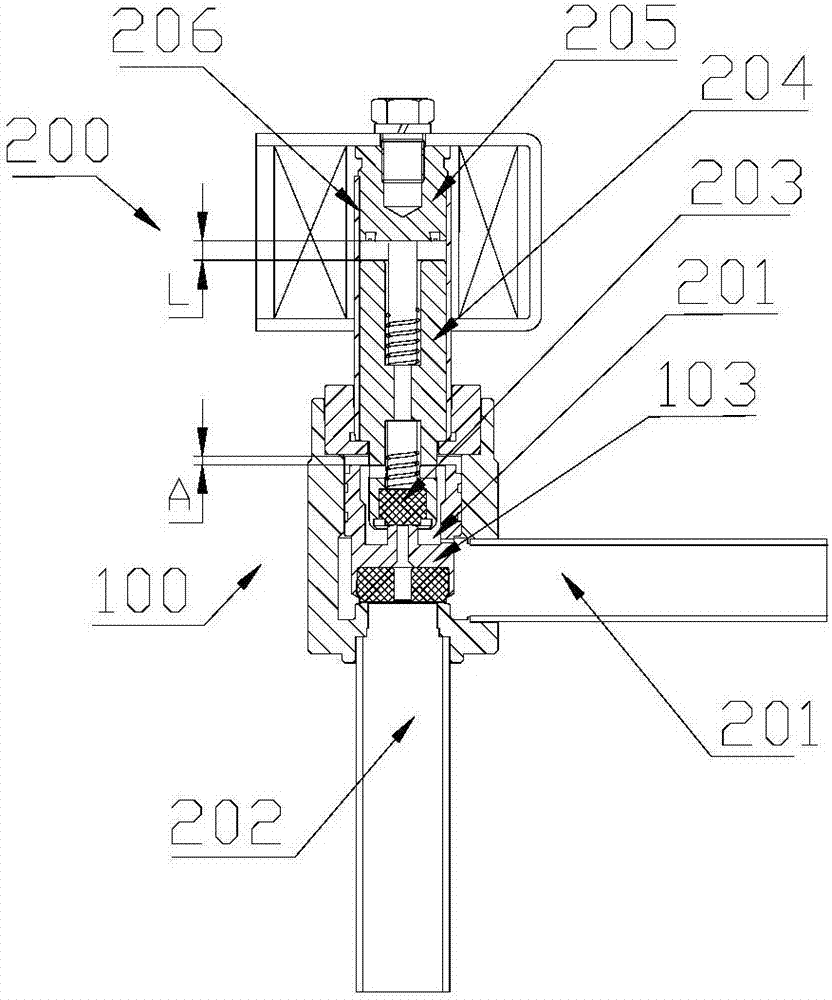

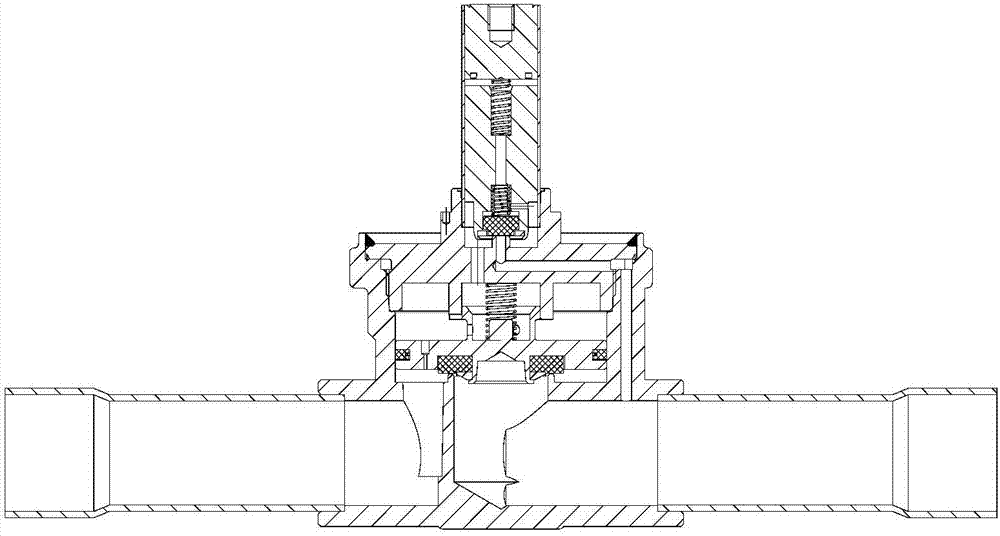

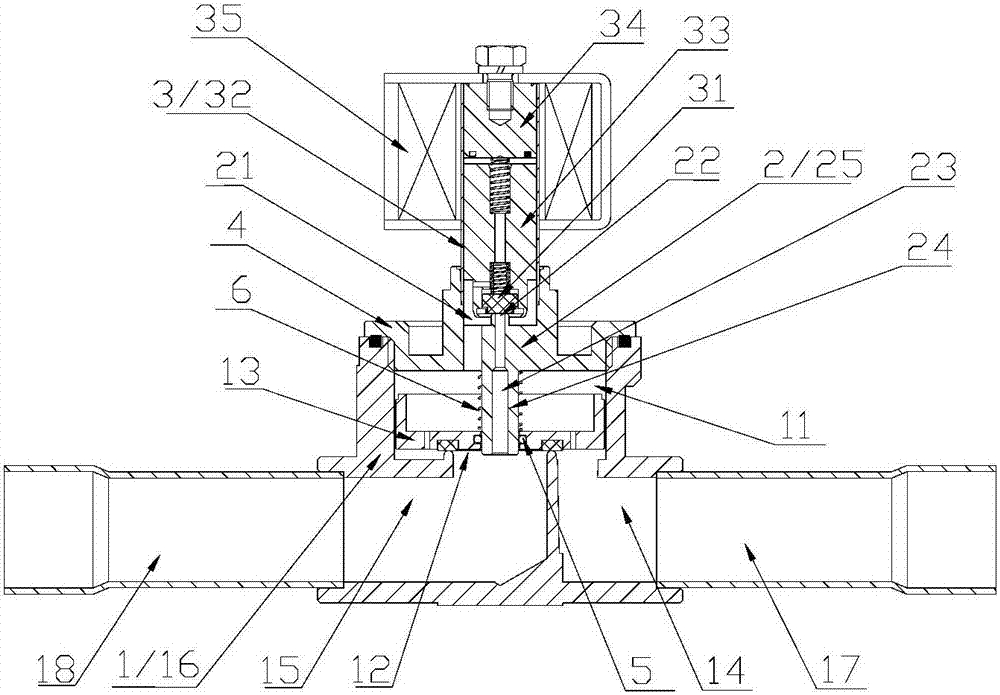

Pilot-operated electromagnetic valve

ActiveCN107514465ASimple structureSave energyOperating means/releasing devices for valvesLift valveEngineeringControl valves

The invention relates to the technical field of control valves and particularly discloses a pilot-operated electromagnetic valve. The pilot-operated electromagnetic valve comprises a main valve body component, a pilot valve body component and a pilot valve drive component, wherein the main valve body component comprises a main valve body with a main valve cavity, and a main valve port and a main valve element are arranged in the main valve cavity; the pilot valve body component comprises a pilot valve body with a pilot valve cavity; a pilot valve port is formed in the pilot valve cavity; and the pilot valve cavity communicates with the main valve cavity. The pilot-operated electromagnetic valve is characterized in that the pilot valve body component further comprises a connecting pipe portion which is provided with a pilot valve channel, the pilot valve port communicates with a main valve outlet through the pilot valve channel, and the main valve element is an annular valve element which is arranged on the connecting pipe portion in a sleeving mode and is capable of sliding in the axial direction to control opening or closing of the main valve port. The pilot-operated electromagnetic valve provided by the invention, the travel of the main valve element is not restrained by the travel of a pilot valve element, and the product structure is simplified.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

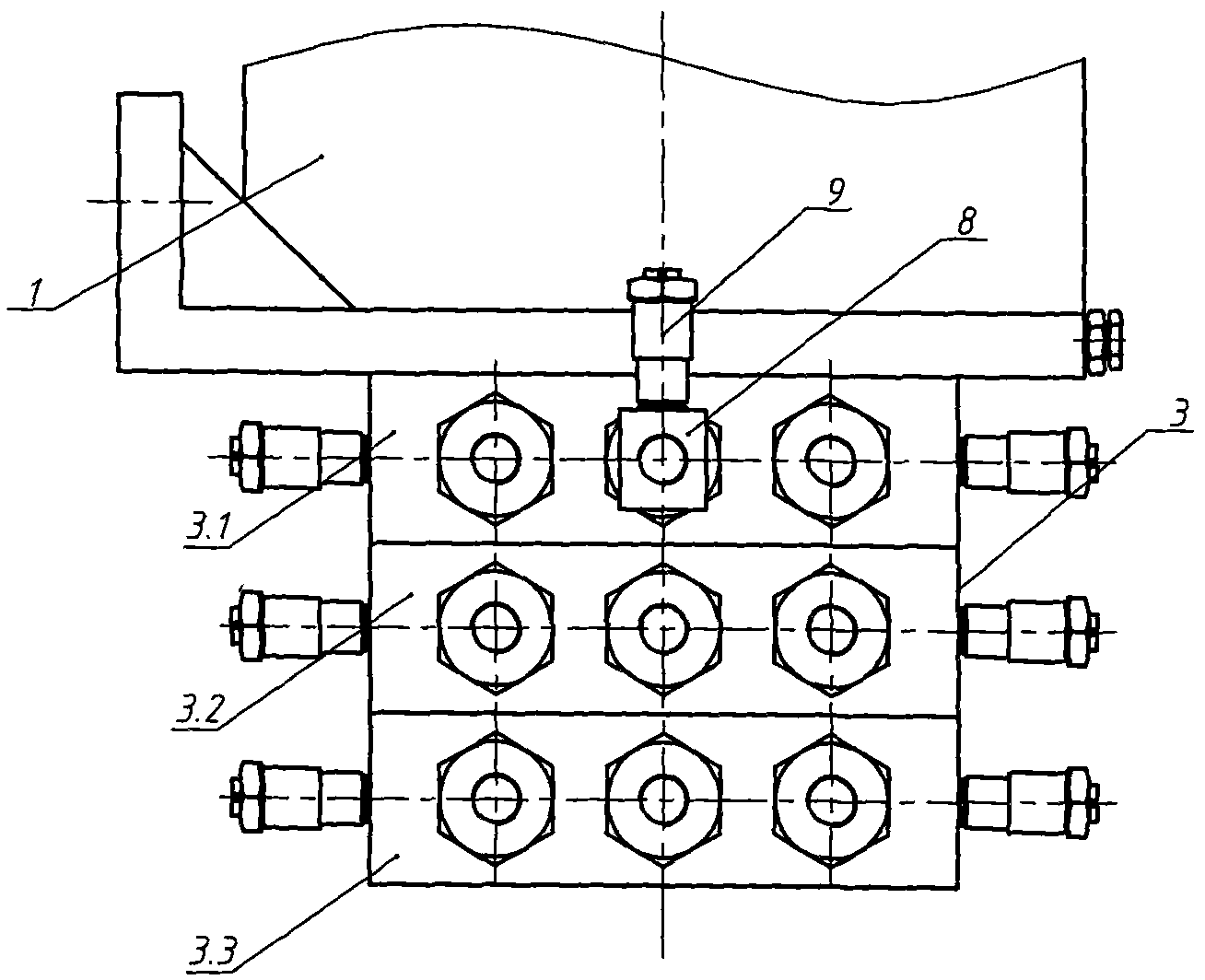

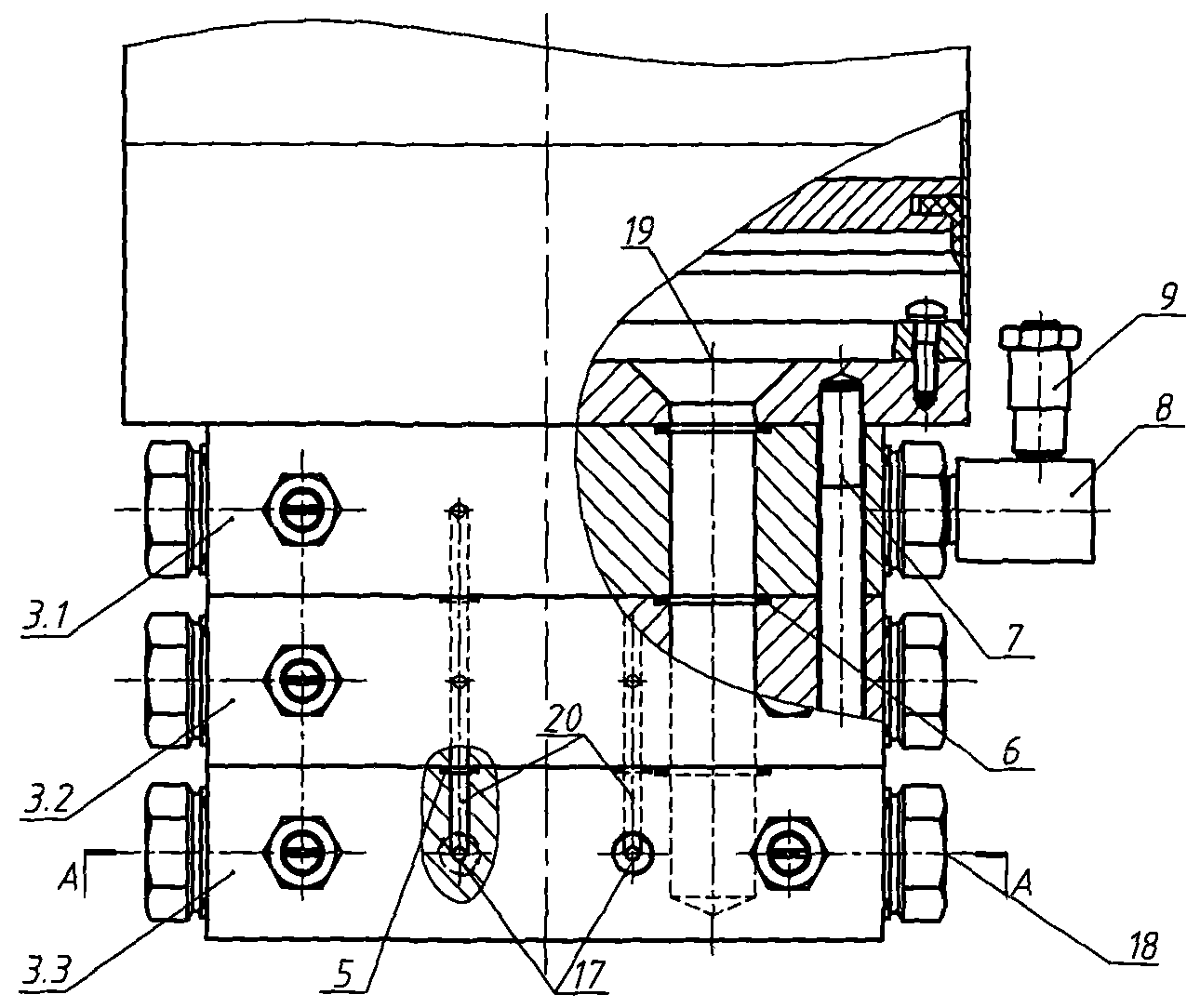

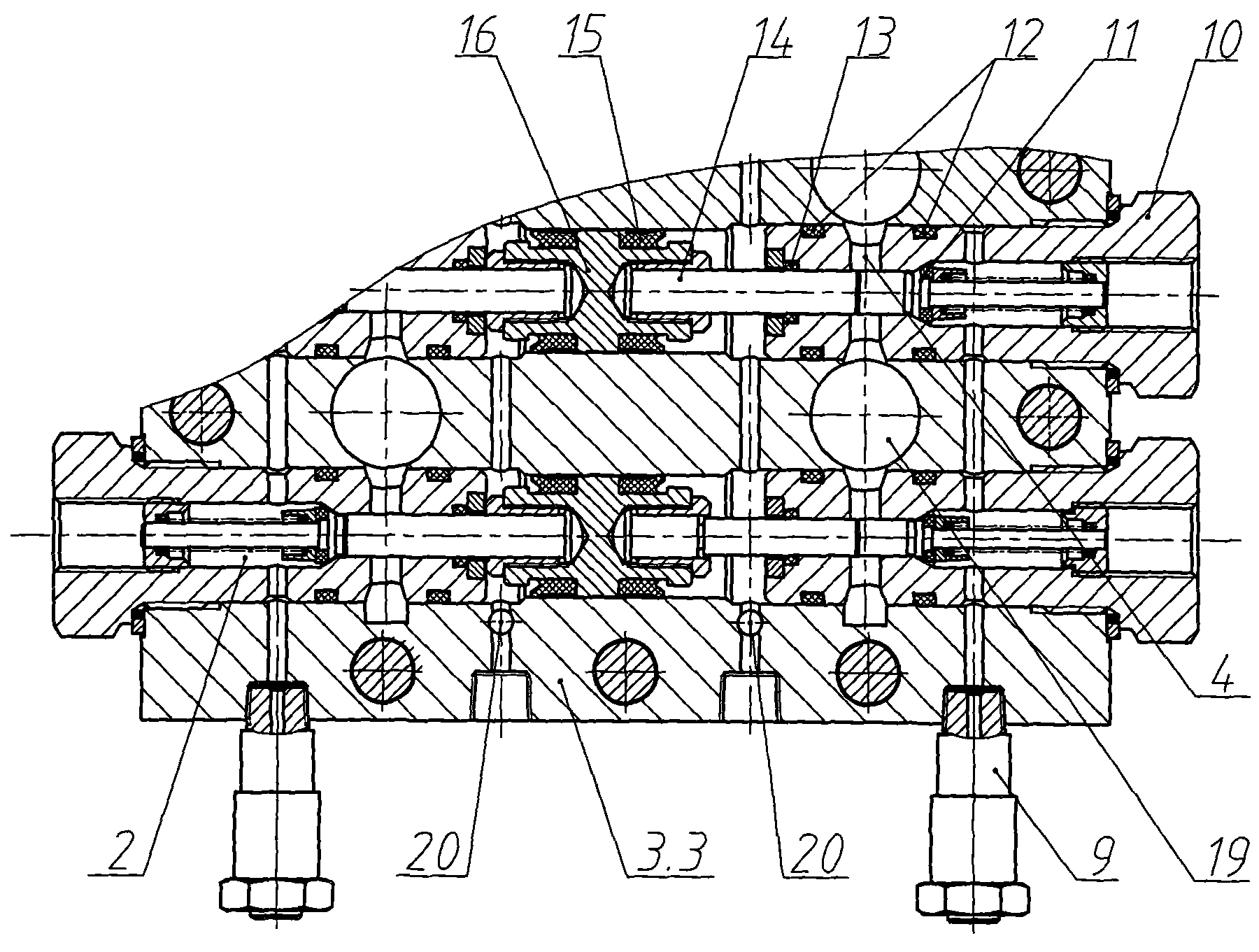

Superposition type multi-point grease lubrication pump

ActiveCN101832459ASimple structureStrong craftsmanshipLubricating pumpsReciprocating motionHigh pressure

The invention discloses a superposition type multi-point grease lubrication pump. A body component formed by superposing a plurality of bodies is installed on the bottom surface of an oil storage cylinder, each body is provided with a plurality of rows of subpumps in parallel, a plurality of common oil suction channel holes and a plurality of common power source channel holes are arranged in the superposition type body component, the common oil suction channel holes are communicated with the inner cavity of the oil storage cylinder, the common power source channel holes are communicated with an external power source on a body arranged at the lowest layer, each row of subpumps comprise a group of double-action pistons and two groups of grease pump units which are driven by the double-action pistons and are symmetrically arranged, via holes which are communicated with two common power source channel holes in the superposition type body component are arranged at motion stop points at both sides of the double-action pistons, compressed air or pressure oil as a power source drives the double-action pistons to reciprocate way passing through the channel holes on the bodies to enable oil pressure plungers of the grease pump units at the both sides connected with the compressed air or the pressure oil to finish the process of oil suction and exhaust in an alternating way and independently exhaust high pressure grease from a respective oil outlet through pressurization, thereby finishing grease supply to a lubrication point.

Owner:LIUBIAN MECHANICAL LUBRICATION YONGJIA

Spring press-fit device with compound stop function

The invention discloses a spring press-fit device with compound stopping function, characterized in that the press-fit device comprises a spring cover, a spring seat, and a cushioning spring positioned between the spring cover and the spring seat. The cushioning spring further includes a vertical stop device and a transverse stop device, and the vertical stop device and the transverse stop deviceare arranged inside the cushioning spring so as to provide effective overload protection to the cushioning spring when the vertical load and the transverse load borne by the cushion spring exceed a limit value. The structure integrates the lateral stop function and the vertical stop function into an integral arrangement inside the spring coil, thereby greatly reducing the space required for the arrangement outside the spring, making the structure of the train bogie more compact, and preventing the spring from disengaging from the safe position in the emergency state of the train.

Owner:CRRC ZIYANG CO LTD

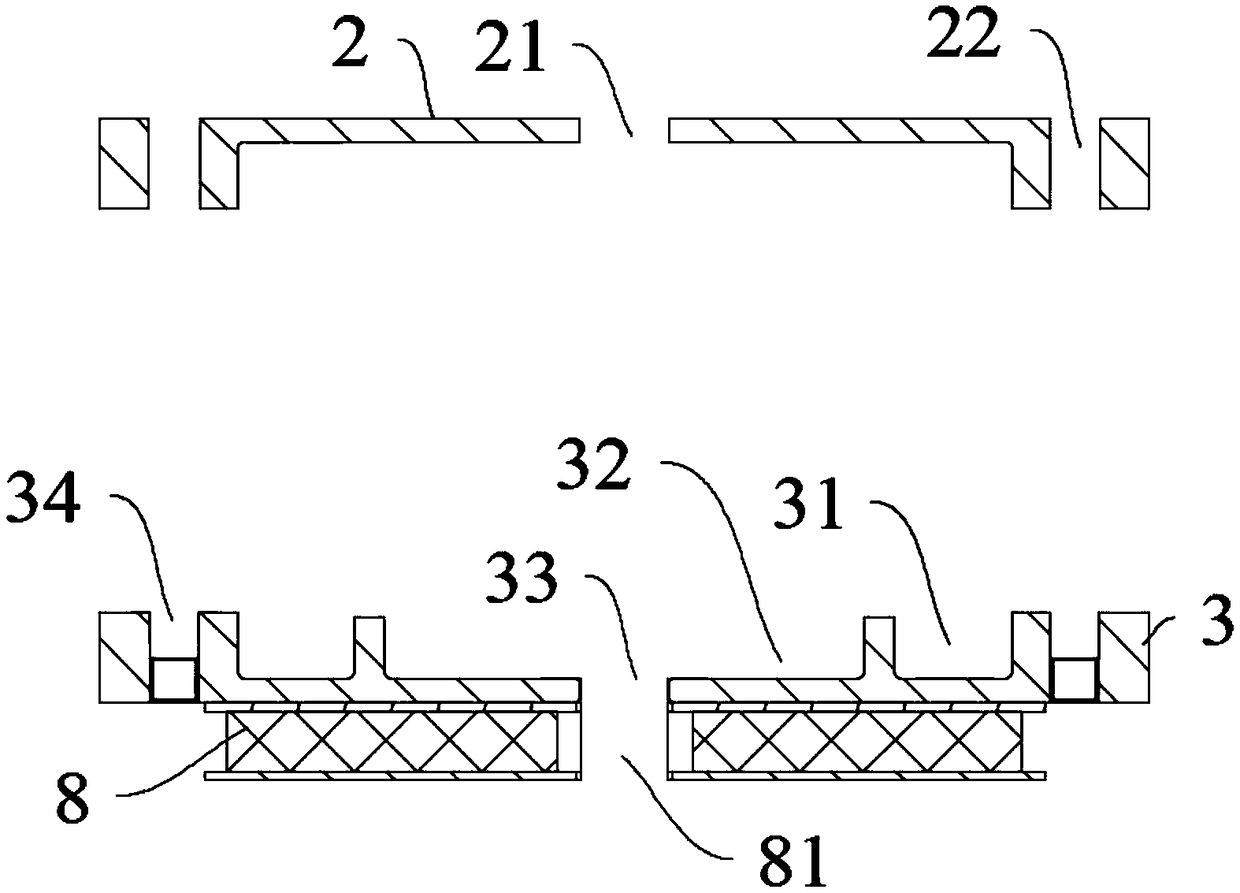

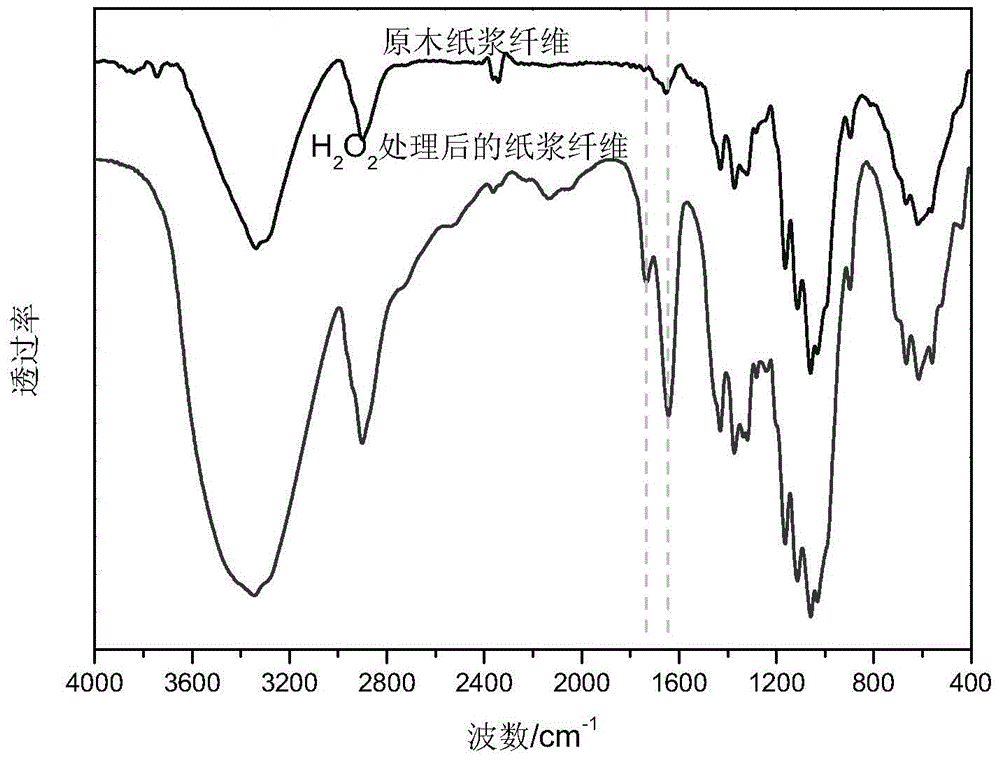

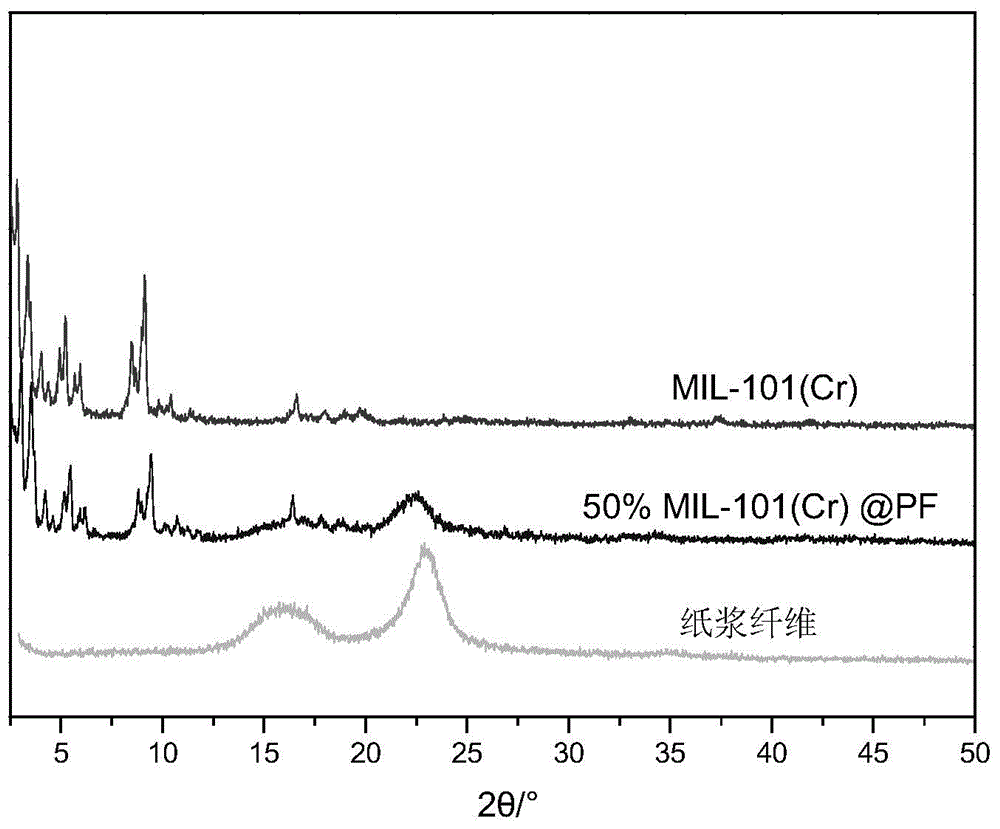

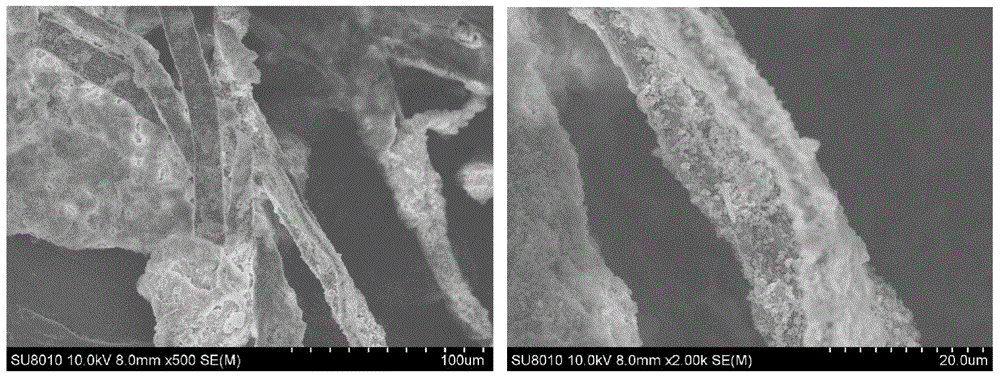

MOFs (metal-organic frameworks) pulp fiber composite and forming and preparing method thereof

InactiveCN104959116AGood flexibilityEasy to useOther chemical processesDispersed particle separationDistilled waterMetal-organic framework

The invention belongs to the technical field of porous material forming, and discloses a MOFs (metal-organic frameworks) pulp fiber composite and a forming and preparing method thereof. The method comprises the following steps of pre-treating wood pulp paper by using hydrogen peroxide solution; dispersing the wood pulp paper in distilled water to obtain pulp solution; adding a MOFs powder material in the pulp solution to obtain mixed pulp; and filtering and drying the mixed pulp and performing vacuum drying on the mixed pulp to obtain the platy MOFs pulp fiber composite. The MOFs material which is in the state of original powder is loaded on pulp fibers with high toughness. The MOFs pulp fiber composite has the advantages of easiness in use, convenience in recycling and recyclability, and has quite high actual application potential.

Owner:SOUTH CHINA UNIV OF TECH

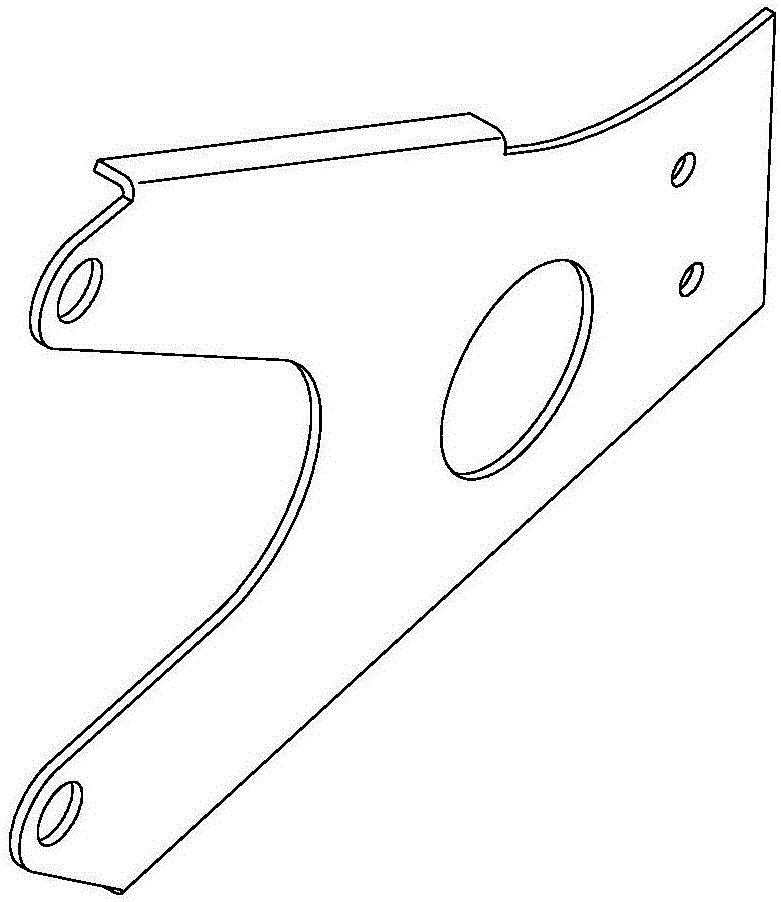

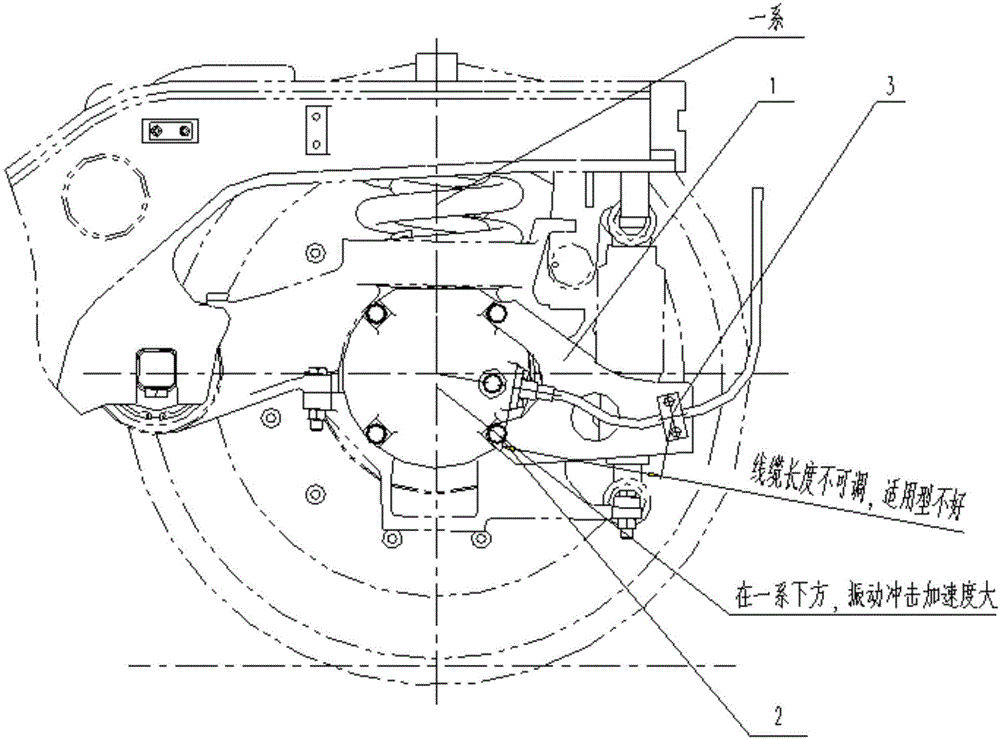

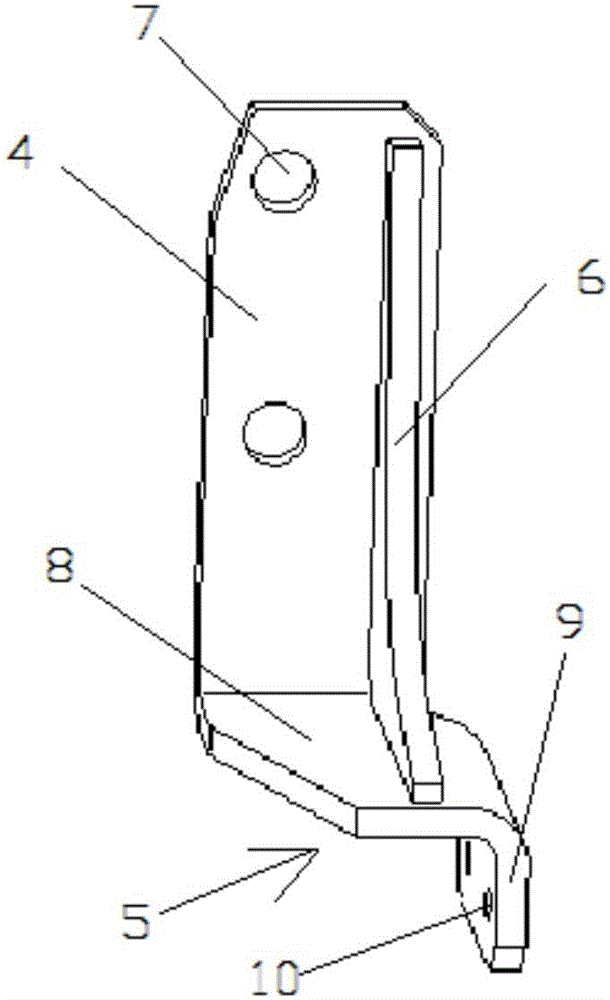

High-strength anti-breaking cable bracket for bogie

ActiveCN106428085AImprove versatilityReduce vibration shock accelerationBogiesBogieImpact acceleration

The invention relates to a high-strength anti-breaking cable bracket for a bogie. The high-strength anti-breaking cable bracket for the bogie is provided with a mounting plate and a cable fixing plate. Circular holes are formed in the mounting plate, and the mounting plate is fixed to the end of a side frame of the bogie through bolts. The cable fixing plate is located on or close to the outer side of the end of the side frame of the bogie, a cable fixing hole is formed in the cable fixing plate, and a cable is fixed to the cable fixing plate through a pipe clamp or a binding belt. The high-strength anti-breaking cable bracket for the bogie is transformed on the basis of an original bracket, and the bracket is fixed to the end of a framework of the bogie instead of being fixed to a shaft box cover of the shaft end of the bogie; and through primary vibration damping, the vibrating impacting acceleration of the high-strength anti-breaking cable bracket for the bogie is reduced, and fatigue break of the high-strength anti-breaking cable bracket for the bogie is better prevented. At the same time of eliminating the disadvantages of the original bracket, the high-strength anti-breaking cable bracket for the bogie can be well applicable to an original shaft end structure, and remaining shaft end structures do not need to be changed. In addition, the high-strength anti-breaking cable bracket for the bogie is good in universality and applicable to various coil-out connecting ports.

Owner:CRRC NANJING PUZHEN CO LTD

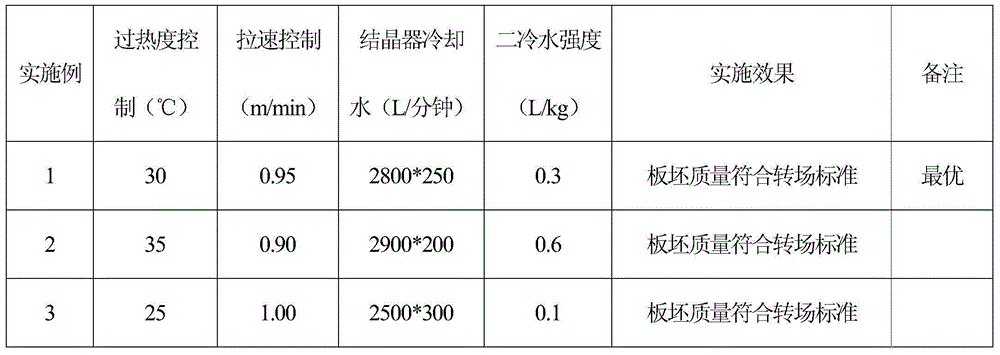

Slab continuous casting manufacturing method for medium-manganese wear-resistant steel

The invention provides a slab continuous casting manufacturing method for medium-manganese wear-resistant steel. The slab continuous casting manufacturing method mainly comprises the electric furnace primary smelting process, the ladle furnace refining process and the continuous casting process, wherein in the steel ladle furnace refining process, argon stirring is carried out before the crane ladle operation of the refining furnace, the stirring area is better to be greater than 40% of the area of a liquid steel surface, the stirring time needs to be longer than 5 min, the standing time after stirring can be longer than 5 min, 2.5-3.75 m / t of a silicon calcium line is fed in, and the crane ladle operation is conducted when the standing time is longer than 3 min; the degree of superheating of a steel liquid inside a tundish is controlled within 25-32 DEG C; the intensity of secondary cooling is controlled within 0.1-0.6 L / kg; meanwhile, the continuous casting speed is controlled. The slab continuous casting manufacturing method is suitable for medium-manganese wear-resistant steel, can effectively reduce the longitudinal crack defect of the medium-manganese wear-resistant steel, the obtained manganese amount is controlled within 6-9% (lower than 13% of high manganese wear-resistant steel), is mainly applied in the industries of coal machines and the like, and is good in processing performance, high in wearing resistance and low in cost meanwhile.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

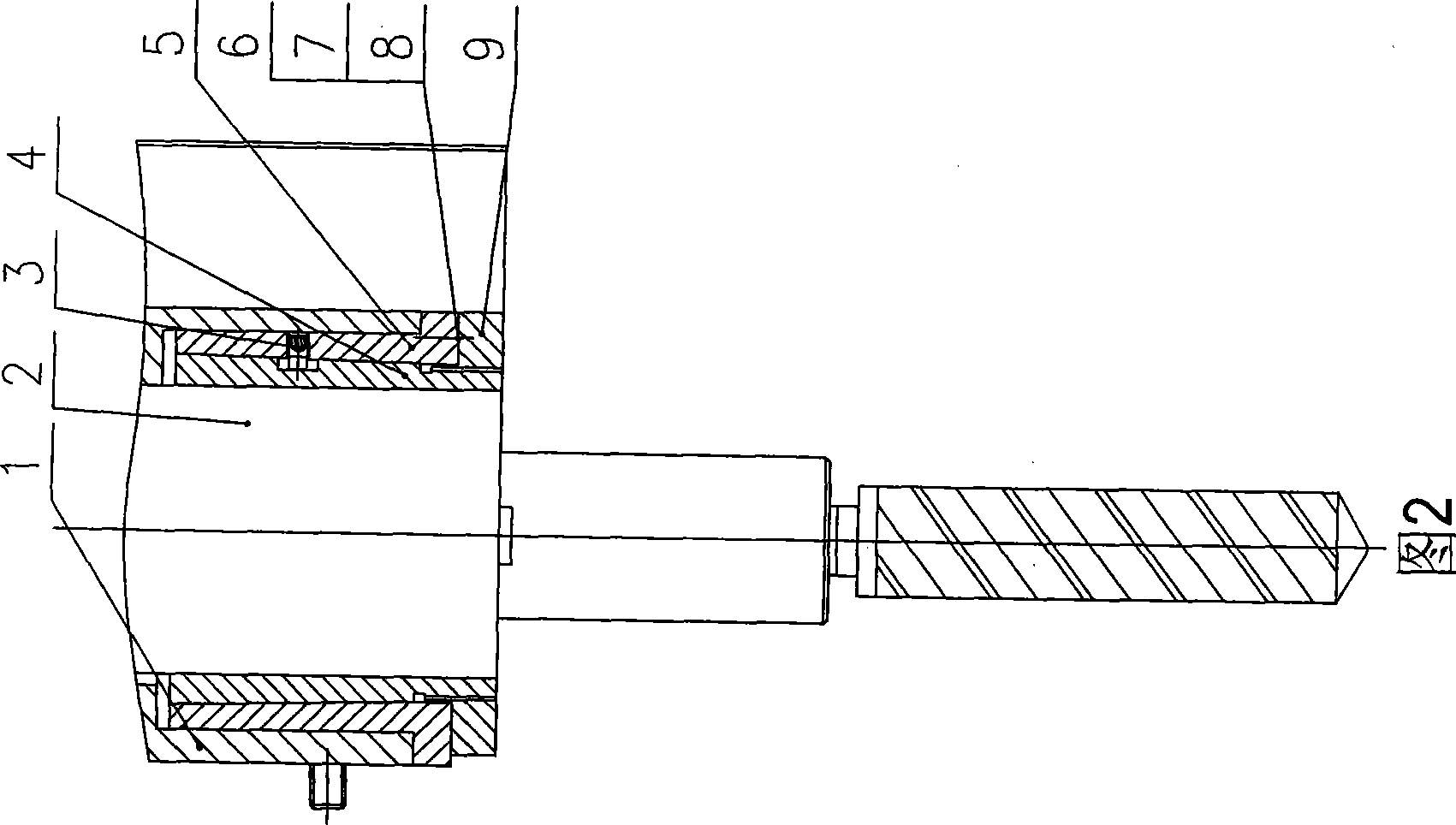

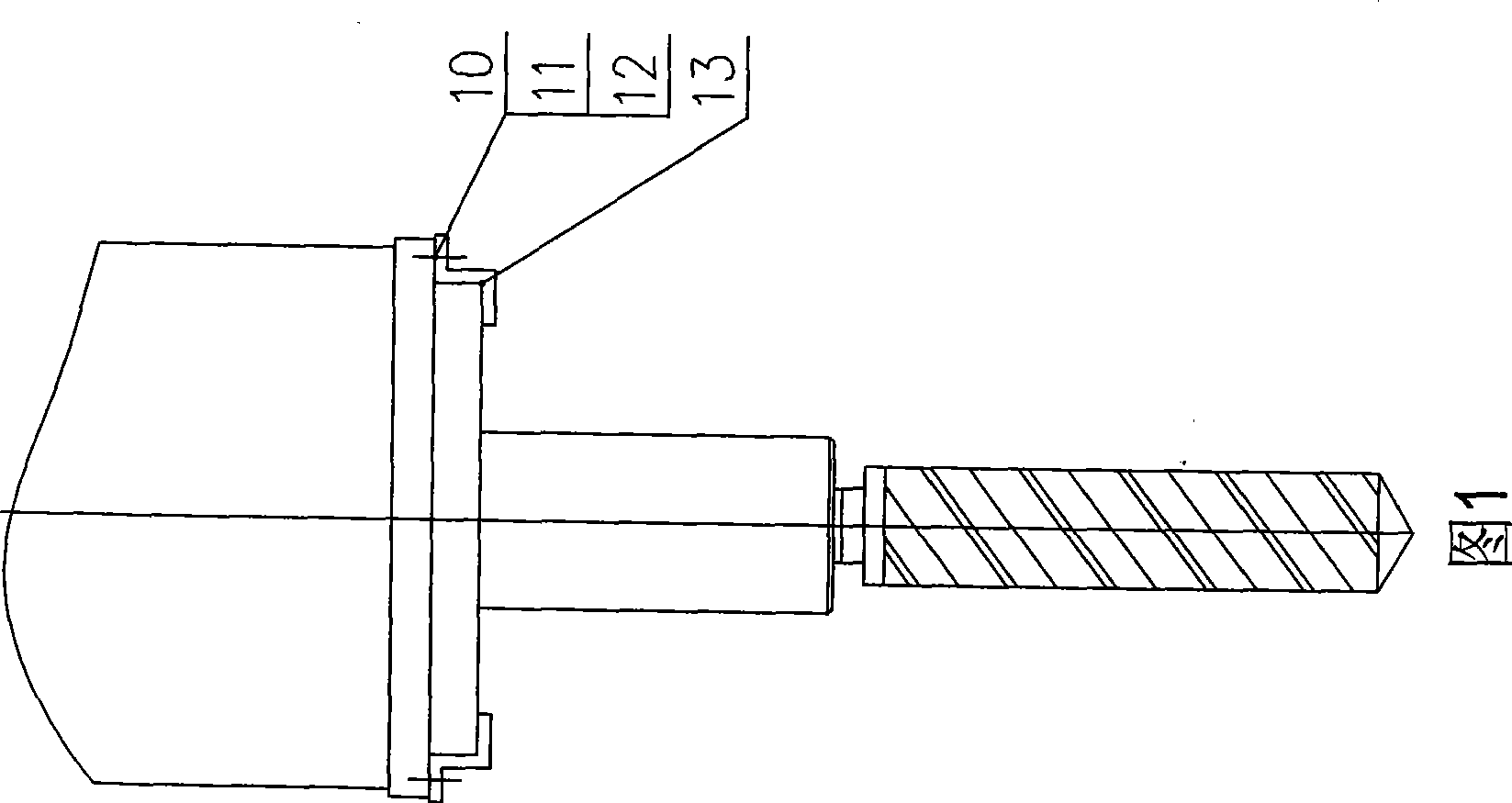

Gap-adjusting structure of high-accuracy numerical control drill

InactiveCN101428351AIncreased accuracy levelReasonable structureMetal working apparatusNumerical controlEngineering

The invention relates to a clearance adjusting structure of a main shaft of a high-precision numerical control drill, in particular to a main shaft structure suitable for numerical control drilling machine, which belongs to the technical field of machine devices. The clearance adjusting structure is characterized in that the clearance adjusting sleeve is mounted in a conical trepan boring, a screw is screwed on and screwed into a clearance adjusting grooving to form a combined unit, the combined unit is mounted in the trepan boring of the main shaft and fixed through a screw bolt, a flat gasket and a spring washer, the main shaft component is mounted into the main shaft seat and the clearance adjusting trepan boring, a clearance adjusting nut is screwed to adjust the clearance, and a pressure plate is used for fixing the position of the clearance adjusting nut through the screw bolt, the flat gasket and the spring washer. The invention has the advantages that the structure is reasonable, the fabrication is convenient, the manufacturability is strong and the positioning accuracy is high; in the practical drilling hole of the numerical control drill, the radial run-out of the main shaft is small, the drilling is stable and the drilling precision is high; therefore, the accuracy class of the numerical control drilling machine can be enhanced, and the application range of the numerical control drilling machine can be widened.

Owner:WUXI HUALIAN SCI & TECH GROUP

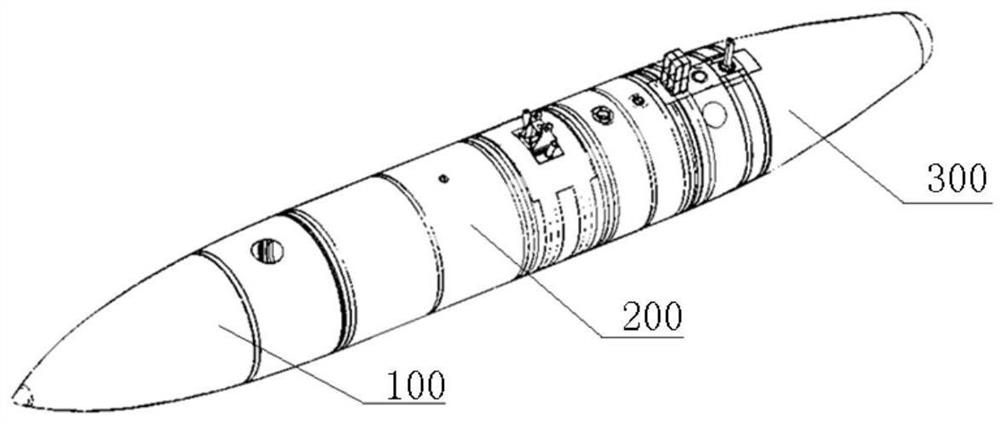

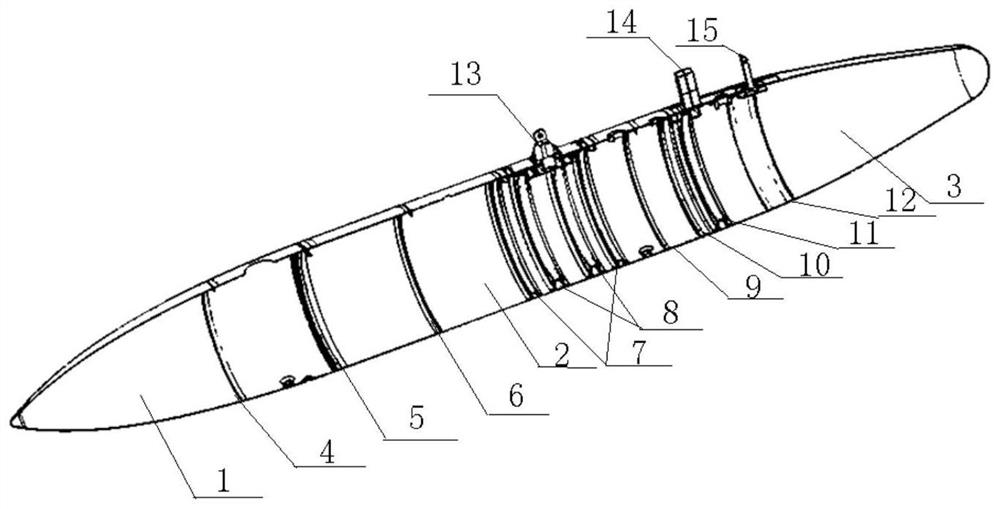

All composite material lightweight fuel tank shell for aircraft

PendingCN112478182AEasy to integrate design and manufactureEasy to ensure sealing propertiesPower plant fuel tanksAviationFlight vehicle

The invention relates to the technical field of components of aviation and aerospace crafts, and particularly relates to an all composite material lightweight fuel tank shell for an aircraft. The whole structure is divided into three sections, namely a front conical section (100), a middle column section (200) and a rear conical section (300). The concrete structure comprises a conical section shell (1), a column section shell (2), a conical section shell (3), an L-shaped ring frame a (4), an L-shaped butt joint ring frame (5), an L-shaped ring frame b (6), a small omega-shaped ring frame (7),a large omega-shaped ring frame (8), an L-shaped ring frame c (9), an L-shaped butt joint b (10), an omega-shaped ring frame (11), a U-shaped ring frame (12), a main lifting point joint (13), a stopblock (14), a rear lifting point joint (15), a concentrated force decomposition structure (16) and an I-shaped beam decomposition joint (17). A cabin section is easy to integrally design and manufacture, high in overall rigidity, light in weight, simple in structure, capable of easily guaranteeing the sealing characteristic of the box body, high in adaptability to severe environments such as saltmist and the like.

Owner:HEFEI JIANGHANG AIRCRAFT EQUIP CORP LTD

Lifting appliance

InactiveCN101269779ASuitable for liftingCompact structureLoad-engaging elementsTransformerEngineering

The invention discloses a lifting device which comprises a ventral shield fastening part, a T-shaped hanger and a cover plate, the ventral shield fastening part is fixed on the ventral shield of an object to be lifted, the T-shaped hanger and the cover plate can be detachably connected and fixed with the ventral shield fastening part, the T-shaped hanger is inverted in an inverted T-shaped space formed by the cover plate and the ventral shield fastening part, and the upper end of the inverted T-shaped hanger exposes. The lifting device has the advantages of compact structure, small occupied space, good intensity, scientific and reasonable design as well as good manufacturability and commonality. The lifting device is especially suitable for the lifting of a high capacity transformer body with a five-column type iron core structure.

Owner:XD JINAN TRANSFORMER

Processing technology of frozen powder-dipped pork-onion string

InactiveCN101999695AEvenly distributedResolution timeClimate change adaptationFood preparationSaline waterSlurry

The invention relates to a processing technology of frozen powder-dipped pork-onion string, belonging to the technical field of food processing. The processing technology comprises the following steps of: flavouring pork; slicing the pork; slicing onions; stringing the pork and the onions for forming; dipping a pork string with base powder, starch slurry and bread making powder; and quickly freezing. The processingtechnology is characterized in that the pork flavouring step is as follows: injecting flavouring liquid into the pork by adopting a saline water injector, and rolling for flavouring by adopting a rolling machine. The production process can fast uniformly distribute the flavouring liquid into meat tissues, thereby solving the technical problems of long flavouring time and nonuniform flavouring liquid distribution of the traditional pork; after the flavouring liquid is injected into the pork, the pork is automatically beaten in the rolling machine and mutually extruded so that meat proteins are decomposed into water-soluble proteins which can be assimilated by human bodies easily, and the flavouring liquid and the meat proteins are mutually fused to achieve the purposes of meat quality tenderization, good taste and high finished product yield.

Owner:TAIXIANG GRP TECH DEV

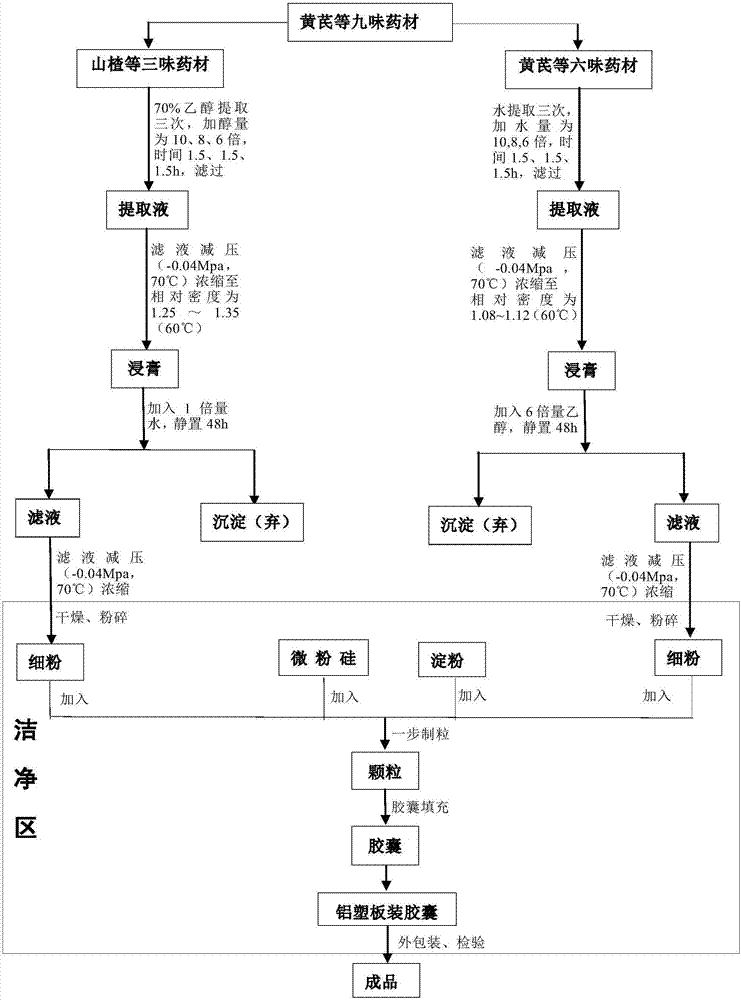

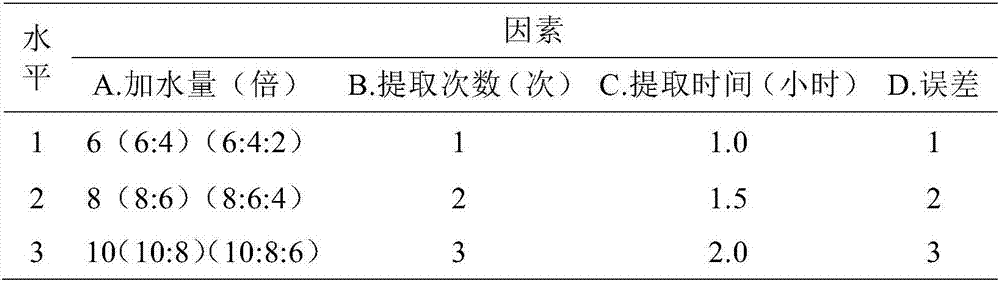

Preparation method of Huang Long cough and asthma capsule

The invention discloses a preparation method of a Huang Long cough and asthma capsule. The preparation method includes the steps of: 1) preparing fine powder A by mixing six medicines including astragalus membranaceus, earthworms, herba epimedii, herba ephedra, belamcanda sinensis and semen lepidii; 2) preparing fine powder B by mixing three medicines including houttuynia cordata, platycodon grandiflorum and hawthorns; 3) uniformly mixing the fine powder A and the fine powder B, adding proper amounts of silica gel micropowder and starch, granulating the mixture and sieving the mixture, and filling capsules with the mixture to obtain the Huang Long cough and asthma capsule. In the preparation method, due to the grouped extraction process, active components are enriched while some useless components are rejected, so that curative effect of the capsule is improved and dose of the capsule is reduced. Compared with a reference group produced through conventional processes, the Huang Long cough and asthma capsule has strong effects even the dose is reduced by 50%.

Owner:SHAANXI DONGKE PHARMA

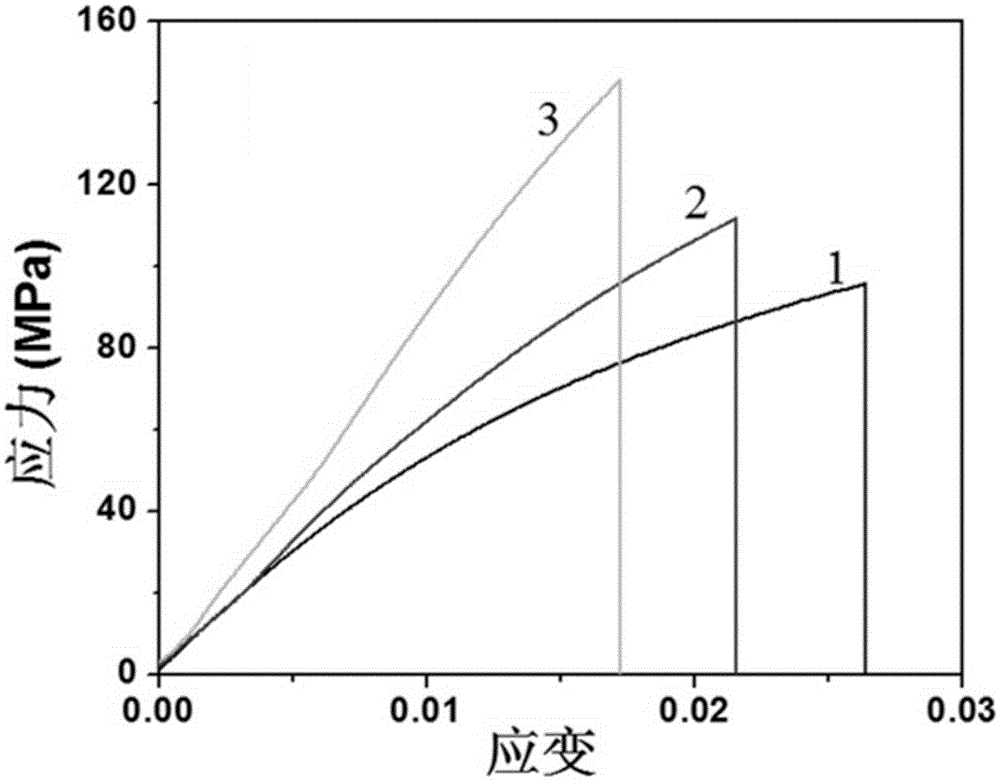

Preparation method of high-strength polyurethane-based composite film

InactiveCN105291512AHigh Strength Mechanical PropertiesAchieve structural controllabilityLaminationLamination apparatusFiberComposite film

The invention provides a preparation method of a high-strength polyurethane-based composite film, and the invention relates to a preparation method of the composite film. The invention solves the problems that the polyurethane-based composite material prepared by a present traditional solvent casting method has nonuniformly mixed two phases, a mechanical property improving effect of the polyurethane-based composite material due to a reinforcing agent is not obvious, the material prepared by a traditional layer upon layer self-assembly method has a single structure and bad manufacturability, continuous sedimentary deposition layer number of each substance cannot be adjusted, active forces between layers are limited, and solidification technology is lacked. The method comprises the following steps: 1, preparation of a Kevlar nanometer fiber solution; 2. preparation of a mixed solution containing polyurethane; 3. coverage with a film on a matrix surface; 4, treatment of a composite film by a stacking and hot-pressing method. The method is used for preparing the high-strength polyurethane-based composite film.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com